Agilent Increasing Productivity and Simplifying Sample Preparation With the SIPS Accessory Technical manual

Page 1

Technical Overview

Increasing Productivity and

Simplifying Sample Preparation With

the SIPS Accessory

Flame Atomic Absorption Spectrometry (FAAS) typically involves element-specific

sample preparation which can be time consuming and prone to operator-introduced

errors. The SIPS 10 and SIPS 20 Sample Introduction Pump System (SIPS) are

optional accessories for Agilent’s SpectrAA FAAS instruments. They offer a range of

powerful features that automate many tedious and error prone sample preparation

tasks. These greatly simplify and speed up the sample preparation process,

improving productivity and reducing costs.

Combining a SIPS accessory with Agilent’s Fast Sequential capabilities results in an

easy to use, highly productive and cost effective atomic absorption solution.

Page 2

Whether you are using an autosampler, or doing manual

sample introduction, a SIPS accessory, combined with the

SpectrAA software, will automatically:

– Prepare up to 10 calibration standards from a single bulk

standard, automating the instrument calibration process

– Intelligently dilute over range samples

– Prepare standard additions calibration from a single

standard

– Introduce analytical spikes, using a single standard

– Add chemical modifiers, e.g. ionization suppressants

– Extend the dynamic range of FAAS to that approaching

ICP-OES

The SIPS accessory is available in two versions:

– The single pump SIPS 10 provides in-line calibration and

sample dilution.

– The dual pump SIPS 20 has the additional capabilities of

in-line spiking of samples and in-line sample modification.

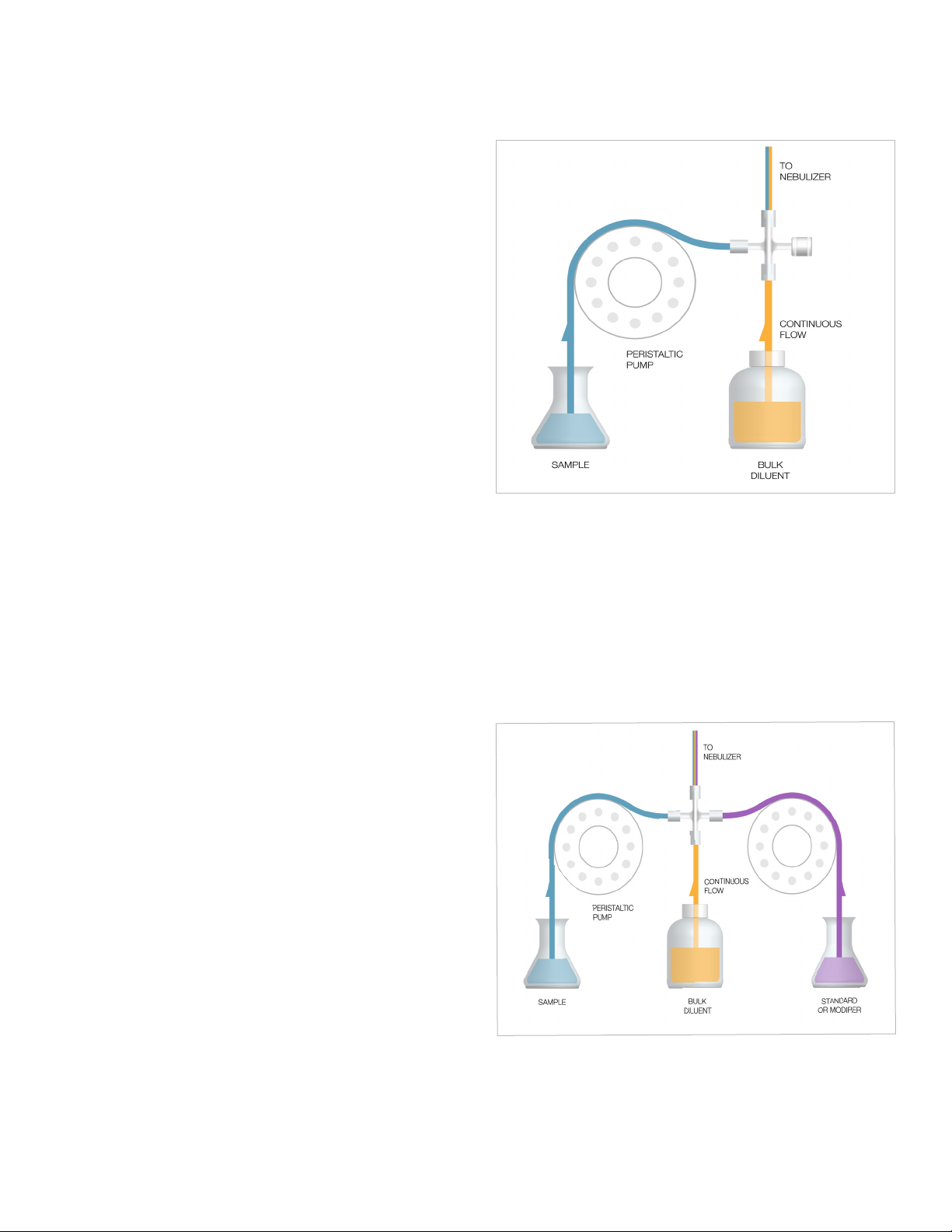

Figure 2. How the SIPS 10 works

How SIPS works

The sample flow rate of conventional peristaltic pumps

changes non-linearly with the pump speed. This makes

them unsuitable for use to automatically dilute samples.

The innovative design of the SIPS’ peristaltic pump system

ensures that the solution flow is proportional to the pump

speed, so the volume of solution being pumped is accurately

controlled. To extend the lifetime of the peristaltic pump

tubing (and thus lower operating costs), the SIPS will

automatically release the pressure on the pump tubing at the

end of run.

The SIPS 10 (Figure 1) combines a small flow of diluent with

the sample flowing to the nebulizer. If the pump speed is

reduced, the flow of sample is reduced. With a constant

nebulizer uptake rate, the diluent flow is thus increased

effectively diluting the sample. This simple approach makes

automatic calibration and in-line dilution possible, by accurately

controlling the pump speed with the SpectrAA software.

Figure 2. How the SIPS 20 works

2

Page 3

The SIPS 20 comprises two pumps (Figure 2). One delivers

the sample and the second delivers a standard or modifier to

the nebulizer. Controlling the relative speeds of both pumps

allows the amount of standard or modifier added to the

sample to be precisely regulated. This allows in-line ‘spiking’

of samples.

No more tedious standard preparation

The SIPS 10 and 20 are capable of preparing calibration standards from a single multi-element bulk standard. This reduces

sample preparation time and the risk of operator error during

standard preparation, which can lead to costly re-runs.

Using the concentration of the bulk standard, the SpectrAA

software can automatically determine standard concentrations

to cover the required concentration range.

Figure 3 shows an example of a calibration curve for Cu prepared from a single standard using the SIPS system. It has a

correlation coefficient of 1.0000, demonstrating the excellent

calibration accuracy that can be achieved with the SIPS.

The dilution accuracy of a SIPS is shown in Table1, demonstrating the ability of the SIPS system to provide accurate

results, even at high dilution factors. Figure 4 shows the dilution performance of a SIPS with increasing dilution factors.

Excellent dilution accuracy was obtained across all dilution

factors with a maximum dilution error of just 1.2%.

Table 1. Typical dilution performance of a SIPS system, obtained by

repeating a number of standard measurements on different days under

different sequence conditions.

Dilution Factor 1 3-20 20-50 50-200

Standard Conc (mg/L) 5-10 10-100 100-320 200-1000

# of determinations 53 65 25 58

Dilution Error (%) -1 2 1 -1

Precision (%RSD) 1 1 1 3

Reproducibility (%) 1 1 2 2

Figure 3. Calibration curve for Cu prepared from a single standard, using

a SIPS. The concentrations of the standards were automatically set by the

SpectrAA software to cover the required concentration range.

Automatic in-line dilution

The dilution capability of a SIPS extends the working range

of AA by automatically diluting samples that are outside the

calibrated range. The SpectrAA software calculates the dilution required to bring over range samples into the top half of

the calibrated range, where maximum precision and accuracy

usually occur. This ensures the integrity of results and eliminates

the need for costly re-analysis of samples at the end of a run.

Figure 4. Dilution performance of a SIPS 20 at different dilution factors.

Excellent dilution accuracy was obtained with a maximum of only 1.2%

dilution error.

Modifier addition

Flame AA methods routinely require the addition of chemical

modifiers for accurate results. These modifiers are normally

added during the sample preparation process. Using the

second pump of the SIPS 20, modifiers can be automatically

added during the analysis, taking a repetitive step out of the

sample preparation process. The amount of modifier added is

controlled by the pump speed, and this pump speed remains

constant during sample dilutions to ensure consistent blank

correction and matrix modification; something that must be

accounted for when adding modifiers manually.

3

Page 4

In-line spiking of samples

The SIPS 20 automatically ‘spikes’ samples in-line, eliminating

sample preparation and reducing the risk of sample contamination. One pump introduces the sample, and the second

spikes the sample with standard.

In-line standard additions calibration

The dual pump SIPS 20 automatically adds addition standards during the analysis. One pump introduces the sample

and the second introduces the standard. The SIPS system automatically adjusts the speed of the second pump to achieve

the required additions—eliminating time-consuming sample

preparation and reducing the risk of contamination.

When maximum accuracy is required, the SIPS system ensures that the calibration is completed using the linear portion

of the curve. Where necessary, the addition standards will be

diluted to ensure the absorbance signals fall within the linear

range.

www.agilent.com/chem

This information is subject to change without notice.

© Agilent Technologies, Inc. 2021

Printed in the USA, January 5, 2021

5991-6613EN

Loading...

Loading...