Page 1

HP 11807A,E Option 100 System Support Tests

User’s Guide for the HP 8920A, HP 8920B,

HP 8921A

Software Revision B.02.00 and above

Manual Part Number: 11807-90141

Manual Revision C

Printed in U.S.A.

August 1999

Page 2

Notice

Information contained in this document is subject to change without

notice.

All Rights Reserved. Reproduction, adaptation, or translation without

prior written permission is prohibited, except as allowed under the

copyright laws.

This material may be reproduced by or for the U.S. Government

pursuant to the Copyright License under the clause at DFARS

52.227-7013 (APR 1988).

© Copyright 1997 Hewlett-Packard Company

2

Page 3

Contents

Introduction

HP 11807A,E System Support Tests . . . . . . . . . . . . . . . . . . . . . . 8

Items Supplied in the Software Package . . . . . . . . . . . . . . . . . . . 9

Equipment Needed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Firmware Revision Requirements . . . . . . . . . . . . . . . . . . . . . . . 9

Hardware That Must be Installed in the Test Set . . . . . . . . . 10

Additional Services Available . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Loading and Running the Software

Testing Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Running Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Loading the Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Starting Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Customizing Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Beginning Software Customization . . . . . . . . . . . . . . . . . . . . . 22

Changing the Order of Tests . . . . . . . . . . . . . . . . . . . . . . . . . . 23

How to Change the Order of Tests . . . . . . . . . . . . . . . . . . . . . 24

Changing the Test Parameters . . . . . . . . . . . . . . . . . . . . . . . . 26

How to Change the Test Environment and Conditions . . . . . 26

Saving a Test Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

How to Save a Test Procedure . . . . . . . . . . . . . . . . . . . . . . . . . 29

Changing Test Execution Conditions . . . . . . . . . . . . . . . . . . . 32

How to Change Test Execution Conditions . . . . . . . . . . . . . . 33

Printing and Saving Test Results . . . . . . . . . . . . . . . . . . . . . . 33

RFTOOLS Library: Procedure, Test, and Parameter Descriptions

Procedures Pre-programmed in the RFTOOLS Library . . . . . . 37

Test Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Swept Gain Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Swept Insertion Loss Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Swept Return Loss Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

AMPS Channel Return Loss Test . . . . . . . . . . . . . . . . . . . . . . 45

Cable Fault Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

ERP Calculator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Replot Data Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Transfer Stored Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

SA Self Calibration ON/OFF . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Catalog Memory Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Create/Edit Data Collection Labels . . . . . . . . . . . . . . . . . . . . . 59

RF Tools: Parameter Descriptions . . . . . . . . . . . . . . . . . . . . . . . 61

Parm_01 Sweep Start Frequency [.4 to 1000 MHz] . . . . . . . . 61

Parm_02 Sweep Stop Frequency [.4 to 1000 MHz] . . . . . . . . 61

Parm_03 Gain: plot scale [1, 5, 10] (dB/div) . . . . . . . . . . . . . . 61

Parm_04 Gain: maximum expected gain [−50 to 20] (dB) . . . 62

Table of Contents

3

Page 4

Contents

Parm_05 Gain: DUPLEX OUT level [−54 to +10] (dBm) . . . . 62

Parm_06 Inser. loss: maximum expected [−50 to 0] . . . . . . . .62

Parm_07 Inser. loss: DUPLEX OUT level [−54 to +10] . . . . . 62

Parm_08 Return loss: maximum expected [−50 to 0] . . . . . . .63

Parm_09 Return loss: DUPLEX OUT level [−54 to +10] . . . . 63

Parm_10 Discrete return loss: start chan [AMPS] . . . . . . . . .63

Parm_11 Discrete return loss: stop chan [AMPS] . . . . . . . . . . 63

Parm_12 Discrete return loss: channel step size . . . . . . . . . . 64

Parm_13 Discrete return loss: off freq [0 to 20] . . . . . . . . . . .64

Parm_14 Discrete return loss: band [0=FWD 1=REV] . . . . . . 64

Parm_15 Discrete return loss: DUPLEX OUT [−54 to +10] . . 64

Parm_16 Cable fault: cable length . . . . . . . . . . . . . . . . . . . . . . 64

Parm_17 Cable fault: length units [0=ft 1=m] . . . . . . . . . . . . 65

Parm_18 Cable fault: [0=RG 1=HELIAX 2=Custom] . . . . . . . 65

Parm_19 Cable type: [1>13 for Heliax, # for RG] . . . . . . . . . . 66

Parm_20 Cable fault: custom cable attenuation (dB/unit) . . . 66

Parm_21 Cable fault: custom cable prop. velocity (<1.0) . . . . 67

Parm_22 Use data collection labels [0=No 1=Yes] . . . . . . . . . 67

Parm_23 Show all data files [0=No 1=Yes] . . . . . . . . . . . . . . .68

FIELD_S Library: Procedure, Test, and Parameter Descriptions

Procedures Pre-programmed in the FIELD_S Library . . . . . . . 70

Setting Up Test Frequencies for the FIELD_S Library . . . . . 70

Test Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

TEST_01 Measure Test Plan . . . . . . . . . . . . . . . . . . . . . . . . . .72

TEST_02 Print Stored Measured Data . . . . . . . . . . . . . . . . . . 73

Field Strength Test: Parameter Descriptions . . . . . . . . . . . . . .74

Parm_01 Antenna Gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Parm_02 Number of times to average reading . . . . . . . . . . . .74

INTRMOD Library: Procedure, Test, and Parameter Descriptions

Procedures Pre-programmed in the INTRMOD Library . . . . . . 76

Test Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

TEST_01 Calculate Intermods . . . . . . . . . . . . . . . . . . . . . . . . . 77

Setting Up Intermodulation Products Parameters . . . . . . . . . 77

SCANNER Library: Procedure, Test, and Parameter Descriptions

Procedures Pre-programmed in the SCANNER Library . . . . . . 80

Setting Up Discrete Scan Frequency Information . . . . . . . . . 80

Setting Up Swept Scan Frequency Information . . . . . . . . . . . 82

Test Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

TEST_01 SCANNER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Parameter Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Parm_01 Receiver dwell time (seconds) . . . . . . . . . . . . . . . . . . 84

Parm_02 Wide IF bandwidth [0=no 1=yes] . . . . . . . . . . . . . . . 84

4

Page 5

Contents

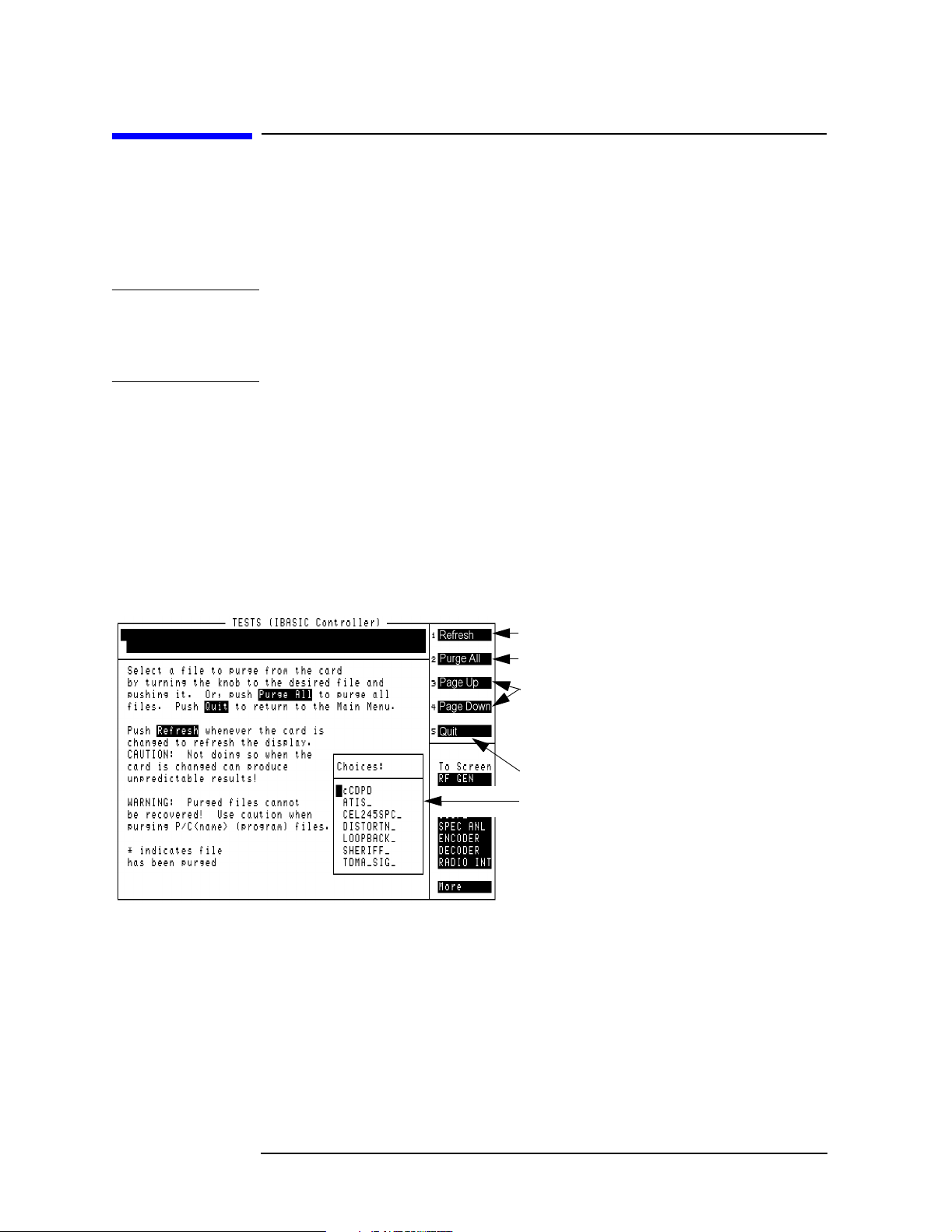

Save/Recall Register Utility (SAVRCL)

Catalog the Memory Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Purge Files from the Memory Card . . . . . . . . . . . . . . . . . . . . . . 88

Saving Registers to a Memory Card . . . . . . . . . . . . . . . . . . . . . . 89

Restoring (Copying) Registers to the Test Set . . . . . . . . . . . . . . 91

Formatting a Memory Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Reference (Alphabetical)

Conventions Used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Copying Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Data Collection (Saving and Retrieving Test Results) . . . . . . . 97

Collection to a Memory Card . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Retrieving Data from a Memory Card . . . . . . . . . . . . . . . . . 100

Collection to a PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Configuration for Terminal or PC Operation . . . . . . . . . . . . 103

HP-IB Control Annunciators . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Memory Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

SRAM Memory Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Memory Card Storage Space . . . . . . . . . . . . . . . . . . . . . . . . . 112

Initializing an SRAM Memory Card . . . . . . . . . . . . . . . . . . . 113

Retrieving Data from a Memory Card . . . . . . . . . . . . . . . . . 114

Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Pass/Fail Limits (specifications) . . . . . . . . . . . . . . . . . . . . . . . . 116

Pausing or Stopping a TEST . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Supported Printers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Printer Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Configuring the Test Set for Printing . . . . . . . . . . . . . . . . . . 120

To Setup a Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Saving a Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Loading a Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Deleting a Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Securing a Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

RAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Initializing RAM Disks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Saving Tests Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Test Execution Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Output Results To: (Output Destination) . . . . . . . . . . . . . . . 135

Output Results For: (Output Results) . . . . . . . . . . . . . . . . . . 135

Output Heading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

If Unit-Under-Test Fails (If UUT Fails) . . . . . . . . . . . . . . . . 136

Test Procedure Run Mode (Run Mode) . . . . . . . . . . . . . . . . . 136

Table of Contents

5

Page 6

Contents

Autostart Test Procedure on Power-Up . . . . . . . . . . . . . . . . .136

USER Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .137

Appendix A: RFTOOLS Program Tutorial 139

Running the RFTOOLS Tests . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Customize the Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Running the Swept Return Loss Test . . . . . . . . . . . . . . . . . . . .148

Running the Replot Data Files Test . . . . . . . . . . . . . . . . . . . . . 156

Plotting Two Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Overview of the Cable Fault Test . . . . . . . . . . . . . . . . . . . . . . . 161

Selecting Cable Class: RG . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Running the Cable Fault Test . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Glossary 175

6

Page 7

Introduction

Chapter 1

1 Introduction

S:\HP11807A\OPT100\MANUAL\intro.fm

7

Page 8

Introduction

HP 11807A,E System Support Tests

HP 11807A,E System Support Tests

The HP 11807A,E Option 100 System Support Tests software is stored

on a one-time programmable (OTP) memory card. The test set’s built-in

computer (operating with HP Instrument BASIC programming

language) allows you to run the following individual programs:

• “RFTOOLS Library: Procedure, Test, and Parameter Descriptions”

on page 35

—Swept Gain

— Swept Insertion Loss

—Swept Return Loss

— AMPS Channel Return Loss

— Cable Fault

— ERP Calculator

— Replot Data Files

— Transfer Stored Data

— SA Self Calibration ON/OFF

— Catalog Memory Card

— Create/Edit Data Collection Labels

• “FIELD_S Library: Procedure, Test, and Parameter Descriptions”

on page 69

— Performs Field Strength Measurements

• “INTRMOD Library: Procedure, Test, and Parameter Descriptions”

on page 75

— Calculates Intermodulation Products

• “SCANNER Library: Procedure, Test, and Parameter Descriptions”

on page 79

— Discrete Frequency Scanning

— Swept Frequency Scanning

• “Save/Recall Register Utility (SAVRCL)” on page 85

— Catalog Memory Card

— Purge Files From a Memory Card

— Copy Save/Recall Registers From a Test Set to a Memory Card

— Copy Save/Recall Registers from a Memory Card to a Test Set

— Format a Memory Card

8 Chapter 1

S:\HP11807A\OPT100\MANUAL\intro.fm

Page 9

Introduction

Items Supplied in the Software Package

Items Supplied in the Software Package

The HP 11807A,E Option 100 Software Package contains the following

items:

• HP 11807A,E Option 100 Software User’s Guide (HP part number

11807-90141)

• HP 11807A Option 100 Software Card (HP part number

11807-10100) or

• HP 11807E Option 100 Software Card (HP part number

118007-10032)

• HP software product license agreement

Equipment Needed

To run the Option 100 System Support Tests, the following hardware

must be configured in the test set or available externally:

Firmware Revision Requirements

All HP 8920B Test Sets can use this software package.

HP 8920A and HP 8921A Test Sets should have firmware revision

A.14.00 or higher to run this software. Although the software may run

successfully on earlier revisions, operation is slightly different and may

not be reliable.

Introduction

Chapter 1

The firmware revision number is displayed at the top of the screen

when the Test Set is turned on, and remains displayed until a button is

pressed or the knob is turned. You can also verify the revision by

pressing the

SHIFT, DUPLEX (CONFIG) keys to access the CONFIGURE

screen; the revision number is displayed in the upper-right corner of

that screen.

If your HP 8920A/21A Test Set has an earlier firmware revision (before

A.14.00), contact your local HP sales representative about getting a

firmware update.

Chapter 1 9

S:\HP11807A\OPT100\MANUAL\intro.fm

Page 10

Introduction

Equipment Needed

Hardware That Must be Installed in the Test Set

• Option 102, spectrum analyzer and tracking generator (for the gain,

swept insertion loss, swept return loss, discrete return loss, and

cable fault tests).

NOTE

The item listed above is available as an option for the HP 8920A,B. It is

standard in the HP 8921A

10 Chapter 1

S:\HP11807A\OPT100\MANUAL\intro.fm

Page 11

Table 1-1 External Hardware for the System Support Tests

Test Procedure Hardware Required Quantity Part Number

Introduction

Equipment Needed

Cable Fault (C_Fault) Resistive Power

Splitter1 GHz,

BNC(f), 3 dB

50 Ω Termination

connector type as

required

Swept Gain and Swept

Insertion Loss

6 dB Pad, BNC(f) to

BNC(m)

BNC(m) to BNC(m)

Cable, 1 ft

BNC (f) to BNC(f)

Adapter

Swept Return Loss and

SWR Bridge 1 Eagle

Discrete Return Loss

Frequency Scanning Antenna with BNC

connector

Field-Strength Measurement Intialized SRAM

Memory Card

1

Eagle HPS101

1

1None

2HP

0955-0698

2HP

08120-1838

2

1HP

1250-0780

RLB150N3B or

equivalent

1None

1(for

HP 11807A,E),

HP 85700A

Introduction

Chapter 1

NOTE

Antenna with BNC (m)

1None

connector

For PC to Serial Port Input DB9(f) to RJ11(m) cable 1 HP

08921-60038

1. Eagle, P.O. Box 4010, Sedona, AZ 86340, (Tel: 520-204-2597)

(Fax: 520-204-2568)

2. Alternate part to substitute for these two components in an N(m) to

BNC(m) cable, Eagle part number CCS050-BN-C2.0

A kit containing all components necessary for performing these tests is

available from Eagle using part number: BKH-8920.

Chapter 1 11

S:\HP11807A\OPT100\MANUAL\intro.fm

Page 12

Introduction

Additional Services Available

Additional Services Available

Consult the test set Reference Guide or call the HP 8920 Hotline

1-800-922-8920 (USA and Canada only) and give your software model

number if you encounter a problem.

12 Chapter 1

S:\HP11807A\OPT100\MANUAL\intro.fm

Page 13

2 Loading and Running the

Loading and Runni n g the

Chapter 2

Software

Software

S:\HP11807A\OPT100\MANUAL\softav14.fm 13

Page 14

Loading and Running the Software

The software can be run on the factory default settings or customized to

your individual needs and specific requirements. This chapter provides

detailed information on how to load, run, and customize the software.

The test set has two methods of accessing on-line help. In each of the

screens in the test environment,

about how to set up/use the current screen. Pressing

k4 (Help) accesses specific information

SHIFT, TX(HELP)

accesses the test set’s complete help file, with an alphabetical listing of

help topics.

14 Chapter 2

S:\HP11807A\OPT100\MANUAL\softav14.fm

Page 15

Loading and Running the Software

Testing Overview

Testing Overview

Pressing TESTS displays the TESTS (Main Menu) screen. To begin

testing, you must first select a procedure filename. From the Main Menu

you have the option to:

Begin running tests:

• The factory default settings are acceptable for your application or

• The software has already been customized and saved to a memory

card

Customize the software:

• Decide which tests you desire to run (Order of Tests)

— you may want to run all, some, or just one of the tests.

• Change the test environment and conditions (Test Parameters)

— decide output format.

— enter specific information about radio equipment and/or

environment.

• Save any or all of the above customized changes to a memory card

(Save/Delete Procedure)

Set Up Test Set:

• Print test results or certain screens.

• Decide when and where test results are displayed (Test Execution

Conditions/External Devices)

Loading and Runni n g the

Chapter 2

Software

Chapter 2 15

S:\HP11807A\OPT100\MANUAL\softav14.fm

Page 16

Loading and Running the Software

Running Tests

Running Tests

The HP 11807A,E Software can be run with its factory default settings,

or it may be customized to your specific needs (see “Customizing

Testing” on page 20).

When tests are run, they are executed in the order in which they were

entered into the Test Procedure.

• When displayed, pressing

(press

k2 (Continue) to continue the test).

CANCEL will pause the current test

16 Chapter 2

S:\HP11807A\OPT100\MANUAL\softav14.fm

Page 17

Loading and Running the Software

Running Tests

Loading the Software

Before you begin testing, you must load the software into the test set

memory. To load the software, you must first select the location to load

from (in this case, it will be Card) and a procedure filename. The

HP 11807A,E Option 100 card comes pre-programmed with five

procedures, and four different libraries. Each library is associated with

its own software program. The actual software program does not get

loaded into the test set memory until

take approximately two minutes for the software program to be loaded

at that time.

The software memory card can be removed after the program is loaded

into the test set memory. The program will remain in memory after a

power-down/power-up cycle, unless it is manually deleted or a new

program is loaded (for example, if you select a procedure in a different

library).

k1 (Run Test) is selected. It will

Loading and Runni n g the

Chapter 2

Software

Chapter 2 17

S:\HP11807A\OPT100\MANUAL\softav14.fm

Page 18

Loading and Running the Software

Running Tests

Starting Up

Press

POWER

Wait about 20 seconds

for a display to appear,

then go to st ep 3.

Insert the card

HP 11807A,E

18 Chapter 2

S:\HP11807A\OPT100\MANUAL\softav14.fm

Page 19

Loading and Running the Software

Running Tests

Loading and Runni n g the

Chapter 2

Software

Chapter 2 19

S:\HP11807A\OPT100\MANUAL\softav14.fm

Page 20

Loading and Running the Software

Customizing Testing

Customizing Testing

Because of the diversity of individual testing needs, the software has

been designed so that changes may be easily made from the test set’s

front panel. You may store these changes on a memory card so that you

may skip these steps in the future. See “Saving a Test Procedure” on

page 28.

Because your needs change, the software allows changes to its default

settings whenever you need to make them. For example, tests may be

inserted or deleted, and later after running the tests you can change the

test parameters.

Most testing customization is accomplished through the customization

screens. These customization screens are accessed from the main

TESTS (Main Menu) screen as shown in the following figure.

Customizing procedures is explained later in this chapter.

20 Chapter 2

S:\HP11807A\OPT100\MANUAL\softav14.fm

Page 21

Loading and Running the Software

Customizing Testing

What is

Not

Explained in This

Manual

Pass/Fail Limits, Channel Information, External Devices, Printer

Setup, and IBASIC will not be explained in this customizing section.

• The Pass/Fail Limits settings are not used with the HP 11807A,E

Option 100 Software.

• The Channel Information settings are used only in the FIELD_S and

SCANNER libraries, each requiring different information. See the

descriptions of these libraries in Chapter 4 , “FIELD_S Library:

Procedure, Test, and Parameter Descriptions,” on page 69 and

Chapter 5 , “INTRMOD Library: Procedure, Test, and Parameter

Descriptions,” on page 75.

• The External Devices settings are used when setting up functions

such as data collection. See“Data Collection (Saving and Retrieving

Test Results)” on page 97.

• The Printer Setup settings are used to print the test results. See

“Printing” on page 118.

• The IBASIC screen is used when writing your own programs and is

not explained in this manual. If you need to write your own IBASIC

programs you may acquire the following manuals:

— HP Instrument Basic User’s Handbook

HP part number E2083-90000.

Loading and Runni n g the

Chapter 2

Software

— HP Instrument Basic User’s Handbook (HP 8920B)

HP part number E2083-90005.

— HP 8920AProgramming Manual

HP part number 08920-90220.

— HP 8921A Programming Manual

HP part number 08921-90031

— HP 8920B Programming Manual

HP part number 08920-90222

Chapter 2 21

S:\HP11807A\OPT100\MANUAL\softav14.fm

Page 22

Loading and Running the Software

Customizing Testing

Beginning Software Customization

All software customization begins by accessing the TESTS (Main Menu)

screen first and then selecting the CUSTOMIZE TEST PROCEDURE field of

your choice. Press

TESTS (Main Menu) screen.

Figure 2-1 TESTS (Main Menu) Screen

TESTS on the front panel of the test set to access the

22 Chapter 2

S:\HP11807A\OPT100\MANUAL\softav14.fm

Page 23

Loading and Running the Software

Customizing Testing

Changing the Order of Tests

You can define the order of tests to include all, some, or just one of the

tests available. Each library has a different set of available tests. You

cannot combine tests from different libraries into one procedure. When

the first test is finished, the next will run. The test sequence will

remain in the test set’s battery backed-up memory until another test

sequence is loaded or set up. For information on saving a customized

test sequence, see “Saving a Test Procedure” on page 28.

NOTE

Libraries are not selected directly. When you select a procedure

filename, the associated library is automatically selected as well. The

Library field on the TESTS (Main Menu) screen displays the current

library. Note that each library has a separate set of tests and

parameters. You may not combine tests from separate libraries into one

procedure.

Defining the order of tests is accomplished by inserting or deleting tests

from the list of tests in the active library. See “Test Descriptions” in

Chapter 4 through chapter 6 describe the tests included in each

library in this software package.

The following procedure describes how to create a new test sequence.

The All Chans field is not used by this software package.

Loading and Runni n g the

Chapter 2

Software

Chapter 2 23

S:\HP11807A\OPT100\MANUAL\softav14.fm

Page 24

Loading and Running the Software

Customizing Testing

How to Change the Order of Tests

24 Chapter 2

S:\HP11807A\OPT100\MANUAL\softav14.fm

Page 25

Loading and Running the Software

Customizing Testing

Loading and Runni n g the

Chapter 2

Software

Chapter 2 25

S:\HP11807A\OPT100\MANUAL\softav14.fm

Page 26

Loading and Running the Software

Customizing Testing

Changing the Test Parameters

The software uses parameters to optimize the test environment and

conditions for your testing situation. Many of the test parameters are

determined by examining your test needs. Each library has a unique set

of parameters. Each procedure comes with default settings for test

parameters. Review the defaults for your particular needs.

NOTE

The HP 11807A,E Option 100 software comes preprogrammed with four

libraries: RFTOOLS, FIELD_S, INTRMOD, and SCANNER. The test,

parameter, and channel information tables are different for each of

these libraries. Each library accesses a separate software program, also

contained on the software card. Each library will be described in its own

chapter (chapters 3 through 6 )

For information on saving customized test parameters, see “Saving a

Test Procedure” on page 28.

The following describes how you can change test parameter values

through the Test Parameter screen to optimize your testing conditions.

How to Change the Test Environment and Conditions

26 Chapter 2

S:\HP11807A\OPT100\MANUAL\softav14.fm

Page 27

Loading and Running the Software

Customizing Testing

Loading and Runni n g the

Chapter 2

Software

Chapter 2 27

S:\HP11807A\OPT100\MANUAL\softav14.fm

Page 28

Loading and Running the Software

Customizing Testing

Saving a Test Procedure

A Test Procedure is a collection of test parameters and testing order

(and channel information for FIELD_S and SCANNER libraries), saved

in a file that customizes the test software to a specific application. You

may save the file to a memory card or disk.

When you save a procedure you will be saving test parameters and

testing order (and channel information in FIELD_S and SCANNER

programs), plus a library containing the names of all test parameters

and tests that are resident in the current library. The HP 11807A,E

Option 100 software contains four libraries: RFTOOLS, FIELD_S,

INTRMOD, and SCANNER. Each library file comes from the software

and cannot be modified by the user. The current library file will be

automatically saved on the card that is being used to store the new test

procedure.

The following example shows how to save a new procedure to a memory

card. For more information concerning procedures, see “Procedures” on

page 125.

28 Chapter 2

S:\HP11807A\OPT100\MANUAL\softav14.fm

Page 29

How to Save a Test Procedure

Loading and Running the Software

Customizing Testing

Loading and Runni n g the

8, Memory Cards.)

Chapter 2

Software

Chapter 2 29

S:\HP11807A\OPT100\MANUAL\softav14.fm

Page 30

Loading and Running the Software

Customizing Testing

30 Chapter 2

S:\HP11807A\OPT100\MANUAL\softav14.fm

Page 31

Loading and Running the Software

Customizing Testing

Loading and Runni n g the

Chapter 2

Software

Chapter 2 31

S:\HP11807A\OPT100\MANUAL\softav14.fm

Page 32

Loading and Running the Software

Customizing Testing

Changing Test Execution Conditions

Test Execution Conditions define where and when test output

occurs. You may decide to:

• Display output on CRT only, or display on CRT and print hardcopy.

(Output Results To)

NOTE

If printing test results is desired, after selecting Printer additional

steps are necessary to connect and configure the printer. See “Printing”

on page 118.

• Display (or print) only measurements that fail, or display (or print)

all measurements that pass or fail. (Output Results For)

• Enter a title for an output heading for the displayed or printed

results. (Output Heading)

• Stop testing when a measurement fails or continue through all of the

tests without stopping. Note: if Stop is selected and the program

pauses as a result of this, you will be given a choice to continue

testing or repeat the measurement. (If Unit-Under-Test Fails)

• Pause between each measurement, or run through entire test. Note:

if Single Step is selected and the program pauses as a result of

this, you will be given a choice to continue testing or repeat the

measurement. (Test Procedure Run Mode)

• Start the program automatically when the Test System is powered

on. (Autostart Test Procedure on Power-up)

Test Execution Conditions is accessed from the SETUP TEST SET:

list. To change a default setting, position the cursor to the desired field.

Pressing the knob (selecting) will toggle the underlined selection.

Test Execution Conditions settings are not retained after a

power-down/power-up cycle, and will return to their default settings.

32 Chapter 2

S:\HP11807A\OPT100\MANUAL\softav14.fm

Page 33

Loading and Running the Software

How to Change Test Execution Conditions

Customizing Testing

Loading and Runni n g the

Printing and Saving Test Results

Printing and saving test results are features of the software which

require additional equipment and configuration. See “Printing” on page

118 for detailed descriptions and instructions for these features.

Chapter 2

Software

Chapter 2 33

S:\HP11807A\OPT100\MANUAL\softav14.fm

Page 34

Loading and Running the Software

Customizing Testing

34 Chapter 2

S:\HP11807A\OPT100\MANUAL\softav14.fm

Page 35

3 RFTOOLS Library: Procedure,

Test, and Parameter Descriptions

RF TOOLS Libr ary

Chapter 3

S:\HP11807A\OPT100\MANUAL\rftools.fm 35

Page 36

RFTOOLS Library: Procedure, Test, and Pa rameter Desc riptions

The RFTOOLS library contains the following tests:

• Swept Gain (page 38)

• Swept Insertion Loss (page 40)

• Swept Return Loss (page 42)

• AMPS Channel Return Loss (page 45)

• Cable Fault (page 47)

• ERP Calculator (page 53)

• Replot Data Files (page 54)

• Transfer Stored Data (page 56)

• SA Self Calibration ON/OFF (page 57)

• Catalog Memory Card (page 58)

• Create/Edit Data Collection Labels (only appears if Parm_22 Use

data collection labels [0=No 1=Yes] is set to 1=Yes). See page 59.

36 Chapter 3

S:\HP11807A\OPT100\MANUAL\rftools.fm

Page 37

RFTOOLS Library: Procedure, Test, and Parameter Descriptions

Procedures Pre-programmed in the RFTOOLS Library

Procedures Pre-programmed in the RFTOOLS

Library

The RFTOOLS library comes pre-programmed with one procedure, also

named RFTOOLS.

• Tests Included in the RFTOOLS Procedure

— RFTOOLS Test Menu

The RFTOOLS Test Menu provides you with quick and easy access to a

menu from which you may select any of RFTOOLS tests to execute. The

tests are selected and run one at a time. For example, if you select

Swept Gain, the software will immediately begin to execute it. When

the selected test is completed and the results are displayed, you will be

given the choice to select an additional test. You may execute the same

test again, select a different test, or exit the program.

See the individual test descriptions for details on each test.

RF TOOLS Libr ary

Chapter 3

Chapter 3 37

S:\HP11807A\OPT100\MANUAL\rftools.fm

Page 38

RFTOOLS Library: Procedure, Test, and Pa rameter Desc riptions

Test Descriptions

Test Descriptions

Swept Gain Test

This test measures the gain of a device by sweeping it over the specified

frequency range. You will be prompted to enter the frequency range

over which the device is to be swept.

This test requires two 6-dB pads. The pads are put on the antenna and

duplex ports on the test set to improve the mismatch of the ports. A

reference level is obtained by connecting a short calibration cable

between the pads on the duplex and antenna ports. Next, the test

device is added between the calibration cable and one of the pads, and a

measurement is made of the additional gain from the reference level.

The trace of the device gain over the frequency range swept is

displayed. The maximum gain is also displayed on the screen.

Running the Swept Gain Test

CAUTION

NOTE

1. From the RFTOOLS Test Menu, select Swept Gain.

2. Enter your desired values for the start frequency, stop frequency,

plot scale in dB/div, maximum expected gain in dB, and duplex out

power level in dBm.

To avoid overdrive damage to your device under test, ensure that you

are setting an appropriately low duplex out power level.

The default values in this list can be changed by editing Parameters 1-5

in the Edit Parameter screen. See “RF Tools: Parameter Descriptions”

on page 61.

3. Press

4. Connect the cables as instructed, and press

k1 (Begin Test).

k2 (Continue).

5. If Parm_22 Use data collection labels [0=No 1=Yes] is set to 1=Yes,

the software will prompt you with the option to label the data from

this test. Press

instructions on the screen for selecting or creating a label. Press

k1 (Yes) if you want to label the data and follow the

k2

(No) if you do not want to label the data.

38 Chapter 3

S:\HP11807A\OPT100\MANUAL\rftools.fm

Page 39

RFTOOLS Library: Procedure, Test, and Parameter Descriptions

Test Descriptions

6. A screen plotting the results will be displayed. You have three

options:

CAUTION

• Continue testing: press

k2 (Continue). You will have the following

choices:

— Perform the test again: press

k1 (Repeat).

— Exit the test and return to the Select Test Menu: press k5

(Return).

• Save the plot on an SRAM card: press k4 (Save Plot) and enter a

filename when prompted.

• Print a hardcopy of the graph: press

k5 (Scr Dump).

— Make sure the printer is connected, and the test set is

configured appropriately. The test set must be in Control

mode if HP-IB is used.

—Press

— After the print is complete, press

SHIFT, PRINT.

k2 (Continue).

Damage may result if the power input to the ANT IN port

exceeds 200 mW. This can be avoided by overestimating the gain

of the test device. You may enter the over-estimated gain in the

Maximum expected gain in dB field on the Swept Gain

Information screen, or change the default value in Parm_04

Gain: maximum expected gain [−50 to 20] (dB).

Parameters Used

• Parm_01 Sweep Start Frequency [.4 to 1000 MHz]

• Parm_02 Sweep Stop Frequency [.4 to 1000 MHz]

• Parm_03 Gain: plot scale [1, 5, 10] (dB/div)

• Parm_04 Gain: maximum expected gain [−50 to 20] (dB)

• Parm_05 Gain: DUPLEX OUT level [−54 to +10] (dBm)

RF TOOLS Libr ary

Chapter 3

Chapter 3 39

S:\HP11807A\OPT100\MANUAL\rftools.fm

Page 40

RFTOOLS Library: Procedure, Test, and Pa rameter Desc riptions

Test Descriptions

Swept Insertion Loss Test

This test measures the loss of a cable or device by sweeping it over the

specified frequency range. You will be prompted to enter the frequency

range over which the cable is to be swept.

This test requires two 6-dB pads. The pads are put on the antenna and

duplex ports on the test set to improve the mismatch of the ports. A

reference level is obtained by connecting a short calibration cable

between the pads on the duplex and antenna ports. Next, the test cable

or device is added between the calibration cable and one of the pads,

and a measurement is made of the addition loss from the reference

level. The trace of the cable loss over the frequency range swept is

displayed. The average loss is also displayed on the screen.

Running the Insertion Loss Test

1. From the RFTOOLS Test Menu, select Insertion Loss.

2. Enter your desired values for the start frequency, stop frequency,

duplex out level in dBm, and maximum expected loss in dB.

CAUTION

NOTE

To avoid overdrive damage to your device under test, ensure that you

are setting an appropriately low duplex out power level.

The default values in this list can be changed by editing Parameters 1,

2, 6, and 7 in the Edit Parameter screen. See “RF Tools: Parameter

Descriptions” on page 61.

3. Press

4. Connect the cables as instructed, and press

k1 (Begin Tst).

k2 (Continue).

5. If Parm_22 Use data collection labels [0=No 1=Yes] is set to 1=Yes,

the software will prompt you with the option to label the data from

this test. Press

instructions on the screen for selecting or creating a label. Press

k1(Yes) if you want to label the data and follow the

k2

(No) if you do not want to label the data.

40 Chapter 3

S:\HP11807A\OPT100\MANUAL\rftools.fm

Page 41

RFTOOLS Library: Procedure, Test, and Parameter Descriptions

Test Descriptions

6. A screen plotting the results will be displayed. You have three

options:

a. Continue testing: press

k2 (Continue). You will have the choices

to:

i. Repeat the measurement or measure another device: press

(Repeat).

ii. Exit the test and return to the Select Test Menu: press

k5(Return).

b. Save the plot on an SRAM card: press

k4 (Save Plot) and enter a

filename when prompted.

c. Print a hardcopy of the graph: press

k5 (Scr Dump).

i. Make sure the printer is connected, and the test set is

configured appropriately. Test set must be in Control mode if

HP-IB is used.

ii. Press

iii. After the print is complete, press

SHIFT, PRINT.

k2 (Continue).

Parameters Used

• Parm_01 Sweep Start Frequency [.4 to 1000 MHz]

• Parm_02 Sweep Stop Frequency [.4 to 1000 MHz]

k1

• Parm_06 Inser. loss: maximum expected [−50 to 0]

• Parm_07 Inser. loss: DUPLEX OUT level [−54 to +10]

RF TOOLS Libr ary

Chapter 3

Chapter 3 41

S:\HP11807A\OPT100\MANUAL\rftools.fm

Page 42

RFTOOLS Library: Procedure, Test, and Pa rameter Desc riptions

Test Descriptions

Swept Return Loss Test

NOTE

The Test Signal Can Cause Interference (Setting Duplex Out

Power Level)

This test radiates a test signal when testing antennas or cables with

antennas attached to them. Verify that the level and frequency span

used for the test cannot result in interference to other nearby antennas.

When running the program, set the duplex out power level to a

minimum value for good measurement resolution. Set the frequency

range carefully.

If you are a cellular operator in an area with other receive antennas

nearby, you may want to use the AMPS Channel Return Loss test. This

test measures the return loss at a frequency offset from a selectable

range of AMPS channels. The offset (in kHz) from the AMPS channels

can be set.

This test measures the return loss of a cable or device in the swept

mode. A SWR bridge and a 6-dB pad are connected to the test set. The

pad is used to improve the mismatch between the SWR bridge and the

ANT IN port on the test set. You will be prompted at the start of the test

to enter the start and stop frequencies. A reference level is measured

with a short or open and the return loss is measured with the cable or

antenna-under-test. The trace showing return loss over the frequency

band selected is displayed on the screen. Measured values for best and

worst case return loss are printed at the top of the screen. VSWR can be

calculated from the return loss. The following Table 3-1 contains some

of the values from a calculation.

Table 3-1 Return Loss (0 to 20 dB) to VSWR

Return

Loss (dB)

VSWR

0 2 4 6 8 101214161820

infinity 8.7 4.4 3.0 2.3 1.92 1.67 1.50 1.38 1.29 1.22

Table 3-2 Return Loss (20 to 40 dB) to VSWR

Return

Loss (dB)

VSWR

20 22 24 26 28 30 32 34 36 38 40

1.22 1.17 1.13 1.11 1.08 1.07 1.05 1.04 1.03 1.03 1.02

42 Chapter 3

S:\HP11807A\OPT100\MANUAL\rftools.fm

Page 43

RFTOOLS Library: Procedure, Test, and Parameter Descriptions

Test Descriptions

The following formula can be used to determine the VSWR from the

return loss (=RL in dB):

RL–

--------- -

20

RL–

--------- -

20

–

VSWR

110+

-----------------------=

110

VSWR is sometimes stated as a ratio. For example: 1.2:1 or “one point

two to one” VSWR. The first number is given in the tables and formula.

The second number is always one.

Estimating Antenna Return Loss

If you are measuring the return loss of an antenna connected to the end

of a known good feed line, you can determine the approximate return

loss of the antenna by subtracting twice the line loss. For example, if

you measure a return loss of 24 dB and the line is known to have 2 dB

loss, the estimated return loss of the antenna is 20 dB. This estimate is

in error if the coaxial line and connectors do not have a return loss

somewhat greater than 24 dB.

NOTE

Running the Swept Return Loss Test

1. From the RFTOOLS Test Menu, select Swept Return Loss.

2. Enter your desired values for the start frequency, stop frequency,

duplex out level in dBm, and the maximum expected loss in dB.

The default values in this list can be changed by editing Parameters 1,

2, 8, and 9 in the Edit Parameter screen. See “RF Tools: Parameter

Descriptions” on page 61.

3. Press

4. Connect the cables as instructed, and press

k1 (Begin Tst).

k2 (Continue).

5. If Parm_22 Use data collection labels [0=No 1=Yes] is set to 1=Yes,

the software will prompt you with the option to label the data from

this test. Press k1 (Yes) if you want to label the data and follow the

instructions on the screen for selecting or creating a label. Press

k2

(No).

if you do not want to label the data.

RF TOOLS Libr ary

Chapter 3

Chapter 3 43

S:\HP11807A\OPT100\MANUAL\rftools.fm

Page 44

RFTOOLS Library: Procedure, Test, and Pa rameter Desc riptions

Test Descriptions

6. A screen plotting the results will be displayed. You have three

options:

• Continue testing: press

k2 (Continue). You will have the following

choices:

— Perform the test again: press

k1 (Repeat).

— Exit the test and return to the Select Test Menu: press

(Return).

• Save the plot on an SRAM card: press

k4 (Save Plot) and enter a

filename when prompted.

• Print a hardcopy of the graph: press

k5 (Scr Dump).

— Make sure the printer is connected, and the test set is

configured appropriately. Test set must be in Control mode if

HP-IB is used.

—Press

— After the print is complete, press

SHIFT, PRINT.

k2 (Continue).

Parameters Used

• Parm_01 Sweep Start Frequency [.4 to 1000 MHz]

• Parm_02 Sweep Stop Frequency [.4 to 1000 MHz]

k5

• Parm_08 Return loss: maximum expected [−50 to 0]

• Parm_09 Return loss: DUPLEX OUT level [−54 to +10]

44 Chapter 3

S:\HP11807A\OPT100\MANUAL\rftools.fm

Page 45

RFTOOLS Library: Procedure, Test, and Parameter Descriptions

Test Descriptions

AMPS Channel Return Loss Test

This test measures the return loss in a device for discrete cellular

AMPS channel frequencies. This test is performed at channels entered

by the user and offset by a frequency to make the measurement

between actual channels. A reference level is measured on the spectrum

analyzer with a short or open on the SWR bridge DUT port. The return

loss is then measured with the cable or antenna-under-test on the SWR

bridge DUT port.

This test should be used when there is a chance that a full frequency

sweep of the band to be tested may cause interference. In this test, the

chance of interference is greatly reduced by selecting an offset that sets

a CW test frequency between the assigned AMPS channels. For

example, selecting an offset of 15 kHz places the test signal between

adjacent AMPS channels and adjacent NAMPS channels.

See “Swept Return Loss Test” on page 42 description for a return loss

to VSWR conversion table and formula and a way to estimate the

return loss of an antenna connected to the end of a feed line.

CAUTION

NOTE

Running the AMPS Channel Return Loss Test

1. From the RFTOOLS Test Menu, select AMPS Channel Return Loss.

2. Enter your desired values for the start channel, stop channel, step

channel, offset frequency in MHz, band RX or TX, and duplex out

level in dBm.

To avoid overdrive damage to your device under test, ensure that you

are setting an appropriately low duplex out power level.

The default values in this list can be changed by editing Parameters

10-15 in the Edit Parameter screen. See “RF Tools: Parameter

Descriptions” on page 61.

3. Press

4. Connect the cables as instructed, and press

5. Measurement results will be displayed. Press

k1 (Begin Test).

k2 (Continue).

k1 (Repeat) if you

want to repeat the measurement or measure another device. Press

k5 (Return) if you want to exit this test.

RF TOOLS Libr ary

Chapter 3

Chapter 3 45

S:\HP11807A\OPT100\MANUAL\rftools.fm

Page 46

RFTOOLS Library: Procedure, Test, and Pa rameter Desc riptions

Test Descriptions

Parameters Used

• Parm_10 Discrete return loss: start chan [AMPS]

• Parm_11 Discrete return loss: stop chan [AMPS]

• Parm_12 Discrete return loss: channel step size

• Parm_13 Discrete return loss: off freq [0 to 20]

• Parm_14 Discrete return loss: band [0=FWD 1=REV]

• Parm_15 Discrete return loss: DUPLEX OUT [−54 to +10]

46 Chapter 3

S:\HP11807A\OPT100\MANUAL\rftools.fm

Page 47

Cable Fault Test

RFTOOLS Library: Procedure, Test, and Parameter Descriptions

Test Descriptions

NOTE

The Test Signal Can Cause Interference

When testing cables attached to antennas, test signals will be radiated.

Verify that the signal used for the test cannot result in interference to

another antenna. The software reduces the signal generator’s level

except when it is needed to actually perform the measurement.

This test operates over a wide frequency band. The test will always

operate with a center frequency of 505 MHz. The frequency span

however will be determined by the length of the cable measured. Longer

cables will use a narrower frequency span. The frequency span will

equal 990 MHz for cables less than 50 feet long and equal

approximately 99 MHz for cables 500 feet long. It is always safe to

assume that the frequency span is less than or equal to 990 MHz.

This test displays the return loss of a transmission line as a function of

the distance down the line. A frequency-swept signal from the DUPLEX

OUT port is applied through a resistive power divider to the

cable-under-test. Signals reflected from faults in the cable are combined

with the DUPLEX OUT signal in the power divider and applied to the

ANT IN port. The changing interference of the forward and reflected

signals, over the swept frequency band, contains information about the

distance to one or more faults. The software uses a Fast Fourier

Transform (FFT) to convert the frequency domain into the distance

domain. The distance displayed on the test set’s CRT is the physical

distance to the fault with correction for the velocity factor of the cable.

Cable Fault Performance

Measurements of the cable fault location can typically be made up to

500 feet on low-loss cables and 300 feet on higher-loss cables.

Resolution of the fault location is approximately 0.4 feet for cable

lengths up to 50 feet and then linearly increases to 4 feet for a 500 foot

cable.

RF TOOLS Libr ary

Chapter 3

Chapter 3 47

S:\HP11807A\OPT100\MANUAL\rftools.fm

Page 48

RFTOOLS Library: Procedure, Test, and Pa rameter Desc riptions

Test Descriptions

Selecting Cable Type

When this test is run, a screen will appear which will prompt you for

the following information:

• Cable length

• Cable length units

— Pressing the knob will toggle the selection between feet and

meters.

• Cable class

— Pressing the knob will provide for Heliax, RG, and custom

options.

• The next prompt varies depending on the selection for cable class:

— If Custom is selected, you will be prompted to enter the cable’s

velocity of propagation constant and attenuation per 100 feet (or

meters). The propagation velocity must be a value between 0 and

1.

NOTE

NOTE

— If RG is selected, you will be prompted to enter the cable type

with the example [RG 58/U = 58]. You must enter a value between

0 and 1000.

— If Heliax is selected, you will be prompted to enter the cable type.

A list will appear with choices of foam, air, and flex of varying

thickness. Push the knob to select the desired cable type.

• Select Begin Test when all the appropriate entries have been made.

• Connect the cables as instructed, and press

k2 (continue).

The default values in this list can be changed by editing Parameters

16-21 in the Edit Parameter screen. See “RF Tools: Parameter

Descriptions” on page 61.

Velocity Factors And Attenuation

Cables that use polyethylene dielectric typically have a propagation

velocity of 0.66, cables that use a teflon dielectric typically have a

propagation velocity of 0.70. If the cable attenuation is unknown, enter

0 dB per 100 feet (or meters). Entering 0 dB/100 will produce return

loss values lower than actual, but fault distance can be accurately

detected.

48 Chapter 3

S:\HP11807A\OPT100\MANUAL\rftools.fm

Page 49

RFTOOLS Library: Procedure, Test, and Parameter Descriptions

Test Descriptions

NOTE

Typical Cable Fault Return Loss Measurements

Return loss is a ratio of input power to reflected power. For example, if

100 Watts was applied to a cable and 10 Watts was returned, the return

loss is 10 dB (10 log (100/10)). In the same example, if 1 Watt was

returned, the return loss would be 20 dB (10 log (100/1)). Typical return

loss measurements for the cable loss test are listed below:

• Open-Circuit Cable = 0 dB

• Short-Circuit Cable = 0 dB

• 50-Ohm Terminated Cable = 20 to 30 dB

• Antenna = 10 to 20 dB

Return loss measurements below 25 dB should be considered excellent.

For best results, the cable output should be terminated in 50 ohms.

Entering Cable Length

The greatest accuracy is obtained when you enter a cable length

slightly greater than the actual cable length, considering length

uncertainty. If you are not sure of the cable length, enter a value 1.5

times the estimated length. Depending on the return loss of the

antenna or device at the end of the cable, you may see a high relative

mismatch displayed at the actual length of the cable.

NOTE

Parm_18 Cable fault: [0=RG 1=HELIAX 2=Custom] selects the cable

class. Parm_19 Cable type: [1>13 for Heliax, # for RG] sets the type of

cable to be measured. If the cable is ‘RG’, enter the RG type in parm_19

(for example: for type RG 58/U, enter 0=RG in parm_18, and ”58” in

parm_19). If the cable is Heliax, enter the number corresponding to the

list below in parm_19. If the cable is Custom, use parameters 20 and 21

to enter the cable attenuation and propagation velocity.

RF TOOLS Libr ary

Chapter 3

Chapter 3 49

S:\HP11807A\OPT100\MANUAL\rftools.fm

Page 50

RFTOOLS Library: Procedure, Test, and Pa rameter Desc riptions

Test Descriptions

HELIAX Cable Types

1. 3/8 foam

2. 1/2 foam

3. 7/8 foam

4. 1 1/4 foam

5. 1 5/8 foam

6. 1/2 air

7. 5/8 air

8. 7/8 air

9. 1 5/8 air

10.2 1/4 air

11.1/4 flex

12.3/8 flex

13.1/2 flex

50 Chapter 3

S:\HP11807A\OPT100\MANUAL\rftools.fm

Page 51

RFTOOLS Library: Procedure, Test, and Parameter Descriptions

Test Descriptions

Running the Cable Fault Test

1. From the RFTOOLS Test Menu, select Cable Fault.

2. Enter your desired values for the cable length, cable length units,

cable class, and cable type (see “Selecting Cable Type” on page 48).

NOTE

The default values in this list can be changed by editing parameters

16-21 in the Edit Parameter screen.

3. Press

k1 (Begin Tst).

4. Connect the cables as instructed, and press k2 (Continue).

5. If Parm_22 Use data collection labels [0=No 1=Yes] is set to 1=Yes,

the software will prompt you with the option to label the data from

this test. Press

instructions on the screen for selecting or creating a label. Press

k1 (Yes) if you want to label the data and follow the

k2

(No) if you do not want to label the data.

6. A screen plotting the results will be displayed. You have three

options:

a. Continue testing: press

k2 (Continue). You will have the choices

to:

i. Perform the test again: press

ii. Display the numerical data values: press

a. To return to the plot, press

ii. Exit the test and return to the Select Test Menu: press

k1 (Repeat).

k3 (Disp Data).

k3 (Plot Data).

k5

(Return).

b. Save the plot on an SRAM card: press

k4 (Save Plot) and enter a

filename when prompted.

RF TOOLS Libr ary

Chapter 3

c. Print a hardcopy of the graph: press

k5 (Scr Dump).

i. Make sure the printer is connected, and the test set is

configured appropriately. Test set must be in Control mode if

HP-IB is used.

ii. Press S

iii. After the print is complete, press

Chapter 3 51

S:\HP11807A\OPT100\MANUAL\rftools.fm

HIFT, PRINT.

k2 (Continue).

Page 52

RFTOOLS Library: Procedure, Test, and Pa rameter Desc riptions

Test Descriptions

Parameters Used

• Parm_16 Cable fault: cable length

• Parm_17 Cable fault: length units [0=ft 1=m]

• Parm_18 Cable fault: [0=RG 1=HELIAX 2=Custom]

• Parm_19 Cable type: [1>13 for Heliax, # for RG]

• Parm_20 Cable fault: custom cable attenuation (dB/unit)

• Parm_21 Cable fault: custom cable prop. velocity (<1.0)

Interpreting Cable Fault Location Results

Distance to the cable fault is accurately quantified when you select the

USER Disp data field. The return loss levels and distance at which the

faults occur are displayed. Numeric data for the six smallest return loss

values of data from the graph are listed. Values greater than 25 dB can

be ignored. The smallest return loss is most likely the location of a cable

fault. Other numeric data points, particularly if they are further down

the line from a point of high relative mismatch, can be ignored. Data

points on the fringe of a point of high relative mismatch are usually

attributable to the single fault.

52 Chapter 3

S:\HP11807A\OPT100\MANUAL\rftools.fm

Page 53

RFTOOLS Library: Procedure, Test, and Parameter Descriptions

Test Descriptions

ERP Calculator

This test automatically calculates ERP (effective radiated power), when

you enter the data for the following variables:

• Input Power

• Feed Cable Loss

• Antenna Gain

This test also allows you the option to enter the ERP and two other

variables to automatically calculate the third. (For example, you may

enter the values for ERP, Input Power, and Feed Cable Loss. The

software will calculate the Antenna Gain).

You may select from the following three options for the units of power

displayed:

•dBm

•Watts

•dBw

The software uses the following equation to make the calculations

described above:

ERP

= Input Power

dBW

− Feed Loss

dBW

+ Antenna GaindB

dB

Running the ERP Calculator Test

1. From the RFTOOLS Test Menu, select ERP Calculator.

2. Position the cursor to the Item to be calculated field and select

it.

a. Select the variable you wish the software to calculate. The choices

are ERP, Input power, Feed cable loss, and Antenna gain.

3. Position the cursor to the Units field and select the desired units:

a. A list will appear with the following choices: Watts, dBW and

dBm.

4. Enter the values for the three known variables.

5. The software will automatically calculate the unknown variable.

Parameters Used

RF TOOLS Libr ary

Chapter 3

• No parameters are used in this test.

Chapter 3 53

S:\HP11807A\OPT100\MANUAL\rftools.fm

Page 54

RFTOOLS Library: Procedure, Test, and Pa rameter Desc riptions

Test Descriptions

Replot Data Files

This test allows you to easily retrieve and display plots which were

previously stored on an SRAM card. One or two plots may be displayed

at one time.

No measurements are performed.

For information on how to store plot data on an SRAM card, see

descriptions of “Swept Gain Test” on page 38, “Swept Insertion Loss

Test” on page 40, “Swept Return Loss Test” on page 42, and “Cable

Fault Test” on page 47.

Displaying One Plot at a Time

1. From the RFTOOLS Test Menu, select Replot Data Files.

2. Insert the memory card containing the plot data files.

3. Files saved on the card will be listed below the double line. Select the

Select files to replot field.

4. Select the plot file(s) you wish to display (if you select more than one,

they will be displayed consecutively with a pause in between).

5. Press

k5 (Return).

6. Select the Replot files selected below field.

✓ A screen plotting the results will be displayed. You have three

options:

— Continue the procedure: press

k2 (Continue). If you selected

more than one plot, the next will be displayed. Otherwise, you

will have the following choices:

— Exit the test and return to the Select Test Menu: press

k5 (Exit Test).

— Select additional files to replot.

— Store the plot on an SRAM card: press

k4 (To Card) and enter

a filename when prompted.

— Print a hardcopy of the graph: press

k5 (Scr Dump).

— Make sure the printer is connected, and the test set is

configured appropriately. Test set must be in Control mode

if HP-IB is used.

—Press

— After the print is complete, press

SHIFT, PRINT.

k2 (Continue).

✓ If you would like to delete plot files from the card, select Purge

(Delete) Selected Files.

✓ Press

54 Chapter 3

k5 (Exit Test) to exit.

S:\HP11807A\OPT100\MANUAL\rftools.fm

Page 55

RFTOOLS Library: Procedure, Test, and Parameter Descriptions

Test Descriptions

Displaying Two Plots on One Screen at the Same Time

1. From the RFTOOLS Test Menu, select Replot Data Files.

2. Insert the memory card containing the plot data files.

3. Select the Plot two files on one screen field.

4. Select the Legend location field, and select the desired location for

the plot reference key. When the plots are displayed, the key covers

part of the graph. Choose the location that will least interfere with

viewing your plot. The selections toggle between top and bottom.

5. Select the Primary plot file name field. The list of files stored on

the memory card will appear. The files ending with _p (or .PLT for

HP11807E) represent plot files. The primary plot data determines

the scale for the graph.

6. Select your desired primary data file.

7. Select the Secondary plot file name field. The list of files stored

on the memory card will again appear.

8. Select your desired secondary data file.

9. Press

k1 (Plot). A screen plotting the results will be displayed. You

have three options:

• Move the legend: press

k4 (Legend) to refresh the screen, moving

the legend to the alternate location.

• Continue the procedure: press

k2 (Continue). You will have the

following choices:

— Return to the RFTOOLS Test Menu: press

— Select additional files to plot.

• Print a hardcopy of the graph: press

k5 (Scr Dump).

— Make sure the printer is connected, and the test set is

configured appropriately. Test set must be in Control mode if

HP-IB is used.

—Press

— After the print is complete, press

SHIFT, PRINT.

k2 (Continue).

Parameters Used

k5 (Return).

RF TOOLS Libr ary

Chapter 3

• No parameters are used in this test.

Chapter 3 55

S:\HP11807A\OPT100\MANUAL\rftools.fm

Page 56

RFTOOLS Library: Procedure, Test, and Pa rameter Desc riptions

Test Descriptions

Transfer Stored Data

This test may be used to easily transfer data collection (test results)

files from an SRAM card over the serial or HP-IB port. You do not need

to write an IBASIC program. No measurements are performed.

Transferring Stored Data

1. From the RFTOOLS Test Menu, select Transfer Stored Data.

2. Insert the memory card containing the test results.

3. Select the appropriate output port: a list will appear with the

selections serial port, parallel port and HP-IB, Addr 701.

4. Make sure the appropriate cables are connected, and serial or HP-IB

settings are correct on the I/O Configure screen (To Screen menu,

select More, IO CONFIG.

5. Files saved on the card will be listed below the double line. Select the

files you wish to transfer.

• Select the files you would like to transfer. An asterisk will appear

after the selected files.

•Press the Select/Deselect Files [*=Selected] field.

• Select Return to menu.

6. Select Transfer Selected Files.

7. Once the files are transferred, if you would like to delete the files

from the card, select Purge (Delete) Selected Files.

8. Press

k5 (Return) to return to the RFTOOLS Test Menu.

Parameters Used

• Parm_23 Show all data files [0=No 1=Yes]

56 Chapter 3

S:\HP11807A\OPT100\MANUAL\rftools.fm

Page 57

RFTOOLS Library: Procedure, Test, and Parameter Descriptions

Test Descriptions

SA Self Calibration ON/OFF

This test allows you to check the status of the test set’s spectrum

analyzer, and change the status if you desire.

The RFTOOLS program uses the test set’s internal spectrum analyzer

for making network analyzer measurements. The internal spectrum

analyzer performs an automatic self calibration every 5 minutes. This

automatic self calibration insures that the spectrum analyzer operates

within specified limits regardless of the operating temperature.

However, this self calibration can introduce instability in spectrum

analyzer output after the test set is operating at a constant

temperature (after approximately 30 minutes).

Each RFTOOLS test includes two parts; calibration and measurement.

If the spectrum analyzer performs a self calibration between the

calibration and measurement of the RFTOOLS test, the spectrum

analyzer automatic self calibration instability will increase RFTOOLS

test measurement error. To avoid this problem, you may use this test to

turn off the spectrum analyzer self calibration. This self calibration

should only be turned off after the unit has reached a constant

powered-on operating temperature (approximately 30 minutes after

power-on). By turning the self calibration off, the measurement

accuracy and stability of RFTOOLS tests will improve.

RF TOOLS Libr ary

Chapter 3

Chapter 3 57

S:\HP11807A\OPT100\MANUAL\rftools.fm

Page 58

RFTOOLS Library: Procedure, Test, and Pa rameter Desc riptions

Test Descriptions

Catalog Memory Card

This test lists all the files contained on the memory card. The memory

card that you wish to catalog must be inserted prior to selecting this

test.

LIF file types are denoted by the following prefixes and suffixes:

• c prefix denotes a program code file

• l prefix denotes a library file

• p prefix denotes a procedure file

• _d suffix denotes a data file

• _p suffix denotes a plot file

DOS file types are denoted by the following suffixes:

• .PGM suffix denotes a program code file

• .LIB suffix denotes a library file

• .PRC suffix denotes a procedure file

• .DAT suffix denotes a data file

• .PLT suffix denotes a plot file

Parameters Used

• No parameters are used in this test.

58 Chapter 3

S:\HP11807A\OPT100\MANUAL\rftools.fm

Page 59

RFTOOLS Library: Procedure, Test, and Parameter Descriptions

Test Descriptions

Create/Edit Data Collection Labels

This test will only appear on the RFTOOLS Test Menu, if Parm_22 Use

data collection labels [0=No 1=Yes] is set to 1=Yes. If this parameter is

set to 1=Yes , before performing the measurement the software will

prompt: Would you like to label the data from this test?. If

you press

choices:

• Return to testing without labeling data (in case you pressed Yes by

mistake).

• Enter label manually, and select label from a list.

This test allows you to create and edit files containing up to 50 labels to

be stored on an SRAM card. These labels can be used later for labeling

test output, in conjunction with the data collection function. Data

collection allows you to store all the test data in a file which is named at

the beginning of the test procedure. Data collection labels allow you to

label each individual measurement. Data collection label files are

stored under the filename uLAB_#, where # can be any value between 1

and 999.

k1 (Yes), the software will prompt you with the following

When test results are stored to a data collection file, (sent to a PC or

printer) it may be convenient to separate the data by labeling each

measurement. For example, you may want to test the insertion loss of

several test cables without repeating the calibration step in between

measurements. The first five tests on the RFTOOLS Test Menu permit

repetitive testing after initial calibrations are performed.

There are two ways to create data collection labels: using this test to

create and store the labels, or waiting until you have a measurement

that you would like to label and creating it then. For either method, you

must set parm_22 Use data collection labels [0=No 1=Yes] to 1=Yes. If

you would like to use the same label(s) several times, it would be useful

to run this test to create the labels and store them in a file which can be

retrieved when desired. If it is not likely that you will use the same

label several times, but you would still like to label the test output, you

may do so when prompted.

Labels can be entered using the characters in the Choices menu, or by

using a terminal emulator program. See “Collection to a PC” on page

100 for information on setting up a terminal emulation program.

RF TOOLS Libr ary

Chapter 3

Chapter 3 59

S:\HP11807A\OPT100\MANUAL\rftools.fm

Page 60

RFTOOLS Library: Procedure, Test, and Pa rameter Desc riptions

Test Descriptions

Creating/Editing Data Collection Labels

1. From the RFTOOLS Test Menu, select Create/Edit Data Collection

Labels.

2. A screen will appear with the following choices:

• Return to the previous menu

— This selection will return you to the RFTOOLS Test Menu.

• Select label filename

— This field is used to create or retrieve the data collection label

filename. Label files are stored as uLAB_#, where # is the

number entered in this field.

• Store labels to file

— This selection will store the label file to the inserted smart

card, under the current filename (see field above).

• Purge label file

— This selection will delete the current label file from the smart

card.

• Edit labels shown below

— This selection will allow access (for editing) to the labels that

appear below the double line.

• Below the double line, fields labeled L1-L50 appear.

— Scroll the cursor to these fields to enter your desired labels. Up

to fifty labels can be stored for each location. Use k2 (Page Up)

and k4 (Page Down) to quickly scroll through this list if

necessary. (This list is accessed by selecting the Edit labels

shown below field, described above).

—Press

k5 (Return) to return to the menu above the double line.

3. Select the Edit labels shown below field.

4. Enter your desired labels.

5. Press

k5 (Return).

6. Select the Select label file name field. Remember that this

number will be used to retrieve the file when desired.

7. Select the Store labels to file field. You will be prompted with

“Do you want to store data collection labels to uLAB_#?” Select

k1(Yes) if you would like to continue.

8. Press

k5 (Return).

Parameters Used

• Parm_22 Use data collection labels [0=No 1=Yes]

60 Chapter 3

S:\HP11807A\OPT100\MANUAL\rftools.fm

Page 61

RFTOOLS Library: Procedure, Test, and Parameter Descriptions

RF Tools: Parameter Descriptions

RF Tools: Parameter Descriptions

Parameters are used to define the conditions under which a test will

run. You may edit the parameters to change the default values, to meet

your specific testing needs and conditions. Parameters may be used in

one or more tests.

For information on editing parameters, see “Customizing Testing” on

page 20.

Parm_01 Sweep Start Frequency [.4 to 1000 MHz]

Enter the starting frequency for swept tests (tests 1 through 3). If the

start frequency is less than 2 MHz, the frequency span (Parm_02 and

Parm_01) must be less than 10 MHz.

This entry will appear as the default on the sweep information menu

each time a swept test begins to run. You have the option to use the

menu to change this value for the current test.

Parm_02 Sweep Stop Frequency [.4 to 1000 MHz]

Enter the stopping frequency for swept tests (tests 1 through 3). The

stop frequency must be greater than the start frequency (entered in

parm_01).

This entry will appear as the default on the sweep information menu

each time a swept test begins to run. You have the option to use the

menu to change this value for the current test.

Parm_03 Gain: plot scale [1, 5, 10] (dB/div)

Enter the desired plot scale for the Swept Gain test. This entry will

appear as the default on the swept gain information menu each time

the swept gain test begins to run. You have the option to use the menu

to change this value for the current test.

RF TOOLS Libr ary

Chapter 3

Chapter 3 61

S:\HP11807A\OPT100\MANUAL\rftools.fm

Page 62

RFTOOLS Library: Procedure, Test, and Pa rameter Desc riptions

RF Tools: Parameter Descriptions

Parm_04 Gain: maximum expected gain [−50 to 20]

(dB)

Enter the maximum expected gain for the Swept Gain test. This

parameter sets the expected worst case power for the ANT IN port. It is

very important to overestimate the expected gain to avoid damage to

the ANT IN port.

This parameter is also used to set the plot resolution (top value of the

plot).

This entry will appear as the default on the swept gain information

menu each time the swept gain test begins to run. You have the option

to use the menu to change this value for the current test.

Parm_05 Gain: DUPLEX OUT level [−54 to +10] (dBm)

Enter the desired DUPLEX OUT level for the Swept Gain test. If you

are testing a power sensitive device, be sure to enter an appropriately

low level to avoid damage.

This entry will appear as the default on the swept gain information

menu each time the swept gain test begins to run. You have the option

to use the menu to change this value for the current test.

Parm_06 Inser. loss: maximum expected [−50 to 0]

Enter the maximum expected loss for the Swept Insertion Loss test.

This parameter is used to set the plot resolution (the bottom limit of the

plot).

This entry will appear as the default on the swept insertion loss

information menu each time the swept insertion loss test begins to run.

You have the option to use the menu to change this value for the current

test.

Parm_07 Inser. loss: DUPLEX OUT level [−54 to +10]

Enter the desired DUPLEX OUT level for the Swept Insertion Loss

test. If you are testing a power sensitive device, be sure to enter an

appropriately low level to avoid damage.

This entry will appear as the default on the swept insertion loss

information menu each time the swept insertion loss test begins to run.

You have the option to use the menu to change this value for the current

test.

62 Chapter 3

S:\HP11807A\OPT100\MANUAL\rftools.fm

Page 63

RFTOOLS Library: Procedure, Test, and Parameter Descriptions

RF Tools: Parameter Descriptions