Page 1

Notice

Hewlett-Packard to Agilent Technologies Transition

This manual may contain references to HP or Hewlett-Packard. Please note that HewlettPackard's former test and measurement, semiconductor products and chemical analysis

businesses are now part of Agilent Technologies. To reduce potential confusion, the only

change to product numbers and names has been in the company name prefix: where a

product name/number was HP XXXX the current name/number is now Agilent XXXX. For

example, model number HP 8648 is now model number Agilent 8648.

Contacting Agilent Sales and Service Offices

The sales and service contact information in this manual may be out of date. The latest

service and contact information for your locatio n can be found on the Web at:

http://www.agilent.com/find/assist

If you do not have acce ss to the Inte rnet, contact your field e ngineer. In any corre sponden ce

or telephone conversation, refer to your instrument by its model number and full serial

number.

Printed in USA July 2004

Page 2

User’s Guide

HP ESG Series Signal Generators

Serial Number Prefixes:

HP ESG-1000A, US3704 through US3723

HP ESG-2000A, US3704 through US3723

HP ESG-3000A, US3704 through US3723

HP ESG-4000A, US3704 through US3723

HP Part No. E4400-90076

Printed in USA

Print Date: December 1997 Supersedes: June 1997

Copyright Hewlett-Packard Company 1997. All Rights Reserved. Reproduction, adaptation, or translation without

prior written permission is prohibited, except as allowed under the copyright laws.

1400 Fountaingrove Parkway, Santa Rosa, CA 95403-1799, USA

Page 3

ii

Page 4

Contents

1 Preparing for Use

Installing the Signal Generator 1-2

Checking the Shi pment 1-2

Installing Front Handles and Rack Mount Flanges 1-4

Meeting Electrical and Environmental Re quirements 1-5

Adjusting the Display Contrast 1-6

Selecting Inverse Video 1-6

Adjusting the Screen Saver 1-6

Selecting the Signal Generator’s HP-IB Address 1-7

Selecting the Signal Generator’s Programming Language 1-8

Verifying Signal Generator Operation 1-9

Operator’s Check 1-9

2 Using Functions

Setting Frequency and Power Levels 2-2

To Set the RF Frequency 2-2

To Set a Frequency Reference and a Frequency Offset 2-3

To Set the RF Output Power Level 2-4

To Set an Amplitude Reference and an Amplitude Offset 2-4

Setting Up Internally-Generated Amplitude Modulation 2-6

Setting the Carrier Frequency 2-6

Setting the Power Level 2-6

Setting the AM Depth 2-6

Setting the AM Rate 2-7

Turning On Amplitude Modulation 2-7

Setting Up Internally-Generated Frequency Modulation 2-8

Setting the Carrier Frequency 2-8

Setting the Power Level 2-8

Setting the FM Deviation 2-8

Setting the FM Rate 2-9

Turning On Frequ en cy Mo du la tio n 2-9

1

Page 5

Contents

Creating a Step Sweep and a List Sweep 2-10

Configuring a Step Sweep 2-10

Turning On Continuous Step Sweep 2-11

Configuring a List Sweep Using Step Sweep Dat a 2-11

Editing List Sweep Points 2-11

Turning On List Sweep for a Single Sweep 2-12

Saving and Recalling an Instrument State 2-13

3 Troubleshooting

If You Encounter a Problem 3-2

• No RF Output? 3-2

• RF Output Power too Low? 3-2

• No Modulation at the RF Output? 3-2

• Can’t Turn Off Sweep Mode? 3-3

• Recalled a Register and Sweep List is Missi ng? 3-3

• All of the Registers Where You Previously Stored Instrument States are

Empty? 3-3

• Saved an Instrument State in a Register but the Register is Empty or Contains the

Wrong State? 3-3

• The Power Supply has Shut Down 3-3

• Incorrect List Sweep Dwell Time? 3-4

• Can’t Turn Off Help Mode? 3-4

• LF OUTPUT Signal is a Sinewave but the RF OUTPUT Signal is a Pulse

Squarewave? 3-4

Error Messages 3-5

The Front Panel Error Queue 3-5

The SCPI Remote Interface Error Queue 3-5

Querying the Error Queu e 3-7

Error Numbers 3 -8

No Error 3-9

2

Page 6

Contents

SCPI Standard Error Messages 3-10

Error Message Description 3-10

Command Er ror 3-11

Command Error Message Descriptions 3-11

Execution Error 3-17

Execution Error Message Descriptions 3-17

Device-Specific Error 3-25

Device-Specific Error Message Descriptions 3-25

Query Error 3-28

Query Error Message Descriptions 3-28

ESG Series S ignal Gener ator Instrum ent-Specific Error

Messages 3-30

Returning Your Signal Generator to HP 3-50

HP Sales and Service Offices 3-51

4 Front and Rear Panel

Front Panel Overview 4-2

Display Annotation 4-7

Rear Panel Overview 4-11

5 Hardkey and Softkey Reference

AM 5-3

AM Depth 5-3

AM Depth Couple Off On 5-4

3

Page 7

Contents

AM Dual-Sine Ampl Ratio 5-4

AM Off On 5-5

AM Path 1 2 5-5

AM Rate 5-6

AM Source 5-7

AM Start Rate 5-8

AM Stop Rate 5-9

AM Sweep Time 5-9

AM Sweep Trigger 5-10

AM Tone 1 Rate 5-10

AM Tone 2 Rate 5-11

AM Waveform 5-11

Bus 5-12

Dual-Sine 5-12

Ext 5-12

Ext 1 AC-Coupled 5-13

Ext 1 DC-Coupled 5-14

Ext 2 AC-Coupled 5-15

Ext 2 DC-Coupled 5-15

Immediate 5-16

Internal 5-16

Noise 5-17

Ramp 5-17

Sine 5-17

Square 5-18

Swept-Sine 5-18

Triangle 5-18

Trigger In Polarity Neg Pos 5-19

Trigger Key 5-19

Trigger Out Polarity Neg Pos 5-20

Ampl 5-21

ALC Off On 5-21

Ampl Offset 5-22

Ampl Ref Set 5-22

Ampl Ref Off On 5-23

Atten Hold Off On 5-24

Do Power Search 5-24

4

Page 8

Contents

Power Search Manual Auto 5-25

Amplitude 5-27

Arrow Keys 5-29

Display Contrast Keys 5-31

FM 5-33

Bus 5-33

DCFM/DC

Dual-Sine 5-34

Ext 5-34

Ext 1 AC-Coupled 5-35

Ext 1 DC-Coupled 5-35

Ext 2 AC-Coupled 5-36

Ext 2 DC-Coupled 5-36

FM/

FM Dev 5-37

FM Dev Couple Off On 5-38

FM Dual-Sine Ampl Ratio 5-38

FM Off On 5-39

FM Path 1 2 5-40

FM Rate 5-41

FM Source 5-42

FM Start Rate 5-43

FM Stop Rate 5-44

FM Sweep Time 5-44

FM Sweep Trigger 5-45

FM Tone 1 Rate 5-45

FM Tone 2 Rate 5-46

FM Waveform 5-46

Immediate 5-47

Internal 5-47

Noise 5-48

Ramp 5-48

Sine 5-48

Square 5-49

ΦM Cal 5-34

ΦM5-37

5

Page 9

Contents

Swept-Sine 5-49

Triangle 5-49

Trigger In Polarity Neg Pos 5-50

Trigger Key 5-51

Trigger Out Polarity Neg Pos 5-51

Freq 5-53

Adjust Phase 5-53

Freq Multiplier 5-54

Freq Offset 5-55

Freq Ref Off On 5-56

Freq Ref Set 5-56

Mode 1 Optimize <10kHz Offset 5-57

Mode 2 Optimize >10kHz Offset 5-57

Optimize

Phase Ref Set 5-58

Φ Noise 5-58

Frequency 5-59

Help 5-61

Hold 5-63

Incr Set 5-65

LF Out 5-67

Bus 5-67

DC 5-68

Dual-Sine 5-68

Ext 5-69

Function Generator 5-69

Immediate 5-70

Internal 5-70

LF Out Amplitude 5-71

LF Out Freq 5-71

LF Out Off On 5-72

LF Out Period 5-72

LF Out Source 5-73

6

Page 10

Contents

LF Out Start Freq 5-74

LF Out Stop Freq 5-75

LF Out Sweep Time 5-76

LF Out Sweep Trigger 5-76

LF Out Tone 1 Freq 5-77

LF Out Tone 2 Ampl % Of Peak 5-78

LF Out Tone 2 Freq 5-79

LF Out Waveform 5-79

LF Out Width 5-80

Noise 5-80

Pulse 5-81

Ramp 5-81

Sine 5-82

Square 5-82

Swept-Sine 5-83

Triangle 5-83

Trigger In Polarity Neg Pos 5-84

Trigger Key 5-85

Trigger Out Polarity Neg Pos 5-85

Local 5-87

Mod On/Off 5-89

Mode 5-91

Numeric Keypad 5-93

Phase Modu lation 5-95

ΦM Dev 5-95

ΦM Dev Couple Off On 5 -97

ΦM Dual-Sine Ampl Ratio 5-97

ΦM Off On 5-98

ΦMPath12 5-99

ΦM Rate 5-100

ΦM Source 5-101

ΦM Start Rate 5-102

ΦM Stop Rate 5-103

ΦM Sweep Time 5-103

7

Page 11

Contents

ΦM Sweep Trigger 5-104

ΦM Tone 1 Rate 5-104

ΦM Tone 2 Rate 5-105

ΦM Waveform 5-105

Bus 5-106

DCFM/DC

Dual-Sine 5-106

Ext 5-107

Ext 1 AC-Coupled 5-107

Ext 1 DC-Coupled 5-108

Ext 2 AC-Coupled 5-108

Ext 2 DC-Coupled 5-109

FM/

Immediate 5-110

Internal 5-110

Noise 5-111

Ramp 5-111

Sine 5-111

Square 5-112

Swept-Sine 5-112

Triangle 5-112

Trigger In Polarity Neg Pos 5-113

Trigger Key 5-114

Trigger Out Polarity Neg Pos 5-114

ΦM Cal 5-106

ΦM Normal High BW 5-109

Power Switch 5-115

Preset 5-117

Pulse 5-127

Ext2 DC-Coupled 5-127

Internal Pulse 5-128

Internal Square 5-128

Pulse Off On 5-129

Pulse Period 5-129

Pulse Rate 5-130

Pulse Width 5-130

Pulse Sourc e 5-131

8

Page 12

Contents

Recall 5-133

Delete All Regs in Seq [n] 5-133

Delete All Sequences 5-133

Delete Seq[n] Reg[ nn] 5-134

Recall Reg 5-134

Select Seq 5-135

Return 5-137

RF On/Off 5-139

Save 5-141

Add Comment To Seq[n] Reg[nn] 5-141

Clear Text 5-142

Delete All Regs in Seq [n] 5-142

Delete All Sequences 5-143

Delete Seq[n] Reg[ nn] 5-143

Editing Keys 5-143

Editing Mode Insert Replace 5-144

Save Seq[n] Reg[nn] 5-144

Select Reg 5-145

Select Seq 5-145

Sweep/List 5-147

# Points 5-147

Ampl 5-148

Ampl Start 5 -148

Ampl Stop 5-149

Bus 5-149

Configure List Sweep 5-150

Configure Step Sweep 5-150

Delete File 5-151

Delete Item 5-151

Delete Row 5-151

Dwell Type List Step 5-151

Edit Item 5-152

Ext 5-152

Freq 5-153

9

Page 13

Contents

Freq&Ampl 5-153

Freq Start 5-154

Freq Stop 5-154

Goto Bottom Row 5-154

Goto Middle Row 5-155

Goto Row 5-155

Goto Top Row 5-155

Immediate 5-156

Insert Item 5-156

Insert Row 5-156

Load From Selected File 5-157

Load List From Step Sweep 5-157

Load/Store 5-157

Manual Mode Off On 5-158

Manual Point 5-158

Off 5-159

Page Down 5 -159

Page Up 5-159

Point Trigger 5-160

Preset List 5-160

Single Sweep 5-160

Step Dwell 5-161

Store to File 5-161

Sweep 5-162

Sweep Direction Down Up 5-162

Sweep Repeat Single Cont 5-163

Sweep Trigger 5-163

Sweep Type List Step 5-163

Trigger In Polarity Neg Pos 5-164

Trigger Key 5-164

Trigger Out Polarity Neg Pos 5 -165

10

Trigger 5-167

Utility 5-169

All 5-169

Binary 5-170

Black Pixels Screen Test 5-170

Page 14

Contents

Brightness 5-170

Catalog Type 5-171

Clear Error Queue(s) 5-171

Clear Text 5-171

Copy File 5-172

Delete All Binary Files 5-172

Delete All Files 5-173

Delete All List Files 5-173

Delete All State Files 5-173

Delete File 5-174

Diagnostic Info 5-174

Display 5-174

Editing Keys 5-175

Editing Mode Insert Replace 5-175

Error Info 5-175

Help Mode Single Cont 5-176

HP8648A/B/C/D 5-176

HP-IB Address 5-177

HP-IB/RS-232 5-177

Instrument Adjustments 5-177

Instrument Info/Help Mode 5-178

Inverse Video Off On 5-178

List 5-178

Memory Catalog 5-179

Mod Status Info Off On 5-179

Off 5-179

Page Down 5-179

Page Up 5-180

Power On Last Preset 5-1 80

Power On/Preset 5-180

Preset Language 5-181

Preset Normal User 5-181

Recall Ref Osc Setting 5-182

Receive Pace None Xon 5-182

Reference Oscillator Adjustment 5-182

Ref Osc Coarse 5-183

Ref Osc Fine 5-183

Remote Languag e 5-183

11

Page 15

Contents

Reset RS-232 5-183

Reverse Power Protect ion Normal HP8648 5-184

RS-232 Baud Rate 5-185

RS-232 Echo Off On 5-185

RS-232 Pace 5-185

RTS/CTS 5-186

RTS/CTS Pacing 5-186

RTS On 5-187

Save User Preset 5-187

SCPI 5-188

Screen Saver Delay 5-188

Screen Saver Mode 5-189

Screen Saver Off On 5-189

State 5-190

Step/Knob Ratio 5-190

Store Ref Osc Setting 5-190

Transmit Pace None Xon 5-191

View Next Error Message 5-191

View Previous Error Message 5-192

White Pixels Screen Test 5-192

12

6 Options and Accessories

Signal Generator Options 6-2

Front Handles (Option 1CN) 6-2

Rack Mount Flanges without Handles (Option 1CM) 6-2

Rack Mount Flanges with Handles (Option 1CP) 6-2

Three Year Warranty (Option W30) 6-2

Move All Front Panel Connectors to Rear Panel (Option 1EM) 6-3

High Stability Timebase (Option 1E5) 6-3

Delete Standard Manual Set (Option 0B0) 6-3

Extra Manual Set (Option 0B1) 6-4

Assembly-Level Service Guide (Option 0BW ) 6-4

Component-Level Informatio n Package (Option 0BV) 6-5

Assembly-Level Service Guide and Component-Level Information Package

(Option 0BX) 6-5

User’s Guide - Traditional Chinese for Taiwan (Option AB0) 6-5

Page 16

Contents

User’s Guide - Korean (Option AB1) 6- 6

User’s Guide - Chinese (Option AB2) 6-6

User’s Guide - German (Option ABD) 6-6

User’s Guide - Spanish (Option ABE) 6-6

User’s Guide - Japanese (Option ABJ) 6-7

Signal Generator Accessories 6-8

Transit Case (HP Part Number 9211-1296) 6-8

Remote Interface (HP 83300A) 6-8

RS-232 Cable Kit 6-8

Upgrade and Retrofit Kits 6-9

Firmware Upgrade Kit 6-9

Firmware Upgrade Kit with Documentation 6-9

Analog to Digital Retrofit Kit 6 -9

7Operation

8 Safety and Regulatory

Safety Note s 8-2

Instrument Markings 8-3

General Safety Considerations 8-4

Statement of Compliance 8-5

Warranty 8-6

Assistance 8-7

Certification 8-8

Declaration of Conformity 8-9

13

Page 17

Contents

Compliance with German Noise Requirements 8-10

9 Specifications

HP ESG Series Signal Generators Specifications 9-2

Frequency 9-2

Sweep Modes 9-3

Internal Reference Oscillator 9-4

Output 9-4

Spectral Purity 9-7

Frequency Modulation 9-8

Phase Modulation 9-10

Amplitude Modulation at fc > 500 kHz 9-11

Pulse Modulation 9-12

Internal Modulation Source 9-13

LF Out (Internal Modulation Source) 9-14

External Modulation Inputs 9-14

Simultaneous Modulation 9-15

Remote Programming 9-15

ISO Compliant 9-15

General 9-16

Accessories 9-16

Options 9-17

14

Index

Page 18

1 Preparing for Use

This chapter contains procedures that show you how to install your signal

generator, and how to perform a functional check to verify signal generator

operation.

1-1

Page 19

Preparing for Use

Installing the Signal Generator

Installing the Signal Generator

This section contains procedures for properly installing your signal generator:

• checking the shipment

• installing front handles and rack flange kits

• meeting electrical and environmental requirements

• adjustin g t he display

• selecting the signal generator’s HP-IB address

• selecting the programming language

Checking the Shipment

1. Inspect the shipping container for damage.

Look for signs of damage such as a dented or torn shipping container or cushioning

material that shows signs of unusual stres s or compacti ng .

2. Carefully remove the content s from the shipping cont ainer and verify that your or der is

complete. Refer to Table 1-1 for a list of items that are shipped standard with the signal

generator and for a list of options that you may also have ordered.

1-2

Page 20

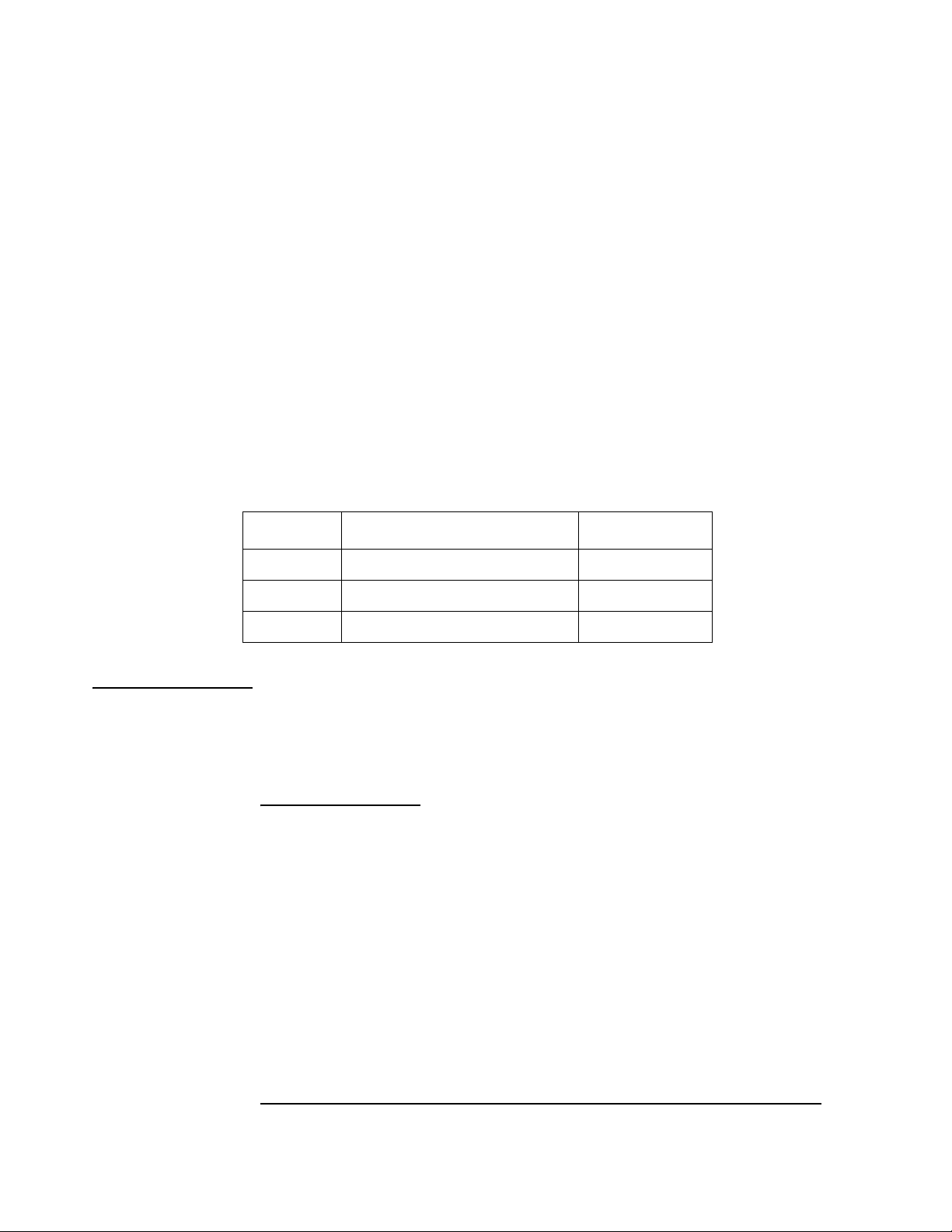

Table 1-1. Shipment Verification List

Part Number Item Description Option

Unique to Country AC Power Cable Standard

5063-9227 Front Handle Kit 1CN

5063-9214 Rack Flange Kit (without handles) 1CM

5063-9221 Rack Flange Kit (with handles) 1CP

Preparing for Use

Installing the Signal Generator

E4400-90076 User’s Guide

(part of manual set E4400-90075)

E4400-90077 Programming Guide

(part of manual set E4400-90075)

E4400-90078 Quick Reference Guide

(part of manual set E4400-90075)

E4400-90079 Calibration Guide

(part of manual set E4400-90075)

E4400-90075 Additional Manual Set OB1

E4400-90008 Service Guide 0BW, 0BX

E4400-90015 Component Level Information Guide 0BV, 0BX

E4400-90024 User’s Guide, Chinese for Taiwan AB0

E4400-90023 User’s Guide, Korean AB1

E4400-90022 User’s Guide, Chinese AB2

E4400-90027 User’s Guide, German ABD

E4400-90026 User’s Guide, Spanish ABE

E4400-90025 User’s Guide, Japanese ABJ

Standard

Standard

Standard

Standard

1-3

Page 21

Preparing for Use

Installing the Signal Generator

Installing Front Handles and Rack Mount Flanges

You can attach handles to the front of the signal generator to facilitate

transportation of the i nstrument. Handles are available in a kit which ca n be

ordered when the signal generator is purchased (Option 1CN), or at any time

afterward. Assembly inst ruc ti ons are i ncl ude d wit h the kit. The kit part number is

listed in Table 1-2.

You can also rack mount the signal generator. Hardware is available in kits to

install rack mount flanges on the signal generator without or with handles. These

kits can be ordered when the signal generator is purchased (Options 1CM and

1CP), or at any time afterward. Assembly instructions are included with the kits.

The kit par t numbers are listed in Table 1 -2.

Table 1-2. Front Handle and Rack Mount Flange Kits

Option Description HP Part Number

Option 1CN Front Handle Kit 5063-9227

Option 1CM Rack Mount Kit without Handles 5063-9214

Option 1CP Rack Mount Kit with Handles 5063-9221

Providing Adequate Ventilation

CAUTION Ventilation Requirements: When installing the product in a cabinet, the

convection into and out of the product must not be restricted. The ambient

temperature (outside the cabinet) must be less than the maximum operating

temperature of the product by 4° C for every 100 watts dissipated in the cabinet.

If the total power dissipated in the cabinet is greater than 800 watts, then forced

convection must be used.

Cooling holes are lo cat ed on t he sides and bottom of the instrument cover and the

rear panel of the instrument. Do not allow these holes to be obstructed as they

allow air flow through the signal generator.

1-4

Page 22

Preparing for Use

Installing the Signal Generator

Meeting Electrical and Environmental Requirements

Line Settings

CAUTION: This product has an autoranging line voltage input. Be sure that the supply voltage is within

the specified range.

The available AC power source must meet the following requirements:

Voltage:

• 100/115 volts nominal (90-132 volt range)

• 230/240 volts nominal (198-254 volt range)

Frequency:

• for 100/115 volts: 50/60/400 Hz nominal

• for 230/240 volts: 50/60 Hz nominal

Power:

• 200 watts maximum

Verify that the po wer cable i s not da maged and tha t the power s ource sock et outle t

provides a protective earth contact.

WARNING This is a Safety Class 1 Product (provided with a protective earthing ground

incorporated in the power cord). The mains plug shall only be inserted in a

socket outlet provided with a protective earth contact. Any interruption of

the protective conductor inside or outside of the product is likely to m ake the

product dangerous. Intentional interruption is prohibited.

CAUTION Always use the three-prong AC power cord supplied with this product. Failure to

ensure adequate earth grounding by not using this cord may cause product

damage.

Environment

This product is designed for use in the following environmental conditions:

• indoor use

• < 15,000 feet (4,572 meters) altitude

•0° to 55° C temperature, unless specified differently

• maximum relative humidity 80% for temperatures up to 31° C, decreasing linearly to

50% relative humidity at 40° C

1-5

Page 23

Preparing for Use

Installing the Signal Generator

CAUTION: This product is designed for use in INSTALLATION CATEGORY II and POLLUTION

DEGREE 2, per IEC 1010 and 664 respectively.

WARNING If this product is not used as specified, the protection provided by the

equipment could be impaired. This product must be used in a normal

condition only (in which all means for protection are intact).

Cleaning the Signal Generator

Clean the instrument cabinet using a damp cloth only.

Adjusting the Display Contrast

You can adjust the contrast of the display by pressing the decrease contrast key

or the increase contrast key . These keys are located on the front

panel below the display.

Pressing the decrease contrast key and holding it down causes the display

background to gradually darken in comparison to the text on the display. The

minimum contrast setting is not a completely black display. Some contrast

between the background and the text will still be visible.

Pressing the increase contrast key and holding it down causes the display

background to gradually brighten in comparison to the text on the display. If the

background does not appear to change, it is probab ly set to the maximu m contrast .

Selecting Inverse Video

The normal display mode for the signal generator is dark text on a light

background. To change to inverse video (light text on a dark background), press

Utility, Display and set Inverse Video Off On to On. Inverse video is a persistent

state; it is not affected by an instrument preset or by a power cycle.

Adjusting the Screen Saver

You can increase the life expectancy of the signal generator’s display light by

turning on the screen saver. Leaving the display lit for long periods of time or

turning the display on and off frequently decreases the life of the bulb. With the

screen saver on, the display light is turned off after a defined period of time with

no input to the front panel. The display light turns on again when any front panel

key is pressed or when a remote command is sent.

1-6

Page 24

Preparing for Use

Installing the Signal Generator

The screen saver is set to off at the factory. You can turn it on by pressing Utility,

Display, Screen Saver Off On. Each time you press Screen Saver Off On the

selection toggles between

Off and On.

You can ad just the screen saver mode to turn the light on and off or to turn both

the light and text on and off. Press

toggle between

Light Only and Light&Text. Setting the mode to Light Only turns the

Utility, Display, Screen Saver Mode. You can

display light off but leaves the text visible at a low intensity. To prevent the text

from burning the display if you are le aving the display unchanged for lon g periods

of time, set the mode to

Light&Text. This mode turns off the display light and the

text.

The screen saver delay i s set to 1 hour at the facto ry. You can view and change the

delay by pressing

Screen Saver Delay in the same menu. The current screen saver

delay is displayed in the softkey label and also in the active entry area. To change

the delay, enter a new value using the numeric keypad and then press

Enter, or

rotate the front panel knob. The acceptable range of delay values is 1 through 12

hours in 1 hour increments.

The screen saver settings do not change when

Preset is pressed, nor when power

to the instrument is cycled.

Selecting the Signal Generator’s HP-IB Address

The signal generator’s HP-IB address is set to 1 9 at t he f actory. You ca n vi ew an d

change the address by pressing

HP-IB address is displayed in the softkey label and also in th e active entry area.

T o change the address, enter a new value using the numeric keypad and then press

Enter, or rotate the front panel knob. The acceptable range of addresses is 0

through 30.

The HP-IB address is a persisten t state; it is not affect ed by an instrume nt preset or

by a power cycle.

Utility, HP-IB/RS-232, HP-IB Address. The current

1-7

Page 25

Preparing for Use

Installing the Signal Generator

Selecting the Signal Generator’s Programming Language

The default programming language for the signal generator is Standard

Commands for Programmable Instruments (SCPI). You can change this language

selection by pressing

Language menu allows you to select between HP 8656/57-compatible language,

HP 8648-compatible language, and SCPI language. Press the softkey for the

selection that you desire.

You can also change the language selection by sending the appropriate command

over HP-IB. Refer to the programming guide for instructions for changing the

language over HP-IB.

You can set the signal generator to default to a selected language as a persistent

state (remains unchanged after an instrument preset or power cycle). Press

Power On/Preset, Preset Language. The Preset Langua ge menu allow yo u to selec t

between SCPI, the HP 8656/57-compatible programming language, and

HP 8648-compatible language. Press the softkey for the selection that you desire.

Utility, HP-IB/RS-232, Remote Language. The Remote

Utility,

1-8

Page 26

Preparing for Use

Verifying Signal Generator Operation

Verifying Signal Generator Operation

The operator’s check is appropriate as a daily functional check by users, or

whenever the integrity of the signal generator is in question. Use the operator’s

check to verify prop er operation of the signal g enerator. The operator’ s check does

not ensure performanc e to specifications. To verify specific ations, refe r to the

calibration guide.

Operator’s Check

Perform the following tasks in order:

1. Power On the Signal Generator and Check for Error Messages

This procedure verifies that the signal generator powers up and that the internal

instrument check identifies no errors.

1. Turn power on to the signal generator by pressing the power switch. The green LED

will light. Let the instrument warm up for one hour.

2. Cycle the power to the signal generator. The green LED should again be lit and the

instrument will perform a check.

3. When the display is lit, check to see if the ERR annunciator is turned on.

4. If the ERR annunciator is turned on, review the error messages in th e queue by pressing

Utility, Error Info. The first error message in the queue will be shown in the text area

of the display. Refer to Chapter 3, “Troubleshooting,” for information about the error

message.

If there is more than one error message (each message will be designated as 1 of n),

press the

5. When you have resolved all of the error messages, press

the messages. Then restart this procedure at step two.

Note: For instruments with Option 1E5, ERROR 514, Reference Oven Cold

will occur whenever the signal generator is first connected to AC line power. The

OVEN COLD annunciator and the ERR annunciator will both turn on. The

OVEN COLD annunciator will automatically clear after approximately 5 minutes. The

error queue cannot be cleared, however , u ntil the OVEN COLD annuncia tor has turned

off.

View Next Error Message softkey until you have seen all of the messages.

ClearErrorQueue(s) to delete

1-9

Page 27

Preparing for Use

Verifying Signal Generator Operation

2. Verify Maximum Specified Powe r is Avai lable at the Maximum Frequency

This procedure verifies that there are no unleveled power indications or error

messages at the maximum specified frequency and power level.

1. Calibrate the power meter with the power sensor. (Refer to the power meter’s manual

for assistance.)

2. Connect the power sensor to the signal generator’s RF OUTPUT connector as shown

in Figure 1-1.

Figure 1-1. Operator’s Check Equipment Setup

3. Preset the signal generator to the factory-defined conditions:

a. Press

b. Press the front panel

Utility, Power On/Preset and toggle Preset until Normal is highlighted.

Preset key.

4. Set the signal generator to its maximum specified frequency:

a. Press

Frequency.

b. Use the numeric keypad to enter the signal generator’s maximum specified

frequency as shown in Table 1-3.

c. Terminate your entry by pressing the

5. Set the signal generator to its maximum specified power level:

a. Press

Amplitude.

b. Use the numeric keypad to enter the signal generator’s maximum specified power

level as shown in Table 1-3.

c. Terminate your entry by pressing the

1-10

GHz softkey.

dBm softkey.

Page 28

6. Togg le the front p anel RF On/Off key to turn on RF power to the RF OUTPUT

connector. The display RF ON annunciator will turn on.

7. Verify that the power meter reads the maximum specified output power including the

power level accuracy limits.

8. Check to see if the UNLEVEL or ERR display annunciators have turned on. If these

annunciators are on, refer to the service guide for troubleshoo ting information.

Table 1-3. Frequency and Power Level Limits

Preparing for Use

Verifying Signal Generator Operation

Instrument

Model

Maximum

Specified

Frequency

Maximum

Specified Power

Power Level

Accuracy

Limits

HP ESG-1000A 1 GHz +13 dBm ±0.7 dB

HP ESG-2000A 2 GHz +10 dBm ±0.7 dB

HP ESG-3000A 3 GHz +10 dBm ±1.0 dB

HP ESG-4000A 4 GHz +7 dBm ±1.0 dB

1. The values provided are confidence levels only; they are not

specifications.

1

1-11

Page 29

Preparing for Use

Verifying Signal Generator Operation

1-12

Page 30

2 Using Functions

This chapter contains procedures that show you how to use some of the major

functions of your signal generator including setting frequency and power levels,

setting up modulations, creating step and list sweeps, and saving and recalling

instrument states.

2-1

Page 31

Using Functions

Setting Frequency and Power Levels

Setting Frequency and Power Levels

Using these procedures, you will learn how to:

• set the RF frequency

• set a frequency reference and a frequency offset

• set the RF output power level

• set an amplitude reference and an amplitude offset

To Set the RF Frequency

1. Turn power on to the signal generator: press the power switch, , so that the green

LED is on. The signal generator will perform an internal check.

2. Press the green

conditions.

NOTE: You can change the preset conditions to a user-defined instrument state. However, for the

purpose of these examples, use the factory-defined preset state (the

softkey in the Utility menu must be set to Normal).

3. Observe the frequency area of the display (in the upper left-hand corner). It should

display the maximum specified frequency of your signal generator.

4. The signal generator is set to output an RF signal, however the

set to

On before the RF signal is available at the RF OUTPUT connector. Press

RF On/Off. Notice that the display annunciator changes from RF OFF to RF ON. The

maximum specified frequency is now being output at the RF OUTPUT connector.

5. Change the frequency to 700 MHz by pressing

is now displayed in the active entry area of the display. Using the numeric keypad, enter

700 and then press the MHz terminator softkey. Th e new 700 MHz RF frequency is now

displayed in the frequency area of the display and also in the active entry area.

6. Fr eque ncy is still the active function until you press another front panel f unc tion key.

Change the frequency again by pressing the up arrow key once. Each press of the up

arrow key increases the frequency by the value set for the

value is displayed in the active entry area.

The down arrow works like the up arrow. Practice stepping the frequency up an d down

in 1 MHz increments. Use the

necessary.

Preset key. The signal gen e rator w ill ret urn t o a s et of facto ry-d e fined

Preset Normal User

RF On/Off key must be

Frequency. The current RF frequency

Incr Set key. The increment

Incr Set key to change the increment value to 1 MHz, if

2-2

Page 32

Using Functions

Setting Frequency and Power Levels

7. You can also adjust the RF frequency using the front panel knob. As long as f requency

is the active function (the frequency is displayed in the active entry area), the front panel

knob will increase and decrease the RF frequency. Use the front panel knob to adjust

the frequency back to 700 MHz.

To Set a Frequency Reference and a Frequency Offset

The following procedure sets the RF output fr equ ency as a reference frequency to

which all other frequency parameters are relative. The frequency initially shown

on the display will be 0 Hz (the frequency output by the hardware minus the

reference frequency.) Although t he display cha nges, the freq uency output doe s not

change. Any subsequent frequency changes are shown as incremental or

decremental to 0 Hz.

1. Press Preset to r e turn the signal g e nerator to the factory-defined instrument state.

2. Set the RF frequency to 700 MHz.

3. Turn on frequency reference mode and set the current output frequency (700 MHz) as

the reference value. Press

frequency output by the hardware, 700 MHz, minus the reference value, 700 MHz).

Notice that the REF indicator is turned on and the

4. Set the

RF OFF to RF ON. The RF frequency at the RF OUTPUT connector is 700 MHz.

5. Increment the output frequency by 1 MHz. Press the up arrow key. The frequency

display changes to show 1 MHz (the frequency output by the hardware,

700 MHz + 1 MHz, minus the reference frequency, 700 MHz) and the output

frequency changes to 701 MHz.

6. Enter a 1 MHz offset. Press the

keypad and pressing th e

(the frequency output by the hardware, 701 MHz, minus the reference frequency,

700 MHz, plus the offset, 1 MHz.) Notice that the OFFSET indicator is turned on. The

frequency at the RF OUTPUT connector is still 701 MHz.

RF On/Off key to On. Notice that the display annunciator has changed from

Freq, Freq Ref Se t. The frequency displayed is 0 Hz (the

Freq Ref softkey has toggled to On.

Freq Offset softkey and enter 1 MHz using the numeric

MHz terminator softkey. The f requency displ ay sho ws 2 MH z

2-3

Page 33

Using Functions

Setting Frequency and Power Levels

To Set the RF Output Power Level

1. Press Preset to r e turn the signal g e nerator to the factory-defined instrument state.

2. Observe the amplitude area of the display (in the upper middle of the disp lay). It should

display −135 dBm. This is the normal preset RF output power level.

3. The signal generator is set to output an RF signal, however the

set to

On before the RF signal is available at the RF OUTPUT connector. Press

RF On/Off. Notice that the display annunciator changes from RF OFF to RF ON. The

RF signal is now being output at a −135 dBm level at the RF OUTPUT connector.

4. Change the power level to −20 dBm. Press

displayed in the active entry area of the display. Using the numeric keypad and the

key, enter −

power is now displayed in the amplitude area of the display and also in the active entry

area.

5. Am plitude is still the active function until you press another front panel function key.

You can also change the amplitude using the up and down arrow keys and the front

panel knob. Practice changing the amplitude using these methods also.

20 and then press the dBm softkey. The new −20 dBm RF output

Amplitude. The current power level is now

RF On/Off key must be

To Set an Amplitude Reference and an Amplitude Offset

The following procedure sets the RF output power as an amplitude reference to

which all other amplitude parameters are relative. The amplitude initially shown

on the display will b e 0 dB ( the power output by t he ha rd ware mi nus t he re feren ce

power). Although the display changes, the output power does not change. Any

subsequent power changes are shown as incremental or decremental to 0 dB.

1. Press Preset to r e turn the signal g e nerator to the factory-defined instrument state.

2. Set the RF output power to −20 dBm.

3. Turn on amplitude reference mode and set the current output power (−20 dBm) as the

reference value. Press

0 dB (the power output by the hardware, −20 dBm, minus the reference value,

−20 dBm.) Notice that the REF indicator is turned on and the

toggled to

4. Set the

RF OFF to RF ON. The power at the RF OUTPUT connector is −20 dBm.

5. Use the up arrow key to increase the output power by 10 dB. The amplitude displa y

changes to show 10 dB (the power output by the hardwar e, −20 dBm + 10 dBm, minus

the reference power, −20 dBm) and t he output power changes to −10 dBm.

2-4

On.

RF On/Off key to On. Notice that the display annunciator has changed from

Ampl, More (1 of 2), Ampl Ref Set. The amplitude displayed is

Ampl Ref softkey has

Page 34

Using Functions

Setting Frequency and Power Levels

6. Enter a 10 dB offset. Press the Ampl Offset softkey and enter 10 dB using the numeric

keypad. The amplitude display shows 20 dB (the power output by the hardware,

−10 dBm, minus the reference power, −20 dBm, plus the offset, 10 dB). Notice that the

OFFS indicator is turned on. The power at the RF OUTPUT connector is still −10 dBm.

2-5

Page 35

Using Functions

Setting Up Internally-Generated Amplitude Modulation

Setting Up Internally-Generated Amplitude Modulation

Using this procedure, you will learn how to generate an amplitude-modulated

signal with the following characteristics:

• carrier frequency set to 1340 kHz

• power level set to 0 dBm

• AM depth set to 90%

• AM rate set to 10 kHz

Setting the Carrier Frequency

1. Press Preset to r e turn the signal g e nerator to the factory-defined instrument state.

2. Press the front panel

normal preset value for frequency is displayed in the active entry area.

3. Enter 1340 kHz using the numeric keypad and pressing the

new carrier frequency is shown in the frequency area of the display. You should see

1.340 000 00 MHz.

Frequency key. Frequency becomes the active function and the

kHz terminator softkey. The

Setting the Power Level

1. Press the front panel Amplitude key. Amplitude becomes the active function and the

normal preset value for amplitude is displayed in the active entry area.

2. Enter 0 dBm using the numeric keypad and pressing the

new power level is shown in the amplitude area of the display. You should see

0.00 dBm.

dBm terminator softkey. The

Setting the AM Depth

1. Press the front panel AM key. The first level menu of softkeys is displayed.

2. Press the

preset value for AM depth is displayed in the active entry area.

3. Enter 90% using the numeric keypad and pressing the

AM depth is displayed below the

second line of the softkey.

AM Depth softkey. AM depth becomes the active function and the normal

% terminator softkey. The new

AM Depth softkey. You should see 90.0 % in the

2-6

Page 36

Using Functions

Setting Up Internally-Generated Amplitude Modulation

Setting the AM Rate

1. In the same AM menu, press the AM Rate softkey. AM rate becomes the active function

and the normal preset value for AM rate is displayed in the active entry area.

2. Enter 10 kHz using the numeric keypad and pressing the

new AM rate is displayed below the

the second line of the softkey.

AM Rate softkey. You should see 10.0000 kHz in

kHz terminator softkey. The

Turning On Amplitude Modulation

The signal generator is now configured to output a 0 dBm, amplitude-modulated

carrier at 1340 kHz with the AM depth set to 90% and the AM rat e set to 10 kHz.

The shape of the waveform is a sinewave (notice that sine is the default for the

AM Waveform softkey). Follow these remaining steps to output the

amplitude-modulated signal.

1. In the same AM menu, press the AM Off On softkey. AM toggles from Off to On.

Notice, also, that the AM display annunciator is turned on indicating that you have

enabled amplitude modulation.

2. Press the front panel

changes from RF OFF to RF ON. The modulated signal is now available at the RF

OUTPUT connector.

RF On/Off key to toggle RF on. Notice that the display annunciator

2-7

Page 37

Using Functions

Setting Up Internally-Generated Frequency Modulation

Setting Up Internally-Generated Frequency Modulation

Using this procedure you will configure the signal generator to output a

frequency-modulated signal with the following characteristics:

• carrier frequency set to 104.9 MHz

• power level set to 0 dBm

• FM deviation set to 75 kHz

• FM rate set to 10 kHz

Setting the Carrier Frequency

1. Preset the signal generator to normal preset conditions.

2. Press the front panel

normal preset value for frequency is displayed in the active entry area.

3. Enter 104.9 MHz using the numeric keypad and pressing the

The new carrier frequency is shown in the frequency area of the display. You should

see 104.900 000 00 MHz.

Frequency key. Frequency becomes the active function and the

MHz terminator softkey.

Setting the Power Level

1. Press the front panel Amplitude key. Amplitude becomes the active function and the

normal preset value for amplitude is displayed in the active entry area.

2. Enter 0 dBm using the numeric keypad and pressing the

new power level is shown in the amplitude area of the display. You should see

0.00 dBm.

dBm terminator softkey. The

Setting the FM Deviation

1. Press the front panel FM/ΦM key. The first level menu of FM sof tkeys is displayed.

2. Press the

preset value for FM deviation is displayed in the active entry area.

3. Enter 75 kHz using the numeric keypad and pressing the

new FM deviation is displayed below the

in the second line of the softkey.

FM Dev softkey. FM deviation becomes the active function and the normal

kHz terminator softkey. The

FM Dev softkey. You should see 75.0000 kHz

2-8

Page 38

Using Functions

Setting Up Internally-Generated Frequency Modulation

Setting the FM Rate

1. In the same FM menu, press the FM Rate softkey. FM rate becomes the active function

and the normal preset value for FM rate is displayed in the active entry area.

2. Enter 10 kHz using the numeric keypad and pressing the

new FM rate i s displayed below the

the second line of the softkey.

FM Rate softkey. You should see 10.0000 kHz in

kHz terminator softkey. The

Turning On Frequency Modulation

The signal generator is now configured to output a 0 dBm, frequency-modulated

carrier at 104.9 MHz with the FM deviation set to 75 kHz and the FM rate set to

10 kHz. The shape of the waveform is a sinewave (notice that sine is the default

for the

remaining steps to output the frequency-modulated signal.

1. In the same FM menu, press the FM Off On softkey. FM toggles f rom Off to On. Notice,

2. Press the front panel

FM Waveform softkey - pr ess More (1 of 2) to see the softkey). Follow these

also, that the FM display annunciator is turned on indicating that you have enabled

frequency modulation.

RF On/Off key to toggle RF on. Notice that the display annunciator

changes from RF OFF to RF ON. The modulated signal is now available at the RF

OUTPUT connector.

2-9

Page 39

Using Functions

Creating a Step Sweep and a List Sweep

Creating a Step Sweep and a List Sweep

Using this procedure, you will learn two ways to set up the signal generator to

sweep a defined set of points. You will create a step sweep and then you will use

these points as the basis for a new lis t sweep.

In the first procedure, you will create a step sweep with the following ten equally

spaced points:

• frequency range from 525 MHz to 600 MHz

• power level from −20 dBm to 0 dBm

• dwell time 500 ms at each point

In the second procedure, you will take the step sweep points and edit several

points to change the sweep informat ion.

Configuring a Step Sweep

1. Press Preset to r e turn the signal g e nerator to the factory-defined instrument state.

2. Press the front panel

Toggle the

3. Press the

that you will use to create the sweep points.

4. Change the start frequency of the step sweep. Press the

525 MHz using the numeric keypad and pressing the

5. Change the stop frequency of the step sweep. Press the

600 MHz using the numeric keypad and pressing the

6. Set the power level for the start of the step sweep. Press the

-20 dBm using the numeric keypad and pressing the

7. Set th e power level for the end of the step sweep. Press the

0 dBm using the numeric keypad and pressing the

8. Set the number of sweep points. Press the

front panel knob until the number 10 is displayed.

Sweep Type List Step softkey to Step.

Configure Step Sweep softkey. Another menu is displayed with softkeys

Sweep/List key. The first level of sweep softkeys is displayed.

Freq Start softkey. Enter

MHz terminator softkey.

Freq Stop softkey. Enter

MHz terminator softkey.

Ampl Start softkey. Enter

dBm terminator softkey.

Ampl Stop softkey. Enter

dBm terminator softkey.

#Points softkey. Enter 10 by rotating the

9. Set the dwell time at each point. Press the

numeric keypad and pressing the

2-10

msec terminator softkey.

Step Dwell softkey. Enter 500 ms using the

Page 40

Creating a Step Sweep and a List Sweep

Turning On Continuous Step Sweep

1. Press Return to move up one menu level.

Using Functions

2. Press the

either the frequency, amplitude, or frequency and amplitude data. Press the

softkey. Selecting this softkey returns you to the previous menu and turns the sweep

function on.

3. Press the

that the SWEEP display annunciator is turned on indicating that the signal generator is

sweeping.

4. Press the front panel

changes from RF OFF to RF ON. The swept RF signal is now available at the RF

OUTPUT connector.

Sweep softkey. Another menu is displayed showing you choices for sweeping

Freq&Ampl

Sweep Repeat Single Cont softkey to toggle from Single to Cont. Notice

RF On/Off key to toggle RF on. Notice that the display annunciator

Configuring a List Sweep Using Step Sweep Data

1. Press the Sweep Type List Step softkey to toggle from Step to List.

2. Press the

you will use to create the sweep points. Notice that the display shows the current list

data (when no list has been previously created, the default is one point, set to the signal

generator’s maximum frequency, −135 dBm, with a dwell time of 2 ms).

3. Press

The points you defined in the step sweep are automatically loaded into the list.

Configure List Sweep softkey. Another menu is displayed wi th softkey s that

More (1 of 2), Load List From Step Sweep, Confirm Load From Step Sweep.

Editing List Sweep Points

1. Change the dwell time for point 1 to 100 ms. Press the right arrow key twice until the

dwell time is highlighted. Press

becomes the active function. Enter 100 ms using t he nume ric keypad and pressi ng the

msec terminator softkey. Notice that the next item in the table (in this case the

frequency value for point 2) becomes hi ghli ghted aft er pressi ng the t erminato r softk ey.

2. Change the frequency for point 4 to 560 MHz. Press the down arrow key two times until

the frequency is highlighted. Press the

becomes the active function. Enter 560 MHz using the numeric keypad and pressing the

MHz terminator softkey.

3. Add a new point between points 7 and 8. Press the down arrow until any column in the

point 8 row is highlighted. Press the

placed between points 7 and 8, creating a new point 8, and renumbering the successive

points.

More (2 of 2), Edit Item. The dwell time for point 1

Edit Item softkey. The frequency for point 4

Insert Row softkey. A copy of point 8 has been

2-11

Page 41

Using Functions

Creating a Step Sweep and a List Sweep

4. Create a new point between points 10 and 11. Use the arrow keys to highlight the

frequency for point 11. Press t he

is placed at point 11 and the frequency item previously occupying that position has

shifted down to point 12. The power and dwell time items do not shift down. Press the

Edit Item softkey. Enter 700 MHz using the numeric keypad and pressing the MHz

terminator softkey.

NOTE: An informational ERR annunciat or is turned on at this time in dicating that the frequency

and power lists are of unequal size. You will correct that problem in the following steps.

The annunciator will not turn off until you clear the error queue in the Utility menu.

Insert Item softkey. Notice that a new frequency item

The power for point 11 should now be highlighted. Press the

press the

the

Edit Item softkey and enter 1 dBm using the numeric keypad and pressing

dBm terminator softkey. A new power item is placed at point 11 and the power

Insert Item softkey , the n

item previously occupying that position has shifted down to point 12.

The dwell time for point 11 should now be highlighted. Press the

Insert Item softkey.

The dwell time from the previous point 11 has been copied into the new point 11. A

new dwell time item is placed at point 11 and the dwell time item previously

occupying that position has shifted down to point 12.

Turning On List Sweep for a Single Sweep

1. Press Return to move up one menu level.

2. Notice that the

You do not need to change it.

3. Press the

that the SWEEP display annunciator is turned off. The sweep will not occur until it is

triggered.

4. Press

Single Sweep. The signal generator will sweep the points in your list once.

Notice that the SWEEP display annunciator is turned on during the sweep.

5. Change the sweep trigger to occur when you press the front panel

More (1 of 2), Sweep Trigger. Another menu is displayed showing you choi ces for

triggering a sweep. Press the

Sweep softkey is still set to sweep both frequency and amplitude data.

Sweep Repeat Single Cont softkey to toggle from Cont to Single. Notice

Trigger key. Press

Trigger Key softkey.

6. Press

More (2 of 2), Single Sweep to arm the sweep. Notice that the ARMED display

annunciator has turned on.

7. Press the front panel

Trigger key. The signal generator will sweep the points in your list

once and the SWEEP display annunciator is turned on during the sweep.

2-12

Page 42

Using Functions

Saving and Recalling an Instrument State

Saving and Recalling an Instrument State

Using this procedure, you will learn how to save instrument settings to a memory

register and to recall the settings.

1. Press Preset to r e turn the signal g e nerator to the factory-defined instrument state.

2. Set up the signal generator with the following changes:

a. Set th e freq uency to 800 MHz.

b. Set the amplitude to 0 dBm.

c. Enable amplitude modulation (

3. Save this instrument state in the signal generator memory in sequence 1, memory

register 01. Press t h e fr ont p anel

sequence number becomes the active function. The signal generator will display the last

sequence that you have used. Set the sequence to 1 using the arrow keys.

Press the

function. The signal generator will either display the last register used [accompanied

by the text: (in use)] or, if no registers are in use, will display register 00

[accompanied by the text: (available)]. Use the arrow keys to select register 01.

4. Press the

frequency, amplitude, and modulation changes you made have been stored in signal

generator memory.

5. Press

6. Recall your instrument state. Press the front panel

Select Seq softkey shows sequence 1. (This is the last sequence that you have used.)

You do not need to change the sequence. Press

recalled in sequence 1 becomes the active function. Press the up arrow key once to

select register 1. Notice that your stored instrument settings have been immediately

recalled.

Select Reg softkey. The register number in sequence 1 becomes the active

Save Seq[1] Reg[01] softkey. The current instrument settings including the

Preset to return the signal ge nerator to the factory-defined instrument state.

AM display annunciator is on).

Save key and then press the Select Seq softkey. The

Recall key. Notice that the

RECALL Reg. The register to be

2-13

Page 43

Using Functions

Saving and Recalling an Instrument State

2-14

Page 44

3 Troubleshooting

This chapter contains instructions for troubleshooting problems you may

encounter during operation of the signal gene rat or, it explains error messages you

might see, and it explains how to return your signal generator to HP for service.

3-1

Page 45

Troubleshooting

If You Encounter a Problem

If You Encounter a Problem

If the signal generator is not operating as you expected, look for help in the

following list of symptoms and possible solutions. If you do not find a solution

here, refer to the service guide.

• No RF Output?

The front panel RF On/Off key must be set to On before the RF signal is available

at the RF OUTPUT connector. Check the annunciator on the display. If it reads

RF OFF, press the RF On/Off key once to toggle the RF output on.

• RF Output Power too Low?

If the RF output power seems too low, look for an OFFSET or REF indicator in the

amplitude area of the display.

OFFSET tells you th at an amplitude offset has been set. An am plitude offset

changes the value shown in the amplitude area of the display but does not affect

the output power. The amplitude displ ayed i s equal to th e cu rrent power o utput b y

the signal generator hard ware plus the value f or the of fset . To eliminate the of fset ,

press

Ampl, Ampl Offset. Enter 0 using the numeric keypad and press the dB

terminator s oftkey.

REF tells you that the amplitude reference mode is turned on. When this mode is

on, the displayed amplitude value is not the output power level; rather, it is the

current power output by the signal generator hardware minus the reference value

set by the

the

Ampl Ref Set softkey. To exit the reference mode, press Ampl and t oggle

Ampl Ref softkey to Off. You can then reset the output power to the desired

level.

• No Modulation at the RF Output?

Although you can set up and enable various modulations, the RF carrier is

modulated by the enabled modulation only when you have also set

On. Check the annunciator on the display. If it reads MOD OFF, press the

Mod On/Off key once to toggle the modulation on.

Mod On/Off to

3-2

Page 46

Troubleshooting

If You Encounter a Problem

• Can’t Turn Off Sweep Mode?

In the sweep mode menu you can choose to set the sweep to various sweep types

or to turn sweep off. Press

Sweep/List, Sweep and choose Off from the sweep

mode selections.

• Recalled a Register and Sweep List is Missing?

Sweep information is not stored as part of the instrument state in a storage

register. Only the current step and list sweep is a vailable to the signal generator

and it cannot be stored nor will it survive a factory preset.

• All of the Registers Where You Previously Stored Instrument

States are Empty?

The save/recall registers are backed-up by a battery when AC power to the signal

generator is not connec ted. The bat tery may need to be repla ced. To verify that t he

battery has failed, turn power off line power to the signal generator and unplug it.

Then plug in the instrument and cycle power on. If either error message

−700 is stored in the error message queue, your battery has failed. Refer to the

−311 or

service guide for battery replacement instructions.

• Saved an Instrument State in a Register but the Register is

Empty or Contains the Wrong State?

If you have intentionally, or unintentionally, selected a register number that is

greater tha n 99, the signal generator will automatically select register 99 to save

your instrument state. If the register number you intended to use is empty or

contains the wrong instrument state, recall register 99 as the instrument state may

be saved there.

• The Power Supply has Shut Down

If the power supply is not working, it requires repair or replacement. There is no

user-replaceable power supply fuse. Refer to the service guide for instructions.

3-3

Page 47

Troubleshooting

If You Encounter a Problem

• Incorrect List Sweep Dwell Time?

If the signal generator does not dwell for the correct period of time at each sweep

list point, first check the sweep list dwell values for accuracy. Press

Configure List Sweep and the sweep list values will be displayed. Edit the dwell

Sweep/List,

values if they are incorrect.

If the list dwell values are correct, check to see if the

is set to

Step. When Step is selected, the signal generator wil l sweep the list points

Dwell Type List Step softkey

using the dwe ll time set for step sweep rather th an the sweep list dwell values. To

view the step swee p dwell t ime, press

set for the

• Can’t Turn Off Help Mode?

Step Dwell softkey.

Configure Step Sweep and observe the value

There are two help modes (single and continuous) available on the signal

generator. In single mode (the factory preset condition) when you press the

Help

key , h elp text i s provi ded f or your next key pr ess. Now pre ss any key an d you wi ll

exit the help function and the function of the key you pressed is also executed.

When you are in continuous help mode, when you press the

Help key, help text is

provided for your next key press and that key’s function is also executed (except

for the

again. To change from continuous to single mode, press

Instrument Info/Help Mode and toggle the Help Mode Single Cont softkey to Single.

• LF OUTPUT Signal is a Sinewave but the RF OUTPUT Signal

Preset key). You will stay in this help mode until you press the Help key

Utility,

is a Pulse Squarewave?

The LF OUTPUT connector wi ll out put a signa l where t he fr equency and sh ape is

set by the internal source as it is being used by a modulation. However, if you are

generating a pulse squarewave, the LF OUTPUT signal is correctly output as a

sinewave. That sinewave is later squared by the modulator to generate the pulse

modulation.

3-4

Page 48

Troubleshooting

Error Messages

Error Messages

If an error condition occurs in the signal generator, it will always be reported to

both the front panel display error queue and the SCPI (remote interface) error

queue. These two queues are viewed and managed separately.

The Front Panel Error Queue

This queue is designed in a circular (rotating) fashion. It can hold up to 30 error

messages. If the queue is full, and additional error messages arrive, the oldest

errors are lost. The previous ly read messa ges are not cleare d from the queue; they

remain in the queue until they are overwritten by a new error message.

The front panel error queue information can be accessed by pressing

Info. From the Error Info menu, you may choose from View Previous Error

Message

, View Next Error Message, or Clear Error Queue(s). You can also use the

Utility, Error

RPG and the arrow keys to review the messages/

If there are any unviewed messages in the front panel error queue, the

ERR

annunciator will be activated on the signal g enerator’s display. you can optional ly

rotate the RPG or use the arrow keys to view the error messages. To empty the

queue, press

Utility, Error Info, Clear Error Queue(s).

There are some special error types called permanent errors. These include

unlock, ovencold, hi/lo, etc. Permanent errors remain in the error queues

until the error condit ion is cl eared. Pre ssing

Utility, Error Info, Clear Error Queue(s)

will empty the front panel error queue, but the permanent errors will be

re-reported if the error condition(s) still exist.

The SCPI Remote Interface Error Queue

This queue is construct ed in a linear first-in/first-out fashion. It can hold up to 30

error messages. As errors and events are detected, they are placed in the queue.

Unlike the front panel error queue, errors in this queue are not overwritten by the

latest incoming error messages. If the queue overflows, the last error in the queue

is replaced with the error:

3-5

Page 49

Troubleshooting

Error Messages

-350,Queue overflow

When the queue overflows, the least recent errors remain in the queue, and the

most recent error is discarded. Reading an error from the head of the queue

removes that error from the queu e, and opens a posit ion in the tail of the queue for

a new error, if one is subsequently detected.

When all the errors have be en read from the queue, further error q ueries will

return:

0,No error

The SCPI query SYSTem:ERRor? is used to view messages in the SCPI error

queue. The error queue will be cleared when any of the following occur (IEEE

488.2, section 11.4.3.4):

• upon power up

• upon receipt of a *CLS command

• upon reading the last item from the queue

In the SCPI error queue, the permanent errors are re-reported after the message 0,

No error is read using the SYSTem:ERRor? query and after the *CLS

command is executed.

3-6

Page 50

Troubleshooting

Querying the Error Queue

Querying the Error Queue

The queue query message is a request for the next entry from the instrument’s

error queue. This queue contains an integer that can range from -32768 to 32767.

Negative error numbers are reserved by the SCPI standard and are defined in this

section. Positive error numbers are instrument-dependent. An error value of zero

indicates that no error or event has occurred.

The signal generator responds to the

SYSTem:ERRor? (or STATus:QUEue?)

query using the following form:

<error number>, <error description>

The <error number> is a unique error descriptor. Certain standard error numbers

are described in this section. The <error description> is a short description of the

error, (optionally) followed by additional information regarding the error. Short

descriptions of the standard error numbers are described in this section. The

information that follows the error message may contain corrective actions that

should be followed to correct the error condition.

The <device-dependent info> section of the response may contain information

which will allow you to determine th e exact error and context. For example:

-131, Invalid suffix;FREQuency:CENT 2.0E+5 dBmV

The maximum string length of <error description> plus <device-dependent info>

is 255 characters. The <error description> will be sent exactly as indicated in this

document, including case.

If there has been no error, that is, if the queue is empty, the signal genera tor will

respond with:

0, No error

If there has been more than one error, the instrument will respond with the first

one in its queue. Subsequent responses to

the queue until it is empty.

SYSTem:ERRor? will continue with

3-7

Page 51

Troubleshooting

Error Numbers

Error Numbers

The system-defined error numbers are chosen on an enumerated (“1 of N”) basis.

The SCPI-defined erro r numbers and t he <error_ descript ion> por tions of t he error

query response are list ed here. The first error described in each cla ss (for example,

-100, -200, -300, -400) is a “gene ric” error. In selectin g the proper error numbe r to

report, mor e specific error codes are preferred.

3-8

Page 52

Troubleshooting

No Error

This message indicates that the error queue contains no errors.

Error Number Error Description [description/explanation/examples]

No Error

0

No error

The queue is empty. Every error in the queue has been read or

the queue was purposely cleared by power-on or

*CLS.

3-9

Page 53

Troubleshooting

SCPI Standard Error Messages

SCPI Standard Error Messages

Error Message Description

The list of error messages in this chapter describes all of the SCPI error messages

associated with signal gener at or operation. A sample error message description is

provided below to help you understand how information will be presented in this

section.

-222

Data out of range;value clipped to lower limit.

Indicates that t he user has entered a deviatio n, depth or internal

source frequency that is beyond the specified limits.

The following list explains each element of the sample error message l i sting

shown above.

• SCPI Error Number - The standard SCPI error number (-22 2 in this example). Standard

SCPI error numbers are always negative, with the exception of 0, No error.

• SCPI Error Message - The SCPI error message is Data out of range; in this

example.

• Detailed Description - The information that appears after the semicolon (;) provides

more detail as to the exact nature of the error. In this example, value clipped to

lower limit tells you that you have entered a value outside the allowable r ange and

the signal generator has changed the value so that it falls within the allowable limits. If

no detailed description exists, it will be omitted from the error mess age.

• Explanation/Action Required - The text that appears below each error message listing

contains an explanation of the er ror message and, in some cases, corrective actions that

should be followed in order to correct the error condition. Though this information is

not shown on the signal generator’s display, it can be found in the following section.

3-10

Page 54

Troubleshooting

Command Error

Command Error

An error number in the range [-199 to -100] indicates that an IEEE 488.2 syntax

error has been detected by the instrument’s parser. The occurrence of any error in

this class will cause the command error bit (bit 5) in the event status regist er

(IEEE 488.2, section 11.5.1) to be set. If this bit is set, one of the f ollowi ng event s

has occurred:

• An IEEE 488.2 syntax er ror has been detected by the parser. That is, a control-to-device

message was received which is in violation of the IEEE 488.2 standard. Possible

violations include a data element which violates device listening formats o r whose type

is unacceptable to the device.

• An unrecognized header was received. Unrecognized headers include incorrect

device-specific headers and incorrect or unimplemented IEEE 488.2 common

commands.

Events that generate co mmand errors will not gen erate execution errors,

device-specific errors, or query errors; see the error definitions in this chapter.

Command Error Message Descriptions

This section lists the signal generator’s command error messages and their

associated descriptions.

Error Number Error Description [description/explanation/examples]

-100

-101

-102

Command error

This is a generic syntax error for devices that cannot detect

more specific errors. The code indicates only that a command

error as defined in IEE 488.2, 11.5.1.1.4 has occurred.

Invalid character

A syntactic command contains a character which is invalid for

that type. For example, a header containing an ampersand,

SETUP&. This error might be used in place of error numbers

-114, -121, -141 and some others.

Syntax error

An unrecognized command or data type was encountered. For

example, a string was recei ved when the device does not accept

strings.

3-11

Page 55

Troubleshooting

Command Error

-103 Invalid separator

The parser was expectin g a separator and encounter ed an illegal

character. For examp le, the semicolon was omitted after a

program message unit.

-104

-105

-108

-109

-110

Data type error

The parser recognized a data element that is not allowed. For

example, numeric or string data was expected, but block data

was encountered.

GET not allowed

A Group Execute Trigger was received within a program

message (see IEEE 488.2, 7.7). Correct the HP-IB controller

program so that the

GET does not occur within a line of HP-IB

program code.

Parameter not allowed

More parameters were received than expected for the header.

For example, the

parameter, so receiving

Missing parameter

*ESE common command only accepts one

*ESE 0,1 is not allowed.

Fewer parameters were received than required for the header.

For example, the

parameter, so receiving

Command header error

*ESE common command requires one

*ESE is not allow ed.

-111

-112

3-12

An error was detected in the header. This message is used when

the device cannot detect the more specific errors described for

errors -111 through -119.

Header separator error

A character which is not a legal header separator was

encountered while parsing the header.

Program mnemonic too long

The header contains more than twelve characters (see IEEE

488.2, 7.6.1.4.1).

Page 56

-113 Undefined header

The header is syntactically correct, but it is undefined for this

specific device. For example,

device.

Troubleshooting

Command Error

*XYZ is not defined for any

-114

-120

-121

-123

-124

Header suffix out of range

The value of a header suffix attached to a program mnemonic

makes the header invalid.

Numeric data error

This error, as well as errors -121 through -129, are generated

when parsing a data element which appears to be numeric,

including non-decimal numeric types. This particular error

message is used if the device cannot detect a more specific

error.

Invalid character in number

An invalid character for the data type being parsed was

encountered. For example, an al pha in a decim al numeric or a

“9” in octal data.

Exponent too large

The magnitude of an exponent was greater than 32000 (see

IEEE 488.2, 7.7.2.4.1).

Too many digits

The mantissa of a decimal-numeric data element contained

more than 255 digits excluding leading zeros (see IEEE 488.2,

7.7.2.4.1).

-128

-130

Numeric data not allowed

A legal numeric data element was r ece ived, b ut th e devi ce does

not accept one in this position for the header.

Suffix error

This error, as well as errors -131 through -139, are generated

when parsing a suffix. This particular error message is used if

the device cannot detect a more specific error.

3-13

Page 57

Troubleshooting

Command Error

-131 Invalid suffix

The suffix does not fol low th e synt ax de scr ib ed in IEEE 488.2,

7.7.3.2, or the suffix is inappropriate for this device.

-134

-138

-140

-141

-144

Suffix too long

The suffix contained more than twelve characters (see IEEE

488.2, 7.7.3.4).

Suffix not allowed

A suffix was encountered after a numeric element which does

not allow suffixes.

Character data error

This error, as well as errors -141 through -149, are generated

when parsing a characte r data elemen t. This parti cular error

message is used if the device cannot detect a more specific

error.

Invalid character data

Either the character data element contains an invalid character

or the particular element received is not valid for the header.

Character data too long

The character data element contains more that twelve

characters (see IEEE 488.2, 7.7.1.4).

-148

-150

-151

3-14

Character data not allowed

A legal character data element was encountered where

prohibited by the device.

String data error

This error, as well as errors -151 through -159, are generated

when parsing a string data element. This particular error

message is used if the device cannot detect a more specific

error.

Invalid string data

A string data element was expected, but was invalid (see IEEE

488.2, 7.7.5.2). For example, an

END message was received

before the terminal quote character.

Page 58

-158 String data not allowed

A string data element was encountered, but not allowed by the

device at th is point in the parsing.

Troubleshooting

Command Error

-160

-161

-168

-170

-171

Block data error

This error, as well as errors -161 through -169, are generated

when parsing a block data element. This particular error

message is used if the device cannot detect a more specific

error.

Invalid block data

A block data element was expected, but was invalid (see IEEE

488.2, 7.7.6.2). For example, an

END message was received

before the end length was satisfied.

Block data not allowed

A legal block data el ement was encoun tered, but not allowed by

the device at this point in the parsing.

Expression data error

This error, as well as errors -171 through -179, are generated

when parsing an expression data element. This particular error

message is used if the device cannot detect a more specific

error.

Invalid expression

-178

-180

The expression data element was invalid (see IEEE 488.2,

7.7.7.2). For example, unmatched parentheses or an illegal

character.

Expression data not allowed

A legal expression data was encountered, but was not allowed

by the device at this point in parsing.

Macro error

This error, as well as errors -181 through -189, are generated

when defining a macro or executing a macro. This particular

error message is used if the device cannot detect a more