Page 1

E7345A and E7355A Performance Upgrade Kits for the 85107B Network Analyzer

Installation Manual

Agilent Part Number: E7350-90003

Printed in USA

Print Date: J une 2001

Supersedes: March 1998

Page 2

Notice

The information contained in this document is subject to change without

notice.

Agilent Technologies makes no warranty of any kind with regard to this

material, including, but not limited to, the implied warran ties of

merchantability and fitness for a particular purpose. Agilent Technologies

shall not be liable for errors contained herein or for incidental or

consequential damages in connection with the furnishing, performance, or

use of this material.

Agilent Technologies assumes no responsibility for the use or reliability of

its software on equipment that is not furnished by A gilent Technologies.

This document contains proprietary information which is protected by

copyright. All rights are reserved. No part of this document may be

photocopied, reproduced, or translated to another language without prior

written consent of Agilent Technologies.

Restricted Rights Legend

Use, duplication, or disclosure by the U.S. Government is subject to

restrictions as set forth in subparagraph (c)(1)(ii) of the Rights in Technical

Data and Computer Software clause at DFARS 252.227-7013 for DOD

agencies, and subparagraphs (c)(1) and (c)(2) of the Commercial Computer

Software Restricted Rights clause at FAR 52.227-19 for other agencies.

Agilent Technologies

Santa Rosa Systems Division

1400 Fountaingrove Parkway

Santa Rosa, CA 95403-1799, U.S.A.

© Copyright 1998, 2001 Agilent Technologies, Inc

ii E7345A/E7355A - Installation Manual

Page 3

Read Me First!

Using this document and an E7345A or E7355A upgrade package, an

Agilent service engineer can upgrade an 85107B network analyzer to full

8510XF capability, in either 85 GHz or 110 GHz.

Agilent Technologies does not recommend customer installation of the

upgrade packages.

Scheduling Installation The E7345A or E7355A performance upgrade packages come with prepaid

installation. Please call your local Agilent office to arrange for a service

engineer to install the upgrade kit (see “Contacting Agilent” on pagevi).

E7345A/E7355A - Installation Manualiii

Page 4

Warranty

Certification

Agilent Technologies certifies that this product met its published

specifications at the time of shipment from the factory. Agilent Technologies

further certifies that its calibration measurements are traceable to the United

States National Institute of Standards and Technology (NIST, formerly

NBS), to the extent allowed by the Institute’s calibration facility, and to the

calibration facilities of other International Standards Organization members.

Warranty This Agilent Technologies system product is warranted against defects in

materials and workmanship for a period corresponding to the individual

warranty periods of it s component products. Inst r uments are warranted f or a

period of one year. During the warranty period, Agilent Technologies will,

at its option, either repair or replace products that prove to be defective.

Warranty service for products installed by and certain other products

designated by Agilent will be performed at Buyer’s facility at no charge

within service travel areas. Outside Agilent service travel areas, warranty

service will be performed at Buyer’s facility only upon Agilent

Technologies’s prior agreement and Buyer shall pay Agilent’s round trip

travel expenses. In all other areas, products must be returned to a service

facility designated by Agilent Technologies.

For products returned to Agilent for warranty serv ice, Buyer s hall prepay

shipping char ges to Agilent and Agilen t sh al l pay shipping char ge s t o return

the product to Buyer. However, Buyer shall pay all shipping charges, dutie s,

and taxes for products returned to Agilent from another country.

Agilent war rants that its software and firmware desig nated by Agilen t for

use with an instrument will execute its programming instructions when

properly installed on that instrument. Agilent does not warrant that the

operation of the instrument , or software , or fir mware will be uni nterrupted or

error free.

LIMITATION OF WARRANTY. The foregoing warranty shall not apply

to defects resulting from improper or inadequate maintenance by Buyer,

Buyer-supplied software or interfacing, unauthorized modification or

misuse, operation outside of the environmental specifications for the

product, or improper site preparation or maintenance.

NO OTHER WARRANTY IS EXPRESSED OR IMPLIED. AGILENT

TECHNOLOGIES SPECIFICALLY DISCLAIMS THE IMPLIED

WARRANTIES OR MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE.

iv E7345A/E7355A - Installation Manual

Page 5

EXCLUSIVE REMEDIES. THE REMEDIES PROVIDED HEREIN ARE

BUYER’S SOLE AND EXCLUSIVE REMEDIES. AGILENT

TECHNOLOGIES SHALL NOT BE LIABLE FOR ANY DIRECT,

INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES, WHETHER BASED ON CONTRACT, TORT, OR ANY

OTHER LEGAL THEORY.

Assistance Product maintenance agreements and other customer assistance agreements

are available for Agilent Technologies products.

For assistance, call your local Agilent Technologies office (refer to

“Contacting Agilent” on pagevi).

E7345A/E7355A - Installation Manualv

Page 6

Contacting Agilent

Online assistance: www.agilent.com/find/assist

United States

(tel) 1 800 452 4844

New Zealand

(tel) 0 800 738 378

(fax) (+64) 4 495 8950

Malaysia

(tel) 1 800 828 848

(fax) 1 800 801 664

Taiwan

(tel) 0800-047-866

(fax) (886) 2 25456723

Latin America

(tel) (305) 269 7500

(fax) (305) 269 7599

Japan

(tel) (+81) 426 56 7832

(fax) (+81) 426 56 7840

Philippines

(tel) (632) 8426802

PLDT subscriber only):

(tel) (

1 800 16510170

(fax) (632) 8426809

(fax) (PLDT subscriber only):

1 800 16510288

People’s Republic of

China

(tel) (preferred):

800-810-0189

(tel) (alternate):

10800-650-0021

(fax) 10800-650-0121

Canada

(tel) 1 877 894 4414

(fax) (905) 282-6495

Australia

(tel) 1 800 629 485

(fax) (+61) 3 9210 5947

Thailand

(tel) outside Bangkok:

(088) 226 008

(tel) within Bangkok:

(662) 661 3999

(fax) (66) 1 661 3714

India

(tel) 1-600-11-2929

(fax) 000-800-650-1101

Europe

(tel) (+31) 20 547 2323

(fax) (+31) 20 547 2390

Singapore

(tel) 1 800 375 8100

(fax) (65) 836 0252

Hong Kong

(tel) 800 930 871

(fax) (852) 2506 9233

vi E7345A/E7355A - Installation Manual

Page 7

Safety and Regulatory Information

Review this product and related documentation to familiarize yourself with

safety markings and instructions before you operate the instrument. This

product has been designed and tested in accordance with international

standards.

WARNING The WARNING notice denotes a hazard. It calls attention to a

procedure, practice, or the like, that, if not correctly performed

or adhered to, could result in personal injury. Do not proceed

beyond a WARNING notice until the indicated conditions are

fully understood and met.

CAUTION The CAUTION notice denotes a hazard. It calls attention to an operating

procedure, practic e, o r the like, which, i f not correctly performed or adhered

to, could result in damage to the product or loss of important data. Do not

proceed beyond a CAUTION notice until the indicated conditions are fully

understood and met.

Instrument Markings

When you s ee th is s ym bol o n your instrument, you should refer to the

!

instrument’s instruction manual for important informa tion.

This symbol indicates hazardous voltages.

The laser radiation symbol is marked on products that have a laser

output.

This symbol indicates that the instrument requires alternating current

(ac) input.

The C-Tick mark is a registered trademark of the Australian Spectrum Agency.

The CE mark is a registered trademark of the European Community.

If it is accompanied by a year, it indicates the year the design was

proven.

The CSA mark is a registered trademark of the Canadian Standards

Association.

E7345A/E7355A - Installation Manual vii

Page 8

1SM1-A This text indicates that the instrument is an Industrial Scientific and

Medical Group 1 Class A product (CISPER 11, Clause 4).

This symbol indicates that the power line switch is ON.

This symbol indicates that the power line switch is OFF or in

STANDBY position.

Safety Earth

Ground

Before Applying

Power

This is a Safety Class I product (provided with a protective earthing

terminal). An uninterrupt i ble saf ety eart h gr ound must be pr ovided from the

main power source to the product input wiring terminals, power cord, or

supplied power cord set. Whenever it is likely that the protection has been

impaired, the product must be made inoperative and secured against any

unintended operation.

Verify that the product is configured to match the available main power

source as described in the input power configuration instructions in this

manual. If this product is to be powered by autotransformer, make sure the

common terminal i s connect ed to t he neut ral (gr ounded) s ide of t he ac po wer

supply .

viii E7345A/E7355A - Installation Manual

Page 9

Typeface Conventions

Italics

• Used to emphasize important information:

only

Use this software

with the xxxxxX system.

• Used for the title of a publication:

Refer to the

xxxxxX System-Level User’s Guide

.

• Used to indicate a variable:

LOAD BIN

Type

Instrument Display • Used to show on-screen prompts and messages that you will see on the

display of an instrument:

The xxxxxX will display the message

[Keycap] • Used for labeled keys on the front panel of an instrument or on a

computer keyboard:

[Return].

Press

{Softkey} • Used for simulate d keys that appear on an instrum ent display:

{Prior Menu}.

Press

User Entry • Used to indicate text that you will enter using the computer keyboard;

text shown in this typeface must be typed

LOAD PARMFILE

Type

filename

.

CAL1 SAVED.

exactly

as printed:

• Used for examples of programming code:

#endif // ifndef NO_CLASS

Path Name

Computer Display • Used to show messages, prompts, and window labels that appear on a

• Used for a subdirectory name or file path:

Edit the file

computer monitor:

Edit Parameters window will appear on the screen.

The

usr/local/bin/sample.txt

• Used for menus, lists, di alog boxes, and button boxes on a computer

monitor from which you make selections using the mouse or keyboard:

Double-click

EXIT to quit the program.

E7345A/E7355A - Installation Manual ix

Page 10

Introduction

Contents: •“Scheduling Installation” on page2

•“System Configurations” on page3

•“Overview of the Upgrade Packages” on page5

•“Installation Procedure Outline” on page6

•“Step 1. Secure Static Safe Work Station” on page8

•“Step 2. Verify Upgrade Package Contents” on page9

•“Step 3. Secure Additional Installation Equipment” on page11

•“Step 4. Check the 85107B System Operation and Memory” on page12

•“Step 5. Install Non-Volatile Memory Upgrade (if needed)” on page14

•“Step 6. Disconnect Unneeded Equipment” on page17

•“Step 7. Install the Millimeter Wave Controller” on page18

•“Step 8. Install the 83621B RF Source” on page19

•“Step 10. Reconnect the System” on page21

•“Step 11. Load 8510XF Operating System (Firmware)” on page23

•“Step 12. Perform the 8510XF Performance Verification” on page24

NOTE The 8510C works with all 8360 synthesized sweeper models. To take

advantage of two 8510C system features (quick step and test port power

flatness correction), however, some 8360 instruments must be upgraded.

NOTE This chapter covers both the CRT and LCD displays. Some display-related

adjustments apply only to instruments with a CRT display.

E7345A/E7355A - Installation Manual1

Page 11

Scheduling Installation

The E7345A and E7355A performance upgra de packages come wi th prepaid

installation. Please call your local Agilent Technol ogies office t o arrange for

a service engineer to install the upgrade kit (r efer to “Contacting Agile nt” on

pagevi).

NOTE Agilent Technologies does not recommend customer installation of these

upgrade packages. Customer installation of these upgrade packages will

void the warranty.

2E7345A/E7355A - Installation Manual

Page 12

System Configurations

The system may be configured either for coaxial measurement or on-wafer

measurement.

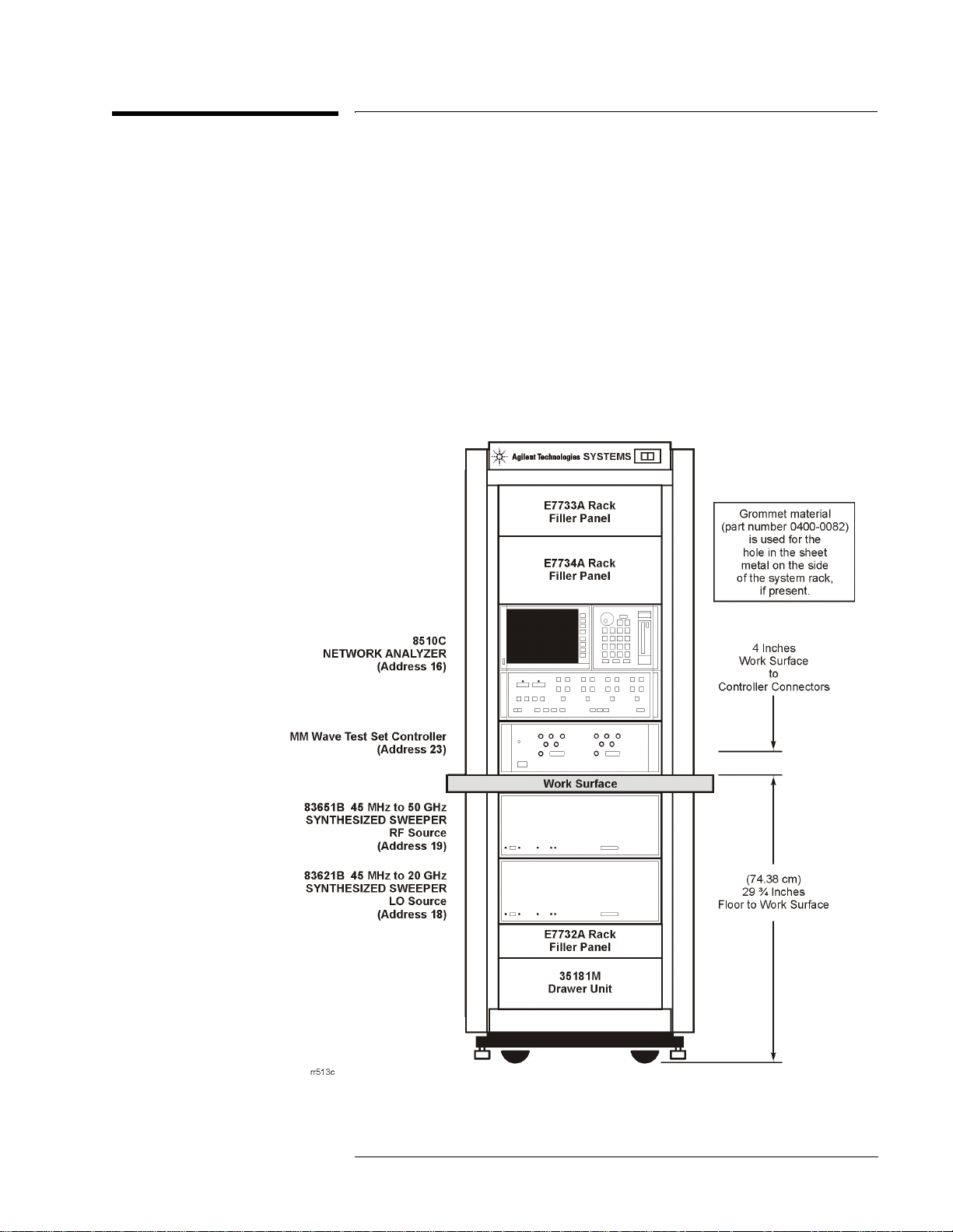

Coaxial Configuration When the 8510XF is configured for measurement through coaxial

connections, the network analyzer, millimeter wave controller, and RF and

LO sources are all installed in the system rack as show n in Figure 1. The t est

heads are placed on a work surface which is mounted below the millimeter

wave controller.

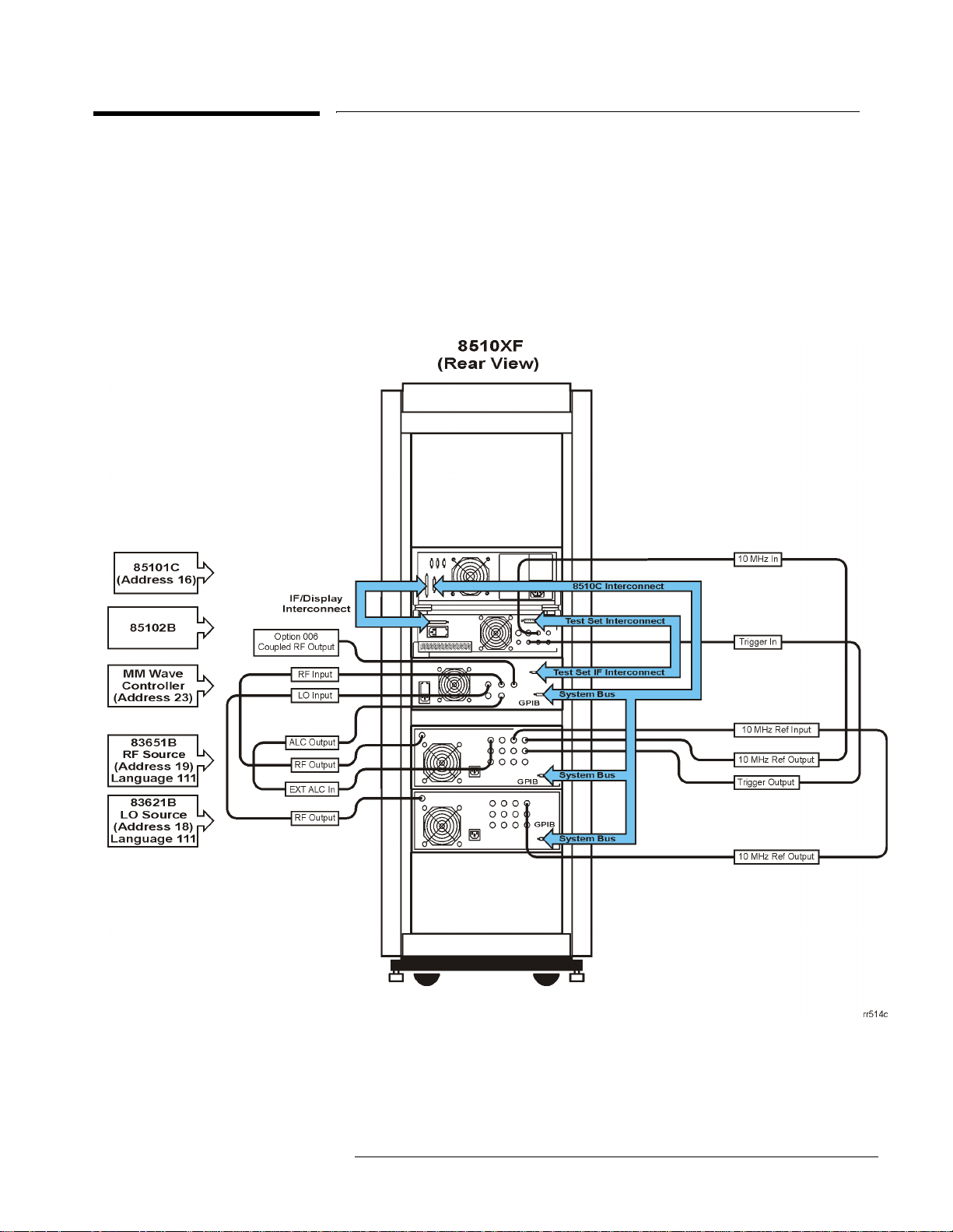

Figure 1 Network analyzer mounted in system rack

E7345A/E7355A - Installation Manual3

Page 13

Wafer Probe

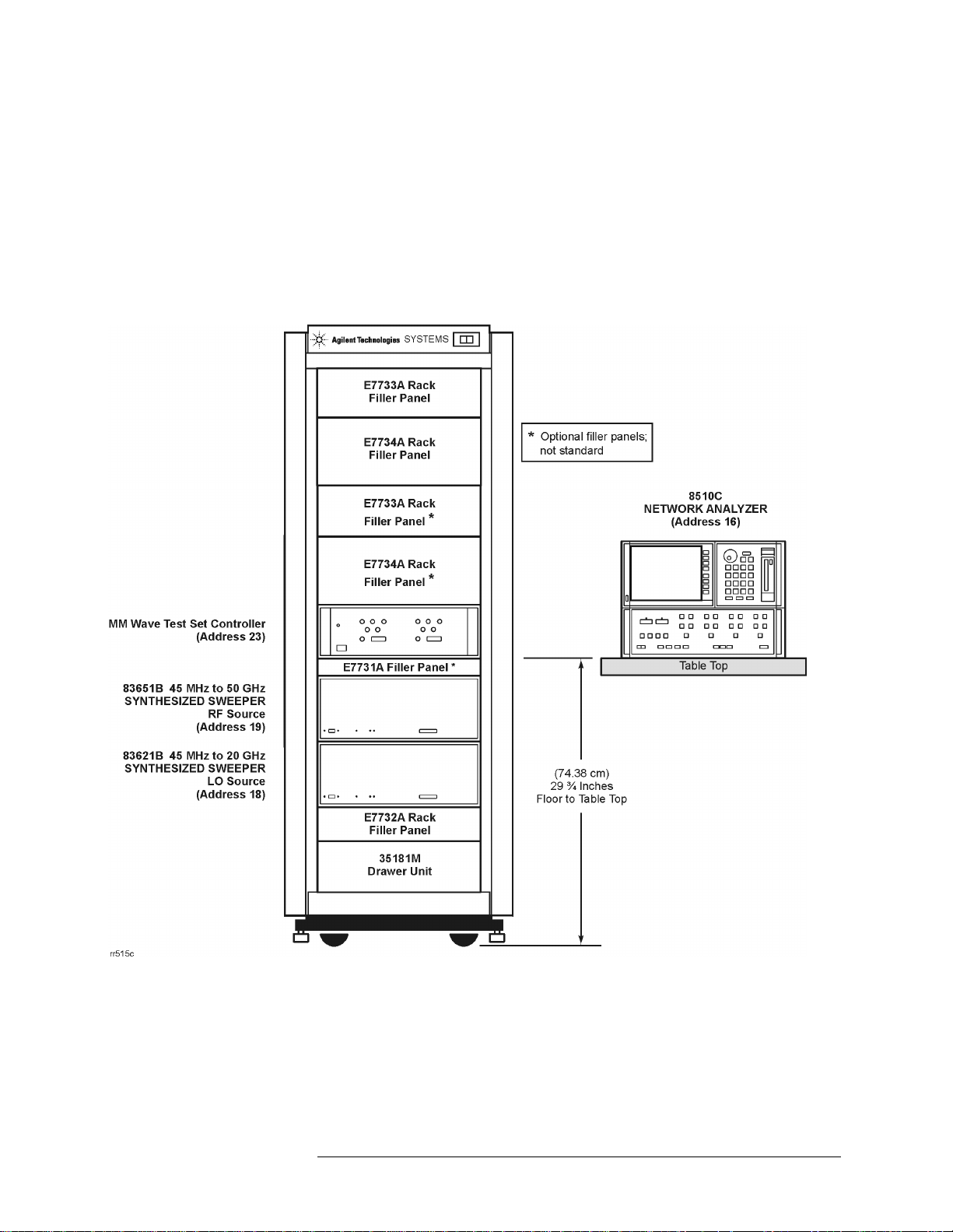

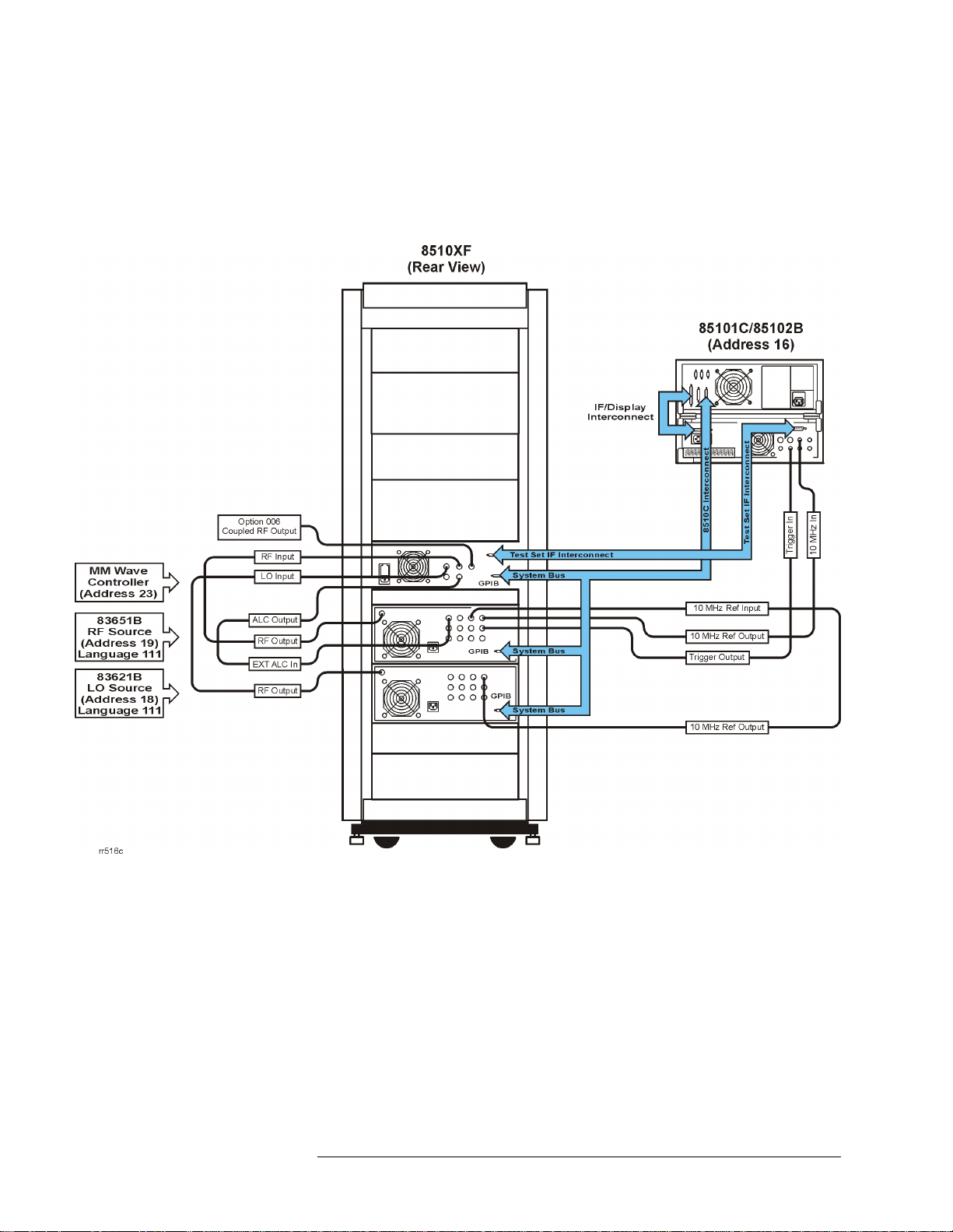

Configuration

When the 8510XF is configured for measurement through on-wafer probe

connections, the millimeter wave controller, and the RF and LO sources are

installed in the rack. However, the network analyzer and the wafer probe

station are placed side-by-side on a work surface in front of the test system,

as shown in Figure 2.

Figure 2 Network analyzer located on work surface

4E7345A/E7355A - Installation Manual

Page 14

Overview of the Upgrade Packages

The E7345A or E7355A upgrade packages will upgrade an

existing 85107B network analyzer system to the 8510XF system with

85 GHz or 110 GHz capability, respectively.

8510XF (85 GHz) Use the E7345A package to upgrade an 85107B to an 8510XF with 85 GHz

capability. With this packag e, you will do the following:

• Check the operation of 85107B.

• Check the memory in 8510C vector network analyzer.

• Upgrade the memory in the 8510C vector network analyzer.

• Disconnect unwanted elements from the existing system.

• Install an E7341A millimeter wave controller.

• Install an 83621B RF source.

• Install millimeter wave test set.

• Reconnect the system.

• Load the 8510XF operating system.

• Use the 8510C performance verification software to verify performance

of 8510XF in coax.

8510XF (110 GHz) Use the E7355A package to upgrade an 85107B to an 8510XF with

110 GHz capability. With this package, you will do th e following:

• Check the operation of 85107B.

• Check the memory in 8510C vector network analyzer.

• Upgrade the memory in the 8510C vector network analyzer.

• Disconnect unwanted elements from the existing system.

• Install an E7341A millimeter wave controller.

• Install an 83621B RF source.

• Install millimeter wave test set.

• Reconnect the system.

• Load the 8510XF operating system.

• Use the 8510C performance verification software to verify performance

of 8510XF in coax.

E7345A/E7355A - Installation Manual 5

Page 15

Installation Procedure Outline

Follow this outline to install either the E7345A or E7355A performance

upgrade. Detailed procedures are provided in the subsequent sections.

Step 1 Secure a Static Safe Work Station

Check for the following:

• the static mat sits on a clean, flat, sturdy surface.

• the static mat has a connection to an earth ground.

• the static mat has a wrist strap connected to it.

Step 2 Verify the Upgrade Package Contents

Using the packing list for your upgrade kit, check the completeness of

the package. If the kit does not have all the items listed, contact your

local Agilent Technologies office (see table inside the front of this

manual).

Step 3 Secure Items Not Included in Upgrade Package

Using the table p rovi ded in th is se ction, ob tain the items require d b ut not

supplied in the package.

Step 4 Check the 85107B System O peration and Memory

Using the instructions in this section, check that the system you plan to

upgrade functions.

Step 5 Install Non-Volatile Memory Upgrade (if needed)

Using the in structions in this section, install additional memory in the

8510C.

Step 6 Disconnect Unneeded Equipment

Using the instructions in this section, disconnect the equipment not

needed for the upgraded system and remove them from the system rack.

Step 7 Install the Millimeter Wave Controller

Using the instructions in this section, install the E7341A

millimeter wave controller.

6 E7345A/E7355A - Installation Manual

Page 16

Step 8 Install the 83621B RF Source

Using the instructions in this section, install the 83621B RF source.

Step 9 Reconnect the System

Using the instructions in this section, reconnect the system.

Step 10 Install the Millimeter Wave Test Set

Using the instructions in this section, install the millimeter wave test set.

Step 11 Load the 8510XF Operating System (Firmware)

Using the instruc ti ons i n this section, l oad the 8510XF operating system.

Step 12 Performance Check the Upgraded 8510XF System

Using the instructions in this section, performance check the upgraded

85107B system.

E7345A/E7355A - Installation Manual 7

Page 17

Step 1. Secure Static Safe Work Station

Static electricity builds up on the body and on tools, including calibration

components and devices under test. When static electricity is accidentally

discharged, sensitive circuit elements can be damaged.

CAUTION It is important that appropriate measures are taken to adequately discharge

static electricity which may otherwise damage test equipment circuitry.

Circuit elements wit hin a de vic e can be damaged fr om static e lectric ity, such

as through acciden tal contact with the center conductor of a connector. Even

a discharge that is too small to be felt can cause circuit damage.

Protection against electrostatic discharge (ESD) is essential while

connecting, cleaning, or inspecting connectors attached to static-sensitive

circuits, such as those found in test sets. Protective measures appropriate to

the 8510 series systems are described below.

• Always use a grounded anti-static mat in front of your test equipment,

and wear a grounded wrist strap attached to it.

• Ground yourself before you clean, inspect, or make a connection to a

static-sensitive device or test port. You can, for example, grasp the

grounded outer shell of the tes t port briefl y to disc harge static from your

body .

• Discharge static electricity from a device before connecting it, such as

by touching the device briefly through a resistor of at least 1 M

either the outer shell of the test port or to another exposed ground.

ESD Accessories The following accessories for preventing electrostatic discharge can be

ordered from Agilent Technologies:

Item Part Number

Grounding wrist strap 9300-1367

Grounding cord for wrist strap (5 ft) 9300-0980

Conductive table mat (2 x 4 ft)

with ground wire (15 ft)

ESD heel strap (for conductive floors) 9300-1126

9300-0797

Ω to

8 E7345A/E7355A - Installation Manual

Page 18

Step 2. Verify Upgrade Package Contents

Following are the content s of the E7345A and E7355A performanc e upgrade

packages. Compare this list against the packing list and against the actual

package contents. If the kit does not have all of the item s list ed, contact your

nearest Agilent Technologies office (refer to “Contacting Agilent” on

pagevi).

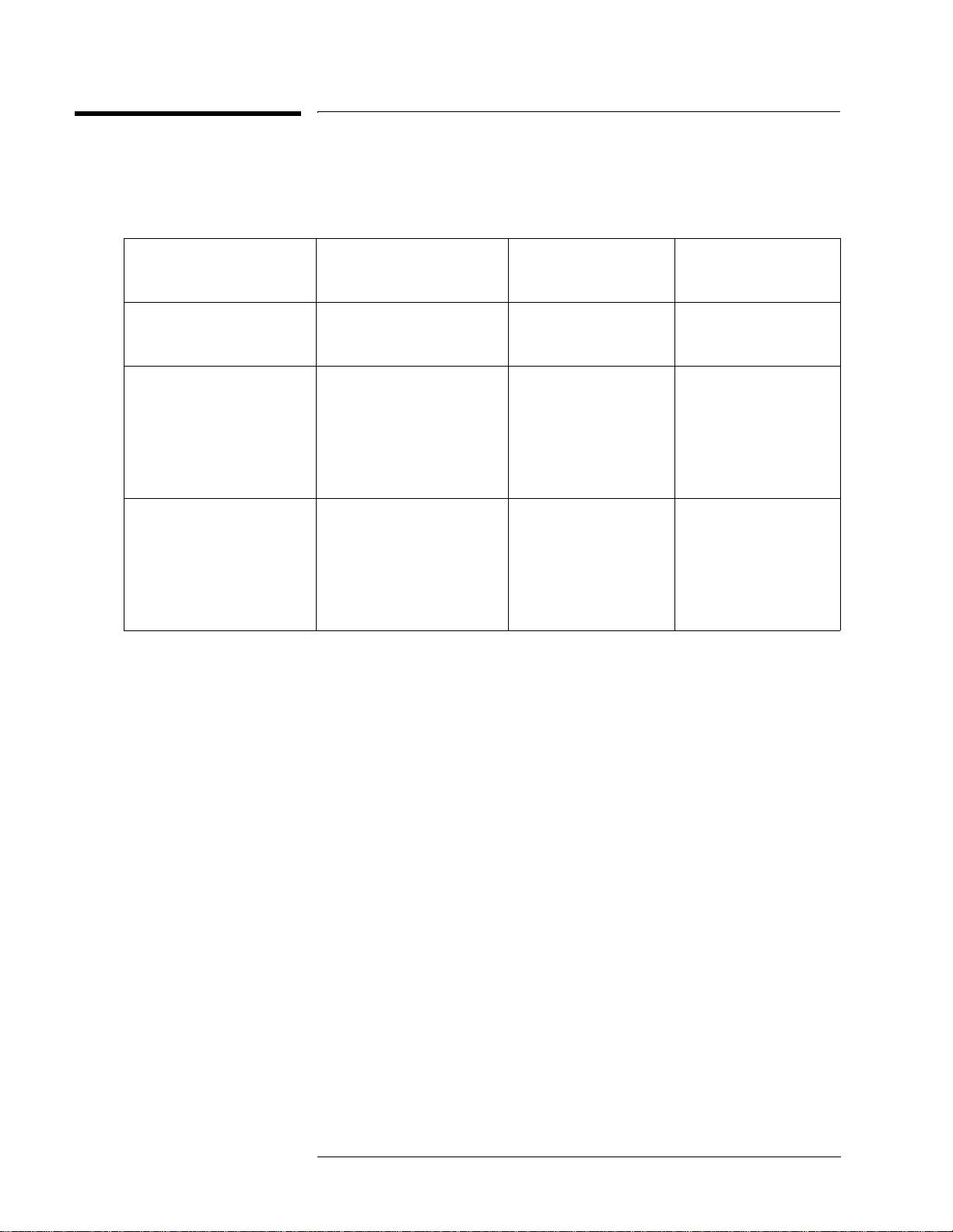

Table 1 Performance Upgrade Package Contents

Item Part Number

Software Data Disk 08510-10033 1 1

Cable, IF Interconnect 08510-60107 1 1

Cable, IF Interconnect 08510-60126 2 2

IC EEPROM, 32K X 8 (Memory Chips) 1818-7167 8 8

Adapter, 3.5mm (f-f) 5061-5311 1 1

Power Cable, 03C 03f-03m 8120-1348 2 2

Power Cable, 03C 03F-03M 8120-1405 1 1

Cable Assembly, BNC 8120-1838 1 1

Cable Assembly, BNC 8120-1839 1 1

Cable, GPIB 8120-3447 1 1

Cable Assembly, BNC 8120-5370 2 2

Synthesized Sweeper 83621B 1 1

Rack Flange Kit 83621B number 913 1 1

Adapter, 2.4mm (f-f) 85056-60006 1 1

E7345A

Quantity

E7355A

Quantity

8510XF Operating System E7340-10001 1 1

Semirigid Cable E7340-20075 1 1

Semirigid Cable E7340-20076 1 1

Cable, DC Bias E7340-60009 2 2

System Rack, 1.6 m, 120V E7340-60097 1 1

Service Quick Reference Guide E7340-90013 1 1

Millimeter Controller E7341A 1 1

Head Assembly, Left E7342L 1 0

Head Assembly, Right E7342R 1 0

LO Cable, 3.5mm-3.5mm E7342-60004 2 2

E7345A/E7355A - Installation Manual9

Page 19

Table 1 Performance Upgrade Package Contents (Continued)

Item Part Number

RF Cable, 2.4mm E7342-60005 4 4

Head Assembly, Left E7352L 0 1

Head Assembly, Right E7352R 0 1

System Manual E7350-90001 1 1

Upgrade Installation Manual E7350-90003 1 1

E7345A

Quantity

E7355A

Quantity

NOTE The table top is not included with the E7345A or the E7355A upgrade kit s. It

may be ordered from Agilent Technologies using part number 85106-60038

(refer to “Contacting Agilent” on pagevi).

10E7345A/E7355A - Installation Manual

Page 20

Step 3. Secure Additional Installation Equipment

Equipment Required But

Not Supplied

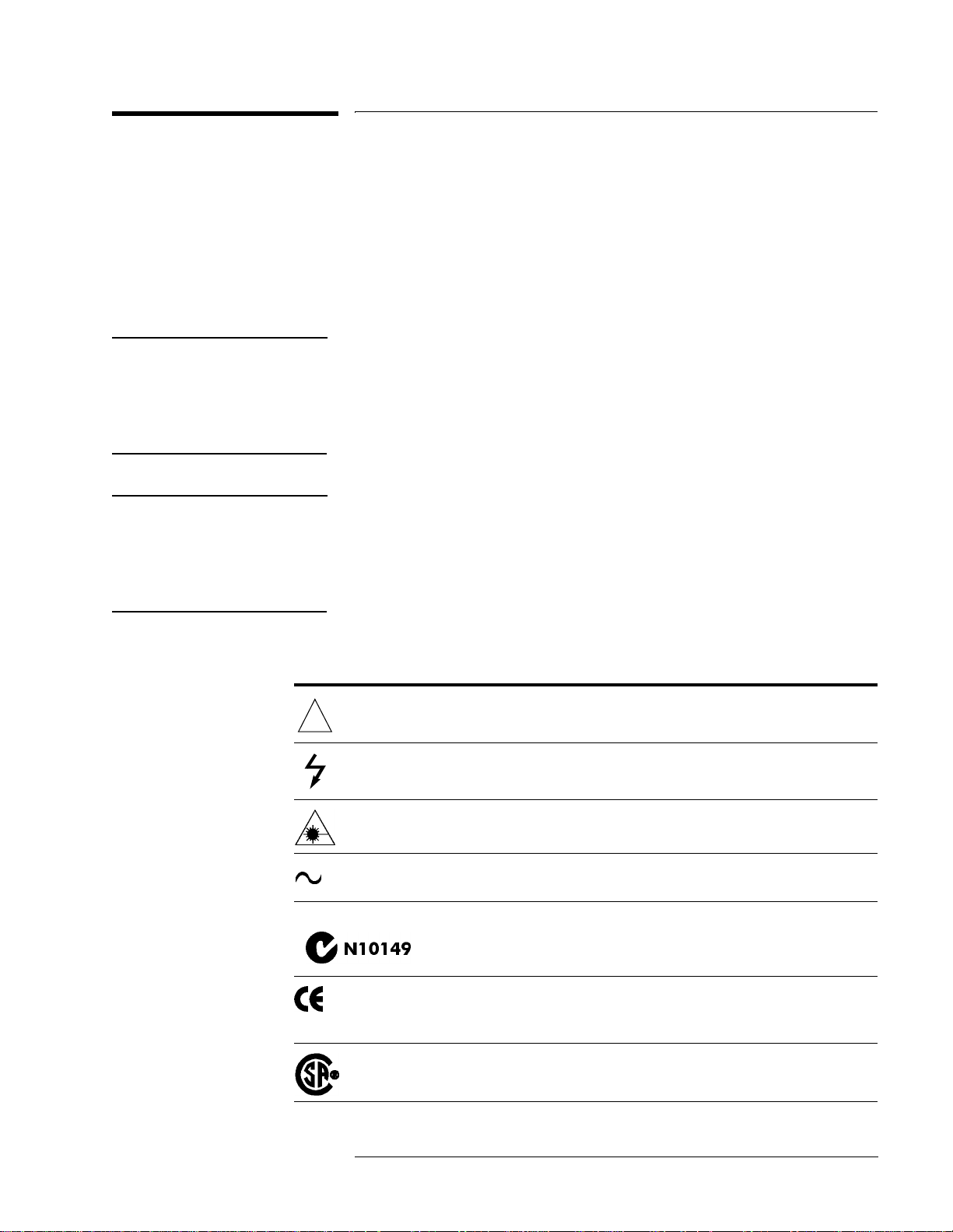

Table 2 Equipment Required But Not Supplied

The following additional equipment will aid in the installation of the

upgrade package, but are not included in the upgrade kit.

Make sure that these items are available and at hand before proceeding with

the upgrade.

Item Part Number

Network Analyzer 8510C

Source 83650B or 83651B

Test Set (optional) 8517B

Calibration/Verification kit 85059A

GPIB cables 10833A

BNC to BNC cable 10503A

Small Pozi-drive (#1) 8710-0899

Medium Pozi-drive (#2) 8710-0900

Flat blade screwdriver not supplied

Static control table mat 9300-0797

Wrist strap 9300-1367

Wrist-strap-to-mat cord (5 ft) 9300-0980

PC with BASIC for Windows (Rev. 6.3 or

higher)

not supplied

E7345A/E7355A - Installation Manual 11

Page 21

Step 4. Check the 85107B System Operation and

Memory

The followi ng info rmatio n appli es to both t he E7345A and E7355A upgr ade

kits. Use this procedure to ensure that the existing 85107B system works

properly before installing the upgrade package.

Procedure 1. Turn on the instruments in the following order:

a. the 83651B source (be sure to turn the switch to power on, not

standby)

b. the 8517B test set

c. the 8510C network analyzer

2. On the 85102, press the green preset key.

3. Does the system pass self-test (85101 self tests, 85102 running error

messages, and test set unratio of power tests) and display a

trace? If not, do not perform the upgrade until the system has been

serviced.

LOG MAG S

11

4. Initialize a blank disk, as follows:

a. load a blank diskette (with write-protect off),

b. on the 85102, press

c. on the 85101, select

5. Does the system initialize the disk and display

not, tag the 85101, indicating that it has a defective disk drive. The disk

drive must be working to load the 8510XF firmware.

NOTE Steps 6 and 7 below apply only to a CRT based display.

6. Turn the CRT to its highest intensity. Does the image remain focused? If

not, return the CRT to its normal intensity and tag the 85101, indicating

that it has a defective CRT.

7. Return the CRT to its normal intensity. As long as the CRT functions

properly, continue with this procedure.

DISK,

INITIALIZE DISK: YES.

DISK INITIALIZED? If

12 E7345A/E7355A - Installation Manual

Page 22

8. If the system displays a self-test,* running error message, or unratio

power test failure, check the equipment setup. Do not perform the

upgrade until either you correct the setup problem, or you have the

system serviced.

* You may have to rely on the red LEDs rather than the display.

E7345A/E7355A - Installation Manual 13

Page 23

Step 5. Install Non-Volatile Memory Upgrade

(if needed)

The 8510XF firmware requires at least 832 Kbytes of non-volatile memory.

To determine how much

memory is installed in the

system

CAUTION Incorrect useage of the password can erase the non-volatile memory.

To increase the

non-volatile memory

1. With the 85107B system on, press [SYSTEM] {More} {Service Functions} {Test

Menu}.

2. Select

3. Select

4. Select

5. A password is required, which is “8515”.

6. Select

1. Place the 8510C on an ESD safe work surface and insure t here is no AC

2. Remove the two plastic feet on the rear upper portion of the 8510C, and

22: run service program.

1: 85101 Display/processor service program.

4: non-volatile memory board.

8. If the Number of Pages reading is equal to or greater than

30BB, there is enough memory for running the 8510XF firmware. Skip

the balance of this procedure and go to “Step 6. Disconnect Unneeded

Equipment” on page17.

power connected to the rear panel.

then remove the top cover. The PC boards are located beneath the metal

cover that runs the length of the right side of the chassis.

3. Remove the 21 screws that secure the cover and remove the cover to

access the PC boards. The board that contains the non-volatile memory

is the A6 board, and is easily identified by its orange card extractor.

4. Remove the plastic card spacers that position the A6 board.

5. Gently grab the card extractor tabs on the ends of the board, and pull

away and up to remove the board.

6. Place the board on an ESD safe work surface. There ar e 16 ba nks on the

board, and 8510XF requires at least 13 banks. There are 8 IC chips

supplied with this kit. Fill the empty slots until at least 13 banks are

filled. The ICs to be loaded in these sockets are a CMOS version of the

original replacement IC (part number 1818-4653).

14E7345A/E7355A - Installation Manual

Page 24

7. Carefully bend the leads of the IC chips so that the leads are

perpendicular to the body and insert them into the empty sockets. Be

sure to match up the notch on the top of the chips with the notch on the

sockets. Gently press them into place making su re that all le ads go into

the socket.

8. After the ICs have been installed, gently insert the A6 board back into its

connector.

Verify the memory

upgrade with chassis open

9. Plug the power cord into the 85101C, turn on the power, and allow the

instrument to complete its initialization.

10. With the 85101C box on, press

11. Select

12. Select

13. Select

22: run service program.

1: 85101 Display/processor service program.

4: non-volatile memory board.

[=marker] to enter the Test menu.

14. A password is required, which is “8515”.

CAUTION Incorrect useage of the password can erase the non-volatile memory.

15. Select

16. On the front panel of the 8510C, select

1:Initialize Memory.

Prior Menu, then Show Non-Volatile

Memory Parameters. The 8510C should be displaying the memory board

parameters. If the EEPROM in the highest memory page was read

successfully, then the # of pages should read at least

30BB. Ignore the

present position information. The number-of-pages information is only

useful for indicating whether the last bank of upgraded memory is good

or not.

Memory Write/Read Test 17. To determine if all of the added memory banks are functioning, select

Prior Menu, then

18. Press

[=Marker] [x1]. This test takes a few minutes to run. If all the memory

banks are working, the display will read that the first useable memory

bank location is

following chart to determine which EEPROM chip is at fault.

Complete Memory Board Unformatted Write/Read Test (2).

10 hex. If any other hex location is listed, refer to the

E7345A/E7355A - Installation Manual 15

Page 25

First Unuseable Memory

Location Read

0C Hex U13 or U29

0D Hex U14 or U30

0E Hex U15 or U31

0F Hex U16 or U32

Possible Fault Location

Try replacing one or the other or both of the EEPROMS listed if you do

not get 10 Hex as the first useable memory location. Continue repeating

the above test until the bad EEPROM(s) are identified.

19. When the EEPROMs are found to be working properly, turn off the

8510C and remove the power cord from the rear panel.

20. Reinstall the plastic spacers on the A6 board.

21. Place the cover over the PC board cage and secure the original 21

screws.

22. Install the top cover on the 8510C and finish integrating the

8510C into the system depending on the configuration.

16 E7345A/E7355A - Installation Manual

Page 26

Step 6. Disconnect Unneeded Equipment

If upgrading to an 8510XF with Option 006, the 8517B test set must have

Option 001, multi-test set compatibility. If 8517B does not have Option 001

installed, you will need to order and install this upgrade kit (p/n

08510-60008).

If this is the case, the 8517B will need to b e relocated to facilitate the

millimeter wave controller. The 8517B should be removed from the rack and

placed on the work surface or another rack. The 8517B should be placed as

close to the millimeter wave controller as possible.

If the 8510XF does not include Option 006, the n remov e the 8517 B from the

test system prior to installing the upgrade.

E7345A/E7355A - Installation Manual 17

Page 27

Step 7. Install the Millimeter Wave Controller

Install the 7341A millimeter wave controller into the system rack as shown

in Figure1 on page3 (in-rack configuration) or Figure2 on page4

(table-top configuration).

18E7345A/E7355A - Installation Manual

Page 28

Step 8. Install the 83621B RF Source

Install the second source into the system rack as shown in Figure 1 (in-rack

configuration) or Figure 2 (table-top configuration).

E7345A/E7355A - Installation Manual19

Page 29

Step 9. Install the Millimeter Wave Test Set

Using the following procedure, install the millimeter wave test set:

1. Place the test heads on the table top or work surface in front of the

millimeter wave controller.

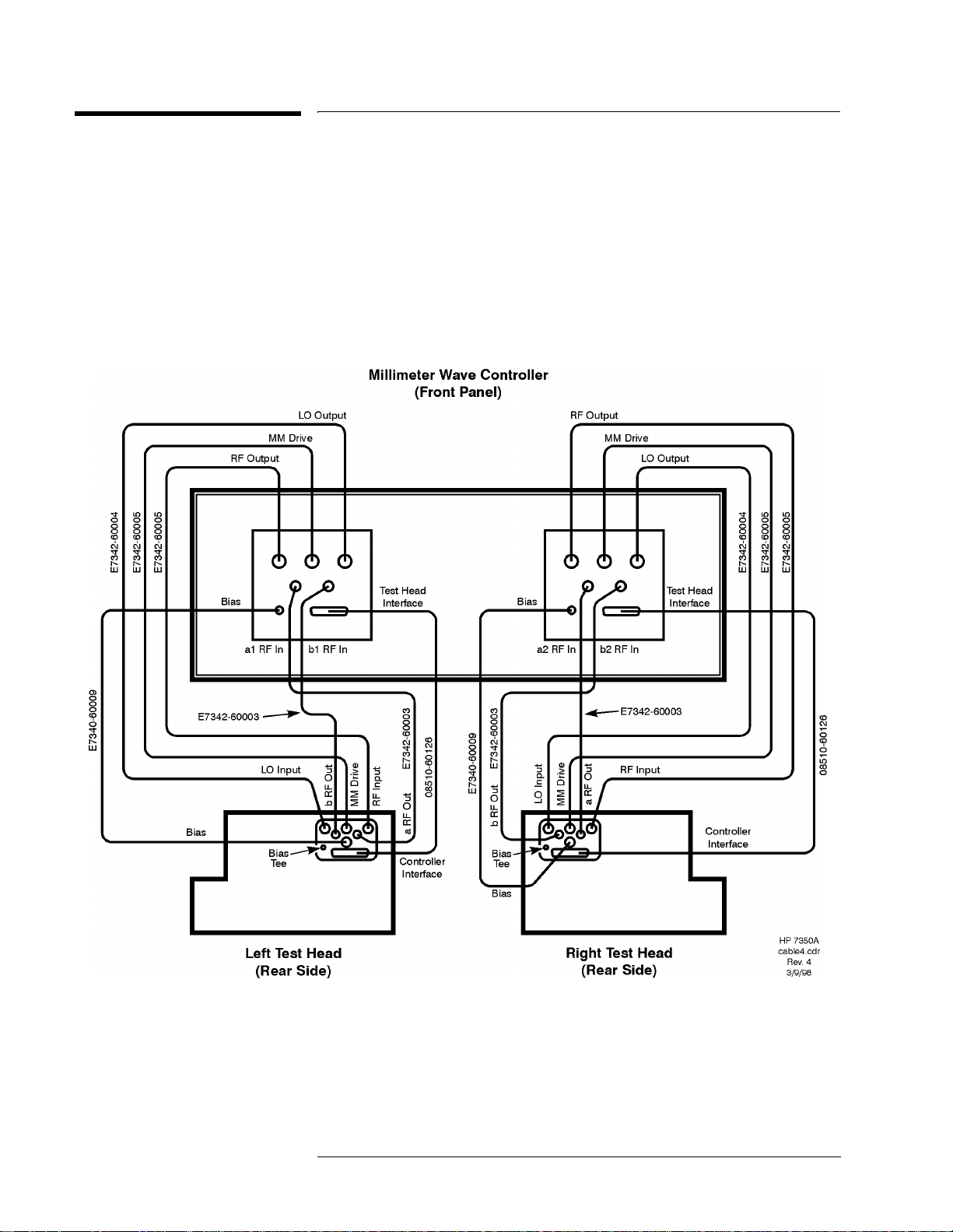

2. Connect the cables as shown in Figure 3. Installat ion of these cables may

require a long, 5/16-inch open-ended wrench.

Figure 3 Controller to Test Heads Cabling

20E7345A/E7355A - Installation Manual

Page 30

Step 10. Reconnect the System

Reconnect the test system according to the desired configuration. Figure 4 shows the

system wiring for the coaxial configuration. Figure5 on page22 shows the system

wiring for the on-wafer configuration.

Figure 4 Coaxial configuration system cabling diagram

E7345A/E7355A - Installation Manual21

Page 31

Figure 5 On-wafer configuration system cabling diagram

22 E7345A/E7355A - Installation Manual

Page 32

Step 11. Load 8510XF Operating System (Firmware)

Step 11. Load 8510XF Operating System

(Firmware)

Perform the following procedure to load the 8510XF software.

1. Insert the operating system disk into the 85101 disk drive.

Introduction

2. On the 8510C, press

3. Select

{Test Menu}, and then 19. It takes about 3 minutes to load the

software and reinitialize the system.

[SYSTEM] {More}, and then select {Service Function}.

E7345A/E7355A - Installation Manual 23

Page 33

Introduction

Step 12. Perform the 8510XF Performance Verification

Step 12. Perform the 8510XF Performance

Verification

Refer to the 8510XF System Manual for the procedures to perform a

Performance Verification on the upgraded system.

24 E7345A/E7355A - Installation Manual

Loading...

Loading...