$JLOHQW7HFKQRORJLHV,QF

(0LVVLRQ

/LEHUW\/DNH:$

-XQH

ZZZDJLOHQWFRP

Dear Customer,

As of November 1, 1999, four of Hewlett-Packard’s businesses, test and measurement,

semiconductor products, health care solutions, and chemical analysis became a new company,

Agilent Technologies. Now, many of your Hewlett-Packard products and services are in the care of

Agilent Technologies.

At Agilent Technologies, we are working diligently to make this transition as smooth as possible for

you. However, as a result of this transition, the products and related documentation contained in this

shipment may be labeled with either the Hewlett-Packard name and logo, the Agilent Technologies

name and logo, or a combination of both. Information in this package may refer to Hewlett-Packard

(HP), but applies to your Agilent Technologies product. Hewlett-Packard and Agilent branded

products with the same model number are interchangeable.

Whatever logo you see, the information, products, and services come from the same reliable source.

If you have questions about Agilent Technologies products and services, please visit our website at

http://www.agilent.com.

6LQFHUHO\

5HEUDQGLQJ7HDP

HP

8901B

MODULATION

Service

SERIAL

This

manual provides complete information for in-

2314A

struments

to

2914A

For

numbers, refer

THIS

This

Government pursuant

der the clause at DFARS

with

serial-number prefixes:

and all

additional important information about serial

MANUAL"

material may be reproduced by

MAJOR

rev.

to

"INSTRUMENTS

in Section

Fourth Edition

ANALYZER

Manual

NUMBERS

changes that

12NOV92

1.

to

the Copyright License

52.227-7013

occur

COVERED

or

for the

(APR

to

your

1988).

instrument.

BY

US.

un-

Copyright@ H EWLETT-PACKARD COMPANY 1 987

EAST 24001 MISSION AVENUE, TAF C-34, SPOKANE, WASHINGTON, U.S.A. 99220

Service Manual (Volume 1, 2,

Other Documents Available:

Operation and Calibration Manual HP Part 08901-901

Basic Operation and Application Guide 08901-901

Microfiche Operation and Calibration Manual HP Part 08901-901 15

Microfiche Service Manual

3)

HP Part 08901-901 14

13

17

HP

Part 08901-901 16 Printed in USA. : April 1995

Pia

HEWLETT

PACKARD

1

Regulatory Information

(Updated

March

1999)

1

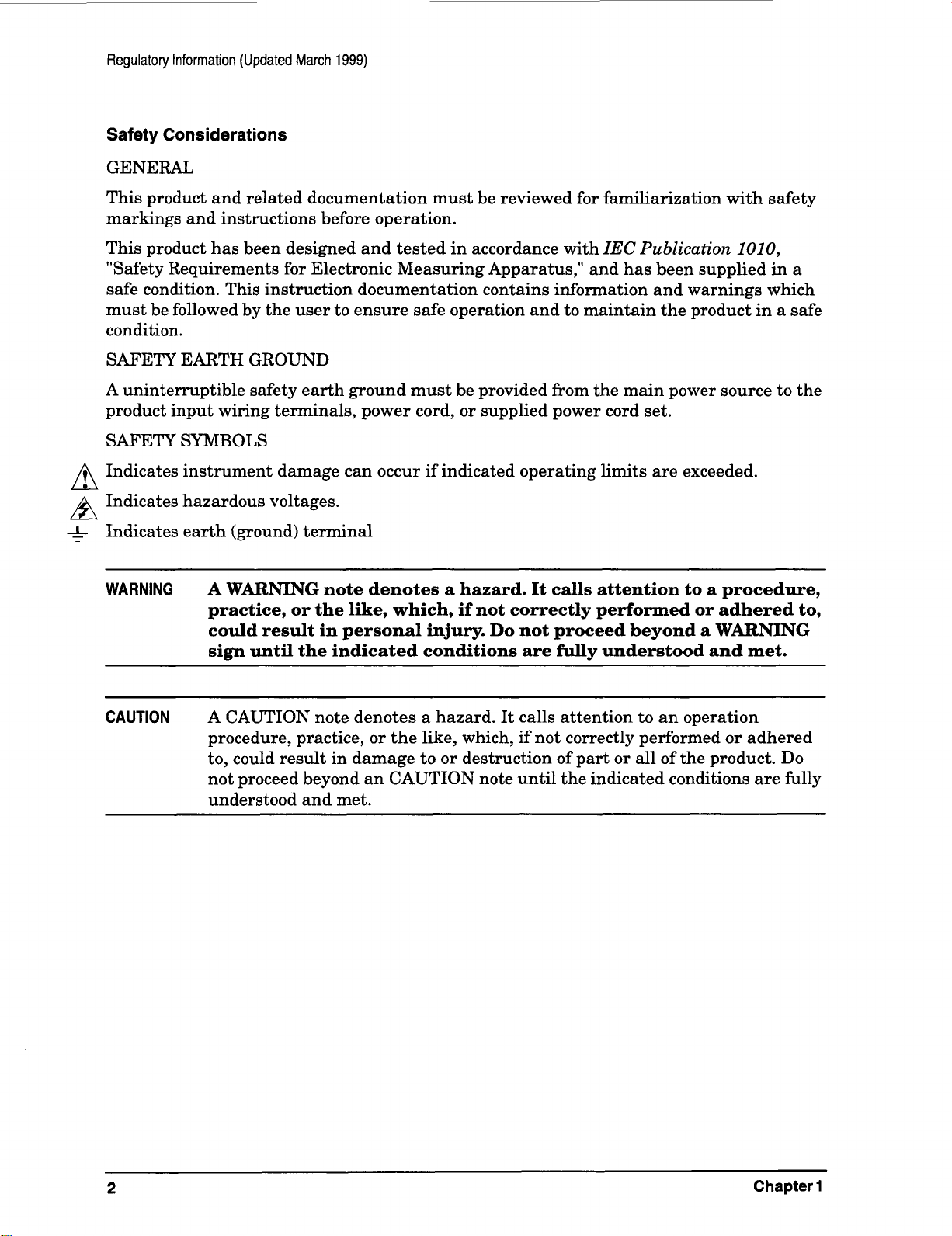

Regulatory Information (Updated March 1999)

Safety Considerations

GENERAL

This product and related documentation must be reviewed for familiarization

markings and instructions before operation.

This product

"Safety Requirements for Electronic Measuring Apparatus," and

safe condition. This instruction documentation contains information and warnings which

must be followed by the user to ensure safe operation and to maintain the product

condition.

SAFETY

A uninterruptible safety earth ground

product input wiring terminals, power cord, or supplied power cord set.

SAFETY

A

Indicates instrument damage can occur if indicated operating limits are exceeded.

A

Indicates hazardous voltages.

Indicates earth (ground) terminal

4

-

WARNING

has

been designed and tested in accordance with

EARTH

GROUND

SYMBOLS

A

WARNING

IEC

Publication

has

been supplied

must

be provided from the main power source to the

note denotes a hazard. It calls attention to a procedure,

with

practice, or the like, which, if not correctly performed or adhered to,

could result in personal injury.

sign until the indicated conditions are

Do

not proceed beyond a

fully

understood and met.

WARNING

safety

1010,

in

in

a

a

safe

CAUTION

A CAUTION note denotes a hazard.

procedure, practice, or the like, which, if not correctly performed or adhered

to, could result in damage to or destruction of part or

not proceed beyond

understood and met.

an

CAUTION note

It

calls attention to

until

the indicated conditions

an

operation

all

of the product.

are

Do

fully

2

Chapter

1

Safety Considerations for this Instrument

Regulatory

Information

(Updated

March

1999)

WARNING

This product is a Safety Class I instrument (provided with a

protective earthing ground incorporated in the power cord). The

a

mains plug shall only be inserted in

protective earth contact.

conductor inside

or

Any

outside

interruption

of

the product is likely to make the

product dangerous. Intentional interruption

Whenever

it

is

likely that the protection has been impaired, the

socket outlet provided with

of

the protective

is

prohibited.

instrument must be made inoperative and be secured against any

unintended operat ion.

If

this instrument

is

to be energized via an auto transformer

(for

voltage reduction), make sure the common terminal is connected to

the earth terminal of the power source.

If

this product

is

not used

as

specified, the protection provided by

the equipment could be impaired. This product must be used in a

normal condition (in which

No

operator serviceable parts in this product. Refer servicing

all

means for protection are intact) only.

to

qualified personnel. To prevent electrical shock, do not remove

covers.

Servicing instructions are for use by qualified personnel only.

To

avoid electrical shock, do not perform any servicing unless you are

qualified to do

so.

a

The opening of covers or removal of parts

dangerous voltages. Disconnect the product from

is

likely to expose

all

voltage sources

while it is being opened.

The power cord is connected to internal capacitors that

live for

5

seconds after disconnecting the plug from its power supply.

my

remain

For Continued protection against fire hazard, replace the line fuse(s)

only with

example, normal blow

250

V

fuse(s) or the same current rating and type (for

or

time delay). Do not use repaired fuses

or

short circuited fuseholders.

Always use the three-prong ac power cord supplied with this

product. Failure to ensure adequate earth grounding by not using

this cord may cause product damage.

This product

Pollution Degree

INDOOR

USE

is

designed

2

ONLY.

per

for

ZEC

use in Installation Category

1010

and

ZEC

664

respectively. FOR

I1

and

This product has autoranging line voltage input, be sure the supply

voltage

is

within the specified range.

Chapter

1

3

Regulatory Information (Updated March

To

prevent electrical shock, disconnect instrument

before cleaning. Use a dry cloth or one slightly dampened with water

to

clean the external case parts.

Ventilation Requirements: When installing the product in a cabinet,

the convection into and out of the product must not be restricted.

The ambient temperature (outside the cabinet) must be less than the

maximum operating temperature of the product by

watts dissipated in the cabinet.

cabinet is greater than

used.

1999)

from

Do

not attempt

If

the total power dissipated in the

800

watts, then forced convection must be

to

clean internally.

4"

C

for

mains (line)

every

100

Product

CE - the CE mark

Markings

is

a

registered trademark

of

the European Community. A CE mark

accompanied by a year indicated the year the design was proven.

CSA - the

CSA

mark

is

a registered trademark

of

the Canadian Standards Association.

4

Chapter

1

Model

8901B

Service

SAFETY CONSIDERATIONS

GENERAL

This product and related documentation must be reviewed for familiarization with safety markings and

instructions before operation.

This product is a Safety Class I instrument (provided

with a protective earth terminal).

BEFORE APPLYING

Verify that the product is set to match the available

line voltage and the correct fuse is installed.

POWER

SAFETY EARTH GROUND

An uninterruptible safety earth ground must be provided from the main power source to the product input

or

wiring terminals, power cord,

set.

supplied power cord

SAFETY SYMBOLS

Instruction manual symbol: the product will

A

is

manual (refer to Table of Contents).

be marked with this symbol when it

necessary for the user

Indicates hazardous voltages.

to

refer to the instruction

I

WARNING

Any interruption of the protective (ground-

ing) conductor (inside

or

ment)

terminal will cause a potential shock hazard

that

ing one conductor of a two conductor outlet

is not sufficient protection).

Whenever it

been impaired, the instrument must be made

inoperative and be secured against any unin-

tended operation.

If this instrument

autotransformer (for voltage reduction) make

sure the common terminal is connected to the

earth terminal of the power source.

Servicing instructions are for use by servicetrained personnel only.

electric shock,

unless qualified to do

disconnecting the protective earth

could result

is

likely that the protection has

do

or

outside the instru-

in

personal injury. (Ground-

is

to be energized via an

To

avoid dangerous

not perform any servicing

so.

Indicates earth (ground) terminal.

The WARNING sign denotes a

hazard. It calls attention to a

or

procedure, practice,

or

performed

Do

jury.

the indicated conditions are fully understood and met.

operating procedure, practice,

correctly performed

to

age

or

not proceed beyond a CAUTION sign until the indicated conditions are fully understood and met.

adhered to, could result in personal in-

not proceed beyond a WARNING sign until

destruction of part

the like, which,

The CAUTION sign denotes a haz-

It

ard.

or

calls attention to an

or

adhered to, could result in dam-

or

all of the product.

if

not correctly

the like, which,

if

not

Do

Adjustments described

formed with power supplied to the instrument

while protective covers are removed. Energy

available at many points may,

sult

in

personal injury.

Capacitors inside the instrument may still be

charged even if the instrument has been disconnected from its source of supply.

For

continued protection against fire hazard,

replace the line fuse(s) only with

of the same current rating and type (for exam-

ple, normal blow, time delay, etc.).

repaired fuses

fuseholders.

in

the manual are per-

if

contacted, re-

250V

Do

or

short circuited

fuse(s)

not use

ATTENTION

Static Sensitive

Devices

This instrument was constructed

protected environment. This

devices used

discharge.

Depending on the magnitude of

punctured

The results can cause degradation of device performance, early failure,

or

immediate destruction.

These charges are generated

separation of materials, and normal motions of persons working with

static sensitive devices.

When handling

devices, adequate precautions

or

destruction.

Only those who are thoroughly familiar with industry accepted

techniques for handling static sensitive devices should attempt to

service circuitry with these devices.

In

all instances, measures

build-up on work surfaces and persons handling the devices.

in

this instrument are susceptible to damage

or

destroyed

by

contact

or

servicing equipment containing static sensitive

in

an ESD (electro-static discharge)

is

because most of the semi-conductor

by

the

charge, device substrates can be

or

mere proximity of a static charge.

in

numerous ways such

must

be taken to prevent device damage

must

be taken to prevent static charge

as

simple contact,

static

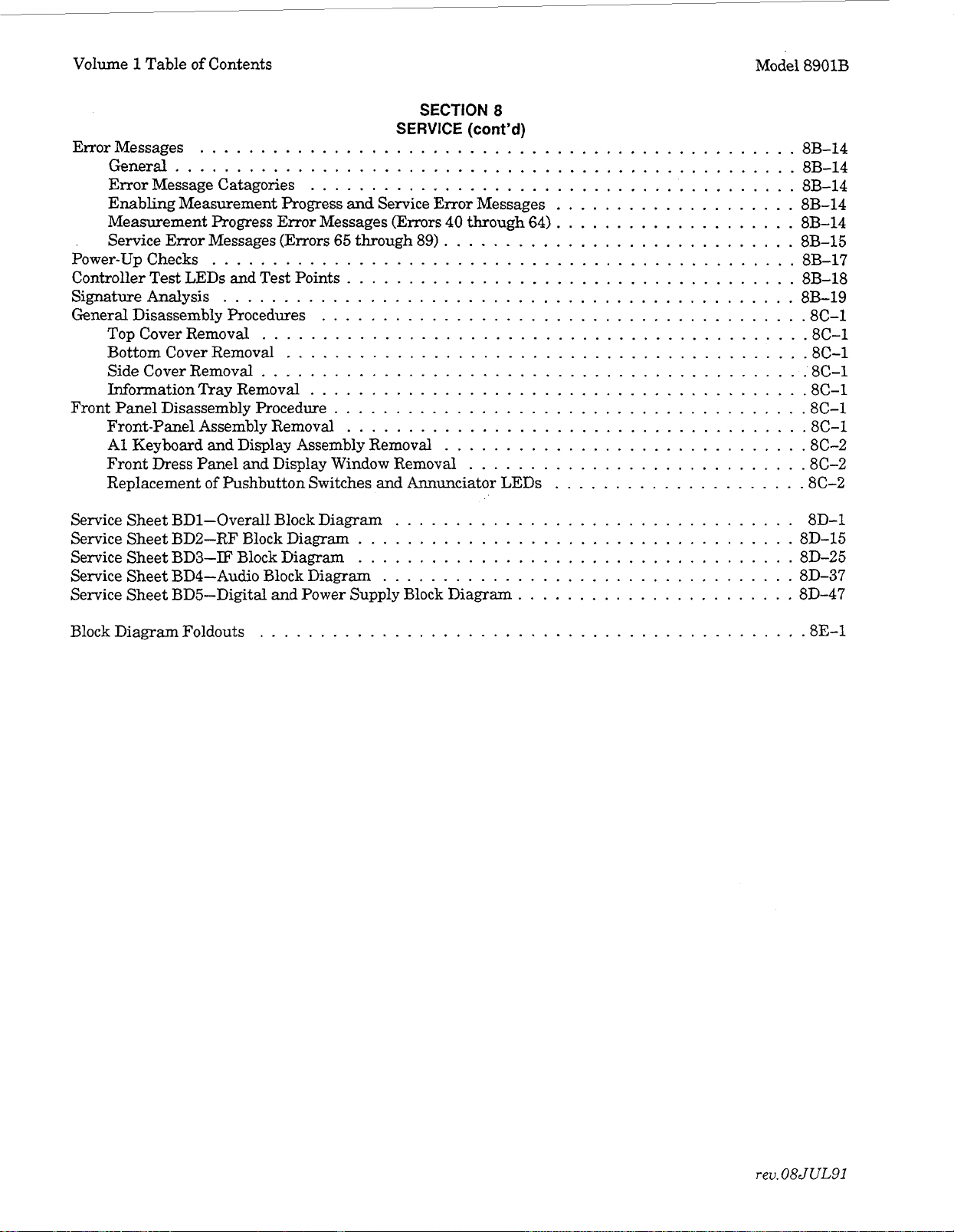

Model 8901B

Volume 1 Table of Contents

VOLUME

Introduction

Reference Designators and Abbreviations

Replaceable

OrderingParts

Replaceable

Mechanical and Chassis

Recommended Spares List

Introduction

Firmware Change

Introduction

How

This

Safety Considerations

Before Applying Power

Safety

Service

Service Accessory Kit

Heat-Staking

Assembly Locations

Parts

Other Service Documents

Recommended Test Equipment

General Troubleshooting

Operator Errors

Operation Out

Catastrophic Failures

Schematic Symbology and Schematic Diagram Notes

Special Functions

General

Direct Control Special Functions (Prefix

Service Special Functions (Prefm

To

This

Parts

Section

List

...........................................

..............................................

................................................

Parts

List Updating

Part

(Manual

Locations and Reference Designations

............................................

to

This

Section

Summary

to

This

Section

Section is Organized

..............................................

....................................................

Tools

and Aids

Tool

and Cable Locations

..............................................

of

Specifcation

................................................

....................................................

...........................................

(23l4A

..........................................

.........................................

..........................................

.............................................

...........................................

.............................................

............................................

........................................

.........................................

............................................

...........................................

1

TABLE

SECTION 6

REPLACEABLE PARTS

....................................

Updates)

SECTION

INSTRUMENT CHANGES

to

2644A)

and

......................................

40-99)

.................................

SECTION

SERVICE

Accessories

0)

.....................

................................

OF

CONTENTS

..............................

....................

7

8

............................

............................

:

.........

6-1

6-1

6-1

6-1

6-2

6-2

6-2

7-1

7-1

8A-1

8A-1

8A-2

8A-2

8A-2

8A-3

8A-3

8A-4

8A-4

8A-5

8A-5

8A-5

8A-5

8A-5

8A-5

8A-6

8A-10

.8 B-1

8B-1

.8

B-1

.8 B-5

rev.08JUL91

~

Volume 1 Table

Error Messages

General

Error Message Catagories

Enabling Measurement Progress

Measurement Progress Error Messages (Errors

Service Error Messages (Errors

Power-Up Checks

Controller Test LEDs and Test Points

Signature Analysis

General Disassembly Procedures

Top Cover Removal

Bottom Cover Removal

Side Cover Removal

Wormation Tray Removal

Front Panel Disassembly Procedure

Front-Panel Assembly Removal

A1 Keyboard and Display Assembly Removal

Front

Replacement

of

Contents

.................................................

...................................................

........................................

and

65

through 89)

................................................

.....................................

...............................................

.......................................

............................................

..........................................

............................................

........................................

......................................

.....................................

Dress Panel and Display Window Removal

of

Pushbutton Switches and Annunciator LEDs

SECTION

SERVICE

Service Error Messages

40

8

(cont’d)

through 64)

.............................

.............................

...........................

Model 8901B

....................

....................

....................

8B-14

8B-14

8B-14

8B-14

8B-14

8B-15

8B-17

8B-18

8B-19

.8

C-1

.8

C-1

.8

C-1

.8

C-1

.8

C-1

.8

C-1

.8

C-1

.8

C-2

.8

C-2

.8

C-2

Service Sheet BD1-Overall Block Diagram

Service Sheet BD2-RF Block Diagram

Service Sheet BD3-IF Block Diagram

Service Sheet BD4-Audio Block Diagram

Service Sheet BD5-Digital

Block Diagram Foldouts

and

Power Supply Block Diagram

............................................

....................................

....................................

.................................

..................................

.......................

8D-1

8D-15

8D-25

8D-37

8D-47

.8

E.l

rev.08JUL91

Model

8901B

Replaceable

Parts

Section

6

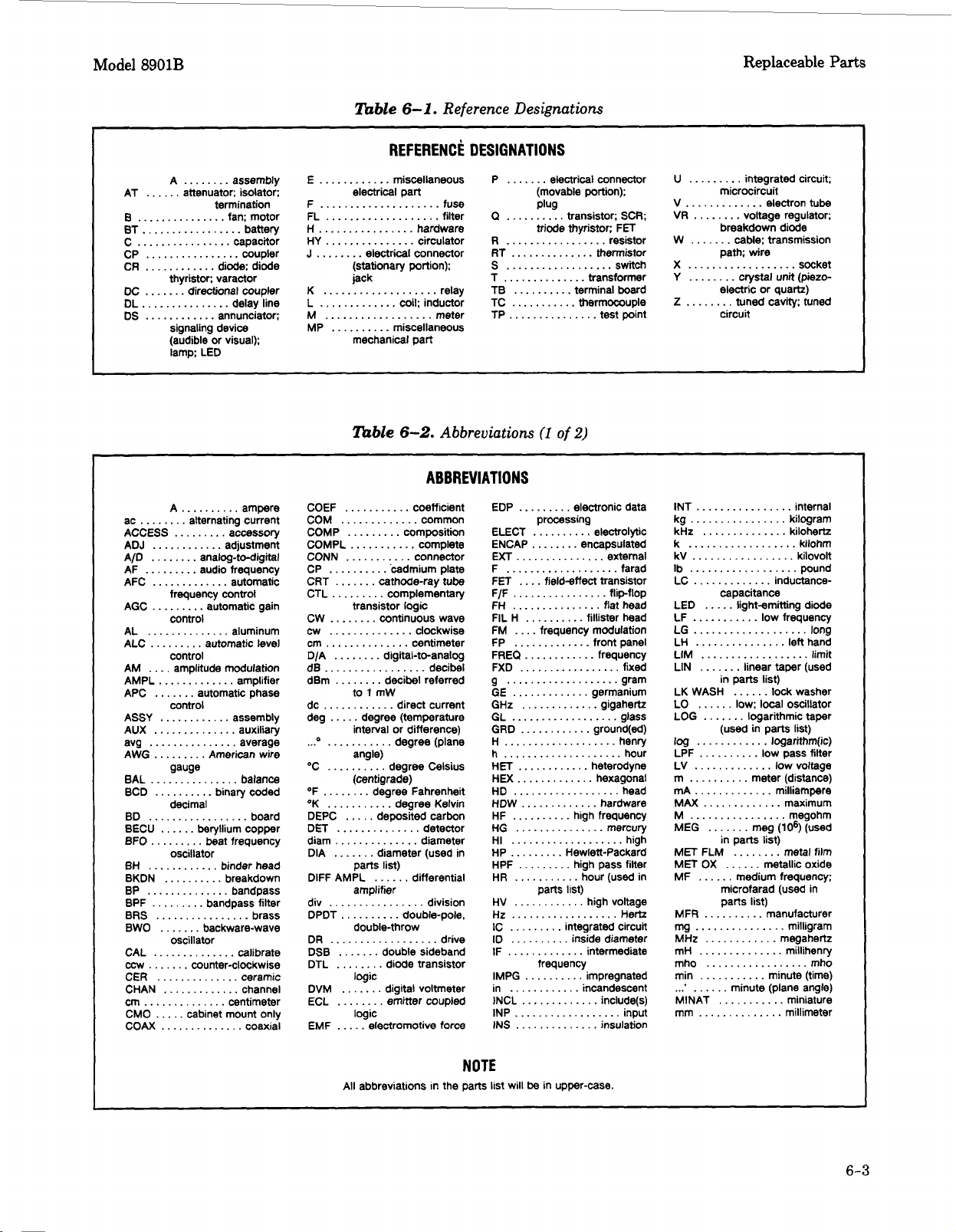

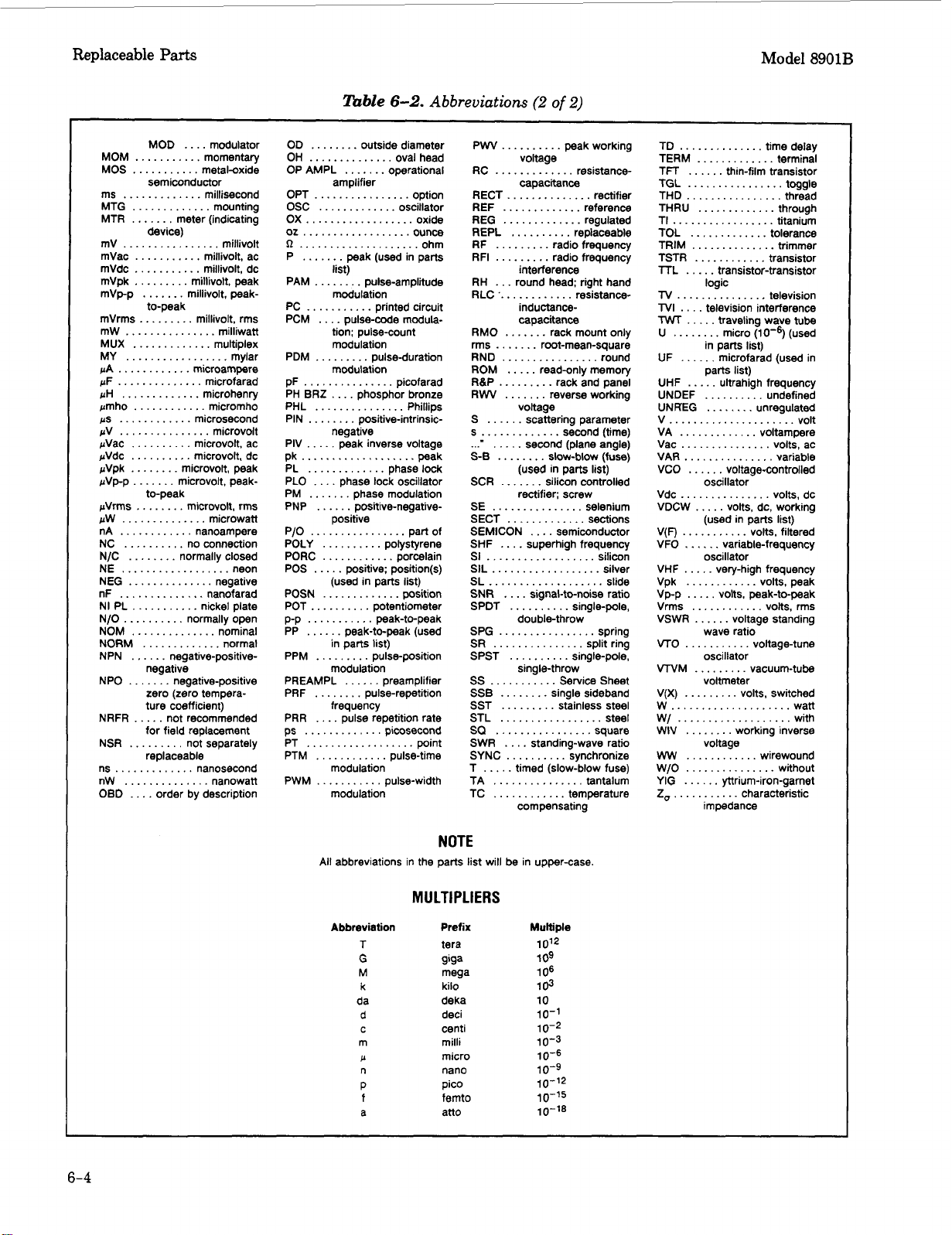

REPLACEABLE PARTS

6-1.

INTRODUCTION TO THIS SECTION

This section contains information

6-2

Table

parts in the instrument. Table

manufacturer’s code numbers listed in Table

drawings

6-2.

REFERENCE DESIGNATIONS AND ABBREVIATIONS USED IN THIS MANUAL

Table

designations found in Table

designation for each part in the instrument.

particular resistor

Table

6-3.

REPLACEABLE PARTS LIST

lists abbreviations that are used in the Replaceable Parts List. Table

to

aid in identifying and ordering chassis mounted parts and mechanical parts.

6-1

lists the reference designation letters for electrical parts in the instrument. The letter

6-1

R1

on assembly A17.

6-2

lists abbreviations used in the parts list and on schematics.

for

ordering parts. Table

6-4

contains the names and addresses that correspond

6-3.

Also included in this section are photographs and

are coupled with numeric designations to provide a unique reference

For

example A17R1 is the reference designation

6-1

lists reference designations, and

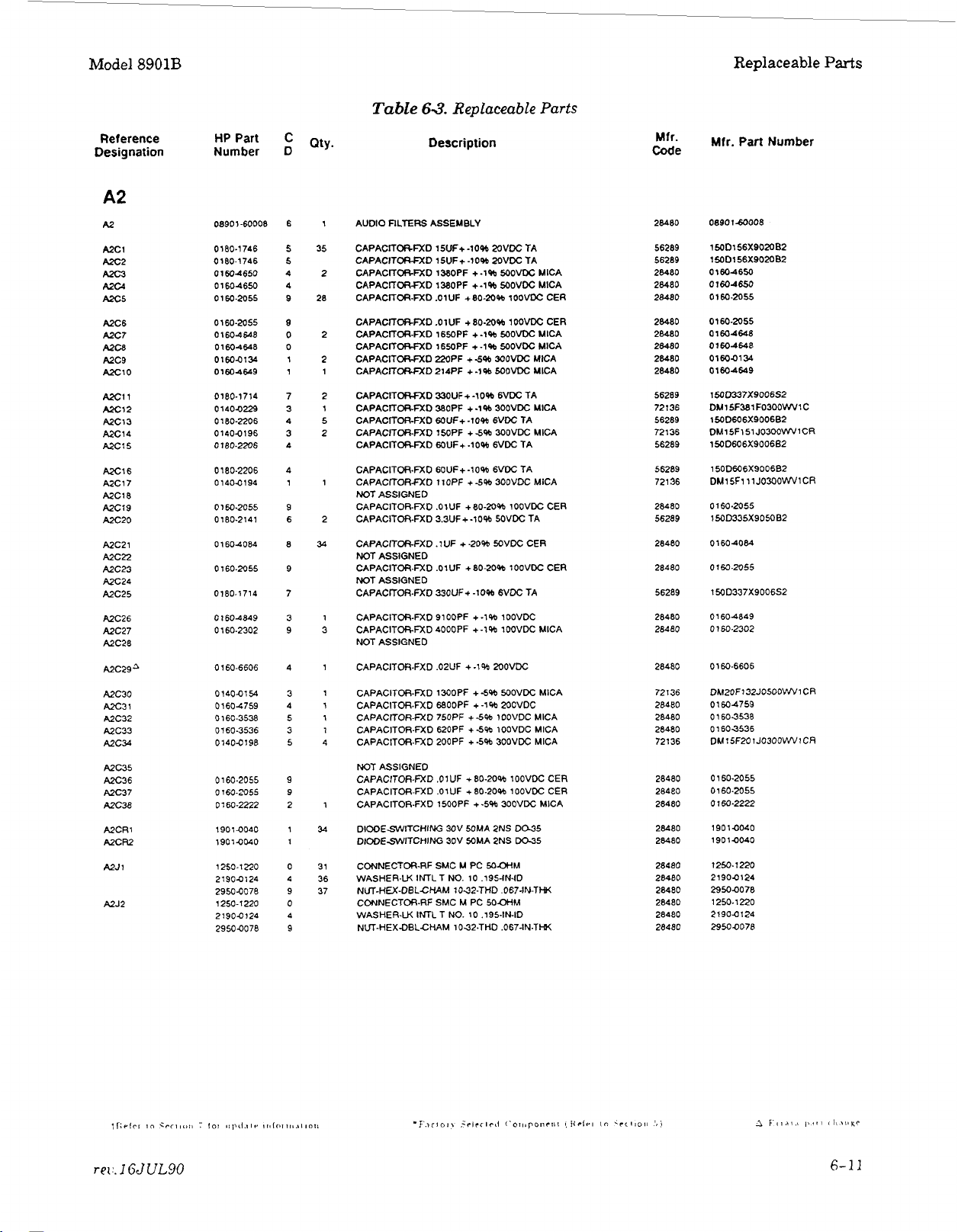

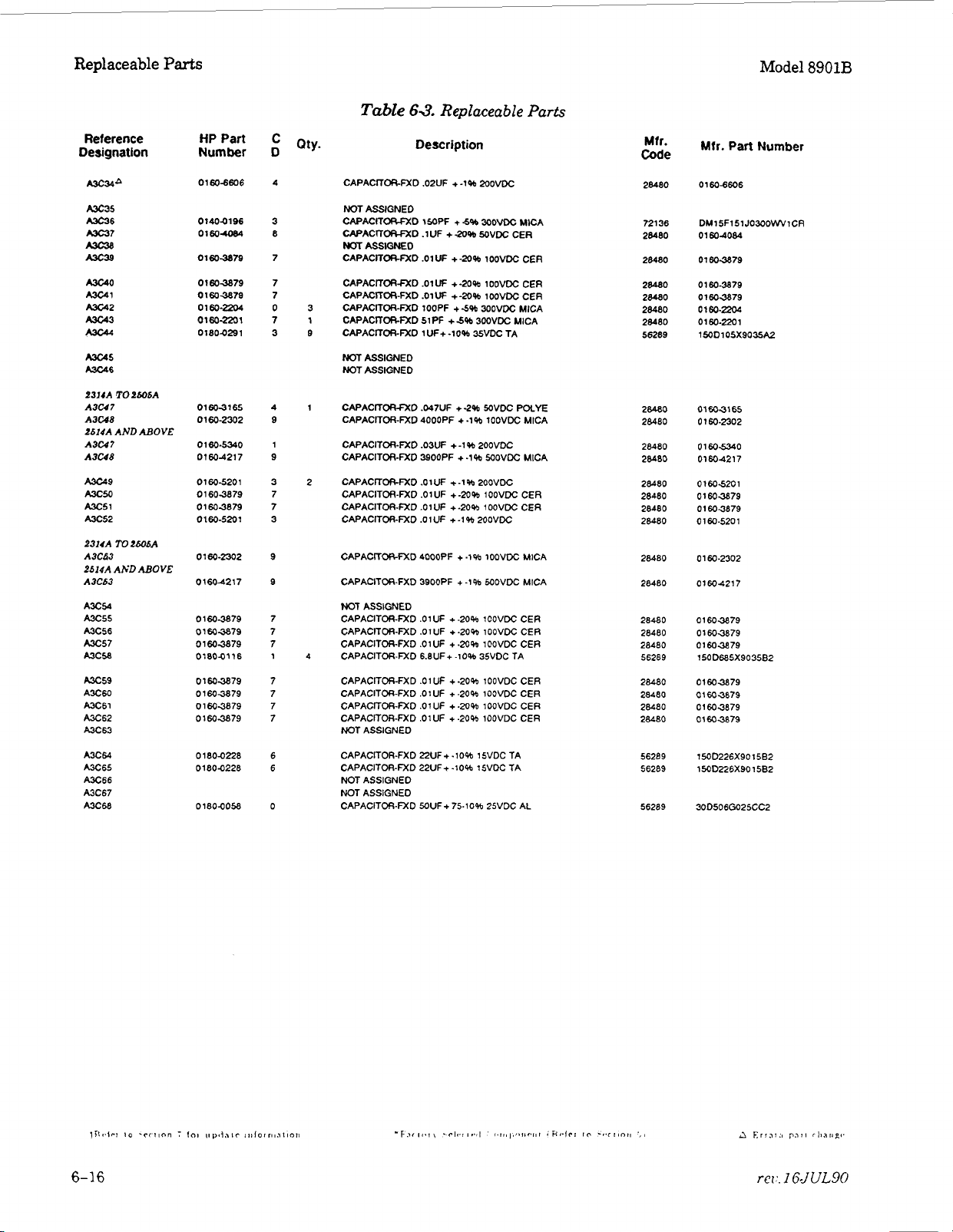

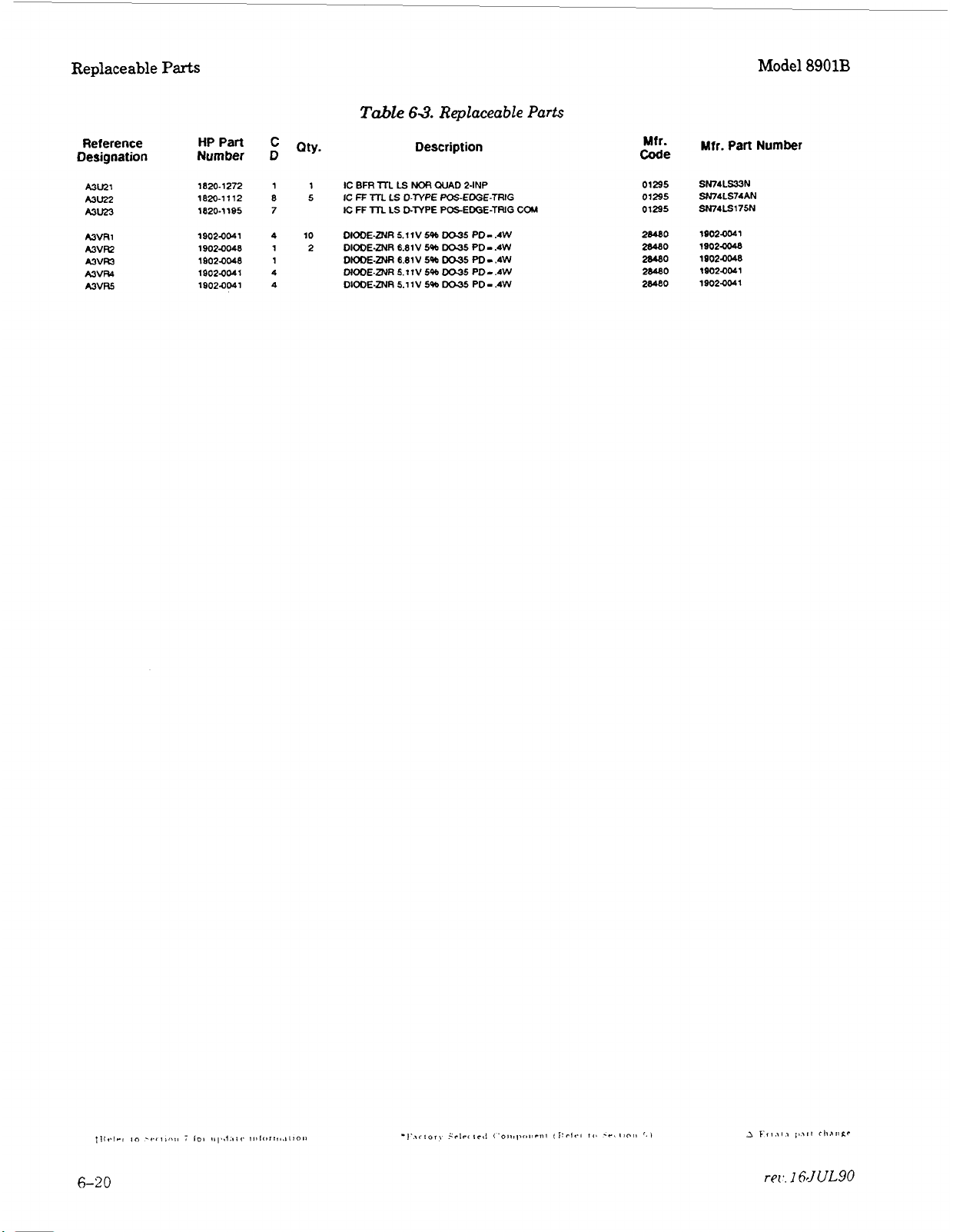

6-3

lists all replaceable

to

the

of

a

Table

6-3

is

a list of replaceable parts and is organized

a.

Electrical assemblies and their components with reference designations in alphanumeric order.

b. Chassis-Mounted parts with reference designations in alphanumeric order.

c. Mechanical parts with reference designations in alphanumeric order.

For your convenience, the Replaceable Parts List

6

removed from Section

Ordering

Parts.

instrument Serial Numbers.

Attached to the rear of the instrument

are the instrument serial-number prefix. The last five digits (serial-number suffix) are unique to each

instrument. When parts in the instrument are changed, the serial-number prefix of the instrument may

also

change. This means that sometimes a part will be listed more than once in the the replaceable

parts list along with a serial-number prefix

prefix on the serial plate of your instrument and order the part listed under the corresponding prefix

in the table. If no serial prefix information is listed, the part is compatible

numbers.

It is possible that some assemblies in your instrument have been updated

(through service

serial-number prefixes later than that shown on your instrument serialnumber tag. Be sure to note the board number

or

replaced when ordering parts

and collated into Section 8 with

is

a serial-number plate. The first four digits and the letter

or

range of serial-number prefixes. Find the serial-number

NOTE

or

retrofitting) to reflect changes made to instruments with

for

as

follows:

is

paginated so that each assembly listing can be

its

corresponding service information.

in

instruments of all serial

of

the assembly being repaired

your instrument.

6-

1

Replaceable Parts Model 8901B

How

to

Order

To order a part in the Replaceable Parts

List,

call

or

write the nearest Hewlett-Packard Sales Office.

Have the following information ready to speed the ordering process:

1.

The Hewlett-Packard part number with the check digit. (The check digit will ensure accurate and

timely processing of your order.)

2.

The quantity required.

3. An approved purchase order number. (Sometimes required.)

NOTE

Within

Mountain View California.

the

USA,

it

is

better to order directly from the HP Parts Center

Ask

your nearest HP ofice for information and

in

forms for the “Direct Order System”.

Replaceable Parts List Updating (Manual Updates)

A

“MANUAL UPDATES” packet is shipped with the manual, when necessary, to provide the most

current information available at the time of shipment. These packets consist of replacement and

addition pages which should be incorporated into the manual

Hewlett-Packard offers a Documentation Update Service that will provide you with further updates

If

as they become available.

you operate

recommend that you join this service immediately

or

service instruments of different serial prefixes, we strongly

to

ensure that you manual

information, refer to the Documentation Update Service reply card included in this manal,

Technical Writing Department (509) 922-4001,

to

bring

it

up

to

is

date.

kept current.

For

or

more

call:

6-4.

6-5.

or

write:

Hewlett-Packard Company

Technical Writing Department

-

24001 E. Mission

TAF C-34

Spokane, WA 99220

MECHANICAL AND CHASSIS PART LOCATIONS AND REFERENCE DESIGNATIONS

Most mechanical parts are identified in Figures 6-1 to 6-9. These figures are located at the end of

this section. Major mechanical parts have reference designations that begin with the letters MP. To

find the part number and description of a mechanical part, find the part in one of the photographs

or

drawings, and then look up the reference designation in Table 6-3. Mechanical hardware, such as

For

screws, are listed under the part which they attach.

to the rear panel are listed under

B1.

example, the screws that attach the fan (Bl)

RECOMMENDED SPARES LIST

Stocking spare parts for an instrument is often done

occurs. Hewlett-Packard has prepared a “Recommended Spares” list for this instrument. The contents

list

of the

are based on failure reports and repair data. Quantities given are for one year of parts

support. You can request a complimentary copy of the “Recommended Spares” list from your nearest

Hewlett-Packard office.

When stocking parts to support more than one instrument

instruments,

adding together stocking quantities

it

may be more economical to work from one consolidated list rather than simply

from

the individual instrument lists. Hewlett-Packard will prepare

consolidated “Recommended Spares” lists for any number

nearest Hewlett-Packard office for details.

to

ensure quick return to service after a malfunction

or

to

support a variety

or

combination of instruments. Contact your

of

Hewlett-Packard

6-2

Model

8901B

Replaceable

Parts

A

AT

B ............... fan: motor

BT

................ capacitor

C

CP

CR

DC

DL

DS

ac

ACCESS

ADJ ............ adjustment

A/D ........ analog-to-digital

AF

AFC ............. automatic

AGC

AM

AMPL

APC

ASSY

AUX

avg

AWG

BAL

BCD

BD ................. board

BECU

BFO

BH ............ binder head

BKDN

BP

BPF

BRS

BWO ....... backware-wave

CAl

ccw

CER

CHAN

cm

CMO

COAX

........ assembly

...... attenuator; isolator;

.................

................

............

.......

...............

............

........

.........

.........

....

.............

.......

............ assembly

..............

...............

......... American wire

...............

termination

battery

coupler

thyristor: varactor

signaling device

(audible or visual);

lamp; LED

A

frequency control

control

control

control

gauge

diode; diode

directional coupler

delay line

annunciator:

..........

alternating current

.........

amplitude modulation

ampere

accessory

audio frequency

automatic gain

amplifier

automatic phase

auxiliary

average

balance

.......... binary coded

decimal

......

beryllium copper

.........

..............

.........

..............

....... counter-clockwise

.............. ceramic

..............

.....

beat frequency

oscillator

..........

oscillator

breakdown

bandpass

bandpass filter

...........

.............

centimeter

cabinet mount only

..............

brass

calibrate

channel

coaxial

Table

6-1.

Reference Designations

REFERENCE

E

............

....................

F

FL

...................

H

................ hardware

HY

...............

J

........

K

...................

L

.............

M

..................

..........

MP

miscellaneous

electrical part

electrical connector

(stationary portion):

jack

mechanical part

Table

circulator

relay

coil; inductor

meter

miscellaneous

6-2.

Abbreviations

fuse

filter

ABBREVIATIONS

CP

..........

.......

CRT

CTL

.........

........

CW

cw

..............

dB

.................

dBm

........

OF ........ degree Fahrenheit

OK

...........

DEPC

DET

..............

diam

..............

DIA

....... diameter (used in

DlFF AMPL ...... differential

.......

DSB

DTL

........

.......

DVM

ECL

........

.....

EMF

'cadmium plate

cathode-ray tube

complementary

transistor logic

continuous wave

clockwise

decibel

decibel referred

angle)

..... deposited carbon

degree Kelvin

detector

diameter

parts list)

amplifier

double-throw

double sideband

diode transistor

logic

digital voltmeter

emitter coupled

logic

electromotive force

DESIGNATIONS

P

.......

electrical connector

(movable portion);

Plug

Q

..........

R

.................

RT

.............. thermistor

S

.................. switch

T

..............

TB

..........

TC

...........

TP

...............

EDP

.........

ELECT

ENCAP ........ encapsulated

EXT

...............

................... farad

F

FET

....

FH

...............

FIL H

FM

....

FP

.............

g

...................

GE

.............

GHz

HEX

.............

HD

..................

HDW

HF

..........

HG

...............

HI

...................

HP

......... Hewlett-Packard

HPF

.........

HR

...........

HV ............ high voltage

Hz

..................

IC

.........

ID .......... inside diameter

IF

.............

in

............

INCL

INP

..................

INS

.............. insulation

transistor; SCR;

triode thyristor; FET

transformer

terminal board

thermocouple

(1

of

2)

electronic data

processing

..........

field-effect transistor

..........

frequency modulation

fillister head

.............

........

............. hardware

.............

high frequency

high pass filter

hour (used in

parts list)

integrated circuit

intermediate

incandescent

resistor

test point

electrolyhc

external

flat head

front panel

gram

germanium

gigahertz

hour

hexagonal

head

mercury

high

Hertz

include(s)

input

U

.........

.............

V

VR

........ voltage regulator;

W

.......

X

..................

Y

........ crystal

2

........

INT

................

kg

................

kHz

k

..................

LC

.............

LED

LF

...........

LIM

LIN

LK WASH ck washer

LO

LOG

log

LPF

LV

.............

m

..........

mA

.............

MET OX

MF

MFR

mg

...............

MHz

mH

mho

min

..........

MlNAT

mm

integrated circuit;

microcircuit

breakdown diode

path; wire

electric or quartz)

circuit

.............. kilohertz

capacitance

.....

..................

.......

in

......

.......

(used in parts list)

............

..........

......

..........

...

....

.................

...........

...........

.............. millimeter

electron tube

cable; transmission

socket

unit

(piezo-

tuned cavity; tuned

internal

kilogram

kilohm

.

. kilovolt

...

pound

inductance-

light-emitting diode

low frequency

linear taper (used

I

oscillator

logarithmic taper

logarithm(ic)

low pass filter

low

voltage

meter (distance)

milliampere

......

metallic oxide

medium frequency:

microfarad (used in

parts list)

manufacturer

milligram

megahertz

.

millihenry

minute (time)

minute (plane angle)

miniature

limit

mho

NOTE

All abbreviations in the parts list will be in upper-case.

6-3

Replaceable

Parts

Model

8901B

MOD

....

modulator

...........

MOS

semiconductor

.............

ms

MTG

.............

.......

MTR

mV

mVac

mVdc

mVpk

mVp-p

MUX

MY

pA

pF .............. microfarad

pH

pmho

ps

pV

pVac

pVdc

pVpk

pVpp ....... microvolt, peak-

NC

N/C

N/O

NOM

NORM

NPN ...... negative-positive-

NPO

NRFR ..... not recommended

NSR

ns

nW

OB0

device)

................

........... millivolt. ac

...........

.........

.......

to-peak

.............

.................

............ microampere

.............

............

............

............... microvolt

..........

..........

........

..........

........

..........

..............

.............

negative

.......

zero (zero tempera-

ture coefficient)

for field replacement

.........

replaceable

......

....

....

metal-oxide

millisecond

mounting

meter (indicating

millivolt

millivolt, dc

millivolt, peak

millivolt, peak-

.

.

millivolt, rms

multiplex

mylar

microhenry

micromho

microsecond

microvolt, ac

microvolt, dc

microvolt, peak

no connection

normally closed

normally open

nominal

normal

negative-positive

not separately

..

nanosecond

nanowatt

....

order by description

lbble

OD .. outside diameter

OH

..............

OP AMPL

amplifier

OPT

................

OSC

.............

ox

.........

list)

PAM

........

modulation

PC

...........

PCM

....

pulse-code modulation; pulse-count

modulation

PDM

.........

modulation

pF

...............

negative

PIV

.....

peak inverse voltage

...................

pk peak

PL

............. phase lock

PLO

....

phase lock oscillator

POLY .......... polystyrene

PORC

............ porcelain

used in parts list)

p-p

...........

PP

......

peak-to-peak (used

PREAMPL

frequency

PRR

....

ps ...

PT

PTM

PWM

pulse repetition rate

..................

............

modulation

...........

modulation

6-2.

.......

......

oval head

operational

pulse-amplitude

printed circuit

pulseduration

peak-to-peak

preamplifier

...

picosecond

pulse-time

pulse-width

Abbreviations

option

oscillator

picofarad

point

(2

of

2)

PWV

..........

..........

RECT..

RH

...

round head; right hand

.............

RLC

capacitance

RMO

.......

....... root-mean-square

rms

RND

................

ROM

.....

RBP

.........

RW

....... reverse working

S

...I

S-B

SCR

SE

SECT

SEMICON

SHF

SI

SIL..

SL

SNR

SPDT

SPG

SS

SSB

SQ

SWR

SYNC

T

TA

TC

voltage

......

.....

........

(used

.......

rectifier; screw

...............

.............

....

..................

................

...................

....

..........

double-throw

................

...........

........

..........

....

..........

..... timed (slow-blow fuse)

...............

............

compensating

peak working

voltage

capacitance

............

interference

inductance-

scattering parameter

second (plane angle)

superhigh frequency

signal-to-noise ratio

resistance-

resistance-

rack mount only

read-only memory

rack and panel

slow-blow (fuse)

in parts list)

silicon controlled

selenium

sections

.... semiconductor

single-pole,

Service Sheet

single sideband

standingwave ratio

synchronize

tantalum

temperature

rectifier

round

silicon

silver

slide

spring

TD

..............

TERM

.............

TFT

......

TGL

................ toggle

TI

.................

TOL

.............

TSTR

......

TV

TVI

TWT

logic

...............

....

television interference

.....

U

........

in parts list)

...

UHF

UNDEF .......... undefined

U

VA

Vac

VAR

VCO

V(F)

VFO

VHF

Vpk

Vpp

Vrms

VTO

VNM

V(X)

w

W/

WW

W/O

YIG

2,

parts list)

.....

N KEG

........

.............

...............

.............. .variable

......

oscillator

(used

...........

......

oscillator

.....

very-high frequency

............

.....

............

...........

oscillator

.........

voltmeter

.........

....................

...................

voltage

............

...............

......

...........

impedance

time delay

thin-film transistor

traveling wave

micro (used

microfarad (used in

ultrahigh frequency

voltage-controlled

variable-frequency

volts, peak-to-peak

yltrium-iron-garnet

terminal

titanium

tolerance

television

tube

unregulated

voltarnpere

volts, ac

in

parts list)

volts, filtered

volts, peak

volts, rms

voltage-tune

vacuum-tube

volts, switched

characteristic

wan

with

wirewound

without

6-4

NOTE

All

abbreviations in the parts list will be in upper-case.

MULTIPLIERS

Abbreviation

T

G

M

k

da

d

C

m

P

n

P

f

a

Prefix

tera

gigs

mega

kilo

deka

deci

centi

milli

micro

nano

pic0

femto

atto

Multiple

10'2

1

09

106

103

10

10-1

10-2

10-3

10-6

10-9

10-12

lo+

10-18

Model

8901B

Replaceable

Parts

Reference

HP

Part

Designation Number D

A1

A1

AlCl

A1 C2

A1

C3

Ala

A1C5

A1C6

A1C7

A10

A1C9

AlClO

AlCll

A1C12

AlC13

AlC14

AlCl5

AlC16

AlC17

AlC18

AlC19

AlCRl

AlCFt?

AlCR3

A1CR4

AlDSl

A1 DS2

AlDS3

AIDS4

A1

OS5

AlDS6

AIDS7

AlDS8

AIDS9

AlDSlO

AlDSll

AIDS12

AlDS13

AlDSl4

AlDSl5

AIDS16

AIDS17

AIDS18

AIDS19

A1 OS20

AlDS2l

AlDS22

A1 OS23

08901.60143

01804228 6

0160.2291

01604576 5

01600576

01604576 5

01604576 5

01600576 5

01604576

01600576

01600576 5

01600576

01600576

0160-0576

01604576

01604576

01600576

01600576 5

01600576

01604576

1901.1098

1901-1098

1901.1098

1901-1098

1990-0759

12004423

19904759

12004423

1990-1273

1990-1273

1990.1273 1

1990-1273

1990-1273

1990-1273

1990-1273 1

1990-1273

1990-1273

1990-1273

1990-1273

1990-1273

1990-1273 1

1990-1273

1990-1273

1990-1273 1

19904759

12004423

1990-0759

12000423

1990-1273

1990-1273

5

6

8

6

8

1

1

1

1

1

6

8

6

8

1

1

5

5

5

5

5

5

5

5

5

1

1

1

1

1

1

1

1

1

1

1

C

0

5

5

Table

Q~,,.

1

KEYBOARD

5

CAPACITORFXD

1

CAPACITORFXD .18UF +-1OW 8OVDC

44

CAPACITOR-FXD .lUF

CAPACITOR-FXD .1UF

CAPACITORFXD

CAPACITORFXD .1UF

CAPACITOR-FXD

CAPACITORFXD .1UF

CAPAClTOAFXD .lUF

CAPACITORFXD

CAPACITORFXD

CAPACITORFXD .lUF

CAPACITOR-FXD .IUF

CAPACITOR-FXD .lUF

CAPACITOR-FXD .lUF

CAPACITORfXD .lUF

CAPACITOR-FXD .lUF

CAPACITOR-FXD .lUF

CAPACITOR-FXD .lUF

71

DIODESWITCHING lN415O 50V 200MA 4NS

DlODESWlTCHlNG 1N4150 50V 200MA 4NS

DIODESWITCHING 1N4150 5OV 2OOMA 4NS

DIODESWITCHING 1N4150 MV MOMA

1

LED-UGM BAR MODULE LUM-INT-3MCD

4

SOCKET-IC 16CONT DIP DIPSLOR

LEDUGM BAR MODULE LUM-INT-3MCD

SOCKET-IC 1sCONT DIP DIPSLDR

28

LED-LAMP-RED LUM-INT

LED-LAMP-RED LUM-INT-8.6MCD BVR-5V

LED-LAMPRED LUM-INT - 8.6MCD BVR - 5V

LED-LAMP-RED LUM-INT -8.6MCD BVR- 5V

LED-LAMP-RED LUM-INTI 8.6MCD BVR- 5V

LEDLAMP-RED LUM-INT

LED-LAMP-RED LUM-INT - 8.6MCD BVR - 5V

LED-LAMP-RED LUM-INT-8.6MCD BVR - 5V

LEDLAMP-RED LUM-INT-8.6MCD BVR-5V

LED-IAMP-RED

LED4AMP-RED LUMWT-8.6MCD BVR-5V

LED-LAMPRED LUM-INT-8.6MCD BVR- 5V

LED-IAMP-RED LUM-INT - 8.6MCD BVR I 5V

LED-LAMP-RED LUM-INT-8.6MCD BVR-5V

LED-LAMP-RED LUM-INT

LED-IAMPAED LUM-INT-8.6MCD BVR-5V

LED-UGHl BAR MODULE LUM-INT

SOCKET-IC

NOT

ASSIGNED

LED-LlGHl BAR MODULE LUM-INT

SOCKET-IC 16CONT

LED-IAMP-RED LUM-IM- 8.8MCD BVR- 5V

LED-LAMP-RED LUMJNT

63.

Description

AM)

MSPLAY ASSEMBLY

PW+

.l

UF

.lW

.lW

.lW

LUM-INT

1

6CONT

DIP DIPSLDR

DIP

Replaceable

-10% 1SvM: TA

+a%

+-a%

+

-20%

+-209b

+-20%

+-2oW

+-Ow

+-a%

+-2Oab

+-20%

+-a%

+-MW

+-20%

+-2Oab

+-20%

+-M%

+.20%

-

8.6MCD BVR - 5V

-

8.6MCD BVR I 5V

-

8.6MCD BVR I 5V

-

8.6MCD BVR - 5V

DIPSLDR

-

8.6MCD

POLYE

SOVDC CER

SOVDC CER

SOVDC

CER

WVDC CER

SOVDC CER

MVDC CER

50VDC

CER

MVDC CER

5OVDC CER

SOVDC CER

50VDC CER

WVDC

CER

50VDC CER

50VX CER

50VDC

CER

5OVDC CER

SOVOC CER

4NS

I

3MCD

-

3MCD

BVR

-

Parts

5V

Code

28480

56289

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

2wo

28480

28480

28480

28480

28480

28480

28480

9N171

9N171

9N171

9N171

28480

28480

28480

28480

01542

01542

01542

01542

01542

01542

01542

01542

01542

01542

01542

01542

01542

01542

01542

01542

28480

28480

28480

28A80

01542

01542

Mfr. Part Number

08901-60143

1 SOD226X9015B2

0160-2291

01604576

01 604576

01600576

01600576

01600576

01604576

01600576

01600576

01 604576

01600576

01604576

01600576

01604576

01604576

01

600576

01600576

01604576

1N4150

1N4150

1N4150

1N4150

HLMP-2620

12004423

HCMP-2620

12004423

OLMP-1613

OLMP-1613

OLMP-1613

OLMP.1613

QLMP-1613

OLMP-1613

OLMP-1613

OCMP-1613

OLMP.1613

OLMP-1613

OLMP.16 13

OLMP-1613

OLMP-1613

OLMP.1613

OLMP-1613

OLMP-1613

HLMP-2620

12004423

HLMP-2620

12000423

QLMP-16 13

OLMP-1613

Replaceable

Parts

Model

8901B

Reference

Designation

AlDS24

A1 OS25

A1 DS26

A1 DS27

1

OS28

A

At DS29

AIDS30

2305A

TO

2914A

AlDS3li

AlDS32t

AlDS331

AlDS3Qt

AlDS3St

AIDS361

AlDS3d

492OA

Ah'D

AlDS3Jt

A

1

AlDS33i

AJDS~Q~

A IDS351

AlDS3Gt

AJDS37i

AlDS38

A1

AlDS40

AlDSll

2305A TO2914A

ABOVE

DS32t

DS39

AIDMI

AJDS43t

AIDS445

AlDS45t

2920A Ah'DABOVE

AIDM2i

AID93t

AJDS44i

AlliS45t

AIDS6

AlJl

A1J2

HP

Part

Number

1990-1273

1990-1273

1990-1 273

1990-1273

1990-1273

1990-1273

19900699

1

200490

19904670

19904670

19904670

10904670

19904670

1~04678

10900950

19904487

19904487

19904487

19904487

19904487

19904835

1990-1273

1990-1273

1990-1273

1990.1 273

1990-1273

19900950

19904950

19904950

19904678

1990.1273

1990-1273

1990-1273

19904835

19900699

12004901

1251-51 69

12004507

Table

C

Qty.

D

LED-LAMP-RED LUM-INT-8.6MCD

LED-LAMP-RED LUM-INT-8.6MCD

LED-LAMP-RED LUM-INT-8.6MCD

LEDCAMP-RED LUM-IW - 8.6MCD

LEDCAMP-FED LUU-INT- 8.6MCD

1

3

7

1

3

7

6

9

LEDIAMP-RED LUM-INT - 8.6MCD

2

LED-LIGHT

2

SOCKETSTRP

5

LEDCAMP.YLW LUM-INT- lMCD IF-MMA-MAX

LEDCAMP-YLW LUM-INT- lMCD IF-MMAMAX

LED-LAMP-YLW LUM-INT- 1MCD IF-MMA-MAX

LEDLAMP-YLW LUM-INT- lMCD IF-20MAUAX

LED-LAMP-YLW LUM-INT

2

LEDCAMPGRN

5

LED-LAMP-RED LUM-INT- 1MCD IF- 13MA-MAX

5

LEDLAMP-YLW LUM-INT- lMCD

LED-LAMP.YLW LUM4NT- lMCD IF- ZOMAUAX

LED-LAMP.YLW LUM-INT- 1MCD IF

LED-LAMP-YLW LUM-INTI lMCD IF- =MA-MAX

LEDCAMP-YLW LUM-INT- 1MCD IF-MMA-MAX

2

LED-LAMPGRN LLJM.INT

5

LED-LAMP-RED LUM-INT-8.6MCD

LED-LAMP-RED LUM-INT - 8.6MCD

LED-LAMP-RED LUM-INT - 8.6MCD

LED4AMP-RED LUM-INT - 8.6MCD

LED-LAMP-RED LUM-INT - 8.6MCD

LED-LAMP-RED LUM-INT- lMCD IF- 13MA-MAX

LED-LAMP-RED LUM-INT- lMCD IF- 13MA-MAX

LED-LAMP-RED LUM-INT- 1MCD

LED-LAMPGRN LUM-INT

LED-LAMPAED LUM-INT-8.6MCD

LED-LAMP-RED LUM-INT - 8.6MCD

LED-LAMP-RED LUM4NT I 8.6MCD

LED-LAMPGRN LUM-INT - 6MCD

LEDLIGHT

SOCKET-STRP

5

CONNECTOR &PIN

2

SOCKET-IC

63.

Replaceable

Description

BAR

MODULE LUM-INT - 7MCD

8CoNT

W-WRAP

-

1

MCD

LUM-INT

-

8OOUCD

-

6MCD IF I 30MA-MAX

-

8OOUCD IF

BAR

MODULE

8CONT

1

6CONT

LUM-INT

W.WRAP

M

POST TYPE

DIPSLDR

BVR- 5V

BVR-5V

BVR- 5V

BVR - 5V

BVR

BVR - 5V

IF

-

=MA-MAX

IF

-

IF

-

20MAMAX

-

2OMAMAX

BVR-5V

BVR - 5V

BVR - 5V

BVR - 5V

BVR I 5V

IF-

13MA - MAX

-

BVR- 5V

BVR- 5V

BVR-

IF

-

30MA - MAX

-

7MCD

Parts

-

5V

JOMA-MA

3OMA-MAX

5V

Mfr.

We

01542

01542

01542

01542

01542

01502

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

01542

28480

28480

28480

28480

28480

28480

28480

28480

01542

01542

01542

28480

28480

28480

28480

28480

Mfr.

OLMP-1613

OLMP.1613

OLMP-1613

OLMP-1613

OLMP-1613

WP-1613

1

LM1-2350

12004901

19904670

19904670

19904670

19904670

19900670

19904678

19904950

19904487

19904487

19904487

19904487

19904487

HLMP.1523

OLMP-1613

1990-1 273

1990.1

1990.1273

1990.1 273

19904950

19909950

19904950

19904678

QLMP-1613

OLMP.1613

OLMP.1613

HLMP-1523

1LM 1.2350

12004901

125 1-51 69

12004507

Part

273

Number

Model

8901B

Replaceable

Parts

Reference

Designation

AlMPl

AIMP2

AlMP3

A1 MP4

AlMP5

AlMP6

AlMP7

AlMP8

AlMPS

AlMPlO

AlMPll

AlMPl2

AIMPl3

AIMP14

AlMPlS

AlMP16

AlMPl7

AlMP18

AlMPlS

AlMF70

AlMPZl

AlMPP

A1 UP23

AlMP24

AlMP25

A1

MP26

AlMP27

AlMP28

AlMP29

AlMP30

AlMP31

AlMP32

A1 MP33

AlMP34

AlMP35

AlMP36

A1 MP37

AlMP38

AlMP39

AlMP40

AlMP41

A1 MP42

AlMP43

AlMP44

AlMP45

AlMP46

A1 R1

A1R2

AlR3

AIR4

A1R5

HP Part

Number

50410252

50114943

50414252

50414319

50414484

50414351

50414252

50414252

50414319

50414386

5041.0508

50414286

50414286

50414451

504

14252

5041.0252

50414319

5041-0386

50414835

50414832

5041

4829

50414838

504 10252

504

10252

50414319

50414386

50410836

50410833

50410830

50414839

504

10252

50410252

50414319

50410386

50410837

50414834

5041

4831

504

1-1

672

504

10252

504

10252

504

1031

0

50410386

504

1-2753

1

-2750

504

5041.2751

504

1.2752

18100279

18100207

07570199

07570123

07570461

Table

Qty.

D

7 12

31

7

75

71

71

7

7

7

85

61

72

7

81

7

7

7

8

21

91

41

51

7

7

7

8

31

01

71

61

7

7

7

8

41

1

81

71

7

7

81

8

71

41

51

61

51

91

3

31

24

KEY CAP

KEY CAP HALF LOCAL

KEY CAP

KEY CAP+lALF GRAYUT

KEY CAP

KAY CAP OUARTER

KEY CAP WARTER GY-LlT

KEY CAP QUARTER GY-LIT

KEY CAPMLF GRAY-LIT

KEY CAP FULL BK-LIT

KEY CAPMLF GR

KEY CAP LT PIPE

K€Y

CAP LT PIPE

KEY CAP LT PBLUE

KEY CAP QUARTER GY-LIT

KEY CAP QUARTER GY-LIT

K& CAP-HALF GRAY-LIT

KEY CAP FULL

KEY CAPlFULL 7 LT GY

KEY CAPffUU 4 LT GY

KEY CAPlFULL 1 LT GY

KEY CAPlFULL

KEY CAP WARTER GY-LIT

KEY CAP OUARTER GY-LIT

KEY CAPMLF GRAY-LIT

KEY CAP FULL BK-LIT

KEY CAP/FULL

K€Y CAPlFULL

KEY CAPlFULL

KEY CAPlFULL GY DOT

KEY CAP WARTER GY-LIT

KEY CAP OUARTER GY-LIT

KEY CAP-HALF GRAY-LIT

KEY CAP FULL BK-LIT

KEY CAPlFULL

1

KN CAPlFULL 6 LT GY

KEY CAPlFULL

KN CAPlFULL CLEAR

KEY CAP OUARTER GY-LIT

KEY CAP OUARTER GY-LIT

KEY CAP HALF GY

KFf CAP FULL BK-LIT

KEY CAP-FULL

KEY CAP-FULL KHZ UP

KEY CAP-FULL KHZ DN

KEY CAP-FULL SF'CL

NElWORK-RES 10SlP4.7K

NETWORK-RES 8SIP22.OK

AESISTOR21.5K 1% .12W FTC-0+.100

16

RESlSTOR34.8K

RESlSTOR68.1K 1% .125WFTC-0+-100

63.

Description

WARTER

WARTER

MU

YELLW

BK-LIT

0

LT GY

8

LT GY

5

LT GY

2

LT GY

9

LT GY

3

LT GY

MHZ

lab

Replaceable Parts

GY-LIT

GY-LIT

LED

OHM

X

9

OHM

X

7

.12W FTC-0+-100

Mfr.

Code

28480

28480

28480

28480

28480

28400

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

2ed80

28480

28480

28480

28480

28480

28480

28480

26480

28480

28480

28480

28480

28480

28480

28480

01121

01121

24546

28480

24546

Mfr.

Part Number

504

10252

50414943

504

14252

50410319

50414484

50410351

50414252

504

14252

50410319

50414386

504

10508

50410286

50414286

50414451

504

10252

504

1

4252

50410319

50410386

50410835

50410832

50410829

50410838

504

10252

504 1 0252

50410319

50410386

50414836

504

14833

50410830

50410839

50414252

504

14252

50410319

50414386

50414837

50410834

50414831

1.1

672

504

504 1 0252

504

10252

50410310

50414386

504

1-2753

5041-2750

5041-2751

504

1.2752

210P.472

208A223

Cd-1/8-T0-2152-F

07574123

a-

118.T0-68

12-F

Replaceable

Parts

Model

8901B

Reference

Designation

A1

R6

A1 A7

A1

R8

A1

R9

AlRlO

AlRll

AlR12

AlR13

AlA14

AIR15

AlR16

AlR17

AlR16

AIR19

A1

Fw)

AlFal

A1

Rp

AlF123

A1W4

A1

Fa5

AlR26

A1 P27

AIR28

R29

A1

A1

R30

AlR31

AlR32

AlR33

A1

R34

AlSl

A1S2

A1S3

AIS4

A1S5

A1S6

A1S7

AIS

A1S9

AIS10

AlSll

A1S12

AlS13

AlS14

AlS15

A1S16

AlS17

AIS18

AlS19

AlS20

HP

Part

Number

07574199

06980082

06984453

07574461

07574461

07574447

18104402

18104402

18104402

18100402

18

104402

18104402

18 10.0402

18104402

18104402

18104402

18 104370

18'104370

18104370

18 lOQ370

18 100370

18 104370

06983138

06983438

18100370

5060-9436

5060-9436

5060-9436

5060-9436

5060-9436

5060-9436

5060-9436

50608436

5060-9436

5060-9436

50604436

50608436

50

60-9436

5060-9436

5060-9436

5060.9436

5060-9436

5060.9436

5060-9436

5060-9436

Table

Qty.

D

3

7 23

21

2

2

45

6 10

6

6

6

6

6

6

6

6

6

77

7

7

7

7

7

3

3

7

7

7

7

7

7

RESISTOR 21.M 1% .12W F TC-O+-IOO

RESISTOR464 1% .12W FTC-O+-rOO

RESISTOR 19% 1% .12W FTC-O+-rOO

RESISTOR 68.1K 1%

RESlSTOR68.1K 1% .12!5WFTC-0+-100

RESISTOR 16.S 1% .12W FTC-0+-100

NRWORKRES 16-DlP330.0

NOWORKAES 16-DIP330.0

NETWORK-RES 16-DIP330.0

N€IWOW-RES 16-DIP330.0

NRWOFK-RES lMIP330.0

NETWORKRES 16-DIP330.0

NETWORK-RES 16-DIP330.0

NETWOW-RES 16DIP330.0

N€IWOWRES 16-DIp330.0

NEIwoFp(.RES

NETWORK-RES

NRWW.RES

N!3WORK-RES

NRWOW-RES 6SIP220.0

NETWORK-RES 8SIP220.0

NElWWRES 8SIP220.0

10

RESISTOR 147 1% .12W FTC-O+-100

NOT ASSIGNED

NOT ASSIGNED

NOT

NOT ASSIGNED

RESISTOR 147 1% .12W FTC-0+-100

NETWORK-RES

PUSHBUTTON WITCH P.C. MOUNT

46

PUSHBUlTON SWITCH P.C. MOUNT

PUSHBUTTON SWITCH P.C. MOUNT

PUSHBUlTON SWITCH P.C. MOUNT

PUSHBUlTON MCH P.C. MOUNT

PUSHBUlTON SWITCH P.C. MOUNT

PUSHBUTON SWITCH P.C. MOUNT

PUSHBUITON SWITCH P.C. MOUNT

PUSHBUTTON WITCH P.C. MOUNT

PUSHBUlTON SWITCH P.C. MOUNT

PUSHBUTON SWITCH P.C. MOUNT

PUSHBUTON SWITCH P.C. MOUNT

PUSHBUTTON SWITCH P.C. MOUNT

PUSHBUITON SWITCH P.C. MOUNT

PUSHBUITON WITCH P.C. MOUNT

PUSHBUTON SWITCH P.C.

PUSHBUTON SWITCH P.C.

PUSHBUlTON MCH P.C. MOUNT

PUSHBUTON SWITCH P.C. MOUNT

PUSHBUTTON SWITCH P.C. MOUNT

ASSIGNED

63.

Replaceable

Description

.12sw

16-DlP330.0

8SIp2M.O

8SIP220.0

8SIP220.0

8SIP220.0

OHM

OHM X 7

OHM

OHM

OHM

OHM

OHM

F

TC-O+-loO

OHM

X

OHM

X

OHM X 6

OHM

X

OHM X 8

OHM

X

OHM

X

OHM

X

OHM X 8

OHM

X

X

7

X

7

X

7

X

7

X

7

X

7

MOUNT

MOUNT

8

8

8

8

8

8

8

Parts

Mfr.

Code

24546

24546

24546

24546

24546

24546

01121

01121

01121

01121

01121

01121

01121

01121

01121

01 121

01121

01121

01121

01121

01121

01121

24546

24546

01121

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

2wo

28480

28480

Mfr. Part

C4-1/8-TO-2152-F

00-llB.TOd640-F

C4-ll8-TO-1963-F

CO-118-TO-68 12-F

c4-ll8-TO6812-F

00-118-TO-1622-F

3168331

3168331

3168331

3168331

3168331

3168331

3168331

3168331

3168331

3168331

208A22l

20BA22l

208Anl

208A22l

208A221

2Q8A22l

Cb-118-TO-147R.F

Cd-1/8-TO-147R-F

200Apl

50604436

50604436

50608436

5060-9436

50608436

5060-9436

5060-9436

5060-9436

5060.9436

50604436

5060-9436

5060-9436

50608436

5060-9436

5060-9436

5060-9436

5060-9436

50608436

50604436

960-9136

Number

Model

8901B

Replaceable

Parts

Reference

Designation

AlS21

A1

Sp

AlS23

AlS24

A1

525

A1

S26

A1 S27

AS28

A1529

AIS24

AlS31

AIS32

S34

A1

A1

535

AIS36

A1 S37

A1

s3s

AlS39

AtS40

AlS41

A1 S42

AlS43

AlSM

AS45

AlS46

AITPl

AlTP2

AlTP3

AlTP4

AlTPS

AlUl

A1

U2

A1

U3

AlUP

A1U5

A1U6

A1U7

A1W

A1

W

AlUlO

HP

Part

Number

50604436

50604436

50604436

50604436

50609436

50604436

50604436

50604436

50604436

50604436

50604436

50604436

50604436

50604436

50604436

50604436

50604436

50604436

50804436

50604436

50604436

50604436

50608436

50604436

50604436

12514600

1251 4600

12514600

12514600

12514600

1820-1729

1820-2075

19900574

12000803

19900574

12000803

19900574

12004803

19904574

12000803

19904574

12000803

19904574

12004803

19904574

12004803

19904574

12004803

Table

C

Qty.

D

PUSHBUTTON SWITCH P.C. MOUNT

PUSHEUTTCW SWITCH P.C.

PUSHBUTTON SNITCH P.C.

PUSHBUTTON SNITCH P.C.

PUSHBUTTCW SWlTCH P.C.

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

0

0

0

0

0

3

4

3

8

3

8

3

8

3

8

3

8

3

8

3

B

3

8

PUSHBUTTON SWlTCH P.C. MOUNT

PUSHBUTTON SwrrCH P.C.

WSHEUTTON

PUSHBUTTON SWITCH P.C.

PUSHBUTTON SNITCH P.C.

PUSHBUTTON SNITCH P.C. MOUNT

PUSHBUTTON SNITCH P.C. MOUNT

PUSHBUTTON SNITCH P.C. MOUNT

PUSHBUTTON SWrrCH P.C.

PUSHBUTTON SWITCH P.C. MOUNT

WSHBUTTCW

PUSHBUTTON SNITCH P.C. MOUNT

PUSHBUTTON SWITCH P.C. MOUNT

PUSHBUTTON SWITCH P.C.

PUSHBLJTTON SWlTCH P.C. MOUNT

PUSHBUTTON SWlTCH P.C. MOUNT

PUSHEmON

PUSHBUTTON SWITCH P.C. MOUNT

PUSHBUTTON SWITCH P.C. MOUNT

PUSliBmON SWITCH P.C. MOUNT

CONNECTORSGL CONT PIN 1.14-MM-BSCSZ

101

CONNECTORSOL CONT PIN 1.14-MM-BSCSZ

CCWNECTORSGL CONT PIN 1.14-MM-BSCSZ

CONNECTORSGL CONT PIN 1.14-MM-BSCSZ

CONNECTORSGL CONT PIN 1.14-MM-BSCSZ

19 tC LCH TTL

5

IC TRANSCEIVER lTL LS BUS OCTL

10 DISPLAY-NUMSEG 1CHAR .43-H

10 SOCKET-IC 14CONT DIP DIP-SLDR

DISPLAYNUMSEG

SGCKET-IC

DISPLAY-NUMSEG

SOCKET-IC 14CONT DIP

DISPLAY-NUMSEG lCHAR

SOCKET-IC 14Cm DIP DIPSLDR

DISPLAY-NUMSEG 1CHAR .43-H

SOCKET-IC

DISPLAY-NUM-SEG lCHAR ,4344

SOCKET-IC l4CONT DIP DIPSLOR

DISPLAY-NUMSEG lCHAR .43.H

SOCKEF-IC

DISPLAYNUM-SEG ICHAR .43-H

SOCKR-IC

63.

Description

SNITCH P.C. MOUNT

SNITCH P.C. MOUNT

SWITCH

LS

COM CLEAR 6-BIT

14CONT

i4CONf DIP DIPSLDR

14Cw

l4CoKl

Replaceable

MWNT

MOUNT

MOUNT

MouNl

MOUNT

MOUNT

MOUNT

MOUNT

MOUNT

P.C. MOUNT

1CHAAR

A3.H

OIP DIPSLDR

1

CHAR

.43-H

DIPSWR

.43-H

DIP DIPSWR

DIP DIP-SLDR

Parts

So

SO

SO

SQ

SQ

Mfr.

Code

28480

28480

28480

28480

2Me.o

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28460

28480

28480

28480

28480

28480

28480

01295

28460

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

Mfr.

Part

60604436

5060-9436

50604436

50604436

50604436

50604436

50604436

60604436

60604436

50604436

50604436

60604436

50608436

6060-9436

50604436

50604436

5060-9436

50608436

506043436

50604436

50604436

50608436

5060-9436

5060-9436

5060-9436

1251

4

600

12514600

12514600

1251 4600

12510600

SN74LS259N

1820-2075

5082-7651

12004803

5082-7651

12004803

5082-7651

1MOD803

5082-7651

12004803

5082-7651

12004803

5082.7651

12004803

5082-7651

12004803

we2.7651

lM04803

Number

~

Replaceable

Reference

Designation

AlUll

AlU12

AlU13

AlU14

AlUl5

AlU16

AlU17

AlUl8

AlU19

A1

U20

AlU21

A1W

AlU23

A1 U24

AlU25

AlU26

A1W7

AlU28

U29

A1

A1

U30

AlU31

AlU32

AlU33

AlU34

A1U35

AlU36

AlU37

AlU38

U39

A1

AlU0

AlU41

AlWl

A1W2

A1W3

A1W4

A1W5

Parts

HP Part

Number

19904574

12004803

19900574

12004803

182604 12

1820-1

144

1820-2075

1820-1729

1820.2075

1820-2075

1820-1427

1820-1 198

1820-1198

1820-1729

1820-1729

1820-1 729

1820-1729

1820-1 729

1820-1729

1

729

18201820-1 729

1820.1729

1820-1729

1820-1729

1820-1729

1820.1 729

1820- 1 729

1820-1216

1820-1216

1820-1216

1820.1729

1820-1 729

1820-2075

8

1

500447

03624227

81590005

8

1594005

81594005

8159.0005

C

D

3

8

3

8

4

3

4

4

8

0

0

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

4

6

1

0

0

0

0

Model

Table

Qty.

DISPIAY-NUMSEG ICWR .43-H

SOCKET-IC

DISPIAY-NUMSEG lCWR .4W

1

6

SOCKET-IC

2

IC COMPARATOR PRCN DUAL 8DlPP

2

IC

QATE

tC TRANSCENER TTL LS BUS

IC LCH TTL LS

IC

TRANSCEIVER

IC TRANSCEIVER lTL

1

IC DCDR

10

IC GATE TTL LS NAND WAD 24NP

IC GATE lTL LS NAND

IC LCH TTL LS

IC

LCH

LCH

tc

IC LCH lTL LS COM CLEAR 8-BK

IC LCH lTL LS COM CLEAR

IC LCH TTL LS COM CLEAR &BIT

IC LCH TTL LS COM CLEAR

IC LCH lTL LS

IC LCH TTL LS COM CLEAR

IC LCH TlL LS COM CLEAR &BIT

IC LCH lTL LS COM CLEAR 8-BIT

IC LCH

IC LCH 7TL LS COM CLEAR &BIT

IC LCH TTL LS COM CLEAR &BIT

15

IC DCDR TTL LS 3-TW-LINE 3-INP

IC DCDR lTL LS 3-TW-LINE 51NP

IC DCDR TTL LS 3-TW-LINE 3-INP

IC LCH TTL LS COM CLEAR

IC LCH TTL LS COM CLEAR &BIT

IC TRANSCEIVER TTL LS BUS

1

WIRE 24AWG BK

1

CMJNECTORSGL CONl

RESISTOR-ZERO

RESISTOR-ZERO

RESISTOR-ZERO

RESISTOR-ZERO

63.

Replaceable Parts

Description

14CM

DIP DIPSLDR

14CM

DIP

DIPSLDR

lTL

LS

NOR

WAD 24NP

COM

CLEAR 8-BIT

ITL

LS

m

m

LS

ITL

LS

lTL

LS COM CLEAR 881T

LS

LS 2-TWNE DUAL 2-INP

WAD

COM

CLEAR

COM

CLEAR

COM

CLEAR

COM

CLEAR 8-81s

300V

PVC 7x32 8OC

SKT

OHMS

22 AWG LEAD DIA

OHMS

22 AWG LEAD DIA

OHMS

22 AWG LEAD RIA

OHMS

22 AWG LEAD DIA

OCn

BUS

ocn

BUS OCTL

24NP

&BIT

8-BIT

8arr

&BIT

88tT

8-BIT

8-BIT

OCTL

1.14-MM-BSCSZ

PKQ

Mfr.

Code

28480

28480

28480

28480

27014

01295

28480

01295

28480

28480

01295

01295

01295

01295

01295

01295

01295

01295

01295

01295

01295

01295

01295

01295

01295

01295

01295

01295

01295

01295

01295

01295

28480

28480

28480

28480

28480

28480

28480

Mfr.

Part Number

5082.7651

12004803

5082-7651

12004803

LM393N

SN74LS02N

1820-2075

SN74LS259N

1820.2075

1820-2075

SN74LSl56N

SN74LSQ3N

SN74LS03N

SN74LS259N

SN74LS259N

SN74LS259 N

SN74LS259N

SN74LS259N

SN74LS259N

SN74LS259 N

SN74LS259N

SN74LS259N

SN74LS259N

SN74LS259N

SN74LS259N

SN74LS259N

SN74LS259N

SN74LS138N

SN74LS138N

SN74LS138 N

SN74LS259N

SN74LS259N

1820-2075

81504447

03624227

81590005

81594005

81

594005

81594005

8901B

Model

8901B

Replaceable

Parts

Reference

Designation

A2

A2

A2c

1

Ax2

Ax3

A2a

Ax5

Ax6

Ax7

A2a

A2c9

Ax10

Ax1 1

Ax12

A2C13

A2C14

A2C15

Ax16

A2C17

A2C18

A2c19

Ax20

A2c21

A2CZ

A2C23

A2C24

A2C25

A2C26

A2C27

A2C28

A2C29$

A2C30

-3

1

A2C32

A2c33

A2C34

A2c35

Ax36

A2c37

Ax38

A2CR1

A2CR2

A2J

1

A2J2

HP

Part

Number

08901-60008 6 1

0180-1746

0180-1746

01604650

01604650

0160.2055

0160-2055

01604648

01604648

01600134

01604649

0180-1714

01404229

0180-2206 4

01400196

0180-22Q6 4

0180-2206

01400194

0160-2055

0180-2141 6 2

01604084

01602055 9

0180-1714

01604849

0160-2302

0160-6606

01400154 3 1

01604759

016C-3538

01603536

01400198 5

0160-2055

0160-2055 9

01602222

19010040

19014)MO 1

1250-1220

21904124

29500078 9 37

1250-7220

21900124

29500078 9

C

Qty. Description

D

5

35

5

4

4

9

28

9

0

0

1 2

1 1

7 2

3

3

4

1 1

9

8

34

7

3

9

4

4

5

3

9

2 1

1

0

4

0

4

Table

AUDIO

CAPACITORFXD

CAPACITORFXD 15UF+ -10% 2oVDC TA

CAPACITORFXD 138OPF +.l% 50OVDC MICA

2

CAPACITOR-FXD 138OPF +-I% SOOVDC MICA

CAPACITOR-FXD .OlUF

CAPACITORFXD .OIUF

CAPACITOR-FXD 1650PF +-1%

2

CAPACITORFXD 1 650PF

CAPACITORFXD 2MPF

CAPACITOAFXD 214PF

CAPACITORFXD 330UF+-10% GVDC TA

CAPACITORFXD 38OPF

1

CAPACITOR-FXD 60UF

5

CAPACITOR-FXD 1SOPF

2

CAPACITORFXD WUF+-10% 6VDC TA

CAPACITOR-FXO 60UF+-1096 GVDC TA

CAPACITOR-FXD 1 lOPF

NOT ASSIGNED

CAPACITOR-FXD .OIUF

CAPACITOR-FXD 3.3UF+ -10% 50VDC TA

CAPACITORFXD .lUF + -20% SOVDC CER

NOT ASSIGNED

CAPACITORFXD .OIUF +80-20% 100VDC CER

NOT ASSIGNED

CAPACITOR-FXD 330UF+ -10% GVDC TA

CAPACITOR-FXD 91OOPF

1

CAPACITORFXD 4000PF

3

NOT

CAPACITOR-FXD .02UF + -1 % 20OVDC

1

CAPACITOR-FXD 13OOPF

CAPACITORFXD 68OOPF

1

CAPACITOR-FXD 750PF

1

CAPACITOR-FXD 620PF

1

CAPACITOR-FXD 200PF

4

NOT

CAPACITOR-FXD .01UF

CAPACITOR-FXD .01UF +EO-20% lOOVDC CER

CAPACITOR-FXD 1 5OOPF

DIOOESWITCHING 3OV SOMA

34

DIODESWITCHING 30V SOMA 2NS

CONNECTOR-RF SMC M PC

31

WASHERLK

36

NUT-HEX-DBLCHAM 10-32-THO .067-IN-THK

CONNECTOR-RF SMC

WASHERU

NUT-HEXDBLCHAM 1032.TH0 .067-IN.Ttb(

nLTERS

ASSIGNED

ASSIGNED

63.

Replaceable Parts

ASSEMBLY

15W+

-10%

+80-20%

+

80.20%

+

-1 96 SOOVDC MICA

+

-5%

+

-1%

+-1%

+

-1096 6VDC TA

+

5%

+

5%

+80-20%

+

-1%

+-1%

+

5%

+

-1% POOVDC

+&ab

+5%

+-5%

+

80.20% lOOVDC CER

+

INTL T NO.

INTL

10 .19S-IN-ID

M

PC

T NO. 10 ,195-lN-ID

20VDC TA

lOOVDC CER

lOOVDC

SOOVDC

3oOVDC MICA

SOOVDC

300VDC MICA

3OOVDC MICA

3OOVDC MICA

100VDC CER

lOOVDC

IOOVDC MICA

SOOVDC MICA

10OVDC MICA

lOOVDC MICA

300VDC MICA

-5%

300VDC MICA

ZNS

0035

Do35

50-OnM

50-OnM

MICA

MICA

CER

Mfr. Mfr.

Code

28080

56289

56289

28480

28480

28480

28480

28480

28480

28480

28480

56289

72136

56289

72136

56289

56289

72136

28480

56289

28480

28480

56289

28480

28480

28480

72136

28480

28480

28480

72136

28480

2weo

28480

28480

28480

28480

28480

28480