Page 1

Installation and Verification Guide

HP 71450B/1B/2B Optical

Spectrum Analyzers

ABCDE

USA

Printed

in

Page 2

HP Part No. 70950-90047

Edition 1

Printed in USA June 1995

1400 FountaingroveParkway,

Santa Rosa, CA

95403-1799, USA

Notice.

The information contained in this document is subject to change without notice.

Hewlett-Packard makes no warrantyofany kind with regard to this material, including

but not limited to, the implied warranties of merchantability and tness for a particular

purpose. Hewlett-Packard shall not be liable for errors contained herein or for incidental or

consequential damages in connection with the furnishing, performance, or use of this material.

Restricted Rights Legend.

Use, duplication, or disclosure by the U.S. Governmentissubject

to restrictions as set forth in subparagraph (c) (1) (ii) of the Rights in Technical Data and

Computer Software clause at DFARS 252.227-7013 for DOD agencies, and subparagraphs

AR

F

(c) (1)

and (c)

52.227-19

for

(2) of

other

Commercial

the

agencies.

Computer

Soft

are

w

Restricted

Righ

ts

clause

at

c

Cop

Righ

All

ermission

p

yrigh

ts

Hewlett-P

t

Reserv

prohibited,

is

ed.

k

ac

Repro

except

Compan

ard

duction,

as

1995

y

adaptation,

under

ed

w

allo

translation

or

copyrigh

the

without

ws.

la

t

prior

written

Page 3

Installation and Operation Verification

of the Optical Spectrum Analyzer

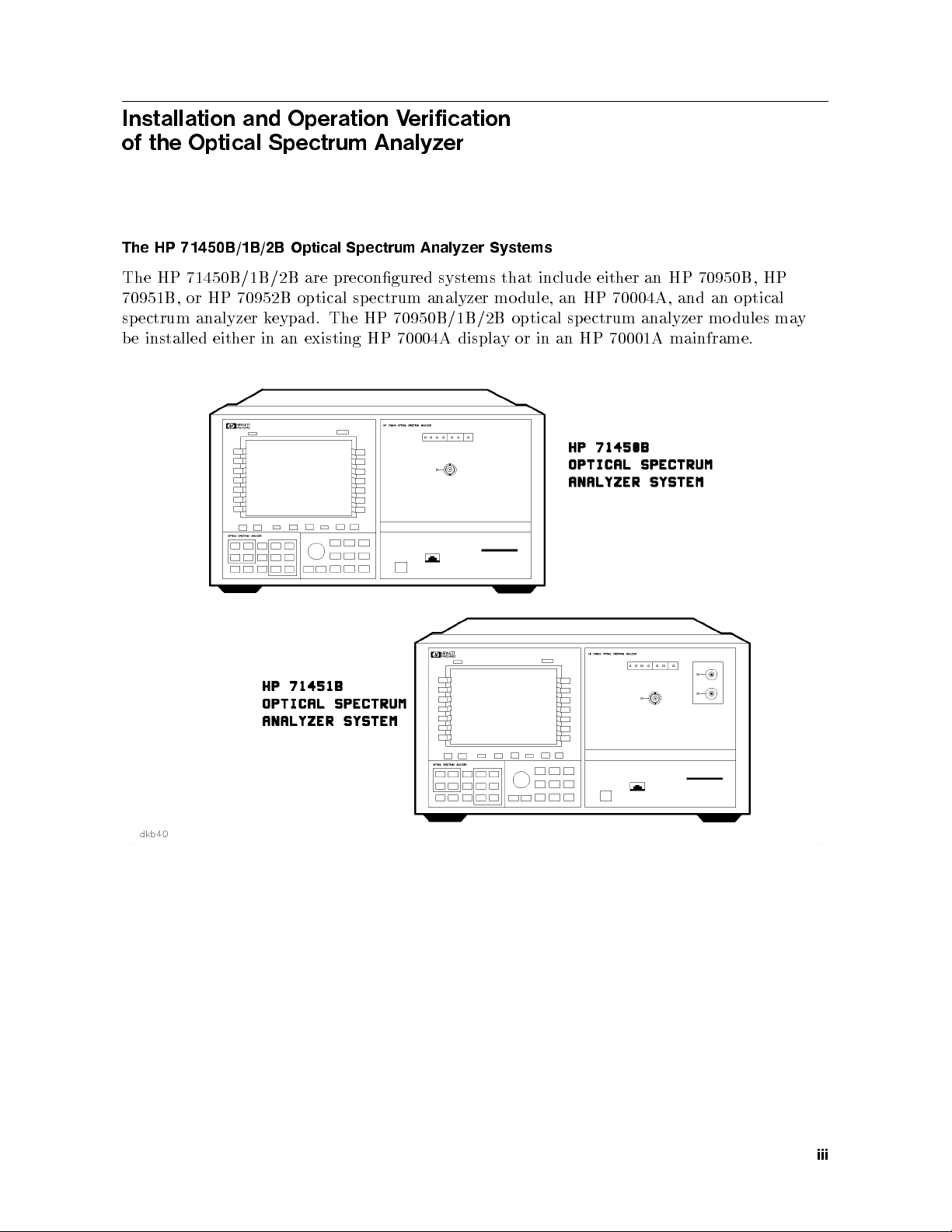

The HP 71450B/1B/2B Optical Spectrum Analyzer Systems

The HP 71450B/1B/2B are precongured systems that include either an HP 70950B, HP

70951B, or HP 70952B optical spectrum analyzer mo dule, an HP 70004A, and an optical

spectrum analyzer keypad. The HP 70950B/1B/2B optical spectrum analyzer modules may

be installed either in an existing HP 70004A display or in an HP 70001A mainframe.

iii

Page 4

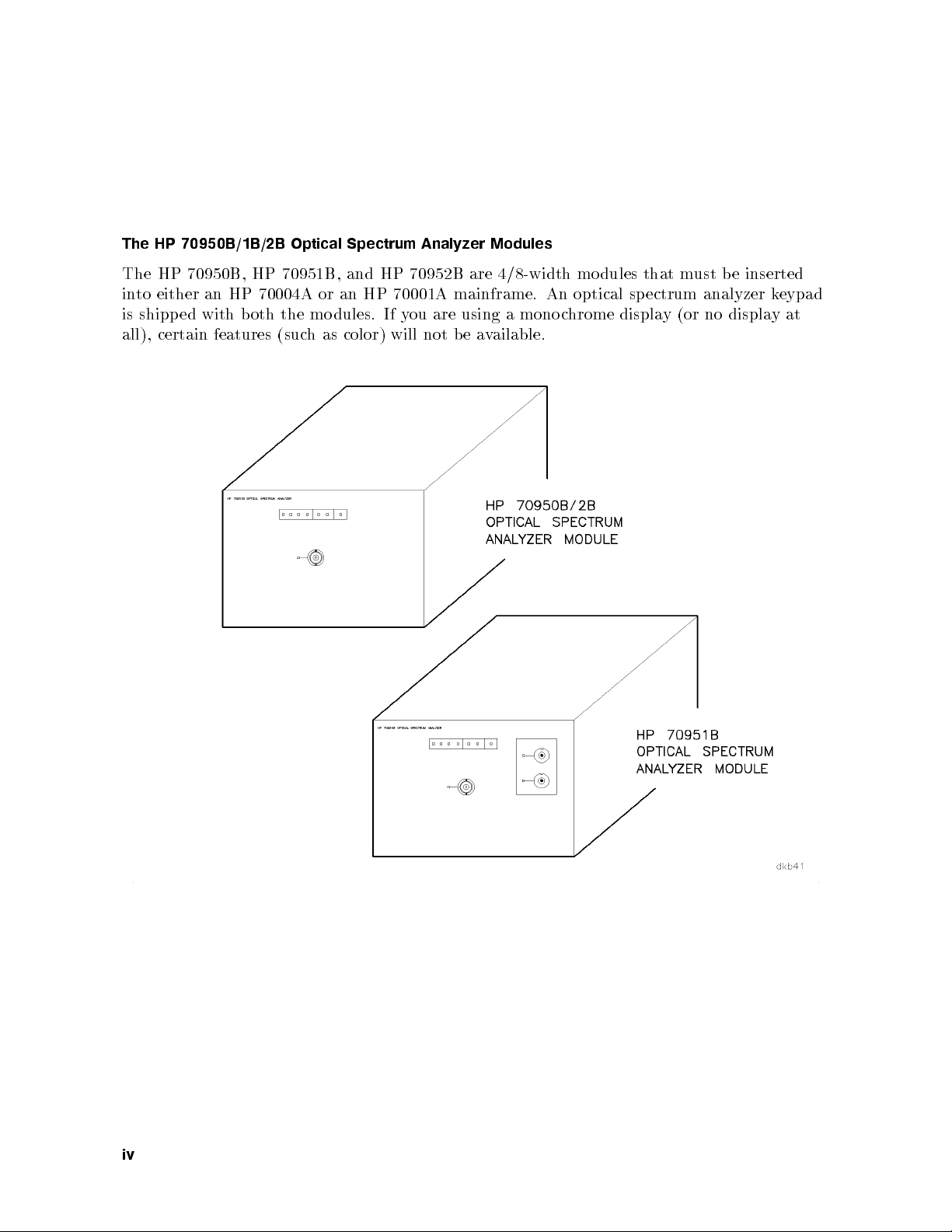

The HP 70950B/1B/2B Optical Spectrum Analyzer Modules

The HP 70950B, HP 70951B, and HP 70952B are 4/8-width mo dules that must be inserted

into either an HP 70004A or an HP 70001A mainframe. An optical sp ectrum analyzer keypad

is shipped with b oth the mo dules. If you are using a mono chrome display (or no displayat

all), certain features (such as color) will not be available.

iv

Page 5

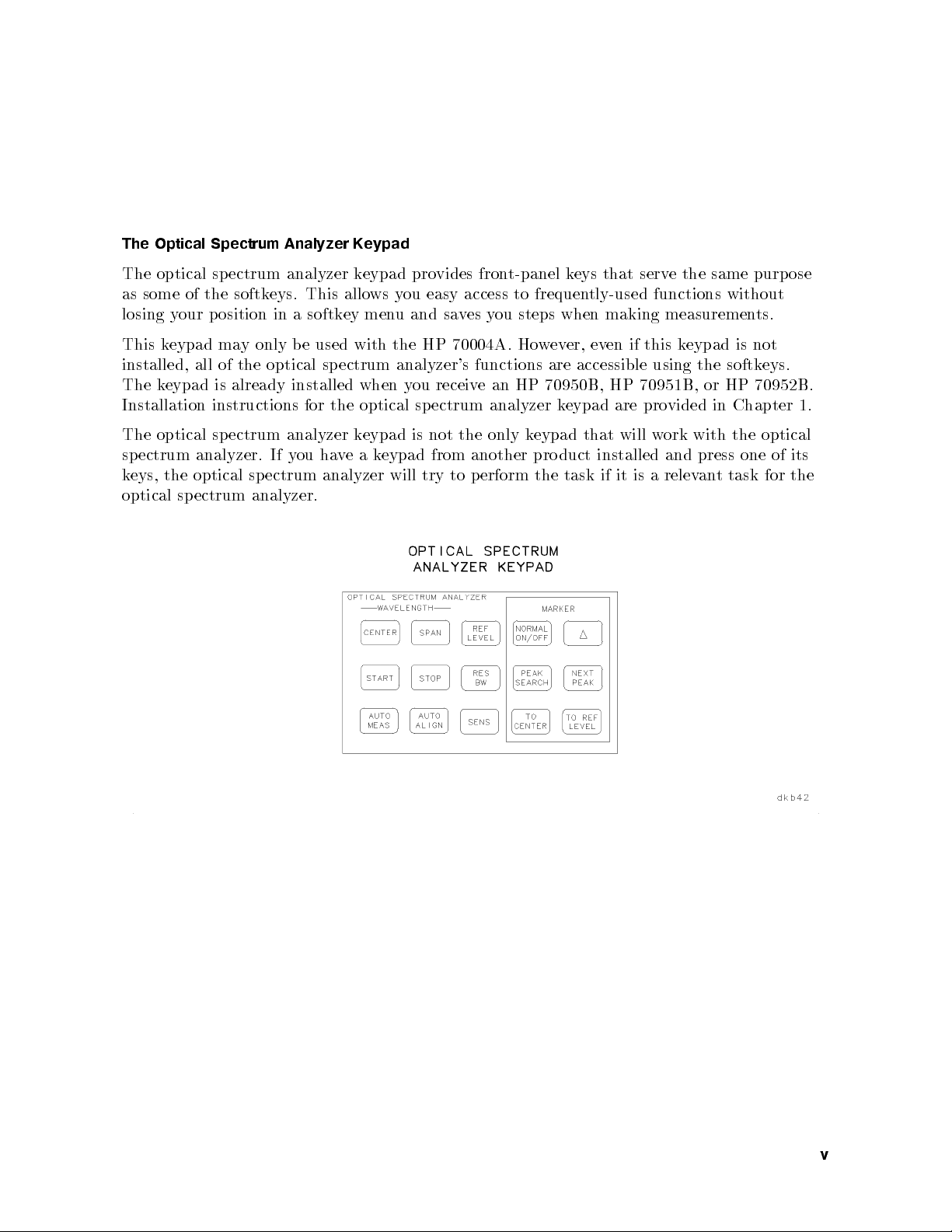

The Optical Spectrum Analyzer Keypad

The optical spectrum analyzer keypad provides front-panel keys that serve the same purpose

as some of the softkeys. This allows you easy access to frequently-used functions without

losing your p osition in a softkey menu and saves you steps when making measurements.

This keypad may only be used with the HP 70004A. However, even if this keypad is not

installed, all of the optical spectrum analyzer's functions are accessible using the softkeys.

The keypad is already installed when you receive an HP 70950B, HP 70951B, or HP 70952B.

Installation instructions for the optical spectrum analyzer keypad are provided in Chapter 1.

The optical spectrum analyzer keypad is not the only keypad that will work with the optical

spectrum analyzer. If you haveakeypad from another product installed and press one of its

eys, the

k

optical

optical

ectrum

sp

ectrum

sp

analyzer.

analyzer

will

try

to

erform

p

the

task

ttask

an

relev

a

is

it

if

for the

v

Page 6

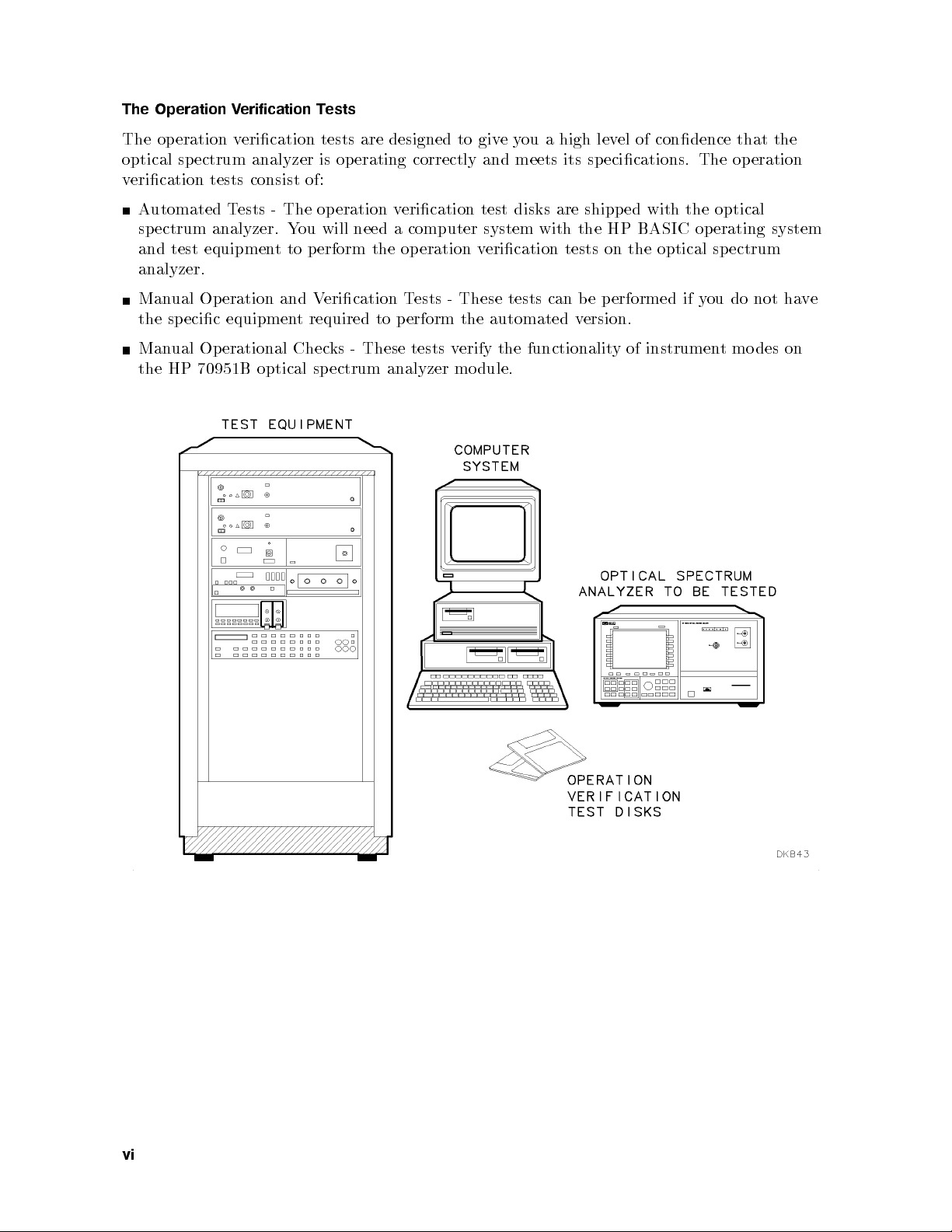

The Operation Verification Tests

The operation verication tests are designed to giveyou a high level of condence that the

optical spectrum analyzer is op erating correctly and meets its specications. The op eration

verication tests consist of:

Automated Tests - The op eration verication test disks are shipp ed with the optical

spectrum analyzer. You will need a computer system with the HP BASIC op erating system

and test equipment to p erform the operation verication tests on the optical sp ectrum

analyzer.

Manual Operation and Verication Tests - These tests can be performed if you do not have

the specic equipment required to perform the automated version.

Manual Operational Checks - These tests verify the functionality of instrument mo des on

the HP 70951B optical spectrum analyzer mo dule.

vi

Page 7

Note

In this bo ok, normal front-panel keys are indicated in

Softkeys are indicated by

NNNNNNNNNNNNNNNNNNNN

shaded

letters.

4

boxed

5

letters.

vii

Page 8

Page 9

Contents

1. Installation

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Installation at a Glance . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Installing the HP 71450B/1B/2B Optical Spectrum Analyzer System . . . . 1-4

Installing an HP 70950B/1B/2B Optical Spectrum Analyzer Mo dule . . . . 1-6

Step 1. Prepare to Install the Optical Spectrum Analyzer Mo dule. . . . . 1-6

Step 2. Check the Address of the Optical Spectrum Analyzer Mo dule. . . . 1-7

Step 3. Check the System's HP-MSIB Addresses. . . . . . . . . . . . . 1-8

Step 4. Install the Optical Sp ectrum Analyzer Module in the HP 70001A

Mainframe or the HP 70004A Display. . . . . . . . . . . . . . . . 1-10

Optional: Changing

Mo

Optional:

Optional:

Optional:

Displa

Optional:

Optional:

.

dule

Installing

Moun

Connecting

or Mainframe

y

Displa

Changing

.

the HP-MSIB

.

.

.

.

the

the

ting

the

the

ying

the

.

.

Optical

System

Optical

.

Time

Time

.

.

and

and

.

Sp

in

Sp

.

Address of

.

.

.

.

Rac

Analyzer's

k

ectrum

a

ectrum

.

.

.

.

Date

the

Date

the

the Optical

. .

.

.

.

.

.

.

Analyzer

.

.

.

.

.

.

.

.

.

.

. .

. .

Keypad

. .

.

System

.

.

.

.

.

.

.

.

.

ectrum

Sp

. .

.

.

. .

. .

the

in

.

Another

to

.

.

.

.

.

Analyzer

.

.

.

Displa

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

1-12

.

.

1-13

.

y

1-14

.

.

1-16

.

.

1-17

.

1-18

.

.

v

Ha

ou

Y

If

2.

duction

tro

In

Problems Requiring

Exp

the

to

Optical

What

If

a

e

ect

Problem

.

.

.

Additional T

When

ectrum

Sp

During

. .

.

ou

Y

Analyzer

Installation

.

. .

ec

on

urn

T

.

.

hnical

the

Will

.

.

.

Resources

Optical

T

Not

.

.

Sp

urn On

.

.

.

.

.

ectrum

. .

.

.

.

.

.

.

Analyzer

. .

.

.

. .

.

.

.

.

.

.

.

.

.

.

. .

. .

.

.

.

.

.

If the Front-Panel LEDs Do Not Light When the Optical Spectrum Analyzer is

Turned On . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

If the Optical Spectrum Analyzer Front-Panel ERR LED Remains Lit or Blinks

after the Self-Test . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

If Errors Are Reported on the Display. . . . . . . . . . . . . . . . . . 2-7

Lit

.

.

.

.

.

.

t Remains

.

Remain

. .

.

If

the

Self-T

Optical

est

Spectrum

.

.

.

.

Analyzer

. .

.

.

HP-IB

anel

t-P

ron

F

.

.

.

.

.

.

.

LEDs

.

.

.

If the Display HP-MSIB or the Mainframe I/O CHECK Indicator Ligh

Lit .

. . . . . . . . . .

If the Mainframe CURRENT Indicator Ligh

If the Optical Spectrum Analyzer Needs to be Returned for

To return the instrumen

. . . . . . . . . . . . . . . . . . . . . 2-10

t Remains Lit

. . . . . . . . . 2-11

Service . . . . . 2-12

t for service .

. . . . . . . . . . . . . . . .

the

after

Sales and service oces . . . . . . . . . . . . . . . . . . . . . . . 2-16

.

.

2-1

2-1

2-2

.

.

2-3

2-8

. 2-12

Contents-1

Page 10

3. Installation Reference

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Optical Sp ectrum Analyzer Accessories . . . . . . . . . . . . . . . . . 3-2

HP-MSIB Cables . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Connector Interfaces . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Memory Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Miscellaneous Parts and Supplies . . . . . . . . . . . . . . . . . . . 3-3

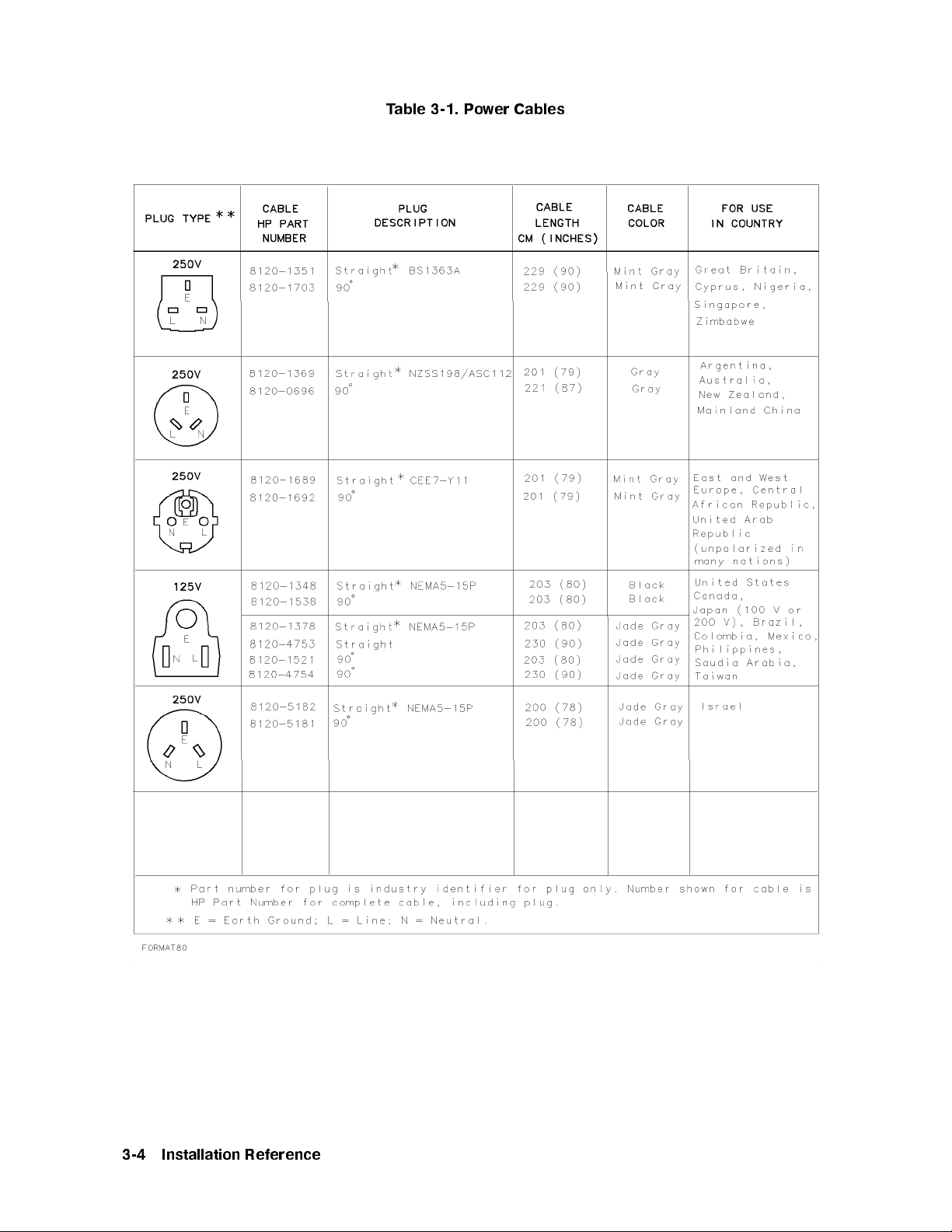

Power Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

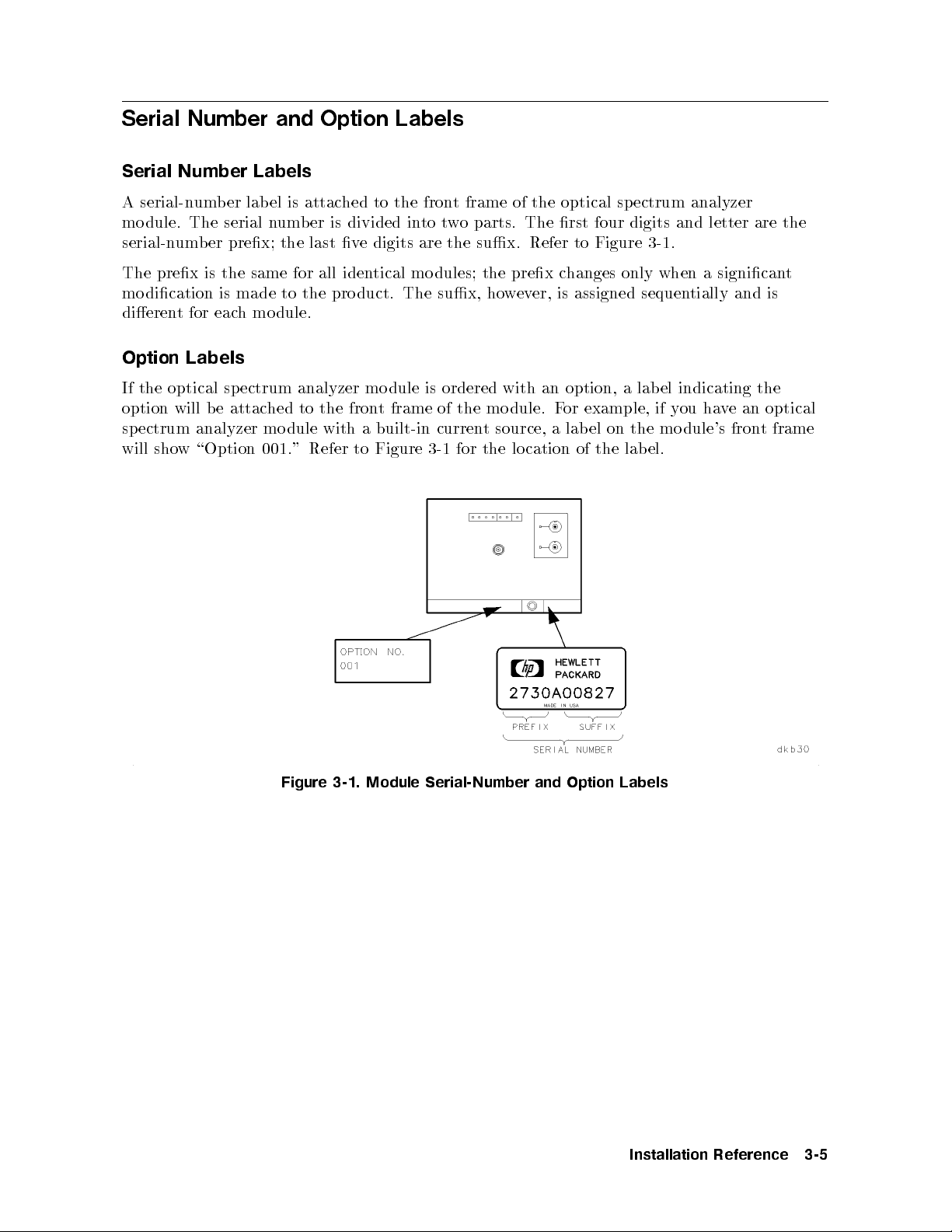

Serial Number and Option Labels . . . . . . . . . . . . . . . . . . . . 3-5

Serial Number Labels . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Option Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

ESD Information . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Reducing ESD Damage . . . . . . . . . . . . . . . . . . . . . . . 3-7

Static-Safe Accessories . . . . . . . . . . . . . . . . . . . . . . . . 3-7

4. Operation Verication Testing

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

. .

. .

. .

esting

erication

eration

Op

for

are

w

ware

ou

Y

Equipmen

est

eration

Optical

the

the

the

Line

the

Default

the

the Op

are

an SRM

on

. .

ectrum

Sp

ectrum

Sp

t

an

W

erication

V

.

.

erature

emp

T

Humidit

requency

F

est

T

MS

eration

.

.

.

Analyzer's

Analyzer's

to Output

.

t

.

.

.

ectrum

Sp

.

.

.

Setting

y

Equipment

Equipmen

File's

erication

V

Hardw

the

up

Set

1.

Step

Soft

Install

2.

Step

3. Load

Step

Select

4.

Step

En

5.

Step

Select

6.

Step

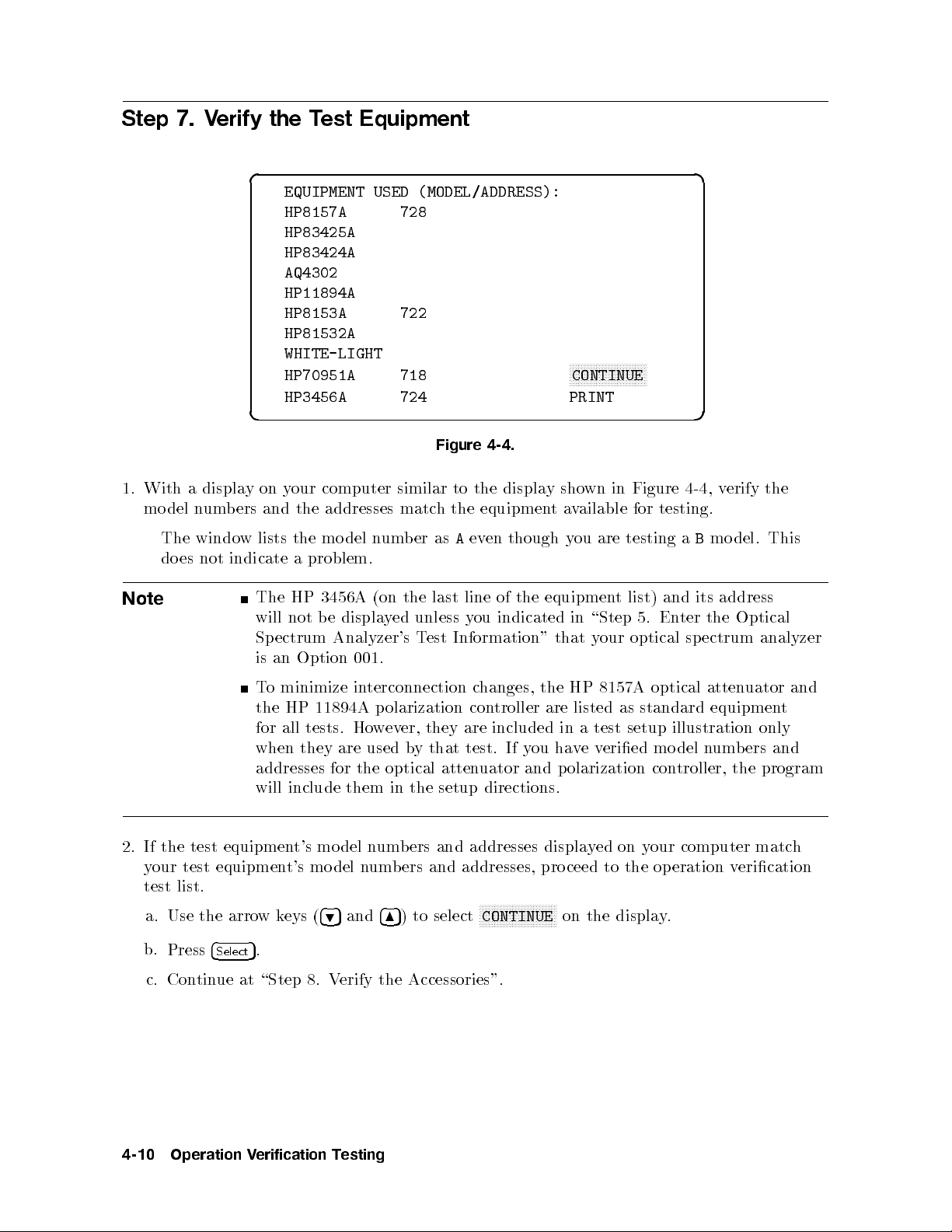

Verify

7.

Step

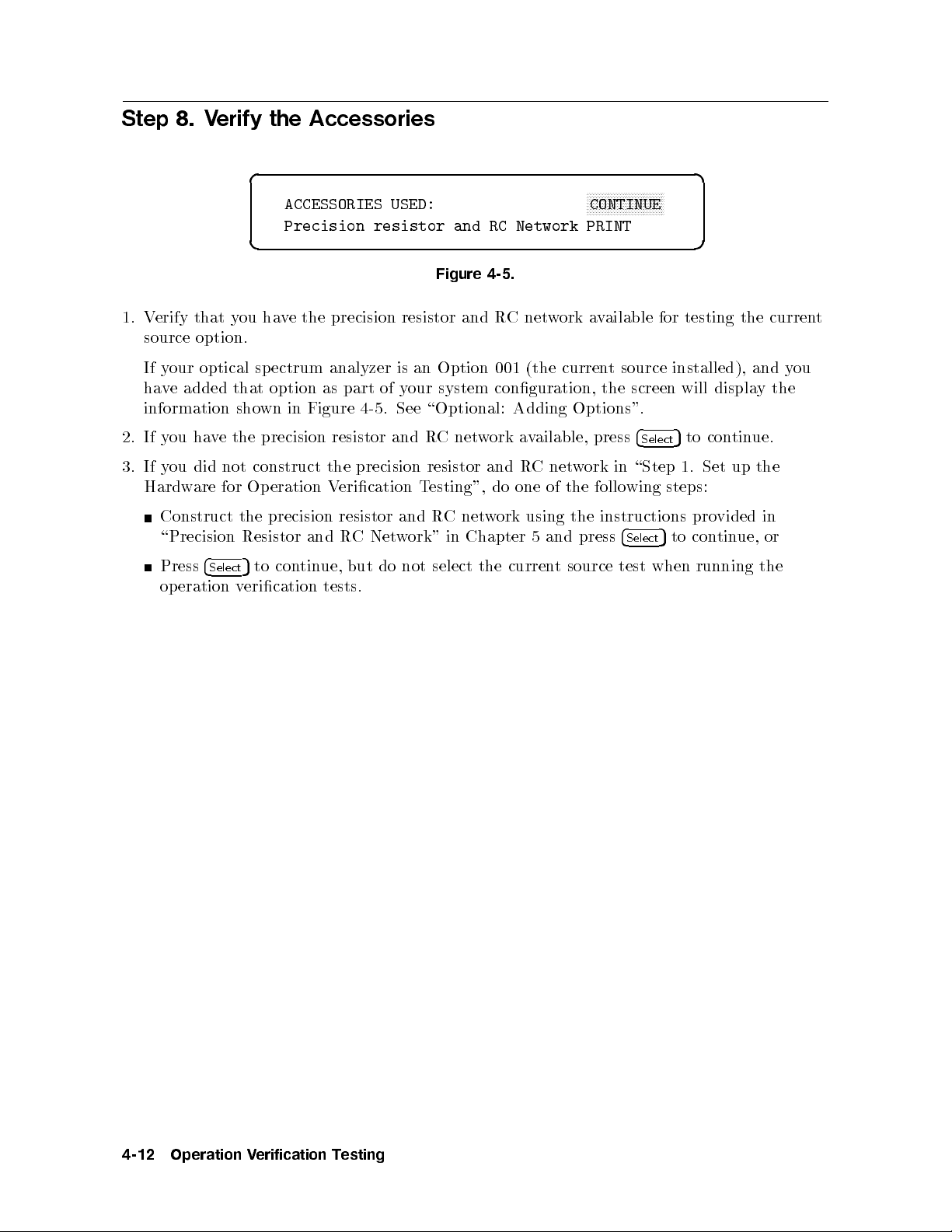

V

8.

Step

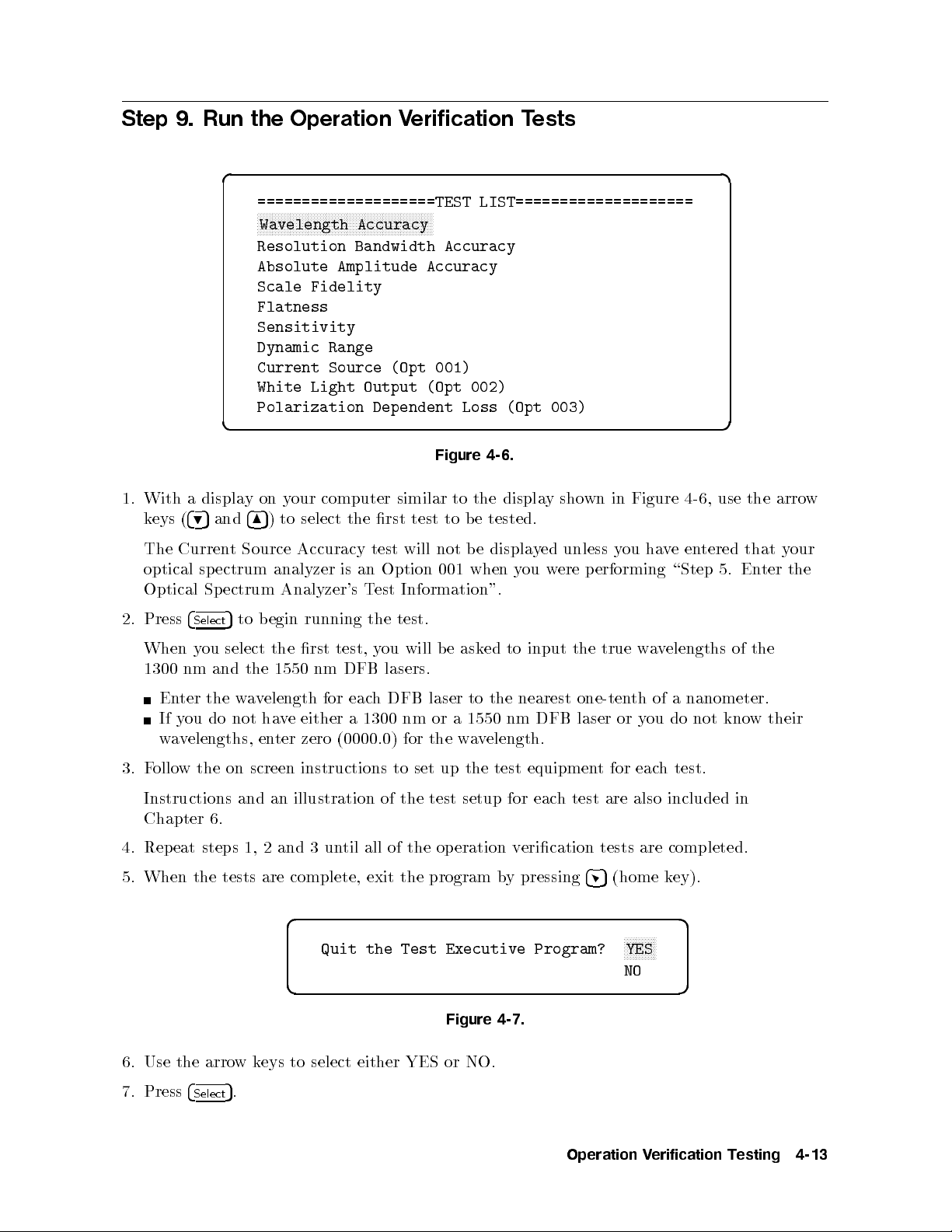

Run

9.

Step

Optional:

Optional:

Optional:

Optional:

Optional:

Optional:

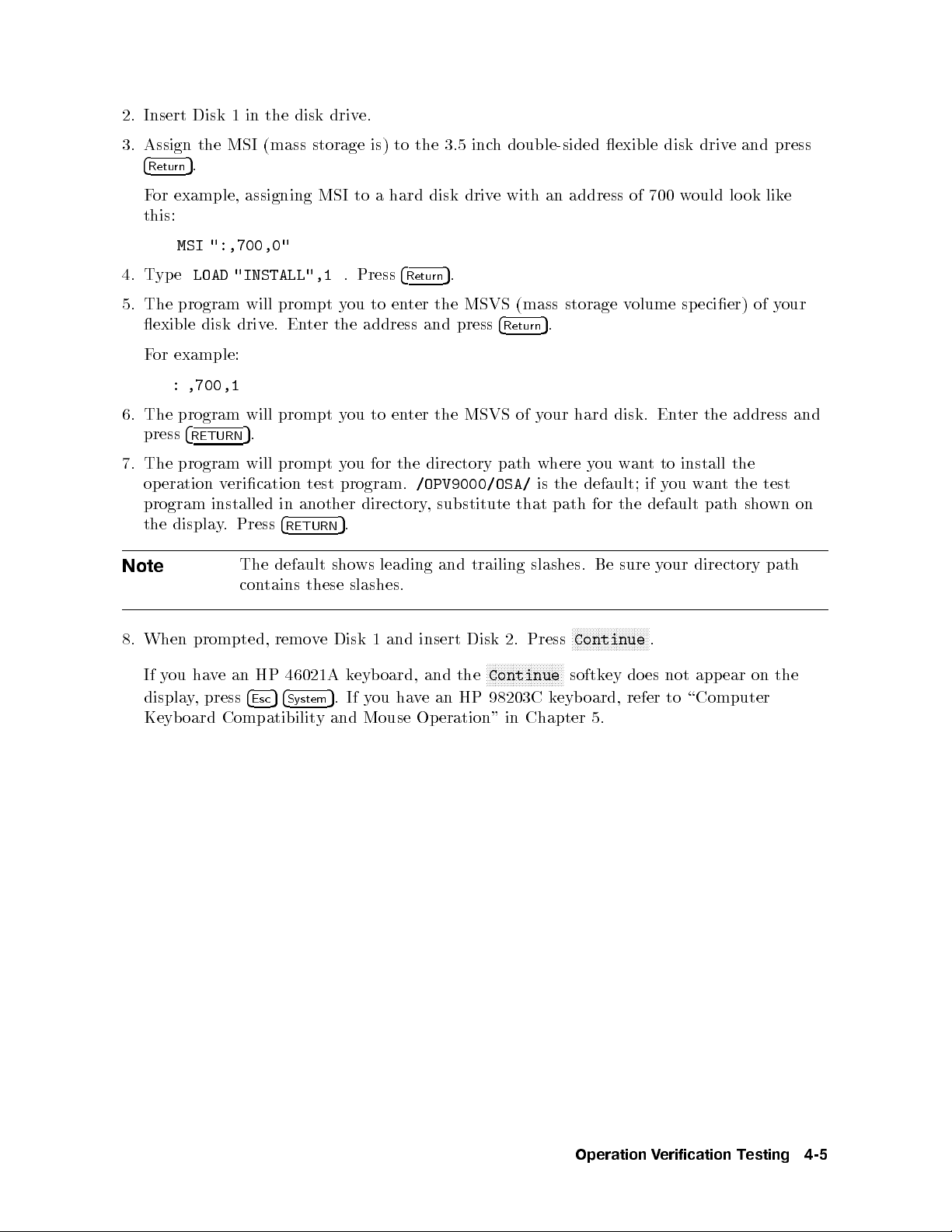

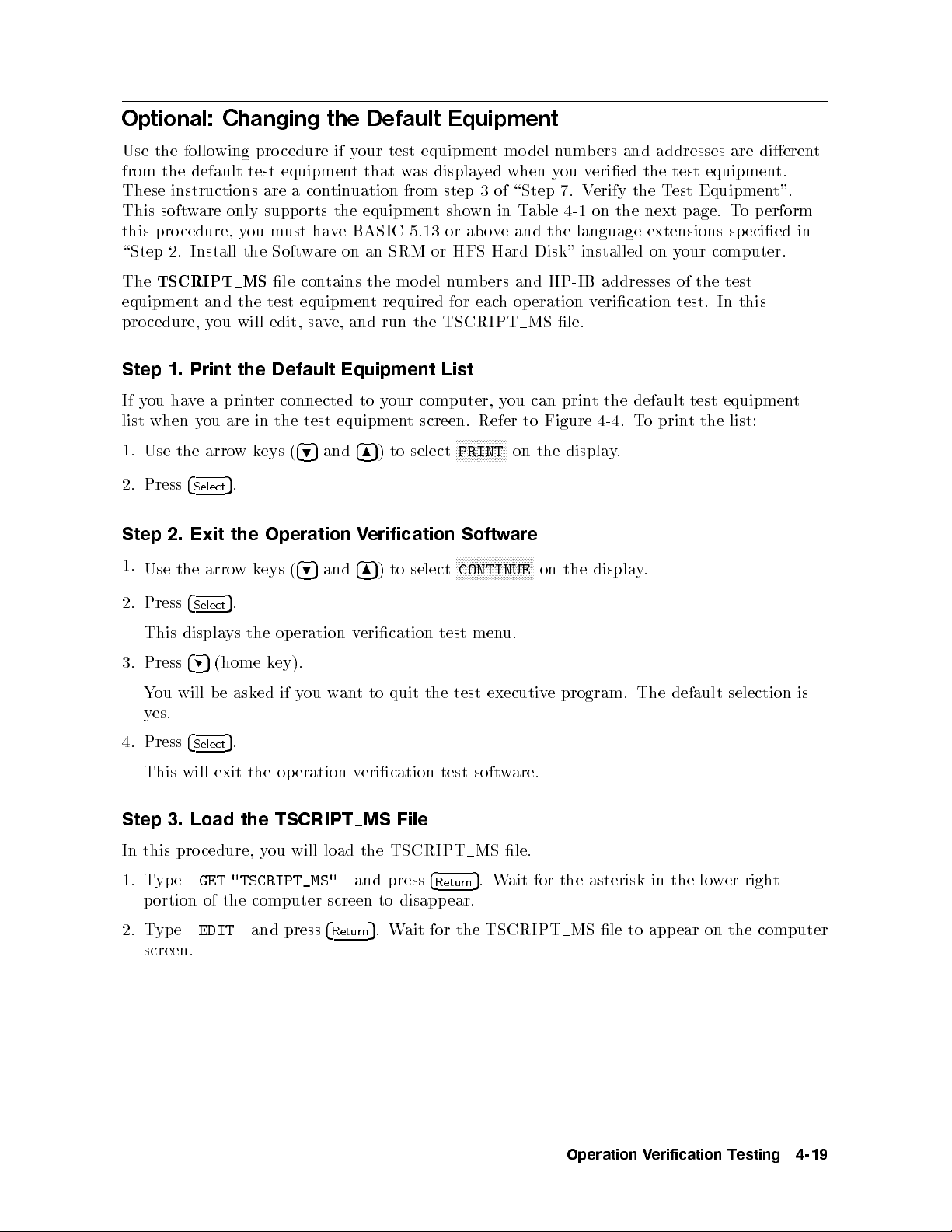

Step 1. Print the Default Equipment List . . . . . . . . . . . . . . . 4-19

Step 2. Exit the Operation Verication Software . . . . . . . . . . . . 4-19

Step 3. Load the TSCRIPT MS File . . . . . . . . . . . . . . . . . 4-19

Step 4. Edit the Test Equipment and HP-IB Address Lists . . . . . . . . 4-20

5.

Step

6.

Step

Optional:

the

the Soft

Optical

the

Optical

the

ter

Where

T

the

Accessories

the

erify

Op

the

Selecting

Adding Options

difying

Mo

difying

Mo

Selecting

Changing

the Required

Edit

TSCRIPT

the

e

v

Sa

Running

V

or HFS

.

.

.

.

.

.

ests

T

.

.

Setting

.

Edits

Hard Disk

.

.

.

Mo

est

T

est

T

the

.

.

.

.

.

.

.

.

Analyzer's Address

.

.

.

.

.

.

.

. .

.

.

. .

Lists

t

.

ests

T

T

.

.

.

.

.

.

del

Information

Results

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

. .

.

.

. .

.

.

.

.

.

.

.

a

from

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

. .

.

.

.

. .

.

.

.

. .

Flexible

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

. .

.

.

.

.

.

.

.

.

Disk

.

.

. .

.

.

. .

.

.

.

.

.

.

.

.

.

.

. .

.

. .

. .

.

.

.

.

.

.

.

.

Driv

4-3

.

.

.

. 4-10

.

.

.

.

. 4-17

.

.

.

.

e 4-22

4-4

4-6

4-7

4-8

4-9

4-12

4-13

4-14

4-15

4-16

4-18

4-19

4-21

4-21

5. Operation V

Introduction

System Requiremen

Computer Hardw

Operating System . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Computer Keyboard Compatibility and Mouse Operation . . . . . . . . . 5-4

Using

Using

Using

Recommended

Contents-2

erication T

. . . . . . . . . . . . .

46021A

HP

an

98203C

HP

an

T

with

est

Mouse

a

est Reference

. . . . . . . . . . . . . . . . . . . . . . . . 5-2

ts .

are .

. . . . . . . . . . . . . .

Keyb

Keyb

Series 300

a

Equipmen

oard

oard

t

with

with

Computer

.

.

.

. . . . . . . . . . . . . . . . 5-1

. . . . . . . . . . 5-2

.

.

.

.

.

a

a

.

Series

Series

.

.

.

.

300

300

.

.

Computer

Computer

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

5-4

5-4

5-5

5-5

Page 11

Precision Resistor and RCNetwork . . . . . . . . . . . . . . . . . . . 5-8

6. Operation Verication Test Descriptions

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Automated Test Pro cedures . . . . . . . . . . . . . . . . . . . . . . 6-3

Wavelength Accuracy (Automated) . . . . . . . . . . . . . . . . . . . 6-4

Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Equipment Setup . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

In Case of Failure . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

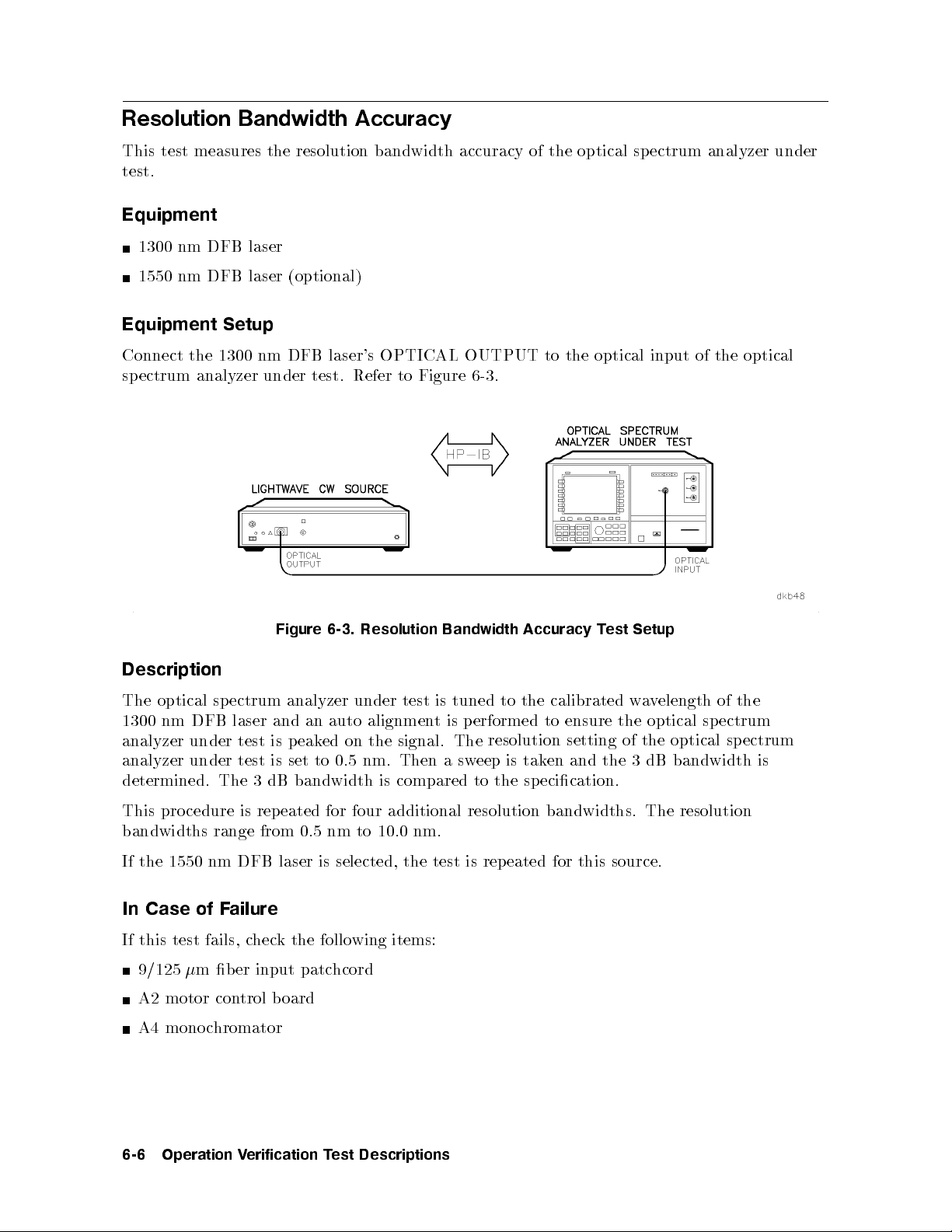

Resolution Bandwidth Accuracy . . . . . . . . . . . . . . . . . . . . 6-6

Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Equipment Setup . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

In Case of Failure . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Absolute Amplitude Accuracy . . . . . . . . . . . . . . . . . . . . . 6-7

Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Equipment Setup . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

.

.

.

.

.

.

.

.

. .

. .

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

Description

Case

In

Fidelity

Scale

Equipmen

Equipmen

Description

Case

In

Flatness

Equipmen

Equipmen

Description

Case

In

Sensitivit

Equipmen

Description

In Case of Failure . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

Dynamic Range (Automated) . . . . . . . . . . . . . . . . . . . . . . 6-15

Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Equipment Setup . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Description

Case

In

Curren

White Light Output Power, Option 002 . . . . . . . . . . . . . . . . . 6-19

P

t

Equipment.

Equipment Setup . . . . . . . . . . . . . . . . . . . . .

Description .

In Case of F

Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

Equipment Setup . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

Description

Case

In

olarization

Equipmen

.

ailure

F

of

. .

.

t

Setup

t

.

ailure

of F

erication

V

.

t

Setup

t

. .

ailure

F

of

.

.

y

Setup

t

.

.

ailure

F

of

Source, Option

ailure .

.

ailure

F

of

Dep

.

t

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

. .

.

.

. . . . . . . .

. . . . . . . . . .

. .

.

.

enden

.

.

.

.

.

.

.

.

.

. .

. .

. .

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

. .

.

.

.

.

.

.

.

.

.

.

.

. .

. .

. .

. .

.

.

.

.

.

.

.

.

.

.

.

.

. .

. .

. .

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

. .

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

System

. .

. . . . . . . . . . . . . . . . . . . . 6-17

. . . . . . . . . . . . . . . . . . 6-18

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

003

.

.

.

.

.

.

Accuracy

.

.

.

.

Option

,

.

.

001

. . . . . . . . . . . . . . . . . .

.

.

Loss

t

.

.

.

.

.

.

.

.

.

. .

. .

. .

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. . . . . 6-17

. . . . . . . 6-18

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. 6-14

.

.

.

.

.

6-8

6-8

6-9

6-9

6-9

6-10

6-10

6-11

6-11

6-11

6-12

6-13

6-14

6-14

6-16

6-16

6-17

6-20

6-20

6-21

6-21

Contents-3

Page 12

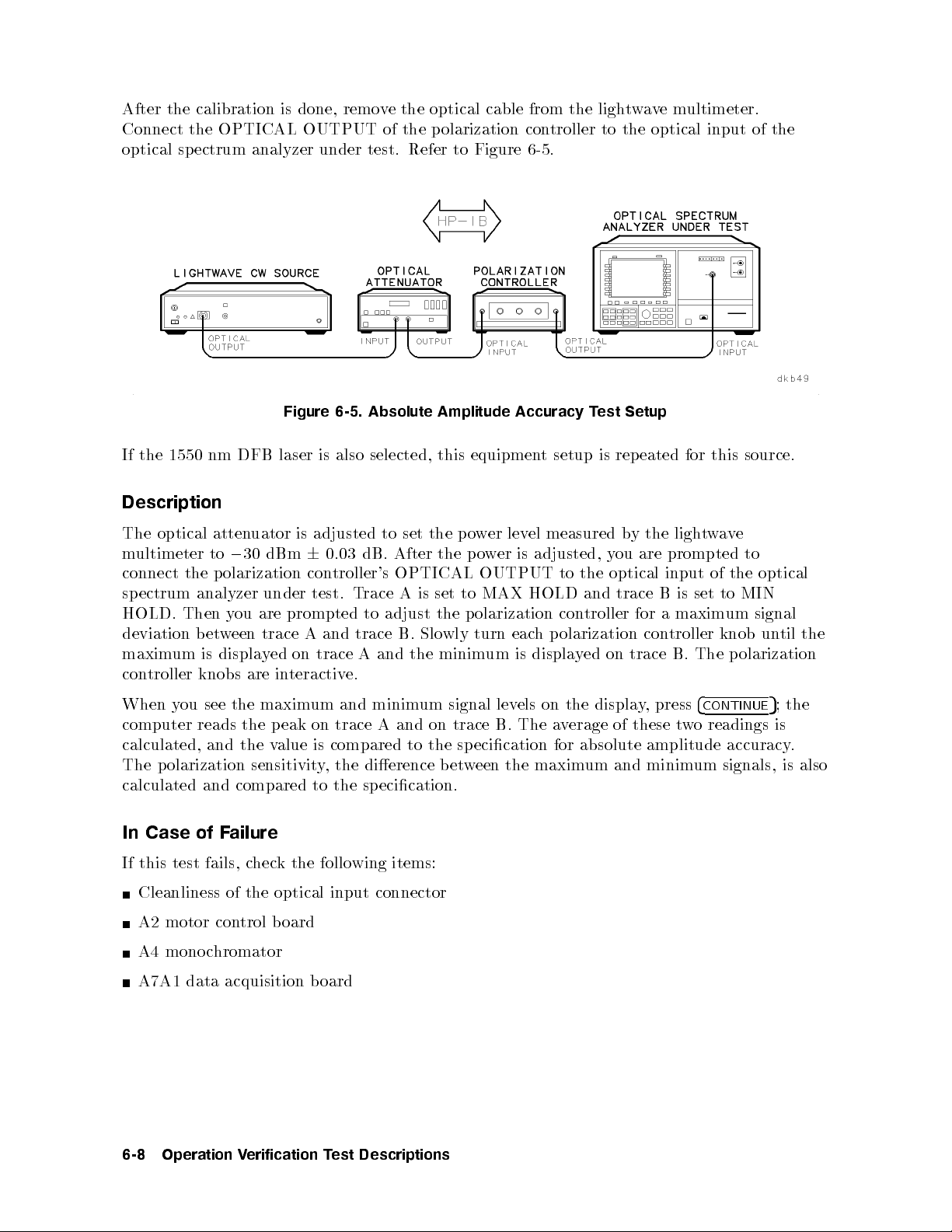

Equipment setup . . . . . . . . . . . . . . . . . . . . . . . . . . 6-21

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

In Case of Failure . . . . . . . . . . . . . . . . . . . . . . . . . . 6-23

Manual Test Procedures . . . . . . . . . . . . . . . . . . . . . . . . 6-24

Wavelength Accuracy (Manual) . . . . . . . . . . . . . . . . . . . . . 6-25

Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-25

EquipmentSetup . . . . . . . . . . . . . . . . . . . . . . . . . . 6-25

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-26

Dynamic Range (Manual) . . . . . . . . . . . . . . . . . . . . . . . 6-27

Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-27

EquipmentSetup . . . . . . . . . . . . . . . . . . . . . . . . . . 6-27

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-27

Flatness (Manual) . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-29

Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-29

EquipmentSetup . . . . . . . . . . . . . . . . . . . . . . . . . . 6-29

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-31

Manual Operational Checks for the HP 70951B Optical Sp ectrum Analyzer

Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-32

. 6-33

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

. .

.

.

detector

.

.

.

.

.

.

.

6-33

.

.

.

.

.

. .

. .

. .

. .

.

.

.

.

.

.

.

.

6-33

.

.

.

.

.

.

.

.

.

.

.

.

. .

. .

.

.

.

.

.

6-33

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

6-35

.

.

.

. .

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. 6-36

.

.

.

.

.

.

.

.

.

.

.

k

Input

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Chec

6-36

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

6-36

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

6-36

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

6-37

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

Transimp

Equipmen

Equipmen

cedure

Pro

Case of

In

hromator

c

Mono

Equipmen

Equipmen

cedure

Pro

Case

In

edance Input

.

.

.

t

Setup

t

.

.

.

ailure

F

Output/Photo

.

.

.

t

Setup

t

.

.

.

ailure

F

of

Check

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

Index

Contents-4

Page 13

Figures

2-1. Optical Spectrum Analyzer FrontPanel (HP 71451B Shown) . . . . . . . 2-2

2-2. Line Voltage Selector . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2-3. Line Fuse Removal and Replacement . . . . . . . . . . . . . . . . . 2-4

2-4. Optical Spectrum Analyzer FrontPanel LEDs (HP 71451B Shown) . . . . 2-5

2-5. Optical Spectrum Analyzer Error Information (HP 71451B Shown) . . . . 2-6

2-6. Optical Spectrum Analyzer Displayed Errors (HP 71451B Shown) . . . . . 2-7

2-7. Optical Spectrum Analyzer HP-IB LEDs (HP 71451B Shown) . . . . . . 2-8

2-8. HP-MSIB and I/O CHECK Indicator Lights . . . . . . . . . . . . . . 2-10

2-9. Current Indicator Light . . . . . . . . . . . . . . . . . . . . . . . 2-11

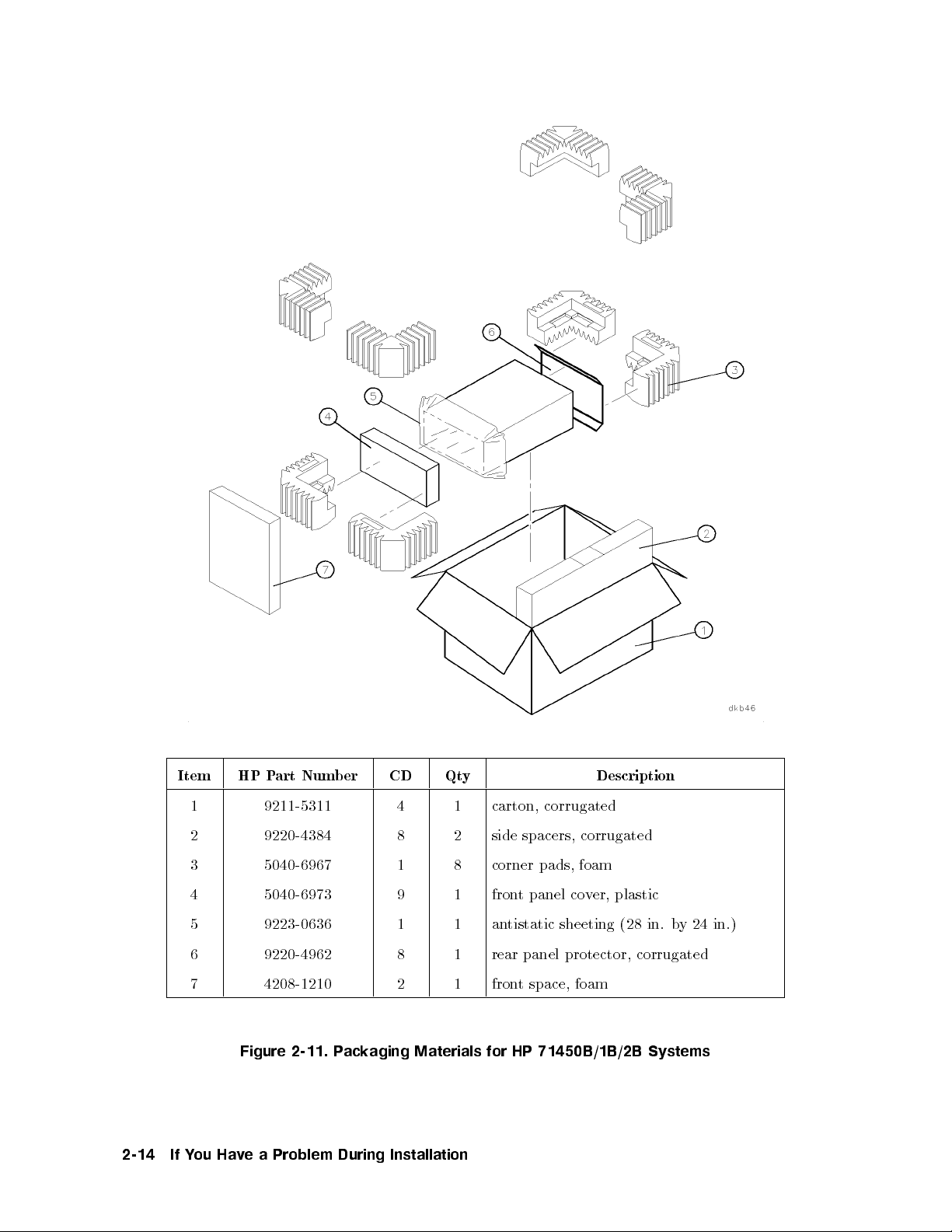

2-10. Packaging Materials for HP 70950B/1B/2B Mo dules . . . . . . . . . . 2-13

.

.

.

.

.

.

.

. .

Materials

aging

k

ac

P

2-11.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

elength

v

a

t

t

Ligh

Serial-Numb

orkstation

W

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

. .

.

.

.

. .

. .

Accuracy

Bandwidth

yT

est Setup

Source

Source

Output

t

Module

3-1.

Static-Safe

3-2.

.

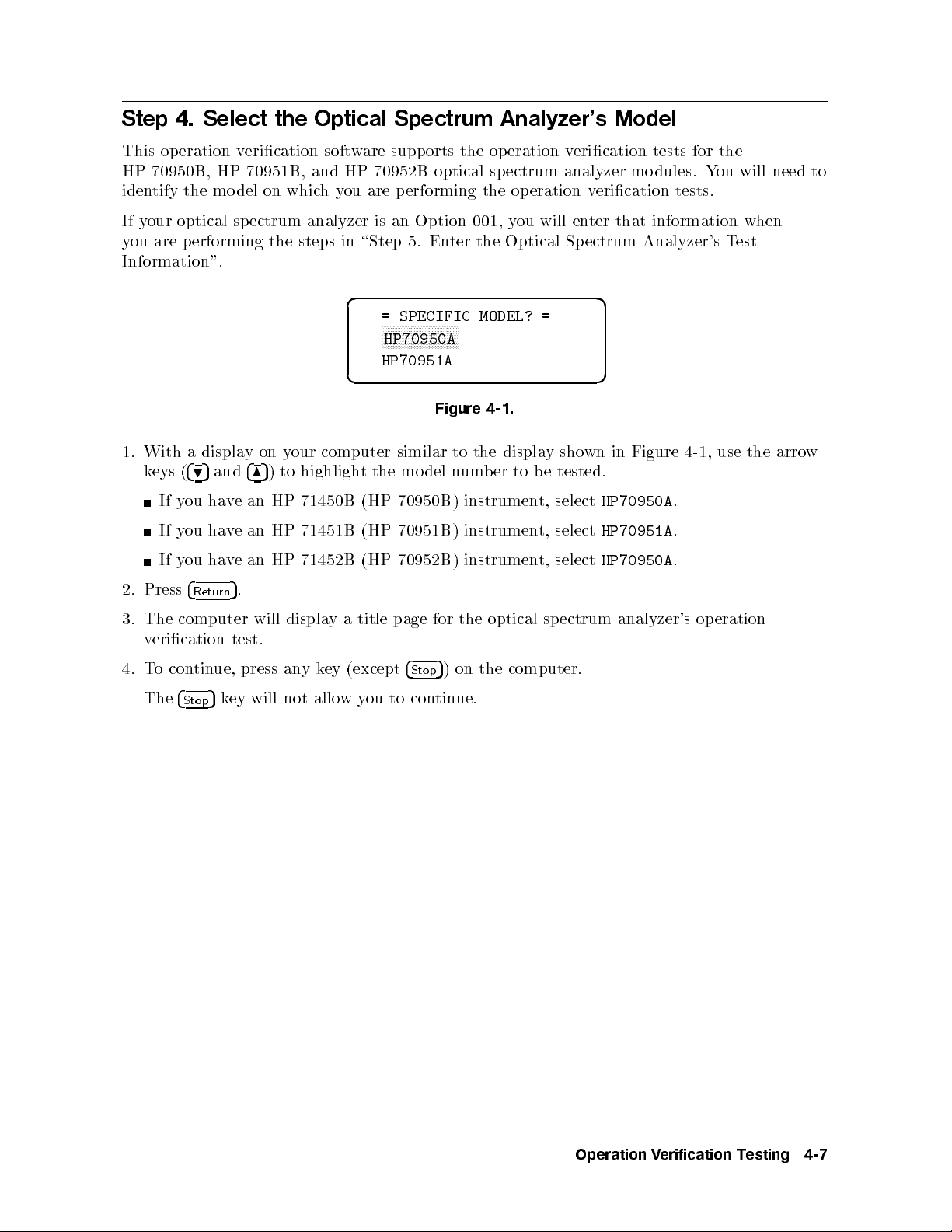

4-1.

.

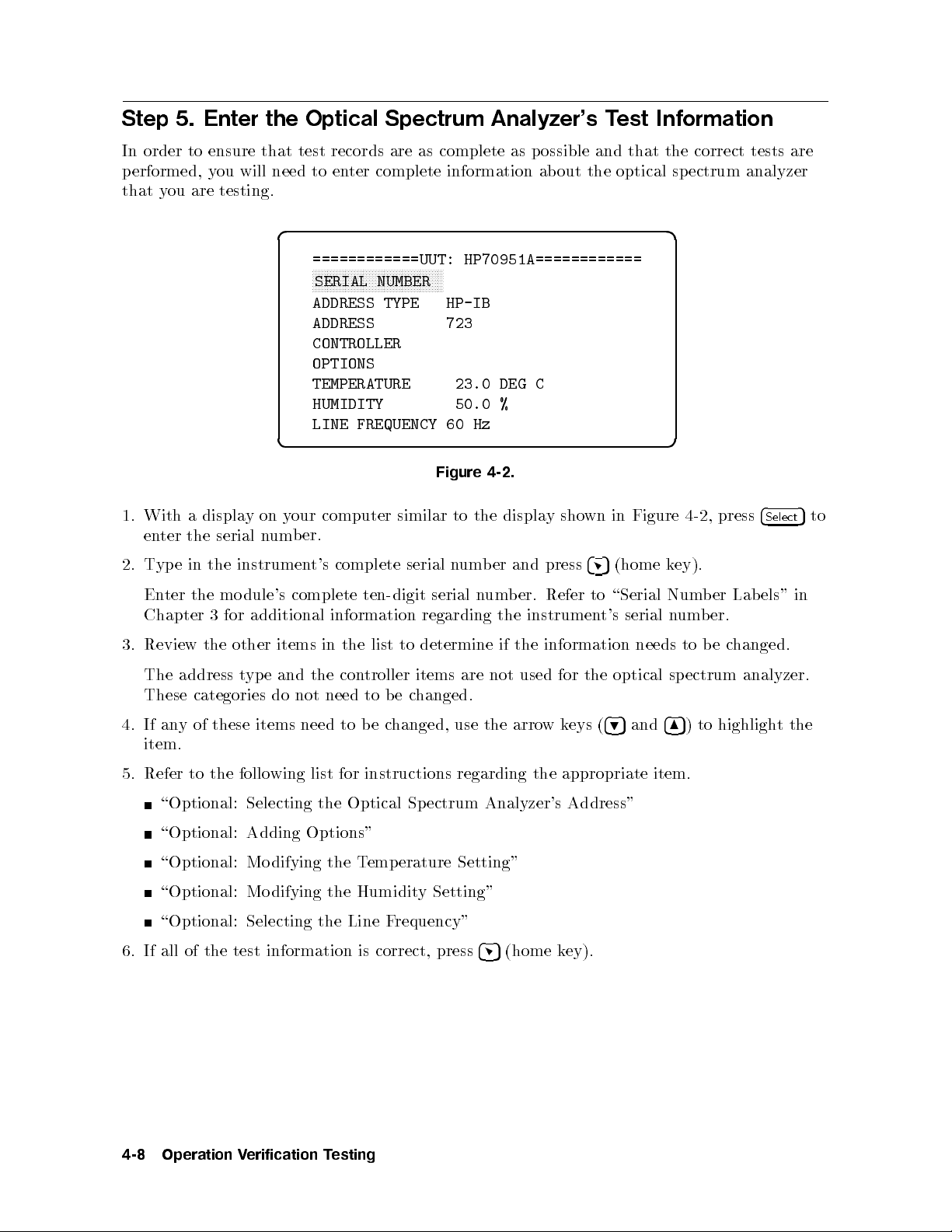

4-2.

.

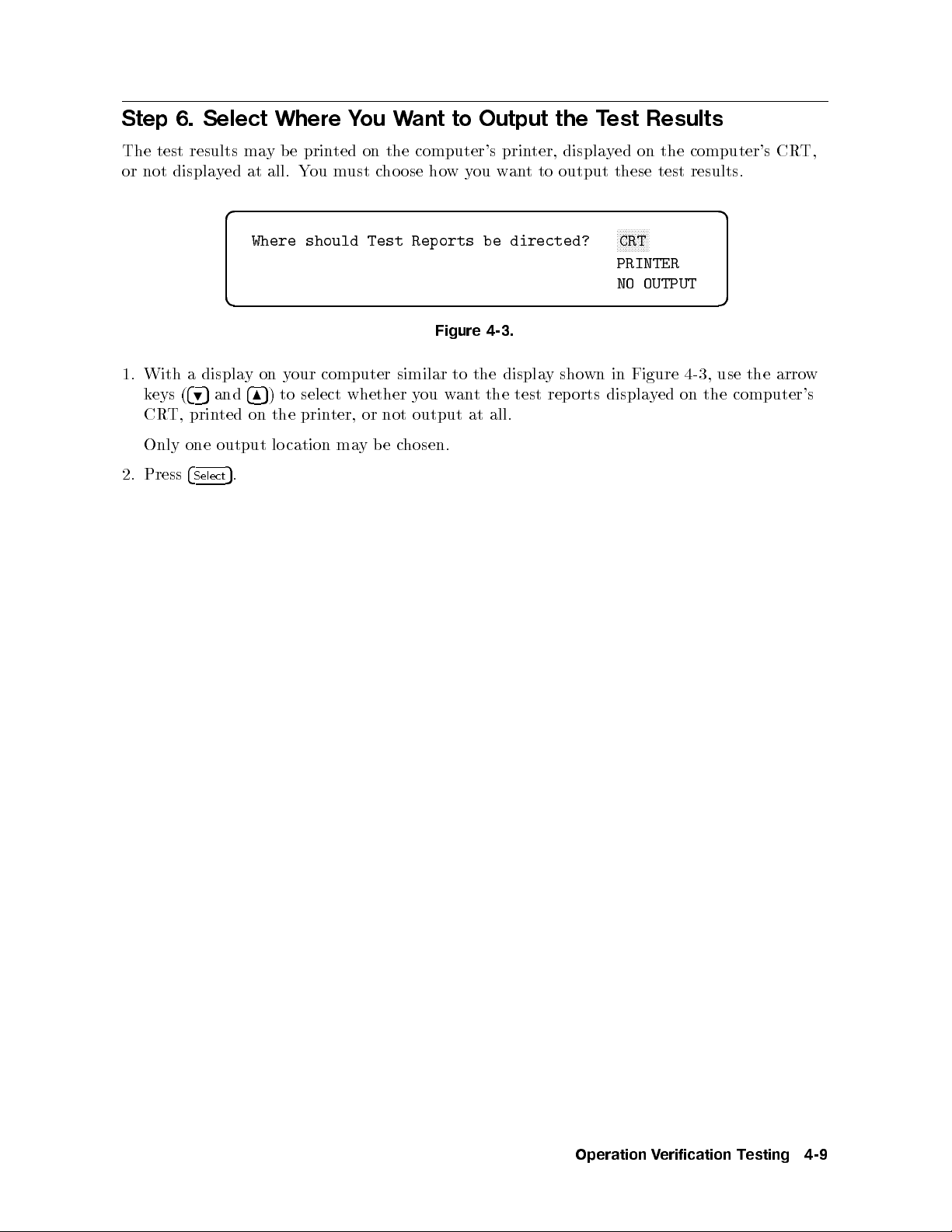

4-3.

. .

4-4.

.

4-5.

.

4-6.

.

4-7.

4-8. .

.

4-9.

4-10.

4-11. .

4-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

4-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

4-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

6-10. Dynamic Range Test System Alignment Setup . . . . . . . . . . . . . 6-15

6-11.

6-12.

6-13.

6-14.

.

5-1. Precision Resistor and RCNetwork Schematic Diagram . . . . . . . . . 5-8

6-1. Wavelength Accuracy Test Setup 1 . . . . . . . . . . . . . . . . . . 6-4

W

6-2.

Resolution

6-3.

6-4. Absolute Amplitude Accuracy Calibration Setup

6-5. Absolute Amplitude Accuracy T

6-6. Scale Fidelit

6-7. Flatness Calibration Setup .

6-8. Flatness T

6-9. SensitivityTest Setup . . . . . . . . . . . . . . . . . . . . . . . . 6-14

Dynamic Range

Curren

Curren

White

for HP

er and

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

est Setup

. .

Setup

est

T

Calibration

Setup

est

T

P

71450B/1B/2B Systems

.

.

els

Option

.

.

. .

.

. .

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

. .

. .

.

.

.

Setup

Test

Accuracy

. . . . . . . . . . . . . . . . . . . . . . . 6-9

. . . . . . . . . . . . . . . . . . . . . . . 6-12

Setup

.

T

er

ow

Lab

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

2

Setup

est

T

est Setup

. . . . . . . . . . . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

est

Setup

1

.

. . . . . . . . . . . .

.

.

.

.

.

.

.

. .

.

.

.

. .

. 3-5

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. 4-15

. .

.

.

.

.

.

.

.

.

.

.

.

.

. .

. .

. .

. .

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

. . . . . . . . . . . . 6-7

. . . 6-8

. . . . . . . 6-11

. 6-16

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

2-14

3-6

4-7

4-8

4-9

4-10

4-12

4-13

4-13

4-14

4-15

4-16

6-4

6-6

6-17

6-18

6-19

Contents-5

Page 14

6-15. White Light Output Power Test Setup 2 . . . . . . . . . . . . . . . . 6-20

6-16. PDL System Accuracy Test Setup . . . . . . . . . . . . . . . . . . . 6-21

6-17. Manual Wavelength Accuracy Test Setup . . . . . . . . . . . . . . . 6-25

6-18. Manual Dynamic Range Test Setup . . . . . . . . . . . . . . . . . . 6-27

6-19. Manual Flatness Test Setup 1 . . . . . . . . . . . . . . . . . . . . 6-29

6-20. Manual Flatness Test Setup 2 . . . . . . . . . . . . . . . . . . . . 6-30

6-21. Transimp edance Input Check Setup . . . . . . . . . . . . . . . . . . 6-33

6-22. Monochromator Output/Photodetector Input Check Setup . . . . . . . . 6-36

Contents-6

Page 15

Tables

3-1. Power Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3-2. Static-Safe Accessories . . . . . . . . . . . . . . . . . . . . . . . . 3-7

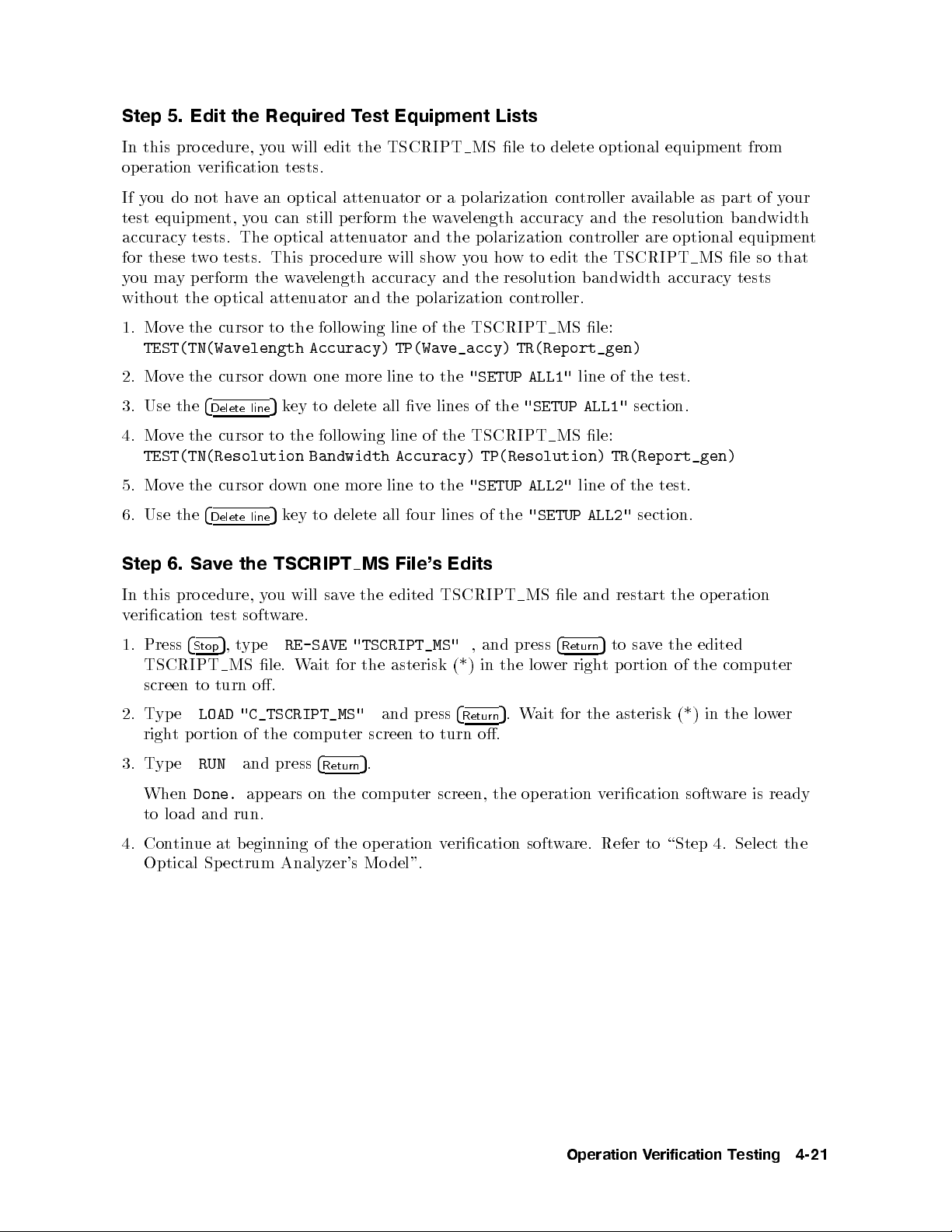

4-1. Test EquipmentVariable Names . . . . . . . . . . . . . . . . . . . 4-20

5-1. Required Computer Hardware . . . . . . . . . . . . . . . . . . . . 5-2

5-2. Required BASIC 5.13 Language Extensions . . . . . . . . . . . . . . 5-3

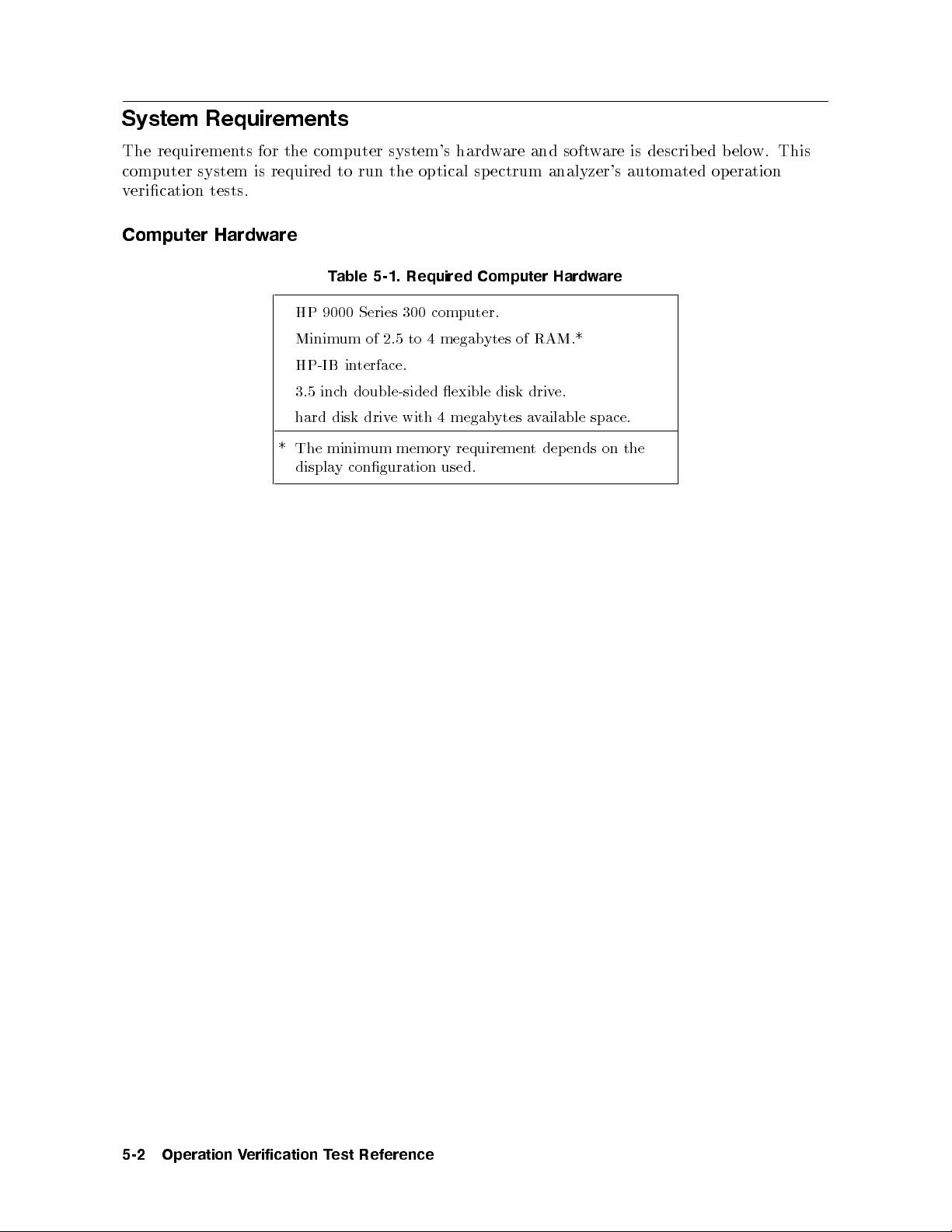

5-3. Equivalent Keys for the Operation Verication Tests . . . . . . . . . . 5-4

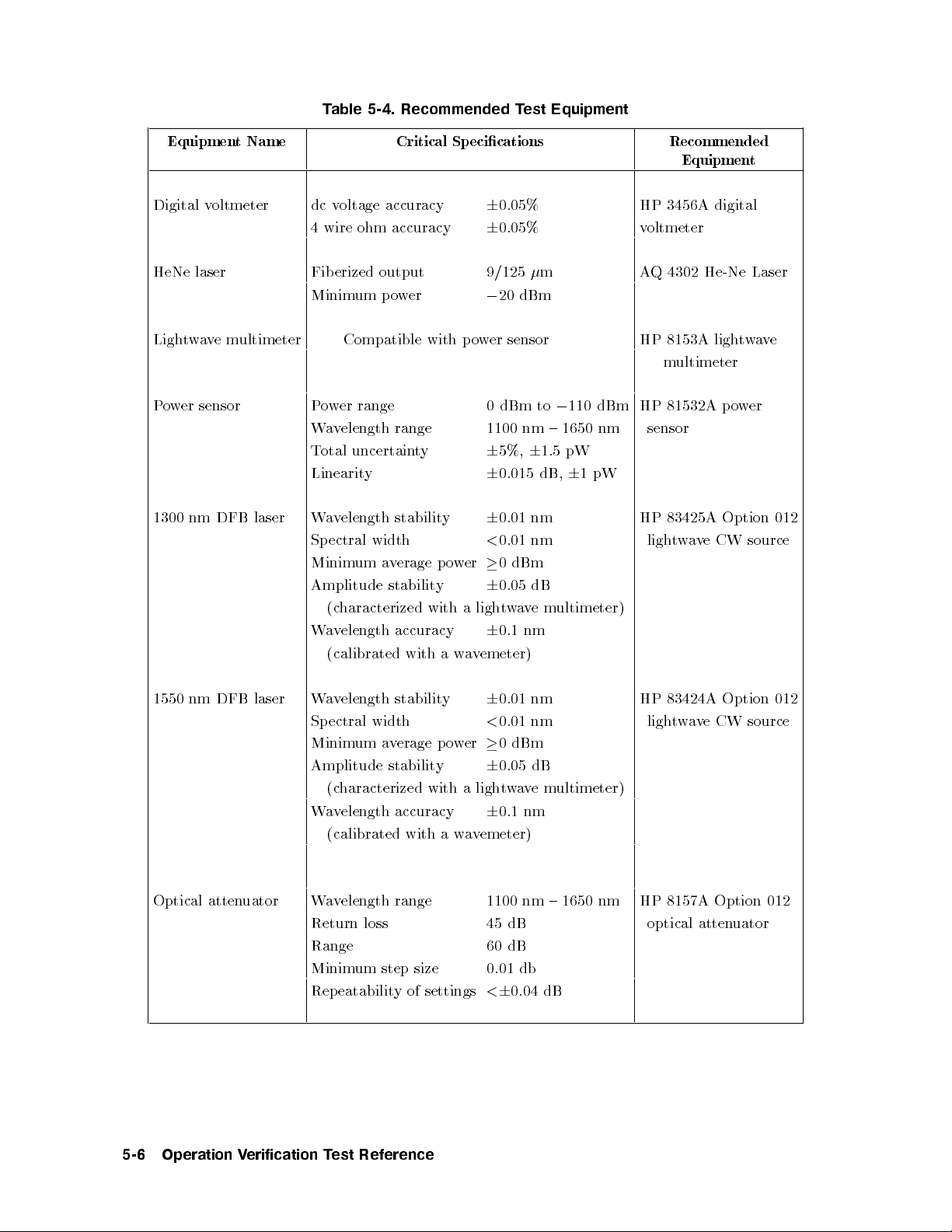

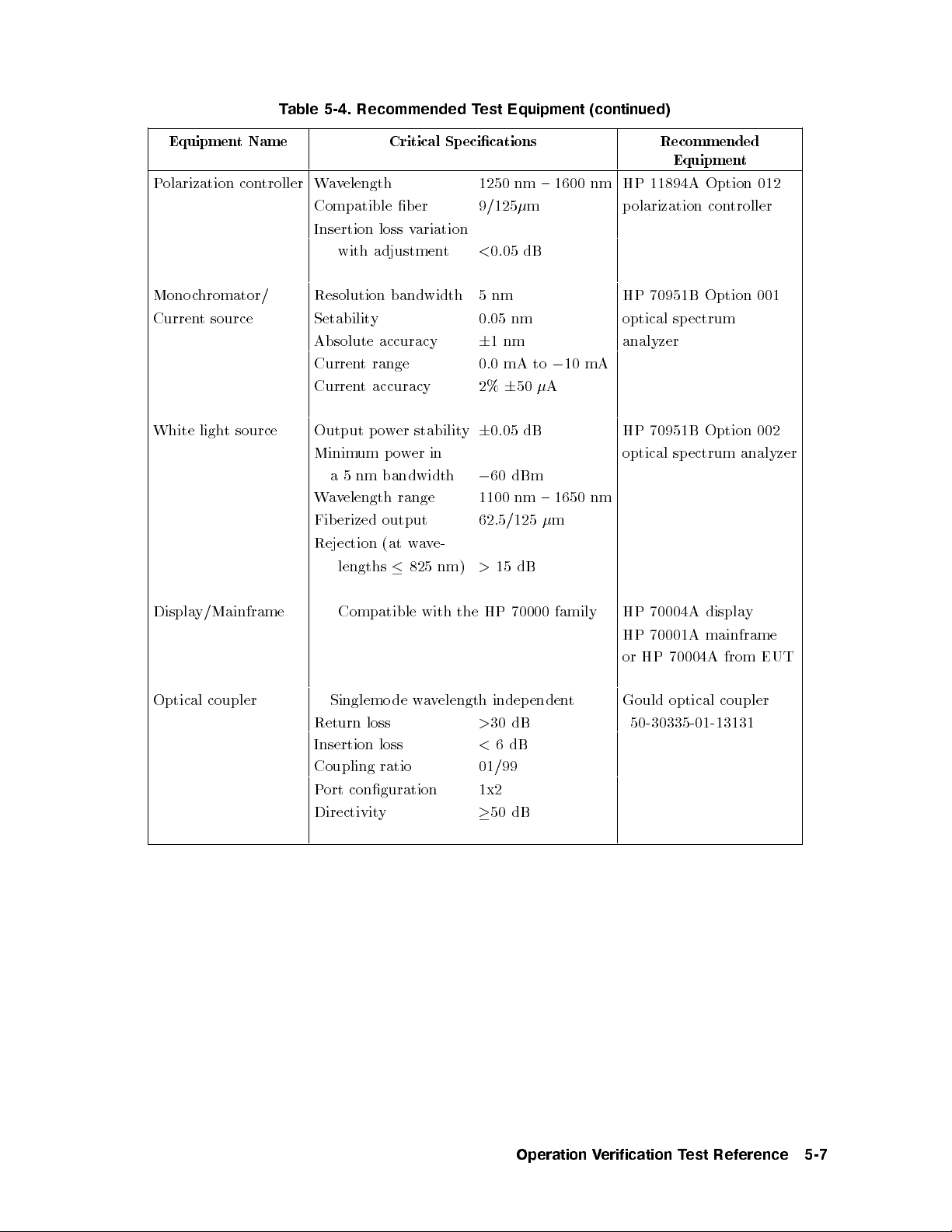

5-4. Recommended Test Equipment . . . . . . . . . . . . . . . . . . . . 5-6

5-5. Precision Resistor and RCNetwork Parts List . . . . . . . . . . . . . 5-8

6-1. Knob Settings for the Polarization Controller . . . . . . . . . . . . . . 6-22

Contents-7

Page 16

Page 17

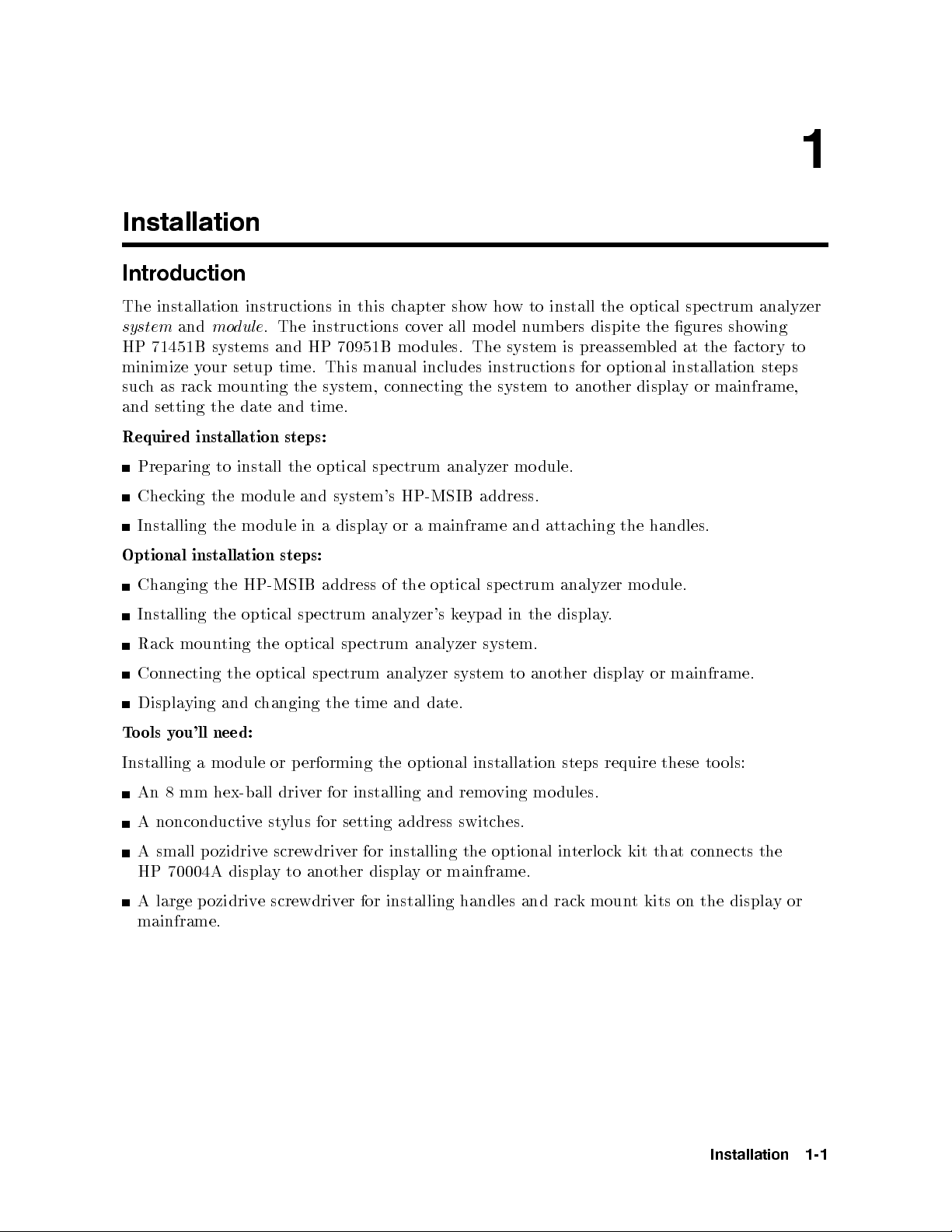

1

Installation

Introduction

The installation instructions in this chapter showhow to install the optical sp ectrum analyzer

system

and

module

. The instructions cover all model numbers dispite the gures showing

HP 71451B systems and HP 70951B modules. The system is preassembled at the factory to

minimize your setup time. This manual includes instructions for optional installation steps

suchasrack mounting the system, connecting the system to another display or mainframe,

and setting the date and time.

Required installation steps:

dule.

Preparing

to

install

the

optical

ectrum

sp

analyzer

mo

king

Chec

Installing the

Optional

installation

Changing

Installing

moun

k

Rac

Connecting

ying

Displa

ou'll need:

ols y

o

T

the

the

the

ting

the

and c

dule

mo

module

steps:

HP-MSIB

the

sp

optical

optical

optical

hanging the

and system's

displa

a

in

address

ectrum

sp

ectrum

sp

HP-MSIB address.

mainframe

a

or

y

optical

the

of

analyzer's

ectrum

analyzer system.

analyzer

date.

and

time

eypad

k

system

ectrum

sp

and

the

in

another

to

attac

analyzer

displa

hing

.

y

display

handles.

the

dule.

mo

or mainframe.

Installing a module or p erforming the optional installation steps require these tools:

An 8 mm hex-ball driver for installing and removing modules.

A nonconductivestylus for setting address switches.

screwdriv

displa

e

another

to

y

A

HP

small

70004A

ozidriv

p

A large pozidrive screwdriv

optional

er for

displa

installing

y

the

mainframe.

or

er for installing handles and rac

in

kmoun

t kits on the displa

connects

that

kit

k

c

terlo

mainframe.

the

yor

Installation

1-1

Page 18

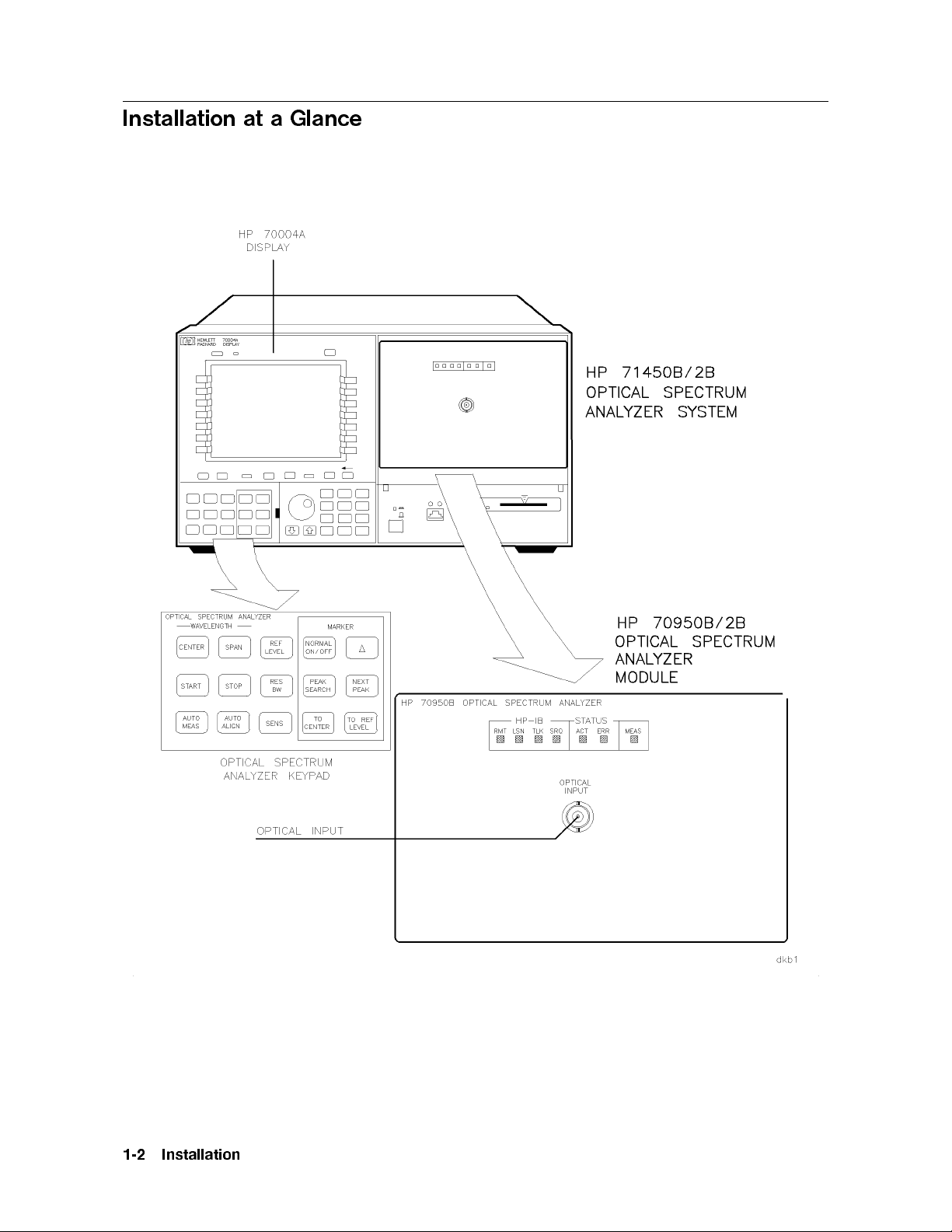

Installation at a Glance

1-2

Installation

Page 19

Installation

1-3

Page 20

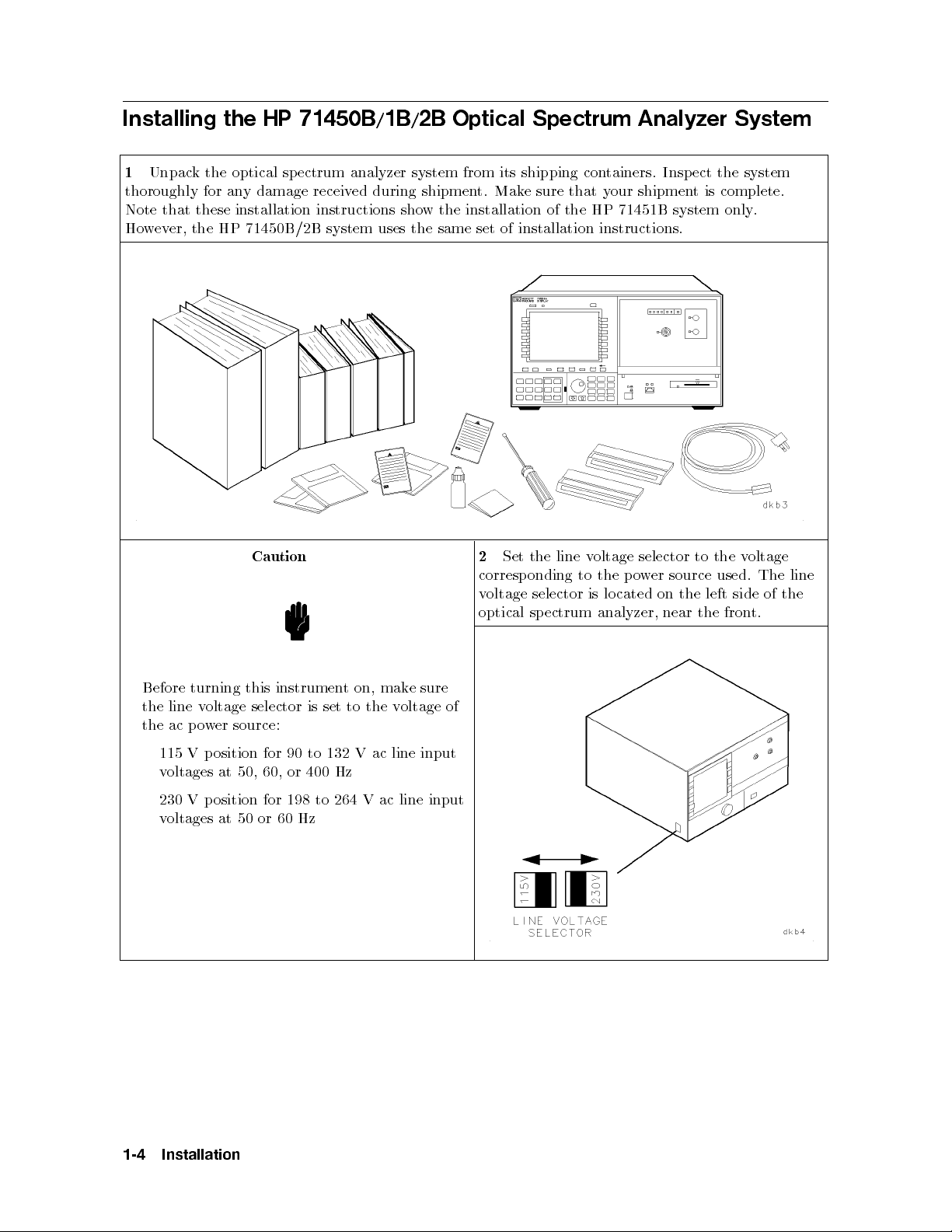

Installing the HP 71450B/1B/2B Optical Spectrum Analyzer System

1

Unpack the optical spectrum analyzer system from its shipping containers. Inspect the system

thoroughly for any damage received during shipment. Make sure that your shipment is complete.

Note that these installation instructions show the installation of the HP 71451B system only.

However, the HP 71450B/2B system uses the same set of installation instructions.

oltage

v

Caution

Set

2

corresp

oltage

v

optical

line

the

onding

selector

ectrum

sp

oltage

v

the

to

lo

is

analyzer,

selector

o

p

cated

er

w

on

near

to

source

the

the

the

used.

left

side

fron

t.

The

of

line

the

e

mak

on,

is

t

to

set

132 V

the

ac line

oltage

v

Before

line

the

ac p

the

115

turning

oltage

v

er

w

o

osition

p

V

this

selector

source:

for

instrumen

90 to

voltages at 50, 60, or 400 Hz

230 V position for 198 to 264 V ac line input

voltages at 50 or 60 Hz

sure

of

input

1-4

Installation

Page 21

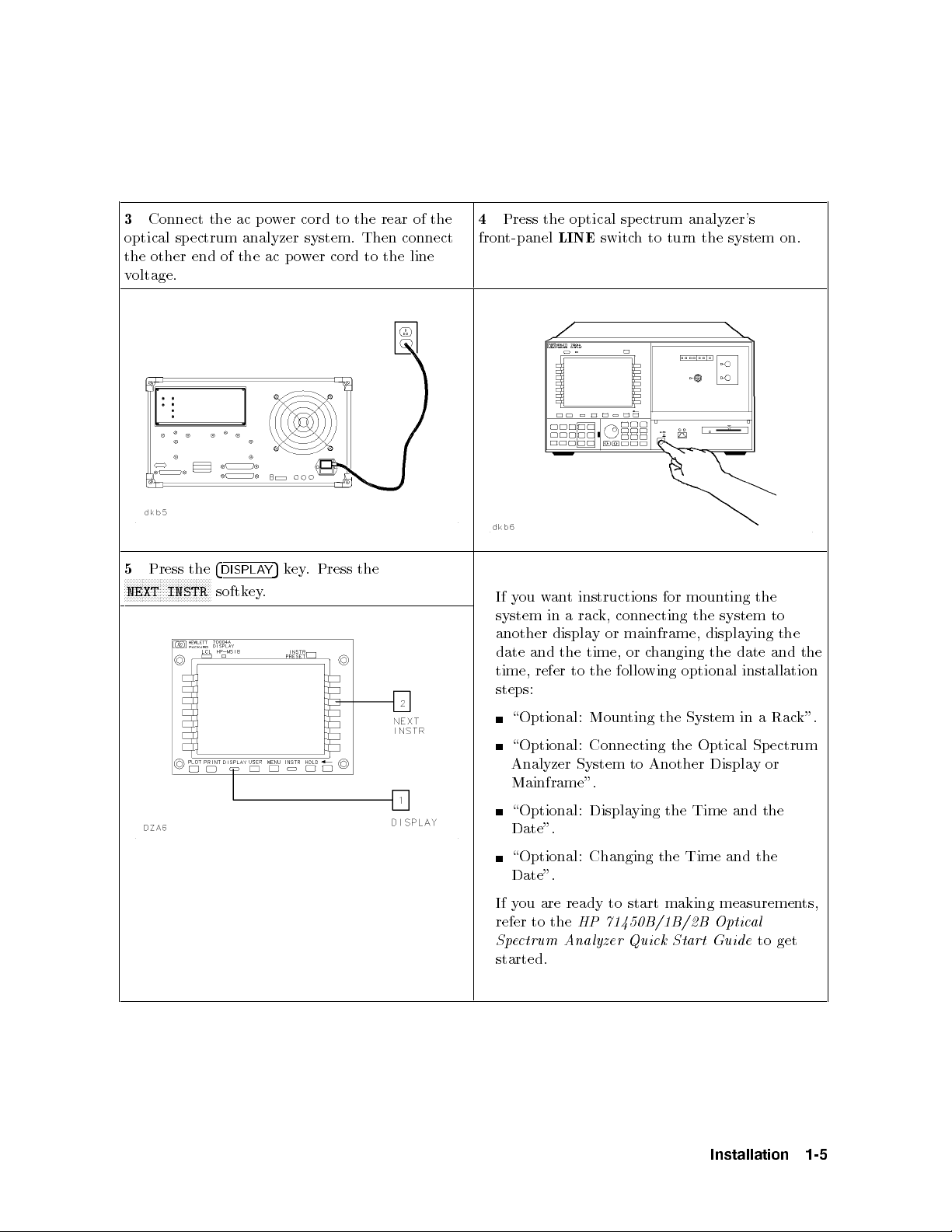

3

Connect the ac p ower cord to the rear of the

optical spectrum analyzer system. Then connect

the other end of the ac power cord to the line

voltage.

4

Press the optical sp ectrum analyzer's

front-panel

LINE

switch to turn the system on.

5

N

N

N

N

N

N

N

NEXT

Press

N

N

N

N

N

N

N

the

N

N

N

N

N

N

NN

N

INSTR

N

N

N

N

N

N

4

DISPLA

softk

ey

the

Press

.

ey

k

5

Y

.

ou

y

If

system

another

and

date

time,

an

w

in

displa

refer

instructions

t

k,

rac

a

or

y

time,

the

the

to

connecting

follo

for moun

mainframe,

hanging

c

or

optional

wing

the

displa

ting

system to

ying

date

the

installation

the

the

and

the

steps:

ting

\Optional:

Moun

\Optional: Connecting

System

the

the Optical

in

ectrum

Sp

k".

Rac

a

Analyzer System to Another Display or

Mainframe".

\Optional: Displaying the Time and the

Date".

the

\Optional:

Changing

the Time

and

Date".

ou are ready to start making measuremen

If y

refer to the

Spectrum A

HP 71450B/1B/2B Optic

nalyzer Quick Start Guide

al

ts,

to get

started.

Installation

1-5

Page 22

Installing an HP 70950B/1B/2B Optical Spectrum Analyzer Module

Step 1. Prepare to Install the Optical Spectrum Analyzer Module.

1

Unpack the optical spectrum analyzer module from its shipping containers. Insp ect the module

thoroughly for any damage received during shipment. Make sure that your shipment is complete.

Note that these installation instructions only show the installation of the HP 70951B module.

However, the HP 70950B/2B mo dules uses the same set of installation instructions.

2

that

the

Install

the

will

ou

y

appropriate

instructions.

mainframe

using

e

b

installation

with

or

the

the

man

displa

dule.

mo

ual

for

y

Refer

to

The

3

dules.

mo

for

slots

installed

en

op

to

70950B/1B/2B

HP

eac

They

installation.

dules

mo

necessary

the

require

h

from

Remo

the

slots.

are

four

or

e

v

displa

4/8-width

adjacen

previously

e

v

mo

mainframe

or

y

t,

empt

y

1-6

Installation

Page 23

Step 2. Check the Address of the Optical Spectrum Analyzer Module.

1

Locate the eight address switches on the top of

the mo dule. These switches are factory preset to

row address 0 and column address 23.

When using the HP 70950B/1B/2B optical

spectrum analyzer mo dule with other

factory-preset mo dules, the factory-preset

address of the HP 70950B/1B/2B does not need

to b e changed.

However, if two optical spectrum analyzers are

in the system, you must change the address of

one of them.

the

er

v

unique

a

hes.

o

8-bit

determined

is

three

The

the

ro

binary

most

w

device

h

Eac

HP-MSIB

HP-MSIB

eigh

the

y

b

signican

that

bus

address.

address

t

t bits

comm

ust

m

(MSB)

unicates

e

v

ha

This

switc

determine

address

address. The ve least signicant bits (LSB)

determine the column address. This manual

refers to the decimal equivalent of the binary

address.

Determine

2

address

the

equiv

alen

t.

the

switc

hes

mo

dule's

calculating

and

address

b

the

lo

y

oking

decimal

at

Installation

1-7

Page 24

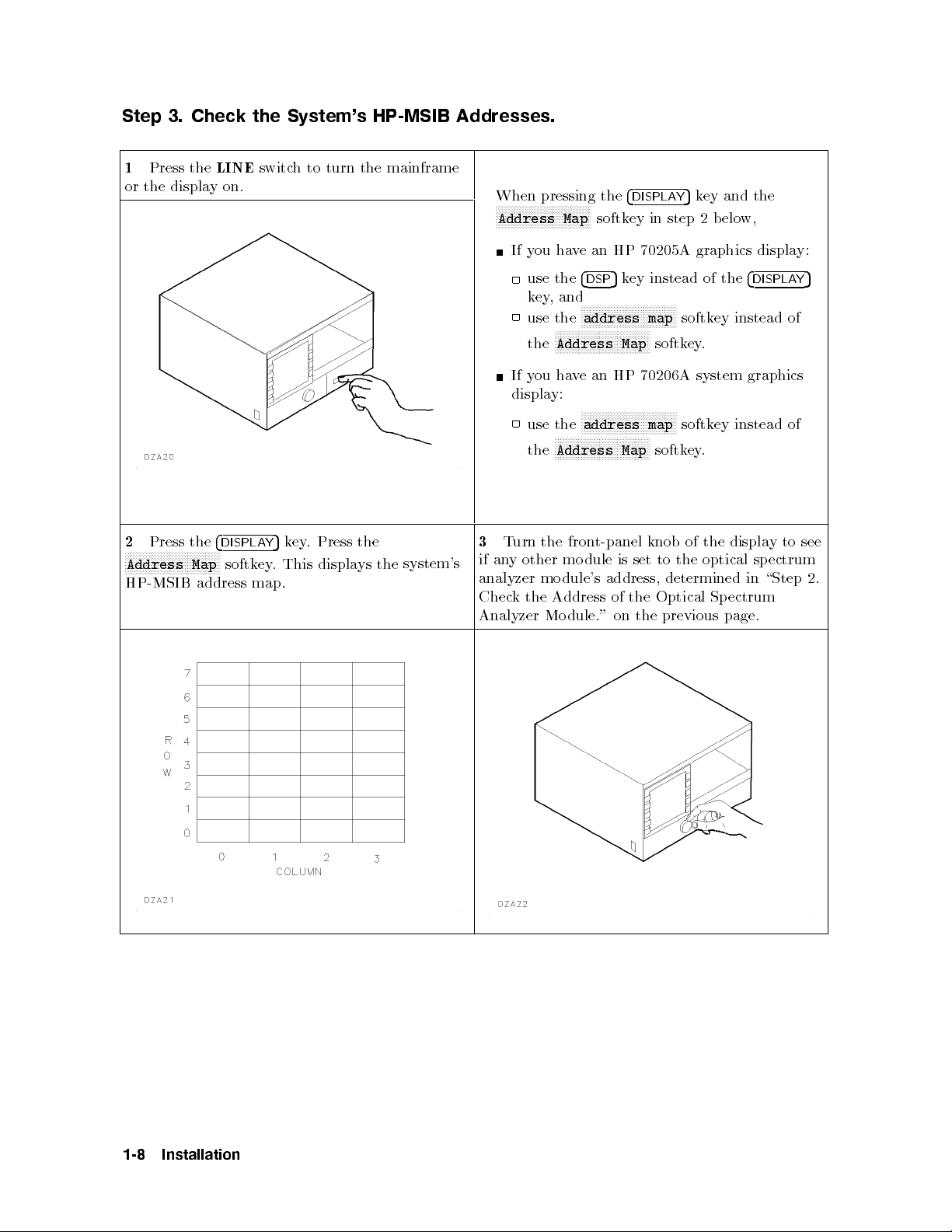

Step 3. Check the System's HP-MSIB Addresses.

1

Press the

or the displayon.

LINE

switch to turn the mainframe

When pressing the

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

Address Map

If you have an HP 70205A graphics display:

4

DISPLAY

5

key and the

softkey in step 2 below,

Press

2

N

N

N

N

N

N

N

N

N

N

N

N

NN

NN

N

N

N

Address

HP-MSIB

the

N

N

N

N

N

N

N

N

N

Map

address

4

DISPLA

N

N

N

N

softk

5

Y

.

ey

map.

ey

k

This

Press

.

displa

the

ys

the

system's

use the

key,and

use the

the

4

5

key instead of the

DSP

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

address map

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

Address Map

softkey instead of

softkey.

If you have an HP 70206A system graphics

display:

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

urn

T

3

other

y

an

if

analyzer

the

k

Chec

Analyzer

use the

the

address map

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

Address Map

t-panel

fron

the

dule

mo

address,

dule's

mo

Address

dule."

Mo

of

on

set

is

the

softkey instead of

softkey.

of

knob

the

to

determined

Optical

previous

the

the

optical

Sp

page.

4

DISPLAY

displa

sp

in

ectrum

to

y

ectrum

\Step

5

see

2.

1-8

Installation

Page 25

4

Press the

LINE

display to turn it o.

switch of the mainframe or the

If no other mo dule is set to the same HP-MSIB

address as the optical spectrum analyzer

module, continue at \Step 4. Install the Optical

Spectrum Analyzer Module in the HP 70001A

Mainframe or the HP 70004A Display." on the

following page.

there

If

can

ou

y

mo

other

ou

y

If

\Optional:

ou w

y

If

dule.

mo

Optical

on the

another

is

the

hange

c

assigned

dule

c

to

t

an

w

Changing

c

to

ant

After the

ectrum Analyzer

Sp

following

dule

mo

HP-MSIB

to

hange

the

hange

address of

page.

same

at

that

address

the

HP-MSIB

address

the

the

address

address.

that

Module

HP-MSIB

either

the

of

Address

the

of

dule

mo

the

in

the

of

optical

of

other

has

HP

address

optical

ectrum

sp

Optical

the

dule,

mo

c

een

b

70001A

the

as

ectrum

sp

analyzer

refer

hanged,

Mainframe

optical

ectrum

Sp

to

con

analyzer

mo

installation

the

ue

tin

or

ectrum

sp

dule,

Analyzer

\Step

at

HP

the

analyzer

dule

mo

contin

Mo

man

4.

70004A

of

or

at

ue

dule".

ual

Install

Displa

module,

the

that

for

the

y

."

Installation

1-9

Page 26

Step 4. Install the Optical Spectrum Analyzer Module in the HP 70001A

Mainframe or the HP 70004A Display.

1

Open the front-panel door on the mainframe

or the display.

2

Slide the optical sp ectrum analyzer mo dule

into the mainframe or the display.

Press

3

tening

tigh

hex-ball

against

the

er

driv

the

hex-n

(HP

mo

ut

part

dule fron

with the

h

latc

um

n

t panel

8710-1651).

ber

while

8mm

4

or

Close

the

the

displa

fron

.

y

t-panel

door

on the

mainframe

1-10

Installation

Page 27

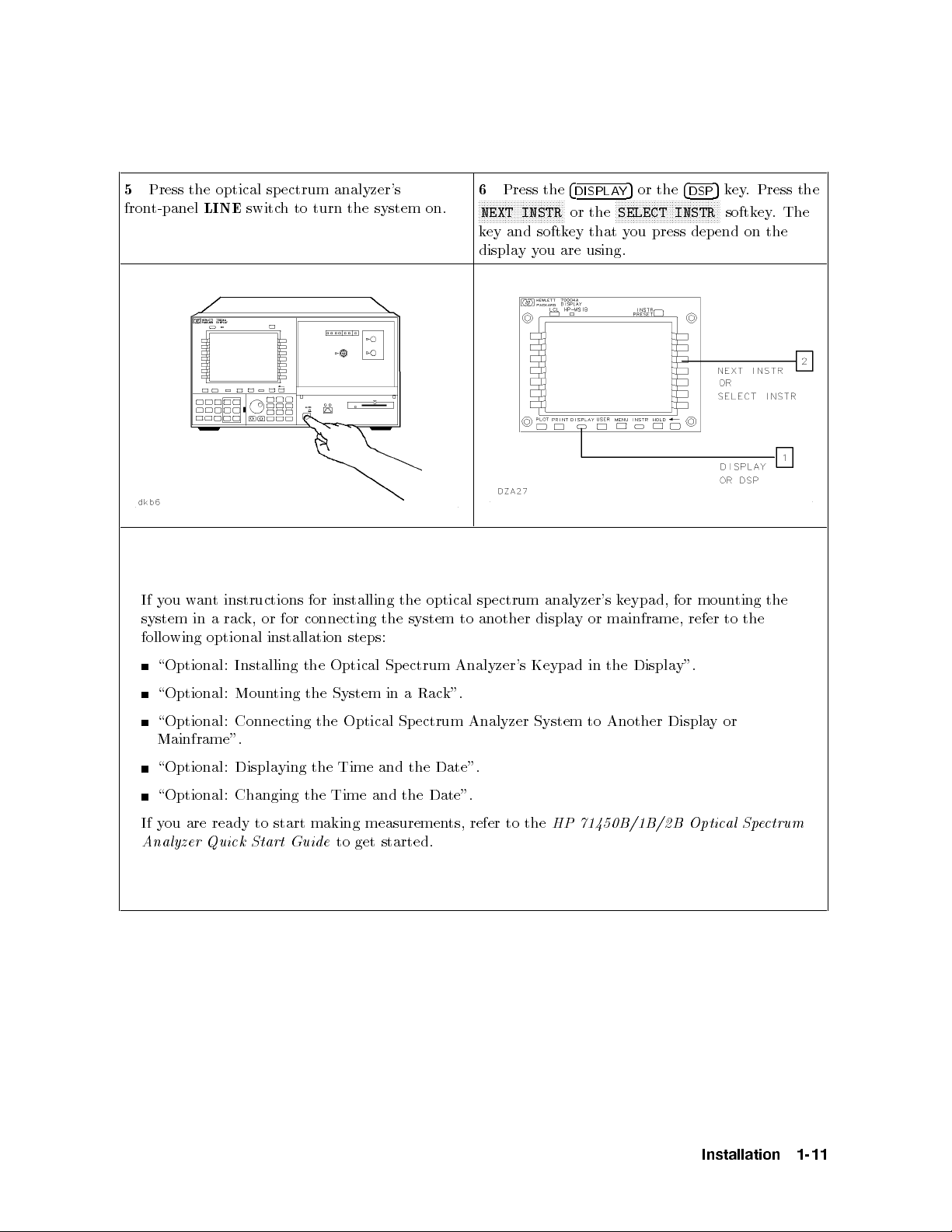

5

Press the optical sp ectrum analyzer's

front-panel

y

If

system

follo

ou

wing

LINE

an

w

in

optional

t

a

switch to turn the system on.

installing

instructions

or

k,

rac

for

connecting

for

installation

steps:

the

the

system

6

NNNNNNNNNNNNNNNNNNNNNNNNNNNNN

key and softkey that you press depend on the

displayyou are using.

optical sp

to another

Press the

NEXT INSTR

ectrum

analyzer's

displa

4

DISPLAY

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

or the

SELECT INSTR

k

mainframe,

or

y

5

or the

eypad,

for

4

5

key. Press the

DSP

softkey.The

moun

to

refer

ting

the

the

\Optional:

\Optional:

\Optional:

Installing

ting

Moun

Connecting

the

the

Optical

System

the

Optical

Sp

in

Sp

ectrum

Rac

a

ectrum

Analyzer's

k".

Analyzer

Keypad

System

Mainframe".

\Optional: Displaying the Time and the Date".

\Optional: Changing the Time and the Date".

If you are ready to start making measurements, refer to the

Analyzer Quick Start Guide

to get started.

y".

Displa

the

in

or

y

Another

to

Displa

HP 71450B/1B/2B Optical Spectrum

Installation

1-11

Page 28

Optional: Changing the HP-MSIB Address of the Optical Spectrum

Analyzer Module

1

Locate the eight HP-MSIB address switches on

top of the mo dule. These switches are factory

preset to row address 0 and column address 23.

Each device that communicates over the

HP-MSIB bus must have a unique 8-bit binary

HP-MSIB address. This address is determined

by the eight address switches. The three most

signicant bits (MSB) determine the row

address. The ve least signicant bits (LSB)

determine the column address. This manual

refers to the decimal equivalent of the binary

address.

Only the modules and the stand-alone

instruments that have addresses in row 0 can

communicate over the HP-IB bus.

device

is

No

useful

for

Address

yb

ma

thin,

A

setting

is

31

0,

this

to

set

e

nonconductiv

address

the

illegal

an

address.

switc

e

st

ylus

hes.

address.

the

Set

2

HP-MSIB

assigned

dule

mo

address

address

to

switc

in

an

ro

an

to

dule

mo

the

of

hes

a

e

v

ha

not

es

do

that

0

w

column.

that

in

w

ro

y

Con

Sp

tin

ectrum

Mainframe or

ue

at

\Step

Analyzer

the HP

4.

Mo

Install

dule

70004A

the

in

Displa

Optical

the

HP

70001A

.".

y

1-12

Installation

Page 29

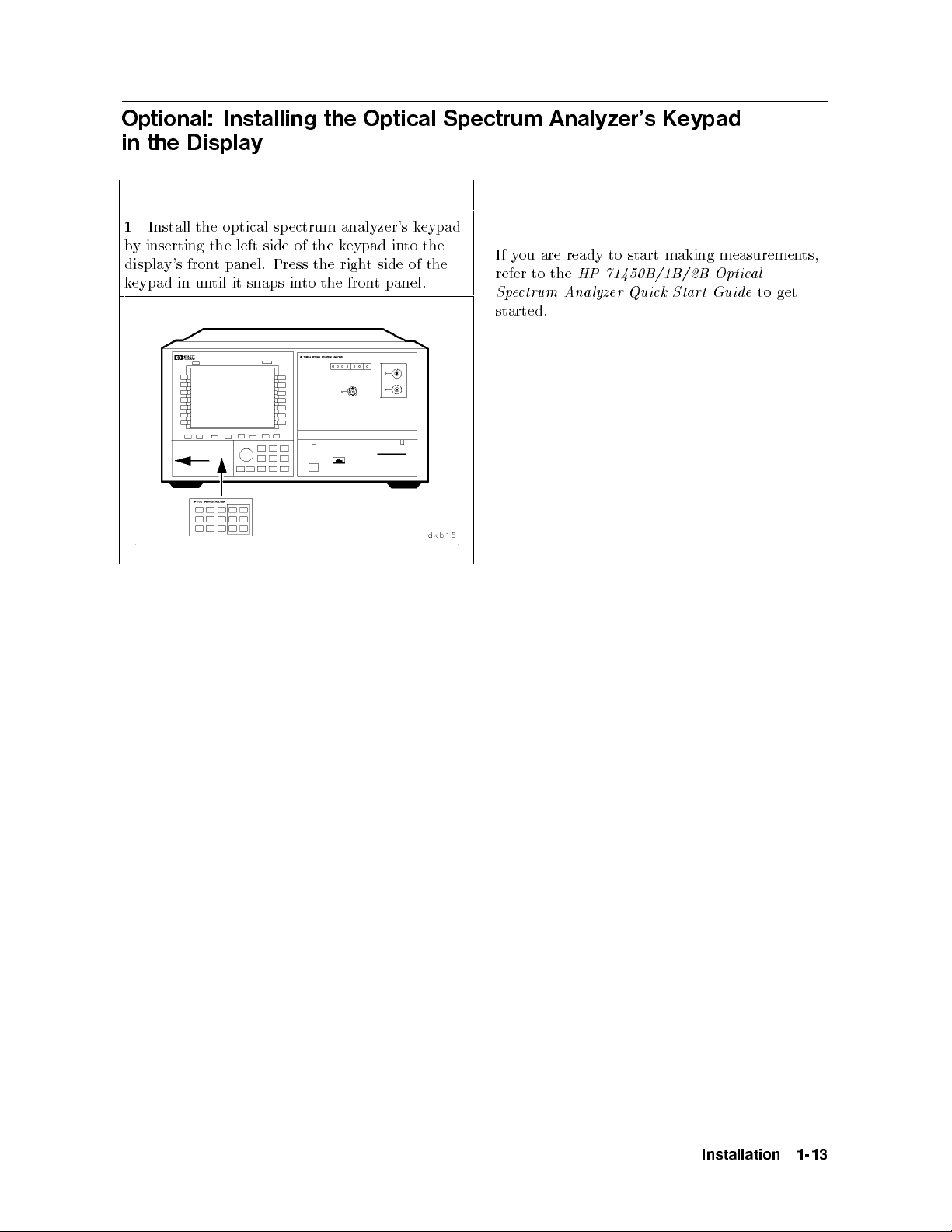

Optional: Installing the Optical Spectrum Analyzer's Keypad

in the Display

1

Install the optical sp ectrum analyzer's keypad

by inserting the left side of the keypad into the

display's front panel. Press the rightsideofthe

keypad in until it snaps into the front panel.

If you are ready to start making measurements,

refer to the

Spectrum Analyzer Quick Start Guide

started.

HP 71450B/1B/2B Optical

to get

Installation

1-13

Page 30

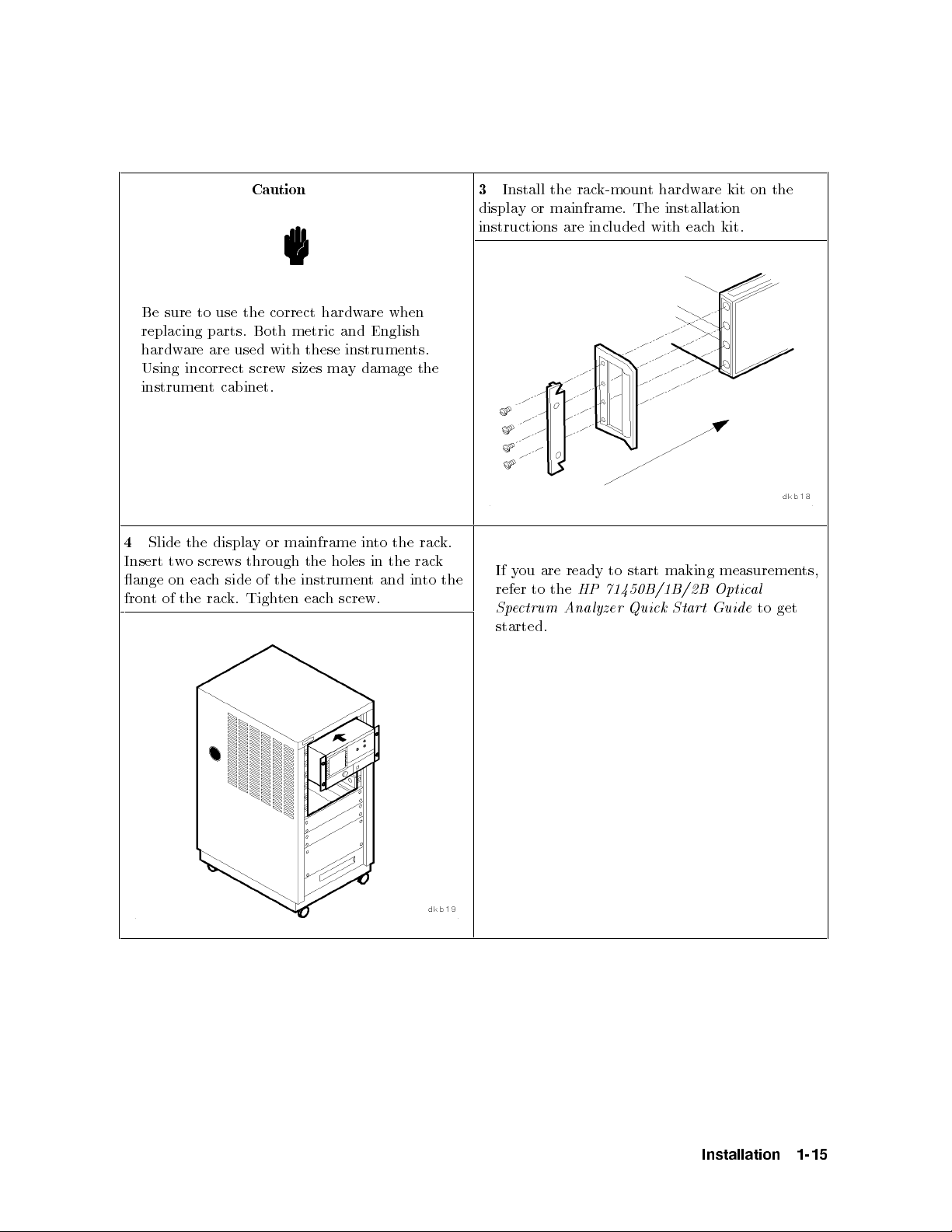

Optional: Mounting the System in a Rack

Hardware kits are needed to rack-mount the

system. Refer to the lists of the hardware kits,

below, for the options, the descriptions, and the

HP part numbers.

For HP 70004A display:

Caution

Option 810

rackmount slide kit

(HP part number 5062-7086)

Option 908

rack ange kit without handles

(HP part number 5062-3979)

Option 913

rack ange kit with handles

(HP part number 5062-4073)

For HP 70001A mainframe:

Option 810

rackmount slide kit

(HP part number 5062-0781)

ange kit

Option 908

Option

the

If

1

plastic

e

v

remo

handle

trim

them.

to

rack

(HP part

rac

913

part

(HP

handles

strip

Remov

instrumen

the

ber

num

ange

k

b

um

n

are already

each

on

the

e

without

5062-3978)

with

kit

5062-4072)

er

installed,

handle

screws

t.

handles

handles

ard

forw

securing

slide

and

eac

the

h

Make sure that the rackthatyou are mounting

the optical spectrum analyzer system in does

not vibrate substantially. Excessive vibration

may cause signal amplitude measurements to be

inaccurate.

Do not rack-mount multiple displays or

mainframes with a single rack-mount hardware

kit. One rack-mount hardware kit must be

ordered for eachdisplay or mainframe.

(if

legs

stand

tilt

the

the

and

ottom of

b

the

displa

or

y

Remo

2

installed)

the feet

e

v

from

mainframe.

1-14

Installation

Page 31

Caution

Be sure to use the correct hardware when

replacing parts. Both metric and English

hardware are used with these instruments.

Using incorrect screw sizes may damage the

instrument cabinet.

the

to

holes

h

in

screw.

in

t

the

and

Slide

4

Insert

ange

t

fron

of

t

on

w

the

the

screws

o

eac

displa

side

h

rac

through

Tigh

k.

or

y

the

of

ten

mainframe

the

instrumen

eac

in

rac

rac

to

3

Install the rack-mount hardware kit on the

display or mainframe. The installation

instructions are included with eachkit.

k.

k

the

y

If

refer

e

Sp

are

ou

to

ctrum

the

A

ready

HP

nalyzer

start

to

71450B/1B/2B

Quick

started.

making

Start

measuremen

al

Optic

to

Guide

ts,

get

Installation

1-15

Page 32

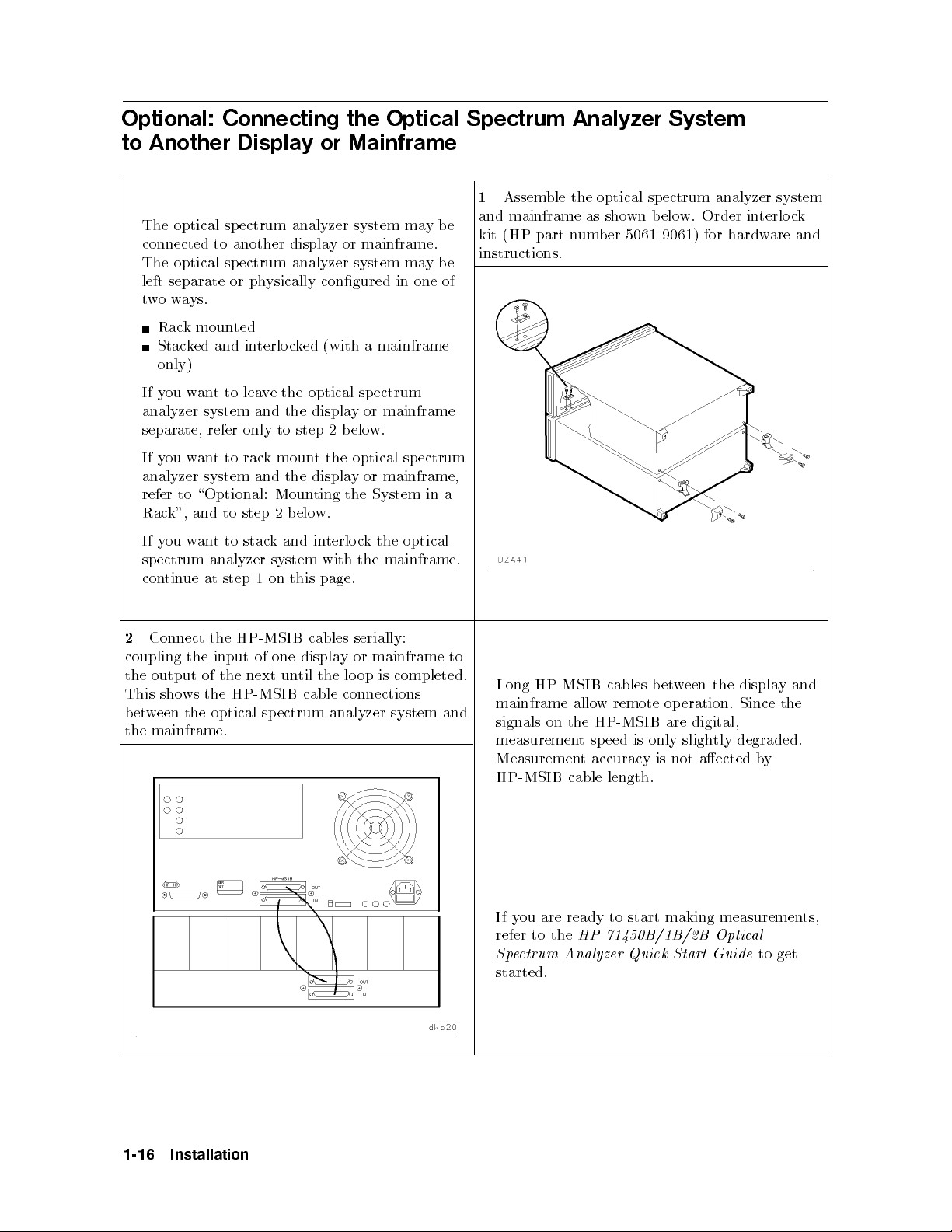

Optional: Connecting the Optical Spectrum Analyzer System

to Another Display or Mainframe

1

Assemble the optical spectrum analyzer system

The optical spectrum analyzer system maybe

connected to another display or mainframe.

The optical spectrum analyzer system maybe

and mainframe as shown below. Order interlock

kit (HP part number 5061-9061) for hardware and

instructions.

left separate or physically congured in one of

twoways.

Rack mounted

Stacked and interlocked (with a mainframe

only)

If you want to leave the optical spectrum

analyzer system and the display or mainframe

separate, refer only to step 2 b elow.

If you want to rack-mount the optical spectrum

mainframe,

or

y

displa

the

step

to

stac

to

t

analyzer

step

and

1

k

on

Moun

elo

b

2

and

system

this

ting

w.

terlo

in

with

page.

the

k

c

the

System

optical

the

mainframe,

in

a

analyzer

to \Optional:

refer

k",

Rac

ou

y

If

ectrum

sp

ue

tin

con

w

and

an

system

at

Connect

2

coupling

output

the

sho

This

ween

bet

mainframe.

the

the HP-MSIB

input of

the

of the

ws the

HP-MSIB cable

the optical

one

next un

spectrum

cables

displa

the

til

serially:

mainframe

or

y

is

op

lo

connections

analyzer

to

completed.

system

and

displa

the

een

is

only

etw

operation.

are digital,

tly

sligh

Since

degraded.

HP-MSIB

Long

mainframe

signals on

the HP-MSIB

measuremen

w remote

allo

sp

t

cables b

eed

Measurement accuracy is not aected by

HP-MSIB cable length.

ou are ready to start making measuremen

If y

refer to the

Spectrum A

HP 71450B/1B/2B Optic

nalyzer Quick Start Guide

al

to get

started.

y

the

and

ts,

1-16

Installation

Page 33

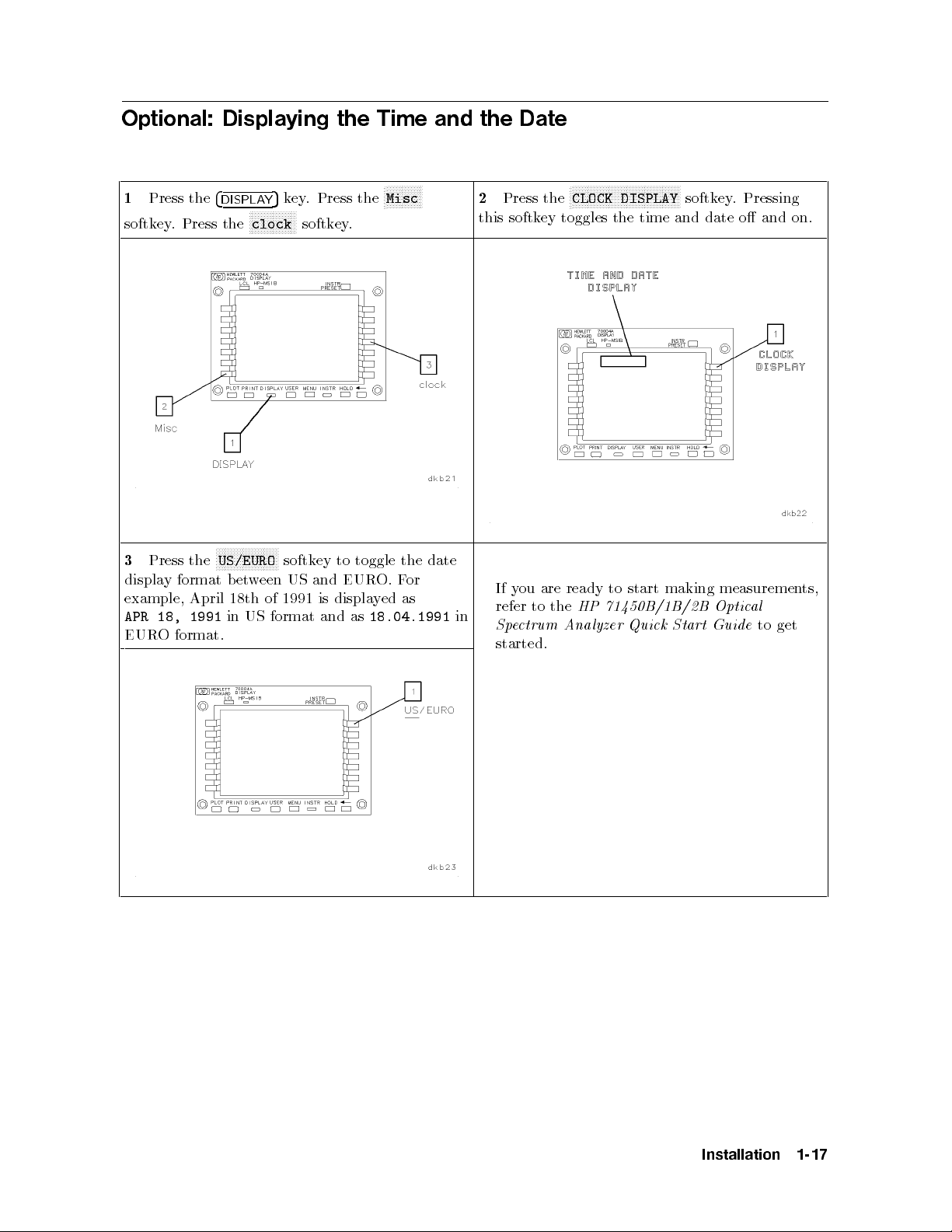

Optional: Displaying the Time and the Date

1

Press the

4

DISPLAY

softkey. Press the

N

N

N

N

N

N

the

Press

3

display

example, April

18,

APR

O

EUR

format

1991

format.

US/EURO

b

18th

in

NN

N

N

N

N

et

US

5

key. Press the

NNNNNNNNNNNNNNN

N

clock

N

N

N

N

N

N

N

NN

softk

US

een

w

1991

of

format

softkey.

to

ey

and

displa

is

and

NNNNNNNNNNNN

N

Misc

toggle

O.

EUR

ed

y

18.04.1991

as

the

F

as

or

date

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

2

Press the

N

CLOCK DISPLAY

softkey. Pressing

this softkey toggles the time and date o and on.

measuremen

al

Optic

Guide

in

y

If

refer

e

Sp

are

ou

to

ctrum

the

A

to

ready

71450B/1B/2B

HP

nalyzer

start

Quick

making

Start

started.

to

ts,

get

Installation

1-17

Page 34

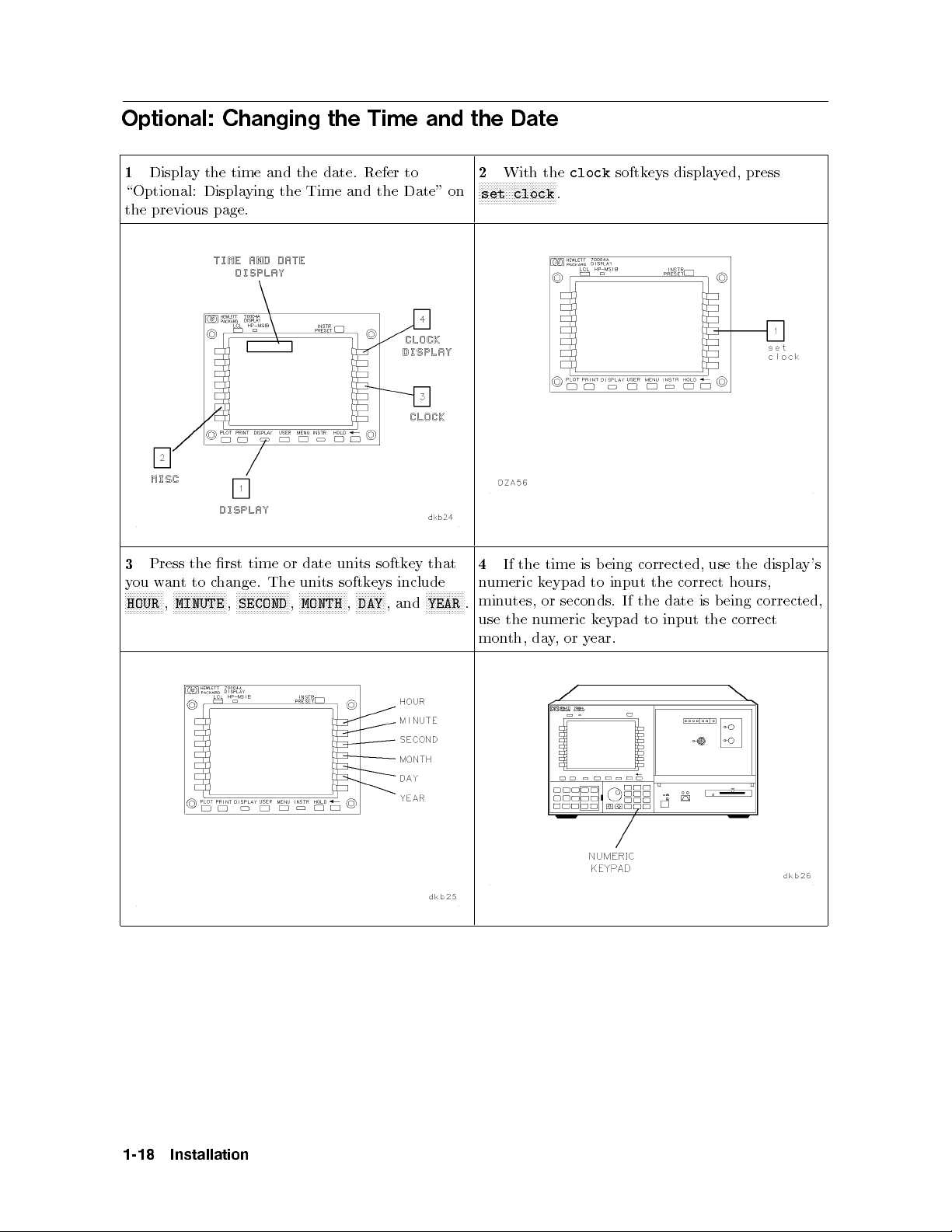

Optional: Changing the Time and the Date

1

Display the time and the date. Refer to

\Optional: Displaying the Time and the Date" on

2

With the

NNNNNNNNNNNNNNNNNNNNNNNNNN

set clock

the previous page.

that

ey

softk

units

date

or

time

rst

the

Press

3

ou

y

N

N

N

N

N

N

N

HOUR

N

N

N

an

w

N

NN

,

to

t

NN

N

N

N

N

N

N

N

N

N

N

MINUTE

hange.

c

N

N

N

N

N

N

,

The

NN

N

N

N

N

N

N

N

N

N

N

SECOND

4

units

N

N

N

N

N

N

,

N

N

N

N

N

N

N

N

N

MONTH

N

N

N

N

NN

N

N

N

N

N

N

N

N

N

N

N

,

,

DAY

and

N

N

N

N

N

N

YEAR

umeric

n

N

NN

N

N

N

N

min

.

include

eys

softk

use

mon

the

If

utes,

the

th,

time

eypad

k

or

umeric

n

da

clock

.

seconds.

or

,

y

softkeys displayed, press

corrected,

eing

b

is

correct

the

input

to

is

date

the

If

input

to

eypad

k

ear.

y

use

the

hours,

eing

b

correct

displa

the

corrected,

y's

1-18

Installation

Page 35

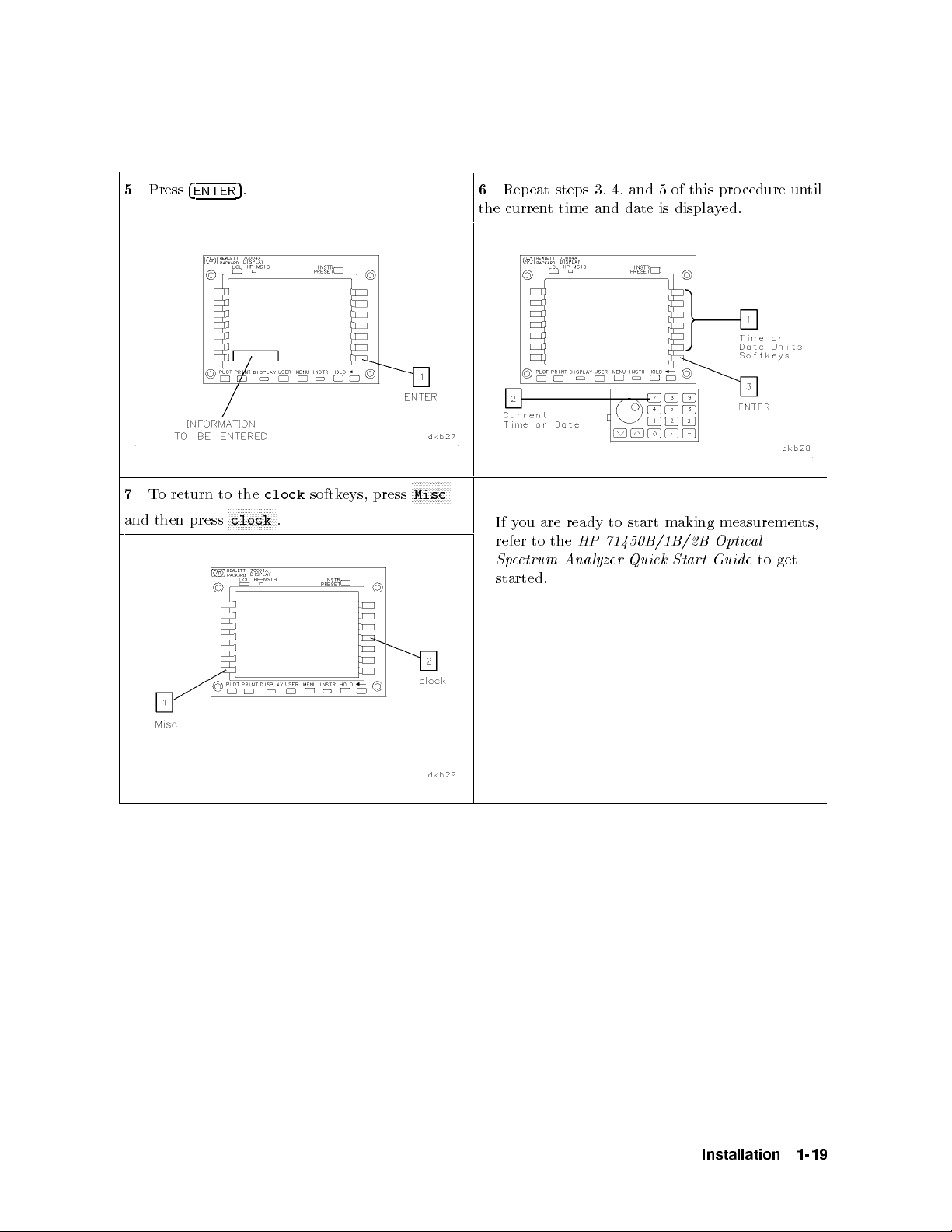

5

7

and

Press

return

To

then

4

ENTER

press

to

NN

N

clock

5

the

NN

.

N

N

N

N

N

N

N

clock

N

N

N

N

.

softk

eys,

press

N

N

N

N

N

N

Misc

6

Repeat steps 3, 4, and 5 of this pro cedure until

the current time and date is displayed.

N

N

N

N

N

N

N

to

ts,

get

y

If

refer

e

Sp

are

ou

to

ctrum

the

A

to

ready

71450B/1B/2B

HP

nalyzer

start

Quick

making

Start

measuremen

al

Optic

Guide

started.

Installation

1-19

Page 36

Page 37

2

If You Have a Problem During Installation

Introduction

This chapter will help you correct problems you may encounter during installation of the

optical spectrum analyzer. The problem or symptom is listed at the top of each page. Most

problems have a brief description or explanation, followed byachecklist of items that could

be causing the problem. Using the checklist of possible solutions will help you correct the

problem. If the problem is internal to the optical spectrum analyzer, the checklist will also

help to identify the faulty module, display, or mainframe.

Refer to \What to Expect When You Turn on the Optical Spectrum Analyzer" in this chapter

information

for

regarding

the

normal

steps

that

ccur

o

when

instrumen

the

turned

rst

is

t

on.

Problems Requiring

ternal

in

are

Problems

hnical

tec

mainframe

or

returning

Returned

that

information.

return

or

instrumen

the

for Service".

Refer

the

are

t

Additional T

a

dule,

mo

a

to

service

the

to

to

vided

t

in

\If the

instrumen

pro

echnical

,

y

displa

cumen

do

Hewlett-P

Optical

a

or

tation

ac

k

Resources

mainframe

fault

the

for

servicing.

for

ard

ectrum

Sp

require

will

mo

y

Analyzer

additional

displa

dule,

Instructions

Needs

to

for

b

,

y

e

Problem

a

e

v

Ha

ou

Y

If

During

Installation

2-1

Page 38

What to Expect When You Turn on the Optical Spectrum Analyzer

Each time the optical sp ectrum analyzer is turned on, the following actions take place:

1. The module self-test pro cedure turns on all the LEDs, except the STATUS LEDs. The

STATUS LEDs will turn on one second later. Refer to Figure 2-1.

This description identies the optical spectrum analyzer mo dule LEDs that light.

Depending on the display or mainframe used, their LEDs will also light during turn on.

2. After the preliminary self-test, all optical spectrum analyzer mo dule front-panel LEDs are

turned o.

3. The display's model number is briey displayed on screen.

4. The system begins running an instrument INITIALIZING routine.

5. At the b eginning of the INITIALIZING routine, the ACT LED lights and remains lit.

6. At the end of the INITIALIZING routine, the MEASURE LED lights as the optical

spectrum analyzer sweeps across the display. If the mo dule is an HP 70951B, the

MONOCHROMATOR INPUT LED will also light.

2-2

Figure 2-1.

Optical Spectrum Analyzer Front Panel

wn)

71451B

(HP

Problem

a

e

v

Ha

ou

Y

If

During

Installation

Sho

Page 39

If the Optical Spectrum Analyzer Will Not Turn On

Pressing the LINE switch on the front panel of each display and mainframe in system should

turn the system on. If there is a problem providing power to the system, these symptoms will

occur:

The display will remain blank.

The LINE LED on the front panel of the display or mainframe will not light.

The actions describ ed in \What to Expect When You Turn on the Optical Spectrum

Analyzer" will not occur.

If you press the LINE switch on the front panel of the display or the mainframe and the

optical spectrum analyzer does not turn on, check the follo wing items:

Check that the optical spectrum analyzer is connected to the ac p ower source.

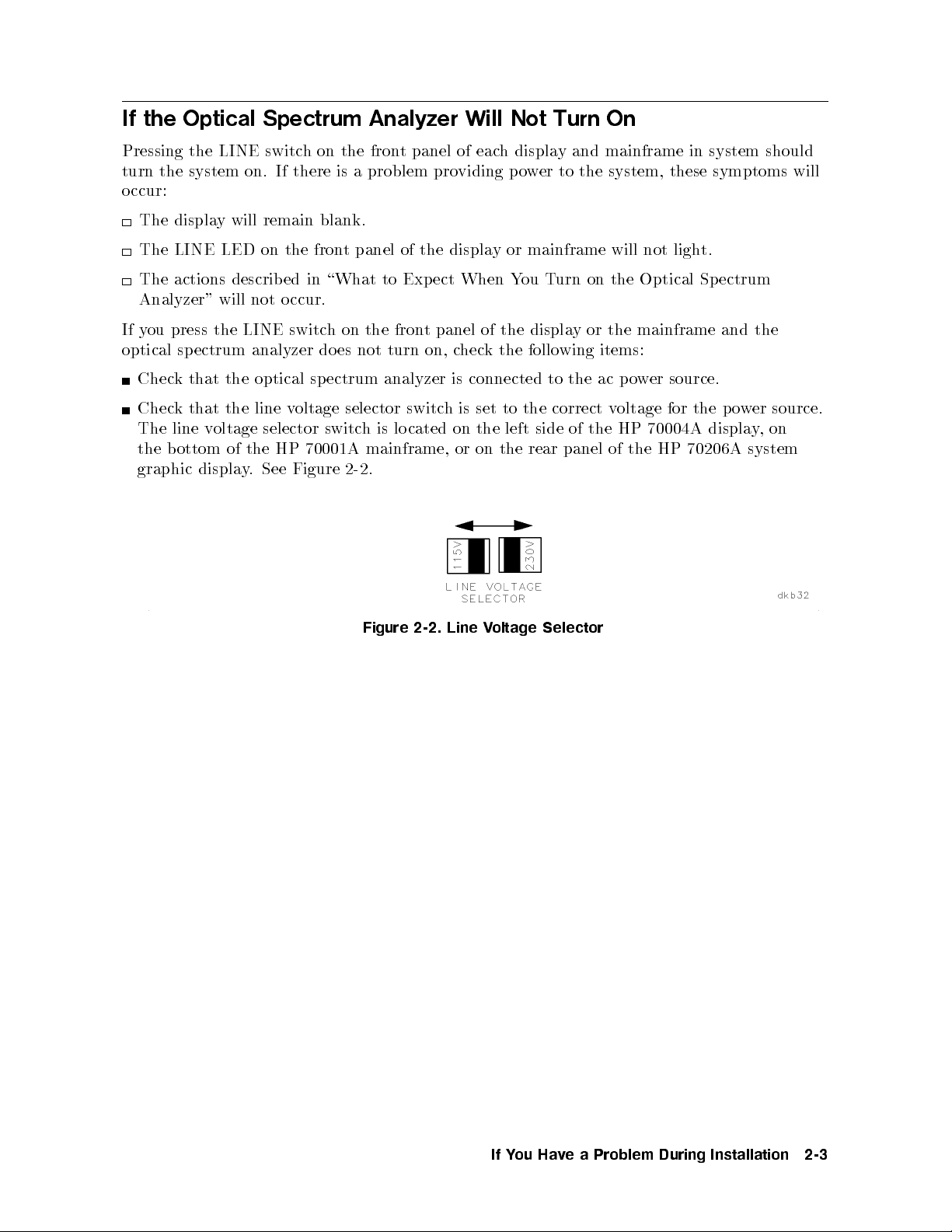

Check that the line voltage selector switch is set to the correct voltage for the power source.

The line voltage selector switch is located on the left side of the HP 70004A display,on

the bottom of the HP 70001A mainframe, or on the rear panel of the HP 70206A system

graphic

displa

Figure

See

.

y

2-2.

Figure

2-2.

Line

oltage

V

Selector

Problem

a

e

v

Ha

ou

Y

If

During

Installation

2-3

Page 40

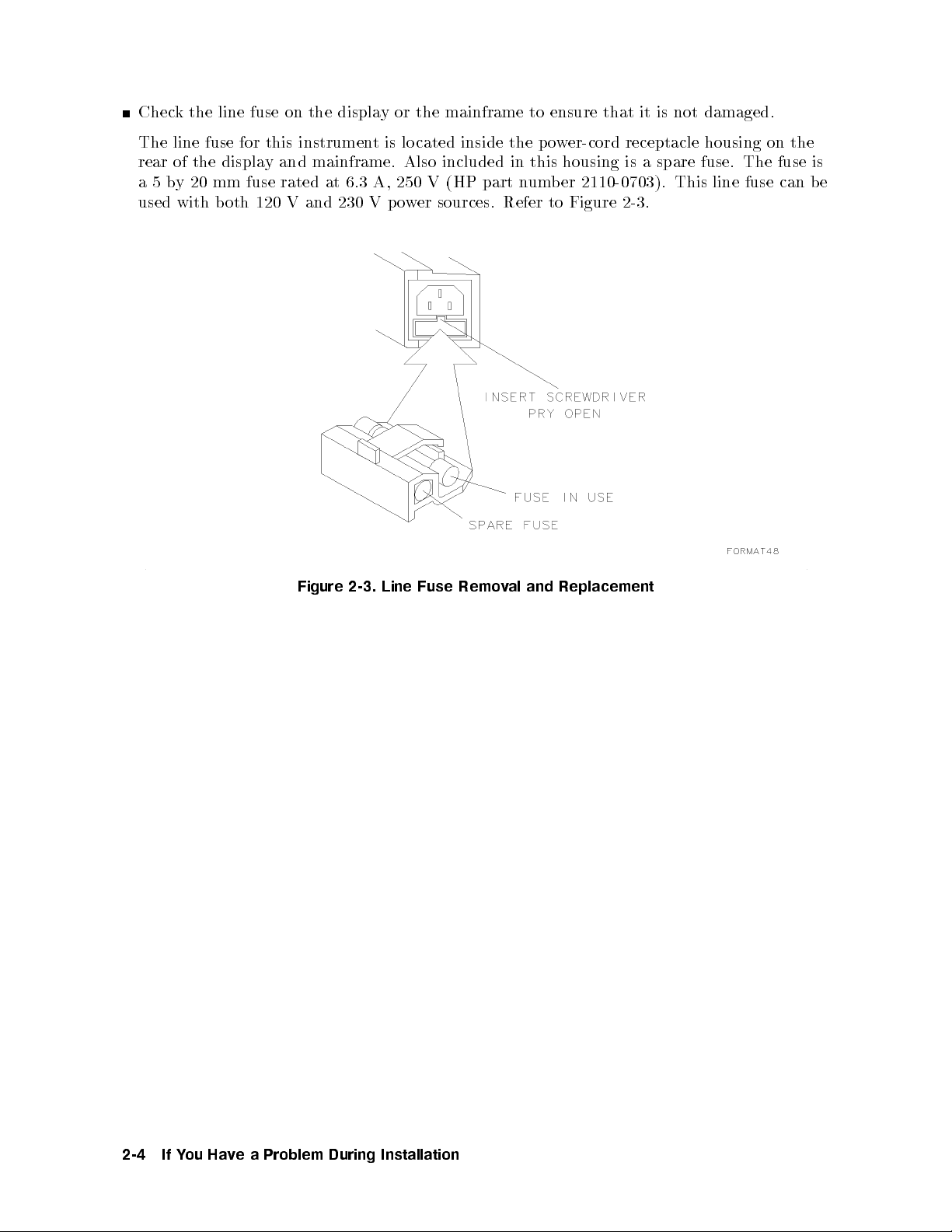

Check the line fuse on the display or the mainframe to ensure that it is not damaged.

The line fuse for this instrument is lo cated inside the power-cord receptacle housing on the

rear of the display and mainframe. Also included in this housing is a spare fuse. The fuse is

a5by 20 mm fuse rated at 6.3 A, 250 V (HP part number 2110-0703). This line fuse can be

used with both 120 V and 230 V p ower sources. Refer to Figure 2-3.

Figure

2-3.

Line

Fuse

Remo

Replacement

and

al

v

2-4

Problem

a

e

v

Ha

ou

Y

If

During

Installation

Page 41

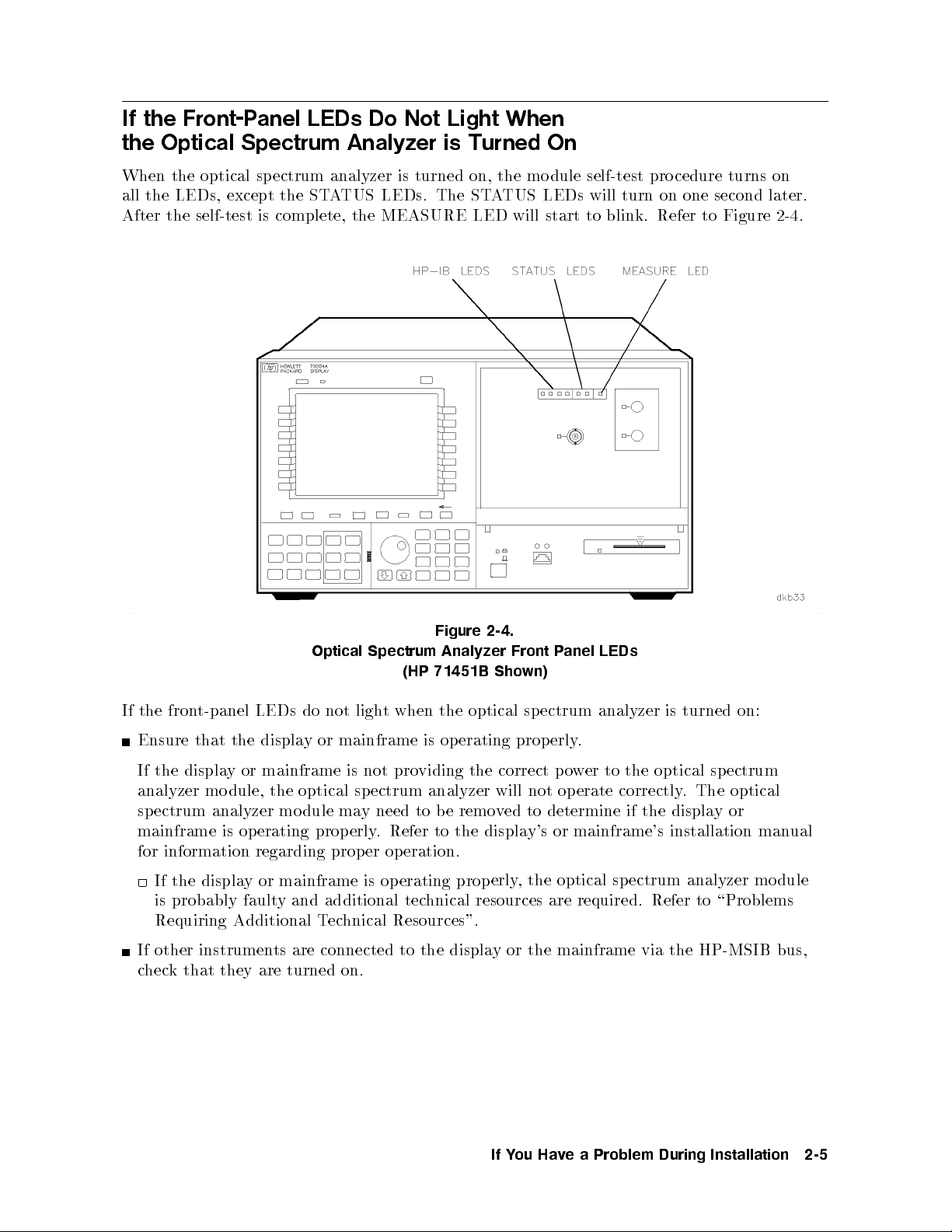

If the Front-Panel LEDs Do Not Light When

the Optical Spectrum Analyzer is Turned On

When the optical spectrum analyzer is turned on, the mo dule self-test procedure turns on

all the LEDs, except the STATUS LEDs. The STATUS LEDs will turn on one second later.

After the self-test is complete, the MEASURE LED will start to blink. Refer to Figure 2-4.

2-4.

Analyzer

optical

erating

op

Front

wn)

sp

prop

anel

P

ectrum

.

erly

LEDs

analyzer

turned

is

on:

the fron

If

Ensure

t-panel LEDs

displa

the

that

Optical

do not

or

y

Spectrum

(HP

when

t

ligh

mainframe

Figure

71451B Sho

the

is

If the display or mainframe is not providing the correct power to the optical sp ectrum

analyzer module, the optical sp ectrum analyzer will not operate correctly. The optical

spectrum analyzer mo dule may need to be removed to determine if the displayor

mainframe is operating prop erly. Refer to the display's or mainframe's installation manual

eration.

op

information

for

the

If

displa

regarding prop

mainframe

or

y

is probably faulty and additional tec

Requiring Additional T

If other instrumen

ts are connected to the displa

er

operating

is

prop

hnical resources are required. Refer to \Problems

echnical Resources".

erly

,

the

optical

ectrum

sp

analyzer

mo

y or the mainframe via the HP-MSIB bus,

check that they are turned on.

dule

Problem

a

e

v

Ha

ou

Y

If

During

Installation

2-5

Page 42

If the Optical Spectrum Analyzer Front-Panel ERR LED

Remains Lit or Blinks after the Self-Test

The ERR LED is one of the twoSTATUS LEDs on the front panel of the optical spectrum

analyzer module. The ERR LED should light during the optical spectrum analyzer's self-test.

It is turned on and o so quickly during the self-test that you may not be able to see it light.

Refer to Figure 2-5.

After the self-test, the ERR LED lights when an error (problem) is encountered. When it

lights, it will either remain on continuously or it will blink.

Figure 2-5.

Information

Optical

Spectrum

Analyzer

Error

(HP 71451B Shown)

If the ERR LED remains on continuously, it is indicating that there may b e a problem with

the optical spectrum analyzer. Perform the following steps:

Press

Press

k the displa

4

DISPLA

N

N

N

N

N

N

N

N

N

N

NN

N

REPORT

or

4

5

Y

DSP

NN

N

N

N

N

N

N

N

N

N

N

N

NN

N

N

N

N

N

N

N

N

N

N

NN

N

ERRORS

y for the rep orted

.

5

.

error.

1.

2.

3. Chec

4. Refer to \If Errors Are Reported on the Display" for help correcting the error.

If the ERR LED blinks,

it is indicating that there ma

y be a problem with the HP-MSIB.

Check the following items:

If more than one mainframe is connected together, check that all HP-MSIB cables are

op.

lo

a

form

securely connected

whether

k

Chec

Chec

3.

\Step

to

v

Ha

ou

Y

If

2-6

e

there

a

and

are

System's

the

k

Problem

ensure

o

w

t

During

that

dules

mo

HP-MSIB

Installation

they

are

the

in

Addresses."

connected

system

with

serially

in

to

same

the

Chapter

HP-MSIB

for instructions.

1

address.

Refer

Page 43

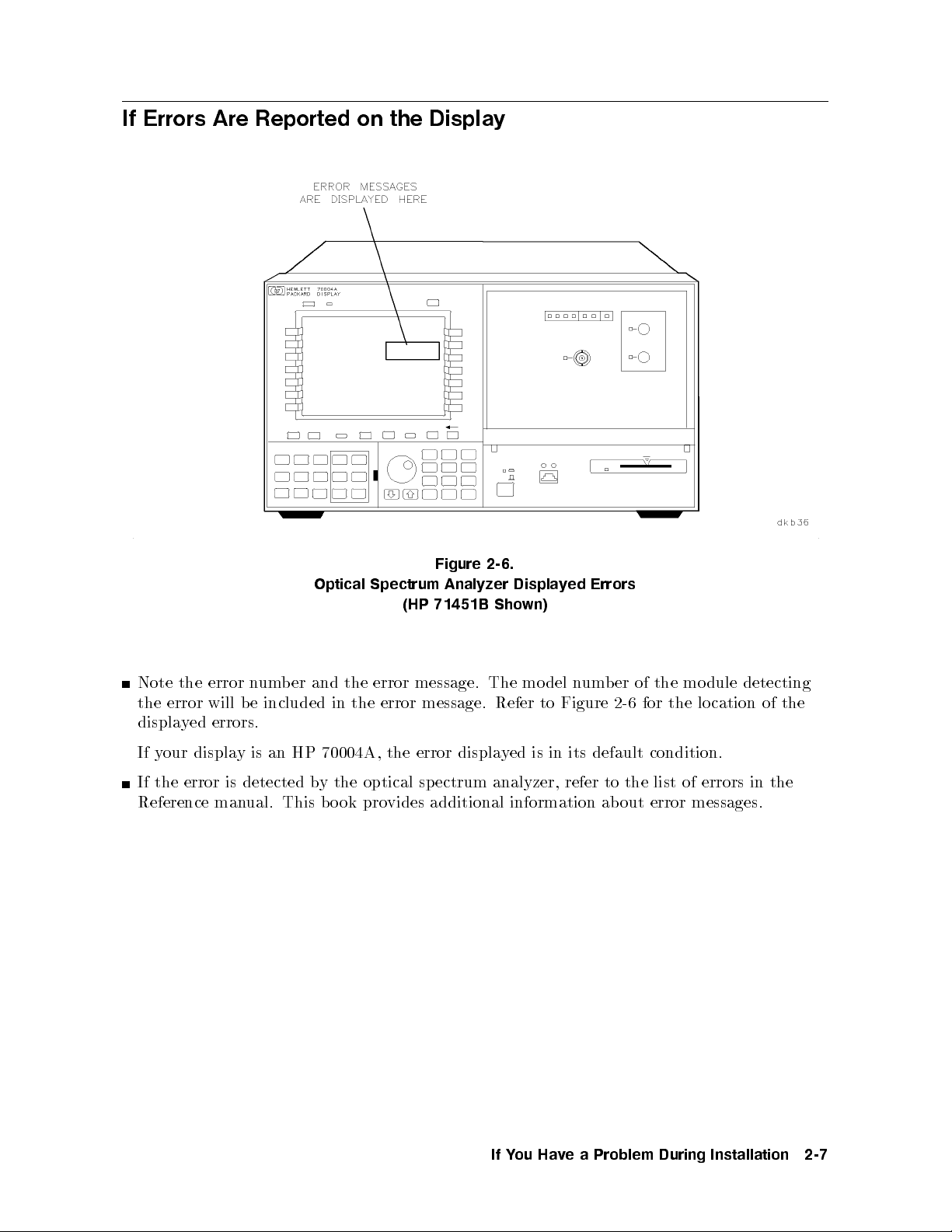

If Errors Are Reported on the Display

2-6.

Analyzer

Sho

The mo

Refer

displa

Displa

ed

y

wn)

is

del

to

in

Errors

ed

y

um

n

Figure

its

er

b

2-6

default

the

of

the

for

condition.

mo

dule

cation

lo

detecting

of

Note

error

the

displa

your

If

the

ed

y

displa

error

will b

errors.

y

er

b

um

n

e included

HP

an

is

Optical

the

and

in

70004A,

Spectrum

(HP

error message.

message.

error

the

error

the

Figure

71451B

If the error is detected by the optical spectrum analyzer, refer to the list of errors in the

Reference manual. This b ook provides additional information about error messages.

the

Problem

a

e

v

Ha

ou

Y

If

During

Installation

2-7

Page 44

If the Optical Spectrum Analyzer Front-Panel HP-IB LEDs

Remain Lit after the Self-Test

The HP-IB LEDs on the front panel of the optical sp ectrum analyzer are turned on then o,

one at a time, during the optical sp ectrum analyzer's self-test. The four HP-IB LEDs are:

service request (SRQ), talk (TLK), listen (LSN), and remote (RMT). Refer to Figure 2-7 for

the location of each of the HP-IB LEDs. The HP-IB LEDs reveal the status of the optical

spectrum analyzer module when it is b eing controlled by a computer.

Optical

Figure

Spectrum

71451B

(HP

2-7.

Analyzer

Sho

HP-IB

wn)

LEDs

2-8

Problem

a

e

v

Ha

ou

Y

If

During

Installation

Page 45

The follo wing lists and describes the HP-IB LEDs, and suggests what to checkif anLED

remains on after the self-test.

LED Solution

SRQ The service request (SRQ) LED lights when the optical spectrum analyzer has

requested computer service. Check for error messages on the display.

TLK

LSN

RMT