Page 1

Agilent E8257D

Option HAR

User’s and Service Guide

Agilent Technologies

Page 2

Notices

© Agilent Technologies, Inc. 2007

No part of this manual may be reproduced

in any form or by any means (including

electronic storage and retrieval or translation into a foreign language) without prior

agreement and written consent from Agilent Technologies, Inc. as governed by

United States and international copyright

laws.

Manual Part Number

E8251-90319

Edition

October 2007

Printed in USA

Agilent Technologies, Inc.

1601 California Street

Palo Alto, CA 94304 USA

Warranty

The material contained in this document is provided “as is,” and is subject to being changed, without notice,

in future editions. Further, to the maximum extent permitted by applicable

law, Agilent disclaims all warranties,

either express or implied, with regard

to this manual and any information

contained herein, including but not

limited to the implied warranties of

merchantability and fitness for a particular purpose. Agilent shall not be

liable for errors or for incidental or

consequential damages in connection

with the furnishing, use, or performance of this document or of any

information contained herein. Should

Agilent and the user have a separate

written agreement with warranty

terms covering the material in this

document that conflict with these

terms, the warranty terms in the separate agreement shall control.

Technology Licenses

The hardware and/or software described in

this document are furnished under a

license and may be used or copied only in

accordance with the terms of such license.

Restricted Rights Legend

computer software” as defined in FAR

52.227-19 (June 1987) or any equivalent

agency regulation or contract clause. Use,

duplication or disclosure of Software is

subject to Agilent Technologies’ standard

commercial license terms, and non-DOD

Departments and Agencies of the U.S. Government will receive no greater than

Restricted Rights as defined in FAR

52.227-19(c)(1-2) (June 1987). U.S. Government users will receive no greater than

Limited Rights as defined in FAR 52.227-14

(June 1987) or DFAR 252.227-7015 (b)(2)

(November 1995), as applicable in any

technical data.

Safety Notices

CAUTION

A CAUTION notice denotes a hazard. It calls attention to an operating procedure, practice, or the like

that, if not correctly performed or

adhered to, could result in damage

to the product or loss of important

data. Do not proceed beyond a

CAUTION notice until the indicated

conditions are fully understood and

met.

WARNING

A WARNING notice denotes a

hazard. It calls attention to an

operating procedure, practice, or

the like that, if not correctly performed or adhered to, could result

in personal injury or death. Do not

proceed beyond a WARNING

notice until the indicated conditions are fully understood and met.

If software is for use in the performance of

a U.S. Government prime contract or subcontract, Software is delivered and

licensed as “Commercial computer software” as defined in DFAR 252.227-7014

(June 1995), or as a “commercial item” as

defined in FAR 2.101(a) or as “Restricted

Page 3

Safety Notes

The following safety notes are used throughout this document. Familiarize yourself with

each of these notes and its meaning before performing any of the procedures in this

document.

WAR NING

CAUTION

Warning denotes a hazard. It calls attention to a procedure which,

if not correctly performed or adhered to, could result in injury or

loss of life. Do not proceed beyond a warning note until the

indicated conditions are fully understood and met.

Caution denotes a hazard. It calls attention to a procedure that, if not

correctly performed or adhered to, could result in damage to or destruction

of the instrument. Do not proceed beyond a caution sign until the indicated

conditions are fully understood and met.

Definitions

• Specifications describe the performance of parameters covered by the product warranty

(temperature –0 to 55 °C, unless otherwise noted.)

• Typical describes additional product performance information that is not covered by the

product warranty. It is performance beyond specification that 80% of the units exhibit

with a 95% confidence level over the temperature range 20 to 30 °C. Typical

performance does not include measurement uncertainty.

• Nominal values indicate expected performance or describe product performance that is

useful in the application of the product, but is not covered by the product warranty.

• Characteristic Performance describes performance parameter that the product is

expected to meet before it leaves the factory, but is not verified in the field and is not

covered by the product warranty. A characteristic includes the same guard bands as a

specification.

iii

Page 4

iv

Page 5

Contents

E8257D Option HAR

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Verifying the Shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Phase Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Maximum Level Output Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Typical Performance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Phase Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Amplitude . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Modulation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Frequency Modulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Phase Modulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Amplitude Modulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Pulse Modulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

ALC Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Ramp Sweep . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

E8257D Option HAR Using the E5500 Phase Noise Measurement Subsystem . . . . . . . . . 8

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Replaceable Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Performance Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Setting up the E5500 Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

10 MHz Phase Noise Test Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

10 MHz Test Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Making the 10 MHz Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

100 MHz Phase Noise Test Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

100 MHz Test Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Making the 100 MHz Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Modifying Synthesizer Self Test Limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Safety and Regulatory Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Cleaning the Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Connector Care and Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Statement of Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Shipping Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Compliance with Canadian EMC Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Compliance with German FTZ Emissions Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Compliance with German Noise Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

General Safety Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Safety Earth Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Before Applying Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Electrostatic Discharge Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Regulatory Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Instrument Markings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Contacting Agilent Sales and Service Offices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Contents-1

Page 6

Contents

Contents-2

Page 7

E8257D Option HAR

User’s and Service Guide 1

Page 8

E8257D Option HAR Description

Description

The E8257D Option HAR is a frequency divider designed to provide improved phase noise

in the 0.98 MHz to 500 MHz frequency range of the E8257D Signal Generator.

The Option HAR uses frequency division as a replacement for heterodyne mixing to create

frequencies in the 0.98 to 500 MHz range. This provides improved phase noise in this

mode. The mode will be referred to as “Divider Mode” throughout this document.

Verifying the Shipment

After the unit has been unpacked, keep the original packaging materials so it can be

used if you need to transport the instrument.

After the test set has been unpacked, keep the original packaging materials so they can be

used if you need to transport the instrument.Inspect the test set and all accessories for any

signs of damage that may have occurred during shipment. If your test set or any

accessories appear to be damaged or missing refer to “Contacting Agilent Sales and Service

Offices” on page 26.

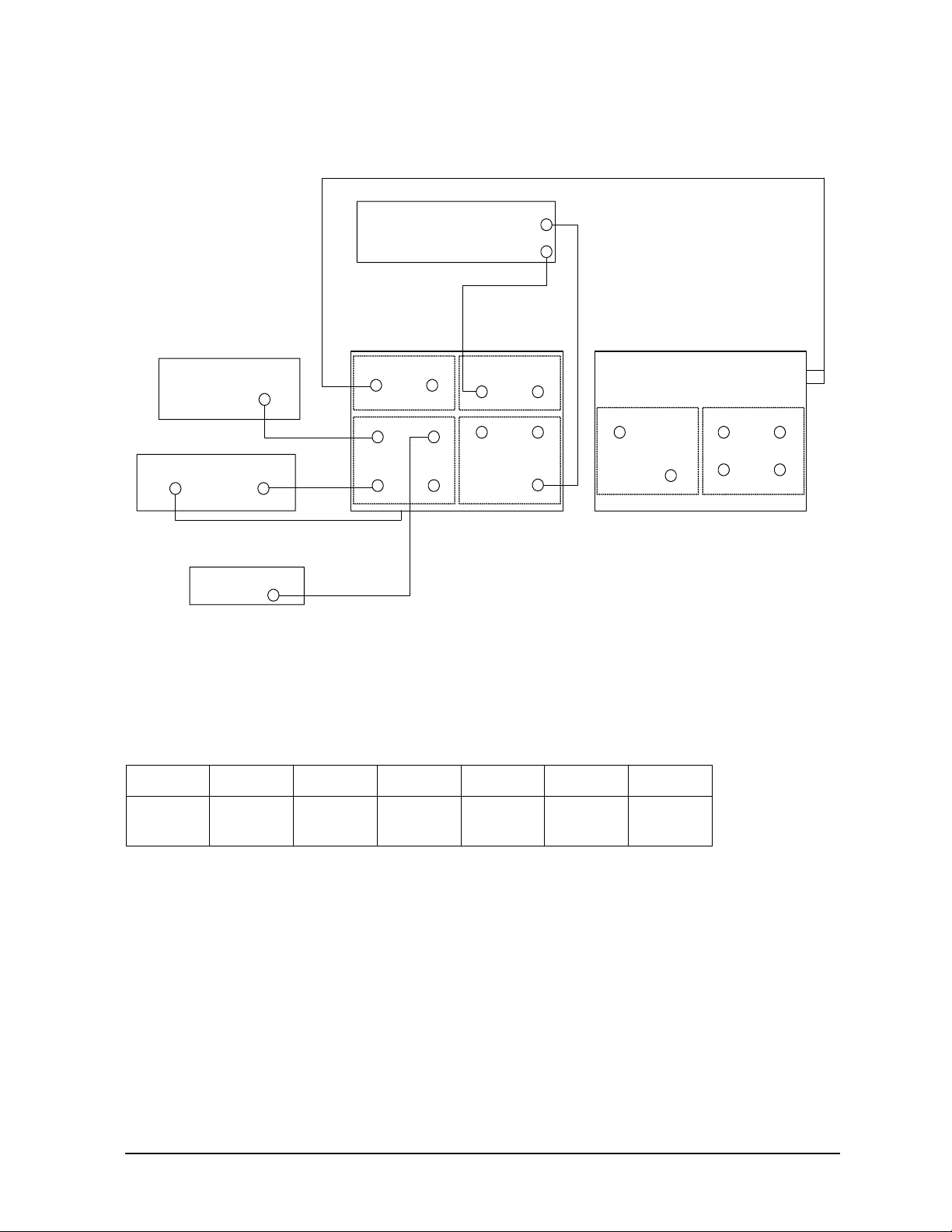

Block Diagram

Figure 1 Block Diagram

P1 P2 P4

p/o Frac N board

N

/ 2

/ 2NRamp Swp

0.25-3.2

GHz

Divider assembly

1

2

N

/ 2

Output Board

N

/ 2

From ALC

board

ALC

TC226

ALC

Scan

Digital Control

1GHz from

Ref board

1 - 250 MHz

1

2

Opt 1EH

Filters

P3

2 User’s and Service Guide

Page 9

E8257D Option HAR Specifications

Specifications

The E8257D Option HAR provides improved absolute phase noise in the 0.98 to 500 MHz

frequency range. To achieve these improvements the Divider Mode must be turned On.

See “Operation” on page 8.

The E8257D Option HAR impacts standard instrument performance for frequencies

≤ 3.2 GHz. Standard operation for frequencies above 3.2 GHz has not been affected. If

Divider Mode is left on for frequencies outside of 0.98 to 500 MHz the “ALC Bandwidth”

will be limited to 100 Hz.

Phase Noise

Divider Mode On

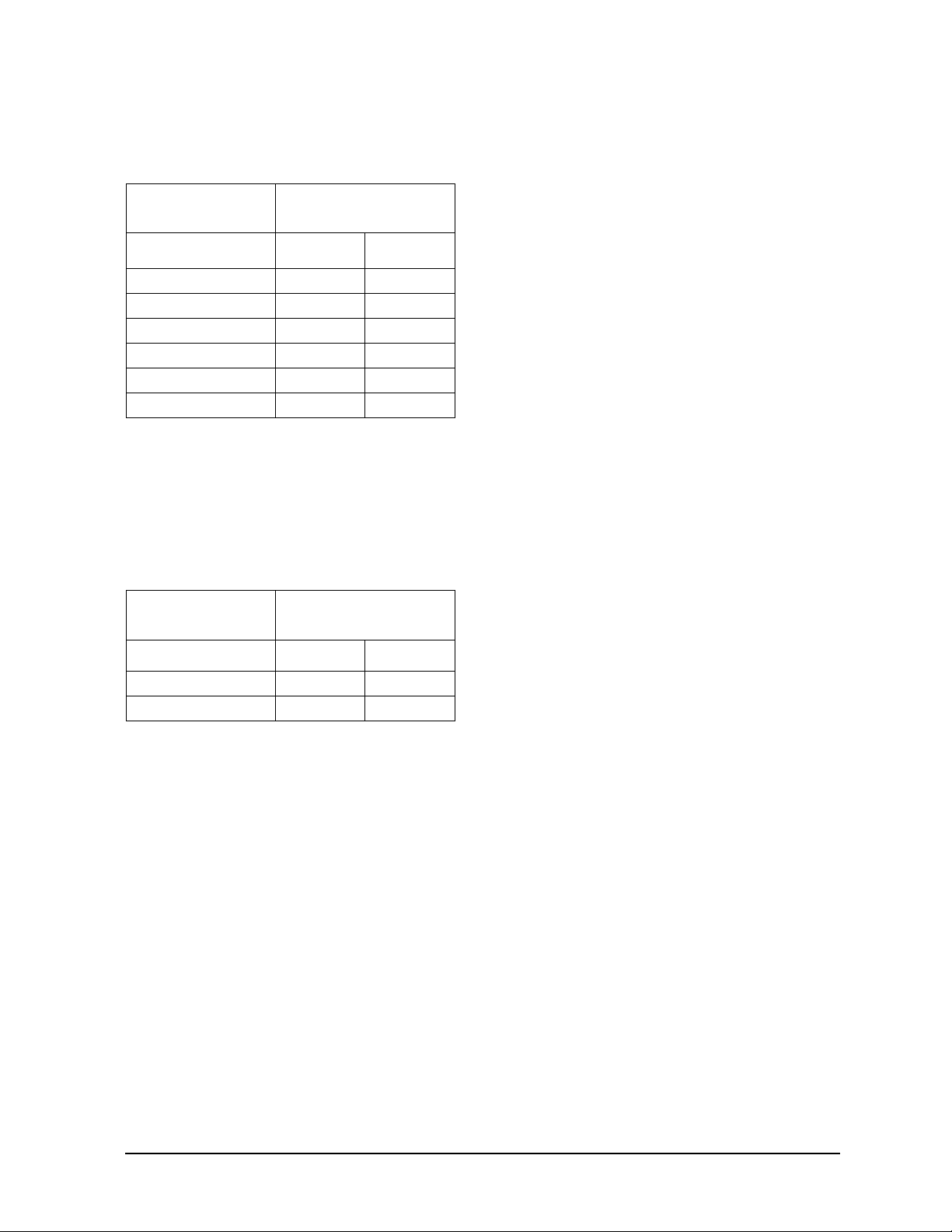

Tabl e 1

Frequency 1 Hz 10 Hz 100 Hz 1 kHz 10 kHz 100 kHz

10 MHz −93 −120 −142 −152 −158 −158

100 MHz −73 −100 −122 −140 −145 −145

1. +16 dBm

E8257D Option HAR Specifications1 (25 °C)

Divider Mode Off

Standard performance per the E8257D data sheet.

Maximum Level Output Power

Divider Mode On

Typical performance see Table 4 and Table 5 on page 5.

Divider Mode Off

Table 2 Maximum Power Specification Impacts

Frequency Delta

250 kHz to 3.2 GHz −3 dB from Standard specification

> 3.2 GHz no change from standard specifications

User’s and Service Guide 3

Page 10

E8257D Option HAR Typical Performance

Typical Performance

Phase Noise

Table 3 Absolute Single Sideband Phase Noise (dBc/Hz) Frequency Offset

from Carrier

1

(Typical)

2

Carrier

Frequency (MHz)

1 MHz −120 −142 −155 −160 −160 −160

10 MHz −106 −132 −148 −160 −160 −160

100 MHz −86 −112 −129 −144 −149 −149

160 MHz −81 −107 −122 −142 −145 −145

250 MHz −76 −104 −121 −138 −142 −142

500 MHz −70 −98 −115 −132 −136 −136

1. +16 dBm

Divider Mode On.

2.

1 Hz 10 Hz 100 Hz 1 kHz 10 kHz 100 kHz

Amplitude

Table 4 Option 520 Maximum Leveled Output Power1 dBm

Carrier

Frequency

1 MHz 19 19

10 MHz 19 13

100 MHz 17 11

160 MHz 17 11

250 MHz 17 10

500 MHz 16 10

Lowband Filter

Off

On

4

2

(Typical)

3

1.Amplitude accuracy is not specified in diver mode.

2.Divider Mode On.

3.Option 1EA installed. Divider mode on, without Option IEA max power is

the lower of 10 dBm, or refer to Tabl e 4.

4.For improved amplitude accuracy the lowband filters must be on.

4 User’s and Service Guide

Page 11

E8257D Option HAR Typical Performance

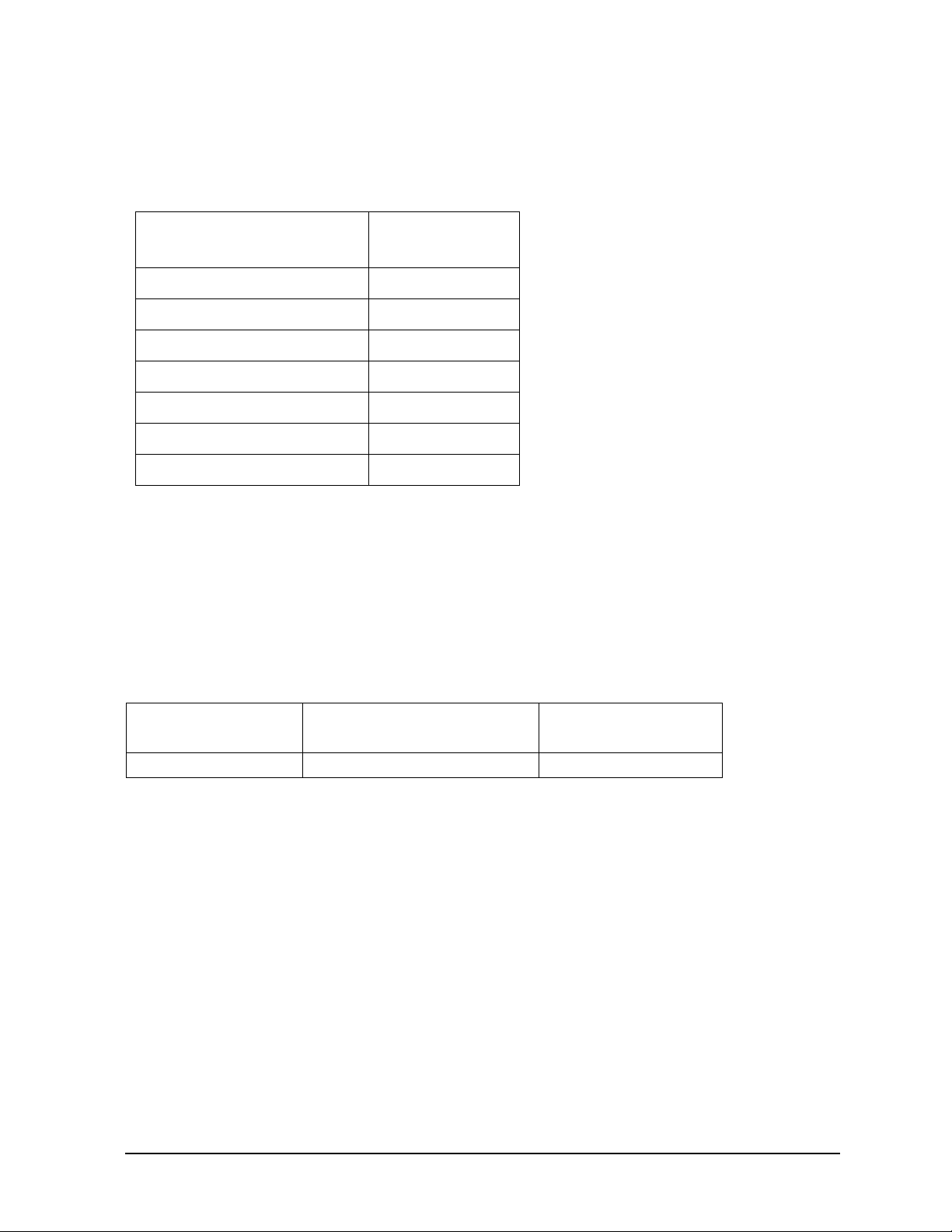

Table 5 Option 532 or 540 Maximum Leveled Output Power1 dBm

Carrier

Frequency

1 MHz 15 15

10 MHz 15 10

100 MHz 15 9

160 MHz 15 8

250 MHz 15 8

500 MHz 13 9

1.Amplitude accuracy is not specified in diver mode.

2.Divider Mode On.

3.Option 1EA installed. Divider mode on, without Option IEA max power is

the lower of 10 dBm, or refer to Tabl e 5.

4.For improved amplitude accuracy the lowband filters must be on.

Table 6 Harmonic Level dBc1 (Typical)

Carrier

Frequency

Lowband Filter

Off

Lowband Filter

On

4

2

2

(Typical)

3

Off On

< 10 MHz − 10 − 10

10 to 500 MHz − 10 − 55

1. Divider Mode On.

2. Harmonic levels in divider mode are high (the output

is a square wave)

User’s and Service Guide 5

Page 12

E8257D Option HAR Typical Performance

Modulation

Frequency Modulation

Table 7 Maximum FM Modulation Deviation (Typical)

Carrier Frequency kHz

> 0.98 MHz to 1.953 MHz 3.906

> 1.953 MHz to 3.906 MHz 7.8125

> 3.906 MHz to 7.813 MHz 15.625

> 7.813 MHz to 15.63 MHz 31.25

> 15.63 MHz to 31.25 MHz 62.5

> 31.25 MHz to 62.5 MHz 125

> 62.5 MHz to 125 MHz 250

> 125 MHz to 250 MHz 500

> 250 MHz to 500 MHz 1000

1.Divider Mode On.

Phase Modulation

Table 8 Maximum Phase Modulation (Typical)

Carrier Frequency

Normal Bandwidth

Mode (radians)

1

High Bandwidth

Mode (radians)

1

> 0.98 MHz to 1.953 MHz 0.0039063 0.0039063

> 1.953 MHz to 3.906 MHz 0.0078125 0.0078125

> 3.906 MHz to 7.813 MHz 0.015.625 0.015.625

> 7.813 MHz to 15.63 MHz 0.03125 0.03125

> 15.63 MHz to 31.25 MHz 0.0625 0.0625

> 31.25 MHz to 62.5 MHz 125 0.125

> 62.5 MHz to 125 MHz 250 0.250

> 125 MHz to 250 MHz 500 0.500

> 250 MHz to 500 MHz 10 1

1.Divider Mode On.

6 User’s and Service Guide

Page 13

E8257D Option HAR Typical Performance

Amplitude Modulation

AM modulation is not recommended in divider mode. In divider mode, ALC Bandwidth is

limited to 100 Hz and dynamic range is restricted below 500 MHz.

Pulse Modulation

Divider Mode On:

Standard Pulse (UNU) can not be used in divider mode. Option UNW can be used.

Divider Mode Off:

Pulse On/Off ratio is degraded by 10 dB from 2.0 to 3.2 GHz in Standard Pulse (UNU).

Option UNW is not affected.

ALC Performance

The ALC bandwidth is limited to 100 Hz in divider mode. Operation with ALC off is not

recommended.

Ramp Sweep

Ramp Sweep is unavailable with Divider Mode On.

User’s and Service Guide 7

Page 14

E8257D Option HAR Operation

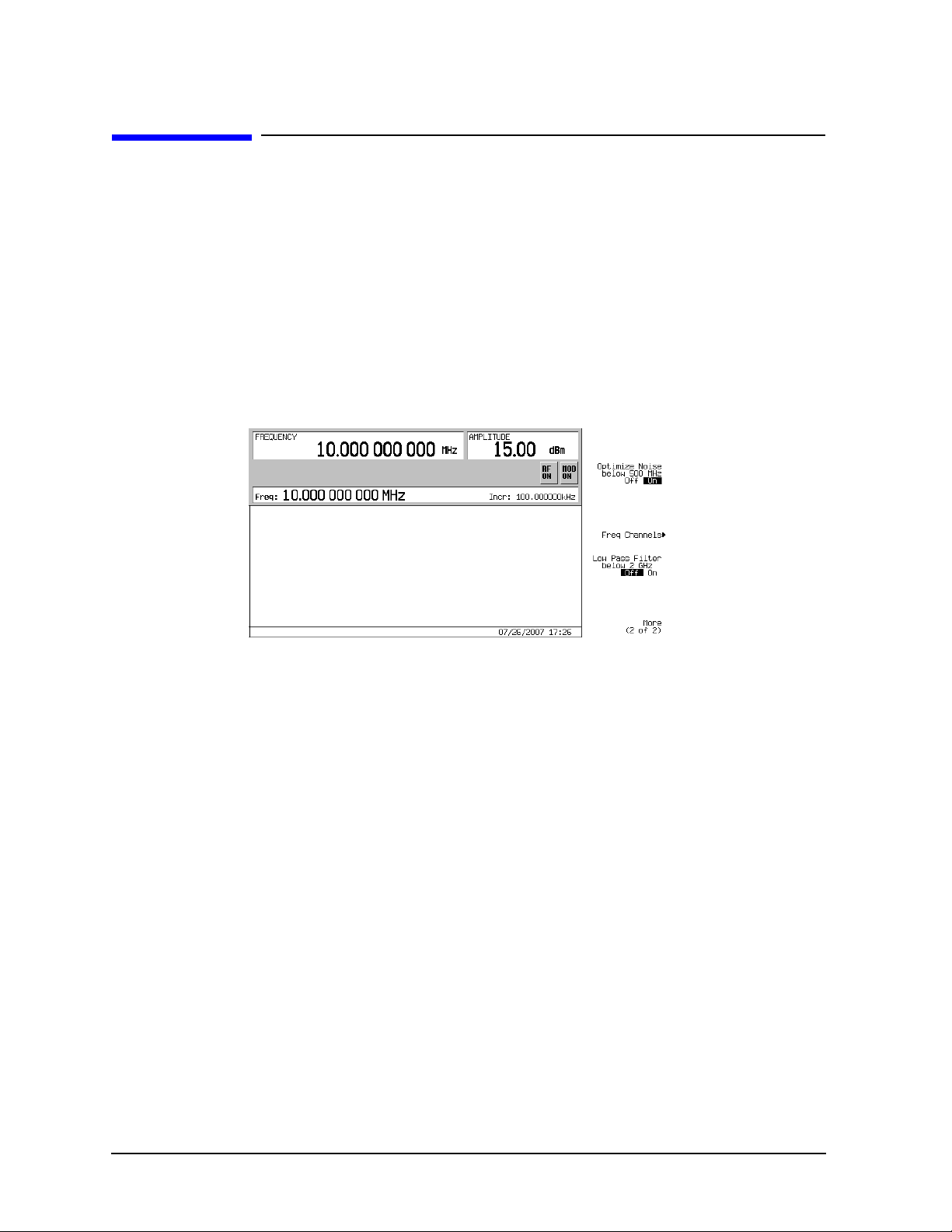

Operation

E8257D Option HAR requires firmware revision ≥ C.04.94.

To turn on the frequency divider circuitry (Divider Mode) select [Frequency] >

MORE (1 of 3) > MORE (2 of 3) > Optimize noise below 500 MHz > toggle On or Off.

The normal preset state is Off.

The SCPI command is as follows:

[:SOURce]: LFDivider ON|OFF|1|0

[:SOURce]: LFDivider?

Figure 2

Frequency Divider Circuitry

E8257D Option HAR Using the E5500 Phase Noise Measurement Subsystem

The E5500 software currently does not recognize Option HAR. To improve reference phase

noise when using your E8257D Option HAR with the E5500, manually turn the Divider

Mode On (refer to Operation), when the “Agilent E5500 Instrument Connections” window

appears.

8 User’s and Service Guide

Page 15

E8257D Option HAR Service

Service

Troubleshooting

1. Before troubleshooting E8257D Option HAR, verify that the standard instrument is

operating properly with the Divider Mode Off. If not, troubleshoot in Standard Mode.

2. For the instrument to operate properly with the Option HAR circuitry installed (Divider

Mode On or Off), licenses are needed for the following options:

•Option HAR

• Option 1EH

3. If the Phase Noise in Divider Mode is does not meet specification (refer to “Performance

Test” on page 11), replace the Divider Assembly.

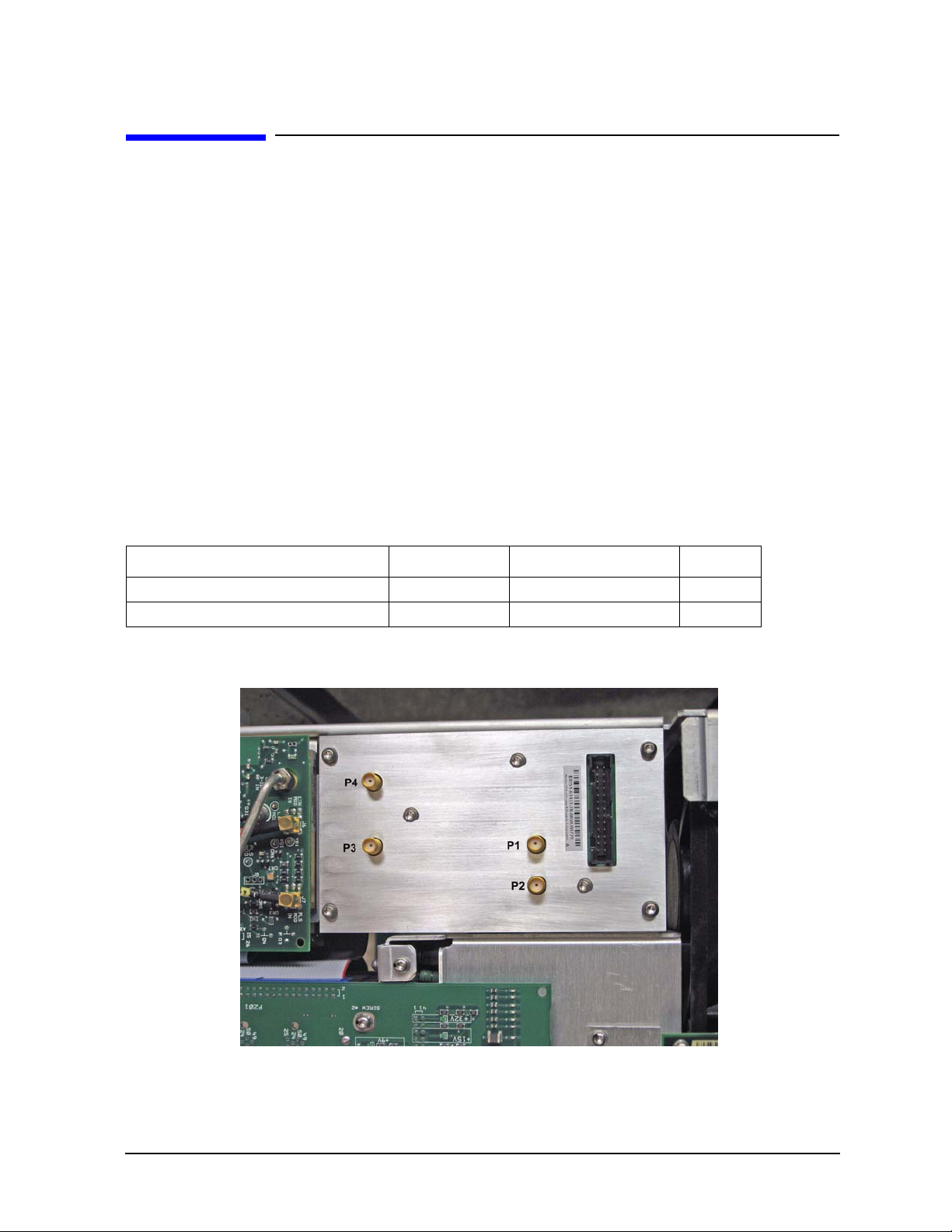

4. Measure the losses through Option HAR in Standard Mode (Divider Mode Off).

Table 9 Divider Assembly

Assembly Path Frequency Loss

Divider Assembly E8251-60433 P1 to P2 250 MHz to 3.2 GHz ≤ 3 dB

Divider Assembly E8251-60433 P4 to P3 250 MHz to 3.2 GHz ≤ 3 dB

Figure 3 Divider Assembly with Connectors Labeled

User’s and Service Guide 9

Page 16

E8257D Option HAR Service

5. If there is excessive loss in one path, replace the Divider Assembly.

6. If there is excessive loss in both paths, remove the ribbon cable from the Divider

Assembly and measure the following voltages at the end of the ribbon cable.

Pin Voltage

23 > 14.5

24 ≤ −4.5

25 > 8

26 ≤ −14.5

7. If any of the voltages are wrong, measure the same voltages on the Lowband Filter

Assembly (J6).

a. If the voltage at pin 25 is incorrect, measure the voltage on the motherboard at P142,

pin 7.

1. If the voltage at P142, pin 7 is < 8 volts, replace the Motherboard.

2. If the Motherboard is working properly, replace the Lowband Filter Assembly.

b. If the voltage on the Lowband Filter Assembly (J6) pin 23, 24 or 26 is incorrect.

1. Replace the Lowband Filter Assembly.

2. If the Lowband Filter Assembly is working properly, replace the ribbon cable from

the Lowband Filter Assembly to the Divider Assembly.

8. Set the instrument frequency to 1 MHz, Output power to maximum and RF On.

9. With all other cables connected, make the following measurements on the Divider

Assembly with a spectrum analyzer.

P2 P3

Divider Mode On Off On Off

Frequency 256 MHz 999 MHz 1 MHz 1 MHz

Amplitude −35 dBm +9 dBm +12 dBm +11 dBm

10.If the frequencies at connector P2 are incorrect.

a. Troubleshoot the standard synthesizer system.

11.If the amplitude at connector P2 is incorrect.

a. Replace the Divider Assembly.

12.If the frequencies or amplitude at connector P3 are incorrect.

a. Replace the Divider Assembly.

10 User’s and Service Guide

Page 17

E8257D Option HAR Service

Replaceable Parts

Table 10 Replaceable Parts

Description Agilent Part

Number

Option 1EH Board E8251- 60595

Div Board E8251- 60433

Ribbon Cable E8251- 60594

Cable (Frac- N to Div) E8251-20394

Cable (Div to Lowband filter) E8251- 20395

Cable (Lowband Out to Div) E8251-20396

Cable (Div to Lowband filter) E8251- 20397

• If the mother board is changed, it must be replaced with an E8251-60441 or later.

• If the modulation filter (5087-7061) is changed, reuse the thermal pad.

• If the synthesizer assembly (E8251-60328) is replaced, refer to “Appendix” on page 19 to

modify the self test limits.

Performance Test

Table 11 Performance Test Equipment

Instrument

Phase Noise System Sensitivity E5504B Option 001

Critical Specifications

(for this test)

Recommended

Model

User’s and Service Guide 11

Page 18

E8257D Option HAR Service

Setting up the E5500 Software

Step 1. If necessary, install the E5500 revision A.03.03 (or later) software.

Step 2. Open the E5500 Software User Interface.

Step 3. Select System > Asset Manager.

Step 4. Verify that the Agilent E8257D is listed under Source. If not, double-click Source

and click Next.

Step 5. In the list of Sources, select Agilent E8257D and click Next.

Step 6. In the Interface drop-down menu, select GPIB.

Step 7. In the Address field, enter the GPIB address of the E8257D. Example, 19.

Step 8. Verify that the Library field identifies Agilent Technologies VISA.

Step 9. Click Next > Finish.

Step 10. In the list of Sources, select Agilent E8257D.

Step 11. Select the icon with the green check-mark. Verify that the connection to the

selected asset has been completed. Press OK.

Step 12. Verify that the Library field identifies Agilent Technologies VISA.

Step 13. Close the Asset Manager.

Step 14. Verify that the Phase Noise System is connected as shown in Figure 4. The

connections from the 70427A should not be made at this time. The user will be

instructed to make the appropriate connections as part of the following

Performance Test procedure.

12 User’s and Service Guide

Page 19

E8257D Option HAR Service

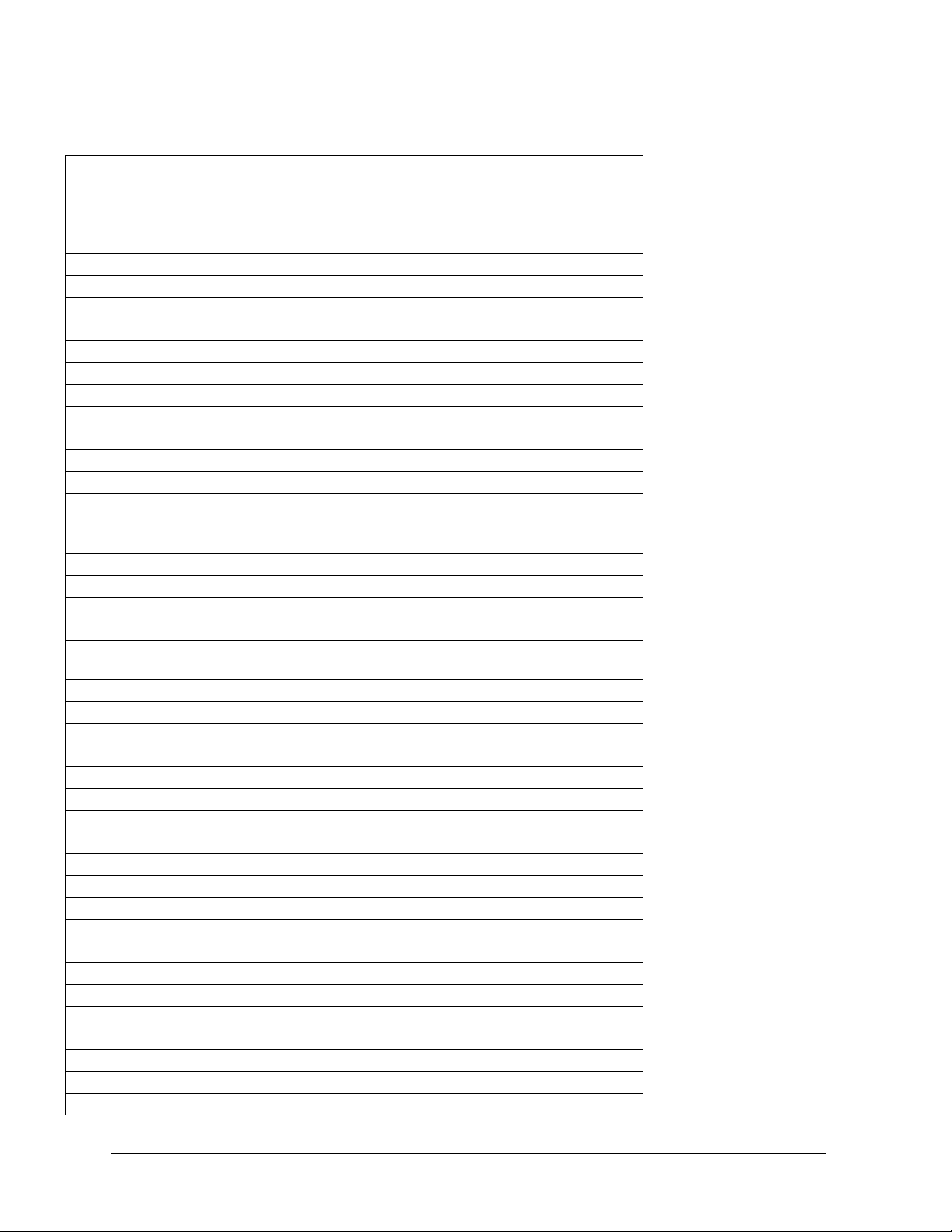

Figure 4 Test Setup Block Diagram

E8257D Option HAR under test

EXT 1 Input

RF OUTPUT 50 Ω

Spectrum Analyzer *

INPUT 50 Ω

9 kHz - 1.5 GHz

PC Controller/Digitizer *

Digitizer

Output

TO NOISE SOURCE Input on Rear Panel

Frequency Counter *

Digit izer

Input

Channel 1

70420A-001 Test Set *

SIGNAL NOISE

RF Analyzer MONITOR

ANALYZER ANALYZER

< 100 kHz < 100 MHz

REF INPUT

50 KHz -

1600 MHz

+ 15 dBm min

From

Down

Converter

1.2 -

26.5 GHz

+ 7 dBm min

To

Down

Converter

TUNE

VOLTAGE

* P/O Phase Noise Measurement System.

70427A Downconverter *

10 MHz Oven Output +18 dBm (REAR PANEL)

SIGNAL

5 MHz - 26.5 GHz

VOLTAGE CONTROL

+ 10 Volts Max

10 MHz Phase Noise Test Limits

Table 12 Phase Noi se Te st Limits

10 MHz 1 Hz 10 Hz 100 Hz 1 kHz 10 kHz 100 kHz

100 MHz +8 dBm (REAR PANEL)

AM NOISE RF Analyz er

IF

5 - 1500 MHz

µW LO

2.4 - 25.8 GHz

+10 dBm

Noise

Spec

10 MHz Test Procedure

−93 −120 −142 −152 −158 −158

Using the E5504B Phase Noise Measurement System.

Step 1. Select Define > Limit Lines.

Step 2. Enter the Noise Spec data (Table 12) in the Upper Noise Limit tab.

Step 3. Select Define > Measurement. Refer to Table 13.

User’s and Service Guide 13

Page 20

E8257D Option HAR Service

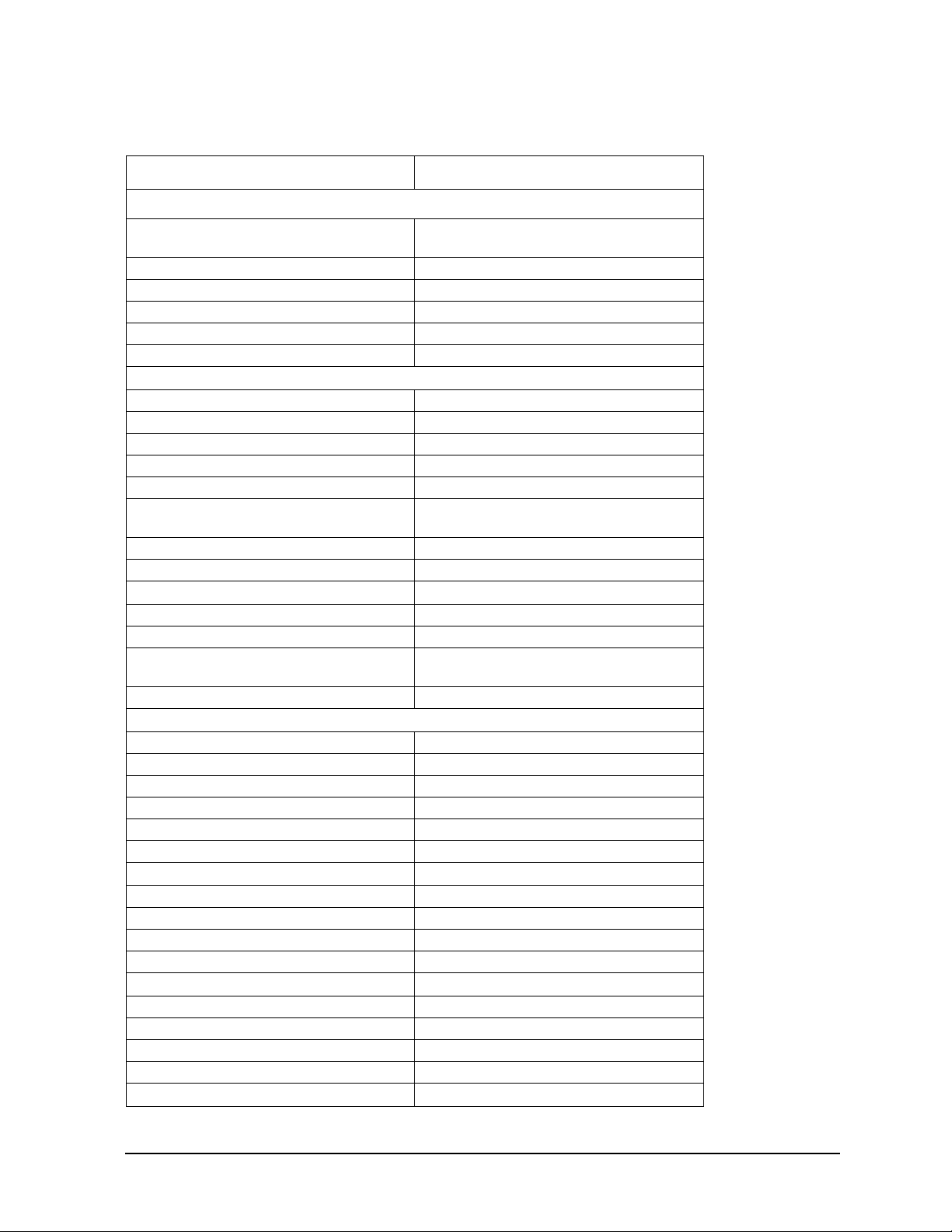

Table 13 10 MHz Phase Noise System Setup

Parameter Setting

Type and Range Tab:

Measurement Type Absolute Phase Noise

(using a phase locked loop)

Start Offset Frequency 1 Hz

Stop Offset Frequency 2 MHz (2E+6)

FFT Averages 10

FFT Quality High Resolution

Swept Quality High Resolution

Source Tab:

Carrier Source Connected Test Set

Carrier Source Frequency 10 MHz (10E+6)

Carrier Source Power +15 dBm

Detector Input Frequency No entry needed

Reference Source Power 16 dBm

VCO Tune Constant 0.1 ppm x Carrier

0.1 ppm x 10 MHz = 1 Hz/Volt

VCO Tune Range ±5 Volts

VCO Input Resistance 600 Ohms

Cal Tab:

Measure Phase Detector Constant Measure Phase Detector Constant

Calculate VCO Tune Constant Measure VCO Tune Constant

Verify calculated phase lock loop

suppression

If Limit is exceeded Use Theoretical Value

Block Diagram Tab:

Carrier Source Manual

Downconverter None

Reference Source Agilent E8257D

Phase Detector Mode Automatic Detector Selection

Test Set Tune Voltage Destination Reference Source

VCO Tune Mode DC FM

Test Set Tab:

Input Attenuation 0 dB

LNA Low Pass Filter Auto

LNA Gain Auto Gain

PLL Integrator Attenuation 0 dB

Downconverter Tab:

Input Attenuation Auto

IF Gain Auto

Microwave/Millimeter Band Microwave (0 to 26.5 GHz)

Reference Chain Reference 10 MHz

Graph Tab:

Title 10 MHz Agilent E8257D SNxxxxxxxx

Check

14 User’s and Service Guide

Page 21

E8257D Option HAR Service

Table 13 10 MHz Phase Noise System Setup

Parameter Setting

Graph Type Single- sideband Phase Noise (dBc/Hz)

X Scale Minimum 1 Hz

X Scale Maximum 100E+6

Y Scale Maximum 0

Y Scale Minimum −170

Normalize Trace Data to 1 Hz Bandwidth

Making the 10 MHz Measurement

Step 1. In the Measure drop-down menu verify that the Pause at Connect Diagram is

selected. If not, select it.

Step 2. In the Measure drop-down menu select New Measurement.

Step 3. Select Yes in the Do you want to perform a new Calibration and Measurement?

dialog box. The Agilent E5500 Instrument Connections window will appear.

Step 4. On the 70427A rear panel, remove the jumper from the 105 MHz Oven Out to 10

MHz In. Refer to Figure 4 on page 13.

Step 5. Connect the 10 MHz Oven Out on the 70427A rear panel to the Signal Input on

the 70420A.

Step 6. Turn On the Divider Mode. Refer to “Operation” on page 8

.

Step 7. Select Continue and allow Phase Noise Measurement to complete.

Step 8. Compare the estimated mean value of the trace with the noise specification line

(lower line). If the estimated mean value of the trace falls on or below the

specification line, the LNSG is regarded as having met the noise specification.

Step 9. Print the E5500 Phase Noise Plot.

Step 10. Connect the jumper that was removed in Step 4.

User’s and Service Guide 15

Page 22

E8257D Option HAR Service

100 MHz Phase Noise Test Limits

Table 14 Ph ase Noise Tes t Li mits

100 MHz 1 Hz 10 Hz 100 Hz 1 kHz 10 kHz 100 kHz

Noise

Spec

−73 −100 −122 −140 −145 −145

100 MHz Test Procedure

Using the E5504B Phase Noise Measurement System.

Step 1. Select Define > Limit Lines.

Step 2. Enter the Noise Spec data (Table 14) under the Upper Noise Limit tab.

Step 3. Select Define > Measurement. Refer to Table 15.

16 User’s and Service Guide

Page 23

E8257D Option HAR Service

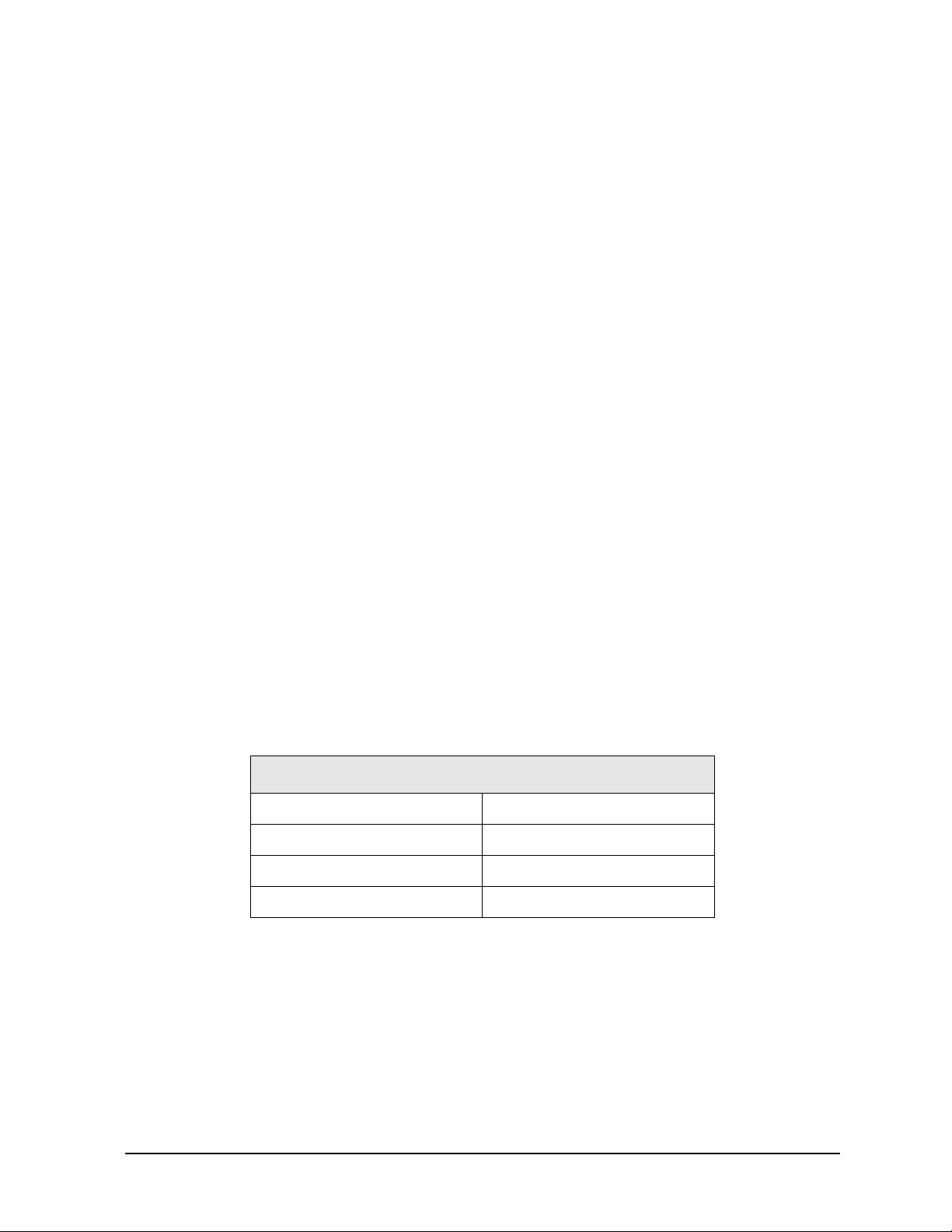

Table 15 100 MHz Phase Noise System Setup

Parameter

Setting

1

Type and Range Tab:

Measurement Type Absolute Phase Noise

(using a phase locked loop)

Start Offset Frequency 1 Hz

Stop Offset Frequency 20 MHz (20E+6)

FFT Averages 10

FFT Quality High Resolution

Swept Quality High Resolution

Source Tab:

Carrier Source Connected Test Set

Carrier Source Frequency 100 MHz (100E+6)

Carrier Source Power +15 dBm

Detector Input Frequency No entry needed

Reference Source Power 16 dBm

VCO Tune Constant 0.1 ppm x Carrier

0.1 ppm x 100 MHz = 10 Hz/Volt

VCO Tune Range ±5 Volts

VCO Input Resistance 600 Ohms

Cal Tab:

Measure Phase Detector Constant Measure Phase Detector Constant

Calculate VCO Tune Constant Measure VCO Tune Constant

Verify calculated phase lock loop

suppression

If Limit is exceeded Use Theoretical Value

Check

Block Diagram Tab:

Carrier Source Manual

Downconverter None

Reference Source Agilent E8257D

Phase Detector Mode Automatic Detector Selection

Test Set Tune Voltage Destination Reference Source

VCO Tune Mode DC FM

Test Set Tab:

Input Attenuation 0 dB

LNA Low Pass Filter Auto

LNA Gain Auto Gain

PLL Integrator Attenuation 0 dB

Downconverter Tab:

Input Attenuation Auto

IF Gain Auto

Microwave/Millimeter Band Microwave (0 to 26.5 GHz)

Reference Chain Reference 10 MHz

Graph Tab:

User’s and Service Guide 17

Page 24

E8257D Option HAR Service

Table 15 100 MHz Phase Noise System Setup

Parameter

Title 100 MHz Agilent E8257D SNxxxxxxxx

Graph Type Single- sideband Phase Noise (dBc/Hz)

X Scale Minimum 1 Hz

X Scale Maximum 100E+6

Y Scale Maximum 0

Y Scale Minimum −170

Normalize Trace Data to 1 Hz Bandwidth

1.Delta settings are indicated with a bold font.

Setting

1

Making the 100 MHz Measurement

Step 1. In the Measure drop-down menu verify that the Pause at Connect Diagram is

checked. If not, select it.

Step 2. In the Measure drop-down menu select New Measurement.

Step 3. Select Yes in the Do you want to perform a new Calibration and Measurement?

dialog box. The Agilent E5500 Instrument Connections window will appear.

Step 4. Connect the 100 MHz +8 dBm Output on the 70427A rear panel to the Signal

Input on the 70420A. Refer to Figure 4 on page 13.

Step 5. Turn On the Divider Mode. Refer to “Operation” on page 8

.

Step 6. Select Continue and allow Phase Noise Measurement to complete.

Step 7. Compare the estimated mean value of the trace with the noise specification line

(lower line). If the estimated mean value of the trace falls on or below the

specification line, the LNSG is regarded as having met the noise specification.

Step 8. Print the E5500 Phase Noise Plot.

18 User’s and Service Guide

Page 25

E8257D Option HAR Appendix

Appendix

Modifying Synthesizer Self Test Limits

This procedure allows you to modify the synthesizer A6 Frac N self test limits for test 704,

after replacing the A6 Frac N assembly. (Firmware versions C.04.70 and later).

Open a browser window and type the IP address of the instrument, followed by ‘/update’ as

shown: http://xxx.xxx.xxx.xxx/update.

1. Enter the following text in the “Manual Update” form as shown below.

ll "SYNTH", 14, 0.5

ul "SYNTH", 14, 13.5

ll "SYNTH", 15, 0.5

ul "SYNTH", 15, 13.5

ll "SYNTH", 16, 1.5

ul "SYNTH", 16, 13.5

ky 53004

2. Press Execute (next to the manual update form). When the update is complete

“Operation Completed” will be displayed.

3. Cycle the power on the instrument.

If you need to revert to the standard self test limits, use the following sequence:

ll "SYNTH", 14, 1.5

ul "SYNTH", 14, 13.5

ll "SYNTH", 15, 3.0

ul "SYNTH", 15, 13.5

ll "SYNTH", 16, 2.0

ul "SYNTH", 16, 13.5

ky 51873

User’s and Service Guide 19

Page 26

E8257D Option HAR Safety and Regulatory Information

Safety and Regulatory Information

Introduction

Review this product and related documentation to familiarize yourself with safety

markings and instructions before you operate the instrument. The documentation contains

information and warnings that must be followed by the user to ensure safe operation and

to maintain the product in a safe condition.

Cleaning the Instrument

WAR NING

To prevent electrical shock, disconnect the Agilent Technologies

E8257D Option HAR from mains before cleaning. Use a dry cloth or

one slightly dampened with water to clean the external case parts.

Do not attempt to clean internally.

Connector Care and Cleaning

Cleaning connectors with alcohol shall only be done with the instrument power cord

removed, and in a well ventilated area. Allow all residue alcohol moisture to evaporate and

the fumes to dissipate prior to energizing the instrument.

WAR NING

Use isopropyl alcohol with adequate ventilation and avoid contact with eyes,

skin, and clothing. It causes skin irritation, may cause eye damage, and is

harmful if swallowed or inhaled. It may be harmful if absorbed through the skin.

Wash thoroughly after handling.

Keep isopropyl alcohol away from heat, sparks, and flame. Store in a

tightly closed container. It is extremely flammable. In case of fire, use

alcohol foam, dry chemical, or carbon dioxide; water may be

ineffective.

In case of spill, soak up the sand or earth. Flush spill area with water.

Dispose of isopropyl alcohol in accordance with all applicable

federal, state, and local environmental regulations.

Declaration of Conformity

For a copy of the manufacturer’s Declaration of Conformity for this apparatus, contact your

local Agilent Technologies office or sales representative. Refer to “Contacting Agilent Sales

and Service Offices” on page 26.

20 User’s and Service Guide

Page 27

E8257D Option HAR Safety and Regulatory Information

Statement of Compliance

This instrument has been designed and tested in accordance with IEC Publication 1010,

Safety Requirements for Electronic Measuring Apparatus, and has been supplied in a safe

condition. The instruction documentation contains information and warnings which must

be followed by the user to ensure safe operation and to maintain the instrument in a safe

condition.

Shipping Instructions

You must always call the Agilent Technologies Instrument Support Center to initiate

service before retuning your instrument to a service office. See “Contacting Agilent Sales

and Service Offices” on page 26. Always transport or ship the instrument using the

original packaging if possible. If not, comparable packaging must be used. Attach a

complete description of the failure symptoms.

Compliance with Canadian EMC Requirements

This ISM device complies with Canadian ICES-001.

Cet appareil ISM est conforme a la norme NMB du Canada.

Compliance with German FTZ Emissions Requirements

This product complies with the German FTZ 526/527 Radiated Emissions and Conducted

Emission requirements.

Compliance with German Noise Requirements

This is to declare that this instrument is in conformance with the German Regulation on

Noise Declaration for Machines (Laermangabe nach der Maschinenlaermrerordnung-3.

GSGV Deutschland).

Acoustic Noise Emission/Geraeuschemission

LpA<70 dB Lpa<70 dB

Operator Position am Arbeitsplatz

Normal Operation normaler Betrieb

per ISO 7779 nach DIN 45635 t. 19

User’s and Service Guide 21

Page 28

E8257D Option HAR Safety and Regulatory Information

General Safety Considerations

Safety Earth Ground

WAR NING

Before Applying Power

Verify that the product is configured to match the available main power source. If this

product is to be powered by autotransformer, make sure the common terminal is connected

to the neutral (grounded) side of the ac power supply.

Cautions applicable to this instrument.

CAUTION

CAUTION

This is a Safety Class I product (provided with a protective earthing

ground incorporated in the power cord). The mains plug shall only

be inserted in a socket outlet provided with a protective earth

contact. Any interruption of the protective conductor, inside or

outside of the instrument, will make the instrument dangerous.

Intentional interruption is prohibited.

Always use the three-prong ac power cord supplied with this instrument.

Failure to ensure adequate earth grounding (by not using this cord) can cause

instrument damage.

This product is designed for use in Installation Category II and Pollution

Degree 2 per IEC 61010 Second Edition and 664 respectively.

CAUTION

CAUTION

This instrument has autoranging line voltage input; be sure the supply

voltage is within the specified range.

Ventilation Requirements: When installing the instrument in a cabinet, the

convection into and out of the instrument must not be restricted. The ambient

temperature (outside the cabinet) must be less than the maximum operating

temperature of the instrument by 4 °C for every 100 watts dissipated in the

cabinet. If the total power dissipated in the cabinet is greater than 800 watts,

forced convection must be used.

22 User’s and Service Guide

Page 29

E8257D Option HAR Safety and Regulatory Information

Servicing

Warnings applicable to this instrument

WAR NING

To prevent electrical shock, disconnect the Agilent Technologies

E8257D Option HAR from the mains before cleaning. Use a dry cloth

or one slightly dampened with water to clean the external case parts.

Do not attempt to clean internally.

WAR NING

This is a Safety Class I product (provided with a protective earthing

ground incorporated in the power cord). The mains plug shall be

inserted only into a socket outlet provided with a protective earth

contact. Any interruption of the protective conductor, inside or

outside the product is likely to make the product dangerous.

Intentional interruption is prohibited.

WAR NING

WAR NING

These servicing instructions are for use by qualified personnel only.

The opening of covers or removal of parts is likely to expose

dangerous voltages. Disconnect the instrument from all voltage

sources while it is being opened.

WAR NING

This product is designed for use in Installation Category II and

Pollution Degree 2 per IEC 61010-1: 2001.

.

WAR NING

WAR NING

No operator serviceable parts inside. Refer servicing to qualified

personnel.

If this product is not used as specified, the protection provided by

the equipment could be impaired. This product must be used in a

normal condition (in which all means for protection are intact) only.

User’s and Service Guide 23

Page 30

E8257D Option HAR Electrostatic Discharge Protection

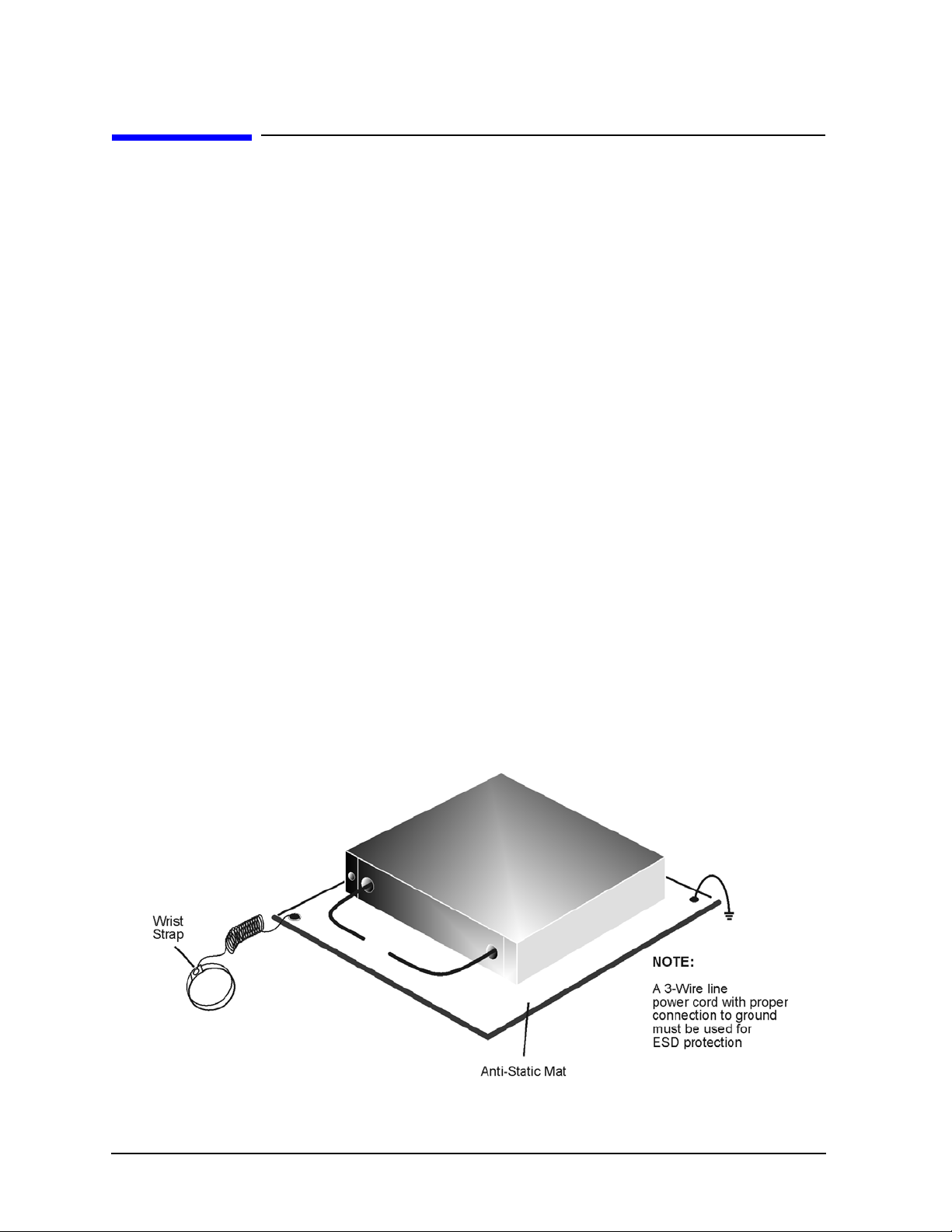

Electrostatic Discharge Protection

Protection against electrostatic discharge (ESD) is essential while removing assemblies

from or connecting cables to the network analyzer. Static electricity can build up on your

body and can easily damage sensitive internal circuit elements when discharged. Static

discharges too small to be felt can cause permanent damage. To prevent damage to the

instrument:

• always have a grounded, conductive table mat (9300-0797) in front of your test

equipment.

• always wear a grounded wrist strap (9300-1367) with grounding cord (9300-0980),

connected to a grounded conductive table mat, having a 1 MΩ resistor in series with it,

when handling components and assemblies or when making connections.

• always wear a heel strap (9300-1126) when working in an area with a conductive floor.

If you are uncertain about the conductivity of your floor, wear a heel strap.

• always ground yourself before you clean, inspect, or make a connection to a

static-sensitive device or test port. You can, for example, grasp the grounded outer shell

of the test port or cable connector briefly.

• always ground the center conductor of a test cable before making a connection to the

analyzer test port or other static-sensitive device. This can be done as follows:

1. Connect a short (from your calibration kit) to one end of the cable to short the center

conductor to the outer conductor.

2. While wearing a grounded wrist strap, grasp the outer shell of the cable connector.

3. Connect the other end of the cable to the test port and remove the short from the

cable.

Figure 5 ESD Protection Setup

24 User’s and Service Guide

Page 31

E8257D Option HAR Regulatory Information

Regulatory Information

Instrument Markings

The instruction documentation symbol. The product is marked with this symbol

when it is necessary for the user to refer to the instructions in the documentation.

This symbol indicates that the instrument requires alternating current (ac) input.

This symbol indicates separate collection for electrical and electronic equipment,

mandated under EU law as of August 13, 2005. All electric and electronic equipment

are required to be separated from normal waste for disposal (Reference WEEE

Directive, 2002/96/EC).

This symbol indicates that the power line switch is ON.

This symbol indicates that the power line switch is in the STANDBY position.

ICES/NMB-001

This symbol indicates that the power line switch is in the OFF position.

This symbol is used to identify a terminal which is internally connected to the

product frame or chassis.

The CE mark is a registered trademark of the European Community. (If accompanied

by a year, it is when the design was proven.)

The CSA mark is a registered trademark of the Canadian Standards Association.

This instrument complies with Canada: CSA 22.2 No. 000000061010-1, Second

Edition.

This is a symbol of an Industrial Scientific and Medical Group 1 Class A product.

This is a marking to indicate product compliance with the Canadian

Interference-Causing Equipment Standard (ICES-001).

Direct Current.

This is a required mark signifying compliance with an EMC requirement. The C-Tick

mark is a registered trademark of the Australian Spectrum Management Agency.

China RoHS regulations include requirements related to packaging, and require

compliance to China standard GB18455-2001.

This symbol indicates compliance with the China RoHS regulations for

paper/fiberboard packaging.

User’s and Service Guide 25

Page 32

E8257D Option HAR Contacting Agilent Sales and Service Offices

Contacting Agilent Sales and Service Offices

Assistance with test and measurement needs, and information on finding a local Agilent

office are available on the Internet at:

http://www.agilent.com/find/assist

You can also purchase accessories or documentation items on the Internet at:

http://www.agilent.com/find

If you do not have access to the Internet, contact your field engineer.

NOTE

In any correspondence or telephone conversation, refer to the product by its

model number and full serial number. With this information, the Agilent

representative can determine whether your unit is still within its warranty

period.

26 User’s and Service Guide

Loading...

Loading...