Motorola AMPS/NAMPS Cell Site Test Software

HP 11807B Option 040 Software User’s Guide

for the HP 8921A

Software Version B.01.00 and above

HP Part No. 11807-90153

Printed in U. S. A.

May 1997

Rev A

1

Copyright © Hewlett-Packard Company 1995

RESTRICTED

RIGHTS LEGEN D

Use, duplication or disc losu re by the U.S. Gover nment is subj ect to restr ictio ns as

set forth in su bparagr aph ( c) (1) ( ii) of t he Right s in Techni cal Data a nd Computer

Software clause in DFARS 252.227-7013.

Hewlett-Packar dCompany

3000 Hanover Street

Palo Alto, CA 94304

U.S.A.

Rights for non-DOD U.S. Government Departm ents and Agencie s are as set forth

in FAR 52.227-19 (c) (1, 2)

2

Contents

1 Product Description

About the Test Software 24

About the Test System 25

Testable Cell Site Equipment 26

Using the Test Software 27

Firmware Differences 28

To Setup Printer Using HP 8921A FW Below Rev A.14.00 32

Table of Contents

Table of Contents

Getting Started 34

To Turn On and Set Up the Test Set: 35

To Select T est Software Procedure Location: 36

To Select T est Software Procedure Location: (Co ntinued) 37

To Load and Run Tes t Software: 38

To Load and Run Tes t Software: (Continued) 39

To Change the Order of Tests: 40

To Change the Order of Tests: (Continued) 41

To Select URDM or RDM Frequency/Level test: 42

To Select URDM or RDM frequency/level test: (Continued) 43

To run TEST_02 URDM or RDM Fr equency/Level: 44

To run TEST_02 URDM o r RDM Fr equency/Level: (Continued) 45

Learning To Use the Test Software 46

In this Manual 47

Manual Contents 48

Conventions Used 49

3

Contents

2 Equipment

Cell Site Equipment 52

Memory Ca rd s 53

Test Software Memory Cards 54

SRAM Cards 55

Memory Card Storage Space 56

HP 8921A Cell Site Test Set 57

Test Set Firmware 57

Test Set Op tio n 57

Other Software Tools 58

Peripheral Items 59

HP Supplied Peripheral Items 60

61

RF and Audio Switching Arrangements 61

RF and Audio Switches 61

Switch Control Input Buffer 62

RF Couplers 62

50-Ohm Terminations 62

Cables, A dapters, and Connecto rs 63

HP Supplie d Connector Kit 65

VSWR and Cable Fault Ancillary Equipment 65

High Accuracy Frequency Reference 65

Documentation 66

Vendor Information 67

4

Contents

Table of Contents

3 Setting Up

Equipment Connections 70

Receiver RF Connections 74

Transmitt er RF Connections 74

Audi o C on nect ions 7 5

Conne ction for

RS-232 Base Station Control 75

Serial Port Connections for Dat a C ollection 75

Printer Connection 76

Serial Port Location 76

Parallel Port Location 78

Disk Drive Connections 78

Radio Interface Connections 79

DC Power to the RF and Audio Swit ches 80

Determining Calibration Parameters 81

Transmitter Path Loss Calibration 81

Receiver Path Loss Calibration 85

Referen ce D istribution Module Level Correction Factor 88

Combiner to Test Set Path Loss Factor 90

Procedures 91

Saving a Procedure 92

Loading a Procedure 94

Deleting a Procedure 94

Securing a Procedure 95

Un-Securing a Procedure 96

Copying a Procedure 97

Entering Parameters, Pass/Fail Limits, and External Device

Configuration 99

Parameters 99

Pass/Fail Limits (Specifications) 101

External Device Configuration 102

Making Entries in a Test Set Configuration Screen 10 8

Serial Ports 108

5

Contents

Serial Port Configuration 109

HP-IB Port C on f ig ur ation 112

Data Collection 113

Collection to an SRAM Card or Disk 113

Collection to a PC 116

Retrieving Data from an SRA M Card 116

Retrie ving Data from a D isk 118

6

Contents

Table of Contents

4 Running Tests

What are Tests? 120

TESTS 120

TESTs 120

Tests 121

Order of TEST s 121

TESTS (Main Menu) Screen 122

Starting the Program 124

When the Program Starts Running 130

Entering the Order of TESTs 132

TEST Configuration Settings 134

Test Execution Conditi ons 135

If Unit-Under-Test Fails: 135

Test Pr oced ur e Run Mo de: 135

Output Results For: 136

Output Results To: 136

Output Heading: 136

HP-IB Control Annunciators 137

Pausing or Stopping a TEST 138

Continuing a TEST 139

Test Time Summary 140

Saving Test Results 141

7

Contents

5 TESTs - Reference

USER Keys 144

All Cal 144

Clr Scr 144

Continue 144

Del Chan 144

Delet Stp 144

Disp Data 144

Done 144

HDII Loc

LD Loc

NAMPS Loc 144

Insrt Stp 145

Key/Dekey 145

Laptop 145

LNA Offs 145

Next Wind 145

Next Chan 145

Next Ant 146

Page Up

Page Down 146

Prev Ant 146

Prev Chan 146

Print All 146

Prt Full 146

Re-test 146

Run 146

Run Test 147

Send ESC 147

Send FREE 147

Send TM 147

Send USE 147

Show Log 147

Skip Sens

Skip SAT

Next Ant

Skp N SSI 147

Sngl Step 148

8

Contents

Stop Test 148

Take It 148

Tns off

Tns quiet

Tns loud 148

To Chan 148

Yes,

No 148

Zoom 148

-60 dBm

-90 dBm

-100 dBm 148

Table of Contents

TEST_01 - Laptop Emulator 149

Sending Commands 149

Using the

PC/Modem mode 150

Messages 151

Baud Rate 151

Base Station Password 152

Base Station Report 152

Exiting TEST_01 152

TEST_02 - URDM or RDM Frequency/Level 153

Selecting the T est State 153

Calibration Factor 153

Questions Displayed 154

Frequency Error Refers To 154

Tests 154

Pass/Fail Limits 155

Param eters 155

TEST_03 - Voice Transceiver 156

Selecting the T est State 156

AMPS or NAMPS 156

Calibration Parameters 157

Questions Displayed 157

Frequen cy Error 157

Keying the Transmitter 157

Tests 158

9

Contents

Pass/Fail Limits 159

Param eters 161

TEST_04 - Signaling Transceiver MANUAL Mode 163

MANUAL Mode 163

HDII or LD Equipment 164

Calibration Parameters 164

Questions Displayed 164

Tests 167

Pass/Fail Limits 167

Param eters 168

TEST_05 - Scanning Receiver MANUAL Mode 169

MANUAL Mode 169

AMPS or NAMPS 169

Connections 169

Calibration Parameters 169

Questions Displayed 169

Tests 171

Pass/Fail Limits 171

Param eters 172

TEST_06 - Combiner Adjustment 173

Calibration Parameter 173

Running TEST_06 - Com biner Adjustment 174

Questions Displayed 174

Test 174

Pass/Fail Limits 174

Param eters 174

TEST_07 - Wideband Data on an Active Voice Channel 175

Test 176

Pass/Fail Limits 176

Param eters 176

TEST_08 - Manual Switch and Calibratio n Aid 177

Routines 177

Pass/Fail Limits 178

10

Contents

Table of Contents

Parameters 178

TEST_09 - Calculate Transmitter Power 179

Avai la bl e Entri es 179

Pass/Fail Limits 180

Param eters 180

TEST_10 - Voice Channel Manual Test Mode 181

Pass/Fail Limits 182

Param eters 183

TEST_11 - Test Menu 184

Pass/Fail Limits 185

Param eters 185

11

Contents

6 Parameter s - Refer en ce

Parameter Descriptions 189

GN alwa ys cal si g/ scan [0= n o 1=yes] 189

GN auto exit adj [0=no xx=times in spec] 189

GN perform adj [0=n o 1=fail 2 =always] 189

GN perform extended tests [0=no 1=yes] 189

GN site Average Voice Level (AVL) (dBm) 189

GN sit e ha s L N As [0=n o 1 = yes] 190

GN site [0=non-wireline 1=wireline] 190

GN test state of [0=INS_OPT 1=MANUAL] 190

GN type of site [0=omni 1=sec .skip ant] 190

GN verify all select ions [0=no 1=yes] 190

RDM lev e l co rrecti o n fa ctor (dB ) 190

RX level for scanner DSA T detector (dBm) 190

RX level for scanner SAT detector (dBm) 191

RX level for voice DSAT/ D ST detecto r (dBm) 191

RX level fo r voice SAT/ST detector (dBm ) 191

RX path loss to antenna 1 (dB) 191

RX path loss to antenna 2 (dB) 191

RX path loss to antenna 3 (dB) 191

RX path loss to antenna 4 (dB) 191

RX path loss to antenna 5 (dB) 191

RX path loss to antenna 6 (dB) 191

RX/TX audio f req response step [.01-2.7] 191

SC fewer li nearity channels [0=no 1=yes] 192

SC skip items in scan test [0=no 1=yes] 192

TX output power for l evel 0 (Watts) 192

TX output power for l evel 1 (Watts) 192

TX output power for l evel 2 (Watts) 192

TX output power for l evel 3 (Watts) 192

TX output power for l evel 4 (Watts) 192

TX output power for l evel 5 (Watts) 192

TX output power for l evel 6 (Watts) 192

TX output power for l evel 7 (Watts) 192

TX output power for si gnaling unit (Watts) 192

TX path loss to combiner for adjustment (dB) 193

TX path loss to harmonic filter 1 (dB) 193

12

Contents

Table of Contents

TX path loss to harmonic filter 2 (dB) 193

TX path loss to harmonic filter 3 (dB) 193

TX path loss to harmonic filter 4 (dB) 193

TX path loss to harmonic filter 5 (dB) 193

TX path loss to harmonic filter 6 (dB) 193

TX path loss to harmonic filter 7 (dB) 193

TX path loss to harmonic filter 8 (dB) 193

TX perform loopback test [0=no 1=yes] 194

TX steppi ng PA p w r lvls tested [0-127] 194

TX peak voice limit step 194

TX voice/signal pwr use [0=anz 1=pwrmtr] 194

ZZZZ test mode [0=normal 1=demo] 195

13

Contents

7 Pass/Fail Limits (Speci fi cations) - Reference

Pass/Fail Limit (Specification) Descriptions 199

RDM frequency error (Hz) 199

RDM output level (volts peak to peak) 199

RX audio distortion (percent) 199

RX audio output level (dBm) 199

RX audio res ponse dev from -6 dB/ oct R1 (dB) 199

RX audio res ponse dev from -6 dB/ oct R2 (dB) 199

RX expandor track erro r < 0 dB (dB) 199

RX expandor track erro r > 0 dB (dB) 200

RX hum and noise ( dB) 200

RX scan and si g calibrati on reading (dBm ) 200

RX scan sig li nearity error (dB) 200

RX sensitivity with LNA (dBm) 200

RX sensitivity without LN A (dBm ) 200

RX sensitivity without LN A narrow mode (dBm) 200

RX SINAD at sensitivity spec (dB) 200

TX audio dist ortion (p ercent ) 20 0

TX audio res ponse dev fr om 6 dB /oct (dB) 201

TX compre ssor track error <0 dB (dB ) 201

TX compre ssor track error >0 dB (dB ) 201

TX data deviation (kHz) 201

TX DSAT deviation (Hz) 201

TX FM hum and nois e (dB) 201

TX frequency error (ppm) 201

TX loopback level (dBm) 201

TX output power error at level 0 (percent) 201

TX output power error at level 1 (percent) 202

TX output power error at level 2 (percent) 202

TX output power error at level 3 (percent) 202

TX output power error at level 4 (percent) 202

TX output power error at level 5 (percent) 202

TX output power error at level 6 (percent) 202

TX output power error at level 7 (percent) 202

TX output power erro r for signa ling unit (percent) 202

TX SAT deviation (kHz) 202

TX SAT frequency error (Hz) 202

14

Contents

Table of Contents

TX test point JK output (dBm) 203

TX voice deviation (kHz) 203

TX voice deviation nar row mode (kH z) 203

TX voice limiting deviation (kHz) 203

TX voice limiting deviation narrow mode (kHz) 203

15

Contents

8 Problem Solving

Base Station Control Difficulties 207

Data-Collection Function Does Not Work 208

Exiting the Program 210

Equipment Control 212

Memory Space Problems 213

Printing Problems 214

Test Results are Unexpecte d 215

Test Set Doesn’t Power Up 216

Unstable SINAD Readings 217

16

Contents

Table of Contents

A Appendix: Using the HP 3488A Switch/Control Unit 219

17

Contents

B Appendix: Test Set Measurement Settings 223

224

TEST_02 - URDM or RDM Frequency/Level 224

TEST_03 - Voice Transceiver 225

TEST_04 - Signaling Transceiver MANUAL Mode 229

TEST_05 - Scanning Receiver MANUAL Mode 230

TEST_06 - Combiner Adjustment 230

TEST_07 - Wideband Data on Active Voice Channel 230

TEST_08 -Manual Switch and Calibration Aid 230

TEST_09 - Calculate Transmitter Power 231

TEST_10 - Voice Channel Manual Test Mode 231

18

Contents

and Printer 233

Table of Contents

C Appendix: Cable Wiring Diagrams for Data Collection to PC

19

Contents

Glossary 235

20

Contents

Table of Contents

Index 239

21

Contents

22

1

Product Description

Chapter 1

Product Description

23

Chapter 1, Product Description

About the Test Software

About the Test Software

The HP 11807B Option 040 Motorola AMPS/NAMPS Cell Site Test Software is

used with the HP 8921A Cell Site Test Set, and various ancil lary equipment, to

test the functionality of Motorola cellular telephone base stations. The Test

Software package, as shippe d, co ntains the following items:

• HP 11807B Option 040 Cell Sit e Tes t So ftware Card, part number HP 11807- 10012

• HP 11807B Option 040 Test Software User’s Guide, part number HP 11807-90153

• Software licensing agreement, part num ber 5180-1566

• 128-kilobyte Memory (SR AM) Card (part num ber HP 85702A) for st oring customiz ed

tes t pr o gram s and resu lts.

• Cable and adap tor for serial connection to the base station

• 6-Conductor RJ11 (m) — RJ11 (m) cable, part number 08921-61015

• RJ11 (f) — DB25 (m) adaptor, part number 08921-61016

The following features of the Test Softwa re simplify testing:

• The Test Software sends base station control comma nds automaticall y fr om th e Tes t

Set via the RS-232 interface . The Test Softwa re also displays responses from the base

station.

• The Test Software displays the location of an adjustment whenever adjustment is

required.

• The Test Software displays a large meter on the Test Set screen and provides variabl e

auditory feedback while adjustments are being made.

• The Test Software displays system interconnects on the Test Set screen whenever cable

connections mus t change.

• The Test Software displays results of test s and pas s/fail indicat ions on the Test Set

screen, and supplies the results and indications for printing or collecting in an HP

Palmtop comp u t er, a P C , a di s k driv e , or a memory (S R A M ) ca r d .

• The Test Softwar e co n trols switche s that se lect the external RF or audio signal paths.

• The Test Software allows you to cha nge the order of TESTs, pass/fail limits,

parameters, and extern al device configurations.

• The Test Software provi des that bas e stat ion control command s can be sel ecti vely sen t

as the tests proceed.

• The Test Software pr ovides t ha t RF pa th losse s ca n be det ermined and a ccommod ated.

24

About the Test System

Chapter 1, Product Description

About the Test Sy stem

When the Test Software is used with the HP 8921 A Test Set and the various other

equipment, the combined system is called the Test System. The following items

make up the Test System:

• HP 11807B Option 040 Motorola AMPS/NAMPS Cell Site Test Software.

• HP 8921A Cell Site Test Set.

• Accessories:

• HP 83202A Option 040 Base Station Accessory Kit.

or

• Other switch and in terconn ect arrangements.

In addition, it would be helpful to have available the RF Tools in the HP

11807A,E Option 100 System Support Tests software package. The Option 100

software package offers a range of tests that may be used as adjuncts to those in

the Test Software.

Note that the following thre e tests that were in previous versions of the Test

Software w ere rem o ved fo r this version (B.01.00):

• VSWR Swept Return Loss.

• VSWR Discret e Channel Return Loss.

• VS W R vs D ist an ce (cabl e f au l t)

Product Description

Chapter 1

These tests are now included the RF Tools section of Option 100 software

package.

This system performs tests that determine the quality of the RF and audio

performance of several types of Motorola AMPS and AMPS/NAMPS cellular

base stations. Most of the measuremen t methods and specific ations use d for these

tests are derived from Electronic Industri es Association st andards and procedures

recommended by Motorola.

25

Chapter 1, Product Description

Testable C el l Site Eq uipment

Testable Cell Site Equipment

The Test System allows you to test Motorola HDII, HDII/NAMPS, and LD Base

Stations. The firmware revision of the bas e station to be tested must be 4.3.2.1 or

higher.

Specific equipment that you can te st includes voice transceivers, scan receivers,

signaling transc eivers, combiners, power amplifiers, and universal refere nc e

distribution modul es. The Test Software includes major adjustment procedures.

26

Using the Test Software

Chapter 1, Product Description

Using the Test Software

IMPORTANT

CAUTION:

This Test Software can be used during routine cell site verification and after the

installation or repair of cell site equipment. Base stations can be tested while in

the In-Service Optimiz at ion Mode or in the Manual Mode. The Manual Mode

must be used for some of the TESTs. There are instances in which it may be

advantageous to choose one of these modes over the other.

Before you connect the Test Set to a base station, you should underst and the potential

results of your act ions. Dropped calls, accidental modification of base stati on calibration

data, and other undesirable effects can occur.

The next two sections will get you started learning to use the Test Software. The

first of the two, “Getting Started”, contains steps to follow if you have not run

Test Software on a Test Set. The second of the two, “Learning to Use the Test

Software”, describes steps that you should follow in continuing to learn to use the

Test Software.

Product Description

Chapter 1

27

Chapter 1, Product Description

Firmware D ifferences

Firmware Differences

Firmware revision A.14.00 in the HP 8921A,D Cell Site Test Set introduced

several enha ncements to the TESTS menus. Wit h th e enhance ments were cha nges

to the menu structure used in the TESTS (Main Menu) screen and its sub-screens.

This manual is written for instruments with firmware revision A.14.00 and

higher. To assist users with instruments with older firmware, this section

summarizes the change s and shows the corr espondenc e between revis ion A.14 .00

screens and those of the earlier versions.

28

Chapter 1, Product Description

Firmw are D if fer ences

NOTE: If you are unsure of the firmware revision of your unit, press and release the SHIFT key

then press the DUPLEX key. A configuration screen will be displayed and the firmware

revision is sho wn in the upper right of the screen. Contact Hewlett-Packard at

1-800-922-8920 for details on upgrading your instrument if desired.

Product Description

Chapter 1

29

Chapter 1, Product Description

Firmware D ifferences

Using the TESTS

Menu Comparison

NOTE: The information in * and ** are for use rs of Test Sets with firmware revisions below

A.14.00. Please dis regard this materia l if your Test Set has a firmware revi sion of A.14.00

or higher.

The next two figur es show the TESTS (Main Menu) sc reens for the latest TESTS

menu (figure 1 ) and the TESTS menu used in older firmware revisions

(figure 2 ). The illustrations are intended to help you find the corresponding

functions if you are working with older firmware revisions.

To use the comparison, follow these steps:

1. When you enc ounter a procedure or diagram referring to a TESTS (Main Menu) field

selection or name that d oes n ot appe ar on your T ESTS (Ma in Menu) (or ma y a ppear i n

a different location on the display), refer back to these figures.

2. Loo k for t he sel ection desc ript ion or na me in figure 1 and no te the corres ponding l etter .

3. Look for the same letter in figure 2 and note whic h field (or sub-menu) is used in the

older firmware to access the screen or field.

4. Once in the sub- menus, the old a nd new scree ns are very similar a nd you shoul d be able

to use the docu me ntation as-is.

G

F

A

B

C1

C2

C3

C4

C5

Figure 1 TESTS Main Menu for Firmware Revisions of A.14.00 and greater.

30

D

C6

E

C7

Chapter 1, Product Description

Firmw are D if fer ences

Product Description

B

A

D

E*

C**

*See "To Setup Printer Using HP

8921A FW Below Rev A.14.00" on

page 32

Chapter 1

G

F

C3

C1

C4

C2

C6

C5

C7

**Selecting Test Fu nctions

opens the Choices menu.

Figure 2 TESTS Main Menu for Firmware Revision Below A.14.00

31

Chapter 1, Product Description

Firmware D ifferences

To Setup Printer Using HP 8921A FW Below Rev A.14.00

1. Press the TESTS key.

2. Select Edit Cnfg from the Test Function field.

3. Po sition the cursor to the Inst# field and select it.

4. Rotate the knob until an empty Calling Name field appears, and select it.

5. Po sition the curs or to the Callin g Name field and select it.

6. Using the list of characters in the Choices menu , en t er th e w o r d PRI N TER .

Select Done when co mplete.

7. Po sition the cursor to the Addr (address) field and select it.

8. Using th e DATA keypa d, ente r 9 for serial printers, 15 for parallel printers, or 70X for

HP-IB prin ters, then pr ess ENTER.

9. Po sition the cursor to the Options field (directly under Calling Name) and select it.

10. Using the list of characters from the Choices menu, the following command s may be

entered. Separate the commands with commas (example; LN=60,START,END)

• LN equals the number of printed lines per page.

• START causes a form feed at the st art of each p r intout.

• END causes a fo rm feed at the end of each printout.

11. From the To Screen menu, select More.

12. From the Choices menu, select IO CONFIG.

13. For Serial Printers:

• Set the Serial Baud field and other serial communications fields listed under it to

correspond to your printer’s configurati on.

14. For HP-IB Printers:

• Position the cursor to the Mode field and select it.

•From the Choices menu, select Control.

• Position the cursor to the Print Adrs field and select it.

• Rotate the knob and select the HP-IB address of your printer.

• Position the cursor to the Print To field. Pressing the knob will toggle the

underlined selection. Selec t to underline HP-IB.

15. Press the TESTS key to return to the TESTS screen.

32

Chapter 1, Product Description

Firmw are D if fer ences

To print test results

1. Make sure that your printer is pr operly connected and configured as explained ea rlier

in this section.

2. Press the TESTS key.

Product Description

3. Po siti on t he curs or to the Output Results To: field (or the Output Destination field).

Pressing the knob will toggle the underlined selection. Select to unde rline Printer.

4. Po sition the cursor to the Ou tput Heading field and select it.

5. Using the list of characters in the Choices menu, enter a printout heading (optional).

Select Done when the heading is complete.

Chapter 1

33

Chapter 1, Product Description

Getting Started

Getting Started

If you have not run Test Software on a Test Set, follow the procedur e s shown in

the following 11 illustrations to get started.

To perform this procedure, you will use an HP 8921A Cell Site Test Set and the

HP 11807B Option 040 Test Software Card. If you wish to perfor m the steps with

a base station connected, you will r equire the RJ-11 cable and RJ-11/DB25

adaptor to connect the base sta tion RS- 232 connector to the Test Set.

The procedure will guide you in running “TEST_01 - Laptop Emulator”, then in

stopping TEST_01, and then in selecting and running another TEST.

Specifically, the procedure will guide you to:

• Turn-on and set up the Test Set.

• Insert a Test Software card.

• Load and run TEST_01 - Laptop Emulator.

• Stop TEST_01.

• Select and run another TEST.

If you wish to perform these steps with a base station connected, you must

connect the Test S et RJ-11 Seri al B por t to the TTYMP #8 CSC Network Addre ss

Connection. Do this before starting the steps. Se e "Connection for RS-232 Base

Station Control," in chapter 3, on page 75.

For a description of TEST_01, see "TEST_01 - Laptop Emulator" on page 149.

When you have complet ed these steps and feel that you understand the operation,

continue with the next secti on, “Learning to Use the Test Software”.

34

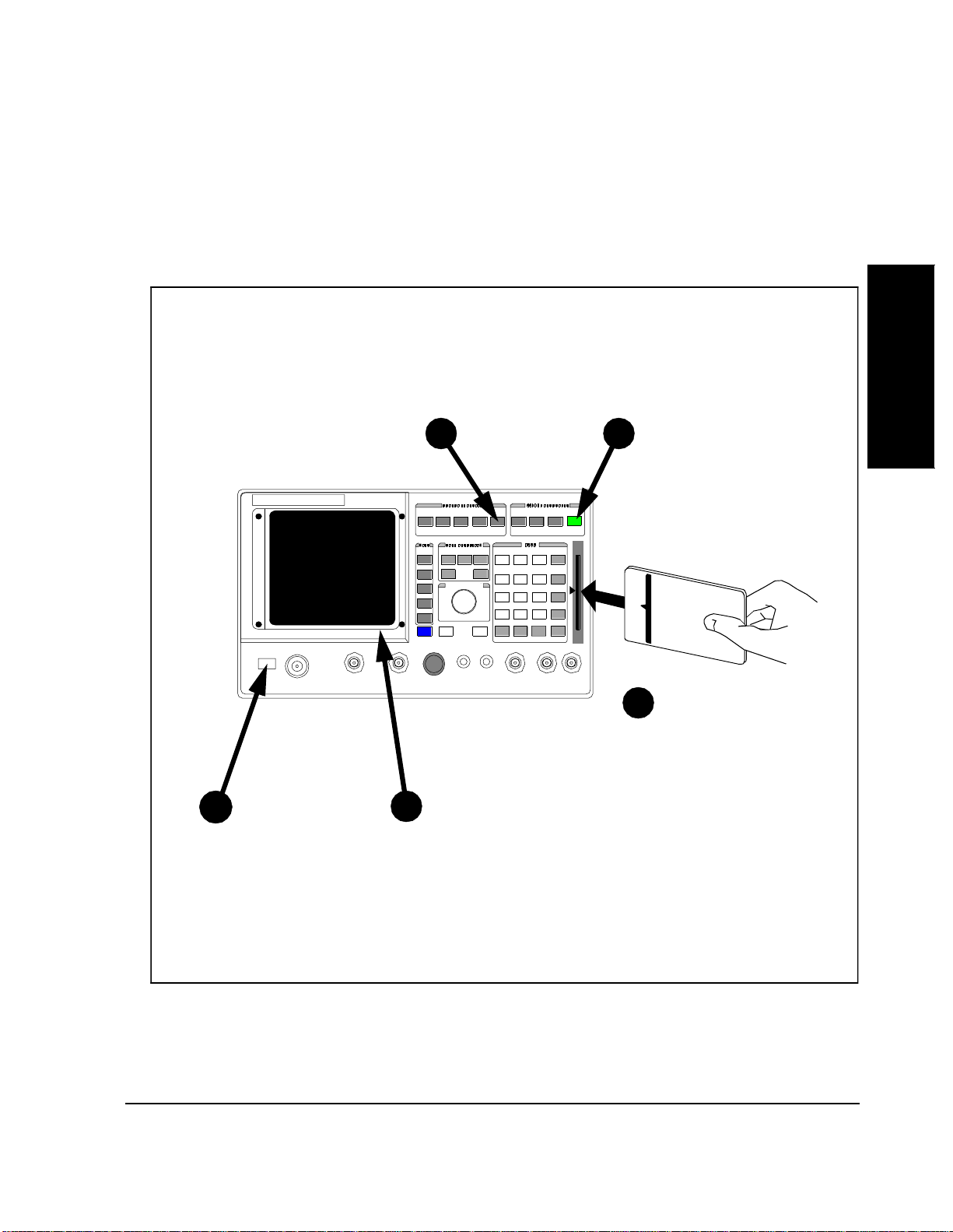

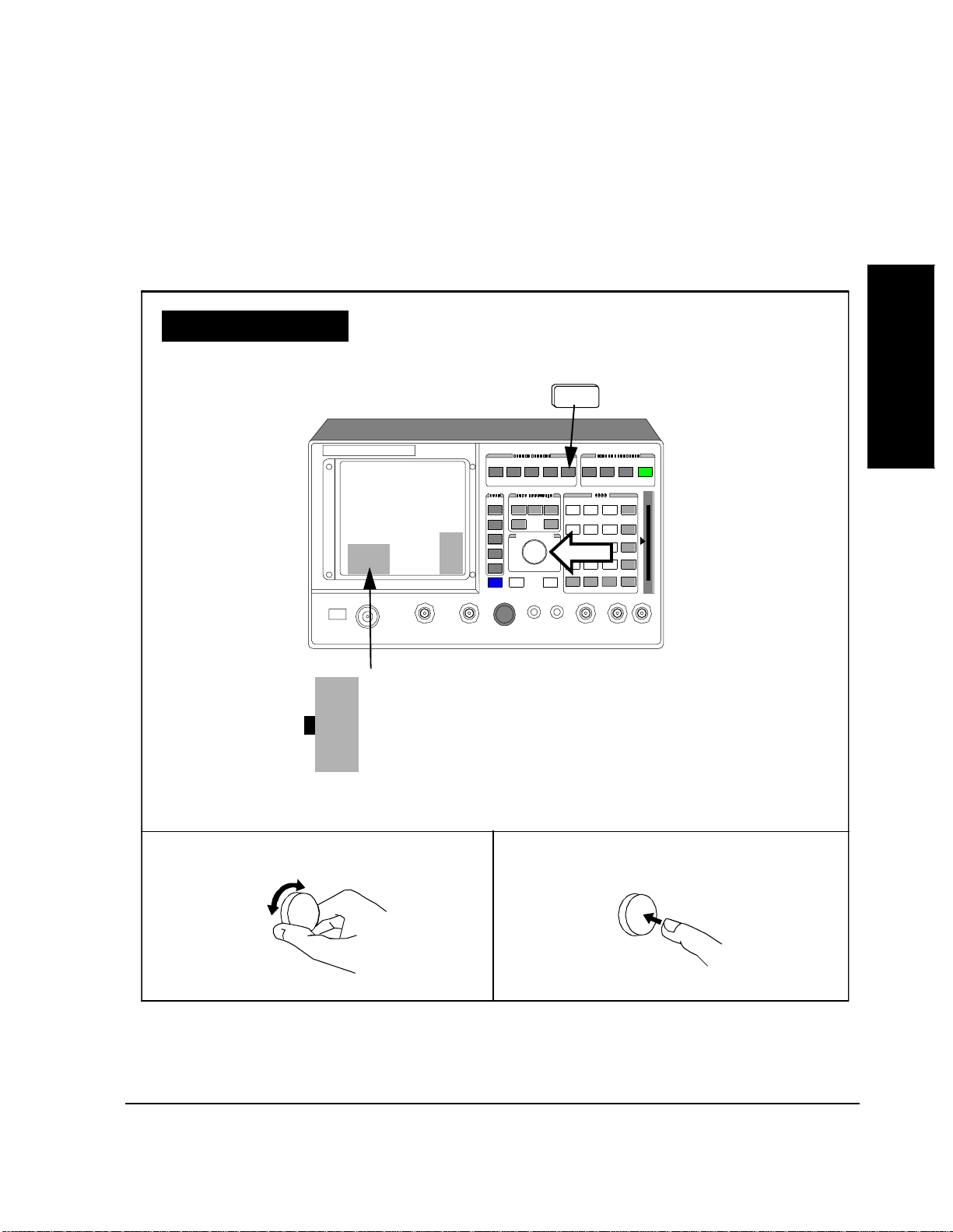

To Turn On and Set Up the Test Set:

Chapter 1, Product Description

Getting St ar ted

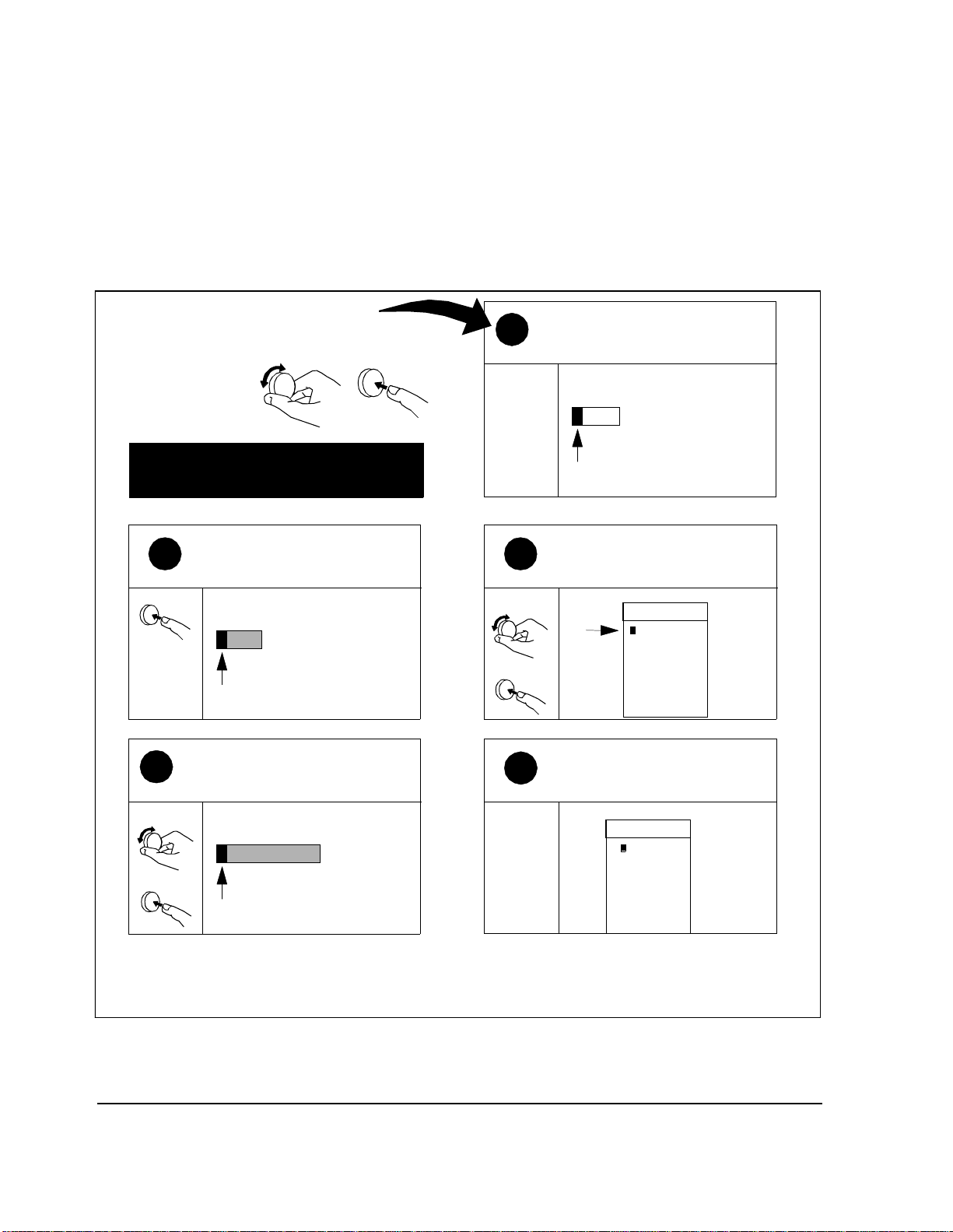

Do steps 1-5 in numbered order.

5

Press TESTS Press PRESET

CURSOR CONTROL

PUSH TO SELECT

4

(PRESET is a reset

command that can be used

at any time to start from the

beginning.)

Insert Card

3

HP 11807B Opt 040

Product Description

Chapter 1

Press POWER

1

Wait about 20 secon ds for

2

a display to appear, th en

go to step 3.

Turn page to list procedures on the memory card

35

Chapter 1, Product Description

Getting Started

To Select Test Software Procedure Location:

Follow Numbered Steps

Use the cursor control

knob on the front panel

to position the cursor

and make selections.

Use figure on opposite page for

reference.

Press the knob to select

2

Select Procedure Location.

Select

Select Procedure Location:

Position cursor at

4

Select Procedure Filename: and

select it.

Position

Select Procedure Filename:

Position Select

Note; cursor is positioned at

1

Select Pr oc ed u re Locatio n.

Select Procedure Locati on:

If previo us entries

appear disregard them.

Position the cursor at Ca rd and

3

select it.

Position

Select

The Choices: menu s h ould

5

now appear as shown.

Choices:

Card

ROM

RAM

Disk

Choices:

MOT_CS

Select

Turn page to load software

36

Reference Page

Select Procedure Location:

Select Procedure Filename:

Chapter 1, Product Description

Getting St ar ted

To Select Test Software Procedure Location: (Continued)

Choices:

MOT_CSChoices:

Card

ROM

RAM

Disk

Product Description

Chapter 1

CURSOR CONTROL

PUSH TO SELECT

Knob

Rotate knob to position cursor. Press knob to select a fiel d.

37

Chapter 1, Product Description

Getting Started

To Load and Run Test Software:

Position cursor at MOT_CS

1

and selec t it.

Position

Select

Position cursor at Run Test

3

and select it.

Position

Select

After MOT_CS is loaded, TEST_1 - Laptop Emulator

begins running.

If the base station is connected, you should see

characters on your display in the box label ed “Base

Station Re s ponse”. See"Serial Port Connections for

Data Collection" on page 75, and "TEST_01 - Laptop

Emulator" on page 149.

Choices:

1

2

4

MOT_CS

Run Test

Continue

Help

Note ; M O T _ C S is no w th e

2

selected proc ed ure filename.

Select Procedure Filenam e:

MOT_CS

The MOT_CS program is loading.

4

Loading program first

time: 2 min. 30 sec.

After first time : 20

sec.

Press <CANCEL> to stop the

5

program.

CANCEL

If the bas e stat ion i s not connec te d, or if y ou wan t to e xit

this TEST and run a new TEST, continue to step 5.

Turn page to select a new TEST

38

Chapter 1, Product Description

To Load and Run Test Software: (Continued)

Getting St ar ted

Product Description

Reference Page

Select Procedure Location:

Card

Select Procedure Filename :

MOT_CS

1

2

4

Run Test

Continue

Help

CURSOR CONTROL

PUSH TO SELECT

Chapter 1

Choices:

MOT_CS

Knob

CANCEL

Rotate knob to position cursor. Press knob to select a field.

39

Chapter 1, Product Description

Getting Started

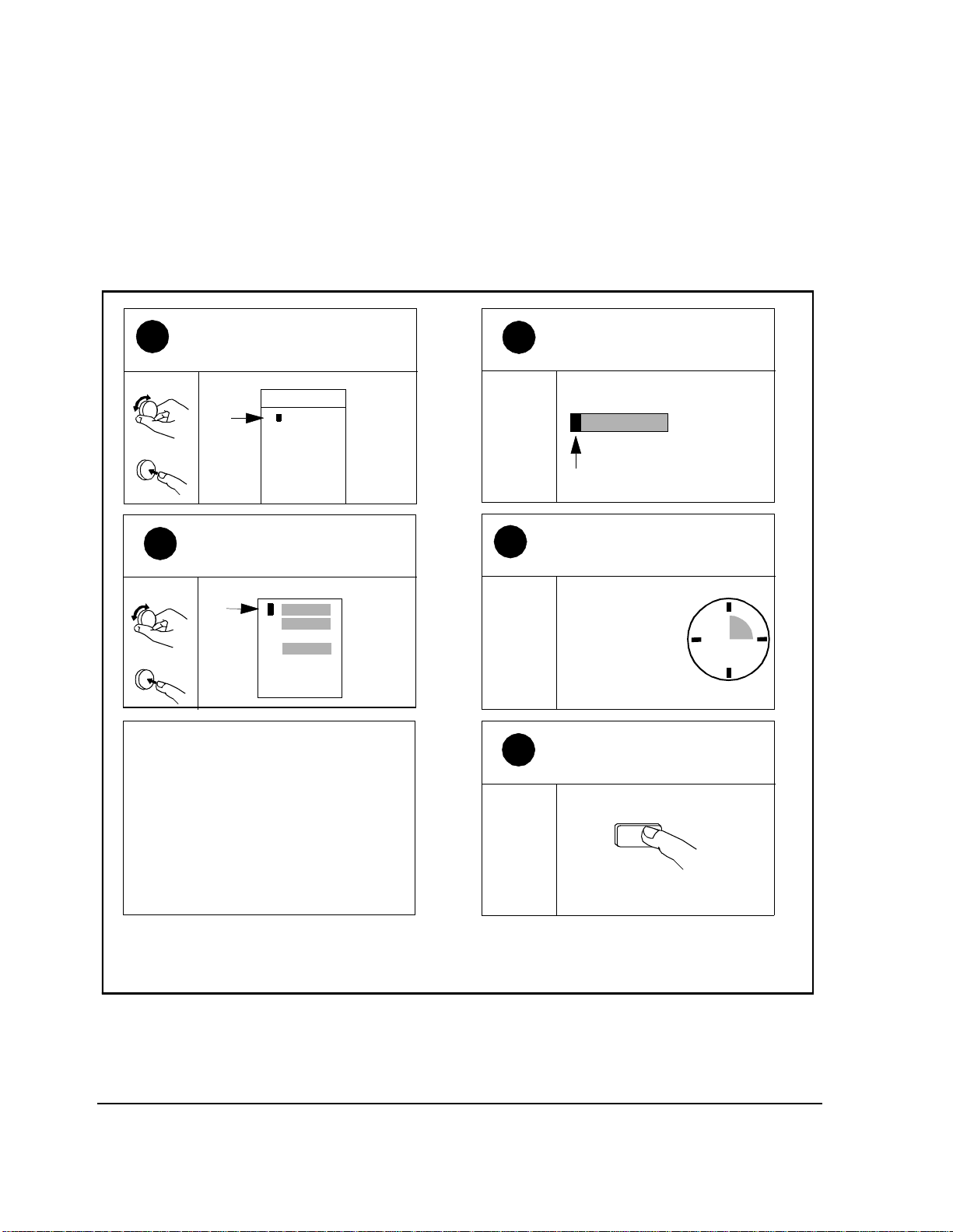

To Change the Order of Tests:

Press TESTS to display the

1

TESTS (Main Menu) scre e n.

If you are in IBASIC, press SHIFT,

CANCEL before pressing TESTS.

TEST

The Order of Te sts sc reen i s now

present on your CRT.

Use the Order of Tests screen to edit the TEST seque nce, sele ct a new TEST, or delete a

4

TEST.

Position cursor at Seqn Order of

2

Tests and select it.

Position

Channel Information

Freq

Parm

Test Parameters

Order of Tests

Seqn

Pass Fail Limits

Select

3

Spec

Proc

Save/Delete Pr ocedure

Note; cursor is located in the

Step # field.

Example

TEST_02

1

URDM or RDM frequency

Position

Select

TEST_02

1

URDM or RDM frequ ency/level

Test shown is an example, actual test name may be different.

Yes/No

Turn page to select a TEST

40

To Change the Order of Tests: (Continued)

Chapter 1, Product Description

Getting St ar ted

Product Description

Reference Page

Freq

Parm

Seqn

Spec

Proc

Chapter 1

TESTS

CURSOR CONTROL

Knob

PUSH TO SELECT

Channel Information

Test Parameters

Order of Tests

Pass Fail Limits

Save/D e l et e P r oc ed u r e

Rotate knob to position cursor.

41

Press knob to select a fie ld.

Chapter 1, Product Description

Getting Started

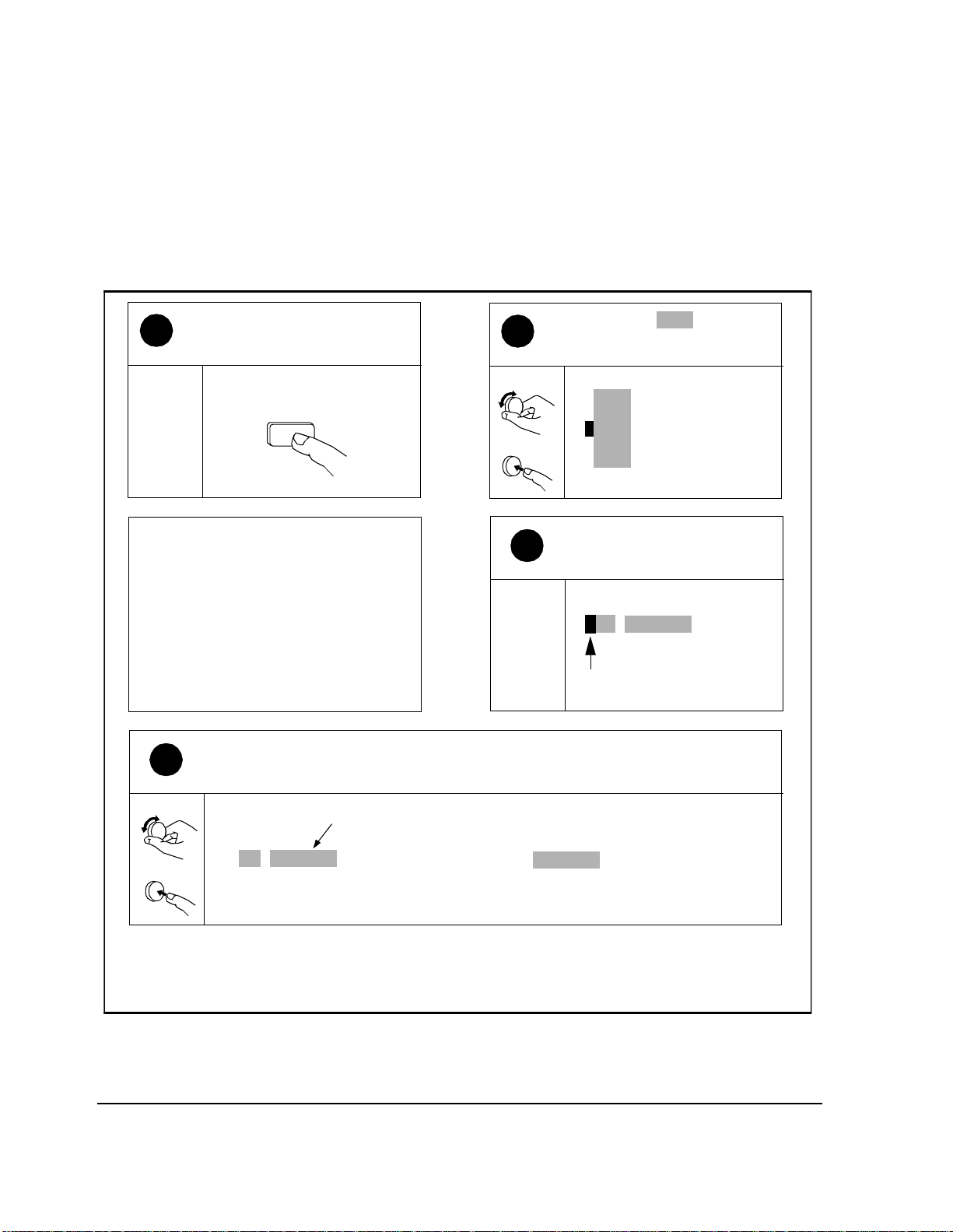

To Select URDM or RDM Frequency/Level test:

Note; cursor is located in the

1

Step # field.

TEST shown is an example only,

actual test may be different.

1 TEST_01

Laptop Emulator

Position curs or at TEST_02 and

3

select it.

Position

Choices:

TEST_01

TEST_02

TEST_03

Select

TEST_04

TEST_05

TEST_06

TEST_07

Position cursor at TEST_01 an d

2

select it.

Position

TEST_01

1

Laptop Emulator

Select

Note; TEST_02 is now ent e r e d.

4

TEST_02

1

URDM or RDM frequency/level

TEST_02 URDM or RDM frequency/

level is now selecte d and ready to run.

To run TEST_02, turn page

42

Chapter 1, Product Description

Getting St ar ted

To Select URDM or RDM frequency/level test: (Continued)

Product Description

Reference Page

1

TEST 02

Choices:

CURSOR CONTROL

PUSH TO SELECT

TEST_01

TEST_02

TEST_03

TEST_04

TEST_05

Chapter 1

Knob

Rotate knob to position cursor.

43

Pres s knob to s elect a f ield.

Chapter 1, Product Description

Getting Started

To run TEST_02 URDM or RDM Frequency/Level:

Press TESTS to display the

1

TESTS (Main Menu) scre e n.

If you are in IBASIC, press SHIFT,

CANCEL before pressing TESTS.

TESTS

The TEST is loading.

3

Wait 20 seconds.

Press <Shift> <CANCEL> to

4

stop the program.

Position cursor at Run Test

2

and select it.

Position

Run Test

1

Continue

2

Help

Select

4

TEST_02 begins running.

If the Test Set is connected to the base

station, see TEST_02 - URDM or RDM

frequency/level in chapter 5.

If the Test Set is not connected, the

program will stop aut omat icall y when it is

unable to continue.

SHIFT

CANCEL

44

To run TEST_02 URDM or RDM Frequency/Level: (Continued)

Reference Page

Run Test

1

2

Continue

Chapter 1, Product Description

USER

Use User keys k1-k5 as

k1

an alternate method

for making selections.

k2

k3

Getting St ar ted

Product Description

Chapter 1

4

Rotate knob to position cursor.

Help

k4

k5

CURSOR CONTROL

PUSH T O SELE CT

TESTS

Knob

Pres s knob to s elect a f ield.

45

Chapter 1, Product Description

Learning To U se the Test Software

Learning To Use the Test Software

To learn to use the

Test Software:

1. Become famil iar with the steps in “Getting Started”

2. Become familiar with the following terms:

• Memory Card and SRAM Card - See "Memory Cards," in chapter 2, on page 53.

• TESTS (Main Menu) Screen - See See "What are Tests?," in chapter 4, on page

120 and see "TESTS (Main Menu) Screen," in chapter 4, on page 122.

• Procedures - See "Procedures," in chapter 3, on page 91.

• TEST_01 through TEST_11 - See chapte r 5, "TESTs - Ref er ence," on page 143.

• Order of Tests - See "Entering the Order of TESTs ," in chapter 4, on page 132 .

• Parameters - See chapter 6, "Parameters - Reference," on page 187.

• Pass/Fail Limits (Specifications) - See chapt er 7, "Pass/Fail Limi ts (Specificat ions)

- Reference," on pag e 197.

3. Bec ome familiar with the tests availa ble in the HP 11807A,E Option 100 System

Support Tests software pack age (commonly referred to as RF Tools).

4. If necessary, calibrate system components, and produce one or more Procedures with

your parameters. See "Dete rmini ng Ca libra tion P aramet ers," in chapte r 3, on p age 81

and See "Procedures," in chapter 3, on page 91.

5. Make the required connecti ons to the base station. See "Equipment Connect ions," in

chapter 3, on page 70.

6. Then, begin performing tests. See chapter 4, "Running Tests," on page 119.

7. If you need detailed information as you are running tests, see chapter 5, "TESTs -

Reference," on page 143, for descriptions of the TESTs.

46

In this Manual

Chapter 1, Product Description

In this Manual

This manual describes the setup and use of the Test Set when running the HP

11807B Option 040 Motorola AMPS/NAMPS Cell Site Test Software. Te st Set

features not descri bed in thi s manual are documented in the HP 8921A User’s

Guide (HP part number 08921-90022).

The chapters in this manual are arranged to help you to ref er to specific

information for the task that you are performing.

Product Description

Chapter 1

47

Chapter 1, Product Description

In this Manual

Manual Contents

Chapter 1 - -Product Description describe s the Test Softwa re and helps you to

get started with the Tes t Soft w are pack a g e.

Chapter 2 - Equipment describes the items that you either will require, or might

require, before you can begin testing. Some of the items might be installed

permanently at the cell site . Skip this chapter if you are certain that necessary

items are present and insta lle d correctly.

Chapter 3 - Setting Up desc ribes installing and connecti ng equipment,

determining calibration factors, and entering parameters, pass/fail limits, and

external device configur ation. The chapter also describes Procedures and data

collection. If tests have been performe d previously at the cell site, you might be

able to refer to figure 3 on page 71 to verify connections, and then skip the rest of

this chapter.

Chapter 4 - Running Tests de scribes selecting a TEST to put into a procedure,

and starting the program.

Chapter 5 - TESTs - Reference describes important aspects of each TEST

available in the Test Software.

Chapter 6 - Paramet ers - Ref erence des cribes a ll para meters av ailab le in the Te st

Software.

Chapter 7 - Pass/Fail Limits (Specifications) - Reference describes all pass/fail

limits available in the Test Software.

Chapter 8 - Problem Solving describes some of the problems that might be

encountered in using the Test Softwa re and Test Set.

Appendix A - Using the HP 3488A Switch/Control Unit describes vari ous

connection factors in use of the Switch/Control Unit.

Appendix B - Test Set Measurement Settings lists the more important Test Set

settings used in manual testing.

Appendix C - Cable Wiring Diagrams for Data Col lection to PC and Printer

includes information required to construct PC and printer interface cables.

The Glossary describes terms that are used in cell site and test descriptions.

48

Chapter 1, Product Description

In this Manual

Conventions Used

Special presentations of text in this manual reflect the appearance of the item

being referenced.

Examples of these special presentations are:

TESTS

A key on the Test Set.

Product Description

Chapter 1

Procedure

USER (Run Test)

0.00000

Characters dis played on the Test Set display.

A USER key in the k ey column next to the Te st Set dis-

play. Run Test appears on the display.

A field on the Test Set display in which entries may be

made.

Titles of documentation are printed in italics.

The term Test Set refers to the HP 8921A.

In the steps in this manual the following words are used to describe cursor and

entry actions:

• select means to rotate the cursor control knob to position the cursor in front of a field

(inverse video area), and then press the knob.

• enter means to use the numeric keypad and the ENTER key or measurement unit s

keys to make entrie s to fi elds. In some p rocedures, enter is used to descr ibe the action

of entering characters into a field.

49

Chapter 1, Product Description

In this Manual

50

2

Equipment

This chapter describes items that you might require before you begin testing.

Some items might become permanent test accessories, installed at the cell site.

Equipment

Chapter 2

51

Chapter 2, Equipment

Cell Site Equipment

Cell Site Equipme nt

A Motorola HDII, HDII/NAMPS, NAMPS-II, or LD Cellular Base Station is

required. Equipment to be tested must be located at an active cell site. All

firmware and downl oadabl e softwa re must be ins ta lled. The base st ation firmware

revision must be 4.3.2.1 or later. Also, a powered-up base station cont roller and

cell site controlle r are required.

52

Memory Cards

Chapter 2 , E quipment

Memory Cards

Memory cards are PC cards that are used for data storage. These cards are

approximately the same length and width as credit cards, but somewhat thicker,

and contain integrat ed cir cuit storage devices.

There are two overall type s of memory cards: Epson card and PCMCIA card. The

principal difference between the cards is the interface connector. The Epson card

is designed to meet Epson Corporation spe cifications. The PCMCIA card is

designed to meet Personal Compute r Memory Card Inter national Associati on

specifications. Both are called PC cards.

For each overall type, there are two sub-types: one-time programmable (OTP),

and static random-access memory (SRAM). Once programmed, OTP cards are

read-only devices. SRAM cards are random-access devi ces from which data may

be read and to which data may be written multiple times.

In the Test System, memory cards are used to store the following:

Equipment

Chapter 2

• HP 11807B Option 040 Test Softwa re co de

• An HP-supplied Procedure, containing:

• A default testing order

• Default parameter values

• Default pass/fail limits

• A Library file

• Procedures that you produce, and that are optim ized for your application

• Data collect ion files

An Epson OTP card serves as the local source medium for the Test Software.

When the OTP card is inserted into the slot on the Test Set front panel, the card

receives power from the Test Set, and the Test Set, upon operator command,

loads the Test Software int o the Test Set memory. Arrows printe d on the card and

Test Set front panel indicate the card direction and orientati on for insertion.

SRAM cards are available for use in storing application oriented Proc edu res and

other application inf ormation.

53

Chapter 2, Equipment

Memory Cards

Test Software Memory Cards

The HP 11807B Option 040 Motorola AMPS/NAMPS Cell Site Test Software is

ordinarily supplie d on an Epson OTP card (HP part number 11807- 10012).

However, the version that you receive might be supplied on an SRAM card.

Determin e the di ffer en ce b etw ee n the two types by looking for a write-protect

switch on the top edge of the car d. If there is a switch, the card is an SRAM card.

If not, it is an OTP card.

CAUTION If your Test Software is resident on an SRAM card, it is possible to delete it accidentally

from the card. To prevent the loss of your program, check the write protect switch on the

SRAM card an d ve rify tha t t he ca rd i s writ e p rote cted. Lea ve the swit ch se t t owar d th e ou tside of the card except while you are writing to it.

The Test Software OTP card may be removed after the program is loaded into the

Test Set memory. The program will remain in memory after a power-down/

power-up cy cle.

54

Chapter 2 , E quipment

Memory Cards

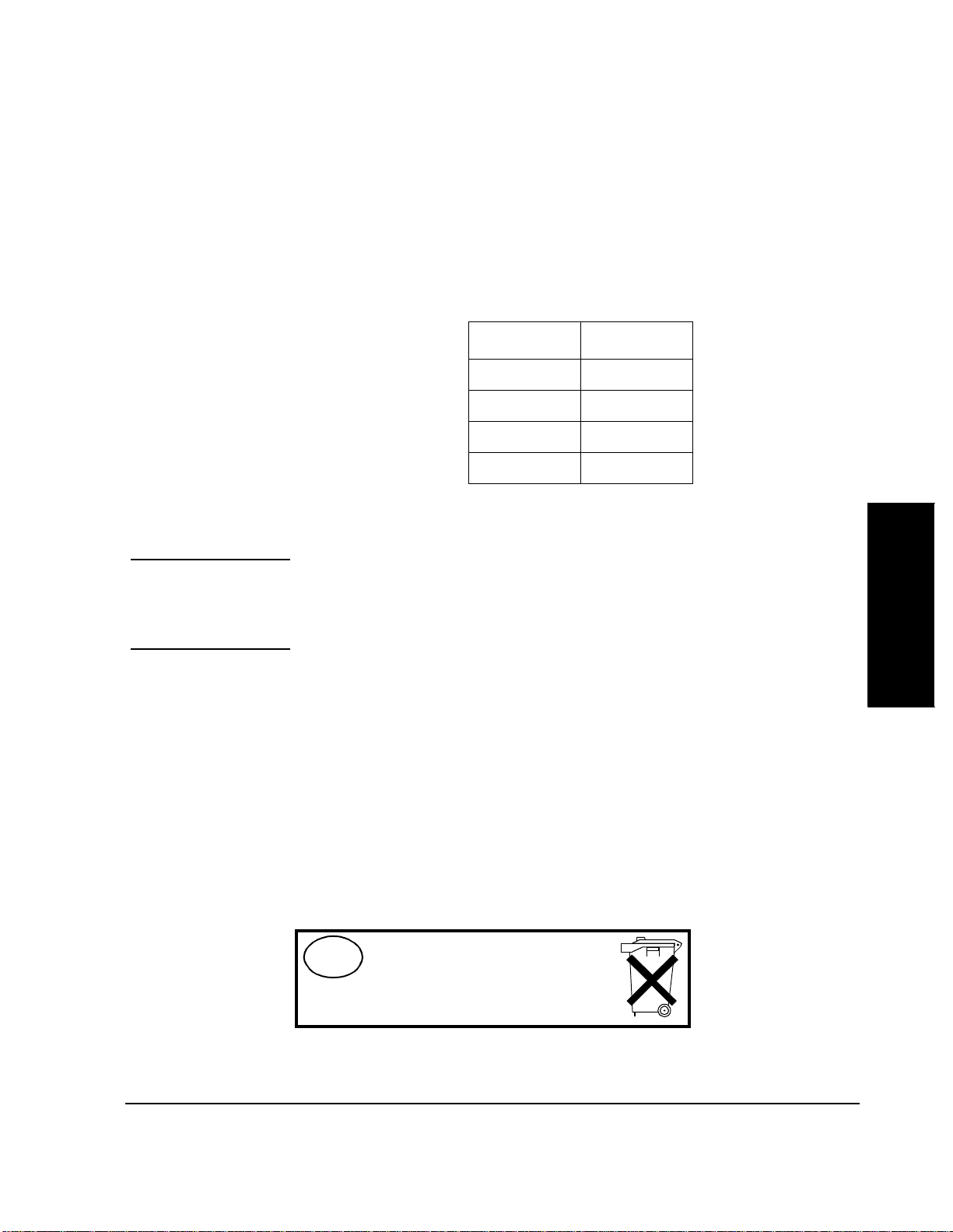

SRAM Cards An SRAM card may be used to store test res ults and Pro cedure s that you produc e.

The SRAM cards listed in table 1 may be used.

Table 1 SRAM Card Part Numbers

Capacity Part Number

32 kilobytes HP 85700A

128 kilobytes HP 85702A

256 kilobytes HP 85704A

512 kilobytes HP 85705A

The SRAM card must be initialized before its fir st use. See "Initiali zing an SRAM

Card," in chapter 3, on page 115.

NOTE: SRAM cards use a battery to retain data while the card is not inserted into a powered-up

Test Set. The lif e o f the b a t te r y dep ends on th e ca r d cap ac i ty an d th e av erage te mp erature

of its environment . S ee the next paragraph.

Each SRAM card uses a li thium batte ry (p art number CR 20 16 or HP par t number

1420-0383). Programs and data will be retaine d for more than one y ear if the card

is stored at 25 degrees Celsius. The card is powered by the Test Set while it is

inserted. When it be comes ne cessary to r eplace th e batt ery, do so while t he card is

inserted into a powered-up Test Set. To retain data and procedures, the battery

should be replaced annually. If you store SRAM cards in a warm environment,

replace the battery more often.

A procedure to replace the battery is described in the HP 8921A User’s Guide.

The write protec t switch on a S RAM card will write-protect the card when it is se t

toward the outside of the card.

NL

Batterij niet

weggooien, maar

inleveren als KCA.

Equipment

Chapter 2

55

Chapter 2, Equipment

Memory Cards

Memory Card Storage Space

Regarding storage space , the following characteristics apply:

• A record is 256 bytes.

• A procedure uses 12 to 16 records.

• A library typically uses 20 to 35 records.

• Only one library is permitted on a card.

• Overhead of approximately 11 kilobytes is required on each card.

Use the following formula to estimate the required storage space:

Storag e Space(in kiloby te s) = (Numbe r of Proced ur es × 4.1) + 17

For example, if you ar e testing ten c ell si tes a nd th e procedur e is di ffer ent for each

site, you will use ten procedures, and 58 kilobytes of memory. Thus, the 128kilobyte card is sufficient.

The storage s pace that you will require for data collection depends on the number

of test res ults to be saved. You will require approximately 4 kilobytes per page of

test results that you save. A page of test results is approximately 57 lines of CRT

or printer output. See "Data Collection" on page 113 for a discussion of memory

card storage space and file types.

In applications in which large quan tities of data will be collected, the sto rage

capacity of smaller SRAM cards is reached quickly. In such instances, data

collection using a PC or printer might be advis able.

56

Chapter 2 , E quipment

HP 8921A Cell Site Test Set

HP 8921A Cell Site Test Set

The HP 11807B Opt 040 Test Software r uns on the HP 8921A Cell Site Test Set.

In this manual, the term Test Set refers to the HP 8921A.

The HP 8921A Cell Site Test Set is an optimized collection of instrument

hardware and firmware, designed to test cellular base stations extensively. Most

of the required hardware and all of the fir mware to tes t cellular base stations has

been included in the standard instrument. Several options may be added,

depending on your applicati on.

Test Set Firmware The HP 8921A firmware revision number must be A.06.09 or later. At the time

this manual was revised, firmware revision A.16.00 was being shipped.

Identify the revision of the firmware by pressing the Test Set SHIFT, CONFIG

keys. The Test Software will display the revision number in the CONFIGURE

screen.

An internal switchable 600-ohm load is supported in firmware revisions A.06.11

and later. If this load is not installed in your instrument, you must place an

external load in line with the connection from the RCV LINE JK to the Test Set

AUDIO IN connector. See "Audio Connections," in chapter 3, on page 75.

Testing a base station with NAMPS capability requires r evision A.06 or later ( but

not including revision A.06.12).

After the Test Software has been loaded into Test Set memory, a pre-run

operation takes place after

much less time if the Test Set firmware revision is A.08.02 or later.

Run Test is pressed. The pre-run will be performed in

Test S et Option Depending on your appl ication, the Radio Interface Card, Option 020, to the Test

Set might be required.

This option is used to control RF and audio switches that route signals from the

base station t o HP 8921A con nectors. If th e appl icat ion will use another switchi ng

arrangement, this option is not required. See "RF and Audio Switches" on page

61.

Equipment

Chapter 2

57

Chapter 2, Equipment

Other Software Tools

Other Software Tools

As an adjunct to the tests included in the Test Soft ware, Hewlett-Packard offer s

the HP 11807A,E Option 100 System Support Tests software package. This

software pack a g e is contai n ed o n an O TP card an d includes a variety of tests to

enhance the testing efficiency of the Test System.

The RF Tools in this package include the following tests:

•Swept Gain

• Swept Insertion Loss

• Swept Ret u rn Loss

• AMPS Channel Retur n Loss.

• Cable Fault.

• ERP Calculator

• Replot Data Files

• Transfer Stored Data

• SA Self Calibration ON/OFF

• Catalo g M emory Card

• Create/Ed it Data Collection Labels

Of particular inter es t to users of the HP 1807B Option 040 Test Software in

maintaining cellula r telephone base stations are the Swept Inser tion Loss, Swept

Return Loss, AMPS Channel Return Loss, and Cable Fault tests.

In addition, the Option 100 package includes a Field Strength test that performs

field strength measurements, an Intermodulation Products test that calculates

intermodulation products, and a Scanner test that performs discrete and swept

frequency scanning on the system under test.

58

Peripheral Items

Chapter 2 , E quipment

Peripheral Items

This section describ es ite ms required t o inter connect the major component s of the

Test System. An HP-supplied solution is described in this section. Individual

switch and interconnect ite ms from other suppliers are also descri bed. See figure

3 on page 71, figure 4 on page 72, and chapter 3, "Setting Up," on page 69.

Equipment

Chapter 2

59

Chapter 2, Equipment

Peripheral Items

HP Supplied Peripheral Item s

Table 2 Motorola Cables/Adapters

A Base Station Accessory Kit is available from Hewlett-Packard

(HP 83202A Opt 040). The kit contains the following ite ms:

Description Purpose Q Part Number

Directional couplers See figure 4 on page 72 in HP

50-Ohm SMA(m)

termination

N(f) to N(f) Adapter For VSWR and cable

N(m) to N(m) Adapter For VSWR and cable

N(m) to BNC(f) Adapter To adapt HP 8921A

SMA(f) to N(m) Adapter Connects to HP 8921A RF

Phone jack to BNC(f)

Adapter

4 0955-0711

11807B #040 User’s Guide

Terminates coupler port 4 0960-0053

1 1250-0777

calibration

1 1250-0778

calibration

1 1250-0780

RF IN/OUT for

RDM/URD Measurements

1 1250-1250

IN/OUT

For measuring RDM and

URDM power

1 1250-1853

BNC(m) to SMA(f)

Adapter

BNC(m) to Banana(f )

Adapter

Banana( m) to BNC(f)

Adapter

SMA(m) to SMA(m) 20

ft. cable

BNC(m) to BN C( m) 15

ft. cable

Bantam 309 to BNC(m)

15 ft. cable

DB37 to DB37 10 ft.

ribbon cable

60

Connects to HP 8921A

DUPLEX OUT

Connects to HP 8921A

AUDIO IN HI/LO

Connect across HP 8921 A

AUDIO IN HI/LO

From couplers to switc h and to

HP 8921A RFIN/OUT

HP 8921A AUDIO OUT to

switch and HP 8921A

RF IN/OUT to phone jack

From transceiver to HP 8921A

and to switch

From HP 8921A to switch 1 08921 -61013

2 1250-2015

2 1250-2164

1 1251-2277

5 08921 -61006

1 08921 -61007

2 08921 -61008

Table 2 Motorola Cables/Adapters

Description Purpose Q Part Number

Chapter 2 , E quipment

Peripheral Items

RJ11(m) to RJ11(m) 6

wire25 ft. twisted cable

RJ11(f) to DB25(m)

Adapter

RJ11(m) to RJ11 (f) dual

port, 6 wire sp litter

DB9(f) to RJ11(m)

4-wire cable

DB25(m) to RJ11(m)

4-wire cable

Dual miniphone cab le From switch box to base

Switch Matrix Automates switching between

Connects to dual port splitte r

and to RJ(11)to DB(25)

Adapter

Connects to TTYMP #8 1 08921 -61016

Connects to HP 8921A rear

panel serial port

For data collection 1 08921 -61038

For data collection 1 08921 -61039

station (RCV & TEST jacks)

receive antennas and audio

paths

1 08921 -61015

1 08921 -61031

2 08921-61040

1 HP 83202A

K02

Equipment

Chapter 2

RF and Audio Switching Arrangements

RF and Audio Switches

The Test Software supports two method s for switc hing RF and audio paths. The

first uses the optional Te st Set Radio Interface Card and external switches. The

second uses an HP 3488A Switch/Control Unit with optional internal switches.

The main part of this manual describes the method tha t uses the Radio Interface

Card. Appendix A describes the method that uses the HP 3488A Switch/Control

Unit.

It is highly recommended that you select one of these two automatic switching

methods. Manually switching signal paths is cumbersome and can result in time

consuming troublesho oting.

A single-pole six-th row (SP6T) RF switch may be used to route one of the

receiver-c o upled ports to the Test Set DU PLEX OUT connector. It is preferable

that the swit ch have TTL control inputs. The HP 87 106A Opt 050 SP6T switch is

61

Chapter 2, Equipment

Peripheral Items

appropriate. The RLC Electronics Model S-1519A also has the necessary

characteristic s. This switch has SMA connectors. (A TTL buffer should be used

with this switch. See "Switch Control Input Buffer " on page 62.)

The Test Set Ra dio Inte rfac e Card has TTL and CMOS compatible outputs that

control switche s external to the Test Set. The switche s are acti vated aut omatica lly

by the Test Software.

CAUTION: Damage to the Test Set can result if the RF or audio switches generate transients that are

conducted into the Test Set via the Radio Interface connector. It might be necessary to install d iodes on the Ra dio I nte rface contr ol li nes to supp ress trans ients ca used by th e s witches. Refer to the switch manual for the proper inte rface to TTL or CM OS control lines.

An SPDT switch must be installed so that the Test Software can select eithe r the

transmitter TEST JK or the EQUIP RCV to be applied to the Tes t Set Audio In. A

miniature SPDT printed-circuit- board-mounted relay provides the necessary

characteristics.

You might wish to route the Test Set AUDIO OUT through the Switch Unit, and

then to the EQUIP XMT LINE JK. Cables from the Test Set to the Switch Unit

can then be the same length.

Swit c h Control Input Buffer

Depending on the loa ding of the switch control inputs, a buffer might be required

between the Radio Interfac e conne ctor and the Switch Unit.

If a buffer is required, a 7407 non-inverting TTL buffer may be used. The buffer

outputs must be pulled up to the 5-volt supply. This should be done using

1000-ohm resistors.

See "Radio Interface Connections," in chapter 3, on page 79 for connector

pinouts.

RF Couplers A directional couple r with low through-path loss is ordinarily installed in each of

the RX and TX transmissi on lines leading to antennas. The RLC Model M3020A

has the necessary characteristics. Refer to the Motorola cell site manual for

another recommended model.

50-Ohm Terminations

It might be ne cessary to place a termination on the RX RF coupler port leading to

the antenna to prevent received signals from affecting base station receiver tests.

62

Chapter 2 , E quipment

Peripheral Items

While testing the SIG unit, a high-power load must be placed on the RF coupler

output leading to the ant enna. It mu st be cap able of h andling at least 30 watts . The

load is required to prevent the SIG transmitter signal from being radiated to

mobile stations. A 150-watt loa d is available from Lucas Aerospace (part number

M1428).

Cables, Adapters, and Connectors

You might also require some of the following items:

RS-232 Base Station Control Cable

A DB-25 to RJ-11 cable may be assemble d. Alte rnatively, the adapte rs described

in the following paragraphs may be used with RJ-11 cables.

6-pin Modular-to-DB-25 Adapter

The following parts may be used:

• Hewlett-Packard part number 08921-61016

• Radio Shack part number 276-1405

RJ-11 Cable

You will require an RJ-11 cable (6-wire, HP part number 08921-61015) to

connect the adapter to the Test Set. If you use a differ ent RJ-11 cable, make

certain that it has six conductors.

Single-to-Dual RJ-11 Adapter

The other parts described ab ove will provide a single RJ-11 to DB-25 adapter. If

you add a single-RJ-11-to- dual-RJ-11 adapter, you will be able to connect

simultaneously the Serial B port to the base station and the Serial port to a serial

printer, PC, or other device .

Equipment

Chapter 2

An adapter is avail able from Black Bo x (part number FMO-1 1 or HP part numbe r

08921-61031). In addition to the dual-to-single adapter , you will require two

Modular-to-DB-25 adapte rs and two RJ-11 cables.

RF IN/OUT Cables

Connection from the RF IN/OUT connector to the coupled port of the TX coupler

may be made with a cable with SMA connectors on both ends, and a Type N(m)to-SMA(f) adapter (Pomona part number 4297, HP part number 1250-1250).

The connection to the 3-MHz RDM/URDM output may be made using adapters

and a coaxial cable with SMA connectors. Phono(m )-to- BNC(f) (Pomona part

number 5319, HP pa rt number 125 0-1 853) and B NC(m)-to-S MA(f) (Pomona pa rt

63

Chapter 2, Equipment

Peripheral Items

number 4289, HP part number 1250-2015) adapter s on the 3-MHz end, and an

SMA(f)-to-N(m) (Pomona part number 4297, HP part number 1250- 1250)

adapter on the RF IN/OUT end may be used.

Cable lengths should be as short as possible so that losses are minimized. Low

loss cable should be used. To improve accuracy, you might wish to have a set of

calibrated stand ard test cables.

DUPLEX OUT Cable

Connection from t he DUPLEX OUT to the common por t of the RF swi tch may be

made with a cable with SMA connectors on both ends. A BNC(m)-to-SMA(f)

adapter (Pomona part number 4289, HP part number 1250-2015) is required on

the Test Set.

Cable lengths should be as short as possible so that losses are minimized. Low

loss cable should be used. To improve accuracy, you might wish to have a set of

calibrated stand ard test cables.

RX Coupler-to-Switch Cables

Connection from the RX RF coupler to the RF switch ports may be made with

cables with SMA connectors on both ends.

Cable lengths should be as short as possible so that losses are minimized. Low

loss cable should be used. To improve accuracy, you might wish to have a set of

calibrated stand ard test cables.

Audio Cables

Bantam 309-to-BNC cables may be used f or audio inte rconnections . Three c ables

are required, unless the RF switch is used. In that case, two Bantam 309 to

Bantam 309 cables and two Bantam 309 to BNC cables are required.

Two BNC(m)-to-banana(f) adapters (Pomona part number 3430-0 black,

3430-2 red, HP part number 1250-126 3 gray), may be u sed to c onvert th e AUDIO

IN HI and LO connectors to banana type connectors. A banana(m)- to-BNC(f)

adapter (Pomona part number 1269, HP pa rt number 1251-2277) is also required.

RF Switch Control Cable

A cable is required between the Radio Interface Card and the RF and audio

switches. One end must have a 37-pin D-Submin connector (AMP Inc. part

number 747306-1). The ot her end will conne ct to the swi tches. Refer to the s witch

documentation for requi red co nnectors. A 50-foot ribbon cable with a DB-37

connector is available from Hewlett-Packard Company (HP part number 1252-

1682).

64

Chapter 2 , E quipment

Peripheral Items

HP-IB Cables

If an HP-IB printer or disk drive is part of the system, those units must be

connected to the Test Set using HP-IB cables. See the HP Direct Catalog

HP Supplied Connector Ki t

VSWR and Cable Fault Ancillary Equipment

If you are assembling your own switching and interconnect arrangement, you

might wish to ha ve the Connector Kit (HP part number 08920-61061). It contains

the RS-232 to RJ-11 adapter and Radio Interface, Mic/Acc, and DC power

connectors.

If you expect to perform the VSWR or cable f ault tests tha t are include d in the RF

Tools section of the HP 11807A,E Option 100 System Support Tests software

package, you will require additional items.

VSWR measurements require a return loss bridge and a 6-dB pad.

A return loss bridge with the necessa r y characteristics is available from Hewlett-

Packard Company (P/N HP 86205A) or Eagle (P/N RLB150N3B). See "Vendor

Information" on page 67.

A 6-dB pad with BNC connectors is available from Hewlett-Packard Company

(HP P/N 0955-0698). See "Vendor Information" on page 67.

For cable fault tests, a resistive power splitter is required. It is important to note

that some power splitt ers is olate the output s from each othe r, and may not be used

for VSWR tests using this Test Software. The HP 11850C Power Splitter (P/N HP

0955-0733) is a resistive type that does not isolate the outputs; it may be used

with the Test Software. See "Vendor Information" on page 67.

Equipment

Chapter 2

High Accuracy Frequency Reference

To verify the performance of the URDM and the frequency accur acy of NAMPS

signals, a highly accurate 10-MHz reference source is required. The Electronic

Research Co. Model 130 has the required chara ct eristics.

65

Chapter 2, Equipment

Documentation

Documentation

After you have learned to use the Test Software, you will be able to run the tests

without documentati on. Howe ver, if you wish to change Procedures or if you

expect to perform troubleshooting, you will require this manual. In addition, it

might be appropriate to have available the HP 8921A User’s Guide (HP part

number 08921-90022) if you are using the Test Set manually. Motorola base

station documentati on might be re quire d if you expect to perform troubleshooting

or module replacement . I t might also be helpful to have your own docu mentation

describing the particular procedures that you follow when performing testing.

66

Vendor Inform ation

AMP Inc.

PO Box 3608

Harrisburg, PA 17105

(800) 526-5142

Black Box Corporation

1000 Park Drive

Lawrence, PA 15055

(412) 746-5500 (800) 321-0746 FAX

Eagle

P. O. Box 4010

Sedona, AZ 86340

(602) 204-2597 FAX (602) 204-2568

Electronic Researc h Co.

7618 Wedd St.

Overland Park, KS 66204

(913) 631-6700

Chapter 2 , E quipment

Vendor Information

Equipment

Chapter 2

Hewlett-Packard Company. See the list of sales offices in chapter 1 of the HP

8921A User’s Guide.

ITT Pomona Electronics

P.O. Box 2767

Pomona, CA 91769

(714) 469-2900 (714) 629-3317 FAX

Lucas Aerospace Communicati ons and Elec tronics Inc.

P.O. Box 6001

Gaithersburg, MD 20884-6001

(800) 638-2048

RLC Electronics, Inc.

83 Radio Circle

Mt. Kisco, NY 10549

(914) 241-1334

67

Chapter 2, Equipment

Vendor Information

68

3

Setting Up

This chapter describes:

• Making connections to the equipment in the Test System.

• Measuring or determinin g cal ibration parameters.

• Making, loading, deleting, copying, and securing Procedures.

• Entering pass/f ail limits, parameters, and external device configuration.

• Setting up data collection.

69

Setting Up

Chapter 3

Chapter 3, Setting Up

Equipment Connections

Equipment Connections

CAUTION: The Test Set and othe r equipment in this Test Sys tem can be damaged by transient RF

power, continuous RF power, high voltage, electrostatic discharge from cables and other

sources, a nd trans ients cau sed by l ightni ng. Connec tions t o equipme nt, swi tch setti ngs, an d

power-on conditions must be chosen to reduce the risk of damage to the equipm ent.

Many arrangements of test equipment and base station equipment are possible . In

this manual, some of these possibilities are presented. Radio Interface control of

the RF and audio switches is described in this section. Refer to this section and

"Appendix: Using the HP 3488A Switch/Con trol Unit" on page 219 if you are

using an HP 3488A Switch/Control Unit.

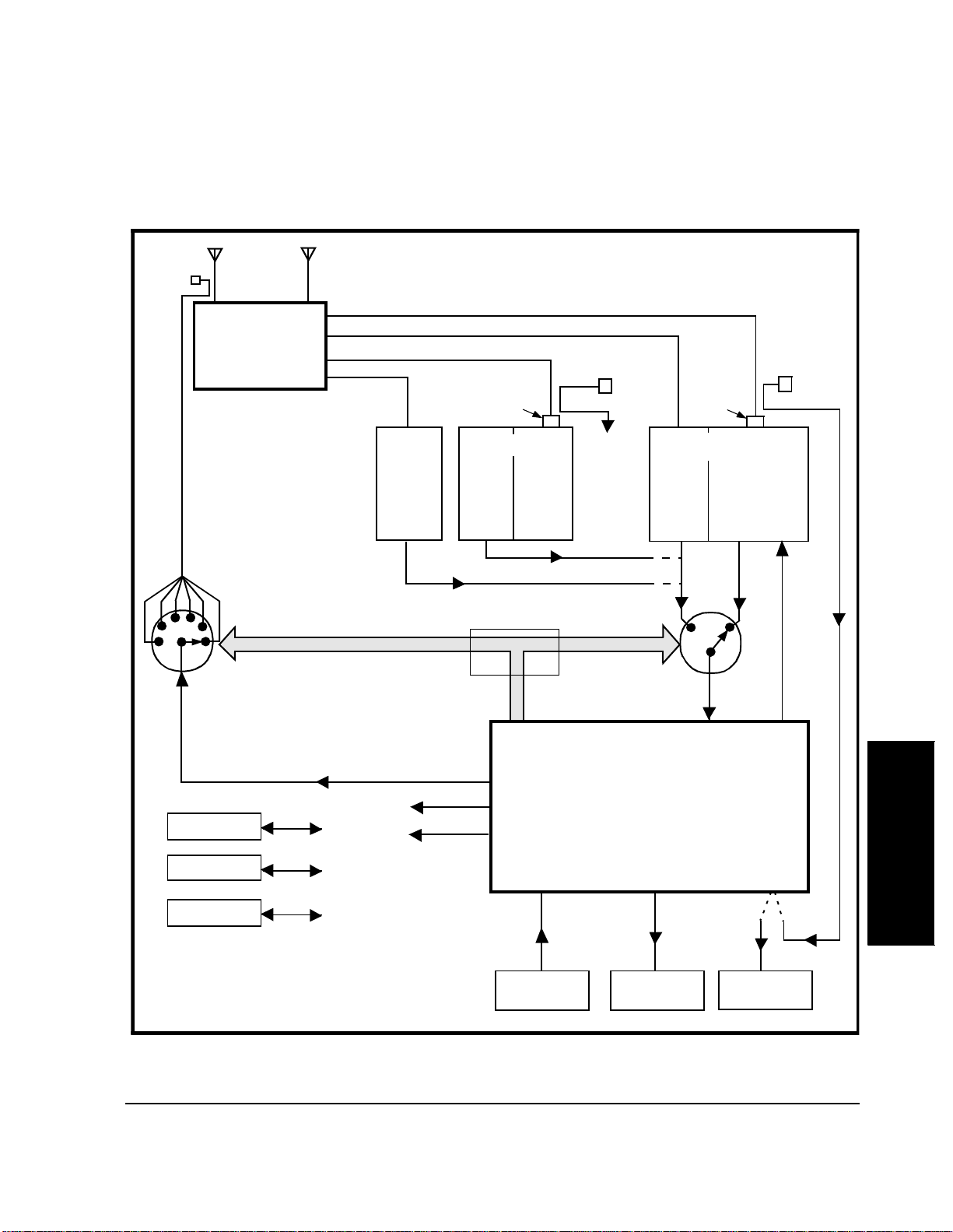

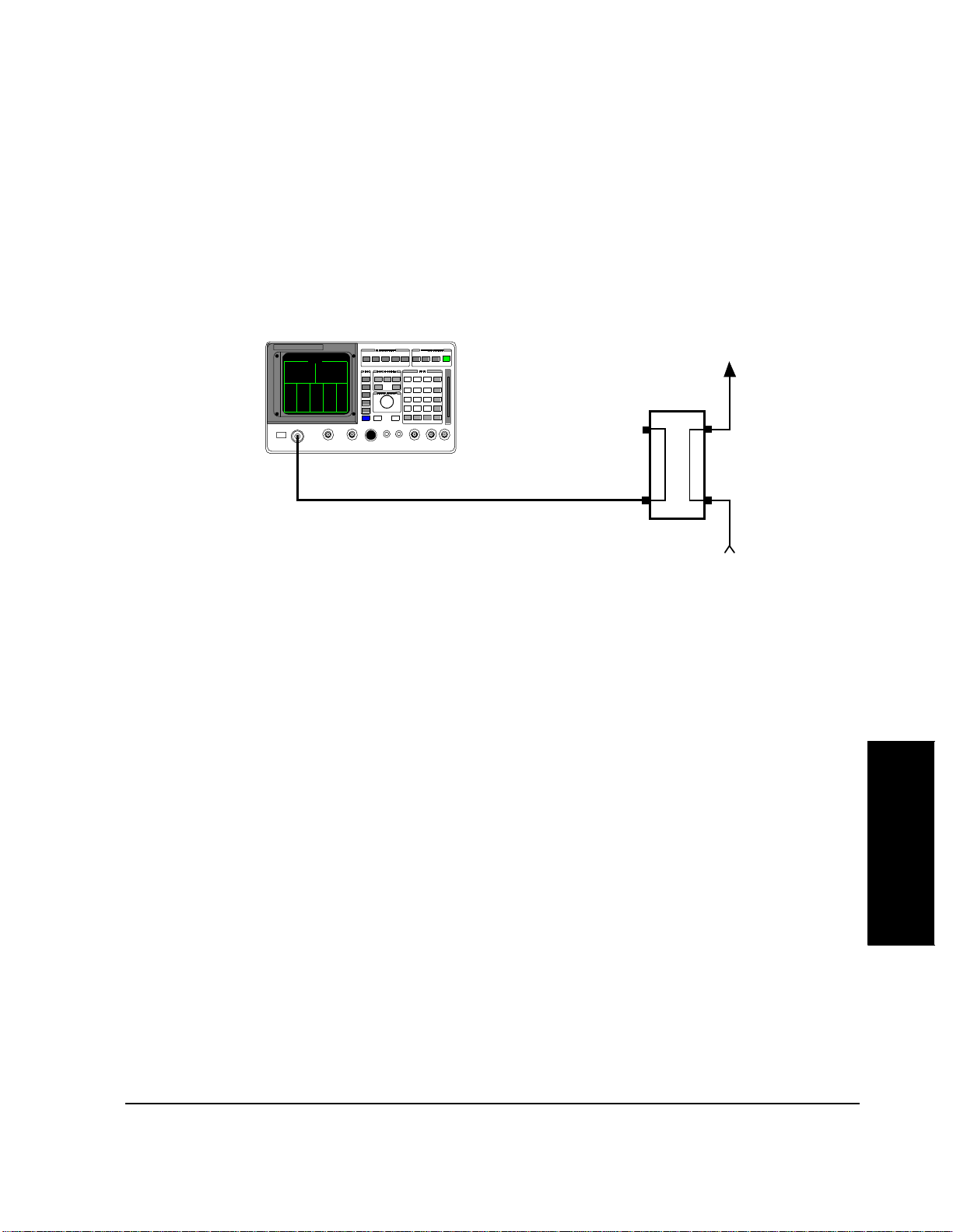

Figure 3 on page 71, is an overall Test System block diagram.

After you have set up your Test System, you will be calibr ating some system

components. Tests s hould be r un wit h the equip ment c onnecte d in the same wa y i t

was when it was calibrated.

70

Chapter 3, Setting Up

Equipment Connections

RF Coupler

(1 of possibly

several.)

RX

ANTENNA(S)

Base

Station

Hardware

RF Switch (1)

TX

TX/RX ANTENNA(S)

SCN(S)

RX

RCV

JK

Harmonic

Filter

SIG(S) To

RX

TX

RCV

JK

Optional Interface

RF Coupler

RF

IN/OUT

Audio S wi tc h (2)

Harmonic

Filter

VOC(S)

RX

RCV

JK

RF Coupler

TX

TESTJKXMT

JK

Radio

Interface

DUPLEX OUT

HP-IB

DISC

PRINTER

PC/TERMINAL

(1)

RF splitter can be used wit h li m ited test

capability. See chapter 3, Configura tion.

(2)

Audio switch not used/controlled if RF

splitte r is us e d in RF p at h .

HP-IB/RS-232

RS-232

RS-232 Serial

HPIB

10 MHz

Reference

Optional

10 MHz

Reference

Figure 3 Overall Test Sy stem Block Diagram

71

RS-232

Serial B

TTYMP #8

CSC Network

Address

Audio

In

HP 8921A

CSC

Audio

Out

RF

IN/OUT

3 MHz

RDM/URDM

Setting Up

Chapter 3

Chapter 3, Setting Up

Equipment Connections

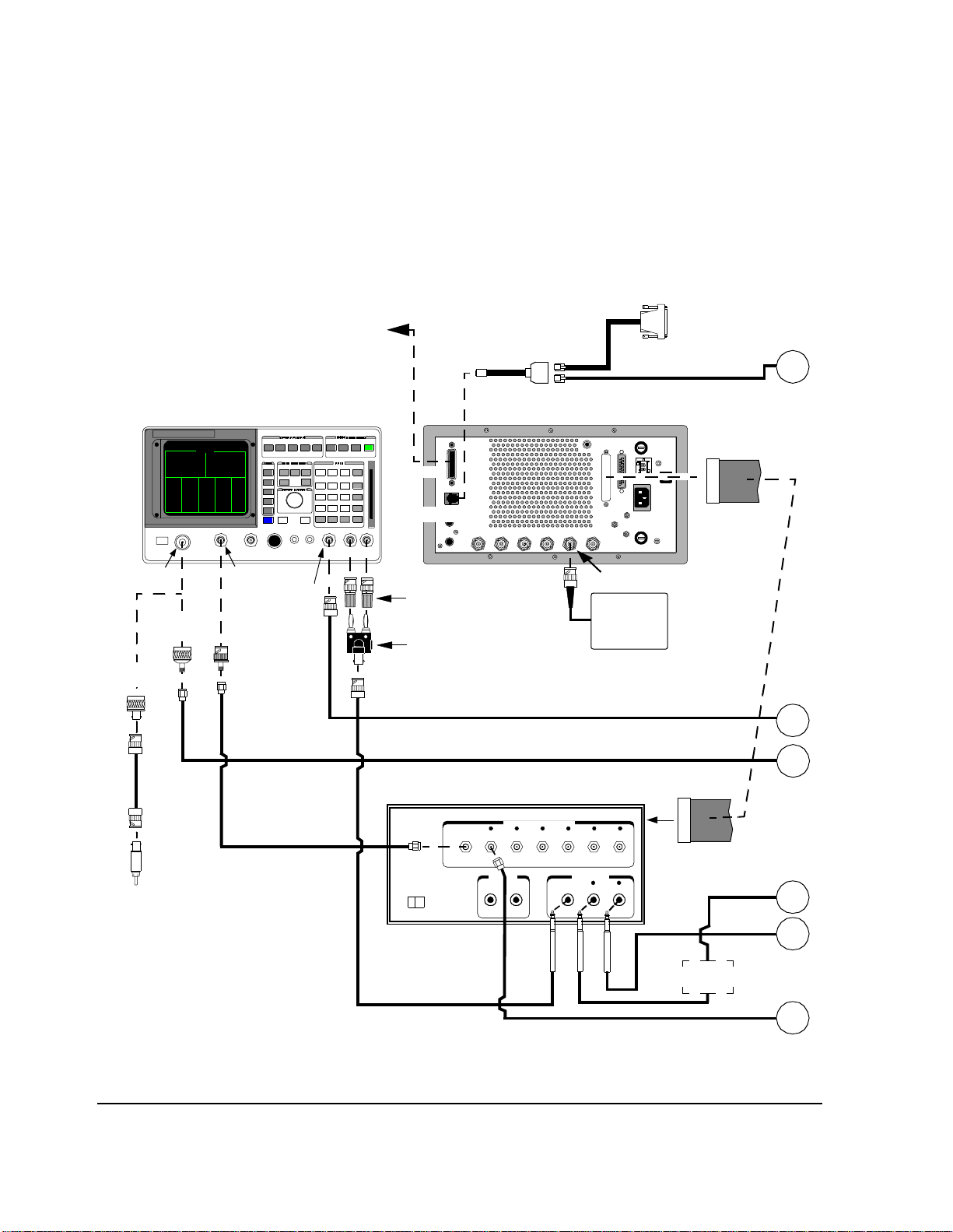

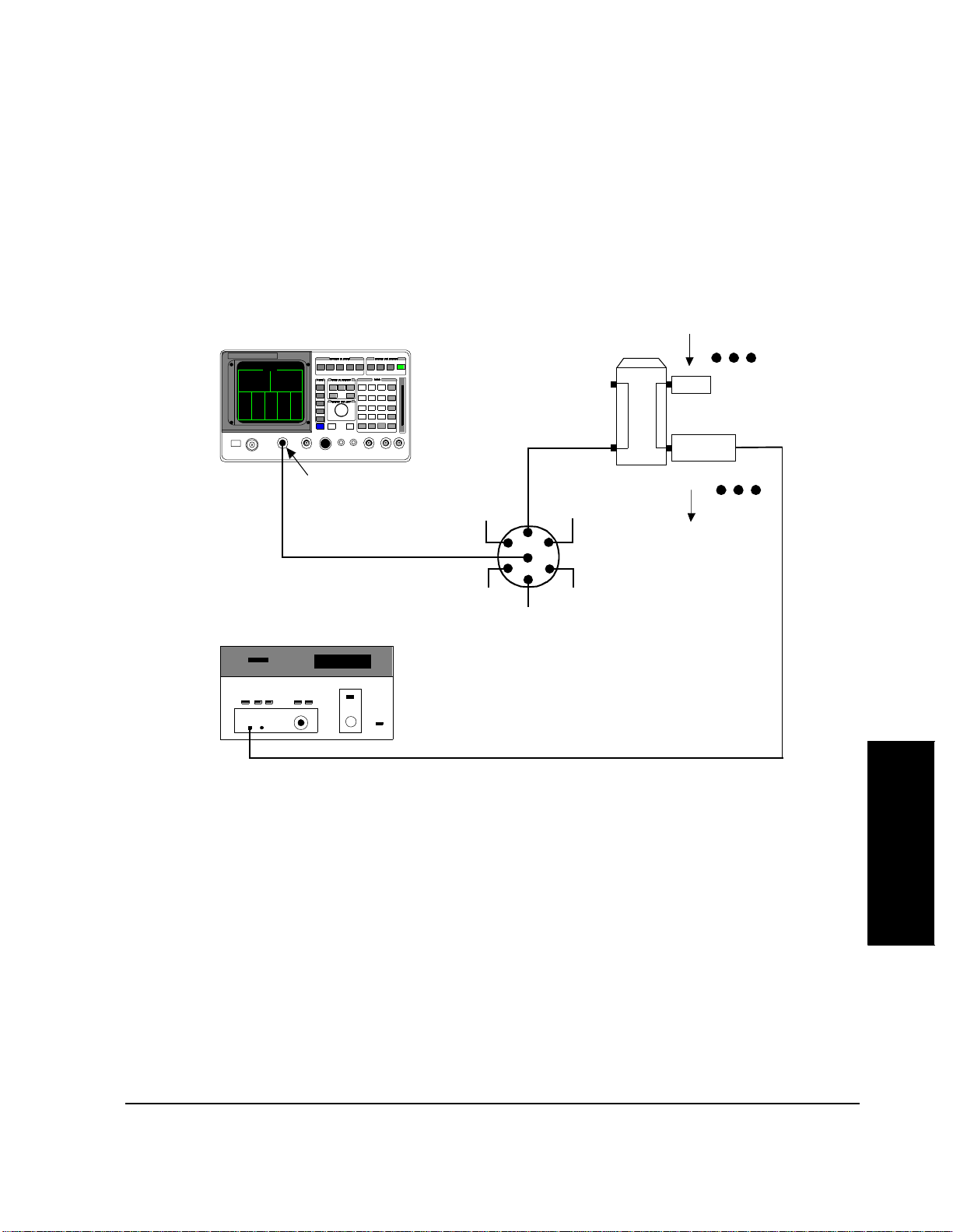

Cell Site to Test Equipment Interconnection

HP-IB (IEEE 488.2)

to Printer, HP 3488A,

or Data Collection PC

HP 8921A Cell Site Test Set

Part 1 of 2

08921-61031

RJ11(m) to RJ11(f)

Back

HP-IB

SERIAL PORT

Splitter

Cable

08921-61038 RJ11 to DB9(f), or

08921-61039 RJ11 to DB25(m)

SERIAL

(Port 9)

SERIAL B

(Port 10)

To Printer, Terminal, or

Data Collection PC RS232

Cable 08921-61015

(25ft) RJ11(m) to RJ11(m)

To RS232 TTYMP #8

CSC Network Address

08921-61013

Ribbon Cable

(10ft) DB37 to DB37

A

DUPLEX OUTRF IN/OUT

AUDIO OUT

Adapter

1250-1250

Adapter

Adapter

1250-0780

Cable (15ft)

08921-61007

Adapter

1250-1853

1250-2015

Cable 08921-61006

(20ft)

To PHONO jacks on

BSC back plane.

* An external 600-ohm load is

required if it is not internally

installed in your Test Set. See

Audio Connections in Chapter 2.

HI

LO

Adap ters 125 0-2164

(AUDIO IN HI & LO)

Adapter 1251-2277

Ground tab on AUDIO IN LO

side.

HP 83202A Opt. K02 Switch Matrix

Optional - Switch needed for Transceiver Tests

83202A OPTION K02 S WITCH MATRIX

H

POWER

OFF ON

Cable 08921-61008 (15ft)

BNC(m) to Mic.(m).

10 MHz REF INPUT

10 MHz Ref .

Cable 08921-61008 (15ft) BNC(m) to Mic.(m).

Cable 08921-61006 (20ft) SMA(m) to SMA(m)

RECEIVER ANTENNA SWITCH

ANT1 ANT2 ANT 3 A N T4 AN T 5 ANT6

DUPLEX OUT

(CS)

(TS)

(CS) (CS) (CS) (CS) (CS)

TX AUDIO

AUDIO SWITCH

AUDIO IN RCV JACK TES T JACK

(TS) (CS) (CS)

10 MHz Ref.

needed for URDM

tests of NAMPS

base station.

600-Ohm

Load*

B

C

D

E

F

Figure 4 Cell Site to Test Equipment Interconnections

72

Equipment Connections

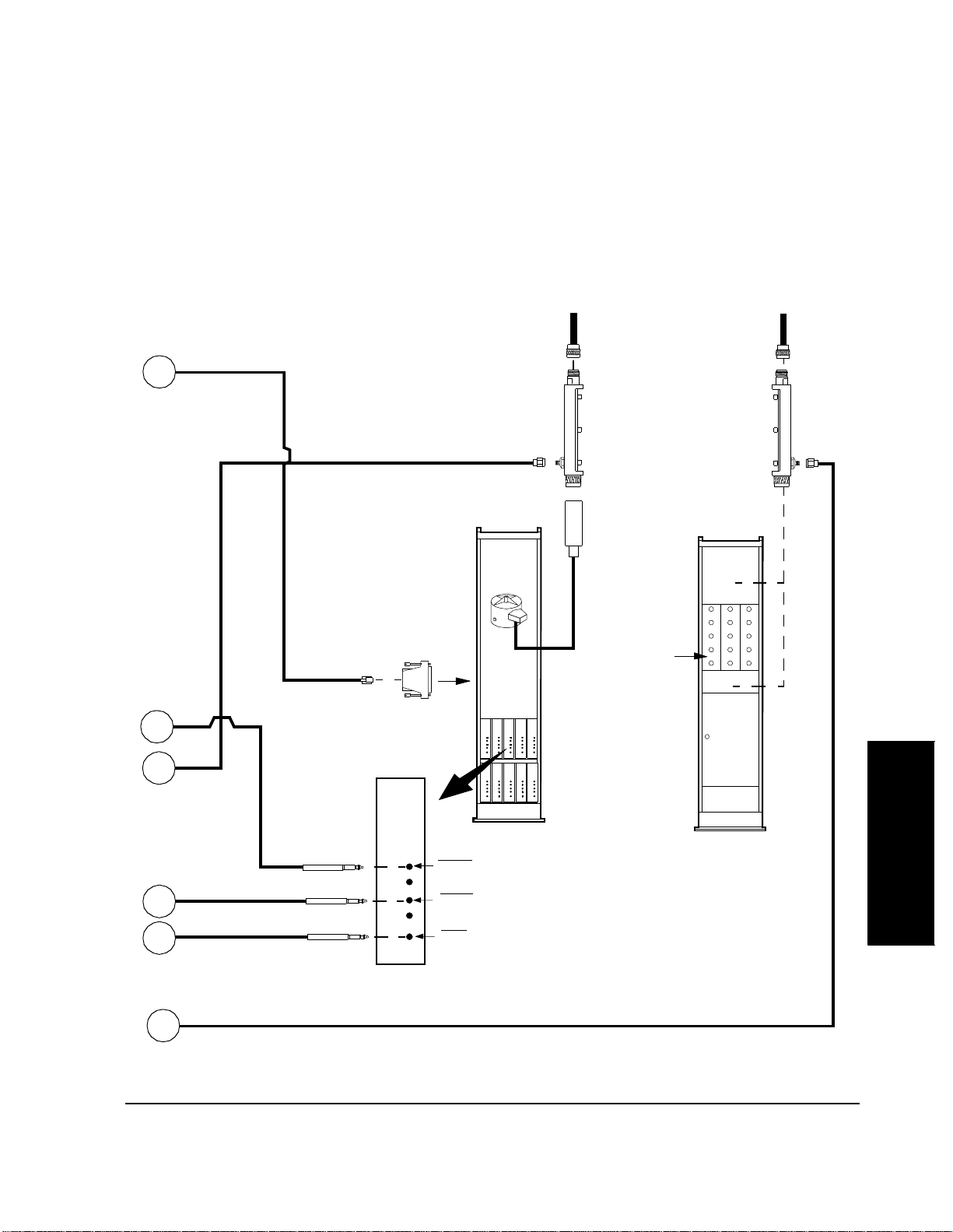

Cell Site to Test Equipment Interconnection

Part 2 of 2

Chapter 3, Setting Up

Cable 08921-61015

(25ft) RJ11(m) to RJ11(m)

A

Cable

08921-61006

(20ft)

B

(1 of possibly several in

TX Harmonic Filter

Base Station

Bay

Adapter

08921-61016

RJ11(f) to DB25(m)

To RS232 TTYMP #8

CSC Network Address

To TX Antenna(s)

RF Coupler

0955-0711

bay. See NOTE 1.)

See NOTE 1

(1 of possibly several

in rack. See NOTE 1.)

Site Filter

Rack

Filters

To RX Antenna(s)

RF Coupler

0955-0711

See NOTE 2

See NOTE 2

C

Cable 08921-61040

Cable

08921-61008

(15ft) BNC(m)

to Mic.(m)

VOC

SIG, VOC, SCN

D

Cable 08921-61040

E

Mic.(m) to Mic.(m)

Cable 08921-61006 (20ft) SMA(m) to SMA(m)

VOC

F

73

VOC,

SIG, or

SCN

EQUIP XMT LINE JK

EQUIP RCV LINE JK

TEST JK

NOTE 1: It is recommended that

each ant enna line in the bay and

rack have its own RF Coupler .

NOTE 2: Depending on the site

filter-rack used, RF couplers can

be inserted before or after filters.

Setting Up

Chapter 3

Chapter 3, Setting Up

Equipment Connections

Receiver RF Connections

An RF coupler must be installed between each of the recei ve antennas and base

station receiver inputs. See figure 4 on page 72 for a description of these

connections. RF cables connect each of the coupled ports to an RF N-way switch

or splitter. The switch will have two selected ports if the site is an omni site, and

six if it is a sectored site. The common port of the switch or splitter is connected

to the Test Set DUPLEX OUT connector. See "Radio Interface Connections" on

page 79 for details of the connection of the Radio In terface to the RF N-Way

switch.

CAUTION: The applica tion of RF p ower greater tha n 200 milliwatt s (mW) (or +23 dBm) can damage

the Test Set DUPLEX OUT port . Make certai n that signal s applied to t his port are less than

200 mW. If an RF power higher than 200 mW is applied, an overpower relay will trip.

Disconnect t he RF si gnal, or tur n it off, press MEAS RESET or tur n t he Tes t Set powe r of f

and then on to reset it, and then reconnect the RF signal, or turn it on again.

Signals that affect the equipment being measured can be picked up by the RX

antennas. To prevent this, terminate the RF coupler when performing tests of the

SIG unit and scan receivers.

In measurements on voice channel receivers, antennas ordinar ily may be left

connected to the RF couplers. Interference may be detected by turning up the

speaker volume of the Test Set. The interfering signal might be the result of a

problem in the frequency plan. If it is impo ssible to proceed with measurements,

terminate the RF coupler port leading to the antenna using a 50-ohm load.

Transmitter RF Connections

An RF coupler must be installed between each cell site transmit antenna and its

associated harmonic filter if you wish to perform any test in the In-Service

Optimization sta te. See fi gure 4 on pag e 72 for a desc ription o f these conne ctions .

A small amount of powe r is ava ilable at t he coup led port a nd is ap plied to the Te st

Set RF IN/OUT connector.

While testing the SIG unit, a high-power load must be placed on the RF coupler

output leading to the ant enna. It mu st be cap able of h andling at least 30 watts . The

load is necess ary to prevent the SIG unit transmitte r signal from being r ad iated to

mobile stations.

74

Chapter 3, Setting Up

Equipment Connections

Audio Connections An SPDT switch must be installed so that the Test Software can automatically

apply either the TEST JK of the tra nsmi tter or the EQUIP RCV of the receiver to

the Test Set AUDIO IN. See figure 4 on page 72 for a description of these

connections. A 600-ohm load must be connected across the EQUIP RCV, if your

Test Set does not have a built-in switcha ble 600-ohm floating load. This inte rn al

load is included in all Test Sets shipped after October 1992. Determine if it is

built-in by looking for its co ntrol field on the AF ANALYZER screen. The field

is labelled

the screen includes these three choices, the switchable load is inst alled.

The HP 11807B Option 040 Test Software selec ts a floati ng AUDIO IN LO if the

Test Set does not have an internal 600-ohm load.

See "Radio Interface Connections" on page 79 for details of the connection of the

Radio Interface to the audio path switch.

The transmitter EQUIP LINE JACK is connected to the Test Set AUDIO OUT

connector with a coaxial cabl e. You might wish to route this connection through

the switch box.

Audio In Lo and has three choice s: Gnd, Float, and 600 to HI. If

Connection fo r RS-232 Base Stat ion Co ntrol

CAUTION: RJ-11 cable and adapters might be wired in several ways . Verify the connect ions bet ween

Serial Port Connections for Data Collection

The HP 11807B Option 040 Test Software supports RS-232 control of the base

station via the TTYMP #8 CSC Network Address connection. Other connections

are not supported. The Test Set has a rear-pa nel RJ-11 connector for serial

communication. See figure 5 on page 76. It has two serial ports on it, Serial A

port and Serial B port. Serial B port is used for base station control and

messaging.

the Test Set RJ-11 conne ctor and the DB-25 base station connector.

The connections between the Test Set RJ-11 connector and the DB-25 TTYMP

#8 CSC Network Address connector are shown in figure 6 on page 77

The Test Software is capable of uploading test results to an external computer.

One way to accompl ish this is by runn ing a terminal pr ogr am on a laptop or other

computer and using terminal logging to save the information sent to the Test Set

Serial port. See figure 5, "Connector on Test Set Rear Panel," on page 76 and

figure 6, "Adapters for Base Station Control," on page 77.

Setting Up

Chapter 3

75

Chapter 3, Setting Up

Equipment Connections

Printer Connection A seri al printer may be connected to the Test Set Serial port. An HP-IB printer

may be connected to the Test Set rear-panel HP-IB connector.

See "Serial Port Configuration" on page 109 for informati on on how to set the

Test Set Serial port settings to match the printer settings. (See also"Appendix:

Cable Wiring Diagrams for Data Collection to PC and Printer" on page 233).

Serial Port Location

A serial pri nter may be atta ched to t he Ser ial por t. Use the following figur e for p in

information and the next figure for adapter information.

Connector on Test Set Rear Panel

Transmit B

6

5

4

3

2

1

Transmit A

Ground

No Connect

Receive A

Receive B

Figure 5 Connector on Test Set Rear Panel

76

HP 8921A Test Set

Serial Port

6

5

4

3

2

1

Chapter 3, Setting Up

Equipment Connections

Adaptors

For Base Station Control

RJ-11 (F) to DB-25 (M)

see Diagram A

RJ-11 Splitter

For PC or Printe r

RJ-11 (F) to DB-25 (M)

see Diagram B

Diagram A

RJ-11 (F)

1 2 3 4 5 6

Transmit BReceive B Gnd.

DB-25 (M)

Pin 2 Pin 3

Pin 1

Pin 14 Pin 25

Pin 20

Pin 7

Pin 8

Pin 13

Diagram B

RJ-11 (F)

1 2 3 4 5 6

Transmit AReceive A

Gnd.

DB-25 (M)

Pin 2

Pin 1

Pin 14 Pin 25

Pin 3

Pin 20

Pin 7

Pin 8

Pin 13

DB-9 (F) NOTE:

pins 1, 4, & 6 jumpered together, and

pins 7 & 8 jumpered together

For a PC

RJ-11 (F) to DB-9 (F)

see Diagram C

Diagram C

RJ-11 (F)

1 2 3 4 5 6

Gnd.

DB-9 (F)

Pin 3

Pin 5

Pin 9

Transmit AReceive A

Pin 2