Page 1

User’s and Service Guide

Agilent Technologies

87050E and 87075C

Multiport Test Sets

For 871x Network Analyzers

Part No. 87050-90026

Printed in USA

Print Date: March 2004

Supersedes: June 2000

© Copyright 1999, 2000, 2004 Agilent Technologies, Inc.

Page 2

WARRANTY STATEMENT

THE MATERIAL CONTAINED IN THIS DOCUMENT IS PROVIDED

“AS IS,” AND IS SUBJECT TO BEING CHANGED, WITHOUT

NOTICE, IN FUTURE EDITIONS. FURTHER, TO THE MAXIMUM

EXTENT PERMITTED BY APPLICABLE LAW, AGILENT

DISCLAIMS ALL WARRANTIES, EITHER EXPRESS OR IMPLIED

WITH REGARD TO THIS MANUAL AND ANY INFORMATION

CONTAINED HEREIN, INCLUDING BUT NOT LIMITED TO THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR A P ARTICULAR PURPOSE. AGILENT SHALL NOT BE LIABLE

FOR ERRORS OR FOR INCIDENTAL

OR CONSEQUENTIAL DAMAGES IN CONNECTION WITH THE

FURNISHING, USE, OR PERFORMANCE OF THIS DOCUMENT

OR ANY INFORMA TION CONTAINED HEREIN. SHOULD AGILENT

AND THE USER HAVE A SEPARATE WRITTEN AGREEMENT

WITH WARRANTY TERMS COVERING THE MATERIAL IN THIS

DOCUMENT THAT CONFLICT WITH THESE TERMS, THE

WARRANTY TERMS IN THE SEPARATE AGREEMENT WILL

CONTROL.

DFARS/Restricted Rights Notice

If software is for use in the performance of a U.S. Government

prime contract or subcontract, Software is delivered and licensed

as “Commercial computer software” as defined in DFAR

252.227-7014 (June 1995), or as a “commercial item” as defined in

FAR 2.101(a) or as “Restricted computer software” as defined in

FAR 52.227-19 (June 1987) or any equivalent agency regulation or

contract clause. Use, duplication or disclosure of Software is

subject to Agilent Technologies’ standard commercial license

terms, and non-DOD Departments and Agencies of the U.S.

Government will receive no greater than Restricted Rights as

defined in FAR 52.227-19(c)(1-2) (June 1987). U.S. Government

ii

Page 3

users will receive no greater than Limited Rights as defined in

FAR 52.227-14 (June 1987) or DFAR 252.227-7015 (b)(2)

(November 1995), as applicable in any technical data.

Certification

Agilent Technologies, Inc. certifies that this product met its

published specifications at the time of shipment from the factory.

Agilent Technologies, Inc. further certifies that its calibration

measurements are traceable to the United States National

Institute of Standards and Technology, to the extent allowed by

the Institute's calibration facility, and to the calibration facilities

of other International Standards Organization members.

Assistance

Product maintenance agreements and other customer assistance

agreements are available for Agilent Technologies, Inc. products.

For information about these agreements and for other assistance,

contact Agilent. Refer to

page 35.

Safety Notes

The following safety notes are used throughout this manual.

Familiarize yourself with each of the notes and its meaning before

operating this instrument. All pertinent safety notes for using this

product are located in

iii

Chapter 10.

Page 4

WARNING Warning denotes a hazard. It calls attention to a procedure

which, if not correctly performed or adhered to, could

result in injury or loss of life. Do not proceed beyond a

warning note until the indicated conditions are fully

understood and met.

CAUTION Caution denotes a hazard. It calls attention to a procedure that, if

not correctly performed or adhered to, could result in damage to or

destruction of the instrument. Do not proceed beyond a caution

sign until the indicated conditions are fully understood and met.

Printing Copies of This Document

To print copies of documentation from the Web, download the PDF

file from the Agilent web site:

• Go to http://www.agilent.com.

• Enter the document’s part number (located on the title page) in

the Quick Search box.

• Click GO.

.

iv

Page 5

Contents

1. Introduction and Installation

Introduction to the Multiport Test Set . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

A Complete Multiport Test System . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Fully Characterize Your Devices with a Single Connection. . . . . . . . 1-2

Improve Your Competitiveness with a Fully Specified Test System . 1-3

Eliminate Redundant Connection of Calibration Standards with Test

Set Cal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Reduce the Effects of Test-System Drift with SelfCal . . . . . . . . . . . . 1-4

Decrease Calibration Times and Increase Production Throughput . 1-4

Improve Measurement Accuracy with Two-Port Calibration . . . . . . 1-4

Key Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

If You Are Using an 8711C/12C/13C/14C Analyzer . . . . . . . . . . . . . . . . 1-6

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Step 1. Check the Shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Step 2. Determine Network Analyzer Compatibility . . . . . . . . . . . . 1-12

Step 3. Connect the Test Set to the Analyzer . . . . . . . . . . . . . . . . . 1-14

Step 4. Satisfy Electrical and Environmental Requirements . . . . . 1-16

Step 5. Activate the Test Set and Check the System Operation . . . 1-19

Step 6. Connect Peripheral Devices. . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

Cleaning the Test Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

2. Getting Started

Brief Tour of System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Port Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Test Set Cal and SelfCal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Making Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Transmission Measurements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Reflection Measurements Using a 1-Port Cal. . . . . . . . . . . . . . . . . . 2-12

Contents-v

Page 6

Contents

Reflection Measurements Using a 2-Port Cal (8712ES/14ES Only) 2-14

Performing the Operator's Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

If the Multiport Test Set Fails the Operator's Check . . . . . . . . . . . . 2-21

Cable and Test Fixture Considerations. . . . . . . . . . . . . . . . . . . . . . . . . 2-22

3. Measurement Examples

Example: Measuring a 50 Ohm Duplexer. . . . . . . . . . . . . . . . . . . . . . . .3-3

Calibrating the Multiport System for Measuring a 50 Ohm

Duplexer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

Measuring Insertion Loss: ANT Port to Rx Port. . . . . . . . . . . . . . . . . 3-8

Measuring Insertion Loss: Tx Port to ANT Port . . . . . . . . . . . . . . . . 3-10

Measuring Isolation: Rx Port to Tx Port . . . . . . . . . . . . . . . . . . . . . .3-12

Measuring Return Loss: ANT Port . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Measuring Return Loss: Rx Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Measuring Return Loss: Tx Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

Example: Measuring a 75 Ohm Tap . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

Calibrating the Multiport System for Measuring a 75 Ohm Tap. . . 3-26

Measuring Insertion Loss: In Port to Out Port . . . . . . . . . . . . . . . . .3-28

Measuring Reverse Isolation:

Out Port to In Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-30

Measuring Insertion Loss: In Port to Tap1 . . . . . . . . . . . . . . . . . . . . 3-32

Measuring Isolation: Tap3 to Tap4 . . . . . . . . . . . . . . . . . . . . . . . . . . 3-34

Measuring Return Loss: In Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-36

Measuring Return Loss: Out Port . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-38

Using Two Measurement Channels Simultaneously . . . . . . . . . . . . .3-41

Using the Same Test Set Port Assignments for Both Measurement

Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-41

Using Different Test Set Port Assignments for Both Measurement

Contents-vi

Page 7

Contents

Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-45

4. Test Set Cal and SelfCal

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Test Set Cal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

SelfCal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Test Set Cal: An Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Setting Up the Measurement Parameters . . . . . . . . . . . . . . . . . . . . . 4-5

Determining the Best Position for the Calibration Reference Plane. 4-8

Determining the Type of Calibration Kit to Use . . . . . . . . . . . . . . . . 4-9

Determine the Number of Test Set Ports to Be Used. . . . . . . . . . . . 4-11

Performing the Test Set Cal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Saving the Test Set Cal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Recalling the Test Set Cal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Setting the SelfCal Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Selecting the SelfCal Method

(For 8712ES/14ES Analyzers Only). . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Test Set Cal Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

Test Set Cal Example #1: The DUT Has Insertable Port Pairs . . . . 4-22

Test Set Cal Example #2: The DUT Has Noninsertable Port Pairs with

Identical Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

Test Set Cal Example #3: The DUT Has a Noninsertable Port Pair with

Dissimilar Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-43

Test Set Cal and SelfCal: Theory of Operation . . . . . . . . . . . . . . . . . . 4-56

SelfCal Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-59

Calibrated-Port Switching Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-65

Factory Test Set Cal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-67

Using Multiple Test Set Cals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-68

Verifying the Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-70

Method #1: Calibration Check

Contents-vii

Page 8

Contents

(8712ET/14ET only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-71

Method #2: Measure an Alternate Set of Calibration Standards. . .4-72

Method #3: Measure a “Golden DUT” . . . . . . . . . . . . . . . . . . . . . . . . 4-74

Using Calibration Verification to Determine Calibration Intervals 4-74

If the Calibration Verification Data Is Bad . . . . . . . . . . . . . . . . . . . . 4-76

Calibration Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-78

Selecting a Calibration Kit Stored in the Analyzer . . . . . . . . . . . . . 4-78

Creating a User-Defined Calibration Kit . . . . . . . . . . . . . . . . . . . . . 4-80

5. Automating Measurements

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Multiport Test Set SCPI Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Usage of *OPC? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

6. Front/Rear Panel

Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Line Power Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

Test Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

The REFLECTION Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-5

The TRANSMISSION Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

The Chassis Ground Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

The PORT CONNECTION Status LEDs . . . . . . . . . . . . . . . . . . . . . . 6-5

Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-6

The PARALLEL IN Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

The PARALLEL OUT Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Line Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

7. Key Reference

Alphabetical Key Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Contents-viii

Page 9

Contents

8. Specifications

About This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

System Performance, Corrected,

2-Port Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

System Performance, Corrected,

T/R Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

System Performance, Uncorrected . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-17

System Performance, General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-20

Test Set Performance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-24

Physical Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-30

Contacting Agilent. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-35

9. Service

Automated Performance Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

Test Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

Program Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

Op Check Test Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

Performance Verification Test Results . . . . . . . . . . . . . . . . . . . . . . . . 9-9

Manual Performance Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-14

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-15

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-16

The Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-16

The LED Display Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-17

The Main Switch Board Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . 9-17

Post-Repair Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-17

Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-18

Contents-ix

Page 10

Contents

Manual Control of the Multiport Test Set . . . . . . . . . . . . . . . . . . . . .9-19

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-22

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-22

Rebuilt-Exchange Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-23

Major Parts and Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-24

Cables, Front Panel, and Main Board Assembly — Option 012

(75 Ω and 50 Ω) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-26

Cables, Front Panel, and Main Board Assembly — Option 008

(50 Ω only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-28

Cables, Front Panel, and Main Board Assembly— Option 006

(75 Ω only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-30

Cables, Front Panel, and Main Board Assembly — Option 004

(50 Ω only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-32

Instrument Covers and Associated Parts . . . . . . . . . . . . . . . . . . . . . 9-34

Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-36

Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-37

10. Safety and Regulatory Information

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-4

Statement of Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-5

Cleaning Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-5

Shipping Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-5

Instrument Markings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-6

Regulatory Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-7

Notice for Germany: Noise Declaration . . . . . . . . . . . . . . . . . . . . . . 10-7

Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-7

Contents-x

Page 11

1 Introduction and Installation

1-1

Page 12

Introduction and Installation

Introduction to the Multiport Test Set

Introduction to the Multiport Test Set

• The 87050E is a 50-ohm multiport test set that is available with 4, 8,

or 12 test ports.

• The 87075C is a 75-ohm multiport test set that is available with 6 or

12 test ports.

A Complete Multiport Test System

87050E and 87075C multiport test sets are designed to work with

8712ET/ES (1.3 GHz) and 8714ET/ES (3 GHz) RF network analyzers to

provide complete measurement systems for 50 ohm and 75 ohm

multiport devices. These test systems offer fast measurement speed, high

accuracy, and productivity features that will maximize your production

throughput. They feature:

• specified performance to 1.3 GHz (87075C) or

2.2 GHz (87050E—with typical performance to 3 GHz)

• solid-state switches for fast, repeatable, and reliable switching

between measurement paths

Fully Characterize Your Devices with a Single Connection

A single connection between the multiport test set and each port of the

DUT allows complete testing of all transmission paths and port

reflection characteristics. Agilent multiport test systems eliminate

time-consuming reconnections to the DUT, keeping your production costs

down and your volumes up. By reducing the number of RF connections,

you also:

• lower the risk of misconnections

• reduce operator fatigue

• minimize wear on cables, fixtures, connectors, and the DUT

1-2 Chapter 1

Page 13

Introduction and Installation

Introduction to the Multiport Test Set

Improve Your Competitiveness with a Fully Specified Test System

A multiport test set coupled with an 8712E series network analyzer

offers fully specified performance at the actual test ports, whether you

measure in a fixture or at the end of test cables. Specified performance

means you can:

• get the same results no matter which test station you use to measure

your DUT

• correlate test data from many DUTs across multiple test systems

• reduce measurement uncertainty to tighten your product

specifications

• increase customer confidence in your products

Eliminate Redundant Connection of Calibration Standards with Test Set Cal

Calibrating a multiport test set using two-port error correction and a

traditional network analyzer requires a unique instrument state for each

measurement path, forcing many redundant connections of calibration

standards. As the number of ports increases, so does the number of

connections required to calibrate all possible measurement paths. Full

calibration of the multiport test system is quick and simple when

performing a Test Set Cal:

• connect short, open, and load standards only once to each

measurement port

• minimize the number of through standards required during

calibration

Chapter 1 1-3

Page 14

Introduction and Installation

Introduction to the Multiport Test Set

Reduce the Effects of Test-System Drift with SelfCal

SelfCal is an internally automated calibration technique that uses

solid-state switches to measure calibration standards located inside the

test set. SelfCal executes automatically in just a few seconds (at an

interval you define), so the impact to your test process is minimal. Use

SelfCal to:

• re-calibrate your multiport test system, returning it to the same

measurement accuracy achieved immediately after performing a Test

Set Cal

• reduce the effects of test-system drift, improving overall

measurement accuracy between Test Set Cals

Since SelfCal does not correct for drift associated with interconnect

elements between the test set and your DUT, it is essential to use

high-quality test cables, adapters, and fixtures to ensure the best

measurement accuracy.

Decrease Calibration Times and Increase Production Throughput

With SelfCal, a Test Set Cal needs to be performed about once per

month, if within the specified temperature range. This is unlike other

test systems that typically require calibration once or twice a day. Using

Test Set Cal and SelfCal, you can:

• easily reduce your overall calibration times by a factor of twenty or

more

• increase the amount of time a test station can be used for measuring

devices—typically, by three days per month.

Improve Measurement Accuracy with Two-Port Calibration

When using a multiport test set with an 8712ES or 8714ES S-parameter

network analyzer, Test Set Cal and SelfCal support full two-port

calibrations. Two-port error correction greatly improves the effective

load match of the test system, providing excellent measurement

accuracy.

1-4 Chapter 1

Page 15

Key Conventions

This manual uses the following conventions:

FRONT-PANEL KEY

analyzer (a “hardkey”).

: This represents a key physically located on the

Introduction and Installation

Key Conventions

Softkey

the instrument’s firmware, and is displayed on the right side of the

instrument’s screen next to the eight unlabeled keys.

: This indicates a “softkey”: a key whose label is determined by

Chapter 1 1-5

Page 16

Introduction and Installation

If You Are Using an 8711C/12C/13C/14C Analyzer

If You Are Using an 8711C/12C/13C/14C

Analyzer

This document is intended for use with 8712ET/ES and 8714ET/ES

analyzers, so some of the information (for example, keypresses and

calibration features) does not apply to your analyzer. The Agilent

Technologies 87075C Multiport Test Set User’s and Service Guide is

specifically written for using the 87075C multiport test set with

8711C/12C/13C/14C analyzers. You can order a copy of this manual (part

number 87075-90005) by contacting Agilent. See page 35 for contact

information. The manual can be also be viewed in the following two

locations:

• CD-ROM (included with your multiport test set)

• Web site http://www.agilent.com/find/manuals (enter 87075C in the

search field)

There is also software available for an operator’s check and performance

tests that support the old version of the specifications for using the

87075C multiport test set with 8711C/12C/13C/14C analyzers.

Both the 87050E and the 87075C multiport test sets are compatible with

8711C/12C/13C/14C analyzers that contain firmware revision C.04.5.x or

later. Analyzers must have 16 MBytes of DRAM and 1 MB of non-volatile

RAM. For more information, refer to the Agilent Technologies 87075C

Multiport Test Set User’s and Service Guide.

1-6 Chapter 1

Page 17

Introduction and Installation

Installation

Installation

This section will guide you through the steps necessary to correctly and

safely install your multiport test set. The steps are:

• “Step 1. Check the Shipment” on page 1-10

• “Step 2. Determine Network Analyzer Compatibility” on page 1-12

• “Step 3. Connect the Test Set to the Analyzer” on page 1-14

• “Step 4. Satisfy Electrical and Environmental Requirements” on

page 1-16

• “Step 5. Activate the Test Set and Check the System Operation” on

page 1-19

• “Step 6. Connect Peripheral Devices” on page 1-21

Chapter 1 1-7

Page 18

Introduction and Installation

Installation

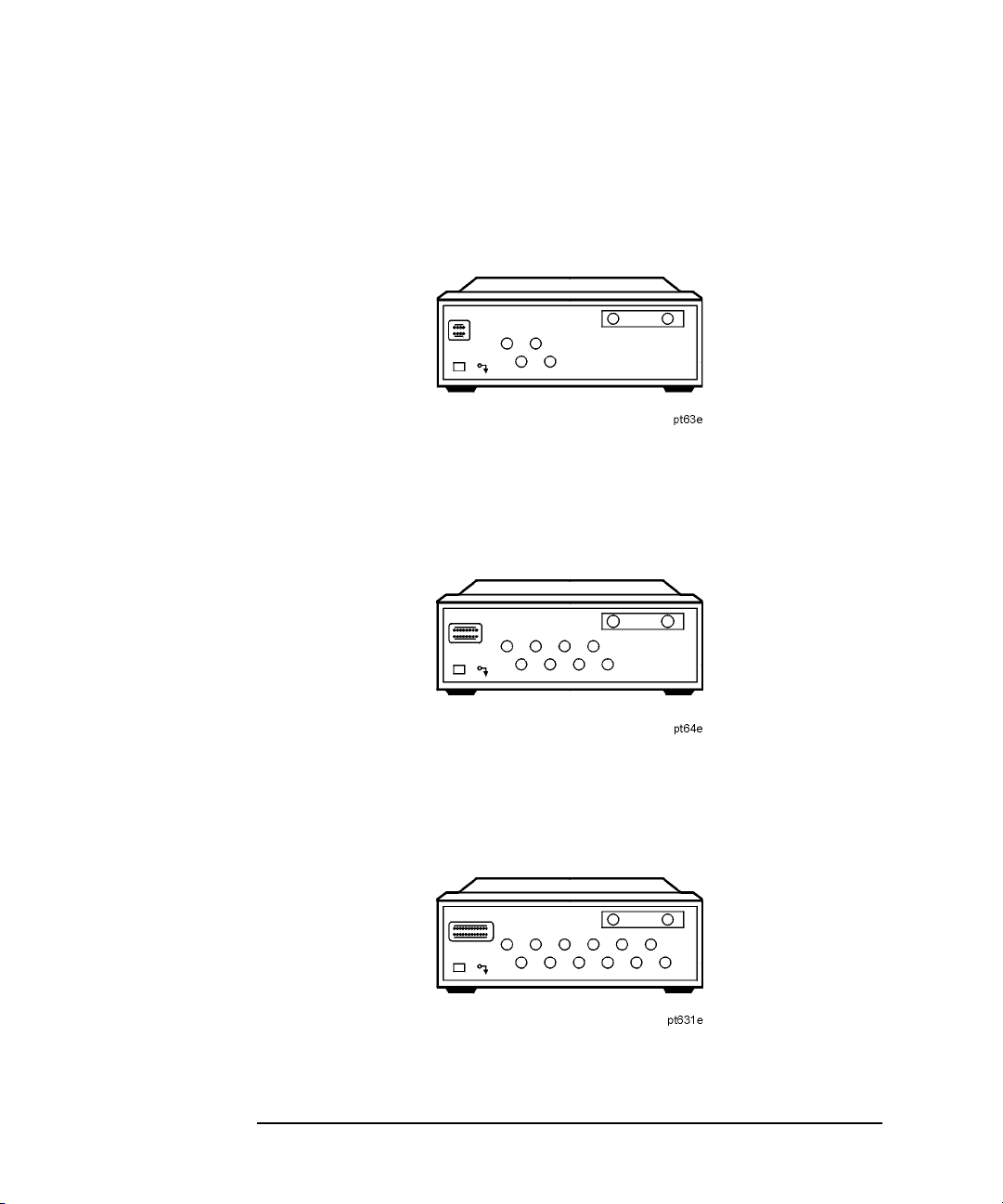

Figure 1-1 87050E Multiport Test Set — Three Versions

87050E Option 004 — Four Port Test Set

87050E Option 008 — Eight Port Test Set

87050E Option 012 — Twelve Port Test Set

1-8 Chapter 1

Page 19

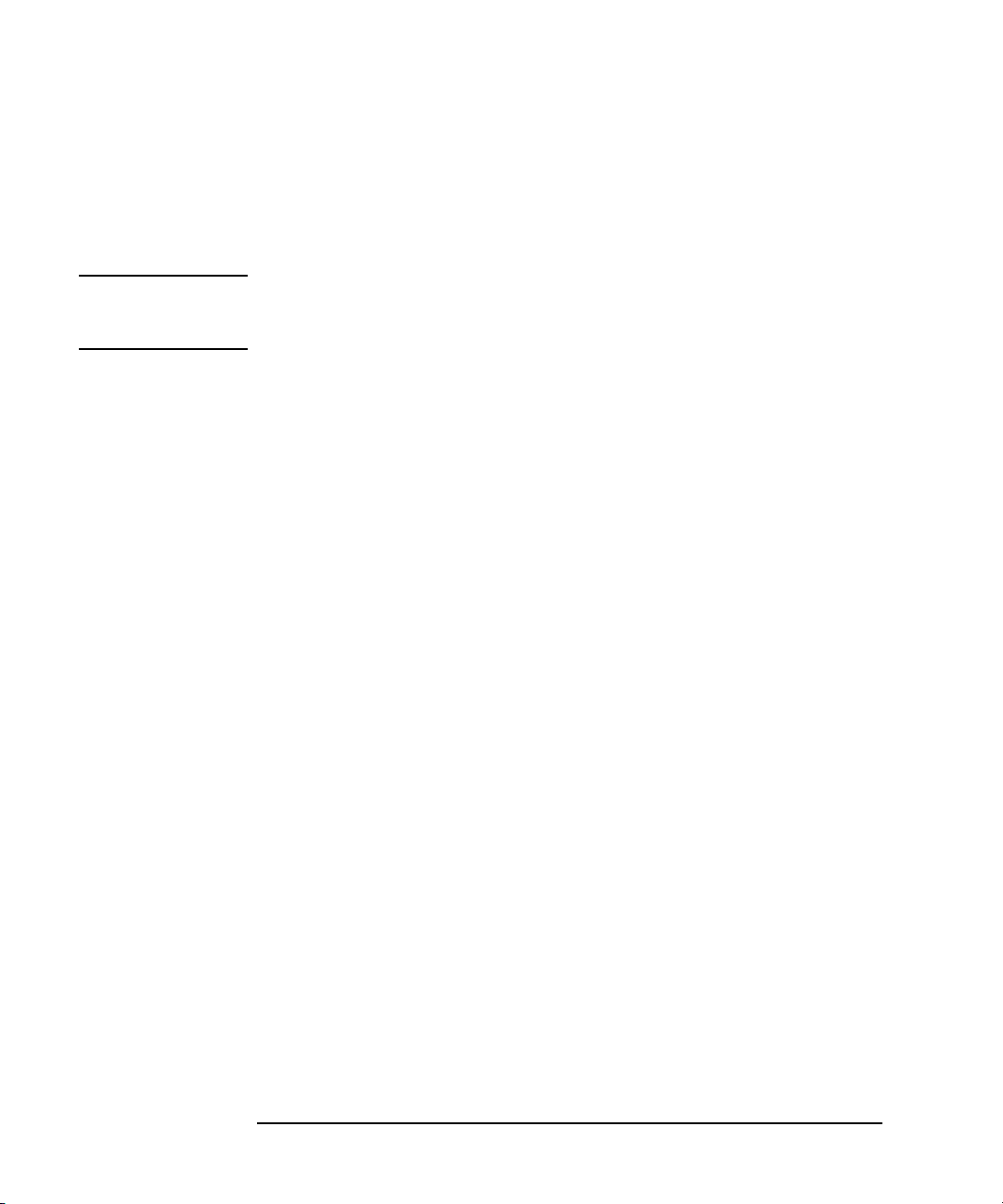

Figure 1-2 87075C Multiport Test Set — Two Versions

87075C Option 006 — Six Port Test Set

87075C Option 012 — Twelve Port Test Set

Introduction and Installation

Installation

Chapter 1 1-9

Page 20

Introduction and Installation

Installation

Step 1. Check the Shipment

After you have unpacked your test set, keep the packaging materials to

use if your instrument should need to be returned for maintenance or

repair.

NOTE The packaging material is designed to protect the test set from damage

that can happen during shipping. Returning the test set in anything

other than the original packaging may result in non-warranted damage.

Check the items received against Table 1-1 on page 1-11 to make sure

that you received everything.

Inspect the test set and all accessories for any signs of damage that may

have occurred during shipment. If your test set or any accessories appear

to be damaged or missing, call Agilent Technologies. Refer to page 35 for

contact information.

1-10 Chapter 1

Page 21

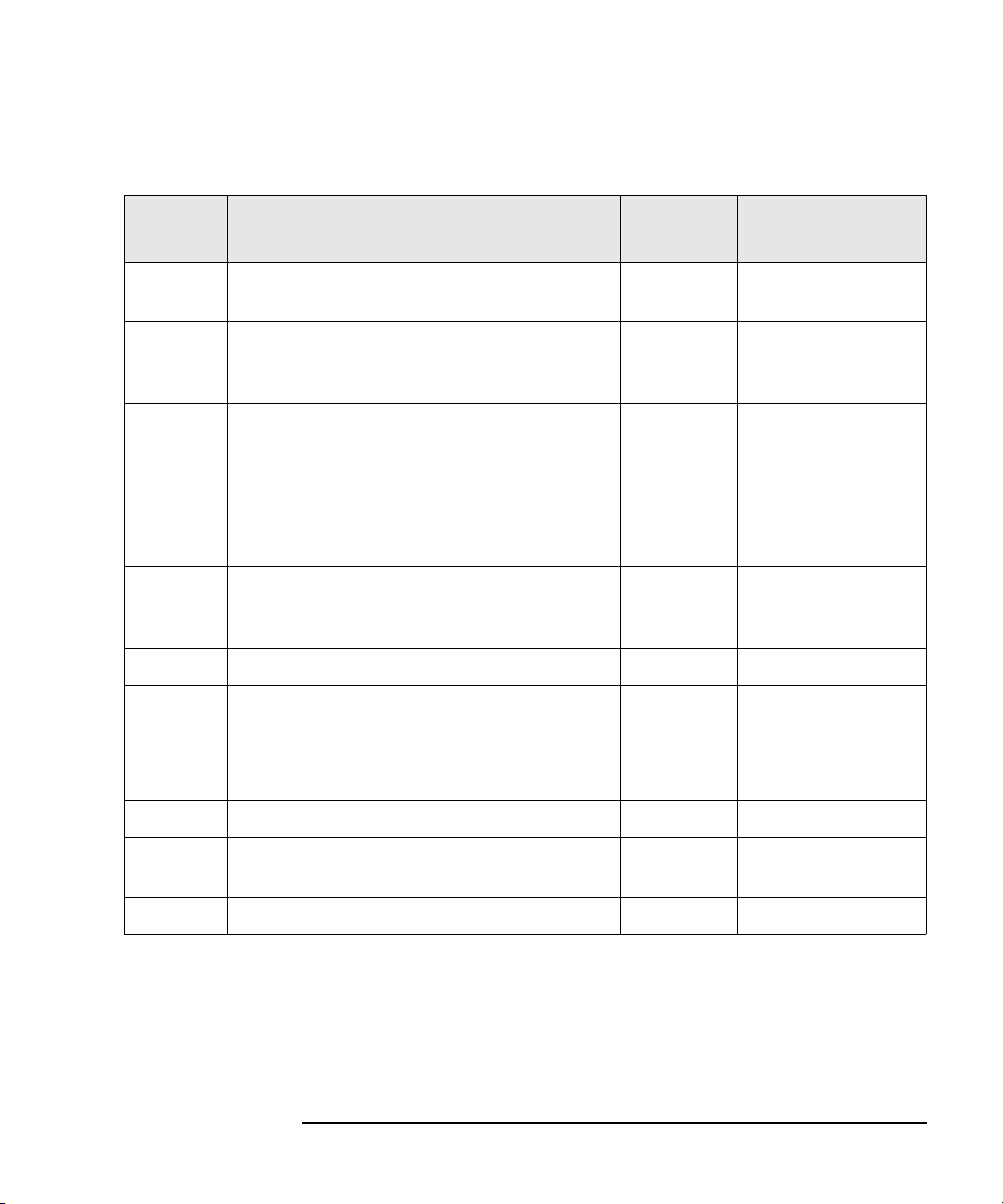

Table 1-1 Test Set Accessories Supplied

Introduction and Installation

Installation

Item

No.

Description Quantity Part Number

1 Power Cord 1 See Figure 6-5 on

page 6-9.

2 Type-N Cable (Analyzer to test set’s

REFLECTION Port)

1

1 (75 Ω) 87075-60026

(50 Ω) 87050-60058

3 Type-N Cable (Analyzer to test set’s

TRANSMISSION Port)

1

1 (75 Ω) 87075-60028

(50 Ω) 87050-60060

4 Type-N Cable (Analyzer to test set’s

REFLECTION Port)

2

1 (75 Ω) 87075-60027

(50 Ω) 87050-60059

5 Type-N Cable (Analyzer to test set’s

TRANSMISSION Port)

2

1 (75 Ω) 87075-60029

(50 Ω) 87050-60061

6 Parallel Port Interface Cable 1 8120-6818

7 87050E and 87075C User's and Service

1

87050-90026

Guide for 871x Network Analyzers

87075C only: 87075C User's and Service

Guide for E506x Network Analyzers

1

87075-90027

8 Test Set Calibration Disk 1 N/A

9 Performance Test Programs Disks

1 08714-60049

(DOS and LIF formats)

10 CD-ROM 1 08714-90051

1. Not to be used with a rack-mounted system or if the analyzer has had its bottom

feet removed. See Figure 1-7 on page 1-19 to see how these cables are to be con-

nected.

2. You will only receive these cables if you ordered Option 1CM (rack mount kit). Use

these cables if you are rack-mounting your system, or if the bottom feet of the analyzer have been removed. See Figure 1-7 on page 1-19 for information on how to

connect these cables.

Chapter 1 1-11

Page 22

Introduction and Installation

Installation

Figure 1-3 Test Set Accessories Supplied

Step 2. Determine Network Analyzer Compatibility

The 87050E multiport test set is designed for use with 8712ET/ES and

8714ET/ES RF network analyzers, 50 Ω impedance.

The 87075C multiport test set is designed for use with

8711C/12C/13C/14C or 8712ET/ES and 8714ET/ES RF network

analyzers, 75 Ω impedance (Option 1EC).

The basic function of the 87050E and the 87075C multiport test sets is

identical. However, their impedance and specifications are different.

1-12 Chapter 1

Page 23

Introduction and Installation

Installation

If you are using a C-series analyzer, refer to “If You Are Using an

8711C/12C/13C/14C Analyzer” on page 1-6.

Check the Firmware Revision

The firmware in your E-series analyzer must be revision E.06.00 or later.

The firmware revision is displayed when you first power up the analyzer,

and can also be viewed by pressing

Instrument Info

If your analyzer does not have firmware revision E.06.00 or later, then

you must upgrade to the latest revision of firmware. You can perform this

upgrade yourself. The current firmware is available as a set of floppy

disks. To order, contact Agilent Technologies. Refer to page 35 for contact

information.

The current firmware revision may also be downloaded, free of charge,

through the internet. There is a link to the download site at the following

URL: http://www.agilent.com/find/enasupport

CAUTION When upgrading firmware from E.05.xx to E.06.xx, it is necessary to

save the correction constants on a floppy disk before loading the new

version of firmware.

.

SYSTEM OPTIONS Service

Chapter 1 1 -13

Page 24

Introduction and Installation

Installation

Step 3. Connect the Test Set to the Analyzer

For using your system on a bench, configure and connect the two

instruments as shown in Figure 1-4. Use the parallel cable that was

shipped with the multiport test set to connect to the analyzer as shown.

If you will be installing your system in a rack, read “Installing the

System in a Rack,” next in this section, before connecting the test set to

the analyzer.

Figure 1-4 System Configuration

1-14 Chapter 1

Page 25

Introduction and Installation

Installation

Installing the System in a Rack

Use only the recommended rack mount kit for the network analyzer

(Option 1CM when ordered with the analyzer, or part number

08712-60036 when ordered separately): it needs side support rails. Do

not attempt to mount the analyzer by the front panel (handles) only. The

recommended rack mount kit allows you to mount the analyzer with or

without handles.

The rack mount kit for the test set is Option 1CM when ordered with the

test set, or part number 5063-9214 when ordered separately.

NOTE There are special semi-rigid cables that should be used to connect the

analyzer’s test ports to the test set’s REFLECTION and

TRANSMISSION ports when used in a rack (or a bench configuration

where the analyzer’s bottom feet have been removed). These cables were

shipped with your analyzer if you ordered Option 1CM. If you order the

rack mount kit separately, you will need to order these special cables

separately also. See Table 1-1 on page 1-11 for part numbers.

To install your system in an 85043D rack, follow the instructions in the

rack manual.

CAUTION When installing your system in other racks, improper installation may

cause shock hazards, overheating, dust contamination, and inferior

system performance. For support details and information about

installation and warranty, call Agilent Technologies. Refer to page 35 for

the nearest office.

CAUTION When installing the system in a cabinet, the convection into and out of

the system must not be restricted. The ambient temperature (outside the

cabinet) must be less than the maximum operating temperature of the

system by 4 °C for every 100 watts dissipated in the cabinet. If the total

power dissipated in the cabinet is greater than 800 watts, then forced

convection must be used.

Chapter 1 1 -15

Page 26

Introduction and Installation

Installation

Step 4. Satisfy Electrical and Environmental Requirements

NOTE Refer to your network analyzer’s User’s Guide for information on

electrical and environmental requirements for your network analyzer.

1. The line power module on your multiport test set has an autoranging

input. It is designed to be used with an ac power source with a

nominal voltage of either 115 V or 230 V.

2. Ensure the available ac power source meets the following

requirements:

Nominal Range

Frequency: 50/60 Hz 47–63 Hz

Line Voltage: 100/115 V or 230/240 V 90–264 V

Power 45 W max

CAUTION This product has an autoranging line-voltage input. Be sure the supply

voltage is within the specified range.

If the ac line voltage does not fall within these ranges, an

autotransformer that provides third-wire continuity to earth ground

should be used.

3. Ensure the operating environment meets the following requirements

for safety:

• indoor use

• altitude up to 15,000 feet (4,572 meters)

• temperature 0 °C to 55 °C

• maximum relative humidity 80% for temperatures up to 31 °C

decreasing linearly to 50% relative humidity at 40 °C

• use only in INSTALLATION CATEGORY II, and POLLUTION

DEGREE 2, per IEC 1010 and 664 respectively

1-16 Chapter 1

Page 27

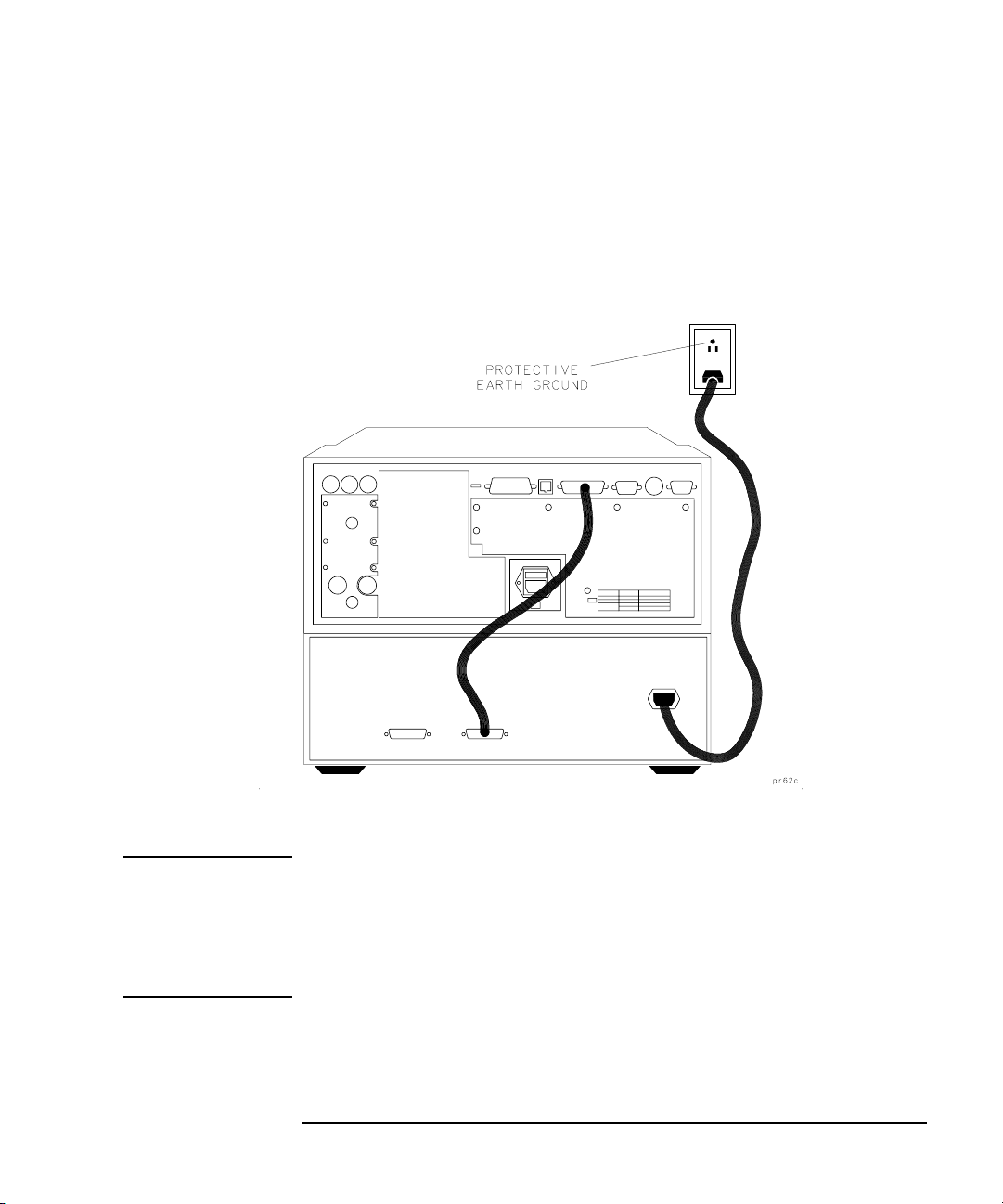

4. Verify that the power cable is not damaged, and that the power source

outlet provides a protective earth ground contact. Note that the

following illustration depicts only one type of power source outlet.

Refer to Figure 6-5 on page 6-9 to see the different types of power cord

plugs that can be used with your test set.

Figure 1-5 Protective Earth Ground

Introduction and Installation

Installation

WARNING This is a Safety Class I product (provided with a protective

earthing ground incorporated in the power cord). The mains

plug shall only be inserted in a socket outlet provided with a

protective earth contact. Any interruption of the protective

conductor, inside or outside the instrument, is likely to make the

instrument dangerous. Intentional interruption is prohibited.

Chapter 1 1 -17

Page 28

Introduction and Installation

Installation

5. Ensure there are at least two inches of clearance around the sides and

back of the test set or the system cabinet.

Figure 1-6 Ventilation Clearance Requirements

6. Set up a static-safe workstation. Electrostatic discharge (ESD) can

damage or destroy components.

• table mat with earth ground wire:

part number 9300-0797

• wrist-strap cord with 1 Meg Ohm

resistor:

part number 9300-0980

•wrist-strap:

part number 9300-1367

• heel straps:

part number 9300-1308

• floor mat

1-18 Chapter 1

Page 29

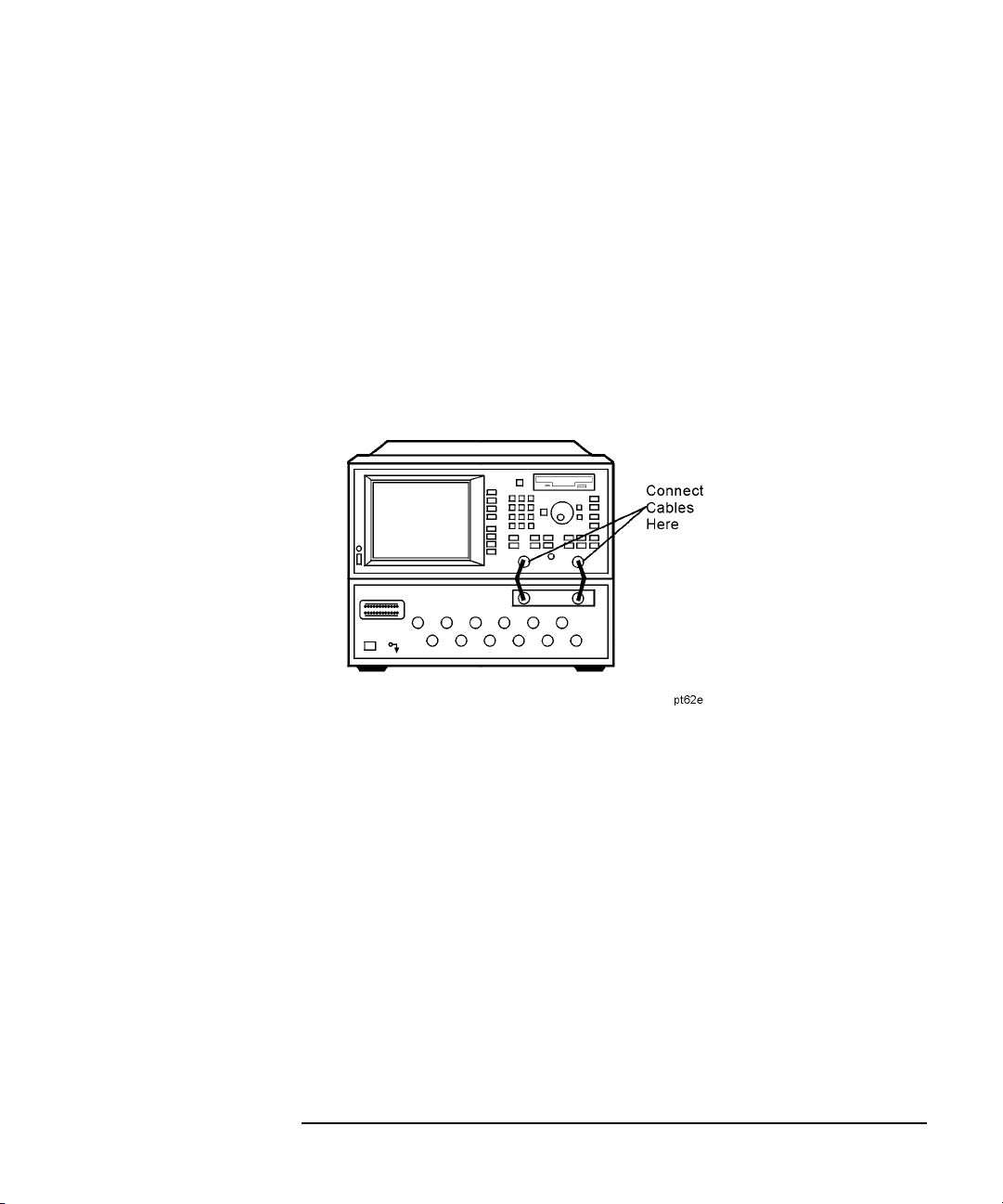

Step 5. Activate the Test Set and Check the System Operation

1. Connect the semi-rigid cables that were shipped with your test set as

shown in Figure 1-7. Check Table 1-1 on page 1-11 to be sure that you

are using the correct cables with your system configuration (the

cables you use will be different depending on whether you are using a

bench system configuration—as shown in Figure 1-7—or a rack

configuration).

Figure 1-7 Connect the Front Panel RF Cables

Introduction and Installation

Installation

Chapter 1 1 -19

Page 30

Introduction and Installation

Installation

NOTE Steps 2 and 3 must be performed before you can use your network

analyzer to control the multiport test set.

2. Turn on the test set.

3. Turn on the analyzer and press

Switching Test Set Multiport

. Toggle to ON.

SYSTEM OPTIONS System Config

4. The operator’s check should be performed on the system to provide a

high degree of confidence that the system is working properly. Refer

to Chapter 2, “Getting Started,” for instructions on how to perform

the operator’s check.

5. After performing the operator’s check, you should connect any

peripheral devices you will be using with your system. Refer to “Step

6. Connect Peripheral Devices,” next in this chapter.

1-20 Chapter 1

Page 31

Introduction and Installation

Installation

Step 6. Connect Peripheral Devices

After you’ve performed the operator’s check to ensure that your system is

working properly, connect any peripherals that you intend to use with

your system.

Connecting Peripherals and Controllers

Figure 1-8 Network Analyzer and Multiport Test-Set Rear-Panel Connectors

Chapter 1 1 -21

Page 32

Introduction and Installation

Installation

Refer to Figure 1-8:

• The GPIB port on the analyzer is for use with computers, other test

instruments, and peripherals (printers, plotters, etc.).

• The PARALLEL PORT on the analyzer connects to the test set’s

PARALLEL IN port as shown with the interconnect cable that was

shipped with your test set.

• The PARALLEL OUT port on the test set, and the analyzer’s SERIAL

port (RS-232) are for peripherals such as printers or plotters. The

serial port can also be programmed via IBASIC for general I/O

control. See your analyzer’s HP Instrument BASIC User’s Handbook

for information on using IBASIC.

• The VIDEO OUT COLOR VGA port on the analyzer allows you to

connect a color VGA monitor for enhanced viewing. See “Using an

External VGA Monitor” in Chapter 4 of your analyzer’s User’s Guide

for more information.

• The LAN ETHERTWIST connector on the analyzer is for connecting

your analyzer to a local area network (LAN) for control and file

access. See The LAN Interface User’s Guide Supplement for

information on how to use your analyzer in a LAN.

• The DIN KEYBOARD connector can be used with an optional

keyboard or bar code reader. See “Using a Keyboard” in Chapter 4 of

your analyzer’s User’s Guide for more information.

NOTE See your analyzer’s User’s Guide for more specific information on GPIB

connections, parallel and serial connections, and configuring peripheral

settings.

1-22 Chapter 1

Page 33

Introduction and Installation

Preventive Maintenance

Preventive Maintenance

Preventive maintenance consists of checking the front panel connectors.

This should be done at least every six months — more often if the test set

is used daily on a production line or in a harsh environment.

Visually inspect the front panel connectors. The most important

connectors are those to which the DUT is connected. All connectors

should be clean and the center pins centered. The fingers of female

connectors should be unbroken and uniform in appearance. If you are

unsure whether the connectors are good, gauge the connectors to confirm

that their dimensions are correct.

Figure 1-9 Maximum and Minimum Protrusion of Center Conductor From

Mating Plane

CAUTION 87050E multiport test sets only:

Connecting 75 ohm cables to the front panel 50 ohm connectors of the

analyzer or test set usually results in intermittent or no electrical

connections.

CAUTION 87075C multiport test sets only:

Never connect 50 ohm cables to the front panel 75 ohm connectors of the

analyzer or test set. Otherwise, irreparable connector damage will occur.

Chapter 1 1 -23

Page 34

Introduction and Installation

Preventive Maintenance

Cleaning the Test Set

Use a dry cloth or one slightly dampened with water to clean the external

case parts. Do not attempt to clean internally.

WARNING To prevent electrical shock, disconnect the test set from power

mains before cleaning.

1-24 Chapter 1

Page 35

2 Getting Started

2-1

Page 36

Getting Started

Brief Tour of System

This chapter provides you with a brief tour of the system and an

overview of the following topics:

• “Port Connections” on page 2-4

• “Test Set Cal and SelfCal” on page 2-6

• “Making Measurements” on page 2-9

• “Performing the Operator's Check” on page 2-16

• “Cable and Test Fixture Considerations” on page 2-22

Brief Tour of System

On the next page, refer to the figure and descriptions of the main keys

and features you’ll use on your multiport system.

You should familiarize yourself with the analyzer’s features by referring

to its User’s Guide.

2-2 Chapter 2

Page 37

Figure 2-1 The Multiport System

Getting Started

Brief Tour of System

Table 2-1 Multiport System Features

Item # Description

1

MEAS 1 MEAS 2

The and keys: Use these keys to access

measurement selection and test set port selection.

2

CAL

The key: Use this key to access the Test Set Cal and SelfCal

features. See Chapter 4, “Test Set Cal and SelfCal,” for more

information.

3 The test set port connection status display.

4 The test set ports.

Chapter 2 2-3

Page 38

Getting Started

Port Connections

Port Connections

When your multiport test system is properly connected and configured as

described in Chapter 1, you have the ability to switch any of the

numbered ports on your test set to either the REFLECTION (or

PORT 1

test set’s switching mechanism is illustrated in Figure 2-4 on page 2-10.

The analyzer controls the test set through the rear panel parallel

interface. Port connections are determined by your keypress selections,

as shown in the “Making Measurements” examples later in this chapter.

The port connection status is displayed on the test set’s front panel and

on the network analyzer’s display in the upper left-hand corner (and in

the softkeys, 8712ES/14ES only). See Figure 2-2 and Figure 2-3, which

show status indicator examples for a transmission measurement and a

reflection measurement.

*

) or TRANSMISSION (or PORT 2*) port on the analyzer. The

* For 8712ES/14ES analyzers only.

2-4 Chapter 2

Page 39

Figure 2-2 Port Connection Status: Transmission Measurement

Getting Started

Port Connections

Figure 2-3 Port Connection Status: Reflection Measurement

Chapter 2 2-5

Page 40

Getting Started

Test Set Cal and SelfCal

Test Set Cal and SelfCal

Before you make any measurements, you must calibrate your multiport

system. By implementing the Test Set Cal and SelfCal features on your

multiport system, you can increase the accuracy of your measurements

and significantly increase the throughput of your multiport

measurements by eliminating frequent and lengthy calibration

procedures.

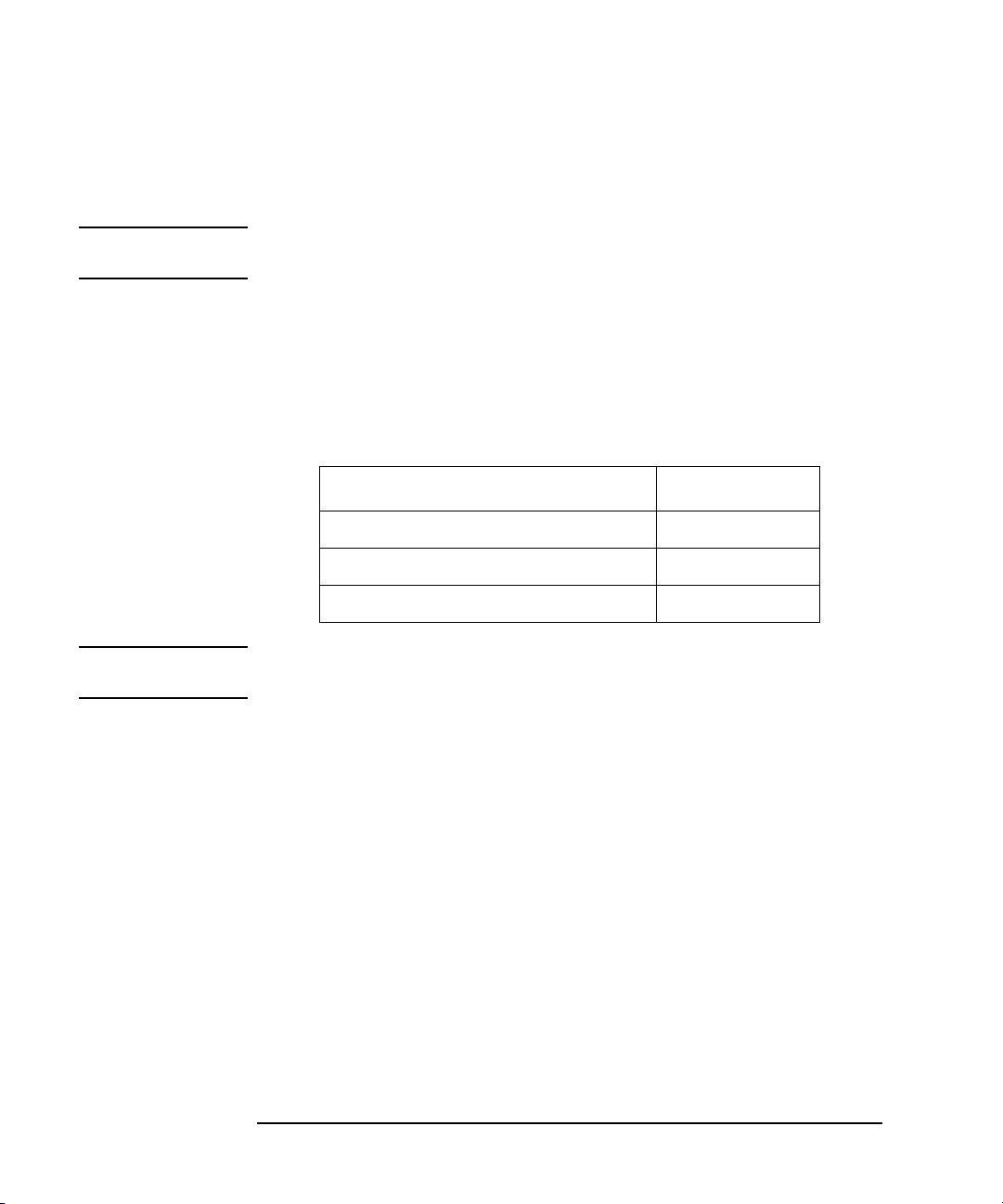

Cal Type What is it? How to do it? When to do it?

Test Set

Cal

SelfCal An internally

A full calibration of the

multiport test system.

Requires connections

of external calibration

standards.

automated calibration

technique. Uses

solid-state switches to

measure calibration

standards located

inside the test set.

The Test Set Cal process that is best suited for your particular

measurements will depend on the type of DUT you are testing. Refer to

the following Test Set Cal examples for one that best matches your DUT.

• “Test Set Cal Example #1: The DUT Has Insertable Port Pairs” on

page 4-22*

• “Test Set Cal Example #2: The DUT Has Noninsertable Port Pairs

with Identical Connectors” on page 4-28*

Press

open, and load standards to each

measurement port. Connect

through-standards to each adjacent port

pair. (Refer to

on page 4-21

You d o

to perform a SelfCal. Press

Details” on page 4-59

CAL Test Set Cal

Create “TSET_CAL”

. Connect short,

“Test Set Cal Examples”

.)

not have to disconnect your DUT

CAL

Test Set Cal Periodic SelfCal

SelfCal Once

( or

). (Refer to “SelfCal

.)

When you first

set up your test

system.

Thereafter,

about once a

month if within

the specified

temperature

range.

Set SelfCal to

execute

automatically as

often as needed

(typically once

an hour).

• “Test Set Cal Example #3: The DUT Has a Noninsertable Port Pair

with Dissimilar Connectors” on page 4-43*

2-6 Chapter 2

Page 41

Getting Started

Test Set Cal and SelfCal

*Insertable Port Pairs versus Noninsertable Port Pairs:

During the through portion of the calibration, if an adjacent port pair (for

example, 1-to-2, 3-to-4, 5-to-6, etc.) can be connected directly without

using a through cable or an adapter, the port pair is insertable. If an

adjacent port pair can only be connected by using a through cable or an

adapter, the port pair is noninsertable.

For all the details on calibrating your test set, refer to Chapter 4, “Test

Set Cal and SelfCal.”

Chapter 2 2-7

Page 42

Getting Started

Test Set Cal and SelfCal

This page intentionally left blank.

2-8 Chapter 2

Page 43

Getting Started

Making Measurements

Making Measurements

This section will show you the basic steps in making the following

measurements:

• “Transmission Measurements” on page 2-10

• “Reflection Measurements Using a 1-Port Cal” on page 2-12

• “Reflection Measurements Using a 2-Port Cal (8712ES/14ES Only)”

on page 2-14

NOTE These measurement examples assume that calibration has already been

performed.

IMPORTANT 8712ES/14ES analyzers only:

The test set port assigned as the must always be the low

numbered test set port while the test set port assigned as the

must always be the high numbered port.

(S11) Port

(S22) Port

For more detailed information on making measurements with your

multiport test set, refer to Chapter 3, “Measurement Examples.”

The multiport test set contains cables and line-lengths on a pc board

which give it a long electrical delay. Your DUT and test cables (if any)

and/or test fixture add even more electrical delay to your test setup. To

maximize measurement accuracy, the effects of this electrical delay must

be minimized. For a discussion of techniques to reduce the effects of

electrical delay in your test setup, refer to “Measuring Devices with Long

Electrical Delay,” located in Chapter 5 of your analyzer’s User’s Guide.

Chapter 2 2-9

Page 44

Getting Started

Making Measurements

Transmission Measurements

Figure 2-4 shows:

• test set PORT 3 switched to the analyzer’s REFLECTION (or

PORT 1

*

) port

• test set PORT 4 switched to the analyzer’s TRANSMISSION (or

*

PORT 2

) port

• all other test set ports terminated with the test set impedance

Figure 2-4 Transmission Measurement: PORT 3 to PORT 4

* For 8712ES/14ES analyzers only.

2-10 Chapter 2

Page 45

Getting Started

Making Measurements

To make the connections as illustrated in Figure 2-4 and perform a

transmission measurement, you would press the following keys on the

analyzer:

1. Press .

2. Press .

3. Press (

(S11) Port

or

4. Press .

MEAS 1

Multiport Selection

Reflection Port Num

*

).

Enter

3

5. Press

Transmissn Port Num

( or

(S22) Port

6. Press

7. Press (

S21 Tran 3–>4

*

).

4 Enter Done

Transmissn

*

or

).

*

Selects measurement channel 1 as the

active measurement channel .

Displays a menu with softkeys for

selecting test set ports for your

measurement.

Allows you to select a test set port for

your measurement.

Selects PORT 3 of the test set.

Allows you to select a test set port for

your measurement.

Selects PORT 4 of the test set. This

.

completes your selection of test set ports

for your measurement.

Selects the forward transmission type of

measurement.

* For 8712ES/14ES analyzers only.

NOTE For 8712ES/14ES analyzers only:

To measure transmission from test set PORT 4 to test set PORT 3, use

the same port assignments as above, but press for the

measurement type.

Chapter 2 2-11

S12 Tran 4–>3

Page 46

Getting Started

Making Measurements

Reflection Measurements Using a 1-Port Cal

Figure 2-5 shows:

• test set PORT 5 switched to the analyzer’s REFLECTION (or

PORT 1

• all other test set ports terminated with the test set impedance

Figure 2-5 Reflection Measurement: PORT 5

*

) port

* For 8712ES/14ES analyzers only.

2-12 Chapter 2

Page 47

Getting Started

Making Measurements

To make the connections as illustrated in Figure 2-5 and perform a

reflection measurement, you would press the following keys on the

analyzer:

1. Press .

2. Press .

3. Press (

(S11) Port

or

4. Press

5. Press ( or

S11 ReflPort5

MEAS 1

Multiport Selection

Reflection Port Num

*

).

Enter Done

5

Reflection

*

).

*

.

* For 8712ES/14ES analyzers only.

Selects measurement channel 1 as the

active measurement channel .

Displays a menu with softkeys for

selecting test set ports for your

measurement.

Allows you to select a test set port for

your measurement.

Selects PORT 5 of the test set. This

completes your selection of test set ports

for your measurement.

Selects the forward reflection type of

measurement.

Chapter 2 2 -13

Page 48

Getting Started

Making Measurements

Reflection Measurements Using a 2-Port Cal (8712ES/14ES Only)

In this reflection measurement it is necessary to assign both test set

ports. This is because, when using a 2-port cal, the analyzer sweeps in

both directions as it measures all four S-parameters. Figure 2-6 shows:

• test set PORT 3 switched to the analyzer’s PORT 1 port

• test set PORT 4 switched to the analyzer’s PORT 2 port

• all other test set ports terminated with the test set impedance

Figure 2-6 Reflection Measurement Using a 2-Port Cal: PORT 3

2-14 Chapter 2

Page 49

Getting Started

Making Measurements

To make the connections as illustrated in Figure 2-6 and perform a

reflection measurement, you would press the following keys on the

analyzer:

1. Press .

2. Press .

3. Press .

4. Press .

5. Press .

6. Press .

7. Press

MEAS 1

Multiport Selection

(S11) Port

3 Enter

(S22) Port

4 Enter Done

S11 ReflPort3

.

Selects measurement channel 1 as the

active measurement channel .

Displays a menu with softkeys for

selecting test set ports for your

measurement.

Allows you to select a test set port for

your measurement.

Selects PORT 3 of the test set.

Allows you to select a test set port for

your measurement.

Selects PORT 4 of the test set. This

completes your selection of test set ports

for your measurement.

Selects the forward reflection type of

measurement.

NOTE For 8712ES/14ES analyzers only:

To measure reflection using test set PORT 4, use the same port

assignments as above, but press for the measurement

type.

Chapter 2 2 -15

S22 ReflPort4

Page 50

Getting Started

Performing the Operator's Check

Performing the Operator's Check

Description

The operator’s check should be performed when you receive your test set,

and any time you wish to have confidence that your test set is

functioning properly. It is not designed to verify specifications or to check

the validity of calibrations. To verify specifications, refer to “Performance

Verification Test Results” on page 9-9. To check a calibration, refer to

“Verifying the Calibration” on page 4-70. The Operator’s Check uses

traditional analyzer calibrations rather than a Test Set Cal. This is

because the multiport test set is treated as a DUT by the analyzer.

NOTE The operator’s check for the test set assumes that the network analyzer

is functioning properly. It also assumes that the analyzer has no test

fixture or DUT attached to the test set, and has a valid default

calibration. Refer to your analyzer’s User’s Guide for information on

performing the analyzer’s operator’s check.

Procedure

The quickest method for performing the operator’s check is to use the

“Op Verif” portion of the performance test software (see Chapter 9). This

method will take approximately one minute to perform and no external

connections to the test set’s test ports are required. You can run this

software using the IBASIC feature in your analyzer.

If you don’t have access to the performance test software, the following

manual procedure can be used instead.

Equipment Required

For 87050E multiport test sets:

• 8712ET/ES or 8714ET/ES

RF network analyzer, 50 Ω impedance

•Cables, 50 Ω type-N, (shipped with the test set—see Table 1-1 on

page 1-11)

• 50 Ω type-N load (part of 85032B calibration kit)

2-16 Chapter 2

Page 51

Getting Started

Performing the Operator's Check

• 50 Ω cable such as the one that was shipped with your analyzer (part

number 8120-6469)

For 87075C multiport test sets:

• 8712ET/ES or 8714ET/ES

RF network analyzer, 75 Ω impedance (Option 1EC)

•Cables, 75 Ω type-N, (shipped with the test set—see Table 1-1 on

page 1-11)

• 75 Ω type-N load (part of 85036B calibration kit)

• 75 Ω cable such as the one that was shipped with your analyzer (part

number 8120-6468)

NOTE The following section contains illustrations depicting the analyzer

display. Your display may appear different, depending on the model of

your analyzer.

Process

Check Unterminated Return Loss.

1. Make sure the test set is properly connected to the analyzer using the

parallel port interface cable and the front panel RF cables as

described in Chapter 1.

2. Make sure that both instruments are turned on, and that the

analyzer is configured for use with a multiport test set as described in

“Step 5. Activate the Test Set and Check the System Operation” on

page 1-19.

3. Press .

4. Press ( or

(S11) Port 1 Enter Done

5. Press ( or

PRESET

MEAS 1 Multiport Selection Reflection Port Num

*

) *.

Reflection S11 ReflPort1

*

) to configure the analyzer to

make a reflection measurement.

6.Press .

7. Press to make sure the analyzer’s default

FREQ

CAL Default 1-Port

Start 3 MHz Stop 1300 MHz

calibration is in place. (This disables the multiport Test Set Cal.)

* For 8712ES/14ES analyzers only.

Chapter 2 2 -17

Page 52

Getting Started

Performing the Operator's Check

8. Verify that the return loss of the selected port, with nothing

connected, is between about 0 dB and −20 dB. See Figure 2-7 on

page 2-18 for an example measurement. Your results should be

somewhat similar.

9. For 8712ET/14ET analyzers only: repeat steps 4 and 8 for all the

remaining ports on your test set.

For 8712ES/14ES analyzers only: repeat steps 4 and 8 for all but the

highest numbered port on your test set. For the highest numbered

port, press

Enter Done S22 ReflPort

MEAS 1 Multiport Selection (S22) Port port number

. Repeat step 8.

Figure 2-7 Operator’s Check: Unterminated Return Loss

2-18 Chapter 2

Page 53

Check Terminated Return Loss.

Getting Started

Performing the Operator's Check

10.Press ( or

(S11) Port 1 Enter Done

11.Press ( or

MEAS 1 Multiport Selection Reflection Port Num

*

) *.

Reflection S11 ReflPort1

*

) to configure the analyzer to

make a reflection measurement.

12.Connect a load (impedance must match that of your test set) to

PORT 1 on the test set.

13.Verify that the return loss of the selected port is below −11 dB across

the frequency range. See Figure 2-8 for an example measurement.

Your results should be somewhat similar.

14.For 8712ET/14ET analyzers only: Repeat steps 9–12 for all the

remaining ports on your test set.

For 8712ES/14ES analyzers only: repeat steps 9–12 for all but the

highest numbered port on your test set. For the highest numbered

port, press

Enter Done S22 ReflPort

MEAS 1

. Repeat step 12.

Multiport Selection (S22) Port port number

Figure 2-8 Operator’s Check: Terminated Return Loss

* For 8712ES/14ES analyzers only.

Chapter 2 2 -19

Page 54

Getting Started

Performing the Operator's Check

Check Transmission Measurement.

CAL Default Response Default 2-Port

15. ( or

16.Press ( or

(S11) Port 1 Enter Transmissn Port Num (S22) Port 2

Enter Done

17.Press ( or

MEAS 1 Multiport Selection Reflection Port Num

*

) ( or

*

.

MEAS 1 Transmissn S21 Tran 1–>2

18.Connect a through cable between PORT 1 and PORT 2 on the test set.

19.Verify that the transmission measurement of the selected ports is

between −2 dB and −19 dB across the frequency range. See Figure 2-9

for an example measurement. Your results should be somewhat

similar.

Figure 2-9 Operator’s Check: Transmission Measurement

*

).

*

)

*

).

* For 8712ES/14ES analyzers only.

2-20 Chapter 2

Page 55

Getting Started

Performing the Operator's Check

If the Multiport Test Set Fails the Operator's Check

If the multiport test set fails the operator’s check, verify that your

analyzer passes its operator’s check. Refer to your analyzer’s User’s

Guide for information on the analyzer’s operator’s check. If the analyzer

passes its operator’s check, your multiport test set may need adjustment

or servicing. Contact Agilent for assistance. Refer to page 35 for the

nearest office. Before shipping your multiport test set, fill out and attach

the blue repair tag, located at the back of the analyzer’s Service Guide.

Chapter 2 2 -21

Page 56

Getting Started

Cable and Test Fixture Considerations

Cable and Test Fixture Considerations

For the most accurate, repeatable measurements, it is imperative that

the cables and test fixtures that you use to test devices introduce as little

drift as possible. Although the system’s Test Set Cal feature can

effectively calibrate out the effects of external cabling and fixtures, the

drift-removing SelfCal feature can only remove subsequent drift internal

to the system. It cannot compensate for subsequent drift associated with

any external cabling or fixturing. See “Test Set Cal and SelfCal: Theory

of Operation” on page 4-56.

Drift can be minimized by using high quality connectors, semi-rigid

cables (when possible), and fixturing that reduces cable movement to a

minimum.

2-22 Chapter 2

Page 57

3 Measurement Examples

3-1

Page 58

Measurement Examples

Your multiport system allows you to measure both forward and reverse

responses of a multiport device without having to manually change

connections. This chapter presents examples of making many types of

measurements on a 50 ohm device and a 75 ohm device.

Although your test set may have a different number of ports, the 12-port

test set (Option 012) will most often be depicted and described here.

See your analyzer’s User’s Guide for example displays of various

measurements. You will also find information on using the analyzer’s

built-in features such as markers and limit lines to help interpret your

measurements quickly and easily.

3-2 Chapter 3

Page 59

Measurement Examples

Example: Measuring a 50 Ohm Duplexer

Example: Measuring a 50 Ohm Duplexer

The following illustration and tables show how with one mechanical

setup you can make multiple measurements on a 50 ohm duplexer

simply by changing the port selections. This example will show how to

make six common duplexer measurements:

• Insertion Loss: ANT port to Rx port

• Insertion Loss: Tx port to ANT port

• Isolation: Rx port to Tx port

• Return Loss: ANT port

• Return Loss: Rx port

• Return Loss: Tx port

Chapter 3 3-3

Page 60

Measurement Examples

Example: Measuring a 50 Ohm Duplexer

Figure 3-1 Measuring a 50 Ohm Duplexer— Six Measurements,

One Test Setup

NOTE Transmission and reflection responses of any multiport device can be

affected by the load match presented to ports of the DUT that are outside

of the measurement path. The effect of test set load match on the

measurements is device dependent and needs to be considered.

3-4 Chapter 3

Page 61

Example: Measuring a 50 Ohm Duplexer

Table 3-1 Making Measurements using an 8712ET/14ET Analyzer

Measurement Examples

Measurement

Type

Measurement ANT to Rx

Test Set Port

Assigned as the

Reflection Port

Test Set Port

Assigned as the

Transmission

Port

INSERTION

LOSS

Transmission

–>2)

(Tran 1

132123

2 1 3 – – –

INSERTION

LOSS

Transmission

Tx to ANT

(Tran 3–>1)

ISOLATION

Transmission

Rx to Tx

(Tran 2–>3)

RETURN

LOSS

Reflection

ANT port

(Refl Port 1)

RETURN

LOSS

Reflection

Rx port

(Refl Port2)

Table 3-2 Making Measurements using an 8712ES/14ES Analyzer

Measurement

Type

Measurement ANT to Rx

INSERTION

LOSS

S

21

–>2)

(Tran 1

INSERTION

LOSS

S

12

Tx to ANT

(Tran 3–>1)

ISOLATION

S21

Rx to Tx

(Tran 2–>3)

RETURN

LOSS

S11

ANT port

(Refl Port 1)

RETURN

LOSS

S

Rx port

(Refl

Port2)

22

RETURN

LOSS

Reflection

Tx port

(Refl Port 3)

RETURN

LOSS

S22

Tx port

(Refl Port 3)

Tes t S e t Po r t

Assigned as the

1 1 2 111

(S11) Port

Tes t S e t Po r t

Assigned as the

233

*

n

*

2

*

3

(S22) Port

* When using a 2-port Test Set calibration, this test set port is assigned as the . “n” is any

test-set port in your measurement configuration that has a higher number than the port assigned as

(S11) Port

the .

IMPORTANT 8712ES/14ES analyzers only: the test set port assigned as the must always

be the low numbered test set port while the test set port assigned as the must

always be the high numbered port.

(S22) Port

(S11) Port

(S22) Port

Chapter 3 3-5

Page 62

Measurement Examples

Example: Measuring a 50 Ohm Duplexer

Calibrating the Multiport System for Measuring a 50 Ohm Duplexer

For a complete calibration process for measuring the 50 ohm duplexer in

this example, refer to “Test Set Cal Example #3: The DUT Has a

Noninsertable Port Pair with Dissimilar Connectors” on page 4-43.

The Test Set Cal process that is best suited for your particular

measurements will depend on the type of DUT you are testing. If your

50 ohm DUT is different from the one used in this example, refer to the

following additional Test Set Cal examples for one that best matches

your DUT.

• “Test Set Cal Example #1: The DUT Has Insertable Port Pairs” on

page 4-22

• “Test Set Cal Example #2: The DUT Has Noninsertable Port Pairs

with Identical Connectors” on page 4-28

For all the details on calibrating your test set, refer to Chapter 4, “Test

Set Cal and SelfCal.”

3-6 Chapter 3

Page 63

This page intentionally left blank.

Measurement Examples

Example: Measuring a 50 Ohm Duplexer

Chapter 3 3-7

Page 64

Figure 3-2

Measurement Examples

Example: Measuring a 50 Ohm Duplexer

Measuring Insertion Loss: ANT Port to Rx Port

To perform the insertion loss measurement (measuring the loss from the

ANT port of the DUT to the Rx port of the DUT), press the following keys

on the analyzer:

3-8 Chapter 3

Page 65

Measurement Examples

Example: Measuring a 50 Ohm Duplexer

1. Press .

2. Press .

MEAS 1

Multiport Selection

3. Press

Reflection Port Num

( or

(S11) Port

4. Press .

*

).

1

Enter

5. Press

Transmissn Port Num

( or

(S22) Port

6. Press

7. Press (

S21 Tran 1–>2

*

).

2 Enter Done

Transmissn

*

or

).

Optional steps—saving the

instrument state:

Selects measurement channel 1 as the active measurement

channel.

Displays a menu with softkeys for selecting test set ports for

your measurement.

Allows you to select a test set port for your measurement.

Selects PORT 1 of the test set.

Allows you to select a test set port for your measurement.

*

Selects PORT 2 of the test set.

.

Selects the forward transmission type of measurement.

These optional steps allow you to save the instrument state.

Recalling an instrument state, rather than manually

re-entering the analyzer parameters, can save time and

improve measurement throughput.

8. Press .

9. Press .

SAVE RECALL

Save State

* For 8712ES/14ES analyzers only.

Chapter 3 3-9

Displays a menu with softkeys for saving and recalling

analyzer data.

Saves the instrument state.

Page 66

Figure 3-3

Measurement Examples

Example: Measuring a 50 Ohm Duplexer

Measuring Insertion Loss: Tx Port to ANT Port

To perform the insertion loss measurement (measuring the loss from the

Tx port of the DUT to the ANT port of the DUT), press the following keys

on the analyzer:

3-10 Chapter 3

Page 67

Measurement Examples

Example: Measuring a 50 Ohm Duplexer

1. Press .

2. Press .

MEAS 1

Multiport Selection

3. Press

Transmissn Port Num

(S11) Port

(

4. Press .

*

).

1

Enter

or

5. Press

Reflection Port Num

( or

(S22) Port

6. Press

7. Press (

S12 Tran 3–>1

*

).

3 Enter Done

Transmissn

*

or

).

Optional steps—saving the

instrument state:

Selects measurement channel 1 as the active measurement

channel.

Displays a menu with softkeys for selecting test set ports for

your measurement.

Allows you to select a test set port for your measurement.

Selects PORT 1 of the test set.

Allows you to select a test set port for your measurement.

*

Selects PORT 3 of the test set.

.

Selects the reverse transmission type of measurement.

These optional steps allow you to save the instrument state.

Recalling an instrument state, rather than manually

re-entering the analyzer parameters, can save time and

improve measurement throughput.

8. Press .

9. Press .

SAVE RECALL

Save State

* For 8712ES/14ES analyzers only.

Chapter 3 3-11

Displays a menu with softkeys for saving and recalling

analyzer data.

Saves the instrument state.

Page 68

Figure 3-4

Measurement Examples

Example: Measuring a 50 Ohm Duplexer

Measuring Isolation: Rx Port to Tx Port

To perform the isolation measurement (a transmission measurement

from the Rx port to the Tx port on the DUT), press the following keys on

the analyzer:

3-12 Chapter 3

Page 69

Measurement Examples

Example: Measuring a 50 Ohm Duplexer

1. Press .

MEAS 1

2. Press

Multiport Selection

.

3. Press

Reflection Port Num

( or

(S11) Port

4. Press .

*

).

Enter

2

5. Press

Transmissn Port Num

( or

(S22) Port

6. Press

Done

7. Press (

S21 Tran 2–>3

*

3

*

.

Transmissn

).

Enter

*

).

or

Optional steps—saving the

instrument state:

Selects measurement channel 1 as the active measurement

channel.

Displays a menu with softkeys for selecting test set ports for

your measurement.

Allows you to select a test set port for your measurement.

Selects PORT 2 of the test set.

Allows you to select a test set port for your measurement.

Selects PORT 3 of the test set.

Selects the forward transmission type of measurement.

These optional steps allow you to save the instrument state.

Recalling an instrument state, rather than manually

re-entering the analyzer parameters, can save time and

improve measurement throughput.

8. Press .

9. Press .

SAVE RECALL

Save State

* For 8712ES/14ES analyzers only.

Chapter 3 3 -13

Displays a menu with softkeys for saving and recalling

analyzer data.

Saves the instrument state.

Page 70

Figure 3-5

Measurement Examples

Example: Measuring a 50 Ohm Duplexer

Measuring Return Loss: ANT Port

To perform the return loss measurement on the ANT port of the DUT,

press the following keys on the analyzer:

3-14 Chapter 3

Page 71

Measurement Examples

Example: Measuring a 50 Ohm Duplexer

1. Press .

2. Press .

MEAS 1

Multiport Selection

3. Press

Reflection Port Num

( or

(S11) Port

4. Press .

5. Press ( or

S11 ReflPort1

*

).

1

Enter

Reflection

*

).

Optional steps—saving the

instrument state:

6. Press .

7. Press .

SAVE RECALL

Save State

Selects measurement channel 1 as the active measurement

channel.

Displays a menu with softkeys for selecting test set ports for

your measurement.

Allows you to select a test set port for your measurement.

Selects PORT 1 of the test set.

Selects the forward reflection type of measurement.

These optional steps allow you to save the instrument state.

Recalling an instrument state, rather than manually

re-entering the analyzer parameters, can save time and

improve measurement throughput.

Displays a menu with softkeys for saving and recalling

analyzer data.

Saves the instrument state.

* For 8712ES/14ES analyzers only.

IMPORTANT For 8712ES/14ES analyzers using a 2-port Test Set cal only:

Measuring the return loss of the ANT port is best done using two

separate measurements in order to obtain the highest measurement

accuracy. The following table explains the two measurements.

Chapter 3 3 -15

Page 72

Measurement Examples

Example: Measuring a 50 Ohm Duplexer

First

Measurement

Second

Measurement

Tes t Set Port

Assigned as

the

(S11) Port (S22) Port

PORT 1

(ANT port)

PORT 1

(ANT port)

Tes t Se t Port

Assigned as

PORT 2

(Rx port)

PORT 3

(Tx port)

the

Measurement Explanation

When test set PORT 2 is assigned as the

(S22) Port

with an error-corrected load, while the DUT’s

Tx port is terminated with the uncorrected

internal load of the test set. Since the

error-corrected load match of the test system is

considerably better than the uncorrected

terminations, the portion of the trace

corresponding to the ANT-to-Rx path will be

more accurate than the portion of the trace

corresponding to the ANT-to-Tx path. For the

first measurement, verify the ANT-port return

loss by using a limit-line on the portion of the

trace corresponding to the ANT-to-Rx path. The

ANT-port return loss corresponding to the

ANT-to-Tx path will be tested in the second

measurement.

When test set PORT 3 is assigned as the

(S22) Port

with an error-corrected load, while the DUT’s

Rx port is terminated with the uncorrected

internal load of the test set. Since the

error-corrected load match of the test system is

considerably better than the uncorrected

terminations, the portion of the trace

corresponding to the ANT-to-Tx path will be

more accurate than the portion of the trace

corresponding to the ANT-to-Rx path. For the

second measurement, verify the ANT-port

return loss by using a limit-line on the portion

of the trace corresponding to the ANT-to-Tx

path. The ANT-port return loss corresponding

to the ANT-to-Rx path was tested in the first

measurement.

, the DUT’s Rx port is terminated

, the DUT’s Tx port is terminated

3-16 Chapter 3

Page 73

Measurement Examples

Example: Measuring a 50 Ohm Duplexer

To set up your test system to perform the two measurements in the

previous table, it is fastest and easiest to use both of the analyzer

measurement channels. For instructions on using both measurement

channels, refer to “Using Different Test Set Port Assignments for Both

Measurement Channels” on page 3-45.

Chapter 3 3 -17

Page 74

Figure 3-6

Measurement Examples

Example: Measuring a 50 Ohm Duplexer

Measuring Return Loss: Rx Port

To perform the return loss measurement on the Rx port of the DUT, press

the following keys on the analyzer:

3-18 Chapter 3

Page 75

Measurement Examples

Example: Measuring a 50 Ohm Duplexer

1. Press .

2. Press .

MEAS 1

Multiport Selection

3. Press

Reflection Port Num

( or

(S22) Port

4. Press .

5. Press ( or

S22 ReflPort2

*

).