Page 1

User’s Guide

Publication Number 54622-97036

September 2002

For Safety Information and Regulatory information,

see the pages behind the Index.

© Copyright Agilent Technologies 2000-2002

All Rights Reserved

Agilent 54621A/22A/24A/41A/42A

Oscilloscopes and

Agilent 54621D/22D/41D/42D

Mixed-Signal Oscilloscopes

Page 2

The Oscilloscopes at a Glance

Choose from a variety of oscilloscopes for capturing

long, non-repeating signals

with 200 MSa/s sample rate and 2 MBytes of

MegaZoom deep memory per channel.

• Agilent 54621A - 2-channel, 60-MHz bandwidth

• Agilent 54621D - 2-channel +16 logic channels, 60MHz bandwidth

• Agilent 54622A - 2-channel, 100-MHz bandwidth

• Agilent 54622D - 2-channel +16 logic channels,

100-MHz bandwidth

• Agilent 54624A - 4-channel, 100-MHz bandwidth

with 2 GSa/s sample rate and 4 MBytes of MegaZoom

deep memory per channel.

• Agilent 54641A - 2-channel, 350-MHz bandwidth

• Agilent 54641D - 2-channel +16 logic channels,

350-MHz bandwidth

• Agilent 54642A - 2-channel, 500-MHz bandwidth

• Agilent 54642D - 2-channel +16 logic channels,

500-MHz bandwidth

Display shows current input signals

• All analog and digital (54621D/22D/41D/42D)

channels displayed in main and delayed mode

• Indicators for channel, time base, digital

(54621D/22D/41D/42D) channel activity, trigger and

acquisition status

• Softkey labels

• Measurement results

Digital channel controls select, position, and label

inputs (54621D/22D/41D/42D)

• Turn channels on or off individually or in groups of 8

• Rearrange order of channels to group related

signals

• Create and display labels to identify channels

Run control keys begin and end data acquisition

• Run/Stop starts and stops continuous acquisitions

• Single performs one acquisition

• Infinite persistence accumulates and displays the

results of multiple acquisitions

General controls measure, save and restore results,

and configure the oscilloscope

• Waveform math including FFT, subtract, multiply,

integrate, and differentiate

• Use Quick Meas to make au tomatic measurements

Integrated counter included with Quick Meas.

• Use cursors to make manual measurements

• Save or recall measurement configurations or

previous results

• Autoscale performs simple one-button setup of the

oscilloscope

Horizontal Controls select sweep speed and delay

parameters

• Sweep speeds from 5 ns/div to 50 ns/div (54620series) and 1 ns/div to 50 s/div (54640-series)

• Delay control moves waveform display to point of

interest

• Delayed mode and delay allow zooming in to show

a portion of waveform in detail (split screen)

Trigger keys define what data the oscilloscope will

trigger on

• Source key allows conventional oscilloscope

triggering

• Modes include Edge, Pulse Width, Pattern, CAN,

Duration, I

triggering

Softkeys extend the functionality of command keys

Select measurement types, operating modes, trigger

specifications, label data, and more

Digital channel inputs through a flexible probing

system (54621D/22D/41D/42D)

• Sixteen channels through a dual 8-channel cable

with micro-clips

• Set logic levels as TTL, CMOS, ECL, or to a userdefinable voltage

Utilities

• Dedicated parallel printer port, controller

operation, floppy disk storage

Built in Quick Help system

• Press and hold any key front-panel key or softkey

to get help in 11 languages.

2

C, LIN, Sequence, SPI, TV, and USB

ii

Page 3

In This Book

This manual will guide you in using the oscilloscopes. This manual is organized

in the following chapters:

Chapter 1 Getting Started—inspecting, cleaning, and setting up your

oscilloscope, using Quick Help.

Chapter 2 Front-panel Overview—A quick start guide to get you familiarize

you with the front-panel operation.

Chapter 3 Triggering the Oscilloscope—how to trigger the oscilloscope using

all the various modes.

Chapter 4 MegaZoom Concepts and Oscilloscope Operation—acquiring

waveforms, horizontal and vertical operation, using digital channels.

Chapter 5 Making Measurements—capturing data, using math function,

making measurement with cursors and automatic measurements.

Chapter 6 Utilities—configuring the I/O, print settings, Quick Help, floppy

disk operations, user cal and self cal, setting the clock and screen saver.

Chapter 7 Performance Characteristics

iii

Page 4

iv

Page 5

Contents

1 Getting Started

Setting up the Oscilloscope 1-4

To inspect package contents 1-5

To inspect options and accessories 1-8

To clean the oscilloscope 1-11

To adjust the handle 1-12

To power-on the oscilloscope 1-13

To adjust the waveform intensity 1-14

To connect the oscilloscope analog probes 1-15

To compensate your analog probe 1-16

To use the digital probes (mixed-signal oscilloscope only) 1-17

To connect a printer 1-21

To connect an RS-232 cable 1-21

To verify basic oscilloscope operation 1-22

Getting started using the oscilloscope interface 1-23

Using Quick Help 1-25

Selecting a language for Quick Help when the oscilloscope starts up 1-25

Selecting a language for Quick Help after you have been operating the

oscilloscope 1-26

Loading an updated language file from floppy disk 1-27

2 Front-Panel Overview

Important Oscilloscope Considerations 2-3

54620/40-series Oscilloscope Front Panels 2-7

Front-Panel Operation 2-10

Interpreting the display 2-11

To use analog channels to view a signal 2-12

To use digital channels to view a signal 2-13

To display signals automatically using Autoscale 2-14

To apply the default factory configuration 2-15

To adjust analog channel vertical scaling and position 2-16

To set the vertical expand reference for the analog signal 2-17

Contents-1

Page 6

Contents

To set analog channel probe attenuation factor 2-17

To display and rearrange the digital channels 2-18

To operate the time base controls 2-19

To start and stop an acquisition 2-20

To make a single acquisition 2-20

To use delayed sweep 2-21

To make cursor measurements 2-22

To make automatic measurements 2-23

To modify the display grid 2-24

To print the display 2-24

3 Triggering the Oscilloscope

Selecting Trigger Modes and Conditions 3-3

To select the Mode and Coupling menu 3-3

To select a trigger mode: Normal, Auto, Auto Level 3-4

To select trigger Coupling 3-6

To select Noise Reject and HF Reject 3-6

To set holdoff 3-7

External Trigger Input 3-9

Trigger Types 3-11

To use Edge triggering 3-12

To use Pulse Width triggering 3-14

To use Pattern triggering 3-17

To use CAN triggering 3-19

To use Duration triggering 3-21

To use I2C triggering 3-24

To use LIN triggering 3-29

To use Sequence triggering 3-31

To use SPI triggering 3-37

To use TV triggering 3-42

To use USB triggering 3-52

The Trigger Out connector 3-54

Contents-2

Page 7

4 MegaZoom Concepts and Oscilloscope Operation

MegaZoom Concepts 4-3

Deep Memory 4-4

Oscilloscope Responsiveness 4-5

Display Update Rate 4-6

To setup the Analog channels 4-7

To setup the Horizontal time base 4-11

Acquisition Modes 4-17

Display modes 4-21

Pan and Zoom 4-23

To pan and zoom a waveform 4-24

Run/Stop/Single/Infinite Persistence Operation 4-25

Acquiring Data 4-26

Memory Depth/Record Length 4-27

To run and stop an acquisition 4-28

To take a single trace 4-28

To capture a single event 4-29

To use infinite persistence 4-30

To use infinite persistence to store multiple repetitive events 4-30

To clear the waveform display 4-31

Contents

Configuring the Mixed-Signal Oscilloscope 4-32

To display digital channels using Autoscale 4-32

Interpreting the digital waveform display 4-33

To display and rearrange the digital channels 4-34

To turn individual channels on and off 4-35

To force all channels on or all channels off 4-36

To change the display size of the digital channels 4-36

To change the logic threshold for digital channels 4-37

Using Digital Channels to Probe Circuits 4-38

Using Labels on the Mixed-Signal Oscilloscope 4-42

To turn the label display on or off 4-43

To assign a predefined label to a channel 4-44

To define a new label 4-45

To reset the label library to the factory default 4-47

Contents-3

Page 8

Contents

Saving and Recalling Traces and Setups 4-48

To Autosave traces and setups 4-49

To save traces and setups to internal memory or to overwrite an existing

floppy disk file 4-50

To save traces and setups to a new file on the floppy disk 4-51

To recall traces and setups 4-52

Saving (printing) screen images to floppy disk 4-53

Recalling the factory default setup 4-54

5 Making Measurements

Capturing Data 5-3

To use delayed sweep 5-4

To reduce the random noise on a signal 5-6

To capture glitches or narrow pulses with peak detect and infinite

persistence 5-10

To use the Roll horizontal mode 5-12

To use the XY horizontal mode 5-13

Math Functions 5-17

Math Scale and Offset 5-18

Multiply 5-19

Subtract 5-20

Differentiate 5-21

Integrate 5-23

FFT Measurement 5-25

Cursor Measurements 5-31

To make cursor measurements 5-32

Automatic Measurements 5-37

Making automatic measurements 5-38

Setting measurement thresholds 5-39

Making time measurements automatically 5-41

Making Delay and Phase Measurements 5-45

Making voltage measurements automatically 5-47

Making overshoot and preshoot measurements 5-50

Contents-4

Page 9

6 Utilities

To configure Quick Help languages 6-3

To update your instrument to the latest application software 6-5

To configure a printer 6-6

To use the floppy disk 6-8

To set up the I/O port to use a controller 6-9

To set the clock 6-11

To set up the screen saver 6-12

To perform service functions 6-14

To set other options 6-16

7 Performance Characteristics

Agilent 54620-series Performance Characteristics 7-3

Agilent 54640-series Performance Characteristics 7-13

Contents

Contents-5

Page 10

Contents-6

Page 11

1

Getting Started

Page 12

Getting Started

When you use the oscilloscopes to help test and troubleshoot your

systems, you may do the following:

• Prepare the oscilloscope by connecting it to power and setting up the

handle and screen intensity as desired.

• Define the measurement problem by understanding the parameters

of the system you wish to test, and the expected system behavior.

• Set up channel inputs by connecting the probes to the appropriate

signal and ground nodes in the circuit under test.

• Define the trigger to reference the waveform data at a specific event

of interest.

• Use the oscilloscope to acquire data, either in continuous or single-

shot fashion.

• Examine the data and make measurements on it using various

features.

• Save the measurement or configuration for later re-use or comparison

with other measurements.

Repeat the process as necessary until you verify correct operation or

find the source of the problem.

MegaZoom Technology Operates with Untriggered Data

With the MegaZoom technology built into the oscilloscope, you can

operate the oscilloscope with untriggered data. All you do is press

or

Single while in Auto trigger mode, then examine the data to set up a

trigger.

1-2

Run

Page 13

Getting Started

The oscilloscope’s high-speed display can be used to isolate infrequently

changing signals. You can then use the characteristics of these signals

to help refine the trigger specification. For more information on

triggering, data acquisition, data examination and measurement, and

configuration, see the later chapters.

Using the Oscilloscope, and Refining the Trigger Specification

1-3

Page 14

Setting up the Oscilloscope

To prepare your oscilloscope for use, you need to do the following tasks.

A ft er y ou ha v e c om pl e te d t he m , y ou w il l b e re ad y t o us e t he o sc il l os co pe .

In the following topics you will:

• inspect package contents

• inspect options and accessories

• learn how to clean the oscilloscope

• adjust the handle

• power-on the oscilloscope

• adjust the display intensity

• connect the oscilloscope probes

• connect the digital probes (with 54621D/22D/41D/42D)

• connect a printer

• connect a RS-232 cable

• verify basic oscilloscope operation

• get started using the oscilloscope interface

• learn how to use Quick Help

1-4

Page 15

Getting Started

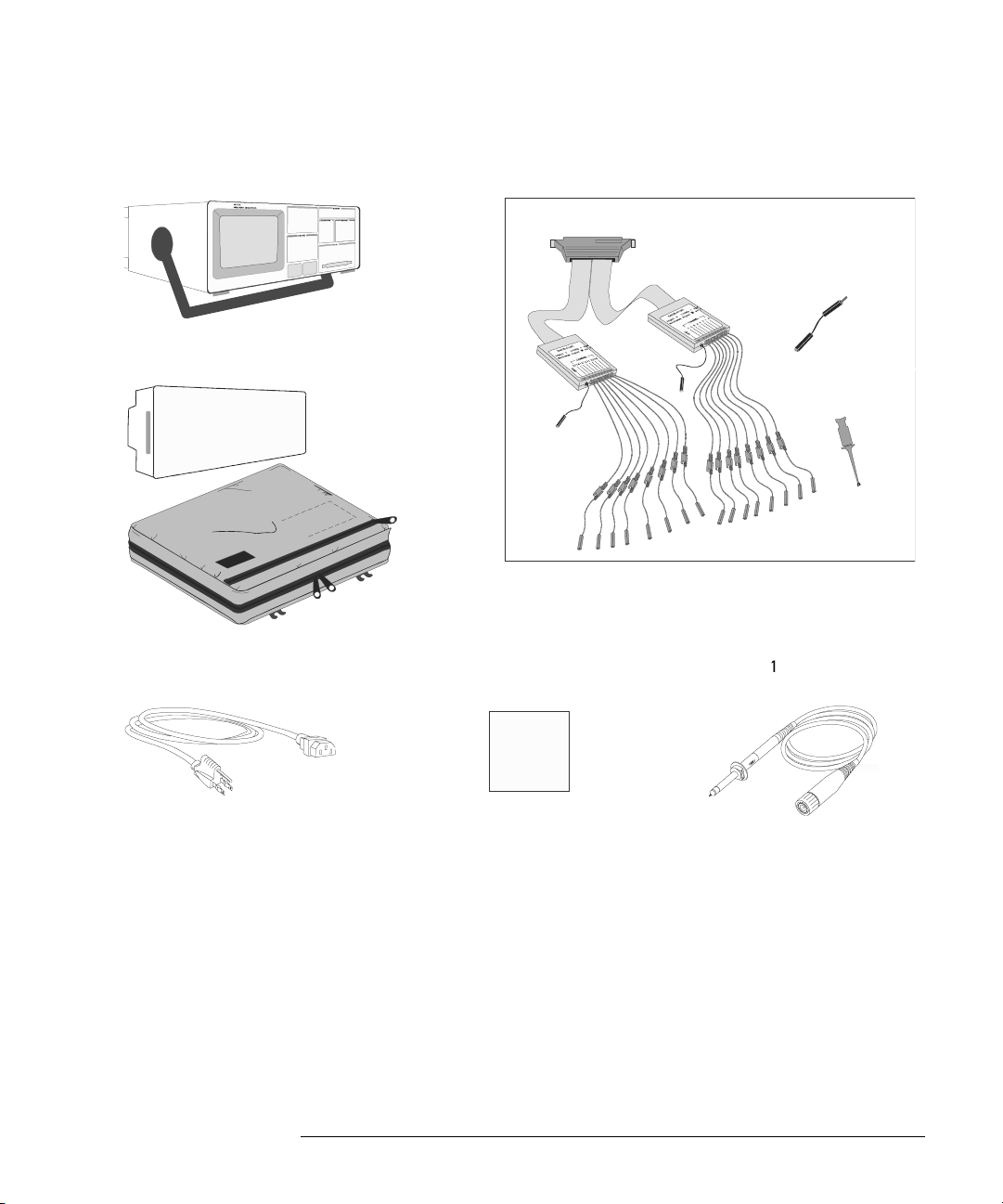

To inspect package contents

To inspect package contents

❏ Inspect the shipping container for damage.

If your shipping container appears to be damaged, keep the shipping container

or cushioning material until you have inspected the contents of the shipment

for completeness and have checked the oscilloscope mechanically and

electrically.

❏ Verify that you received the following items and any optional accessories in

the oscilloscope packaging (see figure following).

• 54620/40-Series Oscilloscope:

54621A, 21D, 22A, 22D, 24A, 41A, 41D, 42A, or 42D

• 10:1 passive probes with id:

(2) 10074C (150 MHz) for 54621A, 21D, 22A, or 22D

(4) 10074C (150 MHz) for 54624A

(2) 10073C (500 MHz) for 54641A, 41D, 42A, or 42D

• 54620-68701 digital probe kit for 54621D, 22D, 41D, or 42D

• Accessory pouch and front-panel cover standard for all except 54621A, 21D.

(54621A and 21D order N2726A)

• Power cord (see table 1-3)

• IntuiLink for 54600-series Oscilloscopes software and RS-232 cable (all

except for 54621A or 21D).

IntuiLink is a Windows application that makes it very easy for you to

download images, waveform data, or oscilloscope setups from the

oscilloscope to your pc using either Microsoft Word or Microsoft Excel. After

installation of IntuiLink, a tool bar in these Microsoft applications will make

connection and data transfer from the oscilloscope very simple.

IntuiLink fov

IntuiLink for 54600-series Oscilloscopes software is available free on the web

at:

www.agilent.com/find/5462xsw

RS-232 cable may be ordered separately, part number 34398A

1-5

Page 16

Getting Started

To inspect package contents

• Agilent IntuiLink Data Capture (all except for 54621A or 21D)

IntuiLink Data Capture is a standalone program for downloading waveform

data from the oscilloscopes to your PC via GPIB or RS-232 interface. It

provides the capability to transfer deep memory data out of the oscilloscope,

allowing up to 4MB (scope channels) and 8MB (logic channels). The

IntuiLink for 54600-Series limits the size of acquisition data available to a

maximum of 2,000 points regardless of actual number of acquisition points

on the screen. With the IntuiLink Data Capture, the amount of points

transferred will be the actual number of acquisition points currently

displayed or you may select the number of points to download. It provides

the following functionality:

• Download waveform data and display the data as a simple chart

• Save the data as binary or text files

• Copy the chart and a selected portion of the data to the clipboard. The

maximum data saved to the clipboard is 50,000 point

• Load saved waveform data back into the application

For 54621A and 21D users, IntuiLink Data Capture software is available free

on the web at:

www.agilent.com/find/5462xsw

RS-232 cable may be ordered separately, part number 34398A

If anything is missing, contact your nearest Agilent Sales Office. If the shipment

was d amag ed, contact the carrier, then c onta ct th e nearest Agilent Sales Office.

❏ Inspect the oscilloscope

• If there is mechanical damage or a defect, or if the oscilloscope does not

operate properly or does not pass the performance tests listed in the Service

Guide, notify your Agilent Sales Office.

• If the shipping container is damaged, or the cushioning materials show signs

of stress, notify the carrier and your Agilent Sales Office. Keep the shipping

materials for the carrier’s inspection. The Agilent Sales Office will arrange

for repair or replacement at Agilent’s option, without waiting for claim

settlement.

1-6

Page 17

Getting Started

To inspect package contents

54620/40-Series Oscilloscope

Accessories pouch and

front-panel cover**

Power cord

54620-68701 digital probe kit*

54620-61801 16-channel cable***

IntuiLink for 54600-series

software, Data Capture

software and serial cable**

5959-9334 2” Probe

ground lead (qty 5)

5090-4833 Grabber

(qty 20)

10073C or

10074C Probes

s

s1

* 54621D /22D/41D/42D only

** All except 54621A/21D

*** The following additional replacement parts (not included) are available for the digital cable:

5959-9333 replacement probe leads (qty 5)

5959-9335 replacement pod grounds (qty 5)

01650-94309 package of probe labels

Package contents for 54620/40-Series Oscilloscopes

1-7

Page 18

Getting Started

To inspect options and accessories

To inspect options and accessories

❏ Verify that you received the options and accessories you ordered and that none

were damaged.

If anything is missing, contact your nearest Agilent Sales Office. If the shipment

wa s d am ag ed, or th e c us hion in g m at eria ls sh ow si gns o f s tr es s, noti fy th e carr ie r

and your Agilent Sales Office.

Some of the options and accessories available for the 54620/40-Series

Oscilloscopes are listed in tables 1-1 and 1-2. Contact your Agilent Sales Office

for a complete list of options and accessories.

Table 1-1

Options available

Option Description

003 Shielding Option for use in severe environments or with sensitive devices under

test–shields both ways (in and out):

RS-03 magnetic interface shielding added to CRT, and

RE-02 display shield added to CRT to reduce radiated interference.

1CM Rackmount kit (same as 1186A)

A6J ANSII Z540 compliant calibration with test data

See table 1-3 for power cord options

1-8

Page 19

Getting Started

To inspect options and accessories

Table 1-2

Accessories available

Model Description

01650-61607 16:16 logic cable and terminator (for use with 54621D/22D/41D/42D)

54620-68701 16:2 x 8 logic input probe assembly (shipped s tandard with 54621D/22D/41 D/42D)

1146A Current probe, ac/dc

1183A Testmobile scope cart

1185A Carrying Case

1186A Rackmount Kit

10070C 1:1 Passive Probe with ID

10072A Fine-pitch probe kit

10075A 0.5 mm IC clip kit

10076A 100:1, 4 kV 250 MHz probe with ID

10100C 50

10833A GPIB cable, 1 m long

34398A RS-232 cable (standard except 54621A/21D)

E2613B 0.5 mm Wedge probe adapter, 3-signal, qty 2

E2614A 0.5 mm Wedge probe adapter, 8-signal, qty 1

E2615B 0.65 mm Wedge probe adapter, 3-signal, qty 2

E2616A 0.65 mm Wedge probe adapter, 8-signal, qty 1

E2643A 0.5 mm Wedge probe adapter, 16-signal, qty 1

E2644A 0.65 mm Wedge probe adapter, 16-signal, qty 1

N2726A Accessory pouch and front-panel cover (standard except on 54621A/21D)

N2727A Thermal printer and pouch

N2728A 10 rolls of thermal printer paper

N2757A GPIB Interface Module

N2758A CAN Trigger Module

N2772A 20 MHz differential probe

N2773A Differential probe power supply

N2774A 50 MHz current probe ac/dc

N2775A Power supply for N2774A

Ω Termination

1-9

Page 20

Getting Started

To inspect options and accessories

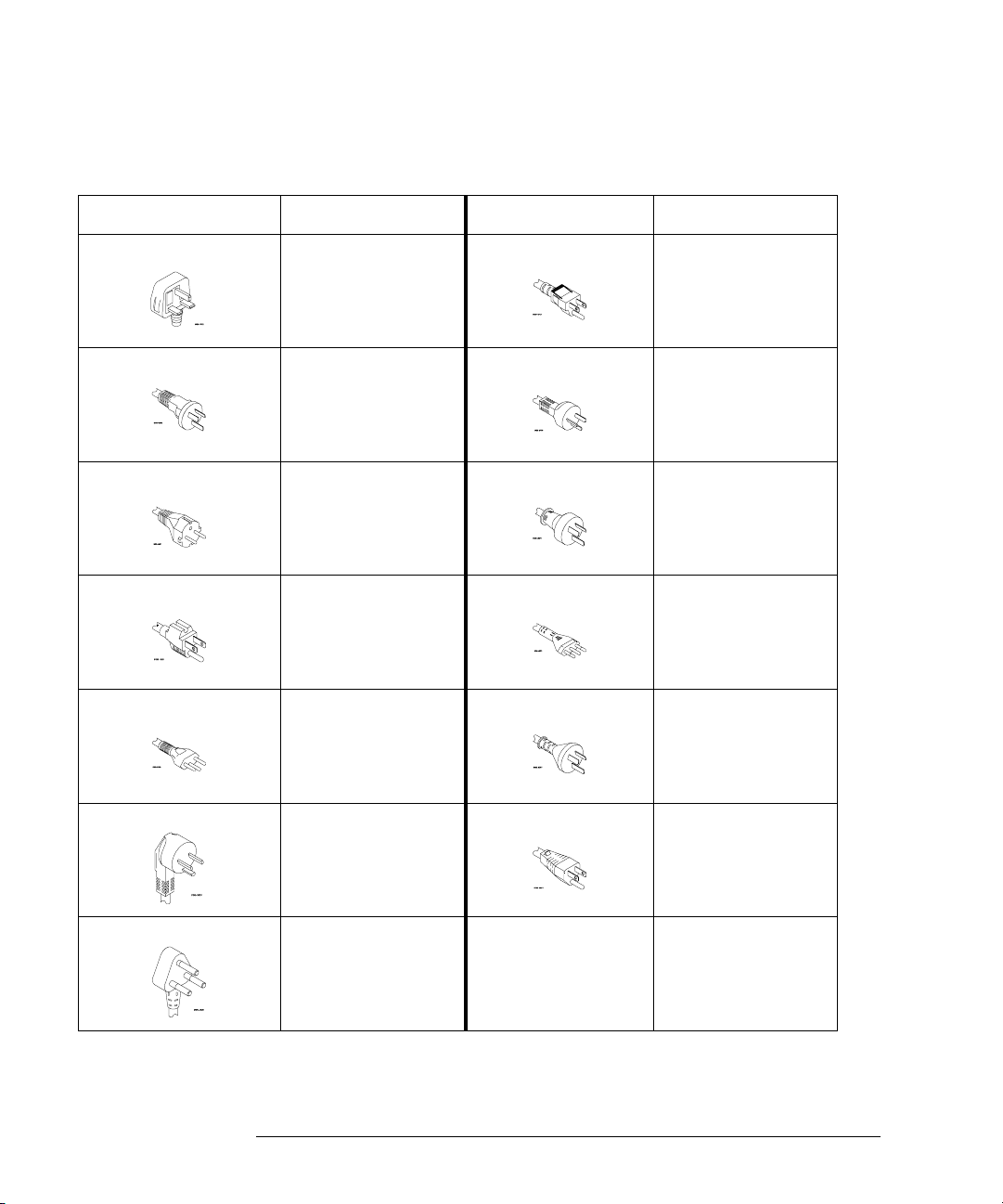

Table 1-3. Power Cords

Plug Type Cable Part Number Plug Type Cable Part Number

Opt 900 (U.K.) 8120-1703 Opt 918 (Japan) 8120-4754

Opt 901 (Australia) 8120-0696 Opt 919 (Israel) 8120-6799

Opt 902 (Europe) 8120-1692 Opt 920 (Argentina) 8120-6871

Opt 903 (U.S.A.) 8120-1521 Opt 921 (Chile) 8120-6979

Opt 906 (Switzerland) 8120-2296 Opt 922 (China) 8120-8377

Opt 912 (Denmark) 8120-2957 Opt 927 (Thailand) 8120-8871

Opt 917 (Africa) 8120-4600

1-10

Page 21

Getting Started

To clean the oscilloscope

To clean the oscilloscope

1 Disconnect power from the instrument.

CAUTION Do not use too much liquid in cleaning the oscilloscope. Water can enter the

front-panel keyboard, control knobs, or floppy disk damaging sensitive

electronic components.

2 Clean the oscilloscope with a soft cloth dampened with a mild soap and

water solution.

3 Make sure that the instrument is completely dry before reconnecting to

a power source.

1-11

Page 22

Getting Started

To adjust the handle

To adjust the handle

1 Grasp the handle pivot points on each side of the instrument and pull

the pivot out until it stops.

54622D

Agilent

MIXED SIGNAL OS CILLOSCOPE

CHANNEL

Select

Time/Div

150

5 ns1 s

INPUTS

2 Without releasing the pivots, swivel the handle to the desired position.

Then release the pivots. Continue pivoting the handle until it clicks into

a set position.

1-12

Page 23

Getting Started

To power-on the oscilloscope

To power-on the oscilloscope

1 Connect the power cord to the rear of the oscilloscope, then to a

suitable ac voltage source.

The oscilloscope power supply automatically adjusts for input line voltages in

the range 100 to 240 VAC. Therefore, you do not need to adjust the input line

voltage setting. The line cord provided is matched to the country of origin.

Ensure that you have the correct line cord. See table 1-3

2 Press the power switch.

Trigger out

~5V

Some front panel key lights will come on and the oscilloscope will be operational

in about 5 seconds.

1-13

Page 24

Figure 1-1

Getting Started

To adjust the waveform intensity

To adjust the waveform intensity

The Intensity control is at the lower left corner of the front panel.

• To decrease waveform intensity, rotate the Intensity control counterclockwise.

• To increase waveform intensity, rotate the Intensity control clockwise.

BrightDim

Intensity control

The grid or graticule intensity on the display can be adjusted by pressing the

Display key, then turn the Entry knob (labeled on the front panel) to adjust

the Grid control.

1-14

Page 25

Getting Started

To connect the oscilloscope analog probes

To connect the oscilloscope analog probes

The analog input impedance of these oscilloscopes is selectable either 50Ω

(54640-series only) or 1 MΩ. The 50Ω mode matches 50Ω cables commonly

used in making high frequency measurements. This impedance matching gives

you the most accurate measurements since reflections are minimized along the

signal path. The 1 MΩ mode is for use with probes and for general purpose

measurements. The higher impedance minimizes the loading effect of the

oscilloscope on the circuit under test.

CAUTION Do not exceed 5 Vrms in 50Ω mode on the 54640-series models. Input

protection is enabled in 50Ω mode and the 50Ω load will disconnect if greater

than 5 Vrm s i s d et ect ed . How ev er th e i np ut s co uld sti ll be dam ag ed , de pe nd ing

on the time constant of the signal.

CAUTION The 50Ω input protection mode on the 54640-series models only functions

when the oscilloscope is powered on.

1 Connect the supplied 1.5-meter, 10:1 oscilloscope probe to an analog

channel BNC connector input on the oscilloscope.

Maximum input voltage for analog inputs:

CAT I 300 Vrms, 400 Vpk

CAT II 100 Vrms, 400 Vpk

with 10073C or 10074C 10:1 probe: CAT I 500 Vpk, CAT II 400 Vpk

2 Connect the retractable hook tip on the probe tip to the circuit point of

interest. Be sure to connect the probe ground lead to a ground point on

the circuit.

The probe ground lead is connected to the oscilloscope chassis and the ground

wire in the power cord. If you need to connect the ground lead to a point in the

circuit that cannot be grounded to power ground, consider using a differential

probe.

1-15

Page 26

Perfectly compensated

Over compensated

Getting Started

To compensate your analog probe

To compensate your analog probe

You should compensate you analog probes to match their characteristics to the

oscilloscope. A poorly compensated probe can introduce measurement errors.

To compensate a probe, follow these steps:

1 Connect the probe from channel 1 to the Probe Comp signal on the lower-

right corner of the front panel.

2Press

3 Use a nonmetallic tool to adjust the trimmer capacitor on the probe for

Autoscale.

the flattest pulse possible.

Under compensated

comp.cdr

1-16

Page 27

Getting Started

To use the digital probes (mixed-signal oscilloscope only)

To use the digital probes (mixed-signal oscilloscope

only)

1 If you feel it’s necessary, turn off the power supply to the circuit under

test.

Off

Turning off power to the circuit under test would only prevent damage that

might occur if you accidentally short two lines together while connecting

probes. You can leave the oscilloscope powered on because no voltage appears

at the probes.

2 Connect the digital probe cable to D15 - D0 connector on the front panel

of the mixed-signal oscilloscope. The digital probe cable is indexed so

you can connect it only one way. You do not need to power-off the

oscilloscope.

Use only the Agilent part number 54620-68701 digital probe kit supplied with

the mixed-signal oscilloscope.

1-17

Page 28

Getting Started

To use the digital probes (mixed-signal oscilloscope only)

3 Connect a grabber to one of the probe leads. Be sure to connect the

ground lead. (Other probe leads are omitted from the figure for clarity.)

Grabber

4 Connect the grabber to a node in the circuit you want to test.

1-18

Page 29

Getting Started

To use the digital probes (mixed-signal oscilloscope only)

5 For high-speed signals, connect a ground lead to the probe lead, connect

a grabber to the ground lead, and attach the grabber to ground in the

circuit under test.

Signal Lead

Ground Lead

Grabber

6 Connect the ground lead on each set of channels, using a probe grabber.

The ground lead improves signal fidelity to the instrument, ensuring

accurate measurements.

Channel

Pod Ground

Circuit

Ground

1-19

Page 30

Getting Started

To use the digital probes (mixed-signal oscilloscope only)

7 Repeat steps 3 through 6 until you have connected all points of interest.

Signals

Ground

8 If you need to remove a probe lead from the cable, insert a paper clip

or other small pointed object into the side of the cable assembly, and

push to release the latch while pulling out the probe lead.

Replacement parts are available. See the Replaceable Parts chapter in the

Service Guide for details.

1-20

Page 31

Getting Started

To connect a printer

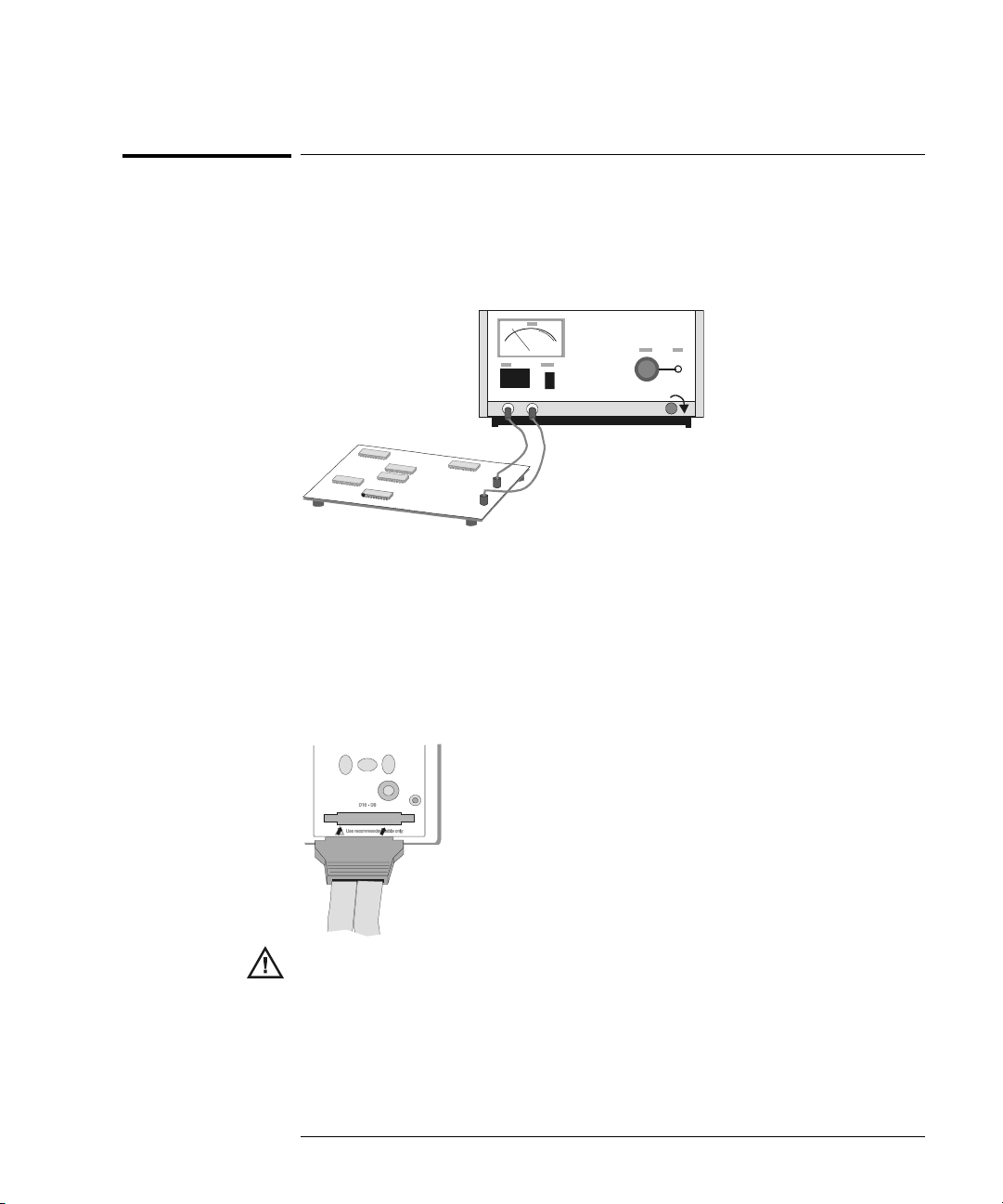

To connect a printer

The oscilloscope connects to a parallel printer through the Parallel output

connector on the rear of the oscilloscope. You will need a parallel printer cable

to connect to the printer.

1 Attach the 25-pin small “D” connector to the Parallel output connector

on the rear of the oscilloscope. Tighten the thumbscrews on the cable

connector to secure the cable.

2 Attach the larger 36-pin “D” connector to the printer.

3 Set up the printer configuration on the oscilloscope.

a Press the Utility key, then press the Print Confg softkey.

b Press the Print to: softkey and set the interface to Parallel.

c Press the Format softkey and select your printer format from the list.

For more information on printer configuration, refer to the “Utilities” chapter.

To connect an RS-232 cable

The oscilloscope can be connected to a controller or a pc through the RS-232

connector on the rear of the oscilloscope. An RS-232 cable is shipped with each

oscilloscope except 54621A/21D and may be purchased for the 54621A/21D

oscilloscopes.

1 Attach the 9-pin “D” connector on the RS-232 cable to the RS-232

connector on the rear of the oscilloscope. Tighten the thumbscrews on

the cable connector to secure the cable

2 Attach the other end of the cable to your controller or pc.

3 Set up the RS-232 configuration on the oscilloscope.

a Press the Utility key, then press the I/O softkey.

b Press the Controller softkey and select RS-232.

c Press the Baud softkey and set the baud rate to match your controller or pc.

d Press the XON DTR softkey and set the handshake to match your controller

or pc.

For more information on RS-232 configuration, refer to the “Utilities” chapter.

1-21

Page 32

Getting Started

To verify basic oscilloscope operation

To verify basic oscilloscope operation

1 Connect an oscilloscope probe to channel 1.

2 Attach the probe to the Probe Comp output on the lower-right side of

the front panel of the oscilloscope.

Use a probe retractable hook tip so you do not need to hold the probe.

3Press the Save/Recall key on the front panel, then press the Default Setup

softkey under the display.

The oscilloscope is now configured to its default settings.

4Press the Autoscale key on the front panel.

You should then see a square wave with peak-to-peak amplitude of about 5

divisions and a period of about 4 divisions as shown below. If you do not see

the waveform, ensure your power source is adequate, the oscilloscope is

properly powered-on, and the probe is connected securely to the front-panel

channel input BNC and to the Probe Comp calibration output.

Verifying Basic Oscilloscope Operation

1-22

Page 33

Getting started using the oscilloscope interface

When the oscilloscope is first turned on, a startup screen is displayed as

shown below.

This menu is only accessible when the oscilloscope first starts up.

1-23

Page 34

Getting Started

To verify basic oscilloscope operation

•Press the Getting Started softkey to view the symbols used in the

oscilloscope softkey menus.

Use the Entry knob labeled to adjust the parameter.

Press the softkey to display a pop up with a list of choices. Repeatedly

press the softkey until your choice is selected.

Use the Entry knob labeled or press the softkey to adjust the

parameter.

✓ Option is selected and operational.

Feature is on. Press the softkey again to turn the feature off.

Feature is off. Press the softkey again to turn the feature on.

Links you to another menu.

Press the softkey to view the menu.

1-24

Press the softkey to return to the previous menu.

Page 35

Using Quick Help

The oscilloscope has a Quick Help system that provides user help for

each front-panel key and softkey on the oscilloscope. To view Quick Help

information:

1Press

2 Release the key after reading the message. Releasing the key returns

and hold down the key for which you would like to view help.

the oscilloscope to the previous state.

Selecting a language for Quick Help when the oscilloscope starts up

When the oscilloscope first powers up, you can press the Language softkey to

select a language for viewing Quick Help. Successively press the Language

softkey until the desired language in the list is selected.

You can also select a language later from the Utility Language menu.

1-25

Page 36

Getting Started

Selecting a language for Quick Help after you have been operating the oscilloscope

Selecting a language for Quick Help after you have been

operating the oscilloscope

1Press the Utility key, then press the Language softkey to display the

Language menu.

2Press the

selected.

Language softkey until the desired language in the list is

When updates occur, an updated language file can be downloaded from:

www.agilent.com/find/5462xsw

www.agilent.com/find/5464xsw

or call an Agilent center and request a language disk for your instrument

1-26

for the 54620-series or

for the 54640-series,

Page 37

Getting Started

Loading an updated language file from floppy disk

Loading an updated language file from floppy disk

When updates occur, an updated language file can be downloaded from:

www.agilent.com/find/5462xsw

www.agilent.com/find/5464xsw

or call an Agilent center and request a language disk for your instrument.

1 Insert the floppy disk containing the language file into the floppy disk

drive on the oscilloscope.

2Press the

Utility key, then press the Language softkey to display the

Language menu.

3Press the

Load Languages softkey to load the updated language file into

the oscilloscope.

4Press the

For more information about loading languages, refer to the “Utilities” chapter.

Language softkey and select the language to be viewed.

for the 54620-series or

for the 54640-series,

1-27

Page 38

1-28

Page 39

2

Front-Panel Overview

Page 40

Front-Panel Overview

Before you make measurements using the Agilent 54620-series and

54640-series Oscilloscopes, you must first set up the instrument using

front-panel controls. Then, make the measurement and read the display

results.

These oscilloscopes operate much like an analog scope, but they can do

much more. Spending a few minutes to learn some of these capabilities

will take you a long way toward more productive troubleshooting. The

“MegaZoom Concepts and Oscilloscope Operation” chapter has more

detail on the things to consider while operating your oscilloscope.

The keys on the front panel bring up softkey menus on the display that

allow access to oscilloscope features. Many softkeys use the Entry

knob to select values.

Throughout this book, the front-panel keys and softkeys are denoted by

a change in the text type. For example, the

panel and the

above its corresponding key. Other softkey graphic conventions used

on the oscilloscope and throughout this guide are shown in the “Getting

started using the oscilloscope interface” topic in chapter 1.

Normal softkey appears at the bottom of the display directly

Cursors key is on the front

2-2

Page 41

Front-Panel Overview

Important Oscilloscope Considerations

Important Oscilloscope Considerations

Using Single versus Run/Stop

The oscilloscopes have a Single key and a Run/Stop key. When you press Run

(key is illuminated in green), the trigger processing and screen update rate are

optimized over the memory depth. Single acquisitions always use the maximum

memory available—at least twice as much memory as acquisitions captured in

Run mode—and the scope stores at least twice as many samples. At slow sweep

speeds, the oscilloscope operates at a higher sample rate when Single is used

to capture an acquisition, as opposed to running, due to the increased memory

available.

Using Auto trigger mode versus Normal trigger mode

Normal trigger mode requires a trigger to be detected before an acquisition can

complete. In many cases, a triggered display in not needed to check signal levels

or activity. For these applications, use Auto trigger mode. If you only want to

acquire specific events as specified by the trigger settings, use Normal trigger

mode. For more detailed discussion of Auto trigger mode and Normal trigger

mode, refer to Chapter 3, “Triggering the Oscilloscope.”

Viewing signal detail with acquire mode

Remember how you had to constantly adjust the brightness on old analog scopes

to see a desired level of detail in a signal, or to see the signal at all? With the

Agilent 54620/40-series oscilloscopes, this is not necessary. The Intensity knob

ope ra te s muc h l ik e the br ig ht nes s k no b o n you r c om pute r s cr ee n, s o y ou sh oul d

set it to a level that makes for comfortable viewing, given the room lighting, and

leave it there. Then you can control the detail by selecting an Acquire mode:

Normal, Peak Detect, Average, or Realtime as described in the following

paragraphs.

Normal acquire mode Normal mode is the acquisition mode that you will

probably use for acquiring samples most of the time. It compresses up to 2

million acquisition points per channel for the 54620-series and up to 4 million

acquisition points per channel for the 54640-series into a 1,000-pixel column

display record.

The 54620-series 200 MSa/s sampling speed specification means that samples

are taken every 5 ns. The 54640-series 2 GSa/s sampling speed specification

means that samples are taken every 500 ps. At the faster sweep speeds, the

running display is built from many individual triggers. If you press the Stop key,

and pan and zoom through the waveform by using the Horizontal and Vertical

knobs, only the last trigger’s acquisition will be displayed.

2-3

Page 42

Front-Panel Overview

Important Oscilloscope Considerations

Whether the oscilloscope is stopped or running, you see more detail as you zoom

in, and less as you zoom out. Zoom means you expand the waveform using

either the main or delayed sweep window. Panning the waveform means you

use the Horizontal Delay time knob( )to move it horizontally. To keep from

losing detail as you zoom out, switch to the Peak Detect acquisition mode.

Peak Detect acquire mode Peak Detect for the 54620-series and for the

54640-series functions as follows:

• 54620-series In Peak Detect acquisition mode, any noise, peak, or signal

wider than 5 ns will be displayed, regardless of sweep speed. In Normal

acq uisition mo de, at sweep speed s fa ster than 1 ms/div, yo u wou ld se e a 5-ns

peak, so peak detect has no effect at sweep speeds faster than 1 ms/div.

• 54640-series In Peak Detect acquisition mode, any noise, peak, or signal

wider than 1 ns will be displayed, regardless of sweep speed. In Normal

acquisition mode, at sweep speeds faster than 500 µs/div, you would see a

1-ns peak, so peak detect has no effect at sweep speeds faster than 500 µs/div.

Using Peak Detect and infinite persistence together is a powerful way to find

spurious signals and glitches.

Average acquire mode Averaging is a way to pull a repetitive signal out of

noise. Averaging works better than either a brightness control or a bandwidth

limit because the bandwidth is not reduced except when in high resolution mode

(number of averages=1) is selected.

The simplest averaging is high-resolution mode (number of averages = 1). For

example, on the 54620-series, the sample rate at a Time/Div setting of 2 ms/div

allows the extra 5-ns sa mple s to b e smoothed together, smo othi ng th e data into

one sample, which is then displayed. Averaging (number of averages > 1) needs

a stable trigger, because in this mode multiple acquisitions are averaged

together. See the “MegaZoom Concepts and Oscilloscope Operation” chapter

for more information about high resolution mode.

2-4

Page 43

Front-Panel Overview

Important Oscilloscope Considerations

Realtime acquire mode In Realtime mode, the oscilloscope produces the

waveform display from samples collected during one trigger event. The sample

rate for the 54620-series is 200 MSa/s for single channel or 100 MSa/s with

channel pairs 1 and 2, 3 and 4, or pod 1 and pod 2 running. The sample rate for

the 54640-series is 2 GSa/s for single channel or 1 GSa/s with channel pairs 1

and 2, or pod 1 and pod 2 running.

When less than 1000 samples can be collected in the time spanned by the screen,

a sophisticated reconstruction filter is used to fill in and enhance the waveform

display.

To accurately reproduce a sampled waveform, the sample rate should be at least

four times the highest frequency component of the waveform. If not, it is

possible for the reconstructed waveform to be distorted or aliased. Aliasing is

most commonly seen as jitter on fast edges.

When Realtime mode is off, the oscilloscope produces the waveform display

from samples collected from multiple triggers, when on fast sweep speeds. In

this case, the reconstruction filter is not used. When the trigger is stable, this

produces the highest fidelity waveform.

Realtime mode is only necessary at sweep speeds of 200 ns/div and faster for

the 54620-series and 2 µs/div and faster for the 54640-series, since on these

ranges <1000 samples can be collected on each trigger. While the effective

bandwidth of the channel is reduced slightly, Realtime mode produces a

complete waveform for each trigger.

Realtime can be turned on when any other acquisition mode is turned on. Use

Realtime to capture infrequent triggers, unstable triggers, or complex changing

waveforms, such as eye diagrams.

Using Vectors (Display menu)

One of the most fundamental choices you must make about your display is

whether to draw vectors (connect the dots) between the samples, or simply let

the samples fill in the waveform. To some degree, this is a matter of personal

preference, but it also depends on the waveform.

• You will probably operate the oscilloscope most often with vectors on.

Complex analog signals like video and modulated signals show analog-like

intensity information with vectors on.

• Turn vectors off when the maximum display rate is required, or when highly

complex or multi-valued waveforms are displayed. Turning vectors off may

aid the display of mulitvalued waveforms such as eye diagrams.

2-5

Page 44

Front-Panel Overview

Important Oscilloscope Considerations

Delayed Sweep

Delayed sweep is a simultaneous display of the waveform at two different sweep

speeds. Because of the deep memory in the MegaZoom technology, it is possible

to capture the main display at 1 ms/div, and redisplay the same trigger in the

delayed display at any desired faster time base.

There is no limit imposed on the zoom ratio between the main and delayed

displays. There is, however, a useful limit when the samples are spaced so far

apart that they are of little value. See the “MegaZoom Concepts and

Oscilloscope Operation” chapter for more information about delayed sweep and

time reference.

Post Acquisition Processing

In addition to changing display parameters after the acquisition, you can do all

of the measurements and math functions after the acquisition. Measurements

and math functions will be recalculated as you pan and zoom and turn channels

on and o ff. As you zoom in and out on a signal using the horizontal sweep spe ed

knob and vertical volts/division knob, you affect the resolution of the display.

Because measurements and math functions are performed on displayed data,

you affect the resolution of functions and measurements.

2-6

Page 45

Figure 2-1

Front-Panel Overview

54620/40-series Oscilloscope Front Panels

54620/40-series Oscilloscope Front Panels

Intensity

control

Display

Softkeys

Floppy

disk

Measure

keys

Entry

knob

Autoscale

key

Power

switch

Horizontal

controls

Vertical

inputs/

controls

Waveform

keys

File

keys

Run

controls

Trigger

controls

Utility

key

Probe

comp

output

External

Trigger

input

54621A, 54622A, 54641A, and 54642A 2-Channel Oscilloscopes Front Panel

2-7

Page 46

Figure 2-2

Front-Panel Overview

54620/40-series Oscilloscope Front Panels

Intensity

control

Display

Softkeys

Floppy

disk

Measure

keys

Entry

knob

Autoscale

key

Power

switch

Horizontal

controls

Vertical

inputs/

controls

Waveform

keys

File

keys

Run

controls

Trigger

controls

Utility

key

Probe

comp

output

54624A 4-Channel Oscilloscope Front Panel

2-8

Page 47

Figure 2-3

Front-Panel Overview

54620/40-series Oscilloscope Front Panels

Intensity

control

Display

Softkeys

Floppy

disk

Measure

keys

Entry

knob

Autoscale

key

Power

switch

Horizontal

controls

Analog Channel

inputs/ controls

Waveform

keys

File

keys

Run

controls

Trigger

controls

Utility

key

Probe

Comp

output

Digital Channel

inputs/ controls

54621D, 54622D, 54641D, and 54642D Mixed-Signal Oscilloscopes Front Panel

2-9

Page 48

Front-Panel Operation

This chapter provides a brief overview of interpreting information on the

display and an introduction to operating the front-panel controls.

Detailed oscilloscope operating instructions are provided in later

chapters.

54621D, 54622D. 54641D, and 54642D digital channels

Because all of the oscilloscopes in the 54620/40-series have analog channels, the

analog channel topics in this chapter apply to all instruments. Whenever a topic

discusses the digital channels, that information applies only to the 54621D, 54622D,

54641D, or 54642D Mixed-Signal Oscilloscopes.

2-10

Page 49

Front-Panel Overview

Interpreting the display

Interpreting the display

The oscilloscope display contains channel acquisitions, setup information,

measurement results, and softkeys for setting up parameters.

Analog

channels

sensitivity

Status line

Analog

channels and

ground levels

Digital

channels

Measurement

line

Softkeys

Digital

channel

activity

Interpreting the display

Trigger point,

time reference

Delay

time

Sweep

speed

Trigger

mode

Trigger

type

Trigger

source

Trigger level

or digital

threshold

Cursor

markers

defining

measurement

Status line The top line of the display contains vertical, horizontal, and trigger

setup information.

Display area The display area contains the waveform acquisitions, channel

identifiers, and analog trigger and ground level indicators.

Measurement line This line normally contains automatic measurement and

cursor results, but can also display advanced trigger setup data and menu

information.

Softkeys The softkeys allow you to set up additional parameters for

front-panel keys.

2-11

Page 50

Front-Panel Overview

To use analog channels to view a signal

To use analog channels to view a signal

• To configure the oscilloscope quickly, press the Autoscale key to display

the connect signal.

• T o un do th e ef fe ct s of Au to s ca l e, pr es s th e

pressing any other key.

This is useful if you have unintentionally pressed the Autoscale key or do not

like the settings Autoscale has selected and want to return to your previous

settings.

• To set the instrument to the factory-default configuration, press the

Save/Recall key, then press the Default Setup softkey.

Example Connect the oscilloscope probes for channels 1 and 2 to the Probe Comp output

on the front panel of the instrument. Be sure to connect the probe ground l ead s

to the lug above the Probe Comp output. Set the instrument to the factory

default configuration by pressing the Save/Recall key, then the Default Setup

softkey. Then press the Autoscale key. You should see a display similar to the

following.

Undo Autoscale softkey before

Autoscale with analog channels

2-12

Page 51

Front-Panel Overview

To use digital channels to view a signal

To use digital channels to view a signal

• To configure the oscilloscope quickly, press the Autoscale key to display

the connected signals.

• T o un do th e ef fe ct s of Au to s ca l e, pr es s th e

pressing any other key.

This is useful if you have unintentionally pressed the Autoscale key or do not

like the settings Autoscale has selected and want to return to your previous

settings.

• To set the instrument to the factory-default configuration, press the

Save/Recall key, then press the Default Setup softkey.

Example Install probe clips on channels 0 and 1 on the digital probe cable. Connect the

pr obes for di gital channe ls 0 and 1 to the P robe Comp o utp ut on t he fr ont pa nel

of the instrument. Be sure to connect the ground lead. Set the instrument to

the factory default configuration by pressing the Save/Recall key, then the

Default Setup softkey. Then press the Autoscale key. You should see a display

similar to the following.

Undo Autoscale softkey before

Autoscale with digital channels (54621D, 54622D, 54641D, and 54642D)

2-13

Page 52

Front-Panel Overview

To display signals automatically using Autoscale

To display signals automatically using Autoscale

• To configure the instrument quickly, press the Autoscale key.

Autoscale displays all connected signals that have activity.

To undo the effects of Autoscale, press the Undo Autoscale softkey before

pressing any other key.

How Autoscale Works

Autoscale automatically configures the oscilloscope to best display the input

signal by analyzing any waveforms connected to the external trigger and

channel inputs. Autoscale finds, turns on, and scales any channel with a

repetitive waveform with a frequency of at leas t 50 Hz, a duty cycle greater than

0.5%, and an amplitude of at least 10 mV peak-to-peak. Any channels that do

not meet these requirements are turned off.

The trigger source is selected by looking for the first valid waveform starting

with external trigger, then continuing with the highest number analog channel

down to the lowest number analog channel, and finally (if applicable) the

highest number digital channel.

During Autoscale, the delay is set to 0.0 seconds, the sweep speed setting is a

function of the input signal (about 2 periods of the triggered signal on the

screen), and the triggering mode is set to edge. Vectors remain in the state they

were before the Autoscale.

Undo Autoscale

Press the Undo Autoscale softkey to return the oscilloscope to the settings that

existed before you pressed the Autoscale key.

This is useful if you have unintentionally pressed the Autoscale key or do not

like the settings Autoscale has selected and want to return to your previous

settings.

The Channels softkey selection determines which channels will be displayed on

subsequent Autoscales.

All Channels - The next time you press Autoscale, all channels that meet the

requirements of Autoscale will be displayed.

Only Displayed Channels - The next time you press Autoscale, only the

channels that are turned on will be displayed. This is useful if you only want

to view specific active channels after pressing Autoscale.

2-14

Page 53

Front-Panel Overview

To apply the default factory configuration

To apply the default factory configuration

• To set the instrument to the factory-default configuration, press the

Save/Recall key, then press the Default Setup softkey.

The default configuration returns the oscilloscope to its default settings. This

places the oscilloscope in a known operating condition. The major default

settings are:

Horizontal main mode, 100 us/div scale, 0 s delay, center time reference

Vertical (Analog) Channel 1 on, 5 V/div scale, dc coupling, 0 V position, 1 MΩ

impedance, probe factor to 1.0 if an AutoProbe probe is not connected to the

channel

Trigger Edge trigger, Auto sweep mode, 0 V level, channel 1 source, dc

coupling, rising edge slope, 60 ns holdoff time

Display Vectors on, 20% grid intensity, infinite persistence off

Other Acquire mode normal, Run/Stop to Run, cursors and measurements off

Labels all custom labels in the Label Library are erased

2-15

Page 54

Front-Panel Overview

To adjust analog channel vertical scaling and position

To adjust analog channel vertical scaling and position

This exercise guides you through the vertical keys, knobs, and status line.

1 Center the signal on the display using the position knob.

The position knob ( ) moves the signal vertically; the signal is calibrated.

Notice that as you turn the pos ition knob, a voltage value is displayed for a short

time, indicating how far the reference ( )is located from the center of the

screen. Also notice that the ground reference symbol at the left edge of the

display moves with the position knob.

Measurement Hints

If the channel is DC coupled, you can quickly measure the DC component of the

signal by simply noting its distance from the ground symbol.

If the channel is AC coupled, the DC component of the signal is removed, allowing

you to use greater sensitivity to display the AC component of the signal.

2 Change the vertical setup and notice that each change affects the status

line differently. You can quickly determine the vertical setup from the

status line in the display.

• Change the vertical sensitivity with the large volts/division knob in the

Vertical (Analog) section of the front panel and notice that it causes the

status line to change.

•Press the 1 key.

If channel 1 was not turned on, a softkey menu appears on the display, and

the channel turns on (the 1 key will be illuminated).

If channel 1 was already turned on, but another menu was being displayed,

the softkeys will now display the channel 1 menu.

When Vernier is turned off, the volts/div knob can change the channel sensitivity

in a 1-2-5 step sequence. When Vernier is selected, you can change the channel

sensitivity in smaller increments with the volts/division knob. The channel

sensitivity remains fully calibrated when Vernier is on. The sensitivity value is

displayed in the status line at the top of the display.

• To turn the channel off, press the channel 1 key until the key is not

illuminated.

2-16

Page 55

Front-Panel Overview

To set the vertical expand reference for the analog signal

To set the vertical expand reference for the analog signal

When changing the volts/division for analog channels, you can have the signal

expand (or compress) about the signal ground point or about the center

graticule on the display. This works well with two signals displayed, because

you can position and see them both on the screen while you change the

amplitude.

• To expand the signal about the center graticule of the display, press the Utility

key, press the Options softkey, then press the Expand softkey and select

Expand About Center.

With Expand About Center selected, when you turn the volts/division, the

waveform with expand or contract about the center graticule of the display.

• To expand the signal about the position of the channel’s ground, press the

Utility key, press the Options softkey. Then press the Expand softkey and

select Expand About Ground.

With Expand About Ground selected, when you turn the volts/division knob,

the ground level of the waveform remains at the same point on the display,

while the non-ground portions of the waveform expand or contract.

To set analog channel probe attenuation factor

If you have an AutoProbe self-sensing probe (such as the 10073C or 10074C)

connected to the analog channel, the oscilloscope will automatically configure

your probe to the correct attenuation factor.

If you do not have an AutoProbe probe connected, you can press the channel

key, then press the Probe submenu softkey, then turn the Entry knob to

set the attenuation factor for the connected probe. The attenuation factor can

be set from 0.1:1 to 1000:1 in a 1-2-5 sequence.

Th e pro be cor rect ion factor must be set prope rly f or m easurements t o be m ade

correctly.

2-17

Page 56

Front-Panel Overview

To display and rearrange the digital channels

To display and rearrange the digital channels

1Press the D15 Thru D8 key or D7 Thru D0 key to turn the display of the digital

channels on or off.

The digital channels are displayed when these keys are illuminated.

2 Turn the Digital Channel Select knob to select a single digital channel.

The selected channel number is highlighted on the left side of the display.

3 Turn the Digital position knob ( ) to reposition the selected channel

on the display.

If two or more channels are displayed at the same position, a pop up will appear

showing the overlaid channels. Continue turning the Channel Select knob until

the desired channel within the pop up is selected.

2-18

Page 57

Front-Panel Overview

To operate the time base controls

To operate the time base controls

The following exercise guides you through the time base keys, knobs, and status

line.

• Turn the Horizontal sweep speed (time/division) knob and notice the

change it makes to the status line.

The sweep speed knob changes the sweep speed from 5 ns/div to 50 s/div for

the 54620-series and 1 ns/div to 50 s/div for the 54640-series in a 1-2-5 step

sequence, and the value of the sweep speed is displayed in the status line at the

top of the display.

•Press the Main/Delayed, then press the Vernier softkey.

The Vernier softkey allows you to change the sweep speed in smaller increments

with the time/div knob. These smaller increments are calibrated, which results

in accurate measurements, even with the vernier turned on.

• Turn the delay time knob ( ) and notice that its value is displayed in

the status line.

The delay knob moves the main sweep horizontally, and it pauses at 0.00 s,

mimicking a mechanical detent. At the top of the graticule is a solid triangle

(

▼) s ym b o l an d a n op e n t r i a ng l e ( ∇) s y mb o l . Th e ▼ symbol indicates the trigger

point and it moves with the Delay time knob. The ∇ symbol indicates the time

reference point and is also where the zoom-in/zoom-out is referenced. If the

Tim e Ref softkey is set to Left, the ∇ is located one graticule in from the left side

of the display. If the Time Ref softkey is set to Center, the

center of the display. If the Time Ref softkey is set to Right, the

graticule in from the right side of the display. The delay number tells you how

far the time reference point ∇ is located from the trigger point

All events displayed left of the trigger point

occurred, and these events are called pre-trigger information. You will find this

fe at ur e v ery u se fu l b ecau se yo u can no w s ee the ev en ts that le d u p to th e t ri gge r

point. Everything to the right of the trigger point

information. The amount of delay range (pre-trigger and post-trigger

information) available depends on the sweep speed selected.

▼ happened before the trigger

∇ is located at the

∇ is located one

▼.

▼ is called post-trigger

2-19

Page 58

Front-Panel Overview

To start and stop an acquisition

To start and stop an acquisition

• When the Run/Stop key is illuminated in green, the oscilloscope is in

continuous running mode.

You are viewing multiple acquisitions of the same signal similar to the way an

analog oscilloscope displays waveforms.

• When the Run/Stop key is illuminated in red, the oscilloscope is stopped.

“Stop” is displayed in the trigger mode position in status line at the top of the

display. You may now pan and zoom the stored waveform by turning the

Horizontal and Vertical knobs.

The stopped display may contain several triggers worth of information, but only

the last trigger acquisition is available for pan and zoom. To ensure the display

does not change, use the Single key to be sure you have acquired only one

trigger.

•The Run/Stop key may flash between a user requesting a Stop and the

completion of the current acquisition.

To make a single acquisition

The Single run control key lets you view single-shot events without subsequent

waveform data overwriting the display. Use Single when you want maximum

memory depth for pan and zoom and you want the maximum sample rate.

1 First set trigger Mode/Coupling Mode softkey to Normal.

This keeps the oscilloscope from autotriggering immediately.

2 If you are using the analog channels to capture the event, turn the

Trigger Level knob to the trigger threshold where you think the trigger

should work.

3 To begin a single acquisition, press the

When you press Single, the display is cleared, the trigger circuitry is armed, the

Single key is illuminated, and the oscilloscope will wait until a trigger condition

occurs before it displays a waveform.

When the oscilloscope triggers, the single acquisition is displayed and the

oscilloscope is stopped (Run/Stop key is illuminated in red). Press Single again

to acquire another waveform.

2-20

Single key.

Page 59

Front-Panel Overview

To use delayed sweep

To use delayed sweep

Delayed sweep is an expanded version of main sweep. When Delayed mode is

selected, the display divides in half and the delayed sweep icon displays in

the middle of the line at the top of the display. The top half displays the main

sweep and the bottom half displays the delayed sweep.

The following steps show you how to use delayed sweep. Notice that the steps

are very similar to operating the delayed sweep in analog oscilloscopes.

1 Connect a signal to the oscilloscope and obtain a stable display.

2Press

3Press the

Main/Delayed.

Delayed softkey.

To change the sweep speed for the delayed sweep window, turn the sweep speed

knob. As you turn the knob, the sweep speed is highlighted in the status line

above the waveform display area.

Th e area of the main disp lay that is e xpanded is in tensified and marked on ea ch

end with a vertical marker. These markers show what portion of the main sweep

is expanded in the lower half. The Horizontal knobs control the size and position

of the delayed sweep. The delay value is momentarily displayed in the

upper-right portion of the display when the delay time ( ) knob is turned.

Delayed sweep is a magnified portion of the main sweep. You can use delayed

sweep to locate and horizontally expand part of the main sweep for a more

detailed (higher-resolution) analysis of signals.

To change th e sweep speed f or the main sweep wind ow, pre ss th e Main softkey,

then turn the sweep speed knob.

2-21

Page 60

Front-Panel Overview

To make cursor measurements

To make cursor measurements

Yo u c an use th e c ur sors to ma ke cust om vo lt age o r t im e m easu re me nts on sc op e

signals, and timing measurements on digital channels.

1 Connect a signal to the oscilloscope and obtain a stable display.

2Press the

Mode Set the cursors results to measure voltage and time (Normal), or display

the binary or hexadecimal logic value of the displayed waveforms.

Source selects a channel or math function for the cursor measurements.

X Y Select either the X cursors or the Y cursors for adjustment with the Entry

knob.

X1 and X2 adjust horizontally and normally measure time.

Y1 and Y2 adjust vertically and normally measure voltage.

X1 X2 and Y1 Y2 move the cursors together when turning the Entry knob.

For more information about using cursors for measurements, refer to the

“Making Measurements” chapter.

Cursors key. View the cursor functions in the softkey menu:

2-22

Page 61

Front-Panel Overview

To make automatic measurements

To make automatic measurements

You can use automatic measurements on any channel source or any running

math function. Cursors are turned on to focus on the most recently selected

measurement (right-most on the measurement line above the softkeys on the

display).

1Press the Quick Meas key to display the automatic measurement menu.

2Press the

on which the quick measurements will be made.

Only channels or math functions that are displayed are available for

measurements. If you choose an invalid source channel for a measurement, the

measurement will default to the nearest in the list that makes the source valid.

If a portion of the waveform required for a measurement is not displayed or does

not display enough resolution to make the measurement, the result will be

displayed with a message such as greater than a value, less than a value, not

enough edges, not enough amplitude, incomplete, or waveform is clipped to

indicate that the measurement may not be reliable.

3Press the Clear Meas softkey to stop making measurements and to erase

the measurement results from the measurement line above the

softkeys.

When Quick Meas is pressed again, the default measurements on an analog

channel will be will be Frequency and Peak-Peak.

4 Choose what measurement you want on that source by pressing the

Select softkey, then turn the Entry knob to select the desired

measurement from the popup list.

5Press the Measure softkey to make the selected measurement.

6To turn off

illuminated.

For detailed information about making automatic measurements, refer to the

“Making Measurements” chapter.

Source softkey to select the channel or running math function

Quick Meas, press the Quick Meas key again until it is not

2-23

Page 62

Front-Panel Overview

To modify the display grid

To modify the display grid

1Press the Display key.

2 Turn the Entry knob to change the intensity of the displayed grid. The

intensity level is shown in the

Grid softkey and is adjustable from 0 to

100%.

Each major division in the grid (also know as graticule) corresponds to the

sweep speed time shown in the status line on the top of the display.

• To change waveform intensity, turn the INTENSITY knob on the

lower-left corner of the front panel.

To print the display

You can print the complete display, including the status line and softkeys, to a

parallel printer or to the floppy disk by pressing the Quick Print key. You can

stop printing by pressing the Cancel Print softkey.

To set up your printer, press the Utility key, then press the Print Confg softkey.

For more information on printing and floppy disk operation, refer to the

“Utilities” chapter.

2-24

Page 63

3

Triggering the Oscilloscope

Page 64

Triggering the Oscilloscope

The Agilent 54620/40-series Oscilloscopes provide a full set of features

to help automate your measurement tasks, including MegaZoom

technology to help you capture and examine the stored waveforms of

interest, even untriggered waveforms. With these oscilloscopes you can:

• modify the way the oscilloscope acquires data.

• set up simple or complex trigger conditions, as needed, to capture

only the sequence of events you want to examine.

The oscilloscopes all have common triggering functionality:

• Trigger modes

Auto

Normal

Auto Level (54620-series only)

• Coupling (including high frequency and noise rejection)

•Holdoff

• Trigger Level

• External Trigger input

• Trigger types

Edge (slope)

Pulse width (glitch)

Pattern

CAN

Duration

2

I

C

LIN

Sequence

SPI

TV

USB

• Trigger Out connector

3-2

Page 65

Selecting Trigger Modes and Conditions

The trigger mode affects the way in which the oscilloscope searches for

the trigger. The figure below shows the conceptual representation of

acquisition memory. Think of the trigger event as dividing acquisition

memory into a pre-trigger and post-trigger buffer. The position of the

trigger event in acquisition memory is defined by the time reference

point and the delay setting.

Trigger Event

Pre-Trigger Buffer

Acquisition Memory

Acquisition Memory

Post-Trigger Buffer

To select the Mode and Coupling menu

•Press the Mode/Coupling key in the Trigger section of the front panel.

3-3

Page 66

Triggering the Oscilloscope

To select a trigger mode: Normal, Auto, Auto Level

To select a trigger mode: Normal, Auto, Auto Level

1Press the Mode/Coupling key.

2Press the

• Normal mode displays a waveform when the trigger conditions are met,

otherwise the oscilloscope does not trigger and the display is not updated.

• Auto mode is the same as Normal mode, except it forces the oscilloscope to

trigger if the trigger conditions are not met.

• Auto Level mode (54620-series only) works only when edge triggering on

analog channels or external trigger. The oscilloscope first tries to Normal

trigger. If no trigger is found, it searches for a signal at least 10% of full scale

on the trigger source and sets the trigger level to the 50% amplitude point.

If there is still no signal present, the oscilloscope auto triggers. This mode

is useful when moving a probe from point to point on a circuit board.

Auto Level and Auto modes

Use th e a uto tr ig ge r mo de s f or sig na ls othe r t ha n l ow- re pe ti tive -r at e sign al s a nd

for unknown signal levels. To display a dc signal, you must use one of these two

auto trigger modes since there are no edges on which to trigger.

Auto Level mode (54620-series only) is the same as Auto mode with an

automatic trigger level adjustment. The oscilloscope looks at the level on the

signals, and if the trigger level is out-of-range with respect to the signal, the

scope adjusts the trigger level back to the middle of the signal.

When you select Run, the oscilloscope operates by first filling the pre-trigger

buffer. It starts searching for a trigger after the pre-trigger buffer is filled, and

continues to flow data through this buffer while it searches for the trigger. While

searching for the trigger, the oscilloscope overflows the pre-trigger buffer; the

first data put into the buffer is the first pushed out (FIFO). When a trigger is

found, the pre-trigger buffer will contain the events that occurred just before

the trigger. If no trigger is found, the oscilloscope generates a trigger and

displays the data as though a trigger had occurred.

When you select Single, the oscilloscope will fill pre-trigger buffer memory, and

continue flowing data through the pre-trigger buffer until the auto trigger

overrides the searching and forces a trigger. At the end of the trace, the scope

will stop and display the results.

Mode softkey, then select Normal, Auto, or Auto Level mode.

3-4

Page 67

Triggering the Oscilloscope

To select a trigger mode: Normal, Auto, Auto Level

Normal mode

Use Normal trigger mode for low repetitive-rate signals or when Auto trigger is

not required. In this mode, the oscilloscope has the same behavior whether the

acquisition was initiated by pressing Run/Stop or Single.

In Normal mode the oscilloscope must fill the pre-trigger buffer with data before

it will begin searching for a trigger event. The trigger mode indicator on the

status line flashes to indicate the oscilloscope is filling the pre-trigger buffer.

While searching for the trigger, the oscilloscope overflows the pre-trigger buffer;

the first data put into the buffer is the first pushed out (FIFO).

When the trigger event is found, the oscilloscope will fill the post-trigger buffer

and display the acquisition memory. If the acquisition was initiated by Run/Stop,

the process repeats. The waveform data will be scrolled onto the display as it

is being acquired.

In either Auto or Normal mode, the trigger may be missed completely under

certain conditions. This is because the oscilloscope will not recognize a trigger

event until the pre-trigger buffer is full. Suppose you set the Time/Div knob to

a slow sweep speed, such as 500 ms/div. If the trigger condition occurs before

the oscilloscope has filled the pre-trigger buffer, the trigger will not be found.

If you use Normal mode and wait for the trigger condition indicator to flash

before causing the action in the circuit, the oscilloscope will always find the

trigger condition correctly.

Some measurements you want to make will require you to take some action in

the circuit under test to cause the trigger event. Usually, these are single-shot

acquisitions, where you will use the Single key.

3-5

Page 68

Triggering the Oscilloscope

To select trigger Coupling

To select trigger Coupling

1Press the Mode/Coupling key.

2Press the

• DC coupling allows dc and ac signals into the trigger path.

• AC coupling places a high-pass filter (3.5 Hz for 54620-series analog channels,

10 Hz for 54640-series analog channels, and 3.5 Hz for all External trigger

inputs) in the trigger path removing any DC offset voltage from the trigger

waveform. Use AC coupling to get a stable edge trigger when your waveform

has a large DC offset.

• LF (low frequency) Reject coupling places a 50-kHz high-pass filter in series

with the trigger waveform. Low frequency reject removes any unwanted low

frequency components from a trigger waveform, such as power line

frequencies, that can interfere with proper triggering. Use this coupling to

get a stable edge trigger when your waveform has low frequency noise.

• TV coupling is normally grayed-out, but is automatically selected when TV

trigger is enabled in the Trigger More menu.

Coupling softkey, then select DC, AC, or LF Reject coupling.

To select Noise Reject and HF Reject

1Press the Mode/Coupling key.

2Press the

softkey to select high frequency reject.

• Noise Rej adds additional hysteresis to the trigger circuitry. When noise reject

is on, the trigger circuitry is less sensitive to noise but may require a greater