Agilent 8702E

Lightwave Component Analyzer

Reference

© Copyright

Agilent Technologies 2001

All Rights Reserved. Reproduction, adaptation, or translation without prior written

permission is prohibited,

except as allowed under copyright laws.

Agilent Part No. 08702-91030

Printed in USA

March 2001

Agilent Technologies

Lightwave Division

3910 Brickway BoulevardSanta Rosa, CA 95403, USA

Notice.

The information contained in

this document is subject to

change without notice. Companies, names, and data used

in examples herein are fictitious unless otherwise noted.

Agilent Technologies makes

no warranty of any kind with

regard to this material, including but not limited to, the

implied warranties of merchantability and fitness for a

particular purpose. Agilent

Technologies shall not be liable for errors contained herein

or for incidental or consequential damages in connection with the furnishing,

performance, or use of this

material.

Restricted Rights Legend.

Use, duplication, or disclosure by the U.S. Government

is subject to restrictions as set

forth in subparagraph (c) (1)

(ii) of the Rights in Technical

Data and Computer Software

clause at DFARS 252.227-7013

for DOD agencies, and subparagraphs (c) (1) and (c) (2)

of the Commercial Computer

Software Restricted Rights

clause at FAR 52.227-19 for

other agencies.

Warranty.

This Agilent Technologies

instrument product is warranted against defects in

material and workmanship for

a period of one year from date

of shipment. During the warranty period, Agilent Technologies will, at its option, either

repair or replace products

which prove to be defective.

For warranty service or repair,

this product must be returned

to a service facility designated by Agilent Technologies. Buyer shall prepay

shipping charges to Agilent

Technologies and Agilent

Technologies shall pay shipping charges to return the

product to Buyer. However,

Buyer shall pay all shipping

charges, duties, and taxes for

products returned to Agilent

Technologies from another

country.

Agilent Technologies warrants that its software and

firmware designated by Agilent Technologies for use with

an instrument will execute its

programming instructions

when properly installed on

that instrument. Agilent Technologies does not warrant that

the operation of the instrument, or software, or firmware

will be uninterrupted or errorfree.

Limitation of Warranty.

The foregoing warranty shall

not apply to defects resulting

from improper or inadequate

maintenance by Buyer, Buyersupplied software or interfacing, unauthorized modification or misuse, operation

outside of the environmental

specifications for the product,

or improper site preparation

or maintenance.

No other warranty is

expressed or implied. Agilent

Technologies specifically disclaims the implied warranties

of merchantability and fitness

for a particular purpose.

Exclusive Remedies.

The remedies provided herein

are buyer's sole and exclusive

remedies. Agilent Technologies shall not be liable for any

direct, indirect, special, incidental, or consequential damages, whether based on

contract, tort, or any other

legal theory.

Safety Symbols.

CAUTION

The

caution

sign denotes a

hazard. It calls attention to a

procedure which, if not correctly performed or adhered

to, could result in damage to

or destruction of the product.

Do not proceed beyond a caution sign until the indicated

conditions are fully understood and met.

WAR NI NG

The

warning

sign denotes a

hazard. It calls attention to a

procedure which, if not correctly performed or adhered

to, could result in injury or

loss of life. Do not proceed

beyond a warning sign until

the indicated conditions are

fully understood and met.

The instruction manual symbol. The product is marked with this

warning symbol when

it is necessary for the

user to refer to the

instructions in the

manual.

The laser radiation

symbol. This warning

symbol is marked on

products which have a

laser output.

The AC symbol is used

to indicate the

required nature of the

line module input

power.

The ON symbols are

|

used to mark the positions of the instrument

power line switch.

The OFF symbols

❍

are used to mark the

positions of the instrument power line

switch.

The CE mark is a registered trademark of

the European Community.

The CSA mark is a registered trademark of

the Canadian Standards Association.

The C-Tick mark is a

registered trademark

of the Australian Spectrum Management

Agency.

This text denotes the

ISM1-A

instrument is an

Industrial Scientific

and Medical Group 1

Class A product.

Typographical Conventions.

The following conventions are

used in this book:

Key type

for keys or text

located on the keyboard or

instrument.

Softkey type

for key names that

are displayed on the instrument’s screen.

Display type

for words or

characters displayed on the

computer’s screen or instrument’s display.

User type

for words or charac-

ters that you type or enter.

Emphasis

type for words or

characters that emphasize

some point or that are used as

place holders for text that you

type.

ii

Contents

1Menu Maps

2 Reference

Instrument Options 2-3

Available Accessories 2-5

Power Cords 2-10

Front Panel Features 2-12

Analyzer Display 2-14

Rear Panel Features and Connectors 2-16

Unsupported Features 2-19

Reference Documents 2-20

Location of Softkeys 2-22

Connectors, Adjustments, and Display Annotation 2-40

Preset Conditions 2-43

Power-on Conditions 2-51

3 Error Messages

Error Messages in Alphabetical Order 3-3

Error Messages in Numerical Order 3-24

4 Specifications and Regulatory Information

Instrument Specifications 4-3

Instrument Specifications (Option 011) 4-10

Instrument General Characteristics 4-18

Environmental Characteristics 4-22

System E/E Characteristics 4-24

System O/E Characteristics 4-53

System E/O Characteristics 4-68

System O/O Characteristics 4-83

Lightwave Receiver Measurement Repeatability 4-94

GPIB Interface 4-96

Regulatory Information 4-97

5 Concepts

How the Agilent 8702E Works 5-2

How the Agilent 8702E Processes Data 5-5

Using the Response Functions 5-10

Contents-1

Contents

What is Measurement Calibration? 5-17

Understanding and Using Time Domain 5-67

Instrument Preset State and Memory Allocation 5-95

Contents-2

1

Menu Maps

Menu Maps

Menu Maps

Menu Maps

The menu maps that are in this chapter graphically represent the softkey

menus. Maps for each softkey menu are shown in alphabetical order.

AVG

AVG

MENU

AVERAGING

RESTART

AVERAGING

FACTOR

AVERAGING

on OFF

SMOOTHING

APERTURE

SMOOTHING

on OFF

AVG

menu map

1-2

IF BW

[ ]

Menu Maps

Menu Maps

CAL

menu map, 1 of 2

1-3

Menu Maps

Menu Maps

CAL

menu map, 2 of 2

1-4

Menu Maps

Menu Maps

COPY

menu map

1-5

Menu Maps

Menu Maps

DISPLAY

FORMAT

1-6

menu map

menu map

Menu Maps

Menu Maps

LOCAL

menu map:

1-7

Menu Maps

Menu Maps

MARKER

1-8

menu map

Menu Maps

Menu Maps

MARKER FCTN

menu map

1-9

Menu Maps

Menu Maps

MARKER SEARCH

menu map

MEAS

menu map, standard and option 011 with test set

1-10

MEAS

menu map, option 011, no test set

Menu Maps

Menu Maps

POWER

menu map

1-11

Menu Maps

Menu Maps

PRESET

menu map

1-12

Menu Maps

Menu Maps

SAVE/RECALL

menu map

1-13

Menu Maps

Menu Maps

SCALE REF

menu map

1-14

Menu Maps

Menu Maps

SEQ

menu map

1-15

Menu Maps

Menu Maps

SWEEP SETUP

1-16

menu map

Menu Maps

Menu Maps

SYSTEM

menu map

1-17

Menu Maps

Menu Maps

1-18

2

Instrument Options 2-3

Available Accessories 2-5

Calibration Kits 2-5

Verification Kit 2-5

Test Port Return Cables 2-6

Adapter Kits 2-6

Transistor Test Fixtures 2-7

System Accessories Available 2-7

Power Cords 2-10

Front Panel Features 2-12

Analyzer Display 2-14

Rear Panel Features and Connectors 2-16

Unsupported Features 2-19

Reference Documents 2-20

General Measurement and Calibration Techniques 2-20

Fixtures and Non-coaxial Measurements 2-20

On-Wafer Measurements 2-21

Location of Softkeys 2-22

Connectors, Adjustments, and Display Annotation 2-40

Preset Conditions 2-43

Power-on Conditions 2-51

Reference

Reference

Reference

Reference

This chapter is a dictionary reference table of front and rear-panel connectors,

front-panel keys (hardkeys), softkeys, and display annotations. With the

exception of a few front-panel keys, softkeys control all instrument functions.

This chapter is designed for quick access of information. For example, during

operation you may find a softkey or hardkey whose function is unfamiliar to

you. Note the key name, find the key in this chapter, and note the applicable

function. Some keys will have more than one function. Keys that begin with a

symbol are listed at the front of the table.

2-2

Instrument Options

Reference

Instrument Options

Option 1D5

Option 002

Option 006

Option 011

Option 075

Option 110

High Stability Frequency Reference. Option 1D5 offers ±0.05 ppm temperature stability from 0 to 60°C (referenced to 25°C).

Harmonic Mode. Provides measurement of second or third harmonics of the

test device’s fundamental output signal. Frequency and power sweep are supported in this mode. Harmonic frequencies can be measured up to the maximum frequency of the receiver. However, the fundamental frequency may not

be lower than 16 MHz.

Extends the maximum source and receiver frequency of the analyzer to

6GHz.

Receiver Configuration. Option 011 allows front panel access to the R, A, and

B samplers and receivers. The transfer switch, couplers, and bias tees have

been removed. Therefore, external accessories are required to make most

measurements.

75Ω Impedance. Option 075 offers 75 ohm impedance bridges with type-N

test port connectors.

Deletes Time Domain. This option

displays the time domain response of a network by computing the inverse

Fourier transform of the frequency domain response. It shows the response of

a test device as a function of time and distance. Displaying the reflection coefficient of a network versus time determines the magnitude and location of

each discontinuity. Displaying the transmission coefficient of a network versus

time determines the characteristics of individual transmission paths. Time

domain operation retains all accuracy inherent with the correction that is

active in the frequency domain. The time domain capability is useful for the

design and characterization of such devices as SAW filters, SAW delay lines,

RF cables, and RF antennas.

removes

the time domain capability, which

2-3

Reference

Instrument Options

Option 1CM

Option 1CP

Rack Mount Flange Kit Without Handles. Option 1CM is a rack mount kit containing a pair of flanges and the necessary hardware to mount the instrument,

with handles detached, in an equipment rack with 482.6 mm (19 inches) horizontal spacing.

Rack Mount Flange Kit With Handles. Option 1CP is a rack mount kit containing a pair of flanges and the necessary hardware to mount the instrument with

handles attached in an equipment rack with 482.6 mm (19 inches) spacing.

2-4

Reference

Available Accessories

Available Accessories

Calibration Kits

The following calibration kits contain prevision standards and required adapters of the indicated connector type. The standards (known devices) facilitate

measurement calibration, also called vector error correction. Refer to the data

sheet and ordering guide for additional information. Part numbers for the

standards are in their manuals.

• Agilent 85031B 7 mm Calibration Kit

• Agilent 85032B 50 Ohm Type-N Calibration Kit

• Agilent 85033D 3.5 mm Calibration Kit

• Agilent 85036B 75 Ohm Type-N Calibration Kit

• Agilent 85039A 75 Ohm Type-F Calibration Kit

Verification Kit

Accurate operation of the analyzer system can be verified by measuring

known devices other than the standards used in calibration, and comparing

the results with recorded data.

Agilent 85029B 7 mm Verification Kit

This kit contains traceable precision 7 mm devices used to confirm the system’s error-corrected measurement uncertainty performance. Also included is

verification data on a 3.5 inch disk, together with a hard-copy listing. A system

verification procedure is provided with this kit and is also located in the

Agilent 8702E Installation Guide

.

2-5

Reference

Available Accessories

Test Port Return Cables

The following RF cables are used to connect a two-port device between the

test ports. These cables provide shielding for high dynamic range measurements.

Agilent 11857D 7 mm Test Port Return Cable Set

This set consists of a pair of test port return cables that can be used in measurements of 7 mm devices. They can also be used with connectors other than

7 mm by using the appropriate precision adapters.

Agilent 11857B 75 Ohm Type-N Test Port Return Cable Set

This set consists of test port return cables for use with the Agilent 8702E

Option 075.

Adapter Kits

Agilent 11852B 50 to 75 Ohm Minimum Loss Pad

This device converts impedance from 50 ohms to 75 ohms or from 75 ohms to

50 ohms. It is used to provide a low SWR impedance match between a 75 ohm

device under test and the Agilent 8702E analyzer (without Option 075) or

between the 50Ω lightwave source and receiver and the Agilent 8702E

Option 075.

Agilent 11853A 50 Ohm Type-N Adapter Kit

Agilent 11854A 50 Ohm BNC Adapter Kit

Agilent 11855A 75 Ohm Type-N Adapter Kit

Agilent 11856A 75 Ohm BNC Adapter Kit

These adapter kits contain the connection hardware required for making measurements on devices of the indicated connector type.

2-6

Reference

Available Accessories

Transistor Test Fixtures

The following Agilent Technologies transistor test fixture is compatible with

the Agilent 8702E. Additional test fixtures for transistors and other devices

are available from Inter-Continental Microwave. To order their catalog,

request Agilent Technologies literature number 5091–4254E, or contact

Inter–Continental Microwave as follows:

1515 Wyatt Drive

Santa Clara, CA 95054-1524

(tel) 408 727-1596

(fax) 408 727-0105

Agilent 11608A Option 003 Transistor Fixture

This fixture is designed to be user-milled to hold stripline transistors for Sparameter measurements. Option 003 is pre-milled for 0.205 inch diameter

disk packages, such as the HP

1

HPAC-200.

System Accessories Available

System Cabinet

Plotters and

Printers

The Agilent 85043D system cabinet is designed to rack mount the analyzer in

a system configuration. The 132 cm (52 in) system cabinet includes a bookcase, a drawer, and a convenient work surface.

The analyzer is capable of plotting or printing displayed measurement results

directly (without the use of an external computer) to a compatible peripheral.

The analyzer supports GPIB, serial, and parallel peripherals. Most HewlettPackard desktop printers and plotters are compatible with the analyzer. Some

common compatible peripherals are listed here (some are no longer available

for purchase, but are listed here for your reference).

These plotters are compatible:

• HP 7440A ColorPro Eight-Pen Color Graphics Plotter

• HP 7470A Two-Pen Graphics Plotter

• HP 7475A Six-Pen Graphics Plotter

• HP 7550A/B High-Speed Eight-Pen Graphics Plotter

1. HP and Hewlett-Packard are registered trademarks of Hewlett-Packard Company.

2-7

Reference

Available Accessories

These printers are compatible:

• HP DeskJet 1200C (can also be used to plot)

• HP DeskJet 500

• HP C2170A, DeskJet 520

• HP DeskJet 500C

• HP DeskJet 540

• HP DeskJet 550C

• HP DeskJet 560C

• HP DeskJet 600, 660C, 682C, 690C, 850C, 870C, 1600C

• All LaserJets (LaserJet III and above can also be used to plot)

• HP C2621A DeskJet Portable InkJet

• PaintJet 3630A PaintJet Color Graphics Printer

• Epson printers which are compatible with the Epson ESC/P2 printer control

language, such as the LQ570, are also supported by the analyzer. Older Epson

printers, however, such as the FX-80, will not work with the analyzer.

Mass Storage

CAUTION

GPIB Cables

Interface Cables

The analyzer has the capability of storing instrument states directly to its

internal memory, to an internal disk, or to an external disk. The internal

3.5 inch floppy disk can be initialized in both LIF and DOS formats and is capable of reading and writing data in both formats. Using the internal disk drive is

the preferred method, but all the capability of previous generation analyzers

to use external disk drives still exists with the Agilent 8702E. Most external

disks using CS80 protocol are compatible.

The analyzer does not support the LIF-HFS (hierarchy file system) directory

format.

Do not use the older single-sided disks in the analyzer’s internal drive.

A GPIB cable is required for interfacing the analyzer with a plotter, printer,

external disk drive, or computer. The cables available are:

• Agilent 10833A GPIB Cable, 1.0 m (3.3 ft.)

• Agilent 10833B GPIB Cable, 2.0 m (6.6 ft.)

• Agilent 10833D GPIB Cable, 0.5 m (1.6 ft.)

• HP C2951A Centronics (Parallel) Interface Cable, 3.0 m (9.9 ft.)

• HP C2913A RS-232C Interface Cable, 1.2 m (3.9 ft.)

• HP 24542G Serial Interface Cable, 3 m (9.9 ft.)

• HP C2950A Parallel Interface Cable, 2 m (6 ft.)

2-8

Reference

Available Accessories

Keyboards

External Monitors

A keyboard can be connected to the analyzer for data input, such as titling

files. The HP C1405B Option ABA keyboard, with the HP part number C140560015 adapter, is suitable for this purpose. Or, the analyzer is designed to

accept most PC-AT-compatible keyboards with a standard DIN connector.

Keyboards with a mini-DIN connector are compatible with the HP part number C1405-60015 adapter.

The analyzer can drive both its internal display and an external monitor simultaneously. One compatible color monitor is the HP 35741A/B. (It is no longer

available for purchase, but is listed here for your reference.)

External Monitor Requirements:

• 60 Hz vertical refresh rate

• 25.5 kHz horizontal refresh rate

• Stadard VGA monitor

2-9

Reference

Power Cords

Power Cords

Plug Type

250V 8120-1351

250V 8120-1369

250V 8120-1689

125V 8120-1378

250V 8120-2104

Cable Part

No.

8120-1703

8120-0696

8120-1692

8120-2857p

8120-1521

8120-1992

8120-2296

Plug Description

Straight *BS1363A

90°

Straight *NZSS198/ASC

90°

Straight *CEE7-Y11

90°

Straight (Shielded)

Straight *NEMA5-15P

90°

Straight (Medical) UL544

Straight *SEV1011

1959-24507

Type 12 90°

Length

(in/cm)

90/228

90/228

79/200

87/221

79/200

79/200

79/200

90/228

90/228

96/244

79/200

79/200

Color Country

Gray

Mint Gray

Gray

Mint Gray

Mint Gray

Mint Gray

Coco Brown

Jade Gray

Jade Gray

Black

Mint Gray

Mint Gray

United Kingdom,

Cyprus, Nigeria,

Zimbabwe,

Singapore

Australia, New

Zealand

East and West

Europe, Saudi

Arabia, So. Africa,

India (unpolarized

in many nations)

United States,

Canada, Mexico,

Philippines,

Taiwan

Switzerland

220V 8120-2956

8120-2957

* Part number shown for plug is the industry identifier for the plug only. Number shown for

cable is the Agilent Technologies part number for the complete cable including the plug.

2-10

Straight *DHCK107

90°

79/200

79/200

Mint Gray

Mint Gray

Denmark

Reference

Power Cords

Plug Type

Cable Part

No.

250V 8120-4211

8120-4600

100V 8120-4753

8120-4754

* Part number shown for plug is the industry identifier for the plug only. Number shown for

cable is the Agilent Technologies part number for the complete cable including the plug.

Plug Description

Straight SABS164

90°

Straight MITI

90°

Length

(in/cm)

79/200

79/200

90/230

90/230

Color Country

Jade Gray Republic of South

Africa

India

Dark Gray Japan

2-11

Reference

Front Panel Features

Front Panel Features

Figure 2-1. Agilent 8702E Front Panel

1

LINE switch. This switch controls ac power to the analyzer. 1 is on, 0 is off.

2

Display. This shows the measurement data traces, measurement annotation,

and softkey labels. The display is divided into specific information areas,

illustrated in Figure 2-2.

3

Softkeys. These keys provide access to menus that are shown on the display.

4

STIMULUS function block. The keys in this block allow you to control the

analyzer source’s frequency, power, and other stimulus functions.

5

RESPONSE function block. The keys in this block allow you to control the

measurement and display functions of the active display channel.

6

ACTIVE CHANNEL keys. The analyzer has four independent display channels.

2-12

Reference

Front Panel Features

These keys allow you to select the active channel, then any function entered

will apply. Then any function you enter applies to this active channel.

7

The ENTRY block. This block includes the knob, the step (⇑, ⇓) keys, and the

number pad. These allow you to enter numerical data and control the markers.

8

INSTRUMENT STATE function block. These keys allow you to control

channel-independent system functions such as the following:

• copying, save/recall, and GPIB controller mode

• limit testing

• external source mode

• tuned receiver mode

• frequency offset mode

• test sequence function

• harmonic measurements (Option 002)

• time domain transform (Option 010)

GPIB STATUS indicators are also included in this block.

PRESET

9

key. This key returns the instrument to either a known factory preset

state or a user preset state that can be defined.

10

PORT 1 and PORT 2. These ports output a signal from the source and receive

input signals from a device under test. PORT 1 allows you to measure S

S

. PORT 2 allows you to measure S21 and S22.

11

11

PROBE POWER connector. This connector (fused inside the instrument)

supplies power to an active probe for in-circuit measurements of ac circuits.

1

and

12

12

R CHANNEL connectors. These connectors allow you to apply an input signal

to the analyzer’s R channel, for frequency offset mode.

13

Disk drive. This 3.5 inch drive allows you to store and recall instrument states

and measurement results for later analysis.

1. Channels 3 and 4 are not functional selections with this model.

2-13

Reference

Analyzer Display

Analyzer Display

Figure 2-2. Analyzer Display (Single Channel, Cartesian Format)

The analyzer display shows various measurement information:

• the grid where the analyzer plots the measurement data.

• the currently selected measurement parameters.

• the measurement data traces.

1

Stimulus Start Value. This value could be any one of the following:

• the start frequency of the source in frequency domain measurements.

• the start time in CW mode (0 seconds) or time domain measurements.

• the lowest power value in power sweep.

When the stimulus is in center/span mode, the center stimulus value is shown

in this space.

2-14

Reference

Analyzer Display

2

Stimulus Stop Value. This value could be any one of the following:

• the stop frequency of the source in frequency domain measurements.

• the stop time in time domain measurements or CW sweeps.

• the upper limit of a power sweep.

When the stimulus is in center/span mode, the span is shown in this space. The

stimulus values can be blanked.

3

Status Notations. This area shows the current status of various functions for

the active channel.

4

Active Entry Area. This displays the active function and its current value.

5

Message Area. This displays prompts or error messages.

6

Title. This is a descriptive alphanumeric string title that you define and enter

through an attached keyboard.

7

Active Channel. This is the number of the current active channel, selected with

ACTIVE CHANNEL

the

keys. If dual channel is on with an overlaid display, both

channel 1 and channel 2 appear in this area.

8

Measured Input(s). This shows the S-parameter, input, or ratio of inputs

currently measured, as selected using the

MEAS

key. Also indicated in this area

is the current display memory status.

9

Format. This is the display format that you selected using the

10

Scale/Div. This is the scale that you selected using the

SCALE/REF

FORMAT

key, in units

appropriate to the current measurement.

11

Reference Level. This value is the reference line in Cartesian formats or the

outer circle in polar formats, whichever you selected using the

SCALE/REF

The reference level is also indicated by a small triangle adjacent to the

graticule, at the left for channel 1 and at the right for channel 2.

12

Marker Values. These are the values of the active marker, in units appropriate

to the current measurement.

13

Marker Stats, Bandwidth. These are statistical marker values that the analyzer

calculates when you access the menus with the

14

Softkey Labels. These menu labels redefine the function of the softkeys that are

MKR FCTN

key.

located to the right of the analyzer display.

15

Pass/Fail. During limit testing, the result will be annunciated as “PASS” if the

limits are not exceeded, and “FAIL” if any points exceed the limits.

key.

key.

2-15

Reference

Rear Panel Features and Connectors

Rear Panel Features and Connectors

Figure 2-3. Agilent 8702E Rear Panel

1

Serial number plate.

2

External Monitor. Standard VGA video output connector provides analog red,

green, and blue video signals.

3

GPIB connector. This allows you to connect the analyzer to an external

controller, compatible peripherals, and other instruments for an automated

system.

4

PARALLEL connector. This connector allows the analyzer to output to a

peripheral with a parallel input. Also included, is a general purpose input/

output (GPIO) bus that can control eight output bits and read five input bits

through test sequencing.

5

RS-232 connector. This connector allows the analyzer to output to a peripheral

2-16

Rear Panel Features and Connectors

with an RS-232 (serial) input.

6

KEYBOARD input (DIN) connector. This connector allows you to connect an

external keyboard. This provides a more convenient means to enter a title for

storage files, as well as a substitute for the analyzer’s front panel keys. The

keyboard must be connected to the analyzer before the power is switched on.

7

Power cord receptacle, with fuse.

8

Line voltage selector switch.

9

10 MHZ REFERENCE ADJUST. (Option 1D5)

10

10 MHZ PRECISION REFERENCE OUTPUT. (Option 1D5)

11

EXTERNAL REFERENCE INPUT connector. This allows for a frequency

reference signal input that can phaselock the analyzer to an external frequency

standard for increased frequency accuracy.

12

AUXILIARY INPUT connector. This allows for a dc or ac voltage input from an

external signal source, such as a detector or function generator, which you can

then measure using the S-parameter menu.

13

EXTERNAL AM connector. This allows for an external analog signal input that

is applied to the ALC circuitry of the analyzer’s source. This input analog signal

amplitude modulates the RF output signal.

Reference

14

EXTERNAL TRIGGER connector. This allows connection of an external

negative-going TTL-compatible signal that will trigger a measurement sweep.

The trigger can be set to external through softkey functions.

15

TEST SEQUENCE. Outputs a TTL signal that can be programmed in a test

sequence to be high or low, or pulse (10 µseconds) high or low at the end of a

sweep for robotic part handler interface.

16

LIMIT TEST. Outputs a TTL signal of the limit test results as follows:

•Pass: TTL high

• Fail: TTL low

17

BIAS INPUTS AND FUSES. These connector bias devices connected to port 1

and port 2. The fuses (1 A, 125 V) protect the port 1 and port 2 bias lines.

18

TEST SET INTERCONNECT. This allows you to connect an Agilent 8702E

Option 011 analyzer to an Agilent 85046A/B or 85047A S-parameter test set

using the interconnect cable supplied with the test set. The S-parameter test

set is then fully controlled by the analyzer.

19

Fan.

2-17

Reference

Rear Panel Features and Connectors

20

Measurement Restart. This is port is not used.

Figure 2-4. Rear Panel Connectors

2-18

Reference

Unsupported Features

Unsupported Features

There are several new buttons on the Agilent 8702E front panel that are not

supported. The following is a list of buttons that when depressed will indicate

Function Not Supported

• Channel 3

• Channel 4

•Return

on the LCD display.

2-19

Reference

Reference Documents

Reference Documents

Hewlett-Packard Company,

HP publication number 5956-4363

Hewlett-Packard Company,

Seminar Papers

Hewlett-Packard Company,

HP 8720 Network Analyzer

5091-1942E

Hewlett-Packard Company,

work Analyzer

, HP publication number 5091-8804E

, Product Note 8753-2A, HP publication number 5952-2771

Simplify Your Amplifier and Mixer Testing

RF and Microwave Device Test for the’90s -

Testing Amplifiers and Active Devices with the

, Product Note 8720-1, HP publication number

Mixer Measurements using the HP 8753 Net-

,

General Measurement and Calibration Techniques

Blacka, Robert J.,

Reprint from

March/April 1989

Montgomery, David,

from

Computer Design

Rytting, Doug,

Hewlett-Packard RF and Microwave Measurement Symposium paper, HP publication number 5954-8378, June 1987

Rytting, Doug,

work Analyzers

sium paper, 1991

TDR Gated Measurements of Stripline Terminations

Microwave Product Digest

Borrowing RF Techniques for Digital Design

, HP publication number 5952-9335, May 1982

Advances in Microwave Error Correction Techniques

Improved RF Hardware and Calibration Methods for Net-

Hewlett-Packard RF and Microwave Measurement Sympo-

, HP publication number 5952-0359,

,

, Reprint

,

Fixtures and Non-coaxial Measurements

Hewlett-Packard Company,

Coaxial Measurements

5091-3645E, February 1992

2-20

Applying the HP 8510 TRL Calibration for Non-

, Product Note 8510-8A, HP publication number

Reference

Reference Documents

Hewlett-Packard Company,

Network Analyzers and Inter-Continental Microwave Test Fixtures

uct Note 8510-17, HP publication number 5091-5674E, September 1992

Hewlett-Packard Company,

Using TRL* Calibration

5091-1943E, August 1991

Hewlett-Packard Company,

Modular Microcircuit Package

ber 5952-1907, May 1990

“Test Fixtures and Calibration Standards,“ Inter-Continental Microwave Product Catalog, HP publication number 5091-4254E

Curran, Jim,

and Microwave Measurement Symposium paper, HP publication number

5954-8346, September 1986

Curran, Jim,

Packard Semiconductor Test Symposium paper

Elmore, Glenn and Louis Salz, “Quality Microwave Measurement of Packaged

Active Devices,”

Techniques for Fixtured Devices

ber 5952-2766, June 1990

Network Analysis of Fixtured Devices

TRL Calibration for Non-Coaxial Measurements

Hewlett-Packard Journal

Measuring Chip Capacitors with the HP 8520C

, Prod-

In-Fixture Microstrip Device Measurement

, Product Note 8720-2, HP publication number

Calibration and Modeling Using the HP 83040

, Product Note 83040-2, HP publication num-

, Hewlett-Packard RF

, Hewlett-

, February 1987,

, HP 8510/8720 News, HP publication num-

Measurement

On-Wafer Measurements

Hewlett-Packard Company,

Network Analyzer and Cascade Microtech Wafer Probes

8510-6, HP publication number 5954-1579

Barr, J.T., T. Burcham, A.C. Davidson, E.W. Strid,

Wafer Probing Calibration Techniques

Measurement Symposium paper, 1991

Lautzenhiser, S., A. Davidson, D. Jones,

Via LRM Calibration

number 5952-1286, January 1990,

erations

1993

, HP 8510/8720 News, HP publication number 5091-6837, February

On-Wafer Measurements Using the HP 8510

Advancements in On-

, Hewlett-Packard RF and Microwave

Improve Accuracy of On-Wafer Tests

, Reprinting from

Microwaves and RF

On-Wafer Calibration: Practical Consid-

, Product Note

, HP publication

2-21

Reference

Location of Softkeys

Location of Softkeys

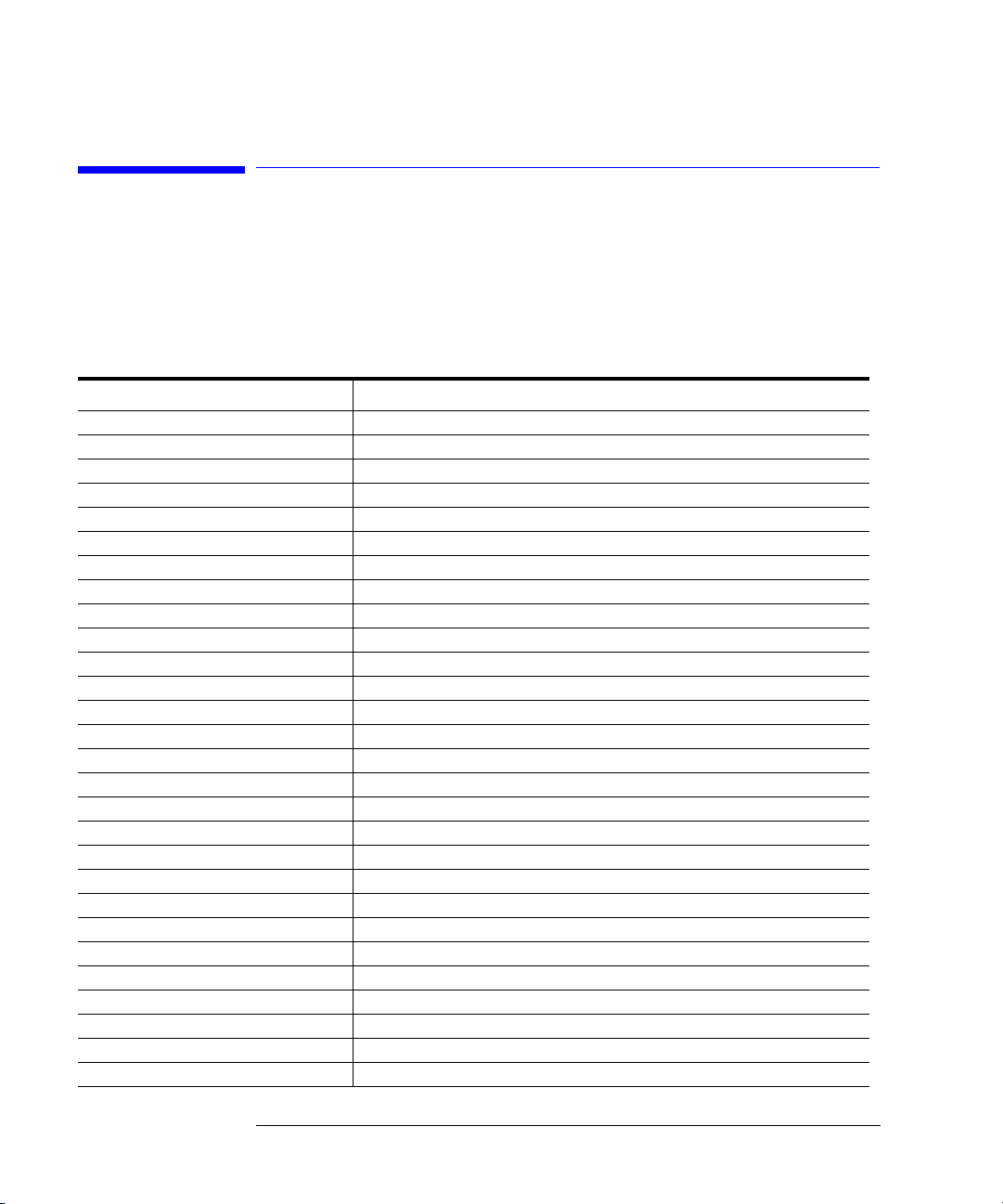

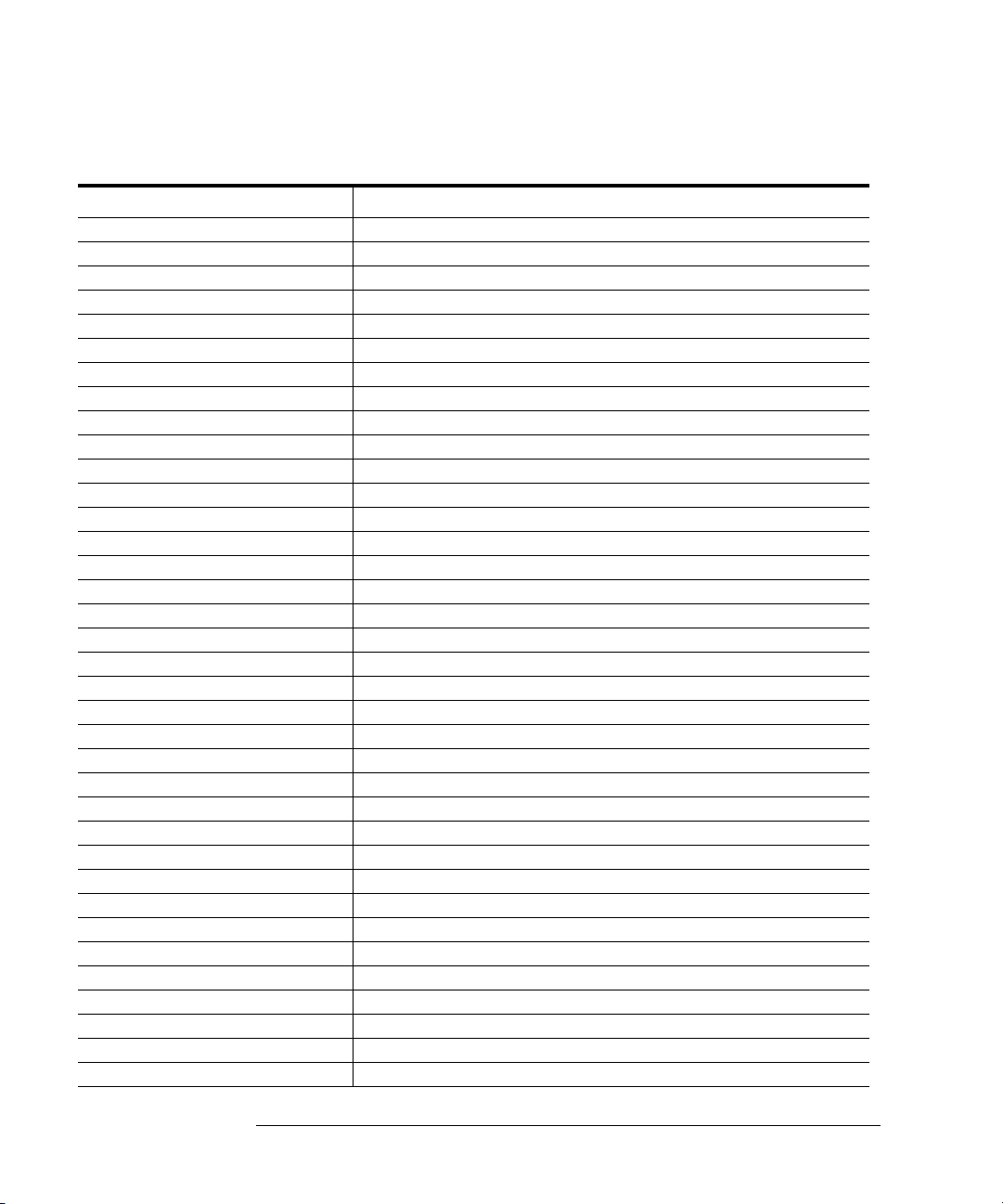

Table 2-1. Location of Softkeys (1 of 18)

Softkey Menu Location

∆

MODE MENU Front-panel access key: MARKER

∆

MODE OFF Front-panel access key: MARKER

∆

REF= 1 Front-panel access key: MARKER

∆

REF= 2 Front-panel access key: MARKER

∆

REF= 3 Front-panel access key: MARKER

∆

REF= 4 Front-panel access key: MARKER

∆

REF= 5 Front-panel access key: MARKER

∆

∆

REF=

FIXED MKR Front-panel access key: MARKER

1/S Front-panel access key: MEAS

2.4 mm Front-panel access key: CAL

2.92* Front-panel access key: CAL

2.92 mm Front-panel access key: CAL

3.5mmC Front-panel access key: CAL

3.5mmD Front-panel access key: CAL

7 mm Front-panel access key: CAL

A Front-panel access key: MEAS

A/B Front-panel access key: MEAS

A/R Front-panel access key: MEAS

ACTIVE ENTRY Front-panel access key: DISPLAY

ACTIVE MKR MAGNITUDE Front-panel access key: DISPLAY

ADD Front-panel access key: CAL and MENU

ADDRESS: 8702 Front-panel access key: LOCAL

ADDRESS: CONTROLLER Front-panel access key: LOCAL

ADDRESS: DISK Front-panel access key: LOCAL

ADDRESS: DISK Front-panel access key: SAVE/RECALL

ADDRESS: P MTR/GPIB Front-panel access key: LOCAL

ADJUST DISPLAY Front-panel access key: DISPLAY

ALIAS SPAN on OFF Front-panel access key: SYSTEM

2-22

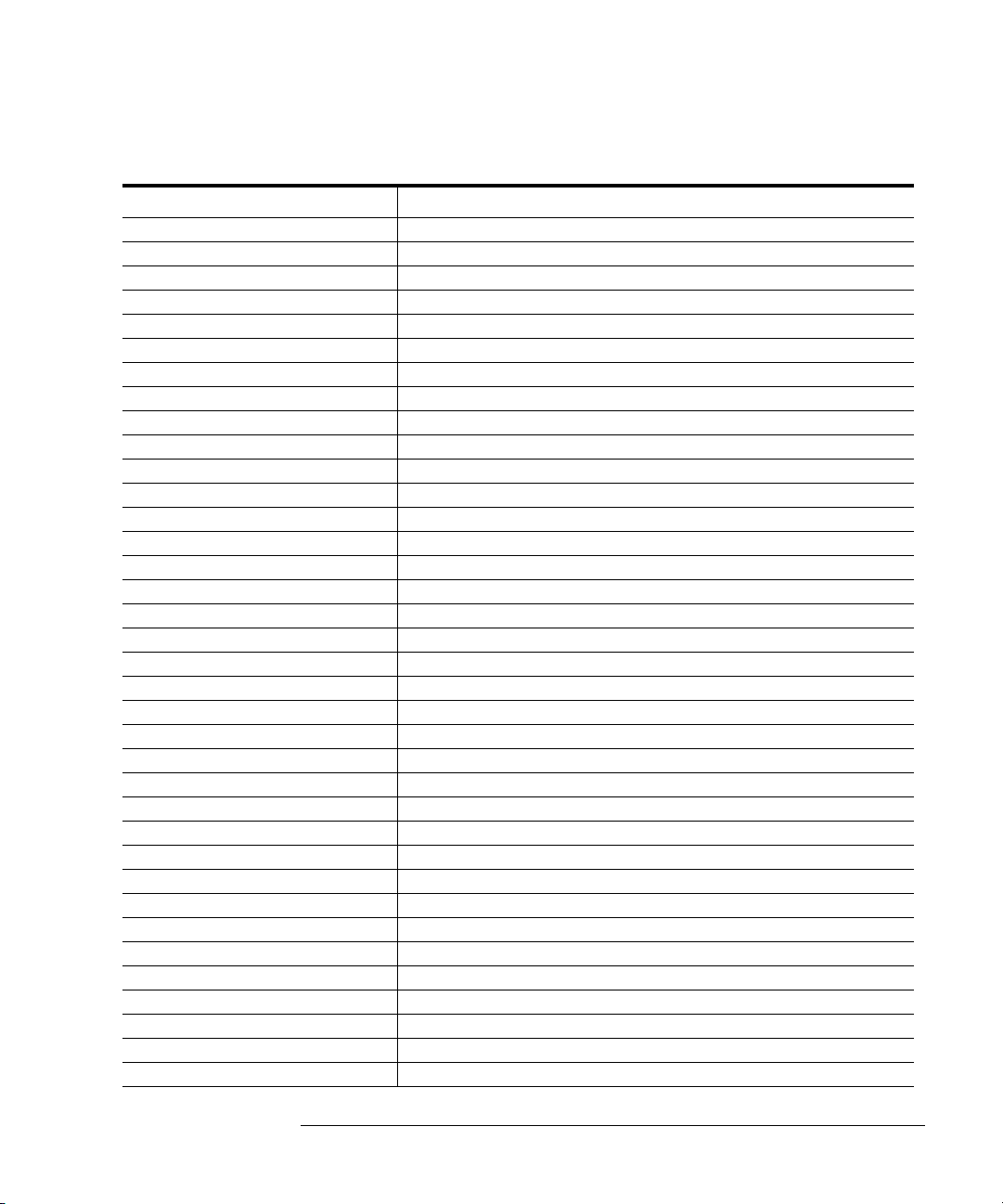

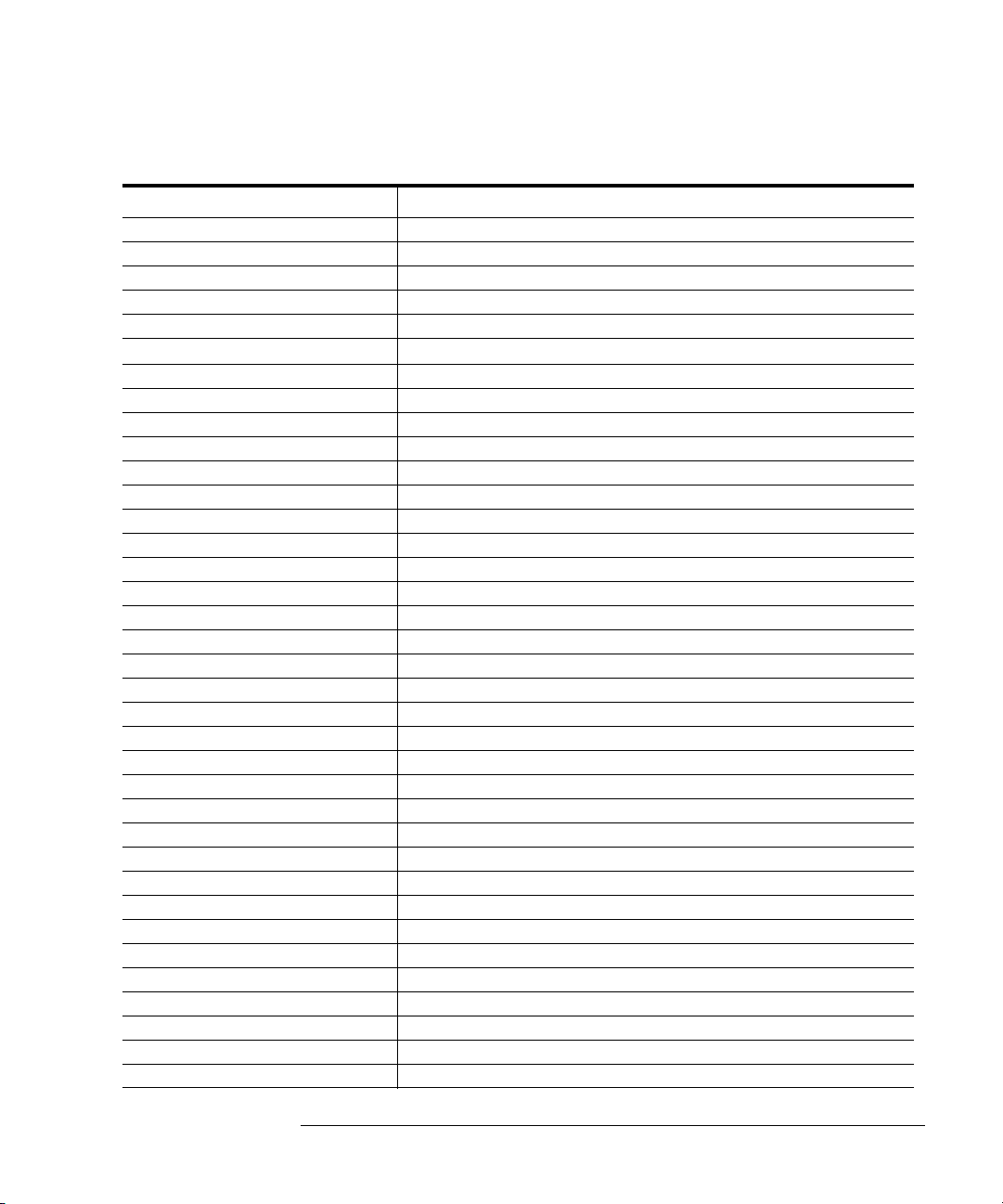

Table 2-1. Location of Softkeys (2 of 18)

Softkey Menu Location

ALL OFF Front-panel access key: MARKER

ALL SEGS SWEEP Front-panel access key: SWEEP SETUP

ALTERNATE A AND B Front-panel access key: CAL

AMPLITUDE Front-panel access key: SYSTEM

AMPLITUDE OFFSET Front-panel access key: SYSTEM

ANALOG IN Aux Input Front-panel access key: MEAS

ARBITRARY IMPEDANCE Front-panel access key: CAL

ASCII Front-panel access key: SAVE/RECALL

ASSERT SRQ Front-panel access key: SEQ

AUTO-FEED ON off Front-panel access key: COPY

AUTO SCALE Front-panel access key: SCALE REF

AVERAGING FACTOR Front-panel access key: AVG

AVERAGING on OFF Front-panel access key: AVG

AVERAGING RESTART Front-panel access key: AVG

B Front-panel access key: MEAS

B/R Front-panel access key: MEAS

BACKGROUND INTENSITY Front-panel access key: DISPLAY

BACKSPACE Front-panel access key: CAL

BANDPASS Front-panel access key: SYSTEM

BEEP DONE ON off Front-panel access key: DISPLAY

BEEP FAIL on OFF Front-panel access key: SYSTEM

BEEP WARN on OFF Front-panel access key: DISPLAY

BLANK DISPLAY Front-panel access key: DISPLAY

BRIGHTNESS Front-panel access key: DISPLAY

C0 Front-panel access key: CAL

C1 Front-panel access key: CAL

C2 Front-panel access key: CAL

C3 Front-panel access key: CAL

CAL FACTOR Front-panel access key: CAL

CAL FACTOR SENSOR A Front-panel access key: CAL

CAL FACTOR SENSOR B Front-panel access key: CAL

CAL KITS & STDS Front-panel access key: CAL

CAL KIT: 2.4 mm Front-panel access key: CAL

CAL KIT: 2.92* Front-panel access key: CAL

CAL KIT: 2.92 mm Front-panel access key: CAL

CAL KIT: 3.5mmC Front-panel access key: CAL

Reference

Location of Softkeys

2-23

Reference

Location of Softkeys

Table 2-1. Location of Softkeys (3 of 18)

Softkey Menu Location

CAL KIT: 3.5mmD Front-panel access key: CAL

CAL KIT: 7mm Front-panel access key: CAL

CAL KIT: N 50

CAL KIT: N 75

CAL KIT: TRL 3.5 mm Front-panel access key: CAL

CALIBRATE MENU Front-panel access key: CAL

CALIBRATE: NONE Front-panel access key: CAL

CAL Z0 LINE Z0 Front-panel access key: CAL

CENTER Front-panel access key: SWEEP SETUP

CENTER Front-panel access key: SYSTEM

CH1 DATA [ ] Front-panel access key: COPY

CH1 DATA LIMIT LN Front-panel access key: DISPLAY

CH1 MEM Front-panel access key: DISPLAY

CH1 MEM [ ] Front-panel access key: COPY

CH2 DATA [ ] Front-panel access key: COPY

CH2 DATA LIMIT LN Front-panel access key: DISPLAY

CH2 MEM [ ] Front-panel access key: COPY

CH2 MEM REF LINE Front-panel access key: DISPLAY

CHAN POWER [COUPLED uncoupled] Front-panel access key: SWEEP SETUP

CHOP A AND B Front-panel access key: CAL

CLEAR BIT Front-panel access key: SEQ

CLEAR LIST Front-panel access key: CAL and SWEEP SETUP

CLEAR SEQUENCE Front-panel access key: SEQ

COAX Front-panel access key: CAL

COAXIAL DELAY Front-panel access key: SCALE REF

COLOR Front-panel access key: DISPLAY

COMPONENT ANALYZER Front-panel access key: SYSTEM

CONFIGURE EXT DISK Front-panel access key: SAVE/RECALL

CONTINUE SEQUENCE Front-panel access key: SEQ

CONTINUOUS Front-panel access key: SWEEP SETUP and MARKER FCTN

CONVERSION [ ] Front-panel access key: MEAS

CORRECTION on OFF Front-panel access key: CAL

COUPLED Front-panel access key: MARKER FCTN

COUPLED CH ON off Front-panel access key: SWEEP SETUP

CW FREQ Front-panel access key: SWEEP SETUP

CW TIME Front-panel access key: SWEEP SETUP

Ω

Front-panel access key: CAL

Ω

Front-panel access key: CAL

2-24

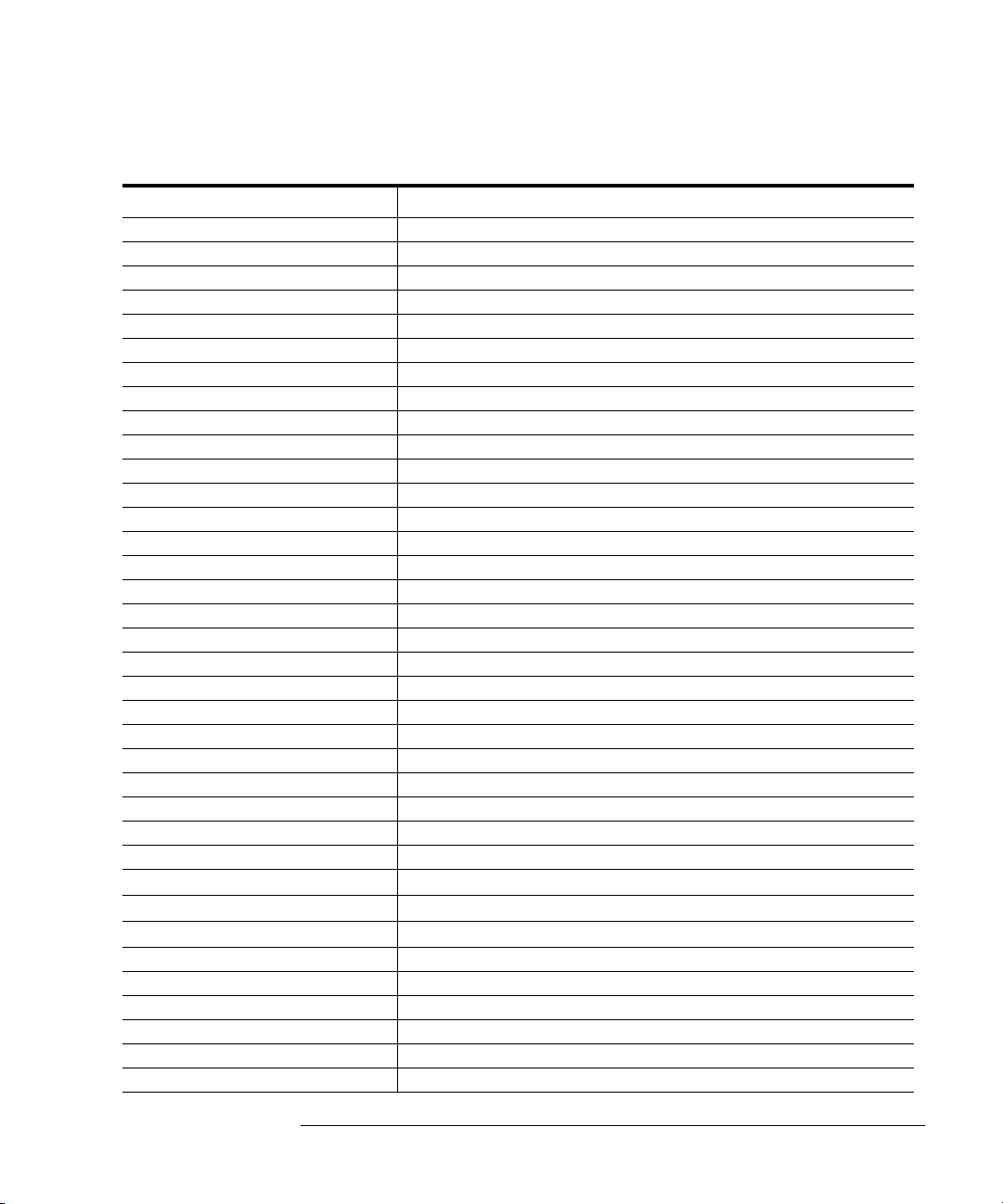

Table 2-1. Location of Softkeys (4 of 18)

Softkey Menu Location

D2/D1 TO D2 on OFF Front-panel access key: DISPLAY

DATA AND MEMORY Front-panel access key: DISPLAY

DATA ARRAY on off Front-panel access key: SAVE/RECALL

DATA/MEM Front-panel access key: DISPLAY

DATA – MEM Front-panel access key: DISPLAY

DATA

→ MEMORY

DATA ONLY on off Front-panel access key: SAVE/RECALL

DECISION MAKING Front-panel access key: SEQ

DECR LOOP COUNTER Front-panel access key: SEQ

DEFAULT COLORS Front-panel access key: DISPLAY

DEFAULT PLOT SETUP Front-panel access key: COPY

DEFAULT PRNT SETUP Front-panel access key: COPY

DEFAULT RCVR COEFF Front-panel access key: CAL

DEFAULT SRC COEFF Front-panel access key: CAL

DEFAULT STANDARDS Front-panel access key: CAL

DEFINE DISK-SAVE Front-panel access key: SAVE/RECALL

DEFINE PLOT Front-panel access key: COPY

DEFINE PRINT Front-panel access key: COPY

DEFINE STANDARD Front-panel access key: CAL

DELAY Front-panel access key: FORMAT

DELAY/THRU Front-panel access key: CAL

DELETE Front-panel access key: CAL, SWEEP SETUP and SYSTEM

DELETE ALL FILES Front-panel access key: SAVE/RECALL

DELETE FILE Front-panel access key: SAVE/RECALL

DELTA LIMITS Front-panel access key: SYSTEM

DEMOD: OFF Front-panel access key: SYSTEM

DIRECTORY SIZE (LIF) Front-panel access key: SAVE/RECALL

DISCRETE Front-panel access key: MA RKER FCTN

DISK Front-panel access key: LOCAL

DISK UNIT NUMBER Front-panel access key: SAVE/RECALL

DISPLAY: DATA Front-panel access key: DISPLAY

DISP MKRS ON off Front-panel access key: MARKER FCTN

DO BOTH FWD + REV Front-panel access key: CAL

DONE 1-PORT CAL Front-panel access key: CAL

DONE 2-PORT CAL Front-panel access key: CAL

DONE LINE/MATCH Front-panel access key: CAL

Front-panel access key: DISPLAY

Reference

Location of Softkeys

2-25

Reference

Location of Softkeys

Table 2-1. Location of Softkeys (5 of 18)

Softkey Menu Location

DONE RESPONSE Front-panel access key: CAL

DONE RESP ISOL’N CAL Front-panel access key: CAL

DONE SEQ MODIFY Front-panel access key: SEQ

DONE TRL/LRM Front-panel access key: CAL

DO SEQUENCE Front-panel access key: SEQ

DOS Front-panel access key: SAVE/RECALL

DOWN CONVERTER Front-panel access key: SYSTEM

DUAL CHAN on OFF Front-panel access key: DISPLAY

DUPLICATE SEQUENCE Front-panel access key: SEQ

EACH SWEEP Front-panel access key: CAL

EDIT Front-panel access key: CAL, SWEEP SETUP and SYSTEM

EDIT LIMIT LINE Front-panel access key: SYSTEM

EDIT LIST Front-panel access key: SWEEP SETUP

ELECTRICAL DELAY Front-panel access key: SCALE REF

EMIT BEEP Front-panel access key: SEQ

END OF LABEL Front-panel access key: DISPLAY

END SWEEP HIGH PULSE Front-panel access key: SEQ

END SWEEP LOW PULSE Front-panel access key: SEQ

ENTER RCVR COEFF MENU Front-panel access key: CAL

ENTER SRC COEFF MENU Front-panel access key: CAL

ERASE TITLE Front-panel access key: DISPLAY

EXT SOURCE AUTO Front-panel access key: SYSTEM

EXT SOURCE MANUAL Front-panel access key: SYSTEM

EXT TRIG ON POINT Front-panel access key: SWEEP SETUP

EXT TRIG ON SWEEP Front-panel access key: SWEEP SETUP

EXTENSION INPUT A Front-panel access key: CAL

EXTENSION INPUT B Front-panel access key: CAL

EXTENSION PORT 1 Front-panel access key: CAL

EXTENSION PORT 2 Front-panel access key: CAL

EXTENSIONS on OFF Front-panel access key: CAL

EXTERNAL DISK Front-panel access key: SAVE/RECALL

FACTORY Front-panel access key: PRESET

FILE UTILITIES Front-panel access key: SAVE/RECALL

FIXED Front-panel access key: CAL

FIXED MKR AUX VALUE Front-panel access key: MARKER

FIXED MKR POSITION Front-panel access key: MARKER

2-26

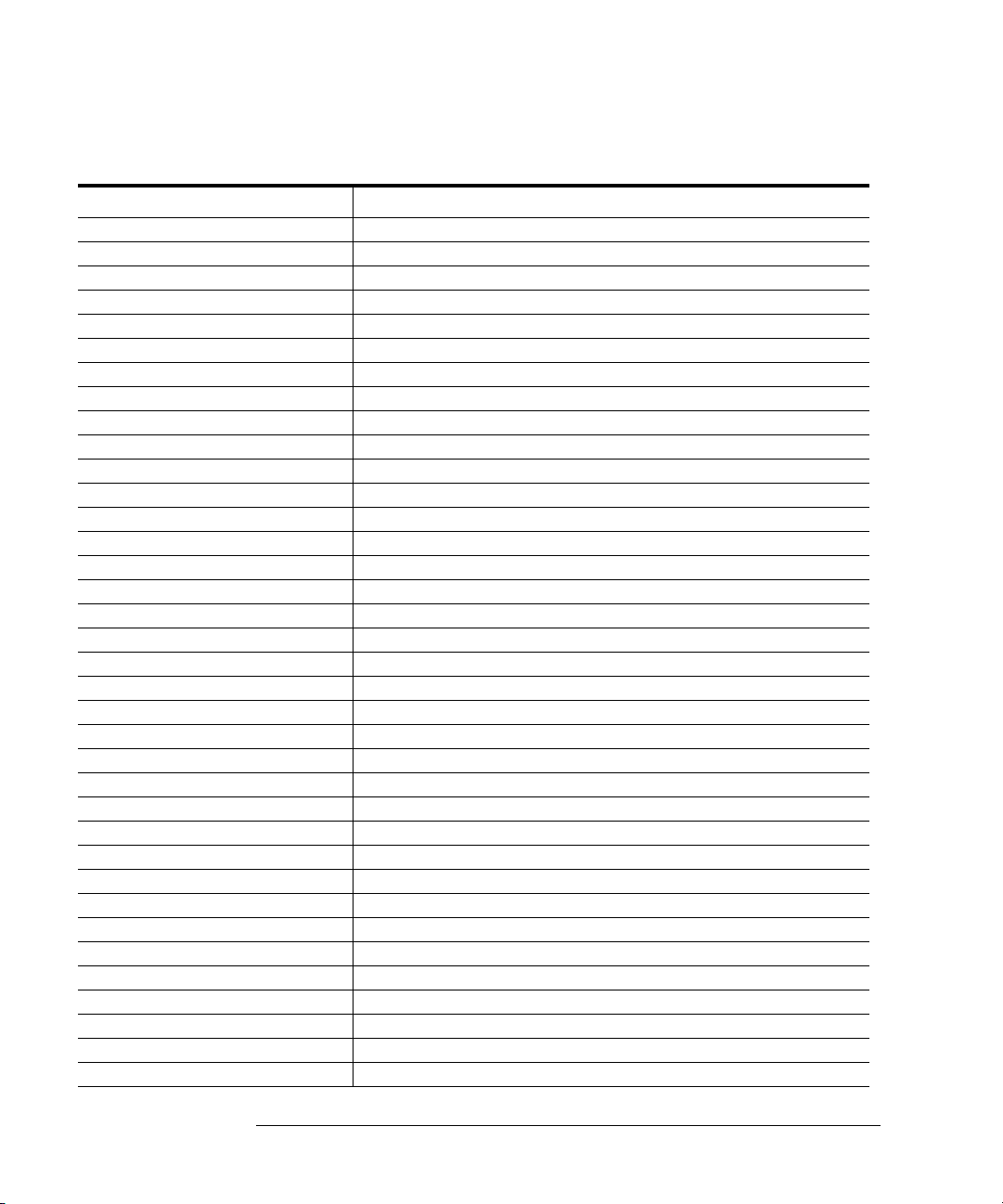

Table 2-1. Location of Softkeys (6 of 18)

Softkey Menu Location

FIXED MKR STIMULUS Front-panel access key: MARKER

FIXED MKR VALUE Front-panel access key: MARKER

FLAT LINE Front-panel access key: SYSTEM

FORM FEED Front-panel access key: DISPLAY

FORMAT ARY on off Front-panel access key: SAVE/RECALL

FORMAT DISK Front-panel access key: SAVE/RECALL

FORMAT: DOS Front-panel access key: SAVE/RECALL

FORMAT EXT DISK Front-panel access key: SAVE/RECALL

FORMAT INT DISK Front-panel access key: SAVE/RECALL

FORMAT INT MEMORY Front-panel access key: SAVE/RECALL

FORMAT: LIF Front-panel access key: SAVE/RECALL

FORWARD: Front-panel access key: CAL

FREQ OFFS MENU Front-panel access key: SYSTEM

FREQ OFFS on OFF Front-panel access key: SYSTEM

FREQUENCY Front-panel access key: CAL

FREQUENCY BLANK Front-panel access key: DISPLAY

FREQUENCY: CW Front-panel access key: SYSTEM

FREQUENCY: SWEEP Front-panel access key: SYSTEM

FULL 2-PORT Front-panel access key: CAL

FULL PAGE Front-panel access key: COPY

FWD ISOL’N ISOL’N STD Front-panel access key: CAL

FWD MATCH Front-panel access key: CAL

FWD MATCH THRU Front-panel access key: CAL

FWD TRANS Front-panel access key: CAL

FWD TRANS THRU Front-panel access key: CAL

G+jB MKR Front-panel access key: MARKER FCTN

GATE: CENTER Front-panel access key: SYSTEM

GATE on OFF Front-panel access key: SYSTEM

GATE SHAPE Front-panel access key: SYSTEM

GATE SHAPE MAXIMUM Front-panel access key: SYSTEM

GATE SHAPE MINIMUM Front-panel access key: SYSTEM

GATE SHAPE NORMAL Front-panel access key: SYSTEM

GATE SHAPE WIDE Front-panel access key: SYSTEM

GATE: SPAN Front-panel access key: SYSTEM

GATE: START Front-panel access key: SYSTEM

GATE: STOP Front-panel access key: SYSTEM

Reference

Location of Softkeys

2-27

Reference

Location of Softkeys

Table 2-1. Location of Softkeys (7 of 18)

Softkey Menu Location

GOSUB SEQUENCE Front-panel access key: SEQ

GRAPHICS on off Front-panel access key: SAVE/RECALL

GRATICULE [ ] Front-panel access key: COPY

GRATICULE TEXT Front-panel access key: DISPLAY

GUIDED SETUP Front-panel access key: PRESET and SYSTEM

HARMONIC MEAS Front-panel access key: SYSTEM

HARMONIC OFF Front-panel access key: SYSTEM

HARMONIC SECOND Front-panel access key: SYSTEM

HARMONIC THIRD Front-panel access key: SYSTEM

HOLD Front-panel access key: SWEEP SETUP

GP-IB DIAG on OFF Front-panel access key: LOCAL

I/O FWD Front-panel access key: SEQ

I/O REV Front-panel access key: SEQ

IF BIT H Front-panel access key: SEQ

IF BIT L Front-panel access key: SEQ

IF BW [ ] Front-panel access key: AVG and SYSTEM

IF LIMIT TEST FAIL Front-panel access key: SEQ

IF LIMIT TEST PASS Front-panel access key: SEQ

IF LOOP COUNTER=0 Front-panel access key: SEQ

IF LOOP COUNTER < > 0 Front-panel access key: SEQ

IMAGINARY Front-panel access key: FORMAT

INCR LOOP COUNTER Front-panel access key: SEQ

INDEX of REFRACTION Front-panel access key: CAL and SYSTEM

INPUT PORT CAL Front-panel access key: CAL

INPUT PORTS Front-panel access key: MEAS

INSTRUMENT MODE Front-panel access key: SYSTEM

INTENSITY Front-panel access key: DISPLAY

INTERNAL DISK Front-panel access key: SAVE/RECALL

INTERNAL MEMORY Front-panel access key: SAVE/RECALL

INTERPOL on OFF Front-panel access key: CAL

1/S Front-panel access key: MEAS

ISOLATION Front-panel access key: CAL

ISOLATION DONE Front-panel access key: CAL

ISOL’N STD Front-panel access key: CAL

ISTATE CONTENTS Front-panel access key: SAVE/RECALL

KIT DONE (MODIFIED) Front-panel access key: CAL

2-28

Table 2-1. Location of Softkeys (8 of 18)

Softkey Menu Location

LABEL CLASS Front-panel access key: CAL

LABEL CLASS DONE Front-panel access key: CAL

LABEL KIT Front-panel access key: CAL

LABEL STD Front-panel access key: CAL

LEFT LOWER Front-panel access key: COPY

LEFT UPPER Front-panel access key: COPY

LIF Front-panel access key: SAVE/RECALL

LIGHTWAVE PARAMETERS Front-panel access key: MEAS

LIMIT LINE OFFSETS Front-panel access key: SYSTEM

LIMIT LINE on OFF Front-panel access key: SYSTEM

LIMIT MENU Front-panel access key: SYSTEM

LIMIT TEST on OFF Front-panel access key: SYSTEM

LIMIT TEST RESULT Front-panel access key: DISPLAY

LIMIT TYPE Front-panel access key: SYSTEM

LINE/MATCH Front-panel access key: CAL

LIN FREQ Front-panel access key: SWEEP SETUP

LIN MAG Front-panel access key: FORMAT

LIN MKR Front-panel access key: MA RKER FCTN

LINE/MATCH Front-panel access key: CAL

LINE Z0: Front-panel access key: CAL

LINE TYPE DATA Front-panel access key: COPY

LINE TYPE MEMORY Front-panel access key: COPY

LIST Front-panel access key: COPY

LIST FREQ Front-panel access key: SWEEP SETUP

LIST VALUES Front-panel access key: COPY

LN/MATCH 1 LOAD Front-panel access key: CAL

LN/MATCH 2 LOAD Front-panel access key: CAL

LO CONTROL on OFF Front-panel access key: SYSTEM

LO MENU Front-panel access key: SYSTEM

LO SOURCE ADDRESS Front-panel access key: SYSTEM

LOAD Front-panel access key: CAL

LOAD RCVR DISK MENU Front-panel access key: CAL

LOAD SEQ FROM DISK Front-panel access key: SEQ

LOAD SRC DISK MENU Front-panel access key: CAL

LOG FREQ Front-panel access key: SWEEP SETUP

LOG MAG Front-panel access key: FORMAT

Reference

Location of Softkeys

2-29

Reference

Location of Softkeys

Table 2-1. Location of Softkeys (9 of 18)

Softkey Menu Location

LOG MKR Front-panel access key: MARKER FCTN

LOOP COUNTER Front-panel access key: DISPLAY and SEQ

LOSS Front-panel access key: CAL

LOSS/SENSR LISTS Front-panel access key: CAL

LOWER LIMIT Front-panel access key: SYSTEM

LOW PASS IMPULSE Front-panel access key: SYSTEM

LOW PASS STEP Front-panel access key: SYSTEM

MANUAL TRG ON POINT Front-panel access key: SWEEP SETUP

MARKER

MARKER → CENTER

MARKER → CW

MARKER

MARKER → MIDDLE

MARKER → REFERENCE

MARKER

MARKER → START

MARKER → STIMULUS

MARKER

MARKER 1, 2, 3, 4, and 5 Front-panel access key: MARKER

MARKER MODE MENU Front-panel access key: MARKER FCTN

MARKERS: CONTINUOUS Front-panel access key: MARKER FCTN

MARKERS: COUPLED Front-panel access key: MARKER FCTN

MARKERS: DISCRETE Front-panel access key: MARKER FCTN

MARKERS: UNCOUPLED Front-panel access key: MARKER FCTN

MAX Front-panel access key: MARKER FCTN and SRCH

MAXIMUM FREQUENCY Front-panel access key: CAL

MEASURE RESTART Front-panel access key: SWEEP SETUP

MEMORY Front-panel access key: DISPLAY

MIDDLE VALUE Front-panel access key: SYSTEM

MIN Front-panel access key: MARKER FCTN and SRCH

MINIMUM FREQUENCY Front-panel access key: CAL

MKR SEARCH [ ] Front-panel access key: MARKER FCTN and SRCH

MKR ZERO Front-panel access key: MARKER

MODIFY [ ] Front-panel access key: CAL

MODIFY COLORS Front-panel access key: DISPLAY

→ AMP. OFS.

→ DELAY

→ SPAN

→ STOP

Front-panel access key: SYSTEM

Front-panel access key: MARKER FCTN

Front-panel access key: SEQ

Front-panel access key: MARKER FCTN

Front-panel access key: SYSTEM

Front-panel access key: MARKER FCTN and SCALE REF

Front-panel access key: MARKER FCTN

Front-panel access key: MARKER FCTN

Front-panel access key: SYSTEM

Front-panel access key: MARKER FCTN

2-30

Table 2-1. Location of Softkeys (10 of 18)

Softkey Menu Location

MODIFY STANDARDS Front-panel access key: CAL

MODIFY THRU/RCVR Front-panel access key: CAL

Ω

N 50

Front-panel access key: CAL

Ω

N 75

Front-panel access key: CAL

NEW SEQ/MODIFY SEQ Front-panel access key: SEQ

NEWLINE Front-panel access key: DISPLAY

NUMBER OF GROUPS Front-panel access key: SWEEP SETUP

NUMBER OF POINTS Front-panel access key: SYSTEM

NUMBER OF READINGS Front-panel access key: CAL

OFFSET DELAY Front-panel access key: CAL

OFFSET LOSS Front-panel access key: CAL

OFFSET Z0 Front-panel access key: CAL

OMIT ISOLATION Front-panel access key: CAL

ONE-PATH 2-PORT Front-panel access key: CAL

ONE SWEEP Front-panel access key: CAL

OP PARMS (MKRS etc.) Front-panel access key: COPY

OPEN Front-panel access key: CAL

OPTICAL STANDARDS Front-panel access key: CAL

P MTR/GPIB TO TITLE Front-panel access key: SEQ

NEXT PAGE Front-panel access key: COPY

PARALLEL Front-panel access key: LOCAL

PARALLEL [ ] Front-panel access key: LOCAL

PARALLEL OUT ALL Front-panel access key: SEQ

PARALL IN BIT NUMBER Front-panel access key: SEQ

PARALL IN IF BIT H Front-panel access key: SEQ

PARALL IN IF BIT L Front-panel access key: SEQ

PAUSE Front-panel access key: SEQ

PEN NUM DATA Front-panel access key: COPY

PEN NUM GRATICULE Front-panel access key: COPY

PEN NUM MARKER Front-panel access key: COPY

PEN NUM MEMORY Front-panel access key: COPY

PEN NUM TEXT Front-panel access key: COPY

PERIPHERAL GPIB ADDR Front-panel access key: SEQ

PHASE Front-panel access key: FORMAT and SYSTEM

PHASE OFFSET Front-panel access key: SCALE REF

PLOT Front-panel access key: COPY and SYSTEM

Reference

Location of Softkeys

2-31

Reference

Location of Softkeys

Table 2-1. Location of Softkeys (11 of 18)

Softkey Menu Location

PLOT DATA ON off Front-panel access key: COPY

PLOT GRAT ON off Front-panel access key: COPY

PLOT MEM ON off Front-panel access key: COPY

PLOT MKR ON off Front-panel access key: COPY

PLOT SPEED [ ] Front-panel access key: COPY

PLOT TEXT ON off Front-panel access key: COPY

PLOTTER BAUD RATE Front-panel access key: LOCAL

PLOTTER FORM FEED Front-panel access key: COPY

PLOTTER PORT Front-panel access key: LOCAL

PLTR PORT GPIB Front-panel access key: LOCAL

PLTR TYPE [ ] Front-panel access key: LOCAL

POLAR Front-panel access key: FORMAT

POLAR MKR MENU Front-panel access key: MARK ER FCTN

PORT EXTENSIONS Front-panel access key: CAL

PORT POWER [COUPLED uncoupled] Front-panel access key: SWEEP SETUP and PWR

POWER Front-panel access key: SWEEP SETUP, SYSTEM and PWR

POWER: FIXED Front-panel access key: SYSTEM

POWER LOSS Front-panel access key: CAL

POWER MTR: [ ] Front-panel access key: LOCAL

POWER RANGES Front-panel access key: SWEEP SETUP and PWR

POWER: SWEEP Front-panel access key: SWEEP SETUP and PWR

PRESET: FACTORY Front-panel access key: PRESET

PRESET: USER Front-panel access key: PRESET

PRINT: COLOR Front-panel access key: COPY

PRINT COLORS Front-panel access key: COPY

PRINT: MONOCHROME Front-panel access key: COPY

PRINT ALL MONOCHROME Front-panel access key: COPY

PRINT MONOCHROME Front-panel access key: COPY and SYSTEM

PRINT SEQUENCE Front-panel access key: SEQ

PRINTER BAUD RATE Front-panel access key: LOCAL

PRINTER FORM FEED Front-panel access key: COPY

PRINTER PORT Front-panel access key: LOCAL

PRNTR PORT GPIB Front-panel access key: LOCAL

PRNTR TYPE [ ] Front-panel access key: LOCAL

PWR LOSS on OFF Front-panel access key: CAL

PWR RANGE AUTO man Front-panel access key: MENU and PWR

2-32

Table 2-1. Location of Softkeys (12 of 18)

Softkey Menu Location

PWRMTR CAL [ ] Front-panel access key: CAL

PWRMTR CAL OFF Front-panel access key: CAL

R Front-panel access key: MEAS

R+jX MKR Front-panel access key: M ARKER FCTN

RANGE 0 –15 TO +10 Front-panel access key: SWEEP SETUP and PWR

RANGE 1 –25 TO 0 Front-panel access key: SWEEP SETUP and PWR

RANGE 2 –35 TO –10 Front-panel access key: SWEEP SETUP and PWR

RANGE 3 –45 TO –20 Front-panel access key: SWEEP SETUP and PWR

RANGE 4 –55 TO –30 Front-panel access key: SWEEP SETUP and PWR

RANGE 5 –65 TO –40 Front-panel access key: SWEEP SETUP and PWR

RANGE 6 –75 TO –50 Front-panel access key: SWEEP SETUP and PWR

RANGE 7 –85 TO –60 Front-panel access key: SWEEP SETUP and PWR

RAW ARRAY on off Front-panel access key: SAVE/RECALL

Re/Im MKR Front-panel access key: MARKER FCTN

REAL Front-panel access key: FORMAT

RECALL COLORS Front-panel access key: DISPLAY

RECALL KEYS MENU Front-panel access key: SAVE/RECALL

RECALL KEYS on OFF Front-panel access key: SAVE/RECALL

RECALL REG1 – 7 Front-panel access key: SAVE/RECALL

RECALL STATE Front-panel access key: SAVE/RECALL

RECEIVER STANDARDS Front-panel access key: CAL

REFERENCE POSITION Front-panel access key: SCALE REF

REFERENCE VALUE Front-panel access key: SCALE REF

Refl: E S11 FWD Front-panel access key: MEAS

Refl: E S22 (B/R) Front-panel access key: MEAS

Refl: E S22 REV Front-panel access key: MEAS

Refl: O (PORT 1

REFLECT Front-panel access key: CAL

REFLECT’N Front-panel access key: CAL

RENAME FILE Front-panel access key: SAVE/RECALL

RE-SAVE STATE Front-panel access key: SAVE/RECALL

RESET COLOR Front-panel access key: DISPLAY

RESPONSE Front-panel access key: CAL

RESPONSE & ISOL’N Front-panel access key: CAL

RESPONSE & MATCH Front-panel access key: CAL

RESTORE DISPLAY Front-panel access key: COPY

→2)

Front-panel access key: MEAS

Reference

Location of Softkeys

2-33

Reference

Location of Softkeys

Table 2-1. Location of Softkeys (13 of 18)

Softkey Menu Location

RESUME CAL SEQUENCE Front-panel access key: CAL

REV ISOL’N ISOL’N STD Front-panel access key: CAL

REV MATCH Front-panel access key: CAL

REV MATCH THRU Front-panel access key: CAL

REV TRANS Front-panel access key: CAL

REV TRANS THRU Front-panel access key: CAL

REVERSE: Front-panel access key: CAL

RF > LO Front-panel access key: SYSTEM

RF < LO Front-panel access key: SYSTEM

RIGHT LOWER Front-panel access key: COPY

RIGHT UPPER Front-panel access key: COPY

ROUND SECONDS Front-panel access key: SYSTEM

S11 1-PORT Front-panel access key: CAL

S11 REFL OPEN Front-panel access key: CAL

S11A Front-panel access key: CAL

S11B Front-panel access key: CAL

S11C Front-panel access key: CAL

S22 1-PORT Front-panel access key: CAL

S22 REFL OPEN Front-panel access key: CAL

S22A Front-panel access key: CAL

S22B Front-panel access key: CAL

S22C Front-panel access key: CAL

SAVE/RECALL MENU Front-panel access key: SAVE/RECALL

SAVE COLORS Front-panel access key: DISPLAY

SAVE RCVR COEFF Front-panel access key: CAL

SAVE SRC COEFF Front-panel access key: CAL

SAVE STANDARDS Front-panel access key: CAL

SAVE STATE Front-panel access key: SAVE/RECALL

SAVE USER KIT Front-panel access key: CAL

SAVE USING BINARY Front-panel access key: SAVE/RECALL

SCALE/DIV Front-panel access key: SCALE REF

SCALE PLOT [ ] Front-panel access key: COPY

SEARCH LEFT Front-panel access key: MARKER FCTN and SRCH

SEARCH: MAX Front-panel access key: MARKER FCTN and SRCH

SEARCH: MIN Front-panel access key: MARKER FCTN and SRCH

SEARCH: OFF Front-panel access key: MARKER FCTNand SRCH

2-34

Table 2-1. Location of Softkeys (14 of 18)

Softkey Menu Location

SEARCH RIGHT Front-panel access key: MARKER FCTN and SRCH

SECOND Front-panel access key: SYSTEM

SEGMENT Front-panel access key: CAL, SWEEP SETUP and SYSTEM

SEGMENT: CENTER Front-panel access key: SWEEP SETUP

SEGMENT: SPAN Front-panel access key: SWEEP SETUP

SEGMENT: START Front-panel access key: SWEEP SETUP

SEGMENT: STOP Front-panel access key: SWEEP SETUP

SEL QUAD [ ] Front-panel access key: COPY

SELECT CAL KEY Front-panel access key: CAL

SELECT CAL KIT Front-panel access key: CAL

SELECT DISK Front-panel access key: SAVE/RECALL

SELECT LETTER Front-panel access key: CAL, DISPLAY and SAVE/RECALL

SEQUENCE 1 SEQ1 Front-panel access key: SEQ

SEQUENCE 2 SEQ2 Front-panel access key: SEQ

SEQUENCE 3 SEQ3 Front-panel access key: SEQ

SEQUENCE 4 SEQ4 Front-panel access key: SEQ

SEQUENCE 5 SEQ5 Front-panel access key: SEQ

SEQUENCE 6 SEQ6 Front-panel access key: SEQ

SERIAL Front-panel access key: LOCAL

SERVICE MENU Front-panel access key: SYSTEM

SET ADDRESSES Front-panel access key: LOCAL

SET BIT Front-panel access key: SEQ

SET CLOCK Front-panel access key: SYSTEM

SET DAY Front-panel access key: SYSTEM

SET FREQ LOW PASS Front-panel access key: SYSTEM

SET HOUR Front-panel access key: SYSTEM

SET MINUTES Front-panel access key: SYSTEM

SET MONTH Front-panel access key: SYSTEM

SET REF Front-panel access key: CAL

SET YEAR Front-panel access key: SYSTEM

SET Z0 Front-panel access key: CAL

SHORT Front-panel access key: CAL

SINGLE Front-panel access key: SWEEP SETUP

SINGLE POINT Front-panel access key: SYSTEM

SINGLE SEG SWEEP Front-panel access key: SWEEP SETUP

SLIDING OFFSET Front-panel access key: CAL

Reference

Location of Softkeys

2-35

Reference

Location of Softkeys

Table 2-1. Location of Softkeys (15 of 18)

Softkey Menu Location

SLOPE Front-panel access key: SWEEP SETUP

SLOPE ON off Front-panel access key: SWEEP SETUP

SLOPING LINE Front-panel access key: SYSTEM

SMITH CHART Front-panel access key: FORMAT

SMITH MKR MENU Front-panel access key: M ARKER FCTN

SMOOTHING APERTURE Front-panel access key: AVG

SMOOTHING on OFF Front-panel access key: AVG

SOURCE PWR ON off Front-panel access key: SWEEP SETUP and PWR

SOURCE STANDARDS Front-panel access key: CAL

SPAN Front-panel access key: SWEEP SETUP

SPAN Front-panel access key: SYSTEM

S PARAMETERS Front-panel access key: MEAS

SPECIAL FUNCTIONS Front-panel access key: SEQ

SPECIFY CLASS Front-panel access key: CAL

SPECIFY CLASS DONE Front-panel access key: CAL

SPECIFY GATE Front-panel access key: SYSTEM

SPECIFY OFFSET Front-panel access key: CAL

SPECIFY TRL THRU Front-panel access key: CAL

SPLIT DISP ON off Front-panel access key: DISPLAY

STANDARDS DONE Front-panel access key: CAL

START Front-panel access key: SWEEP SETUP

START FREQUENCY Front-panel access key: SYSTEM

STATS on OFF Front-panel access key: MARKER FCTN

STD DONE (DEFINED) Front-panel access key: CAL

STD OFFSET DONE Front-panel access key: CAL

STD TYPE:LOAD Front-panel access key: CAL

STD TYPE: OPEN Front-panel access key: CAL

STD TYPE: SHORT Front-panel access key: CAL

STEP SIZE Front-panel access key: SWEEP SETUP

STIMULUS VALUE Front-panel access key: SYSTEM

STIMULUS OFFSET Front-panel access key: SYSTEM

STOP Front-panel access key: SWEEP SETUP

STOP FREQUENCY Front-panel access key: SYSTEM

STORE SEQ TO DISK Front-panel access key: SEQ

SWEEP TIME [ ] Front-panel access key: SWEEP SETUP and SYSTEM

SWEEP TYPE MENU Front-panel access key: SWEEP SETUP

2-36

Table 2-1. Location of Softkeys (16 of 18)

Softkey Menu Location

SWR Front-panel access key: FORMAT

SYSTEM CONTROLLER Front-panel access key: LOCAL

SYSTEM Z0 Front-panel access key: CAL

TAKE CAL SWEEP Front-panel access key: CAL

TALKER/LISTENER Front-panel access key: LOCAL

TARGET Front-panel access key: MARKER FCTN

TERMINAL IMPEDANCE Front-panel access key: CAL

TESTPORT 1 2 Front-panel access key: MEAS

TESTSET SW CONT hld Front-panel access key: CAL

TEXT Front-panel access key: DISPLAY

TEXT [ ] Front-panel access key: COPY

THIRD Front-panel access key: SYSTEM

THRU Front-panel access key: CAL

THRU THRU Front-panel access key: CAL

TIME STAMP ON off Front-panel access key: SYSTEM

TINT Front-panel access key: DISPLAY

TITLE Front-panel access key: DISPLAY

TITLE SEQUENCE Front-panel access key: SEQ

TITLE TO MEMORY Front-panel access key: SEQ

TITLE TO P MTR/GPIB Front-panel access key: SEQ

TITLE TO PERIPHERAL Front-panel access key: SEQ

TITLE TO PRNTR/GPIB Front-panel access key: SEQ

TRACKING on OFF Front-panel access key: MARKER FCTN

Trans: E/E S11 (A/R) Front-panel access key: MEAS

Trans: E/E S12 REV Front-panel access key: MEAS

Trans: E/E S21 (B/R) Front-panel access key: MEAS

Trans: E/E S21 FWD Front-panel access key: MEAS

Trans: E/O (PORT 1

Trans: O/E (PORT 1

Trans: O/O (PORT 1

TRANSFORM MENU Front-panel access key: SYSTEM

TRANSFORM on OFF Front-panel access key: SYSTEM

TRANSFORM PARAMETERS Front-panel access key: SYSTEM

TRANSFORM SPAN Front-panel access key: SYSTEM

TRANSMISSION Front-panel access key: CAL

TRIGGER MENU Front-panel access key: SWEEP SETUP

→2)

→2)

→2)

Front-panel access key: MEAS

Front-panel access key: MEAS

Front-panel access key: MEAS

Reference

Location of Softkeys

2-37

Reference

Location of Softkeys

Table 2-1. Location of Softkeys (17 of 18)

Softkey Menu Location

TRIGGER: TRIG OFF Front-panel access key: SWEEP SETUP

TRL/LRM OPTION Front-panel access key: CAL

TRL*/LRM* 2-PORT Front-panel access key: CAL

TRL 3.5 mm Front-panel access key: CAL

TRL LINE OR MATCH Front-panel access key: CAL

TRL REFLECT Front-panel access key: CAL

TTL I/O Front-panel access key: SEQ

TTL OUT Front-panel access key: SEQ

TTL OUT HIGH Front-panel access key: SEQ

TTL OUT LOW Front-panel access key: SEQ

TUNED RECEIVER Front-panel access key: SYSTEM

UNCOUPLED Front-panel access key: M ARKER FCTN

UP CONVERTER Front-panel access key: SYSTEM

UPPER LIMIT Front-panel access key: SYSTEM

USE MEMORY on OFF Front-panel access key: SYSTEM

USE PASS CONTROL Front-panel access key: LOCAL

USER Front-panel access key: PRESET

USER KIT Front-panel access key: CAL

USE SENSOR A / B Front-panel access key: CAL

VELOCITY FACTOR Front-panel access key: CAL

VIEW MEASURE Front-panel access key: SYSTEM

VOLUME NUMBER Front-panel access key: LOCAL

WAIT X Front-panel access key: SEQ

WARNING Front-panel access key: DISPLAY

WARNING [ ] Front-panel access key: COPY

WAVEGUIDE Front-panel access key: CAL

WAVEGUIDE DELAY Front-panel access key: SCALE REF

WIDE Front-panel access key: SYSTEM

WIDTH VALUE Front-panel access key: MARKER F CTN

WIDTHS on OFF Front-panel access key: MARKER FCTN

WINDOW Front-panel access key: SYSTEM

WINDOW: MAXIMUM Front-panel access key: SYSTEM

WINDOW: MINIMUM Front-panel access key: SYSTEM

WINDOW: NORMAL Front-panel access key: SYSTEM

XMIT CNTRL [ ] Front-panel access key: LOCAL

Y: Refl Front-panel access key: MEAS

2-38

Table 2-1. Location of Softkeys (18 of 18)

Softkey Menu Location

Y: Trans Front-panel access key: MEAS

Z: Refl Front-panel access key: MEAS

Z: Trans Front-panel access key: MEAS

Reference

Location of Softkeys

2-39

Reference

Connectors, Adjustments, and Display Annotation

Connectors, Adjustments, and Display

Annotation

Table 2-2. Connectors, Adjustments, and Display Annotation (1 of 3)

Key Description

↑ = display annotation

* = display annotation Source parameters changed: measured data in doubt until a complete fresh sweep

10 MHZ PRECISION REFERENCE

connector

ADJ adjustment This adjusts the frequency of the Option 1D5 10 MHz reference.

AUX INPUT connector This allows for a dc or ac voltage input from an external signal source, such as a

Avg = display annotation Sweep-to-sweep averaging is on. The averaging count is shown immediately

BIAS CONNECT connector These connect bias devices connected to port 1 and port 2. The fuses (1 A, 125 V)

C? = display annotation Stimulus parameters have changed from the error-corrected state, or interpolated

C2 = display annotation Full two-port error-correction is active when either the power range for each port is

Cor = display annotation Error correction is on.

Del = display annotation Electrical delay has been added or subtracted, or port extensions are active.

DIN KYBD connector This connector is used for the optional AT-compatible keyboard for titles and

Disk drive This 3.5 inch drive allows you to store and recall instrument states and

ext = display annotation Waiting for an external trigger.

Fast sweep indicator. This symbol is displayed in the status notation block when

sweep time is less than 1.0 second. When sweep time is greater than 1.0 second,

this symbol moves along the displayed trace.

has been taken.

Option 1D5

detector or function generator, which you can then measure, using the

S-parameter menu.

below.

protect the port 1 and port 2 bias lines.

error correction is on.

different (uncoupled), or the

remote front-panel operation. This provides a more convenient means to enter a

title for storage files, as well as substitute for the analyzer’s front panel keyboard.

The keyboard must be connected to the analyzer before the power is switched on.

measurement results for later analysis.

TESTSET HOLD

is activated.

2-40

Reference

Connectors, Adjustments, and Display Annotation

Table 2-2. Connectors, Adjustments, and Display Annotation (2 of 3)

Key Description

EXT AM connector This allows for an external analog signal input that is applied to the ALC circuitry

of the analyzer’s source. This input analog signal amplitude modulates the RF

output signal.

EXT MON connector Standard VGA Connector.

EXT REF connector This allows for a frequency reference signal input that can phaselock the analyzer

to an external frequency standard for increased frequency accuracy.

EXT TRIG connector This allows connection of an external negative-going TTL-compatible signal that

will trigger a measurement sweep. The trigger can be set to external through

softkey functions.

Gat = display annotation Gating is on.

H=2 = display annotation Harmonic mode is on, and the second harmonic is being measured. (Harmonics

Option 002 only.)

H=3 = display annotation Harmonic mode is on, and the third harmonic is being measured. (Harmonics

Option 002 only.)

Hld = display annotation Hold sweep.

GPIB connector This connector allows communication with compatible devices including external

controllers, printers, plotters, disk drives, and power meters.

LIMIT TEST connector Outputs a TTL signal of the limit test results. A TTL high state indicates a “pass”

condition. A TTL low state indicates a “fail” condition.

LINE key This switch controls ac power to the analyzer. 1 is on, 0 is off. Refer to Table 2-5,

“Power-on Conditions (versus Preset),” on page 2-51, for more information.

man = display annotation Waiting for manual trigger.

Of? = display annotation Frequency offset mode error, the IF frequency is not within 10 MHz of expected

frequency. LO inaccuracy is the most likely cause.

Ofs = display annotation Frequency offset mode is on.

P? = display annotation Source power is unleveled at start or stop of sweep.

PØ = display annotation Source power has been automatically set to minimum, due to receiver overload.

PARALLEL PORT connector This connector is used with parallel (or Centronics interface) peripherals such as

printers and plotters. It can also be used as a general purpose I/O port, with control

provided by test sequencing functions.

PC = display annotation Power meter calibration is on.

PC? = display annotation The analyzer’s source could not be set to the desired level, following a power

meter calibration.

PORT 1 and PORT 2 connectors These ports output a signal from the source and receive input signals from a device

under test. PORT 1 allows you to measure S12 and S11. PORT 2 allows you to

measure S21 and S22.

PRESET key This key returns the instrument to either a known factory preset state, or a user

preset state that can be defined. Refer to “Preset Conditions” on page 2-43 for

more information.

2-41

Reference

Connectors, Adjustments, and Display Annotation

Table 2-2. Connectors, Adjustments, and Display Annotation (3 of 3)

Key Description

PRm = display annotation Power range is in manual mode.

PROBE POWER connector This connector (fused inside the instrument) supplies power to an active probe for

in-circuit measurements of ac circuits.

R CHANNEL connectors These connectors allow you to apply an input signal to the analyzer’s R channel, for

frequency offset mode.

RS-232 connector This connector allows the analyzer to output to a peripheral with an RS-232 (serial)

input. This includes printers and plotters.

Smo = display annotation Trace smoothing is on.

TEST SEQ connector This connector outputs a TTL signal which can be programmed by the user in a test

sequence to be high or low. By default, this output provides an end-of-sweep TTL

signal. (For use with part handlers).

TEST SET I/O INTERCONNECT connector This allows you to connect an Agilent 8702E Option 011 analyzer to an

Agilent 85046A/B or 85047A S-parameter test set using the interconnect cable

supplied with the test set. The S-parameter test set is then fully controlled by the

analyzer.

tsH = display annotation Indicates that the test set hold mode is engage. That is, a mode of operation is

selected which would cause repeated switching of the step attenuator. This hold

mode may be overridden.

2-42

Preset Conditions

Reference

Preset Conditions

PRESET

PRESET

PRESET

PRESET

key is pressed, the analyzer reverts to a known state called

PRESET

key is pressed, the analyzer performs

SAVE/RECALL

PRESET: USER

,

key is now toggled to the

and selecting

menu).

.

FACTORY

USER

selection and your defined instru-

PRESET

and when you turn

.

When the

the factory preset state. This state is defined in Table 2-4 on page 2-44. There

are subtle differences between the preset state and the power-up state. These

differences are documented in Table 2-5 on page 2-51. If power to batteryprotected memory is lost, the analyzer will have certain parameters set to

default settings.

When line power is cycled, or the

a self-test routine. Upon successful completion of that routine, the instrument

state is set to the conditions shown in Table 2-4 on page 2-44. The same condi-

tions are true following a “PRES;” “*RST;” or “RST;” command over GPIB,

although the self-test routines are not executed.

You also can configure an instrument state and define it as your user preset

state:

a

Set the instrument state to your desired preset conditions.

b

Save the state (

c

Rename that register to “UPRESET”.

d

Press

The

ment state will be recalled each time you press

power on. You can toggle back to the factory preset instrument state by pressing

NOTE

When you send a preset over GPIB, you will always get the factory preset. You

can, however, activate the user-defined preset over GPIB by recalling the register in which it is stored.

2-43

Reference

Preset Conditions