Page 1

Agilent Technologies E8285A CDMA

Mobile Station Test Set

Assembly Level Repair

Firmware Version: A.01.29 to A.02.04 (100-1000, 1700-2000 MHz)

Firmware Version: A.04.53 and above (800-1000, 1700-2000 MHz)

CALL CONTROL UTILITIES

Answer Print Printer I/O config Help

Call/

End/

Page

USER

K1'

K1

K2'

K2

K3'

K3

Assign

K4

Release

K5

Shift

Register Tests Config Previous Message

Release

CDMA SCREENS

Cell config Spectrum SMS

Call

Gen

control

MS report MS FER

RX test

Ref set

Increment

10

Low limit

IBASIC

reset

Cancel

Authen-

control

tication

TX test

TX

range

DATA FUNCTIONS DATA

Meter

Average

Increment

Increment

set

x 10

High limit

ANALOG SCREENS

Call

Duplex Spectrun

control

RX test TX test AF

7 8 9

4 5 6

1 2 3

0 . +/-

Yes

No

Ratio

On/Off

W

DUPLEX OUTRF IN/OUTPOWER ANTENNA IN VOLUME AUDIO OUT AUDIO IN

analyzer

analyzer

%dBHz

High

Preset

Hold

Meas

reset

Address

Local

Save

Recall

Enter

Ghz

dBm

dB

MHz

V

%

kHz

mV

s

mW

µV

ms

Low

DO NOT apply RF

when in standby

Max power 2.5W

Max power 60 mW Max 12V peak Max

Agilent Part Number E8285-90033

Revision C

Printed in U.S.A.

June 2000

42V peak

Page 2

Notice

Information contained in this document is subject to change without

notice.

All Rights Reserved. Reproduction, adaptation, or translation without

prior written permission is prohibited, except as allowed under the

copyrigh t laws.

This material may be reproduced by or for the U.S. Government

pursuant to the Copyright License under the cl ause at DFARS

52.227-7013 (APR 1988).

© Copyright 2000 Agilent Technologies

2

S:\agilent\e8285\ALR\Book\chapters\front.fm

Page 3

Manufacturer’s Declaration

This statement is provided to comply with the requirements of the

German Sound Emission Directive, from 18 January 1991.

This product has a sound pres sur e emission ( at t he ope rato r posit ion) <

70 dB(A).

• Sound Pressure Lp < 70 dB(A).

• At Operator Position.

• Normal Operation.

• According to ISO 7779:1988/EN 27779:1991 (Type Test).

Herstellerbescheinigung

Diese Information steht im Zusammenhang mit den Anf orderungen der

Maschinenlärminformationsverordnung vom 18 Januar 1991.

• Schalldruckpegel Lp < 70 dB(A).

•Am Arbeitsplatz.

• Normaler Betr i e b.

• Nach ISO 7779:1988/EN 27779:1991 (Typprüfung).

3

Page 4

Safety Considerations

!

GENERAL

This product and related documentation must be reviewed for

familiarization with safety markings and instructions before operation.

This product has been designed and tested in accordance with IEC

Publication 1010, “Safety Requirements for Electronic Measuring

Apparatus,” and has been s u pplied in a safe condition. This instruction

documentation contains information and warnings which must be

followed by the user to ensure safe operation and to maintain the

product in a safe condition.

SAFETY EARTH GROUND

A uninterruptible safety earth ground must be provided fro m the main

power source to the product input wiring terminals, power cord, or

supplied power cord set.

CHASSIS GROUND TERMINAL

To prevent a potential shock hazard, always connect the rear -panel

chassis ground terminal to earth ground when operating this

instrument from a dc power source.

SAFETY SYMBOLS

Indicates instrument damage can occur if indicated oper ating limits are

exceeded. Refer to the instructions in this guide.

Indicates hazardous voltages.

Indicates earth (ground) terminal

WARNING A W ARNING note denotes a hazard. It calls attention to a

procedure, practice, or the like, which, if not correctly

performed or adhered to, could result in personal injury. Do not

proceed beyond a W ARNING s ign until the indicated conditi ons

are fully understood and met.

CAUTION A CAUTION note denotes a hazard. It calls attention to an operation

procedure, practic e, or the like, which, if not correctly performed or

adhered to, could result in damage to or destruction of part or all of t he

product. Do not proceed beyond an CAUTION note until the indicated

conditions are fully understood and met .

4

S:\agilent\e8285\ALR\Book\chapters\front.fm

Page 5

Safety Considerations for this Instrument

WARNING This product is a Safety Class I instrument (provided with a

protective earthing ground incorporated in the power cord). The

mains plug shall only be inserted in a socket outlet provided with a

protective earth contact. Any interruption of the protective conductor

inside or outside of the product is li kely to make the product

dangerous. Intentional interruption is prohibited.

Whenever it is likely that the protection has been impaired, the

instrument must be made inoperative and be secured against any

unintended operation.

If this instrument is to be energized via an autotransformer (for

voltage reduction), make sure the common terminal is connected to

the earth terminal of the power source.

If this product is not us ed as specified, the protec tion provid ed by t he

equipment could be impaired. This product must be used in a normal

condition (in which all means for protection are intact) only.

No operator serviceable parts in this product. Refer servicing to

qualified personnel. To prevent electrical shock, do not remove

covers.

Servicing instructions are for use by qualified personnel only. To

avoid electrical shock, do not perform any servicing unless you are

qualified to do so.

The opening of covers or removal of parts is likely to expose

dangerous voltages. Disconnect the product from all voltage sources

while it is being opened.

Adjustments described in the manual are performed with power

supplied to the instrument while protective covers are removed.

Energy available at many points may, if contacted, result in personal

injury.

The power cord is connected to internal capacitors that my remain

live for 5 seconds after disconnecting the plug from its power supply.

For Continued protection against fire hazard, replace the line fuse(s)

only with 250 V fuse(s) or the same current rating and type (for

example, normal blow or time delay). Do not use repaired fuses or

short circuited fuseholder s.

5

Page 6

CAUTION Always use the three -prong ac power cord supplied with this product.

Failure to ensure adequate earth grounding by not using this cord may

cause product damage.

This product is designed for use in Installation Category II and

Pollution Degree 2 per IEC 1010 and IEC 664 respectively. For indoor

use only.

This product has autoranging line voltage input, be sure the supply

voltage is within the specified range.

V entilation Require ments: When installing the prod uct in a cabinet, the

convection into and out of the product must not be restri cted. The

ambient temperature (outside the cabinet) must be less than the

maximum operating temperature of the product by 4° C for every 100

watts dissipated in the cabinet. If the total power dissipated in the

cabinet is greater than 800 watts, then forced convection must be used.

6

S:\agilent\e8285\ALR\Book\chapters\front.fm

Page 7

Product Markings

CE - the CE mark is a registered trademark of the European

Community. A CE mark accompanied by a year indicated the year the

design was proven.

CSA - the CSA mark is a registered trademark of the Canadian

Standards Association.

7

Page 8

Agilent Technologies Warranty Statement

for Commercial Products

E8285A CDMA Mobile Station T es t Set

Duration of Warranty: One Year

1. Agilent warrants Ag ilent hardwar e, a ccessories and supplies aga inst

defects in materials and workmans hip for the period sp ecified above .

If Agilent receives notice of such defect s during the w arranty peri od,

Agilent will, at its option, either repair or replace products which

prove to be defective. Replacement prod ucts may be either new or

like-new.

2. Agilent warrants that Agilent software will not fail to execute its

programming instructions, for the period specified above, due to

defects in material and workmanshi p when properly installed and

used. If Agi l en t re ceives notic e o f su ch d e fe cts during the war ra n ty

period, Agilent will replace softwa re media which does not execute

its programming instructions due to such defects.

3. Agilent does not warrant that the operation of Agilent products will

be uninterrupted or error free. If Agilent is unable, within a

reasonable time, to repair or replace any product to a condition as

warranted, customer will be enti tled to a refund of the purchase

price upon prompt return of the product.

4. Agilent products may contain remanufactured parts equivalent to

new in performance or may have been subject to incident al use.

5. The warranty period begins on the date of delivery or on the date of

installation if installed by Agilent. If customer schedules or delays

Agilent installation more than 30 days after delivery, warranty

begins on the 31st day from delivery.

6. Warranty does not apply to defects resulting from (a) improper or

inadequate maintenance or calibration, (b) sof tware, interfacing,

parts or supplies not supplied by Agilent, (c) unauthorized

modification or misuse, (d) operation outside of the published

environmental specifications for the product, or (e) improper site

preparation or maintenance.

7. TO THE EXTENT ALLOWED BY LOCAL LAW, THE ABOVE

WARRANTIES ARE EXCLUSIVE AND NO OTHER WARRANTY

OR CONDITION, WHETHER WRITTEN OR ORAL IS

EXPRESSED OR IMPLIED AND AGILENT SPECIFICALLY

DISCLAIMS ANY IMPLIED WARRANTIES OR CONDITIONS OR

MERCHANTABILITY, SATISFACTORY QUALITY, AND FITNESS

FOR A PARTICULAR PURPOSE.

8

S:\agilent\e8285\ALR\Book\chapters\front.fm

Page 9

8. Agilent will be liable for damage to tangibl e property per incident up

to the greater of $300,000 or the actual amount paid for the product

that is the subject of the claim, and for damages for bodily injury or

death, to the extent that all suc h damages are d etermined by a cou rt

of competent jurisdiction to have been directly caused by a defective

Agilent product.

9. TO THE EXTENT ALLOWED BY LOCAL LAW, THE REMEDIES

IN THIS WARRANTY STATEMENT ARE CUSTOMER’S SOLE

AND EXCLUSIVE REMEDIES. EXCEPT AS INDICATED ABOVE,

IN NO EVENT WILL AGILENT OR ITS SUPPLIERS BE LIABLE

FOR LOSS OF DATA OR FOR DIRECT, SPECIAL, INCIDENTAL,

CONSEQUENTIAL (INCLUDING LOST PROFIT OR DATA), OR

OTHER DAMAGE, WHETHER BASED IN CONTRACT, TORT, OR

OTHERWISE.

FOR CONSUMER TRANSACTIONS IN AUSTRALIA AND NEW

ZEALAND: THE WARRANTY TERMS CONTAINED IN THIS

STATEMENT, EXCEPT TO THE EXTENT LAWFULLY

PERMITTED, DO NOT EXCLUDE RESTRICT OR MODIFY AND

ARE IN ADDITION TO THE MANDATORY STATUTORY RIGHTS

APPLICABLE TO THE SALE OF THIS PRODUCT TO YOU.

9

Page 10

DECLARATION OF CONFORMITY

according to ISO/IEC Guide 22 and EN 45014

Manufacturer’s Name:

Agilent Technologies

Manufacturer’s Address:

Spokane Division

24001 E. Mission Avenue

Liberty Lake, Washington 99019-9599

USA

declares that the product

Product Name:

Model Number:

Product Options:

CDMA Mobile Station Test Set

Agilent Technologies E8285A

All

conforms to the following Product specifications:

Safety: IEC 61010-1:1990+A1+A2 / EN 61010-1:1993+A2

EMC: CISPR 11:1990/EN 55011:1991- Group 1, Class A

IEC 61000-3-2:1995 / EN 61000-3-2: 1995

EN 50082-1:1992

IEC 801-3:1984 3V/m

IEC 801-4:1988 0.5 kV Sig. Lines, 1 kV Power Lines

Supplementary Information:

This product herewith complies with the requirements of

the Low Voltage Directive 73/23/EEC and the EMC

Directive 89/336/EEC and carries the CE-marking

accordingly.

Spokane, Washington USA November 20, 1998

European Contact: Your local Agilent Technologies and Service Office or Agilent Technologies GmbH

Department ZQ/Standards Europe, Herrenbe rger Strasse 130, D-71034 Böbl inger, Germany (FAX+49-7031-14-3143)

10

Vince Roland

Reliability & Regulatory

Engineeri ng Manager

S:\agilent\e8285\ALR\Book\chapters\front.fm

Page 11

Table 1

United States of America:

Agilent Technologies

Test and Measurement Call

Center

P.O. Box 4026

Englewood, CO 80155-4026

(tel) 1 800 452 4844

Japan:

Agilent Technologies Japan Ltd.

Measurement Assistance Center

9-1 Takakura-Cho, Hachioji-Shi,

Tokyo 192-8510, Japan

(tel) (81) 456-56-7832

(fax) (81) 426-56-7840

Asia Pacific:

Agilent Technologies

19/F, Cityplaz a One,

111 Kings Road,

Taikoo shing, Hong Kong, SAR

Canada:

Agilent Technologies

Canada Inc.

5159 Spectrum Way

Mississauga, Ont ar io

L4W 5G1

(tel) 1 877 894 4414

Latin America:

Agilent Technologies

Latin America Region

Headquarters

5200 blue Lagoon Drive,

Suite #950

Miami, Florida 33126

U.S. A.

(tel) (305) 267 4245

(fax) (305) 267 4286

Europe:

Agilent Technologies

European Marketing

Organization

P.O. Box 999

1180 AZ Amstelveen

The Netherlands

(tel) (3120) 547 9999

Australia/New Zealand:

Agilent Technologies

Australia Pty Ltd

347 Burwood Highway

Forest Hill, Victoria 3131

(tel) 1 800 629 485 (Australia)

(fax) (61 3) 9272 0749

(tel) 0 800 738 378 (New

Zealand)

(fax) (64 4) 802 6881

(tel) (852) 2599 7899

(fax) (852) 2506 9233

11

Page 12

Agilent Technologies E8285A Support

Contacts

The documentation supplied with your Test Set is an excellent source of

reference, application, and service information. Please use these

manuals if you are experiencing technical problems:

Table 2 Support Documentation

User’s Guide Quick Reference Guide

Application Guide Assembly Level Repair

Reference Guide CD-ROM

If you have used the manuals and still have application questions,

contact your local Agilent Technologies Sales Representative.

Repair assistance is available for the Agilent E8285A CDMA Mobile

Station Test Set from the factory by phone and e-mail. External and

internal Agilent users can contact the factory via email. Par ts

information is also available from Agilent.

When calling or writing for repair assistance, please have the following

information ready:

• Instrument model number (E8285A)

• Instrument Serial Number (tag located on the rear panel).

• Installed options - if any (tag located on the rear panel).

• Instrument firmware revision (displayed at the top of the screen

when the Test Set is powered up, and is also displayed on the

CONFIGURE screen).

Support Telephone Numbers:

1 800 827 3848 (RF Comms Service Assistance, U.S. only)

1 509 921 3848 (RF Comms Service Assistance, International)

1 800 227 8164 (Agilent Direct Parts Ordering, U.S. only)

1 800 403 0801 (Agilent Instrument Support Center, U.S. only)

1 916 783 0804 (Agilent Service Parts Identification, U.S. & Intl.)

12

S:\agilent\e8285\ALR\Book\chapters\front.fm

Page 13

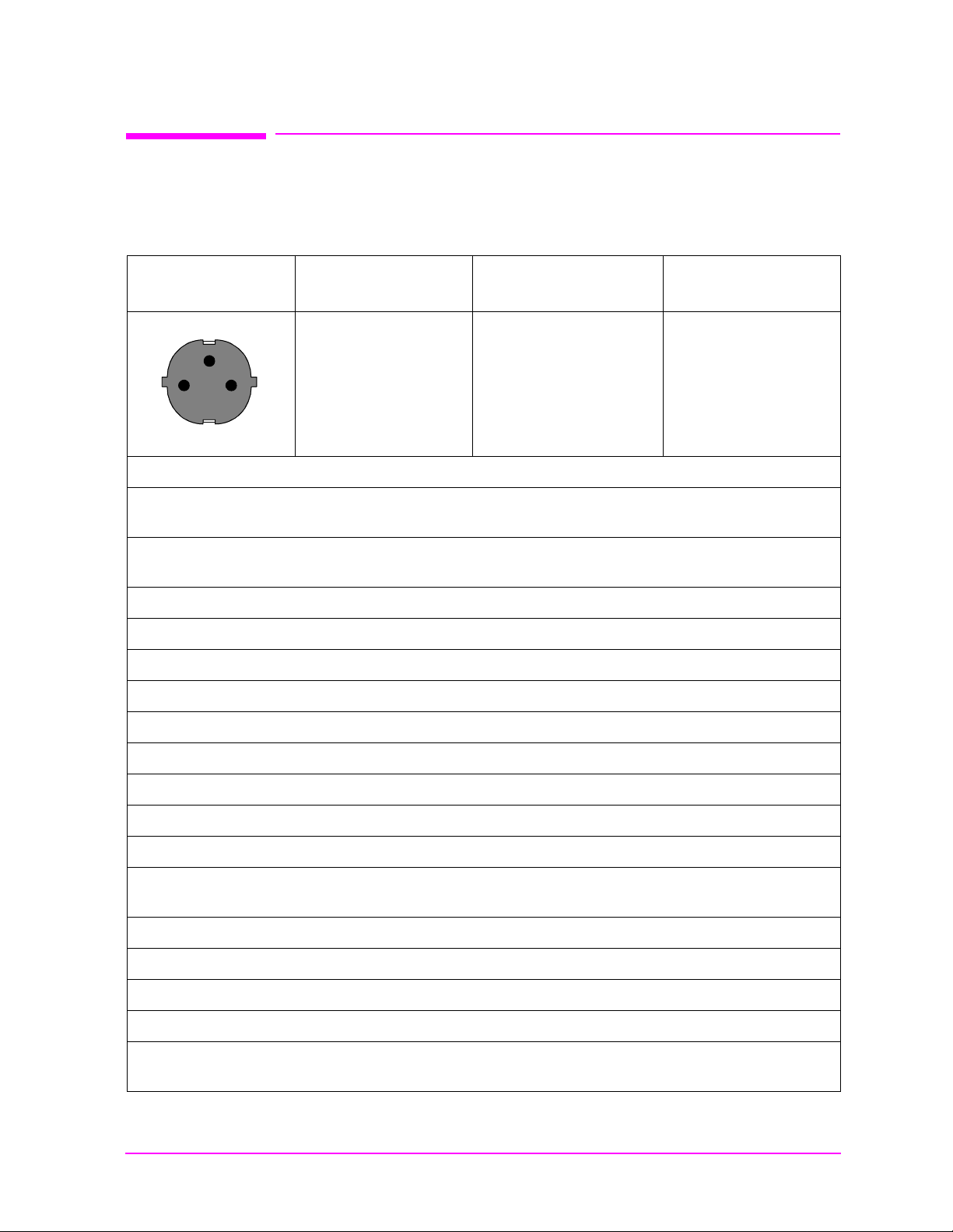

Table 3

Earth

Ground

Line Neutral

Power Cables

Plug type

Plug Descriptions

male/female

Straight/Straight

Straight/90

°

Agilent Part #

(cable & plug)

8120-1689

8120-1692

Cable Descriptions

79 inches, mint gray

79 inches, mint gray

Used in the following locations:

Bangladesh, Belgium, Benin, Bolivia, Boznia-Herzegovina, Bulgaria, Burkina Faso, Burma,

Burundi,Byelarus

Cameroon, Canary Islands, Central African Republic, Chad, Chile, Comoros, Congo, Croatia,

Czech Republic, Czechoslovakia

Denmark, Djibouti

East Germany, Egypt, Estonia, Ethiopia

Finland, France, French Guiana, French Indian Ocean Areas

Gabon, Gaza Strip, Geor gia, Germany, Gozo, Greece

Hungary

Iceland, Indonesia, Iran, Iraq, Israel, Italy, Ivory Coast

Jordan

Kazakhstan, Korea, Kyrgystan

Latvia, Lebanon, Libya, Lithuania, Luxembourg

Macedonia, Madeira Islands, Malagasy Republic, Mali, Malta, Mauritania, Miquelon, Moldova,

Mongolia, Morocco, Mozambique

Nepal, Netherlands, Netherlands Antilles, Niger, Norway

Oman

Pakistan, Paraguay, Poland, Portugal

Rep. South Africa, Romania, Russia, Rwanda

Saudi Arabia (220V), Senegal, Slovak Republic, Slovenia, Somalia, Spain, Spanish Africa, Sri

Lanka, St. Pierce Islands

13

Page 14

Plug type

Earth

Ground

Line Line

Earth

Ground

Line Neutral

Plug Descriptions

male/female

Agilent Part #

(cable & plug)

Sweden, Syria

Tajikistan, Thailand, Togo, Tunisa, Turkey, Turkmenistan

USSR, Ukraine, Uzbekistan

W estern Africa, Western Sahara

Yugoslavia

Zaire

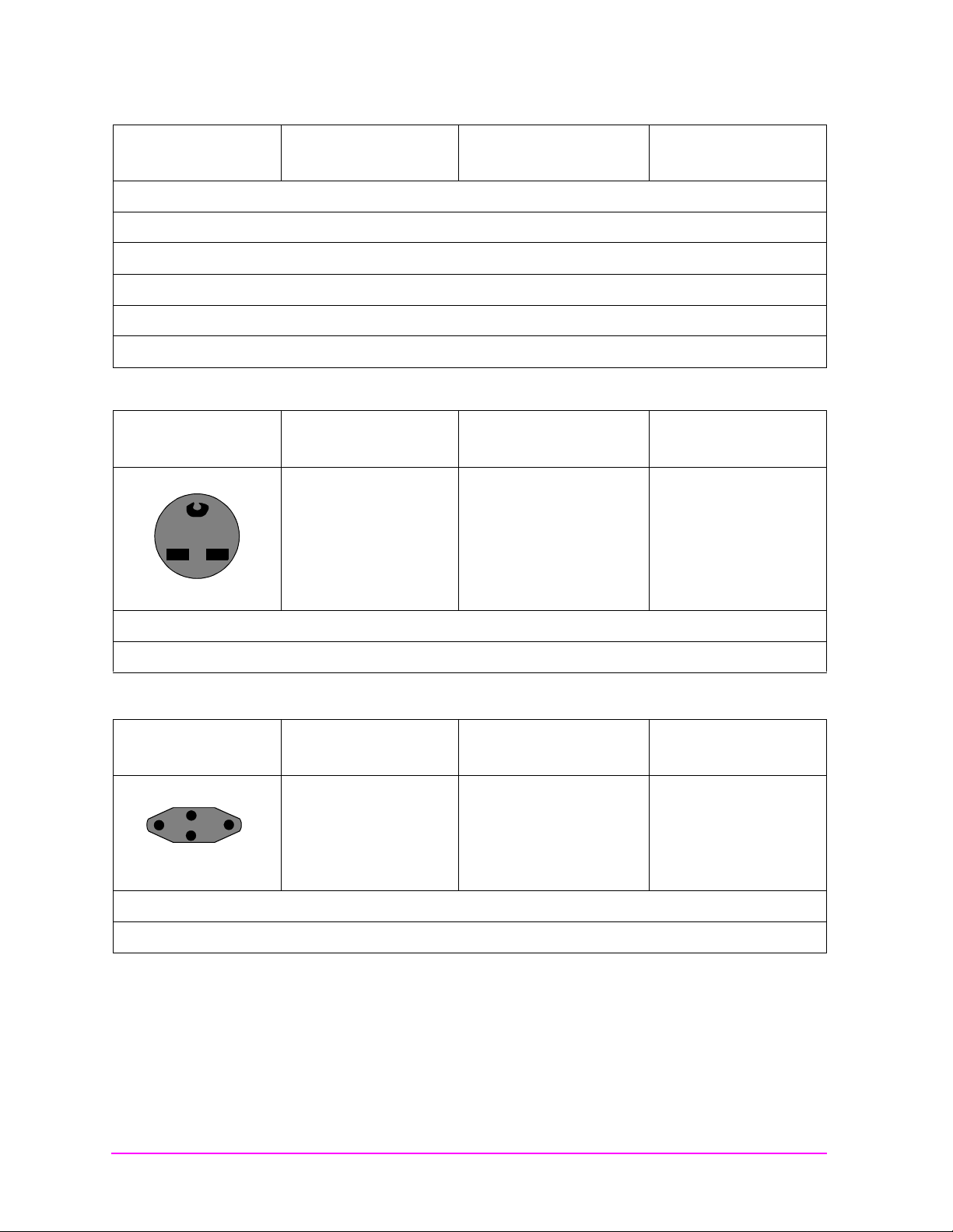

Table 4

Cable Descriptions

Plug Type

Plug Descriptions

male/female

Straight/Straight

Straight/90°

Used in the following locations:

Peru

Table 5

Plug Type

Plug Descriptions

male/female

Straight/Straight

Straight/90°

Agilent Part #

(cable & plug)

Cable Descriptions

8120-0698 90 inches, black

Agilent Part #

(cable & plug)

8120-2104

8120-2296

Cable Descriptions

79 inches, gray

79 inches, gray

Used in the following locations:

Switzerland

14

S:\agilent\e8285\ALR\Book\chapters\front.fm

Page 15

Table 6

125V

Earth

Ground

LineNeutral

Plug Type

Plug Descriptions

male/female

Straight/Straight

Straight/90°

Straight/Straight

Agilent Part #

(cable & plug)

8120-1378

8120-1521

8120-1751

Used in the following locations:

American Samoa

Bahamas, Barbados, Belize, Bermuda, Brazil

Caicos, Cambodia, Canada, Cayman Islands, Columbia, Costa Rica, Cuba

Dominican Republic

Ecuador, El Salvador

French West Indies

Guam, Guatemala, Guyana

Cable Descriptions

90 inches, jade gray

90 inches, jade gray

90 inches, jade gray

Haiti, Honduras

Jamaica

Korea

Laos, Leeward and Windward Islands, Liberia

Mexico, Midway Islands

Nicaragua

Other Pacific Islands

Panama, Philippines, Puerto Rico

Saudi Arabia (115V, 127V), Suriname

Taiwan, Tobago, Trinidad, Trust Territories of Pacific Islands

Turks Island

United States

Venezuela, Vietnam, Virgin Islands of the U.S.

Wa ke Island

15

Page 16

Table 7

JIS C 8303, 100 V

Earth

Ground

LineNeutral

Earth

Ground

Line

Neutral

Plug Type

Plug Descriptions

male/female

Straight/Straight

Straight/90°

Used in the following locations:

Japan

Table 8

Plug Type

Plug Descriptions

male/female

90°/Straight

90°/90°

Straight/Straight

Agilent Part #

(cable & plug)

8120-4753

8120-4754

Agilent Part #

(cable & plug)

8120-2956

8120-2957

8120-3997

Cable Descriptions

90 inches, dark gray

90 inches, dark gray

Cable Descriptions

79 inches, gray

79 inches, gray

79 inches, gray

Used in the following locations:

Denmark

Greenland

16

S:\agilent\e8285\ALR\Book\chapters\front.fm

Page 17

Table 9

Earth

Ground

Line

Neutral

Line

Neutral

Earth

Ground

Plug Type

Plug Descriptions

male/female

Straight/Straight

Straight/90°

Used in the following locations:

Botswana

India

Lesotho

Malawi

South-West Africa (Namibia), Switzerland

Zambia, Zimbabwe

Table 10

Agilent Part #

(cable & plug)

8120-4211

8120-4600

Cable Description

79 inches, mint gray

79 inches, mint gray

Plug Type

Plug Descriptions

male/female

Straight/Straight

Straight/Straight

Straight/90°

Straight/90°

Used in the following locations:

System Cabinets

Agilent Part #

(cable & plug)

8120-1860

8120-1575

8120-2191

8120-4379

Cable Descriptions

60 inches, jade gray

30 inches, jade gray

60 inches, jade gray

15.5 inches, jade gray

17

Page 18

Table 11

Earth

Ground

Line

Neutral

Plug Type (Male)

Plug Descriptions

male/female

90°/Straight

90°/90°

Used in the following locations:

Bahrain, British Indian Ocean Terr., Brunei

Canton, Cyprus

Enderbury Island, Equatorial Guinea

Falkland Islands, French Pacific Islands

Gambia, Ghana, Gibraltar, Guinea

Hong Kong

Ireland

Kenya, Kuwait

Agilent Part #

(cable and plug)

8120-1351

8120-1703

Cable Descriptions

90 inches, mint gray

90 inches, mint gray

Macao, Malaysia, Mauritius

Nigeria

Qatar

Seychelles, Sierra Leone, Singapore, Southern Asia, Southern Pacific Islands, St. Helena, Sudan

Tanzania

Uganda, United Arab Emirates, United Kingdom

Yeman (Aden & Sana)

18

S:\agilent\e8285\ALR\Book\chapters\front.fm

Page 19

Table 12

Line

Neutral

Earth

Ground

Plug Type

Plug Descriptions

male/female

Straight/Straight

Straight/90°

Used in the following locations:

Argentina, Australia

China (People’s Republic)

New Zealand

Papua New Guinea

Urugray

We stern S amoa

Agilent Part #

(cable & plug)

8120-1369

8120-0696

Cable Descriptions

79 inches, gray

80 inches, gray

19

Page 20

ATTENTION

Static Sensitive

Devices

This instrument was constructed in an ESD (electro-static discharge) protected environment. This is

because most of the semi conductor devices used in this instrument are susceptible to damage by

static discharge.

Depending on the magnitude of the charge, device substrates can be punctured or destroyed by

contact or mer e pr oxim ity of a stat ic char ge. Th e r esult can cause degra dation of d evice performance,

early failure, or immediate destruction.

These charges are generated in numerous ways such as simple contact, separation of materials, and

normal motions of persons working with static sen sitive devices.

When handling or s ervicin g equi pment co ntaini ng st atic sensit ive devi ces, ad equate p r eca ution s mus t

be taken to prevent device damage or destruction.

Only those who are thoroughly familiar with industry accepted techniques for handling static

sensitive devices should attempt to service circuitry with these devices.

In all instances, measures must be taken to prevent static charge build-up on work surfaces and

persons handling the devices.

20

S:\agilent\e8285\ALR\Book\chapters\front.fm

Page 21

Contents

1. Introduction

Test Set Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Product Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Troubleshooting Strategy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Repair Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Calibration and Performance Verification . . . . . . . . . . . . . . . . . . . . . . 38

System Power Calibration Program . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Test Equipment Needed for the System Power Calibration Program 40

E8285A Support Contacts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Hardware and Firmware Enhancements . . . . . . . . . . . . . . . . . . . . . . 42

Ordering New Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

2. Troubleshooting

How to Troubleshoot the Test Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Self-Test Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Functional Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

AF, RF, and CDMA Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Frequently Encountered Diagnostic Messages . . . . . . . . . . . . . . . . . . 68

Manual Troubleshooting Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Service Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

3. Disassembly and Replaceable Parts

Before You Start. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Disassembly Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

4. Functional Verification

5. Periodic Adjustments/Calibration

Periodic Adjustments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Storing Calibration Factors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Running the Periodic IQ, or IQ Demod Path Calibration Programs. 130

Periodic Calibration Menu Descriptions. . . . . . . . . . . . . . . . . . . . . . . 131

Setting the Timebase Latches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

IQ Calibration Program Description . . . . . . . . . . . . . . . . . . . . . . . . . 137

IQ Demod Path Calibration Program Description. . . . . . . . . . . . . . . 139

6. Performance Tests

Procedure and Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

RF Generator FM Distortion

Performance Test 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

RF Generator FM Accuracy

Performance Test 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

RF Generator FM Flatness

Performance Test 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

RF Generator Residual FM

Performance Test 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

RF Generator Level Accuracy

21

Page 22

Contents

Performance Test 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

RF Generator Harmonics Spectral Purity

Performance Test 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

RF Generator Spurious Spectral Purity

Performance Test 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

AF Generator AC Level Accuracy

Performance Test 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

AF Generator DC Level Accuracy

Performance Test 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

AF Generator Residual Distortion

Performance Test 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

AF Generator Frequency Accuracy

Performance Test 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

AF Analyzer AC Level Accuracy

Performance Test 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

AF Analyzer Residual Noise

Performance Test 13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

AF Analyzer Distortion and SINAD Accuracy

Performance Test 14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

AF Analyzer DC Level Accuracy

Performance Test 15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

AF Analyzer Frequency Accuracy to 100 kHz

Performance Test 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

AF Analyzer Frequency Accuracy at 400 kHz

Performance Test 17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Oscilloscope Amplitude Accuracy

Performance Test 18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

RF Analyzer Level Accuracy

Performance Test 19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

RF Analyzer FM Accuracy

Performance Test 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

RF Analyzer FM Distortion

Performance Test 21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

RF Analyzer FM Bandwidth

Performance Test 22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

RF Analyzer Residual FM

Performance Test 23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Spectrum Analyzer Image Rejection

Performance Test 24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

CDMA Generator RF IN/OUT Amplitude Level Accuracy

Performance Test 25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

CDMA Generator DUPLEX OUT Amplitude Level Accuracy

Performance Test 26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

CDMA Generator Modulation Accuracy

Performance Test 27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

CDMA Analyzer Average Power Level Accuracy

Performance Test 28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

CDMA Analyzer Channel Power Level Accuracy

Performance Test 29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

22

Page 23

Contents

7. Performance Test Records

RF Generator FM Distortion

Performance Test 1 Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

RF Generator FM Accuracy

Performance Test 2 Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

RF Generator FM Flatness

Performance Test 3 Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

RF Generator Residual FM

Performance Test 4 Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

RF Generator Level Accuracy

Performance Test 5 Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

RF Generator Harmonics Spectral Purity

Performance Test 6 Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

RF Generator Spurious Spectral Purity

Performance Test 7 Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

AF Generator AC Level Accuracy

Performance Test 8 Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

AF Generator DC Level Accuracy

Performance Test 9 Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

AF Generator Residual Distortion

Performance Test 10 Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

AF Generator Frequency Accuracy

Performance Test 11 Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

AF Analyzer AC Level Accuracy

Performance Test 12 Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

AF Analyzer Residual Noise

Performance Test 13 Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

AF Analyzer Distortion and SINAD Accuracy

Performance Test 14 Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

AF Analyzer DC Level Accuracy

Performance Test 15 Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

AF Analyzer Frequency Accuracy to 100 kHz

Performance Test 16 Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

AF Analyzer Frequency Accuracy at 400 kHz

Performance Test 17 Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Oscilloscope Amplitude Accuracy

Performance Test 18 Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

RF Analyzer Level Accuracy

Performance Test 19 Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

RF Analyzer FM Accuracy

Performance Test 20 Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

RF Analyzer FM Distortion

Performance Test 21 Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

RF Analyzer FM Bandwidth

Performance Test 22 Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

RF Analyzer Residual FM

Performance Test 23 Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

Spectrum Analyzer Image Rejection

Performance Test 24 Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

23

Page 24

Contents

CDMA Generator RF IN/OUT Amplitude Level Accuracy

Performance Test 25 Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

CDMA Generator DUPLEX OUT Amplitude Level Accuracy

Performance Test 26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

CDMA Generator Modulation Accuracy

Performance Test 27 Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

CDMA Analyzer Average Power Level Accuracy

Performance Test 28 Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

CDMA Analyzer Channel Power Level Accuracy

Performance Test 29 Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

8. Block Diagrams

Signal Flow and Interconnections . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

RF Input/Output Section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

RF Analyzer Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

Spectrum Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

Audio Analyzer Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

CDMA Analyzer Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

CDMA Generator Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

Audio Generator Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

RF Generator Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

Reference/Regulator Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

Instrument Control Section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 287

GPIB Serial . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 291

9. Service Screen

Troubleshooting with the SERVICE Screen . . . . . . . . . . . . . . . . . . . 294

24

Page 25

1 Introduction

This manual explains how to repair and calibrate the Agilent

Technologies E8285A CDMA/PCS Mobile Station Test Set; called the

“Test Set” throughout this manual.

Throughout this manual you will see this note:

NOTE Test Sets with firmware revision A.04.5X and above operate only at RF

frequencies from 800 to 1000 MHz and 1700 to 2000 MHz. A text only error

message

frequencies are set.

The purpose of this note is to bring attention to RF frequency band

coverage provided by firmware revisi on A.04.5X and above. Test Sets

with firmware revision A.02.XX and below can operate at RF

frequencies from 100 (usable to 30 MHz) to 1000 and 1700 to 2000 MHz.

“Input value out of range”, will be displayed if invalid

25

Page 26

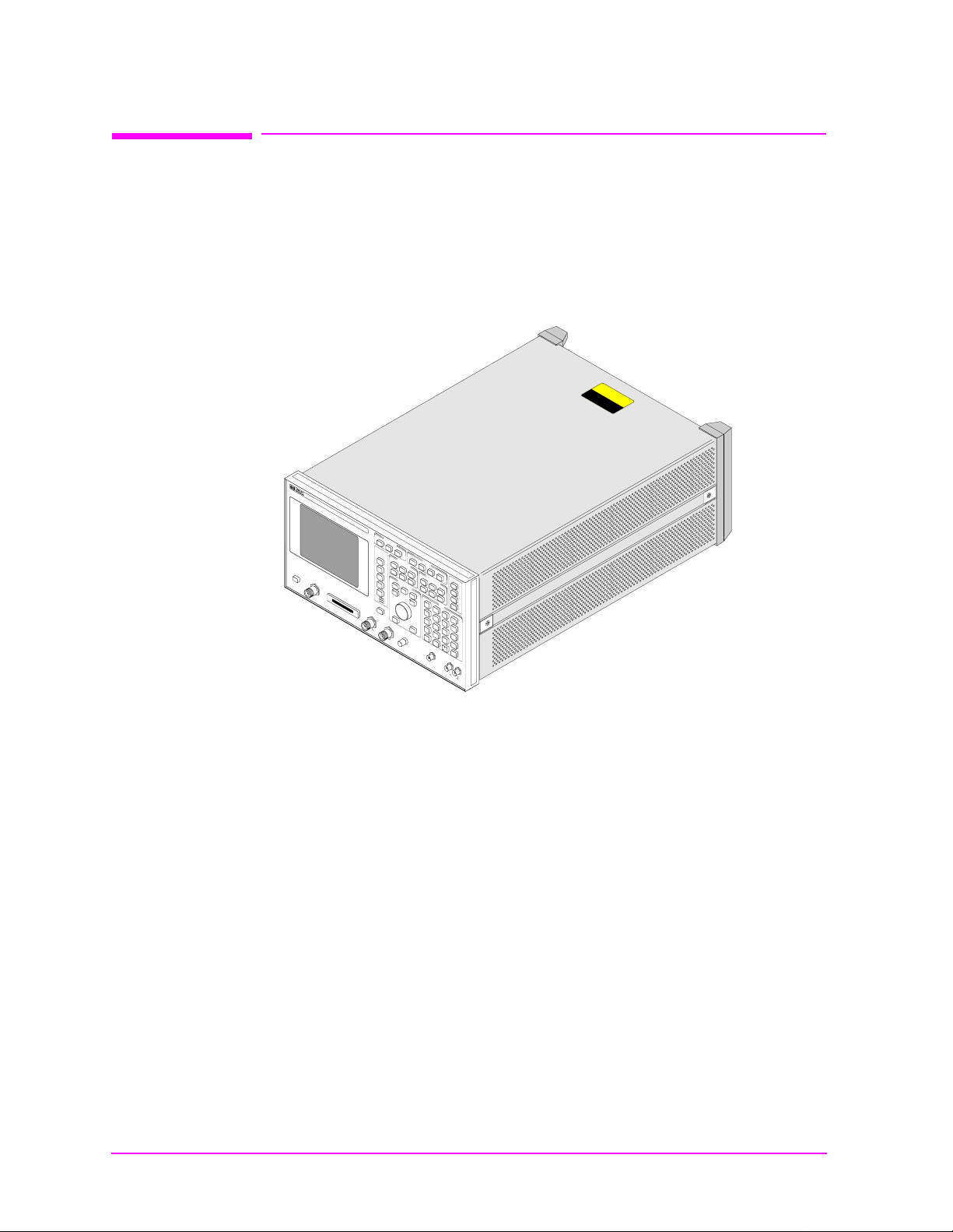

Introduction

Test Set Description

Test Set Description

Several analog and digital test instruments are integrated into the

E8285A CDMA Mobile Station Test Set to test Code Division Multiple

Access (CDMA) digital cellular, PCS, and s everal types of analog mobile

phones, such as AMPS, NAMPS, and TACS.

Figure 1-1 The E8285A CDMA Mobile Station Test Set

N

O

I

T

U

A

C

TWO PERSON LIFT

8285iso.eps

Answer

C

A

L

Call/

L

Call/

C

Pa

O

ge

N

Page

T

R

O

L

End/

En

Relea

d/

Re

se

lease

U

S

R

E

egister

R

Re

gister

K

1

'

Print Printer

K

Tests

1

C

K

Cell config

D

Tests

1

M

U

A

T

Ca

S

I

L

ll

C

Call

I

R

T

control

K

2

'

K

2

K

POW

ER

RF IN/OU

D

O

N

T

w

O

h

T

e

a

n

p

in

p

ly

s

R

t

a

n

F

d

b

y

M

a

x

p

o

w

e

r

2

.

5

W

2

K

3

'

K

3

K

3

A

s

s

ig

K

4

K

4

R

e

le

K

5

K

5

Shift

S

hift

D

U

PL

EX O

UT

M

a

x

p

o

w

e

r

I

E

E

Config

con

E

S

Spectrum

N

C

trol

on

S

fig

M

G

I/O

S report MS F

en

G

con

en

co

R

fig

ntrol

X

control

Previous

SM

R

test

X test

Pr

S

eviou

Authen-

Help

s

Authen-

ER

tication

TX test

tication

Me

T

X test

ssage

Message

A

N

A

L

O

TX

G

C

all

T

S

C

X

range

C

all

Ref

co

n

a

s

e

AN

TENN

6

0

m

W

R

range

D

ntro

control

set

E

A

E

l

T

Increm

N

A

F

Increm

10

U

en

N

t

10

M

ent

eter

Low limit

Increm

Increment

set

set

IBA

SIC

reset

Can

C

cel

an

cel

A IN

VO

LU

C

T

ent

M

IO

N

Increme

x 1

E

S

A

verage

Increment

x 10

nt

0

High lim

RX

test

RX test

it

789

4

1

0.

Y

e

O

7

4

1

0

Y

es

O

s

n/O

AU

D

up

TX

n/O

ff

ff

DIO

M

a

x

Duplex

lex

TX

test

test

56

2

No

R

atio

W

O

1

2

V

p

Preset

S

Preset

Hold

Spe

Meas

Sp

ctrun

analyzer

ectrun

Mea

reset

ana

s

re

lyz

set

er

Address

AF

Local

AF

analyzer

Lo

a

cal

nalyzer

Sav

e

Recall

Recall

D

A

T

A

8

9

5

E

nter

E

nter

6

2

G

hz

G

d

hz

Bm

dB

d

B

m

3

d

B

3

.

M

H

M

z

V

H

z

V

%

+

%

/-

+

/

-

N

o

Ra

k

tio

Hz

W

kH

m

z

V

mV

s

%

s

%

d

B

d

B

m

W

H

z

Hz

UT

µ

V

µV

m

s

m

s

H

igh

AUD

IO IN

e

a

k

Low

M

a

x

4

2

V

p

e

a

k

Some of the instrument functions in the Test Set include:

• Synthesized AM, FM, and IQ modulation signal generator

• AM, FM and IQ modulation analyzer

• Duplex offset signal generator

• SSB demodulator

• RF power meter

• Audio and RF frequency counter and RF frequency error meter

• AC and DC voltmeter

• Distortion, SINAD, and signal-to-noise-ratio meters

• Two variable audio sources

• Oscilloscope

• Spectrum analyzer and tracking generator (optional)

• Signaling encoder and decoder

• DC current meter

26 S:\agilent\e8285\ALR\Book\chapters\intro.fm

Page 27

Introduction

Test Set Description

Some of these functions are dire ctly replaceable as semblies (such as the

spectrum analyzer); some functions are digitally derived from other

assemblies (such as the oscilloscope). Most of the replaceable

assemblies are plug-in components.

Most instrument functions can be cont rolled by front-panel (local)

controls and by remote commands ( using a c onnected controll er). Power

on/off, volume, and squelch controls cannot be accessed remotely.

Controls are grouped together on display screens that are usually

associated with a specific task (suc h as making a call to a CDMA mobile

phone).

An Instrument BASIC (IB ASIC) control ler is also built into the T es t Set

to allow automated operation without using an external controller. This

computer also has the ability to be a system controller to other tes t

system instruments. Refer to the Test Set’s user’s guide for information

on using the IBASIC computer (also referred to as the IBASIC

controller).

27

Page 28

Introduction

Product Description

Product Description

The E8285A CDMA Mobile Test Set is designed to meet the needs of

Cellular Provider Point of Sale Retailers, manufacturing customers,

and other customers who require CDMA Mobile Phone test capability.

The Tes t Set is very similar to it’s predecessor, the Agilent Technologies

8924C with the addition of newly designed RF I/O module, upconverter

and downconverter assemblies. These assemblies extend the Test Set

frequency range to cover the 1800- 1900 MHz PCS Cellular band as well

as providing standard 800 MHz cellular band coverage.

Internal Ope rating System

A Motorola® 68020 − 33 MHz microprocessor acts as the ho st pro cesso r

of the Test Set. It receives commands from the front-panel co ntrols and

communicates directly with almost every assembly inside the Test Set.

The host is also in constant communication with several other

microprocessors located throughout the Test Set.

Communications to the GPIB , s erial, a nd paralle l ports are t hrough the

control int e rface assembly to th e ho st processor.

This processor is also the core for the internal IBASIC computer. The

IBASIC computer is used t o load and run var ious sof tw are pac kages f or

automated radio tests. It is also responsible for executing the internal

diagnostic routines used to troubleshoot a failing inst rument.

Instrument Frequency References

The Test Set reference ti mebase path co n s i st s o f tw o assemblies, an

ovenized high stability reference assembly and a CDMA reference

assembly. These two assemblies provide all frequency, phase, and

timing signals used to accurately synthesize all of the Test Set’s source

and analysis signals. A master reference signal can originate from

either an external source at the 10 MHz input on the rear panel, or

from the internal 10 MHz phase locked loop oscillator located on the

high stability reference asse mbly. The high stability refere nce assembly

provides timebase references for the analog assemblies and a 10 MHz

reference signal to the CDMA reference assembly. The CDMA reference

assembly uses this signal to generate clock and timing signals for

internal CDMA assemblies, provide the 10 MHz output signal to the

rear panel, and generate the AWGN (Additive White Gaussian Noise) I

& Q noise source signals.

28 S:\agilent\e8285\ALR\Book\chapters\intro.fm

Page 29

Figure 1-2 Reference Signal Generation

Introduction

Product Description

Rear Panel External

Reference In

1, 2, 5, 10 MHz

Rear Panel External

Reference Out

10 MHz

OC XO H igh Stability

Reference Assembly

10 MHz In

CDMA Reference

Assembly

AWGN

To internal analo g assemblies.

See block diagrams for mor e

information.

To internal digital assemblies.

See block diagrams for more

information.

To I/Q Modulator Assembly

29

Page 30

Introduction

Product Description

RF Analysis

RF signals connected to the front panel RF IN/OUT connector or

ANTENNA IN connector go to the RF I/O module. The signal level and

RF frequency are measured, and the level is adjusted using fixed step

and variable attenuators in the separate downconverter module.

CAUTION Over-Power Damage

The ANTENNA IN connector is only used for very low level signals

(60 mW or less), and cannot be used for Transmitter (TX) Power

measurements. Exceeding this limit may destroy the RF I/O module.

The RF IN/OUT connector is used to m easure direc t mobile transm itter

power up to 2.5 Watts continuous.

The downconverter mixes the input signal with a local oscillator signal

from the Receiver Synthesizer ass embly to produc e a 114.3 MHz, 6 14.3,

or 385.7 MHz IF signal (depending on the frequency of the received

signal). The signal goes through a bandpass filter and then on to the

Receiver assembly.

If the IF is 614.3 or 385.7 MHz, the Receiver assembly mixes the signal

with a 500 MHz local oscillator (LO) signal from the Reference

assembly to obtain the 114.3 MHz IF. If the IF is 114.3 MHz, the signal

bypasses this downconversion. The 114.3 MHz si gnal divides into two

paths.

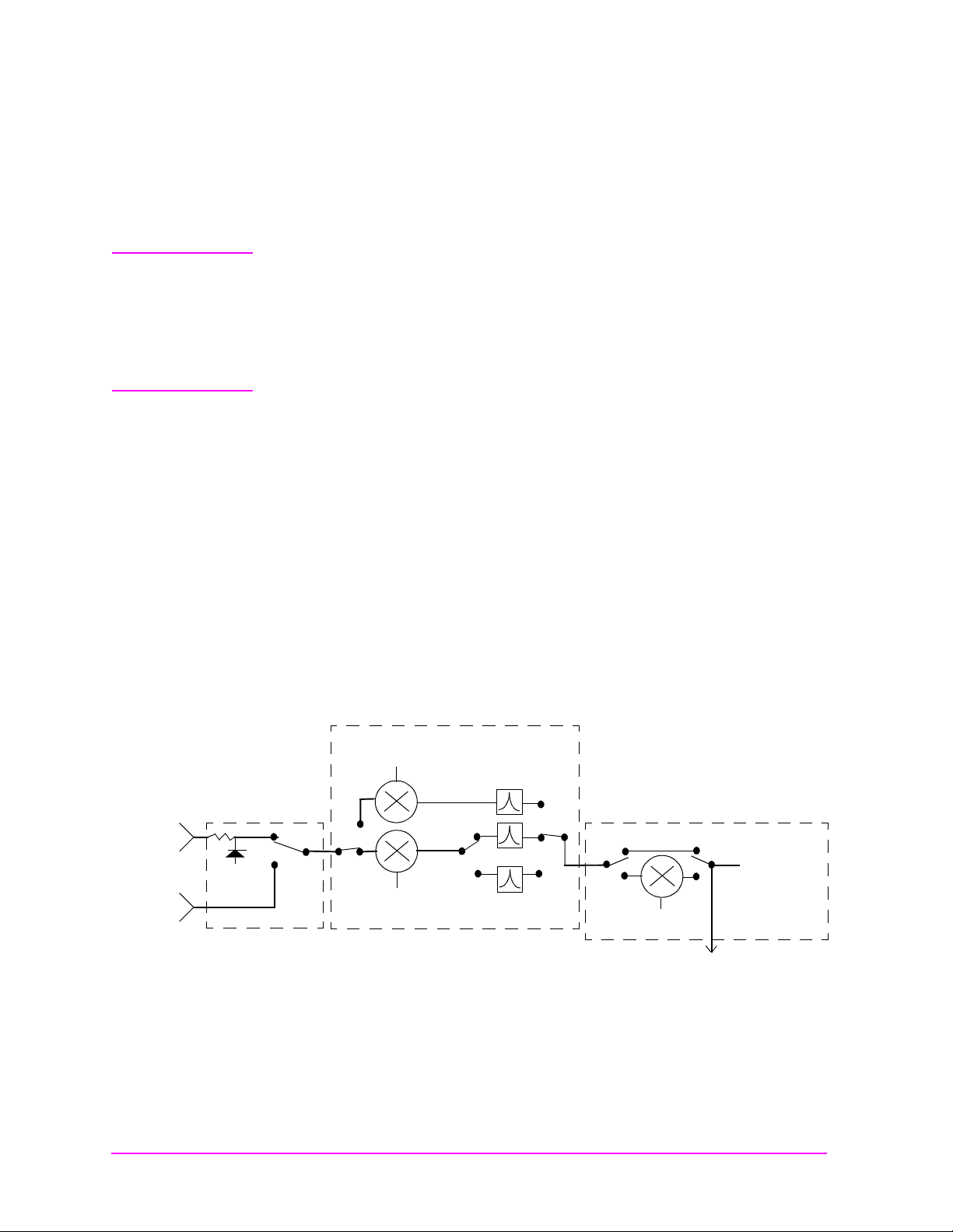

Figure 1-3 Received Signal Downconversion

Downconverter

1200-1700 MHz from

Receiver Synthesizer

Assembly

385.7 MHz

RF I/O

RF IN/OUT

114.3 MHz

614.3 MHz

ANTENNA

IN

Power

Detector

486-1026 MHz from

Receiver Synthesizer

Assembly

Receiver Assembly

114.3 MHz

500 MHz from

Reference Assy

To LO/IF Demod Assembly

114.3 MHz

AM, FM, SSB

Demodulation

30 S:\agilent\e8285\ALR\Book\chapters\intro.fm

Page 31

AM, FM, or SSB Modulation Analysis

For AM, FM, or SSB signals, t h e 114.3 MHz signal is downconverted to

10.7 MHz and routed through a user-selected IF bandpass filter

(15 kHz or 230 kHz) that is centered around the 10.7 MHz IF. AM and

SSB signals are demodulated at this point; FM signals are

downconverted to a 700 kHz IF before demodulation. The demodulated

signal is routed to the Audio Analyzer 1 assembly for audio frequency

filtering. This assembly is also connected to the front-panel AUDIO IN

connector for direct audio measur eme n ts. Several low pass and high

pass filters can be selected, as well as a C-Message or optional CCITT

bandpass filter. Frequency and voltage measurements are then made

on this signal by the Measurement assembly. The signal is then routed

to the Audio Analyzer 2 assembly.

The Audio Analyzer 2 assembly routes the signal through a

user-selectable detector. A variable frequency notch filter may also be

selected for SINAD and distortion measurements. The detector’s si g n al

is then sent to several other assemblies:

Introduction

Product Description

• The Measurement assembly measures and displays the modulation

level (such as FM deviation) and provide the input to the

oscilloscope.

• The Signaling Source Analyzer assembly for signaling decoding.

• The rear-panel AUD MONITOR OUTPUT connector for e xternal use

of the demodulated signal.

• The front-panel VOLUME control and internal speaker to listen to

the demodulat e d sign a l .

Figure 1-4 AM, FM, and SSB Signal Demodulation and Filtering

Receiver Assembly

114.3 MHz

IF

10.7 MHz

125 MHz

Audio Analyzer 2 Assembly

Selectable Detectors

RMS

RMS*SQRT2

Pk+

Pk-

.......

15 kHz

230 kHz

IF Filters

(centered around 10.7 MHz)

Variable Freq.

Notch Filter

10 MHz from

Reference Assembly

RMS

Detector

AM Demod

SSB Demod

FM Demod

Signaling Source Analyzer

AUD MONITOR OUTPUT (Rear panel)

Measurement Assembly

Audio Analyzer 1 Assembly

AUDIO IN

(front pane l)

VOLUME

Selectable

High-Pass

Filters

Selectable

Low-Pass

Filters

DC Volts and

Audio Frequency

Measurements

31

Page 32

Introduction

Product Description

CDMA Signal Analysis

The 114.3 MHz IF also goes to the CDMA LO/IF Demodulation

assembly. This assembly provides a through path to the spec trum

analyzer (Option 102) for all RF signals, and also provides down

conversion for CDMA signals, measurements and call proce ss ing.

To do wnconvert the CDMA signal, the 114.3 MHz IF is mixed with a

117.9864 MHz local oscillator (LO) signal to produce a 3.6864 MHz IF.

(The LO signal is from an oscillator that is phase locked to a 10 MHz

signal from the CDMA Reference module.)

The 3.6864 MHz signal is split and goes to the Receiver DSP assembly,

and also through a variable-gain IF amplifier before IQ demodulation.

The demodulated I and Q baseband signals are then routed to the

Digital Cellsite assemblies.

Under control from the Pr otocol Processor as sembly, the Digital Cellsit e

assemblies use the demodulated IQ inform ation to s et up and mai ntain

calls to CDMA phones. The Digital Cellsite 1 assembly also supplies

feedback to the C D M A L O / I F Demodulation assembly to con t rol the

level of the variable-gain IF amplifier into the demodulator.

The Receive DSP assembly converts, digitizes, and provides final

analysis on the 3.6864 MHz signal to make measurements, such as rho,

timing accuracy, carrier feedthrough, and phase error.

Figure 1-5 Analyzing CDMA Signals

114.3MHz IF

from Receiver

CDMA LO/IF Demodulation Assembly

3.6864 MHz

117.9864 MHz

Demodulator

IQ

IF Gain Control

I data

Q data

T o Spectrum Analyzer

Digital Cellsite

1 & 2 Assemblies

IQ Decoding and

CDMA Generator

Data Coding

Receive DSP Assembly

CDMA IQ Modulation

Measurements

Protocol

Processor

Call Setup and

Control

32 S:\agilent\e8285\ALR\Book\chapters\intro.fm

Page 33

RF Signal Generation

The Signal Generator Synthesizer assembly creates a 500 to 1000 MHz

signal. The reference signal for the synthesizer is supplied by the High

Stability Reference assembly. The synthesizer’s fr equency is varied

using a divider network i n t he feed back ci rcuit of the ph ase loc ked lo op .

Any FM modulation signal (from the Modulation Distributi on

assembly), and the frequency sweep signal for the spectrum analyzer

and tracking generator, are integrated into this feedback loop. If a

CDMA signal is not being generated, the 500-1000 MHz signal is

passed through the I/Q Modulator assembly, bypassing the I/Q

modulator.

IQ Modulation

If a CDMA signal is being generated, the signal is I/Q modulated in the

I/Q Modulator assembly, using data from the Analog Cellsite assembly.

The Analog Cellsite assembly gets its dat a from the two Digital Cellsite

assemblies, which are controlled by the Protocol Pro cessor assembly. Up

to eight code channels of CDMA modulation data and noise may be

summed into the IQ modulator at one time. These channels provide

phone paging, synchronization, voice (traffic) transmission, and other

CDMA system functions.

Introduction

Product Description

Final Frequency Conversion and Leveling

NOTE Test Sets with firmware revision A.04.5X and above operate only at RF

frequencies from 800 to 1000 MHz and 1700 to 2000 MHz. A text only error

message

frequencies are set.

The RF Output assembly performs three tasks:

• Mixes or divides the 500 to 1000 MHz signal to produce signals

• Provides AM modulation (when selected).

• Controls the signal level out of the assembly using an Automatic

The signal from the RF Output assembly is sent to one of two paths in

the Upconverter assembly. RF frequencies from 30 MHz to 1 GHz route

through the bypass path. PCS frequencies are upconverted to supply

frequencies from 1700 to 2000 MHz. The user-selected frequency

contains desired modulation (AM, FM, or CDMA), or a continuou s wa ve

(CW) signal. The level has been adjusted to provide the required level

(after going through RF I/O assembly).

“Input value out of range”, will be displayed if invalid

below 500 MHz (down to 30 MHz). A 1 GHz LO from the Reference

assembly is used for mixing.

Level Control (ALC) loop.

33

Page 34

Introduction

Product Description

RF and Duplex Outputs

NOTE Test Sets with firmware revision A.04.5X and above operate only at RF

frequencies from 800 to 1000 MHz and 1700 to 2000 MHz. A text only error

message

frequencies are set.

The RF I/O assembly receives the signal from the Upconverter

assembly and routes it to the selected output connector: RF IN/OUT or

DUPLEX OUT. The signal first goes to a variable attenuator for level

control.

If the DUPLEX OUT connector is selected, the signal the n goes direct ly

to that connector without additional attenuation. If the RF IN/OUT

connector is used as an output, the signal passes through additional

attenuation before reaching the connec tor. This is why a greater signal

level can be output through the DUPLEX OUT connector than through

the RF IN/OUT connector.

“Input value out of range”, will be displayed if invalid

34 S:\agilent\e8285\ALR\Book\chapters\intro.fm

Page 35

Figure 1-6 RF Generation Path Overview

Introduction

Product Description

1 MHz from

Reference

Assembly

FM Mod. from

Mod. Dist.

Spec. Analyzer

Sweep

500-1000 MHz

Output Assembly

Signal Generator Synthesizer

500-1000 MHz

div/n

Cell Site

Protocol

Processor

500-1000 MHz

div/2

1 GHz from Reference Assembly

(main band)

250-500 MHz

(÷2 band)

250 kHz-250 MHz

(downconverted band)

Digital 1

Cell Site

Digital 2

RF Amplitude

Adjust fro m

Host Controller

IQ Modulator Assembly

I/Q Modulator

4 channels of

I&Q data

1 channel of

I&Q data

Amplitude

Modulator

Automatic

Level Control

Distribution Assembly.

&

ADC

Summing

RF

Amp

AM from Mod.

Analog Cell Site

AWGN (Noise) from

CDMA Reference

Upconverter Assembly

RF I/O Assembly

Variable Step

Attenuator

To the Receiver

Assembly

DUPLEX

OUT

RF IN/OUT

35

Page 36

Introduction

Troubleshooting Strategy

Troubleshooting Strategy

You can repair the Test Set yourself or s end it to your local Agilent

Technologies Instrument Support Center. Before starting a repair, you

should become familiar with basic Test Set operation using the user’s

guide.

Troubleshooting relies on built-in diagnostics. Because some diagnostic

results may be ambiguous, further interpr etation and testing may be

required. There are several diagnostic routines built into the Test Set:

• Power-up self -test diagnostics to test controller functioning. These

are automatically run when the instrument is turned on, and can

also be run after the instrument has been on.

• RF (Radio Frequency) assembly diagnostics.

• AF (Audio Frequency) assembly diagnostics.

• Digital assembly diagnostics for CDMA signals.

Troubleshooting hints in this manual include:

• Instructions on how to begin troubleshooting (see chapter 2,

"Troubleshooting").

• Block diagrams and theory of operation (this chapter and chapter 8,

"Block Diagrams").

• Detailed information about the built-in diagnostics (see chapter 2,

"Troubleshooting").

• Error message explanations (see chapter 10, "Error Messages").

36 S:\agilent\e8285\ALR\Book\chapters\intro.fm

Page 37

Repair Process

Repairing the Test Set consists of:

• Identifying the faulty ass e mb l y – see chapt er 2, "Troubl eshooting"

• Ordering a replacement assembly – see chapter 3, "Disassembly and

Replaceable Parts"

• Replacing the faulty assembly – see chapter 3, "Disassembly and

Replaceable Parts"

• Downloading calibration data – see chapter 2, "Troubleshooting" and

regenerating calibration data – see See “System Power Calibration

Program” on page 39.

• Performing periodic calibration – see chapter 5, "Periodic

Adjustments/Calibration"

• Fu n ctional Verification – see chapter 4 , "Functional Verification"

Introduction

Repair Process

37

Page 38

Introduction

Calibration and Performance Verification

Calibration and Performance Verification

The Tes t Set periodically requires some maintenance to verify that it

meets its published specifications. See “Periodic Adjustments” on page

126. Periodic Adjust men ts (calibration) consists of running several

built-in calibration programs. The recommended interval for periodic

adjustments is 12 months. An external frequency counter and dc

voltmeter are required. See Chapter 5, "Periodic

Adjustments/Calibration" on page 5.

NOTE The recommended Test Set calibration interval is 24 months. This is

accomplished by performing the performance tests (see Chapter 6,

“Performanc e Tests,” on page 141) or sending the Test Set to an Agilent

Calibration Center or other qualified calibration lab.

The performance tests verif y t h at the Te st Set performs as indicated in

the Specifications. These tests should be performed if the Test Set’s

operation is suspect, even though it passes all internal diagnostic

checks. This ident i fies whether a problem actually exists in the Test

Set, or if an application problem exists outside of the Test Set.

Several assemblies, when replaced, require running specific periodic

calibration procedures to crea te calibration factors for that assembly. In

other cases, the ca l i b ration data w ill be included wi th th e replaceme n t

assembly on a memory card. Instructions that come with the

replacement assembly explain how to downl oad the calibration data.

(This is not considered part of periodic calibration.)

NOTE When troubles h oo t i n g the Test Set, it is somet i me s de si r a b le to swap a

known-good assembly (perhaps from another Test Set) for a

suspected-fau l t y as se mb l y. If the swapped assembly requires

calibration data, most assemblies will operate well enough with the

original assembly’s calibration data to troubleshoot and run the

diagnostics. However, do not expect the Test Set to meet its

specifications . Also, some assemblies may appear to fail because of the

incorrect ca l i b ration data.

38 S:\agilent\e8285\ALR\Book\chapters\intro.fm

Page 39

System Power Calibration Program

This adjustment program is not found in ROM of the Test Set. This

program resides on a PCMCIA Memory Card, pa rt-number

E6380-61811. It has to be downloaded from the memory card.

This program generates system power calibration factors for the Test

Set. The purpose of this program is to generate calibration factors for

the RF Input/Output Section. This assures that the Test Set will meet

its power measurement accuracy specifications after repair.

An RF signal generator and a power splitter produce two signals with

the same power level. One signal is measured by the power meter, the

other is applied to the input of the Test Set. The program measures

these levels at selected frequencies and then generates calibration

factors so the Test Set readings match the power readings. These

calibration factors are stored in the Test Set.

Communication between the active instrument(s) is through the Test

Set’s GPIB port. An optional printer can be connected to the Test Set’s

GPIB, serial , or parallel port. Typically this is done from the Printer

Setup field of the SOFTWARE menu screen.

Introduction

System Power Calibration Program

To run the System Power Calibration program:

1. Connect GPIB cables from the Test Set to the signal generator and

power meter.

2. Insert the PCMCIA Memory Card, p/n E6380-61811, into the Test

Set’s memory card slot.

3. Press the Tests key to access the TESTS (M ain Me nu ) sc re e n.

4. Select the field under

5. Select

6. Select the field under

7. Select SYSPWR0

8. Select

9. Follow the instructions on the screen.

Card under the Choices: menu.

Run Test (K1 key).

Select Procedure Location:

Select Procedure Filename:

39

Page 40

Introduction

Test Equipment Needed for the System Power Calibration Program

Test Equipment Needed for the System Power

Calibration Program

For the System Power Calibration program you will need the

equipment listed in table 1-1. Because this calibration program is

written specifically for this equipment, no substitutions are possible.

Table 1-1 Equipment List for System Power Calibration Program

Equipment Ty pe

Signal Generator 8648B Option 1EA

Power Meter 436A

Power Sensor 8482A

Power Splitter 11667A

GPIB Cables (2 cables required, 3 if

GPIB printer is used.)

Printer (op tional) Any serial, parallel, or GPIB printer

Agilent Technologies

Model Number

437B

438A

EPM-441A

EPM-442A

8901B

8902A

ECP-E18A

11722A

Any GPIB cable

40 S:\agilent\e8285\ALR\Book\chapters\intro.fm

Page 41

E8285A Support Contacts

The documentation supplied with your Test Set is an excellent source of

reference, applications, and service information. Please use these

manuals if you are experiencing technical problems:

• Application information is located in the E8285 Application Guide

(p/n E8285-90019) and the GPIB Condensed Programming

Reference Guide (p/n E8285-90020).

• Operation and reference information are included in the E8285A

CDMA Mobile Station T est Set User’s Guide (p/n E8285-90018).

• Calibration and repair information in this manual.

If you have used the manuals and still have application questions,

contact your local representative.

Repair assistance is available from the factor y by phone and email.

Internal Agilent Technologies users can contact the factory through

email. Parts informatio n is also av ailable from Agilent Technologies.

When calling or writing for repair assistance, please have the following

information ready:

Introduction

E8285A Support Contacts

• Instrument model number

• Instrument serial number; tag located on the rear panel.

• Installed options - if any; tag located on the rear panel.

• Instrument firmware revision; displayed at the top of the screen

when the Tes t Set is powered up, and is also displayed on the

CONFIGURE screen.

Support Telephone Numbers and Email Address

• Call Center .................................... ............................1-800-922-8920

• Instrument Support Center......................................1-800-403-0801

• RF Comms Service Assistance,

International..............................................................1-509-921-3848

U.S. only......................................................................1-800-827-3848

• Service Parts Identification,

U.S. & International...................................................1-916-783-0804

Direct Parts Ordering,

U.S. only......................................................................1-800-227-8164

• Ema il . .... ... .... ..... .. .... ..... .... .. ..... .... .. .... Spo ka ne_ Ser vice @ag ile nt .co m

41

Page 42

Introduction

Hardware and Firmware Enhancements

Hardware and Firmware Enhancements

NOTE Test Sets with firmware revision A.04.5X and above operate only at RF

frequencies from 800 to 1000 MHz and 1700 to 2000 MHz. A text only error

message

frequencies are set.

The hardware and firmw a re of the Test Set are enhanced on a

continuous basis. If an assembly is replaced, it is recommended that the

firmware be upgraded at the same time. This is important if an

assembly-level repair is performed because e xchange a ssemblies , whic h

may be of a later revision than the one being replaced, may require a

later revision of the firmware to function correctly.

“Input value out of range”, will be displayed if invalid

42 S:\agilent\e8285\ALR\Book\chapters\intro.fm

Page 43

Ordering New Manuals

The Tes t Set is designed to allow future upgrades to hardw a re and

firmware which may obsole te some of the material in this manual. For

the latest document revisions and information, call the Direct Parts

Ordering office (U.S. only), 1-800-227-8164.

For local and remote operating i nformation, including des criptions of all

controls, connectors, and programming syntax, refer to the E8285

User’s Guide, part number E8285-90018.

For application information refer to the E8285 Application Guide, p/n

E8285-90019. Also, all manuals are available on CD-ROM, p/n

E8285-10003.

Introduction

Ordering New Manuals

43

Page 44

Introduction

Ordering New Manuals

44 S:\agilent\e8285\ALR\Book\chapters\intro.fm

Page 45

2 Troubleshooting

This chapter explains how to isolate a problem to the defective assembly.

Troubleshooting uses the Test Set’s built-in diagnostics. If diagnostics can’t

identify the faulty assembly, supplementary info rmation in the form of manual

troubleshooting procedures is provided.

45

Page 46

Troubleshooting

How to Troubleshoot the Test Set

How to Troubleshoot the Test Set

Document the resul t of e ach step in case y ou need to contact Ag il ent Technologies

for service assi stance. Gene ral trou bleshooti ng steps ar e illust rated in figure 2-2 on

page 47.

NOTE Periodic Adjustment Interval

The calibration p rog rams Periodic Calibration, IQ Calibrati on and IQ Demod Path

Calibration should be performed after the re placement of any assembly re ferred to

in table 5-1, "Assembly Calibr at ion Information" on page 127, or at lea st ever y 24

months. See Chapter 5, "Periodic Adjustments/Calibration" on page 125 for

details.

On power-up, the Test Set runs the Self-Test Diagnostic. Most of the Test Set’s

digital control functions are tested. The outcome of the test appears on the display

(if operating) and on four (DIAG) LEDs 0,1,2, 3, and 4 viewable d igi ta l c ontr oller

unit, see figure 2-1 (you must remove the external and top-interna l covers to view

the LEDs).

Figure 2-1 LEDs

Digital Controller Board

DIAG LEDs

012

J1

3

J4

CAL

MODULE

P1P2

controller5.eps

DS3 DS4

DS2

DS1

46 S:\agilent\e8285\ALR\Book\chapters\trouble.fm

Page 47

How to Troubleshoot the Test Set

Figure 2-2 Agilent E8285A Test Set Troubleshooting Flowchart

BEGIN

Power-up the Test Set to run self diagnostics.

Troubleshooting

Is display blank?

NO

Does a self test error

message appear?

NO

Run the Functional Diagnostics on

the SERVICE MENU. See "AF, RF,

NO

and CDMA Diagnostics" on page 64.

If you still suspect a problem, use the

manual troubleshooting procedures.

See "Manual Troubleshooting

Procedures" on page 70.

YES

YES

NO

NO

Fan is not running or

does T est Set shut off

after a few seconds?

YES

1. Check for a faulty fan.

2. Check for a faulty power supply.

3. Check for a faulty assembly pulling

down line voltage.

1. Check EL Display or ribbon cable.

2. Check display driver.

Refer to "Reading Front Panel or GPIB Codes" on page 51.

Is error code SRBC

or miscellaneous

hardware related?

YES

Turn off Test Set and remove external

and internal top covers. Power-up Test

Set and read Status LEDs for Self-Test

errors. Refer to "Reading LED Codes"

on page 53.

NO

NO

Problem detected?

Problem detected?

YES

YES

Repair Test Set according

to the diagnostic

recommendations.

Repair Test Set according

to findings.

NO

Perform the functional verification tests, refer to Chapter 4 , "Functional Verification" on page 111.

All OK?

YES

END

47

Page 48

Troubleshooting

Self-Test Diagnostics

Self-Test Diagnostics

On power-up the Test Set runs a diagnostic self-test. Most of the Test Set’s digital

functions are tested. The outcome of the test appears on the display (if operating)

and on four LEDs viewable and the digital controller board (you must remove the

external and top-internal covers to view the LEDs).

The self-test diagnostic can be run three ways:

1. The test runs automatically when the Test Set is turned on. After the Test Set

powers up, a message appear s at the top of the dis pla y. If one or more tests fail,

the message reports the failure with a hexadecimal code.

During the test, coded fail ure inf ormati on is dis played on four L EDs on the top

of the controller board, see figure 2 -1 on pa ge 46. The Test Set’s cover must be

removed to view these LEDs. See Chapter 3, “Disassembly and Replaceable

Parts,” on page 83 for disassembly and replacement instructions.

2. The test runs when the Test Set receives the query *TST? over GPIB. The

resultant decimal code can be read over the bus.

3. The test runs when the

menu is selected.

Self Test menu item of the Functional Diagnostics

To Start Troubleshooting

NOTE Test Sets with firmware revision A.04.5X and above operate only at RF

frequencies from 800 to 1000 MHz and 1700 to 2000 MHz. A text only error

message

frequencies are set.

1. Turn on the Test Set to automatically run the self test diagnostics.

2. After power-up, the top line of the Test Set’s display should show copyright

“Input value out of range”, will be displayed if invalid

• If the Test Set does not power up, see "If the Test Set Fails to Power-up" on

page 49.

• If all self-t est diag nostics p ass, and t he front- panel key s and knob wor k, you

can assume that the digi tal control assemblies wo rk.

information and the firmware revision code. The second line should display

All self tests passed.

• If the Test Set powers-up with

failed. Error code:<hexadecimal error code>:”

"Reading Front Panel or GPIB Codes" on page 51.

“One or more self-tests

, see

• See "Frequently Encountered Diagnostic Messages" on page 68 for other

error messages that might appear on the second line of the display.

3. The CDMA CALL CONTROL screen should be displayed. Two conditions

cause a different screen to be displayed on power-up:

48 S:\agilent\e8285\ALR\Book\chapters\trouble.fm

Page 49

Troubleshooting

Self-Test Diagnostics

o A SAVE/RECALL register named POWERON was saved to automatically

power-up the Test Set in a different state. Press the Preset key before

proceeding; this will restore the Test Set to the factory power-up condition.

oThe

Autostart Test Procedure on Power-Up: field (of the

“TESTS [Execution Conditi ons]” screen) is set to

loaded program. Press the Shift key, then press the Cancel key to stop the

program. Press the Preset key to rest ore the Test Set to the factory power-up

condition.

To turn the autostart function off, press the

Execution Cond (under the SET UP TEST SET: heading). The

autostart function is at the bottom of the screen; turn it

If the Test Set Fails to Power-up

1. Is the Test Set plugged in? Listen for fan operation. If you don’t hear it, check

the line fuse, see figure 2-3.

Figure 2-3 Fuse

EXT REF

INPUT

CSD2 SERIAL

10 MHz

OUTPUT

16X CHIP

OUTPUT

On to automatically run a

Tests key, then select

Off.

S1 SERIAL PORT

HP-IB

fuse2.eps

Line Fuse

Spare Fuse

2. If there is no image on the display, remove the Test Set’s covers and check the

power supply LEDs: +5V, −12V, +12V (see figure 2-5 on page 51). If one is

out, the power supply or regulator board is faulty. If no LEDs are lit, confirm

that the Test Set is connected to the main power source. (Also, see step 5.)

3. Check the LEDs on the Controller assembly, see figure 2-5 on page 51. The

LEDs should all light up immediately on power-up, and then go off several

seconds after a beep is heard. If the L EDs do not light when the Test Set is

powered-up, either the Controller or the Memory/SBRC assembly is faulty.

49

Page 50

Troubleshooting

Self-Test Diagnostics