Page 1

HP 70001A Mainframe

Installation and Verication Manual

Supplement for use with HP 70000

Modular Spectrum Analyzer Installation

and Verication Manual and

HP 70900B Local Oscillator Source

ABCDE

No

art

P

HP

A

US

Printed

in

70001-90021

.

September

1999

Page 2

Notice

The information contained in this document is subject to change without notice.

Hewlett-Packard makes no warranty of any kind with regard to this material, including,

but not limited to, the implied warranties of merchantability and tness for a particular

purpose. Hewlett-Packard shall not be liable for errors contained herein or for incidental or

consequential damages in connection with the furnishing, performance, or use of this material.

Restricted Rights Legend.

Use, duplication, or disclosure by the U.S. Government is subject to restrictions as set forth

in subparagraph (c) (1) (ii) of the Rights in Technical Data and Computer Software clause at

DFARS 252.227-7013 for DOD agencies, and subparagraphs (c) (1) and (c) (2) of the Commercial

Computer Software Restricted Rights clause at FAR 52.227-19 for other agencies.

c

Copyright Hewlett-Packard Company 1988, 1999

under

Santa

adaptation,

copyright

the

CA

Rosa,

Rights

All

prohibited,

is

Fountaingrove

1400

Reserved.

except

Reproduction,

allowed

as

arkway

P

,

translation

or

laws

95403-1799,

.

USA

without

prior

written

permission

Page 3

Certication

Hewlett-Packard Company certies that this product met its published specications at the

time of shipment from the factory. Hewlett-Packard further certies that its calibration

measurements are traceable to the United States National Institute of Standards and

Technology, to the extent allowed by the Institute's calibration facility, and to the calibration

facilities of other International Standards Organization members.

Warranty

This Hewlett-Packard instrument product is warranted against defects in material and

workmanship for a period of one year from date of shipment. During the warranty period,

Hewlett-Packard Company will, at its option, either repair or replace products which prove to

be defective.

For warranty service or repair, this product must be returned to a service facility designated by

Hewlett-Packard. Buyer shall prepay shipping charges to Hewlett-Packard and Hewlett-Packard

shall pay shipping charges to return the product to Buyer. However, Buyer shall pay all

another

shipping

country

charges,

.

duties,

and taxes

for

products

returned

Hewlett-P

to

ackard

from

Hewlett-P

with an

use

instrument.

that

a

The

,

tion

foregoing

software

Limit

maintenance

misuse

preparation

site

OTHER

NO

DISCLAIMS

ackard warrants

instrument will

Hewlett-P

rmware

or

of

W

will

arranty

warranty

Buyer

by

operation

,

outside

or

ARRANTY

W

IMPLIED

THE

maintenance

that its

software

execute

ackard does

uninterrupted

be

apply

not

shall

Buyer-supplied

,

environmental

the

of

.

EXPRESSED

IS

ARRANTIES

W

and

programming

its

warrant

not

or

defects

to

software

OR

OF

rmware

instructions

that

error-free

resulting

interfacing,

or

specications

IMPLIED

.

MERCHANT

designated

when

operation

the

.

improper

from

unauthorized

for

HEWLETT-P

ABILITY

by

the

A

AND

CKARD

Hewlett-P

properly

the

of

product,

FITNESS

ackard

installed

instrument,

or inadequate

modication

or improper

SPECIFICALL

FOR

PARTICULAR PURPOSE.

Exclusive Remedies

THE REMEDIES PROVIDED HEREIN ARE BUYER'S SOLE AND EXCLUSIVE REMEDIES.

HEWLETT-PACKARD SHALL NOT BE LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL,

CONTRACT

INCIDENT

ANY

OR

AL,

OTHER

CONSEQUENTIAL

OR

LEGAL

THEORY

ASED

AMA

D

GES,

WHETHER

B

.

ON

Assistance

TORT

,

for

on

or

or

Y

A

,

Product maintenance agreements and other customer assistance agreements are available for

Hewlett-Packard products.

For any assistance, contact your nearest Hewlett-Packard Sales and Service Oce.

iii

Page 4

Safety Symbols

The following safety symbols are used throughout this manual. Familiarize yourself with each

of the symbols and its meaning before operating this instrument.

The

CAUTION

WARNING

DANGER

CAUTION

not correctly performed or adhered to, could result in damage to or destruction

of the product or the user's work. Do not proceed beyond a

until the indicated conditions are fully understood and met.

The

WARNING

which, if not correctly performed or adhered to, could result in injury

to the user. Do not proceed beyond a

conditions are fully understood and met.

The

DANGER

reader of a procedure which, if not correctly performed or adhered to,

could result in injury or loss of life. Do not proceed beyond a

sign until the indicated conditions are fully understood and met.

sign denotes a hazard. It calls attention to a procedure which, if

CAUTION

sign denotes a hazard. It calls attention to a procedure

WARNING

sign denotes an imminent hazard to people. It warns the

sign until the indicated

sign

DANGER

iv

Page 5

General Safety Considerations

WARNING

ARNING

W

The instructions in this document are for use by qualied personnel

only.To avoid electrical shock, do not perform any servicing unless you

are qualied to do so.

The opening of covers or removal of parts is likely to expose dangerous

voltages. Disconnect the instrument from all voltage sources while it is

being opened.

The power cord is connected to internal capacitors that may remain live

for ve seconds after disconnecting the plug from its power supply.

This is a Safety Class 1 Product (provided with a protective earthing

ground incorporated in the power cord). The mains plug shall only be

inserted in a socket outlet provided with a protective earth contact.

Any interruption of the protective conductor inside or outside of the

instrument is likely to make the instrument dangerous. Intentional

interruption is prohibited.

For continued protection against re hazard, replace fuse only with

materials

or

it

fuses

has

power

been

properly

cable

to

a

type

same

prohibited.

is

Before

this

grounded

socket

outlet

ratings,

and

instrument

through

provided

(type nA/nV).

is

protective

the

with

switched on,

conductor

protective

The use

make sure

of

earth

of other

the ac

contact.

interruption

Any

outside

or

terminal

Before

circuitry

ailure

F

damage

the

can

instrument

this

has

set

to

the

to

the

of

instrument,

the

in

adapted

power

ac

result

been

instrument

protective

or

personal

switched

is

to

input

when

(grounding)

disconnection

.

injury

make

on,

the

ac

of

correct

power

the

voltage

to

the

conductor,

of the

sure

ac

the

voltage

cable

protective

primary

its

power

could cause

plugged

is

inside

earth

power

source

in.

.

v

Page 6

Page 7

Contents

1. General Information

Mainframe Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Safety Considerations ............................ 1-3

Mainframes Covered by Manual . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Serial Numbers ...... ...... ...... ...... ..... . 1-3

Manual Updating Supplement . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Initial Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Accessories ................................. 1-5

Options ................................... 1-5

Front/Rear-Panel Features .......................... 1-6

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Indicators

Front-P

Module

Rear-P

Electrostatic

Hazards

Reducing

Care

Static-Safe

Sales

Returning

Packaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

anel

LINE ON

Fault

Inputs/Outputs

Hewlett-P

Hewlett-P

Mainframe/Module

and

and

Instrument Shipping Preparation Procedure................. 1-12

Indicator .

Indicator LEDs

Latch

anel

of

ESD

Service

Instruments

..

Features

ackard

ackard

Discharge

Internal

Damage

Handling

ccessories

A

Oces

.

..

..

..

..

.

.

.

..

.

.

..

..

..

.

Interface

Modular

Interconnect

Information

Repair

of

and

.

.

.

.

Electronic

.

.

.

.

.

.

Service

for

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

(HP-IB) .

Bus

System

A

.

.

.

Interface

.

.

.

djustment

.

.

.

Components

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

Bus

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

(MSIB)

.

.

..

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

..

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

..

..

..

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

.

.

.

.

.

.

.

.

.

..

.

..

..

.

.

.

.

.

.

.

.

..

.

.

.

.

.

..

..

.

.

.

.

.

.

..

1-6

.

1-6

1-6

1-6

.

1-7

.

. 1-7

1-7

.

1-7

.

1-7

.

1-8

.

1-8

.

1-9

.

1-9

1-10

.

1-10

.

1-12

2. Installation

Unpacking ................................. 2-1

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

Use

oltage

V

Hz

Option

for

Selector

Removal

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

...................

...... ...... ..... .....

...... ...... .

.........................

.

.

.

.

.

.

.

.

.

.

.

.

.

...............

..................

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

Preparation

Line

400

Fuse Replacement . . . . . . . . . .

Cabling .. ...... ....

Remote Operation

Addressing ..............

Adjustments.......

Module Installation and Removal .... ...... ...... ...... . 2-5

Module Installation ............................ 2-5

Module

2-2

.

2-2

.

. 2-3

2-3

2-4

2-4

2-4

2-4

2-5

.

Contents-1

Page 8

3. Specications

Specications ................................ 3-1

Nominal Values ............................... 3-1

General Specications .... ...... ...... ..... ...... 3-1

4. Verication

Power-On Self-Test. ...... ...... ...... ...... ..... 4-1

Fault Indicators ............................... 4-1

5. Troubleshooting

Turn On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Line Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Fault Indicators ............................... 5-2

Index

Contents-2

Page 9

Figures

1-1. Typical Serial Number Label .. ...... ...... ...... .... 1-3

1-2. Example of a Static-Safe Work Station ................... 1-9

2-1. Line VoltageSelector... ...... ...... ...... ...... . 2-2

2-2. Line Fuse Removal and Replacement .................... 2-3

Tables

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

.

.

.

.

.

.

.

.

1-1.

1-2.

1-3.

1-4.

ccessories

A

Options

Static-Safe

Service

HP

Supplied

.

.

.

ccessories

A

Centers

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

1-5

1-5

1-10

1-11

Contents-3

Page 10

Page 11

General Information

This 42-page installation and verication manual supplement for the HP 70001A mainframe

supplements the installation and verication manual for the HP 70000 Series, HP 70900B local

oscillator source-controlled modules.For information on installing and verifying components

of the HP 70000 Series modular measurement system, refer to

Analyzer Installation and Verication Manual and HP 70900B Local Oscillator Source

HP 70000 Modular Spectrum

.

This manual contains the following ve chapters:

Chapter 1, \General Information," describes the mainframe and its accessories,gives

electrostatic discharge and packaging information, and lists Hewlett-Packard Sales and

Service Oces.

using

and

use

\Installation,"

Chapter

as

it

2,

structural

a

70000 Modular

provides

environment

information

installing

for

Measurement Systems

mainframe

for

conguring

and

preparing

a

instrument

.

for

modules

into

HP

1

Chapter

Chapter

Chapter

front-panel

by

resolve

help

\Specications,"

3,

\Verication,"

4,

\Troubleshooting,"

5,

indicators

fault

problems

these

lists mainframe

contains tests

explains

provides

and

,

.

specications

required

probable

the

diagnosis

to

verify

causes

and

characteristics

and

mainframe

faults

of

problem

.

specications

problems

and

isolation

techniques

.

indicated

to

General

Information 1-1

Page 12

Mainframe Description

A mainframe is a device into which plug-in modules may be installed to create an instrument

in the modular measurement system. The HP 70001A mainframe provides the structural

environment for plug-in instrument modules along with cooling, power, and digital

communication interface buses.

It can accommodate 1/8-, 1/4-, 3/8-, and 1/2-width modules, and has a maximum capacity of

eight 1/8-width modules.

Standard rack compatibility is provided, and bench-top use is facilitated with integral bails and

retracting handles.

The Hewlett-Packard Modular System Interface Bus (MSIB) supports high-speed digital

communication among instrument modules within a mainframe and among instruments

connected to the external MSIB loop.

Every module in a mainframe has access to the standard Hewlett-Packard Interface Bus

(HP-IB). This bus provides a path of communication among controllers, other HP-IB instruments

and individual modules.

The ac power input is switchable between several ranges.

, 47|66

90-132

199-264

103-132

The

power

ac

compatible

The

atts

W

Two

The

Vac

Vac

ac

V

mainframe

for

line

primary

of

fans

cooling

power

power

provide

fans

the

increasing their

provides

This

,47|66

,

.

adequate cooling

Hz

Hz

356|444

power

modules

Hz

supply

5

,

syncronization

output,

cooling

operate

speed

for

at

linearly

Option

(with

processes

for

Vdc

signal.

ac

V

24.3

both

variable

above

over the

400)

the

MSIB

the

(average

mainframe

the

speeds:

30

Cto

permitted range

line

ac

dc

,

voltage

they

maximum

a

power

power for

not

,

to

up

and

slow

are

speed

of temperatures

produces

to

cooling

the

at

rms)

eight

temperatures

at

for

regulated

fans

provides

kHz,

40

installed

1/8-width

below

temperatures

.

and

40

a

30

above

kHz

TTL

to

up

modules

C,

55

200

Mainframes with serial numbers 2704A01796 and lower may have single speed fans.AFan

Speed modication kit can be ordered for these units. This modication will provide variable

speed fans, reducing fan noise about 3 dB at ambient temperatures below 30C.

.

C.

General Information

1-2

Page 13

Safety Considerations

Before operating this mainframe, familiarize yourself with any safety markings on the

mainframe and the safety instructions in this manual. This mainframe has been manufactured

and tested according to international safety standards. The cautions and warnings in this

manual and on the mainframe must be followed to ensure the safe operation of the mainframe

and protection of personnel. Refer to the summary of safety considerations at the front of this

manual.

Mainframes Covered by Manual

The contents of this manual apply to HP 70001A mainframes with the serial number prex(es)

listed under \Serial Numbers" on the manual title page.

Serial Numbers

Attached to the front lower right frame of the mainframe, behind the swing-down door,isa

and

digits

four

rst

The

.

parts

two

mylar serial-number

a letter

are the

The prex

identical

made

is

mainframes;

to

sequentially

serial number

is coded

product.

the

is

and

label. The

the

for

prex

a

The

dierent

date

letter

for

serial

prex,

of

break

each

number

the

and

conguration

last

the

change

or

designates

mainframe

divided

is

ve

last

only

the country

.

into

are

digits

change

occurs when

of origin.

sux.

the

the

is

and

a signicant

The

See

same

modication

sux

Figure

for

assigned

is

1-1.

all

Figure

1-1.

Typical

Serial

Number

Label

General

Information 1-3

Page 14

Manual Updating Supplement

A mainframe manufactured before or after this manual was printed may have a serial

number prex other than that listed under \Serial Numbers" on the manual title page.A

lower serial-number prex means that all current changes may not have been made to

this mainframe. A higher serial-number prex means that changes have been made to the

mainframe since the manual was printed. These changes are documented in the Manual

Updating Supplement for this manual. The Manual Updating Supplement may also contain

information for correcting errors in the manual. To keep the manual as current and accurate as

possible, periodically request the latest Manual Updating Supplement for this manual from your

nearest Hewlett-Packard Sales and Service oce.

Initial Inspection

Inspect the shipping container for damage. If the shipping container or cushioning material

is damaged, it should be kept until the contents of the shipment have been checked for

completeness and the mainframe has been checked mechanically and electrically. Refer to

the

If

1-1

table

shipping

Service

determine

to

contents

.

Oce

what

incomplete

are

accessories should

damaged, notify

or

have been

the nearest

shipped with

Hewlett-Packard

mainframe

the

.

Sales and

General Information

1-4

Page 15

Accessories

The accessories supplied with an HP 70001A Mainframe ordered separately or as part of

a precongured HP 70000 Modular Measurement System are the same. These accessories

are listed in Table 1-1. Contact the nearest Hewlett-Packard Sales and Service Oce for a

description of all power cables currently available for dierent country destinations.

Table 1-1. Accessories Supplied

Accessory HP Part Number

8 mm hex ball driver 8710-1651

Power Cable Part number depends

on country of destination

When ordered with a precongured HP 70000 Modular Measurement System, cables are

supplied to connect the modules in that conguration. Refer to the installation and verication

manual for the system master for cables available for custom congurations.

Options

The

and

following

Service

options

Oce

Option

are

available

and

can

be

ordered

from

nearest Hewlett-P

the

.

Options

1-2.

able

T

number

400 400

Isolation

913 Rack

with

Description HP

Input

Hz

Transformer

mount

handles

908 Rack mount

P

70001-60066

5061-9772

5061-9678

without handles

010 Rack slide 5062-0781

art

Number

ackard

Sales

General

Information 1-5

Page 16

Front/Rear-Panel Features

Front-Panel Indicators

LINE ON Indicator

A green LINE ON indicator LED, located on the lower left front-panel, is illuminated when

power is applied to the unit.

Fault Indicator LEDs

The following three fault indicators are located on the lower center front-panel.

VOLT/TEMP red fault LED.

CURRENT red fault LED

I/O red fault LED

Some older models may have a fourth fault indicator labeled AIR FLOW. The circuitry for this

indicator has been disabled.

description

A

Chapter

Module

module

The

removed

or

into

module

conditions

of

\Troubleshooting."

5,

Latch

hex-nut

latch

from

Refer

.

screw

latch

an

that

secures

70001A

HP

Chapter

to

cause these

can

module

a

Mainframe

\Module

2,

fault indicators

mainframe

a

in

8

an

,

Installation."

to turn

When a

.

mm hex-ball

module

driver

on is

is

supplied

being

is

used

to

in

installed

the

turn

General Information

1-6

Page 17

Rear-Panel Features

Inputs/Outputs

Two MSIB Input/Output connectors and one HP-IB connector are located on the rear panel.

Each module can have an interface to the MSIB bus and to the HP-IB bus.

Hewlett-Packard Interface Bus (HP-IB).

The HP-IB connector provides feedthrough

communication among controllers, other HP-IB instruments, and with each module installed in

the mainframe.

Hewlett-Packard Modular System Interface Bus (MSIB).

The MSIB is the high-speed digital

bus used by master, slave modules and other elements for exchanging control information and

data. It consists of both an internal and an external bus. The internal bus is housed in the HP

70001A Mainframe and connects to each installed module within the mainframe. External

MSIB cables connect mainframes to each other, to the Graphics Display, and to other MSIB

compatible devices. This external MSIB bus allows multiple instruments to communicate and

be displayed simultaneously. The use of longer MSIB cables allows you to locate a display some

distance from the rest of the instrument. See \Remote Operation" in Chapter 2, \Installation."

Refer to the installation and verication for the system master for additional information

related

to

HP-IB

the

Mainframe/Module

slots

mainframe

The

holes

MSIB

deliver

to

connections

has

cooling

for

buses and

MSIB

and

Interconnect

accommodate

to

a

and

air

module

communication

cabling instructions

eight

multiple-pin

1/8-width

connector providing

control.

and

.

modules.

Each of

these

has

slots

power-supply voltages

air

and

General

Information 1-7

Page 18

Electrostatic Discharge Information

Electrostatic discharge (ESD) can damage or destroy electronic components. All work on

electronic assemblies should be performed at a static-safe work station. Figure 1-2 shows an

example of a static-safe work station using two types of ESD protection: (1) wrist-strap (with

greater than 1m isolation to ground) and table-mat combination, (2) heel-strap (with greater

than 1m isolation to ground) and conductive oor-mat combination. The two types must

be used together to ensure adequate ESD protection. Isolation to ground must be provided

for personnel protection. Refer to Table 1-3 for a list of static-safe accessories and their part

numbers.

WARNING

In order to provide proper personnel protection, the wrist- and

heel-straps must have greater than 1mohm isolation to ground.

Hazards of Internal Repair and Adjustment

If the HP 70001A bottom cover is removed for any reason, the following precautions must be

observed.

ARNING

W

Disassembly

qualied

by

mainframe

The

in

currents

ANGEROUS

D

power

Board

,

o.

is

assembly voltages

transformer

adjustments

,

technical

internal

.

areas

all

GES

A

T

OL

V

.

and internal

,

personnel.

power

on

exist

cannot

supplies

boards

safely

be

repairs should

have

in

lethal

this

voltages

instrument

measured

only be

without

attempted

with

,

when

even

isolation

an

lethal

AC power line voltage is present on the power supply board, even when

the power switch is o.

the

General Information

1-8

The power supply board circuit common can be at approximately0200 V,

not earth ground.

Capacitors

may

retain

high-voltage

stored

charges

for

several

minutes

,

even with no power applied.

Page 19

Reducing ESD Damage

Care and Handling of Electronic Components

Handle these items at a static-safe work station.

Store or transport these items in static-shielding containers.

Use proper handling techniques.

Figure 1-2. Example of a Static-Safe Work Station

General

Information 1-9

Page 20

Static-Safe Accessories

Table 1-3. Static-Safe Accessories

HP Part

Description

Number

9300-0797* set includes: 3M static control mat 0.6 m21.2 m ( 2ft24ft) and 4.6 cm

(15 ft) ground wire. (The wrist-strap and wrist-strap cord are not included.

They must be ordered separately.)

9300-0980* Wrist-strap cord 1.5 m (5 ft)

9300-1383* Wrist-strap, color black, stainless steel, without cord, has four adjustable

links and a 7 mm post-type connection.

9300-1169* ESD heel-strap (reusable 6 to 12 months).

9300-0793* Shoe ground strap.

*Order through any Hewlett-Packard Sales and Service Oce.

ft)

5

2

ft

(4

m

1.5

2

m

1.2

control

cm

1.8 m

1.8

mat,

76

2

m

2

2

2.4 m

mat,

cm

1.2

1.2

(23

m

m

2

1.2

(6

(6

in

1.2

ft

ft

m

2

2

m(8

0.9

2

30

4

2

4

in)

ft)

ft)

ft)

4

2

ft

ft

(4

m

92175A

92175B

92175C

92175T

92176A

92176C

**

**

**

**

**

**

Black,

Brown,

Small,

abletop

T

Natural

Russet

surface

hard

soft-surface

black, hard

control

static

anti-static

color

anti-static

color

static

,

static

,

surface

mat,

carpet,

control

control mat,

static

,

58

carpet,

ft)

3

2

92176B

**

Natural

92176D ** Russet color

DIRECT

ackard

P

HP

**Order

Hewlett

by

calling

color

Sales

anti-static

anti-static carpet,

Phone

and

(800)

Service

Oce

carpet,

538

2.4

2.4

8787

.

Sales and Service Oces

Hewlett-P

products

ackard

o

T

.

Sales

obtain

Service

and

servicing

Oces

information,

provide

or

Hewlett-Packard Sales and Service Oce listed

complete

order

to

able 1-4. In any correspondence

in T

include the pertinent information about model numbers

numbers.

ft

(8

m

1.2

2

m

2

ft

(8

m

1.2

2

m

through

or

any

support

for

replacement parts

, serial

numbers, and/or assembly part

ft)

4

2

ft)

4

Hewlett-Packard

nearest

contact

,

the

, be sure to

General Information

1-10

Page 21

A current list of Hewlett-Packard Service Centers can be accessed on the Internet at:

http://www.tmo.hp.com/tmo/contacts/

If you do not have access to the Internet, one of the following Hewlett-Packard locations can

direct you to your nearest Hewlett-Packard representative:

Table 1-4. HP Service Centers

United States

Canada

Europe

Japan

America

Latin

Austrailia/New

Zealand

Asia-Pacic

Hewlett-Packard Company

Test and Measurement Call Center

(800) 403-0801

(800) 857-8161 (FAX)

Hewlett-Packard Canada Ltd.

5150 Spectrum Way

Mississauga, Ontario L4W 5G1

(905) 206-4725

(905) 206-4739 (FAX)

Hewlett-Packard European Marketing Centre

Postbox 667

1180 AR Arnstelveen

Netherlands

(31/20) 547-6669

647-8706

(31/20)

Ltd.

Hewlett-Packard

abe

Y

27-15,

Sagamihara,

Japan

1-Chome

Kanagawa

,

229

Japan

(81426)

567

(81426)

Hewlett-P

Blue

5200

Florida

Miami,

.S.A.

U

267

(305)

267

(305)

Hewlett-P

Joseph

31-41

Blackburn,

4245

4288

AX)

(F

843

Latin

ackard

Lagoon

Drive

33126

AX)

(F

Calibration

ackard

Street

Victoria 3130

America

Floor

9th

,

Services

Region

Headquarters

ustrailia

A

832

567

Austrailia

1800 802 540

1800 681 776 (FAX)

Hewlett-Packard Asia-Pacic Ltd.

17-21/F Shell Tower, Times Square

1 Matheson Street, Causeway Bay

Kong

Hong

(852)

(852)

25

25

997

069

777

261

AX)

(F

Ltd.

General

Information 1-11

Page 22

Returning Instruments for Service

If a mainframe is being returned to Hewlett-Packard for servicing, ll in and attach a blue

service tag. Service tags are supplied at the end of this manual. Please be as specic as

possible about the nature of the problem. Include copies of error messages, data related to

mainframe performance, type of system, etc., along with the mainframe being returned.

Packaging

The original shipping containers should be used. If the original materials were not retained,

identical packaging materials are available through any Hewlett-Packard oce.

Caution

Instrument damage can result from using packaging materials other than

those specied. Never use styrene pellets as packaging material. They do not

adequately cushion the instrument or prevent it from shifting in the carton.

They also cause instrument damage by generating static electricity.

Instrument Shipping Preparation Procedure.

out

Fill

1.

instrument.

a

If

blue

blue

a

repair

repair

Include

tag

is

card

any

not

(located

error

available

at

messages

the

,

specic

or

following

of

end

the

the instrument.

a. Type

b. Description

problem

c. Is

d. Name

Return

e.

Model

f.

Full

g.

List

h.

the

ack

P

2.

equivalent

the

instruments

Caution

service

of

and

address

number

serial

any

of

instrument

can

required

problem

the

of

intermittent

constant

phone

number

accessories

should

be

or

number

returned

of

of

the

in

be

packaged

technical

of

instrument

returned

returned

appropriate

If

used.

for

contact

instrument

instrument

with

packaging materials

original

the

shipment

using

or

Inappropriate packaging of instruments may result in damage to the instrument

during transit.

manual) and

this

performance

information

person

equivalent

following

the

attach it

data

should

. Original

materials

instructions

to the

related

be noted

shipping

cannot

.

the

to

and sent

materials

obtained,

be

problem.

with

or

General Information

1-12

Page 23

a. Wrap the instrument in anti-static plastic to reduce the possibility of damage caused by

ESD.

b. For instruments that weigh less than 54 kg (120 lb), use a double-walled, corrugated

cardboard carton of 159 kg (350 lb) test strength.

c. The carton must be large enough to allow three to four inches on all sides of the

instrument for packing material and strong enough to accommodate the weight of the

instrument.

d. Surround the equipment with three to four inches of packing material, to protect the

instrument and prevent it from moving in the carton.

e. If packing foam is not available, the best alternative is S.D.-240 Air Cap from Sealed Air

Corporation (Commerce, California 90001). Air Cap looks like a plastic sheet lled with

1-1/4 inch air bubbles.

f. Use the pink (anti-static) Air Cap to reduce static electricity. Wrapping the instrument

several times in this material will protect the instrument and prevent it from moving in

the carton.

3. Seal the carton with strong nylon adhesive tape.

4. Mark the carton `FRAGILE, HANDLE WITH CARE'.

5. Retain copies of all shipping papers.

General

Information 1-13

Page 24

Page 25

2

Installation

This chapter contains information needed to prepare a mainframe for use, and describes how

instrument modules are installed to congure the HP 70001A Mainframe into an HP 70000

Series system.

The information presented is general in nature.For more detailed information on conguration

and HP-MSIB addressing, refer to the installation and verication manual for the system master

(e.g., HP 70900A Local Oscillator).

The HP 70001A mainframe is a rugged structure into which modules of various widths

can be placed. It provides power, cooling, and a suitable environment for electromagnetic

compatibility for the modules, and manages all digital communications among the system

elements. LED fault indicators, on the lower front-panel, report mainframe or module

problems

specic

or

F

.

LED

indicator

fault

information,

refer

Chapter

to

5

manual.

this

of

Unpacking

damaged,

Inspect

check

damaged

of

the

the

oces is

contents

or

replacement

the shipping

Keep

shipping

defective

included

of the

materials

container

shipment

the

of

contact

,

Chapter

in

damaged

for

your

1

defective

or

the

for

damage

both

nearest

this

of

carrier's

container

the

If

.

mechanically

Hewlett-P

manual.

Hewlett-P

equipment

inspection.

and

ackard

without

cushioning

or

electrically

and

Sales

ackard

will

waiting

If

.

Service

arrange

a

for

material

the

claim

is

contents

Oce

repair

for

settlement.

are

list

A

.

or

Installation

2-1

Page 26

Preparation for Use

Line Voltage Selector

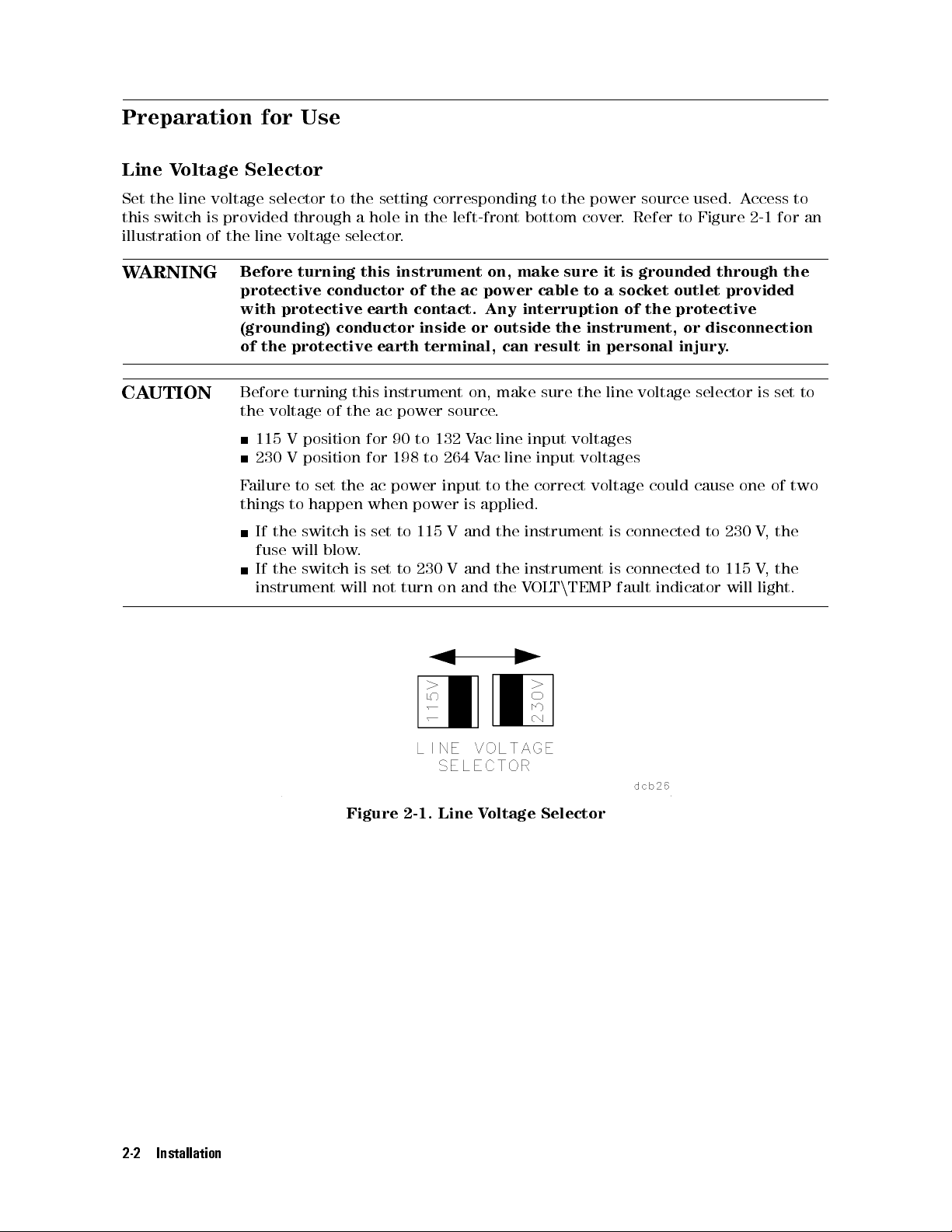

Set the line voltage selector to the setting corresponding to the power source used. Access to

this switch is provided through a hole in the left-front bottom cover. Refer to Figure 2-1 for an

illustration of the line voltage selector.

WARNING

CAUTION

Before turning this instrument on, make sure it is grounded through the

protective conductor of the ac power cable to a socket outlet provided

with protective earth contact. Any interruption of the protective

(grounding) conductor inside or outside the instrument, or disconnection

of the protective earth terminal, can result in personal injury.

Before turning this instrument on, make sure the line voltage selector is set to

the voltage of the ac power source.

115 V position for 90 to 132 Vac line input voltages

230 V position for 198 to 264 Vac line input voltages

the

,

V

the

,

V

light.

two

ailure

F

things

to

the

If

fuse

the

If

instrument

set

to

happen

switch

will

switch

the

blow

will

is

.

is

power

ac

when

set

set

not

power

to

to

turn

115

230

input

V

V

on

to

applied.

is

and

and

and

the

instrument

the

instrument

the

V

the

correct

TEMP

n

T

OL

voltage

connected

is

connected

is

fault

could cause

to

to

indicator

one of

230

115

will

2-2

Figure 2-1. Line Voltage Selector

Installation

Page 27

400 Hz Option

The HP 70001A Mainframe is available with an option that allows it to operate on a power-line

frequency of 400 Hz. The 400 Hz option comes with an external in-line 600 V-A isolation

transformer that must be used when the instrument uses a 400 Hz power source.

WARNING

Never operate a 400 Hz option instrument on a 400 Hz power line without

using the in-line isolation transformer supplied for this purpose.Failure

to follow this precaution can create a shock hazard which may result in

personal injury.

The in-line isolation transformer must be removed from the 400 Hz option for 50/60 Hz power

source operation. Failure to remove the in-line 400 Hz transformer will result in the 400 Hz

transformer input fuse. When the isolation transformer is removed, a standard power cord

must be used. The in-line transformer must be reinstalled when using a 400 Hz power source,

in order to protect the user from electric shock hazard.

Fuse Replacement

the

a

is

fuse

on

20

by

5

removal

mm

The line

back of

the instrument.

fuse rated

fuse

at 6.3

for

instrument

this

250

A,

Also

,

V

included

part

HP

located

is

number

in

this

inside

the

housing

2110-0703.

power

spare

a

is

Refer

cord

to

receptacle

The

.

fuse

Figure

2-2

housing

fuse

for

and replacement.

Figure

2-2.

Line

Fuse

Removal

Replacement

and

Installation

2-3

Page 28

Cabling

The HP-MSIB cables are connected in a serial (daisy-chain) manner, coupling the input of one

element to the output of next until the loop is completed.

Remote Operation

The use of long HP-MSIB cables to separate the mainframe and display, or other products

supporting HP-MSIB, allows remote operation. Since the signals on the HP-MSIB are digital,

only measurement speed is slightly degraded.

Addressing

The HP 70001A Mainframe does not have an HP-MSIB address. The mainframe acts as an

HP-MSIB arbitrator, allocating time on the HP-MSIB bus to any module or device designed to

work with an HP 70000 Series system that requests it.

Adjustments

The HP 70001A Mainframe has only internal service-related adjustments. These adjustments

should

only

attempted

be

qualied

by

technical

personnel.

2-4

Installation

Page 29

Module Installation and Removal

Module Installation

To install modules into a mainframe, follow these steps.

1. Turn the mainframe o.

2. Swing open (down) the front door. Note that the door will not swing down unless the line

switch is o.

3. Slide the module into the mainframe.

4. Tighten the module latch using an 8 mm hex-balldriver.

5. Connect intermodule cabling.

Module Removal

The removal of modules is accomplished by following these steps.

1. Turn the mainframe o.

2. Disconnect

3. Swing

Loosen

4.

Slide

5.

open the

and

the

Note

UTION

CA

intermodule cabling.

door

front

out

should

is

the

of

not

must

the

be

modules

disengage

module

Care

of

moved

Modules

adjacent

Be sure

ower

(P

.

module

mainframe

taken

carefully

slid

be

switch

latch

.

when

easily

can

guided

straight

check

to

must

an 8

using

installing

be

into

into

of

rear

the

o.)

be

mm hex-balldriver

removing

and

out

and

its

of

of the

scratched

out

or

and

module

the

modules

dented

slot.

mainframe slots

.

.

front

The

.

module

the

if

or the

edges of the module covers may contact and abrade the covers of adjacent

modules and mainframe guides.

If extreme environmental conditions exist where dust and debris may be drawn

into the air ow and distributed throughout the instrument, a Frame-Fine

Filter (HP part number 70000-40017) can be ordered from the nearest HP Sales

.

and

Service

Oce

panels

being

sharp

Installation

2-5

Page 30

Page 31

3

Specications

The following specications apply to the HP 70001A mainframe.For system specications,

refer to the \Specications" chapter of the installation and verication manual for the system

master.

Specications

Specications describe warranted performance over the temperature range 0Cto55C (except

where noted) after one hour of continuous operation.

Nominal V

Nominal

performance

General

emperature

T

values

parameters

Specications

EMI

Warm-up time

Weight

(nominal value) 14.5 kg (32 lb) (mainframe only)

Dimensions

Input

ower

P

C

A

Line Ranges

VA Rating

alues

provide

useful

information

by

.

Operation

+55

to

0C

Radiated

within

is

MIL-STD

interference

requirements

the

Class

,

461B

One hour from a cold start

(0to 55C)

Height 177 mm (6.97in)

Width

Length

90|132

198|264 V

103|132 V

310 W maximum

A maximum

570 V

non-warranted,

giving

functional,

but

Storage

C

40

0

to

C

of

RE02

A1c

1

(16.75

mm

425

(20.7

mm

526

ac

V

ac

47|66

47|66 Hz

ac 365|444 Hz

(with Option 400)

+75

Hz

in)

in)

C

1

mainframe

The

an

into

instrument,

requires

the

maximum

a

other

elements

of

minutes

5

may

require

warm-up

hour

1

however

time;

warm-up

time

,

.

congured

when

Specications

3-1

Page 32

Page 33

4

Verication

This chapter normally contains unit performance-verication tests, which evaluate the

electrical performance of the unit against its specications. There are no performance-

verication tests that apply to the HP 70001A mainframe specications.

Power-On Self-Test

The act of turning on an HP 70000 Series system causes any modules installed in the system to

execute a power-on self-test. The mainframe is not involved in these tests except in supplying

power and communication for the modules.

detailed

a

or

F

installation

the

ault

F

The HP

Indicators

70001A

indicate a

Chapter 5,

explanation

verication

and

of

Mainframe

condition

the

fault,

\Troubleshooting."

the

has

power-on

manual

OL

V

must

for

T/TEMP

cleared

be

self-tests

system

the

CURRENT

,

before

refer

,

the

master

,

the

to

.

I/O

and

mainframe

\Troubleshooting"

fault

indicators

will

.

operate

If

Refer

.

chapter

of

any

of

these

to

erication 4-1

V

Page 34

Page 35

Troubleshooting

This chapter provides troubleshooting information on the HP 70001A mainframe. Problem

isolation and diagnosis related to the front-panel fault indicator lights, fan operation, fuse

replacement, and power-on light are discussed as operator-level repairs.

Turn On

When the HP 70001A as part of an HP 70000 Modular Measurement System is turned on, the

mainframe monitors its condition as it brings power and cooling air up to specication. Once

power

The

The

The

cooling

and

T/TEMP

OL

ON

power

V

CURRENT

established,

is

should

light

I/O

and

indicator

fault

come

fault

modules

the

and

on

indicators

should

not

begin

on.

stay

should

light.

their

blink

self-test

and

on

sequences

turn o.

then

.

5

After

complete

is

models

not

.

CT

A

about

may

light.

inside

and

a

the

,

have

The

the

ERR

minute

power

fourth

a

circuitry

power

of

lights

these

indicator

ON

fault-indicator

for

receptacle

all

lights

this

the

should

function

on

modules

settle

only

the

is

labeled

back

the

instrument

the

in

down

mainframe

AIR FLOW

should be

the

of

steady

a

to

. This

disabled.

instrument.

The

During

will

state

After the

that

Note

Line

6.3

A

fan

this

turning

be

.

should

Fuse

250

A,

noise

self-test,

module

remain

V

be

will

and

on

self-test

on.

older

Some

indicator

line fuse

noticeable

module

the

o.

should

located

is

The most common reason for an open fuse is improper setting of the line voltage selector

however, internal problems can also cause a fuse to open.

See Figure 2-2

Manual

for troubleshooting information.

for fuse removal and replacement information. Refer to the

HP 70001A Service

light

,

roubleshooting 5-1

T

Page 36

Fault Indicators

The HP 70001A has three fault indicators. While these indicators are located in the mainframe,

problems external to the mainframe can cause the indicators to turn on. External problems

should be investigated before troubleshooting the mainframe.

VOLT/TEMP If this fault indicator is on steady, check for the following problems before

deciding the mainframe needs repair.

Note

Temperature

limits

input

Low

voltage

ery long

V

drop

.

line

a

as

ac wiring

below an

will

This

result.

Excessive ambient temperature, exceeding 55C will cause the

VOLT/TEMP fault indicator to come on and stay on. Move

the mainframe to a cooler environment and wait for the

temperature to decrease to the normal operation range.1When

the temperature decreases the mainframe will restart itself.

If the indicator goes out after the mainframe has cooled the

mainframe is probably not at fault.

If the problem persists; when the mainframe attempts to restart

itself, verify that both cooling fans are operating by checking

the airow into both of the rear-panel fan-intake openings of

the mainframe.

the line

If

agree

come

will

selector

V

115

V

230

the

If

voltage is

with the

on.

switch

position

position

voltage

low

low or

input voltage

as

the

follows

for

for

90|132

198|264

Check

condition

the voltage

, the

input

ac

.

corrected,

is

T/TEMP

VOL

voltage

line

ac

V

ac

V

selector

and

input

input

line

the

setting

fault

set

voltage

voltage

unit

does

indicator

voltage

the

.

restart

will

.

itself.

mainframe

the

runs

acceptable limit,

the

cause

to

is

cure

The

cause

may

when

mainframe

correct the

power

ac

the

mainframe

the

to cycle

on and

power wiring

voltage

at

applies

o. No

damage will

or voltage

its

.

load

to

the

occur

not

to

ac

A ashing VOLT/TEMP fault indicator can be caused by an

impedance mismatch between the ac line and the mainframe

input. This usually occurs only at extremely low temperatures

(below 0C). The cold input thermistors (now a high impedance)

reduce the

and the

sensed line

1

Keep in mind

that the internal temperature of the instrument will change with a

corresponding change in the ambient

a change in ambient temperature and

voltage

line

mainframe

voltage

shuts

rise

to

room temperature

under

An

.

o.

and

voltage

reduced

The

unit

the

, and that there is a delay between

a change in internal temperature

condition

load

back

turns

. It can take 20

is

allows

on.

minutes or more for an overheated mainframe to cool internally to an acceptable

temperature, since no cooling air is being moved by the fans when the supply is shut down.

Troubleshooting

5-2

sensed

the

Page 37

This cycling will continue until the input thermistors warm up

to a point where the sensed voltage is within tolerance.At

this point the fault indicator stops ashing, the mainframe is

operational.

If the condition does not go away after several minutes, check

the input line voltage under load or change the ambient

operating temperature.

High output

voltage and

Fan voltage

failure

These two conditions will also cause the the VOLT/TEMP fault

indicator to come on and the instrument will latch in a fault

condition. The mainframe is in need of internal repair or

adjustment. It will shut down and not attempt to restart until

ac line power is cycled.

CURRENT This circuitry senses and indicates if the load on the mainframe power supply

is too high. Upon sensing an over-current condition, the power supply is shut

down and latched. It will not attempt to restart until ac line power is cycled.

If a CURRENT fault indicator is on, check for a faulty module before

attempting to repair the mainframe. The following steps will help isolate the

problem.

Turn

1.

Remove

2.

Cycle

3.

NO

YES

mainframe

the

all

power

the

Turn

power

repair

system

repair

If the

been

internal

pin

50

Refer

the

o

each

procedures in

master or

alternatives.

CURRENT indicator

removed from

module

to

o.

modules

the

Is

.

mainframe

the

time)

problem.

connectors

HP

the

the

from

CURRENT

and

the

until

installation

the

service

the

the mainframe

Check

70001A

to

Service

mainframe

indicator

by

one

faulty

module

manual

on

still

is

ensure

not

are

Manual

.

still

replace

one

and

related

when

mainframe

the

,

the

that

shorting

on?

modules

the

identied.

is

the

the

manual

faulty

modules

verication

to

of

all

probably

grounding springs

the 40

KHz to

for additional

(cycling

the

to

Refer

the

for

module

for

have

an

has

on the

ground.

troubleshooting

information.

roubleshooting 5-3

T

Page 38

I/O This circuitry senses the readiness of the external HP-MSIB. If the indicator is

on, HP-MSIB communications are inhibited. The I/O fault indicator light will be

on if one of the following conditions is true.

The external HP-MSIB loop is not complete. Check that both ends of all

HP-MSIB cables are securely connected.

2

Not all the elements on the external HP-MSIB loop have the power

turned on. Verify that the power is on to all mainframes and stand-alone

instruments on the external HP-MSIB.

The mainframe is in need of repair.

HP-MSIB communication will resume as soon as the problem is corrected.

If an I/O light fault is indicated, the following steps will help isolate the

problem.

Disconnect both HP-MSIB cables from the mainframe at the mainframe

connectors. Is the I/O fault indicator still on?

NO The problem is either with the cables, or the element that was

connected to the mainframe with the cables.

does

with

on?

connectors

not

these

for

probably

is

Loop each

If the

come

cables

troubleshooting

The

YES

faulty

I/O

on

is

HP

Remove

.

cable

light

either

for

faulty

70001A

to

\IN"

comes

on,

cable

to

Refer

.

information.

Mainframe

modules

the

all

\OUT"

that

then

,

the

or

to

cable

the

service

one of

.Does

mainframe

the

faulty

is

element

manual

the

the

If

.

connected

for

installed

still

light

HP-MSIB

light

the

element

that

modules

come

.

to

information.

time

a

at

dierent

a

in

mainframe

the

manual

until

module

for

a

or

repair

Note

es

Y

No

mainframe

The

Manual

Replace

located.

is

occurs

only

problem

the

faulty module

the

for

the

is

troubleshooting

the

one

module

the

slot

the

modules

Try

one

in

follows

service

module

.Refer

faulty

It is possible that a module may disrupt all HP-MSIB communication with no

HP

the

mainframe fault or no module error lamp turned on.

2

more

If

cables

than

must

mainframe

one

connected

be

used,

is

otherwise;

or

the

if

HP-MSIB

other

elements

will not

with no external elements is used, there should be no HP-MSIB

external HP-MSIB connectors of that mainframe

, although a single cable looped from

connected to

are

operate

.

cables connected to the

input connector to the output connector will allow the mainframe to operate

70001A

faulty

If

slot.

connector

faulty

is

instructions

the

single

a

If

Service

module

problem

the

faulty

is

Refer

.

HP-MSIB

mainframe

.

slot

or

If

.

to

.

all

,

the

Troubleshooting

5-4

Page 39

If problems persist, refer to the installation and verication manual for the system master or

the

HP 70001A Service Manual

for additional troubleshooting information.

Keep in mind that mainframe internal adjustments or repairs should only be attempted by

qualied technical personnel. Review the \Hazards of Internal Repair or Adjustment" and

associated warning notice in Chapter 1, \General Information."

roubleshooting 5-5

T

Page 40

Page 41

Index

A

accessories supplied, 1-5

C

cooling, 1-2

E

ESD

heel-strap, 1-9

protection, 1-9

mat;oor,

Static

mat;table,

Static

wrist-strap,

1-9

1-9

1-9

F

1-6

1-6

5-2

,

5-4

,

5-4

failure

fault

recovery,

indicators

CURRENT,

1-6

I/O,

T/TEMP,

OL

V

,

5-4

fuse

location,

replacement,

size,

2-3

2-3

2-3

H

help, 1-10

HP-IB, 1-7

I

installing

modules,

2-5

L

line voltage selector, 2-2

M

MSIB, 1-7

O

option, 400Hz, 2-3

options, 1-5

P

packaging, 1-4

containers, 1-12

power

input,

output,

power

1-2

1-2

requirements,

R

removing

modules,

2-5

S

4-1

test,

self

number

serial

1-3

label,

1-4

,

prex,

sux,

shipping

1-3

1-3

containers,

specications

EMI, 3-1

power requirements, 3-1

temperature, 3-1

U

updating

manuals,

1-4

W

weight, 3-1

3-1

1-12

Index-1

Page 42

Loading...

Loading...