Page 1

POWER SUPPLY/AMPLIFIER

PS,‘A SERIES, MODEL 6824A

41

&

SERIAL NUMBER PREFIX 6F

Printed:

July, 1966

@ Stock Number: 06824-90001

Gv

+

Page 2

COPYRIGHT AND DISCLAIMER NOTICE

Copyright - Agilent Technologies, Inc. Reproduced with the permission of Agilent

Technologies Inc. Agilent Technologies, Inc. makes no warranty of any kind with regard

to this material including, but not limited to, the implied warranties of merchantability

and fitness for a particular purpose. Agilent Technologies, Inc. is not liable for errors

contained herein or for incidental or consequential damages in connection with the

furnishing, performance, or use of this material or data.

Page 3

MANUAL ClWNGES

DC POWER SUPPLY

Model 6824A

Manual Serial Number Prefix 6F

Make all corrections in the manual according to errata below, then check the following table for

power supply serial number and enter any listed change(s) in the ma1’1ua1.

CHANGE 1:

In the replaceable parts table, make the follaving changes:

06: Change to MOPOrOla, SS2109, @ Stock No. 1853-0037.

Fan Motor: Change to Howard 1175-06-4155, @ Stock No. 3140-0406.

Fan Blade: Change to Howard 6-128-125, @ Stock No. 3160-0098.

ERRATA: QS,,ll: Change to 2N2907A, Sprague, 56289, 1853-0099.

YOUI

Page 4

MANUAL CHANGES

DC POWER SUPPLY

Model 6824A

Manual Serial Number Prefix 6F

Make all corrections in the manual according to errata below, then check the following table fox your

power supply serial

number and enter any listed

change(s) in the manual.

SERIAL

Prefix m

6F

AU

6E

0361-0710

0711-0760

MAKE

CHANGE$

1

Errata

1.2

Prefix Number CHANGES

SERIAL

6F 0761-UP 1,2,3

CHANGE 1: In the replaceable parts table, make the following changes:

QS: change TOSS PNP Si., SSZ109, Motorola. $ Part No. 1853-0037.

Fan Motor: Change to Howard 1175-06-4155, $ Stock No. 3140-0406.

Fan Blade: Change to Howard 6-128-125, ‘@ Stock No. 3160-0098.

ERRATAi Q5,11: Change to SS PNP Si.,

.CHANGE 2:

Tn the replaceable parts table make the following changes:

2N2907A, Sprague, $ Part No. 1853-0099.

ClO, 11: ‘Change to $ Part No. 0180-2193.

Add Clamp (ClO,Cll): Quantity 2, @! Part No. 0160-2149.

bCHANGE 3:

In Section II

of the manual, add The following note under rack mounting, two units:

NOTE

When rack mounting two units, attach the sides of the Unit6 TOgether using the 6-32 screw (supplied with the 14525A rack kit)

and the threaded insert nut attached to the right side of each unit

under the heat sink. Disregard the 6-32 hex nw’lockwasher SUP-

plied with the rack mounting kit,

MAKE

Page 5

TABLE OF CONTENTS

SectIon

I

GENERAL INFORMATION

l-l

DescriPcion

l-3

Power Supply Features

1-7

Amplifier Features

l-10

Specifications

1-12

OPtionS

l-14

Accessories

1-16

Instrument Identification

1-19

Ordering Additional Manuals

I I INSTALLATION

2-1

Initial Inspection

2-3

Mechanical Check

2-5

Elmctric~l Check

2-7

Insmilation Data

2-9

Location

2-13

Rack Mounting

2-15

Input Power Requirements

2-17

Connections For 230 Volt

operation

2-19

Power Gable

2-22

Repackaging For Shipment

I I I OPERATING INSTRUCTIONS

3-l

Operating Controls And

Indicators

3-3

Operating

3-9

tieneral Notes And Operating 4-41

Modes

Considerations

3-10

Diagrams 3-l

3-13

External Resistors

3-15

Connecting Loads

3-19

Fine/Zero Control

3-21

Ground Loops

3-23

Reverse Current Loading

3-26

constant ,vo1tage

Operating Modes

3-27

Normal Operating Modes

3-30

Remote Sensing

3-35

Remote Programmixrg,

Positive output 3-4

3-40

Remote Programming,

Negative Output

3-42

Remote Programming,

Bipolar Output

3-47

Switchless Bipolar Programming 36

3-50

Power Supply With Super-

imposed AC Output

3-54

Constant Voltage Amplifier

With Remote Gain Control

3-61

Constant Current Operating

Modes

3-65

Selecting RS 3-9

3-70

Normal Operating Modes

3-73

Remote Prosrcmmins,

Bipolar O&put 3-10

Pass No.

1:1

Section

I I I OPERATING INSTRUCTIONS

1-I

l-l

l-l

1-l.

1-l

l-l

1-2

l-2

2-1

2-1

2-l

2-l 4-1

2-l

2-l. 4-3

2-1

2-2

2-2

2-3 4-26

2-3

3-1

3-l

3-1 4-37

3-l

IV PRINCIPLES OF OPERATION

4-9

4-14

4-18

4-19

4-28

4-30

4-33

4-35

v MAINTENANCE

3-2

3-2

3-2

3-2

3-2

5-l Introduction

5-3 General Measurement

5-8

5-10 Performance Test

5-12 Power Supply Tests

3-3

3-3

3-3

5-21 Amplifier Tests

5-24 Troubleshooting

5-26

5-34 Repair And Replacement

5-36 Adjustment And Calibration

5-38

3-5

5-40 Voltmeter Twoking

5-43 Ammeter Tracking

3-5

5-45

5-47 Current Limit Adjustment

3-7

3-7

3-6

3-10

VI REPLACEABLE PARTS

6-l Introduction

6-4

6-8

Paae No.

3-76 Switchloss Bipolar

Programming

3-76

Constant

Superimposed

Current Supply With

AC Output

3-81 Constant Current Amelifier With

Remote Gain Con&l

3-87

Series And Parallel operatixlg

MO&S

3-90 Coordinated Series Operation

3-98 Auto-Parallel Operation

Overall Block Diagram

Discussion

Power Supply Operation

AmpXifier

Operation

Simplified Schematic

Detailed Circuit Analysis

Input circuit

Mode

Selection Circuit

Error And Driver Amplifiers

Regulator/Output Amplifier

Circuit

Current Limiting Circuit

Reference Circuit

Meter Circuit

Auxiliary Voltage Source

Techniques

Test Equipmant Required

Trouble Analysis

Meter Zero

Programming Current

Ordering Information

Reference Designators

Abbreviations

Manufacturers

Code List of Manufacturers

Parts List Table

3-11

3-11

3-12

3-12

3-13

3-15

4-l

4-l

4-l.

4-2

4-2

4-3

4-3

4-3

4-4

4-4

4-4

4-4

4-4

4-4

5-l

5-1

5-l

5-l

5-3

5-3

5-6

5-6

5-6

5-11

5-12

5-12

5-12

5-12

5-12

5-13

6-l

6-1

6-1

6-2

Page 6

LIST OF TABLES

Table

l-1

5-1

5-2

5-3

5-4

5-5

Fi’wrc

l-l

2-l

2-2

2-3

3-l

3-2

3-3

3-4

3-5

3-6

3-10

3-11

3-12

3-13

3-14

3-15

3-16

3-17

Specifications 1-3

Page NO.

Test Equipment Required

Reference Circuit Troubleshooting

5-2

5-7 5-7

nigh Positive Output Voltage

Troubleshooting

5-8

High Negative Output Voltage

Troubleshooting

5-8

LOW Positive output Voltage

Troubleshooting

5-8

LIST OF ILLUSTRATIONS

DC Power Supply/Amplifier

Rock Mounting, Two Units

Rack Mounting, One Unit

Primary Connections

Front Panel Controls And Indtcators

Standard Power Supply

Operation (CV)

Standard Amplifier Operation (CV)

Remote Error Sensing

3-2

3-3

3-3

Remote Resistance Programming,

Positive Output

3-4

Unaligned Resistance

Programming Characteristics

3-4

Aligned Resistance Programming

Transfer Function

3-4

Remote Resistance Programming,

Negative Output

3-5

Remote Resistance Programming,

l&Polar Output (CV)

Swit,ched Resistor Substitutes

3-s

3-6

Ei-Polar Programming

(cO~St~,,t VQltage)

3-6

Constant Voltage Supply With

Superimposed AC Output

3-7

Constant Voltage Ampllfler With

Linear Remote Gain Control

3-8

Constant Voltage Amplifier,

TWO Inputs

3-8

Current Sampling Resistor,

Connection Method

3-9

Standard Constant Current

Power

supply

3-10

Standard Constant

Current Ampltrler

3-10

Table

5-6

5-8

5-9

5-10

3-19

3-20

3-21

3-22

3-23

3-24

3-25

3-26

3-27

3-28

4-1

4-2

5-1

5-2

5-3

5-4

5-5

5-6

5-7

5-8

'5-9

5-10

5-11

Page NO.

Low Negative Output Voltage

Troubleshooting

Common Troubles

5-9

5-9

Selected Semiconductor

Characteristics

5-11

Checks And Adjustments After Replace-

ment of Semiconductor Devices

Calibration Adjustment Summary

5-11

5-12

eogc No

Remote Resistance Programming.

Bloolar outwut (CC)

3-11

Swi~chlessB~pbl~rPr~gramming(CC)3-11

CC Power Supply With Super-

imposed AC Output

3-11

CC Amplifier With Linear

Remote Gain Control

CC Ampllfler With Two Inputs

3-12

3-13

Auto-Series Operation, Two Units 3-l 3

Auto-Series Operation, Three Units 3-14

Balanced Input/Output Series

Operation, Two Units

3-1.4

Balanced Input/Ou’Cput Series

Opetation,‘Four Units

3-15

Auto-Parallel Operation.

Constz.nr voltige output

3-16

Auto-Parallel Operation,

coLstant current output

Overall Block Diagram

Simplified Schematic

3-16

4-1

4-2

Front Panel Terminal Connections 5-l

Differential Voltmeter Substitute,

Test setup

Output Current,

Test

Setup

Load Regulation, Test Setup

Transient Response, Test Setup

Transient Response Waveforms

Programming Speed, Test Setup

5-3

5-3

5-4

5-4

5-5

5-5

ryp1co1 Programmixlg Speed

WaVefOrmS

Output Impedance, Test Setup

GbinAnd Frequency

Respdnse,

Test setup

Servicing Printed Wiring Boards

5-5

5-5

5-6

S-10

Page 7

-

Figure 1-l. DC Power Supply/Amplifier, Model 6824A

Page 8

SECTION I

GENERAL INFORMATION

l-l

DESCRIPTION

1-2 The Power Supply/Amplifier (PS/A) shown on

Figur$ l-1, is D general purpose instrument useful in any laboratory engaged in research and

development of electronic systems or components.

The PS/A CB” be operated in one of two basic

operating modes: power supply or amplifier. Ter-

minals on the rear barrier strip permit access to

vwIous control points within the unit to further

expand the operating capabilities of the lnstrumerit. The resulting flexibility lends the PS/A to

an almost unlimited “umber of applications. Some

of these applications we outlined in Section III of

this manual; but e more comprehensive description

of the features and applications of the PS,‘A are

lncludcd in Applicatibn Note 82 published by the

Harrison Dlvtslon. A copy of Application Note 82

can be obtained from your local Hewlett-Packard

field office. The following paragraphs describe

some of the features of the, PS/A both as D power

supply and an amulifier.

1-3 POWER SUPPLY FEATURES

l-4 The unit can be made to function as a regulated dc power supply by setting the front panel

MODE switch to the SUPPLY position. The supply

can furnish either a Constant Voltage output or a

Constant Current output (with the addition of B”

external current sampling resistor). The dc out-

put is bi-polar and is continuously adjustable

from its maximum rated positive value to a” equal

negative value: smoothly through zero with no

polarity switch. Both the supply and the load ere

protected ageinst overloads by a fixed current

limit which is set by means of B” internal adjustment.

1-S The supply can he programmed (controlled)

at a very high rate of speed (less than 50 psec

for output voltage change over the entire voltage

span). The supply can be programmed locally; by

means of the front panel control. or remotely: by

means of a resistance, voltage. or current source.

1-6 A single meter is used to measure dc output

voltage or current. A front panel METER switch

allows the dual purpose selection.

l-7 AMPLIFIER FEATURES

1-8 As a power amplifier the unit has a high

signal-to-noise ratio (80 db et full output) e”d en

‘adjustable gain of from 0 to 10 (20 db). The out-

put distortio”.is low - less than 0. 02% et 1 KHz.

The amplifier contains a push-pull output Stage

That can oe” furnish either B Constant Voltage

output or a Constant Current output (with the sddition of en external current sampling resistor).

The external input can be

from

either B voltage or

a current source. The bandwidth of the amplifier

is from dc to 20KHz (+3db).

1-9 The oo component of the output signal can

be measured with the front panel meter (Model

6824~ only).

I-10 SPECIFICATIONS

1-11 Detailed specification for the PS/A are given

in Table 5-l.

1-12 OPTIONS

1-13 Options are factory modifications of d standard instrument that ore requested by the customer.

The following option is available for the instrument covered by this manual.

Option No. DeSCriutlon

28 Rewire For 23OV AC Input: Supply

OS normally shipped is wired for 115

vat input. option 28 CO”SiSTU of

reconnecting the input transformer

for 230 Vat operation.

l-14 ACCESSORIES

1-15 The applicable accessories lisrad in the fol-

lowing chqrt may be ordered with the lnsrrumenf or

Page 9

Page 10

Page 11

Page 12

Page 13

Page 14

Page 15

Page 16

Page 17

Page 18

Page 19

Page 20

Page 21

Page 22

Page 23

Page 24

Page 25

Page 26

Page 27

Page 28

Page 29

Page 30

Page 31

Page 32

Page 33

Page 34

Page 35

Page 36

Page 37

Page 38

Page 39

Page 40

Page 41

Page 42

Page 43

Page 44

Page 45

Page 46

Page 47

Page 48

Page 49

Page 50

Page 51

Page 52

Page 53

Page 54

Page 55

Page 56

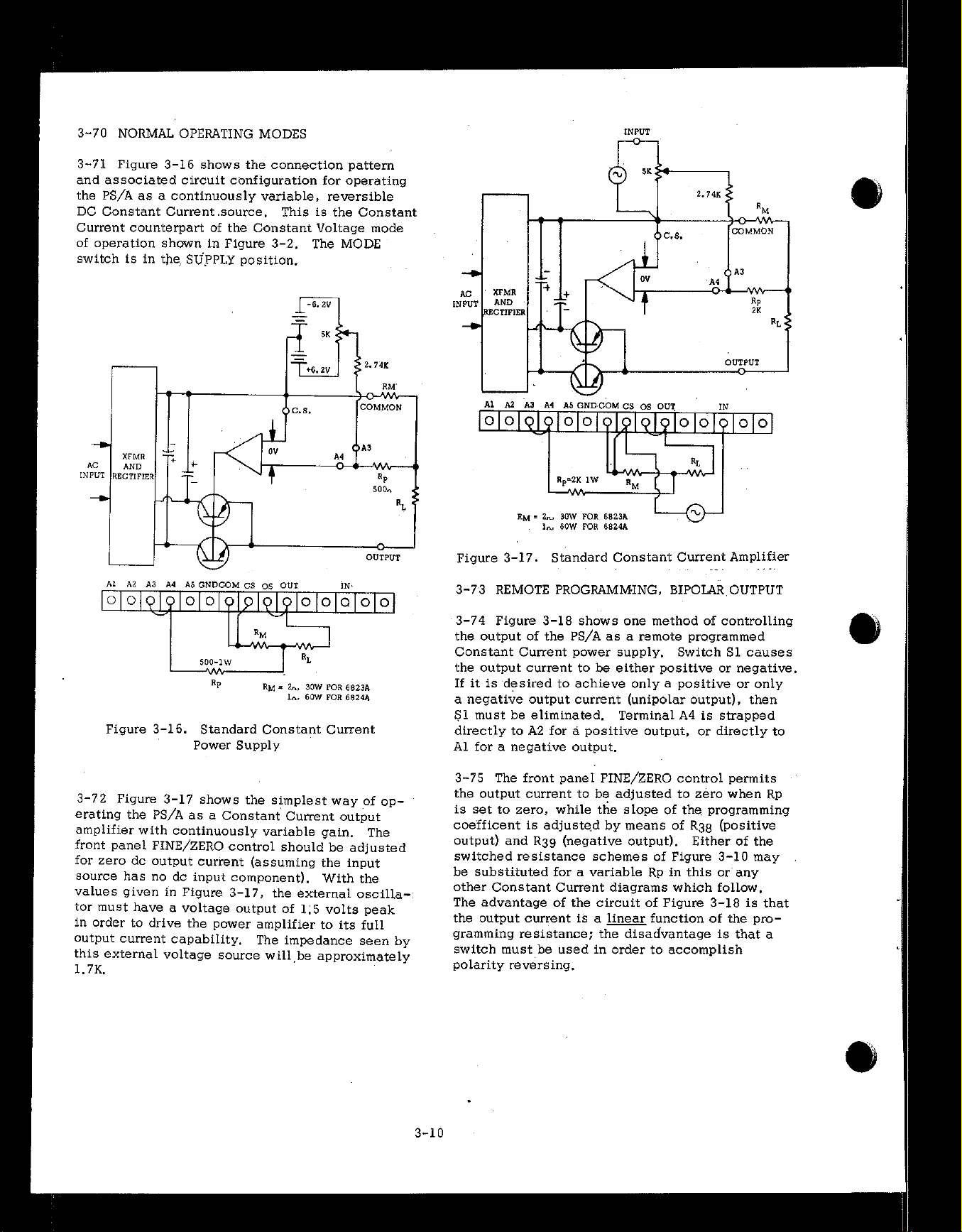

Loading...

Loading...