Page 1

Agilent 6100 Series

Quadrupole LC/MS

Systems

Concepts Guide

Agilent Technologies

Page 2

Notices

CAUTION

WARNING

© Agilent Technologies, Inc. 2011

No p art o f this manu al may be re produce d in

any form or by any means (including electronic storage and retrieval or translation

into a foreign language) without prior agreement and written consent from Agilent

Technologies, Inc. as governed by United

States and international copyright laws.

Manual Part Number

G1960-90079

Edition

Revision A, September 2011

Printed in USA

Agilent Technologies, Inc.

5301 Stevens Creek Blvd.

Santa Clara, CA 95051

Microsoft® is a U.S. registered trademark

of Microsoft Corporation.

Software Revision

This guide is valid for the B.04.02 SPI1 or

later revision of the Agilent

ChemStation software for the Agilent 6100

Series Quadrupole LC/MS systems, until

superseded.

If you have any comments about this guide,

please send an e-mail to

feedback_lcms@agilent.com.

Warranty

The material contained in this document is provided “as is,” and is subject to being changed, without notice,

in future editions. Further, to the maximum extent permitted by applicable

law, Agilent disclaims all warranties,

either express or implied, with regard

to this manual and any information

contained herein, including but not

limited to the implied warranties of

merchantability and fitness for a particular purpose. Agilent shall not be

liable for errors or for incidental or

consequential damages in connection with the furnishing, use, or performance of this document or of any

information contained herein. Should

Agilent and the user have a separate

written agreement with warranty

terms covering the material in this

document that conflict with these

terms, the warranty terms in the separate agreement shall control.

Technology Licenses

The hardware and/or software described in

this document are furnished under a license

and may be used or copied only in accordance with the terms of such license.

Restricted Rights Legend

U.S. Government Restricted Rights. Software and technical data rights granted to

the federal government include only those

rights customarily provided to end user customers. Agilent provides this customary

commercial license in Software and technical data pursuant to FAR 12.211 (Technical

Data) and 12.212 (Computer Software) and,

for the Department of Defense, DFARS

252.227-7015 (Technical Data - Commercial

Items) and DFARS 227.7202-3 (Rights in

Commercial Computer Software or Computer Software Documentation).

Safety Notices

A CAUTION notice denotes a hazard. It calls attention to an operating procedure, practice, or the like

that, if not correctly performed or

adhered to, could result in damage

to the product or loss of important

data. Do not proceed beyond a

CAUTION notice until the indicated

conditions are fully understood and

met.

A WARNING notice denotes a

hazard. It calls attention to an

operating procedure, practice, or

the like that, if not correctly performed or adhered to, could result

in personal injury or death. Do not

proceed beyond a WARNING

notice until the indicated conditions are fully understood and

met.

Agilent 6100 Series Quadrupole LC/MS System Concepts Guide

Page 3

In This Guide...

The Concepts Guide presents an overview of the Agilent

6100 Series Quadrupole LC/MS systems, to help you

understand how the hardware and software work.

If you have any comments about this guide, please send an

e-mail to feedback_lcms@agilent.com.

1Overview

Learn how the hardware works in the Agilent 6100 Series

Quadrupole LC/MS systems, and get a brief introduction to

ChemStation software.

2 Instrument Preparation

Learn the concepts you need to prepare the LC and column

for an analysis, and to tune the MS.

3 Data Acquisition

Learn about setting up methods and running samples.

4 Data Analysis

Learn the concepts you need for qualitative and quantitative

data analysis with ChemStation software.

5Reports

Learn about predefined results reports and about setting up

custom reports.

6 Verification of Performance

Learn the concepts for Operational Qualification/

Performance Verification (OQ/PV) and system verification

with ChemStation software.

7 Maintenance and Troubleshooting

Agilent 6100 Series Quadrupole LC/MS System Concepts Guide 3

Page 4

Learn about tools that are proved in ChemStation software

to help you maintain your system and diagnose and fix

problems.

4 Agilent 6100 Series Quadrupole LC/MS System Concepts Guide

Page 5

Contents

1 Overview of Hardware and Software 9

How the Agilent quadrupole LC/MS systems work 10

Overview 10

Details 11

Types of data you can acquire 15

Scan versus selected ion monitoring (SIM) 15

Generation of fragment ions: low versus high fragmentor 16

Positive versus negative ions 19

Multiple signal acquisition 19

Ion sources 22

Electrospray ionization (ESI) 22

Atmospheric pressure chemical ionization (APCI) 28

Atmospheric pressure photoionization (APPI) 30

Multimode ionization (MMI) 31

Introduction to ChemStation software 32

Overview 32

Reviewing data remotely 34

2 Instrument Preparation 35

Preparation of the LC system 36

Purpose 36

Summary of procedures 36

Setting parameters for LC modules 38

Column conditioning and equilibration 39

Monitoring the stability of flow and pressure 41

Preparation of the MS – tuning 42

Agilent 6100 Series Quadrupole LC/MS System Concepts Guide 5

Page 6

Contents

Overview 42

Ways to tune 44

When to tune – Check Tune 45

Autotune 47

Manual tuning 49

Tune reports 51

Gain calibration 53

3 Data Acquisition 57

Working with methods 58

Method and Run Control View 58

Loading, editing, saving and printing methods 60

More on editing methods 61

Running samples 64

Running a single sample 65

Running a sequence 66

Flow injection analysis 69

Monitoring analyses 73

Online signal plots 73

Quick method overview 74

Logbooks 74

Instrument shutdown 76

4 Data Analysis 77

The Data Analysis View 78

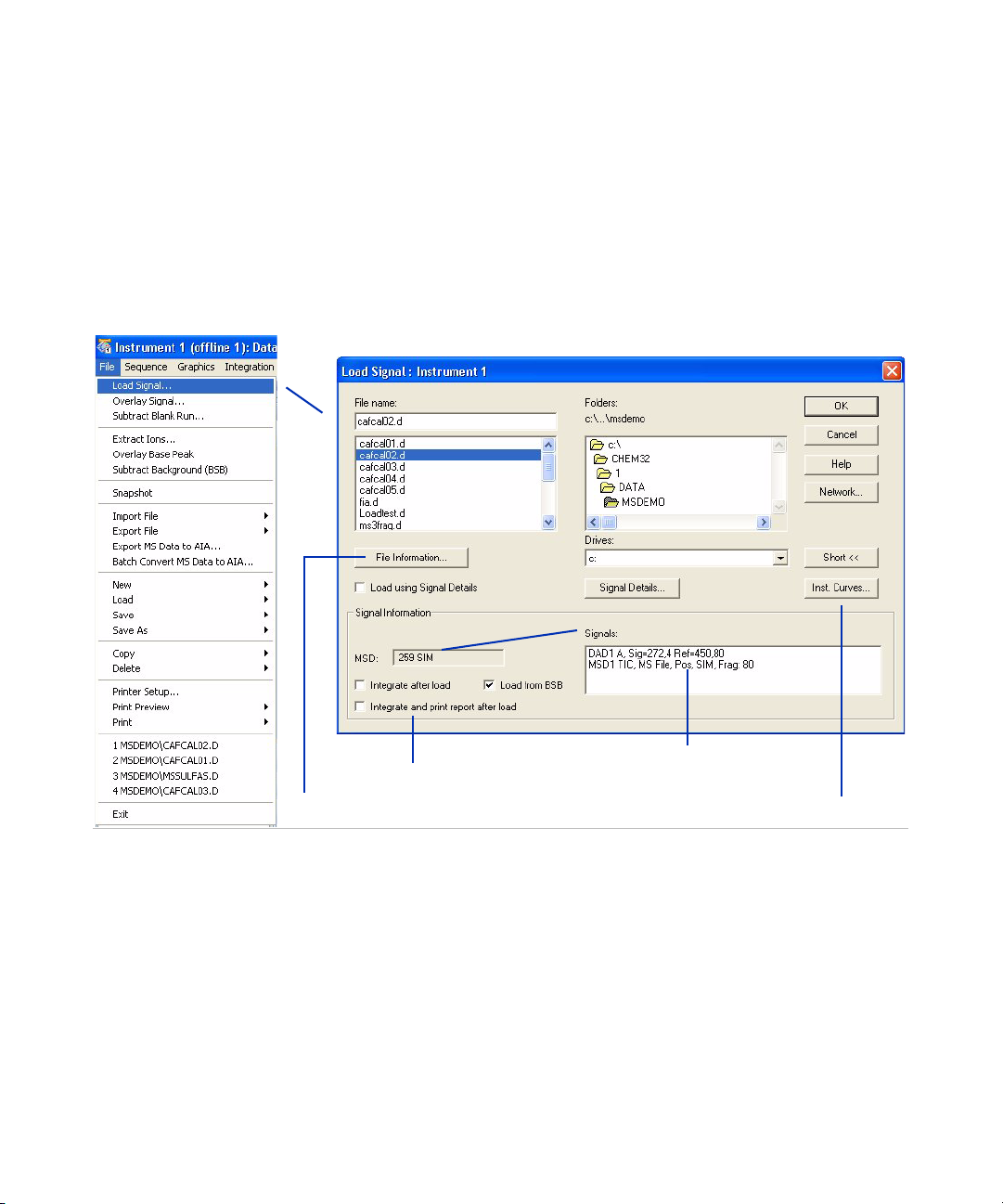

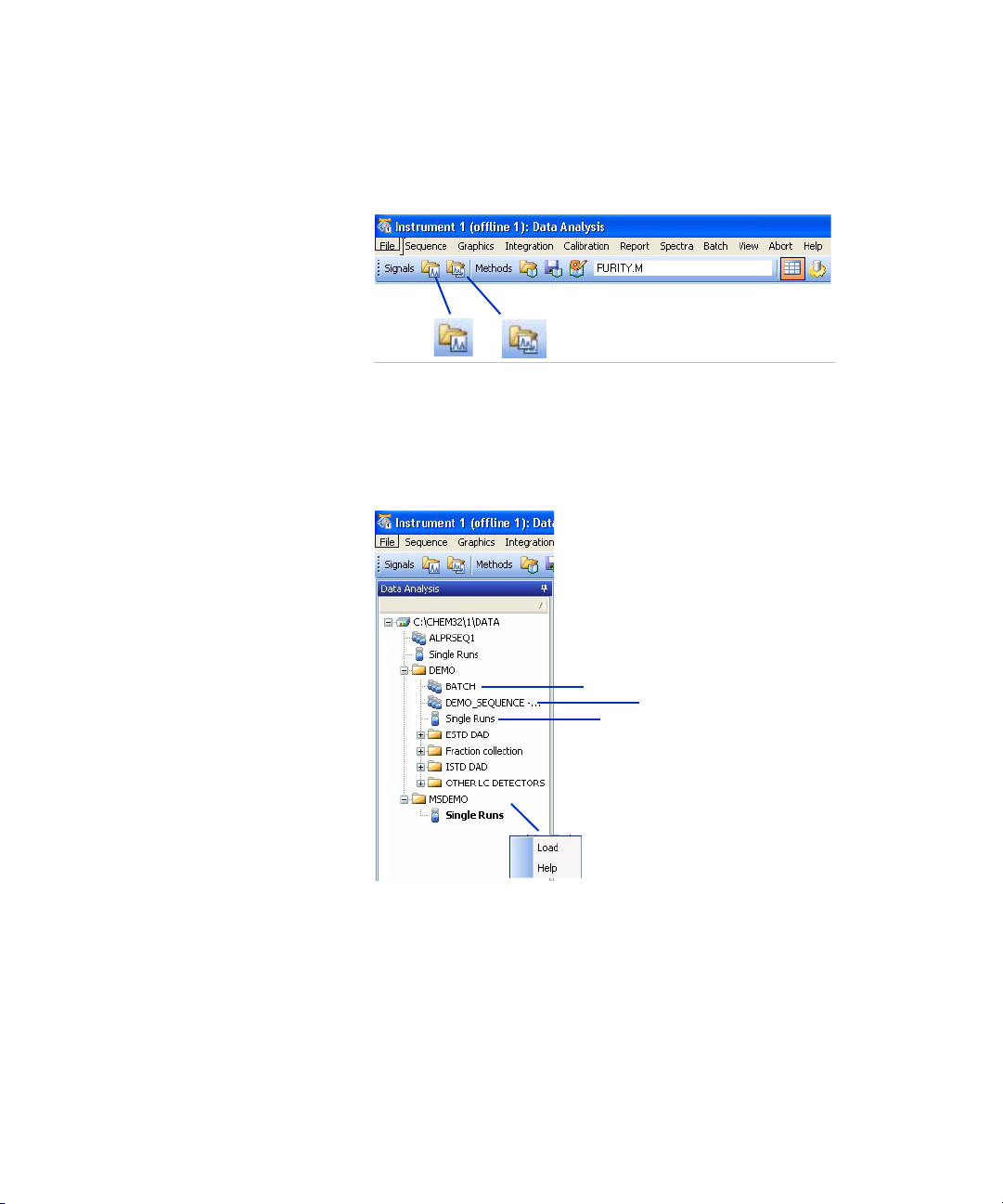

Loading and manipulating chromatograms 80

Loading signals 81

Removing signals from the chromatogram display 85

Changing how chromatograms are displayed 85

Working with spectra 87

Displaying spectra 88

6 Agilent 6100 Series Quadrupole LC/MS System Concepts Guide

Page 7

Peak purity 89

Performing quantification 90

Integrating peaks 90

Calibration 92

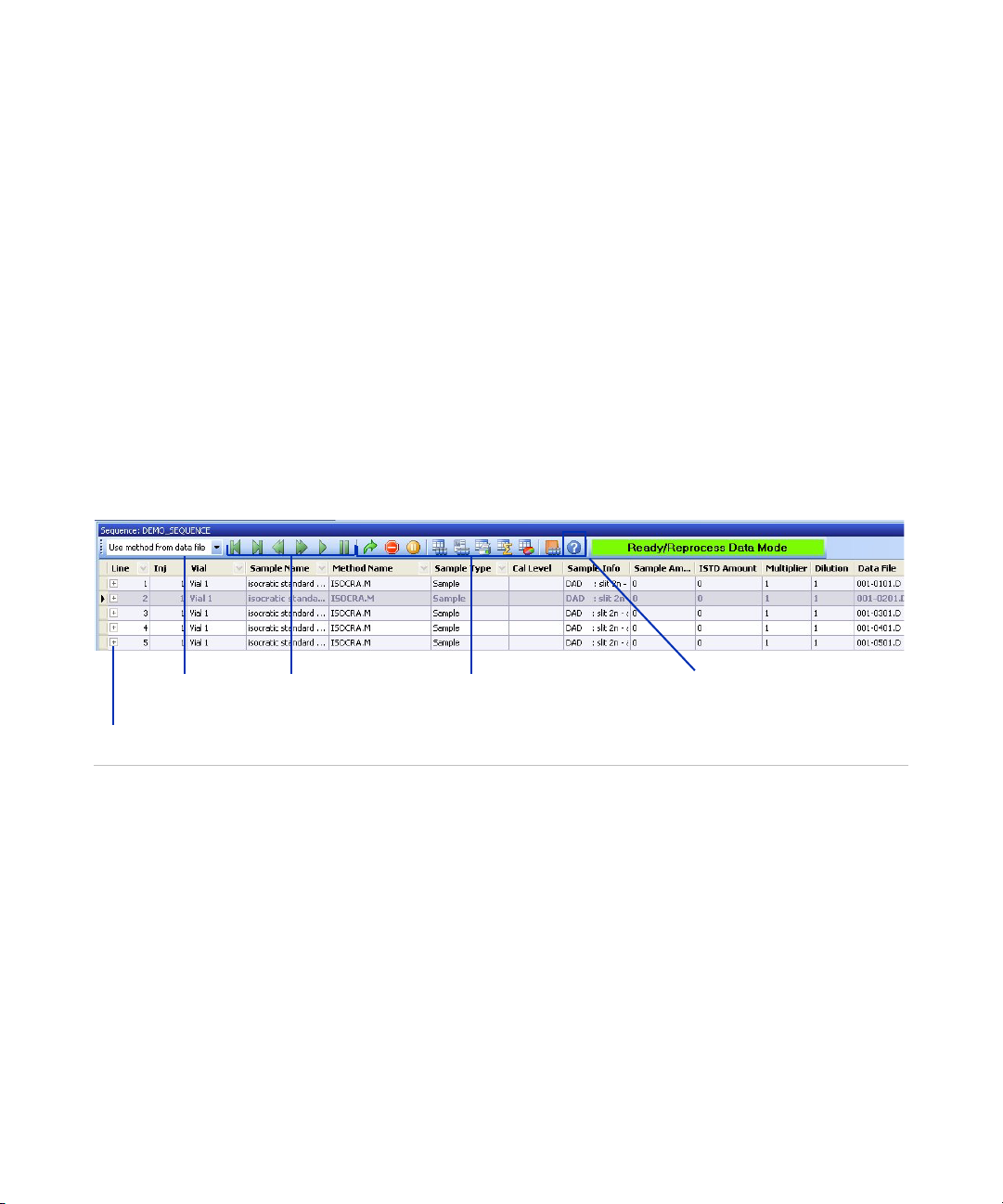

Data review and sequence reprocessing 94

The Navigation Table 94

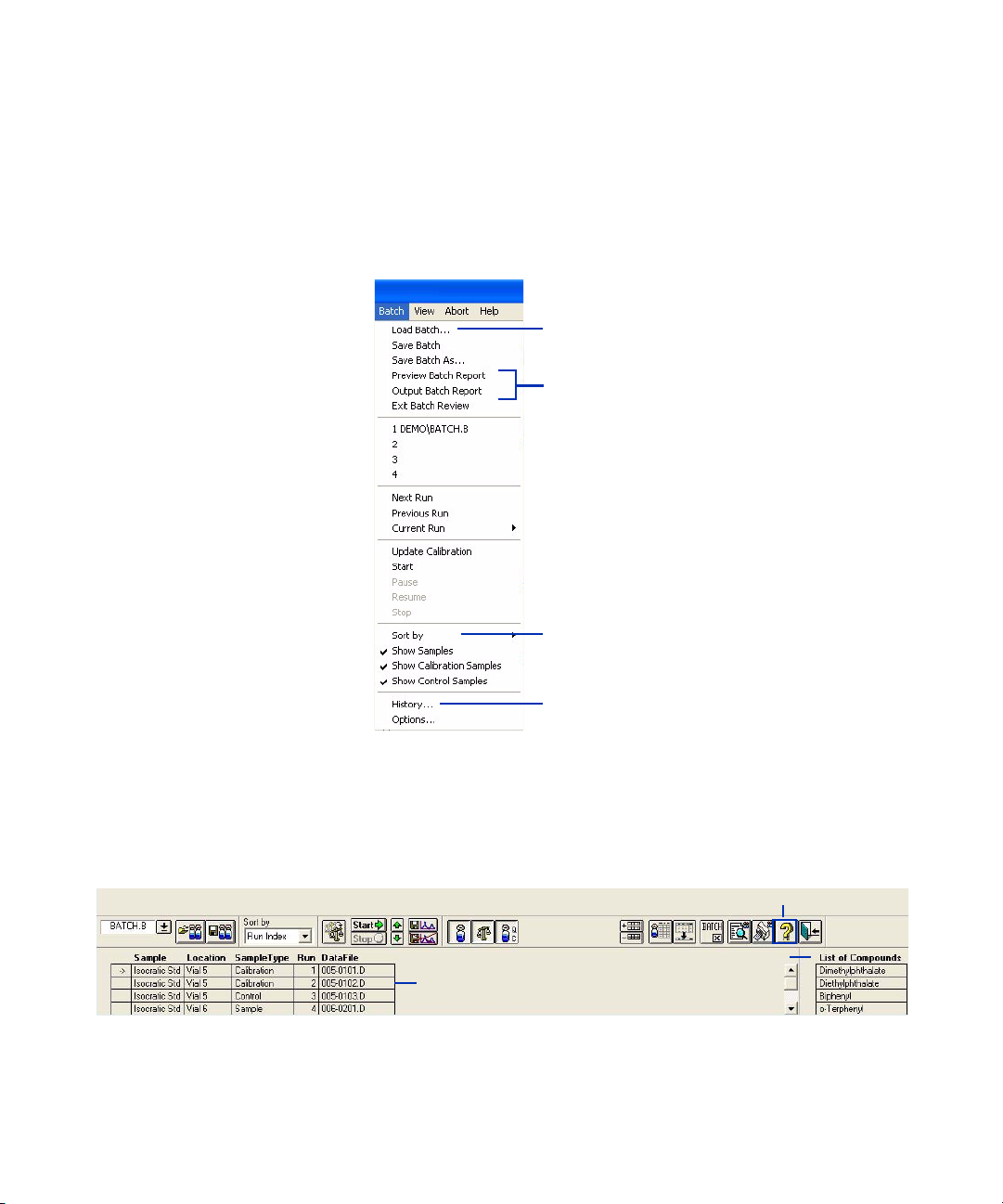

Batch review 94

5Reports97

Using predefined reports 98

Generating reports 98

Report styles 99

Defining custom reports 101

Summary of process 101

Example report templates 101

The Report Layout View 102

Contents

6 Verification of Performance 105

The Verification (OQ/PV) View 106

Instrument verification 107

Setting up and running instrument verification 108

Available OQ/PV tests 110

Verification logbook 111

System verification 112

Overview 112

Setting up and running system verification 113

7 Maintenance and Troubleshooting 115

The Diagnosis View 116

Overview 116

Instrument panel 117

Agilent 6100 Series Quadrupole LC/MS System Concepts Guide 7

Page 8

Contents

Logbooks 119

Maintenance 120

Early maintenance feedback 120

Maintenance logbook 121

Maintenance procedures 122

Venting and pumping down the MS 122

Diagnosing and fixing problems 124

Symptoms and causes 124

Diagnostic tests for the MS 125

Fixing problems 126

8 Agilent 6100 Series Quadrupole LC/MS System Concepts Guide

Page 9

Agilent 6100 Series Quadrupole LC/MS Systems

Concepts Guide

1

Overview of Hardware and Software

How the Agilent quadrupole LC/MS systems work 10

Overview 10

Details 11

Types of data you can acquire 15

Scan versus selected ion monitoring (SIM) 15

Generation of fragment ions: low versus high fragmentor 16

Positive versus negative ions 19

Multiple signal acquisition 19

Ion sources 22

Electrospray ionization (ESI) 22

Atmospheric pressure chemical ionization (APCI) 28

Atmospheric pressure photoionization (APPI) 30

Multimode ionization (MMI) 31

Introduction to ChemStation software 32

Overview 32

Reviewing data remotely 34

This chapter provides an overview of the hardware and

software that comprises the Agilent 6100 Series Quadrupole

LC/MS systems. The family consists of three models: 6120B,

6130B, and 6150B.

Agilent Technologies

9

Page 10

1 Overview of Hardware and Software

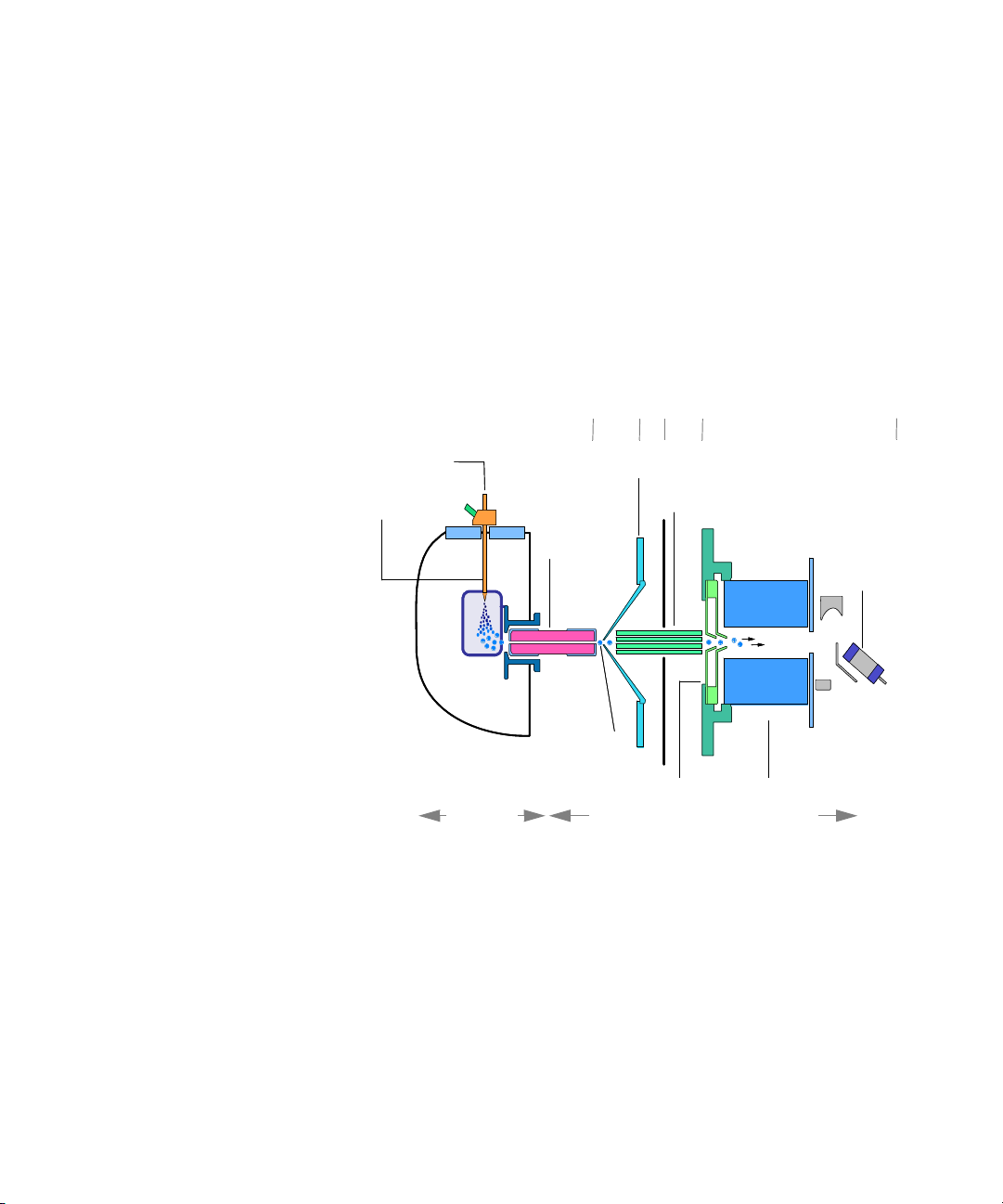

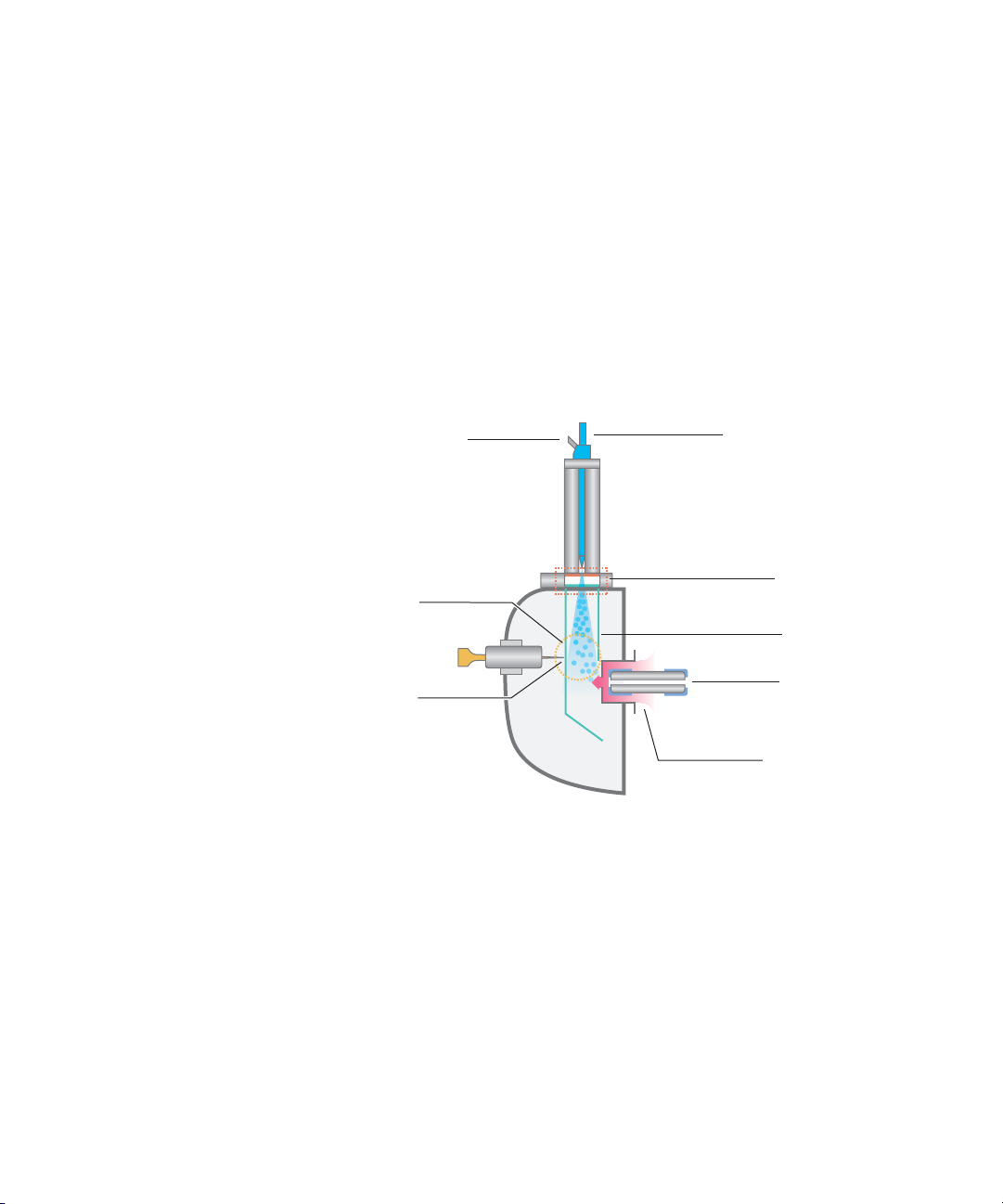

capillary

nebulizer

HPLC inlet

ion

source

rough

pump

split-flow

turbo pump

detector

quadrupole

mass filter

ion optics

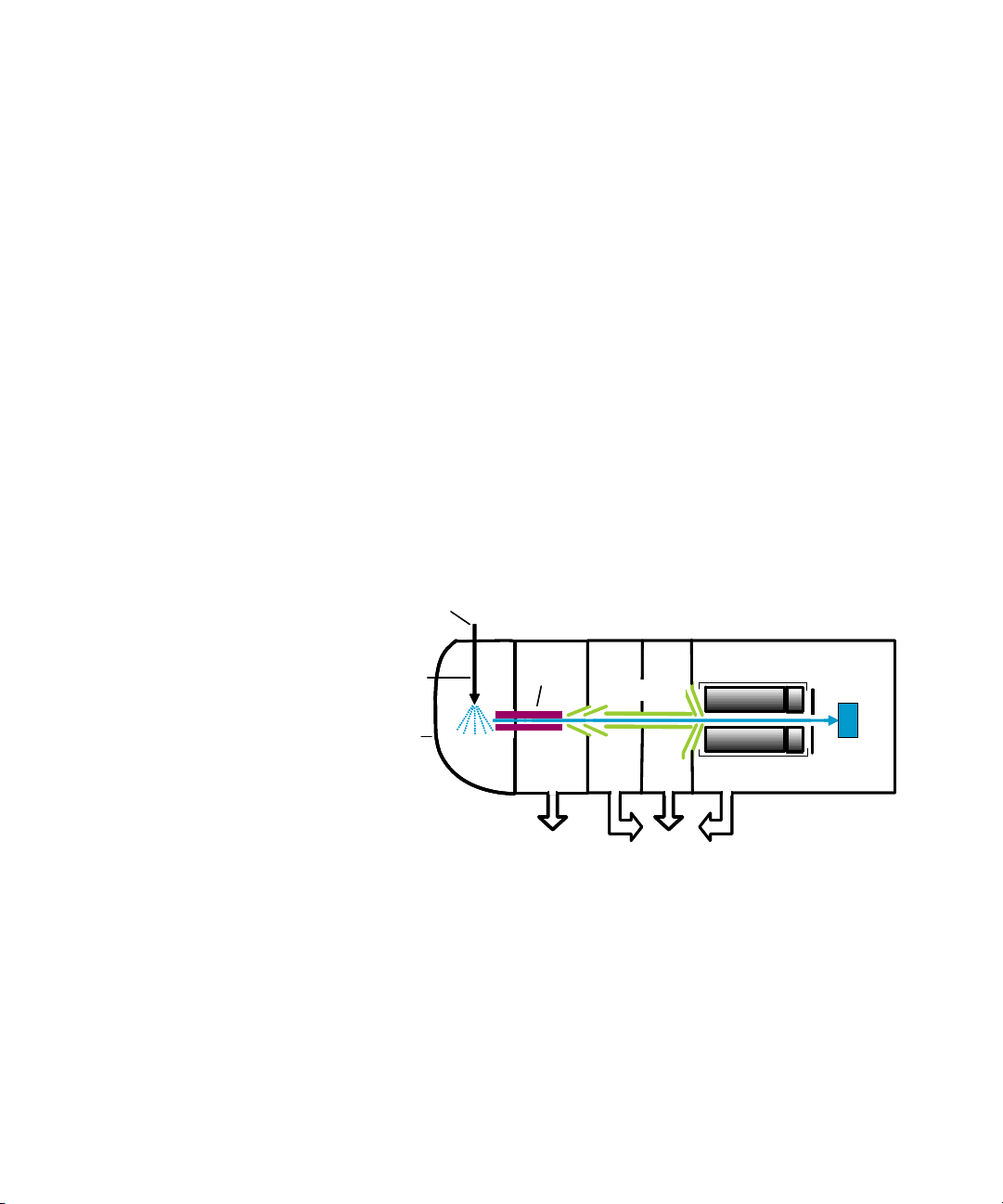

How the Agilent quadrupole LC/MS systems work

How the Agilent quadrupole LC/MS systems work

Overview

Mass spectrometry (MS) is based on the analysis of ions

moving through a vacuum. The result is mass spectra, which

provide valuable information about the molecular weight,

structure, identity, quantity, and purity of a sample. MS adds

specificity to both qualitative and quantitative analyses.

A quadrupole mass analyzer is

sometimes called a quadrupole

mass filter or a quadrupole.

API – atmospheric pressure

ionization

Figure 1 shows a diagram of the Agilent 6100 Series Quadrupole

LC/MS systems. The ionization of a sample occurs at

atmospheric pressure in the ion source that is shown on the left.

The Agilent 6100 Series Quadrupole LC/MS systems are

compatible with a number of Agilent atmospheric pressure

ionization (API) sources.

Figure 1 Block diagram for an Agilent quadrupole LC/MS system

A common atmospheric sampling interface introduces ions

from these ionization sources into the vacuum system of the

mass spectrometer. Various ion-optic elements focus and

guide the ions through a series of vacuum stages until they

reach the quadrupole mass analyzer, which separates the

ions. The ions then travel to the detector, where they are

recorded as signals.

10 Agilent 6100 Series Quadrupole LC/MS System Concepts Guide

Page 11

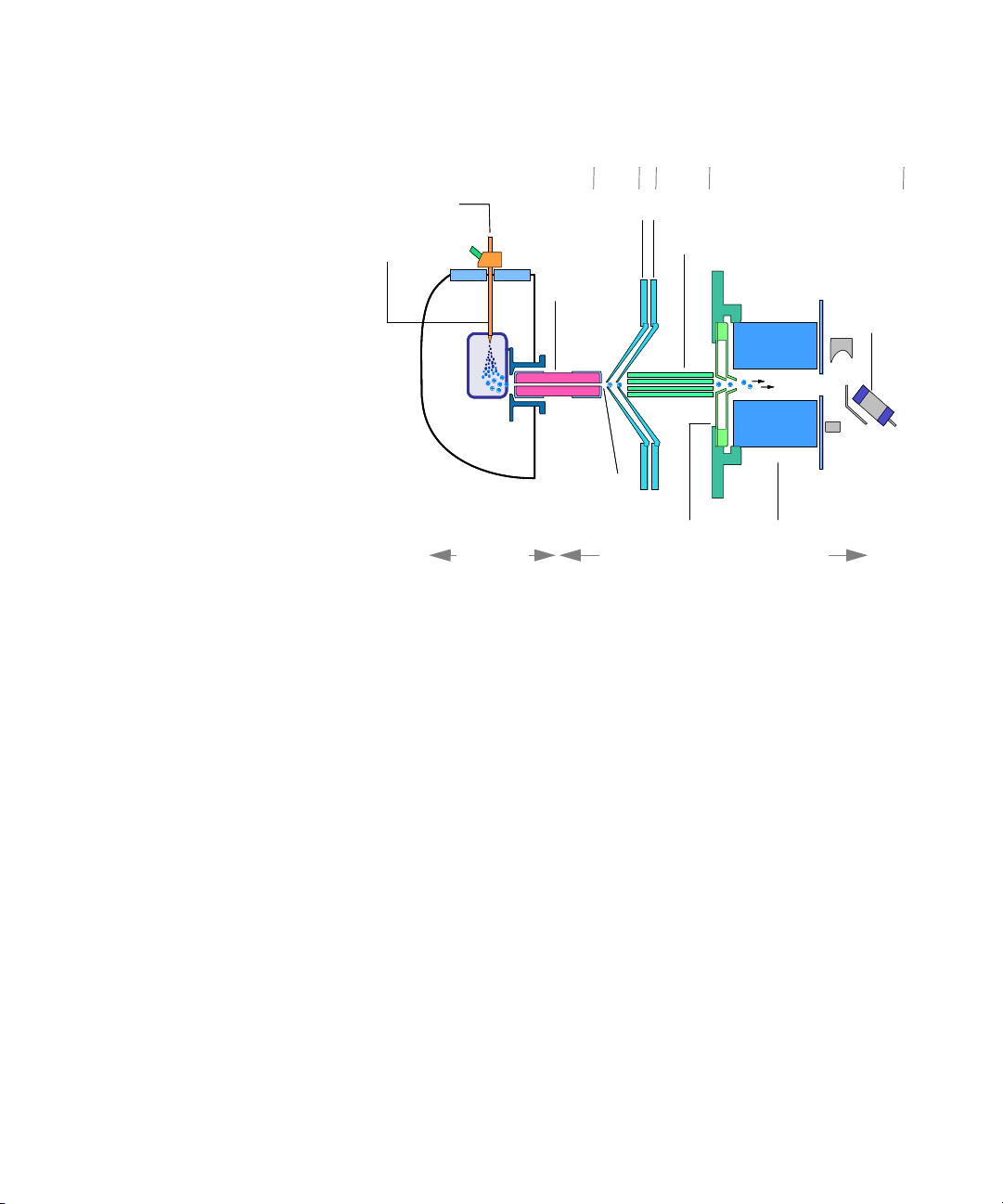

Details

4321Vacuum stage:

Ion source Ion transport and focusing region

quadrupole

capillary

nebulizer

HPLC inlet

fragmentation

zone (CID)

detector

skimmer

octopole

lenses

3 torr

5X10

-6

torr

Overview of Hardware and Software 1

Details

Figure 2 and Figure 3 show more detailed schematics of the ion

paths in the Agilent 6100 Series Quadrupole LC/MS systems.

After the API source forms ions, the ion-optic elements in the

ion transport and focusing region of the system direct the ions

toward the quadrupole and the detector. During transit, the

ions move from atmospheric pressure (760 torr) at the source to

a vacuum in the 10

-6

torr range at the quadrupole and detector.

Agilent 6100 Series Quadrupole LC/MS System Concepts Guide 11

Figure 2 Ion path for Agilent 6130 and 6150 Quadrupole LC/MS sys-

tems

Page 12

1 Overview of Hardware and Software

4321

Vacuum stage:

Ion source Ion transport and focusing region

quadrupole

capillary

nebulizer

HPLC inlet

fragmentation

zone (CID)

detector

skimmers

octopole

lenses

2 torr

6X10

-6

torr

Details

Figure 3 Ion path for Agilent 6120 Quadrupole LC/MS system

The ion transport and focusing region of the Agilent 6100 Series

Quadrupole LC/MS systems is enclosed in a vacuum manifold.

The function of the vacuum system is to evacuate regions of ion

focusing and transport and keep the quadrupole at low

pressure.

Because the nebulizer is at a right angle to the inlet capillary,

most of the solvent is vented from the spray chamber and never

reaches the capillary. Only ions, drying gas, and a small amount

By autotuning the instrument, you

automatically set most of the

voltages for the elements in the ion

path. See “Preparation of the MS –

tuning” on page 42.

of solvent are transmitted through the capillary.

The following discussion of the ion optics is organized

according to the stages of the ion path and the vacuum

stages of the mass spectrometer.

Ion transport and fragmentation (first vacuum stage)

Ions produced in the API source are electrostatically drawn

through a drying gas and then through a heated sampling

capillary into the first stage of the vacuum system. Near the exit

of the capillary is a metal skimmer with a small hole. Heavier

12 Agilent 6100 Series Quadrupole LC/MS System Concepts Guide

Page 13

CID – collision-induced

dissociation

Overview of Hardware and Software 1

Details

ions with greater momentum pass through the skimmer

aperture. Most of the lighter drying gas (nitrogen) molecules are

deflected by the skimmer and pumped away by a rough pump.

The ions that pass through the skimmer move into the second

stage of the vacuum system.

The atmospheric pressure ionization techniques are all

relatively “soft” techniques. They generate primarily:

+

• Molecular ions M

• Protonated molecules [M + H]

• Simple adduct ions [M + Na]

or M

-

+

+

• Ions representing simple losses, such as the loss of a

water molecule [M + H - H

+

O]

2

These types of ions give molecular weight information, but

you often need complementary structural information. To

gain structural information, you can fragment the analyte

ions in the first vacuum stage. To do that, you give them

extra energy and collide them with neutral molecules in a

process known as collision-induced dissociation (CID). A

voltage is applied at the end of the atmospheric sampling

capillary to add energy to the collisions and create more

fragmentation. For more information, see “Generation of

fragment ions: low versus high fragmentor” on page 16.

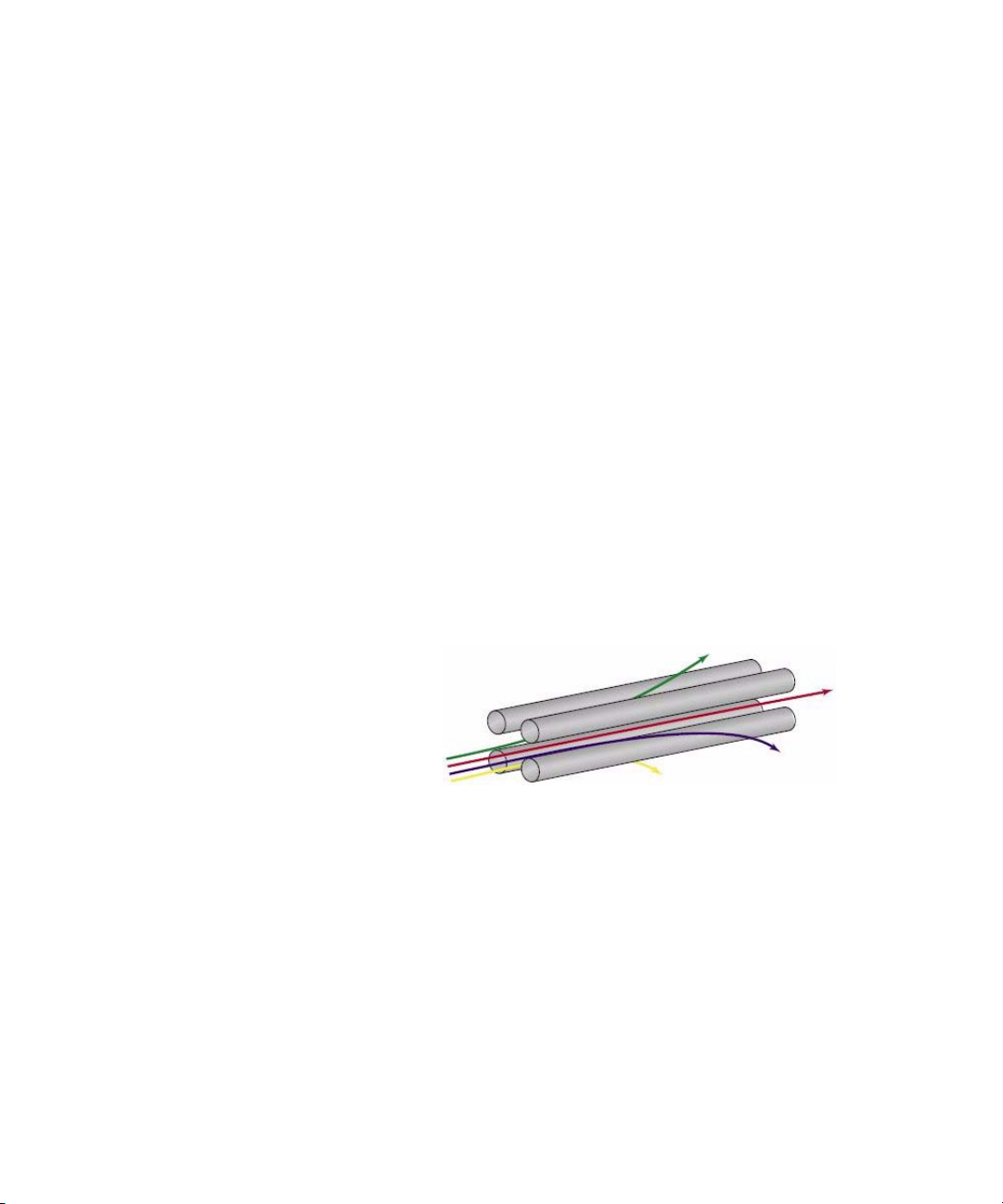

Ion transport (second and third vacuum stages)

An octopole ion guide is a set of

small parallel metal rods with a

common open axis through which

the ions can pass.

Agilent 6100 Series Quadrupole LC/MS System Concepts Guide 13

Agilent 6130 and 6150 Quadrupole LC/MS systems In the second

vacuum stage, the ions are immediately focused by an octopole

ion guide that traverses two vacuum stages. The ions pass

through the octopole ion guide because of the momentum they

received from being drawn from atmospheric pressure through

the sampling capillary. Radio-frequency voltage applied to the

octopole rods repels ions above a particular mass range to the

open center of the rod set. The ions exit this ion guide and then

pass through two focusing lenses into the fourth stage of the

vacuum system.

Page 14

1 Overview of Hardware and Software

From ion

source

To d e t ec t or

Details

Agilent 6120 Quadrupole LC/MS system In the second vacuum

stage, the ions are transported between skimmer 1 and

skimmer 2. They then enter the third vacuum stage, where

they pass through the octopole ion guide. The ions exit this

ion guide and then pass through two focusing lenses into the

fourth stage of the vacuum system.

Ion separation and detection (fourth vacuum stage)

In the fourth vacuum stage, the quadrupole mass analyzer

separates the ions by mass-to-charge ratio. An electron

multiplier then detects the ions.

m/z – mass/charge ratio The quadrupole mass analyzer (Figure 4) consists of four

parallel rods to which specific direct-current (DC) and

radio-frequency (RF) voltages are applied. The analyte ions

are directed down the center of the rods. Voltages applied to

the rods generate electromagnetic fields. These fields

determine which mass-to-charge ratio of ions can pass

through the filter at a given time. The ions that pass through

are focused on the detector.

Figure 4 Quadrupole mass analyzer

14 Agilent 6100 Series Quadrupole LC/MS System Concepts Guide

Page 15

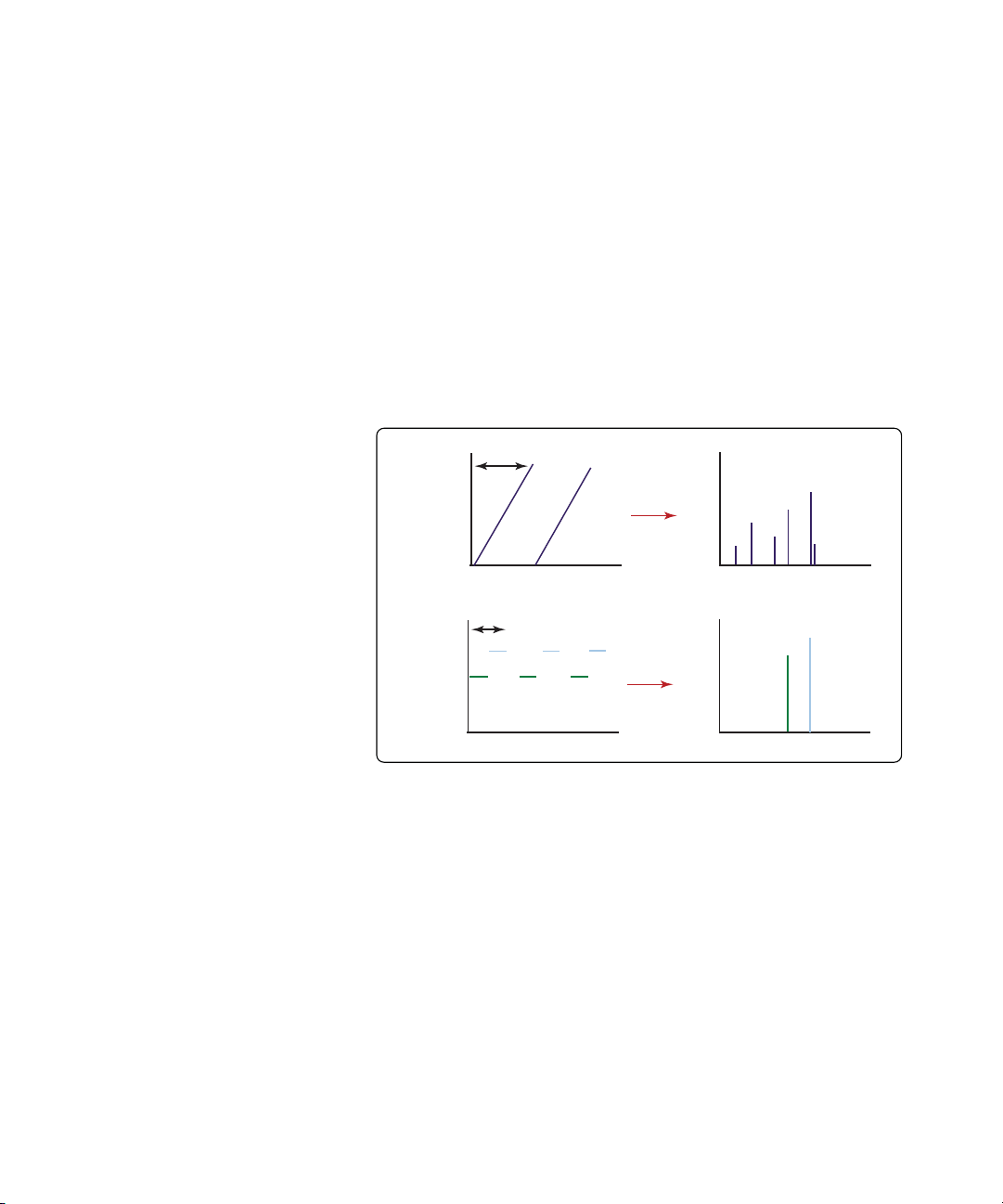

Types of data you can acquire

m/z

m/z

m/z

m/z

1 scan

1 scan

SIM

scan

discrete masses

mass range

abundance

abundance

time

time

Scan versus selected ion monitoring (SIM)

Overview of Hardware and Software 1

Types of data you can acquire

You set up a scan or SIM analysis

in the Method and Run Control

view, described in Chapter 3.

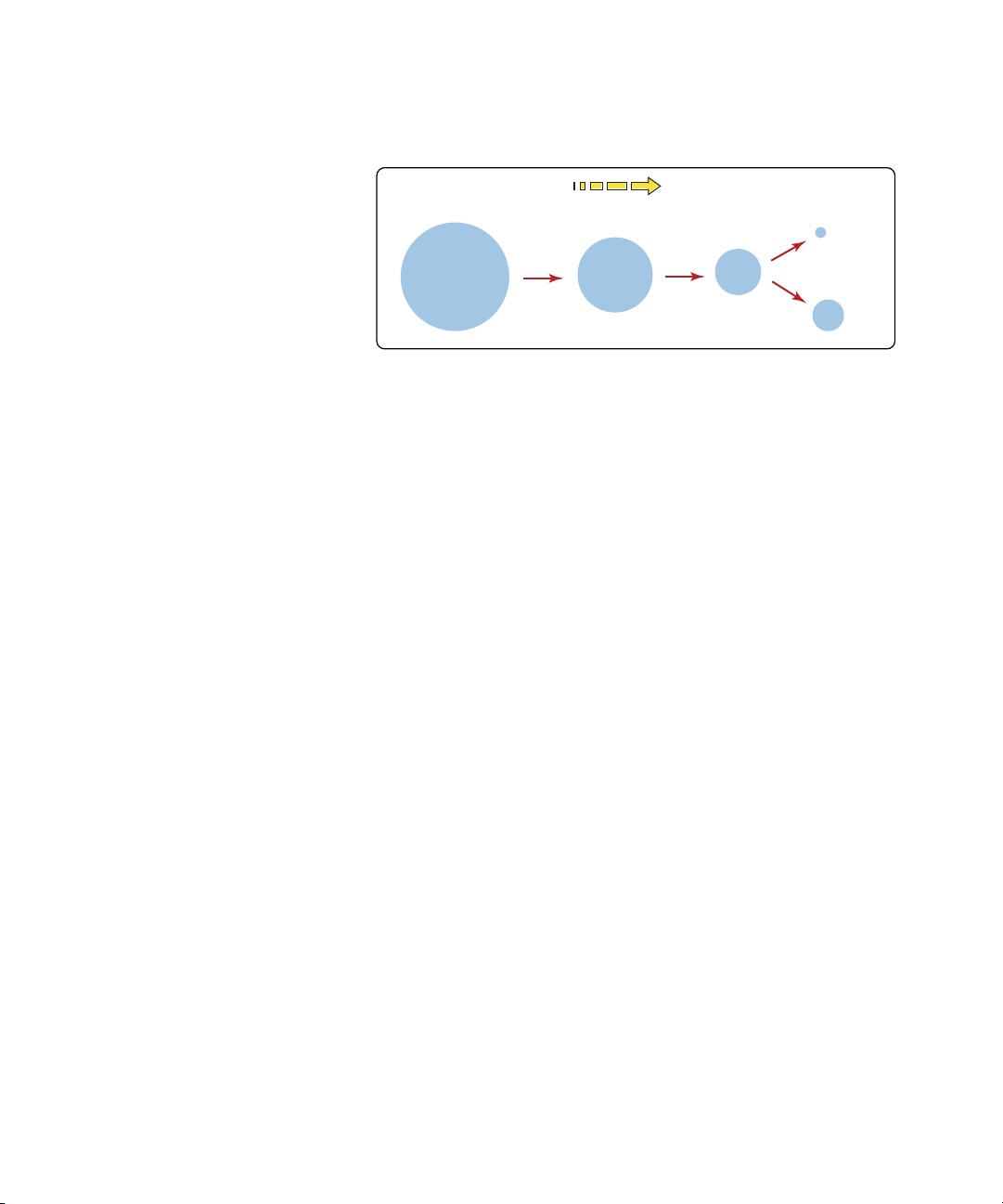

As shown in Figure 5, quadrupole mass analyzers can operate

in two modes. To get the most from your analysis, it is

important to pick the appropriate mode. The discussion below

will help you choose.

Figure 5 A quadrupole mass analyzer can operate in either scan mode

or selected ion monitoring (SIM) mode

Scan mode

Agilent 6100 Series Quadrupole LC/MS System Concepts Guide 15

In scan mode, a range of m/z values are analyzed, for

example, m/z 200 to 1000. The quadrupole sequentially

filters one mass after another, with an entire scan typically

taking about a second. (The exact time depends on mass

range and scan speed.) The MS firmware steps the

quadrupole through increasing DC and RF voltages, which

sequentially filters the corresponding m/z values across a

mass spectrum.

Page 16

1 Overview of Hardware and Software

Generation of fragment ions: low versus high fragmentor

A full scan analysis is useful because it shows all of the ions in a

given mass range that are present in the ion source. Because it

provides a complete picture of all the ionized compounds that

occur above the detection limit in the chosen mass range, a full

scan analysis is often used for sample characterization,

structural elucidation, and impurity analysis. It is also the

starting point for development of methods for SIM data

acquisition (discussed next).

Selected ion monitoring (SIM) mode

To obtain the best sensitivity, the quadrupole is operated in

SIM mode. In SIM mode, the quadrupole analyzes the signals

of only a few specific m/z values. The required RF/DC

voltages are set to filter one mass at a time. Rather than

stepping through all the m/z values in a given mass range,

the quadrupole steps only among the values that the analyst

chooses. Because the quadrupole spends more time sampling

each of these chosen m/z values, the system can detect lower

levels of sample.

SIM mode is significantly more sensitive than scan mode but

provides information about fewer ions. Scan mode is

typically used for qualitative analyses or for quantitation

when analyte masses are not known in advance. SIM mode

is used for quantitation and monitoring of target compounds.

Generation of fragment ions: low versus high fragmentor

When you set up a method for data

acquisition, you can control the

amount of fragmentation with the

fragmentor setting. You set up a

method in the Method and Run

Control view, described in

Chapter 3.

16 Agilent 6100 Series Quadrupole LC/MS System Concepts Guide

Fragment ions, also known as product ions, are formed by

breaking apart precursor ions. On the Agilent 6100 Series

Quadrupole LC/MS systems, the fragmentation region is

between the capillary exit and the skimmer, where the gas

pressure is about 2 to 3 torr. Depending on the voltage in this

region, precursor ions may pass through unchanged or they may

be fragmented.

Page 17

Overview of Hardware and Software 1

m/z

100

200

300

0

50000

100000

150000

200000

250000

300000

350000

279.1

301.0

280.0

281.0

[M + Na]

+

[M + H]

+

S

NH

H

2

N

O

O

N

N

CH

3

CH

3

Generation of fragment ions: low versus high fragmentor

When a lower voltage is applied across this region, the ions

pass through unchanged. Even if these ions collide with the

gas molecules in this region, they usually do not have

enough energy to fragment. (See Figure 6.)

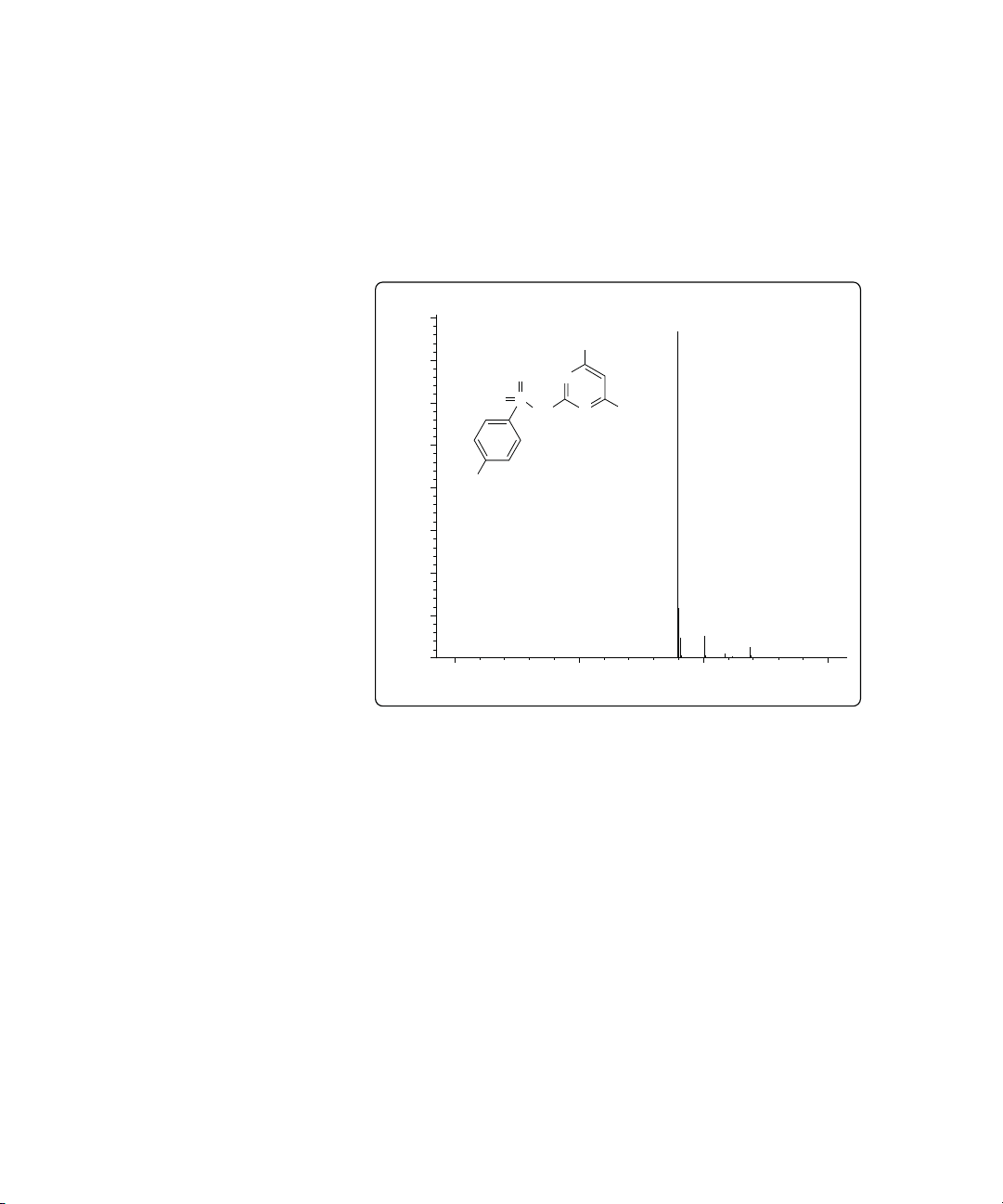

Figure 6 Mass spectrum of sulfamethazine – low fragmentor

Agilent 6100 Series Quadrupole LC/MS System Concepts Guide 17

Page 18

m/z

100

200

300

0

20000

40000

60000

[M + H]

+

[M + Na]

+

80000

124.1

186.0

279.1

156.1

108.2

301.0

323.0

213.2

107.1

280.1

125.1

187.0

157.1

NH

H

2

N

O

O

N

N

CH

3

CH

3

S

m/z

156

m/z

186

m/z

124

m/z

213

m/z

108

1 Overview of Hardware and Software

Generation of fragment ions: low versus high fragmentor

Figure 7 Mass spectrum of sulfamethazine – high fragmentor

If the voltage is increased, the ions have more translational

energy. Then, if the ions collide with gas molecules, the

collisions convert the translational energy into molecular

vibrations that can cause the ions to fragment. This is called

collision-induced dissociation (CID). Figure 7 shows an

example. Even though this fragmentation does not occur where

the ions are formed at atmospheric pressure, it is a tradition to

call this type of fragmentation “in-source CID.” The ions from

molecular fragments are used for structural determination or

confirmation of the presence of a particular chemical species.

FIA – flow injection analysis The ideal fragmentation voltage depends on the structure of

It is possible to produce both molecular ions and fragment

ions within the same spectrum by using an intermediate

fragmentation voltage.

the compound and the needs of the analysis. For target

compound analysis, it is good practice to determine in

advance the compound’s response to fragmentor setting. The

fastest way to accomplish this is with a flow injection analysis

18 Agilent 6100 Series Quadrupole LC/MS System Concepts Guide

(FIA) series. An FIA series allows you to inject the compound

multiple times within the same run, and to vary the fragmentor

Page 19

setting in different time windows. From the resulting data, you

can judge the best fragmentor setting. For more information on

FIA, see “Flow injection analysis” on page 69.

Positive versus negative ions

Overview of Hardware and Software 1

Positive versus negative ions

You set the ion polarity when you

set up a method in the Method and

Run Control view, described in

Chapter 3.

Multiple signal acquisition

You establish the conditions for

multiple signal acquisition in the

Method and Run Control view,

described in Chapter 3.

Atmospheric pressure ionization techniques can produce

both positive and negative ions. For any given analysis, the

predominant ion type depends on the chemical structure of

the analyte and (particularly for electrospray ionization) the

pH of the solution. While either or both ion types may be

present in the ion source, the polarity of the ion optics in

the ion transport and focusing region determines which ion

type is detected.

Analyses of positive and negative ions require different

settings for the ion optics. The software-controlled autotune

process optimizes the settings for both positive and negative

ions, and stores them in a single tune file. During data

acquisition, the software accesses the tune file for the

appropriate settings.

The Agilent 6120, 6130 and 6150 LC/MS models allow you to

acquire multiple types of data during a single analysis.

Within a single analytical run, you can choose alternating

positive and negative ionization; alternating high and low

fragmentor settings; and alternating scan and SIM modes.

Because optimum MS conditions vary from compound to

compound, this multisignal capability enables you to analyze

more compounds, with greater sensitivity, within a single

run.

Agilent 6100 Series Quadrupole LC/MS System Concepts Guide 19

Page 20

1 Overview of Hardware and Software

Multiple signal acquisition

Polarity switching

The Agilent 6120, 6130 and 6150 LC/MS models allow you to

switch from scan to scan between analysis of positive ions

and analysis of negative ions. To switch polarities very quickly,

these models incorporate fast-switching power supplies for the

API source, the lens system, the quadrupole, and the detector.

The ability to switch polarities on the chromatographic time

scale is very useful for analysis of complete unknowns because

it obviates the need to run the sample twice to detect both types

of ions.

Alternating high/low fragmentor

With the Agilent 6120, 6130 and 6150 LC/MS models, you

can also alternate from scan to scan between high and low

fragmentation voltages. This capability allows you to acquire

scans at low fragmentor settings for molecular weight

information, and high fragmentor settings for structural

information.

Alternating SIM/scan

Many analyses require use of SIM mode to monitor and/or

quantitate target compounds at very low levels. Sometimes it is

also desirable to characterize the other sample components

with a scan analysis. The Agilent 6120, 6130 and 6150 LC/MS

models allow you to alternate between SIM and scan modes, so

you can accomplish both goals in a single analysis.

Putting it all together

The 6120, 6130 and 6150 LC/MS models can cycle through

four different user-selected acquisition modes on a

scan-by-scan basis within a single run. For example, you can

set up a single run to do the following:

• Positive ion scan with low fragmentor voltage

• Positive ion scan with high fragmentor voltage

• Negative ion scan with low fragmentor voltage

• Negative ion scan with high fragmentor voltage

20 Agilent 6100 Series Quadrupole LC/MS System Concepts Guide

Page 21

Overview of Hardware and Software 1

Multiple signal acquisition

Such an analysis is ideal for a mixture of compounds where

some respond better in positive mode and some respond

better in negative mode, and where you need both molecular

ions and fragment ions.

The time required for one cycle varies depending on the

number of modes chosen, the scan range, and the interscan

delay required for the switching. For separations with narrow

chromatographic peaks, it is important to ensure that total

cycle time is short enough that the instrument makes sufficient

measurements across the peak.

Agilent 6100 Series Quadrupole LC/MS System Concepts Guide 21

Page 22

1 Overview of Hardware and Software

NOTE

Ion sources

Ion sources

The Agilent 6100 Series Quadrupole LC/MS systems operate

with the following interchangeable atmospheric pressure

ionization (API) sources:

• ESI (electrospray ionization)

• ESI with Agilent Jet Stream technology

• APCI (atmospheric pressure chemical ionization)

• APPI (atmospheric pressure photoionization)

• MMI (multimode ionization)

The sources that are used on the 6100 Series LC/MS systems are the

B-type sources. The 6100 Series LC/MS systems are not compatible with

the A-type sources that were used on previous Agilent LC/MS models.

Electrospray ionization (ESI)

You control the spray chamber

parameters (nebulizer pressure,

drying gas flow and temperature,

and capillary voltage) when you set

up a method in the Method and

Run Control view, described in

Chapter 3.

22 Agilent 6100 Series Quadrupole LC/MS System Concepts Guide

Electrospray ionization relies in part on chemistry to

generate analyte ions in solution before the analyte reaches

the mass spectrometer. As shown in Figure 8, the LC eluent is

sprayed (nebulized) into a spray chamber at atmospheric

pressure in the presence of a strong electrostatic field and

heated drying gas. The electrostatic field occurs between the

nebulizer, which is at ground in the Agilent design, and the

capillary, which is at high voltage.

The spray occurs at right angles to the capillary. This

patented Agilent design reduces background noise from

droplets, increases sensitivity, and keeps the capillary

cleaner for a longer period of time.

Page 23

Overview of Hardware and Software 1

heated drying gas

capillary

nebulizer

HPLC inlet

solvent

spray

Electrospray ionization (ESI)

Figure 8 Electrospray ion source

Electrospray ionization (ESI) consists of four steps:

1 Formation of ions

2 Nebulization

3 Desolvation

4 Ion evaporation

Formation of ions

Ion formation in API-electrospray occurs through more than

one mechanism. If the chemistry of analyte, solvents, and

buffers is correct, ions are generated in solution before

nebulization. This results in high analyte ion concentration

and good API-electrospray sensitivity.

Agilent 6100 Series Quadrupole LC/MS System Concepts Guide 23

Page 24

1 Overview of Hardware and Software

Electrospray ionization (ESI)

Preformed ions are not always required for ESI. Some

compounds that do not ionize in solution can still be

analyzed. The process of nebulization, desolvation, and ion

evaporation creates a strong electrical charge on the surface

of the spray droplets. This can induce ionization in analyte

molecules at the surface of the droplets.

Nebulization

Nebulization (aerosol generation) takes the sample solution

through these steps:

a Sample solution enters the spray chamber through a

grounded needle called a nebulizer.

b For high-flow electrospray, nebulizing gas enters the

spray chamber concentrically through a tube that

surrounds the needle.

c The combination of strong shear forces generated by the

nebulizing gas and the strong voltage (2–6 kV) in the spray

chamber draws out the sample solution and breaks it into

droplets.

d As the droplets disperse, ions of one polarity

preferentially migrate to the droplet surface due to

electrostatic forces.

e As a result, the sample is simultaneously charged and

dispersed into a fine spray of charged droplets, hence

the name electrospray.

Because the sample solution is not heated when the aerosol

is created, ESI does not thermally decompose most analytes.

Desolvation and ion evaporation

Before the ions can be mass analyzed, solvent must be removed

to yield a bare ion.

A counter-current of neutral, heated drying gas, typically

nitrogen, evaporates the solvent, decreasing the droplet

diameter and forcing the predominantly like surface-charges

closer together (see Figure 9).

24 Agilent 6100 Series Quadrupole LC/MS System Concepts Guide

Page 25

Overview of Hardware and Software 1

+

+

+

+

+

+

+

+

+

+

+

-

-

-

-

-

-

+

+

+

+

+

+

+

+

+

+

+

-

-

-

-

-

-

+

+

+

++

+

+

+

+++

-

-

-

-

-

-

+

+

+

+

+

+

-

-

-

-

+

evaporation analyte ion ejected

Electrospray ionization (ESI)

Figure 9 Desorption of ions from solution

Coulomb repulsion – repulsion

between charged species of the

same sign

When the force of the Coulomb repulsion equals that of the

surface tension of the droplet, the droplet explodes,

producing smaller charged droplets that are subject to

further evaporation. This process repeats itself, and droplets

with a high density of surface-charges are formed. When

charge density reaches approximately 10

evaporation occurs (direct ejection of bare ions from the

droplet surface). These ions are attracted to and pass

through a capillary sampling orifice into the ion optics and

mass analyzer.

The importance of solution chemistry

The choice of solvents and buffers is a key to successful

ionization with electrospray. Solvents like methanol that have

lower heat capacity, surface tension, and dielectric constant,

promote nebulization and desolvation. For best results in

electrospray mode:

• Adjust solvent pH according to the polarity of ions

desired and the pH of the sample.

• To enhance ion desorption, use solvents that have low

heats of vaporization and low surface tensions.

• Select solvents that do not neutralize ions through

gas-phase reactions such as proton transfer or ion pair

reactions.

• To reduce the buildup of salts in the ion source, select

more volatile buffers.

8

V/cm3, ion

Agilent 6100 Series Quadrupole LC/MS System Concepts Guide 25

Page 26

1 Overview of Hardware and Software

Electrospray ionization (ESI)

Multiple charging

Electrospray is especially useful for analyzing large

biomolecules such as proteins, peptides, and

oligonucleotides, but can also analyze smaller molecules like

drugs and environmental contaminants. Large molecules

often acquire more than one charge. Because of this multiple

charging, you can use electrospray to analyze molecules as

large as 150,000 u even though the mass range (or more

accurately mass-to-charge range) for a typical quadrupole

LC/MS instrument is around 3000 m/z. For example:

100,000 u / 10 z = 1,000 m/z

The optional Agilent LC/MSD

Deconvolution & Bioanalysis

Software performs the calculations

to accomplish deconvolution.

When a large molecule acquires many charges, a

mathematical process called deconvolution is used to

determine the actual molecular weight of the analyte.

Agilent Jet Stream Technology

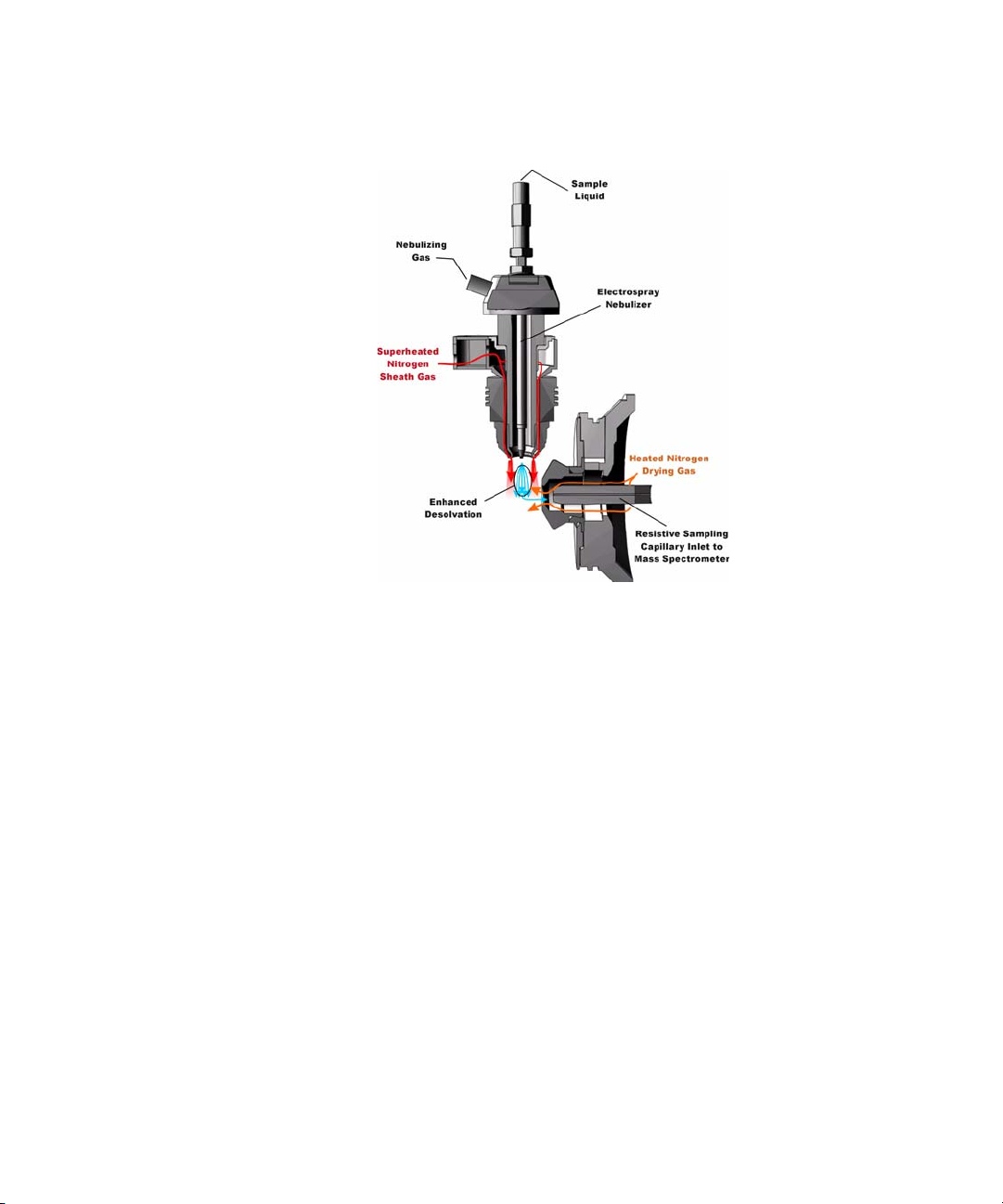

The Agilent Jet Stream technology is supported on compatible

Agilent 6100 Series LC/MS system.

Agilent Jet Stream Technology enhances analyte desolvation

by collimating the nebulizer spray and creating a

dramatically “brighter signal.” The addition of a collinear,

concentric, super-heated nitrogen sheath gas (Figure 10) to the

inlet assembly significantly improves ion drying from the

electrospray plume and leads to increased mass spectrometer

signal to noise allowing the triple quadrupole to surpass the

femtogram limit of detection. The Agilent Jet Stream

Technology is patent pending.

26 Agilent 6100 Series Quadrupole LC/MS System Concepts Guide

Page 27

Overview of Hardware and Software 1

Electrospray ionization (ESI)

Figure 10 Electrospray Ion Source with Agilent Jet Stream Technology

Agilent Jet Stream thermal gradient focusing consists of a

superheated nitrogen sheath gas that is introduced collinear

and concentric to the pneumatically assisted electrospray.

Thermal energy from the superheated nitrogen sheath gas is

focused to the nebulizer spray producing the most efficient

desolvation and ion generation possible. The enhanced

molecular ion desolvation results in more ions entering the

sampling capillary as shown in Figure 10 and concomitant

improved signal to noise. Parameters for the Agilent Jet Stream

Technology are the superheated nitrogen sheath gas

temperature and flow rate and the nozzle voltage.

Agilent 6100 Series Quadrupole LC/MS System Concepts Guide 27

Page 28

1 Overview of Hardware and Software

+

+

+

+

+

+

+

++

++

++

++

++

++

++

drying gas

capillary

nebulizer (sprayer)

HPLC inlet

vaporizer

corona

(heater)

discharge

needle

Atmospheric pressure chemical ionization (APCI)

Atmospheric pressure chemical ionization (APCI)

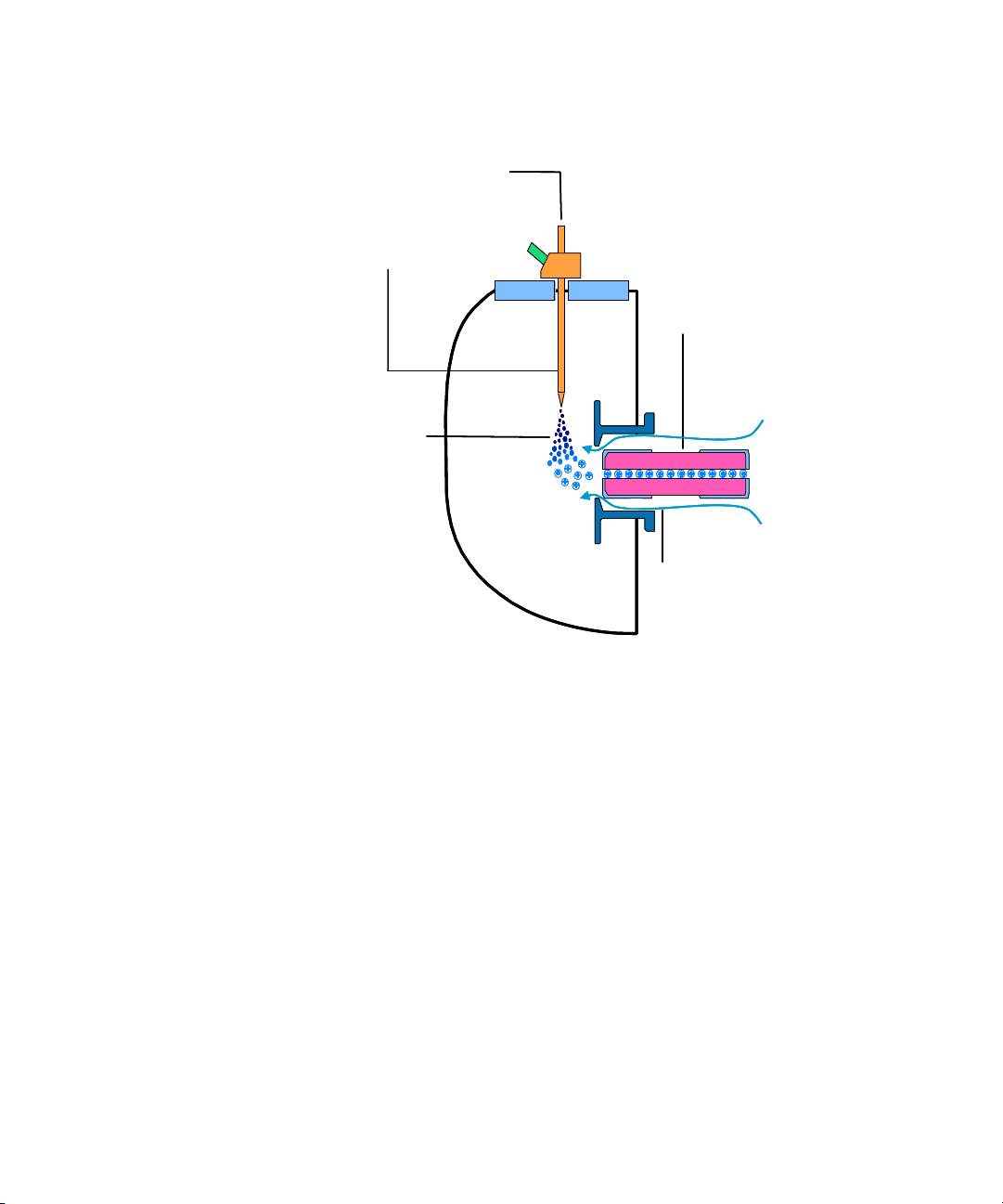

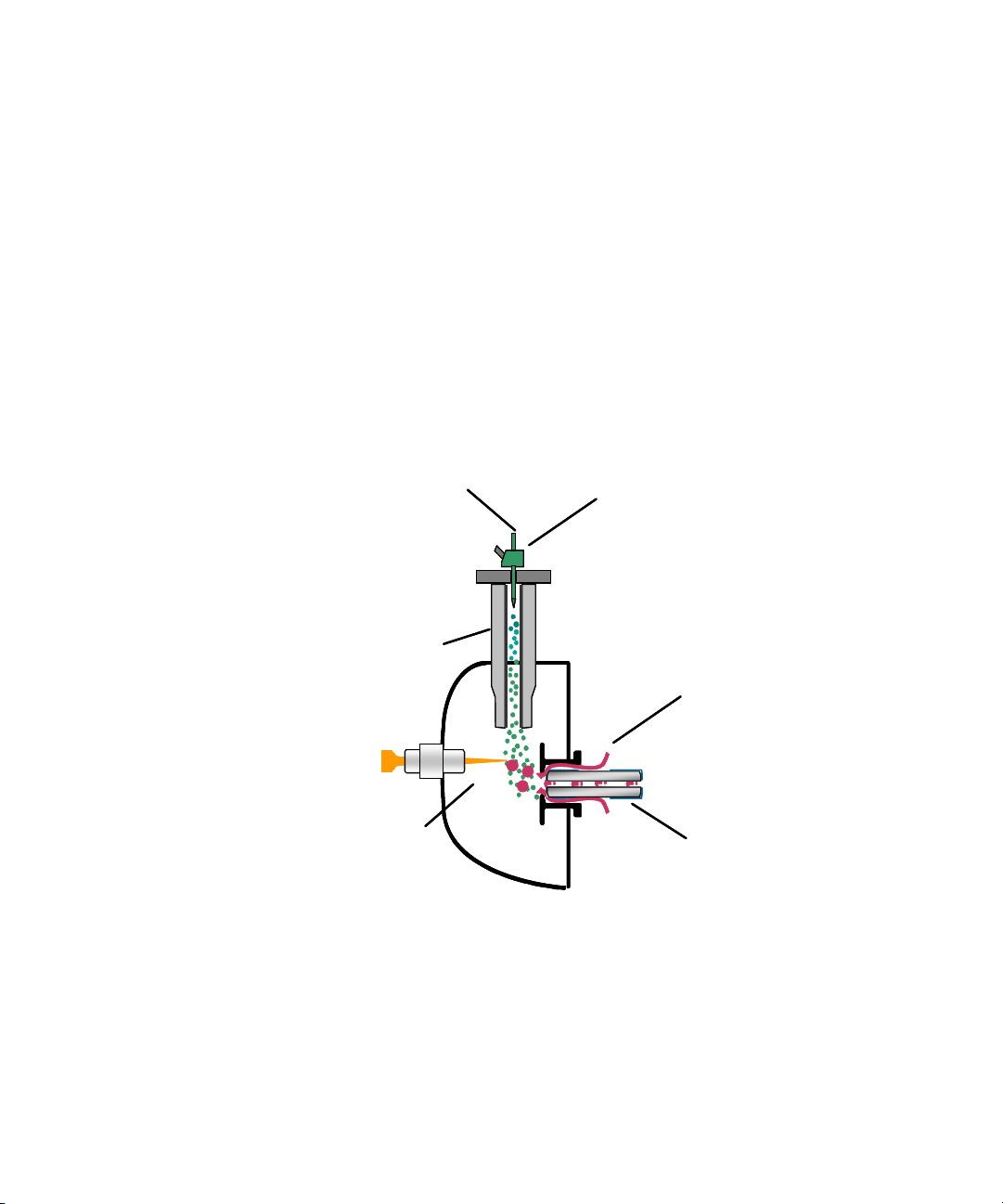

APCI is a gas-phase chemical ionization process. The APCI

technique passes LC eluent through a nebulizing needle,

which creates a fine spray. The spray is passed through a heated

ceramic tube, where the droplets are fully vaporized

(Figure 11).

The resulting gas/vapor mixture is then passed over a

corona discharge needle, where the solvent vapor is ionized

to create reagent gas ions. These ions in turn ionize the

sample molecules via a chemical ionization process. The

sample ions are then introduced into the capillary.

Figure 11 Atmospheric pressure chemical ionization (APCI) source

APCI requires that the analyte be in the gas phase for

ionization to occur. To vaporize the solvent and analyte, the

APCI source is typically operated at vaporizer temperatures

of 400 to 500 °C.

28 Agilent 6100 Series Quadrupole LC/MS System Concepts Guide

Page 29

Overview of Hardware and Software 1

Atmospheric pressure chemical ionization (APCI)

APCI is applicable across a wide range of molecular

polarities. It rarely results in multiple charging, so it is

typically used for molecules less than 1,500 u. Because of this

molecular weight limitation and use of high-temperature

vaporization, APCI is less well-suited than electrospray for

analysis of large biomolecules that may be thermally unstable.

APCI is well suited for ionization of the less polar compounds

that are typically analyzed by normal-phase chromatography.

Agilent 6100 Series Quadrupole LC/MS System Concepts Guide 29

Page 30

1 Overview of Hardware and Software

+

+

+

+

+

+

+

++

++

++

++

++

++

++

drying gas

capillary

nebulizer (sprayer)

HPLC inlet

vaporizer

UV lamp

(heater)

hν

Atmospheric pressure photoionization (APPI)

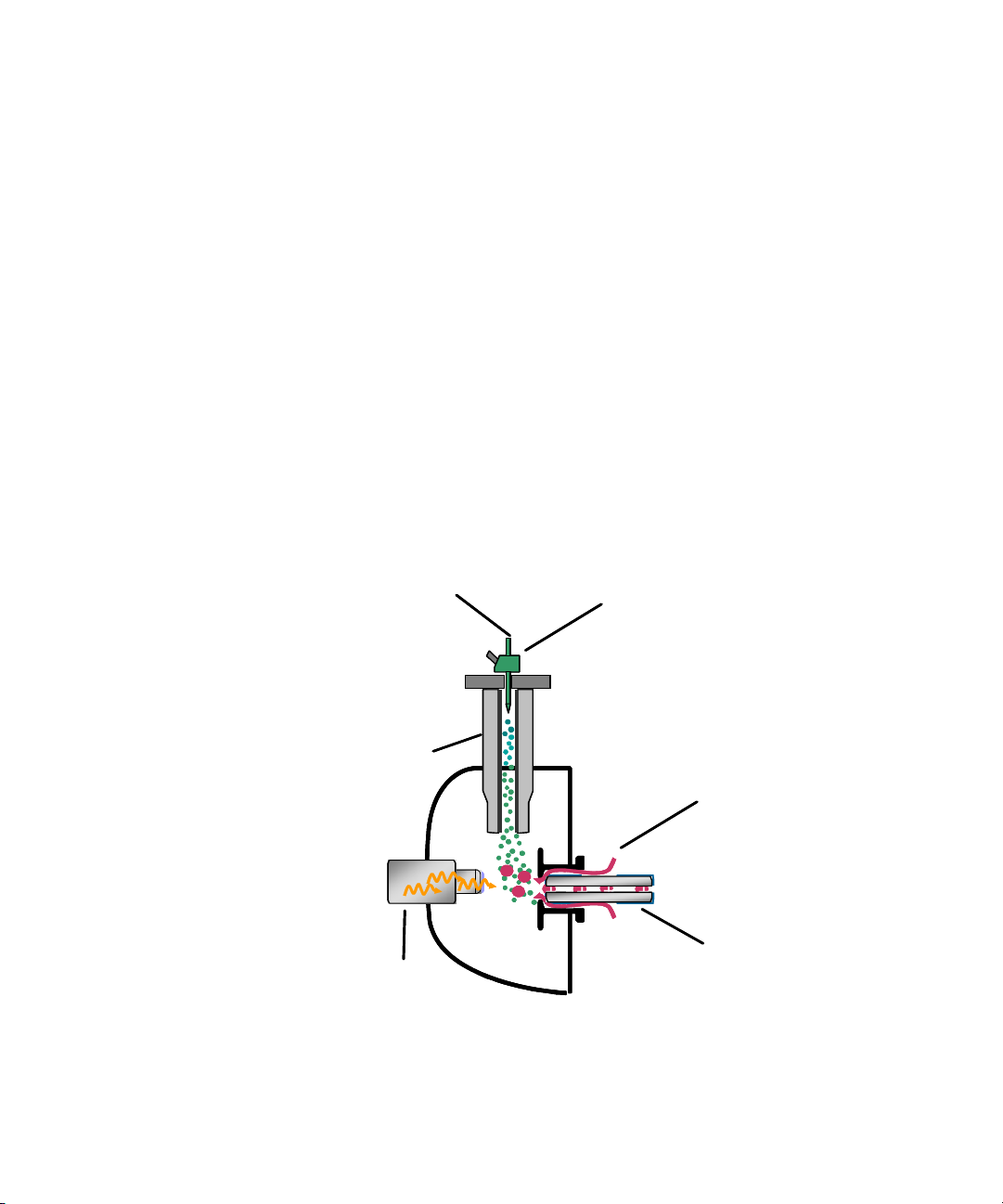

Atmospheric pressure photoionization (APPI)

With the APPI technique, LC eluent passes through a

nebulizing needle to create a fine spray. This spray is passed

through a heated ceramic tube, where the droplets are fully

vaporized. The resulting gas/vapor mixture passes through

the photon beam of a krypton lamp to ionize the sample

molecules (Figure 12). The sample ions are then introduced into

the capillary.

APPI and APCI are similar, with APPI substituting a lamp

for the corona needle for ionization. APPI often also uses an

additional solvent or mobile phase modifier, called a

“dopant”, to assist with the photoionization process.

APPI is applicable to many of the same compounds that are

typically analyzed by APCI. APPI has proven particularly

valuable for analysis of nonpolar compounds.

Figure 12 Atmospheric pressure photoionization (APPI) source

30 Agilent 6100 Series Quadrupole LC/MS System Concepts Guide

Page 31

Multimode ionization (MMI)

drying gas

capillary

nebulizer

HPLC inlet

APCI

thermal container

ESI zone

zone

corona

discharge

needle

The multimode source is an ion source that can operate in

three different modes—APCI, ESI or simultaneous APCI/ESI.

The multimode source incorporates two electrically

separated, optimized zones—one for ESI and one for APCI.

During simultaneous APCI/ESI, ions from both ionization

modes enter the capillary and are analyzed simultaneously by

the mass spectrometer.

Overview of Hardware and Software 1

Multimode ionization (MMI)

Figure 13 Multimode source

Multimode ionization (MMI) is useful for screening of

unknowns, or whenever samples contain a mixture of

compounds where some respond by ESI and some respond

by APCI. In these cases, the multimode source obviates the need

to run the samples twice to accomplish a complete analysis.

Unlike the APCI and APPI sources where the temperature of

the vaporizer is monitored, in the multimode source the

actual vapor temperature is monitored. As a result, the

vaporizer is typically set to between 200 and 250 °C.

Agilent 6100 Series Quadrupole LC/MS System Concepts Guide 31

Page 32

1 Overview of Hardware and Software

Introduction to ChemStation software

Introduction to ChemStation software

Overview

ChemStation software for the Agilent 6100 Series Quadrupole

LC/MS systems is organized into views. Each view allows you to

do a specific set of tasks. The menus and toolbars change with

each view.

Figure 14 These buttons allow you to switch among the six ChemSta-

tion views

The following summarizes the ChemStation views and their

functionality:

For more information about the

Method and Run Control view, see

Chapter 3.

32 Agilent 6100 Series Quadrupole LC/MS System Concepts Guide

Method and Run Control

• Set up methods

• Change setpoints for the Agilent 1100/1200/1260/1290

Series LC Series LC modules, including the Chip Cube

• Change setpoints for the Agilent 6100 Series Quadrupole

LC/MS systems

• Change setpoints for the Agilent API sources

• Run single samples

• Run automated sequences

• Run an FIA series

• View data in real time, as it is acquired

Page 33

Overview of Hardware and Software 1

Overview

For more information about the

Data Analysis view, see Chapter 4.

For more information about the

Report Layout view, see Chapter 5.

For more information about the

Verification view, see Chapter 6.

For more information about the

Diagnosis view, see Chapter 7.

Data Analysis

• View chromatograms and spectra from the MS and UV

detectors

• Integrate chromatographic peaks

• Perform quantitation

• Check peak purity

• Deconvolute multiply charged spectra

• Generate reports

• Reprocess data from sequences

Report Layout

• Design custom report templates

Verificat ion (OQ/PV)

• Verify system performance

Diagnosis

• Learn possible causes of instrument problems

• Run tests to diagnose instrument problems

• Receive notification when it is time to perform system

maintenance

• Pump down and vent the system

For more information about the

MSD Tune view, see Chapter 2.

Agilent 6100 Series Quadrupole LC/MS System Concepts Guide 33

MSD Tune

• Optimize and calibrate the MS

Page 34

1 Overview of Hardware and Software

Reviewing data remotely

Reviewing data remotely

There are two ways to set up a computer so you can review

ChemStation data remotely.

One way is to install a Data Analysis-only version of

ChemStation software on the remote computer. This

installation provides the same Data Analysis functionality

that you have on the ChemStation that controls your Agilent

6100 Series LC/MS system. It is ideal if you need full features

for in-depth data analysis.

Another way is to install the Analytical Studio Reviewer on

the remote computer. Analytical Studio Reviewer lets you

easily review ChemStation LC and LC/MS data files, but the

functionality is different than with the full ChemStation

Data Analysis. The Analytical Studio Reviewer software is

ideal for synthetic chemists and others who use the LC/MS

system for “walk-up” analysis.

34 Agilent 6100 Series Quadrupole LC/MS System Concepts Guide

Page 35

Agilent 6100 Series Quadrupole LC/MS Systems

Concepts Guide

2

Instrument Preparation

Preparation of the LC system 36

Purpose 36

Summary of procedures 36

Setting parameters for LC modules 38

Column conditioning and equilibration 39

Monitoring the stability of flow and pressure 41

Preparation of the MS – tuning 42

Overview 42

Ways to tune 44

When to tune – Check Tune 45

Autotune 47

Manual tuning 49

Tune reports 51

Gain calibration 53

In this chapter, you learn the concepts that help you prepare

the instrument for an analysis. This chapter assumes that

the hardware and software are installed, the instrument is

configured and the performance verified. If this has not been

completed, see the Agilent 6100 Series Single Quad LC/MS

System Installation Guide.

Agilent Technologies

35

Page 36

2 Instrument Preparation

Preparation of the LC system

Preparation of the LC system

Purpose

To achieve good sensitivity, it is important to properly

prepare the LC and column prior to an LC/MS analysis.

For best signal-to-noise, the entire LC system must be free

of contamination from salts (such as nonvolatile buffers) and

unwanted organic compounds. Some contaminants that are

not bothersome for a UV detector can cause problems for

the MS. Contaminants may cause ion suppression and/or

high background, and these problems can seriously degrade

sensitivity.

To achieve a smooth baseline with little noise, the LC flow

must also be very stable.

Summary of procedures

The exact LC preparation steps depend on how the LC was

used previously and the type of analysis to be performed.

The following provides guidelines:

Typical preparation

Before beginning an analysis, the entire LC path should be

contaminant-free and the flow should be stable. Usually, you

can accomplish these goals by doing the following:

1 Purge the pump to remove air bubbles. Purge each

channel that you plan to use.

For instructions to purge the pump, search the online

Help for the keyword “purge” and scroll down the list of

topics until you see entries that begin with the word

“purge.”

2 Condition the column to remove impurities or residual

sample.

36 Agilent 6100 Series Quadrupole LC/MS System Concepts Guide

Page 37

Instrument Preparation 2

Summary of procedures

For more information, see “Column conditioning and

equilibration” on page 39.

3 Equilibrate the column at the initial mobile phase

composition.

For more information, see “Column conditioning and

equilibration” on page 39.

4 Ensure that the system f low and pressure are stable.

For more information, see “Monitoring the stability of flow

and pressure” on page 41.

More extensive preparation

While the four-step procedure that is outlined above works

well on a day-to-day basis, more extensive LC/column

flushing may be necessary if any of the following are true:

• You have not used this LC for MS.

• The column is new.

• You are changing to a different mobile phase composition.

• The LC was used to analyze dirty samples.

• The next analysis requires ultimate sensitivity.

A protocol for more thorough LC cleaning is given in the

Agilent 6100 Single Quad System Installation Guide. See

the section on conditioning the LC in the chapter on system

verification.

When you flush the LC, remember to flush all channels that

you plan to use. Also, flush the injector by making several

injections of the same solvent(s) that you use to flush the

system.

Agilent 6100 Series Quadrupole LC/MS System Concepts Guide 37

Page 38

2 Instrument Preparation

Injection

Pump

Mass spectrometer

Diode-array detector

Column thermostat,

Column switching valve

Solvent bottles

Setting parameters for LC modules

Setting parameters for LC modules

You set up the LC modules in the Method and Run Control

view. Within the system diagram, click each module to set

parameters.

Figure 15 Example system diagram (yours may be different)

To access help for any system module, click Help on the

module context menu. To access help for a given dialog box,

click the Help button on the dialog box.

To set module control parameters

This procedure uses the pump module as an example.

1 Click More Pump > Control HPLC Pump on the

Instrument menu to open the Pump Control dialog box.

2 Set desired control parameters and click OK.

Alternate

method

38 Agilent 6100 Series Quadrupole LC/MS System Concepts Guide

Select the desired control parameter such as Standby from

the Pump context menu.

Page 39

Column conditioning and equilibration

To set module setpoint parameters

This procedure uses the binary pump module as an example.

1 Click Set up Instrument Method on the Instrument menu

to open the Setup Method dialog box.

2 Click the BinPump tab.

3 Set desired setpoints and click OK.

To access other instrument parameters

1 Click to open the Instrument menu.

2 Click the desired command such as Select Injection

Source, Columns, or Instrument Configuration.

Column conditioning and equilibration

There are several ways to set parameters to condition and

equilibrate a column.

Instrument Preparation 2

Conditioning

Column conditioning eliminates any previously separated

compounds or impurities from the column, particularly after

runs with solvent of a single composition (isocratic runs).

There are a number of ways to condition a column before a

sample run. One way is to pump the organic solvent that

you intend to use (100% solvent B) through the column for a

period of time. Another way is to run the gradient that you

intend to use, then extend the time at the final composition

until no further peaks elute.

When a column is new, “conditioning” may include injecting

a few samples or high-level standards until peak area and

retention time are stable.

Agilent 6100 Series Quadrupole LC/MS System Concepts Guide 39

Page 40

2 Instrument Preparation

Column conditioning and equilibration

Equilibration

Column equilibration returns column characteristics to their

initial state after a gradient run. To equilibrate a column

before a sample run, you pass the solvent of initial

composition through the column for a period of time.

Column conditioning and equilibration

You can condition and equilibrate a column in one of three

ways with ChemStation software.

• Interactively

You set the pump to the solvent composition for the end

of the run and higher-than-normal flow rates. You can

then immediately apply these setpoints to the pump. After

you pump about three column-volumes of solvent, then

set the pump to the solvent composition and flow rate for

the beginning of the run. With this procedure, you do not

store a data file.

If you use this procedure, you can tune the MS while you

condition and equilibrate the column. When you tune the

MS, the MS stream selection valve automatically diverts the

LC effluent to waste. For information on tuning, see

“Preparation of the MS – tuning” on page 42.

You set up a method or sequence in

the Method and Run Control view,

described in Chapter 3.

40 Agilent 6100 Series Quadrupole LC/MS System Concepts Guide

• With a method in an interactive run

You set up a method for your analysis and then run a

solvent blank. The run uses the method stop time. You

can also use a post-run time within the method to

equilibrate the column.

With this procedure, you store a data file.

• With a sequence

You set up a method for your analysis and then set up a

solvent blank as the first run in a sequence. The method

includes a post-run time to equilibrate the column.

With this procedure, you store a data file.

Page 41

Instrument Preparation 2

Monitoring the stability of flow and pressure

Monitoring the stability of flow and pressure

The LC solvent flow and the system backpressure must be

stable to ensure a quiet baseline and best results for

API-MS. The best time to monitor the stability of flow and

pressure is after you have equilibrated the column, and

before you start the analysis.

Chapter 3 provides more

information about online signals,

which are also called online plots.

You can measure stability with ChemStation software. To do

this, you set up an isocratic method with the same solvent

composition as the initial composition you intend to use for

your analysis. During the run, you monitor the online signals

for flow and pressure.

Agilent 6100 Series Quadrupole LC/MS System Concepts Guide 41

Page 42

2 Instrument Preparation

Preparation of the MS – tuning

Preparation of the MS – tuning

Overview

Use the MSD Tune view for all

tasks that relate to tuning.

Tuning is the process of adjusting MS parameters to

generate high quality, accurate mass spectra. During tuning,

the MS is optimized to:

• Maximize sensitivity

• Maintain acceptable resolution

• Ensure accurate mass assignments

Parameters that are adjusted

The Agilent 6100 Series Quadrupole LC/MS systems have two

sets of parameters that can be adjusted. One set of parameters

is associated with the formation of ions. These parameters

control the spray chamber (for example, electrospray or APCI)

and fragmentor. The other set of parameters is associated with

the transmission, filtering, and detection of ions. These

parameters control the skimmer, octopole, lenses, quadrupole

mass filter, and high-energy dynode (HED) electron multiplier

(detector).

Tuning is primarily concerned with finding the correct

settings for the parameters that control the transmission,

filtering, and detection of ions. It is accomplished by

introducing a calibrant into the MS and generating ions.

Using these ions, the tune parameters are then adjusted to

achieve sensitivity, resolution, and mass assignment goals.

With a few exceptions, the parameters that control ion

formation are not adjusted. They are set to fixed values

known to be good for generating ions from the calibrant

solution.

42 Agilent 6100 Series Quadrupole LC/MS System Concepts Guide

Page 43

Instrument Preparation 2

Overview

Tune files and reports

The product of tuning is a tune file (actually a directory)

that contains parameter settings for both positive and

negative ionization. When data acquisition uses a tune file,

the settings appropriate for the ion polarity specified by the

data acquisition method are loaded automatically.

Autotune, the automated tuning program, also generates a

report. See page 51.

Use of tune files during data acquisition

During data acquisition, the parameters associated with ion

formation are controlled by the data acquisition method. The

parameters associated with ion transmission are controlled

by the tune file assigned to the data acquisition method.

Agilent 6100 Series Quadrupole LC/MS System Concepts Guide 43

Page 44

2 Instrument Preparation

NOTE

CAUTION

Ways to tune

Ways to tune

Access this functionality via the

Tune menu in the MSD Tune view.

ChemStation software provides the following two ways to

tune the MS:

• Autotune is an automated tuning program that tunes the

MS for good performance over the entire mass range. It

uses known compounds in a standard calibration mixture

that is introduced via the Calibrant Delivery System

(CDS). This is the tuning method that you use in most

cases.

• Manual Tune allows you to tune the MS by adjusting one

parameter at a time until you achieve the desired

performance. Manual tuning is most often used when you

need maximum sensitivity, when your analysis targets a

restricted mass range, or when you need a tuning

compound other than the standard calibrants.

In addition, a Check Tune program allows you to determine

whether you need to tune.

Check Tune, Autotune, and Manual Tune are discussed in

more detail in the next sections.

Frequent tuning is not required for normal operation. Once tuned, the

LC/MS is very stable. Tuning is generally not needed more often than

monthly, or at most weekly. If you suspect problems related to tuning, use

the Check Tune program to confirm that the MS is out of adjustment

before you retune it.

44 Agilent 6100 Series Quadrupole LC/MS System Concepts Guide

Wait at least four hours after pump-down before tuning or operating

your Agilent 6100 Series LC/MS system. Ceramic components in the

quadrupole mass filter can absorb moisture from the air. Tuning or

acquiring data too soon may result in arcing. Further, it takes the

analyzer at least nine hours to reach thermal equilibrium. Tune files

created or data acquired before the MS is at thermal equilibrium may

have incorrect mass assignments and other inaccuracies.

Page 45

When to tune – Check Tune

Check Tune allows you to quickly determine whether the MS

is correctly tuned without performing a complete autotune.

It performs a single profile scan of the tune masses and

compares the peak widths and mass axes with target values.

If the values obtained by Check Tune are within acceptable

ranges, the tune report indicates that Check Tune passes.

(See Figure 16 on page 46.) If the values are outside of

acceptable ranges, Check Tune suggests that you adjust peak

widths or calibrate the mass axis.

A third parameter, gain, may be added to the parameters

checked by Check Tune. If so, Check Tune compares the

current gain value with the gain value from the most recent

autotune. For a discussion of gain, see page 53.

Instrument Preparation 2

When to tune – Check Tune

Agilent 6100 Series Quadrupole LC/MS System Concepts Guide 45

Page 46

2 Instrument Preparation

All masses pass the

mass axis and peak

width tests

When to tune – Check Tune

Figure 16 Check Tune report

46 Agilent 6100 Series Quadrupole LC/MS System Concepts Guide

Page 47

Autotune

Instrument Preparation 2

Autotune

Autotune is a program that adjusts the MS for good

performance over the entire mass range.

Autotune files

A tune file, ATUNES.TUN is provided as a starting point for

autotune.

The results of autotune are saved to the current autotune

file. This makes autotune faster because each autotune

begins from the most recent good tune parameters. This

means, however, that previous tune values are lost. You may

want to occasionally save the autotune file to a different file

name before using autotune.

A single autotune file contains the results of both positive

ionization and negative ionization autotunes.

Autotune polarity and scan speed

You have up to six choices for running an autotune, depending

on 6100 model:

• Dual Polarity

• Positive Polarity

• Negative Polarity

• Dual Polarity Fast Scan

• Positive Polarity Fast Scan

• Negative Polarity Fast Scan

The Dual Polarity modes perform an autotune for both

positive ionization and negative ionization. Positive Polarity

and Negative Polarity modes perform autotunes only for the

specified polarity.

Gain checking in autotune

Gain checking occurs only in the positive polarity autotune

or the positive portion of a dual polarity autotune. For more

information on gain checking, see “Gain calibration” on page 53.

Agilent 6100 Series Quadrupole LC/MS System Concepts Guide 47

Page 48

2 Instrument Preparation

Autotune

Spray chamber parameters

Autotune adjusts the parameters that affect ion transmission.

The spray chamber parameters, which affect ion formation,

are not adjusted by autotune. They are set to default values

known to be good for generating ions of the calibrant

solution.

Because there may be slight variations from spray chamber

to spray chamber, the default parameters may not be

optimum for a particular spray chamber. Changes such as

adjustment of the nebulizer and normal aging of the LC/MS

system components can also result in a system where the

default values are not optimum. Therefore, it is possible to

manually set the spray chamber parameters. Typically, this is

necessary only when the instrument fails autotune or when

the results of autotune show a significant decrease in system

performance. Be aware that other factors can also decrease

system performance.

48 Agilent 6100 Series Quadrupole LC/MS System Concepts Guide

Page 49

Manual tuning

CAUTION

The autotune program adjusts the MS for good performance

over the entire mass range, and this tune program is

sufficient for most applications. There are times, however,

when it is advantageous to tune the MS manually. These

include:

• When you want to achieve maximum sensitivity by

• When you want to tune specifically for the very low end

• When you want to tune with a compound other than the

The calibrant delivery system (CDS) is designed specifically for precise

delivery of the Agilent calibrants in a 90:10 acetonitrile:water solvent

mix. Other solvents and mixes may have different flow rates, which

may not be optimum for tuning. Further, the O-ring seals in the CDS are

ethylene-propylene. They can be damaged by aliphatic, aromatic, or

halogenated hydrocarbons. Never use these types of solvents in the

CDS. We recommend delivering non-standard calibrants through the

LC.

Instrument Preparation 2

Manual tuning

sacrificing some resolution

of the mass range (< 150 u)

standard calibrants.

Agilent 6100 Series Quadrupole LC/MS System Concepts Guide 49

Tips for manual tuning

Ionization

modes

Polarity Separate tuning is required for positive and negative

Separate tuning is not required for electrospray, APCI/APPI

and multimode-ESI+APCI. Tuning involves adjusting the

parameters that control the transmission of ions. It does not

matter how those ions are generated. A tune file created in

electrospray mode often will provide good results for

APCI/APPI samples. The reverse is also true.

ionization. The MS must, at some time, be tuned twice —

once with positive ions and once with negative ions. The two

tunes can be stored under the same tune file name. Positive

ion and negative ion settings can be updated separately.

Page 50

2 Instrument Preparation

Manual tuning

Mass range Tuning is almost always done over the entire mass range.

The exception is if all the ions of interest are smaller than

approximately 150 u. Correct manual tuning over a reduced

mass range can improve transmission and detection of these

very low mass ions.

Steps to manual tune

The online Help includes step-by-step instructions for

manual tuning. The instructions assume the use of one of

the standard calibrants and tuning over the entire mass

range, but they can be altered for non-standard calibrants or

narrower mass ranges.

To access the manual tuning instructions:

1 Open the online Help.

2 Click to expand “How to Work with Your ChemStation.”

3 Click to expand “Basic Tasks.”

4 Click to expand “Method and Run Control.”

5 Click to expand “MSD Tune.”

6 Click the link to “Manually Tuning the LC/MSD or

CE/MSD.”

7 Scroll down until you see “Steps.”

50 Agilent 6100 Series Quadrupole LC/MS System Concepts Guide

Page 51

Tune reports

Instrument Preparation 2

Tune reports

At the end of every autotune, the system prints a tune

report. You can also manually print a tune report from the

File menu.

Agilent 6100 Series Quadrupole LC/MS System Concepts Guide 51

Page 52

2 Instrument Preparation

Tune reports

Figure 17 Tune report (page 1 of 4)

52 Agilent 6100 Series Quadrupole LC/MS System Concepts Guide

Page 53

Gain calibration

Gain calibration sets the electron multiplier voltage in a way

that simplifies method development and portability. Gain

calibration is performed automatically during autotune. You

can also check and adjust the gain calibration during manual

tune.

What is gain?

The HED electron multiplier receives an input current that is

generated by the ions that strike it, amplifies that current,

and generates a proportional output current.

Gain = Output current / input current

Gain is controlled by the electron multiplier voltage (EMV).

The higher the EMV, the higher the gain. The relationship

between EMV and gain is log linear. This linear relationship

is common for all multipliers. Since the slope of this line is

constant, to set the gain, the software needs only to adjust

the intercept. The gain calibration routine simply adjusts the

value of the intercept for the specific instrument. The

instrument-specific gain curve coefficients are then stored in

the MS.

Instrument Preparation 2

Gain calibration

Gain calibration curve

A gain calibration curve is generated by taking readings of

the ion current generated at discreet multiplier settings

across the range of the multiplier. Separate gain calibration

curves are generated for positive and negative polarities,

since the ion current generated in these two modes varies to

some extent. A gain of 1 is set to be a multiplier value of

1e6. That is, one electron striking the input side of the

detector will generate 1e6 on the output side. A gain check

can be generated on both polarities or on the current

polarity.

Agilent 6100 Series Quadrupole LC/MS System Concepts Guide 53

Page 54

2 Instrument Preparation

Gain calibration

Gain and method portability

The use of gain enables the distribution of methods from

instrument to instrument. In principle, using the same gain

on two different instruments should result in the same

signal response, thereby easing method development and

instrument portability. Because the relationship between

EMV and gain is log linear, a gain of 2.0 should give twice

the abundance of a gain of 1.0.

More gain is not always better

In general, it is best to run the detector at the lowest gain

that still produces adequate abundance. High gains increase

noise as well as signal and often result in poorer

signal-to-noise ratios. Increasing the gain increases the EMV,

which shortens the life-span of the electron multiplier. The

maximum EMV is 3000 eV no matter how high you set the

gain; a gain of 70 or higher elicits the 3000 eV setting.

As an electron multiplier ages, it slowly becomes less

efficient. For a given ion current input, it generates a

smaller and smaller output current (abundance). Low

abundance caused by an aging electron multiplier is not

easily distinguished from low abundance caused by poor ion

generation or transmission (low ion current input). It may be

tempting to compensate for poor ion generation or

transmission by increasing the gain (thereby increasing the

EMV) even though the electron multiplier is actually

performing correctly at its previous gain. The increased gain

will improve abundance, but may decrease the

signal-to-noise ratio and will shorten the life-span of the

electron multiplier.

Check Gain Calibration

Access this functionality via the

Tune menu in the MSD Tune view.

54 Agilent 6100 Series Quadrupole LC/MS System Concepts Guide

During a Gain Calibration check, a reading of the ion

current is taken and checked against the current gain

calibration curve for the current polarity. If it is within

acceptable limits, no change is made to the curve for that

polarity. If the reading falls outside the limits, a new gain

curve is generated. A gain of 1 is set to be a multiplier of

Page 55

Instrument Preparation 2

Gain calibration

1e6. That is, one electron striking the input side of the

detector will generate 1e6 on the output side. If that

multiplier setting exceeds 2600 volts, which indicates

decreasing electron multiplier performance or instrument

performance, you are warned that system maintenance may

be required.

Agilent 6100 Series Quadrupole LC/MS System Concepts Guide 55

Page 56

2 Instrument Preparation

Gain calibration

56 Agilent 6100 Series Quadrupole LC/MS System Concepts Guide

Page 57

Agilent 6100 Series Quadrupole LC/MS Systems

Concepts Guide

3

Data Acquisition

Working with methods 58

Method and Run Control View 58

Loading, editing, saving and printing methods 60

More on editing methods 61

Running samples 64

Running a single sample 65

Running a sequence 66

Flow injection analysis 69

Monitoring analyses 73

Online signal plots 73

Quick method overview 74

Logbooks 74

Instrument shutdown 76

In this chapter, you learn the concepts that help you run

samples and acquire data. This chapter assumes that the

hardware and software are installed, the instrument is

configured and the performance verified. If this has not been

completed, see the Agilent 6100 Series Single Quad LC/MS

System Installation Guide.

Agilent Technologies

57

Page 58

3 Data Acquisition

Working with methods

Working with methods

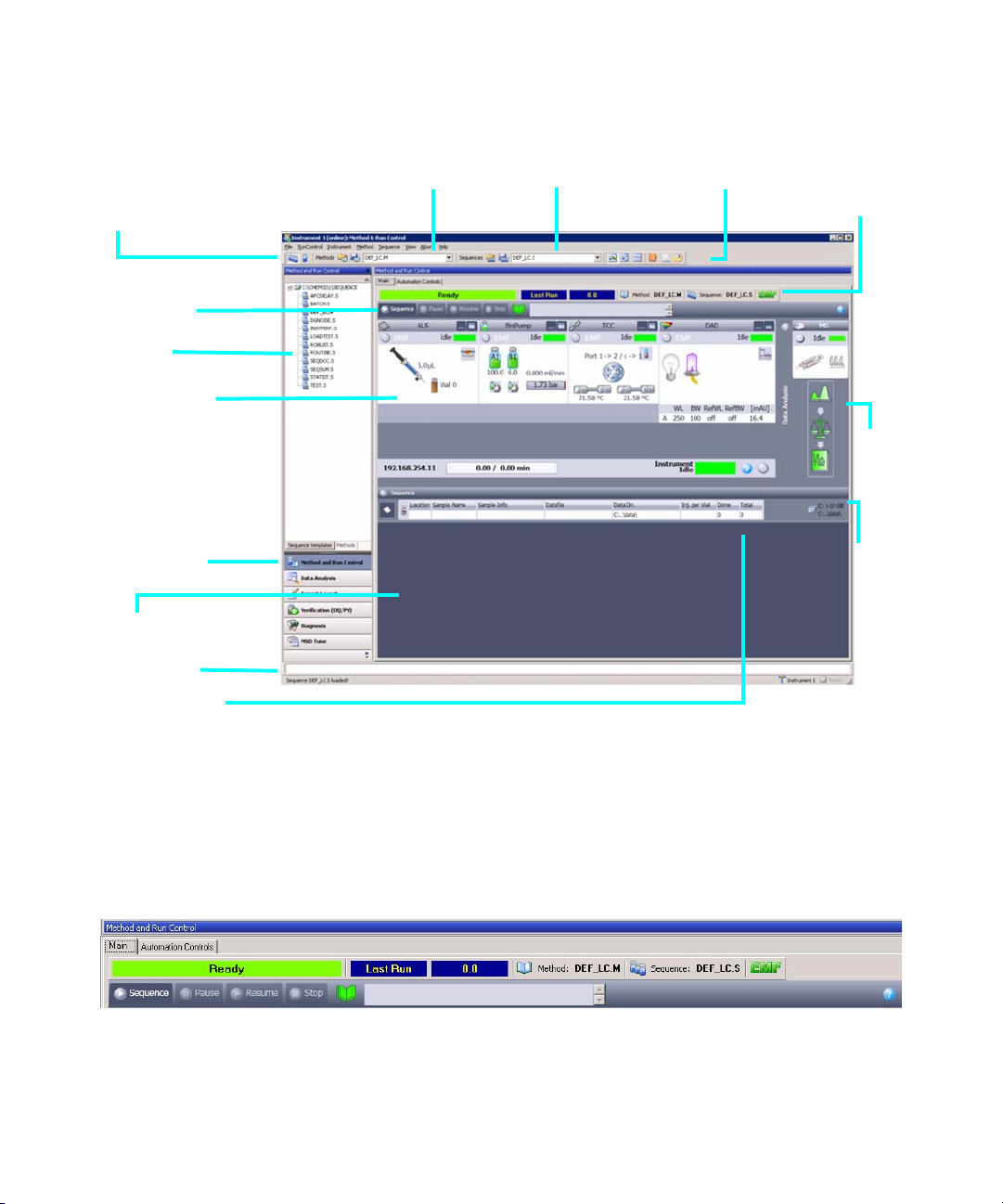

Method and Run Control View

You set up methods and run analyses from the Method and

Run Control view, shown in Figure 18.

ChemStation methods control the instrument during data

acquisition. The easiest way to prepare a method is to load

a similar method (or load DEF_LC.M), save it with a new

name, modify (edit) it, and save it again. Then you can use

the method to run a single sample or multiple samples via a

sequence.

You can also set up a method for flow injection analysis

(FIA), where you make multiple injections in a single run.

58 Agilent 6100 Series Quadrupole LC/MS System Concepts Guide

Page 59

Data Acquisition 3

View Selection

Tool Set Selection: Sequence

or Single Sample

Message Line

Run Control

System Diagram

Top To ol ba r

Online Plot

Method Overview

File List

Method Sequence

Data

Analysis

Status Bar

MS, FIA

Disk

Space

Method and Run Control View

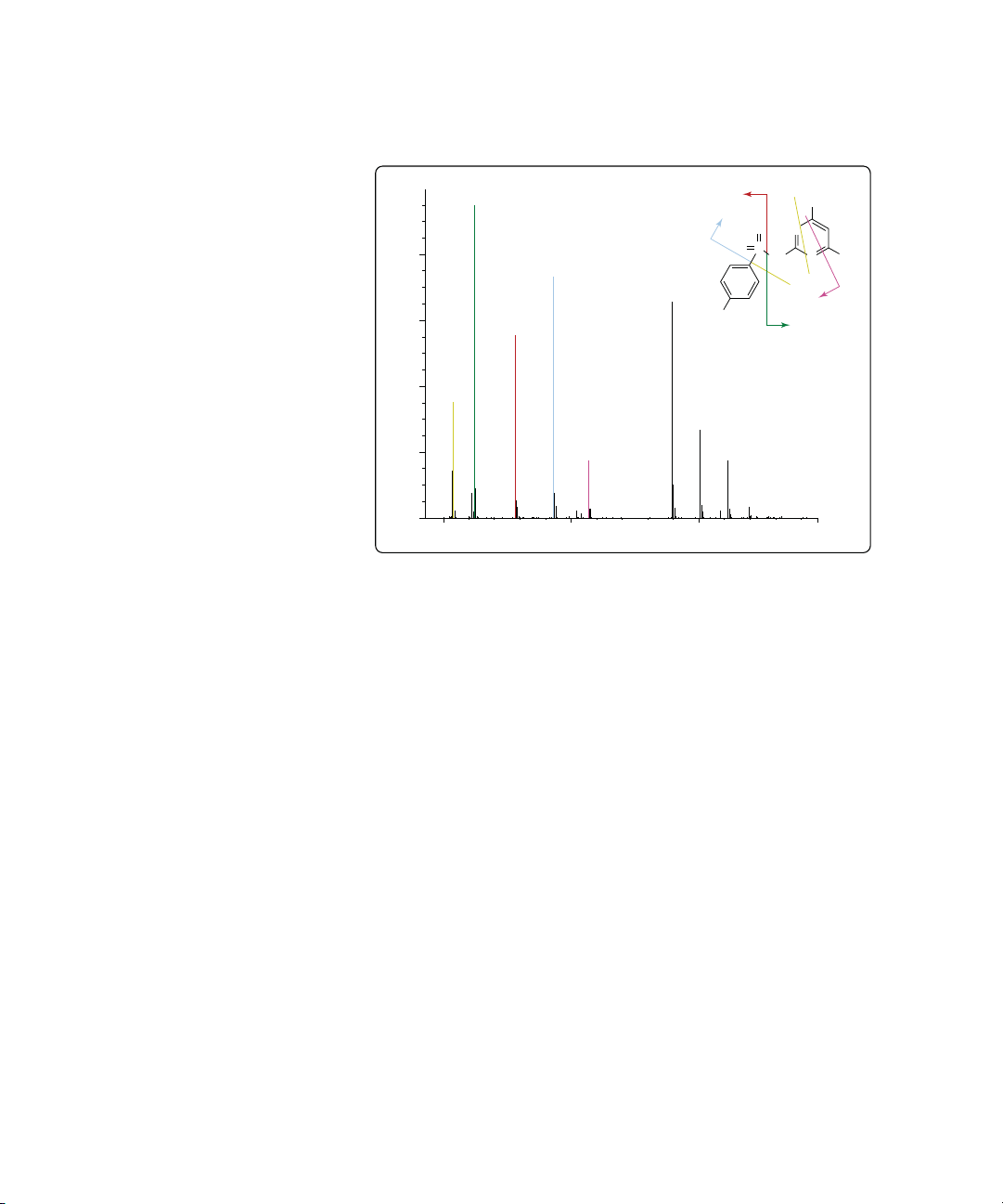

Figure 18 In this view, you set up methods, establish instrument settings, and inject samples.

Status and Run Bars: Main Tab Right-click the Method icon to see the following commands:

Agilent 6100 Series Quadrupole LC/MS System Concepts Guide 59

Run Time Checklist, Method Information, Edit Entire

Method, Method Audit Trail, Print Method, and Help.

Page 60

3 Data Acquisition

Sequence

Single sample

Load a

Save

Edit entire

MethodMethod method

Select method from

list of recent methods

current

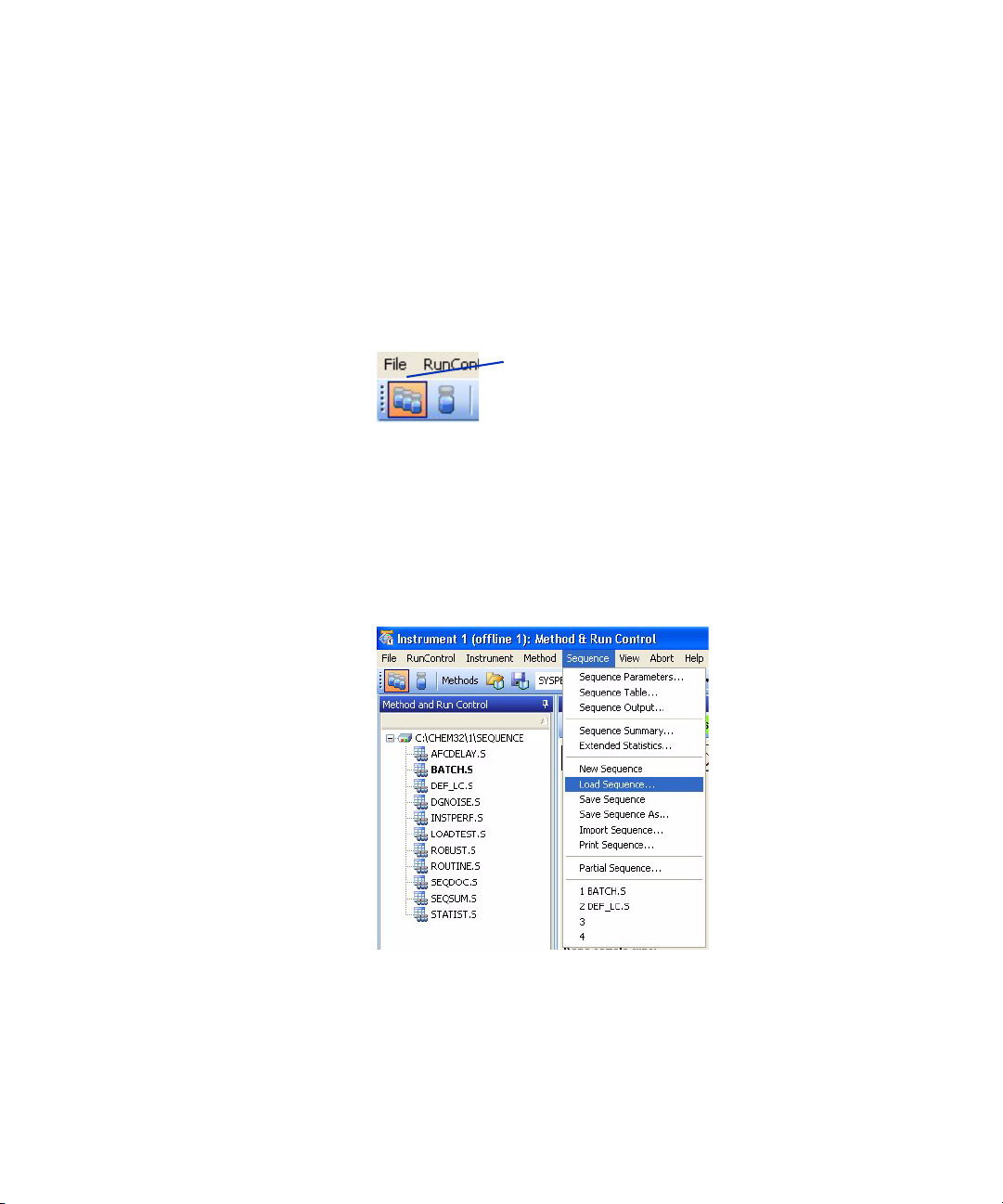

Loading, editing, saving and printing methods

Loading, editing, saving and printing methods

When you need to work with methods, there are several

ways to access the necessary functionality:

• Select from the Method menu, which allows you to load,

• Use the Method icon in the Run Control Bar.

• Use the toolbar or method drop-down list.

Figure 19 Toolset selection

edit, save, and print methods.

Right-click the icon to access the context menu.

When you want to view all the tools for methods (or to run a

single sample interactively), you first click the icon for the

Single Sample Toolset, as shown in Figure 19.

Figure 20 When you click the icon for the Single Sample Toolset, you access tools to work with methods.

• Use the ChemStation Explorer pane on the left side of the

Method and Run Control view.

Click the Method tab at the bottom to display the method

files.

Double-click a method to load it.

Right-click in the white area to view the context menu,

which contains options such as Load Method.

60 Agilent 6100 Series Quadrupole LC/MS System Concepts Guide

Page 61

More on editing methods

NOTE

There are a number of ways to edit a method. If you need to

create a new method for a new analysis, then it is best to

review and edit the entire method, as described just below.

If you want to make only a few changes to an existing

method, then it is easiest to edit only the settings that need

to change, as described in “Editing a portion of the method” on

page 62.

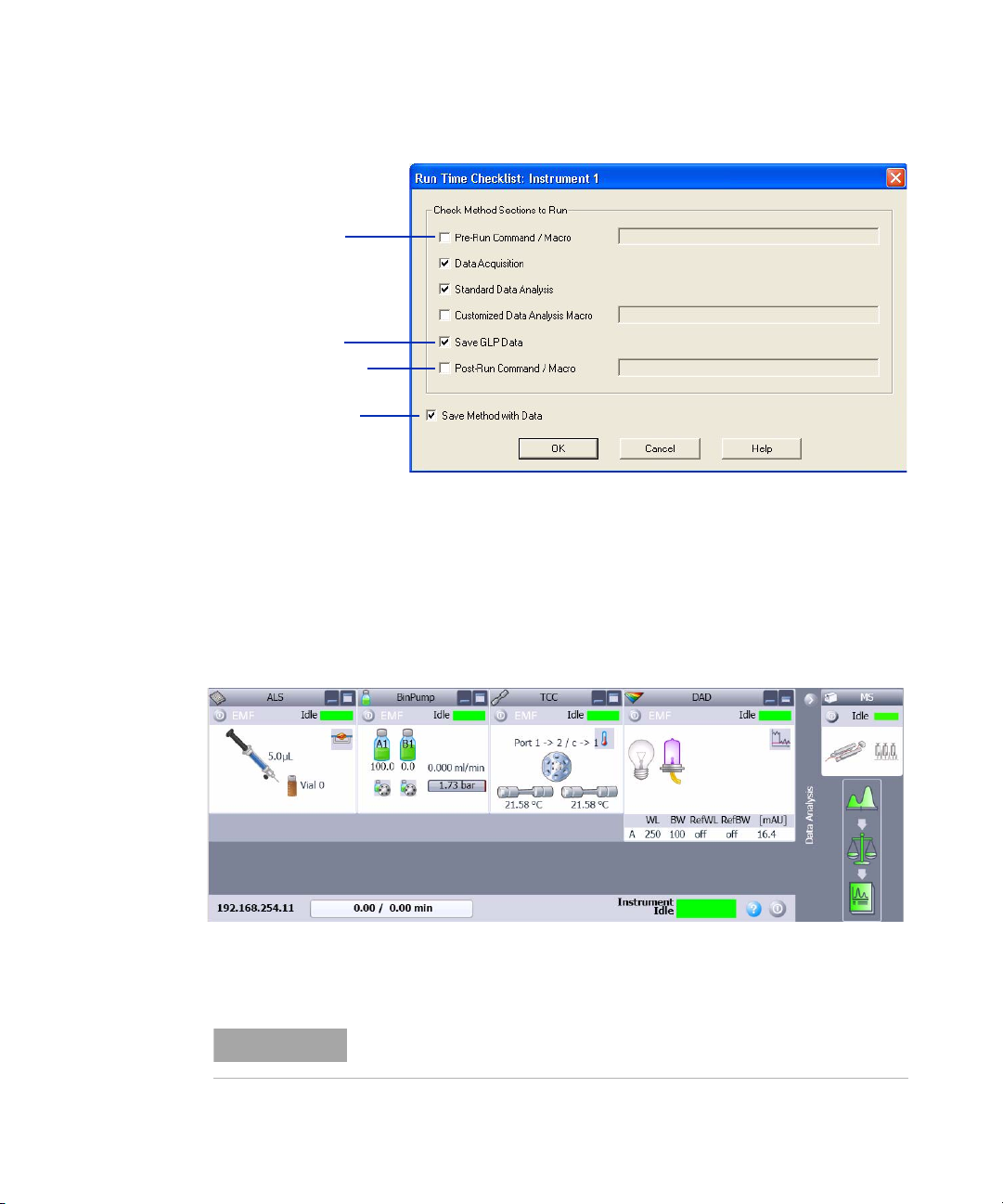

Editing the entire method

You can edit the entire method from the Method menu or

the Edit entire Method icon in the Run Control Bar or

the Method icon in the Status Bar. If you elect to edit the

entire method, the appropriate dialog boxes are displayed in

succession. The first dialog box (Figure 21) lets you select the

parts of the method to view and edit. For more information as

you edit the method, click the Help button in each dialog box.

Data Acquisition 3

More on editing methods

Figure 21 Parts of the method that you can view and edit

The Run Time Checklist, the last item listed in Figure 21,

controls which parts of the method the software executes when

you run your analysis. As shown in Figure 22, a complete

method can include both data acquisition and data analysis.

Be sure to save the method after you edit it.

Agilent 6100 Series Quadrupole LC/MS System Concepts Guide 61

Page 62

3 Data Acquisition

Run a command or macro prior to an

analysis in a sequence

Run a command or macro at the end of

an analysis (for example, run an Excel macro)

Save a checksum-protected register file

for Good Laboratory Practices (GLP)

Save a complete record of the analysis

conditions

NOTE

More on editing methods

Figure 22 Run Time Checklist

Editing a portion of the method

If you need to change only a few settings in a data

acquisition method, you can edit a subset of the method. You

can do that either from the system diagram (Figure 23) or the

Instrument menu.

62 Agilent 6100 Series Quadrupole LC/MS System Concepts Guide