Page 1

About this Manual

We’ve added this manual to the Agilent website in an effort to help you support

your product. This manual is the best copy we could find; it may be incomplete

or contain dated information. If we find a more recent copy in the future, we will

add it to the Agilent website.

Support for Your Product

Agilent no longer sells or supports this product. Our service centers may be able

to perform calibration if no repair parts are needed, but no other support from

Agilent is available. You will find any other available product information on the

Agilent Test & Measurement website, www.tm.agilent.com.

HP References in this Manual

This manual may contain references to HP or Hewlett-Packard. Please note that

Hewlett-Packard's former test and measurement, semiconductor products and

chemical analysis businesses are now part of Agilent Technologies. We have

made no changes to this manual copy. In other documentation, to reduce

potential confusion, the only change to product numbers and names has been in

the company name prefix: where a product number/name was HP XXXX the

current name/number is now Agilent XXXX. For example, model number

HP8648A is now model number Agilent 8648A.

Page 2

Installation, Verification, Operation,

Programming, and Service Manual

HP 70590A Options H62 and H72

Test Module Adapters

ABCDE

70590-90023

No.

Part

HP

Printed

in

USA

No

ember

v

1989

Page 3

Notice

The information contained in this do cument is sub ject to change without notice.

Hewlett-Packard makes no warrantyofany kind with regard to this material, including,

but not limited to, the implied warranties of merchantability and tness for a particular

purpose. Hewlett-Packard shall not be liable for errors contained herein or for incidental or

consequential damages in connection with the furnishing, performance, or use of this material.

Restricted Rights Legend.

Use, duplication, or disclosure by the U.S. Government is sub ject to restrictions as set forth

in subparagraph (c) (1) (ii) of the Rights in Technical Data and Computer Software clause

at DFARS 252.227-7013 for DOD agencies, and subparagraphs (c) (1) and (c) (2) of the

Commercial Computer Software Restricted Rights clause at FAR 52.227-19 for other agencies.

c

Copyright Hewlett-Packard Company 1989

All Righ

ermission

p

oun

F

1400

Reserv

ts

is

taingro

Repro

ed.

prohibited,

arkw

P

e

v

duction,

except

Santa

,

y

a

adaptation,

allo

as

Rosa,

written

prior

ws.

yrigh

USA

without

la

t

translation

or

cop

under

ed

w

CA

the

95403-1799,

Page 4

Certification

Hewlett-Packard Company certies that this product met its published specications at the

time of shipment from the factory. Hewlett-Packard further certies that its calibration

measurements are traceable to the United States National Institute of Standards and

Technology, to the extent allowed by the Institute's calibration facility, and to the calibration

facilities of other International Standards Organization members.

Warranty

This Hewlett-Packard instrument pro duct is warranted against defects in material and

workmanship for a perio d of one year from date of shipment. During the warranty period,

Hewlett-Packard Company will, at its option, either repair or replace products whichproveto

be defective.

For warranty service or repair, this pro duct must be returned to a service facility designated

and

ard

k

Buy

to

by

when

to

ac

w

Ho

er.

Hewlett-P

Hewlett-Pac

erly installed

prop

instrumen

the

of

ev

er,

ac

k

Buy

ard

k

ard

er

for

on

or

t,

Hewlett-P

y

b

Hewlett-P

pay

shall

another

from

Hewlett-P

with

use

instrumen

that

are,

w

soft

ac

kard

ac

shipping

all

coun

ard

k

ac

instrumen

an

rm

or

ard.

k

shall pa

try

arran

w

Hewlett-P

t.

are

w

er

Buy

y shipping

harges,

c

.

ts

will

t

will

shall

that

execute

kard

ac

unin

e

b

prepa

duties,

soft

its

do

terrupted

shipping

y

charges

its

es

to

taxes

and

and

are

w

programming

w

not

or

harges

c

return

pro

for

w

rm

that

t

arran

error-free.

Hewlett-P

to

duct

pro

the

returned

ducts

designated

are

instructions

op

the

eration

Limita

tion

foregoing w

The

tenance

main

misuse,

preparation

site

eration

op

y

b

arrant

Buy

outside

or

not

shall

y

er-supplied

Buy

er,

the

of

maintenance.

apply

vironmen

en

to

soft

defects

are

w

sp

tal

resulting

terfacing,

in

or

from

ecications for

improp

er

unauthorized

the pro

duct, or

inadequate

or

dication

mo

improper

arranty

W

of

NO OTHER WARRANTY IS EXPRESSED OR IMPLIED. HEWLETT-PACKARD

SPECIFICALLY DISCLAIMS THE IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE.

Exclusive Remedies

THE REMEDIES

REMEDIES.

HEWLETT-P

PR

VIDED

O

HEREIN

CKARD

A

INDIRECT, SPECIAL, INCIDENT

BASED ON CONTRA

CT, TOR

T, OR

ARE

SHALL

BUYER'S

NOT

SOLE

BE LIABLE

AL, OR CONSEQUENTIAL D

ANY OTHER LEGAL THEOR

AND

DIRECT,

ANY

OR

F

AMAGES, WHETHER

Y.

CLUSIVE

EX

Assistance

available

e

duct

o

Pr

lett-Packar

Hew

any

or

F

maintenanc

pr

d

assistanc

e,

agr

e

ducts.

o

ontact

c

ements

e

your

and

ne

ar

other

est

customer

lett-Packar

Hew

assistanc

Sales

d

e

agr

and

ements

e

Service

ar

Oc

e.

or

for

iii

Page 5

Safety Symbols

The following safetysymbols are used throughout this manual. Familiarize yourself with each

of the symbols and its meaning b efore operating this instrument.

CAUTION

CAUTION

sign denotes a hazard. It calls attention to a pro cedure

The

which, if not correctly p erformed or adhered to, could result in damage to

or destruction of the product or the user's work. Do not proceed beyond a

WARNING

CAUTION

The

WARNING

sign until the indicated conditions are fully understoo d and met.

sign denotes a hazard. It calls attention to a procedure which,

if not correctly performed or adhered to, could result in injury to the user. Do

not proceed beyond a

WARNING

sign until the indicated conditions are fully

understood and met.

DANGER

DANGER

sign denotes an imminent hazard to people. It warns the reader

The

of a procedure which, if not correctly performed or adhered to, could result

the

until

of

loss

or

injury

in

indicated conditions

life. Do

are fully

not proceed

understood and

beyond

a

met.

ANGER

D

sign

iv

Page 6

General Safety Considerations

WARNING

ARNING

W

The instructions in this document are for use by qualified personnel only.To

avoid electrical shock, do not perform any servicing unless you are qualified

to do so.

The opening of covers or removal of parts is likely to expose dangerous

voltages. Disconnect the instrument from all voltage sources while it is being

opened.

The power cord is connected to internal capacitors that may remain livefor

five seconds after disconnecting the plug from its power supply.

This is a Safety Class 1 Product (provided with a protective earthing ground

incorporated in the power cord). The mains plug shall only be inserted in a

socket outlet provided with a protective earth contact. Any interruption of the

protective conductor inside or outside of the instrument is likelytomakethe

instrument dangerous. Intentional interruption is prohibited.

same

with

only

fuses

fuse

or

materials

is

continued

For

type

protection

and ratings,

against

(type nA/nV).

hazard,

fire

The use

replace

of other

prohibited.

properly

been

has

it

sure

e

mak

conductor

e

earth

e

on,

contact.

of

the

ac

po

et

sock

a

to

cable

er

w

Before

this instrument

grounded

pro

outlet

through

vided

with

is

protectiv

the

protectiv

switched

sure

e

ac po

correct

conductor,

e earth

primary

its

source.

wer

voltage

interruption

Any

instrument,

the

personal injury

instrument

been

ailure

this

adapted

set

to

Before

has

F

the

of

disconnection

or

.

to

po

ac

the

protectiv

switched

is

oltage

v

the

er

w

input

(grounding)

e

protectiv

the

of

mak

on,

the

of

the

to

to the instrument when the ac power cable is plugged in.

po

or

w

can

er

inside

terminal

could cause

outside

result

circuitry

damage

in

v

Page 7

Page 8

Contents

1. General Information

Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Front-Panel Features . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Rear-Panel Features . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Input/Output Characteristics . . . . . . . . . . . . . . . . . . . . . . 1-5

Discrete Fault Indicator (DFI) . . . . . . . . . . . . . . . . . . . . 1-5

Modules Covered byManual . . . . . . . . . . . . . . . . . . . . . . 1-5

Serial Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Manual Updating Supplement . . . . . . . . . . . . . . . . . . . . 1-6

Electrostatic Disc

Equipmen

est

Mo

kaging

Service

the

1 .

2

d

the

ESD

Reducing

Handling

T

Returning

ac

P

Instrumen

and

Sales

Installation

2.

king

Chec

Method

Metho

Installing

Removing Mo dules . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

harge Information

Damage

Electronic

of

.

.

.

t

Service

for

dules

.

.

.

.

.

.

Shipping

t

Oces

cal

Lo

.

.

.

dule

Mo

.

.

Preparation

.

Oscillator

.

.

.

.

.

.

.

.

.

.

Comp

.

.

.

.

.

.

Firm

.

.

.

.

.

.

.

onen

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

ware

.

.

.

.

. .

.

ts

.

.

.

Pro

.

.

.

. .

.

. .

.

.

.

.

.

.

. .

.

.

. .

.

.

.

cedure

. .

.

.

.

. .

.

.

.

. .

.

. .

.

.

.

. .

.

.

.

.

. .

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

. .

. .

. .

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

. .

.

.

.

.

.

.

.

.

.

.

.

.

1-6

1-6

1-6

1-7

1-9

1-9

1-9

1-10

2-1

2-1

2-1

2-2

3. Verication

System Verication . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

1. Calibration Switch Signal (H69) . . . . . . . . . . . . . . . . . . 3-2

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

Calibration

2.

Discrete

3.

4. Programming

Measurement System

Noun Modiers .

Compatibility with Native Operation

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

MeasurementModes . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

.

.

CLS

CNF

FNC

FTH

.

.

.

Switc

Indicator

ault

F

. . . . . . . . . . . . . . . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

(DFI)

. . . . . .

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

ath (H72)

P

h

.

. .

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

. . . . . . . . . . . . . . . . . . . 4-2

. . . . . . . . . 4-2

. . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. . . . . . . . . . . . . . . 4-2

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

Contents-1

.

.

.

.

.

3-4

3-6

4-4

4-5

4-7

4-8

Page 9

GAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

INX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

IST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

OPN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

RST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

SET, SRN, and SRX . . . . . . . . . . . . . . . . . . . . . . . . 4-17

STA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

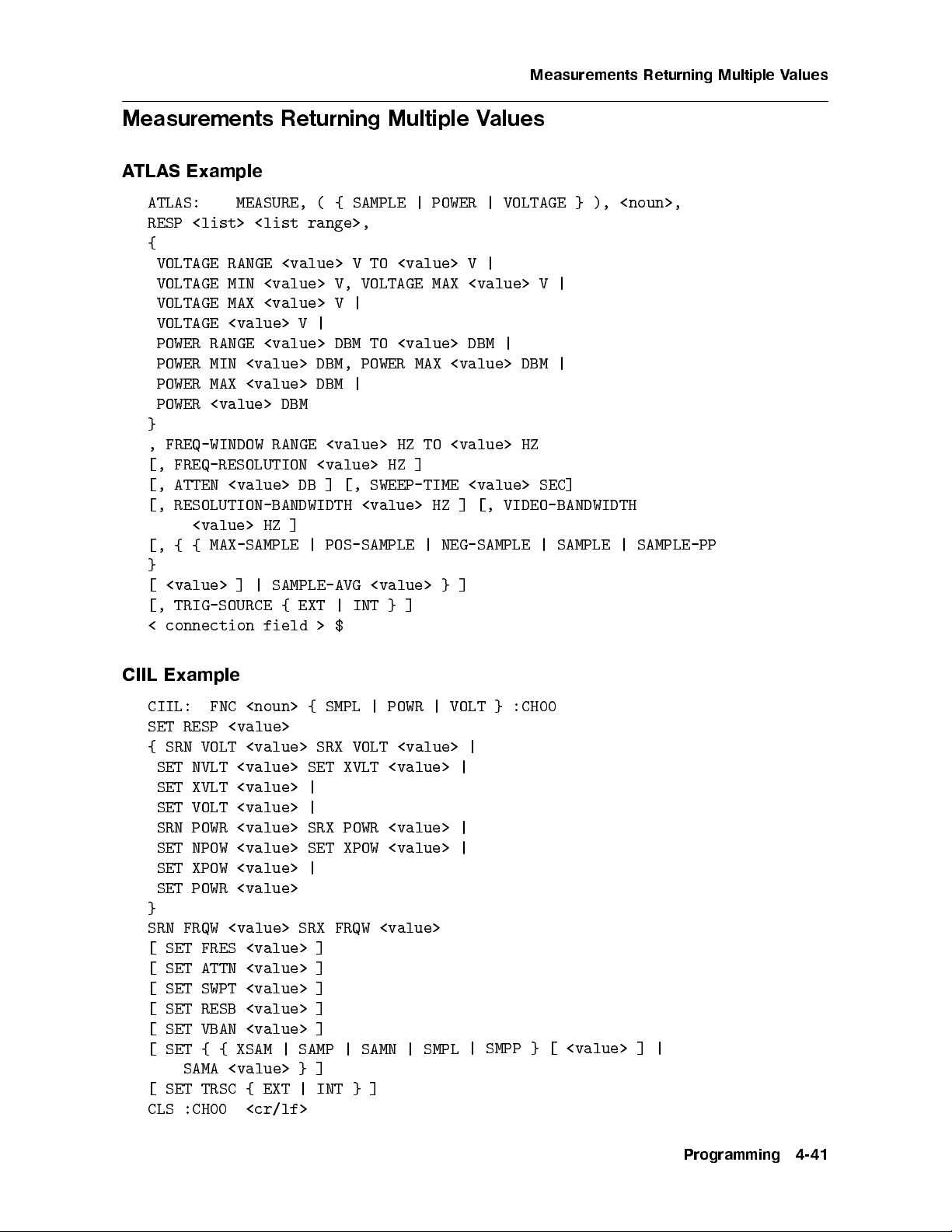

Programming Examples . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Syntax: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Trace Transfers Using CIIL . . . . . . . . . . . . . . . . . . . . 4-23

Measuring Power . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

Measuring Voltage . . . . . . . . . . . . . . . . . . . . . . . . 4-27

Measuring Frequency . . . . . . . . . . . . . . . . . . . . . . . 4-29

Measuring Bandwidth . . . . . . . . . . . . . . . . . . . . . . . 4-31

Measuring Spectrum . . . . . . . . . . . . . . . . . . . . . . . 4-33

Measuring Modulation Frequency . . . . . . . . . . . . . . . . . . 4-35

Measuring Modulation Amplitude . . . . . . . . . . . . . . . . . . 4-37

Measuring AM-Shift . . . . . . . . . . . . . . . . . . . . . . . . 4-39

4-41

.

.

.

.

.

.

.

.

.

.

.

.

.

Measurements

Setting

Setting

Implemen

ted

Conditioner

a

Up

Calibration

Up

Nouns

Returning Multiple

.

.

.

diers

and

Data

Noun-mo

.

.

Values

.

.

.

.

. .

.

. 4-43

. .

. .

. .

.

.

.

.

.

.

.

.

.

4-45

.

.

.

.

.

.

.

. .

. .

.

.

.

.

.

4-46

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

roublesho

T

5.

Service

ron

F

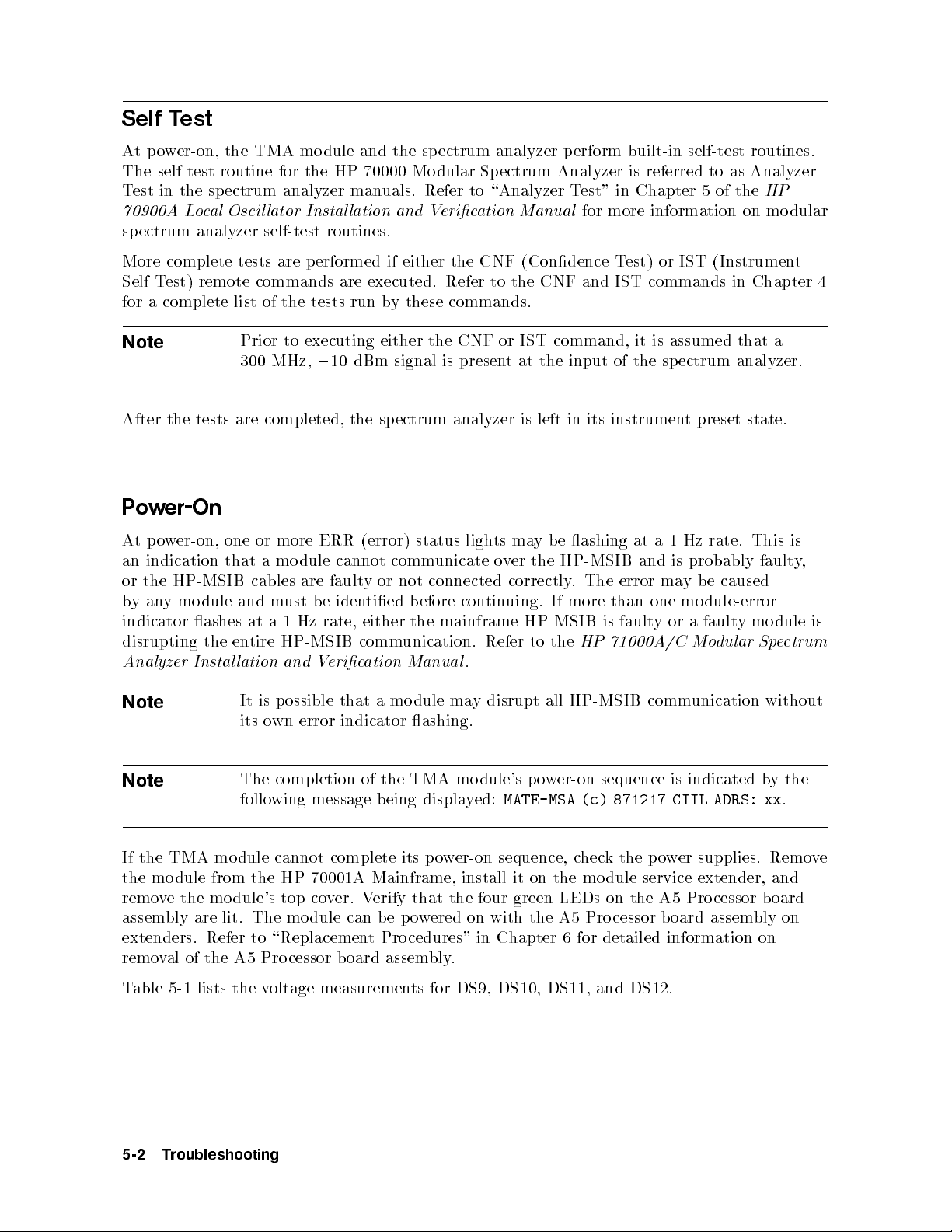

Self

o

P

Error

Assem

6.

Replaceable

7.

t-P

T

er-On

w

oting

Accessories

Op

anel

.

.

est

.

Codes

Replacemen

bly

P

eration

.

.

. .

.

.

.

arts

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

t

Replaceable Parts List Format . . . . . . . . . . . . . . . . . . . . . 7-1

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Direct Mail Order System . . . . . . . . . . . . . . . . . . . . . . . 7-2

Direct Phone-Order System . . . . . . . . . . . . . . . . . . . . . . 7-2

Regular

Hotline

Major Assem

8.

9. Componen

Orders

Orders .

t-Level Information

.

.

.

.

.

.

.

.

bly and Cable Locations

. .

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

Index

. 5-1

.

.

.

.

.

.

5-1

5-2

5-2

5-3

7-2

7-2

Contents-2

Page 10

Figures

1-1. Front-Panel Features . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-2. Rear-Panel Features . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-3. Typical Serial Number Label . . . . . . . . . . . . . . . . . . . . . 1-5

1-4. Example of a Static-Safe Work Station . . . . . . . . . . . . . . . . 1-7

1-5. Factory Packaging Material . . . . . . . . . . . . . . . . . . . . . 1-11

3-1. Calibration Switch Signal Test Setup . . . . . . . . . . . . . . . . . 3-2

3-2. Calibration SwitchPath Test Setup . . . . . . . . . . . . . . . . . . 3-4

3-3. Discrete Fault Indicator Test Setup . . . . . . . . . . . . . . . . . . 3-6

6-1. H72 Wire Routing Diagram . . . . . . . . . . . . . . . . . . . . . 6-2

7-1. H69 Right-Side View . . . . . . . . . . . . . . . . . . . . . . . . 7-10

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

. .

.

bly

bly

(1

(2

. .

. .

. .

. .

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

. .

.

.

.

.

.

.

.

.

.

. .

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

of

of

and

and

2)

2)

Cable

Cable

. .

.

.

Lo

Lo

.

.

.

.

cations

cations

.

.

H69

7-2.

H72 F

7-3.

Rear

7-4.

H69

8-1.

H72

8-2.

Graphic

9-1.

Graphic Sym

9-2.

ron

F

ront

P

Ma

Ma

t

anel

jor

jor

Sym

anel .

P

Panel

.

.

Assem

Assem

ols

b

ols

b

7-12

7-13

.

7-14

.

.

.

.

.

8-1

8-1

9-2

9-3

ables

T

. .

. .

. .

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

1-1. Static-Safe

Accessories

.

1-2. Hewlett-Packard Sales and Service Oces . . . . . . . . . . . . . . . 1-12

3-1. Verication Pro cedures According to Option . . . . . . . . . . . . . . 3-1

3-2. Calibration Switch Signal Voltages . . . . . . . . . . . . . . . . . . 3-3

3-3. Calibration Switch's CAL IN Path . . . . . . . . . . . . . . . . . . 3-5

3-4. Calibration Switch's RF IN Path . . . . . . . . . . . . . . . . . . . 3-5

Indicator

ault

3-5. Discrete

Corresp

4-1.

F

onding

A

4-2. Corresponding A

5-1. A5 Pro cessor T

est P

6-1. Required Hand T

6-2. T

orque V

alues . .

tlas

tlas and CIIL Noun Mo diers

ools

Readings

CIIL

and

oint Measuremen

. . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

7-1. Reference Designations, Abbreviations and Multipliers .

.

Nouns

.

. . . . . . . . .

. . . . 4-47

.

.

.

.

. .

.

.

.

.

.

.

.

.

ts . . . . . . . . . . . . . . . . 5-3

. . . . . . . . . . 6-1

. . . . . . . . . 7-3

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

7-2. Multipliers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

7-3. Manufacturers Code List . . . . . . . . . . . . . . . . . . . . . . . 7-8

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

arts

in

P

This

Chapter

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

7-4.

9-1.

Assem

Assem

bly-Lev

Do

blies

Replaceable

el

cumen

ted

1-8

.

.

3-7

4-46

6-3

.

.

7-9

9-1

Contents-3

Page 11

Page 12

General Information

The HP 70590A Options H69 and H72 TMAs (Test Module Adapters) are MATE modules

for HP 70000 Series spectrum analyzers. The mo dules translate CIIL (control intermediate

interface language) into the HP 70000 Series native code.

Option H69 mo dules provide a calibration switch signal at the rear panel. Option H72

modules switch the RF and Calibrator signals to the analyzer's RF input.

1

Note

There are no adjustment pro cedures for either the Option H69 or Option H72

Test Module Adapters.

follo

The

Chapter

disc

Chapter

Chapter

Chapter

op

Chapter

Chapter

Chapter

for

ual

man

harge,

eration

mo

the

divided

is

General

1,

k

pac

and

Installation

2,

erication

V

3,

Programming

4,

des.

co

roubleshooting

T

5,

Assem

6,

Replaceable

7,

dule.

bly

Refer

nine

to

in

Information

aging

information.

contains

,

vides

pro

,

con

,

,con

Replacemen

arts

P

to Chapter

hapters

c

,

tains

tains

con

,

as

manual

ers

v

co

instructions on

necessary

tests

information

troublesho

instructions

es

giv

,

t

information

tains

ordering comp

9for

Chapter 8, Ma jor Assembly and Cable Locations

assemblies and cables.

Chapter 9, Comp onentLevel Information

blies.

assem

jor

ma

all

diagrams

for

,contains component locations and schematic

ws:

ersions, electrostatic

lev

mo

to

el

dule v

dule.

op

mo

the

all

order

parts

eration

dule

jor

ma

assembly

oard

b

for

the

of

using

assem

level

assem

mo

CI

blies.

organization, mo

installing

v

to

programming

on

oting

the

electrical

erify

information.

replacing

for

necessary

onent

,contains illustrations identifying all ma jor

dule.

IL

parts

blies.

General

Information

1-1

Page 13

Compatibility

The HP 70590A Option H69 and Option H72 TMAs are compatible with the following

systems:

HP 71201A

HP 71100A/C

HP 71200A/C

HP 71210A/C

HP 71400A/C

The HP 70590A Option H69 and Option H72 TMAs are compatible with the following HP

70000 modules.

HP 70300A Tracking Generator (Range 100 Hz to 2.9 GHz)

HP 70301A Tracking Generator (Range 2.7|18 GHz)

HP 70310A Frequency Reference Module (FR)

HP 70600A Preselector Section (Range 0|22 GHz)

HP 70601A Preselector Section (Range 0|26.5 GHz)

HP 70810A Lightwave Section (Range 1200|1600 nm wavelength)

later

70900A

HP

70900B

HP

70902A

HP

HP 70903A

70904A

HP

70905A/B

HP

70906A

HP

70906B

HP

70907A

HP

70907B

HP

70908A Preselected

HP

Lo

Lo

IF

IF

RF

RF

RF

External

External

Oscillator:

cal

Oscillator

cal

Section

Section

Section

Section

RF

Section

Section

(RES

(RES

(Range

(Range

(Range 50

(Range

Mixer

Mixer

Microw

rm

BW 10

BW

100

50

terface

In

terface

In

a

v

w

100

e

are

Hz to

KHz

Hz

KHz

50

KHz

KHz

(EMIM)

(EMIM)

ron

F

ersion

v

to

to

to

End

t

861015

300

3

to

GHz)

2.9

22

to

26.5

GHz)

22

(YTFMD)

KHz)

GHz)

or

MHz)

GHz)

Note

Safety

to the

Refer

The

Considerations

safet

summary

of

are

w

rm

information is found in the c

revision

considerations

y

hapters describing sp ecic use

app

Before servicing this module, familiarize y

and the safet

y instructions

according to in

in this man

ternational safet

y standards. T

ual. This mo dule has b een man

of

t displa

this

ears

on

at

instrumen

the

fron

the

t

of the mo dules.

ourself with the safet

y markings on the module

o ensure safe operation of the module

yat

manual.

Additional

ufactured and tested

safet

and

wer-on.

po

personal safety of the user and service p ersonnel, the cautions and warnings in this manual

must be heeded.

1-2

General

Information

y

Page 14

Front-Panel Features

Features

anel

features.

the

of

output.

RF

status

calibration

the

(Option

the

of

This

H69 mo

mo

signal.

output

dule.

is

dules do

hed

switc

ha

not

from either

Figure

connectors.)

RF

IN

CAL

OUT

RF

illustrates

1-1

Option

The fron

This

This

Figure

H72's

fron

t-panel LEDs

connector

connector

is

pro

Front-P

1-1.

t-panel

indicate

input

for

vides

the CAL IN or RF IN connector.

RF IN This connector is for input of the RF signal.

ERR LED If this light is on, one of the following conditions has o ccurred: the

error

mo

an

dule's

ectrum

sp

encoun

analyzer has

tered,

ACT LED The active (A

the

or

CT) indicator is a standard HP-IB status indicator. When

illuminated, it do es not represen

RMT LED If the mo dule is addressed b

lights and the LST, TLK, or SR

incorrect

an

t,

presen

self-test

failed.

t an error condition.

y a computer, the remote (RMT) indicator

Q indicators will

syn

light, depending on the

as

w

tax

computer instructions.

LSN LED Lights when the analyzer is receiving data or instructions.

SR

Q

LED

Ligh

ts

when

the

analyzer

has

requested

computer

service.

the

e

v

General

Information

1-3

Page 15

Rear-Panel Features

Features

anel

features.

(Option

half of

dules

mo

H72

the normally

not

do

closed rela

ha

y

of

the

e

v

the

illustrates

Figure

CAL

1-2

SIG

ENABLE

DISCRETE

FAULTIND1

DISCRETE

FAULTIND2

Rear-P

Option

Figure 1-2.

rear-panel

H69's

connector.)

connector is

e

yp

t

(m)

SMB

This

discrete fault indicator.

This SMB (m) type connector is half of the normally closed relayofthe

discrete fault indicator.

CAL SIG ENABLE This SMB (m) type connector is the calibration switch signal. (Available

.)

only

on

Option

H69 mo

dules

1-4

General

Information

Page 16

Input/Output Characteristics

Characteristics provide useful information by giving functional, but non-warranted,

performance parameters. The calibration switch will op erate upon issuance of the following

CIIL (control intermediate interface language) commands:

CNF

IST

CH 16 through 19

Discrete Fault Indicator (DFI)

The DFI is implemented as a normally closed relay whose coil is connected across the TMA's

power supply. The contacts op en when power is applied. The contacts close when p ower is

removed from the system, the power supply shuts itself down, or the HP-MSIB lo op is broken.

Maximum current carrying capability ........................................ 100 mA

man

frame

t

ual

Refer

is

y Manual

apply

listed

the

of

rst

to

iden

all

made

Modules

ten

con

The

serial-n

the

hed

ttac

divided

digits

Numbers

to

Serial

A

is

ve

The prex

signican

t

Co

of

ts

um

the

to

in

are

is the

dication

mo

ered b

v

this

er

b

fron

wo

t

the

same for

prexes

sux.

parts. The

and is dierent for eachmodule.

to

under

mo

four

Figure

tical

the

to

HP

\Serial

dule

digits

1-3.

mo

pro

70590A

Num

m

is a

and

dules;

duct.

Option

b

ylar

letter

prex

a

The

ers"

serial-n

are

break

sux,

H69

on

the

ho

um

the

and

b

or

ev

w

Option

man

er

serial

hange

c

er,

lab

H72

title

ual

The

el.

er

b

um

n

only

is assigned

dules

mo

page.

serial

prex;

ccurs

o

sequentially

with

um

n

the

when

er

b

last

a

Figure

1-3.

Typical

Serial

Number

Label

General

Information

1-5

Page 17

Manual Updating Supplement

A mo dule manufactured after this manual was printed mayhave a serial number prex other

than that listed under \Serial Numbers" on the manual title page. A higher serial number

prex than stated on the title page indicates changes have been made to the mo dule since the

manual was printed.

Anychanges that aect information in this manual are documented in the Manual Updating

Supplement for this manual. The Manual Up dating Supplementmayalsocontain information

for correcting errors in the manual. Tokeep the manual as current and accurate as possible,

periodically request the latest Manual Updating Supplement for this manual from your

nearest Hewlett-Packard Sales and Service Oce.

Electrostatic Discharge Information

Electrostatic discharge (ESD) can damage or destroy electronic comp onents. All work on

electronic assemblies should be performed at a static-safe work station.

protection:

ESD

of

es

yp

t

o

w

t

to

using

conductiv

(2)

ensure

part

e

adequate

ers.

b

um

n

table-mat

protection.

ESD

and

heel-strap

Refer

Figure

conductiv

(1)

bination.

com

able

T

to

1-4 sho

1-1 for

ws an

table-mat

e

t

The

a list

example

yp

t

o

w

static-safe

of

of

wrist-strap

and

m

es

static-safe

a

ust b

accessories

e used

w

bination,

com

together

ork

and

station

their

Reducing

Handling

P

Store

Use

of

erform

or

prop

Caution

ESD

Electronic

on these

work

handling

er

ort

transp

Damage

Components

station.

ork

w

tainers.

con

these

tec

items

items

hniques.

static-safe

a

at

static-shielding

in

PC board traces are easily damaged.

Do not touch traces with the bare hands.

Always handle board assemblies by the edges.

1-6

General

Information

Page 18

Equipment

est

T

Before

momen

Personnel

pin

sure

Be

harge.

c

connecting

tarily

y

an

of

that

short

should

b

connector

instrumen

all

Figure

coaxial

y

an

cen

the

grounded

e

and

1-4.

ter and

efore

b

are

ts

Example

cable

outer

with

remo

properly

Static-Safe

a

of

instrumen

an

to

conductors

resistor-isolated

a

assem

y

an

ving

earth grounded

W

connector

t

the

of

wrist

from

bly

Station

ork

cable

strap

the

to prev

the rst

for

together.

touc

efore

b

instrument.

build-up

ent

time

hing

of

eac

the

static

h

da

cen

y

ter

,

General

Information

1-7

Page 19

Table 1-1. Static-Safe Accessories

Accessory Description HP Part Number

Static-control mat and ground

Set includes: 9300-0797

wire

3M static-control mat, 0.6 m21.2 m

(2 ft24 ft)

ground wire, 4.6 m (15 ft)

(The wrist strap and wrist-strap cord are

not

included. They must be ordered

separately.)

Wrist-strap cord 1.5 m (5 ft) 9300-0980

Wrist strap Black, stainless steel with four adjustable

9300-1383

links and 7-mm post-type connector (The

wrist-strap cord is

not

included.)

ESD heel strap Reusable 6 to 12 months 9300-1169

5ft)

ft

2

in)

ft

8ft)

ft)

6

2

ft)

4

2

92175A

92175C

92175B

92175T

92176A

92176C

Hard-surface

Soft-surface

tistatic

static-con

carp

abletop

T

An

static-con

static-con

trol

et*

trol

trol

mat*

mat*

mat*

Large,

Small,

wn,

Bro

cm

58

Small,

natural

russet

blac

black,

1.2

76

2

1.2

color

color

k,

m

1.2

0.9 m

m

cm

2

m(4

2

1.5

m

m(3

2

1.2

ft

(4

m

2.4

2

30

2

in

(23

2

ft

(4

m

1.8

ft)

8

2

ft

m(4

2.4

2

m

1.2

Large,

color

color

through

Hewlett-P

a

ac

k

ard

Sales

Oce

These accessories

*

can b

e ordered

natural

russet

either

HP DIRECT Phone Order Service. In the USA, the HP DIRECT phone number is

(800) 538-8787. Contact your nearest Hewlett-Packard Sales Oce for more information

about HP DIRECT availability in other countries.

through

or

92176B

92176D

1-8

General

Information

Page 20

Returning Modules for Service

If a mo dule is being returned to Hewlett Packard for servicing, ll in and attach a blue repair

tag. Repair tags are provided at the end of this chapter. Please b e as sp ecic as p ossible

about the nature of the problem. Include copies of error messages, data related to mo dule

performance, type of system, etc., along with the module being returned.

Packaging

The original shipping containers should be used. If the original materials were not retained,

identical packaging materials are available through any Hewlett-Packard oce. Figure 1-5

illustrates the factory packaging material. When ordering packaging material to ship mo dules,

it is necessary to order the prop er number of foam inserts.

A 3/8-width mo dule requires no foam inserts.

A 2/8-width mo dule requires one foam insert.

A 1/8-width mo dule requires two foam inserts.

Caution

Instrument

out

Fill

1.

instrumen

problem.

the instrumen

with

yp

T

a.

Description

b.

Whether

c.

Instrumen

those

adequately

They

Shipping

blue

a

Include

t.

a

If

service

of

e

problem

specied.

also

Preparation

repair

repair

blue

t.

required

the

of

damage

t

cushion

cause

(lo

tag

error

y

an

tag

problem

constan

is

can

Never

use st

the

instrumen

Procedure

at

cated

messages

not

is

intermitten

tor

result

instrumen

the

av

from

p

yrene

t

damage

t

of

end

ecic

sp

or

ailable, the

t

or

this

d. Name and phone number of technical contact person

e. Return address

f. Model number of returned instrument

g. Full serial number of returned instrument

instrumen

List

h.

Caution

y accessories

an

of

Inappropriate

returned

pac

with

kaging

instrumen

of

instrument during transit.

using pac

as

ellets

en

prev

generating

y

b

hapter)

c

erformance

p

wing

follo

t

y

ma

ts

kaging

aging

k

pac

from

it

t

static

and

data

information

in

result

materials other

material.

shifting

electricit

h

attac

related

They

the

in

y

the

to

it

to

should

the

damage

to

than

carton.

.

the

returned

e

b

do

not

ack the instrumen

2. P

t in the appropriate pac

Original shipping materials or the equiv

kaging materials. (Refer to Figure 1-5.)

alent should be used. If the original or equiv

materials cannot be obtained, instruments can b e packaged for shipment using the

following instructions.

damage caused

of

a.

W

rap

instrumen

the

ossibilit

p

reduce

ti-static

an

in

t

plastic

to

the

y

ESD.

General

alent

Information

y

b

1-9

Page 21

b. For instruments that weigh less than 54 kg (120 lb), use a double-walled, corrugated

cardboard carton of 159-kg (350-lb) test strength.

c. The carton must be large enough to allow three to four inches on all sides of the

instrument for packing material and strong enough to accommo date the weightofthe

instrument.

d. Surround the equipment with three to four inches of packing material, to protect the

instrument and preventitfrommoving in the carton.

e. If packing foam is not available, the best alternative is S.D.-240 Air CapTMfrom Sealed

Air Corporation (Commerce, California 90001). Air Cap looks like a plastic sheet lled

with air bubbles.

f. Use the pink (anti-static) Air CapTMto reduce static electricity.Wrapping the

instrument several times in this material will protect the instrument and prevent it from

moving in the carton.

3. Seal the carton with strong nylon adhesive tap e.

4. Mark the carton `FRAGILE, HANDLE WITH CARE.'

5. Retain copies of all shipping papers.

Sales

Hewlett-P

ducts.

pro

Hewlett-P

include

to

umb

n

part

and Service

and Service

Sales

ard

k

ac

T

ac

the

obtain

o

ard

k

p

servicing

Sales

ertinen

and

t

ers.

Offices

information,

Service

information

Oces

Oce

out

ab

pro

or

listed

model

vide

to

in

complete

order

able

T

um

n

supp

replacemen

In

1-2.

serial

ers,

b

Hewlett-P

for

ort

parts,

t

correspondence,

y

an

ers,

b

um

n

tact

con

and/or

k

ac

the

assem

ard

nearest

sure

e

b

bly

1-10

General

Information

Page 22

Figure 1-5. F

actory P

ackaging Material

General

Information

1-11

Page 23

Table 1-2. Hewlett-Packard Sales and Service Offices

IN THE UNITED STATES IN AUSTRALIA IN JAPAN

California

Hewlett-Packard Australia Ltd. Yokogawa-Hewlett-Packard Ltd.

Hewlett-Packard Co. 31-41 Joseph Street 29-21 Takaido-Higashi, 3 Chome

1421 South Manhattan Ave. Blackburn, Victoria 3130 Suginami-ku Tokyo168

P.O. Box 4230 895-2895 (03) 331-6111

Fullerton, CA 92631

(714) 999-6700

Hewlett-Packard Co. 17500 South Service Road

IN CANADA

Hewlett-Packard (Canada) Ltd.

IN PEOPLE'S REPUBLIC

OF CHINA

301 E. Evelyn Trans-Canada Highway China Hewlett-Packard, Ltd.

Mountain View, CA 94039 Kirkland, Quebec H9J 2X8 P.O. Box 9610, Beijing

(415) 694-2000 (514) 697-4232 4th Flo or, 2nd WatchFactory

Main Bldg.

Colorado IN FRANCE

Shuang YuShu, Bei San Huan Rd.

Hewlett-Packard Co. Hewlett-Packard France Beijing, PRC

24 Inverness Place, East F-91947 Les Ulis Cedex 256-6888

Englewood, CO 80112 Orsay

907-78-25

649-5000

(303)

Georgia

Hewlett-P

South

2000

x

Bo

.O.

P

ta,

tlan

A

955-1500

(404)

Illinois

Hewlett-P

ollview

T

5201

Rolling

(312)

New

Meado

255-9800

Jersey

k

ac

P

105005

GA

k

ac

ard

ark

30339

ard

Driv

ws,

Co.

Place

Co.

e

60008 Hewlett-P

IL

(6)

GERMAN

IN

REPUBLIC

Strasse

560

h

rankfurt

F

50-04-1

GREAT

ac

Hewlett-P

ertriebszen

V

Berner

ostfac

P

D-6000

(0611)

IN

ack

King Street

Winnersh,

Berkshire

R

IN

FEDERAL

Hewlett-P

Pte.

ard

k

trale

117

140

BRIT

ard

bH

Gm

rankfurt

F

56

AIN

Ltd.

1150 Dep

Singap

273

elex

T

ax

F

IN

Hewlett-P

Lane 8th

okingham Building

W

G11 5AR

337 F

SINGAPORE

ard

k

ac

Ltd.

ot Road

0410

ore

7388

HPSGSO

2788990

(65)

AN

AIW

T

ard

k

ac

Hewlett-Pac

Floor,

uHsing

North

Singap

RS34209

an

aiw

T

k

Road

ore

ard

Hewlett-Packard Co. 0734 784774 Taipei

120 W. Century Road (02) 712-0404

Paramus, NJ 07653

(201) 265-5000

exas

T

Co. CH-8967

ard

k

Hewlett-P

930 E. Campbell

ac

Rd. (0041) 57 31 21 11

IN OTHER EUROPEAN

COUNTRIES

eiz)

w

h

(Sc

ard

k

Hewlett-P

Allmend

ac

2

Widen

(Zuric

h)

OTHER

ALL

IN

AG

ard

Deer

k

Creek

Hewlett-Pac

3495

Palo Alto, California 94304

TIONS

LOCA

ter-Americas

In

Rd.

Richardson, TX 75081

(214) 231-6101

1-12

General

Information

Page 24

2

Installation

The following paragraphs provide instructions on installing the HP 70590A Option H69 and

Option H72 TMA modules.

Checking the Local Oscillator Firmware

If an HP 70900A Local Oscillator is used, the local oscillator's rmware version must be

861015 or later. To display the rmware, you must use one of the two methods listed below.

The metho d you use depends on the vintage of the local oscillator module and the keys that

ailable.

av

are

ersion

v

1

4

5

MENU

N

N

N

N

N

N

N

N

N

N

N

N

N

N

Misc

N

N

N

N

N

N

NN

N

N

N

N

N

N

more

N

NN

N

N

N

N

N

N

N

N

N

N

N

N

N

N

service

N

N

N

N

N

N

N

N

NN

NN

N

N

N

N

N

VERSION

ROM

date

N

N

N

N

N

N

N

N

N

N

N

N

app

N

N

Method

1.

Press

2.

Press

3.

Press

4.

Press

5.

Press

The

Method 2

1.

Press

4

5

MENU

2.

3.

The v

NNNNNNNNNNNNNNNNNNNN

Press

CONFIG

N

N

N

NN

N

N

N

N

N

N

N

N

N

N

NN

N

N

N

N

N

N

N

N

Press

ROM

VERSION

ersion date app ears in the

N

NN

NN

N

N

N

N

N

.

y

displa

the

of

k

c

general

the

in

ears

NN

N

N

N

N

N

N

N

N

annotation

general annotation blo c

blo

k of the displa

y.

Installation

2-1

Page 25

Installing the Module

After completing the following pro cedure, the TMA mo dule's HP- MSIB address will meet the

following criteria:

TMA's row address will b e 0.

TMA's column address will be equal to the local oscillator module's column address.

1. Turn the system mainframe's power OFF.

2. Remove the lo cal oscillator mo dule from the system mainframe. For information on how

to remove modules from the mainframe, refer to \Removing Mo dules" in this chapter.

3. Set the lo cal oscillator module's HP-IB switch to OFF.

4. Set the lo cal oscillator module's HP-MSIB row address switches to a value of 1.

Note

The HP-IB switch, HP-MSIB ROW switches, and HP-MSIB COLUMN

switches are located on the top of the module.

address

1,

w

no

to

hes

mo

is

Refer to

of

0.

the same

to

dule,

these

and

the lo

mo

all

dules.

v

other

Because

5.

mo

installation

6. Set

Set

7.

Set

8.

mo

Install

9.

the

urn

T

10.

11.

Press

the

the

in

dules

man

TMA

the

TMA

the

TMA

the

dule's

column

the

TMA

mainframe.

o

p

the

4

the

DISPLAY

lo

er

w

cal

system

ual

dule's

mo

dule's

mo

dule's

mo

address.

mo

on.

5

oscillator

ma

prop

to

HP-IB

ro

column

dule,

N

NN

NN

and

address

mo

ha

y

erly set

address

w

the

N

N

N

N

N

N

N

N

N

N

dule's

to b

e

v

switc

address

cal

lo

NN

NN

N

N

N

N

N

N

oscillator

NN

NN

map

address

w

ro

e increased.

the addresses

ON.

to

h

hes

switc

switc

N

N

N

N

N

N

eys.

k

12. Use the front-panel knob to movethebox to the TMA mo dule.

Note

If the system does not work (locks up), then an HP-MSIB address is likely

duplicated.

alue

v

oscillator

cal

as

system

alues of

lo

the

other

cal

mo

dule's

mo

oscillator

in

dules

to

NN

13. Press

the

Adjust Row

14. Use the fron

15.

Press the

softkey

NNNNNNNNNNNNNN

ASSIGN DISPLAY

.)

Note

Installation

2-2

N

N

N

N

N

NN

N

N

N

N

N

N

N

N

N

N

N

NN

N

N

N

N

N

N

N

N

N

N

t-panel knob to

NNNNNNNNNNNNNNNNNNNNNNNNN

The display's

cal

lo

TMA

or

.

ey

softk

movethe bo

NNNNN

softkey

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

Next INSTR

oscillator

x to the LO module.

. (Some displa

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

and

Select INSTR

modules.

ys ma

NNNNNNNNNNNNNNNNNNNNNNNNN

yha

vethe

NNNNNNNNNNNNNN

ALLOC DISPLAY

softkeys will not lo cate the

NN

Page 26

Note

Removing Modules

To remove a mo dule from the system mainframe, perform the following steps:

1. Set the instrument LINE switch to OFF.

2. Remove the rear-panel inter-module cables.

3. Swing the mainframe frontdoordown. Note that the door will not open unless the LINE

switch is OFF.

4. For any mo dule requiring an address change, loosen its latch using an 8 mm hex-ball

driver.

v

Remo

5.

The TMA does not require rear-panel inter-module connections.

dule.

mo

the

e

Installation

2-3

Page 27

Page 28

3

Verification

The three pro cedures provided in this chapter verify the electrical performance of HP 70590A

Option H69 and Option H72 Modules. If the mo dule passes this verication, its operation is

assured within the Mo dular Measurement System.

Table 3-1 lists the verication pro cedures that should be performed for each option.

Table 3-1. Verification Procedures According to Option

MODULE PERFORM THESE PROCEDURES

Option H69 1. Calibration Switch Signal (H69)

(DFI)

ath

P

(DFI)

System

70590A

system.

the

system

(H72)

erformance

P

Option H69

yp

t

and

the

e

on

ests

T

or Option

wing

follo

the

H72

System

erform

p

o

T

70000

HP

Module

est

T

ypass

b

o

T

erification

V

dular

Op

Sp

System

Mo

Adapter m

the TMA,

Option

eration

ectrum

eb

ust b

connect a

Discrete

3.

H722.Calibration

Discrete

3.

erication

V

Analyzer

ypassed

remote con

or

System,

remo

or

troller to

Indicator

ault

F

Switc

ault Indicator

F

11990A

HP

HP

the

from

ed

v

the

h

program line (where XX is the TMA's address):

OUTPUT 7XX;"GAL;"

If the TMA is removed from the system, the row address of the local oscillator must be set to

to

need

not

ests soft

T

do

can

are

w

HP-IB

its

and

0

hange.)

c

The System

Op

switc

eration

ust

hm

erication

V

addresses

w

module

e

v

sla

(The

ON.

to

set

e

b

or

HP

11990A

System

ro

erformance

P

then b e run in the normal manner.

erification

V

3-1

Page 29

1. Calibration Switch Signal (H69)

Description

This test checks the calibration switch for prop er op eration.

Equipment

Test Equipment:

Controller ................................................HP 9000 Series 200/300

Modular Measurement System ........................ HP 71100A/C, HP 71200A/C,

HP 71201A/C, HP 71210A/C,

or HP 71300A/C

Digital Voltmeter .....................................................HP 3456A

Adapters:

BNC (f) BNC (f)barrel ................................................ 1250-0080

Banana Plug to BNC (f ) . . . . . . . . . . . . . . . . ............................... 1251-2277

Cables:

85680-60093

HP

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

BNC

(m)

to SMB

(f )

3-2

erification

V

Figure

3-1.

Calibration

Switch

Signal

T

est

Setup

Page 30

1. Calibration Switch Signal (H69)

Procedure

1. Connect equipmentasshown in Figure 3-1. Connect the DVM to the HP 70590A's rear

panel CAL SIG ENABLE connector.

2. Note the voltage on the voltmeter and record the value in Table 3-2. (This is the voltage

when the switch is OFF.)

3. Send the CNF programming command to the HP 70590A module:

OUTPUT 7XX;"CNF;"

4. Note the voltage on the voltmeter and record the value in Table 3-2. (This is the voltage

when the switch is ON.)

Table 3-2. Calibration Switch Signal Voltages

SWITCH SETTING ACTUAL VOLTAGE TEST LIMITS

Calibration SwitchOFF

ON

h

Calibration

Switc

<

>

0.7 V

2.4

V

erification

V

3-3

Page 31

2. Calibration Switch Path (H72)

Description

This test checks the calibration switch path for proper op eration.

Equipment

Test Equipment:

Controller ................................................HP 9000 Series 200/300

Modular Measurement System ........................ HP 71100A/C, HP 71200A/C,

HP 71201A/C, HP 71210A/C,

or HP 71300A/C

Digital Voltmeter .....................................................HP 3456A

50 termination .......................................................HP 909D

Adapters:

Banana Plug to BNC (f ) . . . . . . . . . . . . . . . . ............................... 1251-2277

Cables:

85680-60093

HP

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

BNC

(m)

to SMB

(f )

3-4

erification

V

Figure

3-2.

Calibration

Switch

P

ath

T

est

Setup

Page 32

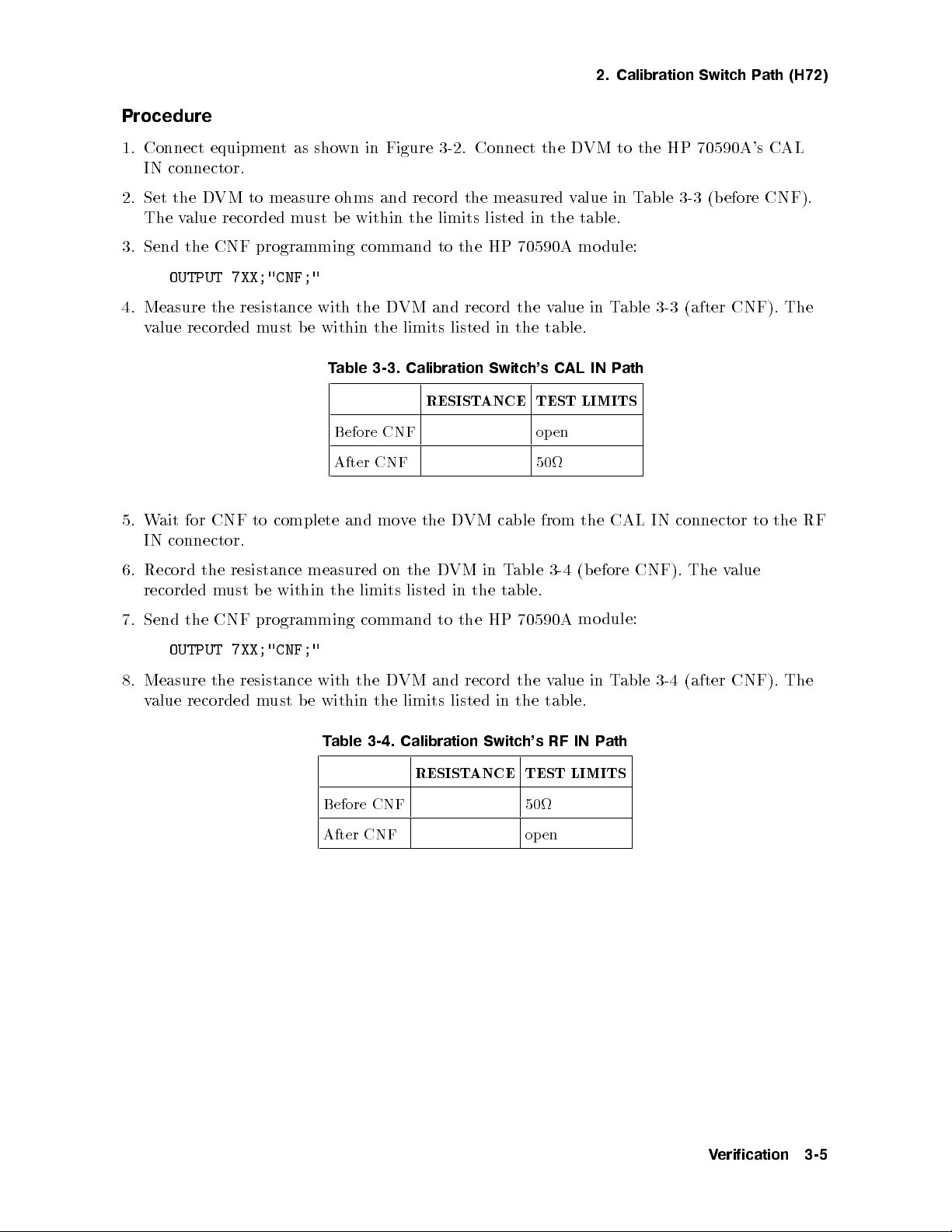

2. Calibration Switch Path (H72)

Procedure

1. Connect equipmentasshown in Figure 3-2. Connect the DVM to the HP 70590A's CAL

IN connector.

2. Set the DVM to measure ohms and record the measured value in Table 3-3 (before CNF).

The value recorded must be within the limits listed in the table.

3. Send the CNF programming command to the HP 70590A module:

OUTPUT 7XX;"CNF;"

4. Measure the resistance with the DVM and record the value in Table 3-3 (after CNF). The

value recorded must b e within the limits listed in the table.

Table 3-3. Calibration Switch's CAL IN Path

RESISTANCE TEST LIMITS

Before CNF open

CNF

5.

ait

W

connector.

IN

for

CNF to

After

complete and

mo

VM

D

the

e

v

cable

50

from

the

CAL

connector

IN

to

the

RF

6. Record

recorded

Send

7.

OUTPUT

Measure

8.

value

resistance

the

ust

m

CNF

the

7XX;"CNF;"

resistance

the

recorded m

measured

e

b

within

the

programming

with

within

e

b

ust

able

T

Before CNF 50

After CNF open

the

on

limits

listed

command

VM and

D

the

limits

the

Calibration

3-4.

efore

(b

3-4

able

T

in

VM

D

table.

the

in

dule:

alue

v

table.

RF

mo

IN

in

P

T

ath

the

to

record the

listed

70590A

HP

the

in

Switch's

RESISTANCE TEST LIMITS

CNF).

able

3-4

The

(after

alue

v

CNF).

The

erification

V

3-5

Page 33

3. Discrete Fault Indicator (DFI)

Description

The DFI is normally implemented as a closed relay whose coil is connected across the power

supply of the HP 70590A Option H69 Test Module Adapter. The relay op ens when power is

applied and closes when power is removed from the system. The relay also closes when either

the p ower supply shuts itself down or the HP-MSIB loop is broken.

Equipment

Test Equipment:

Modular Measurement System ........................ HP 71100A/C, HP 71200A/C,

HP 71201A/C, HP 71210A/C,

or HP 71300A/C

Digital Voltmeter .....................................................HP 3456A

50 Termination . . . . . ..................................................HP909D

Adapters:

BNC

(2

re

(f

quir

)to

e

BNC (f

d)

) barrel

..

1250-0080

HP

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Cables:

11001-60001

HP

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

BNC

BNC

(2

r

(m)

(m)

quir

e

to

to

ed)

banana

dual

SMB (f

plug

85680-60093

HP

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

)

3-6

erification

V

Figure

3-3.

Discrete

F

ault

Indicator

est Setup

T

Page 34

3. Discrete Fault Indicator (DFI)

Procedure

1. Connect equipmentasshown in Figure 3-3.

2. Set the digital voltmeter to read out in ohm units (resistance).

3. Turn the power on to the modular spectrum analyzer system.

4. Note the resistance on the digital voltmeter and record in Table 3-5.

5. Turn the power o to the modular spectrum analyzer system.

6. Note the resistance on the digital voltmeter and record in Table 3-5.

Table 3-5. Discrete Fault Indicator Readings

Power Setting Resistance

(ohms)

Power ON OPEN

Power OFF 50

Test Limit

erification

V

3-7

Page 35

Page 36

4

Programming

Adding the HP 70590A Option H69 or Option H72 TMA to an HP Mo dular Spectrum

Analyzer allows operation of the spectrum analyzer using either CI IL or its native language

command set. This chapter contains the following information:

Detailed information on the native language commands can be found in the HP 70000

Modular Spectrum Analyzer Programming Manual. The CIIL op eration co des are described

in this manual. They are followed byseveral ATLAS/CIIL examples. Finally, there is a

list of all of the ATLAS nouns and noun mo diers (that are implemented) with their CIIL

equivalent.

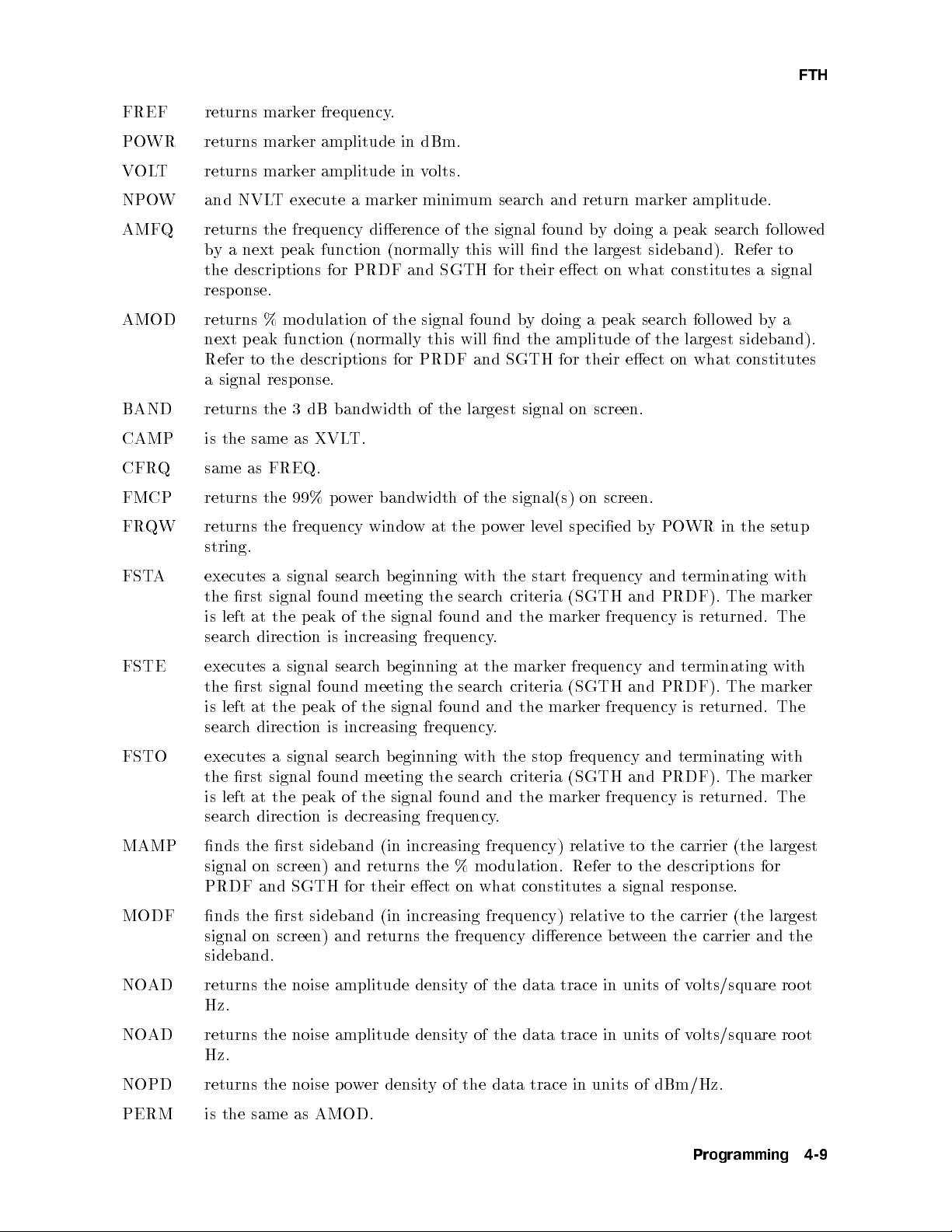

The ASA resp onds to the following CI IL operation codes: CLS, CNF, FNC, FTH, GAL, INX,

and

A.

noun-mod

<

>

will

hav

ciated

asso

>

alue

v

<

one

e

IST,

Unless

with

OPN,

otherwise

them.

RST,

SET,

stated,

SRN,

all

SRX,

mc

<

har

and ST

>

Programming

4-1

Page 37

Measurement System

The measurement system will hereafter b e referred to as the ASA (Automatic Spectrum

Analyzer). The ASA contains two separate parsers: one for CI IL and one for the nativemode.

The language selected at power-up will be CI IL.

The ASA op erates as b oth a STIM device (for signal conditioning purp oses) and a SENSOR

device for measurements.

At the end of each measurement, the ASA is left with the sweep enabled to facilitate ASA

integration until RST o ccurs.

Noun Modifiers

The ASA reads into variables all of the NOUN MODIFIERS and marks a ag for each

modier that is encountered (an RST function p erforms an instrument preset and clears all

modier ags). From the collection of ags and the ATLAS NOUN, an inference will be made

to

as

their

NOUN

exactly whic

implications)

CIIL

MODIFIERS

h measuremen

pro

are

trigger

whic

t the

vided

h

user is

illustrate

to

actions.

attempting

what

A

e.

mak

to

measuremen

TLAS

will

ts

examples

done

e

b

(and

and

whic

h

Compatibility

After

y

An

GAL

the

In

only

the

de and

mo

Note

receiving

ending

p

command.

nativ

w

a

setup

mo

e

return to

yto

a

will not

When the PROGRAM MESSAGE method is used to switchbetween

languages, there is no change in the POWER UP language state.

Note

Device

A

A Device Clear do

with

command,

GAL

information

the

de,

generate

Clear,

TR

TN

Nativ

IL

CI

CIIL

a

commands

UE

Operation

e

commands

all

to

onds

will

IL

function

switc

T

resp

the

to

in

from nativ

h

dened

e

b

rigger, Serial

dened

as

as

P

ASA

emo

dumm

a

oll,

b

the

e

b

will

command

mode.

error.

tax

syn

Group

Execute

analyzer

programmed

will

CI

will

es NOT cause the language mode to be c

efore

b

de

and

ythe

in

the

IL

CI

to

command

y

other

language

hanged.

nativ

the

completion

de.

mo

in

device

dep

that

mo

e

This

the

enden

activ

is

de.

of the

is

IL

CI

t

e.

Programming

4-2

Page 38

Calibration

The ASA is calibrated byproviding a suitable signal at the selected input and specifying

:CH16 through :CH19 (for inputs 0-3). This calibrates the insertion loss dierences of the

resolution bandwidth lters, their frequency osets, step gain osets, etc. The calibration will

remain in eect until another calibration is performed. In addition, path loss correction may

be performed by sending the setup string:

FNC CAL POWR :CHnn

SET FREQ <value> SET PRDF <value>

..

SET FREQ <value> SET PRDF <value>

<cr/lf>

Up to 20 points may b e supplied. The PRDF values are correction factors to b e added to the

measurements. This correction will remain eectiveuntil the next RST command. For further

information, refer to the AMPCOR command in the ASA command reference manual.

Note

Measurement

ASA

The

with

and

gather

to

up

commands.

FETCH

will

parameters from

MONITOR

the

The frequency/amplitude pairs MUST be sent in ascending frequency order

(lo

est

w

frequency

rst).

Modes

h

(suc

erbs

tended

in

is

single

data

Therefore,

erform data

p

to

and

the

v

b

same

action

statemen

used

be

(suc

erbs

able

e

INITIA

TE

reduction on

INITIA

function

to

t

to

with

as

h

return

will

TE.

m

oth

b

INITIA

ultiple

m

ys

a

alw

the

in

This

correctly

ultiple

and

TE

measuremen

a

(as

gathered

teraction

.

action

A

FETCH).

minimum)

allo

data

een

w

et

b

TLAS

v

is

ASA

The

through

ts

a

trigger another

return

the

wing

FETCH

and

sp

series

INITIA

MEASURE)

as

ecically

of FETCH

eep

sw

eral

sev

of

TE

and

It is expected that the measurement throughput will be b etter using single action verbs

because it is p ossible to avoid multiple setups to accomplish related measurements.

set

allo

ws

Programming

4-3

Page 39

CLS

Syntax

CLS :CH00

Description

This command closes the sensor connection. When REFO has b een sent as part of the setup,

this command will trigger the programming of the ASA. (The ASA is being used as a signal

conditioner in this case.) Otherwise, this command causes no action. The CLS command will

also put the analyzer in continuous sweep mode. (Again, REFOmust be sent as part of the

setup string.)

Programming

4-4

Page 40

CNF

CNF

Syntax

CNF

Description

The following tests are executed by this command. After execution, the ASA will be left in its

instrument preset state.

Note

Always wait approximately three minutes after p ower-on to execute this

command. If this command is executed too early, not all of the following test

will b e run.

Note

This command assumes a 300 MHz,010 dBm signal is present at the ASA's

input port.

ests

T