Page 1

Application Note

Cell Migration and

Invasion

Incorporation of a Novel, Automated

Scratch Tool and Kinetic Label-Free

Imaging to Perform Wound

HealingAssays

Author

Brad Larson

Agilent Technologies, Inc.

Abstract

The wound healing or "scratch" assay is one of the most highly used in vitro methods

to monitor and quantify collective cell migration. The current standard involves

manual wound creation, which yields low reproducibility between wounds, high

variability within generated data, and possible false conclusions regarding test

molecules. Using an automated wound creation tool, in addition to kinetic image

capture and analysis, repeatable wounds and robust and repeatable results are

easily attained.

Page 2

Introduction

Materials and methods

The movement of cells when influenced by interactions

with neighboring cells, otherwise known as collective cell

migration, plays a role in numerous critical physiological

processes, including morphogenesis and tissue regeneration.

This type of movement as a cohesive group has also been

shown to be critical in wound healing and cancer metastasis.

In wound healing, epithelial cells collectively migrate as a

sheet of cells. Wounding of the epithelial layer induces cell

migration in a directional manner. During this process, cells

maintain tight intercellular adhesion, healing the original

2

wound.

Similarly, collective cell migration has also been

implicated as playing a major role in cancer metastasis. An

increasing number of publications indicate that metastatic

cells cluster and invade collectively in the vasculature and

3-4

lymphatics of cancer patients.

Therefore, attaining a better

understanding of collective cell movement is of critical value

for the treatment of multiple disease types.

One of the most widely used methods to measure collective

cell migration is the wound healing or "scratch" assay.

Following creation of a wound, or cell-free zone, within the

confluent cell layer, cell movement back into the wound

area is monitored over time using cellular imaging. Kinetic

and endpoint data then allow for quantification of cell

migration, either when uninhibited or under the influence of

a test molecule. For wound creation, commonly a pipette

tip is manually dragged through the cells, which can lead

to wounds that vary drastically in width, orientation, and in

placement within the well. This yields increased variability in

calculated measurements within replicate wells and across

titrations, complicating final conclusions regarding the

migratory ability of test cell models and treatments, especially

when comparing assay to assay data. To increase the

robustness of generated data, a method to create consistent

wounds is necessary.

This study demonstrates the use of a novel, automated tool

to create scratch wounds in cell monolayers formed on the

bottom of a microplate. With the single push of a button, and

using a 4- or 8-pin head, consistent scratches of equivalent

size and area are made in either 24- or 96-well plates. A

multi-reservoir cleaning trough is also incorporated on the

deck of the tool. Using the onboard programmed procedure,

unattended cleaning and decontamination of each pin is

accomplished before and after use. The small footprint

permits insertion of the tool; using any size laminar flow

hood enabling wound creation in a sterile manner. Following

washing, the plate can then be transferred to an Agilent

BioTek automated imager or the Agilent BioTek BioSpa live

cell analysis system to kinetically monitor cell migration.

Materials

Cells

1

HT-1080 fibrosarcoma cells (partnumberCCL-121)

were purchased from ATCC (Manassas, VA).

Human neonatal dermal fibroblasts expressing RFP

(partnumbercAP-0008RFP) were purchased from

Angio-Proteomie (Boston, MA). U-87 glioblastoma cells

expressing GFP were generously donated by Dr. Sachin Katyal

(University of Manitoba, Winnipeg, Manitoba, Canada).

Experimental components

Advanced DMEM (partnumber12491- 015), fetal bovine

serum (partnumber10437-036), penicillin-streptomycinglutamine (100x) (partnumber10378-016), TrypLE express

enzyme (1x), phenol red (partnumber12605-010), Alconox

powdered precision cleaner (partnumber16-000-104),

Virkon-S (partnumberNC9821357), and CellTracker Green

CMFDA Dye (partnumberC2925) were purchased from

Thermo Fisher Scientific (Waltham, MA). Cytochalasin

D (partnumber1233) was purchased from Bio-Techne

Corporation (Minneapolis, MN). 24-well clear TC-treated

multiple well plates (partnumber3524) and 96-well

clear, flat bottom, polystyrene TC-treated microplates

(partnumber3598) were purchased from Corning Life

Sciences (Corning, NY).

Agilent BioTek AutoScratch wound making tool

The Agilent BioTek AutoScratch wound making tool

automatically creates reproducible scratch wounds in cell

monolayers grown in microplates. The simple pushbutton

operation and tool-free scratch pin manifold exchange

make it easy to process either 96- or 24-well plates, which

are commonly used in migration and invasion assays. The

compact system features an onboard, preprogrammed

cleaning routine to keep the scratch pins free of buildup and

avoiding contamination. AutoScratch precisely and efficiently

automates the sample prep for imaging workflows with

Agilent BioTek Cytation cell imaging multimode readers and

Agilent BioTek Lionheart automated microscopes.

2

Page 3

Agilent BioTek Cytation 5 cell imaging multimode reader

Cytation 5 is a modular multimode microplate reader

combined with an automated digital microscope. Filter- and

monochromator-based microplate reading are available, and

the microscopy module provides up to 60x magnification in

fluorescence, brightfield, color brightfield and phase contrast.

The instrument can perform fluorescence imaging in up to

four channels in a single step. With special emphasis on

live cell assays, Cytation 5 features shaking, temperature

control to 65 °C, CO

gas control and dual injectors

2/O2

for kinetic assays and is controlled by integrated Agilent

BioTek Gen5 microplate reader and imager software, which

also automates image capture, analysis and processing.

The instrument was used to capture kinetic high contrast

brightfield and fluorescent images over the incubation period.

Agilent BioTek BioSpa 8 automated incubator

The BioSpa 8 automated incubator links Agilent BioTek

readers or imagers together with Agilent BioTek washers

and dispensers for full workflow automation of up to eight

microplates. Temperature, CO

and humidity levels are

2/O2

controlled and monitored through the Agilent BioTek BioSpa

software to maintain an ideal environment for cell cultures

during all experimental stages. Test plates were incubated in

the BioSpa to maintain proper atmospheric conditions during

incubation and automatically transferred to the Cytation 5 for

high contrast brightfield and fluorescentimaging.

Agilent BioTek MultiFlo FX multimode dispenser

The MultiFlo FX is a modular, upgradable reagent dispenser

that can have as many as two peristaltic pump (8-tube

dispensers), two syringe pump dispensers and a strip washer.

The syringe and washer manifolds can be configured for plate

densities from 6- to 384-well.

Methods

Cell preparation

Cells were cultured in T-75 flasks until reaching 80%

confluency. Subsequent to detachment from the flask

with TrypLE, cells were resuspended to preoptimized

concentrations depending on plate well density and culture

conditions (Table 1).

Table 1. Automated 3D tumoroid invasion imaging

parameters.

Cell Plating Concentrations

24-Well Format 96-Well Format

HT-1080

Fibroblast

U-87

2.4 × 105 cells/mL 4.0 × 105 cells/mL

– 2.0 × 105 cells/mL

2.4 × 105 cells/mL 4.0 × 105 cells/mL

AutoScratch cleaning procedure

Prior to wound creation in test plates, the AutoScratch

tool pins were cleaned and sterilized. The four cleaning

components were added to individual reservoirs of the

cleaning trough, labeled to assist with appropriate component

and volume addition (Table 2).

Table 2. Cleaning trough reagent setup.

AutoScratch Cleaning Components

Reservoir 1

Reservoir 2

Reservoir 3

Reservoir 4

Alconox, 0.5% 12 mL

Virkon-S, 1% 12 mL

Sterile DI H2O 12 mL

70% Ethanol 12 mL

The “Clean” button was pressed to initiate the cleaning

procedure. During the process, the scratching arm containing

the pins moves from the home position into the reservoir

containing 0.5% Alconox, agitates in the Y-axis for 3seconds,

then soaks the pins in the component for 5 minutes. At the

completion of the 5-minute incubation period, the arm moves

the pins to the Virkon-S. The process is then automatically

repeated for each of the remaining components. At the end of

the 20-minute cleaning cycle, the pins were cleaned, sterilized,

and ready to be used for woundcreation.

Scratch wound creation

Following completion of the cleaning procedure, the test plate

was added to the deck of the AutoScratch tool and the lid

removed. The “Scratch” button appropriate for the microplate

density being used, “24” or “96”, was pressed to begin the

wounding process. Here the arm moves the pins from the

home position to column 1 of the plate where a scratch is

made vertically at the center of the well. The arm then moves

the pins back to the reservoir containing the DI H

O and

2

performs a three second agitation to remove any dislodged

cells sticking to the pins. The pins are then moved to

column2 and the scratching and cleaning steps are repeated

for each column of the plate.

3

Page 4

Post scratch plate washing

Wt = IA – Object Sum Area

t

Upon completion of the wound creation routine, the plate was

transferred to a separate laminar flow hood containing the

Agilent BioTek MultiFlo FX. Here a plate washing procedure

was carried out to remove cells dislodged from the bottom

of the plate. The stainless steel tubes of the strip washer,

previously sterilized using 70% ethanol, were used to aspirate

media while the peristaltic pump and an autoclaved 5 uL

cassette dispensed back fresh media. For uninhibited wells,

the procedure was repeated 3x. For wells containing the

cytochalasin D titration, media containing inhibitor was added

manually following the third aspiration cycle.

Kinetic image-based monitoring of cell migration

Plates were then placed into the BioSpa 8, with atmospheric

conditions previously set to 37 °C/5% CO

. Water was

2

added to the pan to create a humidified environment. The

BioSpa8 software was programmed such that the plates

were automatically transferred to Cytation 5 for high contrast

brightfield or high contrast brightfield and fluorescent imaging

of the test wells, depending on the incorporated cell types.

A single 4x image was taken with each channel (Table 3) to

capture potential cell movement into the original wound area.

Table 3. Included imaging channels per test

cell model.

Incorporated Imaging Channels

HT-1080

Fibroblast

U-87

High contrast brightfield/GFP

High contrast brightfield/RFP

High contrast brightfield/GFP

Plates were then transferred back to the BioSpa 8. Kinetic

imaging cycles were carried out using iterations optimized

depending on the speed of migration for each cell model

(Table 4).

Table 4. Optimized imaging intervals per

cell model.

Kinetic Imaging Intervals

HT-1080

Fibroblast

U-87

Fibroblast/U-87 Co-culture

60 minutes

90 minutes

90 minutes

90 minutes

Table 5. Image preprocessing parameters.

Incorporated Imaging Channels

Channel

High Contrast

Brightfield

RFP

GFP

Apply Image

Processing Background Rolling Ball Priority

Yes Dark 25 μm Fine results

Yes Dark Auto Fine results

Yes Dark Auto Fine results

Cellular analysis of preprocessed images

Cellular analysis was carried out on the processed images

to quantify the cell containing areas of each image using the

criteria in Table 6.

Table 6. Object mask analysis parameters.

Primary Cellular Analysis Parameters

Channel

Threshold

Background

Split Touching Objects

Fill Holes in Masks

Minimum Object Size

Maximum Object Size

Include Primary Edge Objects

Analyze Entire Image

Advanced Detection Options

Rolling Ball Diameter

Image Smoothing Strength

Evaluate Background On

Expand the Threshold Mask

Analysis Metric

Metric of Interest

Tsf[Brightfield]

2,000

Dark

Unchecked

Checked

100 μm

10,000 μm

Checked

Checked

40

20

1% of lowest pixels

5 μm

Object sum area

Wound healing metric calculation

The kinetic cell area coverage values (object sum area) were

then used to generate three additional wound healing metrics,

including wound width, wound confluence, and maximum

wound healing rate. Each metric is automatically calculated

by the Agilent BioTek Gen5 wound healing protocol.

Wound width

Wound width, or the average width of the cell-free zone over

time, is calculated using the following formula:

Image processing

Following capture, using the settings in Table 5, high contrast

brightfield images were processed to increase the contrast

in brightfield signal between background and cell containing

areas of the image, while fluorescent images were processed

to remove background signal.

4

I

H

Where Wt is the average wound width (µm) over time, IA is

the total area of the 4x image, Object Sum Area

covered by cells at each time point, and I

is the area

t

is the height of a

H

4ximage.

Page 5

Wound confluence

Ct = Object Sum Areat – Object Sum Area0 * 100

AB

AB

AB

Wound confluence, or the percentage of the original wound

area covered by migrating cells over time, is calculated using

the following formula:

from the 24-well plate once again illustrated consistent

wound shape and size similar to that seen from the 96-well

plates (Figure 2).

IA - Object Sum Area

0

Where Ct is the percent wound confluence over time, Object

Sum Area

Object Sum Area

is the area covered by cells at each time point,

t

is the area covered by cells at time 0, and IA

0

is the total area of the 4x image.

Maximum wound healing rate

The maximum wound healing rate is calculated using a

Kinetic Analysis step in Gen5. The Max V calculation type

is selected and the rate is calculated using six data points

along the sum area curve. The value is then expressed as

2

perhour.

µm

Results and discussion

Validation of consistency within scratch wound creation

To validate the ability of the Agilent BioTek AutoScratch unit

to create wounds of a consistent size, HT-1080 cells were

plated into each well of 96-well microplates using a volume of

100µL and a concentration of 4.0 × 10

an overnight incubation to allow for attachment, the plates

were placed one at a time onto the deck and scratched by

the AutoScratch tool to create wounds in each well. Visual

inspection of the high contrast brightfield images illustrated

the consistent wound shape and size that could be achieved

from well to well (Figure 1).

5

cells/mL. Following

Figure 2. Images captured from a 24-well plate immediately following

wound creation with the Agilent BioTek AutoScratch using the high contrast

brightfield imaging channel and a 4x objective.

To quantify the consistency of wound creation, high contrast

brightfield images (Figure 3A) were then preprocessed using

the parameters described in Table 5. Using this method,

the contrast between image areas containing cells and

background is increased (Figure 3B). This allows accurate

object mask placement around cell containing areas

(Figure3C) using the cellular analysis criteria in Table 6.

C

Figure 1. Images captured from a 96 -well plate immediately following

wound creation with the Agilent BioTek AutoScratch using the high contrast

brightfield imaging channel and a 4x objective.

Validation of consistent wound creation was also performed

in 24-well plates. Here HT-1080 cells were added to

each well using a volume of 1 mL and concentration of

5

2.4×10

incubation period, the plates were again placed onto the

deck and scratched by the Agilent BioTek AutoScratch tool.

cells/mL. Following the overnight cell attachment

Visualinspection of high contrast brightfield images captured

Figure 3. High contrast brightfield image processing and analysis. (A) Raw

high contrast brightfield image; (B) preprocessed high contrast brightfield

image; and (C) preprocessed high contrast brightfield image with object

mask placement.

Using the wound width formula described previously, the

average wound width at time 0 following wound creation

was generated for each well of the 96- and 24-well plates.

The %CV of the wound width values across all wells of the

96-well test plate was calculated to be 2.1%, whereas the %CV

of the wound width values across the 24-well test plate was

1.4%, illustrating the high degree of repeatability in created

wound size when using the AutoScratch tool with either plate

welldensity.

5

Page 6

Cell carryover testing

AB

Because wound creation takes place in a column wise fashion

across the microplate, it was necessary to confirm that the

cleaning process that follows wounding in each column

effectively presents carryover and cross-contamination

(cells were not carried from column to column on the pins

of the AutoScratch tool). For this experiment, HT-1080 cells

in column 1 of a 96-well plate were stained with CellTracker

Green fluorescent probe, whereas all other wells in columns

2to12 were left unstained (Figure 4).

C D

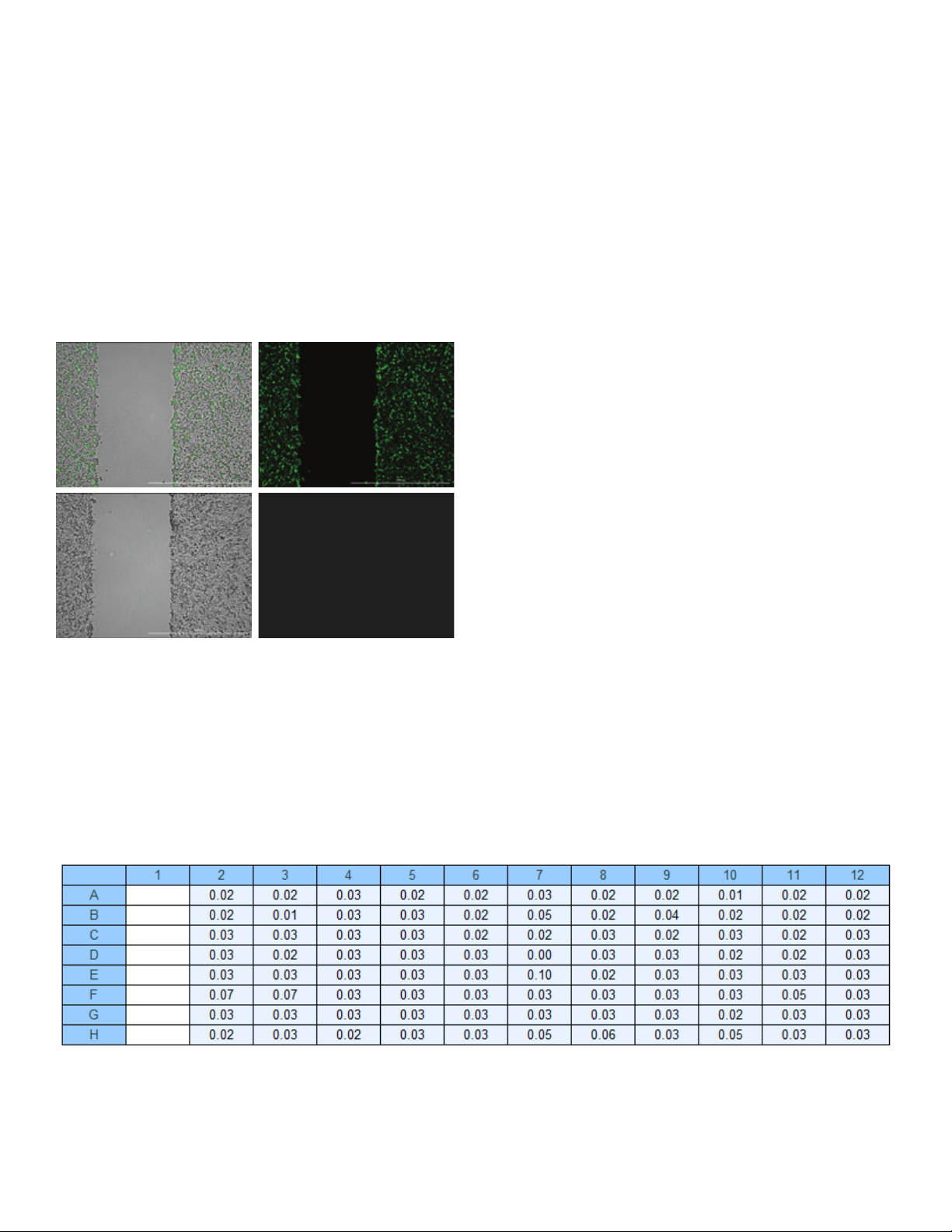

Figure 4. High contrast brightfield and GFP images. (A) High contrast

brightfield/GFP overlaid images; and (B) GFP images only following wound

creation for CellTracker Green stained cells in column 1. (C) High contrast

brightfield/GFP overlaid images; and (D) GFP images only following wound

creation for unstained cells in column 2.

Wound creation was then allowed to proceed as previously

described. Following image processing, image analysis was

performed to quantify the total GFP signal per image. The

percent GFP signal in columns 2to12 compared to the signal

in column 1, per row, was then calculated.

As seen in Figure 5, signal percentages were less than 0.1%

for every well subsequent to column 1, demonstrating that

the cleaning process following wounding in each column

effectively prevents cells from being carried from column

to column, eliminating carryover and cross-contamination

(carryover and cross-contamination between the columns of

each test plate).

Kinetic wound healing metrics

Kinetic imaging of the test plates was then allowed to

proceed to monitor cell migration into the wound area. Test

plates were added to the BioSpa 8 and robotically transferred

to the Cytation 5 at predefined intervals. Due to the fact

that HT-1080 cells migrate rapidly, a more frequent imaging

interval of 60 minutes was selected to properly capture

movement of the cells over time. As with the wound width

metric, sum area values were used to calculate wound

confluence for each well over the entire incubation period.

All metrics for each plate type, including the original sum

area values in addition to calculated wound width and wound

confluence, were then plotted versus time to assess data

consistency by comparing the kinetic curves from each well

(Figure 6).

The kinetic sum area graphs were also used to calculate the

final kinetic wound healing metric, maximum wound healing

rate. From examining the kinetic curves generated from each

metric, it is clear that a high degree of similarity is seen from

well to well. In addition, the average of the maximum wound

healing rate values from each well of the 96- or 24-well plates,

5

at a 95% confidence interval was 1.61 ±0.01×10

with a %CV of 3.8% for 96-, and 1.612 ±0.005×10

µm2/hour

5

µm2/hour

with a %CV of 2.1% for 24-well format, confirm that use of

the AutoScratch tool yields kinetic wound healing results with

high levels of consistency within wells of a single plate, and

also between different plate well formats.

Figure 5. Calculated percent GFP signal carryover values from stained cells in column 1.

6

Page 7

A B

C

E

D

F

Figure 6. Full plate screenshots of plotted kinetic wound healing metric data. Kinetic sum area, wound width and wound confluence graphs for (A, C, and E)

96- and (B, D, and F) 24-well plates, respectively.

7

Page 8

Cell migration inhibition analysis

A

B

A

B

The AutoScratch tool was also used to prepare for a wound

healing inhibition test. Here the automated wounding and

washing procedures were carried out as previously described.

However, in this case, following the third wash aspiration step,

media containing varying concentrations of cytochalasin

D was added to the wells. Twelve replicates of an 8-point

titration were added across the plate in 96-well format, and

four replicates of a 6-point titration were added down the

plate in 24-well format. Test plates were once again added

to the BioSpa 8 and automatically imaged as previously

defined. The kinetic migration curves demonstrate the

consistency achieved amongst replicates within each inhibitor

concentration (Figure7).

Average kinetic curves from each tested concentration were

then plotted on a single graph for data generated in either

96- or 24-well format (Figure 8).

Figure 8. Average kinetic cytochalasin D titration wound confluence graphs.

Average, plus/minus standard deviation plotted for each test cytochalasin D

concentration at every captured timepoint in (A) 96-well; and (B) 24-well plate

formats.

Upon observation of the individual kinetic curves, it is then

possible to see the total effect of the compound titration

over time. The advantage of being able to collect images

over the entire incubation period, and generate kinetic data,

as opposed to performing endpoint imaging at a predecided

Figure 7. Kinetic cytochalasin D titration wound confluence graphs.

(A) 96-well plate containing 12 replicates each of an 8-point titration.

Cytochalasin D titrated from 10,000 nM using serial 1:4 dilutions from rows

AtoG, with row H being no compound negative control. (B) 24-well plate

containing 4 replicates each of a 6-point titration. Cytochalasin D titrated

from 10,000nM using serial 1:10 dilutions from column 1to5, with column 6

being no compound negative control.

upon time, becomes apparent when comparing IC

and values generated from individual incubation periods

(Figure 9).

curves

50

8

Page 9

A

B

Manual scratch wound creation

AB

Wound creation was also carried out manually using a P200

pipette tip in 96-well format to compare results achieved

using a commonly incorporated manual method to those

described previously using the AutoScratch tool.

From the images in Figure 10, the variability within each

created wound is noticeably greater than those made by the

AutoScratch. Images in Figures 10A and 10B show wounds

having greater widths at the top of the image, while being

visibly smaller towards the bottom of the image. Even when

the wound is of a more consistent width down the image

(Figure 10C), the lack of verticality can also skew generated

results. This is apparent from the %CV calculated using Gen5

generated wound widths from 48 wells where wounds were

manually created. The final value of 9.2% is greater than 4x

that seen when using the AutoScratch to create wounds in a

96-well plate (2.1%) and greater than 6x that seen when using

the AutoScratch to create wounds in a 24-well plate.

Figure 9. Variable incubation cytochalasin D dose response graphs. Dose

response curves and generated IC

cells with cytochalasin D for 5, 10, 15, or 20 hours in (A) 96-well; and

(B) 24-well plate formats.

values following incubation of HT-1080

50

From the 5-hour incubation dose response curves generated

from experiments run in either 96- or 24-well format, it

is obvious that cell migration is incomplete in negative

control and low compound treatment wells. Therefore

calculated IC

values would not properly reflect the ability

50

of the compound to inhibit cell migration. By increasing

the incubation period by an additional five hours it is then

apparent that wells containing little or no compound achieve

total wound closure. Complete inhibition is also attained with

the highest concentrations, yielding a full dose response and

more accurate IC

period, equivalent dose response curves and IC

also seen. However, if the cells are allowed to migrate for

20 hours, dose response curve shapes change dramatically

and IC

values increase 2.5to3.5x over those seen from

50

value. When using a 15-hour incubation

50

values are

50

the 10- and 15-hour incubation periods. By using the

information from the complete data set, a proper incubation

period of 10to15 hours can then be decided upon for

futureexperiments.

C

Figure 10. Images captured from a 96-well plate immediately following

wound creation with a P200 pipette tip using the high contrast brightfield

imaging channel and a 4x objective.

The difference in data quality between plates containing

wounds created manually and with the AutoScratch is further

illustrated upon view of cytochalasin D dose response curves

(Figure 11) generated from kinetic cell migration data.

9

Page 10

Figure 11. Manual and Agilent BioTek AutoScratch cytochalasin D dose

AB

response graphs. Dose response curves and generated IC

incubation of HT-1080 cells with cy tochalasin D for 10 hours in 96-well plates

scratched manually or with the AutoScratch tool.

values following

50

C D

When using the same compound incubation period, the

curve shape lacks the sigmoidal dose response seen with

AutoScratch created wounds and the IC

value is 5x greater,

50

which could lead to false assumptions being made regarding

the potency of the test molecule when incorporating a manual

wounding process.

AutoScratch wound creation using variable size

cellmodels

As a wide variety of cell models are incorporated into 2D

scratch wound healing assays, the AutoScratch tool was also

used to create wounds using primary fibroblasts and U-87

glioblastoma cells, which have a larger size and different plate

attachment pattern compared to HT-1080 cells. Because

the Cytation 5 can capture images using both high contrast

brightfield and fluorescence, the fibroblasts, which express

RFP, and the U-87 cells, which express GFP, could be captured

using the high contrast brightfield and either RFP or GFP

signal from the cells in a single imaging step (Figure 12).

Figure 12. High contrast brightfield and fluorescent images of primary

fibroblasts and U-87 glioblastoma cells. (A) High contrast brightfield; and

(B) RFP images of RFP expressing primary fibroblasts. (C) High contrast

brightfield; and (D) GFP images of GFP expressing U-87 cells.

Percent CV values calculated from wound widths generated

at time 0 using high contrast brightfield images across

96wells for fibroblasts (3.2%), and across 24 wells for U-87

cells (2.6%) demonstrate that the AutoScratch tool can create

consistent wounds in each well despite the irregular shape of

the cell models.

The similarity in the kinetic wound healing inhibition curves

following cytochalasin D treatment of the fibroblasts or U-87

cells (Figure 13), compared to the curves seen in Figure 8

using HT-1080 cells also proves that Gen5 cellular analysis

metrics can place accurate object masks around cells of

varying size and shape.

10

Page 11

A

B

Figure 13. Average fibroblast and U -87 kinetic cytochalasin D titration

wound confluence graphs. Average, plus/minus standard deviation plotted

for each test cy tochalasin D concentration at every captured timepoint with

(A)primar y fibroblasts; or (B) U-87 cells.

Conclusion

The Agilent BioTek AutoScratch wound making tool creates

consistent wounds in an automated fashion in both 96- and

24-well plate formats. The disinfection and sterilization

procedure before and after wounding, in addition to cell

removal between columns, simplifies cleaning of the tool and

also prevents carryover of cells from column to column. When

compared to results generated from plates with wounds

created manually, initial wound widths and kinetic values

show improved reproducibility and increased robustness. The

combination of the automated wound creation procedure,

kinetic imaging, and Agilent BioTek Gen5 cellular analysis

method creates an easy to use, dependable process to

carryout wound healingassays.

References

1. Li, L. et al. Collective Cell Migration: Implications for

Wound Healing and Cancer Invasion. Burns Trauma,

2013, 1(1), 21–26.

2. Poujade, M. et al. Collective Migration of an Epithelial

Monolayer in Response to a Model Wound. Proc. Natl.

Acad. Sci., 2007, 104(41), 15988–93.

3. Giampieri, S. et al. Localized and Reversible TGFbeta

Signalling Switches Breast Cancer Cells from Cohesive to

Single Cell Motility. Nat. Cell Biol., 2009, 11(11), 1287–96.

4. Friedl, P.; Hegerfeldt, Y.; Tusch, M. Collective Cell Migration

in Morphogenesis and Cancer. Int. J. Dev. Biol., 2004,

48(5-6), 441–9.

www.agilent.com/lifesciences/biotek

For Research Use Only. Not for use in diagnostic procedures.

RA44216.561724537

This information is subject to change without notice.

© Agilent Technologies, Inc. 2018, 2021

Printed in the USA, April 1, 2021

5994-2585EN

AN100118_10

Loading...

Loading...