Page 1

User's Guide

AC Power Solutions

HP Models 6814B, 6834B, and 6843A

For instruments with Serial Numbers:

HP 6814B: 3601A-00101 through 00270

US36010101-up

HP 6834B: 3601A-00101 through 00140

US36010101-up

HP 6843A: 3540A-00101 through 00140

US35400101-up

HP Part No. 5962-0887 Printed in U.S.A.

Microfiche No 5962-0888 December, 1998

Page 2

Warranty Information

CERTIFICATION

Hewlett-Packard Company certifies that this product met its published specifications at time of shipment from the

factory. Hewlett-Packard further certifies that its calibration measurements are traceable to the United States

National Bureau of Standards, to the extent allowed by the Bureau's calibration facility, and to the calibration facilities

of other International Standards Organization members.

WARRANTY

This Hewlett-Packard hardware product is warranted against defects in material and workmanship for a period of

three years from date of delivery. HP software and firmware products, which are designated by HP for use with a

hardware product and when properly installed on that hardware product, are warranted not to fail to execute their

programming instructions due to defects in material and workmanship for a period of 90 days from date of delivery.

During the warranty period Hewlett-Packard Company will, at its option, either repair or replace products which

prove to be defective. HP does not warrant that the operation for the software firmware, or hardware shall be

uninterrupted or error free.

For warranty service, with the exception of warranty options, this product must be returned to a service facility

designated by HP. Customer shall prepay shipping charges by (and shall pay all duty and taxes) for products

returned to HP for warranty service. Except for products returned to Customer from another country, HP shall pay

for return of products to Customer.

Warranty services outside the country of initial purchase are included in HP's product price, only if Customer pays

HP international prices (defined as destination local currency price, or U.S. or Geneva Export price).

If HP is unable, within a reasonable time to repair or replace any product to condition as warranted, the Customer

shall be entitled to a refund of the purchase price upon return of the product to HP.

LIMITATION OF WARRANTY

The foregoing warranty shall not apply to defects resulting from improper or inadequate maintenance by the

Customer, Customer-supplied software or interfacing, unauthorized modification or misuse, operation outside of the

environmental specifications for the product, or improper site preparation and maintenance. NO OTHER

WARRANTY IS EXPRESSED OR IMPLIED. HP SPECIFICALLY DISCLAIMS THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

EXCLUSIVE REMEDIES

THE REMEDIES PROVIDED HEREIN ARE THE CUSTOMER'S SOLE AND EXCLUSIVE REMEDIES. HP SHALL

NOT BE LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES,

WHETHER BASED ON CONTRACT, TORT, OR ANY OTHER LEGAL THEORY.

ASSISTANCE

The above statements apply only to the standard product warranty. Warranty options, extended support contacts,

product maintenance agreements and customer assistance agreements are also available. Contact your nearest

Hewlett-Packard Sales and Service office for further information on HP's full line of Support Programs.

2

Page 3

Safety Summary

The following general safety precautions must be observed during all phases of operation of this instrument.

Failure to comply with these precautions or with specific warnings elsewhere in this manual violates safety

standards of design, manufacture, and intended use of the instrument. Hewlett-Packard Company assumes no

liability for the customer's failure to comply with these requirements.

WARNING: LETHAL VOLTAGES

Ac sources can supply 425 V peak at their output. DEATH on contact may result if the output terminals or

circuits connected to the output are touched when power is applied.

GENERAL

This product is a Safety Class 1 instrument (provided with a protective earth terminal). The protective features of

this product may be impaired if it is used in a manner not specified in the operation instructions.

Any LEDs used in this product are Class 1 LEDs as per IEC 825-1.

ENVIRONMENTAL CONDITONS

This instrument is intended for indoor use in an installation category III, pollution degree 2 environment. It is

designed to operate at a maximum relative humidity of 95% and at altitudes of up to 2000 meters. Refer to the

specifications tables for the ac mains voltage requirements and ambient operating temperature range.

BEFORE APPLYING POWER

Verify that the product is set to match the available line voltage, the correct fuse is installed, and all safety

precautions are taken. Note the instrument's external markings described under "Safety Symbols".

GROUND THE INSTRUMENT

To minimize shock hazard, the instrument chassis and cover must be connected to an electrical ground. The

instrument must be connected to the ac power mains through a grounded power cable, with the ground wire

firmly connected to an electrical ground (safety ground) at the power outlet. Any interruption of the protective

(grounding) conductor or disconnection of the protective earth terminal will cause a potential shock hazard that

could result in personal injury.

ATTENTION: Un circuit de terre continu est essentiel en vue du fonctionnement sécuritaire de l'appareil.

Ne jamais mettre l'appareil en marche lorsque le conducteur de mise … la terre est d‚branch‚.

FUSES

Only fuses with the required rated current, voltage, and specified type (normal blow, time delay, etc.) should be

used. Do not use repaired fuses or short-circuited fuseholders. To do so could cause a shock or fire hazard.

DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE

Do not operate the instrument in the presence of flammable gases or fumes.

DO NOT REMOVE THE INSTRUMENT COVER

Operating personnel must not remove instrument covers. Component replacement and internal adjustments must

be made only by qualified service personnel.

DO NOT EXCEED INPUT RATINGS

Operation at line voltages or frequencies in excess of those stated on the line rating label may cause leakage

currents in excess of 5.0 mA peak.

Instruments that appear damaged or defective should be made inoperative and secured against unintended

operation until they can be repaired by qualified service personnel.

3

Page 4

SAFETY SYMBOLS

Direct current

Alternating current

Both direct and alternating current

Three-phase alternating current

Earth (ground) terminal

Protective earth (ground) terminal

Frame or chassis terminal

Terminal is at earth potential. Used for measurement and control circuits designed to be

operated with one terminal at earth potential.

Terminal for Neutral conductor on permanently installed equipment

Terminal for Line conductor on permanently installed equipment

WARNING

Caution

On (supply)

Off (supply)

Standby (supply). Units with this symbol are not completely disconnected from ac mains

when this switch is off. To completely disconnect the unit from ac mains, either disconnect

the power cord or have a qualified electrician install an external switch.

In position of a bi-stable push control

Out position of a bi-stable push control

Caution, risk of electric shock

Caution, hot surface

Caution (refer to accompanying documents)

The WARNING sign denotes a hazard. It calls attention to a procedure, practice, or the like,

which, if not correctly performed or adhered to, could result in personal injury. Do not

proceed beyond a WARNING sign until the indicated conditions are fully understood and

met.

The CAUTION sign denotes a hazard. It calls attention to an operating procedure, or the like,

which, if not correctly performed or adhered to, could result in damage to or destruction of

part or all of the product. Do not proceed beyond a CAUTION sign until the indicated

conditions are fully understood and met.

4

Page 5

Declaration Page

Manufacturer's Name: Hewlett-Packard Company

Manufacturer's Address: 150 Green Pond Road

declares that the Product

Product Name: a) AC Power Source/Analyzer

Model Number(s): a) HP 6814A, 6814B, 6834A, 6834B

conforms to the following Product Specifications:

DECLARATION OF CONFORMITY

according to ISO/IEC Guide 22 and EN 45014

Rockaway, New Jersey 07866

U.S.A.

b) Harmonic/Flicker Test System

b) HP 6843A

Safety: IEC 1010-1:1990+A1(1992) / EN 61010-1:1993

EMC: CISPR 11:1990 / EN 55011:1991 - Group 1 Class A

Supplementary Information:

The product herewith complies with the requirements of the Low Voltage Directive

73/23/EEC and the EMC Directive 89/336/EEC and carries the CE-marking accordingly.

New Jersey January 1997 __ __

Location Date Bruce Krueger / Quality Manager

European Contact: Your local Hewlett-Packard Sales and Service Office or Hewlett-Packard GmbH,

Department TRE, Herrenberger Strasse 130, D-71034 Boeblingen (FAX:+49-7031-14-3143)

IEC 801-2:1991 / EN 50082-1:1992 - 4 kV CD, 8 kV AD

IEC 801-3:1984 / EN 50082-1:1992 - 3 V / m

IEC 801-4:1988 / EN 50082-1:1992 - 0.5 kV Signal Lines

1 kV Power Lines

5

Page 6

Acoustic Noise Information

Herstellerbescheinigung

Diese Information steht im Zusammenhang mit den Anforderungen der

Maschinenläminformationsverordnung vom 18 Januar 1991.

* Schalldruckpegel Lp <70 dB(A)

* Am Arbeitsplatz

* Normaler Betrieb

* Nach EN 27779 (Typprüfung).

Manufacturer's Declaration

This statement is provided to comply with the requirements of the German Sound Emission Directive,

from 18 January 1991.

* Sound Pressure Lp <70 dB(A)

* At Operator Position

* Normal Operation

* According to EN 27779 (Type Test).

Printing History

The edition and current revision of this manual are indicated below. Reprints of this manual containing

minor corrections and updates may have the same printing date. Revised editions are identified by a new

printing date. A revised edition incorporates all new or corrected material since the previous printing date.

Changes to the manual occurring between revisions are covered by change sheets shipped with the manual.

In some cases, the manual change applies only to specific instruments. Instructions provided on the change

sheet will indicate if a particular change applies only to certain instruments.

This document contains proprietary information protected by copyright. All rights are reserved. No part of

this document may be photocopied, reproduced, or translated into another language without the prior

consent of Hewlett-Packard Company. The information contained in this document is subject to change

without notice.

Copyright 1996, 1998 Hewlett-Packard Company Edition 1 _________January, 1996

Edition 2 ________December, 1998

6

Page 7

Table of Contents

Warranty Information 2

Safety Summary 3

Declaration Page 5

Acoustic Noise Information 6

Printing History 6

Table of Contents 7

1. GENERAL INFORMATION 9

Document Orientation 9

Safety Considerations 10

Options, Accessories, and User Replaceable Parts 10

Description 11

Capabilities 11

Front Panel/Remote Operation 12

Output Characteristic 12

Ranges 12

Output VA Capability 13

2. INSTALLATION 15

Inspection 15

Damage 15

Packaging Material 15

Items Supplied 15

Cleaning 15

Location 16

Bench Operation 16

Rack Mounting 16

Input Connections 17

Input Source and Line Fuse 17

Installing the Power Cord 17

Output Connections 18

Wire Considerations 19

Voltage Drops 19

Remote Sense Connections 20

OVP Considerations 21

Output Rating 21

Trigger Connections 21

Digital Connections 21

Controller Connections 22

HP-IB Connector 22

RS-232 Interface 23

3. TURN-ON CHECKOUT 27

Introduction 27

Preliminary Checkout 27

Using the Keypad 28

Checkout Procedure 28

In Case of Trouble 31

Error Messages 31

Line Fuse 31

7

Page 8

4. FRONT PANEL OPERATION 33

Introduction 33

Front Panel Description 33

System Keys 35

Function Keys 36

Immediate Action Keys 36

Scrolling Keys 37

Meter Display Keys 37

Output Control Keys 38

Protection and Status Control Keys 40

Trigger and List Control Keys 41

Entry Keys 42

Examples of Front Panel Programming 43

1 - Setting the Output Voltage Amplitude 43

Procedure for Three-Phase AC Sources 44

2 - Setting the Output Frequency 45

3 - Setting a Protection Feature 45

4 - Using Transient Voltage Modes 46

5 - Trigger Delays and Phase Synchronization 49

6 - Using Slew Rates to Generate Waveforms 52

7 - Measuring Peak Inrush Current 54

8 - Setting the HP-IB Address and RS-232 Parameters 55

9 - Saving and Recalling Operating States 55

10 - Switching Between Single- and Three-phase Operation (HP 6834B only) 56

A. SPECIFICATIONS 57

Specifications 57

Supplemental Characteristics 58

B. VERIFICATION AND CALIBRATION 61

Introduction 61

Equipment Required 61

Test Setup 62

Performing the Verification Tests 62

Turn-On Checkout Procedure 62

Voltage Programming and Measurement Accuracy 63

RMS Current Readback Accuracy 63

Performing the Calibration Procedure 64

Front Panel Calibration Menu 65

Front Panel Calibration 65

Enable Calibration Mode 65

Calibrating and Entering Voltage Calibration Values 66

Calibrating and Entering Current Calibration Values 67

Calibrating the Output Impedance (HP 6843A only) 68

Saving the Calibration Constants 68

Changing the Calibration Password 69

Calibration Error Messages 69

Calibration Over the HP-IB 69

HP Calibration Program Listing 69

C. ERROR MESSAGES 73

Error Number List 73

INDEX 77

8

Page 9

1

General Information

Document Orientation

This manual describes the operation of the HP 6814B/6834B/6843A AC Power Solutions. These units will

be referred to as "ac sources" throughout this manual. Operation of the HP 6843A is described for normal

mode operation only. The following documents are shipped with your ac source:

♦ a Quick-Start Guide, to help you quickly get started using the ac source

♦ a User's Guide, containing detailed installation, checkout, and front panel information

♦ a Programming Guide, containing detailed HP-IB programming information

♦ a Quick Reference Card, designed as a memory jogger for the experienced user

♦ Regulatory Test Solution User's Guides are shipped with HP 6843A units only

You will find information on the following tasks in these guides. Refer to the table of contents of each guide

for a complete list of the topics.

Topic Location

Accessories and options Chapter 1 - this guide

Calibrating the ac source Appendix B - this guide

Front panel keys Chapter 4 - this guide

Front panel programming examples Chapter 4 - this guide

Line voltage connections Chapter 2 - this guide

Line voltage ratings Appendix A - this guide

Operator replaceable parts Chapter 1 - this guide

Operator troubleshooting Chapter 3 - this guide

Operating characteristics Appendix A - this guide

Performance specifications Appendix A - this guide

Quick operating checkout Chapter 3 - this guide

Rack mounting Chapter 2 - this guide

RS-232 operation Chapter 2 - this guide

SCPI programming examples Chapter 3 - Programming Guide

SCPI programming commands Chapter 4 - Programming Guide

Turn-on/checkout Chapter 3 - this guide

Wiring - discrete fault indicator (DFI) Chapter 2 - this guide

- HP-IB controller Chapter 2 - this guide

- load or loads Chapter 2 - this guide

- voltage sensing (local and remote) Chapter 2 - this guide

- remote inhibit (RI) Chapter 2 - this guide

Page 10

1 - General Information

Safety Considerations

This ac source is a Safety Class 1 instrument, which means it has a protective earth terminal. That terminal

must be connected to earth ground through a power source equipped with a ground receptacle. Refer to the

Safety Summary page at the beginning of this guide for general safety information. Before installation or

operation, check the ac source and review this guide for safety warnings and instructions. Safety warnings

for specific procedures are located at appropriate places in the guide.

Options, Accessories, and User Replaceable Parts

Table 1-1. Options

Option Description

400 Input power 360-440 Vac, three-phase, 47-63 Hz

1CM 2- Rack mount kit (HP 5062-3977)

Support rails (HP 5064-0001) are required (rails are not included in rack mount kit).

Table 1-2. Accessories

Item HP Part Number

Fuse replacement kits

30A for 180-235 Vac, 3-phase line

HP-IB cables

0.5 meters (1.6 ft)

1.0 meter (3.3 ft)

2.0 meters (6.6 ft)

3.0 meters (13.2 ft)

Heavy duty slide mount kit

5060-3513

10833D

10833A

10833B

10833C

5063-2310

Table 1-3. User Replaceable Parts List

Description HP Part No.

Rack mount kit See “Options”

Slide mount kit See “Accessories”

7-terminal sense connector plug 1252-3698

Sense connector cover 4040-2268

4-terminal digital connector plug 1252-1488

AC input safety cover (with strain relief and brushing) 5001-9837

Screw (4), ac input safety cover (6-32 x 1.5in) 2360-0405

Screw (8), ac input barrier block (8-32 x 5/16in) N/A

AC output safety cover 5001-9811

Screw (2), ac output safety cover (6-32 x .3in) 2460-0012

Screw (8), ac output barrier block (10-32 x .37in) N/A

Fuse safety cover 5001-9810

Screw (2), fuse safety cover (6-32 x .3in) 2460-0012

User’s Guide (this manual) 5962-0887

Programming Guide 5962-0889

Quick Start Guide 5962-0883

Quick Reference Card 5962-0885

Appropriate HP Regulatory Test Solution Software HP 14761A, HP 14762A, HP 14763A

10

Page 11

General Information - 1

Description

The ac source combines three instruments in one unit as shown in the following figure. The function

generator produces waveforms with programmable amplitude, frequency, and shape. The power amplifier

amplifies the function generator signal to produce the ac power for your application. The measurement

functions range from a simple readback of rms voltage and current, to sophisticated capabilities such as

waveform analysis.

DAC

WAVEFORM

GENERATOR

SOURCE

BIPOLAR

AMPLIFIER

shunt

MEASUREMENT

BLOCK

POWERMETER

FFT ANALYZER

Figure 1-1. AC Source Functional Elements

The following model ac power sources are described in this User's Guide:

Model Description

HP 6814B 3000 VA single –phase operation

HP 6834B 1500 VA/ phase for three-phase operation

(4500 VA for single-phase operation)

HP 6843A 4500 VA single-phase operation

Capabilities

♦ Programmable ac voltage, dc voltage, frequency, phase, and current limit.

♦ Sine, square, clipped sine, and user-definable waveforms.

♦ Voltage and frequency slew control.

♦ Synthesized waveform generation for high resolution and accuracy in frequency, low waveform

distortion, and glitch-free phase transitions.

♦ Step and pulse output transients for generating surge, sag, dropout, and other line disturbance

simulations.

♦ Nonvolatile list programming for generating complex output transients or test sequences.

♦ Three-phase/single-phase output capability (HP 6834B only)

♦ Extensive measurement capability:

• Ac rms, dc, ac+dc voltage and current and peak current.

• Real, reactive, and apparent power.

• Harmonic analysis of voltage and current waveforms gives amplitude, phase, and total

harmonic distortion results up to the 50th harmonic.

• Triggered acquisition of digitized voltage and current with extensive post-acquisition

calculations.

• Additional total power and neutral curent measurementts in the three-phase model.

• All measurements made with 16-bit resolution.

♦ Trigger In and Trigger Out for synchronizing transient events or measurements with external

signals.

♦ Front panel control with 14-character vacuum flourescent display, keypad, and rotary pulse

generators for voltage and frequency settings.

♦ Built-in HP-IB and RS-232 interface programming with SCPI command language.

11

Page 12

1 - General Information

♦ Nonvolatile state and waveform storage and recall.

♦ Over-voltage, over-power, over-current, over-temperature, and RI/DFI protection features.

♦ Built-in output and sense disconnect relays.

♦ Extensive selftest, status reporting, and software calibration.

Front Panel/Remote Operation

The front panel has both rotary (RPG) and keypad controls for setting the output voltage and frequency.

The panel display provides digital readouts of a number of output measurements. Annunciators display the

operating status of the ac source. System keys let you perform system functions such as setting the HP-IB

address and recalling operating states. Front panel Function keys access the ac source function menus.

Front panel Entry keys let you select and enter parameter values. Refer to chapter 4 for a complete

description of the front panel controls.

Remotely programming is accomplished from either the HP-IB bus or from an RS-232 serial port. HP-IB

and RS-232 programming uses SCPI commands (Standard Commands for Programmable Instruments) that

make the ac source programs compatible with those of other instruments. AC source status registers permit

remote monitoring of a wide variety of ac source operating conditions

NOTE: Refer to the ac source Programming Guide for further information about remotely

programming the ac source. If you are using the HP 6843A, refer to the appropriate

Regulatory Test Solution User’s Guide for information about regulatory testing.

Output Characteristic

Ranges

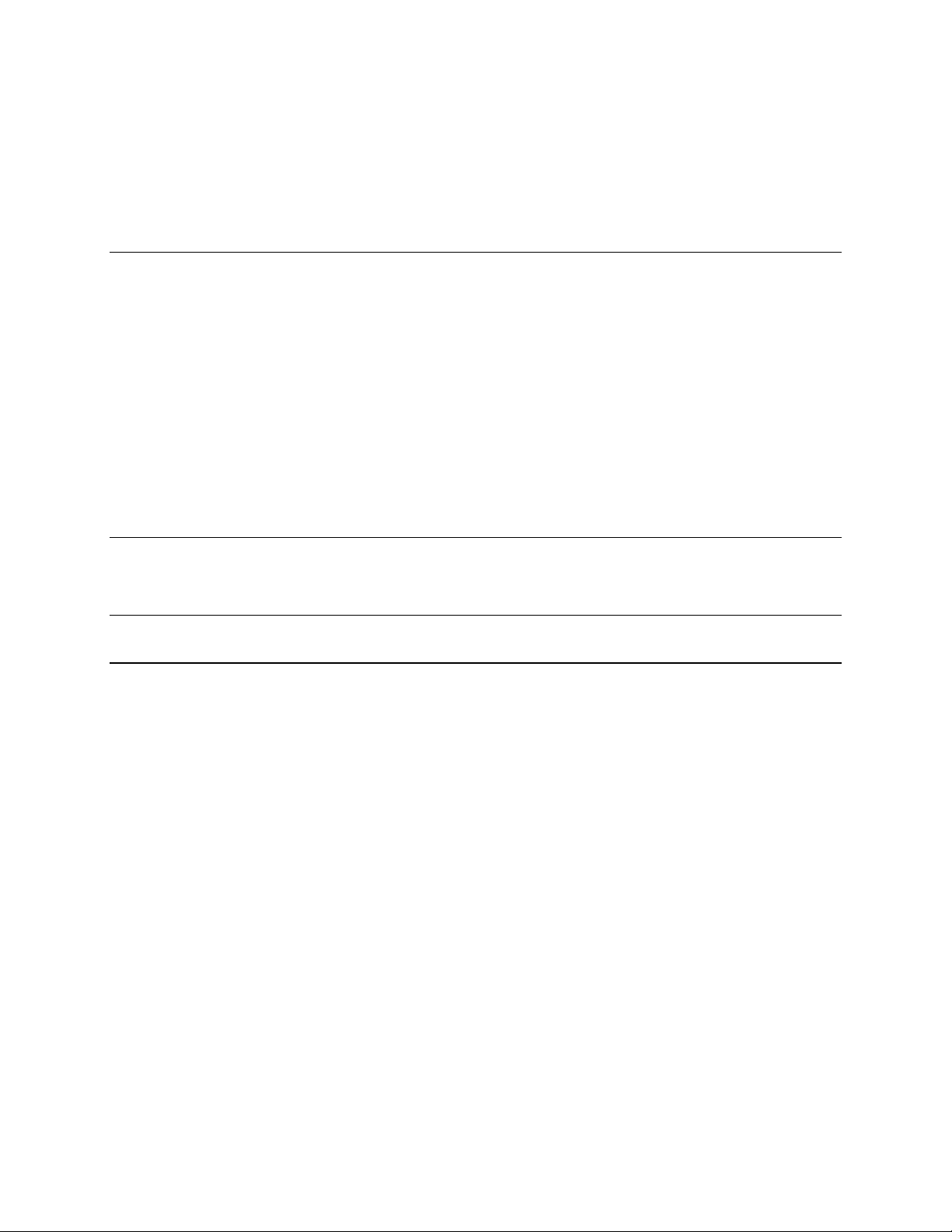

The ac source’s output characteristic is shown in the following figure. The output voltage of the ac source

may be adjusted to any value within the range of the unit. On three-phase units, each phase can be adjusted

independently of the other two.

Rated output VA and conversion efficiency is greatest when the output voltage is set near maximum. For

this reason, the ac source is designed to operate on one of two ranges: 150 volts full-scale, or 300 volts fullscale. You should choose the range that allows you to operate nearest the full-scale output capability of the

selected range.

12

Page 13

Vrms

300 V

150 V

General Information - 1

See Figure 1-3

0

5A 10A (6834B 3phase)

15A 30A (6834B 1phase)

10A 20A (6814B)

16A 32A (6843A)

Irms

Figure 1-2. AC Source Output Characteristic (in real-time mode)

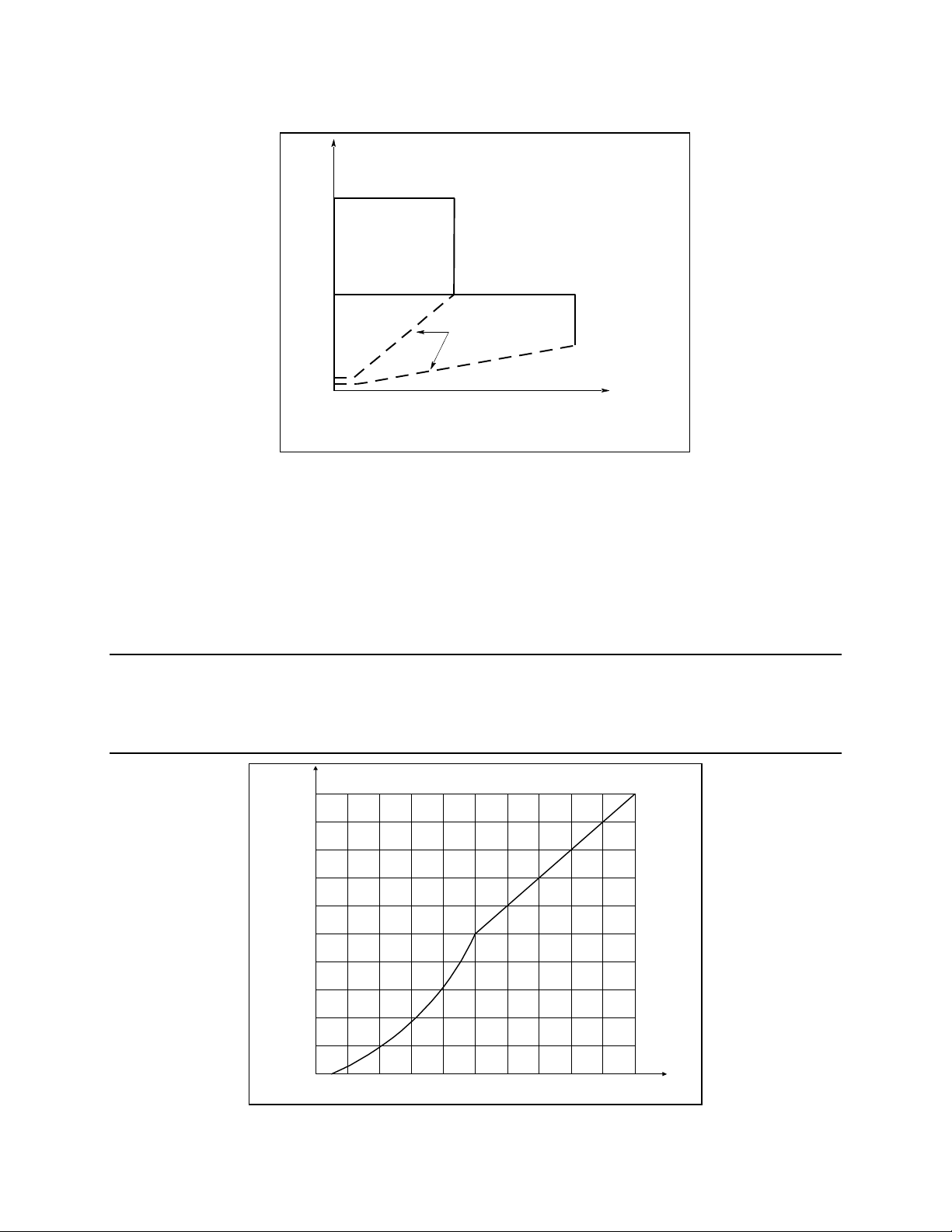

Output VA Capability

The output capability of each output phase is limited by VA (volts-amps) rather than power (watts). The

amount of VA available to a load can be determined by examining figure 1-3, the output power curve. This

curve rates the available VA versus output voltage. Full VA is available only at a full-scale voltage. Full

current is available at voltages between 50% and 100% of the output voltage range. Appendix A

documents the ac source's specifications and supplemental characteristics.

NOTE: The load on the ac source may draw full VA at any power factor between 0 and 1, and

may draw maximum current with a crest factor of 4 (3 for HP 6843A). If the load draws

current in excess of the maximum rated rms or peak current, the voltage amplitude will be

clipped to prevent excessive internal power dissipation.

100

90

80

70

60

50

40

30

20

OUTPUT VA, PERCENT OF MAXIMUM

10

0

OUTPUT VOLTAGE, PERCENT OF RANGE

Figure 1-3. AC Source VA Capabilities

70 80 90 10010 20 30 40 50 60

13

Page 14

Page 15

2

Installation

Inspection

Damage

When you receive your ac source, inspect it for any obvious damage that may have occurred during

shipment. If there is damage, notify the shipping carrier and the nearest HP Sales and Support Office

immediately. The list of HP Sales and Support Offices is at the back of this guide. Warranty information

is printed in the front of this guide.

Packaging Material

Until you have checked out the ac source, save the shipping carton and packing materials in case the unit

has to be returned. If you return the ac source for service, attach a tag identifying the model number and the

owner. Also include a brief description of the problem.

Items Supplied

Check that the following items are included with your ac source. Some items are installed in the unit.

Power Cord

Sense/Digital connector

Safety covers

Manuals

Change page

A power cord appropriate for your location. The cord may or may not be terminated

in a power plug (see "Options" in chapter 1). If the cord is not included, contact your

nearest HP Sales and Support Office (refer to the list at the back of this guide).

a 4-terminal digital plug that connects to the back of the unit.

a 7-terminal sense plug that connects to the back of the unit.

Ac input cover with strain relief

Ac output cover

Fuse cover

User’s Guide

Programming Guide

Quick Start Guide

Quick Reference Card

Regulatory Test Solutions Guides (supplied with HP 6843A units)

If applicable, change sheets may be included with this guide. If there are change

sheets, make the indicated corrections in this guide.

Cleaning

Use a dry cloth or one slightly dampened with water to clean the external case parts. Do not attempt to

clean internally.

WARNING: To prevent electric shock, unplug the unit before cleaning.

Page 16

2 - Installation

Location

Refer to the Safety Summary page at the beginning of this manual for safety-related information about

environmental conditions.

WARNING: HP 6814B units weigh 79.5 kg (175 lbs.)

HP 6834B/ 6843A units weigh 87.7 kg (193 lbs.)

Obtain adequate help when moving the unit or mounting the unit in the rack.

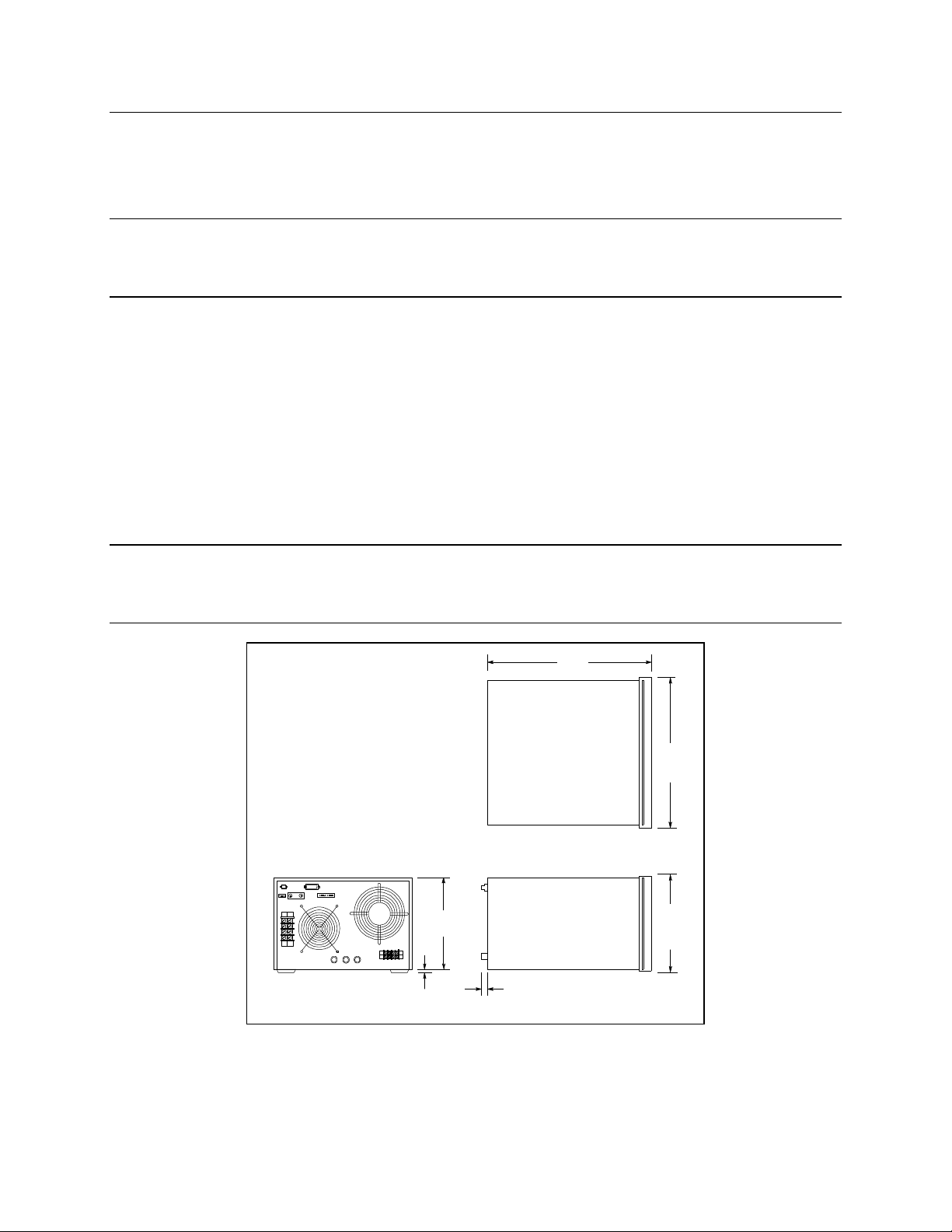

Bench Operation

The outline diagram in figure 2-1 gives the dimensions of your ac source. The feet may be removed for

rack mounting. Your ac source must be installed in a location that allows sufficient space at the sides and

back of the unit for adequate air circulation. Minimum clearances are 1 inch (25 mm) along the sides. Do

not block the fan exhaust at the rear of the unit.

Rack Mounting

The ac source can be mounted in a standard 19-inch rack panel or cabinet. Rack mounting kits are

available as Option 1CM or 1CP. Installation instructions are included with each rack mounting kit

CAUTION: HP 6814B/ 6834B/ 6843A units require instrument support rails for non-stationary

installations. These are normally ordered with the cabinet and are not included with the

rack mounting kits.

TOP

574.7mm

22.6"

425.5mm

16.75"

REAR

12.7mm

0.5"

262.6mm

10.3"

19.1mm

0.8"

SIDE

266.7mm

10.5"

16

Figure 2-1. Outline Diagram

Page 17

Installation - 2

Input Connections

Input Source and Line Fuse

The ac source requires a 3-phase power service that provides 7350 VA (6000 W) maximum. The power

service should have a current rating greater than or equal to the ac source's circuit breaker rating. The ac

source has a delta input (no neutral connection) and will accept power from either delta (triangle) or wye

(star) services.

CAUTION: Two input voltage ranges are available (see "AC Input Ratings" in appendix A). The ac

source will be damaged if it is operated at an input voltage that is outside of its configured

input range.

In order to maintain phase current balancing, the power service should be a dedicated line with only HP

6814B/6834B/6843A ac sources drawing current from it. A disconnect box located near the ac source is

recommended for all installations and is mandatory for direct-wired installations.

Installing the Power Cord

WARNING: Installation of the power cord must be done by a qualified and licensed electrician and

must be in accordance with local electrical codes.

The power cords supplied with the ac source do not include a power plug. Terminating connectors and a

ground lug are attached to one end of the cord. See Figure 2-2 while performing the following procedure.

1. Check the line fuses as follows:

a. Examine the FUSES label on the rear panel.

b. Remove the safety cover in front of the fuse caps.

c. Unscrew the line fuse caps from the rear panel and verify that all fuses are as

specified on the label. Reinstall the fuses.

d. Reinstall the safety cover in front of the fuse caps.

2. Remove the ac input cover from the back of the unit.

3. Open the line clamp on the ac input cover and insert the line cord through the opening.

4. Position the power cord so that the clamp is near the end of the outside insulating sheath

on the power cord. Tighten the screws to secure the clamp.

5. Secure the three ac lines to the ac power strip as follows:

Phase 1 to L1 (black).

Phase 2 to L2 (red).

Phase 3 to L3 (orange).

6. Secure the ground wire (green) to the chassis earth ground terminal.

7. Slip the safety cover over the ac input terminal strip and secure the cover with the four

screws.

8. If required, wire the appropriate power plug to the other end of the power cord. For usermade cables, strip back the sheath 10 cm (4 in).

17

Page 18

2 - Installation

2

CAUTION

LINE RATING

WARNING

F 1

F 2 F 3

1

5

WARNING

L 2 L 3

L 1

6

7

3

4

10cm (4 in.)

Figure 2-2. Connecting the Power Cord

Output Connections

The power output terminal block has a termination for each of the output phases (φ1, φ2, φ3 ) and a

floating neutral line (COM) for the phase return connections. A separate earth ground terminal (⊥) is

located near the output terminals.

18

These screw terminals are

internally connected in

single-phase mode only

(when NOUPUTS = 1)

HP 6834B HP 6814B / 6843A

φ

1

These screw terminals

φ 2

are internally connected

on HP 6843A units

φ

3

COM

These screw terminals

are internally connected

on HP 6814B units

⊥

Figure 2-3. Output Connections

φ

COM

⊥

1

Page 19

Installation - 2

NOTE: To minimize the possibility of instability on the output, keep load leads as short as possible

bundle or twist the leads tightly together to minimize inductance

Wire Considerations

Current Ratings

Fire Hazard To satisfy safety requirements, load wires must be large enough not to overheat when

carrying the maximum short-circuit current of the ac source. If there is more than one

load, then any pair of load wires must be capable of safely carrying the full-rated

current of the ac source.

Table 2-1 lists the characteristics of AWG (American Wire Gage) copper wire.

Table 2-1. Ampacity and Resistance of Stranded Copper Conductors

AWG No. Ampacity

14 25 0.0103 6 80 0.0016

12 30 0.0065 4 105 0.0010

10 40 0.0041 2 140 0.00064

8 60 0.0025 1/0 195 0.00040

1. Ampacity is based on 30°C ambient temperature with conductor rated at 60°C. For ambient

temperature other than 30°C, multiply the above ampacities by the following constants:

Temp. (°C)

21-25 1.08 41-45 0.71

26-30 1.00 46-50 0.58

31-35 0.91 51-55 0.41

36-40 0.82

2. Resistance is nominal at 75 °C wire temperature.

1

Resistance

(Ω/m)

Constant

2

NOTES:

AWG No. Ampacity

Temp. (°C) Temp. (°C)

1

Resistance

(Ω/m)

2

Voltage Drops

The load wires must also be large enough to avoid excessive voltage drops due to the impedance of the

wires. In general, if the wires are heavy enough to carry the maximum short circuit current without

overheating, excessive voltage drops will not be a problem. The voltage drops across the load wires should

be limited to less than 2% of the output voltage.

Refer to Table 2-1 if you need to calculate the voltage drop for some commonly used AWG copper wire.

19

Page 20

2 - Installation

Remote Sense Connections

Under normal operation, the ac source senses the output voltage at the output terminals on the back of the

unit. External sense terminals are available on the back of the unit that allow the output voltages to be

sensed at the load, compensating for impedance losses in the load wiring. As shown in the following figure:

♦ Connect the phase 1 (φ1) through phase 2 (φ) sense terminals to the side of the load that connects

to the corresponding output terminal.

♦ Connect the Neutral (COM) sense terminal connector to the neutral side of the load.

♦ Twist and shield all signal wires to and from the sense connectors.

The sense leads are part of the ac source's feedback path and must be kept at a low resistance in order to

maintain optimal performance. Connect the sense leads carefully so that they do not become open-circuited.

If the sense leads are left unconnected or become open during operation, the ac source will regulate at the

output terminals, resulting in a 3% to 5% increase in output over the programmed value.

Set the ALC command to EXT (external) to enable remote sensing. The ALC command is located under

the Voltage key as explained in chapter 4. Set the ALC command to INT (internal) to disable remote

sensing.

NOTE: Phase 2 and phase 3

connections are not available

on HP 6814B/6843A units.

φ

φ 2

φ

COM

1

3

⊥

COM φ 3 φ 2 φ 1

φ

1 LOAD

φ 2

LOAD

φ

3 LOAD

20

Figure 2-4. Remote Sense Connections

Page 21

Installation - 2

OVP Considerations

The overvoltage protection circuit senses voltage near the output terminals, not at the load. Therefore the

signal sensed by the OVP circuit can be significantly higher than the actual voltage at the load. When using

remote sensing, you must program the OVP trip voltage high enough to compensate for the voltage drop

between the output terminals and the load.

Output Rating

In remote sense applications, the voltage drop in the load leads subtracts from the available load voltage

(see "Remote Sensing Capability" in appendix A). As the ac source increases its output to overcome this

voltage drop, the sum of the programmed voltage and the load-lead drop may exceed the ac source's

maximum voltage rating. This will not damage the unit, but may trip the OV protection circuit, which

senses the voltage at the output terminals.

Trigger Connections

The BNC trigger connectors on the rear panel let you apply trigger signals to the ac source as well as

generate trigger signals from the ac source. The electrical characteristics of the trigger connectors are

described in appendix A. More information on programming external triggers is found in chapter 4 of the

ac source Programming Guide.

Trigger IN Allows negative-going external trigger signals to trigger the ac source.

Trigger OUT Generates a negative-going pulse when the selected transient output has occurred.

Digital Connections

This connector, which is on the rear panel, is for connecting the fault and the inhibit signals. The fault

(FLT) signal is also referred to as the DFI signal in the front panel and SCPI commands. The inhibit (INH)

signal is also referred to as the RI signal in the front panel and SCPI commands.

The connector accepts wires sizes from AWG 22 to AWG 12. Disconnect the mating plug to make your

wire connections. The electrical characteristics of the digital connectors are described in appendix A. More

information on programming the digital connectors is found in chapter 4 of the ac source Programming

Guide.

NOTE: It is good engineering practice to twist and shield all signal wires to and from the digital

connectors

The following examples show how you can connect the FLT/INH circuits of the ac source.

In example A, the INH input connects to a switch that shorts pin + to pin ⊥ whenever it is necessary to

disable output of the unit. This activates the remote inhibit (RI) circuit, which turns off the ac output. The

front panel Prot annunciator comes on and the RI bit is set in the Questionable Status Event register. To reenable the unit, first open the connection between pins + and ⊥ and then clear the protection circuit. This

can be done either from the front panel or over the HP-IB/RS-232.

21

Page 22

2 - Installation

In example B, the FLT output of one unit is connected to the INH input of another unit. A fault condition

in one of the units will disable all of them without intervention either by the controller or external circuitry.

The controller can be made aware of the fault via a service request (SRQ) generated by the Questionable

FLT INH

I

+

-

+

-

. . . .

NOTE: Connectors

are removable

I

+

-

+

-

FLT INH

+

-

+

. . . .

I

+

-

+

-

FLT Output

I

-

INH Input

I

+

-

+

-

INH Input

A) INH Example with One Unit

INH Common

Switch

(Normally

Open)

INH Input

FLT Output

B) FLT Example with Multiple Units

Status summary bit.

Figure 2-5. FLT/INH Examples

Controller Connections

The ac source connects to a controller either through an HP-IB or an RS-232 connector.

HP-IB Connector

Each ac source has its own HP-IB bus address. AC sources may be connected to the bus in series

configuration, star configuration, or a combination of the two. You may connect from 1 to 15 ac sources to

a controller HP-IB interface.

NOTE: The ac source is shipped from the factory with its HP-IB address set to 5. This address can

be changed as described in chapter 4 of this guide.

22

Page 23

Installation - 2

RS-232 Interface

The ac source provides an RS-232 programming interface, which is activated by commands located under

the front panel Address key. When the RS-232 interface is selected, the HP-IB interface is disabled.

NOTE: Sending or receiving data over the RS-232 interface when not configured for REMOTE

operation can cause unpredictable results. Always make sure the ac source is configured

for remote operation when using the RS-232 interface.

Interface Commands

All SCPI commands are available through RS-232 programming. The SYSTem:LOCal,

SYSTem:REMote, and SYSTem:RWLock commands are only available through the RS-232 interface.

SYSTem:LOCal Places the ac source in local mode during RS-232 operation.The front panel keys

are functional.

SYSTem:REMote Places the ac source in remote mode during RS-232 operation. All front panel

keys except the Local key are disabled.

SYSTem:RWLock Places the ac source in remote mode during RS-232 operation. All front panel

keys including the Local key are disabled.

RS-232 Data Format

♦ constant 11-bit data format

♦ one start bit

♦ seven data bits plus a parity bit (even or odd parity), or eight data bits without parity

(parity bit is "0")

♦ two stop bits

You can specify one of the following baud rates: 300 600 1200 2400 4800 9600

NOTE: The ac source always uses one start bit and two stop bits regardless of the baud rate. The

number of start and stop bits is not programmable.

RS-232 Connector

The RS-232 connector is a DB-9, male connector. You can connect the ac source to any computer or

terminal with a properly configured DB-25 connector. You can use a standard HP 24542G or 24542H

interface cable.

Table 2-2. RS-232 Connector

1 2 3 4 5

6 7 8 9

Pin

1

2

3

4

5

6

7

8

9

Input/Output

Output

Input

Output

Output

Common

Input

Output

Description

Reserved for service use

Receive Data (RxD)

Transmit Data (TxD)

Data Terminal Ready

(DTR)

Signal ground

Data Set Ready (DSR)

no connection

no connection

Reserved for service use

23

Page 24

2 - Installation

Hardware Handshake

The RS-232 interface uses the DTR (data terminal ready) line as a holdoff signal to the bus controller.

When DTR is true, the bus controller may send data to the ac source. When DTR goes false, the bus

controller must stop sending data within 10 characters, and must not send any more data until DTR goes

true again. The ac source sets DTR false under two conditions.

1. When the input buffer is full (approximately 100 characters have been received), it will set DTR

false. When enough characters have been removed to make space in the input buffer, DTR will be

set to true, unless condition 2 (see below) prevents this.

2. When the ac source wants to "talk", which means that it has processed a query, and has seen a

<newline> message terminator, it will set DTR false. This implies that once a query has been sent

to the power source, the bus controller should read the response before attempting to send more

data. It also means that a <newline> must terminate the command string. After the response has

been output, the ac source will set DTR true again, unless condition #1 prevents this.

The ac source monitors the DSR (data set ready) line to determine when the bus controller is ready to

accept data. It checks this line before each character is sent, and the output is suspended if DSR is false.

When DSR goes true, transmission will resume. The ac source will leave DTR false while output is

suspended. A form of deadlock exists until the bus controller asserts DSR true to allow the ac source to

complete the transmission.

Control-C is the equivalent to the HP-IB device clear command. It clears the operation in progress and

discards any pending output. For the control-C character to be recognized by the power source while it

holds DTR false, the bus controller must first set DSR false.

Null modem RS-232 interface cables swap the DTR and DSR lines as shown in the following figure. For

other bus controllers or languages, you must determine what form of hardware handshake is used. You may

have to build a customized cable to connect the holdoff lines as necessary. If your bus controller does not

use hardware handshaking, tie the DSR input to the ac source to a signal that is always true. This implies

that your bus controller must always be ready to accept data. You may want to set the baud rate toeither

2400 or 4800 baud to ensure that this is true.

bus controller

TxD (3)

RxD (2)

*DTR (4)

*DSR (6)

Ground (5)

ac source

TxD (3)

RxD (2)

DTR (4)

DSR (6)

Ground (5)

24

Figure 2-7. Null Modem Interface Lines

Page 25

Installation - 2

Response Data Terminator

All RS-232 response data sent by the ac source is terminated by the ASCII character pair <carriage

return><newline>. This differs from HP-IB response data which is terminated by the single character

<newline>.

25

Page 26

Page 27

3

Turn-On Checkout

Introduction

Successful tests in this chapter provide a high degree of confidence that the ac source is operating properly.

For verification tests, see appendix B. Complete performance tests are given in the Service Guide.

NOTE: This chapter provides a preliminary introduction to the ac source front panel. See chapter

4 for more details.

Preliminary Checkout

WARNING: LETHAL VOLTAGES. Ac sources can supply 425 V peak at their output. DEATH on

contact may result if the output terminals or circuits connected to the output are

touched when power is applied.

1. If you have not already done so, connect the power cord to the ac source and plug it in.

2. Turn the front panel power switch to ON (1).

3. The ac source undergoes a self-test when you turn it on. The following items appear on the display:

a. A brief pattern that lights all display segments, followed by the model number and the software

revision number.

b. The display then goes into the meter mode with the Dis annunciator on, and all others off.

"Meter mode" means that the VOLTS digits indicate the output voltage and the FREQ digits

indicate the output frequency. The voltage will be at or near zero and the frequency will be at 60

Hertz.

NOTE: If the ac source detects an error during self-test, the Err anunciator on the display will be

lit. Pressing the Shift and Error keys will show the error number. Go to "In Case of

Trouble" at the end of this chapter.

4. Check that the ac source fan is on. You should be able to hear the fan and feel the air coming from

the unit.

5. Press Output on/off once. The Dis annunciator will go off and the CV annunciator will go on.

6. Turn the unit off.

Page 28

3 - Turn-On Checkout

á

Using the Keypad

(shift) Some of the front panel keys perform two functions, one labeled in black and

the other in blue. You access the blue function by first pressing the blue

shift key. Release the key after you press it. The Shift annunciator will be on,

indicating that you have access to any key's shifted function.

p

and These keys let you scroll up and down through the choices in the presently

and These keys let you select the previous or the next parameter for a specific

Enter

q

selected function menu. All menu lists are circular; you can return to the

starting position by continuously pressing either key.

äã

command. If the command has a numeric range, these keys increment or

decrement the existing value.

The backspace key is an erase key. If you make a mistake entering a digit and

have not yet pressed Enter, you can delete the digit by pressing Å. Delete more

digits by repeatedly pressing this key.

Executes the entered value or parameter of the presently accessed command.

Until you press this key, the parameters you enter with the other keys are

displayed but not entered into the ac source. After pressing Enter, the ac source

returns to Meter mode in most cases. In Harmonic or List mode, the ac source

displays the next point in the list.

Checkout Procedure

WARNING: LETHAL VOLTAGES. Ac sources can supply 425 V peak at their output. DEATH on

contact may result if the output terminals or circuits connected to the output are

touched when power is applied.

The output test requires that you connect light bulbs to the output of the unit and apply a

potentially hazardous voltage of 120 Vac. Properly shield all connections and wires.

The test in this section checks for output voltage and current on the ac source by having you connect light

bulbs to the output of the unit. The following equipment is recommended for performing this output

checkout procedure:

♦ 1 - 100 W light bulb for HP 6814B/6843A; 3 - 100 W light bulbs for HP 6834B

♦ 1 - light bulb socket for HP 6814B/6843A; 3 - sockets for HP 6834B

♦ wires for connecting socket to the unit

NOTE: When the ac source is turned on as shipped from the factory, it asserts the *RST state.

You can subsequently program the unit to turn on according to the state stored in *RCL

location 0, as explained in chapter 4. The following procedures assume that the unit turns

on in the *RST state.

28

Page 29

Turn-On Checkout - 3

Make sure that the unit is turned off, and make the following connections to the output. If you are

verifying a single phase source, you only need to connect one bulb.

100 WATT

100 WATT

100 WATT

NOTE: Phase 2 and phase 3

connections are not available

on HP 6814B/6843A units.

φ

1

φ 2

φ

3

COM

⊥

Figure 3-1.Verification Connections

Procedure Display Explanation

1. Turn the unit on. Meter mode

2. Press the Voltage key. VOLT 0.00 Display indicates the default settings.

3. Press Phase Select

VOLT 0.00 Single phase units use only phase 1.

until only φ1 is lit.

Meter mode is active and the Dis annunciator should

be on.

If you are verifying a thre phase source, all phase

annunciators should be on.

4. Press 1, 2, 0, Enter VOLT 120 Programs the output on phase 1 to 120 Vrms. After the

value is entered, the display returns to Meter mode,

which indicates that no voltage is applied to the output.

5. Press Output On/Off 120 V 60 Hz Turns the output on and applies 120 volts to the phase

1 light bulb. The Dis annunciator should be off and CV

should be on.

If you are verifying three phase sources, repeat steps 2 through 4 for phase 2 and phase 3. All three light

bulbs should be lit when this action is complete.

Continue with step 6 of you are verifying thre phase sources. Otherwise skip to step #10.

6. Press the Voltage key. VOLT 120

7. Press Phase Select

until all phase

annunciators are lit

8. Press 0, Enter VOLT 0 Turns off all light bulbs connected to the three-phase

9. Press Voltage 1, 2, 0,

Enter

10. Press Protect PROT:CLEAR Display accesses the protection menu list.

VOLT 120

source.

VOLT 120 Turns on all light bulbs connected to the three-phase

source.

29

Page 30

3 - Turn-On Checkout

Procedure Display Explanation

11. Press • or ‚ and scroll

to the VOLT:PROT item

12. Press 1, 6, 0, Enter VOLT:PROT 160 Programs the OVP to 160 Vpeak, the rms value of

13. Press Protect, scroll to

the VOLT:PROT item,

and press 3, 2, 0, Enter

14. Press Protect, and

Enter

15. Press Shift, and

Current

16. Press . 5 Enter CURR:LEV .5

VOLT:PROT 500 Display shows the overvoltage protection trip voltage

for your unit. The overvoltage protection voltage is

programmed in peak, not rms volts.

which is less than the previously set rms voltage.

0 V 60 Hz Because the peak OVP voltage entered was less than

the rms output voltage, the OVP circuit tripped. The

output dropped to zero, CV turned off, and Prot turned

on.

VOLT:PROT 320 Programs the OVP to a peak value that is greater than

the rms output voltage value.

Note: You cannot clear an OVP trip until you have

first removed the cause of the condition.

120 V 60 Hz Executes the PROT:CLEAR command, restoring the

output. Prot turns off and CV turns on.

CURR:LEV 5 Indicates the default output current limit setting.

Sets the current limit to .5 amperes. The CC

annunciator is on, indicating that the unit is in current

limit mode and the light bulbs are dimmer because the

output voltage has dropped in its attempt to limit

output current.

17. Press Protect, scroll to

the CURR:PROT item,

and press È to select ON.

Then press Enter.

18. Press Output On/Off 0.5 V 60 Hz

19. Press Protect, scroll to

the CURR:PROT item,

press È to select OFF,

then press Enter.

20. Turn the unit off. The next time the unit turns on it will be restored to the

CURR:PROT ON You have enabled the overcurrent protection circuit.

The circuit then tripped because of the output short.

The CC annunciator turns off and the OCP and Prot

annuciators come on. The output current is near zero.

The output is off and the Dis annunciator turns on.

CURR:PROT OFF You have disabled the overcurrent protection circuit.

The Prot annunciator turns off.

*RST or factory default state

30

Page 31

Turn-On Checkout - 3

In Case of Trouble

Error Messages

Ac source failure may occur during power-on selftest or during operation. In either case, the display may

show an error message that indicates the reason for the failure.

Selftest Errors

Pressing the Shift and Error keys will show the error number. Selftest error messages appear as:

ERROR <n>, where "n" is a number listed in the following table. If this occurs, turn the power off and then

back on to see if the error persists. If the error message persists, the ac source requires service.

Table 3-1. Power-On Selftest Errors

Error No. Failed Test

Error 0 No error

Error 1 Non-volatile RAM RD0 section checksum failed

Error 2 Non-volatile RAM CONFIG section checksum failed

Error 3 Non-volatile RAM CAL section checksum failed

Error 4 Non-volatile RAM WAVEFORM section checksum failed

Error 5 Non-volatile RAM STATE section checksum failed

Error 6 Non-volatile RAM LIST section checksum failed

Error 10 RAM selftest

Error 11 to 18 DAC selftest 1 to 8

Runtime Error Messages

Under unusual operating conditions, the front panel display may show OVLD. This indicates that the

output voltage or current is beyond the range of the meter readback circuit. If the front panel display

indicates -- -- -- -- -- -- , an HP-IB measurement is in progress. Appendix C lists other error messages that

may appear at runtime.

Line Fuse

If the ac source appears "dead" with a blank display and the fan not running, first check your power source

to be certain line voltage is being supplied to the ac source. If the power source is normal, the ac source line

fuse may be defective. If the ac source has a defective fuse, replace it only once. If it fails again, investigate

the reason for the failure. Proceed as follows:

1. Turn off the front panel power switch and remove the input power (unplug the power cord or open

the safety disconnect).

2. Remove the fuse cover from the rear panel.

3. Unscrew the fuse caps and emove the fuses.

4. If any fuses are defective, replace all three with fuses of the same type (see chapter 1).

5. Turn on theac source and check the operation. If it is normal. replace the fuse cover.

Maintenance Note: It is recommended that new fuses be installed every four years.

31

Page 32

Page 33

Front panel Operation

Introduction

Here is what you will find in this chapter:

♦ a complete description of the front panel controls

♦ front panel programming examples that describe:

• how to program the output voltage and frequency

• how to measure the output

• how to program the output pulses and lists

• how to trigger output changes

Front Panel Description

4

HEWLETT

PACKARD

LINE

300 V rms 50 VA 1

6812A

AC POWER SOURCE / ANALYZER

1

115.0V 60.0HZ

CV CC CR CP Unr Dis Tran OCP Prot Cal Shift Rmt Addr Err SRQ

VOLTAGE FREQUENCY

On

Off

1

2 5 6 7

METER

OUTPUT

SYSTEM

Local

Error

Address

Save

Recall

FUNCT ION ENTRY

Harmonic

Current

Index

Voltage

Meter

Output

Phase

Input

Status

Protect

Trigger

Trigger

Control

Index

Freq

Shape

Phase

Select

List

Pulse

Output

on/off

Calibration

7 8 9

5 6

4

E

-

.

0

Enter

321

Clear Entry

4

3

Figure 4-1. Front Panel, Overall View

Page 34

4 - Front Panel Operation

ϕ Display

κ Annunciators

λ Voltage/

Frequency

ν Line

ο System Keys

π Function Keys

θ Entry Keys

14-character vacuum fluorescent display for showing programmed commands and

measured values.

Annunciators light to indicate operating modes and status conditions:

φ1, φ2, φ3 Phase 1, 2, or 3 is being controlled or metered.

CV The ac source output is in constant-voltage mode.

CC The ac source output is in constant-current mode.

Unr The ac source output is in an unregulated state.

Dis The ac source output is disabled (off).

Tran The ac source output is initialized to output a transient.

OCP The overcurrent protection state is enabled.

Prot One of the ac source's output protection features is activated.

Cal The ac source is in calibration mode.

Shift The Shift key is pressed to access an alternate key function.

Rmt The selected interface (HP-IB or RS-232) is in a remote state.

Addr The interface is addressed to talk or to listen.

Err There is a message in the SCPI error queue.

SRQ The interface is requesting service from the controller.

Meter Front panel measurement functions are: ac only, dc only, or ac+dc

AC+DC

Output The ac source output coupling is: ac only, or ac+dc

AC+DC

The rotary pulse generators let you set the output voltage and frequency when the

ac source is in local mode. Their response is rate sensitive.

Turning a control rapidly provides coarse control of the value.

Turning a control slowly provides fine control of the value.

This turns the ac source on or off.

The system keys let you:

Return to Local mode (front panel control)

Set the ac source HP-IB address

Set the RS-232 interface communication baud rate and parity bit

Display SCPI error codes and clear the error queue

Save and recall up to 4 instrument operating configurations

Function access command menus that let you:

Program output voltage, current limit, frequency, and output waveforms

Turn the ouput on and off

Select metering functions

Send immediate triggers from the front panel

Program transient output functions

Set and clear protection functions

Select output phases

Select the coupling for output and meter functions

Monitor instrument status

Entry keys let you:

Enter programming values

Increment or decrement programming values

Calibrate the ac source

34

Page 35

Front Panel Operation - 4

Local

Address

qpã

ä

Recall

System Keys

Refer to the examples later in this chapter for more details on the use of these keys.

SYS T E M

Local

Error

Address

Save

Recall

Figure 4-2. System Keys

This is the blue, unlabeled key, which is also shown as in this guide.

Shift

Pressing this key accesses the alternate or shifted function of a key (such as

ERROR ). Release the key after you press it. When the Shift annunciator is lit,

the shifted keys are active.

Press to change the ac source's selected interface from remote operation to local

(front panel) operation. Pressing the key will have no effect if the interface state is

already Local, Local-with-Lockout, or Remote-with-Lockout.

Press to access the system address menu. This menu lets you configure the ac

source's interface and other system parameters. Address Menu entries are stored

in non-volatile memory.

Display Command Function

ADDRESS <value> Sets the HP-IB Address

INTF <char> Selects an interface (HPIB or RS232)

BAUDRATE<value> Selects baud rate (300, 600, 1200, 2400, 4800, 9600)

PARITY <char> Message parity (NONE, EVEN, ODD, MARK, SPACE)

LANG <char> Selects language (SCPI or E9012)

NOUTPUTS <char> Select number of output phases on HP 6834B only (1 or 3)

value = a numeric value

char = a character string parameter

Use and to scroll through the command list.

Use and to scroll through the parameter list.

Shift

Error

SaveShift

Press to place the ac source into a previously stored state. You can recall up to 16

(0 through 15) previously stored states.

Press to display the system error codes stored in the SCPI error queue. This action

also clears the queue. If there is no error in the queue, 0 is displayed.

Press to store an existing ac source state in non-volatile memory. The parameters

saved are listed under *SAV in the ac source Programming Guide. You can save

up to 16 states (0 through 15).

35

Page 36

4 - Front Panel Operation

On/Off

Select

Function Keys

Refer to the examples later in this chapter for more details on the use of these keys.

Harmonic

Meter

Output

Input

Status

Protect

Trigger

Trigger

Control

FUNCTION

Current

Voltage

Phase

Freq

Shape

List

Pulse

Phase

Select

Output

on/off

Index

Index

Figure 4-3. Function Keys

Immediate Action Keys

Immediate action keys immediately execute their corresponding function when pressed. Other function

keys have commands underneath them that are accessed when the key is pressed.

Output

Phase

This key toggles the output of the ac source between the on and off states. It

immediately executes its function as soon as you press it. When off, the ac source

output is disabled and the Dis annunciator is on.

This key only applies to three-phase ac sources. It selects the phase to which

function commands will be sent, as well as the phase that will be monitored by

the Meter and Harmonic functions. At power-on, all phases are selected or

coupled, indicating that commands will be sent to all phases. The presently

selected phase is indicated by a phase annunciator. Pressing Phase Select

immediately selects a different phase. Phase selection is circular; you can return

to the starting position by continuously pressing Phase Select.

36

Annunciator On Phase Selected

φ1, φ2, φ3 All phases selected (phases coupled= ALL)

1

φ1 Phase #1 selected (phases coupled= NONE)

φ2 Phase #2 selected (phases coupled= NONE)

φ3 Phase #3 selected (phases coupled= NONE)

1

Does not apply to Meter or Harmonic functions.

When the Meter and Harmonic functions are active, Phase Select only rotates

through 1, 2, and 3. This is because the Meter and Harmonic functions cannot

display multiple phase readings simultaneously. Therefore, it is not possible to

select all phases with these functions.

TriggerShift

Sends an immediate trigger to the ac source

Page 37

Front Panel Operation - 4

Ç

È

Enter

qpÇ

È

Scrolling Keys

Scrolling keys let you move through the commands in the presently selected function menu.

• ‚

These scroll keys let you move through the choices in a command list.

Press to bring up the next command in the list. Press to go back

pq

to the previous command in the list. Function menus are circular; you can return

to the starting position by continuously pressing either key. The following

example shows the commands in the Input function menu:

pIndexShift

Shift qIndex

These shifted scroll keys apply only to the Harmonic and List functions.

Press these keys to step through integers 0 through 50 when specifying the

desired harmonic number, or 0 through 99 when specifying the desired list point.

Hold down these keys to rapidly access any harmonic or list point.

These Entry keys let you scroll through choices in a parameter list that apply to

a specific command. Parameter lists are circular; you can return to the starting

position by continuously pressing either key. If the command has a numeric

range, these keys increment or decrement the existing value.

Meter Display Keys

Metering keys control the metering functions of the ac source.

Meter

Input

Press this key to access the meter menu list.

Display Measurement

<reading>V <reading>Hz rms voltage and frequency (the default)

<reading>V <reading>A rms voltage and rms current

<reading>A <reading>Hz rms current and frequency (the default)

<reading>V <reading>W rms voltage and power

<reading> CREST F current crest factor

<reading>A PK REP peak current, repetitive

<reading>A PK NR peak current, nonrepetitive

1

<reading> VA apparent power

<reading> VAR reactive power

<reading>W TOTAL total power of all phases

<reading> PFACTOR power factor

<reading>A NEUTRAL neutral rms current

2

2

Press this key to specify the following metering functions.

Display Command Function

INP:COUP <char> Choose meter coupling (AC, DC or ACDC)

WINDOW <char> Select harmonic measurement window meter

(KBESSEL, RECT)

Notes:

1

Displays the highest peak current since it was last cleared.The value is cleared when

you scroll into this selection or press or

2

This selection only valid for HP 6834B

reading = the returned measurement

char = a character string parameter

and scroll through the command list.

and scroll through the parameter list.

Clear Entry

37

Page 38

4 - Front Panel Operation

Current

HarmonicShift

Press this key to access the harmonic menu list

Display Measurement

<reading>A I:MAG: <index> current harmonic magnitude

<reading>° I:PHASE: <index>

<reading>V V:MAG: <index> voltage harmonic magnitude

<reading>° V:PHASE: <index>

<reading> N:MAG: <index> neutral current harmonic magnitude

<reading>° N:PHASE: <index>

<reading>° CURR:THD

<reading>° VOLT:THD

current harmonic phase

voltage harmonic phase

neutral current harmonic phase

current total % harmonic distortion

voltage total % harmonic distortion

Output Control Keys

Output control keys control the output functions of the ac source.

Voltage

Press this key to access the voltage menu list.

Display Command Function

VOLT <value>

VOLT:T<value>

VOLT:M <char>

RANGE <char>

SLEW <value>

SLEW:T<value>

SLEW:M <char>

ALC <char> Select the voltage sense source (INT or EXT)

Set immediate rms output voltage (φ)

Set triggered rms output voltage (φ)

Select the voltage mode (φ) (FIXED, STEP, PULSE or LIST)

Select the voltage range (φ) (150 or 300)

Set immediate voltage slew rate in volts/second (φ)

Set triggered voltage slew rate in volts/second (φ)

Select the voltage slew mode (φ) (FIXED, STEP, PULSE or

LIST)

Shift

Freq

38

Press this key to access the current menu list.

Display Command Function

CURR:LEV <value> Set immediate rms output current limit

Press this key to access the frequency menu list.

Display Command Function

FREQ <value> Set immediate output frequency

FREQ:T<value> Set triggered output frequency

FREQ:M <char> Select the frequency mode (FIXED, STEP, PULSE or LIST)

SLEW <value> Set immediate frequency slew rate in volts/second

SLEW:T<value> Set triggered frequency slew rate in volts/second

SLEW:M <char> Select the frequency slew mode (FIXED, STEP, PULSE or

LIST)

Notes:

φ = phase selectable on HP 6834B

reading = the returned measurement

index = a numeric value that represents the harmonic number from 0 to 50

char = a character string parameter

Page 39

qpÇÈp

IndexqIndex

Shift

Phase

and scroll through the command list.

and scroll through the parameter list.

and specify the desired harmonic.

Press this key to access the phase menu list.

Display Command Function

PHASE <value>

PHASE:T <value>

PHASE:M <char>

Set immediate output phase (φ)

Set triggered output phase (φ)

Select the phase mode (φ) (FIXED, STEP, PULSE or LIST)

Front Panel Operation - 4

Shape

Pulse

Shift

Output

Press this key to access the shape menu list.

Display Command Function

SHAPE <char> Select the immediate output wave shape 1 (SINE,

SQUARE, or CSINE) CSIN = clipped sine wave

SHAPE:T <char> Select the triggered output wave shape (SINE, SQUARE, or

CSINE) CSIN = clipped sine wave

SHAPE:M <char> Select the shape mode (FIXED, STEP, PULSE or LIST)

CLIP <value> Set the clipping level of the CSIN wave shape. This

specifies the point where clipping starts as a percentage of

the peak amplitude or percentage of THD.

Press this key to access the pulse menu list.

Display Command Function

WIDTH <value> Set the pulse width

COUNT <value> Set the number of output pulses

DCYCLE <value> Set the pulse duty cycle as a percentage of the pulse period

PER <value> Set the pulse period

HOLD <char> Set the parameter that will be held constant as the other

parameters change (WIDTH or DCYCLE)

Press this key to access the output menu list.

Display Command Function

*RST Execute *RST command to place the ac source in the

factory-default state

TTLT:SOUR <char> Select Trigger Out source coupling (BOT, EOT or LIST)

BOT = beginning of trensient

EOT = end of transient

LIST = TTLT trigger (see Programming Guide)

TTLT:STATE <value> Set Trigger Out state (ON or OFF)

PON:STATE <char> Select power-on state command (RST or RCL0)

RI <char> Sets remote inhibit mode (LATCHING, LIVE, or OFF)

DFI <char> Sets discrete fault indicator state (ON or OFF)

DFI:SOUR <char> Select the DFI source (QUES, OPER, ESB, RQS, or OFF)

(see chapter 4 of Programming Guide)

39

Page 40

4 - Front Panel Operation

qpÇ

È

Protect

Enter

qpÇ

È

Notes:

1

User defined waveshapes will also appear in this list when created.

φ = phase selectable on HP 6834B

value = a numeric value

char = a character string parameter

and scroll through the command list.

and scroll through the parameter list.

Protection and Status Control Keys

The Protect and Status keys control the protection functions and status registers of the ac source. Refer to

chapter 4 of the Programming guide for more information on the status registers.

Press this key to access the protection menu list.

Display Command Function

PROT:CLEAR Clear the status registers of all activated protection signals.

The fault causing a signal must be corrected or removed

before the register can be cleared.

CURR:PROT <char> Set overcurrent protection function (ON or OFF).

VOLT:PROT <value> Set the overvoltage protection level

DELAY <value> Set the time delay for activating a protection fault after

programming the output

1

StatusShift

Press this key to access the status menu list. Note that in the following list, commands

ending in ? clear the registers when they are read. For this reason the registers are read

only after you press , not when you scroll to the command

Display Command Function

*CLS Executes the clear status (*CLS) command

STATUS:PRESET Execute the STATus:PRESet command

*ESR? <value> Return Event Status register value

*STB <value> Return Status Byte register value

OPER:EVEN? <value> Return STAT:OPER:EVENT? value

OPER:COND <value> Return STAT:OPER:COND? value

QUES:EVEN? <value> Return STAT:QUES:EVENT? value

QUES:COND <value> Return STAT:QUES:COND? value

Notes:

1

Programmed in peak volts. (Other voltage parameters are programmed in rms volts)

value = a numeric value

char = a character string parameter

and scroll through the command list.

and scroll through the parameter list.

40

Page 41

Front Panel Operation - 4

Control

qpÇ

È

p

IndexqIndex

Trigger and List Control Keys

The Trigger Control key controls output transient triggers. The List key controls the generation of output

lists. A list can contain up to 100 points, each of which can specify an output change (or transient). Refer

to chapter 4 of the Programming Guide for more information about programming triggers and lists.

Trigger

Press this key to access the trigger control menu list.

Display Command Function

INIT:IMMED Initiate the transient trigger sequence immediately.

INIT:CONT <char> Set continuous trigger initiation (ON or OFF).

TRIG:SOUR <char> Select transient trigger source (BUS, EXT, TTLT or

IMM).

DELAY <value> Set trigger delay in seconds.

ABORT Abort all trigger sequences.

SYNC:SOUR <char> Select trigger sync source (PHASE or IMM).

SYNC:PHASE <value> Set synchronous phase reference angle in degrees.

ListShift

Press this key to access the list commands

Display Command Function

COUNT <value> Specifies the number of times a list repeats.

DWEL:<index> <value> List of output dwell times.

FREQ:<index> <value> List of output frequencies.

FSLW:<index> <value> List of output frequency slew rates

PHASE:<index> <value>

SHAP:<index> <char> List of output waveform shapes.

STEP<char> Response of list to triggers (ONCE or AUTO).

TTLT:<index> <value> List of Trigger Out pulses (0=no pulse; 1=pulse).

VOLT:<index> <value>

VSLW:<index> <value>

List of output voltage phase angles (φ)

1

(SINE, SQUARE or CSIN) CSIN = clipped sine wave

List of ac output voltages (φ)

List of output voltage slew rates (φ)

Notes:

1

User-defined waveshapes will also appear in this list when created.

φ = phase selectable on HP 6834B

value = a numeric value

char = a character string parameter

index = a numeric value that represents a list point from 0 to 99

and scroll through the command list.

and scroll through the parameter list.

and scroll through the desired list points. EOL is displayed when the

end of the list is reached. When a value is edited, pressing automatically

advances to the next list point. Pressing truncates or clears the list at the

Clear Entry

Enter

presently displayed list point.

41

Page 42

4 - Front Panel Operation

Å

Entry Keys

Refer to the examples later in this chapter for more details on the use of these keys.

−

.

Calibration

7 8 9

4

E

0

ENTRY

5 6

-

.

321

Clear Entry

Enter

Figure 4-4. Entry Keys

äã

These keys let you scroll through choices in a parameter list that apply to a

specific command. Parameter lists are circular; you can return to the starting

position by continuously pressing either key. If the command has a numeric

range, these keys increment or decrement the existing value.

90

through are used for entering numeric values. is the decimal

.90

point. For example, to enter 33.6 press: 3 3 . 6 Enter.

Enter

Shift

Shift

Clear Entry

Shift

Calibration

The backspace key deletes the last digit entered from the keypad. This key lets

you correct one or more wrong digits before they are entered.