Errata

71612Series of Gb/s Testers

Operating and Programming Manual

71612-90015

March 1, 2001

Title & Document Type:

Manual Part Number:

Revision Date:

HP References in this Manual

This manual may contain references to HP or Hewlett-Packard. Please note that HewlettPackard's former test and measurement, semiconductor products and chemical analysis

businesses are now part of Agilent Technologies. We have made no changes to this

manual copy. The HP XXXX referred to in this document is now the Agilent XXXX.

For example, model number HP8648A is now model number Agilent 8648A.

About this Manual

We’ve added this manual to the Agilent website in an effort to help you support your

product. This manual provides the best information we could find. It may be incomplete

or contain dated information, and the scan quality may not be idea l. If we find a better

copy in the future, we will add it to the Agilent website.

Support for Your Product

Agilent no longer sells or supports this product. You will find any other available

product information on the Agilent Test & Measurement website:

www.tm.agilent.com

Search for the model number of this product, and the resulting product page will guide

you to any available information. Our service centers may be able to perform calibration

if no repair parts are needed, but no other support from Agilent is available.

HP 71612 Series of Gb/s Testers

Operating and Programming Manual

SERIAL NUMBERS

This manual applies directly to HP 71612 12 Gb/s Error Performance Analyzers

comprising the following elements:

HP 70843

HP 70843

HP 70843

For additional important information about serial numbers, see SERIAL NUMBER

INFORMATION on page 1-9 in the Operating Manual.

Serial number information for other elements in the system is contained in the following

manuals:

Display

Mainframe

Clock Source

Option UHF 0.1-12 Gb/s Error Performance Analyzer with serial

number(s) prefixed 3xxxU or GBxxxxxxxx.

Option UHG 0.1-12 Gb/s Pattern Generator with serial number(s)

prefixed 3xxxU or GBxxxxxxxx.

Option UHH Error Detector with serial number(s) prefixed 3xxxU or

GBxxxxxxxx.

see HP 70004A Installation and Verification Manual.

see HP 70001A Installation and Verification Manual.

see HP 70340A Operating and Calibration Manual.

© Copyright (2000, 2001) Hewlett-Packard Ltd.

HP Part No. 71612-90015

Printed in U.K. March 2001

Declaration of Conformity

according to ISO/IEC Guide 22 and EN45014

Manufacturer’s Name: Hewlett-Packard Ltd.

Manufacturer’s Address:

Declares that the product

Product Name

:

Model Number:

Product Options:

Conforms with the protection requirements of European Council Directive 89/336/EEC on the approximation

of the laws of the member states relating to electromagnetic compatibility, against EMC test specifications

EN 55011:1991 (Group 1, Class A) and EN 50082-1:1992.

As Detailed in:

Assessed by:

Technical Report Number:6893/2200/CBR, dated 21 August 1997

Telecomms Networks Test Division

South Queensferry

West Lothian, EH30 9TG

Scotland, United Kingdom

12Gb/s Error Performance Analyzer System

HP 71612B

This declaration covers all options of the above product as detailed in

TCF A-5951-9852-01

Electromagnetic Compatibility (EMC)

Technical Construction File (TCF) No. A-5951-9852-01

DTI Appointed Competent Body

EMC Test Ce ntre,

GEC-Marconi Avionics Ltd.,

Maxwell Building,

Donibristle Industrial Park,

KY11 5LB

Scotland, United Kingdom

Supplementary Information:

The individual components of the product meet relevant international safety standards.

The product herewith complies with the requirements of the Low Voltage Directive 73/23/EEC, and carries the CE

marking accordingly.

South Queensferry, Scotland

Location Date W.R. Pearson / Quality Manager

Europe Contact:

Your Loc al Hewlett-Packard Sales and Ser vice Office or Hewlett-Packard GmbH, Department 2Q / Standards Europe

Herrenberger Strasse 130, D7030 Boblingen (Fax: +49-7031-143143)

15 December 1998

Declaration of Conformity

according to ISO/IEC Guide 22 and EN45014

Manufacturer’s Name: Hewlett-Packard Ltd.

Manufacturer’s Address:

Declares that the product

Product Name

:

Telecomms Networks Test Division

South Queensferry

West Lothian, EH30 9TG

Scotland, United Kingdom

12Gb/s Bit Error Rate Tester

Model Number:

Product Options:

Conforms with the protection requirements of European Council Directive 89/336/EEC on the approximation

of the laws of the member states relating to electromagnetic compatibility, against EMC test specifications

EN 55011:1991 (Group 1, Class A) and EN 50082-1:1992.

As Detailed in:

Assessed by:

Technical Report Number:6893/2200/CBR, dated 23 September 1997

HP 70843B

This declaration covers all options of the above product as detailed in

TCF A-5951-9852-01

Electromagnetic Compatibility (EMC)

Technical Construction File (TCF) No. A-5951-9852-01

DTI Appointed Competent Body

EMC Test Ce ntre,

GEC-Marconi Avionics Ltd.,

Maxwell Building,

Donibristle Industrial Park,

KY11 5LB

Scotland, United Kingdom

Supplementary Information:

The product conforms to the following safety standards:

EN 61010-1(1993)

IEC 1010-1(1990) +A1(1992) +A2(1995)

CSA-C22.2 No. 1010.1-93

EN 60825-1(1994) / IEC 825-1(1993)

The product herewith complies with the requirements of the Low Voltage Directive 73/23/EEC, and carries the CE

marking accordingly.

South Queensferry, Scotland

Location Date W.R. Pearson / Quality Manager

Europe Contact:

Your Loc al Hewlett-Packard Sales and Ser vice Office or Hewlett-Packard GmbH, Department 2Q / Standards Europe

Herrenberger Strasse 130, D7030 Boblingen (Fax: +49-7031-143143)

15 December 1998

WAR NINGS

The following general safety precautions must be observed during all phases of operation, service, and

repair of this product. Failure to comply with these precautions or with specific warnings elsewhere in this

manual violates safety standards of design, manufacture, and intended use of the product. Hewlett-Packard

Company assumes no liability for the customer's failure to comply with these requirements.

This is a safety Class 1 instrument (provided with a protective earthing ground, incorporated in the powercord). The mains plug shall only be inserted in a socket outlet provided with a protective earth contact. Any

interruption of the protective conductor inside or outside of the instrument is likely to make the instrument

dangerous. Intentional interruption is prohibited.

DO NOT operate the product in an explosive atmosphere or in the presence of flammable gasses or fumes.

For continued protection against fire hazard, replace the line fuses only with the same type and ratings (type

nA/nV). The use of other fuses or materials is prohibited (where the fuse type is blown rate).

Keep away from live circuits: Operating personnel must not remove equipment covers or shields. Proce-

dures involving the removal of covers and shields are for use by service-trained personnel only. Under certain conditions, dangerous voltages may exist even with the equipment switched off. To avoid dangerous

electrical shock, DO NOT perform procedures involving cover or shield removal unless you are qualified to

do so.

DO NOT operate damaged equipment: Whenever it is possible that the safety protection features built into

this product have been impaired, either through physical damage, excessive moisture, or any other reason,

REMOVE POWER and do not use the product until safe operation can be verified by service-trained personnel. If necessary, return the product to a Hewlett-Packard Sales and Service Office for service and repair

to ensure the safety features are maintained.

DO NOT service or adjust alone: Do not attempt internal service or adjustment unless another person, capable of rendering first aid and resuscitation, is present.

DO NOT substitute parts or modify equipment: Because of the danger of introducing additional hazards, do

not install substitute parts or perform any unauthorized modification to the product. Return the product to a

Hewlett-Packard Sales and Service Office for service and repair to ensure the safety features are maintained.

If this instrument is not used as specified, the protection provided by the equipment could be impaired. This

instrument must be used in a normal condition (in which all means of protection are intact) only.

No operator serviceable parts inside. Refer servicing to qualified personnel. To prevent electrical shock do

not remove covers.

CERTIFICATION

Hewlett-Packard Company certifies that this product met its published specifications at the time of shipment

from the factory. Hewlett-Packard further certifies that its calibration measurements are traceable to the

United States National Institute of Standards and Technology (formerly National Bureau of Standards), to

the extent allowed by that organization's calibration facility, and to the calibration facilities of other International Standards Organization members.

WARRANTY

This Hewlett-Packard product is warranted against detects in materials and workmanship for a period of one

year from date of shipment. Duration and conditions of warranty for this product may be superseded when

the product is integrated into (becomes part of) other HP products. During the warranty period, HewlettPackard Company will, at its option, either repair or replace products which prove to be defective.

For warranty service or repair, this product must he returned to a service facility designated by HewlettPackard (HP). Buyer shall prepay shipping charges to HP and HP shall pay shipping charges to return the

product to Buyer. However, Buyer shall pay all shipping charges, duties, and taxes for products returned to

HP from another country.

HP warrants that its software and firmware designated by HP for use with a product will execute its programming instructions when properly installed on that product. HP does not warrant that the operation of the

product or software, or firmware will be uninterrupted or error free.

LIMITATION OF WARRANTY

The foregoing warranty shall not apply to defects resulting from improper or inadequate maintenance by

Buyer, Buyer-supplied products or interfacing, unauthorized modification or misuse, operation outside of

the environmental specifications for the products, or improper site preparation or maintenance.

The design and implementation of any circuit on this product is the sole responsibility of the Buyer . HP does

not warrant the Buyer's circuitry or malfunctions of HP products that result from the Buyer's circuitry. In

addition, HP does not warrant any damage that occurs as a result of the Buyer's circuit or any other detects

that result from Buyer-supplied products.

NO OTHER WARRANTY IS EXPRESSED OR IMPLIED. HP SPECIFICALLY DISCLAIMS THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE

EXCLUSIVE REMEDIES

THE REMEDIES PROVIDED HEREIN ARE BUYER'S SOLE AND EXCLUSIVE REMEDIES. HP

SHALL NOT BE LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, WHETHER BASED ON CONTRACT, TORT, OR ANY OTHER LEGAL THEORY.

NOTICE

The information contained in this document is subject to change without notice. HEWLETT-PACKARD

(HP) MAKES NO WARRANTY OF ANY KIND WITH REGARD TO THIS MATERIAL, INCLUDING,

BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE. HP shall not be liable for errors contained herein or for incidental or

consequential damages in connection with the furnishing, performance or use of this material. This document contains proprietary information which is protected by copyright. All rights are reserved. No part of

this document may he photocopied, reproduced, or translated without the prior written consent of the

Hewlett-Packard Company. HP assumes no responsibility for the use or reliability of its software on equipment that is not furnished by HP.

Restricted Rights Legend

Use, duplication or disclosure is subject to restrictions as set forth in subdivision (c)(1)(ii) of the Rights in

Te chnical Data and Computer Software clause at 52.227-FAR14. Hewlett-Packard Company; 3000 Hanover

Street; Palo Alto, California 94304.

Printing History

The Printing History shown below lists all Editions and Updates of this manual and the printing date(s). The

first printing of the manual is Edition 1. The Edition number increments by 1 whenever the manual is

revised. Updates, which are issued between Editions, contain replacement pages to correct the current Edition of the manual. Updates are numbered sequentially starting with Update 1. When a new Edition is created, it contains all the Update information for the previous Edition. Each new Edition or Update also

includes a revised copy of this printing history page. Many product updates or revisions do not require manual changes and, conversely, manual corrections may be done without accompanying product changes.

Therefore, do not expect a one-to-one correspondence between product updates and manual updates.

Edition or

Upd ate Date Pa r t Number

Edition 1 Feb 1994 71612-90000 New Edition Mar 2000 71612-90011

Edition 2 Jul 1995 71612.90000 New Edition Mar 2001 71612-90015

New Edition Jun 1998 71612-90007

New Edition Dec 1998 71612-90008

Edition or

Upda te Date Pa rt Number

HP 71612 Series of Gb/s Testers

Operating Manual

Contents - Operating Manual

1 General Information

Introduction 1-2

Safety Considerations 1-2

Safety Information 1-2

General 1-3

Safety Symbols 1-4

Options 1-6

Introduction 1-6

Upgrade Options 1-8

Accessories Supplied 1-8

Recommended Accessory List 1-8

Serial Number Information 1-9

Returning Instruments for Service 1-9

Packaging Requirements 1-9

Preparing an Instrument for Shipping 1-10

Precautions 1-11

ESD Precautions 1-11

Static-safe Workstation 1-11

Static-safe Accessories 1-12

Lifting/Carrying the HP 70843 1-12

Using one arm to lift instrument 1-12

Display Cleaning 1-13

Cabinet Cleaning 1-13

How to Update the HP 70843 Firmware 1-13

To Update Control Processor Firmware 1-13

To Update Measurement Processor Firmware 1-14

2 Installation

Introduction 2-2

Preparation for Use 2-3

Initial Inspection 2-3

To Fit an Instrument Hardkey Panel 2-3

Statement of Compliance 2-4

Instruction for cleaning 2-4

Operating Requirements 2-4

Operating and Storage Environment 2-4

Physical Specifications 2-4

Cooling Considerations 2-5

Lifting the HP 70843 2-5

Power Requirements 2-5

Noise Declaration 2-6

Power Cables 2-6

Contents-1

Contents - Operating Manual

Line Voltage Selection 2-7

Instrument (HP 70843) Line Voltage Selector 2-7

Display (HP 70004A) Line Voltage Selector 2-7

Mainframe (HP 70001A) Line Voltage Selector (HP 71612 options UHF/UKB

and UHG/UKB only) 2-8

Line Fuses 2-9

Accessing the HP 70843 Line Fuse 2-9

Accessing the Display (HP 70004A) and Mainframe (HP 70001A) Fuses 2-9

Fuse Ratings 2-9

HP-MSIB Address Switches 2-10

Factory Preset HP-MSIB Addresses 2-10

HP 70843 Address Switches 2-10

HP 70340A Clock Source Module Address Switches 2-11

HP 70341A Clock Source Module Address Switches 2-11

HP 70004A Display Address Switches 2-12

HP-IB Address Switches 2-12

To Change the HP-IB Address 2-12

Factory Preset HP-IB Addresses 2-12

Bench Operation 2-13

Rack Mount Installation 2-13

System Installation 2-14

Accessories 2-14

Cables 2-14

Connectors 2-14

Terminations 2-14

Procedure 2-15

System Verification 2-17

Error Performance Analyzer System Verification 2-17

Selftest at Power-on 2-18

Installing/Removing Modules 2-19

Installing an HP 70340A Clock Source Module into a Display 2-19

Installing an HP 70341A Clock Source Module into a Mainframe 2-20

3 System Overview

Configurations 3-2

System Options 3-2

Additional System Options 3-3

HP 70843 Instrument Options 3-3

Documentation Overview 3-3

Contents-2

Contents - Operating Manual

4 Operating Features and Specifications

Introduction 4-2

Warm-up 4-2

Operating Temperature Specification 4-2

Calibration Interval 4-2

Pattern Generator 4-3

External connections 4-3

Patterns 4-3

PRBS Test Patterns 4-3

Zero Substitution/Variable Mark Density 4-3

Test Patterns 4-3

Zero Substitution 4-4

Variable Mark Density 4-4

User-programmable test patterns 4-4

Alternate test pattern - pattern generator only 4-4

Internal Disk Drive 4-5

Clock Input 4-5

Features 4-5

Specifications 4-5

Data and Data (inverted) Outputs 4-6

Features 4-6

Data output features not controlled by data output softkeys 4-6

Specifications 4-6

Data outputs - main 4-6

Error Add 4-8

Clock and Clock (inverted) Outputs 4-8

Specifications 4-8

Clock outputs - main 4-8

Subrate Clock & Data (inverted) Outputs 4-9

Features 4-9

Specifications 4-9

Trigger Output 4-9

Features 4-9

Pattern Mode 4-10

PRBS 2^31-1, 2^23-1, 2^15-1, 2^10-1, 2^7-1 4-10

Alternate pattern 4-10

All other patterns 4-10

Divided Clock Mode 4-10

Interface 4-10

Auxiliary Input 4-10

Alternate Pattern Selected 4-11

Data Output Inhibit (Gating mode) 4-11

Contents-3

Contents - Operating Manual

Interface 4-11

To Select Oneshot Mode 4-11

To Select Alternating Mode 4-11

Error Inject Input 4-12

Interface 4-12

Status Indicators 4-12

Pattern Generator indicators 4-12

Error Detector indicators 4-12

General instrument indicators 4-12

Rear Panel Switches 4-12

Error Detector 4-13

External connections 4-13

Clock Input (error detector) 4-13

Features 4-13

Specifications 4-13

Data Input 4-14

Features 4-14

Specifications 4-14

Pattern Trigger Output (error detector) 4-14

Features 4-14

Pattern Mode 4-15

PRBS 2^31-1, 2^23-1, 2^15-1, 2^10-1, 2^7-1 4-15

All other patterns 4-15

Divided Clock Mode 4-15

Specifications 4-15

Errors Output 4-15

Features 4-15

Interface 4-15

Gating Input 4-16

Interface 4-16

Automatic Clock-to-Data Alignment 4-17

Introduction 4-17

Definition 4-17

Eye Width 4-17

Automatic 0/1 Threshold Center 4-18

To perform a 0/1 Threshold Centering 4-18

Data Input 0/1 Threshold 4-18

Introduction 4-18

Measurements 4-18

Error Analysis 4-19

Power-loss Seconds 4-19

Sync-loss Seconds 4-20

Frequency Measurement 4-20

Contents-4

Contents - Operating Manual

Result Logging 4-20

Error Location (HP 71612 or HP 70843 Option UHJ) 4-20

Bit BER 4-20

Measurements 4-20

Error location capture 4-20

Block BER 4-21

Measurement Period 4-22

Measurement Period Features 4-22

Gating modes 4-22

Gating Period Definition 4-23

Burst gating 4-23

Pattern Synchronization 4-24

Synchronization Modes 4-24

Sync Gain Loss Criteria 4-24

Synchronization Times 4-24

Audible Output 4-24

Logging to External Printer 4-25

Functions 4-25

To Set Up Your Own Display of Results or Status Information 4-25

Procedure 4-25

Select and View the User's Page 4-25

To Build Your Own User's Page 4-26

5 Getting Started

Using the HP 70004A Display 5-2

Key Notation 5-2

Display Fixed Label Keys 5-3

Instrument Hardkeys 5-3

Parameter Control Keys 5-3

Instrument Softkeys 5-3

Softkeys and Windows Color Coding 5-3

Multi-State Functions 5-3

To Set Up the Display 5-4

Display Functions 5-4

Instrument Functions 5-5

System Turn-On 5-6

Introduction 5-6

Making Your First Measurement 5-7

Introduction 5-7

Procedure 5-7

Initial Switch On 5-7

Initial settings 5-7

Contents-5

Contents - Operating Manual

Perform a data eye measurement 5-8

Eye Edge Threshold 5-9

Automatic 0/1 Threshold Center 5-9

To Select a Measurement Gating Period 5-9

To Start a Measurement 5-9

Viewing Results and Introducing Errors into the System 5-9

To Select a Fixed Error Rate 5-10

To Add External Errors 5-10

Start a New Measurement 5-10

To View Measurement Results 5-10

To Verify/Demonstrate the Capture Error Feature (Option UHJ

instruments) 5-11

Procedure 5-11

6 Softkey Menu Maps

Introduction 6-2

Menu Map when MENU hardkey Selected 6-2

Menu Map when Result Pages hardkey Selected 6-3

Menu Map when Pattern hardkey Selected 6-3

PRBS Menu Map 6-4

Zerosub Menu Map 6-4

Markdensity Menu Map 6-5

Ram User Menu Map 6-5

Disk User Menu Map 6-6

Disk Utils Menu Map 6-6

Edit Ram User Menu Map 6-7

Edit Disk User Menu Map 6-7

Edit User Menu Map 6-8

Data Output Menu Map 6-8

Clock Output Menu Map 6-9

Error Add Menu Map 6-9

Subrate Outputs Menu Map 6-10

Trigger & Setup Menu Map 6-11

Miscellaneous Menu Map 6-12

Input & Eye Menu Map 6-12

Sync & Audio Menu Map 6-13

Gating Menu Map 6-14

Logging Menu Map 6-15

Error Location Menu Map 6-15

Build User Page Menu Map 6-16

Build User Page Pattern & Trigger Menu Map 6-16

Build User Page Data Output Menu Map 6-17

Contents-6

Contents - Operating Manual

Build User Page Clock Output Menu Map 6-17

Build User Page Error Add Subrate Data/Clock Menu Map 6-18

Build User Page Input and Sync Menu Map 6-18

Build User Page Gating and Error Location Menu Map 6-19

Build User Page Logging Menu Map 6-19

Build User Page Main Results Menu Map 6-20

Build User Page Other Results Menu Map 6-20

Build User Page Interval Results Menu Map 6-21

Build User Page G.821 Results Menu Map 6-21

Build User Page Eye Results Menu Map 6-22

Build User Page Big Results Menu Map 6-22

7 Softkey Menu Descriptions

Introduction 7-2

Softkey Menus 7-2

Softkeys requiring numeric entry 7-2

Softkey Labelling 7-2

Softkeys Color Coding 7-2

Primary Softkeys 7-3

Path Selection 7-3

Pattern Softkey Menus 7-4

Path 7-4

Description 7-4

Edit User Pattern Menu (RAM or disk) 7-6

Path 7-6

Description 7-6

disk Utils 7-9

Path 7-9

Description 7-9

Alternate Pattern Control 7-9

Path 7-9

Description 7-9

Data Output Menu 7-11

Path 7-11

Description 7-11

Clock Output Menu 7-13

Path 7-13

Description 7-13

Error Add Menu 7-14

Path 7-14

Description 7-14

Contents-7

Contents - Operating Manual

Subrate Outputs 7-15

Path 7-15

Description 7-15

Subrate Data Softkeys 7-15

Subrate Clock Softkeys 7-15

Trigger & Setup Menu 7-16

Path 7-16

Description 7-16

Pattern Generator Trigger Output 7-16

Error Detector Trigger Output 7-17

Error Detector Errors Output 7-17

Save and Recall Instrument Setup 7-18

Misc Menu 7-18

Path 7-18

Description 7-18

Result Pages Menu 7-22

Path 7-22

Description 7-22

Main Results Display 7-22

Other Results Display 7-23

Intervl Results 7-23

G.821 Results 7-24

Eye Results 7-24

User's Page 7-24

Build User-Page Menu 7-25

Path 7-25

Description 7-25

Pattern & Trigger USER'S PAGE menu 7-26

Data & Clock Output USER'S PAGE menus 7-26

Err-add Subrate USER'S PAGE menu 7-26

Input & Sync USER'S PAGE menu 7-27

Gating Err-loc USER'S PAGE menu 7-27

Logging USER'S PAGE menu 7-27

Main results USER'S PAGE menu 7-28

Other results USER'S PAGE menu 7-29

Interval results USER'S page menu 7-30

G.821 results USER'S PAGE menu 7-31

Eye results USER'S PAGE menu 7-31

BIG results USER'S PAGE menu 7-31

Input & Eye Menu 7-32

Path 7-32

Description 7-32

Contents-8

Contents - Operating Manual

Sync & Audio Menu 7-34

Path 7-34

Description 7-34

Gating Menu 7-35

Path 7-35

Description 7-35

Gating after a Power Loss 7-35

Error Location 7-37

Path 7-37

Description 7-37

Logging Menu 7-38

Path 7-38

Description 7-38

8 User Patterns and Disk Operation

Define, Edit and Store User Defined Patterns 8-2

Introduction 8-2

Basic Editor Operation 8-2

The Editor 8-3

Editor Features 8-3

Pattern Stores 8-3

Current Pattern 8-3

Choosing a Pattern 8-4

RAM-Based File Catalog 8-4

Disk-Based File Catalog 8-4

User Pattern Memory 8-5

Exiting the Editor By Mistake 8-5

Procedure 8-5

How to Set Up and Edit Your Own User Pattern 8-6

Introduction 8-6

To Edit User Patterns 8-6

Procedure 8-6

Set Pattern Length 8-7

Insert/Replace Bits in the Pattern 8-7

Delete Bits 8-7

To Save a Pattern 8-8

Procedure 8-8

To Load a Pattern Store Into the Editor 8-8

Procedure 8-8

To Load a PRBS or User Pattern into the Editor 8-9

Contents-9

Contents - Operating Manual

To Load a Block of Data (PRBS) 8-9

Procedure 8-9

To Edit Zero Substitution 8-9

To Edit Mark Density 8-9

To Load a User Pattern Into the Editor 8-10

Procedure 8-10

Load Copies of User Patterns 8-10

To Save a Block of Data 8-11

Procedure 8-11

To Delete a Block of Data 8-12

Procedure 8-12

Alternate Patterns 8-12

To Select Alternate Pattern Control 8-13

Procedure 8-13

To Generate an Alternate Pattern 8-13

Procedure 8-13

To Load a 2^10 PRBS into Half B of the Alternate Pattern 8-15

To Save the Alternate Pattern 8-15

Disk Operation 8-16

Introduction 8-16

Running out of Disk Space 8-16

Unable to Write to Disk 8-17

Disk Organization 8-17

Header String Length 8-18

Header String 8-19

Revision Code 8-19

Pattern Index 8-20

Pattern Label String Length 8-20

Pattern Length 8-20

Trigger Bit 8-20

Type of Pattern 8-20

Pattern Contents 8-20

9 Preset Instrument Configurations

Introduction 9-2

PRESET Instrument Configurations 9-2

Preset 1 Configuration 9-8

Preset 2 Configuration 9-10

User Pattern Default Settings 9-11

Contents-10

Contents - Operating Manual

10 Data Logging

Introduction 10-2

Recommended Printers 10-2

HP-IB (IEEE-488) to Centronics Printer Interface Converter 10-2

Printer Interface Cables 10-3

Printer Address 10-3

Selecting Logging Functions 10-3

To Log Results to an HP-IB External Printer 10-4

Connecting a Printer 10-4

To Log Results 10-4

To Output Results via HP-IB to a Controller 10-4

Procedure 10-4

When Measurement Results can be Logged 10-4

Logging During Gating 10-5

Logging Trigger Threshold 10-5

Results Logged During Gating 10-5

To Log Results During Gating 10-5

Procedure 10-5

End of Measurement Period Logging 10-6

End of Measurement Logging Trigger 10-6

To Log Results at the End of the Measurement Period 10-6

Log On Demand 10-7

Logging Alarms 10-7

To Log Alarms 10-7

Logging Squelch 10-7

To Squelch or not to Squelch 10-7

Results Storage 10-8

Results Storage when Logging is Switched On 10-8

11 Performance Tests

Introduction 11-2

Test Equipment Required 11-2

Parametric Testing 11-3

Preliminary setup 11-3

Data Risetime 11-4

Data Falltime 11-4

Data Jitter 11-5

Data (inverted) Risetime 11-6

Data (inverted) Falltime 11-6

Data (inverted) Jitter 11-7

Clock Risetime 11-8

Clock Falltime 11-8

Contents-11

Contents - Operating Manual

Clock (inverted) Risetime 11-9

Clock (inverted) Falltime 11-9

Pattern Generator Tests 11-10

Clock Input Minimum Level Alarm 11-10

Clock Out and Clock (inverted) Out Amplitude and Frequency 11-11

Data Out and Data (inverted) Out Amplitude 11-13

Data Delay 11-15

Pattern Generator Trigger Output 11-17

Subrate Clock Out 11-18

Parallel Data/4 Outputs 11-20

Auxiliary Input (Alternate word switchover) 11-22

Error Inject (internal and external) 11-23

Error Detector Performance Tests 11-25

Clock Input Level Alarm 11-25

Pattern Sync Output 11-26

Gating Input & Error Measurement 11-27

Error Out 11-27

Audible Error Output 11-28

Data 0/1 Threshold Auto/Manual Test 11-28

Clock/Data Align 11-29

Data Input Sensitivity 11-29

Pattern Verification 11-31

Floppy Disk Read/Write 11-31

Residual Error Rate Test 11-31

To Verify/Demonstrate the Capture Error Feature (Option UHJ

instruments) 11-32

HP 70843 option UHF Line Final Test Data 11-33

HP 70843 Line Final Test Data 11-37

12 Error Messages

Introduction 12-2

Non-Permanent Errors 12-3

Permanent Errors 12-9

13 Troubleshooting

Entry Chart 13-2

System Indicators 13-3

Error Indicators 13-4

Volt/Temp Troubleshooting 13-5

HP-MSIB Troubleshooting 13-6

MMS Error Messages 13-8

Contents-12

Contents - Operating Manual

Error Reporting 13-8

Clock Loss Troubleshooting 13-9

Clock Source Output 13-9

Data Loss Troubleshooting 13-9

Sync Loss and Errors Troubleshooting 13-10

Communication Troubleshooting 13-10

14 Appendix A:

Measurement Definitions

Measurement Definitions A-2

Error Measurements A-2

Error Count A-2

Delta Error Count A-2

Error Ratio A-2

Delta Error Ratio A-2

Errored Intervals A-2

Error Free Intervals A-2

Error Analysis A-2

% Unavailability A-2

% Availability A-3

% Errored Seconds A-3

% Severely Errored Seconds A-3

% Degraded Minutes A-3

Power Loss Seconds A-3

Sync-loss Seconds A-3

Error Location Analysis (Option UHJ instruments) A-3

15 Appendix B:

Operating Notes

Setting Error Detector Sync Thresholds B-2

Introduction B-2

Setting Sync Thresholds B-2

Clock-to-Data Alignment Failure B-2

Pattern Generation B-3

Introduction B-3

Pattern Editor and Subrate Data B-4

Pattern Lengths Divisible By Four B-4

Pattern Lengths Not Divisible By Four B-4

Subrate Output Pattern Change with Trigger Bit Position B-4

Contents-13

1

1 General Information

Gen e ral Informa tion

Introduction

Introduction

This chapter contains general information about the HP 71612 Series System and is

divided into the following sections:

Safety Considerations

Options

Accessories Supplied

Serial Number Information

Returning Instruments for Service

Precautions

Updating Firmware

Safety Considerations

General Safety Information, Safety Symbols

Lists all the options available with your system.

Lists the accessories supplied with your system.

Explains the Hewlett-Packard serial numbering

system.

Contains information on how to re turn an instrument

to Hewlett-Packard for service.

Highlights electrostatic discharge procedures and

accessories available. This section also contains

information on lifting or carrying the HP 70843 and

on cleaning the display.

Provides a procedure for updating the HP 70843

firmware.

This product is a Safety Class 1 instrument (provided with a protective earth terminal).

The instrument and manual should be reviewed for safety markings and instructions

before operation. Also read the Warnings page at the front of this manual.

Safety Information

The following general safety precautions must be observed during all phases of operation,

service, and repair of this instrument. Failure to comply with these precautions or with

specific warnings elsewhere in this manual violates safety standards of design,

manufacture, and intended use of the instrument. Hewlett-Packard Company assumes no

liability for the customer's failure to comply with these requirements.

This is a Safety Class I instrument (provided with a protective earthing ground,

incorporated in the powercord). The mains plug shall only be inserted in a socket outlet

provided with a protective earth contact. Any interruption of the protective conductor

inside or outside of the instrument is likely to make the instrument dangerous. Intentional

interruption is prohibited.

1-2

General

Gen e ral Informa tion

Safe ty Con s id e ra tions

DO NOT

operate the product in an explosive atmosphere or in the presence of flammable

gasses or fumes.

DO NOT

use repaired fuses or short-circuited fuseholders. For continued protection

against fire, replace the line fuse(s) only with fuse(s) of the same voltage and current

rating and type.

DO NOT

perform procedures involving cover or shield removal unless you are qualified

to do so. Operating personnel must not remove equipment covers or shields. Procedures

involving the removal of covers and shields are for use by service-trained personnel only.

DO NOT

service or adjust alone. Under certain conditions, dangerous voltages may exist

even with the equipment switched off. To avoid dangerous electrical shock, service

personnel must not attempt internal service or adjustment unless another person, capable

of rendering first aid and resuscitation, is present.

DO NOT

operate damaged equipment. Whenever it is possible that the safety protection

features built into this product have been impaired, either through physical damage,

excessive moisture, or any other reason, REMOVE POWER and do not use the product

until safe operation can be verified by service-trained personnel. If necessary, return the

product to a Hewlett-Packard Sales and Service Office for service and repair to ensure the

safety features are maintained.

DO NOT

substitute parts or modify equipment. Because of the danger of introducing

additional hazards, do not install substitute parts or perform any unauthorized

modification to the product. Return the product to a Hewlett-Packard Sales and Service

Office for service and repair to ensure the safety features are maintained.

1-3

Gen e ral Informa tion

Safe ty Con s id e ra tions

Safety Symbols

The following symbols on the instrument and in the manual indicate precautions which

must be taken to maintain safe operation of the instrument.

The Instruct ion Do cumen tat ion Symbol . The produc t is marked with this

symbol when it is necessary for the user to refer to the instructions in the

supplied documentation.

Indicates the field wiring terminal that must be connected to earth ground

before opera ting the equip ment - protects against electri cal shock in case

of fault.

Frame or chassi s ground terminal - typically connects to the equipment ’s

metal frame.

Alternating current (ac)

Direct current (dc)

Indica tes hazardous v oltages

Warning denotes a hazard. It calls attention to a procedure, which if not

correctly performed or adhered to could result in injury or loss of life. Do

not proceed beyond a warning note until the indicated conditions are fully

understood and met.

Caution denot es a hazard. It calls attenti on to a procedure , which if not

correctl y performed or adhered to could result in damage to or destruction

of the instrument. Do not proceed beyond a warning note until the

indicated conditions are fully underst ood and met.

The CE mark shows that the product complies with all relevant European

legal Directi ves .

1-4

Gen e ral Informa tion

Safe ty Con s id e ra tions

This is a symbol of an Industrial Scientific and Medical Group 1 Class A

product.

The CSA mark is a registered trade mark of the Canadian Standards

Associat ion. Indi cate s a functional earth termin al.

Indica tes a functiona l earth terminal .

The recycling symbol.

The dispose of proper ly symbo l.

1-5

Gen e ral Informa tion

Options

Options

Introduction

The HP 12 Gb/s BERT products offer a range of product options to suit user applications.

There are two standard core products (HP 71612 and HP 70843) each having a set of user

options. The core products cannot be ordered or supplied on their own; they must be

ordered with an option. They are as follows:

• HP 71612: comprises an HP 70004A display and an HP 70843 product base.

• HP 70843: comprises a Hewlett-Packard MMS system II cabinet with PSU and

control hardware/firmware functions for a BERT, pattern generator or error detector

option. HP 70843 options are provided for users who may not require an HP

70004A display or who wish to operate the instrument remotely via HP-IB.

The following tables list the options available for the HP 71612 and HP 70843 core

products.

HP 71612 Options

Product Option Description Elemen ts In clu ded

Display Pattern

Generator

71612 UHF 12 Gb/s error performance

analy ze r (B ER T )

71612 UHG 12 G b/s patter n gener ator yes y es no yes

71612 UHH 12 Gb/s error detector

system

yes yes yes yes

yes no yes no

Error

Detector

Cloc k

Source

1-6

Gen e ral Informa tion

Options

HP 71612 Options continued

Product Option Descrip ti on Elements Inc lud ed

Mainframe Clock Source

Extension Mo dule

71612 UKB extend lowest frequency to 0.1 Gb/s yes yes

71612 UHJ add error location analysis to option

UHF or UHH

71612 UKC delete clock source from option

UHF or UHG

71612 OB1 extra set of HP 71612 manuals

71612 1CM r ack moun t kit; for instru ment

without handles fitted

71612 1CP rack moun t kit; for instru ment with

handles fitted

HP 70843 Options

Product O ption Description Elements Included

Display Pattern

Generator

70843 UHF 12 Gb/s error performance

analyzer (BERT)

70843 UHG 12 Gb/s pattern generator no yes no no

no yes yes no

Error

Dete ctor

Clock

Source

70843 UHH 12 Gb/s error detector no no yes no

70843 UHJ add error location analysis

to option UHF or UHH

70843 OB1 extra set of HP 71612

manuals

70843 1CM rack mount kit; for

instrument without

handles fitted

70843 1CP rack mount kit; f or

instrument with handles

fitted

1-7

Gen e ral Informa tion

Accessories Supplied

Upgrade Options

The following options upgrade HP 71612 and HP 70843 option UHG pattern generators

and option UHH error detectors to full BERT capability. Both upgrades can only be

carried out at the manufacturing division.

HP 15807A Factory Upgrade to 12 Gb/s BERT

Product Option Description

15807A 001 add pattern generator

15807A 002 add error detector

Accessories Supplied

The accessories supplied with your system are listed below:

• Two HP-MSIB cables.

• Line power cable. (3 off when an HP 70001A mainframe is supplied.)

• 8 mm hex-ball driver.

• 4 off SMA to SMA test cables.

• 1 off N-SMA adapter.

• 5 off APC-3.5 mm connector savers.

• 2 off APC-3.5 mm male-female adapter.

• 7 off 50Ω SMA terminations.

Recommended Accessory List

The following items are not supplied with your instrument but are recommended

accessories.

• APC-3.5 mm cables.

• APC-3.5 mm attenuators.

• APC-3.5 mm 50Ω terminations.

• Torque wrench for APC-3.5 mm.

1-8

Gen e ral Informa tion

Serial Number Information

Serial Number Information

Attached to each element in your system is a serial number plate. A typical serial number

is in the form XXXXUXXXXX. It is in two parts; the first four digits and the letter are the

serial prefix and the last five are the suffix, the letter designates the country of origin - U is

the United Kingdom. The prefix is the same for identical elements, it only changes when a

change is made to an element in your system. The suffix however, is assigned sequentially

and is different for each element. The contents of this manual apply to the elements with

the serial number prefix(es) listed under

A system manufactured after the printing of this manual may have a number prefix that is

not listed on the title page. The unlisted serial number prefix indicates the system is

different from those described in this manual. The manual for this new element is

accompanied by a

information

In addition to change information, the supplement may contain information for correcting

errors in the manual. To keep this manual as current and accurate as possible,

Hewlett-Packard recommends that you periodically request the latest Manual Changes

supplement. The supplement for this manual is identified with the manual print date and

part number, both of which appear on the manual title page. Complementary copies of the

supplement are available from Hewlett-Packard. For information concerning a serial

number prefix that is not listed on the Manual Changes supplement, contact your nearest

Hewlett-Packard office.

that explains how to adapt the manual to the new element.

Manual Changes

SERIAL NUMBERS

supplement. This supplement contains

on the title page.

change

Returning Instruments for Service

This section explains how you return an instrument to Hewlett-Packard for servicing.

Packaging Requirements

Instruments can be damaged as a result of using packaging materials other than those

specified. Never use styrene pellets as packaging material. They do not adequately

cushion the instrument nor prevent it from shifting in the carton. They also cause

instrument damage by generating static electricity.

1-9

Gen e ral Informa tion

Returni ng Instruments fo r Service

Preparing an Instrument for Shipping

1. Fill out a blue repair tag (located at the front of this manual) and attach it to the

instrument. Include any error messages or specific performance data related to the

problem. If a blue tag is not available, the following information should be noted and

sent with the instrument:

• Type of service required.

• Description of the problem.

• Whether problem is constant or intermittent.

• Name and phone number of technical contact person.

• Return address.

• Model number of returned instrument.

• Full serial number or returned instrument.

• List of any accessories returned with the instrument.

2. Pack the instrument in the appropriate packaging materials. Original shipping or

equivalent materials should be used. If the original or equivalent material cannot be

obtained, follow the instructions below:

CAUTI ON

Inappropriate packaging of the instrument may result in damage to the

instrument during transit.

• Wrap the instrument in anti-static plastic to reduce the possibility of damage caused

by ESD.

• Use a double-walled, corrugated cardboard carton of 159 kg (350 lb) test strength.

CAUTI ON

If you are shipping a complete system, remove the module(s) from

Display and Mainframe, individually pack each element, then ship

them to Hewlett-Packard.

• The carton must be large enough to allow 3 to 4 inches on all sides of the instrument

for packing material and strong enough to accommodate the weight of the

instrument.

• Surround the instrument with 3 to 4 inches of packing material, to protect the

instrument and prevent it from moving in the carton.

TM

• If packing foam is not available, the best alternative is S.D.-240 Air Cap

Sealed Air Corporation (Commerce, California 90001). Air Cap

TM

looks like a

from

plastic sheet filled with air bubbles.

TM

• Use the pink (anti-static) Air Cap

to reduce static electricity. Wrapping the

instrument several times in this material will protect the instrument and prevent it

from moving in the carton.

3. Seal the carton with strong nylon adhesive tape.

4. Mark the carton FRAGILE, HANDLE WITH CARE.

5. Retain copies of all shipping papers.

1-10

Gen e ral Informa tion

Precautions

Precautions

ESD Precautions

Electrostatic discharge (ESD) can damage or destroy electronic components. All work on

electronic assemblies should be performed at a static-safe workstation.

NOTE

When the instrument is subjected to air discharges above 2 kV, as

detailed in standard IEC 1000-4-2 (1995), degradation in performance

may be observed in the form of bit errors.

Static-safe Workstation

A typical static-safe workstation is illustrated in the following diagram. There are two

types of ESD protection:

• Wrist-strap (with >1 MΩ isolation to ground) with table mat.

• Heel-strap (with >1 MΩ isolation to ground) with conductive floor mat.

These two types must be used together to ensure adequate ESD protection. Isolation to

ground must be provided for personnel protection.

1-11

Gen e ral Informa tion

Precautions

Static-safe Accessories

The following table lists the accessories that may be ordered through any Hewlett-Packard

sales and service office.

HP Part Number Description

9300- 0797 3M static cont rol mat 0.6 m x 1.2 m (2 ft x 4 ft) and 4.6 m (15 ft) of ground

wire. (The wrist-st r ap and wrist-strap cord are not included. They must be

ordered separ ately.)

9300- 0980 Wrist-st rap cord 1.5 m (5 ft).

9300- 1383 Wrist-st rap, color black, stainl ess steel , has four adjustable links and a

7 m m post-ty pe connect ion.

9300-1169 ESD heel-strap (reusable 6 to 12 months).

*92 175A Black, hard surface, stat ic control mat, 1.2 m x 1.5 m (4 ft x 5 ft)

*92 175B Brown, soft sur face, stat ic control mat, 1.2 m x 2.4 m (4 ft x 8 ft)

*92 175C Small, black, hard surface, static control mat, 0.9 m x 1.2 m (3 ft x 4 ft)

*92 175T Table-top static control mat, 58 cm x 76 cm (23 in x 30 in)

*92 176A Natural color anti-st ati c carpet, 1. 2 m x 1.8 m (4 ft x 6 ft)

*92 176B Natural color anti-st ati c carpet, 1. 2 m x 2.4 m (4 ft x 8 ft)

*92 176C Russet color anti-static carpet , 1.2 m x 1.8 m (4 ft x 6 ft)

*92 176D Russet color anti-static carpet , 1.2 m x 2.4 m (4 ft x 8 ft)

*Can also be ordered by calling HP DIRECT Phone (800) 538 8787.

Lifting/Carrying the HP 70843

Use the handle on the side of he instrument for lifting the HP 70843. Before attempting to

lift or carry the instrument consider the following basic lifting techniques to help avoid

personal injury.

Using one arm to lift instrument

• BRACE your body with the opposite arm, if possible.

• Reach for the instrument - bend your knees and waist, and keep your back straight.

• GRASP the instrument firmly - using the handle.

• LIFT with your legs, using the free arm for balance.

• KEEP your shoulders level - switch hands regularly.

1-12

Gen e ral Informa tion

How to Update the HP 70843 Firmware

Display Cleaning

To avoid damaging the coating on the display, use a thin-film cleaner such as

Hewlett-Packard Video Clean Kit (HP part number 92193). The kit includes an nonabrasive cleaning cloth.

CAUTI ON

Hand and laboratory paper towels are abrasive, if these are used they

may damage the coating on the display.

Cabinet Cleaning

To clean the instrument cabinet: Use a soft, clean cloth to clean the front-panel and side

covers.

How to Update the HP 70843 Firmware

CAUTI ON

The HP 70843 has two processor systems, a Control Processor and a Measurement

Processor. The firmware for either processor can be updated using the instrument floppy

disk drive. The first part of the update process is as follows:

Do not attempt to update instrument firmware unless advised by

Hewlett-Packard and supplied with an appropriate firmware update

disk.

1. Power up instrument and HP 70004A display.

2. Press key on HP 70004A display under screen.

3. Press softkey (bottom left-hand softkey).

USER

misc

4. Insert firmware update disk into instrument.

5. Press softkey.

update frmware

Now either update the Control Processor or Measurement Processor:

To Update Control Processor Firmware

1. Press .

2. Confirm operation by pressing softkey (top left-hand). Wait for update

3. Power cycle.

UpdCntlAppl

UPDATE YES

to complete - this can take several minutes. During the update the HP-IB indicator

LEDs light from left to right and the end of a successful update is indicated by the

green MSIB ACT LED flashing. If the update is unsuccessful the red MSIB ERR LED

flashes.

1-13

Gen e ral Informa tion

How to Update the HP 70843 Firmware

To Update Measurement Processor Firmware

1. Press .

2. Confirm operation by pressing softkey (top left-hand).

UpdMeasAppl

UPDATE YES

3. Wait for update to complete, at the end of the update a message will appear at the

bottom of the screen requesting a power cycle.

4. Power cycle.

1-14

2

2 Installation

Installation

Introduction

Introduction

This chapter enables you to install your system ready for use. The information is presented

under the following headings:

Preparation for Use:

System Installation:

System Verification:

Selftest at Power-on:

Installing/Removing Modules:

WARNIN G

If this instrument is not used as specified, the protection provided

by the equipment could be impaired. This instrument must be used

in a normal condition only (in which all means for protection are

intact).

Provides information you should read before you

install your system. It contains information on initial

inspection, power requirements, address switches

and rack mount kits.

Shows you how to install your system. As you

progress through the procedure, you will be directed

to other relevant information.

Describes how you power-on and verify correct

system installation.

Details the instrument status during selftest at

power-on.

Describes how you install a clock source module

into a Display and Mainframe.

2-2

Installation

Preparation for Use

Preparation for Use

This section should be read before you install your system. It contains the following:

• Initial Inspection

• Operating Requirements

• Line Voltage Selection

•Line Fuses

• Power Cables

• HP-MSIB Address Switches

• HP-IB Address Switches

• Bench Operation

• Rack Mount Kits

Initial Inspection

WARNIN G

T o avoid hazardous electrical shock, do not perform electrical tests

when there are signs of shipping damage to any portion of the

outer enclosure (covers, panels, meters).

Inspect the shipping container for damage. If the shipping container or cushioning

material is damaged, it should be kept until the contents of the shipment have been

checked for completeness and the elements in your system have been checked both

mechanically and electrically. Procedures for checking the electrical operation are given

starting on page 11-1 of this manual.

If any element in your system appears damaged or is defective, contact the nearest

Hewlett-Packard service office. Hewlett-Packard will arrange for repair or replacement of

the equipment without waiting for a claim settlement. Retain the shipping materials for the

carrier to inspect.

Undamaged shipping materials should be kept. Original HP or equivalent shipping

materials are required for system or module re-shipment, as substandard packaging may

result in damage. Refer to

Returning Instruments for Service

on page 1-9 for information

on re-shipment.

To Fit an Instrument Hardkey Panel

On all HP 71612 systems, the instrument hardkey panel is fitted to the display at the

factory. For HP 70843 orders where the user already has an HP 70004A display, refer to

2-3

Installation

Preparation for Use

page 2-11 of the HP 70004A Display Installation and Verification manual (part number

70004-90005) for advice on fitting the instrument hardkey panel.

Statement of Compliance

This instrument has been designed and tested in accordance with LEC Publication

1010-1+A1:1992 Safety requirements for Electrical Equipment for Measurement. Control

and Laboratory Use, and has been supplied in a safe condition. The instruction

documentation contains information and warnings which must be followed by the user to

ensure safe operation and to maintain the instrument in a safe condition.

Instruction for cleaning

To clean the instrument cabinet: Use a soft, clean damp cloth to clean the front-panel and

side covers.

Operating Requirements

Operating and Storage Environment

This instrument is designed for Indoor use only.

o

The module may be operated at temperatures from 5

C to 35oC at altitudes up to 3,000 m

(10,000 ft.) The module may be operated in environments up to 95% relative humidity to

o

C, but it should be protected from temperature extremes which may cause

40

condensation. To ensure adequate cooling do not obstruct air vents in the instrument

cabinet.

CAUTI ON

This instrument is designed for use in Installation Category II and

Pollution Degree 2 per IEC 1010 and 644 respectively.

Physical Specifications

The physical dimensions and weight of each element in your system are as follows:

Table 2-1 Dimensions and weight

Dimensions & Weight HP 70843 HP 70004A + HP 70340A

Height 223 mm 223 mm

Width 426 mm 426 mm

Depth 500 mm 500 mm

Weight <30 kg <30 kg

2-4

Installation

Preparation for Use

Cooling Considerations

o

The HP 70843 12 Gb/s BERT will operate at up to 40

o

optimum performance is obtained close to 25

C ambient temperature.

C ambient temperature but

In use it is important to make sure there is no obstruction to airflow through the

instrument. Cooling air is taken in on the right-hand side and is blown out through the lefthand side of the instrument, looking from the front. If this airflow is obstructed the

performance and reliability of the instrument will be reduced.

In the rack-mounted system it is particularly important to make sure the airflow is not

obstructed. For example, cables in the side of the racks can obstruct the airflow. Also

o

make sure the input air temperature is not increased above 40

C by other instruments in

the rack. If forced ventilation is used in a rack the air pressure on both sides of the

instrument must be the same for the instrument cooling to operate correctly.

Lifting the HP 70843

Use the handles on the side of the instrument for lifting or carrying the HP 70843. Before

attempting to lift or carry the instrument consider the following basic lifting techniques to

help avoid personal injury.

• BRACE your body with the opposite arm, if possible.

• Reach for the instrument - bend your knees and waist, and keep your back straight.

• GRASP the instrument firmly with both hands

• LIFT with your legs.

• KEEP your shoulders level.

Power Requirements

The line voltage requirements for the HP 70843 error performance analyzer and

HP 70004A display are as follows:

115 V line operation:

230 V line operation:

90 to 135 V ac, 47 to 66 Hz

180 to 264 V ac, 47 to 66 Hz

The maximum power consumption is as follows:

HP 70843:

HP 70004A:

850 VA typical

350 VA typical

2-5

Installation

Preparation for Use

WARNIN G This is a Safety Class 1 instrument (provided with a protective

earthing ground, incorporated in the powercord). The mains plug

shall only be inserted in a socket outlet provided with a protective

earth contact. Any interruption of the protective conductor inside

or outside of the instrument is likely to make the instrument

dangerous. Intentional interruption is prohibited.

Noise Declaration

LpA<70db

am Arbeitsplatz (operator position)

normaler Betrieb (normal position)

nach DIN 45635 pt.19 (per ISO 7779)

Power Cables

The display and error performance analyzer are each equipped with a three-wire power

cable. When connected to a properly grounded power outlet, this cable grounds the

instrument case. The power cable shipped with each instrument depends on the country of

destination. The plug configuration and the power cable part numbers are listed below. If

the appropriate power cable(s) are not supplied with your system or are damaged, notify

the nearest Hewlett-Packard sales and service office and replacement(s) will be provided.

The color code used in each power cable is given below:

Brown

Line:

Neutral:

Ground:

CAUTI ON

Blue

Green/yellow

Always use the three-prong ac power cord supplied with this

instrument. Failure to ensure adequate earth grounding by not using

this cord may cause instrument damage.

2-6

Installation

Preparation for Use

Line Voltage Selection

Instrument (HP 70843) Line Voltage Selector

There is no Line Voltage Selector switch on the HP 70843. The instrument line input

circuits are auto-ranging and will operate at any voltage within the specified voltage range

(90 to 135 and 180 to 264 volts). The Line Input module (on the rear panel) incorporates

an ON/OFF switch - the `0' position is the OFF position. Refer to the paragraph on Line

Fuses on page 2-9 for advice on replacing fuses.

NOTE

WARNIN G

See page 2-9 for fuse ratings for 115 V ac and 230 V ac operation.

If this instrument is to be energized via an external

autotransformer for voltage redu ction, make s ure th at i ts common

terminal is connected to a neutral (earthed pole) of the power

supply .

CAUTI ON

This instrument has an autoranging line voltage input, be sure the

supply voltage is within the specified range.

Display (HP 70004A) Line Voltage Selector

CAUTI ON

Before you conne ct the pow er cable t o the di splay , c heck that t he LINE

VOLTAGE SELECTOR switch is set for the correct line voltage

source.

If the wrong voltage is selected, one of the following may happen:

If 115 V line operation is selected and you connect to a 230 V ac line

power source, the fuse may blow.

If 230 V line operation is selected and you connect to a 115 V ac line

power source, the instrument will not power-on correctly.

2-7

Installation

Preparation for Use

The LINE VOLTAGE SELECTOR slide switch is located through a slot in the left sidepanel.

Mainframe (HP 70001A) Line Voltage Selector (HP 71612 options UHF/UKB and

UHG/UKB only)

CAUTI ON

Before you connect the power cable to the mainframe, check that the

LINE V OLT A GE S ELE CT OR swit ch i s se t fo r the co rrec t l in e volta g e

source.

If the wrong voltage is selected, one of the following may happen:

If 115 V line operation is selected and you connect to a 230 V ac line

power source, the fuse may blow.

If 230 V line operation is selected and you connect to a 115 V ac line

power source, the instrument will not power-on correctly.

The LINE VOLTAGE SELECTOR slide switch is located through a slot in the bottom

panel (the switch is set for 115 V operation in the diagram below).

2-8

Installation

Preparation for Use

Line Fuses

The line fuses of the instrument, display and mainframe are located in the line-module

housings on the rear panel.

Accessing the HP 70843 Line Fuse

1. Ensure no power cable is connected to the line-module housing.

2. Use a screwdriver to lever open the fuse holder. There are two fuses in the fuse holder

(one for 115V operation and one for 230V operation).

Accessing the Display (HP 70004A) and Mainframe (HP 70001A) Fuses

The display and mainframe use similar line-module housings. To access the fuses:

1. Ensure no power cable is connected to the line-module housing.

2. Use a screwdriver to lever open the fuse holder. A spare line fuse is located inside the

fuse holder.

Fuse Ratings

The fuse ratings and the part numbers for 115 V ac and 230 V ac operation are listed

below:

• HP 70843: 115 V operation - F 12 A, 250 V, part number 2110-0051

• HP 70843: 230 V operation - M 7 A, 250 V, part number 2110-0326

• The Display and Mainframe fuse ratings are 6.3 A, 250 V (HP 2110-0703) for both 115

and 230 V ac operation.

2-9

Installation

Preparation for Use

HP-MSIB Address Switches

The HP-MSIB address of an HP 70843 error performance analyzer is factory preset to

row 0, column 18. Both error detector and pattern generator share the same HP-MSIB

address.

If you wish to change the HP-MSIB address, ensure you are fully aware of the HP-MSIB

address protocol.

Factory Preset HP-MSIB Addresses

The factory preset HP-MSIB addresses (row, column) are listed below:

HP 70004A display: 0, 20

HP 70843 error performance analyzer: 0, 18*

HP 70340A clock source: 1, 19

HP 70341A low frequency clock source: 2, 19

* The column value defines the factory-preset HP-IB address.

HP 70843 Address Switches

These are accessed via the instrument rear panel. The factory preset settings are shown in

the following diagram:

2-10

Installation

Preparation for Use

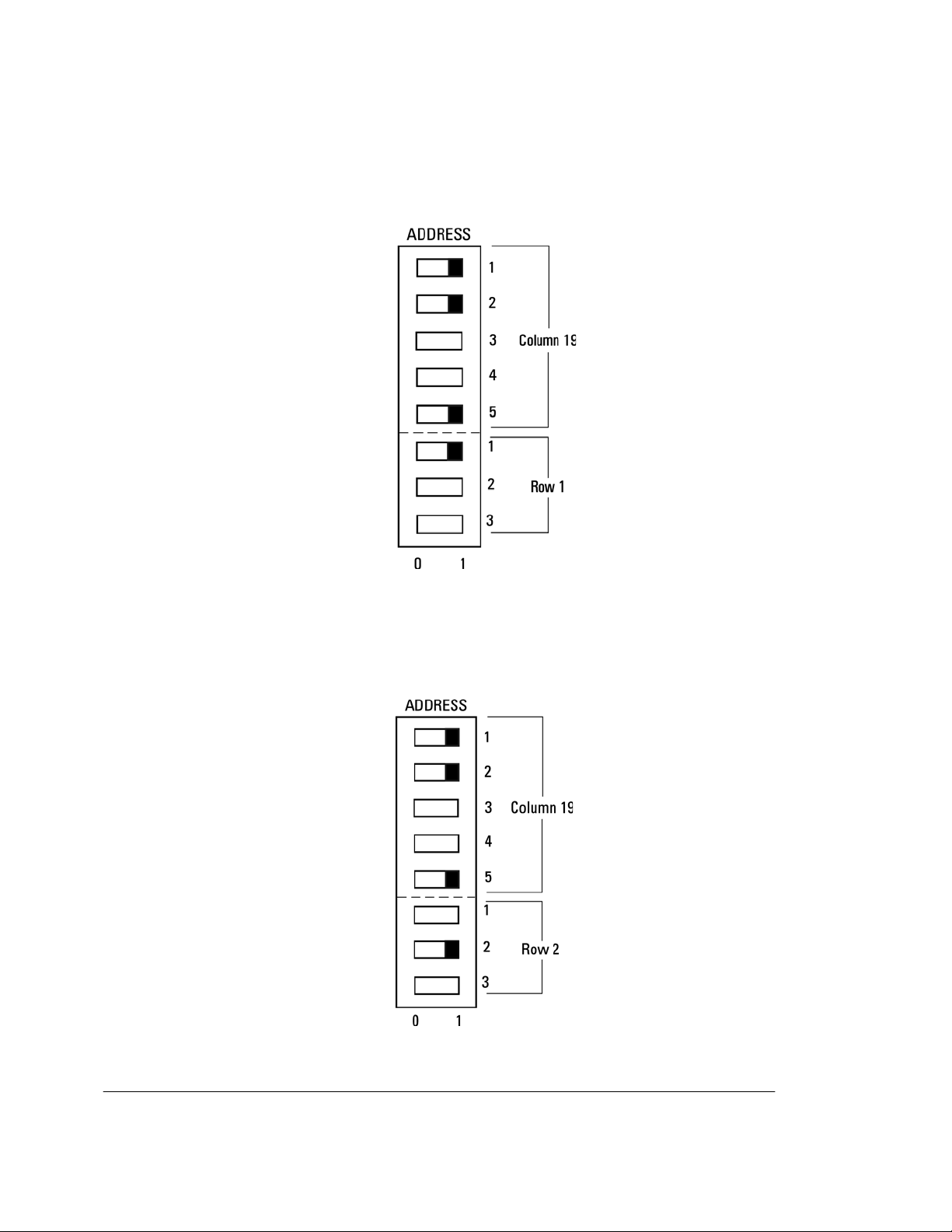

HP 70340A Clock Source Module Address Switches

These switches are located on the clock source rear panel. The factory preset switch

settings are row 1, column 19 as shown in the following diagram:

HP 70341A Clock Source Module Address Switches

These switches are located on the clock source rear panel. The factory preset switch

settings are row 2, column 19 as shown in the following diagram:

2-11

Installation

Preparation for Use

HP 70004A Display Address Switches

These are located on the rear panel of the HP 70004A display, it has no row switches (it

defaults to row 0) - only column switches (the factory preset settings are shown in the

following diagram):

HP-IB Address Switches

The HP-MSIB address switches also act as HP-IB switches. If you want your system to

communicate over the HP-IB:

The row switches must be set to 0.

The column switches define the HP-IB address.

If you want to change the HP-IB address (for example, use an address that is different

from that defined by the column switch settings), it is recommended that you use the

Display, Address Map function keys as follows:

CAUTI ON

It is not recommended that you change the HP-IB address using the

HP -MSI B/H P- IB s wi tche s as th e se al so ch ange th e HP- MS IB addr e ss.

If the HP-MSIB address protocol is violated your system will fail to

operate.

To Change the HP-IB Address

1. Press the Display fixed label key.

2. Press the

Address Map

3. Rotate the large display knob clockwise until the green box rests on the

.

Anl

4. Press , select an address using the numeric keypad then press

HP-IB ADD RS ET

ENTER

.

DISPLAY

left-menu softkey.

70843 Err Perf

Factory Preset HP-IB Addresses

The error performance analyzer HP-IB address is factory preset to 18 (column part of

HP-MSIB switch setting).

2-12

Installation

Preparation for Use

Bench Operation

Plastic feet are included with Mainframes and stand-alone instruments to provide bench

operation convenience. The plastic feet are self-aligning when systems are to be stacked.

Rack Mount Installation

Front handles must be removed when fitting the system rack mount options.

HP 71612 option 1CM - rack mount kit (HP part number 15810A)

HP 71612 option 1CP - rack mount kit with handles (HP part number 15811A)

HP 70843 option 1CM - rack mount kit (HP part number 5062-3979)

HP 70843 option 1CP - rack mount kit with handles (HP part number 5062-4073)

The rack mounts available are illustrated below. Angled brackets (HP 12679C) may be

ordered to provide additional rear or side support for the rack mounted instruments.

2-13

Installation

System Installation

System Installation

The following figure shows an error performance analyzer system.

HP 70004A

Display

HP 70340A

Clock

Source

HP 70843

Error

Performance

Analyzer

Accessories

The following cables, connectors and terminations are suppled with your system.

Cables

4 off SMA cables, part number 8120-4948; use to connect the clock/data ports.

Connectors

5 off APC - 3.5 mm female to female, part number 5061-5311; use as savers for pattern

generator clock/data outputs and error detector data input.

2 off APC - 3.5 mm male to female, part number 1250-2472; use as savers for error

detector clock input and trigger output.

T erminations

7 off SMA terminations, part number 1250-2121; use on unused clock/data outputs.

2-14

Installation

System Installation

Procedure

Use the following procedure to install your HP 71612 series system.

CAUTI ON

Ensure that no power cables are connected. Also check that the LINE

POWER switches are set to OFF.

CAUTI ON

En sure that th e displa y line volt age selec tor swit ches ar e set for th e line

voltage being used, also check the fuse ratings, see pages 2-7 and 2-9.

On HP 71612 option UKB instruments, check also the mainframe Line

Voltage Selector and fuse.

1. Install the HP 70340A clock source module into the display.

2. Arrange the Display and HP 70843 for bench operation. The plastic feet on the Display

and HP 70843 are self-aligning when systems are stacked. To rack mount your system,

refer to

Rack Mount Installation

, see page 2-13.

3. Connect the HP-MSIB cables as follows:

CAUTI ON

Your system must be powered down when connecting or

disconnecting HP-MSIB cables.

The diagram shows the systems viewed from the rear.

2-15

Installation

System Installation

4. Connect the CLOCK IN port of the HP 70843 pattern generator to the CLOCK OUT of

the clock source module.

CAUTI ON

When tightening SMA connectors and terminations, ensure that the

maximum torque setting used is 0.9 N-m.

NOTE

The other front panel ports on the HP 70843 pattern generator and error

detector are interconnected according to the application you want to

undertake. All the necessary cables, a dapters and 50Ω term ination s are

provided with your instrument. Unused ports must be terminated in

50Ω.

CAUTI ON

Check the power cables you intend to use for damage before powering

on your system, see the Power Cables on page 2-6.

5. Connect power cables to your system then connect the cables to the power outlets.

Your system is now ready for System Verification, see page 2-17.

2-16

Installation

System Verification

System Verification

This section contains procedures which will enable you to verify that your

performance analyzer

has been correctly installed.

error

Error Performance Analyzer System Verification

The HP 70843 error detector and pattern generator are connected back-to-back. then the

system selftest and instrument preset parameters are used to verify correct installation. A

description of what you will see during selftest is given in System Selftest at Power-on,

see page 2-18 (since selftest takes only 15 seconds approximately to complete, you should

read the description before powering on your system).

1. Interconnect the front panel ports as shown below, then prior to switching on your

system, read Selftest at Power-on, see page 2-18.

2. Switch on the two Line power switches (in any order) - wait approximately 15 seconds

for selftest to end. Note that the HP 70843 line power switch is on the instrument rear

panel.

3. Press the display key to set up the instrument preset parameters.

4. Check that the displayed clock frequency is 1.000 GHz and that the

INST PRESET

indicator on

ACT

the instrument is lit.

5. Press the display key, the

DISPLAY

indicator should extinguish and an A should

ACT

appear at the top left of the display.

6. Press the display key, the A should disappear and the

MENU

indicators should

ACT

light.

7. Press , , . Wait for the clock and

input & eye

data signals to align, then do a and wait for alignment to com-

0/1 THR AUT O CLK-DAT ALIGN

0/1 THR CEN TER

plete.

8. Press . The

RUN GATING

GATING

indicator on the error detector and the

Gate

flag at

the top right of the display should light.

9. Check that the displayed error count is 0.

If there are no errors, the system is ready for use.

2-17

Installation

Selftest at Power-on

Selftest at Power-on

At power-on the error performance analyzer system performs a selftest (this takes

approximately 15 seconds to complete). During this time the display, instrument, clock

source and mainframe (option UKB instruments) operate as follows:

Display:

The display is blank for the first few seconds of the selftest. It

then shows a multi-colored raster. The raster sweeps to the right,

to show a blue back-ground. For the remainder of the selftest the

display is as follows:

After selftest the display may continue to display the above, or

will display the module parameters present prior to the last power

down.

HP 70843:

All front panel indicators are lit for approximately eight seconds

then extinguished for the remainder of the selftest.

Clock Source Module:

After selftest the

All front panel indicators are lit for approximately five seconds

indicator should light.

ACT

then extinguished for the remainder of the selftest.

Mainframe:

2-18

All front panel indicators extinguish except for

After selftest the

indicator should light.

ACT

LINE

.

Installation

Installing/Removing Modules

Installing/Removing Modules

This section describes how you install a clock source module into a Display and

Mainframe.

Installing an HP 70340A Clock Source Module into a Display

Use the following procedures to install your clock source into the display. To remove a

module, perform the steps in the reverse order.

1. Set the display LINE power switch to off.

2. Open the front panel door then insert the module.

3. Secure the module by pressing against its front panel while tightening the hex-nut latch

with an 8 mm hex-ball driver.

When removing a clock source module, disconnect any cables that may be connected to

the rear panel.

2-19

Installation

Installing/Removing Modules

Installing an HP 70341A Clock Source Module into a Mainframe

1. Open the front panel door, then insert the clock source module into the right side of the

mainframe.

CAUTI ON

The Mainframe LINE power switch must be set to off before the front

panel door will open.

2. Secure the module by pressing against its front panel while tightening the hex-nut latch

with an 8 mm hex-ball driver.

When removing a clock source module, disconnect any cables connected to the rear panel.

2-20

3

3 System Overview

System Overview

Configurations

Configur ations

The HP 71612 Series of Gigabit testers can be configured into one of the following

systems:

System Options

• HP 71612 option UHF: 1-12 Gb/s error performance analyzer system

• HP 71612 option UHG: 1-12 Gb/s pattern generator system

• HP 71612 option UHH: 0.1-12 Gb/s error detector system

Each system comprises an HP 70004A display and an HP 70843 pattern generator or error

detector or both. For HP 71612 option UKB systems, an HP 70001A mainframe and low

frequency clock extension module is added.

An HP 71612 error performance analyzer system is shown in the following figure:

HP 70004A

Display

HP 70340A

Clock

Source

HP 70843

Error

Performance

Analyzer

3-2

System Overview

Configurations

Additional System Options

• HP 71612 option UHJ: error location analysis (cannot be ordered with option UHG

pattern generator system)

• HP 71612 option UKB: low frequency clock extension of options UHF or UHG to

0.1 Gb/s.

• HP 71612 option UKC: delete clock source from option UHF or UHG

Refer to Chapter 1,

General Information

, for a complete list of HP 71612 options.

HP 70843 Instrument Options

• HP 70843 option UHF: error performance analyzer (0.1 to 12 Gb/s)

• HP 70843 option UHG: pattern generator (0.1 to 12 Gb/s)

• HP 70843 option UHH: error detector (0.1 to 12 Gb/s)

• HP 70843 option UHJ: error location analysis (not available with option UHG)

Documentation Overview

The manuals supplied with each system are listed in the following table:

Element Product Number Manual HP Part Number Comments

System HP 71612 Operating/

Programming

Display HP 70004A Operation

Installation/

Verification

Mainframe HP 70001A Installation/

Verification

71612-90011 This manual is supplied

with all systems.

70004-90031

70004-90005

70021-90021 This manual is only

These manuals are

supplied with all

systems.

supplied with HP 71612

option UKB (low

frequency extension)

systems.

*Clock

source

Instrument HP 70843 Operating/

HP 70340A User’s Guide 70340-90001 This manual is supplied

with all systems.

71612-90011 This manual is supplied

Programming

with all instruments.

*Clock source documentation is not supplied if option UKC is ordered with your system.

The clock source is only supplied with HP 71612 options UHF or UHG. It is not supplied

with an HP 71612 option UHH, nor with any HP 70843 option.

3-3

4

4 Operating Features and

Specifications

Operating Feat ur es and Speci f ications

Introduction

Introduction

This chapter lists and describes the features and specifications of an HP 70843 error

performance analyzer. Refer to Chapter 1

options and accessories.

General Information

for advice on instrument

Warm-up