Page 1

Data Sheet

Agilent Bio-Monolith Protein A,

rProtein A, and Protein G Columns

Characteristics and shipping conditions

The information in this data sheet is provided to ensure proper product care and

maximum product lifetime.

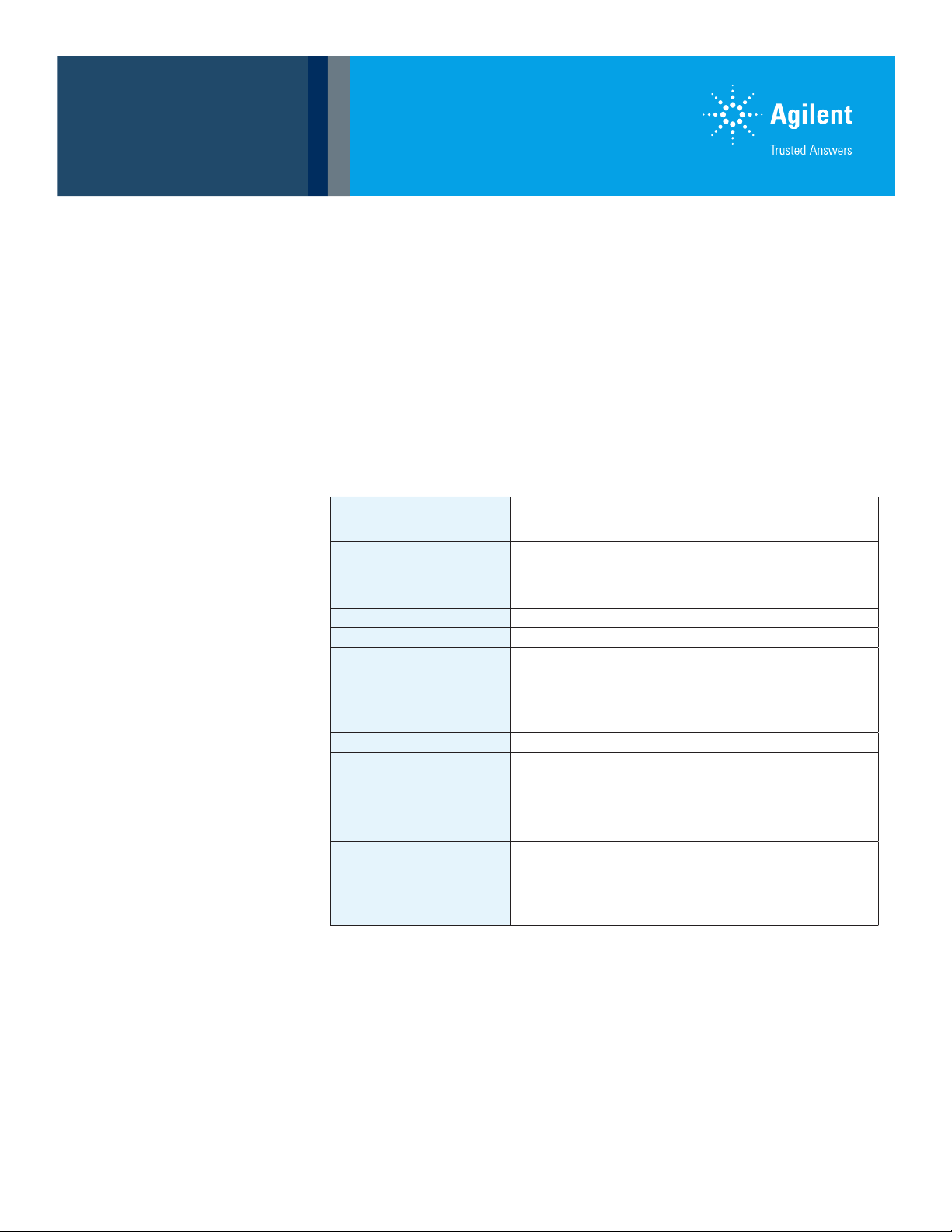

Agilent Bio-Monolith Protein A (p/n 5069-3639)

Catalog Number

Immobilized Ligand

Agilent Bio-Monolith Protein A

Agilent Bio-Monolith rProtein A

Agilent Bio-Monolith Protein G

Support Matrix

Column Dimensions

Dynamic Binding Capacity

Agilent Bio-Monolith Protein A

Agilent Bio-Monolith rProtein A

Agilent Bio-Monolith Protein G

Maximum Loading Capacity

Working Flow Rates

Maximum Allowed Pressure Over

the Column

Temperature Stability

Recommended pH*

Shipping Solvent

* At high pH, ligands can slowly degrade, therefore, only use pH higher than 11 for regeneration, cleaning-in-place,

and sanitization procedures.

Agilent Bio-Monolith rProtein A (p/n 5190-6903)

Agilent Bio-Monolith Protein G (p/n 5190-6900)

Immunoaffinity Protein A from Staphylococcus aureusis

Immunoaffinity r-Protein A from Escherichia coli

Immunoaffinity r-Protein G from Escherichia coli

Poly(glycidyl methacrylate-co-ethylene dimethacrylate) highly porous monolith

Diameter 5.2 mm, length 4.95 mm, bed volume (CV) 0.10 mL

>8 mg hIgG/mL wet support

>5 mg hIgG/mL wet support

>9 mg hIgG/mL wet support

(Conditions: hIgG 0.5 mg/mL, PBS buffer, pH 7.4, flow rate 1 mL/min)

0.4 to 0.5 mg

Recommended: 0.2 to 2 mL/min (1 to 10 cm/min, 2 to 20 CV/min)

Maximum: 3 mL/min (15 cm/min, 30 CV/min)

150 bar (15 MPa, 2,100 psi)

WARNING: Do not exceed the maximum allowed pressure, as this might

seriously damage your column.

Working 4 to 40 °C Storage 4 to 8 °C

WARNING: Avoid prolonged use at elevatedtemperatures.

Working range: 2 to 11

Cleaning in place: 2 to 13

20 mM Tris, pH 7.4 and 20 % ethanol

Page 2

Agilent Bio-Monolith Protein A, rProteinA,

Flat end

direction

Pointed end

and Protein G columns are analytical

affinity columns designed for fast

separation, isolation, and quantitation

of antibodies in fermentation (cell

culture supernatants and lysates). The

columns are compatible with HPLC and

preparative LC systems. The monolithic

structure enables high reproduciblity

and long lifetimes for separation and

quantitation of immunoglobulin G (IgG)

at high speeds.

Preparing the column

before first use

Connecting the column

The flow direction is indicated in

Figure1. The flat end is the inlet, and the

pointed end is the outlet.

Flow

Figure 1. Flow direction through the flat end of

the column.

1. Remove both end caps.

2. Connect the flat end* to the nut of the

capillary, which is already connected

to the HPLC system.

3. Tighten the fitting as instructed by

themanufacturer.

4. Flow liquid into the column.

5. Connect outlet (pointed end) to

thedetector.

* Long to extra long fittings and ferrules

(p/n 5065-9967) should be used.

Column equilibration

1. The columns should be washed

with at least 2 mL (20 CV) of a 0.1M

buffer such as sodium phosphate

buffer or Tris buffer containing 1 M

NaCl, pH 7.0 to 8.0 at a flow rate of

0.5 to 1.0 mL/min.

2. Wash the columns with at least 2 mL

(20 CV) of eluting buffer (see eluting

buffers below).

3. Equilibrate the column with 30 CV of

the binding buffer (see binding and

washing buffers below) at a flow rate

of 0.5 to 1.0 mL/min.

4. The column is ready for injection.

Binding and washing buffers

Bio-Monolith Protein A, rProtein A, and

Protein G columns are compatible with

many buffers for binding and washing.

The most common ones are:

1. Sodium phosphate buffer and

Trisbuffer, 25 to 100 mM. We

recommend using 50 mM as the

starting concentration.

2. Binding and washing buffers with

pH 6 to 9. We recommend starting

with pH 7.4. This pH seems to be

the optimal for the columns to

absorb/bind most antibodies.

3. Room temperature or 24 to 25°C

is recommended for optimal

performance and extended column

lifetime. Higher temperature can be

also used, but might reduce column

lifetime.

4. The columns are compatible with

neutral salts such as sodium chloride

(NaCl) or potassium chloride (KCl).

Salt concentrations of 0.1 to 0.2

M can improve the peak shape

and recovery in some cases for

somesamples.

Note: Filtration of buffers through a 0.22

or 0.45-µm membrane is recommended

to reduce buffer impurities that build up

on the frits inside the column. This will

prevent column blockage.

Note: Binding/washing buffers should be

freshly made.

Eluting buffers

Bio-Monolith Protein A, rProtein A, and

Protein G are compatible with many

low pH buffers. The buffers commonly

used are citric, glycine, HCl, and acetate

acid. Table 1 provides details for these

commonly used buffers.

Table 1. Some common eluting buffers for use

with AgilentBio-Monolith Protein A, rProtein A, and

Protein G columns.

Column Buffer Conc. pH

Agilent

Bio-Monolith

Protein A and

rProtein A

Agilent

Bio-Monolith

Protein G

Citric acid 0.1 M 2.5 to 3.0

Glycine 0.1 M 2.5 to 3.0

Acetic acid 5 to 20 %

Citric acid 0.1 M 2.0 to 2.5

Glycine 0.1 M 2.0 to 2.5

Acetic acid 5 to 20 %

Note: Commonly, elution buffers for

affinity columns have a refractive index

(RI) very different from binding/washing

buffers; therefore, baseline noise and

an artifact peak could appear when the

eluents start flowing. This peak could

interfere with the quantitation of low

concentration samples. To minimize

this effect, high-quality chemicals are

recommended to be used and blank

runs should be included to establish the

artifact peak. Blank runs can be used for

baseline subtraction if desired.

Note: HCl has a lower RI compared to

other eluents. If a low concentration

sample is used and baseline noise and

artifact peaks are of concern, HCl can be

used as an eluent.

2

Page 3

Sample preparation

Bio-Monolith Protein A, rProtein A, and

Protein G columns are compatible with

many buffers. However, some minor

preparation is required before injection

to optimize column performance and

extend column lifetimes.

Centrifuge or filter samples to remove

host cell debris and particulates from

the supernatant or lysate, to prevent

blockage of the columns.

Optimization/

re-optimization

Please keep in mind that we provide

some general guidelines on how to use

the columns. Optimization of methods

might be needed for some samples.

Methods from existing protocols with

other affinity columns might not work

with Agilent columns due to differences

in chemistry between columns and

differences between the antibody

sources. Therefore, method optimization

might be required.

Optimization methods include sample

preparation, buffer compositions, buffer

pH, binding time, washing time, and

eluting time.

Taking care of the column

Cleaning/washing the columns

between injections

It is a good practice to monitor column

performance and include regular column

cleaning cycles.

Cleaning-in-Place (CIP) protocol

1. Wash the column with 1 to 2 mL

(10to 20 CV) 0.1 M NaOH.

Note: Reverse the flow direction

and use flow rates between 0.2 to

0.5mL/min

2. Wash the column with 1 to 2 mL

(10to 20 CV) deionized (DI) water at

the working flow rate.

3. Wash the column with 1 to 2 mL

(10to 20 CV) concentrated buffer

(for example, 0.1 to 0.5 M phosphate

buffer, pH 7.4) to quickly restore the

appropriate pH.

4. Equilibrate with at least 5 mL (50 CV)

of binding phase buffer at the working

flow rate.

If the impurities are highly hydrophobic

or lipidic, and are not easily removed

from the column, 2-propanol (up to 30%)

or guanidine hydrochloride (up to 3 M)

can be used to remove these impurities.

After using these alternative cleaning

solutions, follow steps 1 through 4.

WARNING: When you wash the column

with these cleaning solutions, always

decrease the flow rate on the column to

avoid generation of high pressures that

might exceed the maximum allowed

pressure over the column.

Short-term storage

For storage overnight or for a few days,

the columns can be flushed with binding

buffer, disconnected from the instrument,

capped, and stored at 4 to 8 °C. Columns

should be equilibrated before the first

injection after short-term storage.

Long-term storage

If the column will not be in use for more

than 2 days, it should be washed with

at least 1 mL (10 CV) of DI water and

afterwards flushed with at least 2 mL

(20 CV) of 20 % ethanol with 20 mM

Tris buffer, pH 7.4 at a flow rate of 0.2 to

0.5mL/min. It should then be sealed with

column end stops and stored at 4 to 8 °C

(39 to 46 °F).

www.agilent.com/chem

DE44230.0856712963

This information is subject to change without notice.

© Agilent Technologies, Inc. 2015, 2021

Printed in the USA, February 4, 2021

5991-6040EN

Loading...

Loading...