Page 1

Agilent B1500A

Semiconductor Device

Analyzer

Programming Guide

Agilent Technologies

Page 2

Notices

© Agilent Technologies 2005, 2006, 2007

No part of this manual may be reproduced in

any form or by any means (including electronic storage and retrieval or translation

into a foreign language) without prior agreement and written consent from Agilent

Technologies, Inc. as governed by United

States and international copyright laws.

Manual Part Number

B1500-90012

Edition

Edition 1, August 2005

Edition 2, April 2006

Edition 3, June 2007

Agilent Technologies, Inc.

5301 Stevens Creek Blvd

Santa Clara, CA 95051 USA

Warranty

The material contained in this document is provided “as is,” and is subject to being changed, without notice,

in future editions. Further, to the maximum extent permitted by applicable

law, Agilent disclaims all warranties,

either express or implied, with regard

to this manual and any information

contained herein, including but not

limited to the implied warranties of

merchantability and fitness for a particular purpose. Agilent shall not be

liable for errors or for incidental or

consequential damages in connection with the furnishing, use, or performance of this document or of any

information contained herein. Should

Agilent and the user have a separate

written agreement with warranty

terms covering the material in this

document that conflict with these

terms, the warranty terms in the separate agreement shall control.

Tec hn ol og y L i c e ns es

The hardware and/or software described in

this document are furnished under a license

and may be used or copied only in accordance with the terms of such license.

defined in FAR 52.227-19(c)(1-2) (June

1987). U.S. Government users will receive

no greater than Limited Rights as defined in

FAR 52.227-14 (June 1987) or DFAR

252.227-7015 (b)(2) (November 1995), as

applicable in any technical data.

Restricted Rights Legend

If software is for use in the performance of a

U.S. Government prime contract or subcontract, Software is delivered and licensed as

“Commercial computer software” as

defined in DFAR 252.227-7014 (June 1995),

or as a “commercial item” as defined in FAR

2.101(a) or as “Restricted computer software” as defined in FAR 52.227-19 (June

1987) or any equivalent agency regulation or

contract clause. Use, duplication or disclosure of Software is subject to Agilent Technologies’ standard commercial license

terms, and non-DOD Departments and

Agencies of the U.S. Government will

receive no greater than Restricted Rights as

Page 3

Page 4

In This Manual

This manual provides the information to control the Agilent B1500 via GPIB

interface using an external computer, and consists of the following chapters:

•“Programming Basics”

This chapter provides basic information to control the Agilent B1500.

• “Remote Mode Functions”

This chapter explains the functions of the Agilent B1500 in the remote mode.

• “Programming Examples”

This chapter lists the GPIB commands and explains the programming examples

for each measurement mode or function. The examples have been written in the

Microsoft Visual Basic .NET or the HP BASIC language.

• “Command Reference”

This chapter provides the complete reference of the GPIB commands of the

Agilent B1500.

• “Error Messages”

This chapter lists the error codes, and explains them.

Microsoft, Windows, and Visual Basic are registered trademarks of Microsoft Corporation. All other trademarks are the

property of their respective owners.

Page 5

Contents

1. Programming Basics

Before Starting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

About Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

To Reset the Agilent B1500 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

To Read Query Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

To Perform Self-Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

To Perform Self-Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

To Perform Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

To Enable Source/Measurement Channels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

To Select the Measurement Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

To Force Voltage/Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

To Set the SMU Integration Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

To Set the Measurement Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

To Pause Command Execution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

To Start Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

To Force 0 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

To Disable Source/Measurement Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

To Control ASU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

To Control SCUU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-15

To Read Error Code/Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

To Read Spot Measurement Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

To Read Sweep Measurement Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

To Read Time Stamp Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

To Perform High Speed Spot Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

Command Input Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

Header. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

Numeric Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

Terminator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

Special Terminator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

Agilent B1500 Programming Guide, Edition 3

Page 6

Contents

Separator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

Data Output Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

ASCII Data Output Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

Binary Data Output Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-34

GPIB Interface Capability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1- 52

Status Byte . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-53

Programming Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-55

To Confirm the Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-56

To Confirm the Command Completion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-56

To Disable the Auto Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-56

To Optimize the Measurement Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-57

To Optimize the Integration Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-57

To Disable the ADC Zero Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-57

To Optimize the Source/Measurement Wait Time. . . . . . . . . . . . . . . . . . . . . . 1-58

To Use the Internal Program Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-59

To Get Time Data with the Best Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . 1-59

To Use Sweep Source as a Constant Source . . . . . . . . . . . . . . . . . . . . . . . . . . 1-59

To Start Measurements Simultaneously. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-59

To Perform Quasi-Sampling Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-60

To Interrupt Command Execution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-60

To Use Programs for Agilent 4142B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-61

To Use Programs for Agilent 4155/4156. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-62

To Use Programs for Agilent E5260/E5270 . . . . . . . . . . . . . . . . . . . . . . . . . . 1-64

2. Remote Mode Functions

Measurement Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Spot Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Pulsed Spot Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Staircase Sweep Measurements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Agilent B1500 Programming Guide, Edition 3

Page 7

Contents

Multi Channel Sweep Measurements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

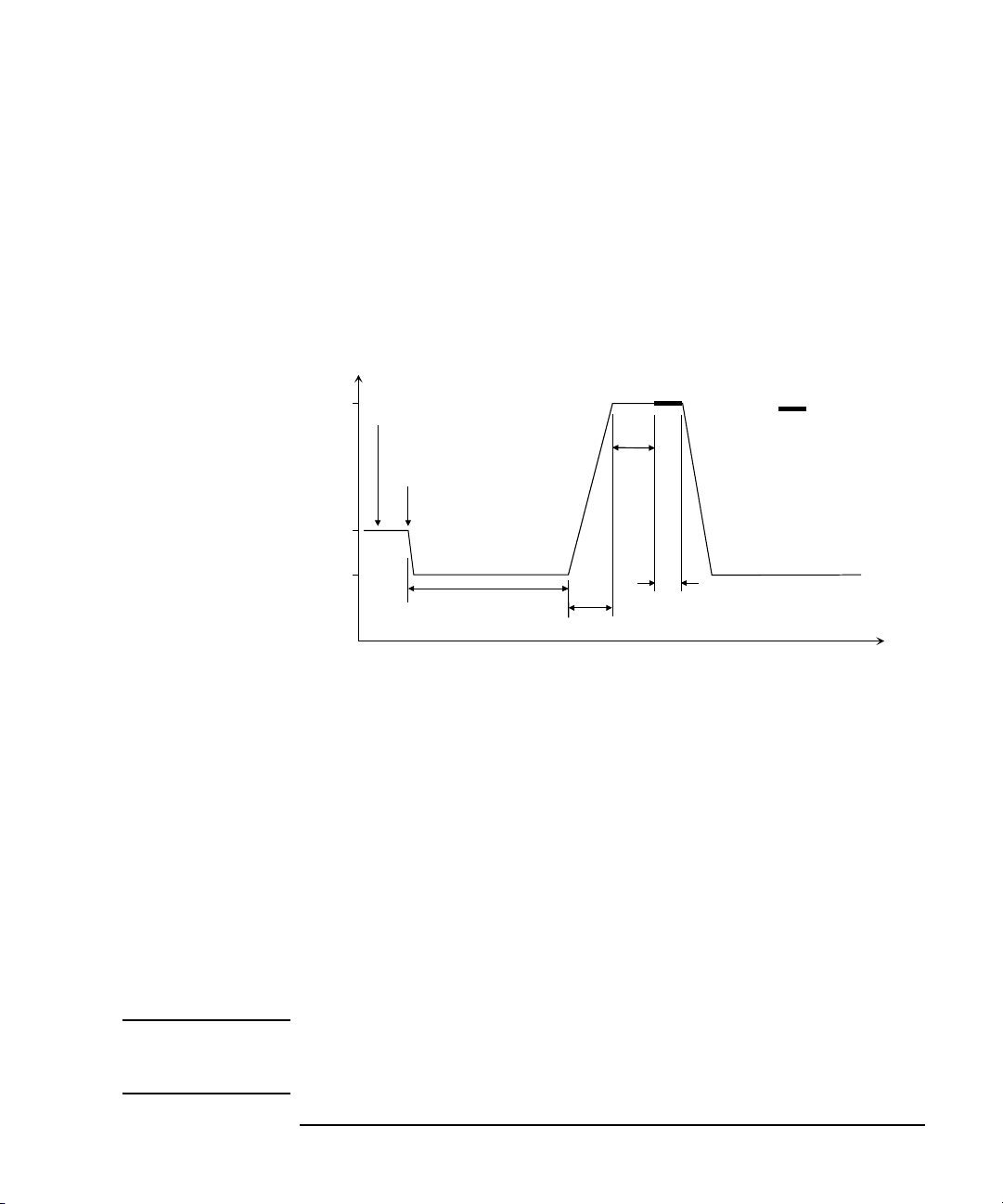

Pulsed Sweep Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Staircase Sweep with Pulsed Bias Measurements . . . . . . . . . . . . . . . . . . . . . . 2-12

Quasi-Pulsed Spot Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Binary Search Measurements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Linear Search Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Sampling Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

Quasi-static CV Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Spot C Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

Pulsed Spot C Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

CV (DC bias) Sweep Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

Pulsed Sweep CV Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

C-f Sweep Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

CV (AC level) Sweep Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

C-t Sampling Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-37

Synchronous Output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-39

Automatic Abort Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-41

Parallel Measurement Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-43

To Set Measurement Channels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-43

To Enable Parallel Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-43

Program Memory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-44

Using Program Memory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-44

Digital I/O Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-47

Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-48

Digital I/O Internal Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-49

Trigger Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-50

Trigger Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-51

Trigger Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-53

Using Trigger Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-55

Agilent B1500 Programming Guide, Edition 3

Page 8

Contents

Trig In/Out Internal Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-61

Initial Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-62

3. Programming Examples

Programming Basics for Visual Basic .NET Users. . . . . . . . . . . . . . . . . . . . . . . . 3-4

To Create Your Project Template. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

To Create Measurement Program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

High-Speed Spot Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Spot Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Pulsed Spot Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Staircase Sweep Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Pulsed Sweep Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

Staircase Sweep with Pulsed Bias Measurements . . . . . . . . . . . . . . . . . . . . . . . 3-32

Quasi Pulsed Spot Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-36

Linear Search Measurements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-39

Binary Search Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-42

Multi Channel Sweep Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-45

Sampling Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-49

Quasi-static CV Measurements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-54

High-Speed Spot C Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-59

Spot C Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-65

CV (DC Bias) Sweep Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-69

Pulsed Spot C Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-74

Pulsed Sweep CV Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-78

Agilent B1500 Programming Guide, Edition 3

Page 9

Contents

CV (AC Level) Sweep Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-83

C-f Sweep Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-88

C-t Sampling Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-93

Using Program Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-98

Tips to use program memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-99

Using Trigger Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-104

Reading Time Stamp Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-116

Reading Binary Output Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-117

Using Programs for 4142B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-120

Using Programs for 4155B/4156B/4155C/4156C. . . . . . . . . . . . . . . . . . . . . . . 3-122

4. Command Reference

Command Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Command Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Command Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

AAD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

AB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

ACH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

ACT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

ACV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

ADJ. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-28

ADJ?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

AIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

AV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-32

AZ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-34

BC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-34

BDM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-35

BDT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-35

Agilent B1500 Programming Guide, Edition 3

Page 10

Contents

BDV. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

BGI. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-37

BGV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-39

BSI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-41

BSM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-42

BSSI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-45

BSSV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-46

BST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-47

BSV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-48

BSVM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-49

CA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-50

*CAL? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-51

CL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-52

CLCORR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-53

CM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-53

CMM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-54

CN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-55

CORR?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-57

CORRDT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-58

CORRDT? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-59

CORRL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-60

CORRL?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-60

CORRST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-61

CORRST? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-61

DCORR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-62

DCORR? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-63

DCV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-64

DI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-65

DIAG? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-66

DO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-67

DV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-68

DZ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-69

Agilent B1500 Programming Guide, Edition 3

Page 11

Contents

EMG? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-70

END . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-70

ERC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-71

ERM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-72

ERR? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-73

ERS?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-74

FC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-75

FL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-75

FMT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-76

*IDN? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-78

IMP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-79

IN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-80

LGI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-81

LGV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-82

LMN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-83

LOP? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-84

*LRN? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-85

LSI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-91

LSM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-92

LSSI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-93

LSSV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-94

LST? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-95

LSTM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-97

LSV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-98

LSVM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-99

MCC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-99

MDCV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-100

MI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-101

ML . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-102

MM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-103

MSC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-105

MT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-106

Agilent B1500 Programming Guide, Edition 3

Page 12

Contents

MTDCV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-108

MV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-109

NUB? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-110

*OPC? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-110

OS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-111

OSX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-111

PA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-112

PAD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-113

PAX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-114

PDCV. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-115

PI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-116

PT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-117

PTDCV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-118

PV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-119

PWDCV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-120

PWI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-121

PWV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-122

QSC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-123

QSL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-123

QSM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-124

QSO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-125

QSR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-126

QST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-127

QSV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-129

QSZ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-131

RC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-132

RCV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-133

RI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-134

RM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-135

*RST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-136

RU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-136

RV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-137

Agilent B1500 Programming Guide, Edition 3

Page 13

Contents

RZ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-138

SAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-138

SAP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-139

SAR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-140

SCR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-140

*SRE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-141

*SRE? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-142

SSL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-143

SSP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-144

SSR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-146

ST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-147

*STB? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-148

TACV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-149

TC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-150

TDCV. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-151

TDI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-152

TDV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-153

TGMO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-154

TGP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-155

TGPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-157

TGSI. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-158

TGSO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-159

TGXO. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-159

TI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-160

TM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-161

TMACV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-162

TMDCV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-163

TSC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-164

TSQ. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-165

TSR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-165

*TST? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-166

TTC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-168

Agilent B1500 Programming Guide, Edition 3

Page 14

Contents

TTI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-169

TTV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-171

TV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-172

UNT? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-172

VAR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-173

VAR? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-173

WACV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-174

WAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-175

WDCV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-177

WFC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-178

WI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-179

WM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-181

WMACV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-182

WMDCV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-183

WMFC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-184

WNU? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-185

WNX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-186

WS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-189

WSI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-190

WSV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-192

WSX. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-194

WT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-195

WTACV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-197

WTDCV. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-198

WTFC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-199

WV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-200

WZ? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-202

XE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-203

5. Error Messages

Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Agilent B1500 Programming Guide, Edition 3

Page 15

Contents

Operation Error. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Self-test/Calibration Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Agilent B1500 Programming Guide, Edition 3

Page 16

Contents

Agilent B1500 Programming Guide, Edition 3

Page 17

1 Programming Basics

Page 18

Programming Basics

This chapter describes basic information to control the Agilent B1500, and contains

the following sections:

• “Before Starting”

• “Getting Started”

• “Command Input Format”

• “Data Output Format”

• “GPIB Interface Capability”

•“Status Byte”

• “Programming Tips”

1-2 Agilent B1500 Programming Guide, Edition 3

Page 19

Programming Basics

Before Starting

Before Starting

Before sta rting the pr ogramming using the Agilent FLEX command , perform

following.

1. If the EasyEXPERT software is running, terminate it as shown b elow:

a. Select the menu function File > Exit on the EasyEXPERT main window.

b. Click [x] at the upper right corner of the Start EasyEXPERT button.

2. Select All Programs > Agilent IO Libraries Suite > Agilent Connection Expert

from the Start menu. The Agilent Connection Expert window appears.

3. At the Instrument I/O on this PC area, highlight GPIB0, and click the Change

Properties... button. The Agilent 82350 PCI GPIB Interface - GPIB0 window

appears.

4. Set the GPIB Address value to the number (ex: 17) as you want.

5. Remove the check from the System Controller box.

6. Remove the check from the Auto-discover instruments connected to this

interface box.

7. Click the OK button on the Agilent 82350 PCI GPIB Interf ace - GPIB0 windo w.

8. On the Reboot Required dialog box, click the Reboot Now button, and reboot

the B1500A.

NOTE Start EasyEXPERT Button

Leave the Start EasyEXPERT button on the B1500A screen. The button must be

displayed on the screen or minimized to the Windows task bar. The Start

EasyEXPERT service must be run to control the Agilent B1500A from an external

computer.

Agilent B1500 Programming Guide, Edition 3 1-3

Page 20

Programming Basics

Before Starting

About Examples

In this section, command execution examples are written in HP BASIC. See the

following instructions for your guidance.

1. Use the ASSIGN statement to assign the I/O path for controlling instruments.

In the next example, the select code of the external computer is 7 and the GPIB

address of the B1500 is 17.

10 ASSIGN @B1500 TO 717

2. Use the OUTPUT statement to send commands to instruments, as shown below.

OUTPUT @B1500;"*RST"

It is available to send multiple commands as shown below.

OUTPUT @B1500;"*CN;MM2,1"

3. Use the ENTER statement to get a query response or data from instruments.

1-4 Agilent B1500 Programming Guide, Edition 3

Page 21

Programming Basics

Getting Started

Getting Started

This section explains the following basic operations. In this section, th e HP BASIC

language is used for the examples.

• “To Reset the Ag ilent B1500”

• “To Read Query Response”

• “To Perform Self-Test”

• “To Perform Self-Calibration”

• “To Perform Diagnostics”

• “To Enable Source/Measurement Channels”

• “To Select the Measurement Mode”

• “To Force Voltage/Current”

• “To Set the SMU Integration Time”

• “To Set the Measurement Range”

• “To Pause Command Execution”

• “To Start Measurement”

• “To Force 0 V”

• “To Disable Source/Measurement Channels”

• “To Control ASU”

• “To Control SCUU”

• “To Read Error Code/Message”

• “To Read Spot Measurement Data”

• “To Read Sweep Measurement Data”

• “To Read Time Stamp Data”

• “To Perform High Speed Spot Measurement”

Agilent B1500 Programming Guide, Edition 3 1-5

Page 22

Programming Basics

Getting Started

To Reset the Agilent B1500

The B1500 returns to the initial settings by the *RST command.

Example OUTPUT @B1500;"*RST"

For the initial settings, see “Initial Settings” on page 2-62.

To Read Query Response

If you enter a query command such as the *TST?, ERR? and so on, the B1500 puts

an ASCII format response to the query buf fer that can stor e only o ne respon se. Read

the response as soon as possible after entering a query command.

Example OUTPUT @B1500;"NUB?"

ENTER @B1500;A

This example returns the number of data stored in the data output buffer.

To Perform Self-Test

The B1500 starts the self-test by the *TST? command. The *TST? command also

returns the test result.

Example OUTPUT @B1500;"*TST?"

ENTER @B1500;Code

IF Code<>0 THEN DISP "FAIL: SELF-TEST"

This example starts the self-test, and reads the test result code. For the test result

code, see “*TST?” on page 4-166.

To Perform Self-Calibration

The B1500 starts the self-calibration by the *CAL? command.

Example OUTPUT @B1500;"*CAL?"

ENTER @B1500;Result

IF Result<>0 THEN DISP "FAIL: CALIBRATION"

This example starts the self-calibration, and reads the result, pass or fail. For details,

see “*CAL?” on page 4-51.

1-6 Agilent B1500 Programming Guide, Edition 3

Page 23

Programming Basics

Getting Started

To Perform Diagnostics

The B1500 starts the diagnostics by the DIAG? command, and returns the result.

You must specify the diagnostics item by the command parameter. Available

parameter values are:

1: Trigger In/Out diagnostics

3: High volt age LED diagnostics

4: Digital I/O diagnostics

To perform diagnostics 1, connect a BNC cable between the Ext Trig In terminal

and the Ext Trig Out terminal before starting the diagnostics.

To perform diagnostics 4, disconnect any cable from the digital I/O port.

Example OUTPUT @B1500;"DIAG? 1"

ENTER @B1500;Result

IF Result<>0 THEN DISP "FAIL: DIAGNOSTICS"

This example starts the Trigger In/Out diagnostics, and reads the result, pass or fail.

For details, see “DIAG?” on page 4-66.

To Enable Source/Measurement Channels

The measurement channels or source channels can be enabled by closing the output

switch. To close the switch, send the CN command. The B1500 closes the output

switch of the specified channels.

Example OUTPUT @B1500;"CN 1"

This example enables channel 1 (the module i nstalled in slot 1 of the B150 0). If you

do not specify the channel, the CN command enables all channels.

To Select the Measurement Mode

The B1500 provides the measurement modes listed in Table 1-1. To select the

measurement mode, send the MM command. In the table, the Mode No. means a

command parameter of the MM command.

Syntax MM Mode#[,Ch#[,Ch#] ... ]

where, Mode# specifies the Mode No., and Ch# specifies the measurement channel.

The available number of measuremen t channels depend s on the meas urement m ode.

For details, see “MM” on page 4-103.

Agilent B1500 Programming Guide, Edition 3 1-7

Page 24

Programming Basics

Getting Started

Example OUTPUT @B1500;"MM 2,1"

This example sets the staircase sweep measurement, and assigns channel 1 (the

module installed in slot 1 of the B1500) as the measurement channel.

NOTE The Mode No. is not assigned for the high speed spot measurement. See “To

Perform High Speed Spot Measurement” on page 1-19. The high speed spot

measurement does not need the MM command.

For the source output commands available for each measurement mode, see Table

1-3 on page 1-10.

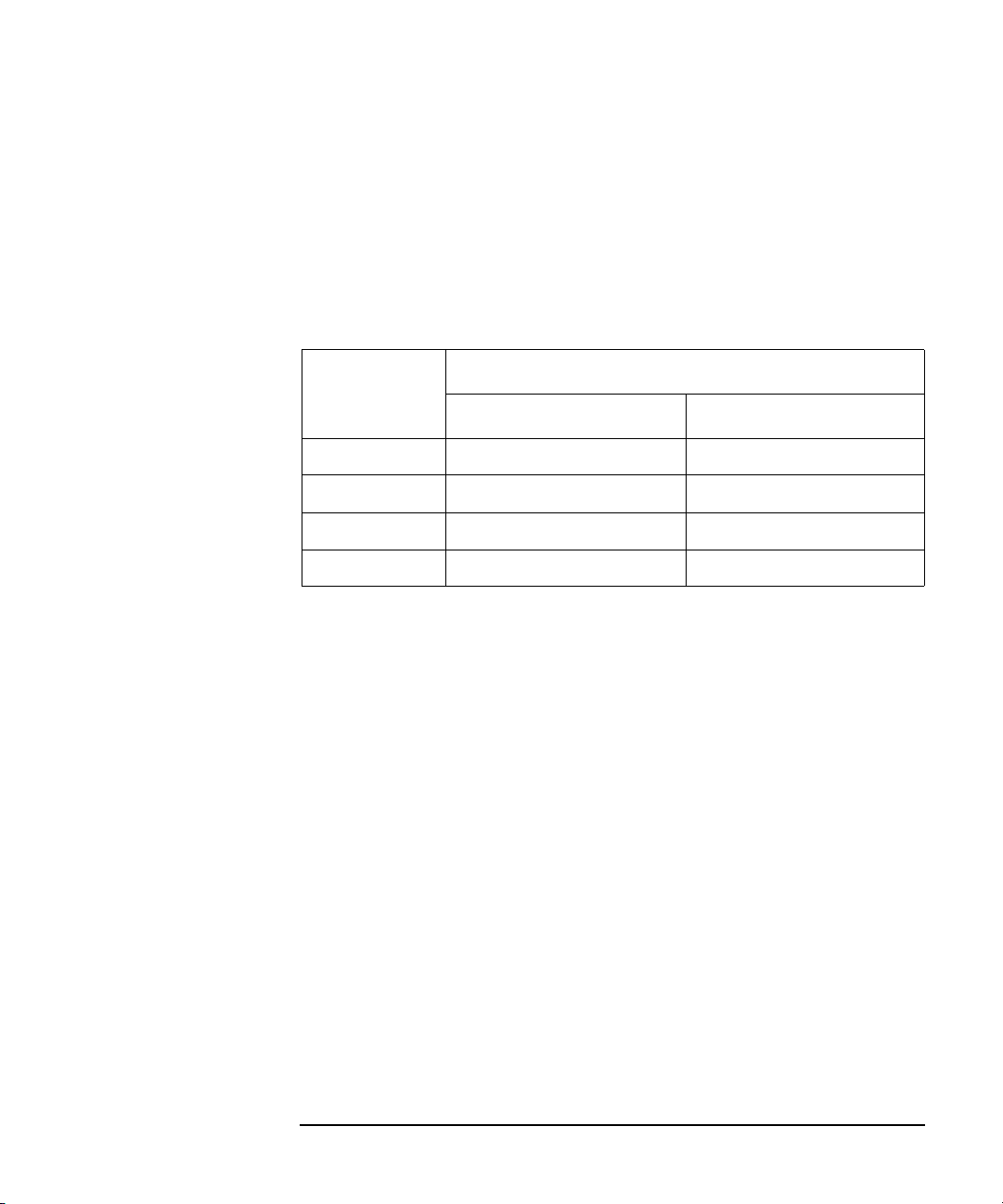

Table 1-1 Measurement Mode

Measurement Mode (measurement parameter) Mode No.

Spot Measurement (current or voltage) 1

Staircase Sweep Measurement (current or voltage) 2

Pulsed Spot Measurement (current or voltage) 3

Pulsed Sweep Measurement (current or voltage) 4

Staircase Sweep with Pulsed Bias Measurement (current or voltage) 5

Quasi-Pulsed Spot Measurement (current or voltage) 9

Sampling Measurement (current or voltage) 10

Quasi-static CV Measurement (capacitance) 13

Linear Search Measurement (current or voltage) 14

Binary Search Measurement (current or voltage) 15

Multi Channel Sweep Measurement (current or voltage) 16

Spot C Measurement (impedance) 17

CV (DC bias) Sweep Measurement (impedance-DC voltage) 18

Pulsed Spot C Measurement (impedance) 19

Pulsed Sweep CV Measurement (impedance-voltage) 20

Frequency Sweep Measurement (impedance-frequency) 22

CV (AC level) Sweep Measurement (impedance-AC voltage) 23

C-t Sampling Measurement (impedance) 26

High Speed Spot Measurement (current, voltage, or impedance) NA

1-8 Agilent B1500 Programming Guide, Edition 3

Page 25

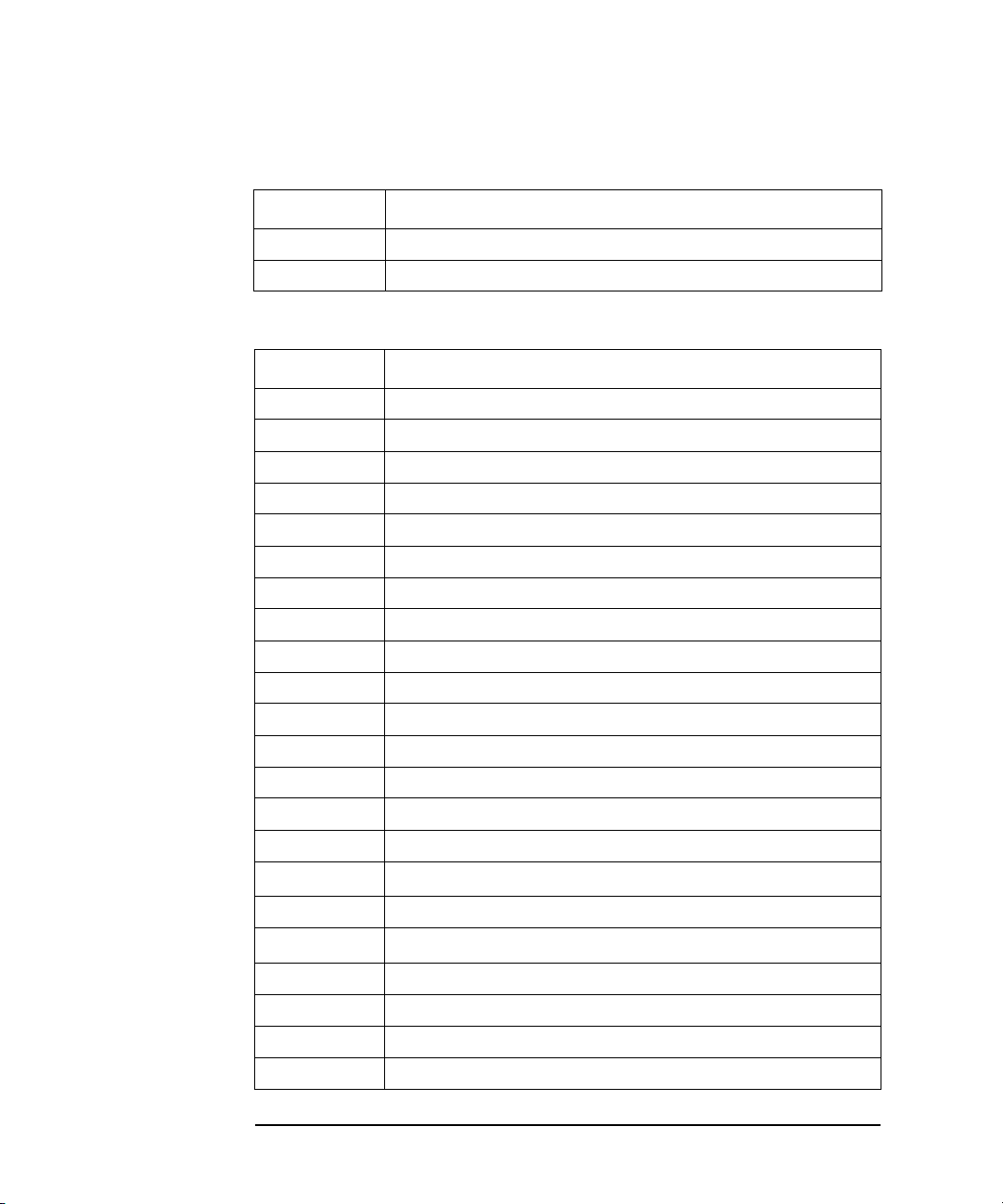

To Force Voltage/Current

The commands listed in Table 1-2 is used to force voltage or current. These

commands start to force the voltage or current immediately when the command is

executed. They can be used regardless of the measurement mode.

See Table 1-3 for the commands available for each measurement mode. The

commands just set the source channel condition, and the source channel starts the

output by the start trigger, such as the XE command. For more details of the

commands, see Chapter 4, “Command Reference.”

Table 1-2 Voltag e /Current Output Commands

Command Description

DV Applies DC voltage from SMU immediately.

DI Applies DC current from SMU immediately.

FC/ACV Applies AC voltage from MFCMU immediately.

DCV Applies DC bias from MFCMU immediately.

Programming Basics

Getting Started

TDV Applies DC voltage from SMU, and returns the time data.

TDI Applies DC current from SMU, and returns the time data.

FC/TACV Applies AC voltage from MFCMU, and returns the time data.

TDCV Applies DC bias from MFCMU, and returns the time data.

Example OUTPUT @B1500;"DV 1,0,5"

This example just forces 5 V using channel 1 (the module installed in slot 1 of the

B1500) with auto ranging.

Agilent B1500 Programming Guide, Edition 3 1-9

Page 26

Programming Basics

Getting Started

Table 1-3 Measurement Mode and Available Source Output Commands

Measurement Mode Command

Staircase Sweep Measurement WV(/WSV) or WI(/WSI)

Pulsed Spot Measurement PV/PT or PI/PT

Pulsed Sweep Measurement PWV/PT(/WSV) or PWI/PT(/WSI)

Staircase Sweep with Pulsed Bias

Measurement

Quasi-Pulsed Spot Measurement BDV

Sampling Measurement MV, MI

Quasi-static CV Measurement QSV

Linear Search Measurement LSV(/LSSV) or LSI(/LSSI)

Binary Search Measurement BSV(/BSSV) or BSI(/BSSI)

Multi Channel Sweep Measurement WNX, and WV or WI

CV (DC bias) Sweep Measurement WDCV

Pulsed Spot C Measurement PDCV/PTDCV

Pulsed Sweep CV Measurement PWDCV/PTDCV

Frequency Sweep Measurement WFC

CV (AC level) Sweep Measurement WACV

C-t Sampling Measurement MDCV

WV(/WSV) or WI(/WSI), and PV/PT or

PI/PT

1-10 Agilent B1500 Programming Guide, Edition 3

Page 27

Programming Basics

Getting Started

To Set the SMU Integration Time

To adjust the balance of the SMU’s measurement accuracy and speed, change the

integration time or the number of averaging samples of the A/D converter (ADC) by

using the AV command. The AV command is compatible with the AV command of

the Agilent 4142B.

For accurate and reliable measurement, set the integration time longer or set the

number of samples larger. For details about the integration ti me settings, see

Chapter 4, “Command Reference.”

The Agilent B1500 has the following two typ es of the A/D converter. Use the AAD

command to select the type of ADC, and use the AIT command to set the integration

time or the number of samples.

Type of ADC Description

High-speed ADC Effective for the high speed measurement. In the multi

channel sweep measurement mode (MM16), multiple

measurement channels can perform synchronous

measurements.

The number of averaging samples must be set by the

AIT or AV command.

High-resolution ADC Effective for the accurate meas ur ement. Cann ot b e u sed

for the pulsed measurement channel and the

simultaneous measurement channel.

The integration time must be set by the AIT command.

Example The following example sets the number of samples to 10 for the high-speed A/D

converter.

OUTPUT @B1500;"AV 10,1"

The following example sets the power line cycle mode (PLC) for both the

high-speed ADC and the high-resolution ADC. And channel 1 uses the

high-resolution ADC and other channels use the high-speed ADC.

OUTPUT @B1500;"*RST"

OUTPUT @B1500;"AIT 0,2"

OUTPUT @B1500;"AIT 1,2"

OUTPUT @B1500;"AAD 1,1"

Agilent B1500 Programming Guide, Edition 3 1-11

Page 28

Programming Basics

Getting Started

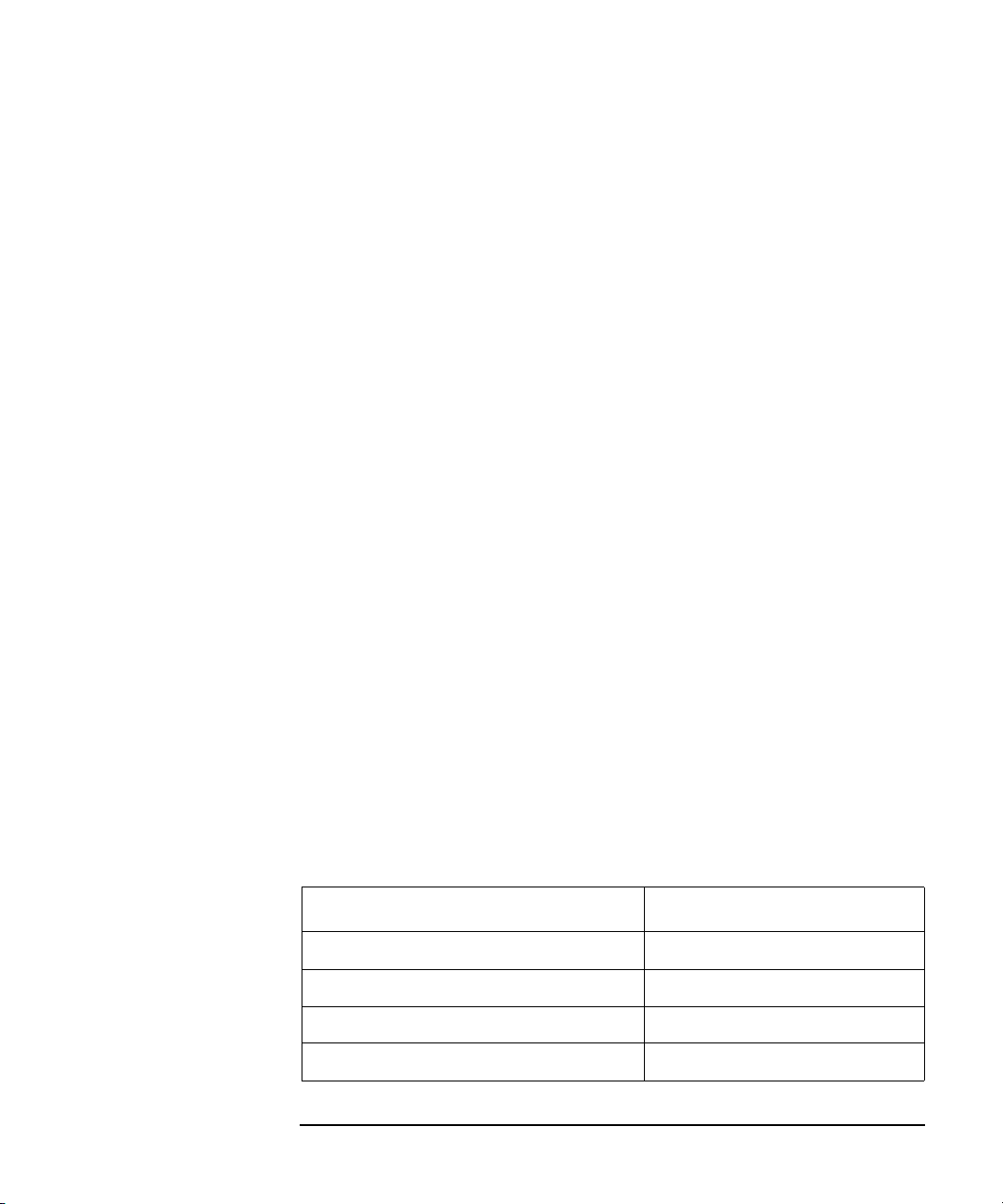

To Set the Measurement Range

To set the measurement range, send the following command:

Command Description

RI Sets the current measurement range. Available for the

current measurements that use the XE command. Not

available for the high speed spot measurement.

TI, TTI Sets the current measurement channel/range, and performs

the high speed spot measurement.

RV Sets the voltage measurement range. Available for the

voltage measurements that use the XE command. Not

available for the high speed spot measurement.

TV, TTV Sets the voltage measurement channel/range, and performs

the high speed spot measurement.

RC Sets the impedance measurement range. Available for the

CV sweep/spot C measurements.

TC, TTC Sets the impedance measurement channel/range, and

performs the high speed spot measurement.

For the current measurement with the auto ranging mode, you can specify the

coverage of each measurement range. To specify the coverage, send the RM

command.

For details, see Chapter 4, “Command Reference.”

Example This example sets the voltage measurement ranging mode of channel 1 to auto.

OUTPUT @B1500;"RV 1,0"

This example sets the current measurement ranging mode of channel 1 to auto, and

specifies coverage between 9 % and 90 % o f the rang e valu e or between 90 mA and

180 mA for the 200 mA range.

OUTPUT @B1500;"RI 1,0"

OUTPUT @B1500;"RM 1,3,90"

NOTE To use 1 pA ra nge of ASU

Set the 1 pA limited auto ranging mode or t he 1 pA fixed ran ge mode. Or enabl e the

1 pA range for the auto ranging mode by using the SAR command. See “SAR” on

page 4-140.

1-12 Agilent B1500 Programming Guide, Edition 3

Page 29

To Pause Command Execution

To pause command execution until the specified wait time elapses, send the PA

command.

Example OUTPUT @B1500;"PA 5"

If this command is sent, the B1500 waits 5 seconds before executing the next

command.

To Start Measurement

To start measurement other than the high speed spot measurement, send the XE

command.

Example OUTPUT @B1500;"XE"

This starts the measurement specified by the MM command.

For the high speed spot measurement, see “To Perform High Speed Spot

Measurement” on page 1-19.

Programming Basics

Getting Started

To Force 0 V

To force 0 V immediately, send the DZ command. The B1500 memorizes the

present source output settings of the specified channel, and changes the specified

channel output to 0 V. If you do not specify the channel, the DZ command function

is effective for all channels.

Example OUTPUT @B1500;"DZ 1"

If this command is sent, the B1500 memorizes the current settings of channel 1 (the

module installed in slot 1 of the B1500), and changes channel 1 output to 0 V.

To restore the settings stored by the DZ command, send the RZ command. For

details, see Chapter 4, “Command Reference.”

Agilent B1500 Programming Guide, Edition 3 1-13

Page 30

Programming Basics

Getting Started

To Disable Source/Measurement Channels

T o dis able the chan nels, s end the C L com mand . Th e B1500 op ens the output switch

of the specified channels. Opening the output switch disables the channel.

Example OUTPUT @B1500;"CL 1"

This example disables channel 1 (the modu le install ed in slot 1 of the B1500) . If you

do not specify the channel, the CL command disables all channels.

To Control ASU

This function is available for the B1500 that is installed with the high resolution

SMU (HRSMU). Atto Sense and Switch Unit (ASU) has two inpu ts, SMU input for

the HRSMU and AUX input for the other instrument. And the ASU input to output

connection can be controlled by the following commands. When the B1500 is

turned on, the SMU input will be connected to the ASU output. However, the SMU

output switch will be off at this time.

Table 1-4 ASU Input Output Connection Control

Previous Connection Command Subsequent Connection

SMU side, Output on/off SAP slot, 1 AUX side

SMU side, Output off CN slot SMU side, Output on

SAP slot, 0

AUX side CN slot

SAP slot, 0

CL [slot] SMU side, Output off

SMU side, Output on CL [slot]

where, slot must be the slot number assigned to the slot that installs the HRSMU

connected to the ASU. See “SAL”, “SAP”, and “SAR” on page 4-140 for the other

function and control commands of the ASU.

When the SMU side is connected to the ASU output, the source output on/off can be

controlled by the CN/CL command. And then the SAP slot, 1 command is used to

change the output connection to the AUX side. When the AUX side is connected,

the output of the instrument connected to the AUX input is appeared to the ASU

output immediately.

1-14 Agilent B1500 Programming Guide, Edition 3

Page 31

To Control SCUU

SCUU (SMU CMU Unify Unit) can be used with one capacitance measurement unit

(CMU) and two SMUs (MPSMU or HRSMU). The SCUU cannot be used with the

HPSMU or when only one SMU is connected. The SCUU input to output

connection can be controlled by the following commands. When the B1500 is

turned on, the SCUU input to output connection is not made (open).

Table 1-5 SCUU Input Output Connection Control

SCUU output connection after the command

Command

CMUH/Force1/Sense1 CMUL/Force2/Sense2

SSP slot, 1 Force1/Sense1 Open

SSP slot, 2 Open Force2/Sense2

SSP slot, 3 Force1/Sense1 Force2/Sense2

SSP slot, 4 CMUH CMUL

Programming Basics

Getting Started

where, slot means the number assigned to the slot that installs the CMU.

Force1/Sense1 is connected to the SMU installed in the slot numbered slot-1.

Force2/Sense2 is connected to the SMU installed in the slot numbered slot-2. When

the SCUU input to output connection is made, the measurement unit output switch

will be automatically set to ON.

When the connection is changed from SMU to CMU, the SMU output will be set as

follows. The other setup parameters are not changed.

Output voltage 0 V

Output range 100 V

Compliance 20 mA

Series resistance OFF

When the connection is changed from CMU to SMU, the SMU output will be set as

follows. The other setup parameters are not changed.

Output voltage 0 V

Output range 20 V

Compliance 100 μA

Series resistance Condition before the connection i s changed from SMU to CMU

Agilent B1500 Programming Guide, Edition 3 1-15

Page 32

Programming Basics

Getting Started

To Read Error Code/Message

If any error occurs, the B1500 will not put the measurement data into the data output

buffer. Hence, confirm that no error has occurred before reading the measurement

data. To read the error code, enter the ERR? command, and to read the error

message, enter the EMG? command.

Example OUTPUT @B1500;"ERR? 1"

ENTER @B1500;Code

IF Code<>0 THEN

OUTPUT @B1500;"EMG? ";Code

ENTER @B1500;Msg$

PRINT "ERROR: ";Msg$

ELSE

::

This example checks the error buffer, and prints the error message on the computer

screen if any error code is stored in the error buffer.

To Read Spot Measurement Data

After the spot measurements, the B1500 puts the measurement data into its output

data buffer. You can read the data as shown below. For the data output format, see

“Data Output Format” on page 1-23.

Example 1 For the HP BASIC users, use the ENTER statement. The example stores the header

information and the measurement data included in the ASCII data set by the FMT5

command into the Head$ and Mdata variables respectively.

ENTER @B1500 USING "#,3A,12D,X";Head$,Mdata

Example 2 For the Microsoft Visual Basic .NET with Agilent T&M Programmer’s Toolkit

users, use the Read, ReadList, UnbufferedRead methods and so on. The example

stores the header information and the measurement data included in the ASCII data

set by the FMT5 command into the head and mdata variables respectively.

ret_value = B1500.Read(True)

head = Left(ret_val, 3)

mdata = Val(Right(ret_val, 12))

1-16 Agilent B1500 Programming Guide, Edition 3

Page 33

Programming Basics

Getting Started

To Read Sweep Measurement Data

For the sweep measurements, the measurement data will be put into the data output

buffer after every step measurement. You can read the data as shown below. For the

data output format, see “Data Output Format” on page 1-23.

• To read data after sweep measurement

This way waits for the measurement completion by using the *OPC? command

after the XE command, and reads the sweep data (all step measurement data) at

once after the sweep measurement is completed.

Example:

B1500.WriteLine("FMT 5,0") ’terminator=comma

B1500.WriteLine("XE")

B1500.WriteLine("*OPC?")

rep = B1500.Read(True)

ret_val = B1500.ReadListAsStringArray() ’string array

For i = 0 To nop - 1 ’nop=number of sweep steps

head = Left(ret_val(i), 3)

mdata = Val(Right(ret_val(i), 12))

ddata = "Data = " & mdata & ", Header = " & head

Console.WriteLine(ddata)

Next i

For the specific example, see Table 3-5 on page 3-19.

• To read data after every step measurement

This way starts to read the data after the XE command. You do not need to wait

for the sweep measurement completion. So you can check the result data before

the sweep measurement is completed.

Example:

B1500.WriteLine("FMT 5,0") ’terminator=comma

B1500.TerminationCharacter = Chr(44) ’Chr(44)=comma

B1500.TerminationCharacterEnabled = True ’enables comma

B1500.WriteLine("XE")

For i = 0 To nop - 1 ’nop=number of sweep steps

ret_val = B1500.Read(True) ’string

head = Left(ret_val, 3)

mdata = Val(Right(ret_val, 12))

ddata = "Data = " & mdata & ", Header = " & head

Console.WriteLine(ddata)

Next i

For the specific example, see Table 3-6 on page 3-22.

Agilent B1500 Programming Guide, Edition 3 1-17

Page 34

Programming Basics

Getting Started

To Read Time Stamp Data

NOTE This function is not available for the quasi-pulsed spot measuremen t (MM 9), search

measurement (MM 14 or 15), and the 4 byte binary data output (FMT 3 or 4).

T o read the time data with the best resolution (100 μs), clear the timer every 100 s or

less (for FMT 1, 2, or 5), or 1000 s or less (for FMT 11, 12, 15, 21, 22, or 25).

The time stamp function records the time from timer reset (Time=0 s) to the start of

measurement. This function is enabled by the TSC command. The timer count is

cleared/reset by the TSR command.

For example, the output data in the staircase sweep measurement will be as follows:

Block1 [,Block2] . . . . <terminator>

BlockN (N: integer) = Time1,Data1 [,Time2,Data2] ... [,Source_data]

TimeN (N: integer) is the time from timer reset to the start of DataN measurement.

Without the TSC command, you can get the time data by the following commands:

• TDV / TDI (for voltage/current output by using a SMU),

TDCV / TACV (for DC voltage/AC voltage output by using the MFCMU):

Starts source output, and returns the time data from timer reset (TSR command)

to the start of output.

Example:

OUTPUT @B1500;"TDV 1,0,20"

ENTER @B1500 USING "#,5X,13D,X";Time

PRINT "Time="; Ti me ;" se c"

• TTV / TTI (for voltage/current measurement by using a SMU),

TTC (for impedance measurement by using the MFCMU):

Executes high speed spot measurement, and returns the measurement data and

the time data from timer reset (TSR command) to the start of measurement.

Example:

OUTPUT @B1500;"TTV 1,0"

ENTER @B1500 USING "#,5X,13D,X";Time

ENTER @B1500 USING "#,5X,13D,X";Mdata

PRINT "Data="; Md at a; " at ";T im e; "s ec "

• TSQ: Returns the time data from timer reset (TSR command) to this command.

Example:

OUTPUT @B1500;"TSR" !Resets count

:

OUTPUT @B1500;"TSQ" !Returns time data

ENTER @B1500 USING "#,5X,13D,X";Time

PRINT "Time="; Ti me ;" se c"

1-18 Agilent B1500 Programming Guide, Edition 3

Page 35

Programming Basics

Getting Started

To Perform High Speed Spot Measurement

The high speed spot measurement does not need the MM and XE commands to set

the measurement mode and start measurement. To start and perform the high speed

spot measurement immediately , send the TI command for current measurement, the

TV command for voltage measurement, or the TC command for impedance

measurement. The following example program measures current by using the TI

command, and displays the measurement result data on the computer screen.

Example

10 ASSIGN @B1500 TO 717

20 OUTPUT @B1500;"*RST"

30 OUTPUT @B1500;"FMT 5"

40 OUTPUT @B1500;"CN 1,2,3,4"

50 OU TP UT @B1 50 0; "D V 1, 0, 0"

60 OUTPUT @B1500;"DV 2,0,0"

70 OU TP UT @B1 50 0; "D V 3, 0, 2"

80 OU TP UT @B1 50 0; "D V 4, 0, 5"

90 OUTPUT @B1500;"TI 4,0"

100 ENTER @B1500 USING "#,3A,12D,X";Head$,Data

110 PRINT Head$,Data

120 OUTPUT @B1500; "D Z"

130 OUTPUT @B1500; "C L"

140 END

Line

Number

Description

10 Assigns the I/O path to control the B1500.

20 Initializes the B1500.

30 Sets the data output format (ASCII with header and <,>).

40 Enables channels 1, 2, 3, and 4.

50 to 80 Forces the DC voltage. Channel 1 and 2 force 0 V, channel 3 forces

2 V, and channel 4 forces 5 V with auto ranging.

90 Performs th e high speed spot measurement using channel 4 with

auto ranging.

100 to 110 Prints the header data and measurement data on the screen.

120 Forces 0 V. All channels force 0 V.

130 Disables all channels.

Agilent B1500 Programming Guide, Edition 3 1-19

Page 36

Programming Basics

Header

Numeric Data Terminator

,

SP : Space

;

Separator

SP

SP

SP

Alpha Character

(A to Z, a to z)

*

?

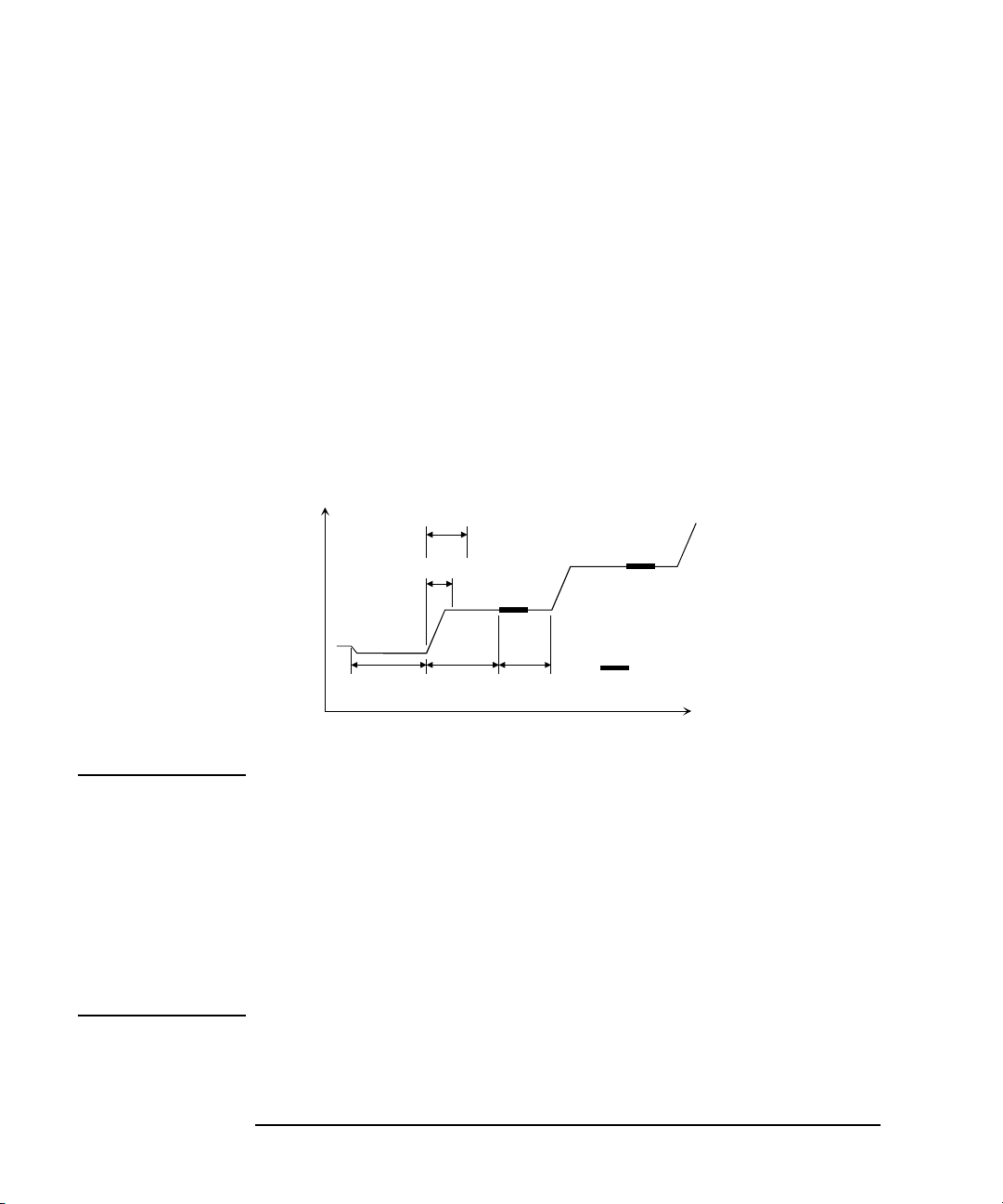

Command Input Format

Command Input Format

Agilent FLEX commands (GPIB commands for the Agilent B1500) are composed

of a header, numeric data, an d terminator, as shown in the following synt ax diagra m.

B1500 Control Command Syntax Diagram

NOTE Terminator

Terminator is necessary to enter the command to the Agilent B1500. For the

available terminators, see “Terminator” and “Special Terminator” on page 1-22.

Header

The header is the command name, always contains alpha characters, and is not

upper or lowercase sensitive. Some command names also contain an asterisk (*) or

question mark (?). The following figure shows the syntax diagram for a header.

Header Syntax Diagram

1-20 Agilent B1500 Programming Guide, Edition 3

Page 37

Programming Basics

Fixed Point Data

Integer Data

Floating Point Data

Digit

(0 to 9)

−

SP

SP : Space

SP

+

Digit

(0 to 9)

−

SP

SP

: Space

SP

+

Digit

(0 to 9)

Digit

(0 to 9)

− SP

SP

: Space

SP

+

Digit

(0 to 9)

−

+

e

E

Digit

(0 to 9)

*1

*1: Here must be 2 digits or less.

Command Input Format

Numeric Data

Numeric data are the command parameters. You can enter numeric data directly

after the header or insert spaces between the header and numeric data. Some

parameters require integer data. The following figure shows the syntax diagram for

numeric dat a.

Numeric Data Syntax Diagram

The following 3 figures show the syntax diagrams for integer, fixed point, and

floating point data, respectively.

Integer Data Syntax Diagram

Fixed Point Data Syntax Diagram

Floating Point Data Syntax Diagram

Agilent B1500 Programming Guide, Edition 3 1-21

Page 38

Programming Basics

CR

EOI

LF

LF

^

EOI

^

CR

EOI

LF

LF

^

;

Command Input Format

Terminator

The terminator completes the GPIB command entry and starts command execution.

The following figure shows the terminator syntax diagram.

Terminator Syntax Diagram

Special Terminator

If a semicolon (;) is inserted before the terminator, as shown in the following figure,

the preceding commands are not executed until the next command line is input and

another terminator is input, without a preceding semicolon. The command lines are

then executed together.

Special Terminator Syntax Diagram

Separator

If you enter multiple commands, use semicolons (;) to separate the commands.

Spaces are allowed before and after the semicolons. Command execution starts

when the terminator is received, not when the semicolon is received. You can input

multiple commands of up to a total of 256 characters (including the terminator). If

you input more than 256 characters, the input buffer overflows, and an error is

indicated.

Use commas (,) to separate numeric data entries.

NOTE Do not include the reset command (*RST) or the abort command (AB) in multiple

command strings (examp le: OUTPUT @B1500;”*RST;CN”). If you do, t he other

commands in the string (example: CN) are not executed.

1-22 Agilent B1500 Programming Guide, Edition 3

Page 39

Programming Basics

Data Output Format

Data Output Format

Agilent B1500 provides the following data output formats:

• “ASCII Data Output Format”

The B1500 supports the ASCII data format that is the common format for the

instruments that support the Agilent FLEX command mode.

• “Binary Data Output Format”

The B1500 supports the 4 bytes binary data format that is the common format

for the instruments that support the Agilent FLEX command mode. The B1500

also supports the dedicated 8 bytes binary format. The binary format enables

faster data transfer time than ASCII format. You need to calculate the data to get

the measurement result.

To select the data output format, use the FMT command. See “FMT” on page 4-76.

For the query response, the returned data is always stored in the query buffer in

ASCII format, regardless of the FMT command setting.

A minimum of 17×1001×2 (34034) measurement data can be stored in the data

output buffer.

Conventions

The following conventions are used in this section.

Data Output data that the B1500 sends after a measurement.

[Data] Optional output data sent when there are multiple output data

items.

For example, source data will be sent with measurement data

after the staircase sweep measurements when the source data

output is enabled by the FMT command.

<terminator> Terminator.

<CR/LF^EOI> (two bytes) or <,> (one byte) for ASCII data.

<CR/LF^EOI> (two bytes) or <^EOI> (0 byte) for binary data.

You can select by using the FMT command.

Agilent B1500 Programming Guide, Edition 3 1-23

Page 40

Programming Basics

Data Output Format

ASCII Data Output Format

This section describes the ASCII data output format, and the elements of the data.

•“Time Stamp”

•“Data Format”

• “Data Elements”

Time Stamp

The B1500 can record the time when the measurement is started, and sends the time

data (Time). This function is enabled by the TSC command. The time data will be

sent just before the measurement data.

For example, in the staircase sweep measurements, the data will be as shown below.

Block1 [,Block2] . . . . <terminator>

where, BlockN (N: integer) = Time1,Data1 [,Time2,Data2] ... [,Source_data], then

TimeN (N: integer) is the time from timer reset to the start of DataN measurement.

The timer count is cleared/reset by the TSR command (Time=0).

The time stamp function is not available for the following measurements.

• High speed spot measurement

• Quasi-pulsed spot measurement (MM9)

• Linear search measurement (MM14)

• Binary search measurement (MM15)

1-24 Agilent B1500 Programming Guide, Edition 3

Page 41

Programming Basics

Data Output Format

Data Format

The data output format depends on the measurement mode as shown below.

High Speed Spot Data <terminator> (by TI, TV, TMACV, or TMDCV command)

Time,Data <terminator> (by TTI or TTV command)

Para1,Para2 <terminator> (by TC command)

Time,Para1,Para2 <terminator> (by TTC command)

Data is the value measured by the channel you specify in the command. Time is the

time from timer reset to the start of measurement. Para1 and Para2 are the primary

parameter and the secondary parameter (ex: Cp and G) measured b y the CMU. They

are selected by the IMP command.

Spot Data1 [,Data2] . . . . <terminator>

DataN (N: integer) is the value measured by a channel. The order of Data is defined

by the MM command.

Spot C,

Pulsed Spot,

Pulsed Spot C,

Quasi-Pulsed Spot

Staircase Sweep,

Multi Channel

Sweep

Data <terminator>

Data is the value measured by the channel you specify by using the MM command.

For the pulsed spot C measurement, Data consists of the following data:

Para1,Para2

For the spot C measurement, Data consists of the following data:

Para1,Para2 [,Osc_level,Dc_bias]

Para1 and Para2 are the primary and secondary parameters (ex: Cp and G). They

are selected by the IMP command. See Table 4-8 on page 4-19. And Osc_level and

Dc_bias are the monitor values of the oscillator level (AC signal level) and the DC

bias respectively. They are sent if the data output is enabled by the LMN command.

Block1 [,Block2] . . . . <terminator>

Block1 is the block of data measured at the first sweep point.

Block2 is the block of data measured at the second sweep point.

where Block consists of the following data:

Data1 [,Data2] . . . . [,Source_data]

DataN (

by the MM command. Source_data is the sweep source output value. It is sent if the

data output is enabled by the FMT command.

N:

integer) is the value measured by a channel. The order of Data is defined

Agilent B1500 Programming Guide, Edition 3 1-25

Page 42

Programming Basics

Data Output Format

Pulsed Sweep,

Pulsed Sweep CV,

CV (DC or AC)

Sweep,

Frequency Sweep,

Staircase Sweep

with Pulsed Bias

Quasi-static CV Block1 [,Block2] . . . . <terminator>

Block1 [,Block2] . . . . <terminator>

Block1 is the block of data measured at the first sweep point.

Block2 is the block of data measured at the second sweep point.

where Block consists of the following data:

Data [,Source_data]

Data is the value measured by the channel you specify by using the MM command.

Source_data is the sweep source output value. It is sent if the data output is enabled

by the FMT command.

For the pulsed sweep CV measurement, Data consists of the following data:

Para1,Para2

For the CV (DC bias) sweep, CV (AC level) sweep, and frequency sweep, Data

consists of the following data:

Para1,Para2 [,Osc_level,Dc_bias]

Para1 and Para2 are the primary and secondary parameters (ex: Cp and G). They

are selected by the IMP command. See Table 4-8 on page 4-19. And Osc_level and

Dc_bias are the monitor values of the oscillator level (AC signal level) and the DC

bias respectively. They are sent if the data output is enabled by the LMN command.

Block1 is the block of the data measured at the first sweep point.

Block2 is the block of the data measured at the second sweep point.

where Block consists o f the following data:

Linear Search,

Binary Search

[DataL,] DataC [,Source_data]

DataL is the leakage current measurement data. DataC is the capacitance

measurement data. Source_data is the sweep source output value. DataL and

Source_data are sent if the data output is enabled by the QSL or FMT command.

Data_search [,Data_sense]<terminator>

This is the data at the measurement point closest to the search tar get. Data_search is

the value forced by the search output channel. Data_sense is the value measured by

the search monitor channel. It is sent if data output is enabled by the BSVM