Page 1

BenchCel Microplate Handler

User Guide

Original Instructions

Page 2

Notices

WARNING

CAUTION

Manual Part Number

G5580-90000 Revision B

November 2020

Copyright

© Agilent Technologies, Inc. 2020

No part of this manual may be reproduced

in any form or by any means (including

electronic storage and retrieval or

translation into a foreign language) without

prior agreement and written consent from

Agilent Technologies, Inc. as governed by

United States and international copyright

laws.

Contact Information

Agilent Technologies Inc.

Automation Solutions

5301 Stevens Creek Blvd.

Santa Clara, CA 95051

USA

Web:

https://www.agilent.com

Contact page:

https://www.agilent.com/en/contactus/page

Documentation feedback:

documentation.automation@agilent.com

Acknowledgments

Microsoft® and Windows® are either

registered trademarks or trademarks of the

Microsoft Corporation in the United States

and other countries.

Warranty

The material contained in this document is

provided “as is,” and is subject to being

changed, without notice, in future editions.

Further, to the maximum extent permitted

by applicable law, Agilent disclaims all warranties, either express or implied, with

regard to this manual and any information

contained herein, including but not limited

to the implied warranties of merchantability

and fitness for a particular purpose. Agilent

shall not be liable for errors or for incidental

or consequential damages in connection

with the furnishing, use, or performance of

this document or of any information contained herein. Should Agilent and the user

have a separate written agreement with

warranty terms covering the material in this

document that conflict with these terms,

the warranty terms in the separate agreement shall control.

Technology Licenses

The hardware and/or software described in

this document are furnished under a license

and may be used or copied only in

accordance with the terms of such license.

Restricted Rights Legend

If software is for use in the performance of

a U.S. Government prime contract or

subcontract, Software is delivered and

licensed as “Commercial computer

software” as defined in DFAR 252.227-7014

(June 1995), or as a “commercial item” as

defined in FAR 2.101(a) or as “Restricted

computer software” as defined in FAR

52.227-19 (June 1987) or any equivalent

agency regulation or contract clause. Use,

duplication or disclosure of Software is

subject to Agilent Technologies’ standard

commercial license terms, and non-DOD

Departments and Agencies of the U.S.

Government will receive no greater than

Restricted Rights as defined in FAR 52.22719(c)(1-2) (June 1987). U.S. Government

users will receive no greater than Limited

Rights as defined in FAR 52.227-14

(June1987) or DFAR 252.227-7015 (b)(2)

(November 1995), as applicable in any

technical data.

Safety Notices

A WARNING notice denotes a hazard. It calls attention to an operating

procedure, practice, or the like that, if

not correctly performed or adhered

to, could result in personal injury or

death. Do not proceed beyond a

WARNING notice until the indicated

conditions are fully understood and

met.

CAUTION notice denotes a hazard.

A

It calls attention to an operating procedure, practice, or the like that, if not

correctly performed or adhered to,

could result in damage to the product

or loss of important data. Do not proceed beyond a

the indicated conditions are fully

understood and met.

CAUTION notice until

Page 3

Contents

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

About this guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

Accessing product user information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

1. Safety guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

General safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safety and regulatory compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Emergency stops . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Safety equipment and features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Potential safety hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

BenchCel Microplate Handler description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Hardware overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Integration options for workstations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Labware considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Software description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3. Installing BenchCel Microplate Handler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Installation workflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Verifying laboratory requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Unpacking BenchCel Microplate Handler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Mounting the robot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

About integrating devices in a BenchCel Workstation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Connecting the power source. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Connecting the pendant directly to the BenchCel device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Connecting the pendant through the Robot Disable Hub . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Connecting and disconnecting the air source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Connecting the computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Installing the shield . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

4. Setting up the BenchCel device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Setup workflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Starting up and shutting down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Creating BenchCel device in the VWorks software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Opening BenchCel Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Creating profiles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Initializing the device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Setting and managing teachpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

iiiBenchCel Microplate Handler User Guide

Page 4

Contents

5. Setting sensor thresholds. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Overview for setting sensor thresholds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Calculating the Plate presence threshold. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Determining the optimum Orientation sensor offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Calculating the Orientation threshold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Worksheet for setting sensor thresholds. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

6. Preparing for a run. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Workflow for operating the BenchCel Microplate Handler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Handling the labware racks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Filling and emptying the labware racks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Installing and uninstalling the labware racks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Performing pre-run checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

7. Maintenance and troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Routine maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Cleaning up after a protocol run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Replacing the fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Hardware problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Software error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Diagnostic tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Adjusting the stacker gripper pressure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Reporting problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

A. Quick reference. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Rack-release button indicator light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

BenchCel Diagnostics - Controls tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

BenchCel Diagnostics - Jog/Teach tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

BenchCel Diagnostics - Labware tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

BenchCel Diagnostics - General Settings tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

BenchCel Diagnostics - Profiles tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Teachpoint Details dialog box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

iviv

BenchCel Microplate Handler User Guide

Page 5

Preface

This preface contains the following topics:

• “About this guide” on page vi

• “Accessing product user information” on page viii

v

Page 6

Preface

About this guide

About this guide

Who should read this guide

This user guide is for people with the following job roles:

Job role Responsibilities

Installer Unpacks, installs, and tests the device before it is used.

Integrator Configures hardware and writes software.

Lab manager,

administrator, or

technician

Operator Performs the daily production work on the device and solves

What this guide covers

This guide describes the G5580A BenchCel Microplate Handler and earlier R-Series

models. This guide covers installation, setup, operation, and maintenance.

This guide does not provide instructions for the following:

• Agilent devices that are integrated with the BenchCel Microplate Handler in a

workstation configuration, such as the Bravo Platform, PlateLoc Thermal

Microplate Sealer, Microplate Labeler, and Labware MiniHub

• Third-party devices

For more information about these topics, see the relevant user guides for these

products.

• Manages the automation system that contains the device

• Develops the applications that are run on the system

• Develops training materials and standard operating

procedures for operators

routine problems.

Software version

This guide is applicable for the following software:

• BenchCel Diagnostics 21.3.0, which is included in VWorks software 14.0 and later.

• BenchCel Diagnostics versions included in VWorks software 12.3 – 13.1.x.

What is new in this edition

and

Description See…

Added descriptions for VWorks software

14.0.

vi

“Software description” on page 29

BenchCel Microplate Handler User Guide

Page 7

Description See…

Preface

About this guide

Related guides

Updated the Robot Disable Hub

descriptions to specify the 3-Port Robot

Disable Hub.

Updated the instructions for creating the

device file to include how to select the

teachpoint for an integrated device.

Updated the profile and teachpoint

descriptions and procedures to reflect

changes introduced in VWorks software

14.0.

Updated the fuse replacement procedure

to make the description consistent for

both 115 V and 230 V power.

Added a description of the indicators on

the Controls tab.

• “Safety equipment and features” on

page 8

• “Connecting the pendant through

the Robot Disable Hub” on page 53

“Specifying BenchCel accessibility at

other devices” on page 72

• “Creating profiles” on page 76

• “Setting and managing teachpoints”

on page 84

• “BenchCel Diagnostics - Profiles

tab” on page 179

“Replacing the fuse” on page 134

“BenchCel Diagnostics - Controls tab” on

page 167

You should use this guide in conjunction with the following guides:

• Automation Solutions Products General Safety Guide. Provides general safety

information and describes potential safety hazards that you might encounter when

using Automation Solutions products. A copy of this safety guide is included with

your shipment.

• VWorks software guides:

– VWorks Automation Control Setup Guide. Explains how to define labware and

labware classes, liquid classes, and pipetting techniques.

The VWorks 14.0 version also explains the VWorks compliance features and

how to set up an experiments databases.

– VWorks Automation Control User Guide. Explains how to create protocols, and

set task parameters for each device in the system.

• BenchCel Microplate Handler Quick Guide. The quick guide summarizes the

instructions in this user guide.

• Agilent Technologies device user guides. These guides explain how to set up and

use the devices that you integrate with the BenchCel Microplate Handler, such as

the Bravo Platform User Guide.

• Third-party device user documents, if applicable. These guides explain how to set

up and use the third-party devices.

BenchCel Microplate Handler User Guide

vii

Page 8

Preface

Accessing product user information

Accessing product user information

About this topic

This topic describes the different formats of user information and explains how to

access it for the Agilent Automation Solutions products.

Where to find user information

The user information is available in the following locations:

• Knowledge base. The help system for the Automation Solutions products is

available from:

– Help menu within the VWorks software: Select Help > Knowledge Base or press

F1.

– From the Windows desktop: Select Start ( ) > All Apps > Agilent

Technologies > VWorks Knowledge Base.

For guidelines on using the VWorks context-sensitive help and knowledge base

features, see Using the knowledge base, below.

• PDF files. The PDF files of the user guides are installed with the VWorks software

(C:\Program Files (x86)\Agilent Technologies\VWorks\UserGuides) and are

available in the VWorks Knowledge Base.

• Website. You can search the online VWorks Knowledge Base or download the latest

version of any PDF file from the Agilent website at www.agilent.com/chem/askb.

Accessing safety information

Safety information for the Agilent Automation Solutions devices appears in the

Automation Solutions Products General Safety Guide and in the corresponding device

safety guide or user guide.

You can also search the knowledge base or the PDF files for safety information.

Using the knowledge base

Knowledge base topics are displayed using web browser software such as Microsoft

Edge.

Note: If you want to use Internet Explorer to display the topics, you might have to allow

local files to run active content (scripts and ActiveX controls). To do this, in Internet

Explorer, open the Internet Options dialog box. Click the Advanced tab, locate the

Security section, and select Allow active content to run in files on my computer.

viii

BenchCel Microplate Handler User Guide

Page 9

Accessing product user information

Opening the help topic for an area in the VWorks window

Preface

To access the context-sensitive help feature:

1 In the main window of the VWorks software, click the help button . The pointer

changes to . Notice that the different icons or areas are highlighted as you

move the pointer over them.

2 Click an icon or area of interest. The relevant topic or document opens.

BenchCel Microplate Handler User Guide

ix

Page 10

Preface

Accessing product user information

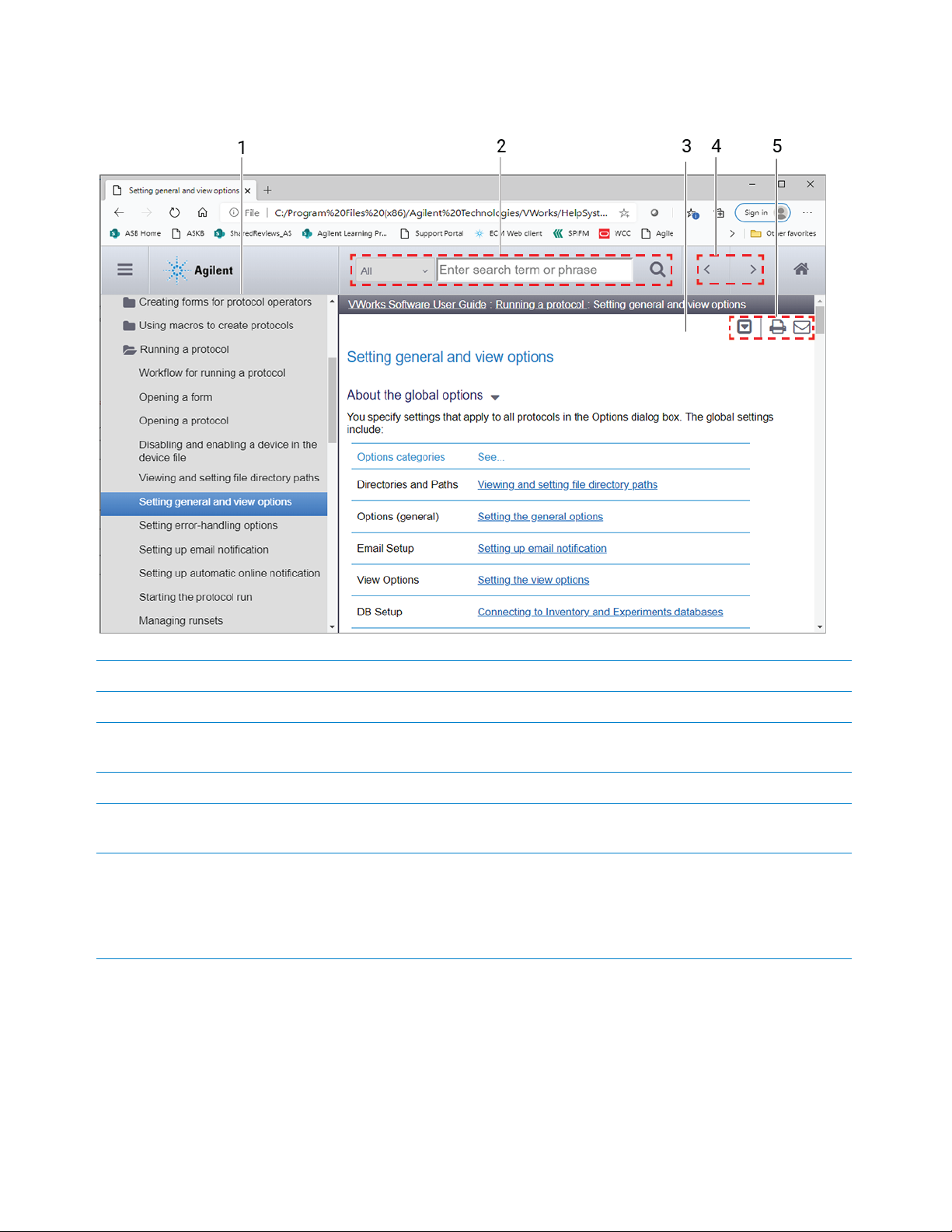

Features in the Knowledge Base window

Step For this task...

1 Contents pane. Lists all the books and the table of contents of the books.

2 Search. Allows you to search the Knowledge Base (all products or selected products) using

keywords.

3 Topic area. Displays the selected online help topic.

4 Navigation buttons. Enable you to navigate through the next or previous topics listed in the Contents

tab.

5 Toolbar buttons: Enable you to:

• Expand or collapse all the sections in a topic that has drop-down headings.

• Print the topic.

• Send feedback by email for a given topic.

x

BenchCel Microplate Handler User Guide

Page 11

1 Safety guidelines

This chapter contains the following topics for the BenchCel Microplate Handler:

• “General safety information” on page 2

• “Safety and regulatory compliance” on page 3

• “Emergency stops” on page 5

• “Safety equipment and features” on page 8

• “Potential safety hazards” on page 10

1

Page 12

1 Safety guidelines

WARNING

General safety information

General safety information

Before installing and using the device

Before using the BenchCel Microplate Handler, make sure that you are properly trained

in:

• General laboratory safety

• The correct and safe operation of the BenchCel Microplate Handler

• The correct and safe operation of devices used in combination with the BenchCel

Microplate Handler

Changing or modifying the BenchCel safety equipment may prevent the safe

operation of the BenchCel Microplate Handler, invalidate its safety compliance, and

lead to personal injury or property damage. Any customer who does not use the

supplied safety equipment or who modifies the supplied safety equipment assumes

full responsibility for providing an appropriate level of safety for its operators and for

providing the applicable safety compliance marking and documentation.

General safety precautions

For the general safety precautions, the intended product use statement, and the list of

safety labels, see the Automation Solutions Products General Safety Guide.

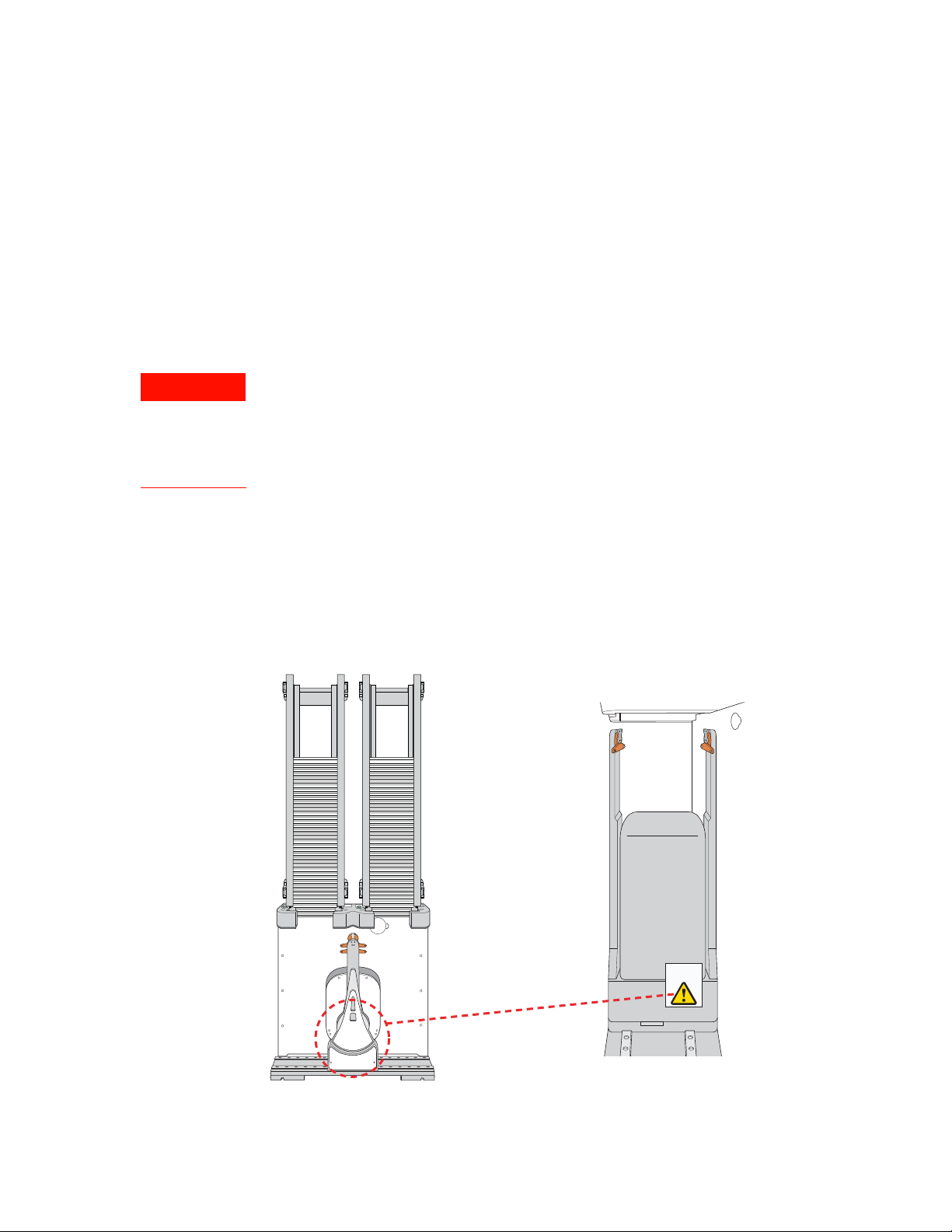

The following figure shows the location of the safety label on the BenchCel Microplate

Handler.

Figure

Safety label location (front view and side view)

2

BenchCel Microplate Handler User Guide

Page 13

Related information

For information about... See...

1 Safety guidelines

Safety and regulatory compliance

General precautions, intended product

use statement, and list of safety labels

Regulatory compliance “Safety and regulatory compliance” on

Stopping in an emergency “Emergency stops” on page 5

Safety equipment “Safety equipment and features” on page 8

Potential hazards specific to the

BenchCel Microplate Handler

Safety and regulatory compliance

About this topic

This topic lists the compliance regulations and standards for the BenchCel Microplate

Handler.

Note: Earlier models of the BenchCel Microplate Handler may not comply with all the

standards listed in this topic.

Automation Solutions Products General

Safety Guide

page 3

“Potential safety hazards” on page 10

Compliance information

The BenchCel Microplate Handler is considered partly completed machinery as defined

by the Machinery Directive of the European Union. Therefore, the BenchCel Microplate

Handler is provided with a Declaration of Incorporation and no CE marking. The

BenchCel Microplate Handler is intended to be integrated into a conforming completed

machine (workstation). A customer in the European Union (EU) that acquires a

standalone BenchCel Microplate Handler is responsible for this integration and for CE

marking the completed workstation. The BenchCel Microplate Handler is designed to

comply with the standards listed in the table below.

Unless specifically requested by the customer, BenchCel Workstations provided by

Agilent Technologies are configured to conform to the Machinery Directive and bear

the CE marking. The Declaration of Conformity shipped with the BenchCel Workstation

describes the specific configuration that has been evaluated for conformity. Any

deviations from the specified configuration may invalidate the Declaration of

Conformity. See the Declaration of Conformity for details.

An EU customer that requests Agilent Technologies to provide a nonconforming

BenchCel Workstation must assume responsibility as the manufacturer for completing

the workstation in conformity with the applicable directives, including the Machinery

Directive. In the case of a nonconforming BenchCel Workstation, each component that

Agilent Technologies supplies will carry a Declaration of Conformity or Declaration of

Incorporation, as appropriate, to be used by the manufacturer to compile the technical

construction file.

BenchCel Microplate Handler User Guide

3

Page 14

1 Safety guidelines

Safety and regulatory compliance

Regulatory Compliance Standard

EMC

European Union EMC Directive 2014/30/EU

Canada ICES/NMB-001:2006

Australia/New Zealand AS/NZS CISPR 11:2011

RoHS

European Union RoHS Directive 2011/65/EU

Safety

European Union Machinery Directive 2006/42/EC

IEC 61326-1:2012 / EN 61326-1:2013

Low Voltage Directive 2014/35/EU

IEC 61010-1:2001 / EN61010-1:2001

IEC 61010-2-081:2001+A1:2003 /

EN 61010-2-081:2002+A1:2003

Canada CAN/CSA-C22.2 No. 61010-1-04

CAN/CSA-C22.2 No. 61010-2-081-04

USA ANSI/UL 61010-1:2004

Electromagnetic compatibility

If the BenchCel Microplate Handler causes interference with radio or television

reception, which can be determined by turning the device off and on, try one or more of

the following measures:

• Relocate the radio or television antenna.

• Move the device away from the radio or television.

• Plug the device into a different electrical outlet, so that the device and the radio or

television are on separate electrical circuits.

• Make sure that all peripheral devices are also certified.

• Make sure that appropriate cables are used to connect the device to peripheral

equipment.

• Consult your equipment dealer, Agilent Technologies, or an experienced technician

for assistance.

Changes or modifications not expressly approved by Agilent Technologies could void

the user's authority to operate the equipment.

Sound emission declaration

Sound pressure: Lp < 70 dB according to EN ISO 779:2010.

4

BenchCel Microplate Handler User Guide

Page 15

Schalldruckpegel: Lp < 70 dB nach EN ISO 779:2010.

WARNING

CAUTION

WARNING

Related information

For more information about… See…

General safety and labels “General safety information” on page 2

Safety hazards “Potential safety hazards” on page 10

Stopping in an emergency “Emergency stops” on page 5

Safety equipment “Safety equipment and features” on page 8

Emergency stops

The BenchCel Microplate Handler is equipped with an interlock circuit and emergencystop pendant.

1 Safety guidelines

Emergency stops

To avoid potential injury, Agilent recommends that you install a main emergency

stop button (Robot Disable Hub) that will stop the BenchCel robot and all other

devices on the safety interlock circuit simultaneously. In addition, all operators must

be instructed in the emergency stop procedure.

You might not be able to resume a protocol after an emergency stop. Do not use an

emergency stop to pause a run. To pause and continue a run, use the appropriate

commands in the automation software.

Stopping in an emergency

After pressing the emergency-stop button, the robot arm might have momentum and

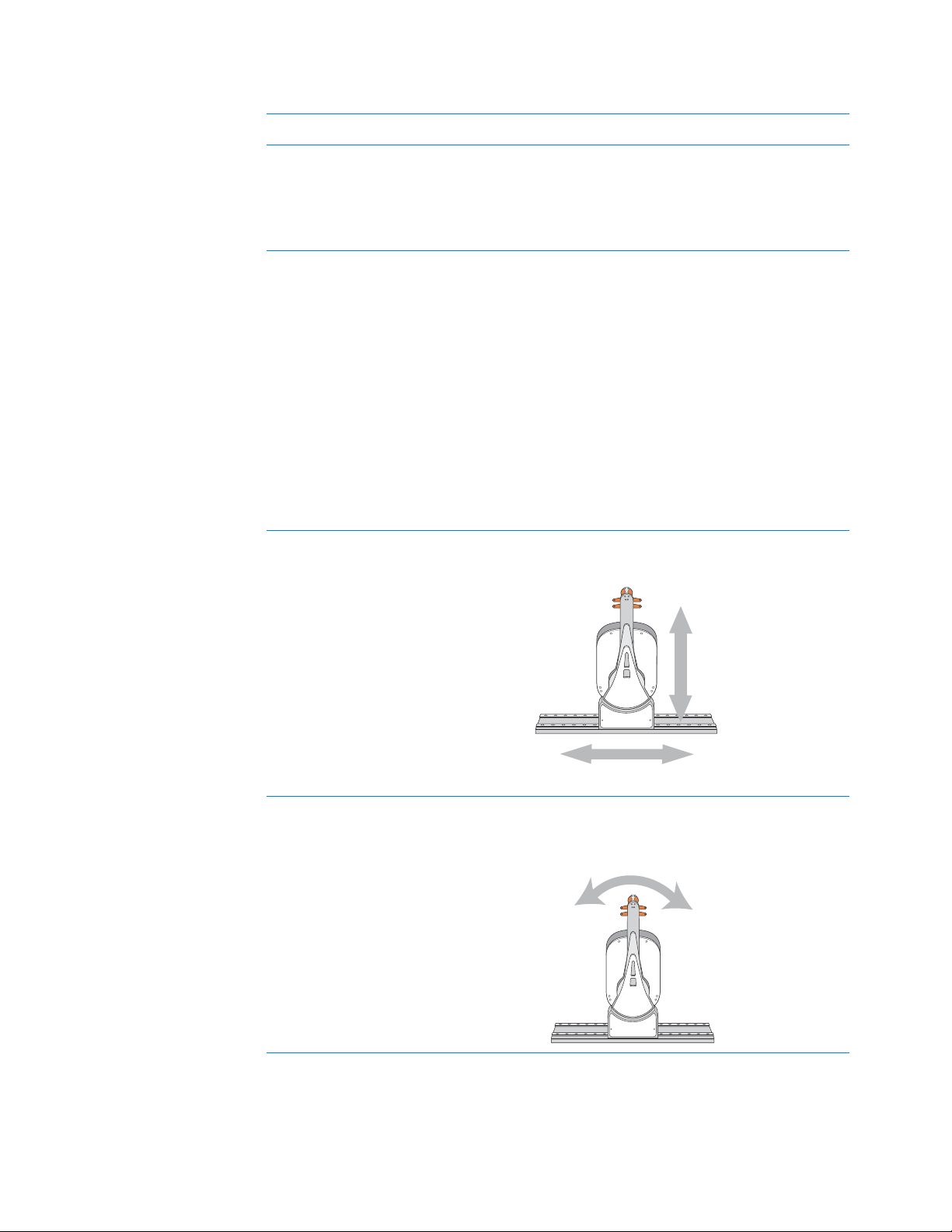

continue to move until it comes to the end of its travel in the x-axis, z-axis, or thetaaxis or until it bumps into an obstacle. Stay clear of the robot until it stops moving.

To perform an emergency stop:

Press the red button on the pendant. The safety interlock circuit is interrupted,

disabling the robot motors. The BenchCel Microplate Handler operation stops.

BenchCel Microplate Handler User Guide

5

Page 16

1 Safety guidelines

Emergency stops

Recovering from an emergency stop

After you press the button on the emergency-stop pendant, the robot stops. One of the

following occurs:

• If you stopped a protocol run, a dialog box opens in the VWorks software.

• If you stopped the robot while diagnosing problems in BenchCel Diagnostics, a

motor-disable message appears on the screen.

Use the following procedure to recover in either case.

To recover the BenchCel device after an emergency stop:

1 If the robot dropped labware before or during the emergency stop, remove labware

that was dropped. Also remove labware at teachpoints or other locations.

2 If the BenchCel robot attempted to place labware at a location that was not free, a

collision might have occurred resulting in misalignment of the robot gripper. Check

the robot gripper alignment:

a Move the robot arms so that they are perpendicular to the x-axis.

b Make sure the bottom of the robot gripper pads are perpendicular to the robot

arms. If they are not, contact Agilent Technical Support.

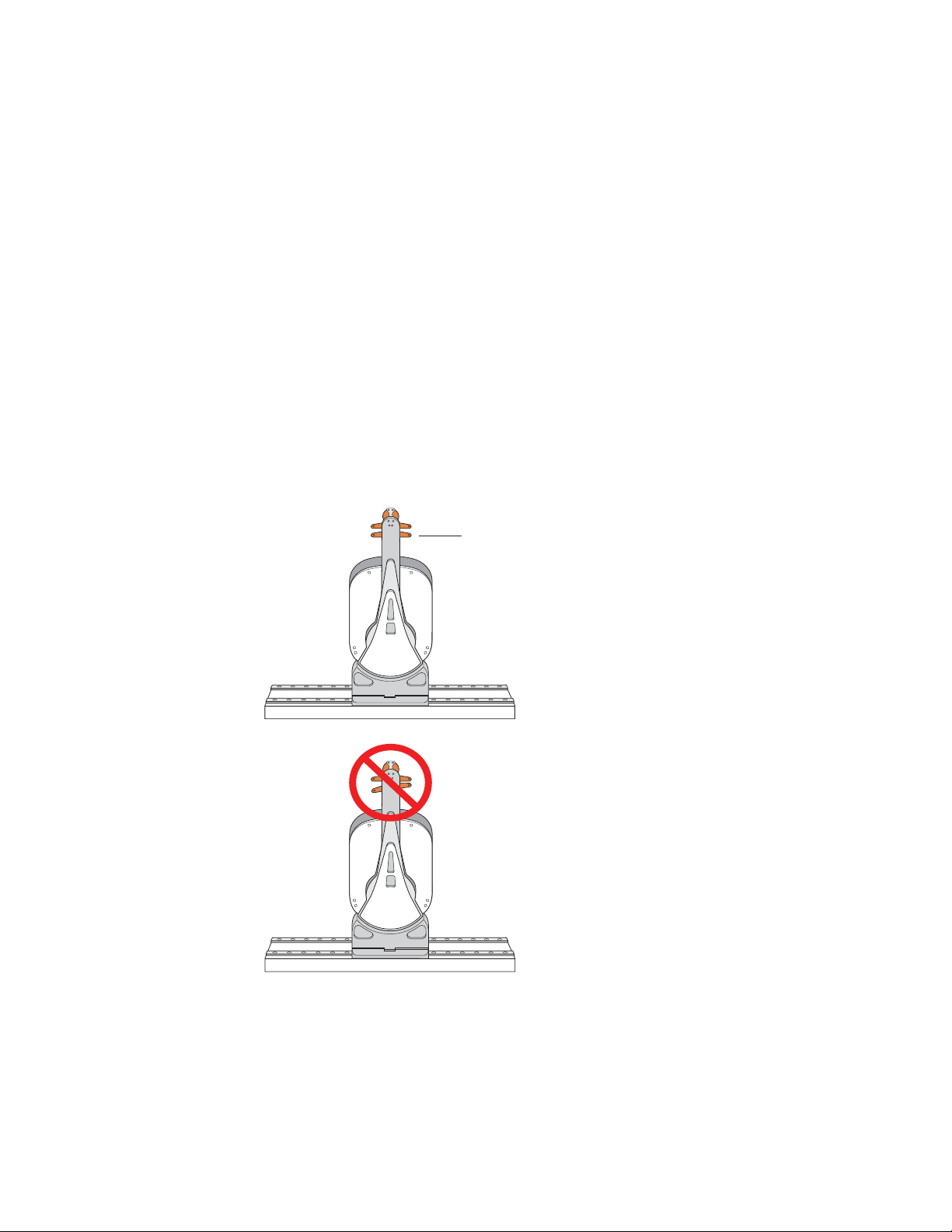

Figure

Gripper alignment: (A) correct alignment, and (B) incorrect alignment

A) Correct alignment

B) Incorrect - misaligned

3 To re-enable the motors:

a At the emergency-stop pendant, turn the button clockwise to release it.

6

BenchCel Microplate Handler User Guide

Page 17

1 Safety guidelines

Emergency stops

b In the VWorks software message dialog box, select an appropriate option to

continue:

Selection Description

Diagnostics Opens the BenchCel Diagnostics dialog box. See step 4.

Note: This selection is available only when you are in the

middle of a protocol run and not while you are in BenchCel

Diagnostics.

Retry Attempts to restart the current command or task in the

run.

Ignore and

continue

Abort Aborts the current command or task in the run. Select

Ignores the current command or task and continues to the

next command or task in the protocol sequence.

Abort if you have determined that the protocol run is not

recoverable.

4 Optional. In BenchCel Diagnostics, use the available commands to manually move

If a physical crash occurred, always start BenchCel Diagnostics to home the robot and

verify teachpoints.

Related information

For information about… See…

Pausing and resuming protocol runs VWorks Automation Control User Guide

Using commands in BenchCel

Diagnostics

Complete list of available commands

in BenchCel Diagnostics

For a full description of the selections, see the VWorks Automation Control User

Guide.

the robot or other components, including:

• Release the microplate that the robot is currently holding.

• Upstack the microplate that the robot is currently holding.

• Replace the lid on the microplate.

• Home the robot.

• Verify teachpoints.

For details, see “Diagnostic tools” on page 146.

“Diagnostic tools” on page 146

“Quick reference” on page 165

Reporting a problem “Reporting problems” on page 162

BenchCel Microplate Handler User Guide

7

Page 18

1 Safety guidelines

WARNING

Safety equipment and features

Safety equipment and features

About this topic

This topic describes the safety equipment and features of the BenchCel Microplate

Handler that are required to protect operators from moving-parts hazards.

Changing or modifying the BenchCel safety equipment may prevent the safe

operation of the BenchCel Microplate Handler, invalidate its safety compliance, and

lead to personal injury or property damage. Any customer who does not use the

supplied safety equipment or who modifies the supplied safety equipment assumes

full responsibility for providing an appropriate level of safety for its operators and for

providing the applicable safety compliance marking and documentation.

Shields

Make sure the BenchCel device is enclosed in the supplied shield. The shield restricts

access to the BenchCel robot while the BenchCel Microplate Handler is operating.

Figure

BenchCel front shield

8

Additional shields may be required on devices that are integrated with the BenchCel

Microplate Handler, such as the Bravo Platform.

In addition, a light curtain connected to the safety interlock circuit may be required.

BenchCel Microplate Handler User Guide

Page 19

WARNING

To reduce the risk of injury from moving parts, ensure that the BenchCel shield and

WARNING

WARNING

the shields for any integrated devices are installed on the workstation.

Operating the Bravo Platform or Microplate Centrifuge with Loader without a safety

shield or a light curtain connected to the safety interlock circuit increases the risk of

injury.

Safety interlock circuit

To avoid potential injury, Agilent recommends that you install a main emergency

stop button (Robot Disable Hub) that will stop the BenchCel robot and all other

devices on the safety interlock circuit simultaneously. In addition, all operators must

be instructed in the emergency stop procedure.

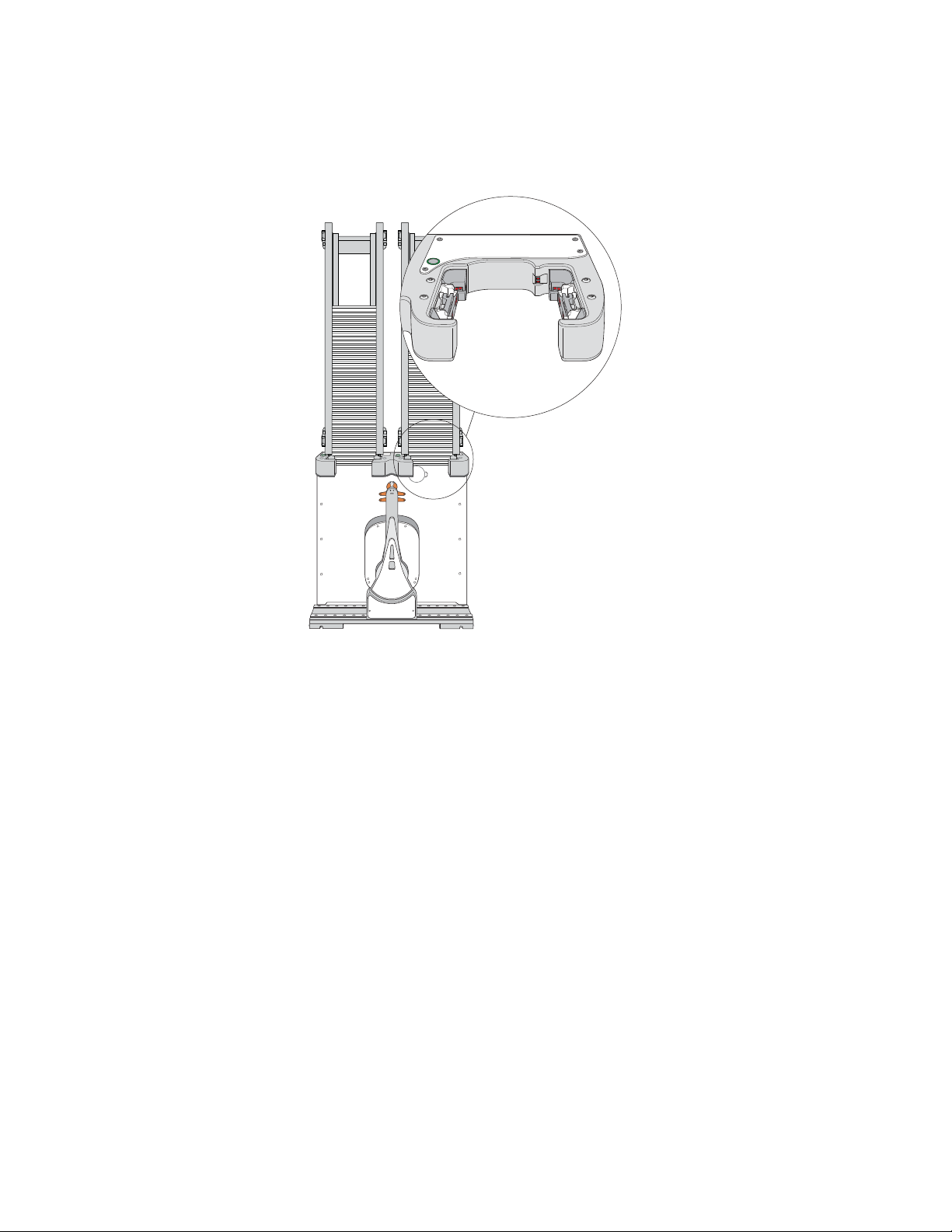

The BenchCel Microplate Handler has a safety interlock circuit that is designed to

protect operators from moving-parts hazards. The safety interlock circuit must be

closed for the device to operate. The pendant connects to the safety interlock circuit.

Pressing the red button on the pendant trips the interlock circuit and causes the motion

of the BenchCel operation to stop.

1 Safety guidelines

Safety equipment and features

Figure

When the BenchCel device is integrated with another device that has a safety interlock

circuit, such as the Bravo Platform, Agilent Technologies uses the Robot Disable Hub to

connect all the devices on the interlock circuit. Pressing the red button on a pendant or

interrupting a light curtain connected to the Robot Disable Hub will trip the safety

interlock circuit and stop all the devices connected to the circuit.

Figure

Related information

For information about… See…

Emergency-stop pendant

Robot Disable Hub

Pendants Power

Devices

Rx

Light Curtain

Tx

BenchCel Microplate Handler User Guide

Stopping in an emergency “Emergency stops” on page 5

Product compliance “Safety and regulatory compliance” on

page 3

9

Page 20

1 Safety guidelines

WARNING

WARNING

Potential safety hazards

For information about… See…

Moving parts and other hazards “Potential safety hazards” on page 10

Safety labels and general information “General safety information” on page 2

Reporting a problem “Reporting problems” on page 162

Potential safety hazards

About this topic

This topic contains precautions about potential hazards that are specific to the

BenchCel Microplate Handler. In addition to the following potential hazards, make sure

that you understand how to avoid the general hazards described in the Automation

Solutions Products General Safety Guide.

The potential hazards that you can encounter when using the BenchCel Microplate

Handler include the following:

• “Moving parts” on page 10

• “Sharp edges and pinch hazards” on page 11

• “Infrared LED injury hazard” on page 11

• “Static electricity” on page 12

• “Improper access or use” on page 12

• “Lifting hazard” on page 12

Moving parts

10

To minimize potential injury, the BenchCel device is designed to stop immediately if the

robot head hits an obstacle while it is in operation. However, be aware that the robot

moves with considerable force in the vertical or z-axis direction and could pierce your

skin with one of its grippers.

Not all circumstances can be foreseen and serious injury is possible. It is the

responsibility of every operator to follow warnings and safety labels and keep out of the

robot’s workspace whenever it is likely to move.

The BenchCel Microplate Handler has moving parts that can injure you if you deviate

from the procedures given in this guide. Keep your fingers, hair, clothing, and jewelry

away from the BenchCel Microplate Handler while it is in motion.

To avoid potential injury, do not touch the BenchCel Microplate Handler as you start

the software. The robot head moves when the device initializes.

BenchCel Microplate Handler User Guide

Page 21

WARNING

Never touch any of the moving parts or attempt to remove or add labware while the

WARNING

WARNING

WARNING

BenchCel Microplate Handler is in operation. The robot head moves with

considerable force and can cause pinching, piercing, or bruising injury if you are in

the path of the robot head or gripper.

Sharp edges and pinch hazards

Pinch hazard! Keep your fingers out of the path of the labware racks when you mount

the racks on the BenchCel device.

Use the rack handle to carry the labware racks. Do not hold a rack by the interior

edges. The interior edges might have sharp surfaces that could cause cuts if handled

improperly.

Figure Sharp surfaces on labware rack

1 Safety guidelines

Potential safety hazards

Infrared LED injury hazard

BenchCel Microplate Handler User Guide

Do not stare directly at the light-emitting diodes (LEDs) inside the stacker heads

when the device is on. Such exposure to the LEDs can cause eye injury.

Each BenchCel stacker head contains seven infrared LEDs that detect the presence of

a labware rack, microplates, and microplate notches. The LEDs are capable of

dissipating 100 mW of power. Do not stare directly at the LEDs when the BenchCel

Microplate Handler is turned on.

11

Page 22

1 Safety guidelines

CAUTION

CAUTION

WARNING

CAUTION

Potential safety hazards

Static electricity

Improper access or use

The rack-release button at the top of the stacker head on the BenchCel device is

sensitive to static electricity. Static electricity can cause a potential loss of motor

control and loss of communication with the BenchCel device. Ensure that you

discharge any potential static electricity before touching the rack-release button. To

discharge static electricity, you can touch the white painted or metal surface of the

BenchCel device before touching the rack-release button.

Improper use by an untrained user could damage the BenchCel Microplate Handler.

For example, the robot gripper could collide with a stacker if a teachpoint is not

defined properly.

Ensure that only fully trained BenchCel administrators have access to the user account

passwords.

Lifting hazard

The BenchCel device without labware racks weighs 28 – 51 kg (61.7 – 112.4 lb),

depending on the configuration. Attempting to lift or move the BenchCel device

without assistance could cause personal injury. Request assistance and use proper

lifting techniques when lifting or moving the device.

If the BenchCel Microplate Handler is incorrectly packaged and moved by someone

other than an Agilent employee, the device may be damaged. Such damage is not

covered by the warranty.

Before moving a BenchCel Microplate Handler, ensure the new location meets the

laboratory requirements.

Related information

For more information about… See…

General safety “General safety information” on page 2

Stopping in an emergency “Emergency stops” on page 5

Shields, pendants, and safety

interlock circuit

“Safety equipment and features” on page 8

12

Locations of hardware components “Hardware overview” on page 15

Site laboratory requirements “Verifying laboratory requirements” on

page 37

Reporting problems with the

BenchCel Microplate Handler

“Reporting problems” on page 162

BenchCel Microplate Handler User Guide

Page 23

2Introduction

This chapter contains the following topics:

• “BenchCel Microplate Handler description” on page 14

• “Hardware overview” on page 15

• “Integration options for workstations” on page 25

• “Labware considerations” on page 27

• “Software description” on page 29

13

Page 24

2 Introduction

BenchCel Microplate Handler description

BenchCel Microplate Handler description

Description

The BenchCel Microplate Handler is a microplate-processing automation device that:

• Stores stacks of labware (microplates, tip boxes, and tube racks) to be processed

during a protocol run.

• Moves labware to and from integrated devices such as the Bravo Platform,

PlateLoc Thermal Microplate Sealer, or Microplate Labeler for processing.

Figure

BenchCel Microplate Handler with safety shield and two labware racks

Configurations

14

The BenchCel Microplate Handler is available in three options:

• BenchCel 2R has two stackers that support two labware racks

• BenchCel 4R has four stackers that support four labware racks

• BenchCel 6R has six stackers that support six labware racks

The BenchCel Microplate Handler is included in the following standard Agilent

workstations:

• G5590A BenchCel Workstation

• G5591A Bravo BenchCel Workstation

BenchCel Microplate Handler User Guide

Page 25

Related information

WARNING

For more information about… See…

2 Introduction

Hardware overview

Agilent devices that you can integrate

in a BenchCel Workstation

Hardware component description “Hardware overview” on page 15

Automation-ready labware “Labware considerations” on page 27

Safety information “Safety guidelines” on page 1

Hardware overview

About this topic

This topic describes the hardware features of the BenchCel device. Note that the

figures in this topic show a BenchCel 2R device with two stackers that support two

labware racks. All the major components and functions are the same for the

BenchCel 4R (four stackers) and BenchCel 6R (six stackers).

Do not operate the BenchCel Microplate Handler without the safety shield. Doing so

increases the risk of injury.

“Integration options for workstations” on

page 25

BenchCel Microplate Handler User Guide

15

Page 26

2 Introduction

1

2

3

4

5

6

7

8

9

Hardware overview

Front view

Item Feature Description

1 Labware

rack

2 Stacker

head

The accessory that stores labware to be processed in a run.

For details, see “Labware racks” on page 24.

The structure at which:

• A labware rack is loaded. Two sensors inside of each

stacker head detect the presence of the racks.

• A microplate is checked for type and orientation using a

plate-presence sensor and four plate-orientation sensors.

• A microplate is lowered into the stacker grippers to begin

a run.

See “Stacker head” on page 20 for the location and detailed

descriptions of the sensors.

3 Air

pressure

regulator

The knob that you turn to adjust the air pressure inside the

device. Compressed air is used to move components inside

the stacker heads. Each regulator controls the air pressure to

the two adjacent stacker heads. For details, see “Adjusting the

stacker gripper pressure” on page 158.

4 Safety

shield

The clear panel that is installed on the front of the BenchCel

device to prevent access while it is in operation.

16

BenchCel Microplate Handler User Guide

Page 27

2 Introduction

theta-axis

+

--

Hardware overview

Item Feature Description

5 Pendant The component that is part of the safety interlock circuit,

which must be closed for the BenchCel device to operate.

Pressing the raised button on the pendant interrupts the

safety circuit and disables the robot motors. Use this method

of stopping the robot for emergencies only.

6 Rack-

release

button

7 Robot

head

The button that unlocks the rack for removal. The rack-release

button at the top of each stacker head displays different

colors to indicate the state of the stacker head:

• Green. The labware rack is installed correctly on the

BenchCel device and the microplates are unloaded. The

stack of microplates are ready for processing or you can

unlock and remove the labware rack.

• Flashing green. The labware rack is unlocked and can be

removed.

• Blue. The stack of microplates is loaded. You cannot

unlock and remove the labware rack.

• Red. The clamps are open without a rack installed. Do not

install a rack until the clamps are closed.

The component that moves horizontally along the x-axis and

vertically along the z-axis.

+

z-axis

--

--

x-axis

8 Robot

arms

Two parallel structures that are attached to and rotate about

the robot head along the theta-axis.

BenchCel Microplate Handler User Guide

+

17

Page 28

2 Introduction

Hardware overview

Item Feature Description

Back view

9 Robot

grippers

The structures inside the robot arms that close and open to

hold and release a microplate. Using the provided software,

you can adjust the distance between the grippers to hold a

microplate loosely or tightly.

Robot grippers

1

2

3

4

5

6

18

BenchCel Microplate Handler User Guide

Page 29

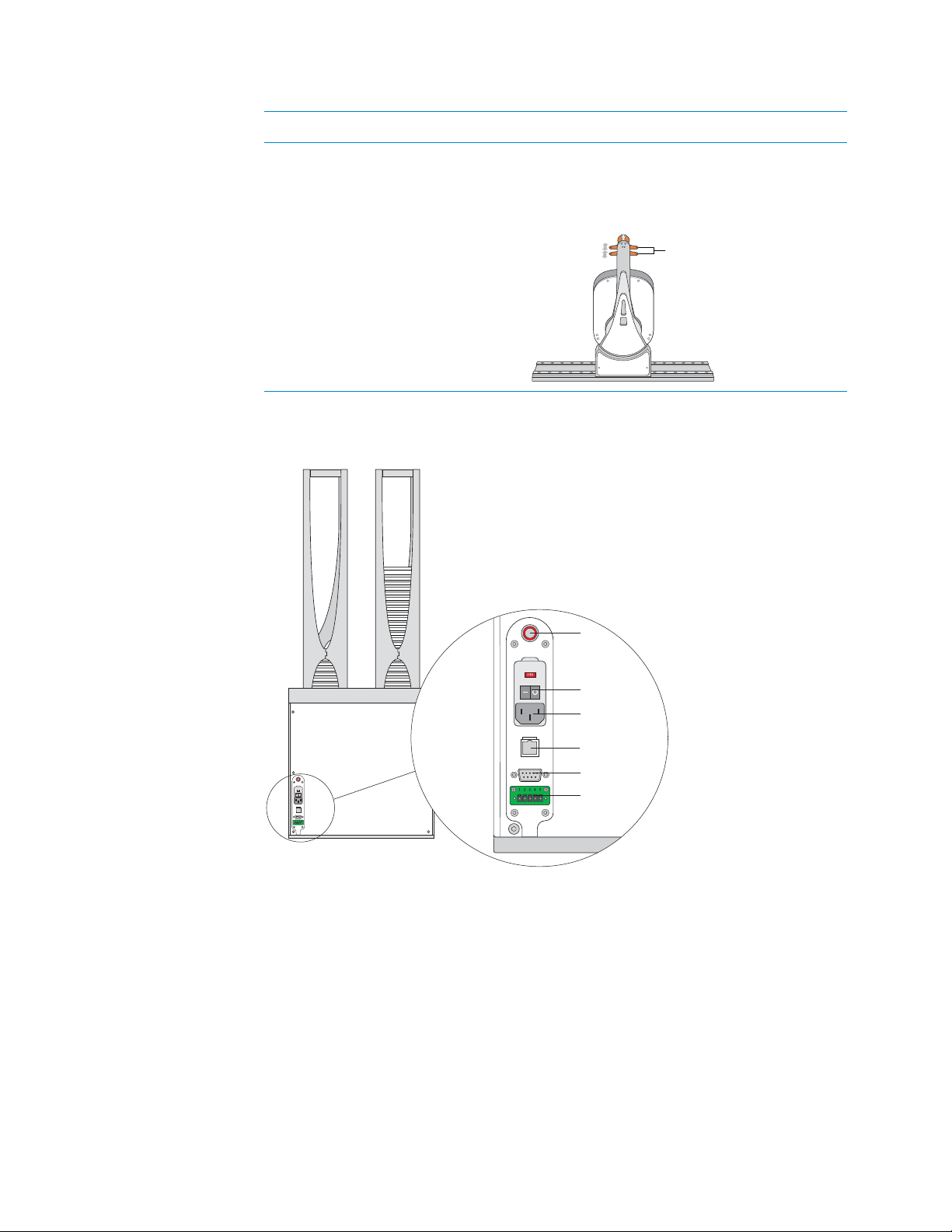

Item Feature Description

2 Introduction

Hardware overview

1 Air-input

fitting

2 Power

Connects the air tubing to the BenchCel device. Compressed

air is used to actuate components inside the stacker head.

Turns on or off the power to the BenchCel device.

switch

3 AC power

Connects the power cord to the BenchCel device.

entry

4 Ethernet

port

Connects the Ethernet cable from the controlling computer to

the BenchCel device to allow communication between the

computer and the device. Use this port as an alternative to the

serial connection.

5 Serial port Connects the serial cable from the controlling computer to the

BenchCel device to allow communication between the

computer and the device. Use this port as an alternative to the

Ethernet connection.

6 Pendant

port

Connects the emergency-stop pendant to the safety interlock

circuit. The connection is made either directly or through an

emergency-stop control, such as the Robot Disable Hub.

IMPORTANT The safety interlock circuit must be closed for

the BenchCel Microplate Handler to operate.

BenchCel Microplate Handler User Guide

19

Page 30

2 Introduction

Hardware overview

Stacker head

At the top of the BenchCel device are stacker heads that contain infrared sensors and

mechanical components that load and unload microplates during operation.

The following table lists and describes the various components inside the stacker head.

20

BenchCel Microplate Handler User Guide

Page 31

Feature Description

Plate-presence sensor

Rack-presence sensors

2 Introduction

Hardware overview

Plate-presence

sensor

Rack-presence

sensors

Detects the presence of a microplate in the stack. One platepresence sensor is on the back wall of each stacker head.

Detect the presence of labware racks. Two rack sensors are on

the back wall of each stacker head.

BenchCel Microplate Handler User Guide

21

Page 32

2 Introduction

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

1234

5678

9 101112131415161718192021222324

Notches

Plate-orientation sensor

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

1234

5678

9 101112131415161718192021222324

Notches

Clamps

Hardware overview

Feature Description

Plate-orientation

sensors

Detect the presence of notches in microplates. Four sensors are

in the inside corners of each stacker head. For details of how the

sensors work, see “Setting sensor thresholds” on page 99.

Clamps Close and open the grippers at the bottom of the labware rack to

hold and release microplates during loading, unloading,

downstacking, and upstacking processes. Two clamps are

inside each stacker head. Compressed air is used to open and

close the clamps.

22

BenchCel Microplate Handler User Guide

Page 33

2 Introduction

Shelves

Hardware overview

Feature Description

Shelves Provide leveling surfaces for the microplates, thus ensuring

accurate robot gripping, during the downstacking process. Two

shelves (four leveling surfaces) are inside each stacker head.

Compressed air is used to move the shelves.

BenchCel Microplate Handler User Guide

23

Page 34

2 Introduction

1

2

3

Hardware overview

Labware racks

The labware racks are available in two models:

• Front-load rack in 250-mm and 660-mm sizes

• Top-load rack in 660-mm and 860-mm sizes

Both rack models have the following basic components.

Figure

Front-load rack components

24

Item Name Description

1 Carrying handle The top-load and front-load racks have fold-down

carrying handles.

2 Tabs A pair of vertical tabs are located at the bottom on the

rack sides. The tabs insert into slots on the device

when you mount the rack onto the device.

3 Stacker grippers A gripper is located on the interior bottom of each tab.

The pair of grippers hold a microplate during the

labware loading, unloading, downstacking, and

upstacking processes. A clamp in the device opens

and closes the grippers.

BenchCel Microplate Handler User Guide

Page 35

2 Introduction

Microplate

Integration options for workstations

The following figure shows a closeup view of a labware rack, with the stacker grippers

holding a microplate. The front wall of the rack is not shown to reveal the stacker

grippers that are hidden from view.

Figure

Related information

For more information about… See…

Automation-ready labware “Labware considerations” on page 27

Software that controls the BenchCel

Microplate Handler

Safety information “Safety guidelines” on page 1

Installation requirements “Verifying laboratory requirements” on

Labware rack closeup view showing microplate held by the stacker grippers

“Software description” on page 29

page 37

Integration options for workstations

About this topic

You can integrate Agilent devices with the BenchCel Microplate Handler to create a

BenchCel Workstation. The BenchCel robot can move labware to and from these

devices as specified by the protocol you create.

This topic lists some of the devices that can be integrated with the BenchCel

Microplate Handler.

Agilent devices

The following figure shows an example of a BenchCel Workstation.

BenchCel Microplate Handler User Guide

25

Page 36

2 Introduction

Integration options for workstations

Figure

six stackers, and (

Example of BenchCel Workstation: (1) computer, (2) Bravo Platform, (3) BenchCel with

4) Labware MiniHub

The following Agilent devices can be integrated with the BenchCel Microplate Handler.

:

Item Device Description

Related information

For more information about… See…

BenchCel Microplate Handler features “Hardware overview” on page 15

Safety information “Safety guidelines” on page 1

Installation requirements “Installing BenchCel Microplate Handler” on

1 Bravo Platform Dispenses liquids.

2 Labware MiniHub Stores labware.

3 Microplate Labeler Prints barcodes and applies the

barcode labels to microplates.

4 Microplate Centrifuge with

Centrifuges microplates.

Automated Loader

5 PlateLoc Thermal Microplate

Applies seal on microplates.

Sealer

page 35

26

BenchCel Microplate Handler User Guide

Page 37

Labware considerations

Microplate

About this topic

This topic provides guidelines for selecting automation-ready labware for use in the

BenchCel Microplate Handler.

Acceptable microplates

The BenchCel device is designed to handle labware that comply with the standards

ANSI/SLAS 1-2004 (R2012) through ANSI/SLAS 4-2004 (R2012). For use of

nonconforming labware, contact Agilent Technical Support.

The BenchCel device uses gripping mechanisms to hold microplates securely and

repeatably in the labware rack and in the robot arms. The BenchCel device typically

holds the microplates halfway between the top of the microplate and the top of the

microplate skirt (5 to 10 mm above the bottom of the microplate).

In the following figure, notice the gripper-microplate contact point.

2 Introduction

Labware considerations

Figure

Lidded microplates

Microplates that do not have lids or have shallow lids (lids that do not reach the

microplate skirt) provide enough clearance to allow secure and repeatable gripping.

Microplates with deeper lids can be more challenging, because the microplate must be

held by the skirt. If the skirt is too flexible, the stacker grippers will bend the skirt. The

bent skirt can grip the microplate lid stacked beneath, inadvertently removing the lid.

Note: Some labware vendors might offer alternative lids that are shallower. Contact the

vendor for details.

Labware rack closeup view showing microplate held by the stacker grippers

BenchCel Microplate Handler User Guide

27

Page 38

2 Introduction

Labware considerations

Figure

Lidded microplate examples

Challenging microplate characteristics

Microplates that have the following characteristics might require additional setup time

to ensure repeatable performance for the BenchCel device:

• Microplate material. Although you can adjust the robot grip distance to compensate

for a microplate’s flexibility, some microplates are too soft and tend to bend in the

robot grippers or become warped after thermal cycling. (for example, low-profile

polypropylene PCR microplates).

• Manufacturing variance. Gross variations in microplate dimensions can reduce

repeatability of secure gripping. In addition, because the BenchCel device uses

reflected light to sense microplate presence and orientation, variations in the

reflective properties of the microplates can affect optimal operation.

• Microplate design. Some microplates have special features specifically designed

for particular instruments but are not optimized for the BenchCel device.

• Thermal cycling effects. Microplates that have been through thermal cycling might

become warped.

• Tall labware. Especially tall tube racks and tip boxes that are taller than 65 mm

might pose challenges in the BenchCel device. Contact Agilent Technical Support

about acceptable tall labware.

• Extra long lid. Some microplates that have lids that extend past the microplate skirt

tend to pose challenges for the BenchCel device. Contact Agilent Technical Support

for guidance.

No lid: excellent

gripper clearance

Shallow lid: good

gripper clearance

Deep lid: no gripper

clearance, must be

held by the skirt

Related information

28

For more information about… See…

Defining labware in the software VWorks Automation Control Setup Guide

Location of plate-orientation sensors “Stacker head” on page 20

How the plate-orientation sensors

work

“Setting sensor thresholds” on page 99

BenchCel Microplate Handler User Guide

Page 39

For more information about… See…

BenchCel Microplate Handler features “Hardware overview” on page 15

Safety information “Safety guidelines” on page 1

Installation requirements “Installing BenchCel Microplate Handler” on

Software description

About this topic

This topic describes the software that you can use to set up, control, and troubleshoot

the BenchCel Microplate Handler.

VWorks software 13.1.x

2 Introduction

Software description

page 35

VWorks 13.1.x enables you to:

• Set up user accounts and privileges

• Set up your devices

• Define labware, liquid classes, and pipetting techniques

• Manage labware inventory

• Create protocols and forms, and run the protocols

VWorks 13.1.x uses the Windows Registry to store records, such as labware definitions

and device profiles, and uses the local file system to store VWorks files, such as device

files and protocols.

BenchCel Microplate Handler User Guide

29

Page 40

2 Introduction

Software description

VWorks software 14.0 and later versions

VWorks 14.0 and later versions are available as VWorks Plus and VWorks Standard

editions. Both editions consist of Agilent OpenLab components and VWorks software.

VWorks Plus includes features that support compliance with Part 11 of Title 21 of the

Code of Federal Regulations (21 CFR Part 11). You use the VWorks software to control

your automation devices

OpenLab components

• Control Panel and Shared Services. Control Panel is the user interface for Shared

Services, which are set of administrative services. An administrator uses Control

Panel to configure VWorks user access, software licenses, and storage.

• Storage types. Shared Services uses a different storage type for each VWorks

edition:

– VWorks Plus. Uses Content Management to store VWorks files, records of

interest, and audit trails. The files are stored in a predefined VWorks Project

folder in the Content Management repository. A system administrator can use

the Content Browser to view and edit the project structure and contents.

– VWorks Standard. Uses the local file system. Shared Services stores the files in

a predefined VWorks Project folder.

/VWorks Projects/VWorks

Note: Unlike earlier versions, the Windows Registry is not used for storing

records, such as labware definitions and device profiles.

VWorks software

You use the VWorks software to do the following:

• VWorks Plus only. Log audit trails and manage record states

• Define labware, liquid classes, and pipetting techniques

• Manage labware inventory (storage devices only)

• Track experiments, if applicable

• Set up devices

• Create protocols and forms, and run the protocols

30

BenchCel Microplate Handler User Guide

Page 41

2 Introduction

Software description

Figure

VWorks software window

BenchCel ActiveX control

You can use the BenchCel ActiveX control instead of the VWorks software to control

the BenchCel Microplate Handler. The BenchCel ActiveX control enables the BenchCel

device to interact with a third-party lab automation system.

BenchCel Diagnostics software

Accessed through the VWorks software or the BenchCel ActiveX control, Diagnostics

enables you to do the following:

• Create and manage profiles. The software uses the information in the profile to

communicate between the BenchCel device and the controlling computer. You

create profiles using the Profiles tab in BenchCel Diagnostics when you set up the

BenchCel Microplate Handler.

BenchCel Microplate Handler User Guide

31

Page 42

2 Introduction

Software description

Figure

BenchCel Diagnostics Profiles tab

Note: In VWorks v14.0 and later versions, BenchCel Diagnostics includes an

activity log for the current session in a box at the bottom of the window. The

Profiles tab also includes a table that displays variables that were modified

since the last was last saved. The VWorks software records these events and

stores the information in the Main log. For details on the logs, see the VWorks

Automation Control User Guide.

• Set and edit teachpoints. Teachpoints are locations that the BenchCel robot will go

to and from during a protocol run. You set teachpoints using the Diagnostics

Controls tab when you set up the BenchCel Microplate Handler.

Figure

BenchCel Diagnostics Controls tab

32

BenchCel Microplate Handler User Guide

Page 43

2 Introduction

Software description

• Diagnose problems. You can use the Jog/Teach tab on the Diagnostics Controls

page to move and adjust individual hardware components. These controls are

useful for diagnosing and troubleshooting problems.

Figure

BenchCel Diagnostics Jog/Teach tab

While testing new or troubleshooting labware definitions, you can change

parameters to refine the labware definition. Diagnostics includes a Labware tab on

the Controls page, which enables you to adjust the labware definitions.

Alternatively, you can use the Labware Editor to update the labware definitions.

Figure

BenchCel Diagnostics Labware tab

BenchCel Microplate Handler User Guide

33

Page 44

2 Introduction

Software description

• Change general device settings. After diagnosing problems, you can change some

of the device settings to repair problems or to optimize operation.

Related information

For more information about... See...

Creating and running protocols in

VWorks

Figure

BenchCel Diagnostics General Settings tab

VWorks Automation Control User Guide

VWorks setup instructions VWorks Automation Control Setup Guide

Setting up profiles and teachpoints “Setup workflow” on page 64

Using Diagnostics to troubleshoot

problems

BenchCel ActiveX control BenchCel ActiveX User Guide

“Diagnostic tools” on page 146

34

BenchCel Microplate Handler User Guide

Page 45

3 Installing BenchCel Microplate Handler

This chapter contains the following topics:

• “Installation workflow” on page 36

• “Verifying laboratory requirements” on page 37

• “Unpacking BenchCel Microplate Handler” on page 42

• “Mounting the robot” on page 44

• “About integrating devices in a BenchCel Workstation” on page 47

• “Connecting the power source” on page 50

• “Connecting the pendant directly to the BenchCel device” on page 51

• “Connecting the pendant through the Robot Disable Hub” on page 53

• “Connecting and disconnecting the air source” on page 55

• “Connecting the computer” on page 57

• “Installing the shield” on page 61

35

Page 46

3 Installing BenchCel Microplate Handler

WARNING

Installation workflow

Installation workflow

About this topic.

This topic presents the sequence of installation procedures for the BenchCel Microplate

Handler. Typically, an integrated BenchCel Workstation will be installed for you.

Changing the configuration or components of the installed workstation might

invalidate the safety compliance and lead to personal injury or equipment damage.

Workflow

Step For this task… See…

1 Verify that the installation

location meets the site

requirements.

2 Unpack the computer and

connect the monitor,

power, mouse, and

keyboard.

3 Install the VWorks

software.

4 Unpack the BenchCel

device.

5 Install the BenchCel risers,

if applicable.

6 Mount the robot head on

the BenchCel device.

7 Integrate external devices. “About integrating devices in a BenchCel

8 Connect the BenchCel

Microplate Handler:

Power

“Verifying laboratory requirements” on

page 37

Manufacturer’s instructions

• VWorks Automation Control Installation

Guide (VWorks 14.0 and later)

• Software release notes (VWorks 13.1.x)

“Unpacking BenchCel Microplate Handler”

on page 42

Agilent Technical Support

“Mounting the robot” on page 44

Workstation” on page 47

“Connecting the power source” on page 50

36

Pendant • “Connecting the pendant directly to the

BenchCel device” on page 51

• “Connecting the pendant through the

Robot Disable Hub” on page 53

Air supply “Connecting and disconnecting the air

source” on page 55

Computer “Connecting the computer” on page 57

BenchCel Microplate Handler User Guide

Page 47

3 Installing BenchCel Microplate Handler

Verifying laboratory requirements

Step For this task… See…

9 Install the safety shield. “Installing the shield” on page 61

10 Install the labware racks. “Installing and uninstalling the labware

racks” on page 123

11 Install the integrated

devices.

12 Set up the BenchCel device

profile and set the

teachpoints.

Related information

For information about… See…

Installing external devices External device user documentation

Setting up the BenchCel Microplate

Handler

Defining labware and writing protocols VWorks Automation Control Setup Guide

Verifying laboratory requirements

Installation guide for the device.

“Setup workflow” on page 64

“Setting up the BenchCel device” on

page 63

Laboratory space

Laboratory table or bench requirements

Make sure the table for the BenchCel Microplate Handler has the following:

• Proximity to power and air sources

• Enough space to accommodate the complete configuration of the BenchCel

Microplate Handler, computer, monitor, pendant, and integrated devices.

• Enough strength to support the weight of the BenchCel Microplate Handler and

integrated devices without excessive shaking or movement.

• Be fixed in place, for example, casters that lock.

• Sufficient clearance on the back side of the BenchCel Microplate Handler to access

power, communication, and air tubing connections and for maintenance tasks.

• Proper height for any operator to comfortably operate the BenchCel Microplate

Handler

The table must be level in the direction of the width and the depth of the platform.

Using a traditional bubble level, the table should be leveled such that the bubble is

centered between the two limit lines of the level.

The table surface must have a thickness relative to the material that will prevent

warping when the BenchCel Microplate Handler and computer are set upon the table.

BenchCel Microplate Handler User Guide

37

Page 48

3 Installing BenchCel Microplate Handler

Verifying laboratory requirements

The table surface must be attached to the table frame.

The table frame must have:

• A leveling mechanism in the feet or casters.

• Dimensions that enable support of the table surface without overhang.

Space requirements

The minimum space requirements for your BenchCel Microplate Handler depends on

its configuration and labware rack size. The following table lists dimensions for a

BenchCel Microplate Handler in a two-, four-, or six-stack configuration.

Dimension Two stacks Four stacks Six stacks

Height, device without Risers 46.3 cm 46.3 cm 46.3 cm

Height, device with Risers (146-mm) 60.8 cm 60.8 cm 60.8 cm

Labware rack height* (250-mm,

660-mm, 860-mm)

Width 43.2 cm 86.4 cm 129.5 cm

Depth 20.3 cm 20.3 cm 20.3 cm

Weight, approximate**

without rack

with rack (660 mm, front-loading)

*Approximately 30-mm of the rack height sits down inside the BenchCel stacker head.

The overall height of a BenchCel device on risers with racks installed is as follows:

82.8 cm (250-mm rack)

126.0 cm (660-mm rack)

1438 cm (860-mm rack)

See the following figure.

**The rack weight is for the front-loading style rack and does not include liquid-filled

microplates. The weight differs slightly between the top-loading and front-loading rack

types.

———

28 kg

32.5 kg

39.5 kg

48.6 kg

51 kg

64.6 kg

38

BenchCel Microplate Handler User Guide

Page 49

3 Installing BenchCel Microplate Handler

250 mm

828 mm

1438 mm

1260 mm

660 mm

860 mm

Verifying laboratory requirements

Figure Example of BenchCel on risers with six stacks showing height requirements of 250-mm, 660-mm, and

860-mm racks

Addition of devices

If you are integrating an Agilent device or third-party device with your BenchCel

Microplate Handler, make sure you include adequate space to accommodate these

devices. See the device user documentation for space requirement information.

Electrical requirements

The BenchCel Microplate Handler has the following power requirements. For power

requirements of other devices in an integrated workstation, see the applicable device

user documentation.

Utility Requirement

Electrical 100–240 V~, 50/60 Hz

Operating AC current 5 A at 120 V~, 2.5 A at 240 V~

Fuse

Compressed air requirements

The BenchCel Microplate Handler requires the use of clean, dry, compressed air to

move pneumatic components inside the device. The compressed air can be from the

following sources:

• Centralized source (house)

• Compressed-air cylinders

• Portable pumps

5 A, 250 V, 5

× 20 mm, fast acting

BenchCel Microplate Handler User Guide

39

Page 50

3 Installing BenchCel Microplate Handler

CAUTION

CAUTION

Verifying laboratory requirements

Using oil compressors can cause oil to leak into the BenchCel Microplate Handler

and void your warranty.

Air pressure greater than 0.69 MPa (100 psi) can damage the BenchCel Microplate

Handler.

To maintain the desired air supply in the device, the BenchCel Microplate Handler

requires a source of air as follows:

Requirement Value

Quality Clean, dry, compressed

Flow rate 34.0 Lpm (1.2 cfm)

Pressure 0.65–0.69 MPa (95–100 psi)

Environmental requirements

The lab must meet the following environmental requirements.

Requirement Value

Ambient temperature

Humidity condition

Elevation 1–2000 m

Make sure the BenchCel Microplate Handler is located away from the following:

• Heat and air conditioning ducts.

• Direct sunlight.

Computer requirements

The requirements of the controlling computer depend on the lab automation software

you are using.

• VWorks 14.0 or later, see the installation guide for the software.

• VWorks 13.1.x, see the software release notes.

For third-party automation software, see the user documentation supplied with the

product.

5–40

°C

10–90%

RH, non-condensing

Networking considerations

40

The supplied computer comes with a serial port and two Ethernet ports. You can

connect the computer to the BenchCel Microplate Handler using either the serial port or

one of the Ethernet ports. You can use the second Ethernet port to connect the

BenchCel Microplate Handler User Guide

Page 51

computer to your local area network (LAN). You must provide an Ethernet cable for the

WARNING

LAN connection and make sure the lab has the proper network hookups for the

connection.

If you are supplying your own computer, consider whether you will:

• Connect the computer to the BenchCel Microplate Handler using a serial or

• Connect the computer to your LAN.

Connecting the BenchCel Microplate Handler to a company or general network can

potentially cause injury. Remote computer operators might accidentally initiate an

operation that causes the robot to move unexpectedly, possibly injuring nearby lab

personnel.

If you plan to connect the computer to the BenchCel Microplate Handler and to your

company’s LAN, the computer might require two Ethernet cards. Two Ethernet cards

allow the BenchCel Microplate Handler to operate on an isolated network.

Related information

3 Installing BenchCel Microplate Handler

Verifying laboratory requirements

Ethernet connection.

For information about… See…

Lab requirements for external devices External device user documentation

Contacting technical support “Reporting problems” on page 162

Installing the BenchCel Microplate

Handler

“Installation workflow” on page 36

BenchCel Microplate Handler User Guide

41

Page 52

3 Installing BenchCel Microplate Handler

WARNING

Unpacking BenchCel Microplate Handler

Unpacking BenchCel Microplate Handler

About this topic

This topic describes how to unpack the BenchCel Microplate Handler from the shipping

containers.

Shipping containers

The shipping containers include:

• BenchCel crate containing the BenchCel device.

• Peripherals box containing the following packages:

– BenchCel utility kit

– Pendant

– BenchCel robot head

– Safety shield with hardware

– Labware racks

• Computer box

Depending on the configuration ordered, additional packages or items can be included.

Before you start

Verify the following:

1 BenchCel utility kit contents. At a minimum, the kit contains the following:

• Power cord

• Serial and Ethernet cables, and Ethernet switch

• Tubing for air line

• Software CD-ROM

2 Site specifications. Ensure the installation site meets the requirements. See

“Verifying laboratory requirements” on page 37.

Note the dimensions of the shipping container before moving it to make sure you

have adequate clearance through doorways and passages.

3 Tools and equipment requirements. Obtain the following:

• Large screwdriver to open the shipping crate

• Hex wrenches: 5-mm and 2-mm for mounting the robot head

• Cart for moving the BenchCel device

4 Personnel requirements. Make sure two people are available to lift the BenchCel

device from the crate.

The BenchCel device without labware racks weighs 28 – 51 kg (61.7 – 112.4 lb),

depending on the configuration. Attempting to lift or move the BenchCel device

without assistance could cause personal injury. Request assistance and use proper

lifting techniques when lifting or moving the device.

42

BenchCel Microplate Handler User Guide

Page 53

Procedure

CAUTION

The packing materials and shipping container were designed to protect the device.

Packing the BenchCel device using other materials might damage the device and

void your warranty. Save the packing materials and shipping container in case you

are required to move or ship the BenchCel device.

To unpack the BenchCel Microplate Handler:

1 Use a large screwdriver to open the BenchCel device shipping container.

2 Lift the contents out of the container and set each item carefully on the lab bench

or final location where you want to install the device.

3 Remove the packing foam from the device.

4 Remove components from the plastic bags or other packing material.