Page 1

Agilent Technologies 8511B

Frequency Converter Test Set

Operating and Service

Manual

Agilent Part Number: 08511-90073

Printed in USA November 2001

Supersedes Nove mber 1999

Page 2

Notice

The information containe d in this doc ument is subject to change without

notice.

Agilent Technologies makes no warranty of any kind with regard to this

material, including, but not limited to, the implied warranties of

merchantability and fitness fo r a particular purpose. Agilent shall not be

liable for error s cont ained herein or for incidenta l or consequential damages

in connection with the furni shing, performance, or use of this material.

Agilent assumes no re sponsibility for the us e or r eliability of its software on

equipment that is not furnished by Agilent.

This document contains proprietary information which is protected by

copyright. All rights are reserved. No part of this document may be

photocopied, reproduced, or translated to another langu age without prior

written consent of Agilent Technologies.

Hewlett-Packard to Agilent Technologies Transition

This documentation supports a product that previously shipped under the

Hewlett-Packard company brand name. The brand name has now been

changed to Agilent Te chnologies. The two products are functionally

identical, only our name has change d. The document still inc ludes references

to Hewlett-Packard products, some of which have been transitioned to

Agilent Technologies.

Restricted Rights Legend

Use, duplication, or disclosure by the U.S. Government is subject to

restrictions as set forth in subparagraph (c)(1)(ii) of the Rights in Technical

Data and Computer Software cla use at DFARS 252.227-7013 for DOD

agencies, and subparagr aphs (c)(1) and (c)(2) of the Commercial Computer

Software Restri cted Rights clause at FAR 52.227-19 for other agencies.

© Copyright Agilent Te chnologies, Inc. 1999, 2001

ii Agilent 8511B Test Set Operating and Service Manual

Page 3

What You’ll Find in This Manual…

Chapter 1 • General Information

Chapter 2 • Specifications

Chapter 3 • Installation

Chapter 4 • Operations

Chapter 5 • Performance Tests

Chapter 6 • Test Set Troubleshooting

Chapter 7 • Replacement Procedures

Chapter 8 • Replaceable Parts

Agilent 8511B Test Set Operating and Service Manual iii

Page 4

Warranty

Certification Agilent Technologies certifies that this product met its published

specifi cations at the time of shipment from the factory. Agilent further

certifi es that its calibration measurements are traceable to the United St ates

National Insti tute of Standards and Technology (NIST, formerly NBS), to the

extent allowed by the Institute’s calibration facility, and to the calibration

facilities of other I nternational Standards Organization members.

Warranty This Agilent system product is wa rranted against defects in materi als and

workmanship for a period corresponding to the individual warranty periods

of its component products. Instruments are warranted for a period of one

year. During the warranty peri od, Agilent will, at its option, either repair or

replace products that prove to be defective.

W arr anty se rvice for products in sta lled b y Agilent and certain other products

designated by Agile nt will be performed at Buyer’s facility at no charge

within Agilent servic e travel areas. Outside Agilent service travel areas,

warranty service will be per formed at Buyer’ s f acility only upon Agilent’s

prior agreement and Buyer shall pay Agilent’s round trip travel expense s. In

all other areas, products must be returned to a service facility designated by

Agilent.

For products returne d to Agilent for warranty serv ice, Bu y er sha ll pr epay

shipping charge s to Agilent and Agilent shall pay shipping char ges to return

the product to Buyer. However , Buyer shall pay all shippi ng charges, duties,

and taxes for products r eturned to Agilent from another country.

Agilent warr ants that its software and firmware designated by Agilent for

use with an instrument will e xecute its programming instructions when

properly install ed on that instrument. Agilent does not warrant tha t the

operation of the instrument, or software, or firmware will be uninterrupt ed or

error free.

LIMITATION OF WARRANTY. The foregoing warranty shall not apply

to defects resulti ng from improp er or inadequate maintenance by Buyer,

Buyer-supplied software or interfacing, unauthorized modification or

misuse, operation outside of the environmenta l spe cifications fo r the

product, or improper site prepa ration or maintenance.

NO OTHER WARRANTY IS EXPRESSED OR IMPLIED. AGILENT

SPECIFICALLY DISCLAIMS THE IMPLIED WARRANTIES OR

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

iv Agilent 8511B Test Set Operating and Service Manual

Page 5

EXCLUSIVE REMEDIES. THE REMEDIES PROVIDED HEREIN ARE

BUYER’S SOLE AND EXCLUSIVE REMEDIES. AGILENT SHALL

NOT BE LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL,

INCIDENTAL, OR CONSEQUENTIAL DAMAGES, WHETHER BASED

ON CONTRACT, TORT, OR ANY OTHER LEGAL THEORY.

Assistance Product maintenance agre emen ts and other customer assistance agreements

are available for Agilent products.

For assistance , c al l your local Agilent Sales and Service Office (refer to

“Service and Support” on page vi).

Agilent 8511B Test Set Operating and Service Manual v

Page 6

Service and Support

Any adjustment, maintenance, or repair of this product must be performed

by qualif ied personnel. Contact your customer engine er through your local

Agilent Service Center. By internet, phone, or fax, get assistance with all

your test and measurement needs.

Online assistance: www.agilent.com/find/assist

United S t ates

(tel) 1 800 452 4844

New Zealand

(tel) 0 800 738 378

(fax) (+64) 4 495 8950

Malays ia

(tel) 1 800 828 848

(fax) 1 800 801 664

Taiwan

(tel) 0800-047-866

(fax) (886) 2 25456723

Latin America

(tel) (305) 269 7500

(fax) (305) 269 7599

Japan

(tel) (+81) 426 56 7832

(fax) (+ 81) 426 56 7840

Philippines

(tel) (632) 8426802

(tel) (

PLDT subscriber on ly):

1 800 16510170

(fax) (632) 8426809

(fax) (

PLDT subscriber o nly):

1 800 16510288

People’s Republic of China

(tel) (preferred): 800-810-0189

(tel) (alternate): 10800-650-0021

(fax) 10800-650-0121

vi Agilent 8511B Test Set Operating and Service Manual

Page 7

Safety and Regulato ry Informat ion

Review this product and related documentation to familiarize yourself with

safety markings and instr uct ions before you operate the instrument. This

product has been designed and teste d in acc ordance with international

standards.

WARNING The WARNING notice denotes a hazard. It calls attention to a proce dure,

practice, or the like, that, if not correctl y performed or adhered to, could result

in personal injury. Do not proceed beyond a WARNING notice until the

indicated conditions are fu lly understood and met.

CAUTION The CAUTION notic e denotes a hazard. It calls attention to an operating

procedure, practice, or the like, which, if not correctly performed or adhered

to, could result in damage to the product or loss of important data. Do not

proceed beyond a CAUTION notice until the indicat ed conditions are fully

understood and met.

Instrument Markings

When you see this symbol on your instrument, you should refer to the instrument’s

!

1SM1-A This text indicates that the instrument is an Industrial Scientific and Medical Group 1

instruction manual for important information.

This symbol indicates hazardous voltages.

The laser radiation symbol is marked on products that have a laser output.

This symbol indicates that the instrument requires alternating current (ac) input.

The CE mark is a registered trademark of the European Community. If it is

accompanied by a year, it indicates the year the design was proven.

The CSA mark is a registered trademark of the Canadian Standards Association.

Class A product (CISPER 11, Clause 4).

This symbol indicates that the power line switch is ON.

This symbol indicates that the power line switch is OFF or in STANDBY position.

Agilent 8511B Test Set Operating and Service Manual vii

Page 8

Safety Earth Ground

This is a Safety Class I product (provided with a protective earthing

terminal). An uninterruptible safety earth ground must be provided from the

main power source to the product input wiring terminals, power cord, or

supplied powe r cord set. Whenever it is likely that the protection has been

impaired, the product must be made inoperative and secured against any

unintended operation.

Before Applying Power Verify that the product is configured to match the available main power

source as described in the input power configura tion instructions in this

manual. If this product is to be powered by autotransformer, make sure the

common terminal is c onnecte d to the neutr al ( grounded) side of t he ac powe r

supply .

viii Agilent 8511B Test Set Operating and Service Manual

Page 9

DECLARATION OF CONFORMITY

According to ISO/IEC Guide 22 and CEN/CENELEC EN 45014

Manufacturer’s Name: Agilent Technologies, Inc.

Manufacturer’s Address: 1400 Fountaingrove Parkway

Santa Rosa, CA 95403-1799

USA

Declares that the products

Product Name: Frequency Converter

Model Number: 8511A, 8511B

Product Options: This declaration covers all options of the above

products.

Conform to the following product specifications:

Standard Limit

EMC: CISPR 11:1990 / EN 55011-1991 Group 1, Class A

IEC 801-2:1984/EN 50082-1:1992 4 kV CD, 8 kV AD

IEC 801-3:1984/EN 50082-1:1992 3 V/m, 80 - 1000 MHz

IEC 801-4:1988/EN 50082-1:1992 0.5 kV sig., 1 kV power

Safety: IEC 61010-1:1990 + A1:1992 + A2:1995 / EN 61010-1:1993 +A2:1995

CAN/CSA-C22.2 No. 1010.1-92

Supplementary Information:

The products herewith comply with the requirements of the Low Voltage Directive

73/23/EEC and the EMC Directive 89/336/EEC and carry the CE-marking accordingly.

Santa Rosa, CA, USA 2 September 2000

Greg Pfeiffer/Quality Engineering Manager

For further information, please contact your local Agilent Technologies sales office, agent or distributor.

Agilent 8511B Test Set Operating and Service Manual ix

Page 10

Ty peface Conventions

Italics • Use d to emphas ize important information:

Use this software only with the Agilent xxxxxX system.

• Used for the title of a publication:

Refer to the Agilent xxxxxX System-Level User’s Guide.

• Used to indicate a varia ble:

LOAD BIN filename.

Type

Instrument Display • Used to show on-screen prompts and messages that you will see on the

display of an instrument:

The Agilent xxxxxX will display the message CAL1 SAVED.

[Keycap] • Used for labeled ke ys on the front panel of an instrument or on a

computer keyboa rd:

[Return].

Press

{Softkey} • Used for simulate d keys that appear on an instrument display:

{Prior Menu}.

Press

User Entry • Used to indicate text that you will enter using the comput er ke yboard;

text shown in this typeface must be typed exactly as printed:

LOAD PARMFILE

Type

• Used for examples of programming code:

#endif // ifndef NO_CLASS

Path Name

Computer Display • Used to show messages, prompts, and window labels that appear on a

• Used for a subdirectory name or file path:

Edit the file

computer monitor:

Edit Parameters window will appear on the screen.

The

usr/loc al /b in/sampl e.txt

• Used for menus, lists, dialog boxes, and button boxes on a computer

monitor from which you make selecti ons using the mouse or keyboard:

Double-click

EXIT to quit the program.

x Agilent 8511B Test Set Operating and Service Manual

Page 11

Contents

Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

What You’ll Find in This Manual… . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Service and Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

Safety and Regulatory Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Safety Earth Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Before Applying Po wer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Typeface Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

1. General Information

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Fi gure 1-1. 8511B Test Set with Acces sorie s Supplied . . . . . . . . . . . 1-2

Verifying the Agilent 8511B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Measurement Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Instrument Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Description and Characte ristics of the Instrument . . . . . . . . . . . . . . . . . . 1-6

Fi gure 1-2. Measureme nt Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Software and Hardware Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Computer Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Option 001 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Option 908 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Option 910 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Option 913 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Service and Support Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Option W30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Option W31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Option 1BN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Option 1BP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Accessories Suppli ed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Accessories Available . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Calibration and Verification Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Operating and Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Electrostati c Discharge Information . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Fi gure 1-3. Example of a Static-Safe Work Station . . . . . . . . . . . . . 1-12

Reduci n g ESD Damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Table 1-1. Static -Safe Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Agilent 8511B Test Set Operating and Service Manual Contents-1

Page 12

Operating Po wer Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Table 1-2. Maximum Operating Power Level . . . . . . . . . . . . . . . . 1-13

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Specifica tions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Recommended Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Miscellaneous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

2. Specifications

Specifications and Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Table 2-1. 8510/8511B Specifications . . . . . . . . . . . . . . . . . . . . . . . 2-1

Table 2-2. 8510/8511B Characteristics . . . . . . . . . . . . . . . . . . . . . . 2-2

Dynamic Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Figure 2-1. Worst Case Dynamic Accuracy (Magnitude) . . . . . . . . 2-3

Figure 2-2. Worst Case Dynamic Accuracy (Phase) . . . . . . . . . . . . 2-3

Table 2-3. 8510/8511B Characteristi cs (co ntinued) . . . . . . . . . . . . 2-4

Specificatio n Assumptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Recommended Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Table 2-4. Recommended Test Equipment . . . . . . . . . . . . . . . . . . . . 2-6

3. Installation

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Initial Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Table 3-1. Contents of the 8511B Shipping Container . . . . . . . . . . 3-1

Environmental Conside rations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Operation and Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Preparation for Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Installing the Test Set in a System Rack . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Fi gure 3-1. Attaching Rack-Mounting Hardware . . . . . . . . . . . . . . 3-4

Installing the Test Set on a Bench . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Connecting the Test Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Mating Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Power and Control Connecti ons . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Signal Path Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Connecting the Test Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Fi gure 3-2. Connecting the Test Set in a System Configuration . . . . 3-7

Packaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

4. Operation

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Front Panel Feature s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Fi gure 4-1. Front Panel Features of the Test Set . . . . . . . . . . . . . . . 4-1

Rear Panel Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Figure 4-2. Rear Panel Features of the Test Set . . . . . . . . . . . . . . . . 4-2

Operator’s Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Table 4-1. Necessary Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Contents-2 Agilent 8511B Test Set Operating and Service Manual

Page 13

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

a1 and b1 Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Fi gure 4-3. Hardware Configuration for Operator’s Check . . . . . . . 4-4

Fi gure 4-4. Typical Operator’s Check CRT Trace . . . . . . . . . . . . . . 4-5

a2 and b2 Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Controlling Multiple Test Sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Fi gure 4-5. RF and IF Switching with Two Test Sets . . . . . . . . . . . . 4-7

Table 4-2. Agilent 33311C Coaxial Switch Positions with Two Test Sets

4-7

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Initializat ion at Power-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Selecting a Test Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Test Set Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

RF Switch Driver Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Fi gure 4-6. RF and IF Switching with Four T est Sets . . . . . . . . . . . 4-11

Table 4-3. Agilent 33311C Coaxial Switc h Positions with Four T est Sets

4-11

Measurement Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Operational Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Performance Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

5. Performance Tests

Port Return Loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

T est Procedure (optiona l) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

6. Test Set Troubleshooting

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Fi gure 6-1. Simplified RF Block Diagram . . . . . . . . . . . . . . . . . . . . . 6-2

Equipment Needed but Not Suppl ied . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Table 6-1. Needed Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Troubleshooting Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Fi gure 6-2. Troubleshooting Flowchart . . . . . . . . . . . . . . . . . . . . . . 6-4

Troubleshooting Procedur es . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Procedure 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

A15 Regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Fi gure 6-3. Power Supply Fuses and Test Points . . . . . . . . . . . . . . . 6-5

A15 Primary Regulator Boar d Assembly . . . . . . . . . . . . . . . . . . . . . . 6-6

Table 6-2. Power Supply Voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

GPIB Address Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Fi gure 6-4. Instrument GPIB Switch Setting . . . . . . . . . . . . . . . . . . . 6-6

Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Procedure 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Self-Test Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Figure 6-5. Location of Self-Test Indicators . . . . . . . . . . . . . . . . . . . 6-8

Table 6-3. Self-Test Failure Indications . . . . . . . . . . . . . . . . . . . . . . . 6-9

If the Self-Test Fails to Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Agilent 8511B Test Set Operating and Service Manual Contents-3

Page 14

Procedure 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Agilent 85102 IF

Amplifier Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Figure 6-6. Service Adapter Connections . . . . . . . . . . . . . . . . . . . 6-10

Fi gure 6-7. Agilent 8511B RF Block Diagram . . . . . . . . . . . . . . . . 6-11

Fi gure 6-8. Agilent 8511B Control Block Diagram . . . . . . . . . . . . 6-13

Fi gure 6-9. Agilent 8511B Motherboard Wiring List (1 of 2) . . . . 6 -1 5

Fi gure 6-10. Agilent 8511B Motherboard Wiring List (2 of 2) . . . 6-17

7. Replacement Procedures

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Equipment Needed But Not Supplied . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Table 7-1. Equipment Needed to Replace Test Set Major Assemblies . .

7-1

Fi gure 7-1. Assembly Location Diagram . . . . . . . . . . . . . . . . . . . . . 7-2

Preliminary Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

(1) Replacing the Frequency Converter . . . . . . . . . . . . . . . . . . . . . . 7-4

(2) Replacing the Regulator Board Assembly . . . . . . . . . . . . . . . . . 7-4

(3) Replacing the Filter Capacitors . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

(4) Repairing a

2.4 mm RF Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Fi gure 7-2. Exploded Diagr am of a 2.4 mm Connector . . . . . . . . . . 7-6

(5) Replacing the

B1 Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

(6) T1 Power Transformer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Fi gure 7-3. Wire Connections to the Line Module FL1 . . . . . . . . . . 7-8

8. Replaceable Parts

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Replaceable Par ts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Reference D esignations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Exchange Assemblies Available . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Fi gure 8-1. Low Cost Rebuilt-Ex change Procedure . . . . . . . . . . . . . 8-3

Fi gure 8-2. Major Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Fi gure 8-3. Semi-Rigid Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Fi gure 8-4. Flexible RF Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Fi gure 8-5. Detailed Views of Rear Panel Misc ellaneous Parts . . . 8-7

Fi gure 8-6. Miscellaneous Mothe rboard Parts . . . . . . . . . . . . . . . . 8-8

Replaceable Par ts Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

Table 8-1. Agilent 8511B Replaceable Parts . . . . . . . . . . . . . . . . . . 8-9

Fi gure 8-7. Parts Unique to Option 001 . . . . . . . . . . . . . . . . . . . . 8-12

Table 8-2. Replaceable Parts for Agilent 8511B Option 001 . . . . . 8-13

Contents-4 Agilent 8511B Test Set Operating and Service Manual

Page 15

1 General Information

Introduction This manual for the Agilent 8511B frequency converter test set is used in

conjunction with the Agile nt 8510 network analyzer manual set. Th ese

manuals provide the inform ation needed to properly configure your system

and make measurements.

NOTE The 8511B manual may be inserted into the 8510 test sets and accessories

binder that was provided with your 8510 manual set.

The 8511B Operating portion consists of:

• General Information

• Specifications

• Installation

• Operation

• Performance Tests

The 8511B Service portion consists of:

• Troubleshooting

• Replacement procedure s

• Replaceable parts

First. Read the chapters titled “General Information” and “Installation.”

These chapters include information on site preparation, unpacking and

inspecting your instr ument for damage, safety considerations, and

configuring your test set to the 8510.

Second. Read the chapters of the Agi lent 85056 Calibr ation Kit Manual, that

pertain to the care, cleaning, gaging, and connection of precision 2.4 mm

devices. This information wil l help you make good connec tions and care for

your precision devices, and to maintain the performance of your test set and

network analyzer system.

Third. Read the chapter titled “Operation.” This chapter will acquaint you

with the front and rear panel features of your test set. Also included is

information on control ling mu ltiple test sets, using the anti-rotation clamps,

and connecting devices to the test set.

Agilent 8511B Test Set Operating and Service Manual 1-1

Page 16

General Information

Figure 1-1 8511B Test Set with Accessories Supplied

1-2 Agilent 8511B Test Set Operating and Service Manual

Page 17

General Information

Verifying the Agilent 8511B

Verifyi ng the A gil ent 8511B

The Agilent 8511B has been designed to operate specifically with the 8510

network analyzer.

• To install the instrument, turn to Chapter 3, “Installation”.

• To verify that the instrument meets its published specifications, use the

Agilent 8511A,B and Antenna Measurement System Performance

Verification Software (part number 08511-60024).

• To troubleshoot the test se t, refer to the troubleshooting information in

the Agilent 8510 On-Site Service Manual. This will determine if the test

set is at fault. Then refer to Chapter 6, “Test Set Troubleshooting” for

more information.

Agilent 8511B Test Set Operating and Service Manual 1-3

Page 18

General Information

Measurement Accuracy

Measurement Accuracy

Any precision measure ment is no bet ter than the calibration of the netw ork

analyzer. As a ge neral rule , the sh orter t he time between a c alibr ation and the

measurement of a devi ce unde r test (DUT), the more precise the

measurement will be, within the limitations of your system. For this r eason,

Agilent recom mends that for prec ision measurements you recalibrate your

system every few hours, or at a minimum, reverify your system calibration.

The frequency of your requ ir ed calibration will depend on the temperature

stability of the location of the network analyzer.

1-4 Agilent 8511B Test Set Operating and Service Manual

Page 19

General Information

Instrument Co m p a tibilit y

Instrument Compatibility

The Agilent 8511B is compatible with all 8510 network analyzers. Agilent

836XX-series sources must ha ve a frequency range that extends to 50 GHz

to take full advantage of the frequency range of the 8511B. If your network

analyzer and/or source do not fulfill the required conditions, it will be

necessary to upgrade your syste m. Plea se consult your Agilent

representative for more information.

Agilent 8511B Test Set Operating and Service Manual 1-5

Page 20

General Information

Description and Characteristics of the Instrument

Description and Characteristics of the

Instrument

The 8511B four channel frequenc y converter test set is designed to operate

with all 8510 netw ork analyzers. The test set provides a con ve nient means of

customizing a test configuration for a variety of applications within the

frequency range of 45 MHz to 50 GHz. In addition to conf igurations for

measuring reflection and transmission parameters of one-port or two-port

devices, you can build configurations to characterize antenna parameters,

radar cross section s and freque ncy translation de vices. Figure 1-2 on

page 1-7 shows one possible measurement set-u p.

1-6 Agilent 8511B Test Set Operating and Service Manual

Page 21

General Information

Description and Characteristics of the Instrument

Figure 1-2 Measurement Setup

Agilent 8511B Test Set Operating and Service Manual 1-7

Page 22

General Information

Software and Hardware Requirements

Software and Hardware Requirements

Computer Requirements

The computer requirements to suc cessfully install and operate the

performa nc e verification software are as follows:

• 100% IBM-PC compatible computer.

• Pentium 133 or better.

• Windows 95

, Windows 98 or Windows NT 4.0 installed.

• GPIB interface card and cable, or Agilent GPIB card and cable.

• HP BASIC for Windows, ver sion 6.32 or later installed.

• A CD-ROM drive.

• Agilent 8511A/B and Antenna Measurement System Performance

Verification Software.

• Internet Explorer

4.0 or higher or Netscape 4.0 or higher.

1-8 Agilent 8511B Test Set Operating and Service Manual

Page 23

General Information

Options

Options

Option 001 Option 001 adds IF switching capability to allow up to four test sets to be

connected to the 8510 at the same time. The test set in use is selected from

the 8510 network analyzer. The 20 MHz IF signal is transmitted from the

standard test set thro ugh the option 001 test set(s) to the 8510.

IF switching is performed aut omatic ally by the option 001 test set(s),

without reconnections. For more inf ormation, refer to “Co ntrolling Multiple

Test Sets” on page 4-6.

Option 908 Option 908 supplies the parts requir ed to rack mount the test set with

handles remove d. Refer to Chapter 3, “Installation ” for additional

information.

Option 910 Option 910 provides a duplicate manual at the time of purchase.

Option 913 Option 913 supplies the parts requir ed to rack mount the test set with

handles attached. Refer to Chapter 3, “Installation” for additional

information.

Agilent 8511B Test Set Operating and Service Manual 1-9

Page 24

General Information

Service and Support Products

Service and Support Products

A vari ety of s ervic e and support pr oducts are a v a ilable. These produc ts c ove r

repair , calibration, and ve ri fication. Consult your local Agilent customer

engineer for details.

The instrument include s a one year on-site service warranty. In the event of

failure, Agilent will provide service for the system. Note that system

installation is not included.

Option W30 Option W30 supplies a three year customer return repair covera ge , whic h

adds to the product warranty to provide a total of three years of customer

return to Agilent repair service.

Option W31 Option W31 supplies a three year on-site repair coverage , whic h adds to the

product warranty to provide a total of three years of next day on-site repa ir

service.

Option 1BN Option 1BN adds a MIL-STD 45662A Certificate of Calibration to the

instrument. This option must be ordered when the instrument is ordered.

Option 1BP Option 1BP adds a MIL-STD 45662A Certificate of Calibration and the

corresponding cali bration data to the instrument. This opti on must be

ordered when the instrument is or dere d.

1-10 Agilent 8511B Test Set Operating and Service Manual

Page 25

General Information

Accessories

Accessories

Accessories Supplied The accessories supplie d with the test set, including par t numbers, are listed

in the “Installation” and “Replaceable Parts” chapters of this manual.

Accessories Available

NOTE Additional 8510 syste m access ory inf ormation is locat ed in the 8510 manua l

set.

Calibration and Verification Kits

Agilent offers several calib ration and verification kits suitabl e for use with

2.4 mm interfaces, they are listed below.

Agilent 85056A 2.4 mm Calibration Kit

Contains:

❍ open and short circuits

❍ fixed and sliding loads (2)

❍ 2.4 mm to 2.4 mm adapters

❍ 2.4 mm connector tools and gauges.

Agilent 85057B 2.4 mm Verification Kit

Contains:

❍ precision airline

❍ mismatched airline

❍ 20 and 40 dB attenuators

❍ NIST (National Institute of Standards and Technology) traceable

data and uncertainties.

Agilent 8511B Test Set Operating and Service Manual 1-11

Page 26

General Information

Operating and Safety Precautions

Operating and Safety Precautions

Electrostatic Discharge Information

Electrostati c discha rge (ESD) ca n damage or destr oy e lect ronic compone nts.

All work on electronic assemblies should be performed at a static-safe work

station. Figure 1-3 sho ws an exa mple of a stati c-safe w ork sta tion using ESD

protection. When used properly, this provides a signifi cant level of ESD

protection.

To ensure user safety, the static-safe accessories must provide at least 1 M

of isolation fr om ground. Refer to Ta ble 1-1 on page 1-13 for information on

ordering static- safe accessories.

WARNING These techniques for a static-safe work stat ion should not be used when

working on circuitry with a voltage potential greater than 500 volts.

Ω

Figure 1-3 Example of a Static-Safe Work Station

1-12 Agilent 8511B Test Set Operating and Service Manual

Page 27

General Information

Operating and Safety Precautions

Reducing ESD Damage

The followin g suggestions may help reduce the ESD damage that occurs

during testing and servicing operations.

• Before connecting any coaxial cable to an instrument connector for the

first t ime each day, momentarily gr ound the center and oute r conductors

of the cable.

• Personnel should be gr ounded with a resistor -isolated wrist-strap before

touching the center pin of an y connec tor and before removing any

assembly from the unit.

• Be sure that all instruments are properly earth-grounded to pre vent a

buildup of static charge.

Table 1-1 lists static-safe acc essories that can be obtaine d from Agilent using

the part numbers shown.

Table 1-1 Static-Safe Accessories

Part Number Description

9300-0797 Set includes: 3M static control mat 0.6 m X 1.2 m (2 ft X 4 ft) and 4.6 cm

(15 ft) ground wire. (The wrist-strap and wrist-strap cord are not

included. They must be ordered separately.)

9300-0980 Wrist-strap cord 1.5 m (5 ft).

9300-0910 Wrist-strap, color b lack , stainl ess steel, without cord, has four adjustable

links and a 7 mm post-type connection.

9300-1169 ESD heel-strap (reusable 6 to 12 months).

Operating Power Level Do not exceed the front panel operating level power input as noted:

Table 1-2 Maximum Operating Powe r Level

Maximum Operating Power Level Test Port

+13 dBm a

, a2, b1, b

1

2

• Do not ex ceed +15 dBm source RF input level into the test set and under

no circumstances e ver apply a dc level to the source RF input of the test

set.

• Do not torque anything to the test port connector with greater than

90 N-cm (8 in.-lb.) of torque. The wrench supplied with your accessory

kit is calibrated to 90 N-cm (8 in.-lb.).

• Do not torque anything to the source RF input on the back of your test

set, with greater than 90 N-cm. (8 in.-lb.) of torque.

Agilent 8511B Test Set Operating and Service Manual 1-13

Page 28

General Information

Operating and Safety Precautions

Service The voltages in this test set warra nt normal caution for operator safety.

Nevertheless, service should be performed only by qualified personnel.

Service strate gy, troubleshooting procedures, replaceable parts and similar

information for the 8511B test se t is in this manua l or the 8510 On-Site

Service Manual.

Specifications The specifi cations of the test set with an 8510 network analyzer are listed in

Chapter 2, “Specifications”.

Characteristics The performance parameter s listed in Chapter 2, “Specifications” as

characteristic s are typical or nominal, but are non- warranted characteristics

of the 8510/8511B system.

Recommended Equipment

Additional equipment and acces sories required for use with the test set are

listed in tables in Chapte r 2, “Specific ations”. The tables note which items

are required to verify the performance of the test set, and which are required

to operate it. Othe r equipm ent m ay be subst itut ed if its spe cif ic ations meet or

exceed the specifications listed in the critical specific ations column.

1-14 Agilent 8511B Test Set Operating and Service Manual

Page 29

General Information

Miscellaneous

Miscellaneous

Adjustments The Agilent 8511B had no adjustm ent s. Sp ecifically, no attempt should be

made to adjust the samplers.

Agilent 8511B Test Set Operating and Service Manual 1-15

Page 30

General Information

Miscellaneous

1-16 Agilent 8511B Test Set Operating and Service Manual

Page 31

Specifications

2 Specifications

Specifications and Characteristics

Introduction Specifications and characteristics differ as defined in the Table 2- 1 and

T able 2-2 on page 2-2. Both are based on certain operatin g conditions. Those

conditions are def ined in “Specification Assumptions” on page 2-5.

Specifications describe the warranted performance of the instru m ent . To

verify the specifications follow the Agi le nt 8511A/B and Antenna

Measure ment System P erformance Verification Software assembly

documentation. Characteristics provide information useful in applying the

instrument by giving typical but non-warranted performance parameters.

Table 2-1 8510/8511B Specifications

Parameter 0.045 to 8 GHz 8 to 20 GHz 20 to 40 GHz 40 to 50 GHz

Frequency Response Tracking

Magnitude (ripple)

Phase (ripple)

Magnitude slope

Crosstalk

High Level Noise

Low Level Noise

Conversion Gain

Compression (0.1 dB point)

Input Port

1. Deviation from a least-squares-straight-line fit, excluding noise and slope. Ratio measurement of any two ports.

2. Slope of least-squares-straight-line fit over full frequency range.

3. Uncorrected port to port crosstalk with averaging factor of 1024.

4. Trace noise, sweep to sweep variation.

5. Low level noise measured with 50 ohm load at port, and calculated as the mean value of a 101 point trace with IF averaging set at one. Low level noise varies

6. See figures on page 2-3.

7. Do not exceed −5 dBm input to sampler for proper phase lock operation.

8. Tested with sampler in non-conducting state. When diodes are turned on by the LO pulse, they present a short circuit across the sampler input port.

3

Magnitude (ratio)

Phase (ratio)

8

Impedance Match

(return loss) (all 4 ports)

with averaging factory: 10 log (average factor).

This may affect the measured data.

1

2

4

5

6

7

±1.5 dB

±75 degrees

±0.055 dB/GHz

–85 dB –85 dB –75 dB –70 dB

0.006 dB rms

0.08 degrees rms

–100 dBm –102 dBm –102 dBm –102 dBm

1 dB to –4 dB 1 dB to –4 dB –3 dB to –13 dB –5 dB to –15 dB

–10 dBm –10 dBm –15 dBm –20 dBm

≥

17 dB ≥15 dB ≥9 dB ≥7 dB

±1.5 dB

±75 degrees

±0.055 dB/GHz

0.009 dB rms

0.145 degrees rms

±1.5 dB

±75 degrees

±0.055 dB/GHz

0.040 dB rms

0.245 degrees rms

±1.5 dB

±75 degrees

±0.055 dB/GHz

0.060 dB rms

0.400 degrees rms

Agilent 8511B Test Set Operating and Service Manual 2-1

Page 32

Specifications

Table 2-2 8510/8511B Characteristics

1

Parameter 0.045 to 8 GHz 8 to 20 GHz 20 to 40 GHz 40 to 50 GHz

Dynamic Range

2

all inputs

Accuracy Enhanced Crosstalk

–115 dB

3

110 dB

(–10 to –120 dBm)

112 dB

(–10 to –122 dBm)

107 dB

(–15 to –122 dBm)

102 dB

(–20 to –122 dBm)

–115 dB –113 dB –110 dB –10 5 dB

Typical Drift (typical) Magnitude 0.001 X V °C, linear

Phase (0.01 + 0.01 f (GHz) X V °C, degrees

Input Ports

Connector type: precision 2.4 mm female

Impedance: 50 ohms nominal

Damage level: +13 dBm (20 mW) CWRF input

4

Port input power for phase lock: Frequency Minimum Maximum

0.045 to 8 GHz –41 dBm –5 dBm

8 to 20 GHz –39 dBm –5 dBm

20 to 26.5 GHz –32 dBm –5 dBm

40 to 50 GHz –30 dBm –5 dBm

1. The performance parameters listed are characteristic of the 8511B. They are typical or nominal figures and are not field verifiable.

2. Determined by 0.1 dB compression level and system low level peak noise. Low level peak noise measured with 50 ohm load at port and 1024

averaging factor. Noise floor varies with averaging factor. (10 log averaging factor.) Low lev el noise is calculated from low level noise +10.4 dB.

3. Effective crosstalk with isolation, calibration, excludes noise.

4. Do not exceed –5 dBm input to the sampler for the proper phase lock operation.

2-2 Agilent 8511B Test Set Operating and Service Manual

Page 33

Specifications

Dynamic Accuracy Figure 2-1 and Figure 2-2 illustrate a worst case magnitude and phase

uncertainty due to IF residuals and detector inaccuracies. This data excludes

uncertainty due to noise, frequency response, directivity, port matches and

connector repeatability.

Figure 2-1 Worst Case Dynamic Accuracy (Magnitude)

Figure 2-2 Worst Case Dynamic Accuracy (Phase)

*

* Phase detector accuracy is better than 0.02 degrees, useful for measurements where only phase changes.

Agilent 8511B Test Set Operating and Service Manual 2-3

Page 34

Specifications

Table 2-3 8510/8511B Characteristics (continued)

Source of System Dynamic Accuracy Errors:

The factors affecting dynamic accuracy listed below are primarily a function of the IF detector. However, compression is primarily a function of the

sampler/mixer circuitry. In order to measure these values, some of the system cables must be disconnected to gain access to the individual

instrumen ts.

IF Amplifier Gain Accuracy IF Amplifier Power Range (dBm)

–10 to –34 0

–34 to –46 ±0.005

–46 to –58 ±0.010

–58 to –70 ±0.015

≤ 70 ±0.025

Detector Circularity Error: ±0.003 dB peak

IF Residuals: –140 dBm

IF Linearity: ±0.003 dB

Incremental Phase Accuracy (Phase versus Phase) at Measurement Reference:

±0.001 degrees/degree, not to exceed 0.02 degrees peak.

Operating Temperat ure: 0 °C to 55 °C

Power: 110, 120, 220 or 240 ±10% Vac; 47 to 66 Hz line frequency

Dimensions: 460 mm x 133 mm x 609 mm (18.1 x 5.25 x 24 inches)

Weight: 13 kg (29 lb) net; 17 kg (38 lb) shipping

1. Measured at the IF input to the 8510, not at the test set test ports.

1

1

Maximum Gain Error (dB)

2-4 Agilent 8511B Test Set Operating and Service Manual

Page 35

Specifications

Specification Assumptions

Specification Assumptions

The specif ications of the Agile nt 8511B require that the f ollowing operating

conditions are met:

• All system instruments ha ve reached stable operating temperature.

• RF source: Agilent 83651A. When used with another recommended

source, the pe rform an c e specifications ma y differ from those for the

8510/8511/83651A conf iguration. The performance te st software will

display and print the limits f or the chosen configuration.

• Performance verification tempera ture: 23 ±3 °C.

• RF source power le vels as follo ws:

Test

Compression, Crosstalk

Conversion Gain, Tracking, High Level Noise

Power at Input Level (dBm)

0.045 to 20 GHz 20 to 40 GHz 40 to 50 GHz

–10

–15

–15

–20

–20

–25

Agilent 8511B Test Set Operating and Service Manual 2-5

Page 36

Specifications

Recommended Test Equipment

Recommended Test Equipment

Table 2-4 lists the test equipment that is required when trouble shooting,

operating, and performance testing the 8511B

Table 2-4 Recommended T es t Equipment

Item Critical Specifications

Network analyzer no substitute 8510A,B,C O,P,T

Multimeter range: 0 to 50 V 3456A T

Oscilloscope 50 MHz bandwidth 1740A T

Semi-rigid cables T,P

Power splitter 45 MHz to 50 GHz 11667C P,T

Power meter 436A, 437A, 438A P

Power sensor no substitute 8487A P

2.4 mm coax cables (2) no substitute 08511-20031 P,T

2.4 mm (f) to 2.4 mm (m) adapter no substitute 1250-2186 P

20 dB fixed attenuator no substitute 33340D Option 020

RF cable 2.4 (m) semi-rigid 2-in long 08511-20031A P, T

6 dB fixed attenuator (2) no substitute 33340D Option 006 P

2.4 mm 50 ohm load (m) no substitute 85148A P

2.4 mm 50 ohm load (f) no substitute 85138B P

Recommended Agilent Model

(or Part Number)

2

P

Use

1

1. O = Operation; P = Performance test; T = Troubleshooting

2. Supplied in the 8511B Service Kit (part number 08511-60016)

2-6 Agilent 8511B Test Set Operating and Service Manual

Page 37

Installation

3 Installation

Introduction This section explains how to instal l the test se t. The topics covered include

initial inspection, envir onmental considerations, positioning and connecting

the test set for use, and packaging the instrument. Refe r to the “Installation”

chapter of the 8510 manual for more complete system connection and

turn-on instruct ions.

Initial Inspecti o n Inspect the shipping containe r (including cushioning material) and its

contents for completeness and da mage. If the shippi ng container is da maged

or defective, keep the shipping materials and notif y both the carr ier and the

nearest Agilent office. The Agilent office will arrange for repair or

replacement of the test set withou t waiting f or sett lement of the claim. If any

of the following a ccessories are not received with the test set, notify your

nearest Agilent office and the missing parts will be sent to you.

CAUTION Assemblies in the test set are very sensitive to damage by static electricity.

They may or may not continue to function if subjected to an electrostatic

discharge (ESD). Their reliability will however, be impaired.

Always use an anti- st atic wr ist strap whe n ca librating or v e rifying t he test set

or using the test set to measure devices. Never touch the test port center

conductors. For more information on ESD, refer to “Electrostati c Discharge

Information” on page 1-12 of this manual.

Table 3-1 Contents of the 8511B Shipping Container

Item Part Number

Power Cord 8120-1348

Test set cable assembly 08510-60102

GPIB cable 8120-3445

Performance test software (CD-ROM) assembly 08511-60024

Agilent 8511B Operating and Service Manual 08511-90073

Agilent 8511B Test Set Operating and Service Manual 3-1

Page 38

Installation

Environmental Considerations

Environmental Considerations

Operation and Storage To perform within specifications, the test sets should be operated in

temperatures between 0 °C and +55 °C with relative humidity less than 95%

(at 40 °C dry bulb temperature, maximum). They may be operated at

altitudes up to 4,500 meters (15,000 feet).

The 8511B may be stored in temperatures from

relative humidity up to 90% at +65° C (maximum dry b ulb temperature) and

at altitudes up to 15,240 meters (50,000 feet).

Preparation for Use Positioning the Test Set

T ypic ally t he 8511B i s placed und er the 8510 n etwor k anal yzer or the sourc e

whether it is rack- mounted or used on a bench. To install the flanges to rack

mount the instrument (with or without handles) in a standard 19 inch rack

refer to “Installing the Test Set in a System Rack” on page 3-3.

−40 °C to +75 °C, with

3-2 Agilent 8511B Test Set Operating and Service Manual

Page 39

Installation

Installing the Test Set in a System Rack

Installing the Test Set in a System Rack

The recommended system rack is the Agilent 85043C. I nstructions for

rack-mounting the 8511B test set in a system configuration with the

8510 are provided in the “Installation” chapter of the Agilent 8510 On-Site

Service Manual and in the Agilent 85043C System Rack Manual (part

number 85043-90022).

To install the flanges to rack mount the instr um ent (with or without handles)

in a standard 19 inch rack, refer to Figure 3-1 on page 3-4.

Agilent 8511B Test Set Operating and Service Manual 3-3

Page 40

Installation

Installing the Test Set in a System Rack

Figure 3-1 Attaching Rack-Mounting Hardware

3-4 Agilent 8511B Test Set Operating and Service Manual

Page 41

Installation

Installing the Test Set on a Bench

Installing the Test Set on a Bench

When installing the test set for use on a bench, place it on a grounded

anti-static work surface to lessen the chan c e of ESD damage. The antist at ic

surface should extend far enough in front of the test set to provide effective

protection for the test ports and cable ends. Refer to “Operating and Safety

Precautions” on page 1-12. A grounding receptacle is provided on the test

set as an alternate grounding point for your anti-static wrist -s trap.

Agilent 8511B Test Set Operating and Service Manual 3-5

Page 42

Installation

Connecting the Test Set

Connecting the Test Set

Mating Connectors INPUT PORTS a

and mate with precision 2.4 mm male connectors.

The TEST SET INTERCONNECT connecto r is a series D subminiature

female connector with 7 RF cavities. It mates with the corresponding male

connector.

The 8510 SYSTEM BUS connector is a female GPIB type connector and

mates with the corresponding male connectors of the GPIB cables.

Power and Control Connections

The followin g connections, with the exception of line power , are illustrated

in Figure 3-2 on page 3-7. That figure also sho ws the connections required

for the RF source.

1. Connect the line cord between an electr ical outle t and the line module to

supply power to the fre quency converter.

2. Connect the test set IF interconnect cable from the J11 TEST SET

INTERCONNECT connector on the rear panel of the 8511B to the J1

TEST SET INTERCONNECT connector on the rear panel of the

Agilent 85102 IF detector.

3. Connect the system bus cable from the 8511B J12 8510 SYSTEM BUS

connector to the 8510 INTERCONNECT connector of the 85101

display/proce ssor. The test set IF interconnect cable and the system bus

cable transmit contr ol signals between the test set and the network

analyzer.

, bl, b2 and a2 are precision 2.4 mm female connectors

l

Signal Path Connections

The IF signals from the test set are transmitted to the 85102 1F detector by

the supplied t est set IF interc onnect cable. Longer IF interconnect cables are

ava ilable.

RF signals are typically transm itted from the source to the DUT (device

under test) or signal sepa ration devices by 3.5 mm flexible or semi-rigid

cables.

3-6 Agilent 8511B Test Set Operating and Service Manual

Page 43

Connecting the Test Set

Installation

Connecting the Test Set

Figure 3-2 Connecting the Test Set in a System Configuration

Agilent 8511B Test Set Operating and Service Manual 3-7

Page 44

Installation

Packaging

Packaging

If reshipping is required, the test set should be repackaged in the original

factory package . Cont ainers and materials identical to those used by the

factory are a vailable through Agile nt offic es.

If original packaging material is not avai l abl e:

1. Wrap the test set in heavy paper or anti-static plastic.

2. Use sufficient shock absorbing material on all sides of the test set to

provide a thick, firm cushion and prev ent movement.

3. Seal the shipping container securely and mark it FRAGILE.

4. If shipping to an Agilent office or service center, complete and attach a

service tag (provided in the 8510 manual set).

In any correspondenc e with Agilent, refer to the test set by full model and

serial number.

3-8 Agilent 8511B Test Set Operating and Service Manual

Page 45

4 Operation

Introduction This chapter illustrates the fea tures an d functions of the f ront and rear panels

of the Agilent 8511B (see Figure 4-1 and Figure 4-2 on page 4-2. This

chapter also descri bes the multiple test set option (Option 001). It explains

the setup and use of one or more test sets in a system.

Front Panel Features

Figure 4-1 Front Panel Features of the Test Set

1. Line Switch. This switch turns the test set on and off. When the side of

the switch labeled 0 is depressed, the test set is off; 1 is on.

2. Line LED. This LED goes on and off with the test set line swit ch.

3. A cti ve LED. This LED lights about two seconds after power is turned

on following a succ essful conclusion of self-test. If the test set is used

with other test sets (Option 001) and is not addr essed by the 8510, this

light remains off .

4. Input Ports b

the samplers withi n the i nstr ument. P ort a

phaselock . Th ese ports are precision 2.4 mm connectors and all

connections must be torqued to no more than 90 N-cm (8 in-lb).

, a1, a2, and b2. These input ports tr ansmit RF energy to

1

Agilent 8511B Test Set Operating and Service Manual 4-1

or a2 must be used for sys tem

1

Page 46

Rear Panel Features

Figure 4-2 Rear Panel Features of the Test Set

Operation

1. Line Module. This assembly houses the line cord connector, line fuse

and line vol tage selector. Pull out the right side of the line module cover

to replace or change the fuse, or to change the voltage selection. The

voltage selector drum must be removed to rotate it to a different voltage

setting. Recommended fuse values are printed on the rear panel.

2. J10 Test Set Interconnect. This connector is used only in test sets with

Option 001. It allows connecting another test set to the Option 001 test

set. Up to four test sets can be serially connected to the analyzer. The

8510 system automatically selects the IF output fro m the chosen test set

for processing and dis play . Ref er to “Controlling Multiple Test Sets” on

page 4-6 for more information.

3. J 1 1 Test Set Interconnect. This connector transmits the IF signal from

the test set to the Agilent 85102 IF detector. It also transmits control

signals bidirect ionally.

4. 8510 System Bus Address Switch . This five-pole binary-weighted

switch sets the system bus address of the test set. The binary weight of

each pole is indicated on the rear panel, as well as the on and off

positions. Decimal 20 ( of f- of f-on-off-on, from lef t to rig ht) is the defa ult

setting (see Figure 6-4 on page 6-6).

5. J12 8510 System Bus Connector. This connector is used for GPIB

communications with the Agilent 85101 display/processor.

4-2 Agilent 8511B Test Set Operating and Service Manual

Page 47

Operator’s Check

The purpose of this check is to confirm that the Agilent 8511B functions

properly as part of an 8510 system.

Table 4-1 Necessary Equipment

Description Agilent Model or Part Number

Network analyzer system 8510,B,C

Semi-rigid cables (2) 085 11-20025

Power splitter 1167C

1. Supplied with the 8511B service kit (part number 08511-60016).

08511-20031

1

Operation

Operator’s Check

1

1

NOTE This procedur e must be perfor med with a properly configured and

operational 8510 syst em.

Procedure Plug in and turn on the frequency conver ter. The line LED should light

immediately and the active LED should light in about two seconds. Those

indications mean that the inst rument has passed its self-test. In case of

difficulty, refer to Chapter 6, “Test Set Troubl esh ooting” or contact your

local Agilent Service office.

Turn on the source, then the test set and then the Agilent 8510.

On the Agilent 85102:

1. Press

[RECALL], [MORE], [FACTORY PRESET] to preset the

8510C, or

[PRESET] for the 8510B.

Agilent 8360 series systems:

• Press STIMULUS, [MENU], [STEP] and then use the entry keys to set the

sweep time to 200 ms. In narrow band systems, the power level in the

frequency ba nd gener ated shoul d matc h the le v el sho wn in Figure 4-4 on

page 4-5 for a given frequency.

2. Reduce the source power by pressing STIMULUS,

[MENU], [POWER SOURCE 1], [-10], [x1].

[MENU], POWE R,

NOTE All of the observed traces should decrease from −15 ±5 dB at 45 MHz to

−35 ±5 dB at 50.0 GHz. Refer to F igure 4-4 on page 4-5.

Agilent 8511B Test Set Operating and Service Manual 4-3

Page 48

Operation

Operator’s Check

a1 and b1 Test 3. Loosely connect the RF source cable to the power splitter as shown in

Figure 4-3 below. Connect the other end of the RF source cable to the

output of th e sour ce. R otate the semi -rigid c ables to the r equir ed pos ition

for connection to ports a

and b1. Tighten all connections.

1

Figure 4-3 Hardware Configuration for Operator’s Check

4-4 Agilent 8511B Test Set Operating and Service Manual

Page 49

4. Press PARAMETER, [MENU], [User 1 a1] to observe the a1 power level

trace.

Figure 4-4 Typical Operator’s Check CRT Trace

Operation

Operator’s Check

5. Press

[User 4 b1] to observe the b1 power level trace.

a2 and b2 Test 1. Reconnect the semi-rigid cables (as in step 3 of “a1 and b1 Test”) to

ports a2 and b2. Disregard the running error message

FOUND”.

2. Press [User 3 a2], [REDEFINE PARAMETER], [PHASE LOCK], [a2], [REDEFINE DONE] to

observe the a2 powe r level trace.

3. Press

[User 2 b2], [REDEFINE PARAMETER], [PHASE LOCK], [a2], [REDEFINE DONE] to

see the b2 trace.

4. If any of the traces are not wit hin the limits noted above, check all of the

connections and repeat the above procedure. If symptoms pers ist, refer

to the “Service and Equipment Overview” chapter in the Agilent 8510C

On-Site Service Manual.

“Caution: NO IF

Agilent 8511B Test Set Operating and Service Manual 4-5

Page 50

Operation

Controlling Multiple Test Sets

Controlling Multiple Test Sets

Option 001 for the Agilent 851X-serie s test sets will allo w an 8510 to

alternately control up to four test sets. While a measurement is proceeding

on test set number 1 (equipped with Option 001), a test de vice can be

connected to test set number 2, which does not need to be equipped with

Option 001. When the measurement on test set number 1 is complete, the

8510 can control test set number 2.

In a standard test set, the 20 MHz IF and control signals are applied directly

to the J11 TEST SET INTERCONNECT, which connects to the 8510.

Option 001 adds a set of IF switches, control switches, and the J10 TEST

SET INTERCONNECT connector. Thi s allows the se lection of 20 MHz t est

set IF signals. As shown in Figure 4-5 on page 4-7 test set number 1 can

apply its IF to the 8510, or it can swit ch to pass th e IF from test set number 2

through the J10 TEST SET INTERCONNECT to the 8510.

4-6 Agilent 8511B Test Set Operating and Service Manual

Page 51

Operation

Controlling Multiple Test Sets

Figure 4-5 RF and IF Switching with Two Test Sets

Table 4-2 Agilent 33311C Coaxial Switch Positions with Two Test Sets

New ADDRESS of Test Set Test Set Selected 33311C Coaxial Switch Port Selected

20 1 Port 1

21 2 Port 2

Agilent 8511B Test Set Operating and Service Manual 4-7

Page 52

Operation

Installation

Installation

Set each test set rear panel address switch to the address listed in Table 4-2

on page 4-7 if using a two test set configuration, and Table 4-3 on page 4-11

if configuring more than two test sets. Us the supplied test set interconnect

cable to connect test set number 2, J11, to test set number 1, J10. You may

continue this test set “daisy ch ain” to include up to four test sets if the total

length of all test set interconnect cab les does not exc eed 13 meters ( about 40

feet). The last test set in the chain does not require Option 001.

If the RF coaxial switch(s) is not inc or porated into the system, then the RF

input to the test set must be manually swit ched to the active test set.

4-8 Agilent 8511B Test Set Operating and Service Manual

Page 53

Operation

Operation

Operation

Initialization at Power-Up

Upon power -up, the IF switches must be conf igured so that only one syste m

test set is active. The following procedure shows how to make one test set

active:

1. Check the active lights of all system test sets.

2. Check the analyzer’s expected test set address by pressing

[TEST SET]. The displ ay should matc h the address of the desire d test set. If

not, change the address on the analyzer.

3. If u n sele ct ed test se ts are ac tive (a ctive light on), deactivate the test set

by temporarily add ressing it. Then return to the desired address.

Selecting a Tes t Set Test Set IF Switching

The active test set is selected by the built-in capability of the analyz er to

generate an addresse d command to the test set. Each time the 8510

of TEST SET]

previou sly addressed test set IF to external and the newly addressed test set

IF to internal. The test set front pa nel ACTIVE indicator shows the test set

status. When the test set is active, the IF signals from the test set are applied

directly to the J11 TEST SET INTERCONNECT. When the test set is

inacti ve, the IF signals appearing at J10 are passed thr ough to J11 and on to

the next test set or the analyzer.

function is cha nged (see [LOCAL] menu), the analyz er switches the

[LOCAL],

[ADDRESS

Agilent 8511B Test Set Operating and Service Manual 4-9

Page 54

Operation

Operation

Tes t Se t Ad dress The address of the active test set can be changed manually from the analyzer

front panel by selecting the

address of the test set and pressing

control using the analyzer’s GPIB

a particular test set is set by the address switches on the test sets rear panel

(see Figure 6-4 on page 6-6).

[ADDRESS of TEST SET] func tion, then entering the

[x1], or it can be changed under program

ADDRESS command. The GPIB address of

RF Switch Driver Commands

A related feature of the analyz er is tha t when the 8510 [ADDRESS of TEST SET]

function is changed, a code sequenc e is automatically issued ov e r the 8510

system bus to the device at the

[ADDRESS of RF SWITCH]. In the recommended

configura tion, this device is an Agilent 11713A attenuator/switch driver

which in turn controls one or more coaxia l switches. As sho wn in Figure 4-5

on page 4-7 and Figure 4-6 on page 4-11, these switches are used to select

which of the test s ets receiv es t he RF output of the network ana lyzer source.

The exact command issued depends upon the new value of the

TEST SET]

function, also shown in Figure 4-5 on page 4-7 and Figure 4-6 on

[ADDRESS of

page 4-11.

4-10 Agilent 8511B Test Set Operating and Service Manual

Page 55

Operation

Operation

Figure 4-6 RF and IF Switching with Four Test Sets

Table 4-3 Agilent 33311C Coaxial Switch Positions with F our Test Sets

33311C Coaxial Switch Port Selected

New ADDRESS of Test Set Test Set Selected

20 1 Port 1 P ort 1

21 2 Port 1 P ort 2

22 3 Port 2 P ort 1

23 4 Port 2 P ort 2

Switch #1 Switch #2

Agilent 8511B Test Set Operating and Service Manual 4-11

Page 56

Operation

Operation

Measurement Calibration

NOTE Since the cal set limi ted instrument state does not include the number of the

After selecting the active test set, pe rform the system calibration procedur e

as usual. When you select a different test set, make sure that you recall the

cal set that applies to that test set.

activ e test set, a cal set which does not apply to the current test set can be

turned on without any 8510 caution messages appearing. This will cause

errors in the dis played data be cause i ncorre ct er ror coeffici ents ar e applie d t o

the measured data.

It may be conve nient to store a hardware state file and an instrument state

file for each combina tion of test set and cal set. You may also store your

hardware state f ile on a disk for future use. To change the configuration,

simply recall the appropriate hardware state f ile, which sets the address of

test set and issues the RF switch command, and then the appropriate

instrument state f ile which recalls the cal set.

Operational Checks To check operation of a multiple test set configuration:

1. Connect a devi ce with a known response at test set number 1.

Perf ormance Verification

2. Press 8510

3. Enter the address of test set number 1 (this would be 20).

4. Press

5. Press

for later comparison.

6. Press 8510

number 2.

7. Switch back to test set number 1.

8. O b serve any differen ce in the res ponse between the stored trace and the

result after switching back and forth between the test sets. Repeat for

each of the test sets. Any difference in the data believed due to the

Option 001 IF switch or RF switching must be investigated. Refer to

Chapter 6, “Te st Set Troubleshooting” for more information.

Standard system perfor mance ve rification pr ocedures are used to verify the

operation of the option 001 test set as test set number 1. To verify the

performa nc e of a test set other than an 8511 in the chain, select it as the

active test set and procee d as usu al. Refer to the Agilent 8510 On-Site

Service Manual for the performan ce ver ification p roced u re .

[LOCAL], {TEST SET]}, “ADDRESS of TEST SET” is displayed.

[x1]. The test set number 1 measurement should appear.

[DISPLAY], {DATA and MEMORIES}, {DATA →},{MEMORY 1} to store the trace

[LOCAL], {TEST SET]}, “ADDRESS of TEST SET” to sel e ct test set

4-12 Agilent 8511B Test Set Operating and Service Manual

Page 57

5 Pe rformance Tests

The Agilent 8511B ships with the Agilent 8511A/B and Antenna

Measurem ent Sy ste m Per fo rm an ce Verification So ftw are as sem b ly (p art

number 08511-60024). This assembly includes performance verification

software with on-line help and an installation and getting starte d manual

(part number 5962-0493).

Follow the Agilent 8511A/B and Antenna Mea sur ement Syste m Performance

Verification Software assembly documentation to install the software and to

verify the performance of your test set.

Agilent 8511A Test Set Operating and Service Manual 5-1

Page 58

Performance Tests

Port Return Loss

Port Return Loss

Test Procedure (optional)

NOTE An Agilent 8517B test set is required to perform this test.

1. Disconnect the 8511B from the GPIB, the test set IF interconnect and

the RF source signal. Lea ve it connected to the line power.

2. Place the 8517B test set on top of the 8511B. Connect the

8517B test set in the system by connecting the GPIB, the test set IF

interconnect, the RF source power, and the line power to it.

3. Turn on the 8511B and treat it like a device under test. You will use the

8517B test set to make S11 measurements of each port on the

8511B.

4. Perform the calibration at the end of the cable and take care to avoid

overly sharp cable bends (defined in the cable manual). Then measure

the return loss of each port on the 8511B.

5-2 Agilent 8511A Test Set Operating and Service Manual

Page 59

6 Test Set Troubleshooting

Introduction The troubleshooting strategy f or the Agilent 8511B frequency conver ter test

set is a systematic sequence of proc edures. This troubl eshootin g infor mation

is used after system-level troubleshooting has pin-pointed the test set as the

problem instrument. Use the troubleshooting flowchart Figure 6-2 on

page 6-4 to identify the faulty assembly. The troubleshooting flowcha rt is

keyed to numbered, individual troubleshooting procedures. As you progress

through the flowchart, perform the numbered procedure associated with each

block. Block diagrams are provided at the end of this chapter to assist in

understanding the oper at ion of the test set.

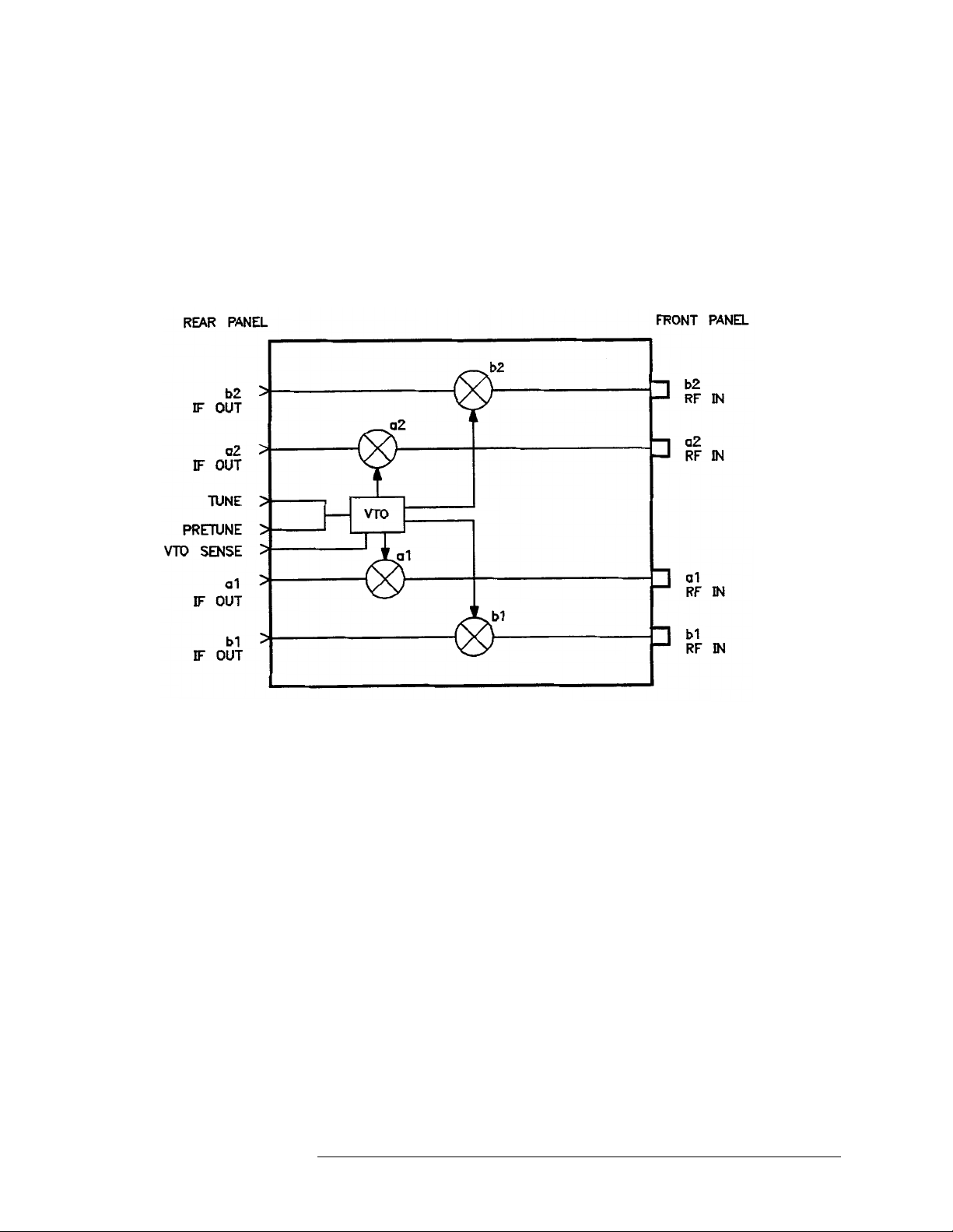

Theory of Operation The RF section of an 8511B frequency converter te st set consists of a

voltage-tun ed osci llator (VT O), a four -wa y po wer spli tte r and fou r samplers .

The frequency converter operates within the frequency range of 45 MHz to

50 GHz. Two reference (a1 and a2), and two test (b1 a nd b2) cha nnels a ccept

RF input by way of the front panel bulkhead connectors.

The VTO/dri ver produces a harmonic that is 20 MHz away from the RF

source frequenc y. The samplers use either the fundamental or a harmonic of

the LO with the reference and test RF signals to develop a 20 MHz IF. The

IF signals are th en routed to the Agilent 85102 by way of the rear panel

connector on the test set.

The LO, generated by the VTO/driver, is phase locked to the source. The

phase lock loop includes the following:

• A3 VTO summing amplifier board

• A14 VTO/driver

• A12 a1 reference sampler assembly

• A13 a2 reference sampl er as sembly and the 8510 network analyzer

A microprocessor on the A4 GPIB board controls the samplers, which may

be switched either on or of f , de pending on the parameter being measured.

The default condition is for all four samplers to be on. This insures that the

test set will be usable in the event of a failure of the A4 GPIB board or a

failure in the communica tion between the test set and the 8510

display/proce ssor.

The 85102 IF detector controls the VTO/dr iver via the VTO summing

amplifie r board. A control voltage is input to the VT O to tune to the corr ect

LO frequency.

Agilent 8511B Test Set Operating and Service Manual 6-1

Page 60

Test Set Troubleshooting

The VTO summing amplifi er board has an output called LENDRA (Low =

END of RAnge) that is sent to the Agilent 85102 IF detector ove r the test set

interconnect cable . This indicates to the Agilent 85101 displa y processor

whether or not the VTO is outside of its nor mal ope rating frequency range.

Should the VTO exceed its normal operating range, the network analyzer

will respond by displ aying the running error message,

message will not be seen in the 8510C. It has been replac ed by

FAILED.

VTO OVER-RANGE. This

PRETUNE

Figure 6-1 Simplified RF Block Diagram

Electrostati c discha rge (ESD) ca n damage or destr oy e lect ronic compone nts.