Page 1

Application Note

Food Testing and

Agriculture

Quantitative Screening of Multiresidue

Veterinary Drugs in Milk and Egg

Using the Agilent 6495C Triple

Quadrupole LC/MS

Authors

Siji Joseph, Aimei Zou,

LimianZhao, Patrick Batoon,

and Chee Sian Gan

Agilent Technologies, Inc.

Abstract

This application note demonstrates the use of the Agilent Comprehensive

Veterinary Drug dMRM Solution for the screening of 210 target residues in milk and

eggmatrices. The workflow specifies conditions for chromatographic separation,

MS detection, and data processing, using a slightly modified sample preparation

procedure. Workflow performance was assessed based on limit of detection (LOD),

limit of quantitation (LOQ), calibration curve linearity, accuracy, precision, recovery,

and repeatability. Over 93% of veterinary drugs showed LOD of ≤1 μg/kg in milk

samples. Calibration curves for all targets ranged from the LOQ to 100 μg/kg with

a coefficient of correlation (R2) ≥0.99. Target peak area response (%RSD) was

<15%, and retention time (RT) %RSD was <0.5%. Method accuracy values, based on

matrix-matched calibration were within 87 to 117%. The average recovery of 95%

of targets was within 60 to 120%, with repeatability %RSD of ≤15%. Both milk and

egg matrices showed similar quantitative results. Injection-to-injection robustness

results demonstrated excellent target peak area and RT reproducibility across

400injections, confirming the workflow capability for routine multiresidue screening

with large-scale sample sets.

Page 2

Introduction

The Agilent Comprehensive Veterinary

Drug dMRM Solution is an end-to-end

workflow solution for targeted screening

or quantitation of 210 veterinary drug

residues in animal origin matrices,

which accelerates and simplifies routine

laboratory testing. The solution includes

comprehensive sample preparation,

chromatographic separations,

optimized MS detection method

conditions, data analysis methods, and

reporting templates for 210 veterinary

drugs in various food matrices. The

Comprehensive Veterinary Drug dMRM

Solution minimizes method development

time and combines multiple food

matrix analyses into one easy-to-follow

protocol. Agilent MassHunter data

acquisition software, together with

the dMRM database offers easy

customization of dMRM submethods

based on preferred target list or

regulation, as determined by the user.

The solution is available and has been

verified with two mass spectrometers

(Agilent 6470 triple quadrupole LC/MS

and the Agilent 6495C triple quadrupole

LC/MS) to address diverse sensitivity

demands based on the choice of sample

matrix and specific regulations that

varyglobally.

The solution was originally developed

for the quantitative screening of

210multiclass veterinary drugs in

chick, beef, and pork.1 It was then

demonstrated to be effective for

seafood using salmon and shrimp as

example matrices.2 This study further

demonstrates the applicability for

milk and eggs using the 6495C triple

quadrupole LC/MS. For the 210 target

analytes screened in this study, 103

of them had maximum residue limits

(MRL) established in milk regulated

by the AOAC3—with an additional

16targets regulated by US FDA-CFR4,

US FSIS5, or EU6 regulations/guidelines.

The MRL values are typically lower in

milk compared to meat and seafood,

thus requiring a higher MS detection

sensitivity. Additionally, the high fat

and protein content in milk demands

effective sample preparation and a

sensitive detector to monitor trace levels

of drug residues. Compared to milk, the

number of MRL-established targets for

the egg matrix is fewer and the residue

limits are more relaxed.

Experimental

Standards and reagents

Veterinary drug standards were

purchased from Sigma-Aldrich (St. Louis,

MO, USA), Toronto Research Chemicals

(Ontario, Canada), and Alta Scientific

(Tianjin, China). Agilent LC/MS-grade

acetonitrile (ACN, partnumber

5191-4496), methanol (MeOH,

partnumber 5191-4497), and water

(part number 5191-4498) were used

for the study. All other solvents used

were HPLC-grade from Sigma-Aldrich.

LC/MS additives for mobile phases were

also purchased from Sigma-Aldrich.

Individual stock solutions of veterinary

drugs were prepared from powdered or

liquid veterinary drug standards at 1,000

or 2,000 µg/mL using an appropriate

solvent (MeOH, dimethyl sulfoxide

(DMSO), ACN, or water or solvent

mixture). A few stock standard solutions

(100 µg/mL) were obtained from the

suppliers listed above.

A comprehensive standard mix

(1µg/mL of each target analyte in

50/50 ACN/water) was prepared from

individual stock solutions and used for

this experiment.

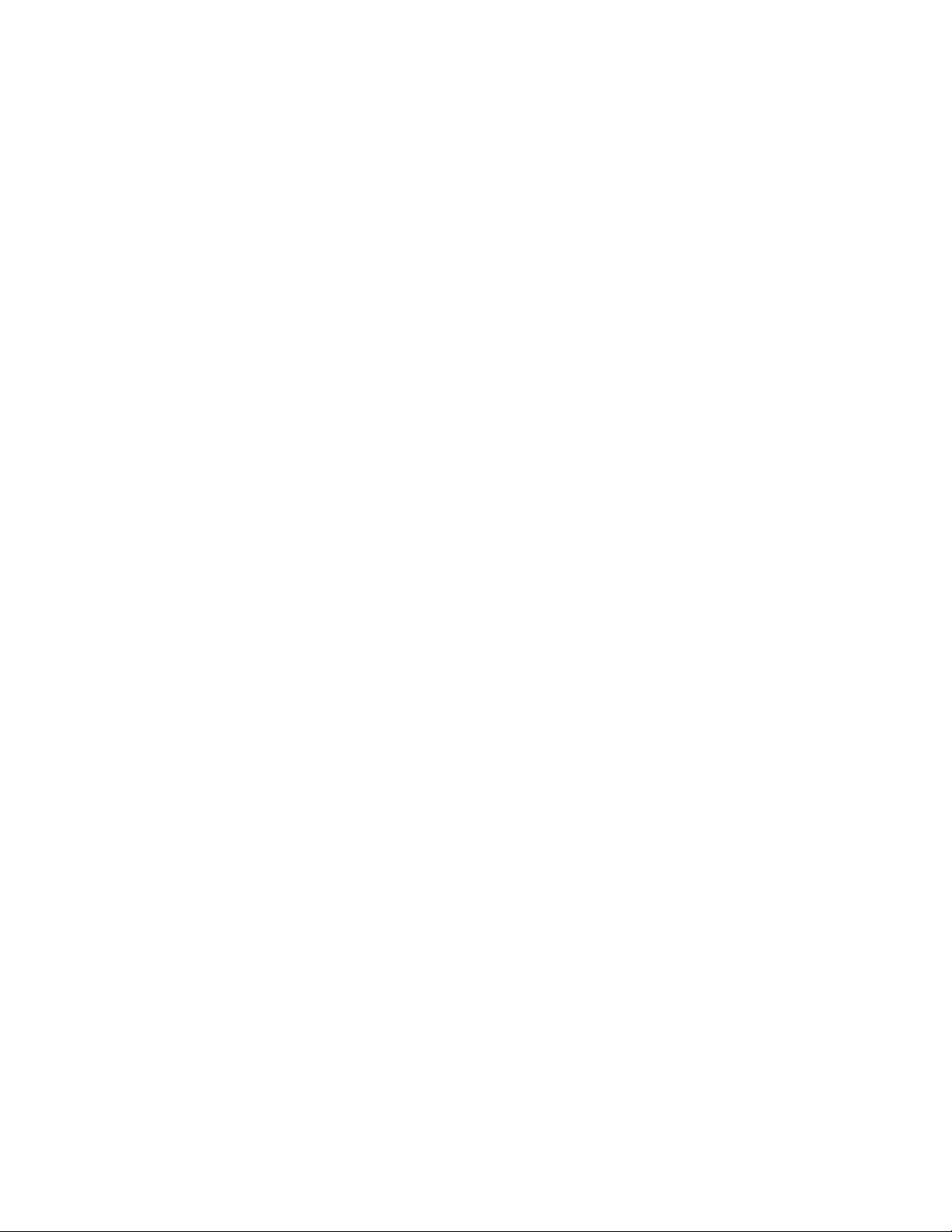

Sample preparation

Milk and egg samples were purchased

from a local grocery. For the analysis

of milk, a 2.0 ±0.1 mL portion of milk

was transferred in a 50 mL conical

polypropylene tube. For the analysis

of egg, a 2.0 ±0.1 g portion of the

homogenized sample was weighed in a

50 mL conical polypropylene tube. If not

analyzed immediately, the samples were

stored at –20 °C.

Sample preparation was performed

as per the procedure defined in the

Comprehensive Veterinary Drug

dMRM Solution (G5368AA) using

solvent extraction followed by

Agilent Captiva EMR—Lipid cleanup

(partnumber5190-1003), aided by

the Agilent positive pressure manifold

processor (PPM-48, part number

5191-4101).7 The sample preparation

procedure is summarized in Figure1. The

aqueous extraction step was modified

to adjust the target dilution due to

increased water content in milk andegg.

The following deviations from the

protocol defined in the Comprehensive

Veterinary Drug dMRM Solution

are recommended for the aqueous

extraction step:

– Milk: Concentration of EDTA solution:

1 M, volume added: 200 µL.

– Egg: Concentration of EDTA solution:

0.1M (same as workflow guide),

volume added: 1 mL

Matrix-spiked (pre-extraction) QC

samples were prepared by spiking the

appropriate veterinary standard solution

into the milk and egg matrices at various

levels: 1 μg/kg for low-range QC (LQC),

10 μg/kg for mid-range QC (MQC), and

25 μg/kg for high-range QC (HQC),

respectively. An additional QC level lower

than the LQC of 0.1 μg/kg (LLQC) was

included in the milk analysis to verify

the analytical characteristics of a few

targets, and to meet the very low MRL

requirement. After spiking standards, the

samples were vortexed for 30seconds,

then equilibrated for 15 to 20 minutes

to allow the spiked standards to

infiltrate the sample matrix before

sampleextraction.

2

Page 3

Matrix-matched calibration standards

Two 50 mL

tubes 2.0 g

sample

for QC samples

Blank matrix eluent

Matrix-matched (postextraction)

calibration standards were prepared

as per the workflow protocol by

spiking appropriate standards into the

blank matrix extract.7 The targeted

concentrations of matrix-matched

calibration levels were 0.1, 0.25, 0.5, 1.0,

2.5, 5.0, 10.0, 25.0, 50.0, and 100.0 μg/kg

(10 levels). An additional matrix-matched

calibration level of 0.05μg/kg was

added for milk analysis for similar

consideration of few targets with very

low MRL requirement. Considering the

10x dilution factor introduced during

sample preparation, the actual spiking

concentrations of postextraction

calibration standards were 0.005, 0.01,

0.025, 0.05, 0.10, 0.25, 0.5, 1.0, 2.5, 5.0,

and 10.0 μg/L (ppb) in the milk blank

matrix extract.

Neat standards at 2.5 μg/L in a 50/50

ratio of ACN/water was used to

evaluate matrix effects by comparing

the responses in the corresponding

postextraction-spiked calibration

standards.

Chromatographic separation was

performed using an Agilent InfinityLab

Poroshell 120 EC-C18 column

(partnumber 695575-302) installed on

an Agilent 1290 Infinity II LC, including

Agilent 1290 Infinity II flexible pump

(G7104C), Agilent 1290 Infinity II

multisampler (G7167A), and Agilent1290

Infinity II multicolumn thermostat

(G7116A).

Mobile phase A was water with 4.5 mM

ammonium formate, 0.5 mM ammonium

fluoride, and 0.1% formic acid; mobile

phase B was 50/50 ACN/MeOH with

4.5 mM ammonium formate, 0.5 mM

ammonium fluoride, and 0.1% formic

acid. The LC system was equipped with

a 20 µL injection loop and multiwash

capability. Please see the workflow guide

included with the Agilent Comprehensive

Veterinary Drug dMRM Solution

(G5368AA) for additional details.

7

The “6495 Veterinary Drug

Comprehensive” method included in the

Comprehensive Veterinary Drug dMRM

Solution for the 6495C triple quadrupole

LC/MS (G6495C) was used directly for

acquisition. The 6495C LC/MS triple

quadrupole with an Agilent Jet Stream

(AJS) ion source was operated in

dynamic MRM (dMRM) mode. Autotune

was performed in unit resolution with

report m/z below 100 mode enabled.

MassHunter acquisition software version

10.0 was used for data acquisition,

and MassHunter quantitative analysis

software version 10.0 was used to

process the data.

Results and discussion

Workflow performance in milk

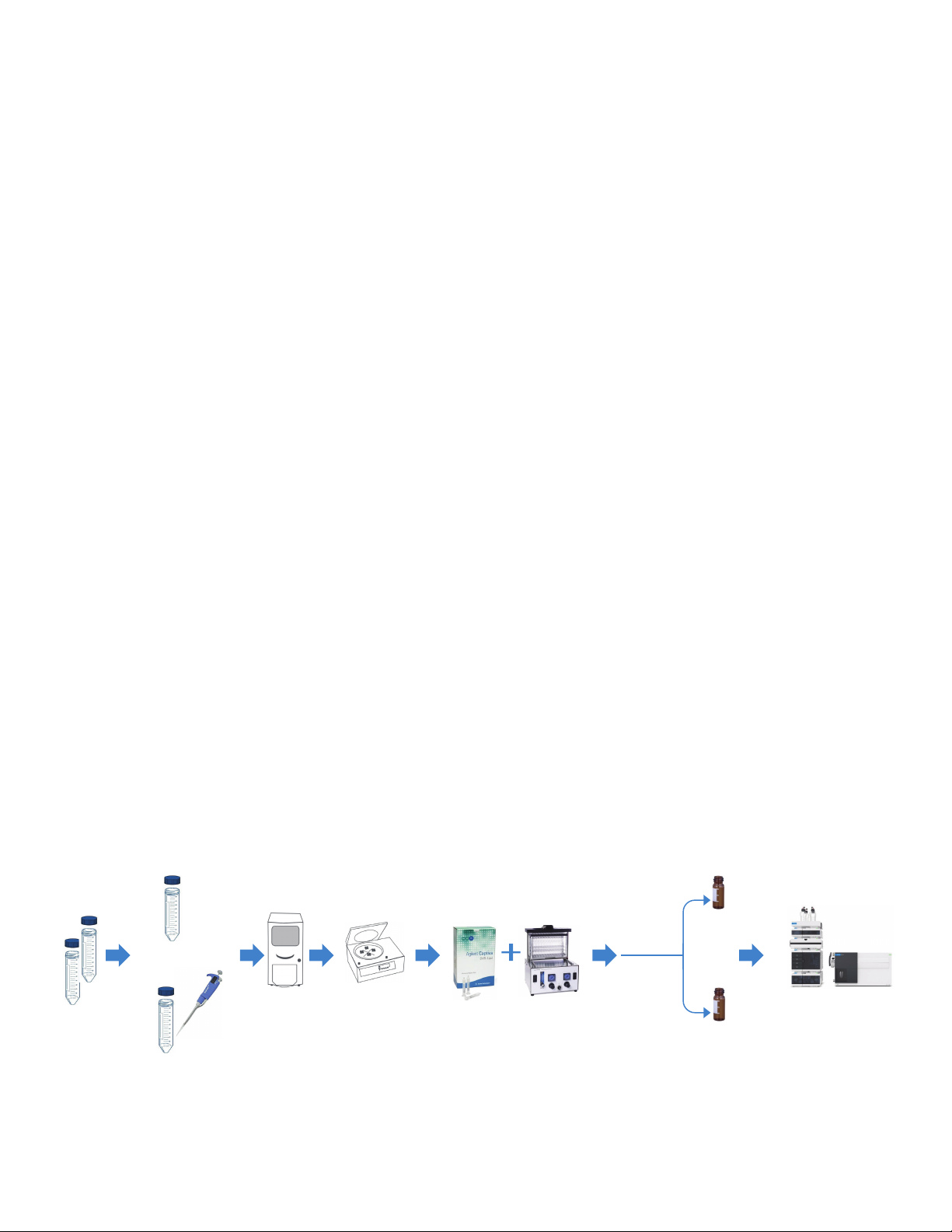

Chromatographic separation using the

Agilent InfinityLab Poroshell EC-C18

column resulted in good separation and

RT distribution of 210 veterinary drugs

within a 13-minute elution window.

Target-specific MRM transitions

included in the dynamic MRM method

helped to meet regulatory requirements

for compound identification and

confirmation. The default dynamic

MRM method utilized a cycle time of

750ms, and dwell times for each dMRM

transition ranged from 7 to 370ms,

offering more than 10 data points

across any given peaks. Figure2 shows

a representative MRM chromatogram

for all 210 veterinary drug targets,

postextraction spiked at 1.0 μg/L in the

milk blank matrix extract. Considering

the dilution factor during sample

preparation was 10x, this 1.0 μg/L

postextraction spike was equivalent to a

10 μg/kg spike in milk. The symmetrically

sharp peaks demonstrate the efficient

chromatographic separation of targets

within the elution window. Table 1 lists

the name, chemical class, CAS number,

and RT of all 210 targets covered in

thiswork.

1

2

1

Figure 1. Sample extraction procedure using solvent extraction followed with Agilent Captiva EMR—Lipid cleanup.

Blank matrix

(no spike)

2

Pre-extraction spike

2-Step solvent

extraction

Centrifuge

Sample cleanup using

Agilent Captiva EMR—Lipid 3 mL

cartridges on Agilent PPM-48

Homogenized

eluents

for matrix blank

and post-extraction

spike calibration levels

LC/MS analysis using

Agilent 6495C TQ

Pre-extraction spike

eluents as QC samples

3

Page 4

×10

5

Acquisition time (min)

Counts

Acquisition time (min)

Counts

2.0

1.5

1.0

0.5

0

1 2 3 4 5 6 7 8 9 10 11 12

Figure 2. Representative MRM chromatogram of 210 veterinary drug targets postextraction spiked at 1.0 μg/L in the milk

blank matrix extract using the Agilent 6495C triple quadrupole LC/MS).

From the AOAC MRL established

list, the early eluted analytes,

including amoxicillin, baquiloprim,

deacetylcefapirin, diminazene, imidocarb,

norgestomet, sulfaguanidine, and

tilmicosin showed split peaks due

to solvent effects. The “spectrum

summation” integrator algorithm was

used to reliably and automatically

integrate these targets for consistent RT,

and thus eliminated the need for manual

reintegrations.8 The peak shape for these

targets can be improved by converting

samples into a higher aqueous mixture

prior to LC/TQ injection.

LOD, LOQ and calibration

curvelinearity

LOD and LOQ were established using

various low level matrix-matched

calibration standards.

1,2

The

signal-to-noise ratio (S/N) was calculated

using the peak height for signal and an

auto-RMS algorithm for noise, included

in the MassHunter quantitative analysis

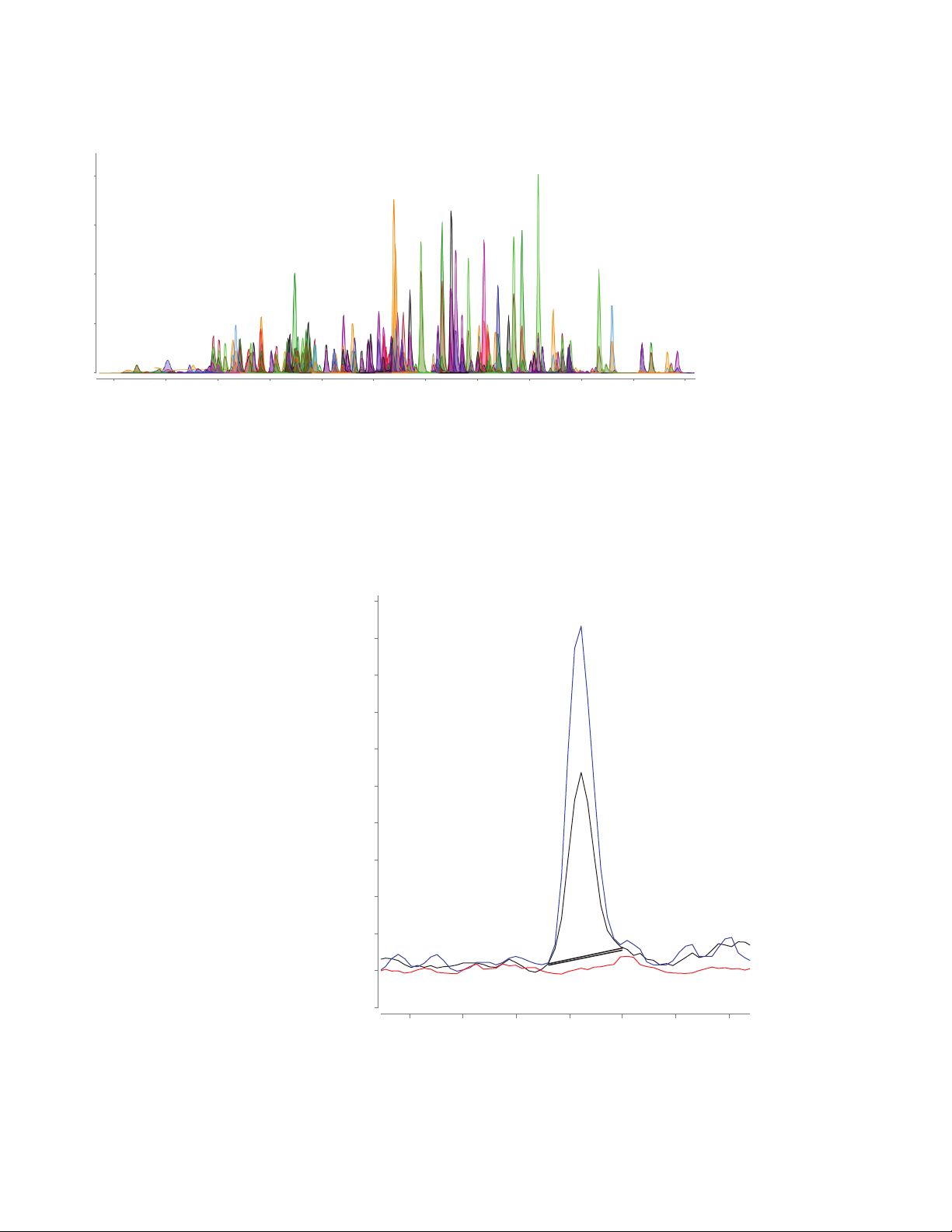

software. The method sensitivity using

the 6495C LC/TQ system offered a

LOD ≤1 μg/kg for over 93% of analytes

tested in both milk and egg. The low

detection limits achieved allowed the

high sensitivity demand for screening

trace level veterinary drug residues in

milk. As an example, AOAC regulated

MRL of 0.05μg/kg for clenbuterol in milk.

The 6495C TQ-based workflow provided

a clean, symmetrical peak with S/N of

calibration level, thus enabling confident

target identification and quantitation

(Figure 3).

32 at the 0.05 μg/kg matrix-matched

2

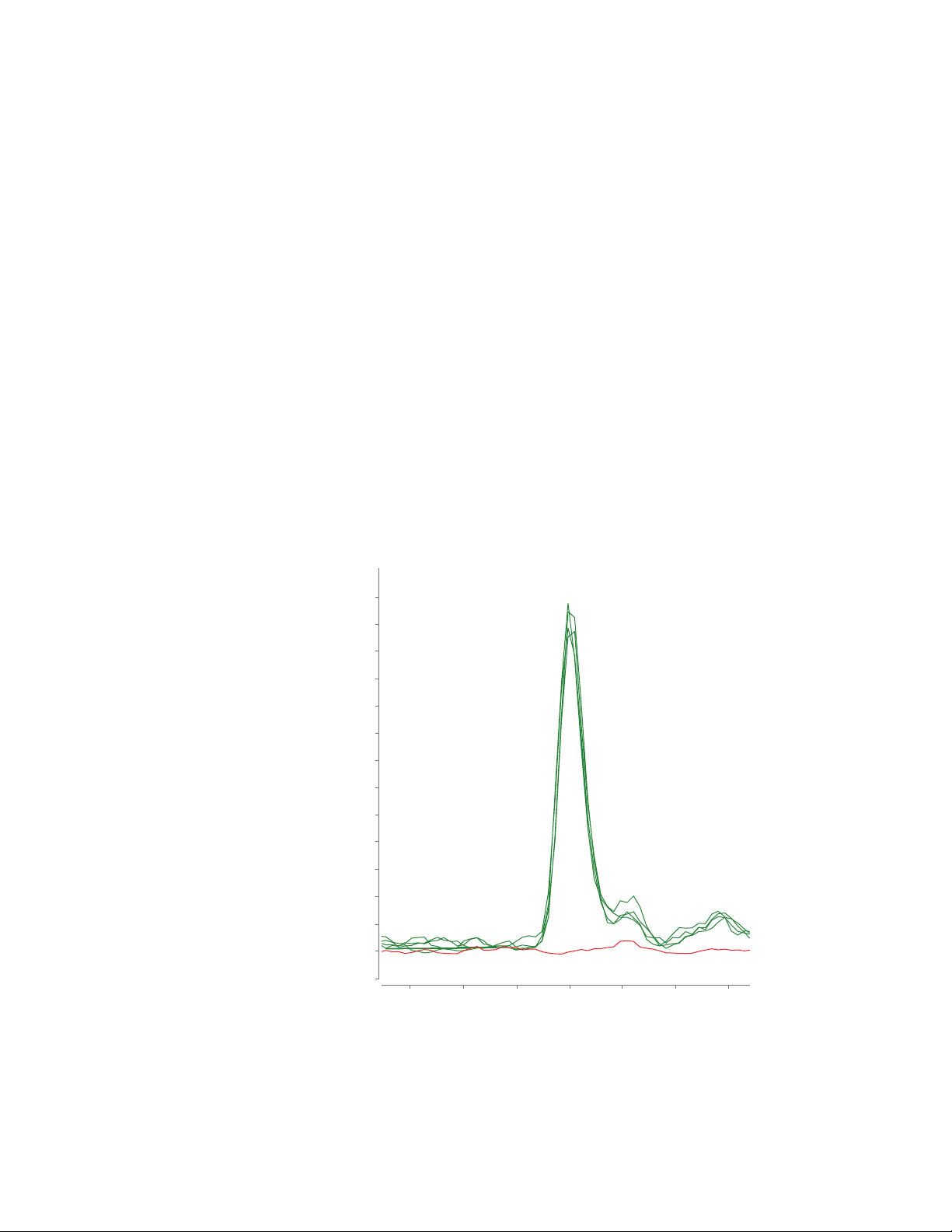

×10

RT: 5.42 (min)

5

4

3

2

1

0

5.1 5.2 5.3 5.4 5.5 5.6 5.7

Figure 3. MRM chromatogram of clenbuterol (MRM 277.1 & 202.9)

postextraction-spiked at 0.005 μg/L (black trace) and 0.01 μg/L (blue trace) in

the milk matrix extract, overlaid with matrix blank (red trace). The defined LOD

of clenbuterol is 0.05 μg/kg (S/N: 32) and LOQ is 0.1 μg/kg (S/N: 76).

4

Page 5

A calibration curve for each target

Acquisition time (min)

Counts

was generated using matrix-matched

calibration standards at levels

ranging from the defined LOQ to

the highest-spiked level. The linear

regression was used with ignored

origin and 1/x or 1/x2 weight. All targets

met the calibration curve linearity

requirement of R2 ≥0.99. The LOD, LOQ,

and calibration curve data of all targets in

the milk are shown in Table1.

Instrument method precision

andaccuracy

Precision was determined by calculating

the %RSD of the target response and

RT using triplicate injections of the

matrix-matched calibration levels.

The average accuracy value for each

matrix-matched calibration level was also

calculated from the triplicateinjections.

Good precision and accuracy values

were obtained for all targets in milk.

Target response %RSD for all targets in

the milk matrix at 10 μg/kg was <15%,

and the RT %RSD of all targets were

within 0.5%.9 The accuracy values of

all targets at 10 µg/kg within a range

of 87 to 117%. These results confirm

the reproducibility of chromatographic

separation and MS detection.

average recovery was calculated from

duplicate injections of four technical

preparations. The intrabatch recovery

repeatability was measured as %RSD

of recovery, calculated using four

technical preparations of matrix-spiked

QCsamples.

The results showed that recoveries of

about 93% of MRL-established targets

reached the acceptable range of 60

to 120% with an excellent intrabatch

RSD ≤20%.9 Recoveries of the

remaining seven targets, baquiloprim,

chlortetracycline, deacetylcefapirin,

diclofenac, imidocarb, oxytetracycline,

and trichlorfon [DEP], were within

a range of 30 to <60% or >120 to

124%. However, for these targets, the

workflow still provided good recovery

repeatability values within a %RSD of

2

×10

7

6

5

RT: 5.40 (min)

9%, demonstrating consistent extraction

behavior. These results confirmed

the entire workflow reproducibility

using Captiva EMR—Lipid sample

extraction and cleanup protocol in the

6495-TQ-based instrument detection.

The recovery and repeatability results

of all 210 targets are included in Table 1

(see Appendix).

The workflow performance combined

with the 6495C LC/TQ detection helped

confident recovery and repeatability

assessment at trace levels in milk.

Figure 4 shows an example of workflow

recovery and repeatability for clenbuterol

at 0.1 μg/kg in milk. The average

recovery of this target using the LLQC

sample is 118% with good recovery

repeatability of %RSD <5%.

Target recovery and

intrabatchrepeatability

The impact of sample preparation on

target recovery was assessed using

matrix-spiked QC samples. Each QC

level was prepared with four technical

preparations and was injected for

instrument analysis in duplicates. An

appropriate level of matrix-spiked QC

sample based on MRL was selected

to evaluate target-specific recovery

and repeatability. Recovery was

calculated using target response in

matrix-spiked QCs, and measured

response using matrix-matched

calibration curve equations. The

4

3

2

1

0

5.1 5.2 5.3 5.4 5.5 5.6 5.7

Figure 4. MRM chromatograms of clenbuterol (MRM 277.1 & 202.9) using

four technical preparations of LLQC samples in milk (green traces) overlaid

with matrix blank (red trace).

5

Page 6

Matrix effect assessment

Matrix effect (ME) is an important

parameter for method sensitivity and

reliability assessments. ME is defined as

the ratio of analyte area response (I) in

matrix-matched samples with those in

the corresponding neat standards (see

Equation1). The closer the ME value is to

100%, the less the matrix effect presents;

results lower than 100% indicate matrix

suppression, while results >100%

indicate potential enhancement.

Equation 1.

I

matrix

I

solvent

× 100

ME =

In this study, ME was investigated

using target response from

postextraction-spiked calibration

levels at 2.5 μg/L in blank matrix

extract, compared with corresponding

neatstandards.

In the milk matrix, within a total of

103 MRL established analytes, >95%

of targets showed an ME of >75%,

indicating negligible matrix suppression.

Four targets (amoxicillin, cefalonium,

nafcillin, and sulfamethizole) resulted in

an ME of 50 to 75%, indicating moderate

ion suppression. Target deacetylcefapirin

showed an ME of 48%, indicating

significant ion suppression.

Method verification in egg matrix

The method sensitivity in the egg was

similar to that of the milk matrix. Linear

matrix-matched calibration curves

ranging from LOQ to 100 μg/kg were

demonstrated with R2 ≥ 0.99. Instrument

method precision (%RSD) for target

responses and RTs were <15% and

<0.5%, respectively. Instrument method

accuracy for the matrix-matched

calibration level at 10.0 μg/kg were within

80 to 113% (n = 3). Recoveries of over

94% targets in the egg matrix were within

60 to 120% acceptance criteria, and

recovery repeatability with %RSD values

≤15%. Targets amprolium, baquiloprim,

chlortetracycline, deacetylcefapirin,

doxycycline, erythromycin,

oxytetracycline, tetracycline, and

rafoxanide showed <60% recoveries, but

recovery repeatability values were within

an acceptable limit of <15%RSD. Severe

ion suppression and poor recovery

(<20%) was observed for the dipyrone

hydrate-metabolite, however, no MRL is

established for this veterinary drug in

theegg.

AOAC MRL-based residue screening

in milk and egg

The MRL values of 103 AOAC-listed

targets range from 0.05 to

200μg/kg in milk.3 The method

sensitivity in milk using the 6495C

LC/TQ enabled confident screening of

all targets, except for diclofenac and

norgestomet. Table 1 summarizes the

MRL requirement and observed results

for all targets. Among the comprehensive

target list, 22 have MRL established for

egg under AOAC guidelines, and the

values range from 0.7 to 4,000μg/kg.3

The method sensitivity easily met

the screening requirement for all

MRL-established targets in egg per the

AOAC guidelines.

High blank contribution was observed

for the analysis of chlorhexidine,

clindamycin, progesterone, and

gonadotropin in both milk and egg,

indicating the potential positive

incurrence in the used sample

matrix. Trace residues of ethopabate,

oxibendazole, piperonyl butoxide

ammonia, and tripelennamine

affected the LOQ determination in

milk. Alternatively, the residues from

imidocarb, oxyphenbutazone, piperonyl

butoxide ammonia, and testosterone

affected the LOQ determination in egg.

Method robustness

The method robustness was assessed

by 400 continuous injections of

AgilentVeterinary Drug System Suitability

test mix (part number5799-0015)

postspiked in milk matrix. Peak

responses and RT consistency were

monitored for all 25 targets over time.

The 25 veterinary drug targets are from

10 different chemical classes, with a

broad range of molecular weight, eluted

evenly across the elution window, and

cover both positive and negative polarity

ionization. The dMRM peak area %RSD

and RT %RSD of all 25 targets were

calculated from the 400 injections of

1.0 μg/L postspiked milk blank matrix

extract. The data acquisition was

continuous, and the instrument was

operated without readjusting any tune

parameters. The entire run lasted for

>120 hours.

The elution profile using the InfinityLab

Poroshell column was extremely

consistent over 400 injections. A good

response reproducibility with %RSD

<4.0% and RT %RSD of <0.2% were

observed for all 25 targets. The response

reproducibility of all 25 standards

over 400 injections is summarized in

Figure 5, and an overlay of five total

ion chromatograms (TIC) of Agilent

Veterinary Drug System Suitability test

mix MRM (spread across 400injections)

are shown in Figure 6. The innovative ion

transfer optics design of Agilenttriple

quadrupole mass spectrometers

minimizes the source contamination

from the matrix, thus providing a robust

analytical platform for the confident

analysis of trace veterinary drug residues

(Figure 7). The sample preparation

procedure here provided efficient

sample matrix cleanup, greatly reduced

the matrix residue accumulation on

the ion source interface, and provided

extended column lifetime and detection

consistency. The method robustness,

calculated from a 5-day continuous data

acquisition, confirmed the sustainable

performance of the LC/TQ workflow for

day-to-day operations.

6

Page 7

500,000

600,000

400

MRM peak area

Injection number

Acquisition time (min)

Counts

400,000

300,000

200,000

100,000

0

050 100 150 200 250 300 350

Figure 5. The response reproducibility of 25 targets included in the Agilent Veterinary Drug System Suitability test mix over 400 continuous injections.

Concentration: postspiked at 1.0 μg/L in milk blank matrix extract (equivalent to a 10 μg/kg matrix spike in milk). Please refer to Table 1 for the list of 25 targets in

the Veterinary Drug System Suitability test mix.

5

×10

2.4

2.2

2.0

1.8

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.2

0

TIC MRM Injection 400

TIC MRM Injection 300

TIC MRM Injection 200

TIC MRM Injection 100

TIC MRM Injection 001

3.5 4.0 4.5 5.0 5.5 6.0 6.5 7.0 7.5 8.0 8.5 9.0 9.5 10.0

Figure 6. Overlay of five selected system suitability mix TIC MRM chromatograms, spread across 400 continuous replicate injections demonstrating the target

elution consistency. Concentration: postextraction spiked at 1.0 μg/L in milk blank matrix extract, LC separation column: Agilent InfinityLab Poroshell 120 EC-C18

(part number 695575-302). (offset X, Y-axis values, injections: 1, 100, 200, 300, and 400).

7

Page 8

Conclusion

A

B

This study demonstrates the applicability

of the Agilent Comprehensive Veterinary

Drug dMRM Solution for the screening

and quantitation of 210 multiclass

veterinary drug residues in milk and egg

matrices. The workflow-recommended

sample preparation protocol, using

solvent extraction followed by Agilent

Captiva EMR—Lipid cleanup, was shown

to be efficient for target extraction

and matrix cleanup from milk and

egg. The workflow performance was

characterized by good results in terms

of linearity, accuracy, recovery, and

repeatability, allowing sensitive detection

of multiclass veterinary drug residues.

The Agilent 6495C triple quadrupole

LC/MS-based workflow provided

sub-1µg/kg (ppb) LODs for most

analytes, and exceeded the sensitivity

requirements set by global regulatory

Figure 7. The Agilent Jet Stream technology ion source (AJS) of

the Agilent6495C triple quadrupole LC/MS before (A) and after

(B)400continuous injections of milk matrix.

agencies for screening trace veterinary

residues in complex matrices like milk

and eggs. The results demonstrated the

method reliability for routine screening

of over 98% of AOAC-listed veterinary

drug targets from the milk matrix, and

100% of AOAC-listed targets from

the egg matrix. The robustness of

400continuous injections confirmed the

method consistency and reliability, with

minimized sample residue accumulation

on the ion source interface.

8

Page 9

References

1. Siji Joseph et al. An End-To-End

Workflow for Quantitative Screening

of Multiclass, Multiresidue Veterinary

Drugs in Meat Using the Agilent

6470 Triple Quadrupole LC/MS,

Agilent Technologies application note,

publication number 5994-1932EN.

2. Siji Joseph et al. Quantitative

Screening of Multiresidue Veterinary

Drugs in Seafood Using the Agilent

6470 Triple Quadrupole LC/MS,

Agilent Technologies application note,

publication number 5994-2832EN.

3. Screening and identification method

for regulated veterinary drug residues

in food, AOAC guidelines, Version 7,

June 20, 2018.

4. The United States, Code of Federal

Regulations (CFR) - Title 21,

Tolerance of Residues in New Animal

Drugs in Food, Part 556, volume 6,

April 1, 2019.

5. The United States, Chemical

contaminants of public health

concern used by the Food Safety and

Inspection Service (FSIS), 2017.

6. Pharmacologically active substances

and their classification regarding

maximum residue limits (MRL),

Official Journal of the European

Union, Commission Regulation (EU)

No 37/2010.

7. G5368AA Comprehensive Veterinary

Drug dMRM Solution, Agilent

Technologies workflow guide,

D0002979.

8. Steven J. Lehotay, Utility of the

Summation Chromatographic Peak

Integration Function to Avoid Manual

Reintegrations in the Analysis of

Targeted Analytes, LCGC North

America June 2017, 35(6), 391.

9. Guidelines for Standard Method

Performance Requirements, AOAC

Official Methods of Analysis (2016)

Appendix F.

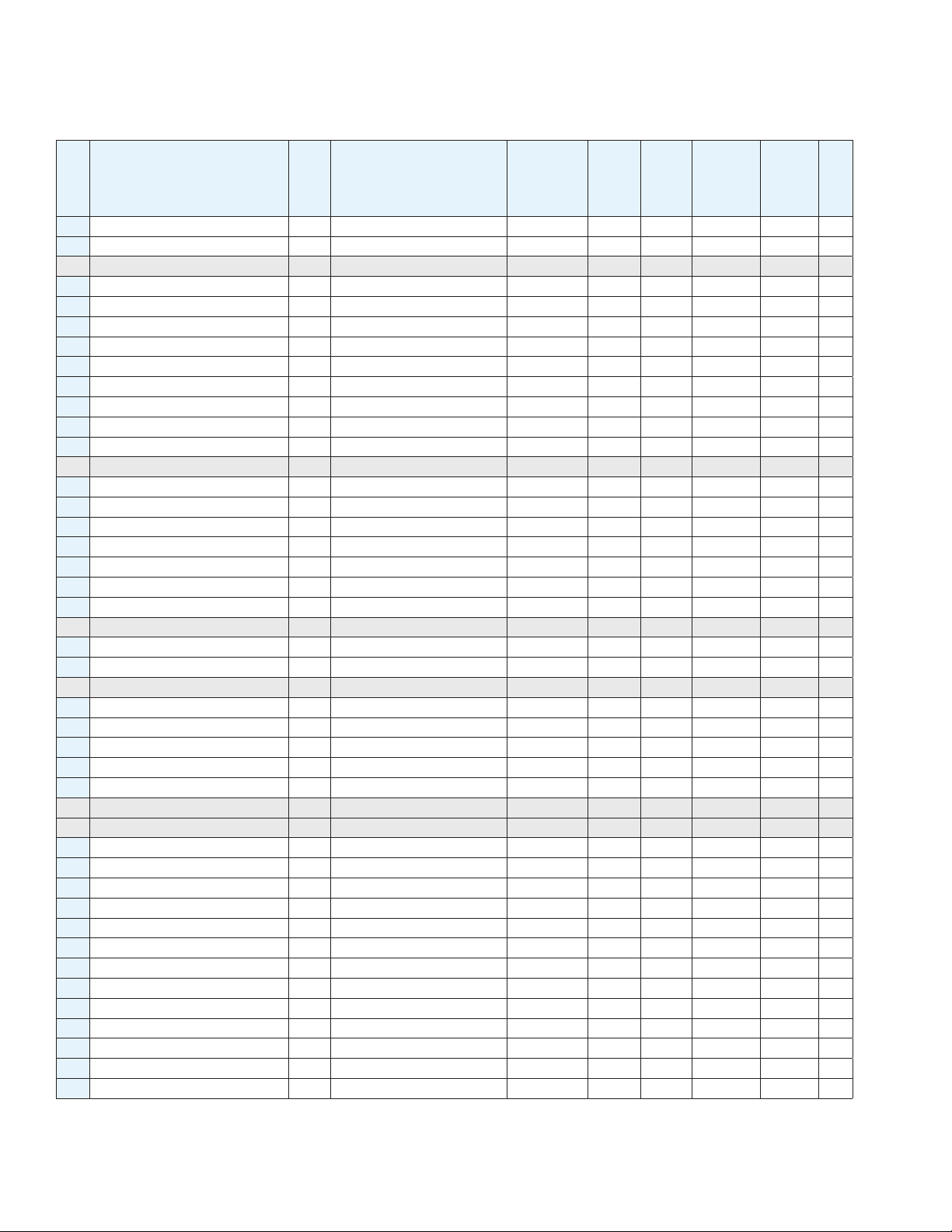

Appendix

Table 1. Target screening results using milk matrix based on AOAC guidelines. The results were generated based on the Agilent 1290 Infinity II LC and

Agilent 6495C triple quadrupole LC/MS systems. Note that these compounds may be obtained from Agilent, and those highlighted in bold are included

in the Agilent Veterinary Drug System Suitability test mix (part number 5799-0015).

Linear

No. Compound Name

2, 4, 6-triamino-pyrimidine-5-carbonitrile 1.62 Insecticide 465531-97-9 N/A 2.5 5 to 100 105 9

1

2,4-DMA [Amitraz Metabolite] 4.45 Insecticide 33089-74-6 10 0.5 1 to 100 108 3

2

2-Quinoxalinecarboxylic acid [QCA] 4.20 Quinoxalines 879-65-2 N/A 2.5 5 to 100 108 4

3

4-epi-oxytetracycline 4.36 Antibiotic/Tetracycline 14206-58-7 100 0.25 0.5 to 100 84 5

4

4-epi-tetracycline 4.28 Antibiotic/Tetracycline 79-85-6 100 0.25 0.5 to 100 82 4

5

5-Hydroxy thiabendazole 3.59 Anthelmintic/Benzimidazoles 948-71-0 50 0.1 0.25 to 100 110 2

6

5-Hydroxyflunixin 8.36 NSAIDs 75369-61-8 2 0.05 0.1 to 100 112* 10*

7

Acepromazine 7.44 Tranquilizer 61-00-7 N/A 0.05 0.1 to 100 100 2

8

Acetyl isovaleryl tylosin [Tylvalosin] 8.80 Antibiotic/Macrolides 63409-12-1 N/A 0.5 1 to 100 106 5

9

Albendazole 8.09 Anthelmintic/Benzimidazoles 54965-21-8 100 0.05 0.1 to 100 110 2

10

Albendazole sulfone 6.22 Anthelmintic/Benzimidazoles 75184-71-3 100 0.1 0.25 to 100 118 2

11

Albendazole sulfoxide 5.62 Anthelmintic/Benzimidazoles 54029-12-8 100 0.1 0.25 to 100 115 3

12

Albendazole-2-aminosulfone 3.81 Anthelmintic/Benzimidazoles 80983-34-2 100 0.25 0.5 to 100 105 2

13

Alpha Zearalanol 8.33 Hormones 26538-44-3 N/A 1 2.5 to 100 110 4

14

Altrenogest 9.05 Hormones 850-52-2 N/A 0.1 0.25 to 100 112 2

15

Aminoflubendazole 6.19 Anthelmintic/Benzimidazoles 82050-13-3 10 0.05 0.1 to 100 112 2

16

Amoxicillin 2.76 Antibiotic/Beta-lactam 26787-78-0 4 1 2.5 to 100 110* 7*

17

Ampicillin 4.00 Antibiotic/Beta-lactam 69-53-4 4 0.5 1 to 100 115* 7*

18

Amprolium 1.22 Antimicrobial 13082-85-4 N/A 1 2.5 to 100 9 4

19

Azaperone 5.87 Tranquilizer 1649-18-9 N/A 0.1 0.25 to 100 96 3

20

RT

(min)

Functional Use/

Chemical Class CAS Number

AOAC3

MRL

(µg/kg)

(µg/kg)

LOD

Calibration

Curve Range

(μg/kg) with

R2 >0.99

MQC

Recovery

(%)

MQC

RSD

(%)

9

Page 10

Linear

Calibration

No. Compound Name

Azithromycin 6.27 Antibiotic/Macrolides 83905-01-5 N/A 0.1 0.25 to 100 76 3

21

Baquiloprim 2.74 Antimicrobial 102280-35-3 30 0.25 0.5 to 100 33 4

22

Betamethasone 7.83 Growth promoters/Corticosteroids 378-44-9 0.3 0.25 0.5 to 100 119* 3*

23

Cabergoline 4.72 Dopamine receptor 81409-90-7 0.1 0.05 0.1 to 100 111• 15•

24

Carazolol 6.16 Tranquilizer 57775-29-8 1 0.05 0.1 to 100 119* 5*

25

Carbadox 4.47 Antimicrobial 6804-07-5 N/A 0.25 0.5 to 100 113 3

26

Carprofen 9.08 NSAIDs 53716-49-7 N/A 1 2.5 to 100 106 3

27

Cefalexin 4.00 Antibiotic/Beta-lactam 15686-71-2 100 2.5 5 to 100 87 8

28

Cefalonium 3.98 Antibiotic/Beta-lactam 5575-21-3 20 1 2.5 to 100 73 8

29

Cefapirin 3.28 Antibiotic/Beta-lactam 21593-23-7 60 0.1 0.25 to 100 81 4

30

Cefazolin 4.39 Antibiotic/Beta-lactam 25953-19-9 50 1 2.5 to 100 112 2

31

Cefoperazone 5.21 Antibiotic/Beta-lactam 62893-19-0 50 1 2.5 to 100 114 8

32

Cefquinome 3.75 Antibiotic/Beta-lactam 84957-30-2 20 0.5 1 to 100 63 4

33

Ceftiofur 6.35 Antibiotic/Beta-lactam 80370-57-6 100 0.5 1 to 100 117 3

34

Cefuroxime 4.47 Antibiotic/Beta-lactam 55268-75-2 N/A 2.5 5 to 100 112 6

35

Chloramphenicol 6.34 Antibiotic/Amphenicols 56-75-7 N/A 0.5 1 to 100 113 5

36

Chlorhexidine 7.20 Antimicrobial 55-56-1 N/A 5 10 to 100 95 4

37

Chlormadinone 9.51 Hormones 1961-77-9 2.5 0.5 1 to 100 114* 6*

38

Chlorpromazine 8.16 Tranquilizer 50-53-3 N/A 0.05 0.1 to 100 97 2

39

Chlortetracycline 6.04 Antibiotic/Tetracycline 57-62-5 100 0.25 0.5 to 100 42 9

40

Ciprofloxacin 4.52 Antibiotic/Quinolones 85721-33-1 N/A 0.1 0.25 to 100 95 3

41

Clenbuterol 5.41 Growth promoters/Beta-agonists 37148-27-9 0.05 0.05 0.1 to 100 118• 5•

42

Clindamycin 6.55 Antibiotic/Macrolides 18323-44-9 N/A 10 25 to 100 106# 1#

43

Clopidol 3.61 Coccidiostats 2971-90-6 20 0.25 0.5 to 100 113 2

44

Closantel 10.60 Anthelmintic 57808-65-8 45 0.25 0.5 to 100 93 3

45

Colchicine 6.78 NSAIDs 64-86-8 N/A 0.1 0.25 to 100 105 4

46

Cotinine 2.23 Insecticide 486-56-6 N/A 0.1 0.25 to 100 90 3

47

Coumaphos 9.64 Anthelmintic 56-72-4 N/A 0.5 1 to 100 108 5

48

Cyromazine 2.52 Anthelmintic 66215-27-8 N/A 1 2.5 to 100 94 7

49

Danofloxacin 4.73 Antibiotic/Quinolones 112398-08-0 30 0.05 0.1 to 100 95 2

50

Dapson 4.76 Antibiotic/Sulfonamides 80-08-0 N/A 0.05 0.1 to 100 117 2

51

Dapson N-Acetyl 5.51 Antibiotic/Sulfonamides 565-20-8 N/A 0.25 0.5 to 100 115 3

52

Deacetylcefapirin 2.37 Antibiotic/Beta-lactam 104557-24-6 60 1 2.5 to 100 41 8

53

Diaveridine 3.83 Antimicrobial 5355-16-8 N/A 0.05 0.1 to 100 111 2

54

Diazinon 9.71 Insecticide 333-41-5 20 0.1 0.25 to 100 108 2

55

Diclofenac 9.21 NSAIDs 15307-86-5 0.1 0.25 0.5 to 100 123* 8*

56

Dicloxacillin 8.18 Antibiotic/Beta-lactam 3116-76-5 30 2.5 5 to 100 118 7

57

Dicyclanil 2.98 Insecticide 112636-83-6 N/A 0.25 0.5 to 100 108 1

58

Difloxacin 5.39 Antibiotic/Quinolones 98106-17-3 N/A 0.1 0.25 to 100 106 4

59

Diflubenzuron 9.18 Insecticide 35367-38-5 N/A 0.5 1 to 100 108 5

60

Dimetridazole 3.74 Coccidiostats 551-92-8 N/A 2.5 5 to 100 108 2

61

Diminazene 3.06 Coccidiostats 536-71-0 150 2.5 5 to 100 60 4

62

Dinitolmide [Zoalene] 5.66 Coccidiostats 148-01-6 N/A 0.5 1 to 100 115 3

63

Dipyrone hydrate- metabolite

64

[4-Methylaminoantipyrine]

(min)

3.40 NSAIDs 519-98-2 N/A 0.25 0.5 to 100 54 7

RT

Functional Use/

Chemical Class CAS Number

MRL

(µg/kg)

(µg/kg)

AOAC3

LOD

Curve Range

(μg/kg) with

R2 >0.99

MQC

Recovery

(%)

MQC

RSD

(%)

10

Page 11

Linear

Calibration

No. Compound Name

Doxycycline 6.36 Antibiotic/Tetracycline 564-25-0 N/A 0.25 0.5 to 100 32 4

65

Emamectin B1a benzoate 10.18 Anthelmintic/Avermectins 121124-29-6 N/A 0.25 0.5 to 100 89 3

66

Emamectin B1b benzoate 9.99 Anthelmintic/Avermectins 121424-52-0 N/A 0.5 1 to 100 95 5

67

Enrofloxacin 4.85 Antibiotic/Quinolones 93106-60-6 100 0.05 0.1 to 100 102 2

68

Erythromycin 7.52 Antibiotic/Macrolides 114-07-8 N/A 0.5 1 to 100 97 13

69

Ethopabate 6.68 Coccidiostats 59-06-3 N/A 0.1 0.25 to 100 115 3

70

Famphur 8.25 Insecticide 52-85-7 N/A 0.25 0.5 to 100 116 7

71

Febantel 9.22 Anthelmintic/Benzimidazoles 58306-30-2 10 0.1 0.25 to 100 115 4

72

Fenbendazole 8.67 Anthelmintic/Benzimidazoles 43210-67-9 10 0.05 0.1 to 100 112 2

73

Fenbendazole Sulfoxide [Oxfendazole] 6.53 Anthelmintic/Benzimidazoles 53716-50-0 10 0.1 0.25 to 100 118 3

74

Firocoxib 8.04 NSAIDs 189954-96-9 N/A 2.5 5 to 100 111 14

75

Florfenicol 5.64 Antibiotic/Amphenicols 73231-34-2 N/A 0.25 0.5 to 100 115 4

76

Fluazuron 10.24 Insecticide 86811-58-7 N/A 0.25 0.5 to 100 108 6

77

Flubendazole 7.80 Anthelmintic/Benzimidazoles 31430-15-6 10 0.05 0.1 to 100 115 2

78

Flugestone acetate 8.42 Hormones 2529-45-5 1 0.5 1 to 100 120* 4*

79

Flumequine 7.47 Antibiotic/Quinolones 42835-25-6 50 0.05 0.1 to 100 119 2

80

Flunixin 8.83 NSAID’s 38677-85-9 N/A 0.05 0.1 to 100 117 2

81

Fluralaner 9.95 Insecticide 864731-61-3 N/A 0.5 1 to 100 111 6

82

Furazolidone 4.77 Antimicrobial/Furans 67-45-8 N/A 1 2.5 to 100 118 5

83

Gamithromycin 6.56 Antibiotic/Aminoglycosides 145435-72-9 N/A 0.1 0.25 to 100 76 4

84

Gonadotropin 7.65 Hormones 33515-09-2 N/A 5 10 to 100 116 7

85

Halofuginone 6.55 Coccidiostats 55837-20-2 N/A 0.25 0.5 to 100 102 5

86

Haloperidol 7.21 Tranquilizer 52-86-8 N/A 0.05 0.1 to 100 116 2

87

Haloxon 8.65 Anthelmintic 321-55-1 N/A 2.5 5 to 100 112 12

88

Imidocarb 3.32 Coccidiostats 27885-92-3 50 1 2.5 to 100 55 5

89

Ipronidazole 6.13 Anthelmintic/Nitroimidazoles 14885-29-1 N/A 1 2.5 to 100 115 3

90

Ipronidazole-OH 4.93 Anthelmintic/Nitroimidazoles 35175-14-5 N/A 0.25 0.5 to 100 114 3

91

Isometamidium 6.09 Anthelmintic 20438-03-3 100 1 2.5 to 100 73 4

92

Josamycin 8.32 Antibiotic/Macrolides 16846-24-5 N/A 0.25 0.5 to 100 110 4

93

Ketamine 4.86 Anesthetic 6740-88-1 N/A 0.05 0.1 to 100 107 2

94

Ketoprofen 8.28 NSAIDs 22071-15-4 50 0.5 1 to 100 118 5

95

Kitasamycin A5 [Leucomycin A5] 7.79 Antibiotic/Aminoglycosides 18361-45-0 N/A 0.25 0.5 to 100 108 4

96

Lasalocid A 11.13 Coccidiostats 25999-31-9 N/A 0.05 0.1 to 100 106 2

97

Leuco Crystal violet 10.44 Fungicides and Dyes 603-48-5 N/A 0.25 0.5 to 100 79 3

98

Leucomalachite green 10.55 Fungicides and Dyes 129-73-7 N/A 0.05 0.1 to 100 96 2

99

Levamisole 3.67 Anthelmintic 14769-73-4 N/A 0.1 0.25 to 100 106 2

100

Lincomycin 3.81 Antibiotic/Aminoglycosides 154-21-2 150 0.05 0.1 to 100 79 3

101

Lufenuron 10.16 Insecticide 103055-07-8 N/A 1 2.5 to 100 113 5

102

Maduramicin Ammonium 11.69 Coccidiostats 79356-08-4 N/A 0.1 0.25 to 100 84 2

103

Malachite green 8.31 Fungicides and Dyes 10309-95-2 N/A 0.05 0.1 to 100 81 2

104

Malathion 9.00 Insecticide 121-75-5 N/A 0.1 0.25 to 100 117 3

105

Marbofloxacin 4.10 Antibiotic/Quinolones 115550-35-1 75 0.1 0.25 to 100 97 2

106

Mebendazole 7.55 Anthelmintic/Benzimidazoles 31431-39-7 N/A 0.05 0.1 to 100 114 2

107

Mefenamic acid 9.75 Anti-inflammatory 61-68-7 N/A 0.1 0.25 to 100 120 3

108

(min)

RT

Functional Use/

Chemical Class CAS Number

MRL

(µg/kg)

(µg/kg)

AOAC3

LOD

Curve Range

(μg/kg) with

R2 >0.99

MQC

Recovery

(%)

MQC

RSD

(%)

11

Page 12

Linear

Calibration

No. Compound Name

Megestrol acetate 9.49 Hormones 595-33-5 N/A 0.1 0.25 to 100 111 3

109

Melengestrol acetate 9.61 Hormones 2919-66-6 N/A 0.1 0.25 to 100 111 4

110

Meloxicam 8.17 NSAIDs 71125-38-7 15 0.05 0.1 to 100 120 2

111

Methylprednisolone 7.86 Growth promoters/Corticosteroids 83-43-2 2 0.25 0.5 to 100 117* 4*

112

Metoserpate 6.66 Tranquilizer 1178-28-5 N/A 0.1 0.25 to 100 113 3

113

Metronidazole 3.28 Anthelmintic/Nitroimidazoles 443-48-1 N/A 0.1 0.25 to 100 116 2

114

Metronidazole-OH 2.84 Anthelmintic/Nitroimidazoles 4812-40-2 N/A 0.25 0.5 to 100 118 2

115

Monensin 11.30 Coccidiostats 17090-79-8 2 0.1 0.25 to 100 98* 5*

116

Monepantel 9.52 Anthelmintic 851976-50-6 N/A 0.1 0.25 to 100 120 3

117

Morantel tartrate 5.39 Anthelmintic 20574-50-9 50 0.1 0.25 to 100 107 2

118

Moxidectin 11.09 Anthelmintic/Avermectins 113507-06-5 40 0.25 0.5 to 100 115 5

119

Nafcillin 8.10 Antibiotic/Beta-lactam 147-52-4 30 0.25 0.5 to 100 100 4

120

Nalidixic acid 7.29 Antibiotic 389-08-2 N/A 0.05 0.1 to 100 117 2

121

Narasin 11.80 Coccidiostats 55134-13-9 N/A 0.1 0.25 to 100 69 7

122

Neo-Spiramycin 5.75 Antibiotic/Macrolides 70253-62-2 200 0.25 0.5 to 100 70 2

123

Nequinate 9.43 Anthelmintic 13997-19-8 N/A 0.05 0.1 to 100 112 3

124

Netobimin 7.11 Anthelmintic 88255-01-0 100 1 2.5 to 100 108 7

125

Nicarbazine 8.84 Coccidiostats 587-90-6 N/A 0.1 0.25 to 100 116 3

126

Nicotine 1.54 Anti-herbivore 54-11-5 N/A 5 10 to 100 67 8

127

Niflumic Acid 9.14 Anti-inflammatory 4394-00-7 N/A 0.05 0.1 to 100 117 2

128

Nitroxynil 6.77 Anthelmintic 1689-89-0 N/A 0.5 1 to 100 114 5

129

Norfloxacin 4.38 Antibiotic/Quinolones 70458-96-7 N/A 0.1 0.25 to 100 95 2

130

Norgestomet 9.44 Hormones 472-54-8 0.12 1 2.5 to 100 117 3

131

Novobiocin 9.82 Antibiotic 303-81-1 50 0.25 0.5 to 100 120 4

132

Olaquindox 3.03 Growth promoters/Anabolic steroids 23696-28-8 N/A 0.25 0.5 to 100 104 2

133

Oleandomycin 7.13 Antibiotic/Aminoglycosides 3922-90-5 50 0.1 0.25 to 100 112 3

134

Orbifloxacin 5.07 Antibiotic/Quinolones 113617-63-3 20 0.1 0.25 to 100 115 3

135

Ormetoprim 4.49 Antibiotic 6981-18-6 N/A 0.1 0.25 to 100 112 2

136

Oxacillin 7.56 Antibiotic/Beta-lactam 66-79-5 30 1 2.5 to 100 114 9

137

Oxibendazole 6.89 Anthelmintic/Benzimidazoles 20559-55-1 50 0.1 0.25 to 100 116 2

138

Oxolinic acid 6.37 Antibiotic/Quinolones 14698-29-4 N/A 0.25 0.5 to 100 112 2

139

Oxyclozanide 9.56 Anthelmintic 2277-92-1 10 0.25 0.5 to 100 112 4

140

Oxyphenbutazone 8.16 NSAIDs 129-20-4 N/A 0.25 0.5 to 100 105 6

141

Oxytetracycline 4.54 Antibiotic/Tetracycline 79-57-2 100 0.25 0.5 to 100 46 9

142

Penicillin G 7.00 Antibiotic/Beta-lactam 61-33-6 N/A 0.5 1 to 100 90 7

143

Penicillin V [Phenoxymethylpenicillin] 7.41 Antibiotic/Beta-lactam 87-08-1 N/A 1 2.5 to 100 117 2

144

Phenylbutazone 9.09 NSAIDs 50-33-9 N/A 0.25 0.5 to 100 106 3

145

Phosalone 9.77 Insecticide 2310-17-0 N/A 0.5 1 to 100 113 9

146

Phoxim 9.70 Insecticide 14816-18-3 N/A 1 2.5 to 100 110 10

147

Piperonyl butoxide Ammonia 10.31 Insecticide 51-03-6 50 0.1 0.25 to 100 116 1

148

Pirlimycin 6.10 Antibiotic/Aminoglycosides 79548-73-5 100 1 2.5 to 100 96 4

149

Praziquantel 8.57 Anthelmintic 55268-74-1 N/A 0.25 0.5 to 100 116 2

150

Prednisolone 7.29 Growth promoters/Corticosteroids 50-24-8 6 0.1 0.25 to 100 120* 2*

151

Prednisone 7.13 Growth promoters/Corticosteroids 53-03-2 N/A 0.25 0.5 to 100 117 3

152

(min)

RT

Functional Use/

Chemical Class CAS Number

MRL

(µg/kg)

(µg/kg)

AOAC3

LOD

Curve Range

(μg/kg) with

R2 >0.99

MQC

Recovery

(%)

MQC

RSD

(%)

12

Page 13

Linear

Calibration

No. Compound Name

Progesterone 9.60 Hormones 57-83-0 N/A 10 25 to 100 117# 4#

153

Propionylpromazin 8.00 Antiemetic 3568-24-9 N/A 0.05 0.1 to 100 98 2

154

Propyphenazone 7.68 NSAIDs 479-92-5 N/A 0.05 0.1 to 100 118 3

155

Pyrantel 4.29 Anthelmintic 15686-83-6 N/A 0.1 0.25 to 100 105 2

156

Pyrimethamine 6.31 Antimicrobial 58-14-0 N/A 0.05 0.1 to 100 112 2

157

Ractopamine 4.66 Growth promoters/Beta-agonists 97825-25-7 N/A 0.1 0.25 to 100 117 1

158

Rafoxanide 11.11 Anthelmintic 22662-39-1 10 0.25 0.5 to 100 70 4

159

Rifaximin 9.07 Antibiotic 80621-81-4 60 0.1 0.25 to 100 104 4

160

Robenidine 8.58 Coccidiostats 25875-51-8 N/A 0.25 0.5 to 100 101 4

161

Ronidazole 3.40 Anthelmintic/Nitroimidazoles 7681-76-7 N/A 0.1 0.25 to 100 119 2

162

Salbutamol [Albuterol] 3.03 Growth promoters/Beta-agonists 18559-94-9 N/A 0.05 0.1 to 100 105 2

163

Salinomycin 11.62 Coccidiostats 53003-10-4 N/A 0.1 0.25 to 100 77 6

164

Sarafloxacin 5.39 Antibiotic/Quinolones 98105-99-8 N/A 0.1 0.25 to 100 107 3

165

Spiramycin I 6.13 Antibiotic/Macrolides 24916-50-5 200 0.25 0.5 to 100 82 2

166

Sulfabenzamide 6.07 Antibiotic/Sulfonamides 127-71-9 100 0.05 0.1 to 100 120 2

167

Sulfacetamide 3.13 Antibiotic/Sulfonamides 144-80-9 100 0.1 0.25 to 100 115 2

168

Sulfachloropyridazine 5.25 Antibiotic/Sulfonamides 80-32-0 100 0.1 0.25 to 100 116 2

169

Sulfaclozine 6.30 Antibiotic/Sulfonamides 102-65-8 100 0.25 0.5 to 100 116 4

170

Sulfadiazine [Silvadene] 3.42 Antibiotic/Sulfonamides 68-35-9 100 0.1 0.25 to 100 120 2

171

Sulfadimethoxine 6.44 Antibiotic/Sulfonamides 122-11-2 100 0.05 0.1 to 100 119 2

172

Sulfadimidine [Sulfamethazine] 4.62 Antibiotic/Sulfonamides 57-68-1 100 0.1 0.25 to 100 114 2

173

Sulfadoxine 5.58 Antibiotic/Sulfonamides 2447-57-6 100 0.05 0.1 to 100 119 2

174

Sulfaethoxypyridazine 5.93 Antibiotic/Sulfonamides 963-14-4 100 0.05 0.1 to 100 117 1

175

Sulfaguanidine 1.72 Antibiotic/Sulfonamides 57-67-0 100 0.25 0.5 to 100 107 1

176

Sulfamerazine 4.02 Antibiotic/Sulfonamides 127-79-7 100 0.1 0.25 to 100 118 1

177

Sulfameter [sulfamethoxydiazine] 4.48 Antibiotic/Sulfonamides 651-06-9 100 0.1 0.25 to 100 113 2

178

Sulfamethizole 4.50 Antibiotic/Sulfonamides 144-82-1 100 0.1 0.25 to 100 115 3

179

Sulfamethoxazole 5.47 Antibiotic/Sulfonamides 723-46-6 100 0.1 0.25 to 100 116 2

180

Sulfamethoxypyridazine 4.68 Antibiotic/Sulfonamides 80-35-3 100 0.1 0.25 to 100 114 1

181

Sulfamonomethoxine 5.23 Antibiotic/Sulfonamides 1220-83-3 100 0.1 0.25 to 100 118 2

182

Sulfamoxole 4.31 Antibiotic/Sulfonamides 729-99-7 100 0.05 0.1 to 100 112 2

183

Sulfanitran 7.33 Antibiotic/Sulfonamides 122-16-7 100 1 2.5 to 100 115 7

184

Sulfaphenazole 6.34 Antibiotic/Sulfonamides 526-08-9 100 0.1 0.25 to 100 115 3

185

Sulfapyridine 3.83 Antibiotic/Sulfonamides 144-83-2 100 0.1 0.25 to 100 115 1

186

Sulfaquinoxaline 6.51 Antibiotic/Sulfonamides 59-40-5 100 0.1 0.25 to 100 119 3

187

Sulfathiazole 3.62 Antibiotic/Sulfonamides 72-14-0 100 0.1 0.25 to 100 115 2

188

Sulfisomidine 3.34 Antibiotic/Sulfonamides 515-64-0 100 0.05 0.1 to 100 111 1

189

Sulfisoxazole 5.76 Antibiotic/Sulfonamides 127-69-5 100 0.1 0.25 to 100 113 3

190

Sulindac 8.03 Antibiotic/Sulfonamides 38194-50-2 100 0.1 0.25 to 100 117 3

191

Teflubenzuron 10.08 Insecticide 83121-18-0 N/A 0.5 1 to 100 117 3

192

Testosterone 8.56 Growth promoters/Anabolic steroids 58-22-0 N/A 0.1 0.25 to 100 119 4

193

Tetracycline 4.78 Antibiotic/Tetracycline 60-54-8 100 0.25 0.5 to 100 64 4

194

Thiabendazole 4.34 Anthelmintic/Benzimidazoles 148-79-8 50 0.05 0.1 to 100 112 2

195

Thiamphenicol 4.33 Antibiotic/Amphenicols 15318-45-3 50 0.25 0.5 to 100 120 3

196

(min)

RT

Functional Use/

Chemical Class CAS Number

MRL

(µg/kg)

(µg/kg)

AOAC3

LOD

Curve Range

(μg/kg) with

R2 >0.99

MQC

Recovery

(%)

MQC

RSD

(%)

13

Page 14

Linear

Calibration

No. Compound Name

Tiamulin 7.68 Antibiotic 55297-95-5 N/A 0.05 0.1 to 100 114 2

197

Tilmicosin 6.87 Antibiotic/Macrolides 108050-54-0 50 1 2.5 to 100 90 7

198

Tolfenamic acid 9.94 NSAIDs 13710-19-5 50 1 2.5 to 100 114 8

199

Trenbolone 7.98 Growth promoters/Anabolic steroids 10161-33-8 N/A 0.25 0.5 to 100 111 4

200

Trichlorfon [DEP] 5.29 Tranquilizer 52-68-6 50 0.5 1 to 100 124 3

201

Triclabendazole 9.74 Anthelmintic/Benzimidazoles 68786-66-3 10 0.1 0.25 to 100 113 2

202

Trimethoprim 4.12 Antibiotic 738-70-5 50 0.1 0.25 to 100 108 3

203

Tripelennamine 6.39 Anthelmintic 91-81-6 20 0.05 0.1 to 100 105 2

204

Tylosin 7.64 Antibiotic/Macrolides 1401-69-0 50 0.5 1 to 100 109 5

205

Valnemulin 8.39 Antibiotic 101312-92-9 N/A 0.1 0.25 to 100 113 3

206

Vedaprofen 9.14 NSAIDs 71109-09-6 N/A 0.1 0.25 to 100 114 2

207

Virginiamycin M1 8.21 Antibiotic/Macrolides 21411-53-0 N/A 0.1 0.25 to 100 114 5

208

Xylazine 5.24 Tranquilizer 7361-61-7 N/A 0.1 0.25 to 100 109 2

209

Zilpaterol 2.98 Growth promoters/Beta-agonists 119520-05-7 N/A 0.1 0.25 to 100 96 3

210

(min)

RT

Functional Use/

Chemical Class CAS Number

MRL

(µg/kg)

(µg/kg)

AOAC3

LOD

Curve Range

(μg/kg) with

R2 >0.99

• Data using LLQC, * Data using LQC, # Data using HQC

MQC

Recovery

(%)

MQC

RSD

(%)

www.agilent.com/chem

DE44270.4828125

This information is subject to change without notice.

© Agilent Technologies, Inc. 2021

Printed in the USA, March 15, 2021

5994-3124EN

Loading...

Loading...