Page 1

Copyright Agilent

Technologies 2000

All rights reserved.

Reproduction, a daptio n, or

translation without prior

written permission is

prohibited, except as

allowed under the

copyright laws.

Agilent Part No.

37718-90218

Printed in U.K. Sept ember

2000.

Warranty

The information co ntained

in this document is subject

to change without notice.

Agilent Technologies

makes no warra n t y of any

kind with regard to this

material, including, but

not limited to, the implied

warranties or

merchantab ility and fitness

for a particular purpose.

Agilent T ec hno logies shall

not be liable for errors

contained here in or f or

incidental or consequential

damages in connection

with the furnishing,

performance, or use of this

material.

WARNING

Warning Symbols Used on

the Product

!

The product is marked

with this symbol when the

user should refer to the

instruction manual in order

to protect the apparatus

against damage.

The product is marked

with this symbol to

indicate that hazardous

voltages are present

The product is mar ked

with this symbol to

indicate that a laser is

fitted. The user should

refer to the laser safety

information in the

Verification Manual.

Agilent Technologies UK Limited

Telecommunications Networks Test Divi sion

South Queensferry

West Lothian, Scotland EH30 9TG

Page 2

2DRAFT

Page 3

User Guide DSn/SONET/ATM/POS Operation

OmniBER 718 SONET User Guide

Page 4

About This Book

This book tells you how to select the features that you want to use for your test.

The selections available are presented in the following groups:

• Transmit and receive interfaces

• Test features, for example, the addition of errors and alarms to the test signal

• Measurements including test timing

• Storing, logging and printing results with general printer information

• Using instrument and disk storage

• Using the “Other” features.

The selections available will depend on the options fitted to your instrument. The

examples given in this book cover all options and therefore may include selections

which are not available on your instrument.

4

Page 5

Contents

1 Introduction

Product Description 14

Conventions 15

Connecting to the Network 16

Connecting Accessories 20

Front Panel Soft Recovery (Cold Start) 21

OmniBER 718 Option Guide 22

2 Setting the Interfaces

Setting PDH/DSn Transmit Interface

(Option 012) 26

Setting DSn THRU Mode 28

Setting SONET Transmit Interface 29

Setting Jitter Transmit Interface 33

Setting Wander Transmit Interface 35

Setting SONET THRU Mode 37

Using Smart Test 40

Setting PDH/DSn Receive Interface 45

Setting SONET Receive Interface 47

Setting Jitter Receive Interface 48

Setting Extended Jitter Receive Interface 49

Setting Wander Receive Interface 50

3 Selecting Test Features

Using Transmit Overhead Setup 52

Using Receive Overhead Monitor 54

5

Page 6

Contents

Setting Overhead Trace Messages 56

Setting Overhead Labels 57

Generating Overhead Sequences 58

Using Receive Overhead Capture 60

Adding Frequency Offset to SONET Signal 62

Adding Frequency Offset to the DSn Signal 64

Setting up Signaling Bits 65

Setting Transmit Structured Payload/Test Signal 68

Setting Receive Structured Payload/Test Signal 70

Setting Transmit N x 64 kb/s/N x 56 kb/s

Structured Payload/Test Signal 71

Setting Receive N x 64 kb/s/N x 56 kb/s

Structured Payload/Test Signal 73

Inserting an External DSn Payload/Test Signal 74

Dropping an External Payload/Test Signal 77

Adding Errors and Alarms at the SONET Interface 80

Adding Errors and Alarms to a DSn Signal 81

Using FEAC Codes 82

Setting DSn Spare Bits 84

Adding Pointer Adjustments 85

Using Pointer Graph Test Function 93

Stressing Optical Clock Recovery Circuits 95

Generating Automatic Protection Switch (APS) Messages 97

Inserting and Dropping the Data Communications Channel 102

Using DS1 LOOP Codes 103

4 Making Measurements

Using Overhead BER Test Function 108

Performing a Trouble Scan 109

6

Page 7

Contents

Test Timing 111

Making SONET Analysis Measurements 112

Making DSn Analysis Measurements 113

Measuring Frequency 114

Measuring Optical Power 115

Measuring Round Trip Delay 116

Monitoring Signaling Bits 118

Measuring Service Disruption Time 119

Performing a SONET Tributary Scan 122

Performing a SONET Alarm Scan 125

Performing a DSn Alarm Scan 126

Measuring Jitter 127

Measuring Extended Jitter 129

Measuring Wander 131

Measuring Jitter Tolerance 134

Measuring Jitter Transfer 138

Measuring Pointer Adjustment (Tributary) Jitter 144

5 ATM Operation

Setting up the Transmitter for ATM Payloads 150

Setting up the Convergence Sublayer 153

Setting Foreground Traffic 155

Setting Background Traffic 157

Setting Foreground and Background Distributions 158

Transmitting ATM Alarms 161

Adding ATM Errors 163

Viewing ATM Results 165

Setting up the Receiver for ATM Payloads 166

Setting up the Receiver ATM signal 168

7

Page 8

Contents

Policing ATM Traffic 170

Measuring ATM Delay Performance 172

Measuring ATM Alarms 175

ATM Service Disruption 176

6 Packet over SONET (POS)

POS Protocol Stack 180

Setting up the Transmitter for POS Payloads 181

Setting HDLC Framing, Scrambling and HDLC Frame Check

Sequence 183

Setting IP Packet (Datagram) Length and Inter-Packet Gap 186

Setting IP Header 188

Setting IP Addresses 189

Setting IP Payload 190

Adding POS Alarms 191

Adding POS Errors 192

Setting up the Receiver for POS Operation 193

Setting up the Receiver POS signal 195

Viewing POS Results 196

POS Applications 197

Channelized Testing 198

Fully Exercising POS Hardware Architecture 200

Throughput Testing 204

Continuity Test 208

POS Service Disruption 211

HDLC Frame Stuffing 214

Jitter Tolerance Testing of POS Equipment 217

8

Page 9

Contents

7 Storing, Logging and Printing

Saving Graphics Results to Instrument Store 222

Recalling Stored Graph Results 223

Viewing the Bar Graph Display 225

Viewing the Graphics Error and Alarm Summaries 227

Logging Graph Displays 229

Logging Results 231

Logging on Demand 241

Logging Jitter Tolerance Results 245

Logging Jitter Transfer Results 247

Logging Results to Parallel (Centronics) Printer 249

Logging Results to GP-IB Printer 250

Logging Results to Internal Printer 251

Logging Results to RS-232-C Printer 252

Printing Results from Disk 253

Connecting a Printer to a Parallel Port 254

Changing Internal Printer Paper 255

Cleaning Internal Printer Print Head 258

8 Using Instrument and Disk Storage

Storing Configurations in Instrument Store 260

Titling Configuration in Instrument Store 261

Recalling Configurations from Instrument Store 262

Formatting a Disk 263

Labeling a Disk 264

Managing Files and Directories on Disk 265

Saving a Screen Dump to Disk 272

Saving Graphical Results to Disk 274

9

Page 10

Contents

Saving Data Logging to Disk 276

Saving Configurations to Disk 277

Recalling Configuration from Disk 278

Recalling Graphics Results from Disk 279

Copying Configuration from Instrument Store to Disk 280

Copying Configuration from Disk to Instrument Store 282

Copying Graphics Results from Instrument Store to Disk 284

9 Selecting and Using "Other" Features

Coupling Transmit and Receive Settings 288

Setting Time & Date 289

Enabling Keyboard Lock 290

Enabling Beep on Received Error 291

In-Band DS1 Loopcode 156MTS Compatibility 292

Suspending Test on Signal Loss 293

REI-L Result/Enable 294

AIS-L Result/Enable 295

Graph Storage Resolution 296

Setting Error Threshold Indication 297

Setting Screen Brightness and Color 298

To Generate a New Jitter Mask 299

To change the parameters of a User-defined jitter mask 301

Running Self Test 303

Trigger Output 306

10

Page 11

Contents

10 STS-1 SPE Background Patterns

11 ETSI/ANSI Terminology

ETSI/ANSI Conversion and Equivalent Terms 312

12 Glossary of Terms

11

Page 12

Contents

12

Page 13

1

"Product Description " page 14

"Conventions " page 15

"Connecting to the Network " page 16

"Connecting Accessories " page 20

"Front Panel Soft Recovery (Cold Start) " page 21

"OmniBER 718 Option Guide " page 22

1 Introduction

Page 14

Product Description

Product Description

The OmniBER Communications Performance Analyzer provides all the test

capability you need to fully verify the performance of today’s high-capacity

transmission systems and networks.

The main features of a dual standard (SDH/SONET) instrument are as follows:

• Multi-rate transmission testing from DS0 to OC-48.

• Supports concatenated payloads of VT 1.5 to STS-48c.

• Full PDH/T- carrier testing.

• Direct measurement of protection switching time.

• Powerful thru-mode testing for SONET ring turn-up.

• Comprehensive SONET overhead testing.

• Packet over SONET/SDH (POS) and ATM payloads up to 2.5 Gb/s.

• Fast access to key measurement tasks via Smart Test.

• Optical power and line frequency measurements.

• J0 section trace for DWDM testing

• J1 and J2 path trace for network path testing

• Optional integrated graphical printer.

• Transmit and Receive can be independently configured.

14

Page 15

Conventions

+

Conventions

The conventions used in this manual to illustrate instrument keys and display

information are as follows:

TRANSMIT

PARALLEL

This is an example of a hardkey. Hardkeys (located to the right of the display) are

used to give access to different sets of instrument settings, or select dedicated

instrument functions. The key shown here displays the transmit settings.

This is an example of a softkey. Softkeys (located below the display) are used to

select instrument settings. The values associated with softkeys change as you move

the display cursor from one instrument setting to another.

These are the cursor control keys. They are used to move the display cursor from

one instrument setting to another.

This is an example of a pop-up menu. Pop-up menus are an alternative way of

selecting instruments settings (instead of using softkeys) . To access a pop-up menu,

highlight an instrument setting, then use the key.

This symbol (when it appears next to settings on the display) indicates that there is a

pop-up application associated with the instrument setting. To access a pop-up

application, highlight the instrument setting which has this symbol, then use the

SET

key.

SET

This symbol appears at the bottom right of the display when an optical transmit

module is fitted to the instrument. The symbol’s background changes from black to

yellow when the optical output goes active.

15

Page 16

Connecting to the Network

Connecting to the Network

The network connectors are located on the modules at the side of the instrument.

The connections available depend on the options fitted to your instrument.

Before Connecting, note the Warning and Caution information given.

Removing/Inserting Modules

Modules should only be removed or inserted by trained personnel.

All Connectors

CAUTION When connecting or disconnecting, ensure that you are grounded or,

make contact with the metal surface of the Mainframe with your free hand to bring

you, the module, and the mainframe to the same static potential.

Modules remain susceptible to ESD damage while the module is installed in the

Mainframe

Additional ESD information is required when servicing, see your Verification

manual for further information.

16

Page 17

Connecting to the Network

Optical Interface Connectors

For your protection, review all laser information given in this manual and th e

Verification manual before installing or using the instrument.

WARN IN G To prevent personal injury, avoid use that may be hazardous to others, and

maintain the module in a safe condition En sure the information given below is

reviewed before operating the module.

Laser Product Classification

All optical modules are classified as Class I (non-hazardous) laser product in the

USA which complies with the United States Food and Drug Administration (FDA)

Standard 21 CFR Ch.1 1040.10, and are classified as Class 1 (non-hazardous) laser

products in Europe which complies with EN 60825 -1 (199 4).

T o avoid hazardous expo sure to laser radiation, it is recommen ded that the f ollowing

practices are observed during system operation:

• ALWAYS DEACTIVATE THE LASER BEFORE CONNECTING OR

DISCONNECTING OPTICAL CABLES.

• When connecting or disconnecting optical cables between the module and device-under-test, observe the connection sequences given below.

Connecting: Connect the optical cable to the input of the device-under-test

before connecting to the module’s Optical Out connector.

Disconnecting: Disconnect the optical cable from the module’s Optical Out

connector before disconnecting from the device-under-test.

Always fit the fibre optic connector dust caps over the laser

aperture.

• NEVER examine or stare into the open end of a b roken, severed, or disconn ected

optical cable when it is connected to the module’s Optical Out connector.

• Arrange for service-trained personnel, who are aware of the hazards invo lved, to

repair optical cables.

17

Page 18

Connecting to the Network

CAUTION 1. Use of controls or adjustments or performance of procedures other than those

specified herein may result in hazardous radiation exposure.

2. Always fit the fibre optic connector dust caps on each connecto r when not in us e.

Before connection is made, always clean the connector ferrule tip with acetone or

alcohol and a cotton swab. Dry the connector with compressed air. Failure to

maintain cleanliness of connectors is liable to cause excessive insertion loss.

Laser Warning Symbols

The front p anel of the optical module has the following label:

CLASS 1 LASER PRODUCT

NOTE CLASS 1 LASER PRODUCT translates as follows:

Finnish - LUOKAN 1 LASERLAITE

Finnish/Swedish - KLASS 1 LASER APPARAT

This label indicates that the radiant energy present in this instrument is nonhazardous.

OPTICAL IN Allows connection of an optical si gnal, wavelengt h 1200 to 1600 n m, at a maximum

input power level of -8 dBm. NEVER EXCEED +3 dBm.

Accepts SONET signals OC-1, OC-3, OC-12 and OC-48 and SDH signals STM-0,

STM-1, STM-4 and STM-16 depending on the instrument options fitted.

OPTICAL OUT Provides optical signals OC-1, OC-3, OC-12 or OC-48 at wavelength 1290 nm to

1330 nm, at a typical power level of +1 dBm. Also provides SDH signals STM-0,

STM-1, STM-4 and STM-16 depending on the instrument options fitted.

18

Page 19

Connecting to the Network

Cleaning Optical Connectors

It is recommended that the optical connectors be cleaned at regular intervals using

the following materials:

Description Part Number

Blow Brush 9300-1131

Isopropyl Alcohol 8500-5344

Lens Cleaning Paper 9300-0761

Adhesive T ape Kit 15475-68701

CAUTION Do not insert any tool or object into t he IN or OUT port s of the instrum ent as damage

to or contamination of the optical fibre may result.

1 Recall Default settings (STORED SETTINGS 0) and remove the power from the

OmniBER 718.

2 Remove the adapters from the IN and OUT ports. Use an 11 mm spanner to

slacken the nut securing the adapter. On re-assembly tighten the nut using a

torque spanner to 1.5 Nm.

3 Using the blow brush with the brush removed blow through the ferrule of the

standard flexible connector and the adapter.

CAUTION If the optical fibre of the fixed connector requires further cleaning this entails

disassembly of the modul e which should only be carried out by suitably trained

service personnel.

4 Apply some isopropyl alcohol to a piece of the cleaning paper and clean the barrel

of the adapter. Us ing a new piece of cleaning paper , clean the face of the adapter .

Repeat this operation, using a new piece of cleaning paper each time.

5 Lightly press the adhesive side of the tape provided against the front of the

adapter, then remove it quickly - repeat twice. This removes any parti cles of

cleaning paper which may be present.

6 Replace the adapters on the flexible connector.

19

Page 20

Connecting Accessories

Connecting Accessories

LID Provides the output for the option 602 printer which is fitted in the cover (LID) of

the instrument.

VGA Provides the output for a display monitor.

HANDSET Allows connection of a telephone handset for communication across the network.

Printer

HP-IB (GPIB),

RS232,

PARALLEL ONLY

Remote Control

HP-IB (GPIB),

RS232,

10 BASE -T

The port selected for external printer use is not available for remote control.

See "Connecting a Printer to a Parallel Port " page 254.

Remote control connection is given in the Remote Control Manual.

The port selected for remote control use is not available for an external printer.

10 Base-T Lan Connection Radiated Emissions

To ensure compliance with EN 55011 (1991) a category 5, STP patch lead, RJ45

cable should be used to connect the LAN port on the processor module marked

"10 Base-T".

20

Page 21

Front Panel Soft Recovery (Cold Start )

Front Panel Soft Recovery (Cold Start)

Use the following procedure if you need to perform a front panel soft recovery (i.e.

cold start) of the instrument.

Soft Recovery Procedure

1 Switch off the instrument.

2 On the instrument front panel - press and hold so ftkeys 0 and 4 simultaneously

(the softkeys immediately below the display; key 0 is on the extreme left).

3 Power up the OmniBER 718 while holding the softkeys pressed.

4 When the LOS LED has flashed OFF and then ON again, the keys can be

released.

5 The LOS LED will flash OFF/ON again several times (7), followed by an audible

‘beep’ and the display indicating ‘Initializing Instrument’.

6 Once the initialization is complete the display will indicate:

‘Firmware Revision Update’

‘Default settings assumed’

Hit any key to attempt restart’

7 Hit any key, then wait approximately 10 seconds. The instrument should return

to its default settings and normal operation.

21

Page 22

OmniBER 718 Option Guide

OmniBER 718 Option Guide

This guide explains the features offered with each OmniBER Mainframe and its

associated options. There are three mainframes as follows:

• The 37718A

• The 37718B

• The 37718C

The instrument test interfaces are:

2.5 Gb/s, 622 Mb/s, 155 Mb/s, 52 Mb/s, DS1 (1.5 Mb/s), DS3 (45 Mb/s),

E1 (2 Mb/s), E2 (8Mb/s), E3 (34 Mb/s).

Mainframe test rate capability

Mainframe T est Rate Capability

37718A 2.5 Gb/s, 622 Mb/s, 155 Mb/s and 52

Mb/s

37718B 622 Mb/s, 155 Mb/s and 52 Mb/s

37718C 155 Mb/s and 52 Mb/s

Note that 52 Mb/s and 155 Mb/s electrical testing is included

in the base mainframe.

SDH/SONET Interf a c e

Interface Option

SDH only 001

Dual standard SDH/SONET (ANSI/ITU-

T)

22

002

Page 23

OmniBER 718 Option Guide

Tributary test options

Option

PDH/T-carrier DS1, DS3, 2 Mb/s, 8 Mb/s, 34 Mb/s

and 140 Mb/s

2 Mb/s into DS3 mapping (also requires option 012) 014

Replaces BNC connector with WECO 560 620

Optical interface

An optical interface must be ordered if an 37718A or 37718B is required.

Option

1310 nm only 104

1550 nm only 105

Dual wavelength 1310 nm/1550 nm 106

Replaces FC/PC adapters with SC 610

Replaces FC/PC adapters with ST 611

Jitter

Option

012

Adds jitter to all rates 200

23

Page 24

OmniBER 718 Option Guide

ATM/POS

Option

ATM payloads (requires option

350)

POS payloads (requires option

350)

Advanced payload engine 350

Please note that in earlier versions of the OmniBER the list of AT M options

included options 300, 301 and 302. These options have now been merged into one

ATM option 300 (as listed above). A new Advanced payload engine option 350 has

been added which must be ordered with an ATM or POS option.

Accessory options

Remote Omnibook controller 600

RS-232-C, GPIB and LAN remote control

interfaces

80-column in-lid printer 602

300

310

Option

601

24

Page 25

2

“Setting PDH/DSn Transmit Interface (Option 012)” page 26

“Setting DSn THRU Mode” page 28

“Setting SONET Transmit Interface” page 29

“Setting Jitter Transmit Interface” page 33

“Setting Wander Transmit Interface” page 35

“Setting SONET THRU Mode” page 37

“Using Smart Test” page 40

“Setting PDH/DSn Receive Interface” page 45

“Setting SONET Receive Interface” page 47

“Setting Jitter Receive Interface” page 48

“Setting Extended Jitter Receive Interface” page 49

“Setting Wander Receive Interface” page 50

2 Setting the Interfaces

This chapter tells you how to set the instrument

interfaces to match the network being tested.

Page 26

Setting the Interfaces

Setting PDH/DSn Transmit Interface (Option 012)

Description DSn transmit interface settings should match network equipment settings of R ate,

Termination and Line Code and determine the Payload to be tested.

TIP: To set the Transmitter and Receiver to the same interface settings choose

SETTINGS CONTROL COUPLED

HOW TO: 1 Choose the required SIGNAL rate from 2 Mb/s, 8 Mb/s, 34 Mb/s, 140 Mb/s PDH,

plus DS1, DS3 T-carrier interfaces.

2 Choose the required CLOCK SYNC source, internally generated, externally

generated or recovered from the received PDH/DSn signal. If you select an

external clock source, connect the external source to the appropriate port on the

OmniBER clock module.

.

OTHER

3 If DS1 or DS3 is chosen, choose the required OUTPUT LEVEL.

4 If you have chosen 2 Mb/s as the SIGNAL rate, choose the required

TERMINATION. (At all other signal rates the impedance is fixed).

26

Page 27

Setting the Interfaces

Setting PDH/DSn T ransmit Interface (Option 012)

5 If you have chosen 8 Mb/s, 2 Mb/s or DS1 as the SIGNAL rate, choose the

required LINE CODE. (At 140 Mb/s, 34 Mb/s and DS3 coding is fixed).

6 If required, choose the FREQUENCY OFFSET value.

See “Adding Frequency Offset to the DSn Signal” page 64.

7 Choose the required PAYLOAD TYPE.

If is required must be chosen.

STRUCTURED FRAMED

If is chosen the DSn test signal must be set up. See “Setting

STRUCTURED

Transmit Structured Payload/Test Signal” page 68.

If you have chosen 2 Mb/s, DS1 or DS3 as the DSn SIGNAL rate, the Framed

choice is expanded to provide a menu of framing types.

8 Choose the PATTERN type and the PRBS POLARITY.

Additional Patterns at DS1

9 If you select a DS1 SIGNAL , two 8-bi t pattern s and a 55 Octe t pat tern are ad ded

to the list of available patterns. The 8-bit patterns are as follows:

Table 1 8-Bit Patterns

Type Pattern

1-in-8 F01000000

2-in-8 F01100000

Note 1: F indicates the position of the framing bit with respect to the 8-bit pattern

when the framed data is generated

Note 2: Both 8-bit patterns and the 55 Octet pattern can only be selected as a

payload for the whole DS1, i.e. they can not be selected as a pattern for an

individual 64 kb/s channel.

Note 3: Bit errors can be added to both 8-Bit and 55 Octet test patterns as with the

other avai lable test pat terns.

The 55 Octet pattern uses the Daly pattern as per ANSI T1.403

27

Page 28

Setting the Interfaces

RECEIVE

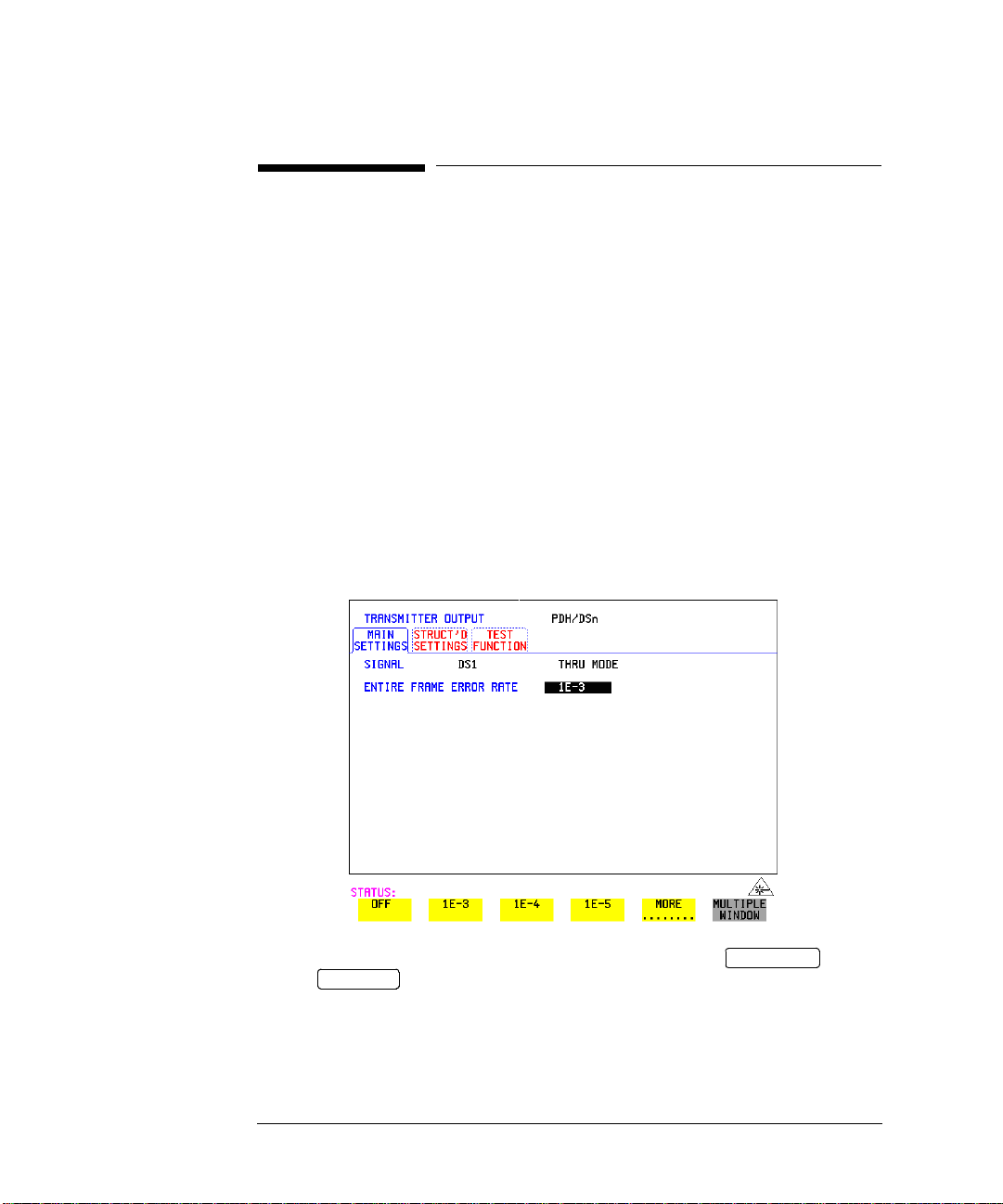

Setting DSn THRU Mode

Setting DSn THRU Mode

Description THRU mode is used to non-intrusively monitor DSn lines where no protected

monitor points are available.

Note that since THRU mode locks some user settings, you must set SIGNAL RATE

(DS1 or DS3), before selecting THRU mode.

Two modes of operation are possible:

Monitor Mode: This is when the Entire Frame Error Rate field is set to OFF. In this

mode the received signal is passed through or transmitted unchanged, and the

instrument monitors errors and alarms as normal DS1 operation.

Full Frame Overwrite Mode: In this mode any bit in the entire frame can be

errorred at a user defined rate. The bit that is errorred can be any bit in the frame,

including the frame bit (hence the title of “Full Frame Overwrite”). The error rates

available are:

Data error rates: 1.0E-3, 1.0E-4, 1.0E-5, 1.0E-6, 1.0-E-7 and user programmable

in 0.1 steps from 1.1E-3 to 1.0E-9

HOW TO: 1 Make the required SIGNAL RATE cho ice on the PDH/DSn

and displays.

2 Select THRU MODE as shown in the figure above.

3 Select an entire frame error rate from the choices given or us e the USER softkey

to program an error rate.

28

TRANSMIT

Page 29

Setting the Interfaces

Setting SONET Transmit Interface

Setting SONET Transmit Interface

Payload Selection

One of the key features of the OmniBER 718 is the ability to test concatenated

payloads. The following gives a brief des cri pti on of concatenat ed payl o ads , and the

benefits of using them.

Concatenated Payloads

Bulk filled or contiguous payload structures e.g. (STS-48c) are designed for

carrying broadband services. The entire payload area is used to carry the service

with no structured mapping or channelization.

In the case of a concatenated STS-48 (denoted STS-48c), the virtual container area

is entirely filled by a single STS-48c SPE. This STS-48c SPE consists one Path

Overhead and a single container capable of carrying a tributary signal operating at

rates up to approximately 2.5 Gb/s. Once assembled a STS-48c SPE is multiplexed,

switched and transported through the network as a single entity.

Benefits: Test the entire bandwidth in one go, and reduce test times. The following

table illustrates the reduced test times using concatenated payloads.

Test Time (based on 100

errors)

Performance

test limit

14

10-

13

10-

12

10-

11

10-

10

10-

STS-48c SPE

payload

48 days >2 years

4.8 days 77 days

1 1.6 hou rs 7.7 days

1.2 hour 18.5 hour

7 minutes 1.9 hours

STS-3c SPE

payload

29

Page 30

Setting the Interfaces

Setting SONET Transmit Interface

Description SONET transmit interface settings should match the network equipment settings of

Rate, Wavelength and Mapping, determine the payload to be tested and set

background conditions to prevent alarms while testing.

TIP: If you wish to set the OmniBER 718 transmitter and receiver to the same interface

settings choose

OTHER

SETTINGS CONTROL COUPLED

Laser On/Off Control

If you wish to switch off the laser when connecting/disconnecting cables, set the

field between the wavelength and INTERNAL selections to OFF. When the laser is

on the laser symbol at the bottom right of the display is illumin a ted (yellow).

.

HOW TO: 1 Make your choice of SIGNAL rate.

If Option 106, Dual Wavelength optical module, is fitted and an optical rate is

chosen, choose the required wavelength (1550 or 1310).

If STS-1 is chosen, choose the required interface level.

Choose unless is required. If is

INTERNAL THRU MODE THRU MODE

chosen, see "Setting SONET THRU Mode " page 37.

2 Make your choice of CLOCK synchronization source. The clock can be

internally sourced from the instrument, recovered from the signal at the optical

RECEIVE port or externally sourced from the CLOCK REF IN ports (MTS 64

kb/s, BITS 1.5 Mb/s or 10 MHz REF).

30

Page 31

Setting the Interfaces

Setting SONET Transmit Interface

3 If required choose the FREQUENCY OFFSET value. See “Adding Frequency

Offset to SONET Signal” page 62.

4 Choose the required and PAYLOAD TYPE, then

B/G MAPPING

F/G MAPPING

and BACKGROUND selection. The FOREGROUND

selection is the channel that is chosen for test purposes. The BACKGROUND

patterns are not used for test purposes and are either the same as the test channel

or set to UNEQUIPPED.

Mapping may be selected from a pictorial display by moving the cursor to

MAPPING and pressing .

SET

Use and to move between STS Layer choice, VT Layer choice and

Payload Layer choice. Use and to choose the mapping.

SET

Use to confirm your choice and return to the

SONET MAIN SETTINGS

display.

5 If VT -6 map ping is chosen, VT CONCATENATION selection is enabled, choose

or the tributary at which the concatenation b e gins, VT6 -2C thr oug h VT6 -

OFF

6C.

The BACKGROUND, PATTERN IN OTHER VT-6s is fixed at NUMBERED,

that is, each VT-6 contains a unique number to allow identification in case of

routing problems.

6 If required, choose DS1/2M/34M/DS3 O F FSET value. See “Adding Frequency

Offset to SONET Signal” page 62

31

Page 32

Setting the Interfaces

Setting SONET Transmit Interface

7 If FULL SPE, VT -6, VT-2 or VT-1.5 mapp ing is chosen, choose the tes t tributary ,

including the STS-3 for an OC-12/OC-48 signal.

8 Choose the payload framing under PAYLOAD TYPE or VT PAYLOAD.

If is required must be chosen.

STRUCTURED FRAMED

If is chosen, the Payload test signal must be set up. See “Setting

STRUCTURED

Transmit Structured Payload/Test Signal” page 68.

If is chosen, see “Inserting an External DSn Payload/Test Signal”

INSERT

page 74.

If you have chosen 2 Mb/s, DS1 or DS3 under Mapping, the Framed choice is

expanded to provide a menu of framing types.

9 Choose the PATTERN type and PRBS polarity.

10 Choose the mapping required in the background (non-test) STS’s. Refer to

Appendix A for a table of background patterns for STS-1 SPE.

11 If VT mapping is chosen for the test STS, choose the PATTERN IN OTHER

VT’s.

32

Page 33

Setting the Interfaces

Setting Jitter Transmit Interface

Setting Jitter Transmit Interface

Description:

Option 200 required

for jitter and option

012 for PDH/DSn.

HOW TO: 1 If you are adding jitter to the DSn signal, set up the DSn transmit interface. See

You can add jitter to the transmitted DSn or SONET signal at DS1, DS3, 2 Mb/s,

34 Mb/s, STS-3, OC-3, OC-12, and OC-48. You can source the jitter modulation

internally or from an external source. Jitter measurement up to 2.5 Gb/s is available

when ATM or POS is selected as a payload.

Chapter “Setting PDH/DSn Transmit Interface (Option 012)”.

2 If you are adding jitter to the SONET signal, set up the SONET tran smit interface.

See “Setting SONET Transmit Interface” page 29.

3 Choose JITTER/WANDER .

If you wish to add wander to the DSn or SONET signal, See “Setting Wander

Transmit Interface” page 35.

4 Choose JITTER .

If you wish to perform a Jitter Tolerance measurement, choose

AUTO TOLERANCE

If you wish to perform a Jitter Transfer measurement choose

TRANSFER FUNCTION

ON

JITTER

. See “Measuring Jitter Tolerance” page 134.

. See “Measuring Jitter Transfer” page 138.

33

Page 34

Setting the Interfaces

Setting Jitter Transmit Interface

Choose the modulation source.

If adding jitter to the DSn signal and is chosen, connect the

EXTERNAL

external source to the MOD IN port of the DSn Jitter TX module. Up to 10 UI of

external jitter modulation can be added at the MOD IN port.

If adding jitter to the SONET signal and is chosen, connect the

EXTERNAL

external source to the MOD IN port of the SONET Clock modu le. Up to 20 UI of

external jitter modulation can be added at the MOD IN port.

5 If you have selected an Modulation Source, choose the JITTER

INTERNAL

CONTROL setting required.

You can choose the jitter range, jitter modulating frequency and jitter amplitude

if is chosen.

OFF

If you choose , the OmniBER 718 will "sweep" through the ITU-T jitter

SWEPT

mask (G.823 for PDH, GR-499 or G.824 for DSn, G.958, G.825 or GR-253 for

SONET) adjusting the jitter amplitude according to the jitter frequency . With the

SWEPT

field selected, press SET on t he instrument front panel for a display of

the jitter mask sweep (an example is given below).

If you choose , you can choose the "spot" jitter frequency. The jitter

SPOT

amplitude is adjusted and controlled according to your jitter frequency choice.

TIP: If, when using the SWEPT MASK capability, a problem occurs around a certain

frequency, this may require closer examination. Stop the sweep at that point by

choosing . You can then control the "spot" jitter frequency to make closer

SPOT

examination of the problem.

34

Page 35

Setting the Interfaces

Setting Wander Transmit Interface

Setting Wander Transmit Interface

Description: You can add Wander to the 2 Mb/s DSn signal and the STS-3, OC-3,

OC-12 or OC-48 SONET signal. Wander is also available when you select an ATM

or POS payload.

HOW TO: DSn Wander (2 Mb/s)

1 Set up the PDH transmit interface, choose CLOCK and select the SOURCE

required from the menu. If you select EXTERNAL connect the ex ternal source to

the REF IN port on the CLOCK module. See “Setting PDH/DSn Transmit

Interface (Option 012)” page 26.

2 Choose JITTER/WANDER .

If you wish to add jitter to the DSn signal, See “Setting Jitter Transmit Interface”

page 33.

3 Choose WANDER .

4 Choose the WANDER MASK setting required.

You can choose the wander modulating frequency and wander amplitude if

is chosen.

OFF

If you choose , you can choose the "spot" wander frequen cy. The wander

amplitude is adjusted and controlled according to your wander frequency choice.

SPOT

WANDER

ON

35

Page 36

Setting the Interfaces

Setting Wander Transmit Interface

SONET Wander (STS -3, OC-3, OC -12, OC-48)

5 Set up the SONET transmit interface. See “Setting SONET Transmit Interface”

page 29.

6 Choose JITTER/WANDER .

WANDER

If you wish to add jitter to the SONET signal, see "Setting Jitter Transmit

Interface " page 33.

7 Choose WANDER .

ON

8 Choose the WANDER MASK setting required.

You can choose the wander modulating frequency and wander amplitude if

is chosen.

OFF

If you choose , you can choose the "spot" wander frequen cy. The wander

SPOT

amplitude is adjusted and controlled according to your wander frequency choice.

36

Page 37

Setting the Interfaces

Setting SONET THRU Mode

Setting SONET THRU Mode

Description THRU mode is used to non-intrusively monitor SONET lines where no protected

monitor points are available. To enable THRU mode select the

MAIN SETTINGS

page. Select SIGNAL RATE before selecting THRU mode.

The entire frame can be errorred at a user defined rate if PAYLOAD OVERWRITE

and TOH+POH CHANNEL OVERWRITE are both set to . If either

overwrite is enabled the ENTIRE FRAME ERROR RATE f unctio n is disabled.

There are nominally three modes of operation as follows:

1. Transparent mode: This is the case when the PAYLOAD OVERWRITE field is

set to OFF. The received signal is passed through the transmitter completely

unchanged. The figure below illustrates the settings for this mode.

TRANSMIT

OFF

2. Hitless THRU Mode:

This mode enables you to change the channel under test and the payload mapping

without causing errors in the line signal or any other payload channel, or having to

switch out of THRU mode. When yo u select a Payload Overwrite choice ( other than

OFF) an additional field is displayed which allows you to enable/disable Payload

Overwrite. If Payload Overwrite is disabled the instrument remains transmitting

while you select another channel/tributary (see figure on next page). In this mode

any Section or Line CV errors are recalculated before transmission.

37

Page 38

Setting the Interfaces

TRANSMIT

Setting SONET THRU Mode

3. Payload Overwrite: In this mode you can overwrite the payload as explained in

the following text. Any Path CV errors are recalculated before transmission. Use the

HOW TO procedure to setup your instrument for THRU Mode operation.

OC-1/STS-1, OC-3/STS-3

You can substitute a new payload, Section and Line Overhead (TOH) and Path

overhead (POH) in the received OC-1/STS-1 or OC-3/STS-3 signal for testing.

OC-12, OC-48

The overhead and payload may be overwritten for STS-3c SPE and STS-1.

PAYLOAD OVERWRITE is not available for STS-12C or STS-48C.

TOH+POH CHANNEL overwrite is available for STS-12C and STS-48C.

HOW TO: 1 Make the required SIGNAL RATE choice, and select THRU MODE on the

SONET

page 29.

2 Make the PAYLOAD OVERWRITE choice required.

Hitless Mode: The Payload Overwrite enable/disable field (next to the

PAYLOAD OVERWRITE field) defaults to OFF.

If STS-3c SPE, STS-1 SPE, VT-6, VT-2 or VT-1.5 is chosen, the Section, Line

and Path CVs are recalculated before transmission and the Mapping, Selected

VT, VT Payload, Pattern, Tributa ry Offset and Pattern in other VT’s settings are

displayed. To choose the settings in these, See "Setting SONET Transmit

Interface " page 29, steps 4 through 10.

38

display, See "Setting SONET Transmit Interface "

Page 39

Setting the Interfaces

Setting SONET THRU Mode

3 Switch the P AYLOAD OVERWRITE enable/disable field to ON. Test functions

are available whilst Payload Overwrite is enabled. Select the

TEST FUNCTION

folder and setup as required.

4 Make the TOH+POH CHANNEL OVERWRITE choice required.

The Section, Line and Path CVs are recalculated before transmission.

39

Page 40

Setting the Interfaces

Using Smart Test

Using Smart Test

Smart Setup The Smart Setup feature simplifies instrument operation by:

• Allowing the instrument to auto-configure on the incoming signal. It will attempt

to identify signal structure, and detect mixed payload signal structures and

alarms.

The OmniBER 718 automatically displays all of the J 1 trace identifiers. Once the

received signal has been identified you can select a channel of interest and

explore further into the payload.

Smart Tests Allows you to quickly access the most commonly used instrument features such as:

• Signal quality

• Functional tests

• Jitter tests

• ATM tests

• POS tests

• Settings (stored, logging, Tx/Rx coupling and trigger output en able)

HOW TO: 1 Connect the 37718A to the network an d choose if necessary the required SONET

RECEIVE

SONET, but can not select between SDH and SONET).

2 Press .

40

interface on the 37718A (Smartsetup will select PDH or SDH/

SMART TEST

Page 41

Setting the Interfaces

Using Smart Test

3 With Smartsetup highlighted, press to auto-discover information about

the receive signal.

Or press to exit Smart Tests.

CANCEL

START

An example of a typical display after choosing t o RUN Smartsetup is shown below.

Note: The channel information displayed is the one obtained the last time a SCAN

was performed. If you have changed the input signal since the last Smartsetup you

must perform a RESCAN now. If you have selected a PDH/DSn interface and a

PDH/DSn signal is received, a channel mapping display indicating the framing and

status of each channel is given, see below.

41

Page 42

Setting the Interfaces

Using Smart Test

SET UP RX

key If you select an individual channel using the cursor control keys, and then select

SET UP RX

, the instrument exits smartsetup and sets the receiver to the test

pattern detected in the selected channel.

To run a Smart Test (Signal Quality - Frequency Measurement):

1 Ensure a valid signal is connected to the instrument’s Receive port.

2 Press .

SMART TEST

3 Use the up and down cursor control keys to select Signal quality.

4 Use the left and right cursor control keys to access the tests.

5 Use the up and down cursor control keys to select Frequency Measurement.

6 Press

START

to display the frequency screen. Or press to exit Smart

CANCEL

Tests.

To run an ATM Smart Test

1 Ensure a valid signal is connected to one of the instrument’s Receive ports.

2 Press .

SMART TEST

3 Use the down cursor control key to select ATM payload setup or ATM tests.

4 Use the right cursor control key to access the setups/tests.

42

Page 43

Setting the Interfaces

Using Smart Test

5 Use the down cursor control key to select required setup/test.

Note: It is not possible for OmniBER to find ATM in a PDH payload in Sm art setu p.

43

Page 44

Setting the Interfaces

Using Smart Test

To run a POS Smart Test

1 Ensure a valid signal is connected to one of the instrument’s Receive ports.

2 Press .

SMART TEST

3 Use the down cursor control key to select POS Setup/Tests.

4 Use the right cursor control key to access the setups/tests.

5 Use the down cursor control key to select required setup/test.

6 Press

SELECT

to display the required S etup screen. Or press to exit

CANCEL

Smart Tests.

44

Page 45

Setting the Interfaces

Setting PDH/DSn Receive Interface

Setting PDH/DSn Receive Interface

Description DSn Receive interface settings should match the network equipment settings of

Rate, Termination and Line Code and determine the Payload to be tested.

TIP: To set the transmitter and receiver to the same interface settings choose

SETTINGS CONTROL COUPLED

HOW TO: 1 Choose the required SIGNAL rate.

2 If you have chosen 2 Mb/s as the SIGNAL rate, choose the required

TERMINATION. (At all other rates the impedance is fixed.)

.

OTHER

3 If you have chosen 8 Mb/s, 2 Mb/s or DS1 as the SIGNAL rate, choose the

required LINE CODE. (At 140 Mb/s, 34Mb/s and DS3 coding is fixed.)

4 If you are measuring at the network equipment monitor point, set the LEVEL

field to . In this case the received signal will be 20 to 30 dB below th e

normal leve l.

Choose the GAIN required to return the received signal to normal.

Choose EQUALIZATION to compensa te for cable losses if required.

5 Choose the PAYLOAD TYPE.

MONITOR

ON

45

Page 46

Setting the Interfaces

Setting PDH/DSn Receive Interface

If is required must be chosen.

STRUCTURED FRAMED

If is chosen, the PDH/DSn test signal must be set up. See

STRUCTURED

“Setting Transmit Structured Payload/Test Signal” page 68.

If you chose 2 Mb/s, DS1 or DS3 as the PDH/DSn SIGNAL rate, the FRAMED

choice is expanded to provide a menu of framing types.

6 Choose the PATTERN type and the PRBS POLARITY required.

Additional Patterns at DS1

7 If you select a DS1 SIGNAL, two 8- bit pa tterns and a 55 Octet p attern are ad ded

to the list of available patterns. They are as follows:

Table 2 8-Bit Patterns

Type Pattern

1-in-8 F01000000

2-in-8 F01100000

Note 1: F indicates the position of the framing bit with respect to the 8-bit pattern

when the framed data is generated

Note 2: Both 8-bit patterns and the 55 Octet pattern can only be selected as a

payload for the whole DS1, i.e. they can not be selected as a pattern for an

individual 64 kb/s channel.

The 55 Octet pattern uses Daly pattern as per ANSI T1.403.

46

Page 47

Setting the Interfaces

Setting SONET Receive Interface

Setting SONET Receive Interface

Description SONET Receive interface settings should match the network equipment settings of

Rate and Mapping, and determine the payload to be tested.

TIP: If you wish to set the OmniBER 718 transmitter and receiver to the same interface

settings, choose

receiver to be configured to the same settings as the transmitter.

OTHER

SETTINGS CONTROL COUPLED

. This causes the

HOW TO: 1 Choose the required SIGNAL source either electrical or optical.

If STS-1 or STS-3 is chosen, choose the required LEVEL.

If the LEVEL chosen is choose the required GAIN.

MONITOR

2 Choose mapping and type of payload.

3 If VT-6 mapping is chosen, and CONCATENATION is enabled, choose the

tributary at which the concatenation begins.

If VT-6, VT-2 or VT-1.5 mapping is chosen, choose the test tributary, including

the STS-3 for an OC-12/OC-48 signal.

4 Choose the payload framing under PAYLOAD TYPE or VT PAYLOAD.

If is required must be chosen.

STRUCTURED FRAMED

If is chosen the Payload test signal must be set up. See “Setting

STRUCTURED

Receive Structured Payload/Test Signal” page 70.

If DROP is chosen, see “Dropping an External Payload/Test Signal” page 77 .

5 Choose the PATTERN type and PRBS polarity.

47

Page 48

Setting the Interfaces

Setting Jitter Receive Interface

Setting Jitter Receive Interface

Description:

Option 200 required

for Jitter operation.

Jitter and error measurements are made simultaneously when a jitter option is fitted.

Jitter measurement up to 2.5 Gb/s is also available when ATM or POS is selected as

a payload. The jitter receive interface is selected with

JITTER

or MEASUREMENT TYPE .

RECEIVE

SONET JITTER JITTER

RECEIVE

PDH/DSn

The choices made on the jitter receive interface determine the jitter measurement

range, the threshold level for determining a jitter hit and which filters are used in the

jitter measurement.

HOW TO: 1 Choose the RECEIVER RANGE - the jitter measurement range.

2 Choose the HIT THRESHOLD level - if the received jitter exceeds the value

chosen a jitter hit is recorded.

3 Choose the FILTER you wish to inclu de in th e peak to peak and RMS jitter

measurement. The choices are:

OFF, LP, HP1, HP2, 12kHz HP, LP+HP1, LP+HP2, LP+12kHz HP

4 If you have selected a PDH/DSn Receive Interface you can also select FILTER

VERSION, O.171 or O.172/GR-499. The selection is not available with a

SONET Receive Interface.

48

Page 49

Setting the Interfaces

JITTER

Setting Extended Jitter Receive Interface

Setting Extended Jitter Receive Interface

Description: Extended Jitter measurements are made in a jitter bandwidth of 0.1 Hz to 25 kHz.

These measurements are made at the upper end of the standard wander frequency

range and the lower end of the standard jitter frequency range. The extended jitter

receive interface is selected with

SONET

MEASUREMENT TYPE .

RECEIVE

PDH/DSn JITTER

EXTENDED

The choices made on the jitter receive interface determine the threshold level for

determining a jitter hit. The measurement Range and the Filters are not selectable.

or

RECEIVE

HOW TO: 1 Choose MEASUREMENT TYPE

2 Choose the HIT THRESHOLD level - if the received jitter exceeds the value

chosen a jitter hit is recorded.

EXTENDED

.

49

Page 50

Setting the Interfaces

MAIN SETTINGS

Setting Wander Receive Interface

Setting Wander Receive Interface

Description: You can measure Wan der at all DSn and SONET rates. An external timing r eference

should be selected on the or

TRANSMIT

display to ensure accurate Wander results.

PDH/DSn SONET

HOW TO: 1 Choose an external timing reference on the

SONET

MAIN SETTINGS

TRANSMIT

display . See, “Setting SONET Tran smit Interface” page 29.

2 If you intend to measure wander on a DSn signal, set up the DSn receive

interface. See, “Setting PDH/DSn Receive Interface” page 45.

3 If you intend to measure wander on a SONET signal, set up the SONET receive

interface. See, “Setting SONET Receive Interface” page 47.

4 Choose MEASUREMENT TYPE

WANDER

.

5 Choose the wander HIT THRESHOLD - if the received wander exceeds the value

chosen a wander hit is recorded.

50

Page 51

3

“Using Transmit Overhead Setup” page 52

“Using Receive Overhead Monitor” page 54

“Setting Overhead Trace Messages” page 56

“Setting Overhead Labels” page 57

“Generating Overhead Sequences” page 58

“Using Receive Overhead Capture” page 60

“Adding Frequency Offset to SONET Signal” page 62

“Adding Frequency Offset to the DSn Signal” page 64

“Setting up Signaling Bits” page 65

“Setting Transmit Structured Payload/Test Signal” page 68

“Setting Receive Structured Payload/Test Signal” page 70

“Setting Transmit N x 64 kb/s/N x 56 kb/s Structured Payload/Test Signal”

page 71

“Setting Receive N x 64 kb/s/N x 56 kb/s Structured Payload/Test Signal”

page 73

“Inserting an External DSn Payload/Test Signal” page 74

“Dropping an External Payload/Test Signal” page 77

“Adding Errors and Alarms at the SONET Interface” page 80

“Adding Errors and Alarms to a DSn Signal” page 81

“Using FEAC Codes” page 82

“Setting DSn Spare Bits” page 84

“Adding Pointer Adjustments” page85

“Using Pointer Graph Test Function” page 93

“Stressing Optical Clock Recovery Circuits” page 95

“Generating Automatic Protection Switch (APS) Messages” page 97

“Inserting and Dropping the Data Communications Channel” page 102

“Using DS1 LOOP Codes” page 103

3 Selecting Test Features

Page 52

Selecting Test Features

Using Transmit Overhead Setup

Description You can set an overhead byte to a known static state to aid troubleshooting, for

example to quickly check for "stuck bits" in path ov erhead bytes. Transport

Overhead, Path Overhead, Trace Messages and Labels can be set using this feature.

HOW TO: 1 Set up the SONET transmit interface and payload required. See "Setting SONET

Transmit Interface " page 29.

2 Choose the type of overhead to SETUP.

If OC-12 or OC-48 is chosen as the SONET interface, choose the STS-3# and

STS-1# you wish to set up.

If STS-3 is chosen as the SONET interface, choose the STS-1# yo u wish to set up.

DEFAULT - Use to set all overhead bytes to the standard values defined by

Bellcore/ANSI.

If a test function is active then the overhead byte value i s determined by the

choices made in the Test Function.

If (Transport Overhead) is chosen, choose the STS-1 to be displayed.

TOH

Many bytes in and are unlabeled as the other overhead

functions have not yet been defined.

52

STS-1# 2 STS-1#3

Page 53

Selecting Test Fe atur es

Using Transmit Overhead Setup

If is chosen, the hexadecimal value of all 81 bytes of the STS-3

STS-1# 1,2,3

section & line overhead selected are displayed (all 324 bytes of an OC-12 or

1,296 bytes of an OC-48 are displayed 81 bytes at a time by selecting each STS3 in turn). The value of the bytes can be set using

INCREASE DIGIT

.

If BYTE NAMES is chosen, the labels for the overhead bytes are

DECREASE DIGIT

STS-1# 1,2,3

displayed.

3 If POH (Path Overhead) is chosen, choose the TYPE of overhead within STS-1

under test to be setup.

J1 and J2 bytes can be set under Path Overhead or Trace Messages. H4 byte has

a choice of sequences for VT-2, VT-1.5 and VT-6 mapping:

Full Sequence - 48 byte bi nary sequence .

Reduced Sequence - Binary count sequence of 0 to 3 i.e. 111111(00 to 11).

COC1 Sequence - Binary count sequence of 0 to 3 i.e. 110000(00 to 11).

H4 byte is transmitted as all zero’s for 34 Mb/s and DS3.

4 If TRACE MESSAGES is chosen, see "Setting Overhead Trace Messages "

page 56.

NOTE Any bit of an overhead byte which is displayed as x or s cannot be set at any time.

All other bits can be set to 0 or 1.

TIP: You can set all overhead bytes to the default state by selecting SETUP .

DEFAULT

You can set all overhead bytes and test functions to the default state by recalling

Stored Settings [0] on the display.

OTHER

53

Page 54

Selecting Test Fe atur es

Using Receive Overhead Monitor

Using Receive Overhead Monitor

Description When first connecting to a SONET network, a start up confidence check can be

made by viewing the behavior of all the overhead bytes. If the SONET network

shows alarm indications, some diagnosis of the problem may be gained from

viewing all the overhead bytes.The OVERHEAD MONITOR display is updated

once per second (once per 8000 frames) approximately.

TIP: A snapshot of the received overhead can be logged to the chosen logging device.

See "Logging on Demand " page 241.

HOW TO: 1 Set up the receive SONET interface and payload as required. See “Setting

SONET Receive Interface” page 47.

2 Choose the type of overhead to MONITOR.

3 If (Transport Overhead) is chosen, choose the STS-3 # and

TOH

STS-1# to be displayed.

Many bytes in and are unlabeled because the other

overhead f unctions have not yet been de fined.

If is chosen, the hexadecimal value of all 81 bytes of section

STS-1# 1,2,3

overhead is displayed (al l 324 bytes of an OC-12 o r 1, 296 by tes of an OC- 48 are

displayed 81 bytes at a time by selecting each S TS-3 in turn).

If BYTE NAMES is chosen, the labels for the overhead bytes are

displayed.

54

STS-1# 2 STS-1#3

STS-1# 1,2,3

Page 55

Selecting Test Fe atur es

Using Receive Overhead Monitor

4 If POH (Path Overhead) is chosen, choose the source of the overhead, SPE or

VTSPE.

J1 and J2 bytes can be monitored under Path Overhead or Trace Messages

5 If TRACE MESSAGES is chosen, you can monitor a data message to verify

portions of the network.

If the 16 byte CRC7 message structure is detected, the 15 characters within the

message are displayed.

If the CRC7 structure is not detected in J1, the 64 byte message format is assumed

and displayed.

If the CRC7 structure is not detected for J0 or J2, all 16 bytes are displayed.

6 If LABELS is chosen, the S1 sync status, STS path label (C2) and the VT Path

label (V5) are monitored.

7 If APS MESSAGES is chosen, choose the TOPOLOGY, (GR-253) or

(GR-1230). The K1 and K2 bytes are monitored.

RING

LINEAR

TIP: If an y abno rmal behavior is observed on a particular path or section overhead byte,

or an associated group of bytes (3XA1,3XA2; D1 - D3, D4 - D12), the

TEST FUNCTION

display of can be used to "Zoom" in

OVERHEAD CAPTURE

RECEIVE

on the suspect byte or bytes on a frame by frame basis. See "Using Receive

Overhead Capture " page 60.

55

Page 56

Selecting Test Fe atur es

Setting Overhead Trace Messages

Setting Overhead Trace Messages

Description You can insert a data message to verify portions of the network:

J0 verifies the section overhead.

J1 verifies the STS-1 SPE or STS-3c SPE path connection.

J2 verifies the VT SPE path connection.

HOW TO: 1 Choose the message for insertion in the chosen trace channel.

How to Edit User Messages

There are two ways you can edit a user message as follows;

• Use the edit keys at the bottom of the display JUMP , PREVIOUS CHAR, NEXT

CHAR and

message or:

• Use

56

the POP UP alphanumerical keypad that is displa yed when you pres s the front

pane

l key. Detailed instructions on how to change instrument settings

SET

using the POP UP keypad is given in the Quick Start Guide (page 13) under the

heading “Changing Instrument Settings”.

that are displayed when you position the cursor on a User

Page 57

Selecting Test Fe atur es

Setting Overhead Labels

Setting Overhead Labels

Description Choosing LABELS in TRACE MESSAGES allows the setting of the S1 SYNC

STATUS, STS PATH LABEL (C2) and VT PATH LABEL (V5).

How to Edit User Defined Labels

1 Choose the overhead label that you want to edit.

2 Edit the label using the softkeys at the bottom of the display. If you select USER,

use

the softkeys at the bottom of the display to edit the labe l key , or press , then use

the softkeys and pop- up keyp ad to edit t he label . Deta iled i nstru ctions on how to

change instrument settings using the pop-up keypad is given in the Quick Start

Guide (page 13) under the heading “Changing Instrument Settings”.

SET

57

Page 58

Selecting Test Fe atur es

Generating Overhead Sequences

Generating Overhead Sequences

Description You may insert a sequence of patterns into a functional group of overhead bytes for

testing or troubleshooting purposes.

HOW TO: 1 Set up the SONET transmit interface and payload required. See “Setting SONET

Transmit Interface” page 29.

2 Select , SONET, SEQUEN CES as shown above.

TEST FUNCTION

3 Choose the type of sequence required.

SINGLE RUN - runs the sequence once and then stops.

REPEAT RUN - runs the sequence repeatedly until STOPPED is chosen.

4 Choose the overhead type as required.

SOH- Section Overhead

LOH- Line Overhead

POH - Path Overhead

5 Choose the byte or bytes of overhead required.

6 Set up the required number of data patterns and the number of frames in which

each data pattern should appear.

Your sequence is derived from up to 5 blocks of hexadecimal data. Each block

can be transmitted in up to 64,000 frames.

The data and the number of frames are set using

INCREASE DIGIT

.

DECREASE DIGIT

58

Page 59

Selecting Test Fe atur es

Generating Overhead Sequences

7 Start the sequence by choos ing .

START

NOTE When you start the sequence illustrated, one Out of Frame alarm and one Loss of

Frame alarm should occur every eight seconds.

A1A2 Boundary Function

A1A2 provide a frame alignment pattern (A1=F6 H, A2=28 H). Use A1A2 to test

the 6 framing bytes at the A1A2 boundary in the section overhead (see display on

previous page). The 6 bytes across the boundary are:

STS-n

STS-3 channel: #n-2 #n-1 #n #1 #2 #3

Overhead byte: A1 #3 A1 #3 A1 #3 A2 #1 A2 #1 A2 #1

A network element, typically only uses three of these bytes (which ones are not

defined in the standards, so will vary between manufacturers) to gain and maintain

frame synchronization. In many cases the A1A2 bytes selected are those at the

A1A2 boundary (i.e. the A1 bytes in the last STS-1 channel and the A2 bytes in the

first STS-1 channel). Therefore, the ability to stress test across the boundary is

necessary to verify a correct synchronization algorithm within a network element.

59

Page 60

Selecting Test Fe atur es

ON

Using Receive Overhead Capture

Using Receive Overhead Capture

Description Section, Line and Path overhead provide network support functions, responding

dynamically to network conditions and needs. It is therefore useful to capture

overhead activity on a frame by frame basis.

TIP: The Overhead Capture display can be logged to the chosen logging device. See

"Logging on Demand " page 241.

HOW TO: 1 Set up the receive SONET interface and payload as required. See “Setting

SONET Receive Interface” page 47.

2 Select , SONET, O/H CAPTURE as shown above.

3 Choose the overhead type as required.

4 Choose the Byte or bytes of overhead to be captured.

Choose the TRIGGER to determine the start point of the capture.

OFF

by frame monitor of the chosen byte or bytes.

used for transient detection from a specified expected state.

60

TEST FUNCTION

SOH- Section Overhead

LOH- Line Overhead

POH- Path Overhead

- starts immediately the capture is initiated. Can be used to provide a frame

-captures activity after your specified overhead state has occurred. Can be

Page 61

Selecting Test Fe atur es

Using Receive Overhead Capture

ON NOT

- captures activity after the first occurrence of a deviation from your

specified overhead state. Can be used for transient detection from a specified

expected state.

5 Up to 16 records of overhead state are provided. Each record will represent

between 1 and 64,000 frames. A capture is started by pressing CAPTURE

START

can be terminated earlier by pressing CAPTURE .

and terminates when up to 16 records have been captured. The capture

STOP

61

Page 62

Selecting Test Fe atur es

Adding Frequency Offset to SONET Signal

Adding Frequency Offset to SONET Signal

Description Frequency offset can be added to the SONET interface rate signal and to the payloa d

signal.

HOW TO: SONET Line Rate Offset

1 Choose the amount of frequency offset required.

You can set the Frequency Offset in the range -999 ppm to +999 ppm in 1 ppm

steps using

SET

DECREASE DIGIT INCREASE DIGIT

for a pop-up numerical keypad.

The amount of applied Frequency Offset can be varied while measurements are

taking place.

If the value of the SONET line rate offset chosen is sufficient to cause the

maximum stuff rate to b e exceeded, the asynchronous pay load is offset to prevent

bit errors occurring and the maximum stuff rate is maintained. When Floating

Byte 2 Mb/s is chosen, in conjunction with SONET line rate offset, the chosen

tributary will be offset as the line rate is offset. (No pointer movements).

62

and or press

Page 63

Selecting Test Fe atur es

Adding Frequency Offset to SONET Signal

Tributary Offs et ±100 ppm

1 Choose the amount of tributary offset required.

You can set the Offset in the range -100 ppm to +100 ppm in 1 ppm steps using

DECREASE DIGIT INCREASE DIGIT SET

and or press for a pop-

up numerical keypad.

The amount of applied Frequency Offset can be varied while measurements are

taking place.

Tributary offset affects the stuff rate but does not cause pointer movements and

can be used to test mapping jitter. If the combined value of SONET line rate offset

and tributary offset chosen is sufficient to cause the maximum stuff rate to be

exceeded the payload is offset to prevent bit errors occurring and the maximum

stuff rate is maintained.

63

Page 64

Selecting Test Fe atur es

Adding Frequency Offset to the DSn Signal

Adding Frequency Offset to the DSn Signal

Description

Option 012 required.

You can add frequency offset to the interface DSn SIGNAL at all rates. Frequency

Offset can be added at preset ITU-T/ANSI values or as User defined values in the

range ±100 ppm. The preset values change with the SIGNAL rate chosen as shown:

DS-1 (1.544 Mb/s) ±32 ppm −32 ppm

2 Mb/s (E1) ±50 ppm −50 ppm

8 Mb/s ±30 ppm -30 ppm

34 Mb/s (E3) ±20 ppm −20 ppm

DS-3 (44.736 Mb/s) ±20 ppm −20 ppm

140 Mb/s ±15 ppm -15 ppm

HOW TO: 1 Choose the FREQUENCY OFFSET required.

2 If you choose USER OFFSET, you can set the frequency offset to be between -

100 ppm and +100 ppm in 1 ppm steps.

Select the field immediately below USER OFFSET and use

DECREASE DIGIT INCREASE DIGIT

offset.

(The amount of frequency offset can be varied while measurements are

,

, and to set the frequency

taking place.)

64

Page 65

Selecting Test Fe atur es

Setting up Signaling Bits

Setting up Signaling Bits

Description When transmitting 2.048 Mb/s signals with timeslot-16 CAS (PCM30 or

PCM30CRC) multiframing the state of A,B,C,D signaling bits can be set. The

signaling bits of all timeslots are set to the user-defined 4-bit value.

When transmitting a DS1 framed, structured signal the values of the A,B signaling

bits for D4 and SLC-96 payloads, and A,B, C,D signaling bits for ESF payloads can

be defined.

HOW TO Tran smit a DS1 payl oad signal with user-defined signaling bits

DSn Operation

1 Choose on the display.

Choose SIGNAL or , and PAYLOAD TYPE on

the display

PDH/DSn

DS1 DS3 STRUCTURED

MAIN SETTINGS

2 Choose TEST SIGNAL

SETTINGS

display.

TRANSMIT

56 kb/s Nx56 kb/s STRUCTURED

or on the

3 Set the A,B bits (for D4 and SLC-96) and A,B,C,D bits (for ESF) as required.

SONET Operation

1 Choose

SONET

on the display.

TRANSMIT

2 Set MAPPING to VT-1.5.

3 Choose MAPPING

PAYLOAD on the

STRUCTURED MAIN SETTINGS

FL BYTE DS1 ASYNC DS1 DS3

, or and VT

display. If you choose

65

Page 66

Selecting Test Fe atur es

Setting up Signaling Bits

FL BYTE DS1

4 Choose TEST SIGNAL

SETTINGS

proceed to step 5.

56 kb/s Nx56 kb/s STRUCTURED

display .

or on the

5 Set the A,B bits (for D4 and SLC-96) and A,B,C,D bits (for ESF) as required.

6 Floating Byte DS1 selection: Set th e ABC D bit s for NO-F-BIT or ESF framing

and/or the AB bits for D4 VT PAYLOAD framing as required.

HOW TO Transmit a 2 Mb/s signal with user-defined signaling bits

DSn Operation

1 Choose

PDH/DSn

2 Choose SIGNAL and PA YLOAD TYPE or on

the display.

MAIN SETTINGS

on the display.

2 Mb/s PCM30 PCM30CRC

TRANSMIT

3 If UNSTRUCTURED is chosen set the 2M CAS ABCD bits value on the

MAIN SETTINGS

display.

If STRUCTURED is chosen set the 2M CAS ABCD bits value on the

STRUCTURED SETTINGS

display.

66

Page 67

Selecting Test Fe atur es

Setting up Signaling Bits

SONET Operation

1 Choose on the display.

SONET

TRANSMIT

2 Set MAPPING to VT-2.

3 Choose MAPPING or and VT PAYLOAD

PCM30 PCM30CRC MAIN SETTINGS

or on the

ASYNC 2Mb/s FL BYTE 2Mb/s

display.

4 If UNSTRUCTURED is chosen set the 2M CAS ABCD bits value on the

MAIN SETTINGS

display.

If STRUCTURED is chosen set the 2M CAS ABCD bits value on the

STRUCTURED SETTINGS

display.

67

Page 68

Selecting Test Fe atur es

Setting Transmit Structured Payload/Test Signal

Setting Transmit St ructured Payload/Test Signal

Description Stru ctured DSn Payload/Test Signal settings determine the payload or the DSn test

signal to be tested and set any background (non test) conditions to prevent alarms

while testing.

TIP: If you wish to set the OmniBER 718 transmitter and receiver to the same Payload

settings, choose .

Interested in International Gateway Testing?

If your instrument has option 014 fitted you can map an E1 or 2Mb/s signal into DS3

as shown below:

OTHER

SETTINGS CONTROL COUPLED

HOW TO: 1 Choose the required TEST SIGNAL rate. If Nx64 kb/s or N X 56 kb/s is chosen,

see "Setting Transmit N x 64 kb/s /N x 56 kb/s S truct ured P ayload/ Test Signal "

page 71.

2 Choose the P AYLOAD framing pattern.

If TEST SIGNAL 2Mb/s is chosen is added to the PAYLOAD

menu. See "Inserting an External DSn Payload/Test Signal " page 74.

If TEST SIGNAL DS1 is chosen is added to the menu.

See "Inserting an External DSn Payload/Test Signal " page 74.

3 Choose the test tributary in the structured payload, under 34Mb, 8Mb, 2Mb, 64

kb/s or DS2, DS1, 56 kb/s.

68

INSERT 2 M b/s

INSERT DS1

Page 69

Selecting Test Fe atur es

Setting Transmit Structured Payload/Test Signal

4 Choose the PATTERN type and PRBS POLARITY.

5 Choose the B/G PATTERN. (background)

The B/G P ATTERN in the non test 56/64 kb/s timeslots is fixed as NUMBERED,

that is, each timeslot contains a unique number to allow identification in case of

routing problems.

Signaling

6 If a 2 Mb/s PAYLOAD with PCM30 or PCM30CRC framing, or 56 kb/s or

Nx56kb/s Test Signal is chosen. See, "Setting up Signaling Bits " page 65.

69

Page 70

Selecting Test Fe atur es

Setting Receive Structured Payload/Test Signal

Setting Receive Structured Payload/Test Signal

Description Stru ctured DSn Payload/Test Signal settings determine the payload or the DSn test

signal to be tested.

TIP: If you wish to set the OmniBER 718 transmitter and receiver to the same Payload

settings, choose

OTHER

SETTINGS CONTROL COUPLED

, .

HOW TO: 1 Choose the required Test Signal rate. If N x 64 kb/s or N x 56 kb/s is chosen, see

"Setting Receive N x 64 kb/s/N x 56 kb/s Structur ed Payload/Test Signal "

page 73.

2 Choose the Framing pattern of the PAYLOAD.

If TEST SIGNAL 2 Mb/s is chosen, is added to the menu. See

DROP 2 Mb/s

"Dropping an External Payload/Test Signal " page 77.

If TEST SIGNAL DS1 is chosen, is added to the menu.

DROP DS1

See "Dropping an External Payload/Test Signal " page 77.

3 Choose the test tribu tary within t he str uctured payl oad, u nder 34 Mb, 8Mb, 2Mb,

64 kb or DS2, DS1, 56 kb/s.

4 Choose the PATTERN type and PRBS polarity.

70

Page 71

Selecting Test Fe atur es

Setting Transmit N x 64 k b / s /N x 56 k b /s Structured Paylo ad / Test Signal

Setting Transmit N x 64 kb/s/N x 56 kb/s

Structured Payload/Test Signal

Description Wideband services such as hig h speed data l inks and LA N intercon nection require a

bandwidth greater than 56/64 kb/s but less than DS1/2 Mb/s for example 112 kb/s or

336 kb/s. These wide band signals are sent in a DS1/2 Mb/s frame by sharing the

signal across multiple timeslots.

N x 64kb/s/N x 56 kb/ s structured payload allows a test pattern to be in serted across

a number of timeslots even if the chosen timeslots are non-contiguous.

HOW TO: 1 Choose the required Test Signal rate.

2 If your instrument has option 014 fitted you can map an E1 or 2Mb/s signal into

DS3. Select DS1 or 2M as shown in the figure above.

3 Choose the Framing pattern of the 2M or DS1 PAYLOAD.

4 Choose the test timeslots within the structured payload usin g

DESELECT SELECT

* marks the chosen timeslot.

5 Choose the PATTERN type and PRBS polarity.

6 Choose the B/G PATTERN.

and softkeys. As each timeslot is selected, an

DESELECT ALL

71

Page 72

Selecting Test Fe atur es

Setting Transmit N x 64 k b / s /N x 56 k b /s Structured Paylo ad / Test Signal

7 The B/G P A TTERN in the non-test 56/64 kb/s timeslots is fixed as NUMBERED,

that is, each timeslot contains a unique identification number.

Signaling

8 If a 2 Mb/s PAYLOAD with PCM30 or PCM30CRC framing, or 56 kb/s or

Nx56kb/s Test Signal is chosen. See, "Setting up Signaling Bits " page 65.

72

Page 73

Selecting Test Fe atur es

Setting Receive N x 64 kb/s/N x 56 kb/s Structured Payload/Test Signal

Setting Receive N x 64 kb/s/N x 56 kb/s

Structured Payload/Test Signal

Description Wideband services such as hig h speed data l inks and LA N intercon nection require a

bandwidth greater than 56/64 kb/s but less than DS1/2 Mb/s e.g. 112 kb/s or

336 kb/s. These wide band signals are sent in a DS1/2 Mb/s frame by sharing the

signal across multiple timeslots.

N x 64kb/s and N x 56 kb/s structured payload/test signal allows the test Timeslots

to be chosen for error measurement even when the Timeslots are non contiguous.

HOW TO: 1 Choose the required Test Signal rate.

2 If your instrument has option 014 fitted you can map an E1 or 2Mb/s signal into

DS3. Select DS1 or 2M as shown in the figure above.

3 Choose the Framing pattern of the 2M or DS1 PAYLOAD.

4 Choose the test timeslots within the structured payload usin g

DESELECT SELECT

marks the chosen timeslot. In the example above T imeslots 3, 5 , 9, 21, 22, 23 are

chosen for test.

5 Choose the PATTERN type and PRBS polarity.

and softkeys. As each timeslot is chosen an *

DESELECT ALL

73

Page 74

Selecting Test Fe atur es

TRANSMIT

Inserting an External DSn Payload/Test Signal

Inserting an External DSn Payload/Test Signal

Description You can insert 2 Mb/s 34 Mb/s or 140 Mb/s into an STS-N line signal when option

012 is fitted. DS3, DS1, E3 and E1 can be inserted when option 014 is fitted.

RATE Availability Option

DS3 SDH & SONET 001, 012, 002

34Mb/s SDH & SONET 001, 012,002

2Mb/s PDH, SDH & SONET 001, 012, 002

DS1 DSn, SDH & SONET 001, 012, 002

HOW TO: Insert 34 Mb/s, 140 Mb/s & DS3

1 Press , select

SONET MAIN SETTINGS

and the page.

2 Set up the required transmit SONET interface, set appropriate MAPPING then

choose VT PAYLOAD

INSERT 140 Mb/s

, or

INSERT 34 Mb/s

INSERT DS3

as required. Connect your external source to the appropriate

port as indicated on the instrument display (when you position the cursor on the

PAYLOAD TYPE field and select INSERT).

74

Page 75

Selecting Test Fe atur es

Inserting an External DSn Payload/Test Signal

Insert 2 Mb/s or DS1 (Unstructured SONET Payload)

1 Connect the external payload to the MUX port of the PDH/DSn T ransmit module.

If 2 Mb/s connect to 75

2 Set up the required transmit SONET interface, and choose VT-2 or

VT-1.5 MAPPING and VT PAYLOAD or .

Ω MUX port. If DS1 connect to 100Ω MUX port.

INSERT 2 M b/s

INSERT DS1

Insert 2 Mb/s or DS1 (Structured SONET Payload or Structured DSn)

1 Connect the external payload to the MUX port of the DSn Transmit module.

If 2 Mb/s connect to 75

Ω MUX port. If DS1 connect to 100Ω MUX port.

75

Page 76

Selecting Test Fe atur es

Inserting an External DSn Payload/Test Signal

Structured SONET Payload

2 Set up the required transmit SONET interface. See "Setting SONET Transmit

Interface " page 29.

3 Set up the SONET structured payload. See "Set ting Transmit Structured

Payload/Test Signal " page 68.

4 Choose 2M PAYLOAD/DS1 PAYLOAD or .

INSERT 2 M b/s

INSERT DS1

5 Choose the LINE CODE.

Structured DSn

6 Set up, the required transmit DSn interface, See "Setting PDH/DSn Transmit

Interface (Option 012) " page 26.