Page 1

Service Guide

Agilent Technologies

PSG Family Signal Generators

This guide applies to the signal generator models and associated serial number prefixes listed below.

Depending on your firmware revision, front panel operation may vary from descriptions in this guide.

E8241A: US4124

E8244A: US4124

E8251A: US4124

E8254A: US4124

Part Number: E8251-90030

Printed in USA

July 2001

© Copyright 2001 Agilent Technologies.

Page 2

ii

Page 3

Contents

1. Troubleshooting

Before Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

ESD Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Getting Started with Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

To Run Self-Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

ILT-1 Power Supply Failure and Self-Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

ILT-2 Temperature Related Power Supply Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

ILT-3 A18 CPU Turn-On Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

ILT4 Front Panel Display Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

Symptom: Dark Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

Symptom: Bright Display Without Characters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

Symptom: Hardkeys or Softkeys Not Functioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

Symptom: RPG Knob Not Functioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-14

Symptom: Screen Saver Not Functioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-14

Self-Test Failures and Related Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-15

Troubleshooting Assembly Level Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-17

Power Supplies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-17

Self-Tests 2xx: A5 Sampler Self-Test Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-24

Self-Tests 3xx: A7 Reference (Standard) Self-Test Errors. . . . . . . . . . . . . . . . . . . . . . . . . .1-26

Self-Tests 4xx: A8 Output Self-Test Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-27

Self-Tests 6xx: A9 YIG Driver Self-Test Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-29

Self-Tests 7xx: A6 Frac-N Self-Test Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-31

Self-Tests 9xx: A10 ALC Self-Test Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-34

Self-Tests 10xx: A7 Reference (Option UNJ) Self-Test Errors . . . . . . . . . . . . . . . . . . . . . .1-36

Self-Tests 11xx: A18 CPU Self-Test Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-38

Self-Tests 12xx: A26 MID Self-Test Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-40

Self-Tests 13xx: A11 Analog/Pulse Modulation Generator Self-Test Errors . . . . . . . . . . .1-43

Troubleshooting Unlocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-46

508 A6 Frac-N Loop Unlock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-46

513 1 GHz Out of Lock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-46

514 Reference Oven Cold. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-46

515 10 MHz Signal Bad. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-46

520 Sampler Unlocked. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-47

521 YO Loop Unlocked . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-47

625 Internal Pulse Generator Unlock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-47

626 Internal Mod Source Unlock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-48

iii

Page 4

Contents

Troubleshooting Unlevels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-49

Troubleshoot and correct any unlock problems before

troubleshooting unleveled problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-49

Troubleshooting Adjustment Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-53

Troubleshooting ADC Adjustment Failures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-55

Troubleshooting Performance Test Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-56

Troubleshooting the RF Path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-58

ALC and RF problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-58

Troubleshooting Pulse Modulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-59

Troubleshooting Problems <3.2 GHz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-59

Troubleshooting Problems >3.2 GHz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-60

Troubleshooting AT1 Attenuator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-61

Troubleshooting Harmonic Spurious . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-62

20 GHz Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-62

20 GHz Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-63

40 GHz Models Only. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-63

Troubleshooting Non-Harmonic Spurious . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-65

Troubleshooting Option UNJ Phase Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-66

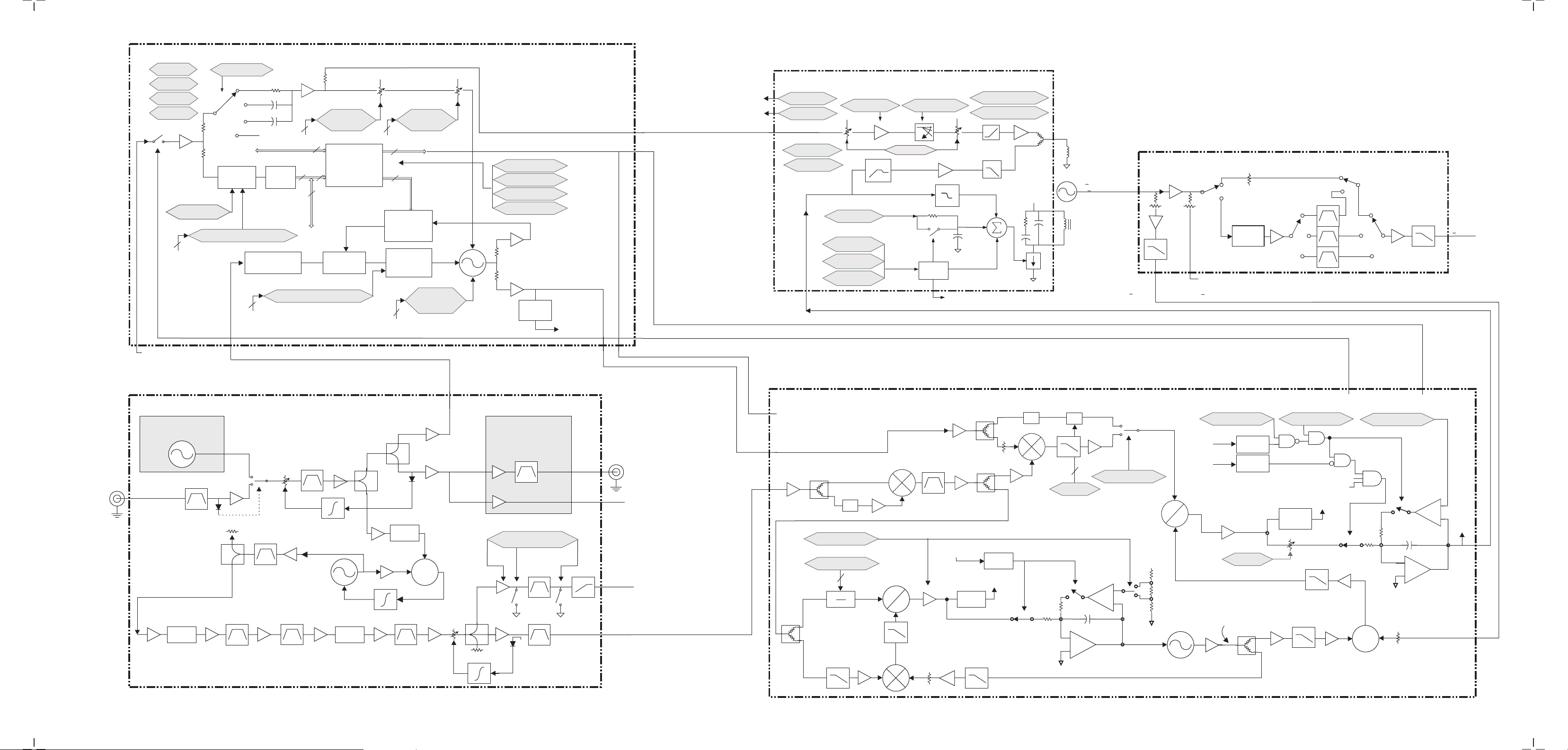

Overall Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-67

Overall Block Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-69

A19 Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-69

A18 CPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-69

Input/Output Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-69

Frequency Generation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-70

Reference/Synthesis Loop Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-73

Reference/Synthesis Loop Block Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-75

A7 Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-75

A5 Sampler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-75

A6 Frac-N . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-76

A9 YIG Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-76

A28 YIG Oscillator (YO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-76

A29 20 GHz Doubler. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-76

RF Path Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-77

RF Path Block Description

(Frequency Generation, Level Control, and Modulation) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-79

Frequency Generation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-79

iv

Page 5

Contents

A29 20 GHz Doubler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-79

A6 Frac-N. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-79

A8 Output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-79

A30 Modulation Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-80

A27 40 GHz Doubler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-80

A23 Low Band Coupler/Detector, A24 High Band Coupler,

and A25 High Band Detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-80

ALC Loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-80

A10 ALC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-80

Modulation (AM, FM, PM, and Pulse) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-81

Self-Test Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-82

Contacting Agilent Technologies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-84

Review the Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-84

Contacting Agilent Sales and Service Offices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-85

Important Information Needed by an Agilent Service Representative . . . . . . . . . . . . . . .1-85

Returning Your Signal Generator for Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-86

2. Assembly Replacement

Before You Replace an Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

After Replacing or Repairing an Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Assemblies That You Can Replace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Outer Instrument Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Inner Instrument Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

A1 Keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

v

Page 6

Contents

A2 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

A2DS1 Display Backlight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

A3 Power Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-16

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

A4 Inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-18

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

A5 Sampler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

A6 Frac-N. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

A7 Reference (Standard and Option UNJ). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

A8 Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

A9 YIG Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

A10 ALC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

vi

Page 7

Contents

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-30

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-30

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-30

A11 Pulse/Analog Modulation Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-32

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-32

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-32

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-32

A18 CPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-34

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-34

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-34

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-34

A18BT1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-36

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-36

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-36

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-36

A19 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-38

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-38

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-38

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-38

Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-40

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-40

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-40

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-40

A20 SMI (Source Module Interface) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-42

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-42

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-42

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-42

A21 Rear-Panel Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-44

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-44

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-44

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-44

A22 Line Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-46

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-46

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-46

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-46

AT1 115 dB Attenuator (Option 1E1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-48

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-48

vii

Page 8

Contents

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-48

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-48

A23 Low Band Coupler/Detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-50

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-50

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-50

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-50

A24 20 GHz High Band Coupler

(E8241A and E8251A Models Only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-52

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-52

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-52

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-52

A24 40 GHz High Band Coupler (E8244A and E8254A Models Only). . . . . . . . . . . . . . . . . . . 2-54

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-54

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-54

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-54

A25 20 GHz High Band Detector with A25B Detector Bias Board

(E8241A and E8251A Models Only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-56

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-56

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-56

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-56

A25 40 GHz High Band Detector with A25B Detector Bias Board

(E8244A and E8254A Models Only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-58

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-58

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-58

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-58

A26 MID (Microcircuit Interface Deck) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-60

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-60

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-60

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-60

A27 40 GHz Doubler (E8244A and E8254A Models Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-62

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-62

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-62

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-62

A28 YIG Oscillator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-64

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-64

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-64

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-64

viii

Page 9

Contents

A29 20 GHz Doubler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-66

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-66

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-66

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-66

A30 Modulation Filter (Standard and Option 1EA). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-68

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-68

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-68

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-68

A31 Motherboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-70

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-70

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-70

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-70

A32 10 MHz Crystal Oscillator (Option UNJ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-72

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-72

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-72

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-72

B1 Fan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-74

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-74

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-74

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-74

3. Replaceable Parts

Ordering Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Call (800) 227-8164 to Order Parts Fast (U.S. Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Save Money with Rebuilt-Exchange Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Shipping the Defective Assembly Back to Agilent Technologies . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Abbreviations Used in Part Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Major Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

Major Assemblies Top View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

Major Assemblies Bottom View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

Major Assemblies Microcircuit Deck View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

Inside Front Panel View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

Main Chassis Top View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

Main Chassis Bottom View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

Inside Rear Panel View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-16

Microcircuit Interface Deck Top View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

MID Bottom View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

ix

Page 10

Contents

Battery-Lithium . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-20

Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

Inside Front Panel View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

Main Chassis Top View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

Rear Panel View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

MID Top View (E8244A and E8254A Models Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

MID Top View (E8241A and E8251A Models Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-30

MID Bottom View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-32

Main Chassis Bottom View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-34

Hardware and Other Instrument Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-36

Front Panel View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-37

Disassembled Front Panel View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-38

Disassembled Rear Panel View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-40

Disassembled A32 10 MHz Crystal Oscillator (Option UNJ). . . . . . . . . . . . . . . . . . . . . . . 3-42

Disassembled AT1 115 dB Attenuator View (Option 1E1). . . . . . . . . . . . . . . . . . . . . . . . . 3-43

Disassembled A29 20 GHz Coupler/Detector (E8241A and E8251A Models Only) . . . . . 3-44

Disassembled A24 High Band Coupler and A25 High Band Detector

(E8244A and E8254A Models Only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-45

Microcircuit Interface Deck Top View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-46

Main Chassis and MID Bottom View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-48

2.4 mm RF Output Connector (E8244A and E8254A Models Only) . . . . . . . . . . . . . . . . . 3-50

APC 3.5 RF Output Connector (E8241A and E8251A Models Only). . . . . . . . . . . . . . . . . 3-51

Type-N RF Output Connector (E8241A and E8251A with Option 1ED Models Only). . . 3-52

Main Chassis with Inside Cover and Right-Side Support Wall . . . . . . . . . . . . . . . . . . . . . 3-53

Outer and Inner Instrument Covers and Associated Parts . . . . . . . . . . . . . . . . . . . . . . . . 3-54

Miscellaneous. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-55

Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-56

Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-56

Electrostatic Discharge (ESD) Protective Supplies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-56

4. Post-Repair Procedures

Post-Repair Procedures Matrix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

x

Page 11

Contents

5. Safety and Regulatory

Safety and Regulatory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

General Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

Lithium Battery Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

Assistance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

xi

Page 12

Contents

xii

Page 13

1 Troubleshooting

1-1

Page 14

Troubleshooting

Before Troubleshooting

Before Troubleshooting

WARNING These troubleshooting instructions are for use by qualified personal only. To avoid

electrical shock, do not perform any troubleshooting unless qualified.

WARNING The opening of covers or removal of parts is likely to expose dangerous voltages.

Disconnect the signal generator from all voltage sources before it is opened.

WARNING The following techniques related to ESD and static-safe workstations should not be

used when working on circuitry with a voltage potential greater than 500 volts.

ESD Information

Protection from Electrostatic Discharge

Electrostatic discharge(ESD) can damage or destroyelectronic components. Allwork on electronic assemblies

should be performed at a static-safe workstation using two types of static-safe workstation protection:

• conductive table-mat and wrist-strap combination

• conductive floor-mat and heel-strap combination

Both types, when used together, provide a significant level of ESD protection. Of the two, only the table-mat

and wrist-strap combination provides adequate ESD protection when used alone. To ensure user safety, the

static-safe accessories must provide at least 1 meg ohm of isolation from ground.

Handling of Electronic Components and ESD

CAUTION Many of the assemblies in this instrument are very susceptible to damage from electrostatic

discharge (ESD). Perform troubleshooting procedures only at a static-safe workstation and

wear a grounding strap.

CAUTION Always handle printed circuit board assemblies by the edges.This will reduce the possibility of

ESD damage to components and prevent contamination of exposed plating.

The possibility of unseen damage caused by ESD is present whenever components are transported, stored, or

used. The risk of ESD damage can be greatly reduced by close attention to how all components are handled.

• Perform work on all components at a static-safe workstation.

• Keep static-generating materials at least one meter away from all components.

• Store or transport components is static-shielding containers.

1-2

Page 15

Troubleshooting

Getting Started with Troubleshooting

Getting Started with Troubleshooting

Determine the starting point in Table1-1 to begin troubleshooting.

• Problems should be worked on in the order they are presented in this table.

• Overviews of Self-Test, Synthesis Loop, RF Path and Instrument are found in this chapter. The

information in these overviews may help the reader better understand how the signal generator operates

and the function of each assembly. Each overview is also intended to be used to troubleshoot the signal

generator.

Table 1-1

If able to run self-test... Go to this section...

Run Self-Test “To Run Self-Test” on page 1-3 and refer to

“Self-Test Failures and Related Troubleshooting” on page 1-15.

If unable to run self-test, check... Go to this section...

Power supply failures

Temperature-related power supply failures

A18 CPU turn-on failures

Front panel display or keyboard operations

If other conditions occur... Go to this section...

Unlocked Conditions

Unleveled Conditions

Adjustment Problems

Performance Test Problems

To Run Self-Test

1. Press the Utility key.

2. Press the Instrument Info/Help Mode softkey.

“ILT-1 Power Supply Failure and Self-Test” on page 1-4

“ILT-2 Temperature Related Power Supply Failure” on page 1-5

“ILT-3 A18 CPU Turn-On Test” on page 1-6

“ILT4 Front Panel Display Troubleshooting” on page 1-9

“Troubleshooting Unlocks” on page 1-46

“Troubleshooting Unlevels” on page 1-49

“Troubleshooting Adjustment Problems” on page 1-53

“Troubleshooting Performance Test Problems” on page 1-56

3. Press the Self Test softkey.

4. Press the Run Complete Self Test softkey.

1-3

Page 16

Troubleshooting

Getting Started with Troubleshooting

ILT-1 Power Supply Failure and Self-Test

When the signal generator appears to be dead (no display or fan) there is often little evidence that points

directly to the cause. This section provides steps and solutions to typical failure modes.

CAUTION Immediately unplug the signal generator from the ac power line if the unit shows any of the

following symptoms:

• Smoke, arcing, or unusual noise from inside the instrument.

• A circuit breaker or fuse on the main ac power line opens.

These potentially serious faults must be corrected before proceeding.

Perform These Power Supply LED Checks

Check the front panel LEDs (located next to the LINE switch) for normal operation in both standby and

power-on conditions. Normal operation is indicated as follows:

Power Switch Yellow LED Green LED

Standby On Off

Power-On Off On

If normal operation is not observed, go to the assembly-level troubleshooting section entitled Power Supplies

vs. Assemblies Matrix (Table 1-13 on page 1-18).

If the fan does not operate when the instrument is powered on

Go to the assembly level troubleshooting section and use the Power Supplies vs. Assembly Matrix

(Table 1-13 on page 1-18) to verify the fan voltage.

If the fan operates when the instrument is powered on

Go to “ILT-3 A18 CPU Turn-On Test” on page 1-6.

1-4

Page 17

Troubleshooting

Getting Started with Troubleshooting

ILT-2 Temperature Related Power Supply Failure

Thermal Shutdown

When a thermalshutdown condition occurs, thefront panel green LED andthe power supply LEDs willblink

until the condition is eliminated. Two thermistors in the signal generator monitor temperature. One is

located in the A19 Power Supply and the other is located on the A8 Output. If the thermistor temperature is

exceeded, a signal is sent to the A3 Power Switch that shuts down the signal generator. The A19 Power

Supply thermistor will shutdown when its temperature exceeds 105 degrees centigrade. The A8 Output

thermistor shuts down when its temperature reaches approximately 92 degrees centigrade.

To troubleshoot, do the following:

1. If the fan is working, allow the signal generator to cool down.

2. If the signal generator is still shutting down, remove A8 Output to eliminate one thermistor.

3. If the signal generator is still shutting down, replace the A19 Power Supply.

1-5

Page 18

Troubleshooting

Getting Started with Troubleshooting

ILT-3 A18 CPU Turn-On Test

A18 CPU Turn-On Test

At turn-on, the A18 CPU is designed to complete a series of operational checks. If all power supply voltages

are present and the A18 CPU is working correctly, the operational checks are completed. Errors are reported

if theA18 CPU has problems identifying other assembliesor communicating withthe backup memorylocated

on the A31 Motherboard.

Failure Symptoms

•display is not functioning

•CPU fails to complete the turn-on check and does not reach normal LCD operation

•display is not functioning after turn-on

•unable to control signal generator from front panel

•error message is displayed after turn-on

A2 Display Not Functioning or A2 Display Not Functioning After Turn-on

Refer to “ILT4 Front Panel Display Troubleshooting” on page 1-9.

A18 CPU Fails to Complete the Turn-On Check

1. Turn power off and remove outer and inner covers.

2. Turn on power and verify A18 CPU LED DS9 (+3.4Vdc) and DS10 (+5.2 Vdc) are on. If either of the LEDs

are off, check the voltages in Table1-2.

Table 1-2

Connector P222 Supply Voltage Acceptable Range

Pin 45-48, 95-98 +3.4 Vdc +3.4 0.07 Vdc

Pin 49, 50, 99, 100 +5.2 Vdc +5.2 0.1 Vdc

3. If the voltages are present on connector P222, turn power off and remove the A18 CPU.

4. Inspect the pins on the A31 Motherboard connector. If the pins look good replace the A18 CPU.

5. If either of the voltages are missing, refer to “Power Supplies” on page 1-17.

6. If DS9 and DS10 are on, proceed to “Checking the A18 CPU Voltages” on page 1-7.

1-6

Page 19

Troubleshooting

Getting Started with Troubleshooting

Checking the A18 CPU Voltages

1. With the external and internal covers removed and the signal generator on its side, turn power on and

check tosee if all the powersupply LEDs on the A31 Motherboard are on. Ifany of the power supplyLEDs

are not on, refer to “Power Supplies” on page 1-17 to troubleshoot.

2. If all the power supply LEDs on the motherboard are on, check the A18 CPU and A31 Motherboard

connector pins for the voltages listed in Table1-3.

Table 1-3

Connector Supply Voltage Acceptable Range

P223-2, 22 +5 VA +5.2 0.16 Vdc

P223-3 -15 V_In -15 0.45 Vdc

P223-4 +32 V_In +32 0.96 Vdc

P223-21 +15 V_Standby +14.85 0.6 Vdc

P223-23 +15 V_In +15 0.75 Vdc

P223-37 -7 Vdc -7.0 0.14 Vdc

P223-39 +10 Vdc +10.2 0.2 Vdc

P223-40 +8 Vdc +7.95 0.21 Vdc

3. If any main power supply voltage problems are detected, refer to “Power Supplies” on page 1-17.

4. If all power supply voltages are good, replace A18 CPU.

1-7

Page 20

Troubleshooting

Getting Started with Troubleshooting

Verifying the A18 CPU Turn-On Sequence

Verify the A18 CPU turn-on sequence byobserving DS1 toDS8 (located alongthe top) sequencepatterns. DS1

to DS8 should match the sequence shown in Table1-4. Before verifying the turn-on sequence, make sure all

switches in the upper left-hand corner of the A18 CPU are in the CLOSED (up) position. If the lights fail to

step through the sequence, replace A18 CPU.

Table 1-4 A18 CPU LED Sequence Table

Sequence DS1 DS2 DS3 DS4 DS5 DS6 DS7 DS8

1 XXXXXXXX

2 00X00000

3 XXX00000

4 0XXXXXXX

5 00000000

6 XXXXXXX0

700XX0X0X

After Preset 00000000

(X) indicates LED is ON, (0) indicates LED is OFF

No Instrument Control From the Front Panel

Refer to “ILT4 Front Panel Display Troubleshooting” on page 1-9.

Error Messages

If error messages are reported after the turn-on check is completed, refer to the Error Messages manual for

details.

1-8

Page 21

Troubleshooting

Getting Started with Troubleshooting

ILT4 Front Panel Display Troubleshooting

Overview

The Front Panel Display Assembly consists of the A1 Keyboard, A2 Display (640 x 320 pixels Liquid Crystal

Display), A3 Power Switch, and the A4 Inverterdc to ac). The A4 Inverter turns the A2 Display on and offvia

control lines received from the A18 CPU. The A4 Inverter also converts the 5.2 Vdc to approximately a 160

Vrms, 40 kHz signal to drive the A2 Display.

The A3 Power Switch contains the power on/off switch, standby LED, and power-on LED. The A3 Power

Switch also containsthe circuitry to pull the ON_OFF control line to a TTL low and disable the power supply.

Another function of the A3 Power Switch is to route the 8 data bits from the A18 CPU to the A2 Display.

A2 Display Contrast Controls

There are two contrast hardkeys below the A2 Display.The left up arrow key increasesthe contrast while the

right down arrow key decreases the contrast.

The A2 Display brightness can be adjusted from 50 (high brightness) to 1 (low brightness) using the RPG,

arrow keys, or the numeric keypad.

Softkey Location: Utility > Display > Brightness

A2 Display Tests

There are two screen tests for the A2 Display. The Black Pixel Screen Test will turn the display dark and the

White Pixel Screen Test will turn the display bright.

Softkey Location: Utility > Display > More (1 or 2)

To exit the test press any front panel key.

Symptom: Dark Display

Ensure that the signal generator is powered-on and the front panel green LED is lit. If the green LED is not

lit refer to the Power Supply Troubleshooting section in this manual. Press any frontpanel key to disable the

screen saver.

If the A2 Display is still not working, check P12 on the A31 Motherboard for the signals in table 1-8.

Table 1-5

Signal State

P12-1 -5.2 Vdc

P12-3 LIGHT_EN >3 Vdc

P12-4 VDISP Brightness=50, VDSP < 50 mVdc

Brightness=1, VDSP = 3 Vdc

If the 5.2 Vdc line is bad refer to the Power Supply Troubleshooting section in this manual. If either the

LIGHT_EN or VDISP are bad, check them at P221-16 and P221-55 respectively on the A31 Motherboard. If

either signal is bad at P221, then replace the A18 CPU.

If the above signals are good, check the A4 Inverter output. To check the A4 Inverter output, the front panel

has to be removed from the chassis frame and laid face down. With CN2-1 (A4W1) open there should be a

160 Vrms 40 kHz signal. If you don’t see this signal, replace the A4 Inverter. If the signal is present at the

A4 Inverter output, then replace the A2 Display.

1-9

Page 22

Troubleshooting

Getting Started with Troubleshooting

Symptom: Bright Display Without Characters

Ensure that the signal generator is powered-on and the front panel green LED is on. If the green LED is not

on refer to “Power Supplies” on page 1-17. If the green LED is lit and the display is still too bright, try

adjusting the contrast controls on the front panel. If adjusting the contrast controls has no effect, check the

connection of the ribbon cable at J9 of the A3 Power Switch.

If the A2 Display is still too bright, use an oscilloscope to checkP11 of the A31 Motherboard for the signalsin

Table1-6.

Table 1-6

Signal State

P11-4 VLCD approx. 21 Vdc

P11-6 LCD_ENABLE_H >3 Vdc

Figure 1-1

P11-9, 10, 12, 13, 15, 16, 18,

19, 21, 22, 24, 25, 27, 28, 30,

31, 33, 36, 37, 39, 40

Refer to Pulsing Activity in Figure

1-1.

1-10

Page 23

Troubleshooting

Getting Started with Troubleshooting

The pulse state signals listed in Table 1-6 on page 1-10 are control lines, clock, and data for the A2 Display. If

any of the above signals are bad, use Table1-7 to check them at P221 of A31 Motherboard. If the signals in

table 1-9 are good, then check the signals in Table1-8 at J9 of the A3 Power Switch. To access J9 the front

panel must be removed from the chassis frame and laid face down.

Table 1-7

Signal State

P221-14 VLCD approx. 21 Vdc

P221-53 LCD_ENABLE_H >3 Vdc

P221-1 to 13, 15, 41, 43, 45,

47, 49 to 52

Refer to Pulsing Activity in Figure

1-1 on page 10.

If any signals in Table1-7 are bad, replace the A18 CPU.

Table 1-8

Signal State

J9-7 VLCD approx. 21 Vdc

J9-4 LCD_ENABLE_H >3 Vdc

J9-5 5.2 Vdc

J9-1, 2, 3, 8 to 15 Refer to Pulsing Activity in Figure

1-1 on page 10.

If the signals in Table1-8 are good, then replace A2 Display. If the signals are not good, then replace

A3 Power Switch.

1-11

Page 24

Troubleshooting

Getting Started with Troubleshooting

Symptom: Hardkeys or Softkeys Not Functioning

Ensure that the signal generator is powered-on and the front panel green LED is on. If the green LED is not

on refer to “Power Supplies” on page 1-17 for troubleshooting. Ensure the signal generator is not being

controlled remotely by pressing the Local hardkey

The A1 Keyboard contains the switches for the hardkeys and softkeys. The keys are arranged in a matrix

with the control lines KEYCOLx and KEYROWx on the x and y axis. When a hardkey or softkey is pressed,

one cell of the matrixis activated. The normally TTL low KEYROWx of the active cell will pulse high and the

normally TTL high KEYCOLx of the active cell will pulse low. See Table1-9 for hardkey and softkey matrix

locations.

Table 1-9

KEYCOL0 KEYCOL1 KEYCOL2 KEYCOL3 KEYCOL4 KEYCOL5 KEYCOL6 KEYCOL7

KEYROW0 softkey 3 N/A Cont Up N/A N/A N/A N/A N/A

KEYROW1 softkey 2 Incr/Set Cont Down Ampl N/A AM Pulse Utility

KEYROW2 softkey 3 Up N/A Freq N/A FM/ϕΜ N/A N/A

KEYROW3 softkey 4 N/A N/A Right

Arrow

KEYROW4 softkey 6 N/A Local Hold Mod On/Off 4 5 6

KEYROW5 softkey 5 N/A Return Down

Arrow

KEYROW6 N/A N/A N/A Left Arrow RF On/Off 0 . +/-

KEYROW7 softkey 7 N/A Preset N/A N/A 1 2 3

Help Save Recall Trigger

N/A 7 8 9

1-12

Page 25

Troubleshooting

Getting Started with Troubleshooting

If a front panel hardkey or softkey is not functioning, use an oscilloscope to monitor the KEYCOLx and

KEYROWx pins at P13 on the A31 Motherboard. Use Table1-10 to identify the appropriate pin number. The

KEYROW pin should be a TTL low and the KEYCOL pin should be a TTL high. If either signal is incorrect,

use Table1-11 and checkthe signal at P221as it leavesthe A18 CPU. If thesignal is badat P221, then replace

the A18 CPU. If both signals are correct, then press the faulty hardkey or softkey while monitoring the

KEYCOL or KEYROW on the oscilloscope. The KEYCOL line should pulse low, while the KEYROW line

should pulse high. If either line is not functioning properly then replace the A1 Keyboard.

Table 1-10

KEYCOL0 P13-1

KEYCOL1 P13-3

KEYCOL2 P13-5

KEYCOL3 P13-7

KEYCOL4 P13-9

KEYCOL5 P13-11

KEYCOL6 P13-13

KEYCOL7 P13-15

KEYROW0 P13-17

KEYROW1 P13-19

KEYROW2 P13-21

KEYROW3 P13-23

KEYROW4 P13-25

KEYROW5 P13-26

KEYROW6 P13-24

KEYROW7 P13-22

Table 1-11

KEYCOL0 P13-1

KEYCOL1 P13-3

KEYCOL2 P13-5

KEYCOL3 P13-7

KEYCOL4 P13-9

KEYCOL5 P13-11

KEYCOL6 P13-13

KEYCOL7 P13-15

KEYROW0 P13-17

KEYROW1 P13-19

KEYROW2 P13-21

KEYROW3 P13-23

KEYROW4 P13-25

KEYROW5 P13-26

KEYROW6 P13-24

KEYROW7 P13-22

1-13

Page 26

Troubleshooting

Getting Started with Troubleshooting

Symptom: RPG Knob Not Functioning

Ensure that the signal generator is powered-on and the front panel green LED is on. If the green LED is not

on refer to “Power Supplies” on page 1-17 for troubleshooting. When the RPG is functioning properly DS1 on

the A18 CPU will blink when the RPG knob is rotated.

Check P13-12 for +5.2 Vdc. If the voltage is not present, refer to “Power Supplies” on page 1-17 for

troubleshooting. Press the Frequency hardkey on the front panel. Using an oscilloscope monitor P13-14 and

P13-10 while rotating the RPG knob. The display frequency value should change and both signals at P13

should pulse to a TTL high. If either signal does not pulse then replace the A1 Keyboard.

If the signals are pulsing at P13 then check the signal at P221 pins 57 and 17 of the A31 Motherboard. If the

signals are pulsing, replace the A18 CPU.

Symptom: Screen Saver Not Functioning

The screen saver delay may be set for any integer from 1 to 12 hours. The A18 CPU controls the screen saver

by pulling the LIGHT_EN line low. If the delay time has elapsed and the display hasn’t gone dark, check the

LIGHT_EN signal at P12-3. If the signal is a TTL low then replace the A4 Inverter. If the signal is a TTL

high, then check it at P221-16 of the A31 Motherboard. If the signal is high at P221, replace the A18 CPU.

1-14

Page 27

Troubleshooting

Self-Test Failures and Related Troubleshooting

Self-Test Failures and Related Troubleshooting

This section hasa two column table: one column has self-test errorsand a second column hasa list of sections

to go for assembly level troubleshooting procedures.

Table 1-12 Self-Test Failures and Related Troubleshooting

If a self-test for this

Go to this assembly troubleshooting section...

assembly fails...

A5 Sampler “Self-Tests 2xx: A5 Sampler Self-Test Errors” on page 1-24

200 Power Supply

201 Tuning + Bias Test

202 Coarse Loop Detector

203 YO Loop Detector

A7 Reference “Self-Tests 3xx: A7 Reference (Standard) Self-Test Errors” on page 1-26

300 1 GHz Detector

301 Tuning Voltage

A8 Output “Self-Tests 4xx: A8 Output Self-Test Errors” on page 1-27

400 Lowband Ground and PTAT Test

401 Prelevel Loop Test

402 Switching Filter Test

403 ALC Mod System Test

404 Mod System Test

405 Het Band Test

406 RF Path Test

A9 YIG Driver “Self-Tests 6xx: A9 YIG Driver Self-Test Errors” on page 1-29

600 Post Regulator

601 DACs

602 PLL Regulators

603 FM Driver

A6 Frac-N “Self-Tests 7xx: A6 Frac-N Self-Test Errors” on page 1-31

700 Ref Voltage

701 Loop Gain

702 Tuning Voltage

703 Output Voltage

704 Filter Test

705 F/2 Test

706 FM Path Test

1-15

Page 28

Troubleshooting

Self-Test Failures and Related Troubleshooting

Table 1-12 Self-Test Failures and Related Troubleshooting

If a self-test for this

Go to this assembly troubleshooting section...

assembly fails...

A10 ALC “Self-Tests 9xx: A10 ALC Self-Test Errors” on page 1-34

900 Power Supply

901 Detector Test

902 Detector Level to ALC Ref

903 Level Test

A7 Reference (Option UNJ) “Self-Tests 10xx: A7 Reference (Option UNJ) Self-Test Errors” on page 1-36

1000 Power Supply

1001 10 MHz Test

1002 1 GHz Test

A18 CPU “Self-Tests 11xx: A18 CPU Self-Test Errors” on page 1-38

1100 Power Supply

A26 Micro Interface Deck “Self-Tests 12xx: A26 MID Self-Test Errors” on page 1-40

1200 Mod Filter

1201 20 GHz Doubler

1202 40 GHz Doubler

1203 RF Path

A11 Pulse/Analog Modulation Generator “Self-Tests 13xx: A11 Analog/Pulse Modulation Generator Self-Test Errors” on page

1-43

1300 Power Supply

1301 Internal Pulse Generator Clock

1302 Output

1303 Voltage Ref DAC

1304 20 GHz Pulse

1305 40 GHz Pulse

1306 Standard 3 GHz Pulse

1307 High Performance 3 GHz Pulse

1308 Numeric Synthesizer

1309 Function Generator Channel 1

1310 Function Generator Channel 2

1311 Frequency Modulator

1312 Low Frequency Out

1313 Amplitude Modulation

1314 External 1

1315 External 2

1-16

Page 29

Troubleshooting

Troubleshooting Assembly Level Problems

Troubleshooting Assembly Level Problems

Power Supplies

The power supplyis a switching supply that has an automatic line-voltageand frequency selection. There are

no switches to change for 115 Vac or 240 Vac operation. The power line fuse is not replaceable. If the fuse

opens, the power supply must be replaced. Use the Power Supplies vs. Assembly Matrix

(Table 1-13 on page 1-18) to troubleshoot the signal generator’s power supplies.

WARNING Wait 30 seconds after unplugging the instrument to allow the supplies to discharge

before removing or installing any assemblies.

1-17

Page 30

Troubleshooting

Troubleshooting Assembly Level Problems

Table 1-13 Power Supplies vs. Assembly Matrix (1 of 3)

Motherboard

+32 Vdc +15 Vdc +10 Vdc +8 Vdc

+9 Vdc +5.2 Vdc

test points for:

A1 Keyboard P13-2

A2 Display P11-44

A2DS1 Backlight

A3 Power Supply P231-1,4 P231-3,4,43,44

A5 Sampler P22-7 P22-6,21 P22-20,5 P22-14,29

A6 Frac-N P32-7 P32-6,21 P32-20,5 P32-14,29

A7 Reference P42-7 P42-6,21 P42-20,5 P42-14,29

A8 Output P52-7 P52-6,21 P52-20,5 P52-14,29

A9 YIG Driver P112-6 P112-5,30

A10 ALC P122-4 P122-28

A11 Mod Gen P132-4 P132-28

A18 CPU P223-4 P223-23 P223-39 P223-40 P223-9 P223-9

A21 Rear Panel P241-17,18 P241-17,18 P241-11,12

Microwave Interface P201-1 P201-2,3,4 P201-5,6,7,8,9,10 P201-29 P201-13,14,15,16,17,

P231-6,7,46,47

P112-15,16,40

P112-17,18,42 P112-17,18,42

P231-15,18,19,55,56,

58,59

18

Microcircuit

test points for:

AT1 J13-1

A23 Low Band

Coupler/Detector

A27 40 GHz Doubler J36-5, J33-5

A29 20 GHz Doubler J32-5 J32-19 J32-21 J32-7,9

A30 Mod Filter J31-5 J31-19 J31-21 J31-7,9

J15-8 J115-12

J36-19 J33-19

J36-21

J33-21

J36-7,9

1-18

Page 31

Table 1-14 Power Supplies vs. Assembly Matrix (2 of 3)

Troubleshooting

Troubleshooting Assembly Level Problems

Motherboard

+5.2 Digital +3.4 Digital +2.6 Vdc -7 Vdc

-6 Vdc

test points for:

A1 Keyboard

A2 Display P12-1

A2DS1 Backlight P12-1

A3 Power Supply P231-21,22,2561,62,

65,

A5 Sampler PP22-3,18

A6 Frac-N P32-3,18

A7 Reference P42-3,18

A8 Output P52-3,18

A9 YIG Driver P111-64,65,129,130 P111-60,61,62,63,

A10 ALC P122-64,65,129,130 P122,60,61,62,63,

A11 Mod Gen P132-64,65,129,130 P132-60,61,62,63,

A18 CPU P222-49,50,99,100 P222-45,46,47,48,

P231-28,29,32,35,

36,68,69,72,75,76

125,126,127,128

125,126,127,128

125,126,127,128

95,96,97,98

P112-57,58,59,123,

124

P122-57,58,59,123,

124

P132-57,58,59,123,

124

P231-9,10,49,50

P112-11,12,13,14,38 P112-19,44

P223-37 P223-3

A21 Rear Panel

Microwave Interface P201-23 P201-24 P201-30,33,46

Microcircuit

test points for:

AT1 J13-2

A23 Low Band

Coupler/Detector

A27 40 GHz Doubler

A29 20 GHz Doubler

A30 Mod Filter

1-19

Page 32

Troubleshooting

Troubleshooting Assembly Level Problems

Table 1-15 Power Supplies vs. Assembly Matrix (3 of 3)

Motherboard

-15 Vdc

-5.2 Vdc +12 Vdc +15 Vdc stby Fan Voltage

test points for:

A1 Keyboard

A2 Display P11-43

A2DS1 Backlight

A3 Power Supply P231-12,13,52,53

A5 Sampler P22-2 P22-4-19

A6 Frac-N P32-2 P32-4,19

A7 Reference P42-2 P42-4,19

A8 Output P52-2 P52-4,19

A9 YIG Driver P112-4,29 P112-1,2,26,27

A10 ALC P122-3 P122-1-26

A11 Mod Gen P132-3 P132-1,26

A18 CPU P223-3 P223-1 P223-21

A21 Rear Panel P241-15,16 P241-9,10 P241-5,6,7,8

Microwave Interface P201-11,12 P201-31,32

P231-80

Microcircuit

test points for:

AT1

A23 Low Band

Coupler/Detector

A27 40 GHz Doubler J36-4, J33-4

A29 20 GHz Doubler J32-4 J32-8 J32-1,3

A30 Mod Filter J31-4 J31-8 J31-1,3

Fan P6-2

J15-10

1-20

Page 33

Troubleshooting

Troubleshooting Assembly Level Problems

Amber Standby LED not working

With the power turned off, and the signal generator plugged in, the front panel amber standby LED and the

+15 Vdc standby LED on the motherboard should be on. The amber Standby LED is controlled by a +15 Vdc

standby line supplied by the power supply, which is routed through the motherboard to the front panel.

To troubleshoot the +15 Vdc Standby line, turn the signal generator off and refer to the Power Supply vs.

Assembly Matrix (Table 1-13 on page 1-18) to follow the signal path.

Green Line Power LED not working

When the powerswitch is turned on, the amber LED will go out and the green LED will come on. The fanwill

start rotating and the front panel display will become illuminated.

Totroubleshoot, refer tothe PowerSupplies vs. Assembly Matrix (Table 1-13 on page 1-18) to verify thepower

supply voltages at P11 of the A31 Motherboard. If the supply voltages are correct, replace the A3 Power

Switch.

Fan not working

The fan is connected to the rear panel assembly and is audible when the signal generator is powered on. The

fan voltage is temperature dependent. At room temperature, the fan will race at power up and then stabilize

after a few seconds to a fan voltage of approximately +8.6 volts. At higher temperatures, the fan voltage will

increase along with the rotation of the fan.

To troubleshoot, disconnect the fan from the rear panel assembly at P6 and check the fan voltage at P6-2 on

the rear panel assembly. If the fan voltage is correct, replace the B1 Fan.

Signal Generator does not power-up and the power supply LEDs not working

Each of the power supplies has an LED located on the bottom of the A31 Motherboard. If the power supply is

functioning, the green LED will be on. Use a voltmeter to measure the supplies on the A31 Motherboard to

ensure the voltages meet the power supply specification in Table1-16.

Table 1-16

Power Supply Acceptable Voltage

+32 Vdc 32 1 Vdc

+15 Vdc 15 .5 Vdc

+15 Vdc Standby 15 .75 Vdc

+10 Vdc 10.2 .2 Vdc

+5.2 Vdc 5.2 0.15 Vdc

+5.2 Digital high 5.2 0.15 Vdc

+3.4 Digital low 3.4 1 Vdc

-7.0 Vdc -7 0.1 Vdc

-15 Vdc -15 0.5 Vdc

With the exception of the +15 Vdc Standby supply, each supply should have a maximum of 10 mV

The +15 Vdc Standby supply has a maximum ripple specification of 20 mV

. The ripple may be measured

p-p

ripple.

p-p

using an oscilloscope.

If any of the supplies LEDs are not on or the measured voltage is less than the acceptable value, one the

1-21

Page 34

Troubleshooting

Troubleshooting Assembly Level Problems

assemblies may be loading down the supply. Refer to the Power Supply vs. Assembly Matrix

(Table 1-13on page 1-18) tofind out where each supply is being used. To isolate the defectiveassembly, power

down the signal generator and remove one of the assemblies being biased by the faulty supply.

NOTE It is important to have only a minimum number of assemblies removed at one time.

The power supply expects to see a minimum load, otherwise the supply voltage will

increase until an overvoltage condition exists.

Turn the signal generator ON and check the faulty supply. If it is still bad, power down the signal generator

and re-install the first assembly removed. Remove the next assembly and see if the problem is alleviated.

Continue this process until the supply is functioning properly. Replace the last assembly that was removed.

Power Switch On/OFF Line

If the control line (ON/OFF) from the A3 Power Switch located in the front panel goes to a TTL low state or if

the line impedance is less than 500 ohms, the power supply will shutdown. This signal can be measured on

the A31 Motherboard at pin 79 of P241.

Totroubleshoot, turn thefront panel switchon. Make sure the +15 Vdc Standbyvoltage is good.The ON_OFF

control line should be >3.5 Vdc. The A3 Power Switch located in the front panel controls this signal.

Front Panel Green LED Not Working and Power Supply LEDs on Motherboard Not Blinking

Overvoltage or Overcurrent Conditions

The individual suppliesin the signal generatorare not fused but do have the capability of shutting down if an

overvolatge condition exists. When either of these conditions exist, the front panel green LED and the power

supply LEDs blink at approximately a 2 Hz rate. The power supply is attempting to revive itself but if the

overvoltage or overcurrent condition hasn’t cleared, the signal generator will remain in this mode. In some

cases, the condition may be cleared by cycling the power off and on.

To troubleshoot, isolate the defective assembly by powering down the signal generator and removing one of

the assemblies being biased by the faulty supply.

NOTE It is important to have only a minimum number of assemblies removed at one time.

The power supply expects to see a minimum load, otherwise the supply voltage will

increase until an overvoltage condition exists.

Turn the signal generator ON and check whether the overvoltage or overcurrent condition still exists. If it is

still bad, power down the signal generator and re-install the first assembly removed. Remove the next

assembly and see whether the problem is alleviated. Continue this process until the supply is functioning

properly. Replace the last assembly that was removed.

1-22

Page 35

Troubleshooting

Troubleshooting Assembly Level Problems

LEDs for +9, -6 or -5.2 Vdc Power Supplies Not Working

These supplies are generated on the A9 YIG Driver.

To troubleshoot, make sure the A9 YIG Driver is receiving the +32, +15, +10, -7, -15 Vdc supplies. These can

be measured at P112 on the A31 Motherboard. Refer to the Power Supplies vs. Assembly Matrix

(Table 1-13 on page 1-18) for pin numbers.

If the supplies are present at P112, use the Power Supplies vs. Assembly Matrix (Table 1-13 on page 1-18) to

find out where each supply is being used. To isolate the defective assembly, power down the signal generator

and remove one of the assemblies being biased by the faulty supply. Power the signal generator up again and

check the faulty supply. If the supply is still bad, power down the signal generator and re-install the first

assembly removed.Remove the nextassembly and seeif the problemis alleviated. Continuethis process until

the supply is functioning properly. Replace the last assembly that was removed.

1-23

Page 36

Troubleshooting

Troubleshooting Assembly Level Problems

Self-Tests 2xx: A5 Sampler Self-Test Errors

Figure 1-2

Before proceeding to the reported self-test error code, check the voltages in Table1-17. If any

voltages are out of specification troubleshoot the supply problem first.

Table 1-17

Supply

Voltage

(Vdc)

+32 P22-7 +31.04 +32.96 Main Supply

+15 P22-6, 21 +14.55 +15.45 Main Supply

-15 P22-2, 17 -14.55 -15.45 Main Supply

+5.2 P22-14, 29 +5.04 +5.37 Main Supply

+9 P22-5, 20 +8.82 +9.18 YIG Driver

200 Power Supply

1. If the supply voltages are good on the connector pins indicated, replace the A5 Sampler.

2. If the supply voltages are bad on any of the connector pins indicated, check the origin of the supply.

3. If the supply voltages are good at the origin, replace the A31 Motherboard.

4. If the supply voltages are bad at the origin, troubleshoot the problem using that assembly’s

Connector

Pins

Minimum

Value

(Vdc)

Maximum

Value

(Vdc)

Origin

1-24

Page 37

Troubleshooting

Troubleshooting Assembly Level Problems

troubleshooting procedure.

201 Tuning + Bias Test

1. Turn power off and remove the A5 Sampler and connect a signal analyzer to the A5 Sampler J1 input

cable on the A31 Motherboard.

2. Turn the signal generator on and check for the presence of a 1 GHz signal at the level of 0 dBm.

3. If the signal is good on the cable connector J1, replace the A5 Sampler.

4. If the signal is bad, remove the A7 Reference and ohm the cable between the center pins (a short should

occur) and between the center pins and shielding (an open should occur) of J3 on the A7 Reference and J1

on the A5 Sampler.

5. If an open is measured between the center pins or a short between center pins and the shielding, replace

the cable.

6. If the cable is good, replace the A7 Reference.

202 Coarse Loop Detector

1. Replace the A5 Sampler

203 YO Loop Detector

1. With power on carefully remove the A5 Sampler, connect a signal analyzer to J3 on the A31 Motherboard.

Set the signal generator to 8 GHz CW then check for an 8 GHz signal at a power level greater than or

equal to -7 dBm on J3.

2. If the J3 signal is bad, troubleshoot the A29 20 GHz Doubler using the procedure in the RF path section. If

the J3 signal is good, go to the next step.

3. Connect the signal analyzer to the A6 Frac-N VCO signal on the J6 connection on the A31 Motherboard.

With the signal generator set to 8 GHz CW, the A6 Frac-N signal should be at a frequency of 593.75 MHz

and at a power level of +7 dBm.

4. If the signal is good, replace the A5 Sampler, if the signal is bad go to the A6 Frac-N troubleshooting

procedure.

1-25

Page 38

Troubleshooting

Troubleshooting Assembly Level Problems

Self-Tests 3xx: A7 Reference (Standard) Self-Test Errors

Figure 1-3

Before proceeding to the reported self-test error code, check the voltages in Table1-18. If any of

the voltages are out of specification troubleshoot the supply problem first.

Table 1-18

Supply

Voltage

(Vdc)

+32 P102-7 +31.04 +32.96 Main Supply

+15 P102-6, 21 +14.55 +15.45 Main Supply

-15 P102-2, 17 -14.55 -15.45 Main Supply

+5.2 P102-14, 29 +5.04 +5.37 Main Supply

+9 P102-5, 20 +8.82 +9.18 YIG Driver

300 1 GHz Detector

1. Check and remove any connection to the 10 MHz external reference on the rear panel.

2. If the signal generator continues to fail self-test, replace the A7 Reference.

301 Tuning Voltage

1. Replace the A7 Reference.

Connector

Pins

Minimum

Value

(Vdc)

Maximum

Value

(Vdc)

Origin

1-26

Page 39

Self-Tests 4xx: A8 Output Self-Test Errors

Figure 1-4

Troubleshooting

Troubleshooting Assembly Level Problems

Before proceeding to the reported self-test error code, check the voltages in Table1-19. If any

voltages are out of specification troubleshoot the supply problem first.

Table 1-19

Supply

Voltage

(Vdc)

+15 P52-6, 21 +14.55 +15.45 Main Supply

-15 P52-2, 17 -14.55 -15.45 Main Supply

+5.2 P52-14, 29 +5.04 +5.36 Main Supply

+9 P52-5, 20 +8.82 +9.18 YIG Driver

-6 P52-3, 18 -5.88 -6.12 YIG Driver

400 Ground and PTAT Test

1. Replace A8 Output.

401 Prelevel Loop Test

1. With the signal generator powered up carefully remove the A8 Output. Set the signal generator to 3 GHz

CW. Connect a spectrum analyzer to the A6 Frac-N RF output at J4 of the A8 Output. The signal at J4

Connector

Pins

Minimum

Value

(Vdc)

Maximum

Value

(Vdc)

Origin

1-27

Page 40

Troubleshooting

Troubleshooting Assembly Level Problems

should be at 3 GHz and ≥0 dBm.

2. If the signal is not present or at the correct level, replace the Frac-N.

3. If the signal is present, replace the A8 Output.

WARNING Don’t re-install the A8 Output with the signal generator powered up. This could

cause serious damage to the signal generator.