Page 1

Installation and Service Guide

Agilent Serial Distribution Network (SDN)

78581B Agilent CareNet Controller (ACC)

Part Number 78581-92000

Printed in the U.S.A. February 1, 2001

First Edition

Page 2

Notice

Proprietary

Information

Warranty

This document contains proprietary information that is protected by

copyright. All Rights Reserved. Reproduction, adaptation, or translation

without prior written permission is prohibited, except as allowed under the

copyright laws.

Agilent Technologies, Inc.

3000 Minuteman Road

Andover, MA 01810-1099

(978) 687-1501

Publication number

78581-92000

Printed in USA

The information contained in this document is subject to change without

notice.

Agilent Technologies makes no warranty of any kind with regard to this

material, including, but not limited to, the implied warranties or

merchantability and fitness for a particular purpose.

Agilent Technologies shall not be liable for errors contained herein or for

incidental or consequential damages in connection with the furnishing,

performance, or use of this material.

Printing History

Copyright and

Trademarks

New editions of this document will incorporate all material updated since

the previous edition.

The documentation printing date and part number indicate its current

edition. The printing date changes when a new edition is printed (minor

corrections and updates that are incorporated at reprint do not cause the

date to change). The document part number changes when extensive

technical changes are incorporated.

First Edition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . February 2001

Copyright © Agilent Technologies, Inc. 2001

Page 3

Contents

1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

SDN System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

SDN Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

SDN Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Operating Reliability — Failure/Restart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

SDN Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Agilent CareNet Controller (ACC), Model 78581B . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

ACC Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

ACC Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Cables, Wall Boxes, and Faceplates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Branch Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Local Distribution Cables (LDC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Wall Boxes and Face Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

SDN Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

78599AI SDN Cabling Installation Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

M3199AI Installation Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

M3180A Wall Mount Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Intended Use of Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

2. Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

SDN Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

SDN General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Logic Convention. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

SDN Topology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Applications of SDN Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Instrument Communication on the SDN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

SDN Timing Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Autopoll Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

SDN Data Structure — System and Instrument Messages . . . . . . . . . . . . . . . . . . . . . 2-9

System Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Instrument Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

SDN Normal Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

SDN Data Timing Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Instrument Status Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

SDN/Autopoll . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

ONLINE/OFFLINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

NETWORK/LOCAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

SDN Status and Error Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

ACC Error Conditions — SDN Failure Detection . . . . . . . . . . . . . . . . . . . . . . . . 2-13

ACC Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Main PCB (78581-60200) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Transition Board (78581-61253) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Power Supply (M2604-60002) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Contents-1

Page 4

3. SDN and ACC System Level Troubleshooting . . . . . . . . . . . . . . . . . 3-1

SDN Troubleshooting Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Troubleshooting Resources, Tools, and Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

SDN Troubleshooting Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

STEP #1: Review Customer’s System Configuration . . . . . . . . . . . . . . . . . . . . . . 3-5

STEP #2: Examine System and Gather Symptoms . . . . . . . . . . . . . . . . . . . . . . . 3-5

SDN Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

SDN Error Messages and Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Diagnose the Problem as SDN or Non-SDN . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

Noisy Branch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

SDN and Non-SDN Related Problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Action. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

STEP #3: Evaluate the Breadth of the Problem . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Action. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

STEP #4: Self-Test Check of SDN Interface Circuitry . . . . . . . . . . . . . . . . . . . . . 3-8

STEP #5: Isolating a Problem on A Local Distribution Network (LDN)

With Two or More Instruments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Miscellaneous Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

Recap of Troubleshooting Procedures: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

Reverification Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Cable Verification Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Hardware Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Verify Instrument End of the Branch Cable . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Verify Proper Operation of Priority Wires . . . . . . . . . . . . . . . . . . . . . . . . . .3-15

SDN Bedside:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Ground Check Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

4. ACC Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

ACC Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

ACC Failure, Power Up, and Power Down Procedures. . . . . . . . . . . . . . . . . . . . 4-1

5. Parts List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Part Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

6. Component Installation and Disassembly Procedures . . . . . . . . . . 6-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Typical SDN System Interconnecting Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Installation Responsibilities—Customer and Agilent Technologies . . . . . . . . . . . . . 6-3

Customer Installation Responsibilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Agilent Installation Responsibilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

7. Site Preparation/Installation Checklists . . . . . . . . . . . . . . . . . . . . . 7-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

Verification Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Overview of SDN/ACC Installation and System

Communication Verification Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Planning and Configuration Review . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-8

Standalone Instrument Verification and Installation . . . . . . . . . . . . . . . . . . . . . 7-8

Contents-2

Page 5

8. Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

SDN Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

SDN Wiring Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Instrument Connection to the SDN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

System Communication Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Practical Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Test and Inspection Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

When to Perform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Installation Tools, Materials, and Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

SDN Installation Restrictions and Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

ACC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Wall Boxes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

ACC Mounting Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Rack Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Service Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

AC Power Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

Important Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

ACC Wall Mounting Procedures and Power Installation . . . . . . . . . . . . . . . . . . . . . 8-8

Plywood Panel Mounting Procedures — Customer’s Responsibility . . . . . . . . . 8-8

ACC Wall Mounting Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8

Install Cable Enclosures, Wall Boxes, and Branch Cables . . . . . . . . . . . . . . . . . . . . 8-9

Install Branch Cable Enclosures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

Selecting Conduit Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

Formula . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

Install Standard NEMA Switch Wall Boxes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

Install Branch Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

SDC Standard System Distribution Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

XSDC Extended System Distribution Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

Unshielded Twisted Pair Distribution Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

SDC and XSDC Wall Box Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

SDN on UTP Wall Boxes Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-15

UTP Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-15

Parts Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

Equipment Needed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

ACC Procedures (78581B). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

Perform Final Operational Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

Serial Communication Controller (SCC) Procedures (78581A) . . . . . . . . . . . 8-19

Terminate UTP Cable at Patch Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-19

Terminate UTP Cable at Wall Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-20

Qualify UTP Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-21

Install Local Distribution Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-23

Connect LDC from Wall Box to Instrument(s) . . . . . . . . . . . . . . . . . . . . . . . . . 8-24

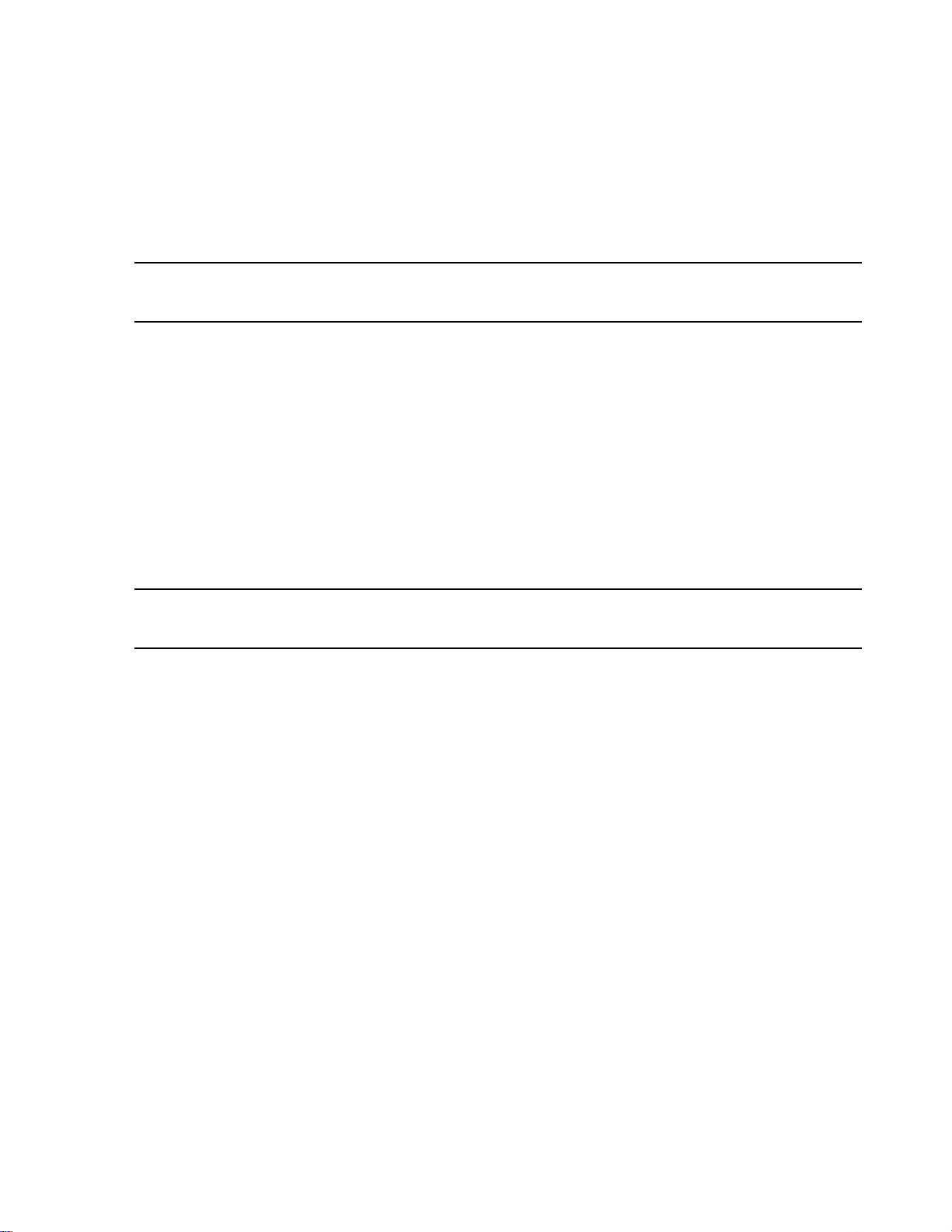

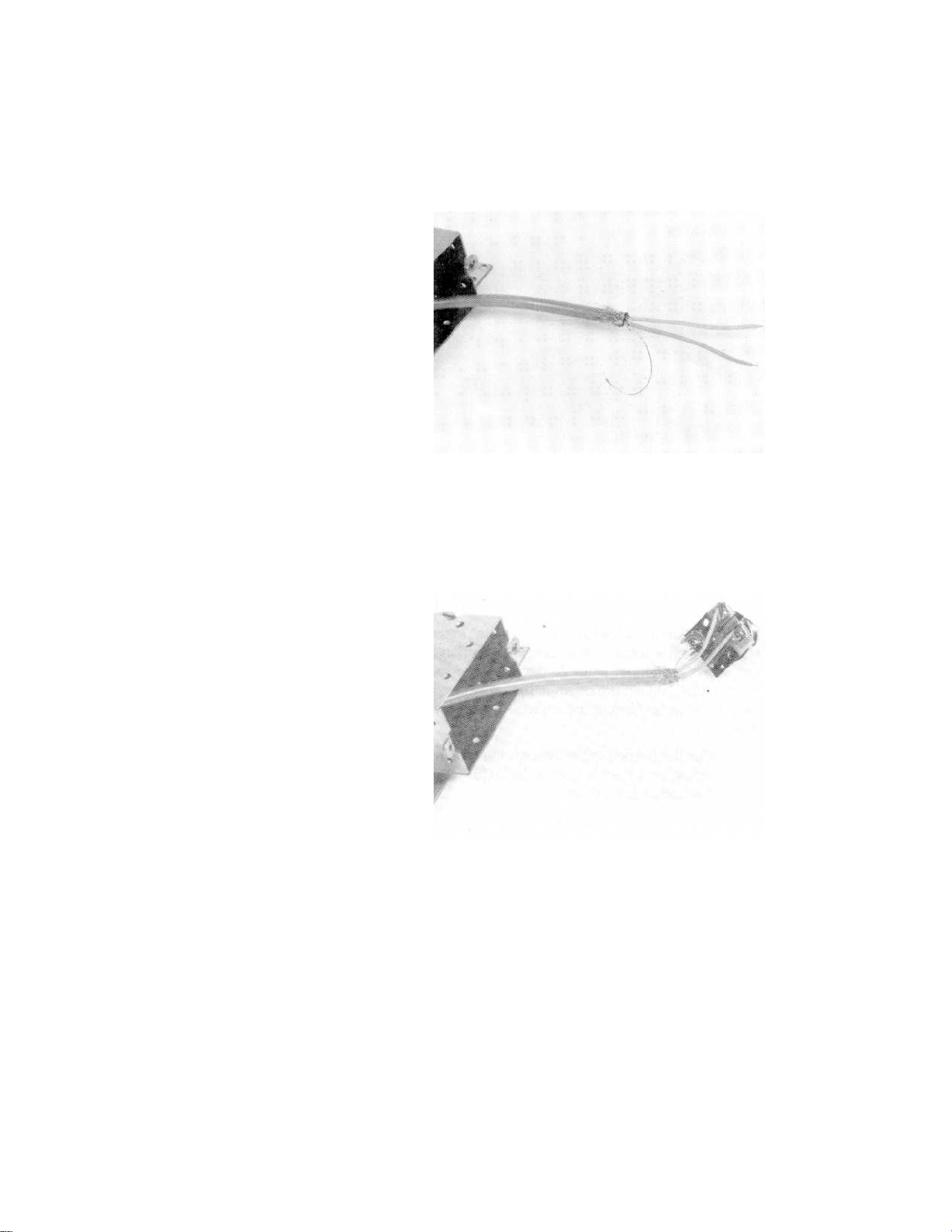

Terminate Variable Length LDC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-25

Terminate SDC and XSDC Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-26

Contents-3

Page 6

9. SDN/ACC System Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Compliance with IEC 60601-1-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Device Grounding on the SDN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-2

10. SDN/ACC Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

SDN Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-1

ACC Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-3

Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-4

System Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-4

Contacts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-5

Contents-4

Page 7

SDN System Description

The Serial Distribution Network (SDN) is a local area communications

network designed to share patient physiological parameters and other

data among bedside instruments, information centers (IC), recorders,

thermal printers, computer systems, and other information systems

connected to the system. The SDN is a digital communications network

that allows real-time transfer of digitized patient data between these

instruments. The communication protocol, data formatting, and hardware

implementation is intended to be flexible enough to accommodate a

variety of communication needs in the patient monitoring environment for

present and future expansion.

Introduction

Section 1: Introduction

SDN

Components

SDN Operation

The components of the SDN consist of the model 78581B Agilent CareNet

Controller (ACC), the SDN interface circuitry located within each

instrument connected to the SDN, and the system distribution cables

(branch cables), local distribution cables, and the associated wallbox

hardware, connectors and receptacles. The components of the SDN are

shown on page 1-2, and a typical SDN configuration is illustrated in Figure

1-2 on page 1-3.

The SDN functions automatically without user interaction and without

direct patient connections. Digitized patient information from each

instrument (branch) is transmitted serially at regular intervals (called poll

cycles) over branch cables to the ACC. The ACC sequentially receives,

synchronizes, and rebroadcasts the digitized patient information to all

instruments connected to the SDN. This patient data is received for use by

each instrument via the SDN interface circuity resident in each

instrument. Patient data are not restricted or allocated by the network,

but are accepted from, and transmitted to, all instruments within the

system. Each instrument decides for itself which patient information it

wants to acquire and process. Each instrument gets a chance to transmit

and receive patient information every poll cycle. A poll cycle lasts 32 ms,

thus, there are approximately 32 poll cycles per second.

Digitized patient information transmitted over the SDN may be either

waveforms (for ECG, pressure, and respiration) or parametric information

(for heart rate/pulse, pressure valves, and respiration rate). The SDN data

transmission rate of 3.6 Mbits can provide up to 7700 usable 12-bit data

1-1

Page 8

SDN System Description

words per 32-millisecond poll cycle. The SDN is a half-duplex network

using terminated shielded twisted pair cable(s). All data is transmitted

differentially and serially using block code modulation. A detailed

description of the SDN system theory of operation is given in a subsequent

section of this manual.

Within the connected instruments, SDN interface circuitry provides the

link between the serial digital network, and the instrument connected to

the SDN (except the ACC) has basically the same interface circuitry, most

of which is contained on a custom integrated circuit called the SDN

Interface Circuit Chip (SIC Chip). A detailed description of the SIC Chip

theory of operation is given in a subsequent section of this manual.

1-2

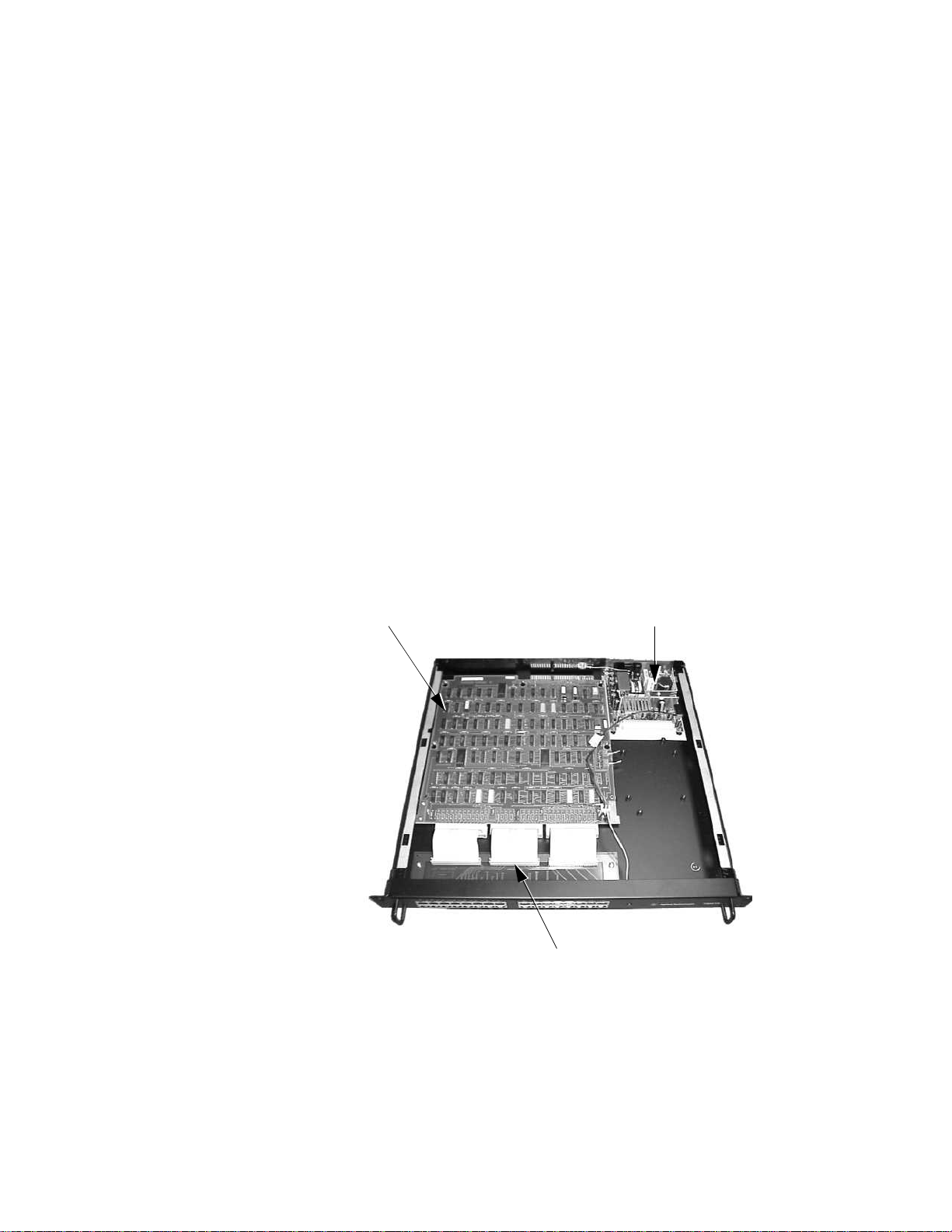

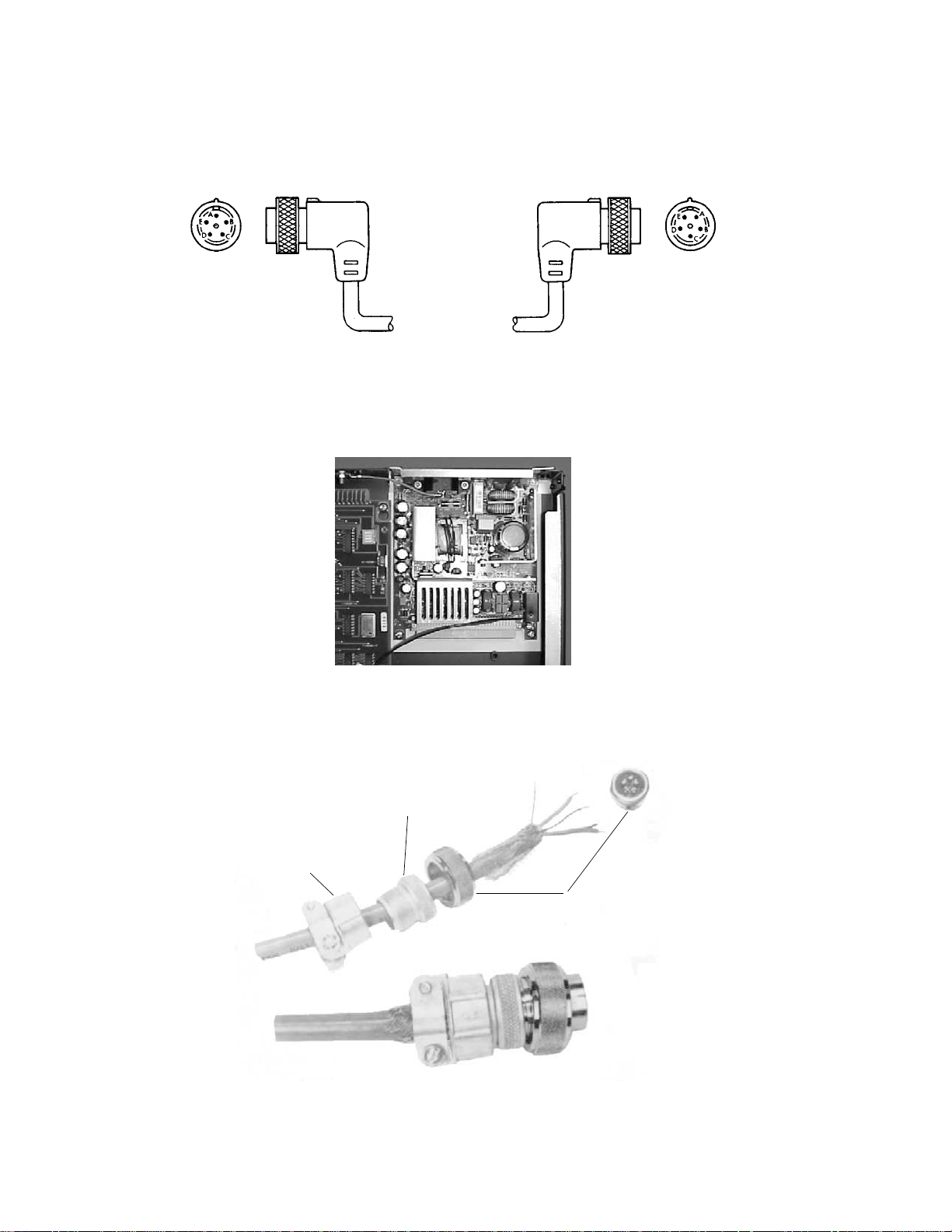

Figure 1-1. SDN Components

Page 9

Introduction

CCU/PCU ER

AIC

8

Bedsides

4 Telepaks

015

16 31

Tele

Mainframe

Figure 1-2. Typical SDN Configuration

Operating Reliability — Failure/Restart

Power Failure: ACC operation resumes automatically after power

restoration. Loss of power to the ACC will not affect local operation

between instruments on a branch that do have power. Loss of power at

one instrument on a branch will not disrupt system communication of

other instruments on the same branch or any other branch of the network.

ACC

AIC

4 Bedsides

AIC

4 Bedsides

4 Telepaks

SDN Configurations

Various combinations of patient monitors and patient information centers

may be connected to the ACC providing the system is configured within

the certain restrictions and limitations.

The ACC can accommodate up to 32 separate branch cables emanating

from it to the wall boxes (instruments). Of the 32 total branches, 24 may

connect to HP and Agilent bedside instruments (one patient per branch—

see note below), 6 may connect to information centers, and 2 may connect

to computerized systems. Refer to the installation section of this manual

for a complete listing of SDN System, ACC, cables, and wall boxes

restrictions and limitations.

1-3

Page 10

Agilent CareNet Controller (ACC), Model 78581B

Agilent CareNet Controller (ACC), Model 78581B

The Agilent CareNet Controller (ACC), model 78581B, is the active node—

in essence the heart—of the Serial Distribution Network (SDN). The

primary functions of the ACC are to provide the physical system

communications link to the instruments connected to the SDN, to establish

the SDN data polling cycles, and to control the data flow, timing,

synchronization, and distribution throughout the system.

The ACC functions in conjunction with the SDN Interface Circuitry located

within each instrument connected to the SDN, and with the system

distribution cables (branch cables), local distribution cables, and the

associated wallbox hardware, connectors and receptacles. A typical SDN

system configuration is illustrated in Figure 1-2 on page 1-3.

Once each poll cycle, data from each instrument is transmitted over the

branch cables to the ACC. All this data are received in sequence,

synchronized, and controlled by the ACC, then transmitted (broadcast)

simultaneously to all of the instruments connected to the SDN during each

32-millisecond poll cycle. The data sent over the SDN bus is received for

use by each instrument via the SDN interface circuitry residing in each

instrument. The ACC cannot store, restrict, or allocate specific

distribution of SDN data.

The ACC controls the data communication sequence during the 32millisecond poll cycle by issuing a variety of system messages that

originate in the ACC. A complete description of system messages,

instrument messages, the SDN data communicating sequence and SDN bus

direction control is described in the SDN system theory of operation

section of this manual.

Additionally, the ACC performs some basic fault detection isolation to

ensure reliability of SDN system communications. Also included in the

ACC are resident self-diagnostic routines for fault detection,

troubleshooting, and servicing of the ACC.

The ACC consists of a metal chassis with cover, a Power Supply Assembly,

a Terminal Interconnect PC board, and a Control/Driver PC board. The

model 78581B Agilent CareNet Controller is illustrated on in Figure 1-3 on

page 1-5.

The Control/Driver PC board contains all the electronic circuitry required

to control the data flow, timing, and distribution of SDN data throughout

the system.

The Terminal Interconnect PC board contains the RJ-45 connection to

connect the branch cables to the ACC, and the signal feed-through ribbon

cables to the Control/Driver PC board.

The Power Supply assembly contains the power ON/OFF indicator, and a

5-volt linear DC voltage supply used to power the circuitry on the Control/

1-4

Page 11

Introduction

Driver PC board. This model of the ACC does not have a power ON/OFF

switch. Power comes on as soon as it’s connected to AC by power cord. To

disconnect the power, remove the plug from the wall receptacle.

ACC Controls and Indicators

There are no operator controls located on the ACC. Once the power cord is

connected and the ACC is running properly, no operator adjustments are

necessary.

The green power ON/OFF indicator is visible on the rear. When

illuminated, it indicates 5-volt power is available from the ACC power

supply.

ACC Servicing

The ACC has been designed for ease of servicing. PC board and assembly

replacement is the primary method of repair. Troubleshooting tests and

integrity routines are specified in detail the ACC Troubleshooting section

of this manual. Complete disassembly procedures of the ACC are

described in the Installation section of this manual.

Figure 1-3. Agilent 78581B Agilent CareNet Controller

1-5

Page 12

Cables, Wall Boxes, and Faceplates

Cables, Wall Boxes, and Faceplates

Branch Cables

There are three types of branch cables that are permanently installed to

provide long distance connection between the ACC and the wall box; the

standard System Distribution Cable (SDC), the Extended System

Distribution Cable (XSDC), and Category 5 Unshielded Twisted Pair

(UTP).

The length of Unshielded Twisted Pair runs must be less than 90 meters

(295 ft.). The length of each standard SDC must be less than 152 meters

(500 ft.). The length of each XSDC must be less than 304 meters (1000 ft.).

Only two XSDC runs are allowable per ACC. Branch cable runs must be

continuous; no splicing or mixing cable types is allowed.

Local Distribution Cables (LDC)

The SDN allows ease and flexibility of user placement of instruments.

Local distribution cables (LDC) must be used for local serial connection

from the wall box/face plate to the instrument, and to other instruments.

The LDC allows bedside instruments to be easily interchanged simply by

connecting them to their new locations.

Wall Boxes and Face Plates

Wall Boxes: only standard size, NEMA, single- or dual-gang, switch wall

boxes with conduit knockouts (KOs) may be used. The depth of the wall

box must be at least 7.0 cm (2.75 in). Wall boxes are usually supplied by

the customer; however, two types are available from Agilent Technologies.

Face Plates: Pre-punched, NEMA, single- or dual-gang faceplates for the

SDN; SDN on UTP US and European wall boxes. Faceplates are included

with the wall box connector kits.

1-6

Page 13

SDN Components

Introduction

Installation of a complete Serial Distribution Network requires the

ordering and selection of several instruments, SDN system components

and options. These include the model 78581B ACC and options from the

78599AI/Cabling Installation Kit to provide Local Distribution Cables

(LDC) and connector hardware. Branch cables are ordered separately

using their associated Agilent part number.

Refer to the Installation section of this manual for a complete description

of the installation instructions and responsibilities for properly installing

the ACC, the cables, and the wall boxes. The general SDN instrument

interconnection procedures are also given in the installation section;

however, the specific details of instrument wiring procedures and ‘tuning”

the instruments into the SDN communications network are explained in

detail in the associated instrument’s service manual.

The ACC may be mounted on a standard 19 inch telecommunications rack.

It may also be wall mounted on a properly prepared wall, using the wall

mount kit (M3180AI),

within the specified length limitations. No special tools are required for

installation—only screw drivers, cable strippers, and pliers are needed.

Environmental conditions, service access requirements, and free space

surrounding the ACC are detailed in the Installation section of this

manual.

that permits the length of each branch cable to be

System Distribution Cable (SDC) 100-ft. reel

Extended System

Distribution Cables (XSDC)

UTP Category 5 Orange 1000-ft. reel 8120-6770

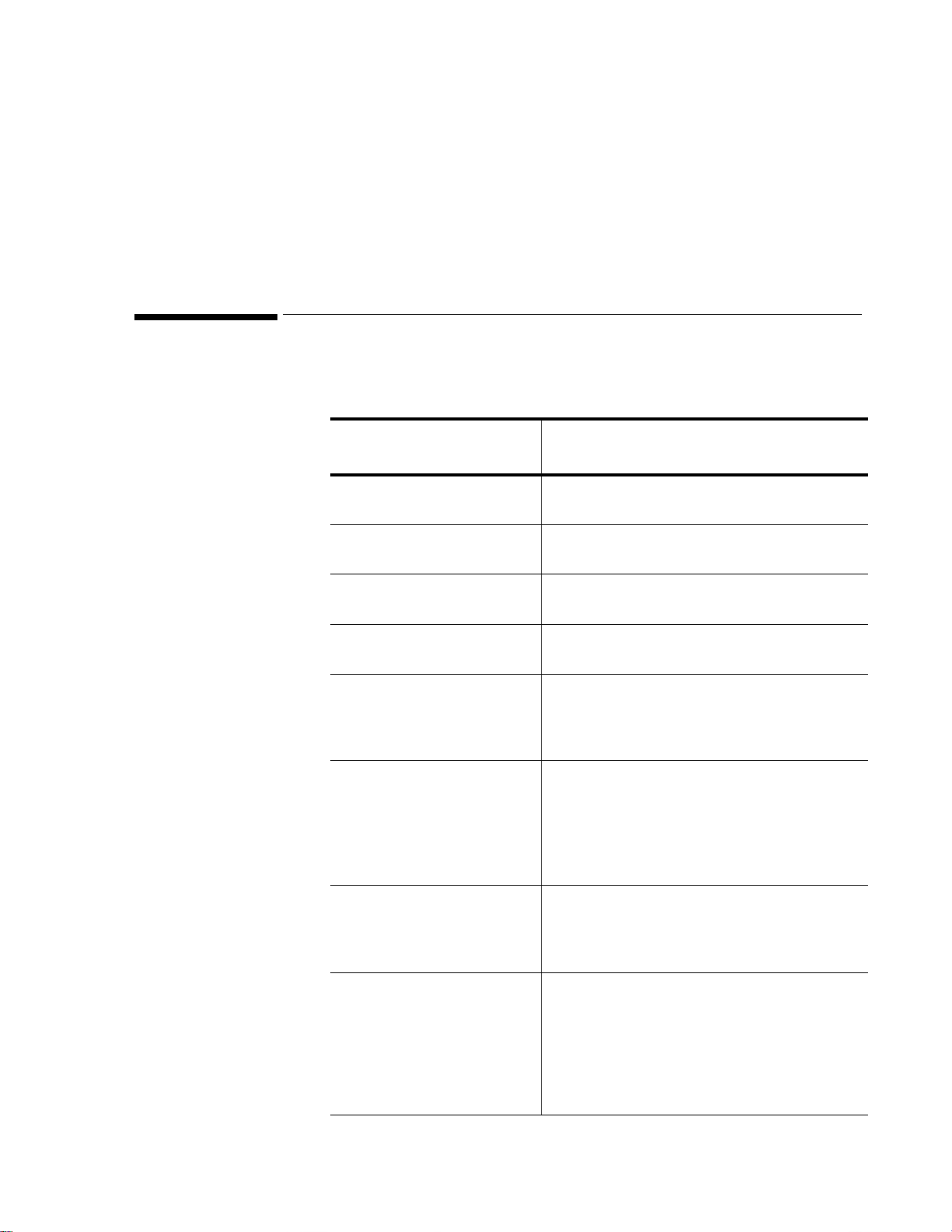

78599AI SDN Cabling Installation Kits

— J01 Single Gang SDN Face Plate/Connector Kit

— J02 Dual Gang SDN Face Plate/Connector Kit

— J12 SDN/UTP Single Wall Box Quantity 1

— J13 SDP/UTP Single Wall Box Quantity 8

— J14 SDN/UTP Dual Wall Box Quantity 1

— J15 SDN/UTP Dual Wall Box Quantity 8

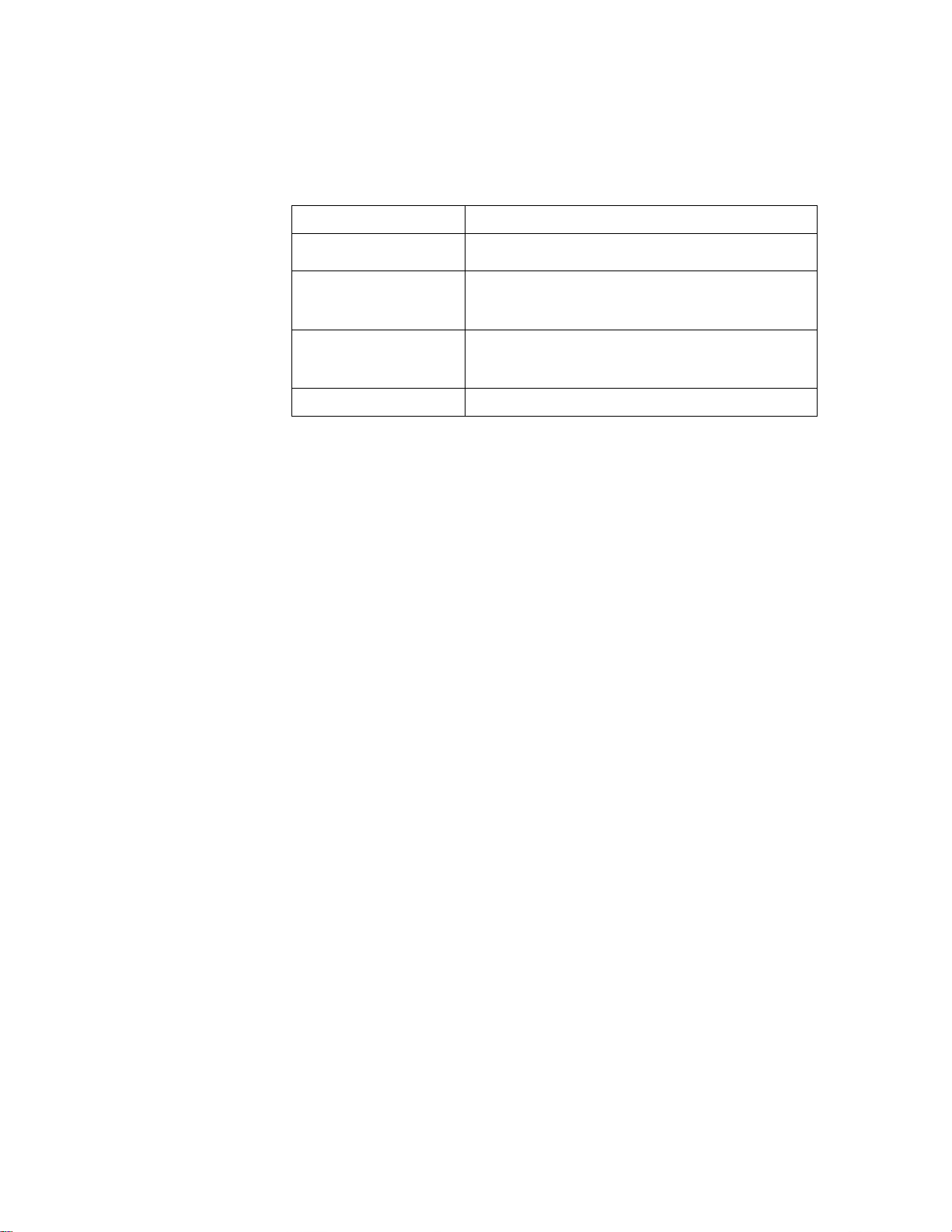

Table 1-1: SDN Branch Cables

250-ft. reel

500-ft. reel

750-ft. reel

1000-ft. reel

8120-3502

8120-3775

8120-3774

8120-3777

8120-3776

1-7

Page 14

Intended Use of Device

— JJ1 SDN on UTP parts (European) Quantity 1

— JJ2 SDN on UTP parts (European) Quantity 8

— J03 3-Foot Local Distribution Cable (LDC)(81 20-3591)

— J06 6-Foot Local Distribution Cable (LDC)(81 20-3587)

— J10 10-Foot Local Distribution Cable (LDC)(8120-3588)

— J20 20-Foot Local Distribution Cable (LDC)(8120-3589)

— J50 50-Foot Variable Length LDC Kit

— J52 Extra SDN Connectors (Two)

— J54 Fifty Feet of Unterminated LDC

M3199AI Installation Materials

— P01 UTP Plenum (Orange) Cat. 5 Cable 1000 Feet

M3180A Wall Mount Kit

Intended Use of Device

The Signal Distribution Network (SDN) allows the sharing of patient

physiological parameters and other electronic data among bedside

instruments, central station processors and displays, recorders, thermal

printers, and other computerized systems.

Warning

United States Federal Law restricts this device to sale by or on the

order of a physician.

This product is not suitable for installation in the patient care

vicinity.

— J03 RJ45 to SDN Cable Connector

— A14 Wall Mount Kit (78581-61257)

1-8

Page 15

Overview

Theory of Operation

Section 2: Theory of

Operation

Theory of operation consists of two distinct subsections:

• SDN Theory of Operation

• ACC Theory of Operation

SDN Theory of Operation describes the overall system Serial Distribution

Network (SDN), its normal operating characteristics, applications, and

error conditions, the format of the SDN digital data, and the SDN system

communications protocol as well as the local distribution network (LDN)

communications protocol. The SDN system communication protocol and

data formatting assures compatibility between a variety of different

instruments communicating together over the SDN. The communication

protocol and hardware implementation is intended to be flexible enough

to accommodate a variety of communication needs in the patient

monitoring environment for the present and for future expansion.

ACC Theory of Operation describes the detailed operating theory of the

Agilent CareNet Controller (ACC). Included in this section are functional

descriptions of the Power Supply Assembly, the Terminal Interconnect PC

board, and the detailed operating principles of the Control/Driver PC

board which includes the transmit/receive driver circuitry, the retiming

circuitry, and the control circuitry.

2-1

Page 16

SDN Theory of Operation

SDN Theory of Operation

SDN General Description

The Serial Distribution Network (SDN) is a digital communications

network designed to share patient physiological parameters and other

data among all instruments connected directly to the SDN.

The SDN uses cables containing a twisted shielded pair of wires to connect

the instruments to the Agilent CareNet Controller (ACC). Digitized patient

data is transmitted SERIALLY through the wires of the NETWORK. The

ACC circuitry manages the timing and DISTRIBUTION of the digital

patient data. Hence, it is appropriately named the SERIAL DISTRIBUTION

NETWORK.

The SDN is a half-duplex network using terminated shielded twisted pair

cable(s) to carry serial digital data. All SDN data is transmitted

differentially and serially using block code modulation. Brief explanations

of the SDN terms are given below.

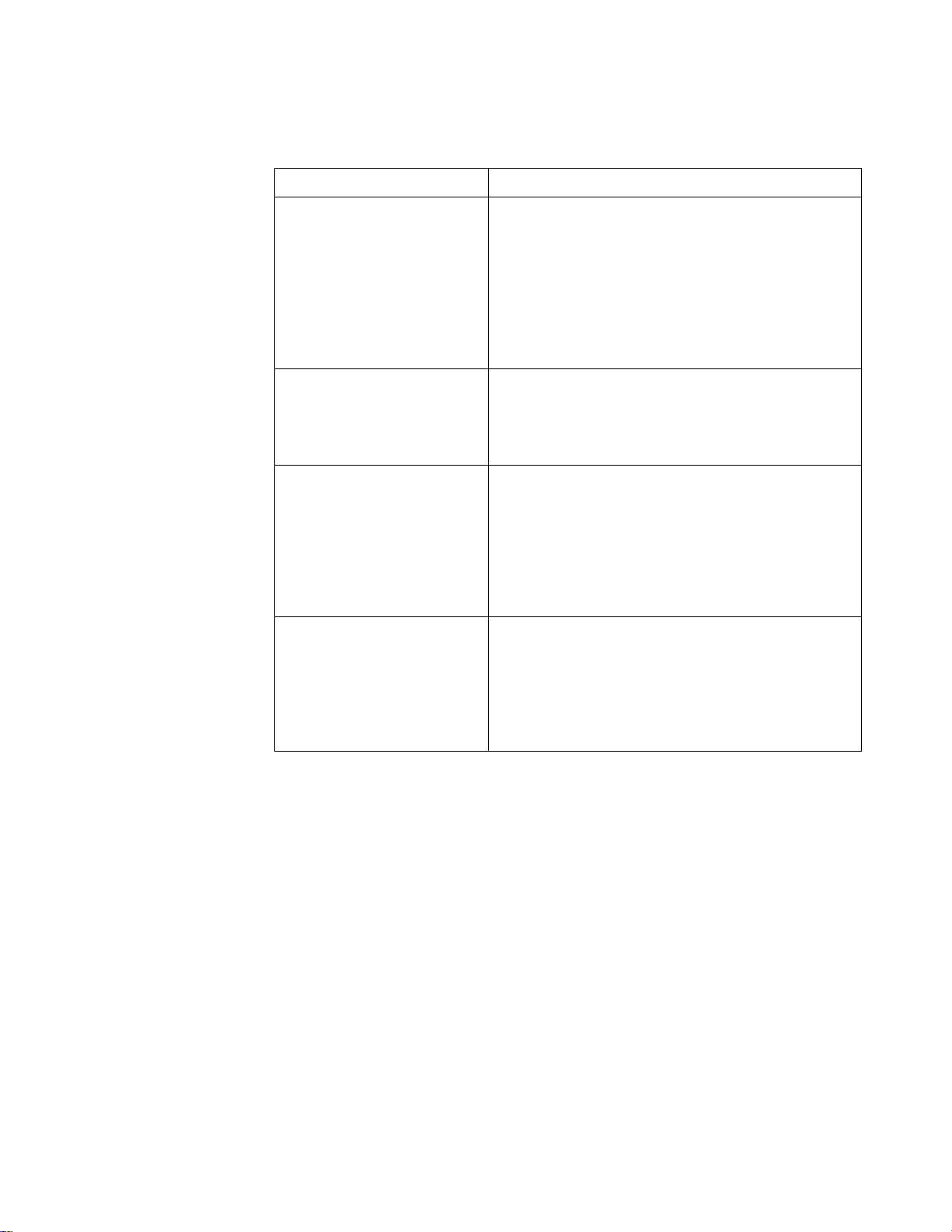

Term Definition

SDN Data Physiological information such as parameters or

waveforms, or non-physiological information such

as bed labels, annotation, alarm messages, or timeof-day.

Digital Using binary logic where a high voltage level is

called a one (1) and a low voltage level is called a

zero (0).

Serial A string of ones (1) and zeros (0) in a row create

defined words, similar to alphabetic letters used to

define known words. However, the SDN words are

all the same length. These words are combined to

make up messages. Different messages have

different lengths.

Half-Duplex Signals move in one direction at a time over the

data wires. Instruments using the SDN never talk

and listen at the same time.

Block Coded A digital coding scheme that facilitates sending

serial digital data by insuring not too many ones (1)

or zeros (0) are transmitted. Timing information is

extracted from the frequent edge transitions (0 to 1,

or 1 to 0). This keeps all instruments synchronized

while minimizing the bandwidth required.

2-2

Page 17

Theory of Operation

Term Definition

Shielded Twisted Pair

Custom Cable

LAN Unshielded Twisted

Pair Category 5

Differential Two wires carry the same signal, with opposite

Termination In order for differential signals to remain clean, the

A cable containing two wires which carry all digital

data on the SDN. The two wires are twisted together

to minimize interference from magnetic fields, and

encased in a braided shield to limit interference

from electrostatic fields. The cable is custom

designed with carefully controlled impedance and is

well shielded to guarantee noise immunity and

ensure system performance. It is necessary to use

only Agilent supplied cables in SDN systems.

A cable containing four pairs of wires. One pair

carries all digital data on the SDN. The wires are

twisted together to minimize interference from

magnetic fields. UTP, unlike shielded twisted pair, is

not encased in a braided shield.

polarity. These two wires are designated as positive

and negative. For a digital one (1), the positive wire

is at a high voltage and the negative wire is at a low

voltage; vice versa for a digital zero (0). The voltage

between these wires (high to low, 1 to 0) is

approximately 3 volts (1.5V minimum, 4V

maximum).

length of the cable must appear infinite to the

circuitry. The cable’s impedance is matched by 120

ohms of resistance connected between the two data

wires at both ends of the branch (at the ACC and at

the instrument). Termination is contained in each

instrument.

Logic Convention

Data Wires (SDC or XSDC)

Positive (+) Wire Pink colored wire

Negative (–) Wire Blue colored wire

High State (1) (True) Pink wire potential is positive with respect to blue wire

Low State (0) (False) Pink wire potential is negative with respect to blue wire

Positive Transition Transition from low state to high state

Negative Transition Transition from high state to low state

by at least 1.5V

by at least 1.5V

2-3

Page 18

SDN Theory of Operation

SDN Quiescent State Pink wire biased O.4V more negatively than blue wire.

Data Wires (LDC only)

Positive (+) Wire Pink colored wire

Negative (–) Wire Blue colored wire

Priority Wires (LDC only)

Positive (+) Wire Gray colored wire

Negative (–) Wire Black colored wire

True State Black wire positive with respect to gray wire

False State Black wire negative with respect to gray wire

UTP

Positive (+) Wire Blue wire with white stripe

Data wires are quiescent during dead time.

Negative (–) Wire White wire with blue stripe

Ground Green wire

2-4

Page 19

SDN Topology

Theory of Operation

The SDN uses a star topology that consists of up to 32 individual branches

emanating from the center of the star—the ACC. Only one ACC may be

used per SDN. One SDN can accommodate up to 24 bedside instruments

(one patient per branch), 6 information centers (ICs), and 2 computerized

monitoring systems. For details on specific operational and topological

limitations, refer to the Installation section.

A typical SDN configuration is illustrated below.

Figure 2-1. Typical SDN Configuration

2-5

Page 20

Applications of SDN Operation

Applications of SDN Operation

Configurations of the SDN will vary from installation to installation. The

SDN is designed to be flexible enough to accommodate a variety of

communication needs in the patient monitoring environment, for the

present and for future expansion. Many hospitals have more than one care

unit. For example, there might be separate care units such as an ICU, a

CCU, an MICU, and an SICU. SDN communication between instruments

can be customized at installation.

One of the applications on the SDN is the OVERVIEW display. This feature

provides a split display screen showing “home bed” and “source bed”

patient information. This OVERVIEW mode can be entered either

manually for observation or automatically upon patient alarm. Any bed/

patient within the same care unit can be displayed in this manner.

Softkeys on the monitor are used to form subgroups under the care of

each nurse, called care groups, to match nursing assignments. The features

of split display screens, message transfer, alarm alert, and care group

configuration are all possible using the digital Serial Distribution Network.

In addition, any defined message can be transmitted via serial digital data

without requiring any changes to network hardware. There are 63

physiological function codes of which 42 are defined and 21 are reserved

for future use. The SDN is flexible enough to accommodate configuration

changes at the bedside instrument via plug-in modules without any system

modifications, user interaction, or hardware changes. Also, SDN

instruments may be disconnected at any time and moved to other system

locations and reconnected without bringing the network down.

Another application on the SDN is the TUNING feature at an Information

Center. This feature provides the ability to choose which patients/beds are

monitored at the IC. Patient information viewed at the IC is displayed in

dedicated positions on the display screen called SECTORS.

The sectors may be individually TUNED to any bedside instrument using

the softkeys. Any number of ICs may tune to the same patient/bed. The

first IC to be tuned to a bedside is called the “primary” IC for that bedside

instrument, and furnishes recordings when requested from that bedside.

Sectors on other ICs displaying the same bedside information are called

“consulting sectors.” All sectors tuned to a given bedside report patient

alarms.

Instrument Communication on the SDN

The ACC is the active node of the SDN. It functions to provide the system

communications link and to control the data flow, timing, synchronization,

and distribution throughout the system. The ACC functions in conjunction

with the SDN interface circuitry located within each instrument connected

to the SDN. The SDN interface circuitry drives and receives SDN data over

2-6

Page 21

SDN Timing Overview

Theory of Operation

the branch cables for instrument-to-system communication via the ACC,

and also over the local distribution cable(s) for instrument-to-instrument

communication when the local distribution network (LDN) exists.

Only one instrument broadcasts patient data at a time and the ACC

rebroadcasts that information from that branch to all other branches on

the system. The ACC functions as a rotary switch successively allowing

each branch to transmit data to all other branches. The communication

system is designed so every instrument gets a chance to transmit all its

available data within predetermined cycles. The functional operation and

timing sequence of the SDN communication cycle is described below.

Most information is broadcast by the SDN instruments once every system

cycle, or approximately once every second, such as bed labels, derived

parameters and time-of- day. Other system information, such as

physiological waveform data, is broadcast once every poll cycle or 32

times a second. The ACC controls data communication on the SDN in

blocks of time called system cycles. One system cycle lasts 1.024 seconds

and is made up of 32 separate poll cycles.

Poll Cycle: One poll cycle lasts 32 milliseconds. Each poll cycle is made up

of three distinct segments, which are:

SYNC TAP 4 MS DEAD TIME TALK TIME

Sync Tap. The sync tap acts as a system synchronization strobe. It is sent

by the ACC to all branches (instruments) simultaneously to synchronize

the instrument’s transceivers and to initiate the beginning of a new poll

cycle. The sync tap also contains coded status information.

4 Ms Dead Time. The 4 ms dead time is an enforced quiet time that

immediately follows the sync tap.

During the 4 ms dead time each instrument reads data stored by the SDN

interface circuitry during the previous poll cycle and stores data to be sent

during this poll cycle. This is the only time SDN data can be loaded into

and retrieved from the instrument’s SDN interface circuitry.

Talk Time. During the talk time a talk tap message is sent to one branch at

a time starting with branch 0 to grant permission to talk on the SDN.

When a talk tap has been received, the instrument on that branch

transmits all of the data stored in its transmit memory. When finished, the

ACC senses silence on the branch and sends a talk tap to the next branch.

The amount of data transmitted during the talk time varies from branch to

branch and changes from poll cycle to poll cycle, so talk taps do not occur

in the same place every cycle. After all branches have been polled once, no

more data is transferred until the next poll cycle.

2-7

Page 22

SDN Data Structure — System and Instrument Messages

Autopoll Mode

In the event that the ACC goes down (loses power, for example), all

instruments on the same branch continue to communicate with each other

in the autopoll mode. Autopoll means that the first instrument (closest to

the wall box) sends sync taps and talk taps to itself and the other

instruments on the branch. The timing is exactly the same as normal SDN

operation. When the ACC resumes proper operation, the instrument

automatically leaves the autopoll mode and returns to SDN

communication.

SDN Data Structure — System and Instrument Messages

Digitized information travels serially on the SDN in 12-bit words. These

words are grouped together in a string to form complete messages. The

SDN uses two types of messages: system messages which originate in the

ACC or in the first instrument on branch when in the autopoll mode and

instrument messages that originate in the instruments.

System Messages

System messages originate in the ACC. System messages consist of three

separate 12-bit words and have the following structure:

FLUSH

Flush: The flush is a unique sequence of 12 bits (101010101010) that are

used to clear the line of capacitive charging to ensure reliable detection of

logic levels. The flush word always follows any silence on the SDN bus.

System Delimiter: The system delimiter is another unique sequence of 12

bits (100000111111) that are used to help the instruments’ transceivers

recognize the system message and establish synchronization.

System Status Word: The system status word consists of either a sync tap

or a talk tap.

Sync Tap: The sync tap carries encoded information to indicate whether

the current poll cycle is the first poll cycle in the system cycle (master poll

cycle), to flag “fire axe” and “poll overflow” error conditions (see “SDN

Status and Error Conditions” on page 2-12), and to identify the “autopoll”

operating mode (see “Autopoll Mode” on page 2-8).

SYSTEM

DELIMITER

SYSTEM STATUS

WORD

2-8

Page 23

Theory of Operation

Talk Tap: The talk tap carries encoded information to indicate the branch

number and to identify the “autopoll” operating mode.

Note

Instrument Messages

INSTRUMENT

DELIMITER

Since the status information is block encoded, there is not a one-to-one

correspondence between status values and bits of the status words. The

condition of these bits are indicated on the status LEDs on the ACC and on

the display screens of the SDN instruments. See “SDN Status and Error

Conditions” on page 2-12.

Instrument messages originate in the instrument. These instrument

messages comprise of all the data broadcast on the SDN, such as

waveforms, derived parameters, alarm status, text messages, bed labels,

time-of-day, and many others. Instrument messages vary in length (i.e.,

number of words) but always consist of the following structure.

HEADER

HEADER

Instrument Delimiter: The instrument delimiter is a unique 12-bit word

(110010011111) used to mark the beginning and the end of the message.

Header: The header is always four words long (48 bits) and is used to

label the content of the message body. The second word is called the

“signature.” Listening instruments examine the signature to determine

whether they want to capture this message.

BODY

INSTRUMENT

DELIMETER

Body: The body of the instrument message contains the actual data. The

number of data words in the body depends upon the type of message being

sent.

2-9

Page 24

SDN Normal Operation

SDN Norma l Operation

This section contains the SDN data timing specifications and a description

of the instrument status message.

SDN Data Timing Specifications

During normal operation SDN digital data travels on the SDN at 3.6 Mbit;

the bit cell width is 1/3,600,000 seconds, or 277.78 ns.

10101

277.78ns

Bit Cell Width

Therefore, the 12-bit word is 3.33 µs long. One poll cycle lasts 32 ms, but

not all of this time is available to transmit data. Considering all of the

overhead time (see breakdown below), approximately 7700 words of data

can be transmitted in every poll cycle. Overhead time consists of the

following:

a. Sync tap (10µs)

b. Dead time (4 ms)

c. Time to listen for activity on each branch before sending a talk tap

(3.33 µs per branch)

d. Talk taps (10µs per branch)

e. Time to listen for silence before going on to the next branch (12.22 µs

per branch)

f. Headers and delimiters in messages

Instrument Status Me ssage

Once every system cycle (approximately once a second) each instrument

connected to the SDN broadcasts a message called the Instrument Status

Message. The content of this message allows all other instruments to

identify its operational status. Contained in every Instrument Status

Message are the following:

2-10

Page 25

Theory of Operation

a. Instrument Identification: Each instrument can be identified as any

SDN bedside monitor, IC, or computer. For bedsides the instrument

identification gives branch number and type of bedside monitor.

b. SDN Communication Error Flags: A variety of SDN system errors are

identified and flagged in the instrument status message. Refer to the

Troubleshooting section for details on the network test and SDN

system troubleshooting.

c. Status Indicators: Three unique status indicators reflect the

instrument’s ability to communicate on the SDN. The three status

indicator bits in the instrument status message are described below.

Each bit can have a value of 0 or 1. In normal operation the status

indicator bits are set to 1.

SDN/Autopoll

ONLINE/OFFLINE

NETWORK/LOCAL

The normal operating mode is SDN. The ACC’s sync tap indicates to the

instruments that they are in the SDN mode. If operation of the ACC fails

(loses power for example), then one instrument on each branch generates

its own sync taps and talk taps that it sends to itself and to the other

instruments on that branch. Thus, the local communication is maintained.

The locally generated sync tap indicates to the instruments on that branch

that the branch is operating in Autopoll mode.

If the ACC becomes active again, then the branch automatically returns to

the SDN mode.

The normal operating mode is ONLINE. The ONLINE status indicates that

an instrument has examined itself and is ready and able to operate

reliably on the SDN. At power up an instrument is OFFLINE. When it

successfully completes its own initialization it may put itself in the

ONLINE state.

The normal operating mode is NETWORK. The NETWORK status indicates

that an instrument is synchronized with the system cycle. This is

important because most of the data on the SDN is sent only once each

system cycle, during a specific poll cycle. An instrument must synchronize

with the master poll cycle in order to know when to transmit specific data.

At power up an instrument is in LOCAL mode and starts searching for the

beginning of a system cycle. As soon as a valid system cycle has been

found, the instrument may set itself in NETWORK mode.

SDN Status and Error Conditions

SDN system status and error conditions can be viewed on the IC display,

bedside, and indicated on the ACC via LED status and error code

indicators. A detailed description of the SDN system errors is described in

the SDN troubleshooting section.

2-11

Page 26

SDN Normal Operation

ACC Error Conditions — SDN Failure Detection

The functional operation of the ACC can be checked and verified to ensure

reliable operation. During normal operation, the following LEDs on the

Control/Driver PC board are illuminated continuously:

RED DS1 (MSB) flickers

RED DS4 (LSB)

GREEN DS5 (RUN)

RED DS6 (Ti)

DS6

DS5

2-12

DS1 DS2 DS4DS3 DS8 DS7

The ACC is designed to detect and isolate certain fault conditions which

may be present on the SDN bus.

Fire Axe: One type of fault condition that could occur is the presence of

activity on a branch which has not yet been sent a talk tap. The ACC

senses the branch for 3.3 µs before sending a talk tap message. If activity

is detected during this time, then no talk tap is sent and the ACC skips

over that branch automatically and cuts it off from the rest of the SDN.

This condition is called “fire axe”, and is indicated at the ACC by

illuminating the yellow fire axe LED DS8. However, if no activity is

detected on a branch, the ACC checks to ensure that the SDN bus is biased

correctly (in the low state). If the bias is correct, a talk tap is issued.

Otherwise, the branch is fire axed.

Poll Cycle Overflow: Another fault condition detected by the ACC is a

poll cycle overflow condition. The yellow poll cycle LED DS7 is illuminated

signifying a poll cycle has overflowed if, before the next sync tap, all 32

branches do not receive a talk tap and an opportunity to transmit all their

data.

Page 27

ACC Theory of Operation

The ACC consists of three PC boards (refer to Figure 2-2):

•Main PCB

• Transition board assembly

• Power supply

Main PCB (78581-60200)

The Main PCB is considered the control/drive board. It connects up to 32

branch cables via the Transition Board to provide timed multiplexed

communication links and system synchronization. The circuitry on the

PCB sets up a polling cycle that allows each branch access to the SDN bus

in a sequential manner. Data coming in from one branch is received and

then “broadcast” simultaneously to the remaining branches of the SDN. As

each branch transmits in sequence, the SCC buffers, retimes, and

retransmits the data.

Theory of Operation

System communications is controlled, timed, and synchronized by the

ACC issuing regular system sync messages every 32 milliseconds and a

master sync message every second.

When power is supplied, the MODE switch is sensed for normal operation.

The ACC then issues a SYNC TAP message to all branches connected to

the ACC. The ACC senses the poll timer for 4 ms elapsed time to allow the

instruments to unload their receive buffers and load their transmit

buffers. Then, branch 0 is set up for a TALK TAP message by first sensing

the branch for activity and line state (polarity 1 or 0). If activity is sensed

within a 2.7 microsecond window, or the line is in the logic 1 state, then

the branch is considered faulty (FIRE AXE condition) and is skipped over

without a TALK TAP being issued. However, if no activity is sensed, a

TALK TAP message is transmitted out the branch in which the branch

number is embedded. The branch number is a 6-bit block encoded word

derived from the Block Code ROM. The 5-bit branch binary counter is the

ROM address pointer.

After the TALK TAP message has been transmitted, the ACC turns around

the line drivers and receivers and senses for activity from branch 0 and,

also, turns on the “broadcast” to all remaining branches. The ACC senses

for transmission activity for 12.2 microseconds and will timeout and

switch to the next branch if no activity is sensed. Activity is defined as one

or more positive transitions trapped within the 12.2 microsecond window.

The ACC senses the end-of-transmission by detecting 12.2 microseconds of

continuous silence; no positive transitions for example. The next branch in

sequence is then sensed for silence (no activity) and issued a TALK TAP

message in the same manner. Each branch is polled sequentially until all

32 branches have been issued a TALK TAP message. The last branch

2-13

Page 28

ACC Theory of Operation

polled at the end of 32 milliseconds must be branch 31 for TALK TAP

messages. If not, the poll cycle is in error and an error flag is set in the

next SYNC TAP message to indicate a POLL OVERLFOW; for example,

system overload or poll sync loss.

Transition Board (78581-61253)

This PCB interfaces from the RJ45 connector to the main PCB. There are

32 ports label from 0 through 31. Port 0 is the master time port for the

central stations. Ports 1 through 24 are bedside ports. Ports 25 through 31

are for other central stations, computers, or mainframes. The transition

board supplies the input/output data from the bedside to and from other

devices.

Power Supply (M2604-60002)

This is a 5V automatic switch power supply. It supplies power for the main

PCB, power on LED and the 5V indicator LED on the rear of the power

supply board.

Power SupplyMain PC Board

Transition Board

Figure 2-2. Internal Components of the ACC

2-14

Page 29

SDN and ACC System Level Troubleshooting

Section 3: SDN and ACC

System Level

Troubleshooting

Caution

Service and repair of the SDN system components is to be performed by

authorized service personnel only.

SDN Troubleshooting Overview

This section describes a logical approach for service personnel to diagnose

and identify the source of an SDN system problem and to isolate the

problem to the instrument/cable level for service and/or repair. The

troubleshooting procedures are presented simply and logically, and should

be followed in the sequence indicated.

The following troubleshooting procedures are written to minimize

disturbance to system patient monitoring and to avoid (and to determine

the need for) bringing down the entire SDN communications system.

When troubleshooting a new SDN system installation (not a patient

connected SDN system), it may be more expedient to power down the ACC

in order to checkout the cables and swap the Control/Driver PC board in

the ACC. Discretion must be applied according to the constraints of the

situation.

The content of this text presumes that the service person is familiar with

Agilent monitoring instrumentation and has a basic understanding of the

SDN system operation, specifically:

• SDN Architecture and Topology

• Agilent CareNet Controller

• Structure of System Cycle and Poll Cycle

•SDN Status

– Autopoll/SDN

– Offline/Online

–Local/Network

• SDN Interface Board — Functional Block Level

– Activity Detection, Autopoll Enable

– Priority Wires (Upstream/Downstream)

– Last Box Detection, Termination

3-1

Page 30

SDN Troubleshooting Overview

In addition, service personnel must be aware of the structure of the SDN

system being troubleshot with respect to:

The following abbreviations are used throughout this section:

•Care Units

•Bed Label/Branch Assignments

• IC Tuning

•IC/Branch Assignments

•BS — Bedside Monitor

• CS — Central Station

• LDC — Local Distribution Cable

• LDN — Local Distribution Network

• M/T — Monitor/Terminal; an SDN Bedside

• NT — Network Test

• IC — Information Center

• ACC — Agilent CareNet Controller

• SDC — System Distribution Cable

• XSDC — Extended System Distribution cable

• SDN — Serial Distribution Network

• SDNIF — SDN Interface

A simplified block diagram of the SDN system components is shown in the

following:

BS or CS

SDNIF

LDC

SDC

Wall Box

ACC

SDC LDC

Wall Box

Figure 3-1. SDN Components—Simplified Block Diagram

BS or CS

SDNIF

3-2

Page 31

SDN and ACC System Level Troubleshooting

Troubleshooting Resources, Tools, and Equipment

The following resources are available with the SDN instruments to

facilitate troubleshooting the SDN system:

•INOP Messages

•Overview Function

•Network Test

• Self-Test Routines

• Error Codes

• Instrument Service Manuals

A flat blade screwdriver and a 50-foot LDC are recommended when

troubleshooting the components of the SDN system.

яюэьыъщшчцхфущщтсрпьоцщнмулът

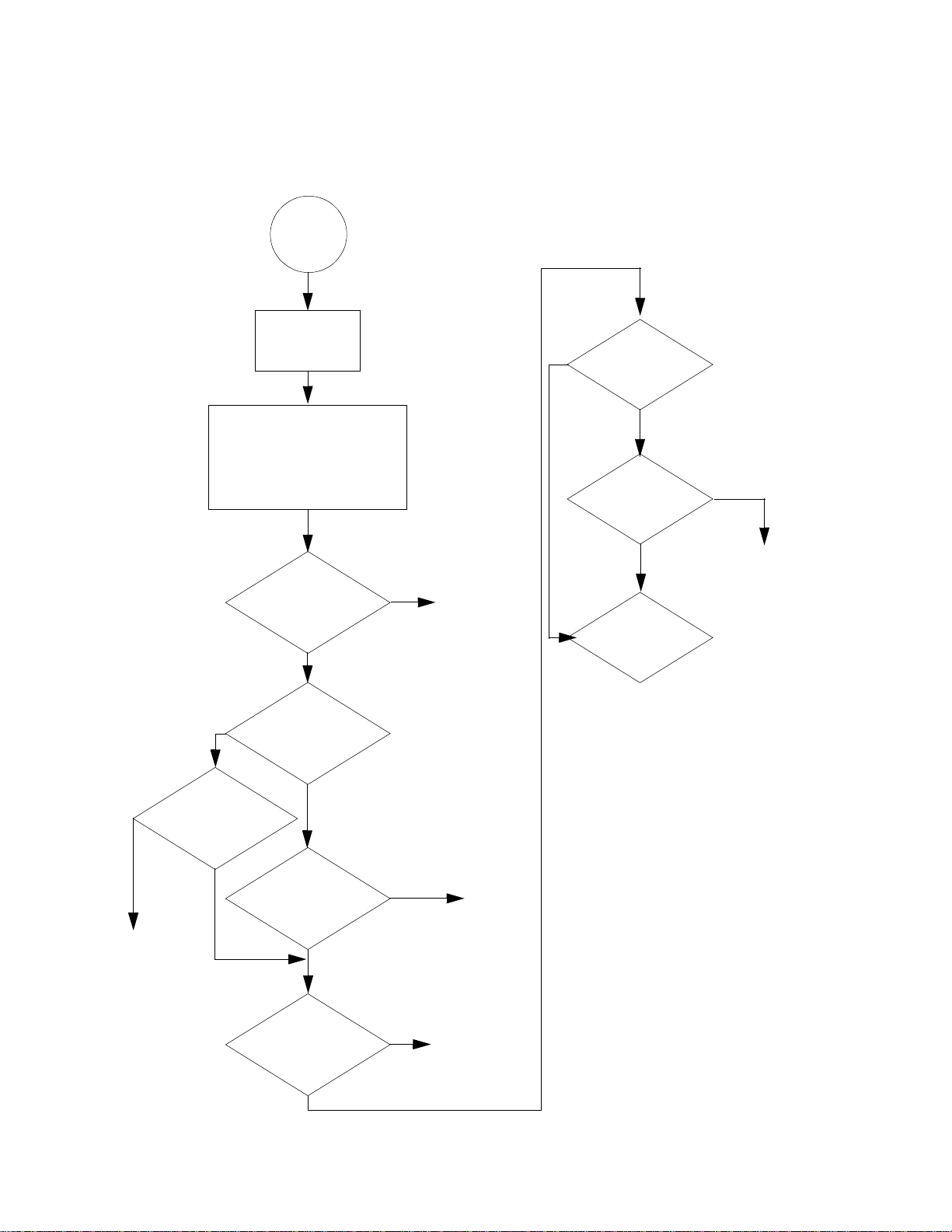

The SDN troubleshooting steps are outlined in a simplified SDN system

troubleshooting flowchart illustrated on page 3-4. Follow the steps

indicated in the sequence shown. Until you are familiar with the

troubleshooting flowchart procedure, refer to the detailed troubleshooting

procedures referenced for each step.

3-3

Page 32

Troubleshooting Resources, Tools, and Equipment

Figure 3-2. SDN System Troubleshooting Flowchart

Start

Step 1

Review system

configuration.

Step 2

Examine system.

1. Check if SDN is connected.

2. Network Test, Self-Test.

3. Error and INOP messages.

4. FIREAXE and overflow LEDs.

SDN

communication

problem (Receive,

Transmit).

Yes

FIRE AXE

LED

on?

Yes

No

Troubleshoot

instrument

Not

all

instrumentson the

instrumentsare on

the branch?

Isolate to one

instrument on

How many

branch are

affected?

How many

More

Step 5

branch.

All

than

one

ACC

Error

Troubleshoot

ACC

(and cable)

One

Troubleshoot

instrument

(and cable)

Troubleshoot

3-4

Look for Noisy

Nonoisy

branch

ACC

Branch

Found branch

No

Step 3

Evaluatebreadth

of problem.

Single Branch (SDN interface,

Step 4

Instrument

Self-Test

Multiple

branches

cable, or ACC)

Troubleshoot

Troubleshoot

ACC

instrument

(See

product’s

service

manual)

Page 33

SDN and ACC System Level Troubleshooting

яыььхсхньшфтщхъфьяфтхьщр спшълтсщр

Obtain a basic understanding of the customer’s system architecture and

topology, and familiarize yourself with the SDN configuration.

Review the instrument branch assignments, care unit definitions, and IC

tuning ranges. Pay particular attention to the configuration of bedsides: to

which IC they are hard-wired, and where they are being monitored.

Review the configuration of IC groups.

If the system configuration documentation is not available, use the branch

number assignment label located inside the ACC and the Network Test to

review the SDN system configuration.

STEP #2: Examine System and Gather Symptoms

An instrument using the SDN such as IC or bedside is more likely to be the

source of a problem than the SDN hardware such as the interconnecting

cables or the ACC. With this in mind, start by looking for the obvious

product malfunctions. To do this, use the resources available and evaluate

the results.

SDN Connections

SDN Error Messages

and Error Codes

SDN COMM FAILURE —

DUPLICATE BED

SDN COMM FAILURE —

ILLEGAL BED NUMBER

• Assure that the instrument is SDN connected.

• Examine INOP messages and error codes.

• Check FIRE AXE and OVERFLOW LEDs in the ACC.

Evaluate the results of the resources listed above to determine if there is

an SDN or non-SDN problem before continuing with this procedure.

The following messages can be found at the bedside, the central station, or

the telemetry mainframe.

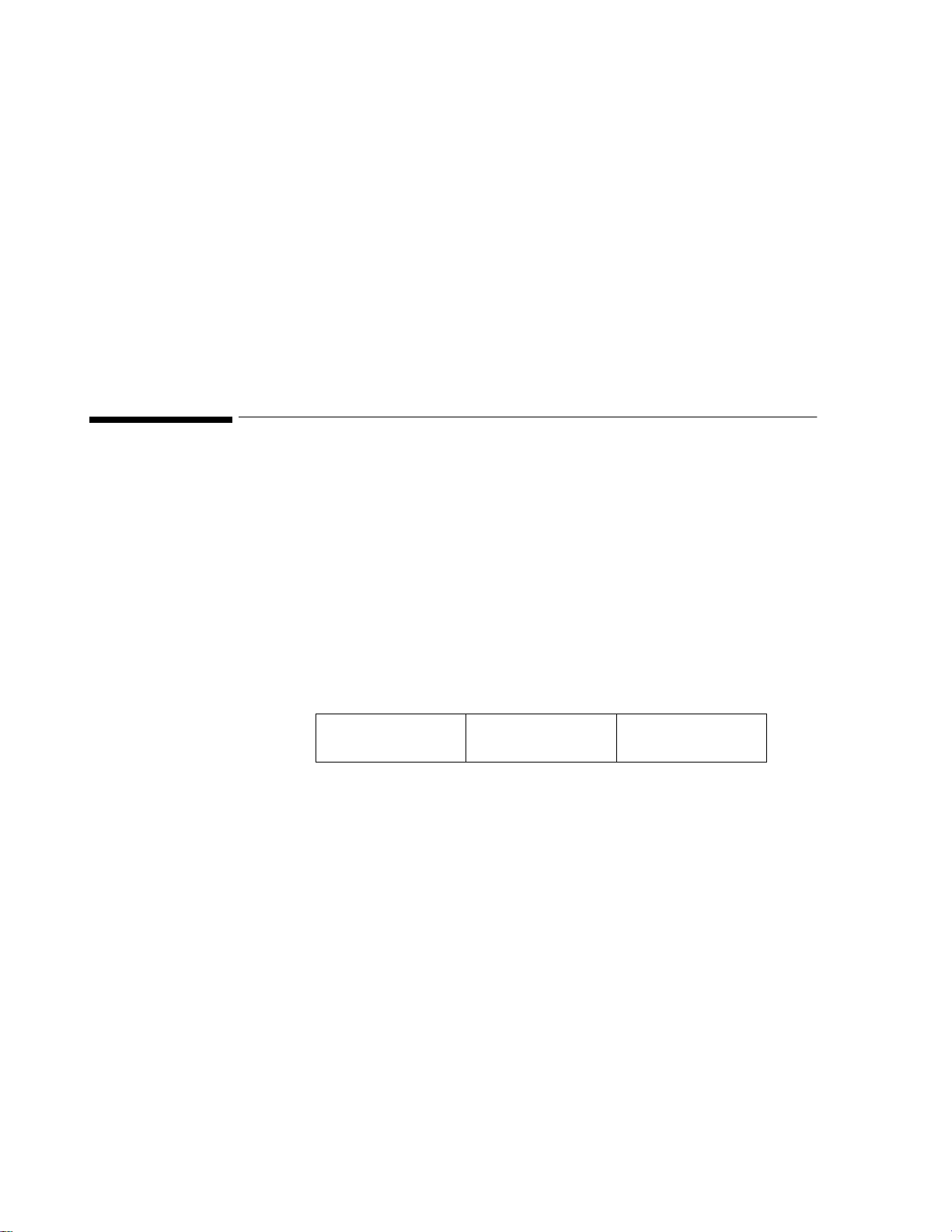

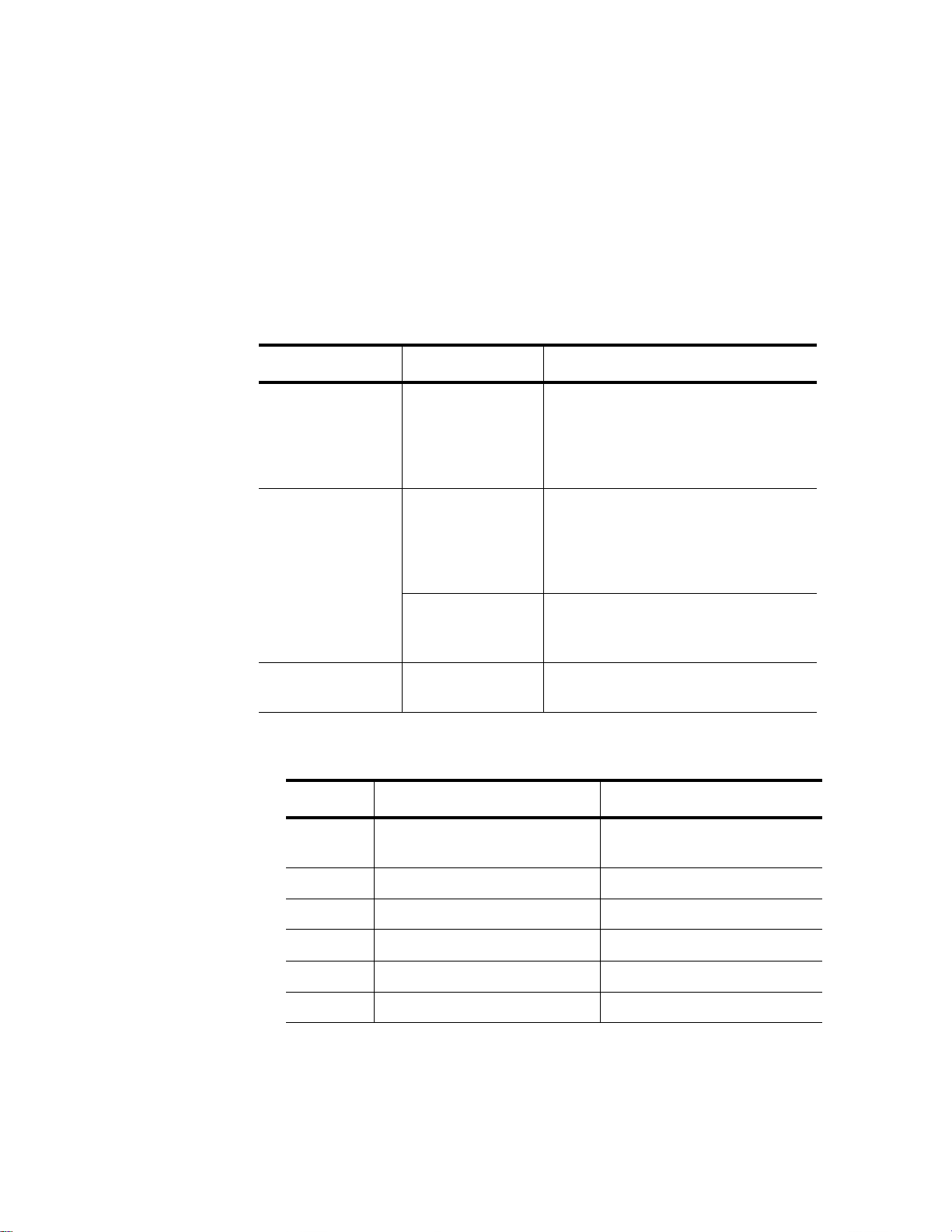

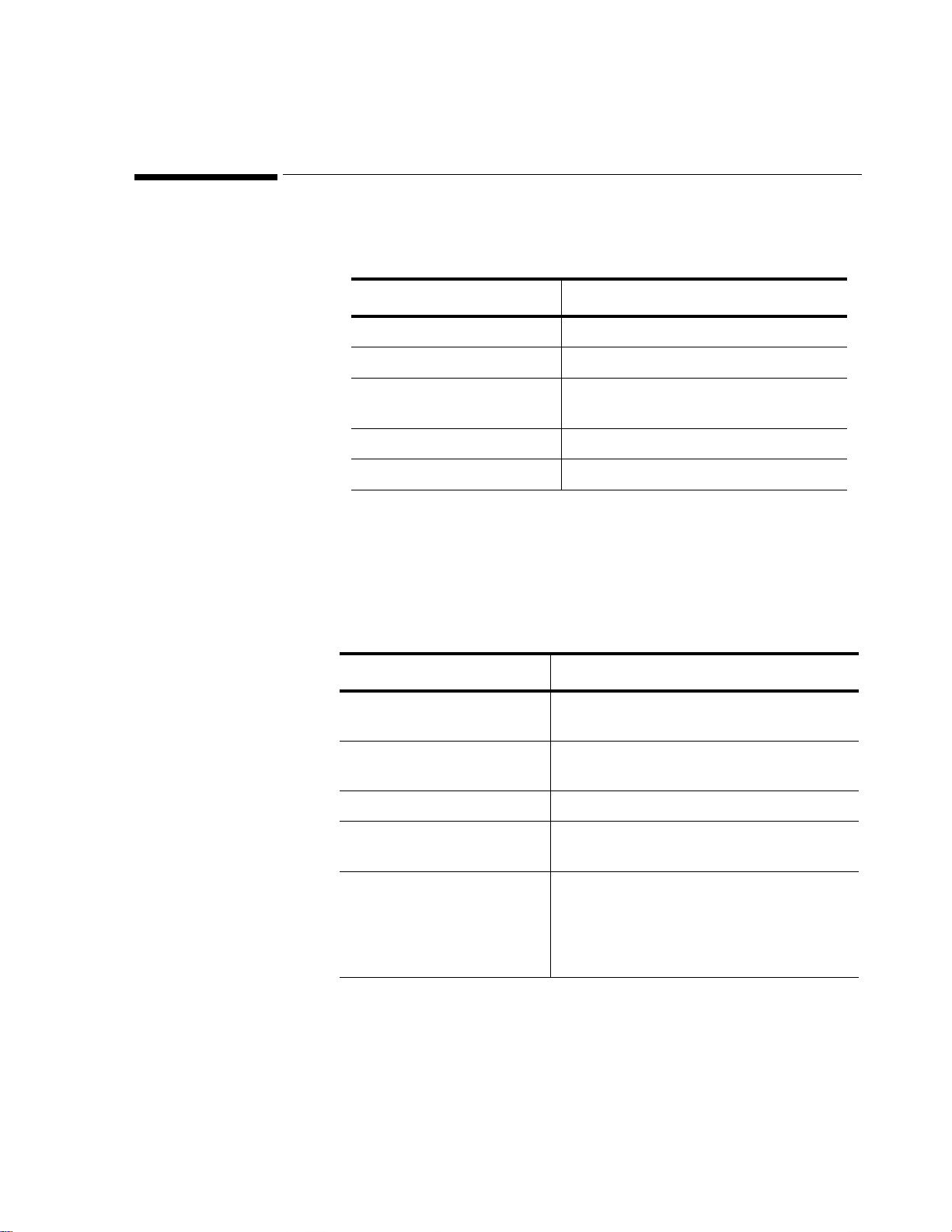

Table 3-1: SDN Error Messages

SDN Error Messages Description

Indicates there is another bed on the system

using the same bed number as this bed. No

data is transmitted on SDN. Message appears

at top of screen.

Indicates this bed is not connected to a

branch in the range #1 through #24. No data

is transmitted on SDN. Message appears at the

top of the screen.

SDN EQUIP MALF Indicates disruption to SDN communication.

Problem may be in this instrument or in SDN.

3-5

Page 34

Troubleshooting Resources, Tools, and Equipment

Table 3-1: SDN Error Messages (Continued)

SDN Error Messages Description

NO OVERVIEW FUNCTIONS

AVAIL AB LE

NO DATA FROM BEDS IN UNIT In this Care Unit there are no beds in the

NO DATA FROM BED A bed which was currently being viewed in

Monitor/terminal is not connected to the

SDN, or it is getting no signals from the ACC;

i.e., it is operating in the Autopoll mode.

same group as this bed and no beds in the All

Beds Care group.

the OVERVIEW section of the screen has

stopped communicating on the SDN. The

message remains until the bed returns or

display is cleared with the CLEAR hard key or

until NEXTBED softkey is used to view

another bed.

Indicates discontinued or cut off data.

Displayed in sector(s) for which no data is

available—in inverse video. If the patient has

been moved or discharged, there are several

ways to clear this message.

Tune the sector to a different bed in the

system using SETUP and NEW BED keys. A

new bed label, waveform data, etc., will

appear if the new bed is active on the

network.

Diagnose the Problem

as SDN or

Non-SDN

Noisy Branch

3-6

NO RECORDER AVAILABLE This message appears when either stored

waveform or real time waveform recordings

are requested if IC recorder is out of paper or

its door is open (IC message CHECK PAPER/

DOOR RECORDER #_____ or NO RECORDER

ON LINE). This message appears for any

record request (stored, real time, or delayed)

if the M/T is in the Autopoll mode or if there

is no primary monitoring IC for this bedside.

Using the symptoms and information gathered in the previous steps,

diagnose and isolate the problem as a malfunction of a specific product or

a problem with the SDN system communication.

Some SDN and non-SDN product related symptoms are listed below.

1. Remove each RJ45 connector one at a time to determine which is the

noisy branch.

Page 35

SDN and ACC System Level Troubleshooting

2. Check the FIRE AXE LED to see if it is still lit and then replace the

RJ45 connector.

3. Check the next branch.

SDN and

Non-SDN Related

Problems

SDN Related Problems Non-SDN Related Problems

Instrument missing on

•

Network Test

Wrong status code for

•

instrument on Network

Test

SDN Error Codes:

•

0 - - - 8 - - - Monitor/

Terminal

5- - - D- - - IC

*If SDN error codes and non-SDN error codes occur, both subsystems must be

considered

Loss of data from one SDN

•

instrument to another

OVERFLOW or FIRE AXE

•

LED illuminated in the

ACC

Refer to the following table for SDN and non-SDN related problems.

Instrument not SDN connected

•

*Product error codes, but none of which

•

are

0 - - - 8 - - - Monitor/Terminal

5- - - D- - - IC

Loss of data at its source

•

Note

Action

• If a product malfunction has been clearly identified, then

troubleshoot that product (or non-SDN subsystem, such as an IC and

recorder) according to the troubleshooting procedures specified in

the associated product’s service manual.

It is highly recommended that the instrument(s) be disconnected from the

SDN during troubleshooting. SDN connections between ICs should be

disconnected when troubleshooting one IC in an IC group if the others are

remaining connected to the network.

• If the FIRE AXE LED in the ACC is illuminated or flickering, look for

a noisy branch. See “Cable Verification Procedures” on page 3-13.

• If SDN communication errors are indicated, and if no specific

product is immediately identified, then go to “STEP #3: Evaluate the

Breadth of the Problem” on page 3-8.

3-7

Page 36

Troubleshooting Resources, Tools, and Equipment

STEP #3: Evaluate the Breadth of the Problem

Decide whether this is a single branch problem or a multiple branch

problem. Find out how many branches are unable to communicate

properly on the SDN; how many branches are unable to receive data from

any other instrument and/or unable to transmit data to any other

instrument.

Test the reception of the bedside with the OVERVIEW mode or with the

NETWORKTEST. Test the reception of ICs under normal monitoring.

Test the transmission of the bedside with the NETWORK TEST at another

bedside or with the OVERVIEW mode at another bedside.

If multiple instruments were missing from the NETWORK TEST display

(STEP #2) or gave status codes other than 001 C normal operation or 0030

self-test, then a multiple branch problem is indicated.

Action

• If more than one branch cannot receive at all or transmit at all, then

troubleshoot the ACC. Refer to the ACC Troubleshooting section.

Other possible sources of multiple branch problems (lower

probability) are given on page 3-12.

• If only 1 branch cannot receive at all or transmit at all, then go to

STEP #4.

Other possible sources of single branch problems (lower probability)

are given on page 3-12.

STEP #4: Self-Test Check of SDN Interface Circuitry

The problem has now been isolated to a system communication problem

on one branch. The problem could reside in the SDN interface board, SDN

cabling, or branch specific circuitry in the ACC. Refer to Figure 3-3.

Note

The SDN interface residing in the bedside/mainframe or IC is more likely to

be the cause of the problem than the branch specific circuitry in the ACC.

Each instrument’s self-test routine checks a portion of its own SDN interface

circuitry (SIC chip, buffer RAM, signature RAM).

3-8

Page 37

SDN and ACC System Level Troubleshooting

Possible Source of Problem

M/T or IC

Wall Box

SDN

Interface

Figure 3-3. SDN Interface Problem Area

If not already done, run the instrument’s self-test on each SDN instrument

on the faulty branch.

Refer to instrument’s service manual for details. Some codes identify

faulty instrument circuitry.

If an instrument malfunction is indicated, troubleshoot that product’s SDN

interface according to the instructions described in the associated

product’s service manual.

Branch Specific Circuitry

in the ACC

ACC

M/T or IC

SDN

Interface

Figure 3-4. SDN Instrument Malfunction

If no specific instrument malfunction is indicated, refer to the following

figure:

Wall Box

ACC

3-9

Page 38

Troubleshooting Resources, Tools, and Equipment

M/T or IC

Wall Box

SDN

Interface

Figure 3-5. SDN Non-Instrument Malfunction

• If the problem affects only one instrument or all the instruments on

the branch, go to STEP #5.

• If the problem does not affect all instruments on the branch, it can

be concluded that the ACC and cabling running up to, but not

including the last “good” instrument, are functioning properly. Go to

STEP #5.

The problem is located in one of the following places:

a. SDN Interface PC Board (drivers, receivers and relays and other

circuitry were not tested in instrument’s self-test routine).

ACC

Caution

b. ACC (components which are branch-specific)

c. Cables/Connectors (LDC, wall box, SDC, connection to ACC)

In order to verify which part of the branch is faulty, it is now necessary to

swap the branch with a known good branch:

At ACC, disconnect RJ45 connectors and jump wires to an unused branch.

CAUTION — Ability to view swapped monitor/terminal:

• If the “unused branch” is not in the same Unit (e.g., same ICU) as the

former branch, then it cannot be viewed in OVERVIEW mode.

Unused bedside branches will be in Care Unit 1 if default values

were programmed in the IC(s) at installation.

• If the “unused branch” is outside the tuning range of the IC, then it

cannot be viewed at that IC.

3-10

Page 39

SDN and ACC System Level Troubleshooting

Warning

Caution

Caution

Warning — Reconnection Warning — Disconnect SDN patient before

swapping:

Disconnect the patient from the monitor/terminal before swapping

branches in the ACC.

EXTEND TEST mode can be used to generate waveforms for

verification.

CAUTION — Disconnection Caution — Data will be missed:

• While a monitor/terminal is disconnected, no alarms are available

from that monitor/terminal at the IC or at any other monitor/

terminal in the OVERVIEW mode.

• While an IC is disconnected, it generates no alarms or alarm

recordings.

CAUTION — Use Appropriate Unused Branch Number:

• For a monitor/terminal, the “unused branch” must be branch #1

through #24. Make sure that the “unused branch” does not have a

telemetry bedside assigned to it.

If a monitor/terminal is placed on branches #0 or #25 through #31,

the message “SDN COMMUNICATION ERROR — ILLEGAL BED

NUMBER” will be displayed. The bedside will be able to receive data,

but will not be able to transmit data.

• For an IC, the “unused branch” must be branch #0 or #25 through

#31.

Make sure that the “unused branch” does not have a telemetry

bedside assigned to it.

STEP #5: Isolating a Problem on A Local Distribution Network (LDN) With Two or More Instruments

The problem has been isolated to one of the SDN interface boards, or to

one of the LDC or system distribution cables (SDC or XSDC).

A problem on the LDN might affect any number of instruments on the

branch.

A problem in one SDN interface might affect other instruments on that

branch without impairing its own function on the SDN.

3-11

Page 40

Troubleshooting Resources, Tools, and Equipment

Miscellaneous Items

The preceding troubleshooting procedures provide a general methodology

which captures the majority of electronic hardware failures. However,

several problems can be identified which will not be caught, and are

elaborated below.

a. Cable checking was not always explicitly stated as a possible problem

source. However, cables should be checked for continuity and shorts

when suspect using the cable verification procedure specified on page

3-13.

Cable intermittents: Moving cables with intermittent connections can

cause symptoms to disappear or reappear unpredictably.

b. Excessive noise on one branch can impair communications on all

branches. This can occur if a raw cable with no wall box connector is

wired to the ACC and the raw ends are shorting to each other or to

conduit. This can also occur if the wall box connections are loose or

LDCs are loosely connected. The FIRE AXE LED will usually be

illuminated. Instruments may disappear and reappear on the Network

Test, or their status may change from 001 C. Noisy branches can be

identified by low voltage levels below ground and high levels above 5V.

Proceed with cable verification procedure specified on page 3-13.

c. Hospital ground may not meet the system specification. If this is

suspected, refer to the ground check procedure on page 3-13.

d. The hospital has installed cables (other than Agilent Technologies SDN

or Agilent Technologies Analog cables) in violation of Agilent

Technologies distance and shielding specifications. The new cables are

causing interference.

e. Overloaded system — Constant or intermittent overflow: In an

overloaded system some branch will be transmitting at the end of the

32 ms poll cycle. All higher numbered branches get no chance to

transmit. The OVERFLOW LED will be illuminated or flickering in the