Page 1

Application Note

Molecular Biology and

Biochemical

Using the Agilent BioTek EL406

Combination Washer Dispenser to

Semi-Automate a Competitive ELISA

for Melamine

Semi-automated melamine quantitation

Author

Paul Held, PhD

Agilent Technologies, Inc.

Abstract

Melamine is a nitrogen rich compound normally used as either a flame retardant

or in conjunction with formaldehyde to produce melamine resin, a durable

thermosetting plastic used in the manufacture of countertops, fabrics, and

glues. However, in addition to the normal use of melamine, several illicit uses

for the material have been reported. This application note describes the use of

the AgilentBioTek EL406 combination washer dispenser in conjunction with

AgilentBioTek BioStack and AgilentBioTek liquid handling control (LHC) software to

semi-automate a melamine ELISA.

Page 2

Introduction

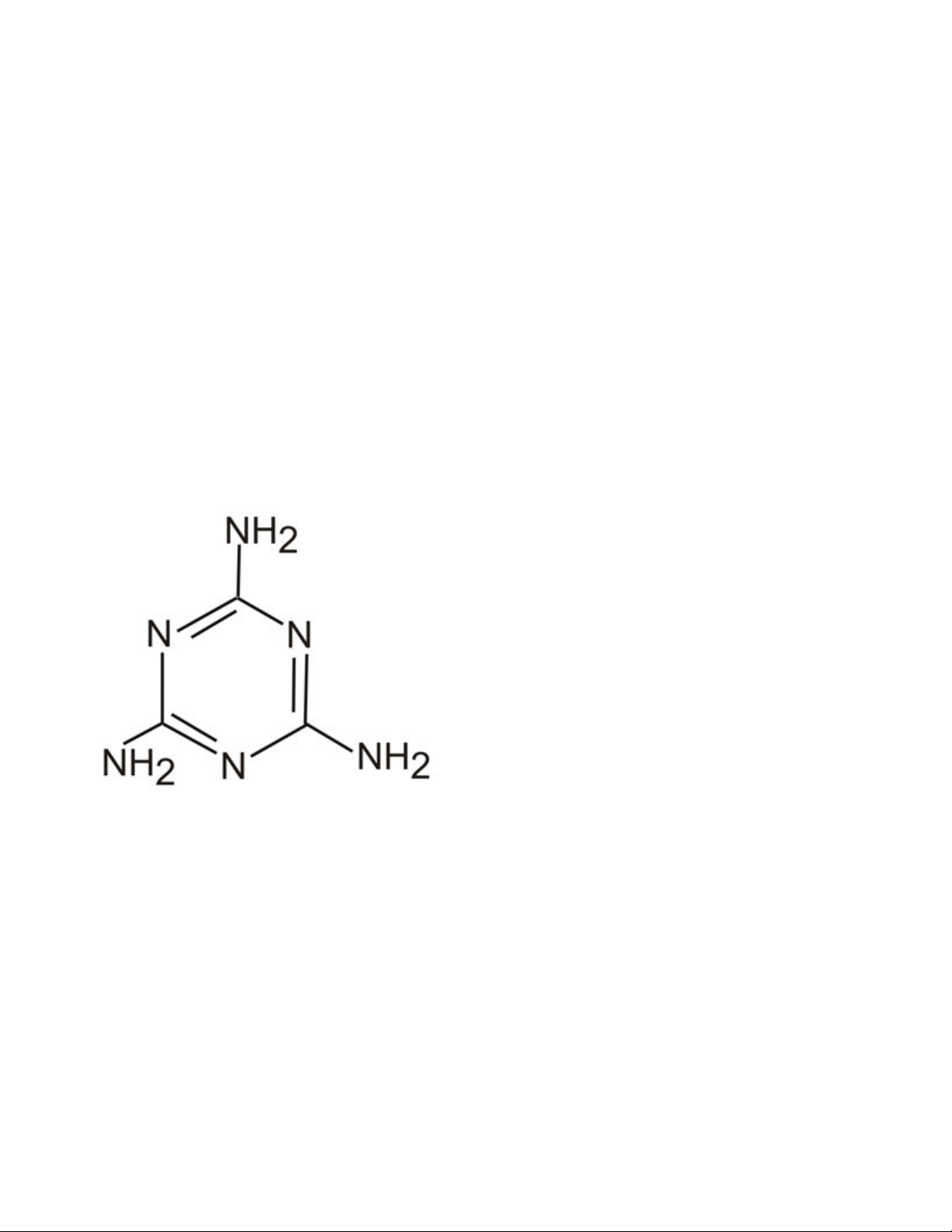

Melamine is a nitrogen rich compound that has gained

notoriety as a result of its illicit use as an additive that mimics

protein in foods. The practice of using melamine scrap as

an additive to animal feed and food products to give the

appearance of increased protein content is widespread in

many countries. The basis for this are the presence of three

primary amine groups, which are known to react with biuret

reagent used in many of the commonly used protein assays

(Figure 1). Recently, a scandal in China has implicated over

two dozen companies and numerous individuals of adding

melamine to milk and infant formula, leading to kidney stones

and renal failure, resulting in the deaths of several infants and

the sickening over 53,000 others. Trace amounts have been

reported by the FDA to be in some infant formula products in

the US as well.

Figure 1. Chemical structure of melamine.

The melamine assay is a competitive ELISA, where

melamine-HRP conjugate competes for binding to the

melamine antibody attached to the wells of the microplate.

Following the completion of the binding reaction, unbound

sample and conjugate is removed by washing. Substrate

reagent is immediately added and the color allowed to

develop. The color-development reaction is terminated by the

addition of stop solution and the absorbance of each well is

determined. Unknown concentrations are then determined

by interpolation from a standard curve generated by running

standards of known melamine concentrations. To easily

compare multiple experiments, the data are expressed as

a ratio to the zero-standard. This ratio is often expressed

asB/Bo.

Materials and methods

The melamine assay used was an ELISA kit from Abraxis

(Warminster, PA) and was performed as described by the

kit instructions. Samples and standards were prepared

offline and 100 µL of each was pipetted manually into the

assay plate. Plates were loaded into the AgilentBioTek

BioStack storage stacker and the assay initiated. Plates were

automatically transferred sequentially to an AgilentBioTek

EL406, where 50 µL of assay conjugate was added using the

peristaltic pump dispenser. The plates were then returned

to the BioStack and restacked to restore their original

order and allowed to complete the 30-minute incubation at

room temperature. After incubation, the plates were again

transferred automatically to the EL406 and washed four

times with 300 µL of washer buffer followed by the addition

of 100 µL of substrate solution using one of the syringe

pump dispensers. Plates were automatically returned to the

BioStack and restacked. The color development continued

for 20 minutes. After color development, the plates were

automatically returned to the EL406. A 100 µL amount of stop

solution was added using the second syringe-pump dispenser

and the plates returned to the BioStack. After restacking, the

absorbance of each well at 450 nm was determined using an

AgilentBioTek Synergy 4 multimode microplate reader.

2

Page 3

This procedure was automated using LHC PC software to

control the plate movement, processing, and incubation steps

(Figure3). Incubation steps were carried out in the BioStack,

while plate processing, such as wash steps, shaking, and

reagent addition was accomplished using the EL406. A

single LHC program file was written to carry out all of the

process steps after the addition of sample to the plate up

to the point of reading the plate. Plates were moved to the

EL406 for liquid handling steps such as wash steps to remove

unbound materials or the addition of reagents (e.g. conjugate,

substrate, and stop solutions). The incubation steps were

carried out using the BioStack as a means to store the plates.

Delay times were calculated such that the process times and

restack procedures were accounted for (Figure 3).

Figure 2. Schematic diagram of the procedural steps of the melamine

ELISA reaction. Processes carried out by the Agilent BioTek EL406 washer

dispenser are indicated in red.

Figure 3. Agilent BioTek LHC process steps for a 3-plate assay batch.

3

Page 4

Results and discussion

The data in Figure 4 demonstrate the efficacy of using the

EL406 to automate the fluid handling tasks of the melamine

ELISA. Unbound material was removed using the washer

function, while the necessary reagents were added using the

three dispensers of the instrument. Using a B/Bo calculation

where the ratio of each standard to that of the zero-standard,

significant changes in signal are observed as a function of

melamine concentration.

Using a 5-parameter logistic fit of the data, unknown sample

concentrations can be determined by interpolation from the

curve. Detection limit calculated by interpolation from the

standard curve of the mean of the zero standards minus

3times its standard deviation, ranged from 10to30 ng/mL in

three different experiments.

The data presented here demonstrate the ability of the

AgilentBioTek EL406 to automate the liquid handling tasks

required to run the melamine ELISA kit from Abraxis. The

resulting data was equivalent to that provided by the kit

insert as example data. EL406 can serve to provide the same

functionality as four different instruments (1 washer and 3

dispensers). In conjunction with the Agilent BioTek BioStack,

the EL406 can be used to automate the liquid handling

processes of thisassay.

The melamine ELISA has the capability to detect melamine

contamination in the parts per billion (PPB) ranges. This is

sufficient for many applications, as the FDA guidelines for

consumption list levels above 1 ppm as being hazardous.

The FDA methods employ LC/MS or GC/MS and have

the advantage of being more sensitive and being able to

detect cyanuric acid concurrently. However, these methods

also require much more expensive instrumentation, more

extensive sample preparation prior to the assay, and a higher

degree of technical training of the technician carrying out the

assay. In many instances, the ELISA method can be used as a

screening tool when there are large numbers of samples and

time to result is critical.

Figure 4. Melamine concentration curve. B/Bo calculations based on

the zero-standard were determined using Agilent BioTek Gen5 data

analysis software from three different plates. The data were plotted using

GraphPad5. Each data point represents the mean and SEM of a total of

72determinations.

Conclusion

Semi-automation of ELISA procedures such as the melamine

assay allow unattended processing of a number of assay

plates. While the assay is not completely “walk-away”, the

time consuming liquid handling steps, such as reagent

addition, washing, and incubation have been automated.

After processing, the plates are read manually using an

absorbance reader. Once the absorbance has been measured,

B/Bo calculations, the generation of a standard curve and

the interpolation of the curve for the determination of

sample concentrations is automatically performed by the

AgilentBioTek Gen5 data analysis software.

www.agilent.com/lifesciences/biotek

DE44173.2272337963

This information is subject to change without notice.

Agilent Technologies, Inc. 2009, 2021

Printed in the USA, February 1, 2021

5994-2689EN

Loading...

Loading...