Page 1

Vacuum Products Division

VS Series Helium

Mass Spectrometer

Leak Detectors

MODELS: PR02, MR15, MD30, BR15, BD30 AND

PD03

OPERATION MANUAL

1 2

D R A F T 9 / 2 5 /

Manual No. 699909942

Revision G

September 2012

Page 2

VS Series Helium Mass Spectrometer

Leak Detector

D R A F T 9 / 2 5 / 1 2

Contra-Flow is a trademark or registered trademark of Agilent, Inc.

Alconox is a registered trademark of Alconox, Inc.

Apiezon is a registered trademark of M&I Materials Ltd.

Copyright 2012

Agilent, Inc

Page 3

VS Series Helium Mass Spectrometer Leak Detectors

Warranty

Products manufactured by Seller are warranted against defects in materials and workmanship for

twelve (12) months from date of shipment thereof to Customer, and Seller’s liability under valid warranty claims is limited, at the option of Seller, to repair, to replace, or refund of an equitable portion of

the purchase price of the Product. Items expendable in normal use are not covered by this warranty. All

warranty replacement or repair of parts shall be limited to equipment malfunctions which, in the sole

opinion of Seller, are due or traceable to defects in original materials or workmanship. All obligations of

Seller under this warranty shall cease in the event of abuse, accident, alteration, misuse, or neglect of

the equipment. In-warranty repaired or replaced parts are warranted only for the remaining unexpired

portion of the original warranty period applicable to the repaired or replaced parts. After expiration of

the applicable warranty period, Customer shall be charged at the then current prices for parts, labor,

and transportation.

Reasonable care must be used to avoid hazards. Seller expressly disclaims responsibility for loss or

damage caused by use of its Products other than in accordance with proper operating procedures.

Except as stated herein, Seller makes no warranty, express or implied (either in fact or by operation of

law), statutory or otherwise; and, except as stated herein, Seller shall have no liability under any warranty, express or implied (either in fact or by operation of law), statutory or otherwise. Statements made

by any person, including representatives of Seller, which are inconsistent or in conflict with the terms of

this warranty shall not be binding upon Seller unless reduced to writing and approved by an officer of

Seller.

Warranty Replacement and Adjustment

All claims under warranty must be made promptly after occurrence of circumstances giving rise thereto,

and must be received within the applicable warranty period by Seller or its authorized representative.

Such claims should include the Product serial number, the date of shipment, and a full description of

the circumstances giving rise to the claim. Before any Products are returned for repair and/or adjustment, written authorization from Seller or its authorized representative for the return and instructions as

to how and where these Products should be returned must be obtained. Any Product returned to Seller

for examination shall be prepaid via the means of transportation indicated as acceptable by Seller.

Seller reserves the right to reject any warranty claim not promptly reported and any warranty claim on

any item that has been altered or has been returned by non-acceptable means of transportation. When

any Product is returned for examination and inspection, or for any other reason, Customer shall be

responsible for all damage resulting from improper packing or handling, and for loss in transit, notwithstanding any defect or non-conformity in the Product. In all cases, Seller has the sole responsibility for

determining the cause and nature of failure, and Seller’s determination with regard thereto shall be

final.

If it is found that Seller’s Product has been returned without cause and is still serviceable, Customer will

be notified and the Product returned at Customer’s expense; in addition, a charge for testing and examination may be made on Products so returned.

D R A F T 9 / 2 5 / 1 2

Page 4

VS Series Helium Mass Spectrometer Leak Detectors

D R A F T 9 / 2 5 / 1 2

This page intentionally left blank.

Page 5

VS Series Helium Mass Spectrometer Leak Detectors

Table of Contents

Preface ..............................................................................................................................................xii

Documentation Standards ..........................................................................................................xii

Hazard and Safety Information ..................................................................................................xiii

Agilent Services ........................................................................................................................xxii

Contacting Agilent .....................................................................................................................xxii

Section 1. Introduction to the VS Series Leak Detector ..................................................................1-1

1.1 The VS Series Leak Detector .............................................................................................1-1

1.2 Unpacking the Leak Detector...............................................................................................1-5

1.2.2 Removing the Leak Detector from the Skid ................................................................1-6

1.3 Installation............................................................................................................................1-8

1.3.2 Recommended Additional Services ..........................................................................1-11

1.3.3 Storage......................................................................................................................1-11

1.4 Front Panel Display and Controls ......................................................................................1-12

1.5 Display Panel Controls.......................................................................................................1-16

1.6 Rear Panel.........................................................................................................................1-18

1.7 Features.............................................................................................................................1-22

Section 2. Operating the Leak Detector ..........................................................................................2-1

2.1 Initial Startup, High Pressure Test Setup, and Shutdown ...................................................2-1

2.1.2 High Pressure Test Set-Up Procedure........................................................................2-3

2.1.3 Shutdown ....................................................................................................................2-4

2.2 Screens................................................................................................................................2-5

2.2.2 Home Screen..............................................................................................................2-7

2.2.3 Control Panel Screen................................................................................................2-12

2.2.4 Menus Screen...........................................................................................................2-16

Section 3. Set-Up ............................................................................................................................3-1

3.1 Set-Up Menu .......................................................................................................................3-1

3.1.2 Manual Tuning ............................................................................................................3-7

3.1.3 Manual Valve Control................................................................................................3-10

3.1.4 Output Control...........................................................................................................3-13

3.1.5 Units..........................................................................................................................3-15

3.1.6 Languages ................................................................................................................3-16

3.1.7 Gauge Calibration.....................................................................................................3-17

3.1.8 Maintenance..............................................................................................................3-19

3.1.9 Password ..................................................................................................................3-24

3.1.10 Fore Pump Set-Up and Exhaust Pump...................................................................3-25

3.1.11 Wireless ..................................................................................................................3-27

3.1.12 System Defaults......................................................................................................3-29

D R A F T 9 / 2 5 / 1 2

Section 4. Maintenance ..................................................................................................................4-1

4.1 Daily Maintenance ..............................................................................................................4-5

v

Page 6

VS Series Helium Mass Spectrometer Leak Detectors

4.2 Dry Nitrogen Vent ................................................................................................................4-5

4.3 Spare Parts List ................................................................................................................... 4-6

4.4 Leak Detector Accessory Item List ...................................................................................... 4-8

Appendix A. Communications Protocol ..........................................................................................A-1

A.2 Communicating with RS-232...............................................................................................A-2

A.2.1 Windows HyperTerminal Set-Up Instructions ............................................................A-2

A.2.2 Printing with HyperTerminal ......................................................................................A-4

A.3 Customer Accessible Inputs and Outputs .........................................................................A-14

A.3.1 Serial Connector ......................................................................................................A-14

A.3.2 I/O Connector ..........................................................................................................A-14

Appendix B. Introduction to Leak Detection ....................................................................................B-1

B.2 Agilent's Helium Leak Detection Technologies ...................................................................B-1

B.3 Methods of Leak Testing .....................................................................................................B-3

B.3.1 Vacuum Testing Method (Outside-in) ........................................................................B-4

B.3.2 Pressure Testing Method (Inside-out) .......................................................................B-5

B.3.3 System Leak Test Methods .......................................................................................B-6

B.4 Typical Leak Detection Applications....................................................................................B-8

B.4.1 Quality Control of Production Parts and Assemblies .................................................B-8

B.4.2 Maintenance of Systems ...........................................................................................B-8

B.4.3 System Integrated Leak Detection ............................................................................B-9

B.4.4 Mass Produced Parts ................................................................................................B-9

Appendix C. Specifications .............................................................................................................C-1

D R A F T 9 / 2 5 / 1 2

vi

Page 7

VS Series Helium Mass Spectrometer Leak Detectors

List of Figures

Figure Title Page

1-1 Portable Leak Detector with Internal DS42 Wet Rotary Vane Pump, Model VS PR02, and

Portable Leak Detector with Internal IDP-3 (PD03) Dimensions1- ........................................3

1-2 Mobile Leak Detector with External DS302 Wet Rotary Vane Pump on a Cart, Model VS

MR15, Dimensions1- ............................................................................................................. 3

1-3 Mobile Leak Detector with External TS620 Dry Scroll Pump on a Cart, Model VS MD30,

Dimensions1-.........................................................................................................................4

1-4 Bench Mount Leak Detector with External DS302 Wet Rotary Vane Pump, Model VS BRI5 .

1-.......................................................................................................................................... 10

1-5 Bench Mount Leak Detector with External TS620 Dry Scroll Pump, Model VS BD30......1-10

1-6 Front Panel Displays and Controls ...................................................................................1-12

1-7 Screen Flow......................................................................................................................1-15

1-8 VS Series Rear Panel.......................................................................................................1-18

1-9 Optional I/O PCB Rear Panel ...........................................................................................1-19

1-10 Rear Panel (with Discrete I/O PCB)..................................................................................1-21

2-1 Helium Background Timer ..................................................................................................2-2

2-2 Home Screen......................................................................................................................2-7

2-3 Gross Test Screen..............................................................................................................2-9

2-4 Control Panel ....................................................................................................................2-12

2-5 20 Minute Warmup Dialog ................................................................................................2-14

2-6 Graphical Display..............................................................................................................2-15

2-7 Menus Screen...................................................................................................................2-16

2-8 Calibration Set-Up.............................................................................................................2-17

2-9 Helium Background Timer ................................................................................................2-18

2-10 Reject and Audio Setpoints...............................................................................................2-19

2-11 Auto Sequencer ................................................................................................................2-23

2-12 Leak Rate Ranging...........................................................................................................2-25

2-13 Transfer Points..................................................................................................................2-28

2-14 Transfer Points with Stabilization Wait Timer ...................................................................2-29

2-15 System Information...........................................................................................................2-30

2-16 Control Panel Access........................................................................................................2-32

3-1 Set-Up Screen - Initial.........................................................................................................3-1

3-2 Set-Up Screen - Second.....................................................................................................3-2

3-3 Advanced Parameters ........................................................................................................3-3

3-4 Manual Tuning ....................................................................................................................3-7

3-5 Manual Valve Control........................................................................................................3-10

3-6 Manual Valve Control - PD03 ...........................................................................................3-11

3-7 Leak Detector Vacuum System Diagram..........................................................................3-12

3-8 Output Control...................................................................................................................3-13

3-9 Leak Detector Linear Output Voltage................................................................................3-14

3-10 Leak Detector Logarithmic Output Voltage.......................................................................3-14

3-11 Units..................................................................................................................................3-15

3-12 Languages ........................................................................................................................3-16

D R A F T 9 / 2 5 / 1 2

vii

Page 8

VS Series Helium Mass Spectrometer Leak Detectors

3-13 Gauge Calibration............................................................................................................. 3-17

3-14 Maintenance .....................................................................................................................3-19

3-15 Vent Turbo Dialog............................................................................................................. 3-20

3-16 Current Date & Time Set-Up............................................................................................. 3-21

3-17 Internal Calibrated Leak.................................................................................................... 3-22

3-18 Cal Leak Expiration Set-Up ..............................................................................................3-23

3-19 Password Screen.............................................................................................................. 3-24

3-20 Fore Pump Set-Up............................................................................................................3-25

3-21 Exhaust Pump ..................................................................................................................3-25

3-22 Date Serviced ...................................................................................................................3-26

3-23 Wireless............................................................................................................................3-27

3-24 System Defaults Screen ...................................................................................................3-29

A-1 Serial Connector Map.......................................................................................................A-14

A-2 Optically Isolated Output Circuit Sketch ...........................................................................A-17

A-3 Optically Isolated Input Circuit Sketch ..............................................................................A-18

B-1 Magnetic Separation Principle............................................................................................B-2

B-2 Selective Ion Pump Detector ..............................................................................................B-3

B-3 Locating Leaks: Outside In .................................................................................................B-4

B-4 Measuring Leaks: Outside In..............................................................................................B-4

B-5 Measuring Leaks: Inside Out..............................................................................................B-5

B-6 Locating Leaks: Inside Out .................................................................................................B-5

B-7 Accumulation: Inside Out....................................................................................................B-6

B-8 Vacuum System..................................................................................................................B-7

D R A F T 9 / 2 5 / 1 2

viii

Page 9

VS Series Helium Mass Spectrometer Leak Detectors

List of Tables

Table Title Page

1-1 VS Series Leak Detector Configurations and Part Numbers ............................................. 1-2

1-2 Installation Requirements .................................................................................................. 1-8

1-3 Screens – General Description........................................................................................ 1-16

1-4 VS Series Features.......................................................................................................... 1-22

2-1 Screen Basic Functional Items .......................................................................................... 2-5

2-2 On-Screen Icons................................................................................................................ 2-6

2-3 Leak Detector Operating States......................................................................................... 2-9

2-4 Leak Detector Condition States ....................................................................................... 2-10

2-5 Range Stop/Sensitivity Requirements ............................................................................. 2-26

2-6 System Information Screen Conditions............................................................................ 2-30

3-1 Leak Detector Valve State Table - Single Mechanical Pump System ............................. 3-12

4-1 Scheduled Maintenance .................................................................................................... 4-3

4-2 As-Required Maintenance ................................................................................................. 4-3

4-3 Fuses and Circuit Breakers................................................................................................ 4-4

4-4 Leak Detector Spare Parts................................................................................................. 4-6

4-5 Leak Detector Accessory Item List .................................................................................... 4-8

D R A F T 9 / 2 5 / 1 2

ix

Page 10

VS Series Helium Mass Spectrometer Leak Detectors

D R A F T 9 / 2 5 / 1 2

This page intentionally left blank.

Page 11

We

CE DECLARATION OF CONFORMITY

Wir

Nous

Nosotros

Wij

Lexington, MA, 02421-3133 USA

Agilent, Inc.

121 Hartwell Avenue

Noi

declare under our sole responsibility that the product,

erklären, in alleniniger Verantwortung, daß dieses Produkt,

déclarons sous notre seule responsabilité que le produit,

declaramos, bajo nuestra sola responsabilidad, que el producto,

verklaren onder onze verantwoordelijkheid, dat het product,

dichiariamo sotto nostra unica responsabilità, che il prodotto,

VS Series Helium Mass Spectrometer Leak Detectors:

Models VS PR02x, VS MR15x, VS MD30x, VS BR15x, VS BD30x and VS PD03x

(With Optional Wireless Remote Control and Discrete I/O)

to which this declaration relates is in conformity with the following standards:

Safety:

• EN 61010-1, Second Edition, 2001 - Safety Requirements for Electrical Equipment for Measurement, Control, and Laboratory Use-Part 1:

General Requirements

per the provisions of the Low Voltage Directive 73/23/EEC of 19 February 1973 as Amended by 93/68/EEC, Article 13, of 22 July 1993.

• CAN/CSA-C22.2 No. 61010-1-04 - Safety Requirements for Electrical Equipment for Measurement, Control, and Laboratory Use-Part 1: General

Requirements (Adopted IEC 61010-1:2001, MOD)

• UL 61010-1, Second Edition, 2004 - Safety Requirements for Electrical Equipment for Measurement, Control, and Laboratory Use-Part 1:

General Requirements

EMC Emission and Immunity:

• EN 55011:1998/A1: 1999/A2: 2002 Group 1 Class A: ISM radio-frequency equipment - Radio disturbance characteristics - Limits and methods

of measurement (EU)

• EN 61326:1997/A1: 1998 /A2:2001 Electrical equipment for measurement, control and laboratory use - EMC requirements (EU)

per the provisions of the Electromagnetic Compatibility Directive 89/336/EEC of 3 May 1989 as Amended by 92/31/EEC of 28 April 1992 and 93/68/

EEC, Article 5 of 22 July 1993

• AS/NZS CISPR 11:2004 Class A: ISM radio-frequency equipment - Electromagnetic disturbance characteristics - Limits and methods of

measurement (Australia)

• FCC: Code of Federal Regulations, 47CFR: 2004, Part 15C, Section 15.24, Class A: Telecommunication, Radio Frequency Devices, Operation

within the bands 902-928 MHz, 2400-2483.5 MHz, and 5725-5850 MHz (USA)

• CAN/IC: Radio Standard Specification RSS-210, Issue 5, for Low Power License- Exempt Radio communication Devices of Industry Canada,

November 2001 (Canada)

EMC and Radio Spectrum Matters:

• EN 300 328-1 V1.3.1 (2001-12) Electromagnetic compatibility and Radio spectrum Matters (ERM): Wiband Transmission systems; Data

transmitting equipment operating in the 2.4 GHz ISM band and using spread spectrum modulation techniques; Part 1: Technical characteristics and

test conditions (EU)

• EN 300 328-2 V1.2.1 (2001-12) Electromagnetic compatibility and Radio spectrum Matters (ERM): Wiband Transmission systems; Data

transmitting equipment operating in the 2.4 GHz ISM band and using spread spectrum modulation techniques; Part 2: Harmonized EN covering

essential requirements under article 3.2 of R&TTE Directive (EU)

• EN 301 489-1 V1.3.1 (2001-09) Electromagnetic compatibility and Radio spectrum Matters (ERM): Electromagnetic Compatibility (EMC)

standard for radio equipment and services: Part 1: Common Technical requirements (EU)

• EN 301 489-17 V1.1.1 (2001-09) Electromagnetic compatibility and Radio spectrum Matters (ERM): Electromagnetic Compatibility (EMC)

standard for radio equipment and services: Part 17: Specific conditions for Wideband data and HIPERLAN equipment (EU)

per the provisions of the Radio and Telecommunications Terminal Equipment (R&TTE) Directive, 1999/5/EC of 9 March 1999

The authorized representative located within Community is:

Agilent (Torino)

John Ehmam

Via F.lli Varian.54

Leini (Torino) - Italy

Tel: (39) 011 997 9 111

Fax: (39) 011 997 9 350

Operations Manager

Agilent, Inc.

Lexington, Massachusetts, USA

Page 12

VS Series Helium Mass Spectrometer Leak Detectors

Preface

Documentation Standards

This manual uses the following documentation standards:

Text

NOTE

CAUTION

WARNING

Hard buttons are depicted in text in bold text.

Soft key screen buttons are depicted in bold text when part of an action.

Italics is used for emphasis or to indicate screen text.

Notes contain important information.

Cautions appear before instructions, which if not followed,

could cause damage to the equipment or data loss.

Warnings appear for a particular procedure or practice which, if

not followed correctly, could lead to serious injury or death.

D R A F T 9 / 2 5 / 1 2

xii

Page 13

VS Series Helium Mass Spectrometer Leak Detectors

l

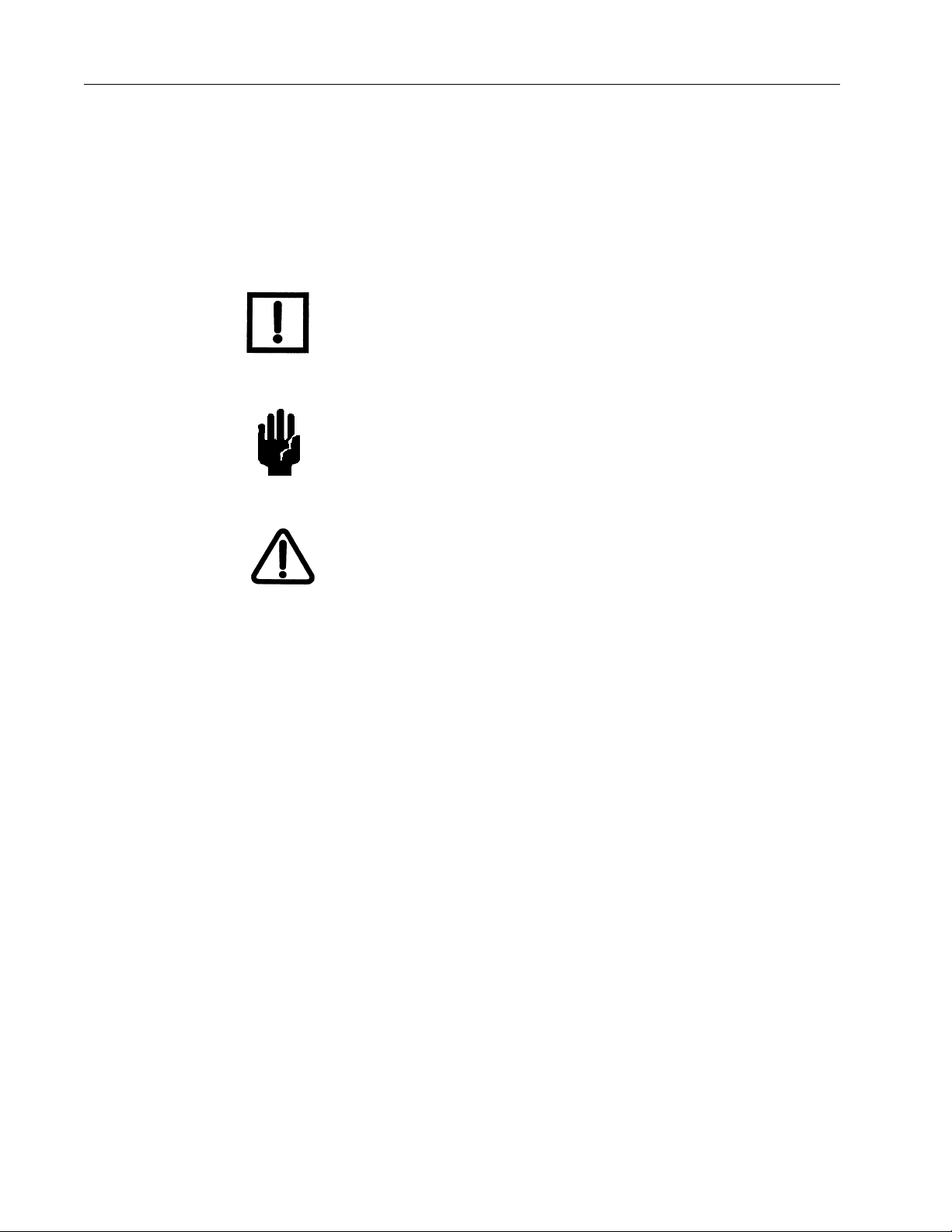

Hazard and Safety Information

The common international symbols used in this manual and on the equipment are defined

below.

OFF Supply (Power) Earth (Ground) Terminal

ON Supply (Power) Caution, Hot Surface

AC – Alternating Current Caution, Risk of Electrical

Warning, Risk of danger Protective Conductor

Frame or chassis Terminal Do Not Place in Trash

Shock

Terminal

Indoor, Dry Location Use

Only

Operators and service personnel must be aware of all hazards associated with this

equipment. They must know how to recognize hazardous and potentially hazardous

conditions, and know how to avoid them. The consequences of unskilled, improper, or

careless operation of the equipment can be serious. Every operator or service person must

read and thoroughly understand operation/maintenance manuals and any additional

information provided by Agilent. All warning and cautions must be read carefully and

strictly observed. Consult local, state, and national agencies regarding specific requirements

and regulations. Address any safety, operation, and/or maintenance questions to your

nearest Agilent office.

Caution, Radio

Restriction

D R A F T 9 / 2 5 / 1 2

xiii

Page 14

Solvents

VS Series Helium Mass Spectrometer Leak Detectors

WARNING

The mechanical components of leak detectors are typically

cleaned with alcohol, methanol, or other solvents.

When heated, sprayed, or exposed to high-temperature

equipment, these solvents become flammable and explosive,

causing serious injury or death. Do not use these solvents near

a high-temperature source. Ventilate the working area with a

blower and work in a large, well-ventilated room.

Alcohol, methanol, or other solvents are irritants, narcotics,

depressants and/or carcinogens. Their inhalation and/or

ingestion may produce serious side effects. Prolonged or

continued contact with the skin results in absorption through

the skin and moderate toxicity. Always ensure that cleaning

operations are carried out in large, well-ventilated rooms, and

wear eye shields, gloves, and protective clothing.

To clean the leak detector plastic enclosure, the LCD display

and Front Panel buttons, use only a soft cloth slightly

dampened with water or a mild soap.

Do NOT use excess water or cleaning solvents of any kind.

Avoid splashing any cleaning solvents into the unit through the

ventilation openings or Front Panel buttons. Wipe the surface

with a dry lint-free cloth.

CAUTION

Vacuum Equipment and Cleanliness

D R A F T 9 / 2 5 / 1 2

Cleanliness is vital when servicing the leak detector or any vacuum equipment. There are

some techniques that are more important in leak detector servicing than in general vacuum

work:

CAUTION

NOTE

Do not clean any aluminum parts with Alconox®. Alconox is

not compatible with aluminum and will cause damage.

Do not use silicone oil or silicone grease.

Use powder-free butyl or polycarbonate gloves to prevent skin

oils from getting on vacuum surfaces.

Agilent does not recommend the use of vacuum grease.

Vacuum grease absorbs helium tracer gas and releases this

slowly resulting in helium background during leak test

operations. If it must be used, use it sparingly and avoid

silicone types. Apiezon®L grease is recommended (Agilent Part

No. 695400004).

xiv

Page 15

O-ring Care

When removing, checking or replacing O-rings, keep in mind the following:

VS Series Helium Mass Spectrometer Leak Detectors

NOTE

NOTE

CAUTION

Agilent recommends replacing all O-rings during routine

maintenance or during any maintenance procedure requiring

that O-rings be removed.

Due to the effective cleaning nature of VacuSolv solvent and

its residue-free properties, Agilent’ Component and

Spectrometer Cleaning Kit (Part Number 670029096), used in

accordance with the kit instructions, is recommended for

cleaning spectrometer components. The kit can also be used for

fine cleaning of other parts in the leak detector’s vacuum

system such as valves and fittings. No rinsing steps or

high-temperature drying are required following cleaning with

VacuSolv. Although appropriate precautions are advised,

VacuSolv is compatible with most materials and does not

contain toxic chemicals or CFCs (chlorofluorocarbons). Other

acceptable solvents are isopropyl alcohol (IPA) or Dow

Corning® OS-20.

Remove O-rings carefully with your fingers. Do not use metal

tools for this task; this prevents scratching of any sealing

surfaces.

❑

Wipe all O-rings clean with a lint-free cloth before

installation to ensure that no foreign matter is present to

impair the seal.

❑

Do not use grease or any other substance on O-rings that

will come in contact with the spectrometer.

❑

Do not use alcohol, methanol or other solvents on O-rings.

Doing so causes deterioration and reduces their ability to

hold a vacuum.

❑

Agilent does not recommend the use of vacuum grease. If

applicable, apply a small amount of Apiezon®L grease and

wipe the O-rings shiny dry.

D R A F T 9 / 2 5 / 1 2

xv

Page 16

Metal Seal Care

VS Series Helium Mass Spectrometer Leak Detectors

CAUTION

Equipment, General

Metal Seals must be replaced during routine maintenance or

during any maintenance procedure required. All fasteners must

be installed and torqued per assembly procedure specifications.

Remove Metal Seals carefully with your fingers. Do not use

metal tools for this task, this prevents scratching of any sealing

surfaces. Wear non-powdered, ESD safe Nitride or equivalent

gloves prior to removing or replacing Metal Seals.

❑

All Metal Seals come in clean room condition packages. No

cleaning is required If necessary, Metal Seals can be cleaned

using alcohol or methanol. Wipe all Metal Seals clean with a

lint free cloth before installation to ensure that no foreign

matter is present to impair the seal.

❑

Do not use grease or any other substance on Metal Seals that

will come in contact with the spectrometer.

Environment of intended use:

❑

Indoors use in an industrial and laboratory installation only.

❑

Altitude up to 2000m

❑

POLLUTION DEGREE 2, Material group III

❑

Operating Temperature: +12 °C to +45 °C, Relative

Humidity (RH) up to 90% max.

❑

Storage ambient conditions: RH from 0% to 95%,

non-condensing, temperature: -20°C to +60°C

D R A F T 9 / 2 5 / 1 2

WARNING ❑

WARNING

Do not use in presence of flammable or explosive gas.

❑

Do not attempt to disassemble or modify the equipment.

Such action could lead to electric shock or injury. Agilent's

authorized technician will do any repair work.

❑

If there is smoke or unusual smell or noise, stop the using the

equipment immediately, and contact the Agilent Service

Center.

The leak detector is not designed for use with hazardous gases.

Verify that the system to be tested has been purged of all

hazardous gases prior to using the leak detector. When testing a

system that contained hazardous gases, connect the exhaust of

the leak detector to a scrubbed or toxic containment exhaust.

Exposure to hazardous gases could result in serious injury or

death.

xvi

Page 17

VS Series Helium Mass Spectrometer Leak Detectors

WARNING

CAUTION

LCD Display

WARNING

CAUTION

Equipment tightness is guaranteed for normal operating

conditions when the equipment leaves the factory. It is the

user’s responsibility to maintain the level of tightness,

particularly when pumping dangerous products.

The performance and operating safety of this equipment can

only be guaranteed if it is operated according to normal

conditions of use.

Allow at least 4" of clearance adjacent to the ventilation slots at

the front, sides and back of the equipment enclosure.

Allow sufficient room for the operator to safely maneuver to

perform testing.

If the LCD display breaks, avoid getting any liquid crystal in mouth

or eyes. If it gets on the operator hands, feet or clothing, wash it

immediately with soap and water.

Do not apply excessive pressure to the LCD display as this may

cause smears.

In general, the lower the temperature, the longer it takes the LCD

display to turn on. Performance of the LCD display may deteriorate

in low temperature.

Radio The Wireless Remote Control is built around an Aerocomm, model

AC4424-100, RF transceiver module operating in 2.4 GHz ISM

band. The same type of the RF module is built in a VS Series Leak

Detector Wireless Base Station PCB and Wireless Remote unit (see

VS Series Leak Detector Wireless Remote Operational Manual

(6999099945A)).

Agency Identification Numbers for Aerocomm, Model

AC4424-100:

❑

US/FCC ID: KQL-AC4424

❑

CAN/IC: CAN2268C391190A

❑

EUR/EN: CE

are also applied to the Agilent's Wireless Remote and VS Series

Leak Detector Wireless Base Station, when the units are used the

approved antennas.

D R A F T 9 / 2 5 / 1 2

xvii

Page 18

VS Series Helium Mass Spectrometer Leak Detectors

WARNING

CAUTION

The Wireless Remote complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions: (1) This

device may not cause harmful interference, and (2) This device

must accept any interference received, including interference that

may cause undesired operation.

To satisfy FCC RF exposure requirements for mobile type transmitting devices, maintain a separation distance of 20 cm or more

between the antenna of the Wireless Remote and persons during

operation, with exception of hands wrist, feet, and ankles. To

ensure compliance, operations at closer distance than this distance

are prohibited.

Maintain a separation distance of 20 cm or more between the operator and the RF antenna of the VS Series leak detector with a wireless base station.

Use only approved type of antennas for:

❑

Wireless Remote: Centurion, Model WCP2400-MMCX2,

www.centurion.com.

❑

VS Series Leak Detector Wireless Base Station, Nearson,

Model S181FL-5-RMM- 2450S, www.nearson.com

Power and Static Sensitivity

WARNING

D R A F T 9 / 2 5 / 1 2

Depending on the unit configuration ordered, the mains power

supply requirements for VS Series leak detectors are:

❑

100 VAC, 50 Hz, 20 A

❑

115 VAC, 60 Hz, 20 A or

❑

230 VAC, 50/60 Hz, 12 A

Before powering the unit for the first time, verify that the unit is

configured to operate for the local mains supply voltage.

xviii

Page 19

VS Series Helium Mass Spectrometer Leak Detectors

CAUTION

CAUTION

CAUTION

Use surge protection to improve the immunity of the leak

detector against unidirectional transients caused by the

following phenomena:

❑

Switching phenomena in the power network

(e.g., switching of capacitor banks, inductive loads,

electrical motors, etc.)

❑

Faults in the power network

❑

Indirect lightning strokes

Many components of the leak detector are static sensitive.

Wear a grounding device when performing any maintenance

on the leak detector, especially when performing maintenance

of static sensitive parts, such as circuit boards and the

spectrometer.

This equipment has been tested and found to comply with the

limits for Class A digital device, pursuant to Part 15 of FCC

Rules. These limits are designed to provide reasonable

protection against harmful interference when it is operated in a

commercial environment.

This equipment generates, uses, and can radiate RF energy,

which if not installed and used in accordance with the

instructional manual, can cause harmful interference to

radio communications.

When this equipment is operated in a commercial

environment, operation is subject to the following two

conditions:

xix

❑

This equipment must not cause harmful interference.

❑

This equipment must accept any interference received,

including interference (RF and ESD) that may cause

undesired operation.

The equipment may need to be reset after RF and/or ESD events

by cycling the Power Switch/Circuit Breaker on the back panel

of the unit.

Operation of this equipment in a residential area is also likely to

cause harmful radio communications interference, in which

case, the users will be required to correct the interference at

their expense.

D R A F T 9 / 2 5 / 1 2

Page 20

VS Series Helium Mass Spectrometer Leak Detectors

WARNING

This equipment is designed to meet current EEC regulations:

LVD (Low Voltage Directive, 73/23/EEC:1993) and EMC

(Electromagnetic Compatibility Directive, 89/336/EEC:1993) for

Material Group III, Pollution Degree 2 environment for

Industrial, Scientific, Measuring and Process Control Electrical

Equipment and R&TTE (Radio and Telecommunications

Terminal Equipment Directive, 199915/EC:1999)

❑

Any modifications on the part of the user are liable to cause

non-compliance with regulations or affect the EMC

performance and the safety of the product. Agilent cannot

be held responsible for consequences resulting from such

intervention.

❑

Before powering the unit the first time, verify that the unit is

configured to operate for the local mains supply voltage.

❑

The equipment can be damaged by:

❑

Incorrect mains AC supply voltages

❑

Radio Frequency (RF) and Electrostatic Discharge (ESD)

energy inputs that exceed the maximum ratings

❑

Operating in very high temperatures or without adequate

ventilation

D R A F T 9 / 2 5 / 1 2

❑

Immersion in liquids

❑

Physical abuse

❑

All electrical connections must be performed by a qualified

electrician and must comply with national and local codes.

❑

Opening the enclosure may expose hazardous voltages.

Always disconnect the power cord and interface cables

before opening the enclosure. Do not touch the power

inlet’s contacts for at least 10 seconds after disconnecting

the power cord.

❑

Electrical installation must include the appropriate branch

circuit (20 A maximum), with a long time delay and a

reliable earth ground.

❑

Use only the power cord that was provided with your leak

detector. The use of extension cords is not recommended

and could result in damage to the equipment and loss of

warranty.

❑

To avoid electric shock, connect the product power cord to

a grounded power receptacle. A power cord with a

grounding conductor is required.

xx

Page 21

Spectrometer

VS Series Helium Mass Spectrometer Leak Detectors

WARNING

CAUTION

CAUTION

CAUTION

Store the Ion Source/Preamplifier sub-assembly in a cool, dry

area in a tightly sealed, ESD protected container. Wear lint-free

gloves when handling the spectrometer. Wash hands

thoroughly after handling the spectrometer filaments and

especially before smoking or eating.

The spectrometer operates at a very high vacuum produced by

the high vacuum pump. Service of the spectrometer requires

that this vacuum be vented to the atmosphere.

Do not use grease or any other substance on O-rings or metal

seals that will come in contact with the spectrometer.

If the spectrometer magnet comes in contact with a magnetic

surface, the magnet can become degraded causing the

spectrometer to lose sensitivity.

Pumps

WARNING

WARNING

To avoid injury, use proper lifting techniques when moving

pumps. Two people may be required to move pumps safely.

D R A F T 9 / 2 5 / 1 2

The vacuum pumps are also compressors; incorrect operation

may be dangerous. Study the Mechanical Pump Operation

Manual enclosed with your pump before starting pumps.

The pumps are designed to prevent any thermal risk for user

safety. However, specific operating conditions may generate

temperatures >70 °C.

Hot oil burns the skin. Service of the pumps in this area must be

performed by authorized personnel only. Stand back from a

mechanical pump before starting it.

xxi

Page 22

VS Series Helium Mass Spectrometer Leak Detectors

WARNING

CAUTION

Agilent Services

Agilent offers:

❑

Rebuilt spectrometers on an exchange basis.

❑

NIST-traceable calibrated leak testing and verification services.

❑

Preventive maintenance services.

❑

Overhaul services.

❑

System recertification.

To avoid injury, wait until the turbo pump is completely

stopped before disconnecting it from the vacuum system.

To vent the turbo, use the system vent function described in

Section 3.1.8.1 “Turbo Vent” on page 3-20.

Check the oil level often. Do not allow oil-based mechanical

pumps to run when the oil level is below the LOW mark.

Damage to pumps can occur if operated with no oil, if the oil

level is too high or if the oil has become discolored.

❑

Support agreements.

❑

On-site support.

Please see our catalog or contact us to learn about available services.

Contacting Agilent

D R A F T 9 / 2 5 / 1 2

In the United States, you can contact Agilent Customer Service at 1-800-882-7426. See the

back cover of this manual for a listing of our sales and service offices.

Visit our web site at: http://www.chem.agilent.com/en-US/Products/Instruments/vacuum/

pages/default.aspx.

xxii

Page 23

VS Series Helium Mass Spectrometer Leak Detectors

Section 1. Introduction to the VS Series

Leak Detector

1.1 The VS Series Leak Detector

The VS Series is a wide-range Helium Mass Spectrometer Leak Detector, which is

comprised of a turbo molecular high vacuum pump, internal mechanical rough pump

(model VS PR02), internal scroll pump (model PD03), external mechanical rough pump

(models VS MR15, VS MD30, VS BR15 and VS BD30), spectrometer tube, valve block, leak

detector electronics, an operator interface (TFT-LCD display with a touch panel and two

hard buttons: TEST and VENT), and optional features, including:

❑

Wireless remote control that is includes:

❑

Wireless Base PCB (P/N R2541301) installed in a VS leak detector

❑

Wireless Remote unit (P/N R3000301).

❑

Optional I/O PCB (P/N R2111301).

Both models VS MR15x and VS MD30x include an optional two-wheel cart.

All models are available in 100/115 VAC and 230 VAC configurations (see Table 1-1 on

page 1-2).

The wireless remote control has the following capabilities:

❑

RF communication between VS leak detector (Base Station or Host) and the Wireless

Remote unit from the distance up to 100 m (300 ft).

❑

Enter the VS leak detector unit into Test and Hold modes from the Wireless Remote

unit keypad.

❑

Read the VS leak detector unit's leak rate in a linear and logarithmic bar graph

format with a numeric range indicator and System status in alphanumeric format on

the Wireless Remote unit LCD display.

❑

Configure up to ten different VS leak detector units for wireless control by toggling

through a MAC address list using one Wireless Remote unit.

The optional I/O PCB compromises:

❑

Optically isolated parallel I/O (DB25 female connector with 12 output and 8 input

lines) to use with an external PLC and should be powered by the user (+5-24 VDC)

via a cable with length less than 10’ and provided by the user (see Appendix A.3.2

“I/O Connector” on page A-14).

D R A F T 9 / 2 5 / 1 2

1-1

Page 24

VS Series Helium Mass Spectrometer Leak Detectors

Model

Number

VS PR02

CAUTION

The usage of a longer cable for the parallel I/O output

connection with an external PLC is fully responsibility of the

user. Some EMC prevention measure may be required by the

user

❑

USB HUB with two downstream type A connectors and one upstream type B

connector.

NOTE

USB features are SW disabled in this release.

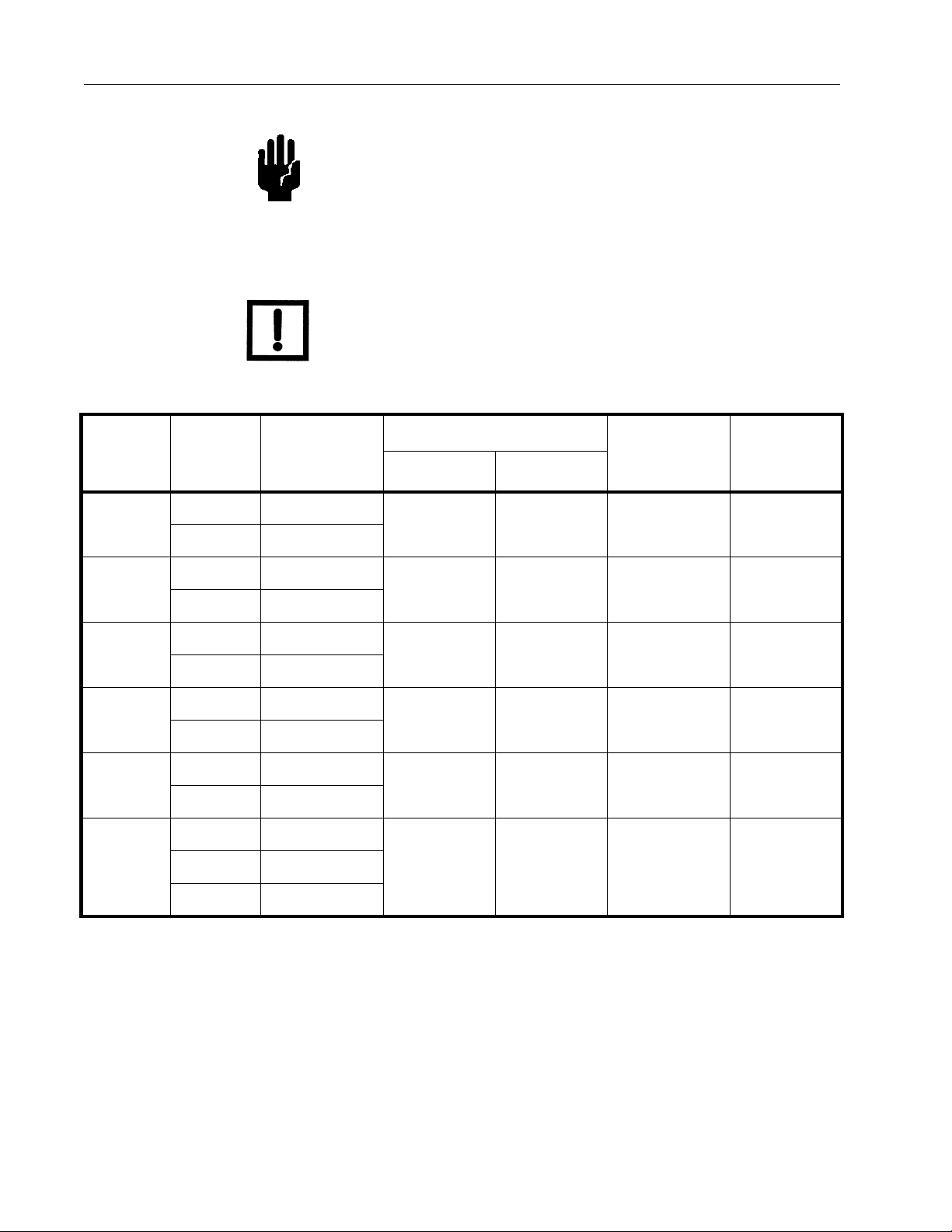

Table 1-1 VS Series Leak Detector Configurations and Part Numbers

Vacuum Pump System

Agilent

P/N

Mains

Voltage

Configuration

VSPR021 100/115 VAC

DS-42 N/A Portable N/A

VSPR022 230 VAC

Two

Wheel

CartInternal External

VS MR15

VS MD30

VS BR15

D R A F T 9 / 2 5 / 1 2

VS BD30

VS PD03

VSMR151 100/115 VAC

N/A DS302 Mobile Yes

VSMR152 230 VAC

VSMD301 100/115 VAC

VSMD302 230 VAC

N/A TS620 Mobile Yes

VSMR151 100/115 VAC

VSBR152 230 VAC

N/A DS302 Bench Mount N/A

VSBD301 100/115 VAC

VSBD302 230 VAC

N/A TS620 Bench Mount N/A

VSPD030 110 VAC

VSPD031 115 VAC

IDP-3 N/A

Portable

N/A

VSPD032 220 VAC

Outline drawings for each configuration are shown in Section 1.1.1 “VS Series Leak

Detector Configurations”.

1-2

Page 25

VS Series Helium Mass Spectrometer Leak Detectors

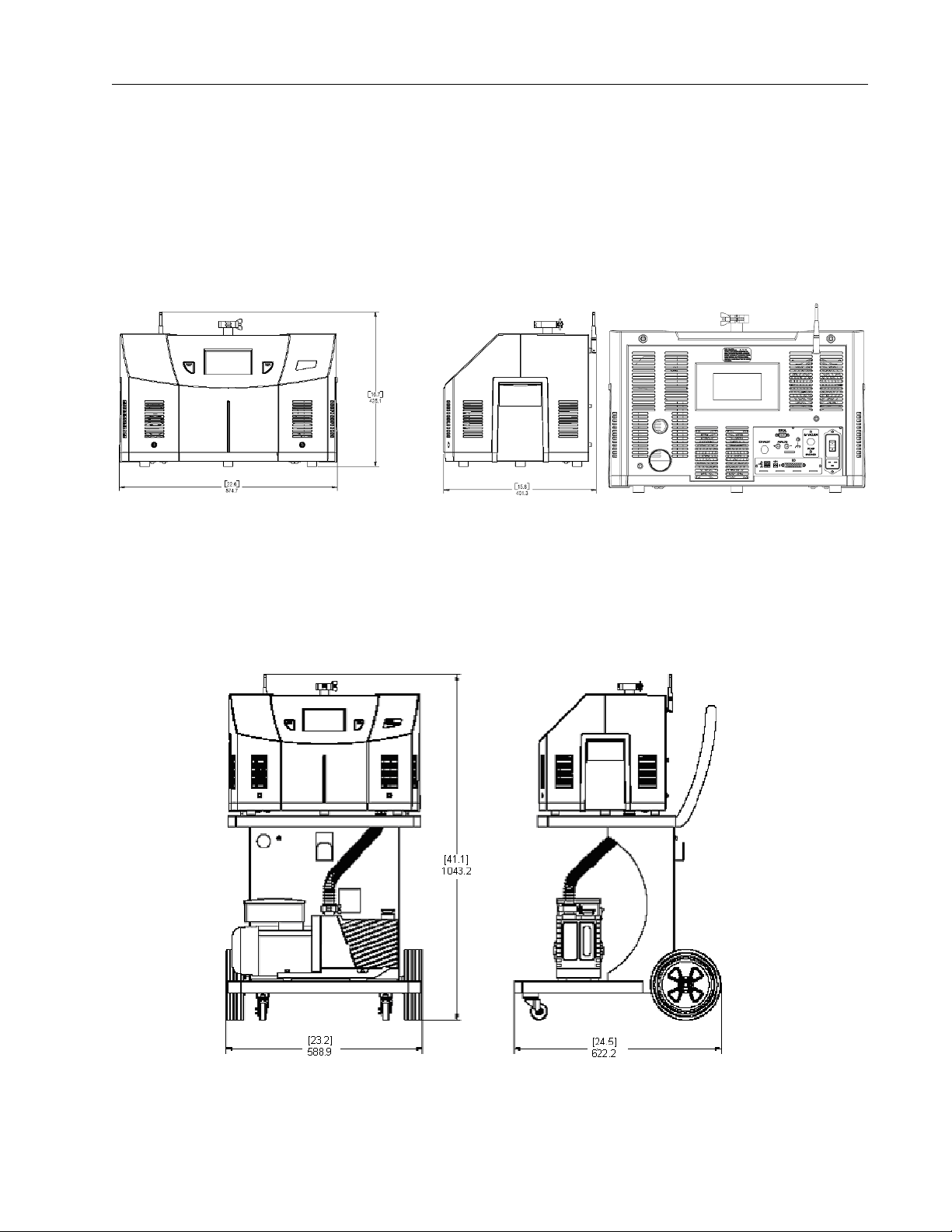

1.1.1 VS Series Leak Detector Configurations

This section contains outline drawings of the leak detector configurations. Dimensions are

given in inches, in brackets, and in mm, below the brackets.

Figure 1-1 shows the outline drawing and physical dimensions of the portable leak detector

with Internal DS42 Wet Rotary Vane Pump, Model VS PR02 and the PD03, which utilizes a

Agilent IDP-3 dry pump.

Figure 1-1 Portable Leak Detector with Internal DS42 Wet Rotary Vane Pump, Model VS

PR02, and Portable Leak Detector with Internal IDP-3 (PD03) Dimensions

Figure 1-2 shows the outline drawing and physical dimensions of a mobile leak detector

with External DS302 Wet Rotary Vane Pump on a Cart, Model VS MR15.

D R A F T 9 / 2 5 / 1 2

Figure 1-2 Mobile Leak Detector with External DS302 Wet Rotary Vane Pump on a Cart,

Model VS MR15, Dimensions

1-3

Page 26

VS Series Helium Mass Spectrometer Leak Detectors

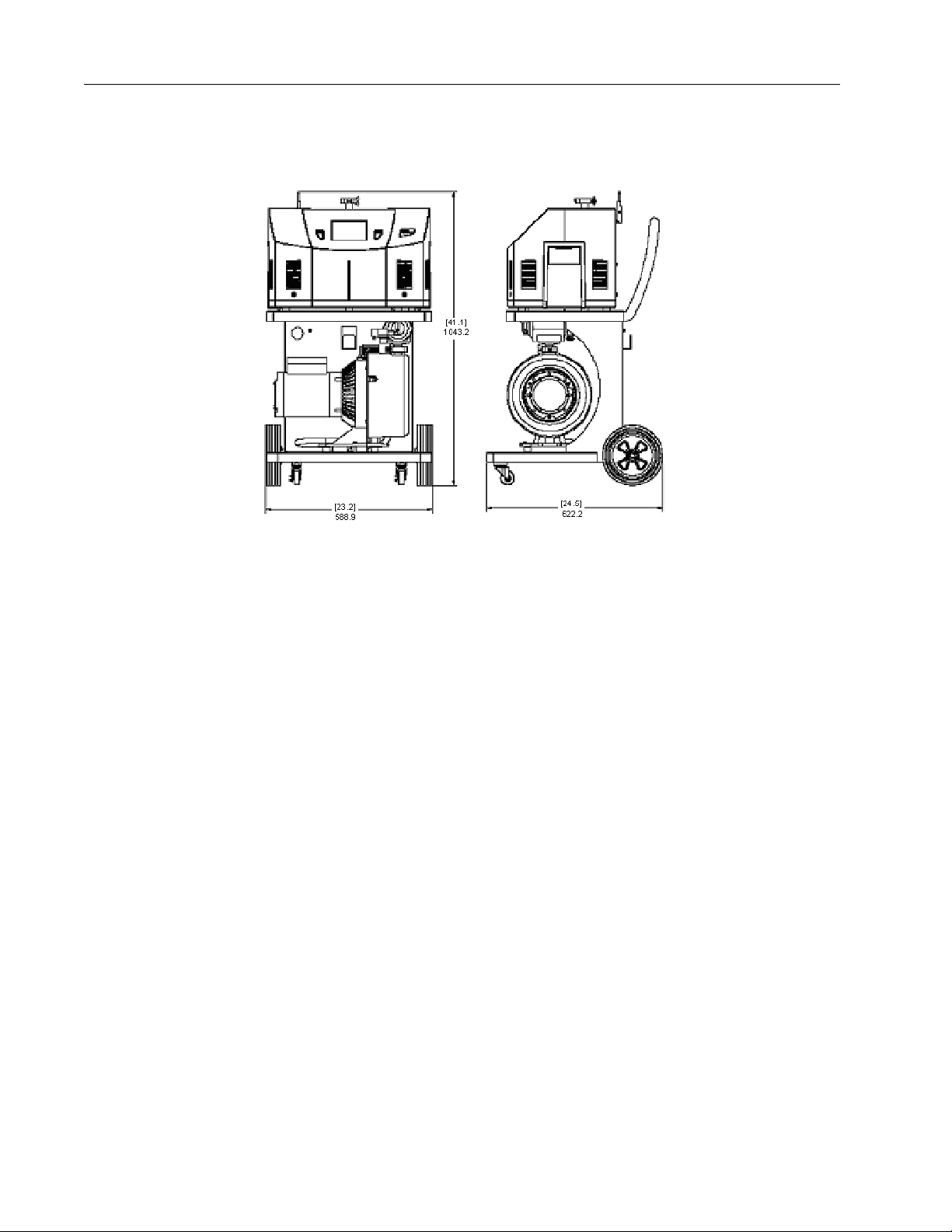

Figure 1-3 shows the outline drawing and physical dimensions of a Mobile Leak Detector

with External TS620 Dry Scroll Pump on a Cart, Model VS MD30.

Figure 1-3 Mobile Leak Detector with External TS620 Dry Scroll Pump on a Cart, Model VS

MD30, Dimensions

D R A F T 9 / 2 5 / 1 2

1-4

Page 27

VS Series Helium Mass Spectrometer Leak Detectors

1.2 Unpacking the Leak Detector

The following items are included in the shipment:

❑

VS Series Helium Mass Spectrometer Leak Detectors Operations Manual

❑

VS Series leak detector configured and completely assembled as ordered

❑

All necessary power cords, as ordered

❑

Pump manuals (for the purchased configuration)

❑

Any optional equipment ordered

❑

Any manuals for optional equipment purchased

1.2.1 Unpacking Instructions

To unpack the leak detector and remove it from the skid:

1. Inspect the container for evidence of damage in shipment.

a. Do not discard evidence of rough handling.

b. Report the damage to the carrier and to Agilent Customer Service without delay. See

the back cover of this manual for a listing of our sales and service offices.

2. Wear safety glasses and carefully cut the outer container holding straps.

3. Carefully remove the outer shipping container.

4. Inspect the leak detector and related items immediately for any indication of shipping

damage.

5. Carefully cut the leak detector holding straps.

6. Remove any loose boxes or packages and put them aside.

Keep the original packing for re-use in the event that it is necessary to return the leak

detector to Agilent.

7. Carefully remove the plastic bag covering the leak detector.

Proceed to Section 1.2.2 “Removing the Leak Detector from the Skid”.

D R A F T 9 / 2 5 / 1 2

1-5

Page 28

VS Series Helium Mass Spectrometer Leak Detectors

1.2.2 Removing the Leak Detector from the Skid

There are three methods for removing the leak detector from the skid, depending on the

leak detector model ordered. All methods require two people. The third method

involves removing the Skid-Mates (the blue donut-shaped mounts at the front of the

skid) from the skid.

WARNING

For portable and bench mount leak detectors (PD, PR, BR and BD models):

Method 1

1. With the assistance of a helper (one person per side), carefully lift the leak detector off

the skid using the leak detector side handles.

CAUTION

2. Gently place the leak detector on a designated flat surface.

3. Remove all loose packing from around the leak detector.

For mobile leak detectors (PD, PR, MR and MD models):

Handle the leak detector carefully and properly in the following

steps. Personal injury or damage to the leak detector could

result from improper handling. The leak detector is heavy and

can cause personal injury if not handled carefully when

removing it from the skid.

Keep the leak detector relatively horizontal when lifting. Lifting

the leak detector at a severe angle could cause oil to spill in

units with oil-sealed mechanical pumps installed.

D R A F T 9 / 2 5 / 1 2

Method 2

1. With the assistance of a helper, carefully roll the leak detector toward the front of

the skid.

2. Lift the front end of the unit and gently lower it onto the floor.

3. Lift the rear of the unit and roll it on the front casters until it is clear of the skid.

4. Gently lower the rear end onto the floor.

5. Take out and remove all loose packing from the leak detector.

1-6

Page 29

VS Series Helium Mass Spectrometer Leak Detectors

Method 3

1. Using a lever, carefully raise the front edge of the skid between 1" and 2".

2. While a helper holds the leak detector against the back brace, unscrew and remove the

front two Skid-Mates by turning them in a counterclockwise direction.

3. Make sure the helper is still holding the leak detector against the back of the skid, then

gently lower the front of the skid to the floor.

4. Carefully and slowly roll the leak detector off the skid and onto the floor.

5. Take out and remove all loose packing from the leak detector.

1-7

D R A F T 9 / 2 5 / 1 2

Page 30

VS Series Helium Mass Spectrometer Leak Detectors

Additional ventilation requirements for

your specific application are discussed in

Section 1.3.2 “Recommended Additional

Services” on page 1-11.

When installing a bench system with a

mechanical pump, the power cord for that

pump, if connected to the back of the leak

detector, cannot exceed three meters.

Additionally, connect the mechanical pump

to the leak detector using the shortest

possible vacuum connection to maximize

vacuum performance.

1.3 Installation

CAUTION

The VS Series Leak Detector is delivered completely assembled as ordered. Installation

requirements are described in Table 1-2.

Item Requirement

Leak Detector Location

Read the Preface for all operational warnings and cautions.

Table 1-2 Installation Requirements

❑

Close to its power source.

❑

Four inch clearance for proper ventilation.

❑

Sufficient room for the operator to safely maneuver to

perform testing.

D R A F T 9 / 2 5 / 1 2

Power Either (depends on configuration ordered):

❑

100 VAC, 50 Hz, 20 A

❑

115 VAC, 60 Hz, 20 A or

❑

230 VAC, 50/60 Hz, 12 A (models PR, MR and MD)

❑

230 VAC, 50 Hz, (model PD03)

1-8

Page 31

VS Series Helium Mass Spectrometer Leak Detectors

See the Mechanical Pump Operation

Manual that was enclosed with your pump.

Table 1-2 Installation Requirements (Continued)

Item Requirement

Mechanical Pump Oil Level Oil-sealed mechanical vacuum pumps are shipped with the

proper initial charge of oil. The oil level sight glass is on the front

of the pump.

❑

In the middle of the glass when the pump is not running.

❑

Check the oil level after running the pump for at least

10 minutes.

Mains Supply Voltage Fluctuations Must not exceed ±10% of the nominal voltage.

Pollution Pollution Degree 2 per EN61010-1 Standard.

Fixed Mains Socket Outlet Connect to a building protective earthing system.

D R A F T 9 / 2 5 / 1 2

1-9

Page 32

VS Series Helium Mass Spectrometer Leak Detectors

Note orientation of

valve

*

1.3.1 Bench System Installations

Figure 1-4 and Figure 1-6 represent the process for installation of the bench system version

of the VS Series Leak Detector.

Figure 1-4 is a drawing of a Bench Mount Leak Detector with External DS302 Wet Rotary

Vane Pump, Model VS BR15 with individual components shown.

Figure 1-4 Bench Mount Leak Detector with External DS302 Wet Rotary Vane Pump, Model

VS BRI5

Figure 1-5 is a drawing of a Bench Mount Leak Detector with External TS620 Dry Scroll

Pump, Model VS BD30 with individual components shown.*

NOTE

Cut the ¾” black tubing into two equal parts as shown.

D R A F T 9 / 2 5 / 1 2

Figure 1-5 Bench Mount Leak Detector with External TS620 Dry Scroll Pump, Model VS

BD30

1-10

Page 33

VS Series Helium Mass Spectrometer Leak Detectors

1.3.1 Helium

Welding grade helium in a standard cylinder with pressure regulating valve and hose is

required for testing products and leak checking.

1.3.2 Recommended Additional Services

The following additional services are recommended, based on the application:

❑

Connect an exhaust hose to the foreline pump and vent it outside of the room, or to

the facility’s exhaust, to reduce the particulate count and the helium background

signal.

❑

When using oil lubricated mechanical pumps, use an oil mist eliminator on the

exhaust port of the mechanical pump to reduce the oil mist from the exhaust.

Oil mist eliminators can, however, become saturated with oil causing slower

pumping speeds and higher helium backgrounds in the leak detector. The

replacement time interval of the oil mist eliminator is determined by whether the

user frequently operates at elevated roughing pressures, pumps on large volumes, or

frequently cycles the system. Refer to Table 4-4 on page 4-6 and Table 4-5 on

page 4-8 for the mist eliminator and replacement cartridge part number.

1.3.3 Storage

If the VS Series leak detector is not used immediately, it can be stored as received without

special precautions. A dry, relatively dust-free area is preferred. The required environmental

conditions for storage are:

❑

Dry nitrogen vent to keep the test port dry. Refer to Section 4.2 on page 4-5 for more

information.

❑

Adequate circulation to prevent an increased helium background level.

❑

0% to 95% relative humidity, non-condensing

❑

-20 °C (-4 °F) to + 60 °C (+ 140 °F) ambient temperature

CAUTION

Never leave any type of cell in the Wireless Remote unit if it is

will not be in use for a long period of time.

D R A F T 9 / 2 5 / 1 2

1-11

Page 34

VS Series Helium Mass Spectrometer Leak Detectors

Display

TEST (Hard)

Test Port

VENT (Hard)

Button

Button

Handle

(Recessed)

Model Label

1.4 Front Panel Display and Controls

The front panel (Figure 1-6) consists of two hard buttons: TEST and VENT and an LCD

display to access the software control screens. All operator control and monitoring of results

are achieved via the resident software accessed using the Home screen. Table 1-3 on

page 1-16 lists the main sub-screens and their purpose. Operational discussions are in

Section 2 “Operating the Leak Detector” on page 2-1 and in Section 3 “Set-Up”.

D R A F T 9 / 2 5 / 1 2

1-12

Figure 1-6 Front Panel Displays and Controls

The front panel display touch panel is calibrated at the factory and should not require

recalibration. If the touch panel buttons do not respond to pushes, recalibrate as follows:

1. Turn off the leak detector power.

2. Press and hold the center of the touch panel and restart power.

A blue screen appears.

3. Press the four cross hairs on the screen and accept the calibration.

Page 35

VS Series Helium Mass Spectrometer Leak Detectors

LCD Display Represents:

❑

Leak Rate - in a Bar Graph format with a numeric range

indicator

❑

Leak Rate, System Status and Parameters - in alphanumeric

format

❑

Series of

interface

Leak Rate, System Status and Parameters in alphanumeric format:

❑

Leak Rate is presented in a scientific notation: XXE-YY with

appropriate units

Where: X .X mantissa is a leak rate value

E- Y = 10-YY exponent is a leak rate range

X and Y are any numbers from 0 to 9

❑

System Status and/or Mode are represented on the screen in

alpha format on the screen and an italic font in this manual

❑

Parameters are represented on the screen in alphanumeric

format a bold font in this manual.

screens

with the soft key buttons for operator

Leak Rate Bar Graph The large bar graph displays the leak rate in one of three forms:

❑

A linear bar graph

❑

A logarithmic bar graph

❑

Both linear and logarithmic bar graphs

Use the Output Control Set-Up screen (Section 3.1.8.3.1 “Cal Leak

Expiration Set-Up” on page 3-23) to change the type of bar graph

that appears.

Over-range and under-range conditions are indicated using two up

and down arrows on the right and left side of the bar graph, respectively.

VENT The VENT button advances the leak detector to the vented state. A

red LED illuminates while the leak detector is in the vented state.

TEST When the system is in the Vent or Hold states, pressing the TEST

button automatically advances the leak detector through roughing,

then through the various test states, depending on the achievable

test port pressures and leak rates. A green TEST LED in the button

illuminates when the leak detector is in the Test or Fine Test state.

Press the VENT button to isolate the test port from the leak detector

vacuum system and vent the test port to atmosphere. The red VENT

LED remains lit while the leak detector is in the vented state. To

activate the VENT function, press and hold VENT for one second.

D R A F T 9 / 2 5 / 1 2

1-13

Page 36

VS Series Helium Mass Spectrometer Leak Detectors

HOLD With the leak detector in Test/Fine Test mode, press TEST again and

the leak detector goes into HOLD mode, isolating the leak detector

from the unit under test. The green LED in the Test button won’t

illuminate and the Home Screen displays Hold.

D R A F T 9 / 2 5 / 1 2

1-14

Page 37

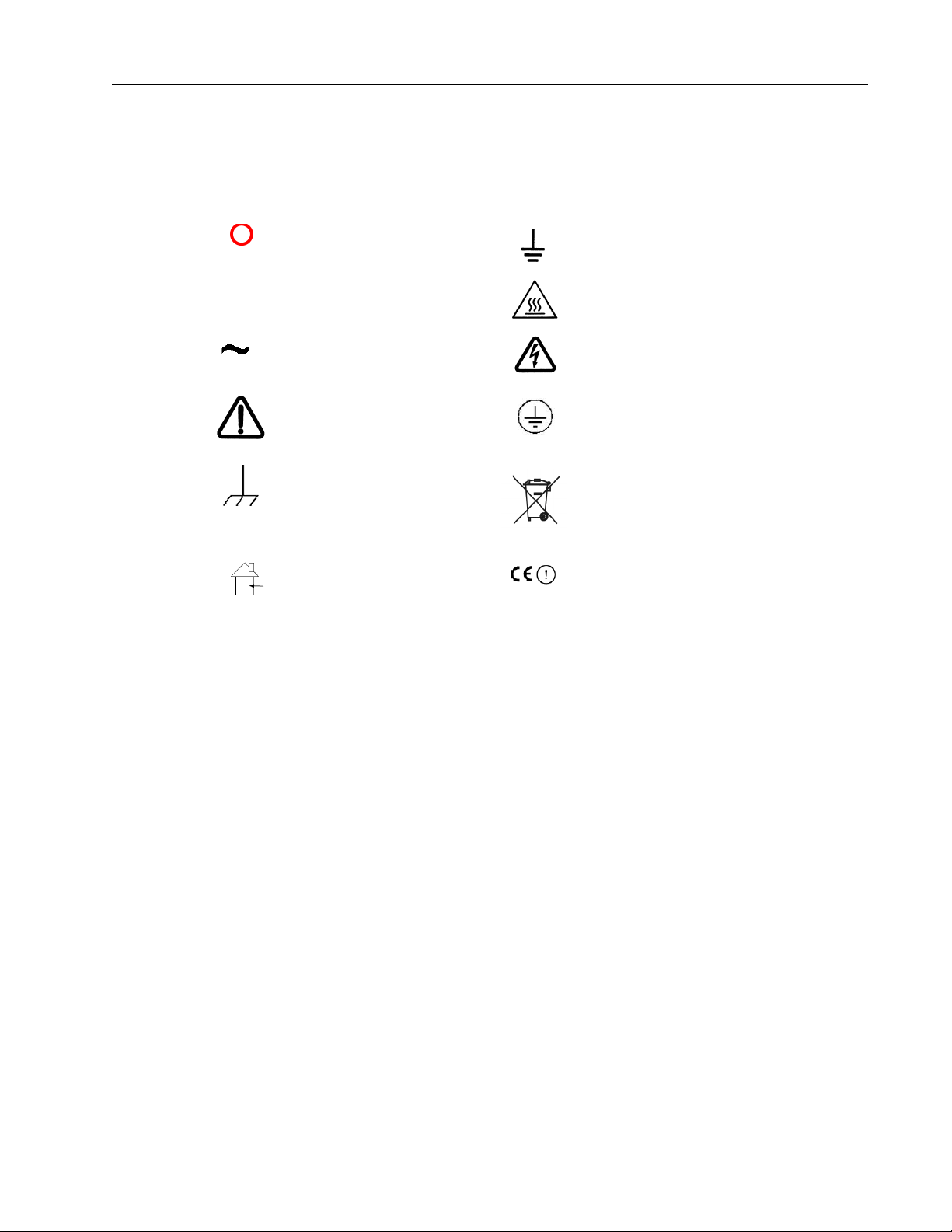

VS Series Helium Mass Spectrometer Leak Detectors

MANUAL

TUNING

OUTPUT

CONTROL

SYSTEM

UNITS LANGUAGES

CONTROL PANEL

ACCESS

AUTO

SEQUENCER

SYSTEM

INFORMATION

TRANSFER

POINTS

LEAK RATE

RANGING

REJECT/AUDIO

SETPOINTS

CONTROL PANEL ZERO MENUS

MAIN SCREEN

CALIBRATION

SET-UP

SET-UP

MANUAL VALVE

CONTROL

ADVANCED

PARAMETERS

SET-UP

NEXT

MAINTENANCE

GAUGE

CALIBRATION

SET-UP

PASSWORD

P

ASSWORD

GROSS TEST

FORE

PUMP

DEFAULTS

EXHAUST PUMP

(PD03 O

NLY

)

WIRELESS

(O

PTION

)

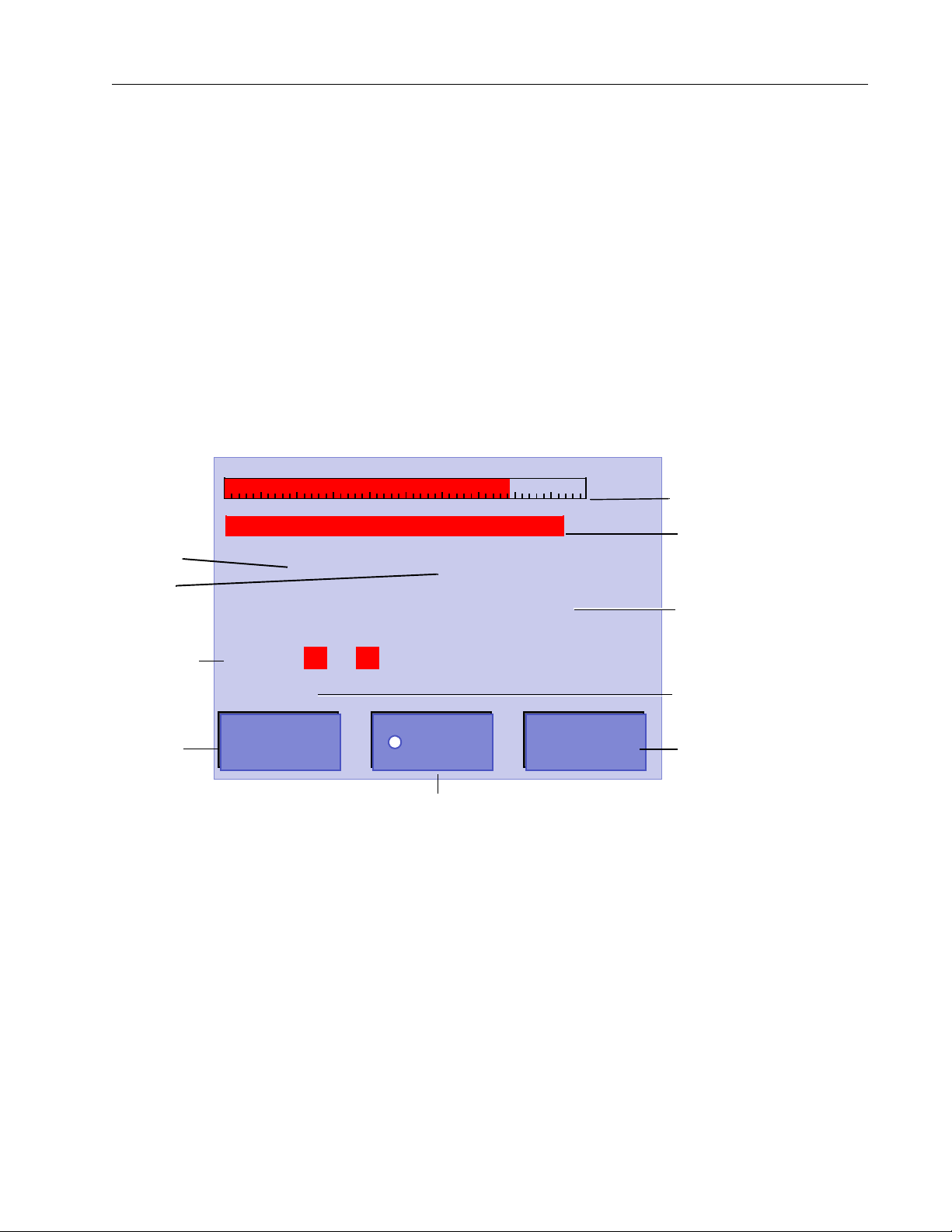

The leak detector operator interface functions through a series of screens, which are

navigated as in Figure 1-7.

D R A F T 9 / 2 5 / 1 2

Figure 1-7 Screen Flow

1-15

Page 38

VS Series Helium Mass Spectrometer Leak Detectors

1.5 Display Panel Controls

Table 1-3 Screens – General Description

Screen Purpose

Home Accesses the Control Panel and Menu screens.

Activates the Zero function. The LED illuminates while zeroing occurs.

Accesses the Gross Leak Test screen, when Gross Test is initiated.

Control Panel Activates/deactivates:

❑

Std Leak

❑

Zero Enable

❑

Hold

❑

Calibrate

Displays the type of leak: Internal or external, associated with Calibrate.

Adjusts the speaker volume.

Menus Accesses the following screens for tailoring leak detector operation:

D R A F T 9 / 2 5 / 1 2

❑

Calibration Set-Up – Configures leak type, mode and parameters

(Section 2.2.4.1 on page 2-17).

❑

Reject & Audio Set Points – Configures parameters and toggles operations

on/off for each reject set point and for the audio threshold

(Section 2.2.4.2 on page 2-19).

❑

Leak Ranging – Configures the Range Stop, Manual Range values, toggles

the high pressure test feature and toggles operations on/off

(Section 2.2.4.4 on page 2-25).

❑

Transfer Pressure – Configures the Maximum Test Pressure

(Section 2.2.4.5 on page 2-28).

❑

System Information – Displays the status of configured and active items

(Section 2.2.4.6 on page 2-30).

❑

Control Panel Access – Activates/deactivates Vent and Panel Lockouts

(Section 2.2.4.7 on page 2-32).

❑

Auto Sequencer – Configures roughing and test times, toggles features

on/off and displays rough timer value (Section 2.2.4.3 on page 2-22).

❑

Set-Up - Accesses all the screens shown in Figure 1-7 on page 1-15.

1-16

Page 39

VS Series Helium Mass Spectrometer Leak Detectors

Table 1-3 Screens – General Description (Continued)

Screen Purpose

Set-Up Accesses the following screens:

❑

Advanced Parameters:

❑

Activates Autozero and Split Flow functions.

❑

Activates the Gross Leak function (Section 3.1.1 “Advanced Parame-

ters” on page 3-3).

❑

Sets Split Flow value (Section 3.1.1 on page 3-3).

❑

Output Control – Configures the Analog Output and

Bar Graph default units (Section 3.1.8.3.1 on page 3-23).

❑

Manual Tuning:

❑

Toggles between Filament 1 and 2.

❑

Sets Emission, Ion and Gain settings (Section 3.1.2 on page 3-7).

❑

Units – Configures Leak Rate and Pressure units

(Section 3.1.5 on page 3-15).

❑

Manual Valve Control – Access to control all valves (Section 3.1.3 on

page 3-10).

❑

Languages – Configures language (Section 3.1.6 on page 3-16).

❑

Gauge Calibration – Calibrates the Test Port Vacuum and Test Port ATM

reference points and displays Test Port Pressure and Spectrometer Pressure (Section 3.1.7 on page 3-17).

❑

Maintenance – Configures:

❑

Date and Time (Section 3.1.8.2 on page 3-21)

❑

Cal Leak Expiration and Internal Calibrated Leak values

(Section 3.1.8.3.1 on page 3-23)

❑

Password (Section 3.1.8 on page 3-19)

❑

Fore Pump and Diaphragm Pump (Section 3.1.10 on page 3-25).

❑

Wireless (Section 3.1.11 “Wireless” on page 3-27).

❑

System Defaults (Section 3.1.12 “System Defaults” on page 3-29).

D R A F T 9 / 2 5 / 1 2

1-17

Page 40

VS Series Helium Mass Spectrometer Leak Detectors

➀

➁

➁

➂

➃

➄

➅

7

9

10

11

➀

8

12

1.6 Rear Panel

The rear panel of the leak detector with an external mechanical pump (Model VS MR15 or

MD30) and a wireless remote control option is shown in Figure 1-8.

D R A F T 9 / 2 5 / 1 2

Figure 1-8 VS Series Rear Panel

➀

Serial Connector A 9-pin male D-type connector to interface with an external PC via

RS-232 type communications protocol for system diagnostic or

control.

➁

Cover Plate Access to expansion slot. This is not used when an optional I/O

➂

Power Entry

Module

A detailed summary of information related to serial communication

is provided in Section A “Communications Protocol” on page A-1.

PCB is installed. A rear panel of the optional I/O PCB is shown in

Figure 1-9 on page 1-19.

Provides supply power, overcurrent and EMI protection for the leak

detector. The Power Entry Module consists of:

❑

Power Input Connector - An IEC/EN60320/C20 standard,

three-prong grounded Inlet connector.

❑

Power Switch (I/O) - A 20A rocker type Power

Switch/Thermal Circuit Breaker.

❑

20 A EMC line filter.

1-18

Page 41

VS Series Helium Mass Spectrometer Leak Detectors

10

11

12

➃

➀ ➁

➂

➃

Fore Pump Power

Connection

➄

Analog Output Banana type output connector for an Isolated Leak Rate Analog

➅

Chassis (Earth)

Terminal

➆

Product Label A product label with part number, serial number and rating infor-

➇

RF Antenna A 2.4 GHz antenna for the optional Wireless Remote Control.

➈

Exhaust Cover Exhaust opening for a VS PR02 model.

Oil Level Cover Oil level window for a VS PR02 model.

An IEC/EN60320/C19 standard, three-prong grounded outlet

connector.

reading. The Red connector is a signal positive terminal; black is

the signal negative terminal. Signal range: From 0 to +10 VDC.

Later models of the VS will be equipped with a DB9F connector for

the analog output. Pin #1 is signal (positive) and Pin #2 is return

(negative).

Provided for additional connection of the leak detector to the

building grounding system to improve ESD protection.

mation.

Oil Drain Cover Oil drain opening for a VS PR02 model.

Nitrogen Vent Port Nitrogen vent port (On newer models).

Test Port Test port adapter (not shown).

2-Wheel Cart 2-wheel cart for an external fore pump (not shown)

Wireless Label A wireless info label for VS leak detector with an optional Wireless

Remote Control.

A rear panel for the optional I/O PCB assembly is shown in Figure 1-9.

Figure 1-9 Optional I/O PCB Rear Panel

D R A F T 9 / 2 5 / 1 2

➀

USB - A1 USB 1.1 full speed downstream port, USB type A receptacle.

➁

USB - A2 USB 1.1 full speed downstream port, USB type A receptacle.

➂

USB - B USB 1.1 full speed upstream port, USB type B receptacle.

1-19

Page 42

VS Series Helium Mass Spectrometer Leak Detectors

➃

I/O Connector A 25-pin female D-sub connector to interface with an external PLC

via a parallel cable.

Inputs:

❑

Four level inputs: optically isolated, (+5 to+24) VDC.

❑

Four momentary inputs: optically isolated, (+5 to+24) VDC,

requires 200 ms pulse width.

All inputs are opto-isolator LEDs with a series 3300 Ohm resistor.

Outputs:

❑

Eight optically isolated emitter followers with a 10 Ohm

series resistor, 14 mA max drive current, +24VDC max.

Power:

❑

An external power supply is supplied by the user.

A detailed summary of information related to I/O pin identifications

is provided in Table A-6 on page A-14.

D R A F T 9 / 2 5 / 1 2

1-20

Page 43

VS Series Helium Mass Spectrometer Leak Detectors

➁

➂

➃

➄

➅

7

9

➀

8

The rear panel of the leak detector (Model VS PR02 and PD03) is shown in Figure 1-10. The

optional Wireless remote control and I/O PCB is not installed.

Figure 1-10 Rear Panel (with Discrete I/O PCB)

Oil Drain For the internal mechanical vacuum pump (PR02 only, not shown).

Glass Window Oil level sight glass reading (PR02 only, not shown).

➀

Exhaust A barbed hose fitting (OD = 12.57 mm) for exhaust of the internal

mechanical vacuum pump.

➁

Serial Connector A 9-pin male D-type connector to interface with an external PC via

RS-232 type communications protocol for system diagnostic or

control

A detailed summary of information related to serial communication

is provided in Section A “Communications Protocol” on page A-1.

➂

USB Standard USB connector (types USB A and USB B).

➃

Power Entry

Module

Provides supply power, overcurrent and EMI protection for the leak

detector. The Power Entry Module consists of:

❑

Power Input Connector - An IEC/EN60320/C20 standard,

three-prong grounded inlet connector.

❑

Power Switch (I/O) - A 20A rocker type Power

Switch/Thermal Circuit Breaker.

❑

20 A EMC line filter.

D R A F T 9 / 2 5 / 1 2

➄

Vacuum Pump

Breaker

A 6 A Thermal Circuit Breaker for the internal mechanical pump.

1-21

Page 44

VS Series Helium Mass Spectrometer Leak Detectors

➅

Analog Output Banana type output connector for an Isolated Leak Rate Analog

reading. The Red connector is a signal positive terminal; black is

the signal negative terminal. Signal range: From 0 to +10 VDC.

Later models of the VS will be equipped with a DB9F connector for

the analog output. Pin #1 is signal (positive) and Pin #2 is return

(negative).

➆

Chassis (Earth)

Terminal

➇

25 Pin I/O

➈

Nitrogen Vent Port Nitrogen vent port (On newer models).

Provided for additional connection of the leak detector to the

building grounding system to improve ESD protection.

❑

Inputs: Opto-isolated, 5 - 24 VDC 3300 Ohm resistive load.

All inputs are opto-isolator LEDs with series resistors.

❑

Momentary Inputs: Opto-isolated, 5 - 24 VDC 3300 Ohm

resistive load, requires 200 ms minimum pulse width.

❑

Outputs: Emitter follower with 10 Ohm series resistor, 14

mA max drive current, 24 VDC max.

For pin identifications, see Table A-6 on page A-14.

1.7 Features

The features for the VS Series leak detector are provided in Table 1-4.

Table 1-4 VS Series Features

Feature Description

Calibration Fully automated tuning and calibration using the internal or external

calibrated leak. The fast calibrate feature allows calibration in less

D R A F T 9 / 2 5 / 1 2

Zero Control Selectable mode background elimination with a unique, patented

Leak Indication A bar graph (linear or log) indicator displays leak rates automatically;

than one minute.

Autozero<0 feature.

alphanumeric indication on LCD display. A leak can also trigger an

audible alarm frequency that varies in proportion to the size of the

leak, dedicated volume control and programmable audio threshold.

Analog voltage is proportional to the leak rate.

1-22

Page 45

VS Series Helium Mass Spectrometer Leak Detectors

Table 1-4 VS Series Features (Continued)

Feature Description

Pressure Indication Test port and spectrometer pressure with alphanumeric indication on

the LCD display.

Spectrometer Sensitivity optimized design, header mounted ion source with dual

thoria-coated iridium filament, a high sensitivity, wide dynamic range

preamplifier, and vacuum gauge.