Installation Guide

HP 8702D

Lightwave Component Analyzer

© Copyright Hewlett-Packard

Company 1998

All Rights Reserved. Reproduction, adaptation, or translation without prior written

permission is prohibited,

except as allowed under copyright laws.

HP Part No. 08702-90051

Printed in USA

February 1998

Hewlett-Packard Company

Lightwave Operations

1400 Fountaingrove Parkway

Santa Rosa, CA 95403-1799,

USA

(707) 577-1400

Notice.

The information contained in

this document is subject to

change without notice. Companies, names, and data used

in examples herein are fictitious unless otherwise noted.

Hewlett-Packard makes no

warranty of any kind with

regard to this material, including but not limited to, the

implied warranties of merchantability and fitness for a

particular purpose. HewlettPackard shall not be liable for

errors contained herein or for

incidental or consequential

damages in connection with

the furnishing, performance,

or use of this material.

Restricted Rights Legend.

Use, duplication, or disclosure by the U.S. Government

is subject to restrictions as set

forth in subparagraph (c) (1)

(ii) of the Rights in Technical

Data and Computer Software

clause at DFARS 252.227-7013

for DOD agencies, and subparagraphs (c) (1) and (c) (2)

of the Commercial Computer

Software Restricted Rights

clause at FAR 52.227-19 for

other agencies.

War ran ty.

This Hewlett-Packard instrument product is warranted

against defects in material and

workmanship for a period of

one year from date of shipment. During the warranty

period, Hewlett-Packard Company will, at its option, either

repair or replace products

which prove to be defective.

For warranty service or repair,

this product must be

returned to a service facility

designated by Hewlett-Packard. Buyer shall prepay shipping charges to HewlettPackard and Hewlett-Packard

shall pay shipping charges to

return the product to Buyer.

However, Buyer shall pay all

shipping charges, duties, and

taxes for products returned to

Hewlett-Packard from another

country.

Hewlett-Packard warrants

that its software and firmware

designated by Hewlett-Packard for use with an instrument

will execute its programming

instructions when properly

installed on that instrument.

Hewlett-Packard does not

warrant that the operation of

the instrument, or software,

or firmware will be uninterrupted or error-free.

Limitation of Warranty.

The foregoing warranty shall

not apply to defects resulting

from improper or inadequate

maintenance by Buyer, Buyersupplied software or interfacing, unauthorized modification or misuse, operation

outside of the environmental

specifications for the product,

or improper site preparation

or maintenance.

No other warranty is

expressed or implied.

Hewlett-Packard specifically

disclaims the implied warranties of merchantability and fitness for a particular purpose.

Exclusive Remedies.

The remedies provided

herein are buyer's sole and

exclusive remedies. HewlettPackard shall not be liable for

any direct, indirect, special,

incidental, or consequential

damages, whether based on

contract, tort, or any other

legal theory.

Safety Symbols.

CAUTION

The

caution

sign denotes a

hazard. It calls attention to a

procedure which, if not correctly performed or adhered

to, could result in damage to

or destruction of the product.

Do not proceed beyond a caution sign until the indicated

conditions are fully understood and met.

WAR NIN G

The

warning

sign denotes a

hazard. It calls attention to a

procedure which, if not correctly performed or adhered

to, could result in injury or

loss of life. Do not proceed

beyond a warning sign until

the indicated conditions are

fully understood and met.

The instruction manual symbol. The product is marked with this

warning symbol when

it is necessary for the

user to refer to the

instructions in the

manual.

The laser radiation

symbol. This warning

symbol is marked on

products which have a

laser output.

The AC symbol is used

to indicate the

required nature of the

line module input

power.

The ON symbols are

|

used to mark the positions of the instrument

power line switch.

The OFF symbols

❍

are used to mark the

positions of the instrument power line

switch.

The CE mark is a registered trademark of

the European Community.

The CSA mark is a registered trademark of

the Canadian Standards Association.

This text denotes the

ISM1-A

instrument is an

Industrial Scientific

and Medical Group 1

Class A product.

Typographical Conventions.

The following conventions are

used in this book:

Key type

for keys or text

located on the keyboard or

instrument.

Softkey type

for key names that

are displayed on the instrument’s screen.

Display type

for words or

characters displayed on the

computer’s screen or instrument’s display.

User type

for words or charac-

ters that you type or enter.

Emphasis

type for words or

characters that emphasize

some point or that are used as

place holders for text that you

type.

ii

Installation at a Glance

Installation at a Glance

The procedures in this book provide step-by-step instructions for installing

the HP 8702D.

Be sure to verify the HP 8702D’s performance

Chapter 2, “Automated Verification”, Chapter 3, “Manual Verification”, and

Chapter 4, “Performance Tests” provide verification procedures and perfor-

mance tests. Verification procedures are intended to provide a high level of

confidence that the instrument is operating properly. Two versions of verification procedures are provided: automated and manual. The performance tests,

along with the verification tests, provide the same quality of performance testing that is done at the factory. Chapter 5, “Automated Verification – Option

011” and Chapter 6, “Performance Tests – Option 011” provide verification

procedures and performance tests for the HP 8702D Option 011.

Hewlett-Packard recommends that you verify your analyzer measurement system every six months. Hewlett-Packard also suggests that you get your verification kit recertified annually. Refer to

Operating and Service Manual

HP 85029B 7 mm Verification Kit

for more information.

These system verification procedures do not apply to analyzers with Option 075 (75 ohm

analyzers).

iii

General Safety Considerations

General Safety Considerations

This product has been designed and tested in accordance with IEC Publication 1010, Safety Requirements for Electronic Measuring Apparatus, and has

been supplied in a safe condition. The instruction documentation contains

information and warnings which must be followed by the user to ensure safe

operation and to maintain the product in a safe condition.

WARNING

WARNING

If this product is not used as specified, the protection provided by the

equipment could be impaired. This product must be used in a normal

condition (in which all means for protection are intact) only.

No operator serviceable parts inside. Refer servicing to qualified

personnel. To prevent electrical shock, do not remove covers.

Certification

Hewlett-Packard Company certifies that this product met its published specifications at the time of shipment from the factory. Hewlett-Packard further

certifies that its calibration measurements are traceable to the United States

National Institute of Standards and Technology, to the extent allowed by the

Institute’s calibration facility, and to the calibration facilities of other International Standards Organization members.

Assistance

Product maintenance agreements and other customer assistance agreements

are available for Hewlett-Packard products. For any assistance, contact your

nearest Hewlett-Packard Sales and Service Office.

iv

Contents

1 Installing the HP 8702D

Step 1. Inspect the Shipment 1-4

Step 2. Set up Static-Safe Workstation 1-5

Step 3. Option 1D5, Connect the Frequency Reference 1-7

Step 4. Check the Fuse and Voltage Selection 1-8

Step 5. Connect the Line-Power Cable 1-10

Step 6. Connect a Keyboard 1-11

Step 7. Turn on the HP 8702D 1-12

Step 8. Connect a Printer or Plotter 1-13

Step 9. If You Connect a Printer 1-14

Step 10. If You Connect a Plotter 1-15

Step 11. Set the Clock 1-16

Step 12. Check the Operation 1-17

Step 13. Check the Operation (Option 011) 1-22

Step 14. Copy the EEPROM Disk 1-27

2 Automated Verification

Step 1. Initialization 2-4

Step 2. Measurement Calibration 2-5

Step 3. Device Verification 2-7

In Case of Difficulty 2-10

3 Manual Verification

Step 1. Initialization 3-3

Step 2. Measurement Calibration 3-5

Step 3. Device Verification 3-7

In Case of Difficulty 3-11

4 Performance Tests

1. Test Port Output Frequency Range and Accuracy 4-4

2. External Source Mode Frequency Range 4-6

3. Test Port Output Power Accuracy 4-8

4. Test Port Output Power Range and Linearity 4-11

5. Minimum R Channel Level 4-14

6. Test Port Input Noise Floor Level 4-19

7. Test Port Input Frequency Response 4-23

8. Test Port Crosstalk 4-34

Contents-1

Contents

9. Calibration Coefficients 4-39

10. System Trace Noise (Only for Analyzers without Option 006) 4-46

11. System Trace Noise (Only for Analyzers with Option 006) 4-48

12. Test Port Input Impedance 4-51

13. Test Port Receiver Magnitude Dynamic Accuracy 4-55

14. Test Port Receiver Phase Dynamic Accuracy 4-63

15. Test Port Receiver Magnitude Compression 4-65

16. Test Port Receiver Phase Compression 4-68

17. Test Port Output/Input Harmonics (Option 002 Analyzers without Option

006 Only) 4-71

18. Test Port Output/Input Harmonics

(Option 002 Analyzers with Option 006 Only) 4-76

Performance Test Records 4-81

5 Automated Verification – Option 011

HP 8702D Option 011 and HP 85046A/47A System Verification 5-4

Step 1. Initialization 5-5

Step 2. Measurement Calibration 5-7

Step 3. Device Verification 5-10

In Case of Difficulty 5-14

HP 8702D Option 011 and HP 85044A System Verification 5-15

Step 1. Initialization 5-16

Step 2. Measurement Calibration 5-18

Step 3. Device Verification 5-20

In Case of Difficulty 5-24

6 Performance Tests – Option 011

1. Source Frequency Range and Accuracy 6-4

2. Source Power Range, Linearity, and Accuracy 6-6

3. Receiver Minimum R Channel Level 6-12

4. Receiver Minimum R Channel Level for External Source Mode 6-15

5. Receiver Channel Noise Floor Level (Only for Analyzers without Option

006) 6-18

6. Receiver Channel Noise Floor Level (Only for Analyzers with Option

006) 6-21

7. Receiver Magnitude Frequency Response 6-25

8. Receiver Phase Frequency Response 6-29

Contents-2

Contents

9. Receiver Input Crosstalk 6-32

10. Receiver Trace Noise 6-38

11. Receiver Input Impedance 6-40

12. Receiver Magnitude Dynamic Accuracy 6-45

13. Receiver Phase Dynamic Accuracy 6-53

14. Receiver Magnitude Compression 6-55

15. Receiver Phase Compression 6-63

16. Source and Receiver Harmonics (Option 002 Only) 6-70

17. Receiver Magnitude Frequency Response

(Option 002 Only) 6-75

Performance Test Records - Option 011 6-78

7 If You Encounter a Problem

If the display does not light 7-4

If the fan does not run 7-5

If data entry keys don’t respond 7-6

If there is no RF signal 7-7

Returning the Instrument for Service 7-8

Hewlett-Packard Sales and Service Offices 7-11

Contents-3

Contents

Contents-4

1

Installing the HP 8702D

Installing the HP 8702D

Installing the HP 8702D

Installing the HP 8702D

The instructions in this chapter show you how to install your HP 8702D. You

should be able to finish these procedures in about ten to twenty minutes.

Refer to “Specifications and Regulatory Information”, in the

ence

manual, for information on operating conditions such as temperature.

If you should ever need to clean the cabinet, use a damp cloth only.

HP 8702D Refer-

WARNING

CAUTION

CAUTION

CAUTION

Any interruption of the protective conductor inside or outside of the

product is likely to make the product dangerous. Intentional

interruption is prohibited.

This product has autoranging line voltage input. Be sure the supply voltage is

within the specified range.

VENTILATION REQUIREMENTS: When installing the product in a cabinet, the

convection into and out of the product must not be restricted. The ambient

temperature (outside the cabinet) must be less than the maximum operating

temperature of the product by 4°C for every 100 watts dissipated in the

cabinet. If the total power dissipated in the cabinet is greater than 800 watts,

then forced convection must be used.

This product is designed for use in INSTALLATION CATEGORY II and

POLLUTION DEGREE 2, per IEC 1010 and 664 respectively.

1-2

What you’ll find in this chapter

Step 1. Inspect the Shipment 1-4

Step 2. Set up Static-Safe Workstation 1-5

Step 3. Option 1D5, Connect the Frequency Reference 1-7

Step 4. Check the Fuse and Voltage Selection 1-8

Step 5. Connect the Line-Power Cable 1-10

Step 6. Connect a Keyboard 1-11

Step 7. Turn on the HP 8702D 1-12

Step 8. Connect a Printer or Plotter 1-13

Step 9. If You Connect a Printer 1-14

Step 10. If You Connect a Plotter 1-15

Step 11. Set the Clock 1-16

Step 12. Check the Operation 1-17

Step 13. Check the Operation (Option 011) 1-22

Step 14. Copy the EEPROM Disk 1-27

Installing the HP 8702D

Installing the HP 8702D

1-3

Installing the HP 8702D

Step 1. Inspect the Shipment

Step 1. Inspect the Shipment

1

Verify that all components ordered have arrived by comparing the shipping

forms to the original purchase order. Inspect all shipping containers.

If your shipment is damaged or incomplete, save the packing materials and notify both the shipping carrier and the nearest Hewlett-Packard sales and service office. HP will arrange for repair or replacement of damaged or incomplete

shipments without waiting for a settlement from the transportation company.

Notify the HP customer engineer of any problems.

WARNING

The HP 8702D weighs approximately 75 pounds (34 kilograms). Use

correct lifting techniques.

The PORT 1 connector moves.

This is

accessories can be more easily connected to the instrument.

2

Make sure that the serial number and options listed on the instrument’s rearpanel label match the serial number and options listed on the shipping

document.

Figure 1-1. Serial Number Label

a defect. This connector is designed to move so that test sets and other

not

1-4

Installing the HP 8702D

Step 2. Set up Static-Safe Workstation

Step 2. Set up Static-Safe Workstation

Electrostatic discharge (ESD) can damage or destroy the input circuits of the

HP 8702D. ESD can also damage or destroy electronic components that you

are measuring. All work should be performed at a static-safe work station. The

following figure shows an example of a static-safe work station (without the

instrument) using two types of ESD protection:

• Conductive table-mat and wrist-strap combination.

• Conductive floor-mat and heel-strap combination.

1-5

Installing the HP 8702D

Step 2. Set up Static-Safe Workstation

Both types, when used together, provide a significant level of ESD protection.

Of the two, only the table-mat and wrist-strap combination provides adequate

ESD protection when used alone.

To ensure user safety, the static-safe accessories must provide at least 1 MΩ of

isolation from ground. Refer to Table 1-1 for information on ordering staticsafe accessories.

WARNING

These techniques for a static-safe work station should not be used

when working on circuitry with a voltage potential greater than 500

volts.

Reducing ESD Damage

The following suggestions may help reduce ESD damage that occurs during

testing and servicing operations.

• Personnel should be grounded with a resistor-isolated wrist strap before removing any assembly from the unit.

• Be sure all instruments are properly earth-grounded to prevent a buildup of

static charge.

Table 1-1. Static-Safe Accessories

HP Part

Number

9300-0797

9300-0980 Wrist-strap cord 1.5 m (5 ft)

9300-1383 Wrist-strap, color black, stainless steel, without cord, has four adjustable

3M static control mat 0.6 m

wire. (The wrist-strap and wrist-strap cord are not included. They must be

ordered separately.)

links and a 7 mm post-type connection.

Description

× 1.2 m (2 ft× 4 ft) and 4.6 cm (15 ft) ground

9300-1169 ESD heel-strap (reusable 6 to 12 months).

1-6

Installing the HP 8702D

Step 3. Option 1D5, Connect the Frequency Reference

Step 3. Option 1D5, Connect the Frequency

Reference

If your instrument has the optional high stability frequency reference

installed, connect the jumper cable on the HP 8702D rear panel as shown in

Figure 1-2.

Figure 1-2. Jumper Cable Connection

1-7

Installing the HP 8702D

Step 4. Check the Fuse and Voltage Selection

Step 4. Check the Fuse and Voltage Selection

1

Locate the line-input connector on the instrument’s rear panel.

2

Disconnect the line-power cable if it is connected.

3

Use a small flat-blade screwdriver to open the pull-out fuse drawer.

WARNING

The power cord is connected to internal capacitors that may remain

live for 10 seconds after you disconnect the cord from the power

supply.

Figure 1-3. Line Fuse Removal and Replacement

4

Verify that the value of the line-voltage fuse in the pull-out drawer is correct.

The recommended fuse is an IEC 127 5×20 mm, 3A, 250 V, HP part number

2110-0780.

Notice that an extra fuse is provided in a drawer located on the fuse holder.

1-8

Installing the HP 8702D

Step 4. Check the Fuse and Voltage Selection

WARNING

For continued protection against fire hazard, replace line fuse only

with same type and ratings, (type T 3A/250V for 100/240V operation).

The use of other fuses or materials is prohibited.

5

Set the rear panel line-voltage selector to the position that corresponds to the

AC power source. Refer to Figure 1-4.

Figure 1-4. Line Voltage Selector

Table 1-2. Line Power Requirements

Power: 115 VAC: 50 WATTS MAX.

230 VAC: 50 WATTS MAX.

Voltage nominal: 115 VAC / 230 VAC

range 115 VAC: 90

range 230 VAC: 198

Frequency nominals: 50 Hz / 60 Hz

range: 47−63 Hz

−

−

132 V

254 V

1-9

Installing the HP 8702D

Step 5. Connect the Line-Power Cable

Step 5. Connect the Line-Power Cable

CAUTION

CAUTION

Always use the three-prong AC power cord supplied with this instrument.

Failure to ensure adequate earth grounding by not using this cord may cause

instrument damage.

not

Do

connect ac power until you have verified the line voltage is correct as

described in the following paragraphs. Damage to the equipment could result.

1

Connect the line-power cord to the instrument’s rear-panel connector. Refer to

Figure 1-5.

2

Connect the other end of the line-power cord to the power receptacle. Refer to

Figure 1-5.

Various power cables are available to connect the HP 8702D to ac power outlets unique to specific geographic areas. The cable appropriate for the area to

which the HP 8702D is originally shipped is included with the unit. You can

order additional ac power cables for use in different geographic areas. Refer to

HP 8702D Reference

the

manual for a list of available power cables.

Figure 1-5. Power Cord Connection

1-10

Installing the HP 8702D

Step 6. Connect a Keyboard

Step 6. Connect a Keyboard

• If you plan to use a keyboard with your HP 8702D, connect it now to the instrument’s rear-panel keyboard connector.

Figure 1-6. Rear Panel Peripheral Connections

1-11

Installing the HP 8702D

Step 7. Turn on the HP 8702D

Step 7. Turn on the HP 8702D

1

Press the front-panel

The front-panel

ply after the EMC filters and before other parts of the instrument.

2

If the HP 8702D fails to turn on properly, consider the following possibilities:

• Is the line fuse good?

• Does the line socket have power?

• Is it plugged into the proper ac power source?

If the instrument still fails, return it to Hewlett-Packard for repair. Refer to

“Returning the Instrument for Service” on page 7-8.

LINE

key. Refer to Figure 1-7.

LINE

switch disconnects the mains circuits from the mains sup-

Figure 1-7. Turning on the Instrument

1-12

Installing the HP 8702D

Step 8. Connect a Printer or Plotter

Step 8. Connect a Printer or Plotter

1

Connect a printer or plotter to the corresponding interface port. Refer to

Figure 1-6 on page 1-11 for the appropriate rear panel connection.

Printer Interface Recommended Cable

Parallel HP 92284A

Serial HP 24542G

HP-IB HP 10833A/B/D

2

If you are using the parallel interface, press

LOCAL

and then

PARALLEL

until

appears.

GPIO

The

selection dedicates the parallel port for general purpose I/O. The

HP 8702D controls the data input or output through the sequencing capability

of the instrument.

3

If you are using an HP-IB printer or plotter, press

LOCAL

SYSTEM CONTROLLER

,

set up the HP 8702D as the controller.

COPY

to

1-13

Installing the HP 8702D

Step 9. If You Connect a Printer

Step 9. If You Connect a Printer

1

2

3

4

5

LOCAL

Press

Press the key that corresponds to the printer interface:

port), or

If you selected

of your printer. The default HP-IB printer address is 1.

If you select

a

Press

select the baud rate.

b

Set the transmission control,

XON/XOFF

al).

XON/XOFF

handshaking. Consult the printer’s manual for the proper settings.

Press

ThinkJet

•

DeskJet

•

• LaserJet

• PaintJet

Epson-P2

•

SET ADDRESSES, PRINTER PORT

,

SERIAL

(serial port).

HPIB

, the HP-IB address is active so you can then set the address

SERIAL

, adjust the HP 8702D’s baud rate and handshaking protocol:

PRINTER BAUD RATE

DTR/DSR

or

selects software handshaking.

PRNTR TYPE

(except for HP DeskJet 540)

until the correct printer choice appears:

(QuietJet)

(printers that conform to the ESC.P2 printer control language)

, and use the up and down arrow front-panel keys to

XMIT CNTRL

(equal to the transmission control set on the peripher-

.

HPIB, PAR AL LEL

(handshaking protocol) to either

DTR/DSR

selects hardware

(parallel

•

1-14

DJ540

(converts 100 dpi raster information to 300 dpi raster format)

Step 10. If You Connect a Plotter

Installing the HP 8702D

Step 10. If You Connect a Plotter

1

2

3

4

5

LOCAL

Press

Press the key that corresponds to the plotter interface:

port), or

If you selected

of your plotter. The default HP-IB plotter address is 5.

If you select

a

Press

select the baud rate.

b

Set the transmission control,

XON/XOFF

al).

XON/XOFF

handshaking. Consult the printer’s manual for the proper settings.

Press

• Choose

copy.

• Choose

to make your hardcopy.

SET ADDRESSES, PLOTTER PORT

,

SERIAL

(serial port).

HPIB

, the HP-IB address is active so you can then set the address

SERIAL

, adjust the HP 8702D’s baud rate and handshaking protocol:

PLOTTER BAUD RATE

DTR/DSR

or

selects software handshaking.

PLTR TYPE

until the correct plotter selection appears:

PLTR TYPE [PLOTTER]

PLTR TYPE [HPGL PRT]

, and use the up and down arrow front-panel keys to

(equal to the transmission control set on the peripher-

if you will be using a plotter to make your hard-

if you will be using an HPGL compatible printer

XMIT CNTRL

.

HPIB, PAR ALL EL

(handshaking protocol) to either

DTR/DSR

selects hardware

(parallel

1-15

Installing the HP 8702D

Step 11. Set the Clock

Step 11. Set the Clock

1

2

3

4

SYSTEM

Press

so the HP 8702D places the time and date on your hardcopies and disk

directories.

Press the appropriate softkey to set the time and date.

ROUND SECONDS

Press

TIME STAMP

Press

RETURN

.

SET CLOCK

,

to begin setting and activating the time stamp feature

when the time is exactly as you have set it.

so that ON is displayed on the softkey label. Then, press

Figure 1-8. Setting the Clock

1-16

Installing the HP 8702D

Step 12. Check the Operation

Step 12. Check the Operation

If your instrument is an HP 8702D Option 011, skip this step and continue

with “Step 13. Check the Operation (Option 011)” on page 1-22.

1

Turn off the

2

Locate the serial number and configuration options shown on the display.

Compare them to the shipment documents.

3

Press

Figure 1-9. Checking the Operation

LINE

power switch. Then, turn back on the

PRESET

, and observe items shown in Figure 1-9.

LINE

power switch.

4

Connect the equipment as shown in Figure 1-10.

1-17

Installing the HP 8702D

Step 12. Check the Operation

Figure 1-10. Operation Check Connections

5

6

7

8

PRESET, SYSTEM

Press

SERVICE MENU, TESTS, EXTERNAL TESTS, EXECUTE TEST

,

Follow the prompts shown on the display, and then press

Press the up-arrow key,

the display. Then press

EXECUTE TEST

CONTINUE

.

, and then follow the prompts shown on

Connect the equipment as shown in Figure 1-11 and press

CONTINUE

PRESET

.

.

The test port return cable should have low-loss characteristics to avoid a degradation in frequency response at higher frequencies.

.

1-18

Figure 1-11. Transmission Mode Connections

Installing the HP 8702D

Step 12. Check the Operation

Press

CHAN2

to check the forward transmission mode for channel 2. Look at the

9

measurement trace displayed on the HP 8702D. It should be similar to the trace

shown in Figure 1-12.

The HP 8702D display shown in Figure 1-12 and Figure 1-13 are HP 8702D Option 006 displays (30 kHz to 6 GHz span).

Figure 1-12. Forward Transmission Display

Press

MEAS

and then

Trans: E/E S12 REV

to check the reverse transmission mode

10

for channel 2. The measurement trace should be similar to the trace shown in

Figure 1-13.

1-19

Installing the HP 8702D

Step 12. Check the Operation

Figure 1-13. Reverse Transmission Display

11

Connect the equipment as shown in Figure 1-14 and press

PRESET

.

Figure 1-14. Transmission Load Match Connections

12

Look at the measurement trace displayed on the HP 8702D. It should be similar

to the trace displayed in Figure 1-15.

1-20

Figure 1-15. Forward Transmission Mode

Installing the HP 8702D

Step 12. Check the Operation

Press

MEAS,

Refl: E S22 REV

to check the reverse reflection mode for channel 1.

13

The measurement trace should be similar to Figure 1-16.

Figure 1-16. Reverse Reflection Mode

14

Continual with “Step 14. Copy the EEPROM Disk” on page 1-27.

1-21

Installing the HP 8702D

Step 13. Check the Operation (Option 011)

Step 13. Check the Operation (Option 011)

An HP 85047A S-parameter test set must be used when making measurements.

1

Turn off the

2

Locate the serial number and configuration options shown on the display.

Compare them to the shipment documents.

3

Press

Figure 1-17.

LINE

power switch. Then, turn back on the

PRESET

, and observe that the analyzer is operating properly as shown in

LINE

power switch.

Figure 1-17. Checking the Operation (Option 011)

4

Connect the equipment as shown in Figure 1-18.

1-22

Figure 1-18. Operation Check Connections

Installing the HP 8702D

Step 13. Check the Operation (Option 011)

5

6

7

8

PRESET, SYSTEM

Press

SERVICE MENU, TESTS, EXTERNAL TESTS, EXECUTE TEST

,

Follow the prompts shown on the display, and then press

Press the up-arrow key,

the display. Then press

EXECUTE TEST

CONTINUE

.

, and then follow the prompts shown on

Connect the equipment as shown in Figure 1-19 and press

CONTINUE

PRESET

.

.

The test port return cable should have low-loss characteristics to avoid a degradation in frequency response at higher frequencies.

.

1-23

Installing the HP 8702D

Step 13. Check the Operation (Option 011)

Figure 1-19. Transmission Mode Connections

Press

CH2

to check the forward transmission mode for channel 2. Look at the

9

measurement trace displayed on the analyzer. It should be similar to the trace

shown in Figure 1-20.

The analyzer display shown in Figure 1-20 and Figure 1-21 are HP 8702D Option 011, Option 006 displays (30 kHz to 6 GHz span).

Figure 1-20. Forward Transmission Display

1-24

Installing the HP 8702D

Step 13. Check the Operation (Option 011)

Press

MEAS

and then

Trans: E/E S12 REV

to check the reverse transmission mode

10

for channel 2. The measurement trace should be similar to the trace shown in

Figure 1-21.

Figure 1-21. Reverse Transmission Display

11

Connect the equipment as shown in Figure 1-22 and press

PRESET

.

Figure 1-22. Transmission Load Match Connections

1-25

Installing the HP 8702D

Step 13. Check the Operation (Option 011)

12

Look at the measurement trace displayed on the analyzer. It should be similar

to the trace displayed in Figure 1-23.

Figure 1-23. Forward Transmission Mode

Press

MEAS

Refl: E S22 REV

,

to check the reverse reflection mode for channel 1.

13

The measurement trace should be similar to Figure 1-24.

Figure 1-24. Reverse Reflection Mode

1-26

Installing the HP 8702D

Step 14. Copy the EEPROM Disk

Step 14. Copy the EEPROM Disk

The HP 8702D is shipped from the factory with an EEPROM backup disk

which is unique to each instrument. The backup disk contains a copy of correction constants which were stored in the instrument’s internal memory at

the factory. If your HP 8702D should ever be damaged, these correction constants may need to be reinstalled from the disk. Use the following procedure

to create a backup copy of the disk.

The disks can be ordered as HP 92192A (box of 10).

1

Insert a 3.5-inch disk into the HP 8702D’s disk drive.

2

3

4

5

6

PRESET

Press

If the disk is not formatted, press

• To format a LIF disk, select

is LIF. The HP 8702D does not support LIF-HFS format.)

• To format a DOS disk, select

Press

Press

SAVE RCL MENU, SELECT DISK, INTERNAL DISK, RETURN, SAVE STATE

correction-constants data onto floppy disk.

A default file “FILE0” is created. The file name appears in the upper left-hand

corner of the display. The file type “ISTATE(E)” describes the file as an instrument-state with EEPROM backup.

Press

softkey to rename the file “FILE0” to “N12345” where 12345 represents the last

5 digits of the instrument’s serial number. (The first character in the file name

must be a letter.) When finished, press

Label the disk with the serial number of the instrument and the words

“EEPROM Backup Disk”.

Whenever the HP 8702D is returned to Hewlett-Packard for servicing and/or

calibration, the EEPROM backup disk should be returned with the HP 8702D.

This will significantly reduce the instrument repair time. The EEPROM backup

disk procedure is now complete.

so that the preset state is stored.

SAVE/RECALL

FORMAT:LIF

FORMAT:DOS

FORMAT INT DISK,

SYSTEM

FILE UTILITIES, RENAME FILE, ERASE TITLE

SERVICE MENU, SERVICE MODES, MORE, STORE EEPR ON

,

and answer

YES

at the query.

DONE

FILE UTILITIES, FORMAT DISK

,

(The supplied EEPROM backup disk

.

SAVE/RECALL,

,

to store the

. Use the RPG and the

.

SELECT LETTER

.

1-27

Installing the HP 8702D

Step 14. Copy the EEPROM Disk

1-28

2

Automated Verification

Automated Verification

Automated Performance Verification

Automated Performance Verification

The automated performance verification procedure in this chapter provide a

high level of confidence that the HP 8702D is working properly. Although this

procedure is automated, it does

to locate the

the manual version located in Chapter 3, “Manual Verification”. If you are

using an HP 8702D Option 011, refer to Chapter 5, “Automated Verification –

Option 011”.

Allow the HP 8702D to warm up for one hour before starting this procedure.

In order to run this procedure, the following equipment is required:

Calibration Kit, 7 mm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . HP 85031B

Verification Kit, 7 mm . . . . . . . . . . . . . . . . . . . . . . . . . HP 85029B Option 001

Test Port Extension Cable Set, 7 mm . . . . . . . . . . . . . . . . . . . . . . . HP 11857D

Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . HP ThinkJet/DeskJet/LaserJet

Verification Data Disk

not

require a computer. However, you’ll need

. If you cannot locate the disk, perform

Hewlett-Packard recommends that you verify your analyzer measurement system every six months. Hewlett-Packard also suggests that you get your verification kit recertified annually. Refer to the

Verification Kit Operating and Service Manual

NOTE

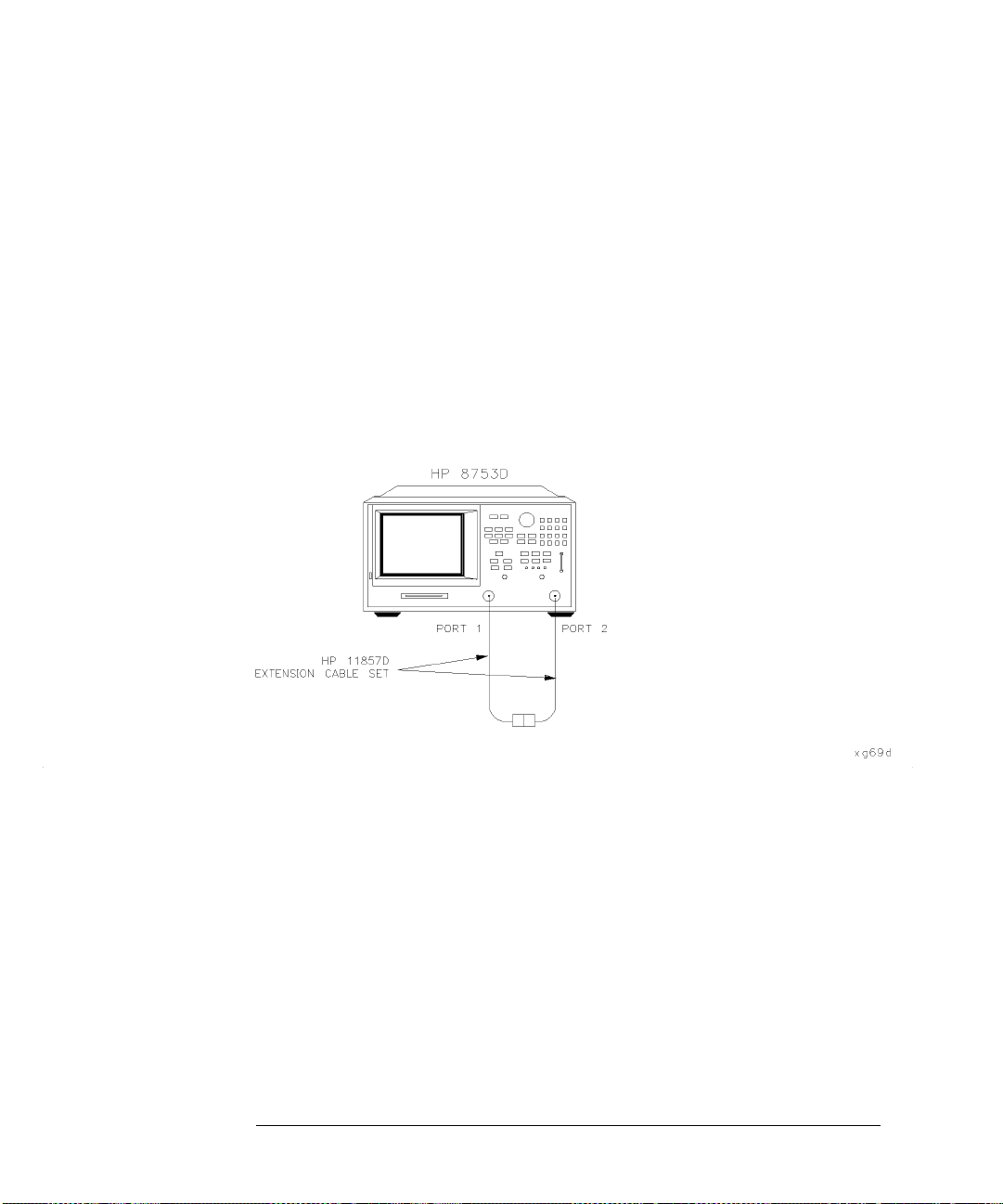

The system verification procedures do

HP 8753D is shown in the figures

The procedures in this chapter are designed to work with HP 8702D and HP 8753D

instruments. Because of this, many of the figures label the instrument being tested as an

HP 8753D. Simply substitute your HP 8702D for the HP 8753D.

2-2

not

HP 85029B Option 001 7 mm

for more information.

apply to analyzers with Option 075 (75 Ω).

Automated Verification

Automated Performance Verification

How to select the system verification procedure

Check to see how the verification kit floppy disk is labeled:

• If the disk is labeled

Mode System Verification in this chapter.

• If the disk is labeled

Mode System Verification procedure, located in Chapter 3, “Manual Verifica-

tion”.

NOTE

If your verification disk is older than your HP 8702D, you may send your HP 85029B

Option 001 7 mm verification kit to the nearest service center for recertification, which

includes a data disk that you can use with the HP 8702D.

Verification Data Disk

Verification Data Disc

, proceed with the HP 8702D Automated

, proceed with the HP 8702D Manual

What you’ll find in this chapter

Step 1. Initialization 2-4

Step 2. Measurement Calibration 2-5

Step 3. Device Verification 2-7

In Case of Difficulty 2-10

2-3

Automated Verification

Step 1. Initialization

Step 1. Initialization

1

Connect the equipment as shown in Figure 2-1. Let the HP 8702D warm up for

one hour.

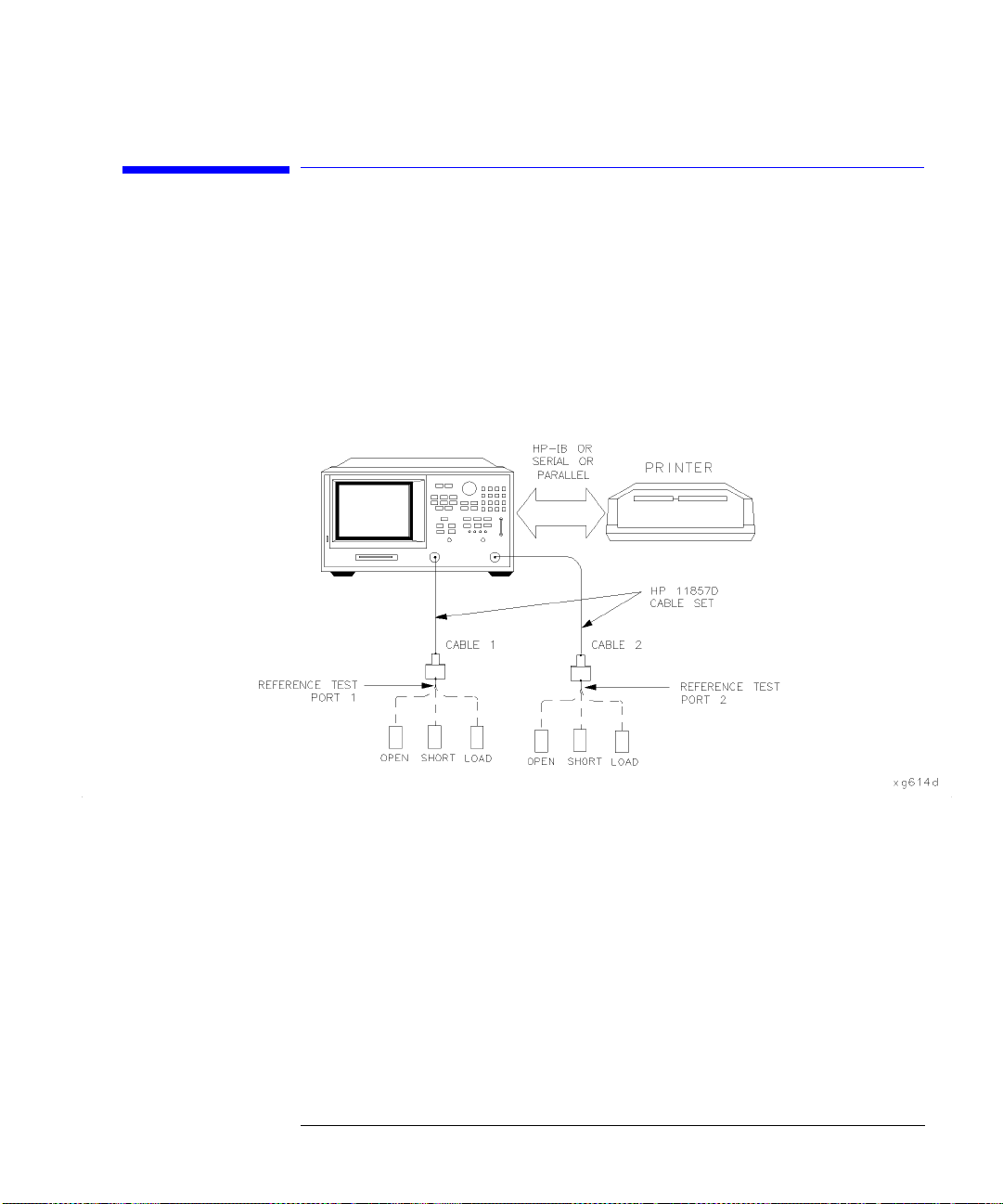

Figure 2-1. System Verification Test Setup

2

While the equipment is warming up, review the connector care information in

HP 8702D User’s Guide

the

3

Insert the verification kit disk into the HP 8702D’s disk drive.

4

5

PRESET, SAVE/RECALL

Press

If you want a printout of the verification data for all the devices, press

SERVICE MENU, TEST OPTIONS, RECORD ON

If you switch on the record function, you

.

SELECT DISK, INTERNAL DISK

,

.

cannot

.

SYSTEM

switch it off during the verifi-

cation procedure.

6

Position the paper in the printer so that printing starts at the top of the page.

Press

SYSTEM

SERVICE MENU

,

When the HP 8702D displays,

7

8

,

SYS VER TESTS, EXECUTE TEST

TESTS

,

Sys Ver Init DONE

.

, the initialization

procedure is complete.

press

PRESET

or recall another instrument state. You must use the in-

Do

not

strument state that you loaded during the initialization procedure.

2-4

,

Step 2. Measurement Calibration

Automated Verification

Step 2. Measurement Calibration

1

2

3

4

CAL

Press

MENU, FULL 2-PORT

Press

Press

CAL KIT & STDS

,

.

ISOLATION, OMIT ISOLATION, ISOLATION DONE

REFLECTION

.

Connect the “open” end of the open/short combination (supplied in the

SELECT CAL KIT

,

CAL KIT:7mm

,

RETURN, RETURN, CALIBRATE

,

.

calibration kit) to reference test port 1, as shown in Figure 2-2.

Figure 2-2. Connections for Measurement Calibration Standards

5

6

FORWARD:OPEN

Press

.

When the HP 8702D finishes measuring the standard, connect the “short” end

of the open/short combination to reference test port 1.

7

8

FORWARD:SHORT

Press

.

When the HP 8702D finishes measuring the standard, connect the 50 ohm

termination (supplied in the calibration kit) to reference test port 1.

9

10

FORWARD:LOAD

Press

.

When the HP 8702D finishes measuring the standard, connect the “open” end

of the open/short combination to reference test port 2.

2-5

Automated Verification

Step 2. Measurement Calibration

11

12

REVERSE:OPEN

Press

.

When the HP 8702D finishes measuring the standard, connect the “short” end

of the open/short combination to reference test port 2.

13

14

REVERSE:SHORT

Press

.

When the HP 8702D finishes measuring the standard, connect the 50 ohm

termination to reference test port 2.

15

16

17

REVERSE:LOAD

Press

.

When the HP 8702D finishes measuring the standard, press

The HP 8702D briefly displays,

COMPUTING CAL COEFFICIENTS

Connect the test port cables as shown Figure 2-3.

STANDARDS DONE

.

.

Figure 2-3. Transmission Calibration Setup

18

19

20

21

22

23

TRANSMISSION, FWD TRANS THRU

Press

.

When the HP 8702D finishes the measurement, press

When the HP 8702D finishes the measurement, press

When the HP 8702D finishes the measurement, press

When the HP 8702D displays,

STD(s)

SAVE/RECALL

Press

, press

STANDARDS DONE, DONE 2-PORT CAL

SELECT DISK, INTERNAL MEMORY, RETURN, SAVE STATE

,

PRESS ’DONE’ IF FINISHED WITH

.

the calibration into the HP 8702D internal memory.

24

When the HP 8702D finishes saving the instrument state, press

INTERNAL DISK

2-6

.

FWD MATCH THRU

REV TRANS THRU

REV MATCH THRU

SELECT DISK

.

.

.

to save

,

Step 3. Device Verification

Automated Verification

Step 3. Device Verification

Press

SYSTEM

SERVICE MENU, TESTS,

,

At the prompt, connect the 20 dB attenuator (supplied in the verification kit)

1

2

28, x1

EXECUTE TEST

,

.

as shown in Figure 2-4.

3

CONTINUE

Press

to run the test:

• If you switched the record function

off

, you have to press

CONTINUE

after

each S-parameter measurement.

• If you switched the record function on, the HP 8702D measures all S-param-

eters (magnitude and phase) without pausing. Also, the HP 8702D only displays and prints the pass/fail information for the S-parameter measurements

that are valid for system verification.

Figure 2-4. Connections for the 20 dB Verification Device

4

When the HP 8702D finishes all the measurements, connect the 50 dB

attenuator (supplied in the verification kit), as shown in Figure 2-5.

2-7

Automated Verification

Step 3. Device Verification

Figure 2-5. Connections for the 50 dB Verification Device

5

Press ⇑, 29, x1,

6

When all measurements are complete, replace the verification device with the

EXECUTE TEST

CONTINUE

,

.

verification mismatch, as shown in Figure 2-6. Be sure that you connect Port A

of the verification mismatch to reference test port 1.

Figure 2-6. Mismatch Device Verification Setup

7

8

RETURN, TESTS,

Press

30, x1,

EXECUTE TEST, CONTINUE

.

When the HP 8702D finishes all the measurements, connect the mismatch

verification device, as shown in Figure 2-7. Notice that Port B is now connected

to reference test port 1.

2-8

Figure 2-7. Mismatch Device Verification Setup

Automated Verification

Step 3. Device Verification

9

10

RETURN, TESTS,

Press

EXECUTE TEST, CONTINUE

31, x1,

.

You have completed the system verification procedure when the HP 8702D

displays,

Ver Def 4 DONE

.

2-9

Automated Verification

In Case of Difficulty

In Case of Difficulty

1

Inspect all connections. Do

ports. Doing so will invalidate the calibration that you have done earlier.

2

3

4

5

PRESET, SAVE/RECALL

Press

Using the front panel knob, highlight the title of the full 2-port calibration that

you have done earlier, then press

Repeat “Step 3. Device Verification” on page 2-7.

If the HP 8702D still fails the test, check the measurement calibration as

follows:

a

b

c

d

e

f

g

h

PRESET

Press

Recall the calibration by pressing

RETURN

RY

,

Use the front panel knob to highlight the calibration you want to recall and

press

Connect the short to reference test port 1.

Press

Press

Check that the trace response is 0.00 ±0.05 dB.

Disconnect the short and connect it reference test port 2.

.

.

RECALL STATE

MEAS

Refl: E S11 FWD,

,

SCALE REF

,

SCALE/DIV

not

disconnect the cables from the HP 8702D test

SELECT DISK, INTERNAL MEMORY, RETURN

,

RECALL STATE

SAVE/RECALL

.

MENU

, .05, x1.

TRIGGER MENU

,

.

SELECT DISK

,

CONTINUOUS

,

.

INTERNAL MEMO-

,

.

i

j

k

2-10

MEAS

Press

Check that the trace response is 0.00 ± 0.05 dB.

If any of the trace responses are out of the specified limits, repeat the “Measurement Calibration” and “Device Verification” procedures.

Refl: E S22 REV

,

.

3

Manual Verification

Manual Verification

Manual Performance Verification

Manual Performance Verification

The manual performance verification procedure in this chapter provides a

high level of confidence that the HP 8702D is working properly. If you can

locate the

instead, which is documented in Chapter 2, “Automated Verification”.

Allow the HP 8702D to warm up for one hour before starting this procedure.

In order to run this procedure, the following equipment is required:

Calibration Kit, 7 mm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . HP 85031B

Verification Kit, 7 mm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . HP 85029B

Test Port Extension Cable Set, 7 mm . . . . . . . . . . . . . . . . . . . . . . . HP 11857D

Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . HP ThinkJet/DeskJet/LaserJet

HP 8702D Verification Data Disk

, perform the automated version

HP 8753D is shown in the figures

The procedures in this chapter are designed to work with HP 8702D and HP 8753D

instruments. Because of this, many of the figures label the instrument being tested as an

HP 8753D. Simply substitute your HP 8702D for the HP 8753D.

What you’ll find in this chapter

Step 1. Initialization 3-3

Step 2. Measurement Calibration 3-5

Step 3. Device Verification 3-7

In Case of Difficulty 3-11

3-2

Manual Verification

Step 1. Initialization

Step 1. Initialization

1

Connect the equipment as shown in Figure 3-1. Let the HP 8702D warm up for

one hour.

Figure 3-1. System Verification Test Setup

2

While the equipment is warming up, review the connector care information in

HP 8702D User’s Guide

the

3

Set up the system to print the verification data:

a

b

c

d

LOCAL

Press

Press

SYSTEM CONTROLLER

,

SET ADDRESSES, PRINTER PORT

Press the softkey that corresponds to your printer port.

If you have difficulty with the printer:

.

.

.

• If the interface on your printer is HP-IB, verify that the printer address is

set to 1.

• If the interface on your printer is serial or parallel, be sure that you correctly selected the printer port

User’s Guide

for more information on how to do these tasks).

and

printer type (refer to the

HP 8702D

3-3

Manual Verification

Step 1. Initialization

4

Insert the verification kit disk into the HP 8702D disk drive.

CAUTION

5

6

7

PRESET, SAVE/RECALL

Press

SYSTEM

Press

SERVICE MENU, TESTS, SYS VER TESTS, EXECUTE TEST

,

SELECT DISK, INTERNAL DISK

,

When the HP 8702D displays,

press

PRESET

or recall another instrument state. You must use the

Do

not

Sys Ver Init DONE

.

, the test is complete.

instrument state that you loaded during the initialization procedure.

.

3-4

Step 2. Measurement Calibration

Manual Verification

Step 2. Measurement Calibration

1

2

3

4

5

6

7

8

9

10

11

12

13

MENU

Press

CAL

Press

MENU, FULL 2-PORT

Press

Press

Connect the “open” end of the open/short combination (supplied in the

calibration kit) to reference test port 1, as shown in Figure 3-1.

Press

When the HP 8702D finishes measuring the standard, connect the “short” end

of the open/short combination to reference test port 1.

Press

When the HP 8702D finishes measuring the standard, connect the 50 ohm

termination (supplied in the calibration kit) to reference test port 1.

Press

When the HP 8702D finishes measuring the standard, connect the “open” end

of the open/short combination to reference test port 2, as shown in Figure 3-1.

Press

When the HP 8702D finishes measuring the standard, connect the “short” end

of the open/short calibration standard to reference test port 2.

POWER

,

CAL KITS & STDS, SELECT CAL KIT, CAL KIT:7mm, RETURN, RETURN, CALIBRATE

,

ISOLATION, OMIT ISOLATION, ISOLATION DONE

REFLECTION

FORWARD:OPEN

FORWARD:SHORT

REFLECTION, FORWARD:LOAD

REVERSE:OPEN

, –2, x1 to set the HP 8702D test port power to –2 dBm.

.

.

.

.

.

.

.

14

15

16

17

18

REVERSE:SHORT

Press

When the HP 8702D finishes measuring the standard, connect the 50 ohm

termination to reference test port 2.

REVERSE:LOAD

Press

When the HP 8702D finishes measuring the standard, press

Connect the test port cables together as shown in Figure 3-2.

.

.

STANDARDS DONE

.

3-5

Manual Verification

Step 2. Measurement Calibration

Figure 3-2. Transmission Calibration Setup

19

20

21

22

23

24

TRANSMISSION, FWD TRANS THRU

Press

.

When the HP 8702D finishes measuring the standard, press

When the HP 8702D finishes measuring the standard, press

When the HP 8702D finishes measuring the standard, press

When the HP 8702D finishes measuring the standard, press

DONE 2-PORT CAL

SAVE/RECALL

Press

.

SELECT DISK, INTERNAL MEMORY, RETURN, SAVE STATE

,

the measurement calibration into the HP 8702D internal memory.

25

SELECT DISK, INTERNAL DISK

Press

.

FWD MATCH THRU

REV TRANS THRU

REV MATCH THRU

STANDARDS DONE

to save

.

.

.

,

3-6

Step 3. Device Verification

Manual Verification

Step 3. Device Verification

1

2

3

4

5

SYSTEM

Press

Connect the 20 dB attenuator (supplied in the verification kit) as shown in

Figure 3-3.

Figure 3-3. Connections for the 20 dB Verification Device

CONTINUE

Press

MENU

Press

COPY

Press

measurement.

SERVICE MENU, TESTS

,

to run the test.

POWER

,

PRINT MONOCHROME

,

, –2, x1,

, 28, x1,

CAL

CORRECTION ON

,

to obtain the graphical representation of the

EXECUTE TEST

.

.

6

7

8

COPY

Press

of the measurement.

Press

Ignore the error message,

Press

LIST, PRINT ALL MONOCHROME

,

SYSTEM

MENU

SERVICE MENU, TEST OPTIONS, CONTINUE TEST

,

POWER

,

, –2, x1,

if you prefer a tabular representation

.

CAUTION: CALIBRATION REQUIRED

CAL

CORRECTION ON

,

.

.

3-7

Manual Verification

Step 3. Device Verification

For those S-parameter measurements with upper and lower point limits shown on the

HP 8702D display, you will notice that when you press the

measurement test status changes from

FAIL

to

PASS

CORRECTION ON

.

softkey, the

If the test status remains

after you press

FAIL

CORRECTION ON

, refer to “In Case of

Difficulty” on page 3-11.

9

Repeat Step 5 through Step 8 until you have made all the S-parameter

measurements for the verification device.

For each verification device, there are a total of eight measurements (magnitude and phase for the four S-parameters).

10

When the HP 8702D displays,

all

if

the tested S-parameter measurements show a

Ver Dev 1 FAIL

, proceed to the next step only

PASS

status after you

activate error correction in Step 8. Otherwise, refer to “In Case of Difficulty” on

page 3-11.

11

Connect the 50 dB attenuator (supplied in the verification kit) as shown in

Figure 3-4.

Figure 3-4. Connections for the 50 dB Verification Device

12

Press

TESTS,

EXECUTE TEST, CONTINUE

29, x1,

.

Ignore the error message.

13

14

MENU

Press

POWER

,

, –2, x1,

Repeat Step 5 through Step 8 until you have made all the S-parameter

CAL

CORRECTION ON

,

.

measurements for the verification device.

3-8

Manual Verification

Step 3. Device Verification

15

When the HP 8702D displays,

all

only if

S-parameter measurements show a

Ver Dev 2 FAIL,

PASS

proceed to the next step

status under the same

condition mentioned in Step 10.

16

Connect the verification mismatch (supplied in the kit) as shown in Figure 3-5.

Be sure port A of the verification mismatch is connected to reference test

port 1.

Figure 3-5. Mismatch Device Verification Setup

17

Press

TESTS

, 30, x1,

EXECUTE TEST, CONTINUE

.

Ignore the error message.

18

19

MENU

Press

POWER,

,

Repeat Step 5 through Step 8 until you have made all the S-parameter

–2, x1,

CAL

CORRECTION ON

,

.

measurements for the verification device.

20

When the HP 8702D displays,

all

if

S-parameter measurements show a

Ver Dev 3 FAIL

PASS

status under the same condition

, proceed to the next step only

mentioned in Step 10.

21

Connect the verification mismatch as shown in Figure 3-6. Notice that port B

of the verification mismatch is now connected to the reference test port 1.

3-9

Manual Verification

Step 3. Device Verification

Figure 3-6. Mismatch Device Verification Setup

22

Press

TESTS,

EXECUTE TEST, CONTINUE

31, x1,

.

Ignore the displayed error message.

23

24

MENU

Press

POWER,

,

Repeat Step 5 through Step 8 until you have made all the S-parameter

–2, x1,

CAL

CORRECTION ON

,

.

measurements for the verification device.

25

The test is complete when the HP 8702D displays,

S-parameter measurements show a

PASS

status under the same condition

Ver Def 4 FAIL

mentioned in Step 10.

, and

all

3-10

In Case of Difficulty

Manual Verification

In Case of Difficulty

1

Inspect all connections. Do

ports. Doing so will invalidate the calibration done earlier.

2

3

4

PRESET, SAVE/RECALL

Press

front panel knob, highlight the full 2-port cal done earlier and press

STATE

.

Repeat “Step 3. Device Verification” on page 3-7.

If the test still fails, do the following to check the calibration:

a

b

c

d

e

f

g

h

i

j

PRESET

Press

Use the front panel knob to highlight the calibration you want to recall and

RECALL STATE

press

MENU

Press

Connect the short to reference test port 1.

MEAS

Press

SCALE REF

Press

Check to be sure the trace response is 0.00 ±0.05 dB.

Disconnect the short and connect it the reference test port 2.

MEAS

Press

Check to be sure the trace response is 0.00 ±0.05 dB.

SAVE/RECALL, SELECT DISK, INTERNAL MEMORY, RETURN

,

TRIGGER MENU, CONTINUOUS

,

Refl: E S11 FWD,

,

SCALE/DIV,

,

Refl: E S22 REV

,

not

disconnect the cables from the HP 8702D test

SELECT DISK, INTERNAL MEMORY, RETURN

,

.

to trigger the continuous sweeps.

MENU

.05, x1.

.

TRIGGER MENU, CONTINUOUS

,

. Using the

.

RECALL

.

k

If any of the trace responses are out of the specified limits, repeat the procedures in this chapter.

3-11

Manual Verification

In Case of Difficulty

3-12

4

Performance Tests

Performance Tests

Manual Performance Tests

Manual Performance Tests

This chapter contains procedures which test the electrical performance of the

HP 8702D. If you are using an HP 8702D Option 011, perform the tests in

Chapter 6, “Performance Tests – Option 011”. Before starting these procedures, allow the instrument to warm up for one hour.

Each procedure has a “Performance Test Record” that is located at the end of

this chapter.

To obtain the same quality of performance testing that Hewlett-Packard has

administered at the factory, you must perform:

• the system verification procedures in Chapter 2, “Automated Verification” or

Chapter 3, “Manual Verification”.

all

•

of the performance test procedures in this chapter.

This quality of performance testing guarantees that the analyzer is performing

all

within

cate of Calibration for your analyzer if two conditions are met.

1

Your analyzer passes all the performed tests.

2

The equipment and standards that you used to perform the tests are traceable

to a national standards institute.

NOTE

If you have a particular type of measurement application that does not use all of the analyzer’s measurement capabilities, you may ask your nearest Hewlett-Packard Sales and

Service Office for a subset of specifications that you want verified. However, this does

create a potential for making incorrect measurements, by using a different application

than what was specified.

4-2

of the published specifications. Hewlett-Packard will issue a Certifi-

Performance Tests

Manual Performance Tests

WARNING

Any servicing, adjustment, maintenance, or repair of this product

must be performed only by qualified personnel. Repair information

provided in the In Case of Difficulty sections of this chapter are

provided for qualified service personnel and are intended to be used

with the HP 8753D Service Guide.

HP 8753D is shown in the figures

The procedures in this chapter are designed to work with HP 8702D and HP 8753D

instruments. Because of this, many of the figures label the instrument being tested as an

HP 8753D. Simply substitute your HP 8702D for the HP 8753D.

What you’ll find in this chapter

1. Test Port Output Frequency Range and Accuracy 4-4

2. External Source Mode Frequency Range 4-6

3. Test Port Output Power Accuracy 4-8

4. Test Port Output Power Range and Linearity 4-11

5. Minimum R Channel Level 4-14

6. Test Port Input Noise Floor Level 4-19

7. Test Port Input Frequency Response 4-23

8. Test Port Crosstalk 4-34

9. Calibration Coefficients 4-39

10. System Trace Noise (Only for Analyzers without Option 006) 4-46

11. System Trace Noise (Only for Analyzers with Option 006) 4-48

12. Test Port Input Impedance 4-51

13. Test Port Receiver Magnitude Dynamic Accuracy 4-55

14. Test Port Receiver Phase Dynamic Accuracy 4-63

15. Test Port Receiver Magnitude Compression 4-65

16. Test Port Receiver Phase Compression 4-68

17. Test Port Output/Input Harmonics (Option 002 Analyzers without Option

006 Only) 4-71

18. Test Port Output/Input Harmonics (Option 002 Analyzers with Option 006

Only) 4-76

Performance Test Records 4-81

4-3

Performance Tests

1. Test Port Output Frequency Range and Accuracy

1. Test Port Output Frequency Range and Accuracy

Perform this test to verify the frequency accuracy of the HP 8702D over its

entire operating frequency range.

Required

Equipment

Procedure

Frequency Counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . HP 5343A

Cable, 50Ω, Type-N, 24-inch . . . . . . . . . . . . . . . . . . . . . . . . HP P/N 8120-4781

Adapter, APC-3.5 (f) to Type-N (f) . . . . . . . . . . . . . . . . . . HP P/N 1250-1745

Adapter, APC-7 to Type-N (f) . . . . . . . . . . . . . . . . . . . . . . . . HP P/N 11524A

Adapter, Type-N (f) to BNC (m) . . . . . . . . . . . . . . . . . . . . HP P/N 1250-1477

Additional Equipment for HP 8702D Option 075:

Minimum Loss Pad, 50Ω to 75Ω . . . . . . . . . . . . . . . . . . . . . . . . . . . HP 11852B

1

Connect the equipment as shown in Figure 4-1.

4-4

Performance Tests

1. Test Port Output Frequency Range and Accuracy

In Case of

Difficulty

Figure 4-1. Test Port Output Frequency Range and Accuracy Test Setup

2

3

PRESET, MENU

Press

Press 30,

CW FREQ

,

k/m

and write the frequency counter reading on the “Performance

.

Test Record.”

4

Repeat Step 3 for each instrument frequency listed in the “Performance Test

Record.”

1

If any measured frequency is close to the specification limits, check the time

base accuracy of the counter used.

2

If the analyzer fails by a significant margin at

all

frequencies (especially if the

deviation increases with frequency), the master time base probably needs

adjustment. In this case, refer to the

HP 8753D Service Guide

. The

“Fractional-N Frequency Range Adjustment” also affects frequency accuracy.

4-5

Performance Tests

2. External Source Mode Frequency Range

2. External Source Mode Frequency Range

Perform this test to verify that the analyzer’s reference channel, input R, is

capable of phase locking to an external CW signal.

Required

Equipment

Procedure

External Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . HP 83640A

Cable, APC-7, 24-inch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . HP P/N 8120-4779

Adapter, APC-3.5 (f) to APC-7 . . . . . . . . . . . . . . . . . . . . . . HP P/N 1250-1747

Adapter, APC-3.5 (m) to APC-7 . . . . . . . . . . . . . . . . . . . . . HP P/N 1250-1746

1

On the external source, press

GHz/dB(m)

2

Connect the equipment as shown in Figure 4-2.

.

PRESET, CW, 10, MHz/msec, POWER LEVEL, –/

←

, 20,

Figure 4-2. External Source Mode Frequency Range Test Setup

3

On the analyzer, press

Press

4-6

SYSTEM

INSTRUMENT MODE

,

4

PRESET, MEAS

EXT SOURCE AUTO

,

INPUT PORTS

,

R

,

.

MENU

,

CW FREQ

,

, 10,

M/

µ

.

Performance Tests

2. External Source Mode Frequency Range

5

Check to see if the analyzer is phase locking to the external CW signal:

• If the analyzer displays any phase lock error messages, write “unlock” in the

“Performance Test Record” for the set CW signal.

In Case of

Difficulty

• If the analyzer does

not

display any phase lock error messages, write “lock”

in the “Performance Test Record” for the set CW signal.

6

On the external source, press CW, 50,

7

On the analyzer, press 50,

8

Repeat Step 5 through Step 7 for the other external source CW frequencies

M/

µ

MHz/

µ

.

.

listed in the “Performance Test Record.” For analyzers with Option 006, change

the power sensor to the HP 8481A for frequencies above 4 GHz.

1

Be sure the external source power is set within 0 to –25 dBm.

2

Make sure the analyzer’s “Ext Source Auto" feature is selected. In addition,

verify that the analyzer is set to measure its input channel R.

3

Verify that all connections are tight.

4-7

Performance Tests

3. Test Port Output Power Accuracy

3. Test Port Output Power Accuracy

Perform this test to confirm the accuracy of the HP 8702D source output

power.

Required

Equipment

Procedure

Equipment Required for 50Ω Analyzers

Power Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . HP 436A/437B/438A

Power Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . HP 8482A

Adapter, APC-7 to Type-N (f) . . . . . . . . . . . . . . . . . . . . . . . . . . . . HP 11524A

Additional Equipment Required for Analyzers with Option 006

Power Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . HP 8481A

Equipment Required for 75Ω Analyzers

Power Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . HP 436A/437B/438A

Power Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . HP 8483A Option H03

1

Zero and calibrate the power meter. For more information of how to perform

this task, refer to the power meter operating manual.

2

Connect the equipment as shown in Figure 4-3.

4-8

Performance Tests

3. Test Port Output Power Accuracy

Figure 4-3. Source Output Power Accuracy Test Setup

Press

PRESET

.

3

NOTE

The factory preset test port power is 0 dBm.

4

Press

MENU

CW FREQ

,

300, k/m

,

. Set the calibration factor on the power meter for

this CW frequency.

4-9

In Case of

Difficulty

Performance Tests

3. Test Port Output Power Accuracy

5

Write the power meter reading on the "Performance Test Record."

6

Repeat Step 4 and Step 5 for each CW frequency listed in the "Performance

Test Record."

1

Be sure the source power is switched on. Press

PWR

softkey, ON

should

be highlighted. Otherwise, press

MENU

POWER

,

SOURCE PWR

. Check the

to switch

on the source power.

SOURCE

2

Refer to the

HP 8753D Service Guide

for more troubleshooting information.

4-10

Performance Tests

4. Test Port Output Power Range and Linearity

4. Test Port Output Power Range and Linearity

Perform this test to verify the analyzer’s test port output power range and

power level linearity at selected CW frequencies.

Required

Equipment

Procedure

Power Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . HP 437B/438A

Power Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .HP 8482A

Adapter, APC-7 to Type-N (f) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .HP 11524A

Additional Required Equipment for Analyzers with Option 006

Power Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .HP 8481A

Additional Required Equipment for Analyzers with Option 075

Power Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .HP 8483A Option H03

1

Zero and calibrate the power meter. Refer to the power meter operating and

service manual for more information on how to do this task.

2

On the analyzer, press

PRESET, MENU

CW FREQ

,

300, k/m

,

. Set the power meter

calibration factor for this CW frequency.

3

Connect the equipment as shown in Figure 4-4.

4-11

Performance Tests

4. Test Port Output Power Range and Linearity

Figure 4-4. Test Port Output Power Range and Accuracy Test Setup

4

On the HP 438A, press

REL

. This sets the current power level for relative power

measurement.

5

On the analyzer, press

6

Write the power meter reading in the "Results Measured" column on the

MENU

POWER

,

PWR RANGE MAN

,

.

"Performance Test Record."

7

Calculate the difference between the analyzer test port power (which appears

on the analyzer’s display) and the power meter reading. Write the result in the

"Power Level Linearity" column on the "Performance Test Record."

4-12

4. Test Port Output Power Range and Linearity

8

Repeat Step 5 through Step 7 for the other power levels listed in the

"Performance Test Record."

Performance Tests

In Case of

Difficulty

9

10

CW FREQ

Press

Set the power meter calibration factor for this CW frequency and press

, 3,

G/n

.

set the reference at this new frequency.

11

12

MENU

Press

POWER

,

Write the power meter reading in the "Results Measured" column on the

–15, x1

,

.

"Performance Test Record."

13

Calculate the difference between the analyzer test port power and the power

meter reading. Write the result in the "Power Level Linearity" column of the

"Performance Test Record."

14

Repeat Step 11 through Step 13 for the other power levels listed in the

"Performance Test Record."

1

Ensure that the power meter and power sensor(s) are operating to

specifications. Be sure you set the power meter calibration factor for the CW

frequency that you are testing.

2

Verify that there is power coming out of the analyzer’s test port 1. Be sure you

not

did

MENU

accidently switch off the analyzer’s internal source. If you did so, press

SOURCE PWR ON

POWER

,

,

.

REL

to

3

Repeat this performance test.

4-13

Performance Tests

5. Minimum R Channel Level

5. Minimum R Channel Level

Perform this test to determine the minimum R channel input power level at

which phase lock can be accomplished.

Required

Equipment

Procedure

For 50Ω Analyzers

Adapter, APC-3.5 (m) to APC-7 . . . . . . . . . . . . . . . . . . . . . HP P/N 1250-1746

Cable, APC-7 24-inch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . HP P/N 8120-4779

For 75Ω Analyzers (Option 075)

Minimum Loss Pad, 50Ω to 75Ω . . . . . . . . . . . . . . . . . . . . . . . . . . . HP 11852B

Cable, 50Ω Type-N, 24-inch . . . . . . . . . . . . . . . . . . . . . . . . HP P/N 8120-4781

Adapter, APC-3.5 (m) to Type-N (f) . . . . . . . . . . . . . . . . . HP P/N 1250-1750

1

Connect the equipment as shown in Figure 4-5.

Figure 4-5. Minimum R Channel Level Test Setup

2

3

4

Press

Press

Press

4-14

PRESET, MEAS

MENU

POWER

,

SCALE REF

REFERENCE VALUE

,

INPUT PORTS

,

PWR RANGE MAN

,

R

.

,

POWER RANGES, RANGE 4 –55 to –30

,

–70, x1

,

.

.

Performance Tests

5. Minimum R Channel Level

In Case of

Difficulty

WARNING

WARNING

Press

Press

MENU

MENU

CW FREQ

,

POWER

,

5

6

The analyzer displays the message,

INPUT LEVEL.

7

Press ⇑ to increase the test port power by 1 dBm.

8

If the analyzer displays a phase lock error message, continue increasing the test

300, k/m

,

–65, x1

,

.

.

CAUTION: NO IF FOUND: CHECK R

port power until phase lock is achieved.

9

Write the test port power, that is displayed on the analyzer, on the

"Performance Test Record."

10

Repeat Step 5 through Step 9 for the other CW frequencies listed in the

"Performance Test Record."

These servicing instructions are for use by qualified personnel only.

To avoid electrical shock, do not perform any servicing unless you are

qualified to do so.

The opening of covers or removal of parts is likely to expose

dangerous voltages. Disconnect the instrument from all voltage

sources while it is being opened.

WARNING

CAUTION

The power cord is connected to internal capacitors that may remain

live for five seconds after disconnecting the plug from its power

supply.

1

Check the flexible RF cable (W8, as shown in Figure 4-6) between the R

sampler assembly (A4) and the A11 phase lock assembly. Make sure it is

connected between A11J1 (PL IF IN) and 1st IF Out.

Loop the W8 cable around the A5 sampler as shown in Figure 4-6.

Do not

the cable down next to the A11 phase lock assembly.

push

4-15

Performance Tests

5. Minimum R Channel Level

Figure 4-6. Flexible RF Cable Location

2

Using an ohmmeter, verify that the RF cable is

not

open. In addition, examine

both the cable connectors - measure the resistance between the cable center

pin and the cable connector and make sure it is

4-16

not

close to zero.

5. Minimum R Channel Level

3

Check the R sampler by substituting it with the B sampler (A6).

a

Move cable W8 to the B sampler (A6), as shown in Figure 4-7.

Performance Tests

Figure 4-7. Connections for Substituting the R Sampler (A4)

4

Connect the equipment as shown in Figure 4-8.

Figure 4-8. Setup for Checking the R Sampler (A4)

4-17

Performance Tests

5. Minimum R Channel Level

5

Repeat the test, but select the B sampler (A6) by pressing

B

in Step 2. Use the following specifications:

MEAS

INPUT PORTS,

,

300 kHz to 3 GHz < –27 dBm

3 GHz to 6 GHz < –22 dBm

6

If the analyzer fails the test, replace the A11 assembly.

7

Verify that the high/low band adjustments are still within specifications. For

more information on how to perform this task, refer to the

Guide

.

8

Refer to the

HP 8753D Service Guide

for more troubleshooting information.

HP 8753D Service

4-18

Performance Tests

6. Test Port Input Noise Floor Level

6. Test Port Input Noise Floor Level

Perform this test to determine the HP 8702D port 1 and port 2 noise floor levels at the input test ports.

Required

Equipment

For 50Ω Analyzers

Calibration Kit, 7 mm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .HP 85031B

For 75Ω Analyzers

Calibration Kit, Type-N . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .HP 85036B

Procedure Port 1 Noise Floor Level from 50 kHz to 3 GHz

(IF BW= 3 kHz)

1

Connect the equipment as shown in Figure 4-9.

Figure 4-9. Source Input Noise Floor Test Setup

Press

Press

Press

PRESET, MENU

MEAS

INPUT PORTS

,

MARKER FCTN

POWER

,

MARKER MODE MENU, STATS ON

,

When the analyzer finishes the sweep, notice the mean value (which appears

2

3

4

5

–85, x1, STOP, 3, G/n

,

TESTPORT 2

A

,

,

FORMAT