㽣

Copyright 1991-2005

Agilent Technologies, Inc.

All Rights Reserved.

Printing His tory

Edition 1, November 1991

Edition 2, March 1992

Edition 3, June 1992

Edition 4, February 1996

Edition 5, March 2003

Edition 6, October 2005

New editions are complete

revisions of the manual.

Update packages, which are

issued between editions,

may contain additional

information and replacement pages which you

merge into the manual.

The dates on this page

change only when a new

edition is published.

Certification

Agilent Technologies cer tifiesthat this product met

its published specifications

at the time of shipment.

Agilent Technologies further certifies that its

calibration measurements

are traceable to the United

States National Institute

of Standards and Technology (formerly National

Bureau of Standards), to

the extent allowed by that

organization’s calibration

facility, and to the calibration facilities of other

International Standards

Organization members.

Warranty

This Agilent Technologies

product is warranted

against defects in materials and workmanship for

a period of one year from

date of shipment.

Duration and conditions o f

warranty for this product

may be superceded when

the product is integrated

into (becomes a part of)

other Agilent products.

During the warr a nty period, Agilent will, at its

option, either repair or replace products which prove

to be defective.

Warranty Service

For warranty service or

repair, this product must

be returned to a service

facility designated by

Agilent Technologies.

For products returned to

Agilent for warranty service, the Buyer shall prepay

shipping charges to

Agilent and Agilent shall

pay shipping charges to return theproduct to the

Buyer. However , th e

Buyer shall pay all shipping charges, duties, and

taxes for products returned to Agilent from

another country.

Limitation of Warranty

The foregoing warranty

shall not apply to defects

resulting from improper or

inadequate maintenance

by the Buyer, Buyersupplied products or

interfacing, unauthorized

modification or misuse,

operation outside of the

environmental specifications for the product, or

improper site preparation

or maintenance.

The design and implementation of any circuit on this

product is the sole responsibility of the Buyer.

Agilent does not warrant

the Buyer’s cir cu itry or

malfunctions of Agilent

products that result from

the Buyer’s cir cu itry.

In addition, Agilent does

not warrant any damage

that occurs as a result of

the Buyer’s cir cu i t o r any

defects that result from

Buyer-supplied products.

No other warranty is

expressed or implied.

Agilent Tec hnologies specifically disclaims the

implied warranties of merchantability and

fitness for a particular purpose.

Exclusive Remedies

The remedies provided

herein are the Buyer’s sole

and exclusive remedies.

Agilent Technologies sh all

not be liable for any direct,

indirect, special, incidental, or consequential

damages, whether based

on contract , to rt, or any

other legal theory.

Notice

The information contained

in this document is subject

to change without notice.

Agilent makes no warrant y

of any kind with regard to

this material , including, but

not limited to, the implied

warranties of merchantability and fitness for a

particular pur po se.

Agilent shall not be liable

for errors containe d he r e in

or for incidental or consequential damages in

connection with the furnishing, performance, or

use of this material. No

part of this document may

be photocopied, reproduced, or translated to

another language without

the prior written consen t

of Agilent.

Restricted Rights

The Software and Documentation have been developed

entirely at private expense.

They are delivered and

licensed as “commercial

computer software” as

defined in DFARS 252.2277013 (Oct 1988), DFARS

252.211-7015 (May 1991),

or DFARS 252.227-7014

(Jun 1995), as a “commercial

item” as defined in FAR

2.101(a), or as “restricted

computer software” as

defined in FAR 52.227-19

(Jun 1987) (or any equivalent agency regulation or

contract clause), whichever

is applicable. You have

only those rights provided

for such Software and

Documentation by the

applicable FAR or DFARS

clause or the Agilent standard software agreement for

the product involved.

Trademark Information

Microsoft

®

and Windows

TM

are trademarks of

Microsoft Corporation.

Safety

Do not install substitute

parts or perform any

unauthorized modification

to the product. Return the

product to an Agilent Sales

and Service Office for

service and repair to

ensure that safety featu res

are maintained.

Safety Symbols

Warning

Calls attention to a procedure, practice, or condition, that could possibly

cause bodily injury or

death.

Caution

Calls attention to a procedure, practice, or condition

that could possibly cause

damage to equipment or

permanent loss of data.

Earth ground symbol.

Chassis ground symbol.

Refer to the manua l for

specific Warning or Caution

information to avoid

personal injury or damage

to the product.

Indicates hazardous

voltages may be present.

Manual Part Number: 34401-90013

Printed: October 2005, Edition 6

Printed in Malaysia

Note: Unless otherwise indicated, this manual applies to all serial numbers.

The Agilent Technologies 34401A is a 6

1

⁄

-digit, high-performance

2

digital multimeter. Its co m bina t io n of benc h-top and sy stem f e a ture s

makes t his multime ter a versatile solu ti on for you r mea su re m en t need s

now and in the future.

Convenient Bench-Top Features

• Highly visible vacuum-fluorescen t displ a y

• Built-in math operations

• Continuity and diode test functions

• Hands-free, Reading Hold feature

• Portable, ruggedized case with non-skid feet

Flexible System Features

• GPIB (IEEE-488) interface and RS-232 interface

• Standard programming languages: SCPI, Agilent 3478A, and

Fluke 8840

• Reading rates up to 1000 readings per second

• Storage for up to 512 readings

Warning

• Limit testing with pass/fail signals

• Optional 34812A IntuiLink/Meter Software

®

for Microsoft

Windows

TM

The procedures in this manual are intended for use by qualified,

service-trained personnel only.

Agilent 34401A

Multimeter

The Front Panel at a Glance

1 Measurement Function keys

2 Math Operation keys

3 Single Trigger / Autotrigger / Reading Hold key

4 Shift / Local key

2

5 Front / Rear Input Terminal Switch

6 Range / Number of Digits Displayed keys

7 Menu Operation k eys

The Front-Panel Menu a t a Glance

The menu is organized in a top-down tree structure with three levels.

A: MEASurement MENU

1: AC FILTER > 2: CONTINUITY > 3: INPUT R > 4: RATIO FUNC > 5: RESOLUTION

B: MATH MENU

1: MIN-MAX > 2: NULL VALUE > 3: dB REL > 4: dBm REF R > 5: LIMIT TEST > 6: HIGH LIMIT > 7: LOW LIMIT

C: TRIGger ME N U

1: READ HOLD > 2: TRIG DELAY > 3: N SAMPLES

D: SYStem MENU

1: RDGS STORE > 2: SAVED RDGS > 3: ERROR > 4: TEST > 5: DISPLAY > 6 : BEEP > 7: COMMA > 8 : REVISION

E: Input / Output MENU

1: HP-IB ADDR > 2: INTERFACE > 3: BAUD RATE > 4: PARITY > 5: LANGUAGE

F: CALibration MENU

1: SECURED > [ 1: UNSECURED ] > [ 2: CALIBRATE ] > 3: CAL COUNT > 4: MESSAGE

The commands enclosed in square brackets ( [ ] ) are “hidden” unless the multimeter

*

is UNSECURED for calibration.

*

3

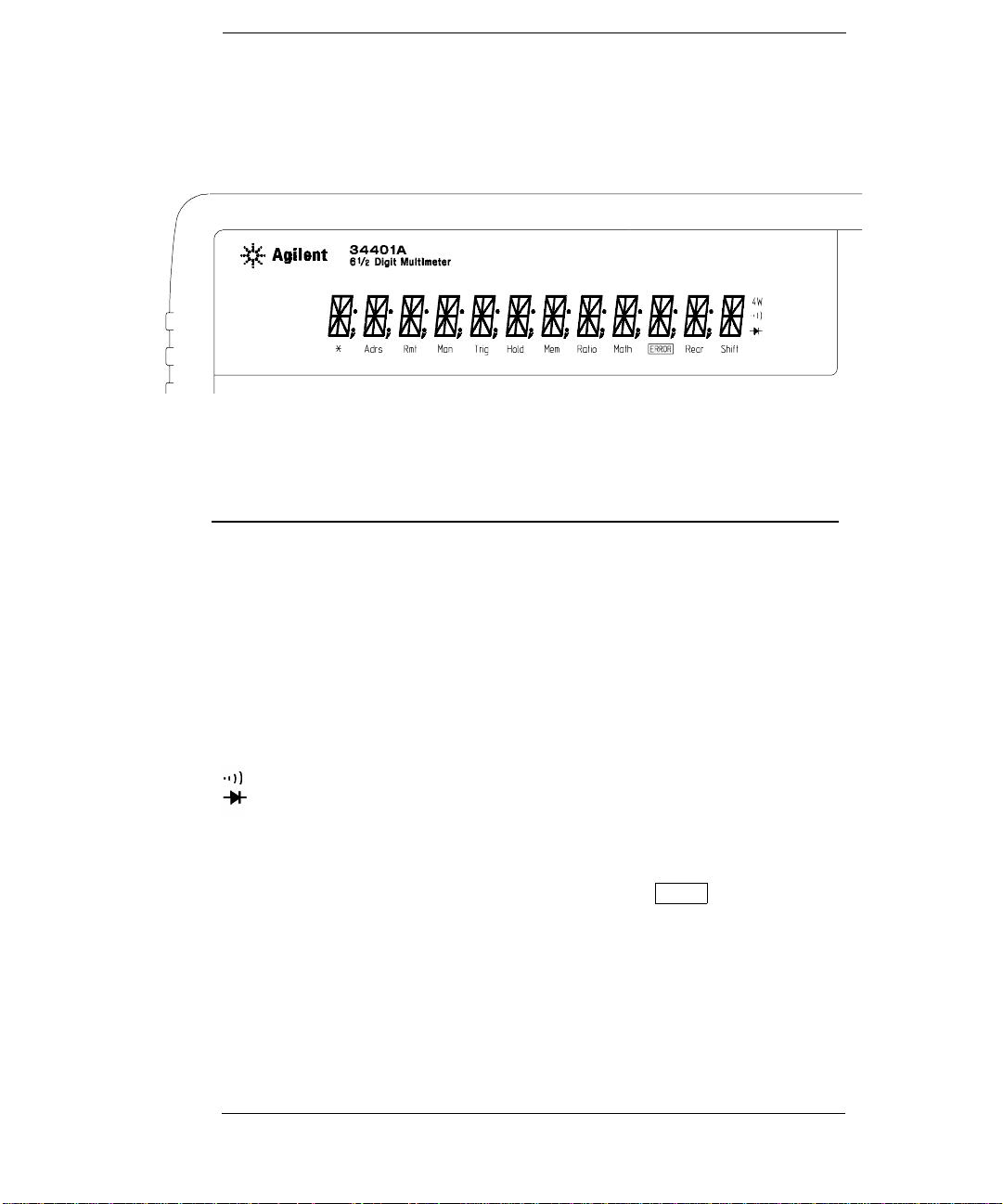

Display Annunciators

∗

Adrs

Rmt

Man

Trig

Hold

Mem

Ratio

Math

ERROR

Rear

Shift

4W

Turns on during a measurement.

Multimeter is addressed to listen or talk over the GPIB interface.

Multimeter is in remote mode (remote interface).

Multimeter is using manual ranging (autorange is disabled).

Multimeter is waiting for a single trigger or external trigger.

Reading Hold is enabled.

Turns on when re ading memory is enabled.

Multimeter is in dcv:dcv ratio function.

A math operation is enabled (null, min-max, dB, dBm, or limit test).

Hardware or remote interface command errors are detected.

Rear input terminals are selected.

“Shift” key has been pressed.

Multimeter is in 4-wire ohms function.

Multimeter is in continuity test function.

Multimeter is in diode test function.

Press “Shif t” ag ain to turn off.

To review the display annunciators, hold down the Shift key as you

turn on the multimeter.

4

The Rear Panel at a Glance

1 Chassis Ground

2 Power-Line Fuse-Holder Assembly

3 Power-Line Voltage Setting

4 Front and Rear Current Input Fuse

5 Voltmeter Complete Output Terminal

6 External Trigger Input Terminal

7 GPIB (IEEE-488) Interface connector

8 RS-232 interface connector

Use the front-panel Input / Output Menu to:

• Select the GPIB or RS-232 interface (see chapter 4 in the “User’s Guide”).

• Set the GPI B bus addr ess (see chapter 4 in the “User’s Guide”).

• Set the RS-232 baud rate and parity (see chapter 4 in the “User’s Guide”).

5

In This Book

Specifications Chapter 1 lists the multimeter’s specifications and

describes how to interpret these specifications.

Quick Start Chapter 2 prepares the multimeter for use and helps you

get familiar with a few of its front-panel features.

Menu Tutorial Chapte r 3 introduces you to the front-panel menu and

steps you through several si mple menu example s.

Calibration Procedures Chapter 4 provides a detailed des c ri ption of

the multimeter’s calibrations and adjustments.

Theory of Operation Chapter 5 describes each functional block in the

multimeter.

Service Chapter 6 provides guidelines for returning your multimeter

to Agilent for servicing, or for servicing it yourself.

Replaceable Parts Chapter 7 contains a detailed parts list of the

multimeter.

Backdating Chapter 8 describes the procedures involved with back

issues of this manu al .

Schematics Chapter 9 provides the multimeter’s schematics.

If you have questions relating to the operation of the Agilent 34401A,

call 1-800-452-4844 in the United States, or contact your nearest

Agilent Sal es Of fic e .

If your 34401A fails within three years of purchase, Agilent will repair

or replace i t free of charge. Call 1-877-444-7278 (“Agilent Express”) in

the United State s, or con tact your n ear est A gile nt Sales Office.

6

Contents

Chapter 1 Specifications

DC Characteristics 12

AC Characteristics 14

Frequency and Period Characteristics 16

General Information 18

Product Dim ensions 19

To Calculate Tota l Me asur em en t Err or 20

Interpreting Multimeter Specifications 22

Configur ing for Highest A ccuracy Measurements 25

Chapter 2 Quick Start

To Prepare the Multimeter for Use 29

If th e M u ltimeter Does Not Turn On 30

To Adjust the Carrying Handle 32

To Measure Voltage 33

To Measure Resistance 33

To Measure Curr en t 34

To Measure Frequ en c y (or Per i od) 34

To Test Continui ty 35

To Check Diod es 35

To Select a Range 36

To Set the Resolution 37

To Make Null (Relative) Measurements 38

To Store Minimum and Maximum Readings 39

To Make dB Measur emen t s 40

To Make dBm Measur em en ts 41

To Trigger the Multimeter 42

To Make dcv:dcv Ratio M eas urem e nts 43

Front-Panel Displ ay For ma ts 44

To Rack Mount the Mu lti met er 45

Contents

Chapter 3 Menu Tutorial

Front-Panel Me nu Refer en c e 49

A Front-Panel Me n u Tutor ial 51

Menu Examples 53

7

Contents

Contents

Chapter 4 Calibration Procedures

Agilent Calibration Services 61

Calibration Interval 61

Time Required for Calibration 61

Automating Cal ibration Pr ocedures 62

Recommended Test Equipment 63

Test Considerations 64

Performance Verification Tests 65

Zero Offs et Verificati on 67

Gain Verification 69

Optional AC Performance Verification Tests 72

Calibration Security Code 73

Calibration Count 75

Calibration Message 75

Calibratio n Proc edu r es 76

Aborting a Calibration in Progress 76

Zero Adjust m ent 77

Gain Adjustment 79

Optional Gain Calibration Procedures 82

Understanding the AC Signal Filter 85

Understanding Resolution 86

Erro r M e s sa g e s 89

Chapter 5 Theory of Operation

Block Diagram 93

Front/Rear Selection 94

Function Switching 95

DC Amplifier 96

Ohms Current Source 98

AC Circuit 99

A-to-D Converter 101

Floating Logic 103

Earth-Referenced Logic 105

Power Supplies 106

Front Panel 107

8

Contents

Chapter 6 Service

Operating Checklist 111

Types of Service Available 112

Repackaging for Shipment 113

Electrostatic Discharge (ESD) Precautions 114

Surface Mount Repair 114

To Replace the Powe r- Lin e Fuse 114

To Replace The Current Input Fuses 115

To Connect Pass/Fai l O utpu t Sign al s 115

Troublesh ooti n g Hint s 117

Self-Test Procedu r es 120

Chapter 7 Replaceable Parts

To Order Replaceable Parts 126

Backdating and Part Changes 126

Replaceable Parts: 34401-66501 (Main Assembly) 127

Replaceable Parts: 34401-66512 (Display Assembly) 133

Replaceable Parts: Agilent 34401A Mainframe 134

Manufacturer’s List 135

Chapter 8 Backdating 137

Chapter 9 Schematics

Mechanical Disassembly 9-3

Component Locator Diagram – Main Board (34401-66501) 9-5

Component Locator Diagram – Front Panel (34401-66512) 9-6

Agilent 34401A Block Diagram 9-7

Front/Rear Selection Schematic 9-8

Function Switching Schematic 9-9

DC Amplifier and Ohms Schematic 9-10

AC Circuit Schematic 9-11

A/D Converter Schematic 9-12

Floating Logic Schematic 9-13

Earth-Referenced Logic Schematic 9-14

Power Supplies Schematic 9-15

Front-Panel Display Schematic 9-16

Contents

9

Contents

10

1

1

Specifications

Chapter 1 Specific ations

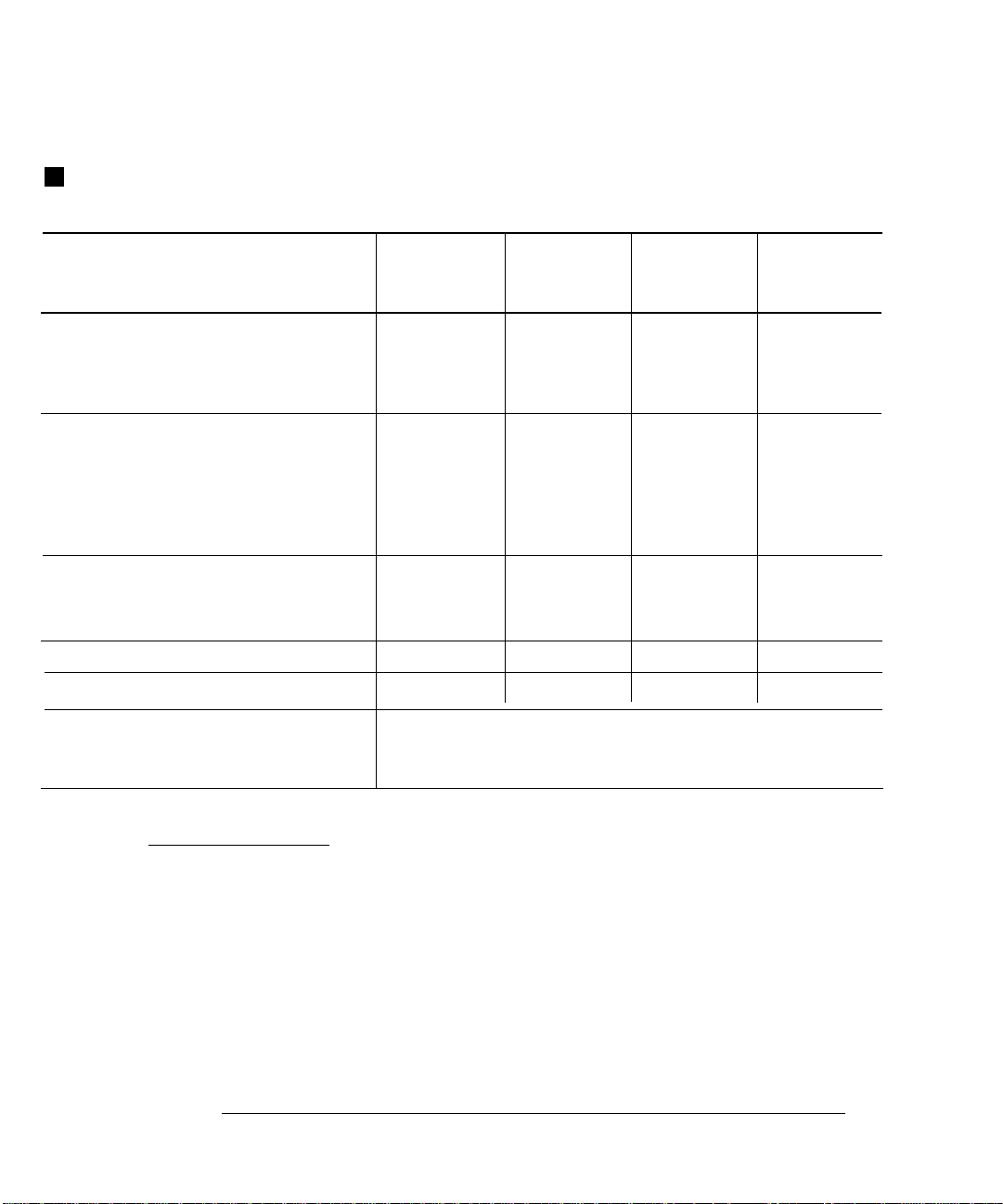

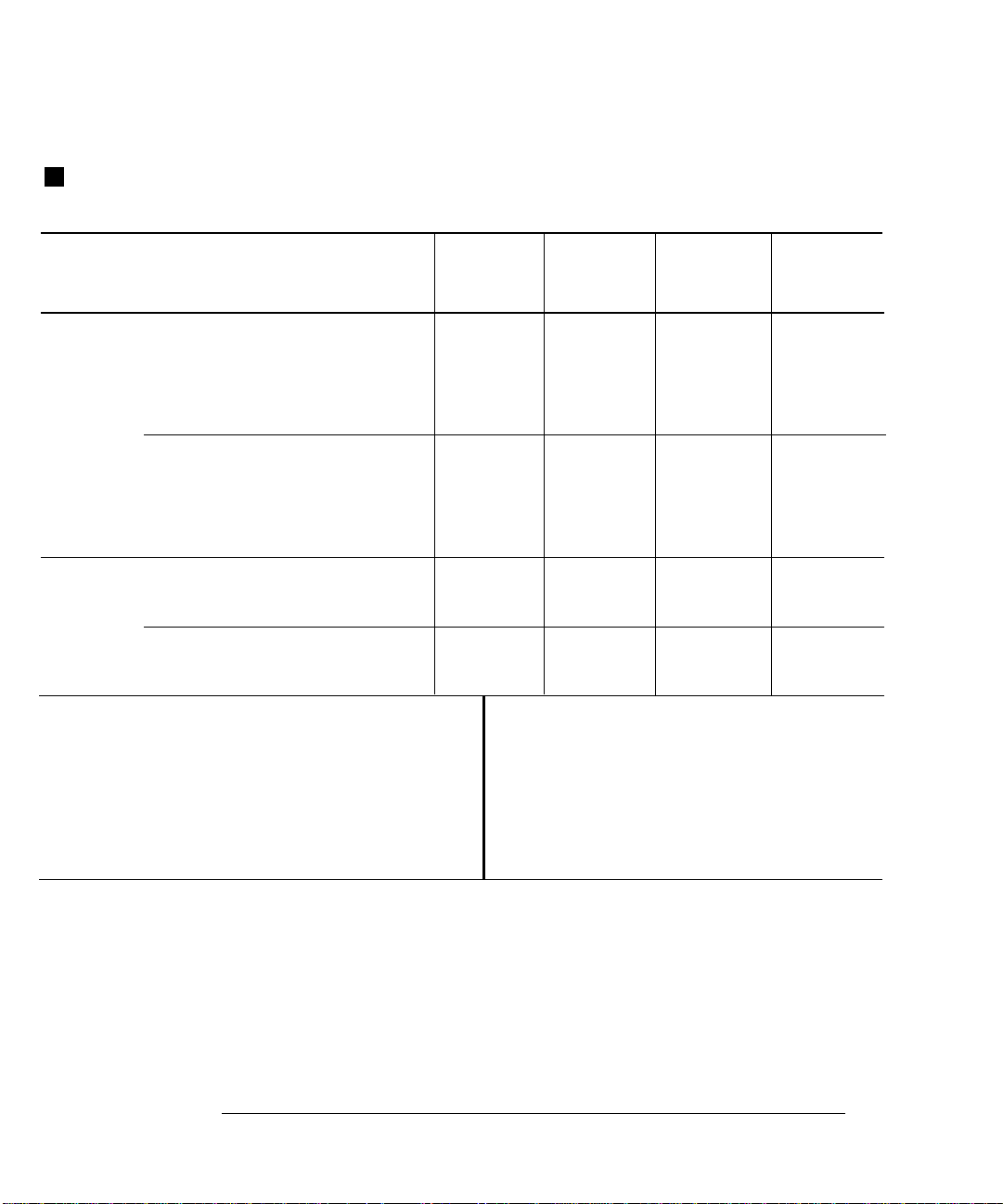

DC Characteristics

DC Characteristics

Function

DC Voltage 100.000 0 mV

Range [ 3 ]

1.000000 V

10.00000 V

100.000 0 V

1000.00 0 V

Test Current or

Burden Voltage

Accuracy Specifications ± ( % of reading + % of range ) [ 1 ]

24 Hour [ 2 ]

23°C

± 1°C

0.0030 + 0.0030

0.0020 + 0.0006

0.0015 + 0.0004

0.0020 + 0.0006

0.0020 + 0.0006

90 Day

23°C

± 5°C

0.0040 + 0.0035

0.0030 + 0.0007

0.0020 + 0.0005

0.0035 + 0.0006

0.0035 + 0.0010

1 Year

23°C ± 5°C

0.0050 + 0.0035

0.0040 + 0.0007

0.0035 + 0.0005

0.0045 + 0.0006

0.0045 + 0.0010

Temperature

Coefficient /°C

0°C – 18°C

28°C – 55°C

0.0005 + 0.0005

0.0005 + 0.0001

0.0005 + 0.0001

0.0005 + 0.0001

0.0005 + 0.0001

Resistance

[ 4 ]

DC Current 10.00000 mA

Continuity 1000.0

Diode Test

[12]

DC:DC Ratio 100 mV

Transfer Accuracy ( typical )

100.0000

1.000000 kΩ

10.00000 kΩ

100.000 0 kΩ

1.000000 MΩ

10.00000 MΩ

100.000 0 MΩ

100.000 0 mA

1.000000 A

3.000000 A

1.00 00 V 1 mA 0.002 + 0.010 0.008 + 0.020 0.010 + 0.020 0.001 + 0.002

to

1000 V

( 24 hour %

Ω

Ω 1 mA 0.002 + 0.010 0.008 + 0.020 0.010 + 0.020 0.001 + 0.002

of range error )

1 mA

1 mA

100

10

µA

5

µA

500 nA

500 nA || 10 M

< 0.1 V

< 0.6 V

< 1 V

< 2 V

2

µA

0.0030 + 0.0030

0.0020 + 0.0005

0.0020 + 0.0005

0.0020 + 0.0005

0.002 + 0.001

0.015 + 0.001

0.300 + 0.010

Ω

0.005 + 0.010

0.01 + 0.004

0.05 + 0.006

0.10 + 0.020

( Input Accuracy ) + ( Reference Accuracy )

Input Accuracy = accuracy specification for the HI-LO input signal.

Reference Accuracy = accuracy specification for the HI-LO reference input signal.

Conditions:

Within 10 minutes and ± 0.5°C.

Within

Following a 2-hour warm-up.

Fixed range between 10% and 100% of fu ll scale.

Using 6

Measurements are made using accepted metrology practices.

0.008 + 0.004

0.008 + 0.001

0.008 + 0.001

0.008 + 0.001

0.008 + 0.001

0.020 + 0.001

0.800 + 0.010

0.030 + 0.020

0.030 + 0.005

0.080 + 0.010

0.120 + 0.020

±10% of initial value.

1

⁄

digit slow resoluti on ( 100 PLC ).

2

0.010 + 0.004

0.010 + 0.001

0.010 + 0.001

0.010 + 0.001

0.010 + 0.001

0.040 + 0.001

0.800 + 0.010

0.050 + 0.020

0.050 + 0.005

0.100 + 0.010

0.120 + 0.020

0.0006 + 0.0005

0.0006 + 0.0001

0.0006 + 0.0001

0.0006 + 0.0001

0.0010 + 0.0002

0.0030 + 0.0004

0.1500 + 0.0002

0.002 + 0.0020

0.002 + 0.0005

0.005 + 0.0010

0.005 + 0.0020

12

Chapter 1 Specific ations

DC Characteristics

1

Measuring Characteristics

DC Voltage

Measurement Method:

A/D Linearity:

Input Resistance:

0.1 V, 1 V, 10 V ranges

100 V, 1000 V ranges

Input Bias Current:

Inpu t Terminals:

Input Protection:

Resistance

Measurement Method:

Max. Lead Resistance:

(4-wire ohms)

Input Protection:

DC Current

Shunt Resistor:

Input Protection:

Continuity / Diode Test

Response Time:

Continuity Threshold:

DC:DC Ratio

Measurement Method:

Input HI-LO

Reference HI -I np ut LO

Input to Refe ren ce

Measurement Noise Rejection

60 Hz ( 50 Hz ) [ 5 ]

DC CMRR

Integration Time

100 PLC / 1.67s (2s)

10 PLC / 167 ms (200 ms)

1 PLC / 16.7 ms (20 ms)

0.2 PLC / 3 ms (3 ms)

0.02 PLC / 400

µs (400 µs)

[12] Accuracy specificat ions are for the voltage measur ed at

the input terminals only. 1mA test current is typical. Variation

in the current source will create some variation in the voltage

drop ac ross a diode junction.

Continuously integrating, multi-slope III

A/D conv ert e r.

0.0002% of reading + 0.0001% of range

Selectable 10 M

Ω or >10 GΩ [11]

10 MΩ ±1%

< 30 pA at 25°C

Copper alloy

1000 V on all ranges

Selectable 4-wire or 2-wire ohms.

Current source referenced to LO input.

10% of range per lead for 100

ranges. 1 k

Ω per lead on all other ranges.

Ω, 1 kΩ

1000 V on all ranges

Ω for 1A, 3A. 5Ω for 10 mA, 100 mA

0.1

Externally accessible 3A, 250 V fuse

Internal 7A, 250 V fuse

300 samples/sec with audible tone

Adjustable from 1

Ω to 1000 Ω

Input HI-LO / Reference HI-LO

100 mV to 1000 V ranges

100 mV to 10 V ranges (autoranged)

Reference LO to Input LO voltage < 2 V

Reference HI to Input LO voltage < 12V

140 dB

Normal Mode Rejection [ 6 ]

60 dB [ 7 ]

60 dB [ 7 ]

60 dB [ 7 ]

0 dB

0 dB

Teflon is a registered trademark of E.I. duPont deNemours and Co.

Operating Characteristics [ 8 ]

Additional

Function

DCV, DCI, and

Resistance

System Speeds

Digits

6

6

5

5

4

[ 9 ]

1

⁄

2

1

⁄

2

1

⁄

2

1

⁄

2

1

⁄

2

Readings/s

0.6 (0.5)

6 (5)

60 (50)

300

1000

Funct ion Change

Range C ha ng e

Autorange Time

ASCII readings to RS-232

ASCII readings to GPIB

Max. Internal Trigger Rate

Max. External Trigger Rate to Memory

Max. External Trigger Rate to GPIB

Autozero OFF Operation

Follow ing in st ru men t warm- u p at ca l ib rat i on temp er atu re ±1°C

and <10 minutes, add 0.0002% range additional error + 5 µV.

Settling Considerations

Reading settling times are affected by source impedance,

cable dielectric characteristics, and input signal changes.

Measurement Considerations

Agilent recommends the use of Teflon

low-dielectric absorption wire insulation for these measurements.

[ 1 ] Specifications are for 1-hour warm-up at 6

[ 2 ] Relat ive to calibr ation standar ds.

[ 3 ] 20% overrange on all ranges, except 1000 Vdc, 3 A range.

[ 4 ] Specifications are for 4-wire ohms func tion, or 2-wir e

ohms using Math Null. Without Math Null, add 0.2

additional error in 2-wire ohms function.

[ 5 ] For 1 kΩ unbala nc e in LO lead .

[ 6 ] For power-line frequency ± 0.1%.

[ 7 ] For power-line frequency ± 1%, subtract 20 dB.

For

[ 8 ] Readings speeds for 60 Hz and ( 50 Hz ) operation,

Autozero Off.

[ 9 ] Speeds are for 4

and Display OFF. Includes measurement and data

transfer over GPIB.

[ 10 ] Add 20 µV for dc volts, 4 µA for dc current, or

20 m

[ 11 ] For these ranges, inputs beyond ±17V are

clamped through 100 k

± 3%, subtract 30 dB.

1

⁄

digits, Dela y 0, A uto ze r o OF F,

2

Ω for resistance.

Ω (typical).

Noise Error

0% of range

0% of range

0.001% of range

0.001% of range

0.01% of range

26/sec

50/sec

<30 ms

55/sec

1000/sec

1000/sec

1000/sec

900/sec

â

or other high-impedance,

1

⁄

digits.

2

[10]

[10]

Ω

13

Chapter 1 Specific ations

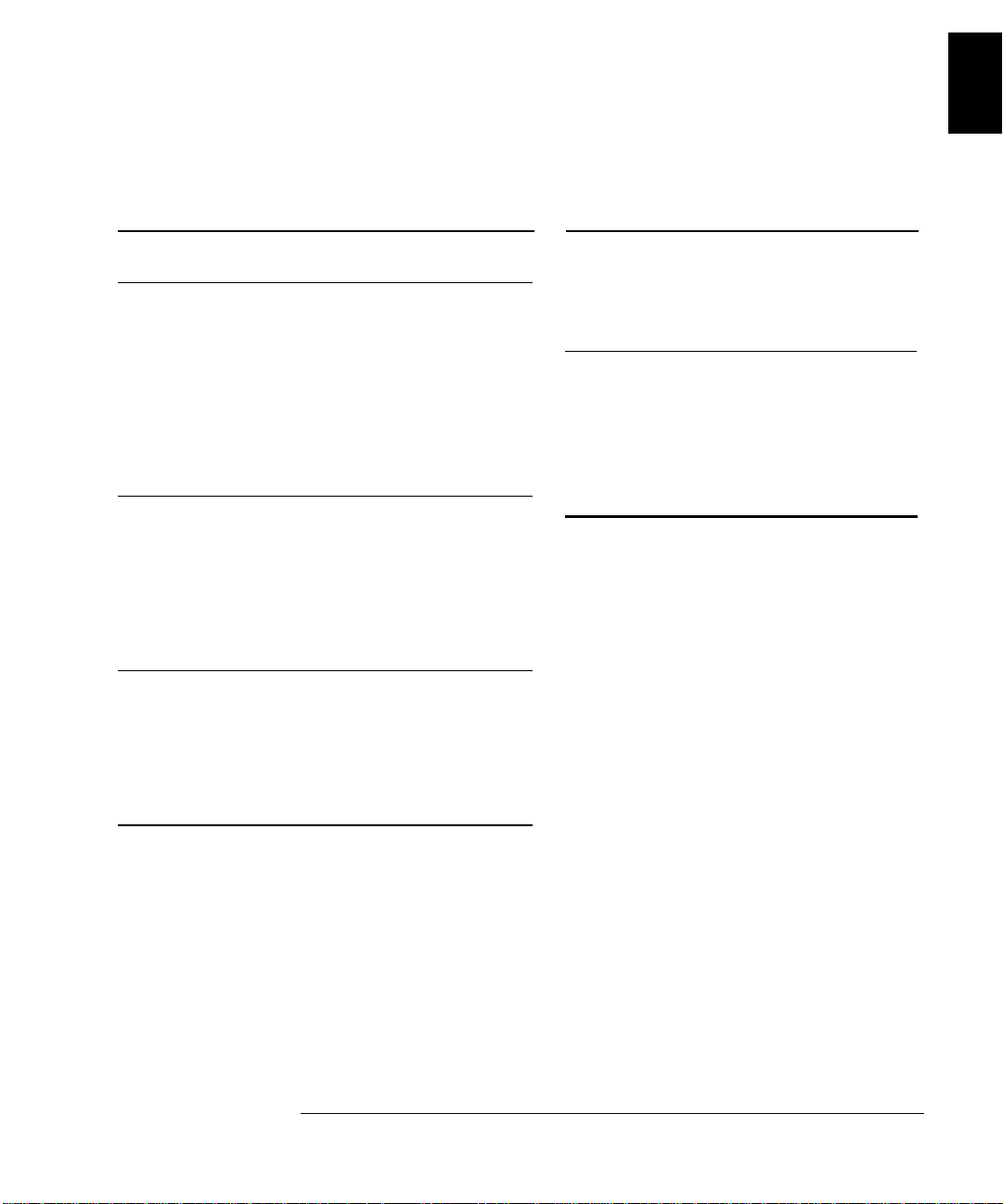

AC Characteristics

AC Characteristics

Accuracy Spe cificati ons ± ( % of reading + % of range ) [ 1 ]

Function Range [ 3 ] Frequency

True RMS

AC Voltage

[ 4 ]

True RMS

AC Current

[ 4 ]

Additional Low Frequency Errors ( % of reading )

100.000 0 mV

1.00 0000 V

to

750.000 V

1.000000 A

3.00 000 A

Frequency

10 Hz – 20 Hz

20 Hz – 40 Hz

40 Hz – 100 Hz

100 Hz – 200 Hz

200 Hz – 1 kHz

> 1 kHz

3 Hz – 5 Hz

5 Hz – 10 Hz

10 Hz – 20 kHz

20 kHz – 50 kHz

50 kHz – 100 kHz

100 kHz – 300 kHz

3 Hz – 5 Hz

5 Hz – 10 Hz

10 Hz – 20 kHz

20 kHz – 50 kHz

50 kHz – 100 kHz

100 kHz – 300 kHz [6]

3 Hz – 5 Hz

5 Hz – 10 Hz

10 Hz – 5 kHz

3 Hz – 5 Hz

5 Hz – 10 Hz

10 Hz – 5 kHz

AC Filter

Slow Medium Fast

0 0.74 ––

0 0.22 ––

0 0.06 0.73

0 0.01 0.22

0 0 0.18

0 0 0

[6]

[5]

24 Hour [ 2 ]

± 1°C

23°C

1.00 + 0.03

0.35 + 0.03

0.04 + 0.03

0.10 + 0.05

0.55 + 0.08

4.00 + 0.50

1.00 + 0.02

0.35 + 0.02

0.04 + 0.02

0.10 + 0.04

0.55 + 0.08

4.00 + 0.50

1.00 + 0.04

0.30 + 0.04

0.10 + 0.04

1.10 + 0.06

0.35 + 0.06

0.15 + 0.06

Additional Crest Factor Errors ( non-sinewave ) [ 7 ]

90 Day

23°C

± 5°C

1.00 + 0.04

0.35 + 0.04

0.05 + 0.04

0.11 + 0.05

0.60 + 0.08

4.00 + 0.50

1.00 + 0.03

0.35 + 0.03

0.05 + 0.03

0.11 + 0.05

0.60 + 0.08

4.00 + 0.50

1.00 + 0.04

0.30 + 0.04

0.10 + 0.04

1.10 + 0.06

0.35 + 0.06

0.15 + 0.06

Crest Factor

1 – 2

2 – 3

3 – 4

4 – 5

1 Year

23°C ± 5°C

1.00 + 0.04

0.35 + 0.04

0.06 + 0.04

0.12 + 0.05

0.60 + 0.08

4.00 + 0.50

1.00 + 0.03

0.35 + 0.03

0.06 + 0.03

0.12 + 0.05

0.60 + 0.08

4.00 + 0.50

1.00 + 0.04

0.30 + 0.04

0.10 + 0.04

1.10 + 0.06

0.35 + 0.06

0.15 + 0.06

Erro r ( % of r eadi ng )

0.05%

0.15%

0.30%

0.40%

Temperature

Coefficient/°C

0°C – 18°C

28°C – 55°C

0.10 0 + 0.004

0.03 5 + 0.004

0.00 5 + 0.004

0.01 1 + 0.005

0.06 0 + 0.008

0.20 + 0.02

0.10 0 + 0.003

0.03 5 + 0.003

0.00 5 + 0.003

0.01 1 + 0.005

0.06 0 + 0.008

0.20 + 0.02

0.10 0 + 0.006

0.03 5 + 0.006

0.01 5 + 0.006

0.10 0 + 0.006

0.03 5 + 0.006

0.01 5 + 0.006

Sinewave Transfer Accuracy ( typical )

Frequency

10 Hz – 50 kHz

50 kHz – 300 kHz

Error ( % of r ange )

0.002%

0.005%

14

Conditions:

Sinewave input.

Within 10 minutes and ± 0.5°C.

Within ±10% of initia l volt ag e and ±1% of initial frequency.

Following a 2-hour warm-up.

Fixed range between 10% and 100% of full scale ( and <120 V ).

Using 6

Measur ements are made using accepted metrology practices.

1

⁄

digit resolution.

2

Chapter 1 Specific ations

AC Characteristics

1

Measuring Characteristics

Measurement Noise Rejection

AC CMRR

True RMS AC Voltage

Measurement Method:

Crest Factor:

AC Fil ter Bandwidth:

Slow

Medium

Fast

Input Impedance:

Input Protection:

True RM S AC Curr ent

Measurement Method:

Shunt Resistor:

Burden Voltage:

Input Protection:

Settling Conside ration s

Applying >300 V rms (or >1 A rms) will cause self-heating in

signal-c on ditionin g co mp on ents. Thes e err o rs ar e inc lu de d in

the instrument specifications. Internal temperature changes

due to s elf-heating may cause addit ional error on lower ac

voltage ranges. The additional error will be less than 0.02%

of reading and will generally dissipate within a few minutes.

[ 8 ]

70 dB

AC-c oupl ed Tr ue R MS – measures

the ac component of input with up

to 400 Vdc of bias on any r ange.

Maximum 5:1 at full scale

3 Hz – 300 kHz

20 Hz – 30 0 kHz

200 Hz – 300 kHz

1 M

Ω ± 2%, in parallel with 100 pF

750 V rms all ranges

Direct coupled to the fuse and shunt.

AC-coupled True RMS measurement

(measures the ac component only).

0.1

Ω for 1 A and 3 A ranges

1 A range: < 1 V rms

3 A range: < 2 V rms

Exter na lly ac ce ss ib l e 3A, 25 0 V f us e

Internal 7A, 250 V fuse

Operating Characteristics [ 9 ]

Function

Digits

ACV, ACI 6

System Speeds

1

⁄

1

6

⁄

1

6

⁄

1

6

⁄

1

6

⁄

[ 11 ] , [ 12 ]

2

2

2

2

2

Reading/s

7 sec/reading

1

1.6

10

50

Functio n or Ra ng e C ha ng e

Autora ng e Tim e

ASCII readings to RS-232

ASCII readings to GPIB

Max. Internal Trigger Rate

Max. External Trigger Rate to Memory

Max. External Trigger Rate to GPIB/RS-232

[ 1 ] Specifications are for 1-hour warm-up at 6

Slow ac filter, sinewave input.

[ 2 ] Relative to calibration standards.

[ 3 ] 20% overrange on all ranges, except 750 Vac, 3 A range.

[ 4 ] Specifications are for sinewave input >5% of range.

For inputs from 1% to 5% of range and <50 kHz,

add 0.1% of range additional error. For 50 kHz to 100 kHz,

add 0.13% of range.

[ 5 ] 750 Vac ran ge limited to 100 kHz or 8x10

[ 6 ] Typically 30% of reading error at 1 MHz.

[ 7 ] For frequencies below 100 Hz, slow AC filter specified

for sinewave input only.

[ 8 ] For 1 kΩ unbalance in LO lead.

[ 9 ] Maximum reading rates for 0.01% of ac step

additional error. Additional settling delay required

when input dc level varies.

[ 10 ] For Externa l Trigger or remote operation using defaul t

settling delay ( Delay Auto ).

[ 11 ] Maximum useful limit with default settling delays defeated.

[ 12 ] Speeds are for 4

1

⁄

digits, Delay 0, Display OFF, and

2

Fast AC filte r.

[ 10 ]

[ 11 ]

AC Filter

Slow

Medium

Fast

Fast

Fast

5/sec

<0.8 sec

50/sec

50/sec

50/sec

50/sec

50/sec

1

⁄

digits,

2

7

Volt-Hz.

15

Chapter 1 Specific ations

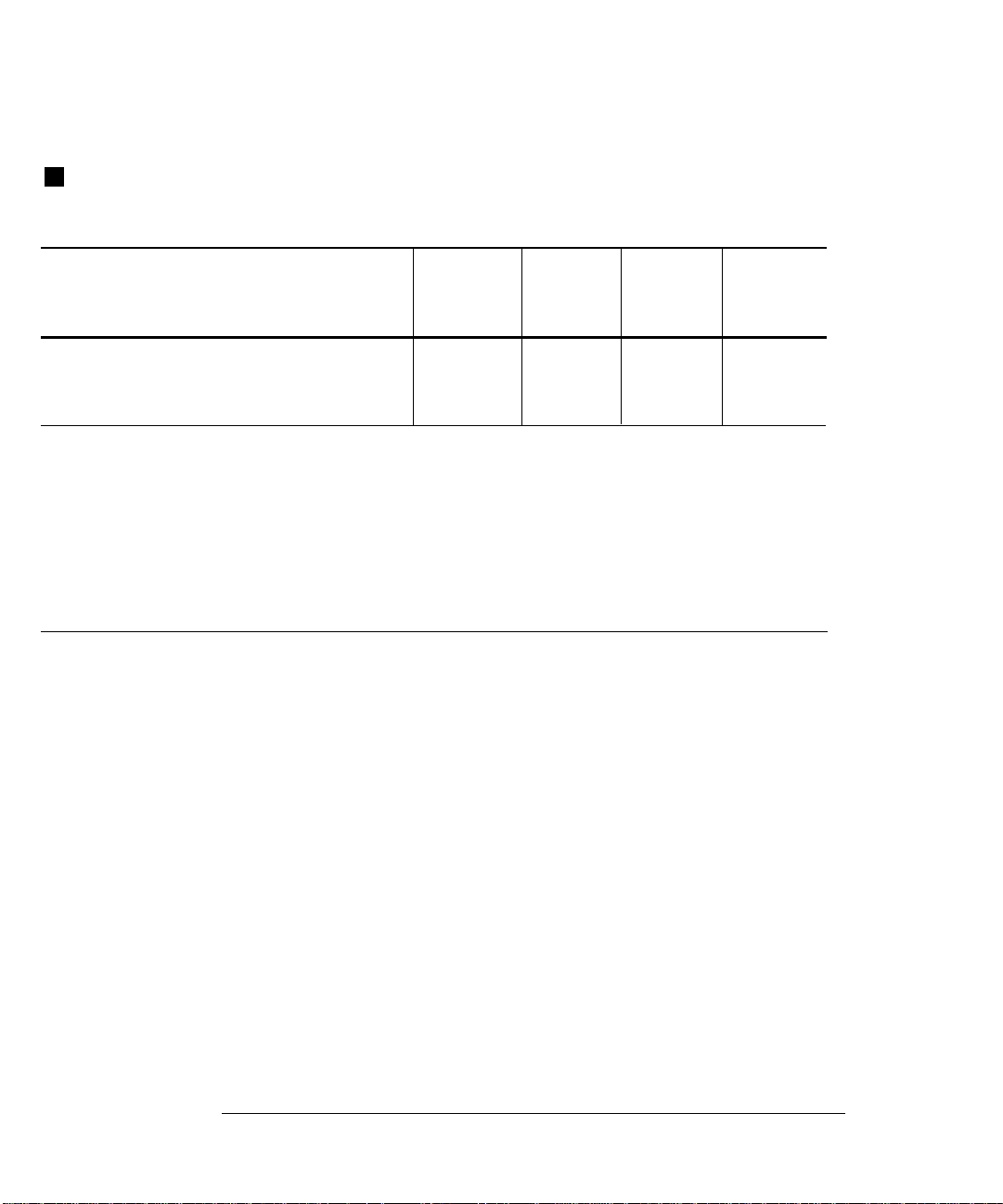

Frequency and Period Characteristics

Frequency and Period Characteristics

Accuracy Specifications ± ( % of reading ) [ 1 ]

Function Range

Frequency,

Period [ 4 ]

[ 3 ] Frequency

100 mV

to

750 V

3 Hz – 5 Hz

5 Hz – 10 Hz

10 Hz – 40 Hz

40 Hz – 300 kHz

Additional Low-Frequency Errors ( % of reading )

Frequency

3 Hz – 5 Hz

5 Hz – 10 Hz

10 Hz – 40 Hz

40 Hz – 100 Hz

100 Hz – 300 Hz

300 Hz – 1 kHz

> 1 kHz

1

6

⁄

2

0 0.12 0.12

0 0.17 0.17

0 0.2 0.2

0 0.06 0.21

0 0.03 0.21

0 0.01 0.07

0 0 0.02

5

1

⁄

4

2

Resolution

Transfer Accuracy ( typical )

0.0005 % of reading Conditions:

24 Hour

[ 2 ]

23°C ± 1°C

90 Day

23°C

± 5°C

1 Year

23°C ± 5°C

Temperature

Coefficient/°C

0°C – 18°C

28°C – 55°C

0.005

0.005

0.001

0.001

[ 4 ]

0.10

0.05

0.03

0.006

1

⁄

2

0.10

0.05

0.03

0.01

0.10

0.05

0.03

0.01

Within 10 minutes and ± 0.5°C.

Within ± 10% of initial value.

Following a 2-hour warm-up.

For inputs > 1 kHz and > 100 mV.

Using 6

1

⁄

digit slow resolution ( 1 second gate time ).

2

Measure ments are made usi ng accepted metrology practi ces.

16

Chapter 1 Specific ations

Frequency and Period Characteristics

1

Measuring Characteristics

Frequency a nd Period

Measurement Method:

Voltage Ranges:

Gate Time:

Settling Considerations

Errors wil l oc cu r wh en at t emp tin g t o meas ur e the f req ue nc y o r

period of an i nput f ol low i ng a dc off se t v olt ag e ch an ge . Th e i np ut

blocking RC time constant must be allowed to fully settle ( up to

1 sec ) before the most accurate measurements are possible.

Measurement Considerations

All frequency count ers are susceptible to error when

measuring low-voltage, low-frequency signals. Shielding

inputs from external noise pickup is critical for minimizing

measurement errors.

Reciprocal-counting technique.

AC-coupled input using the

ac voltage measurement function.

100 mV rms fu ll s ca le to 750 V rms.

Auto or manual rangin g.

10 ms, 100 ms, or 1 sec

Operating Characteristics [ 5 ]

Function

Frequency,

Period

System Speeds

Digits

1

6

⁄

2

1

5

⁄

2

1

4

⁄

2

[ 5 ]

Configuration Rates

Autora ng e Tim e

ASCII readings to RS-232

ASCII readings to GPIB

Max. Internal Trigger Rate

Max. External Trigger Rate to Memory

Max. External Trigger Rate to GPIB/RS-232

[ 1 ] Specifications are for 1- hour warm-up at 6

[ 2 ] Relative to calibration standards.

[ 3 ] 20% overrange on all ranges, except 750 Vac range.

[ 4 ] Input > 100 mV.

For 10 mV input, multiply % of reading error x10.

[ 5 ] Speeds are for 4

1

⁄

digits, Delay 0, Display OFF,

2

and Fast AC filter.

Reading/s

1

9.8

80

14/sec

<0.6 sec

55/sec

80/sec

80/sec

80/sec

80/sec

1

⁄

digit s.

2

17

Chapter 1 Specific ations

Gene r a l Informatio n

General In formation

General Specifications

Power Supply:

Power Line Frequency:

Power Consumption:

Operating Environment:

Storag e Env ironment:

Rack Dimensions (HxWxD):

Weight:

Safety:

EMI:

Vibration and Shock:

Warranty:

Accessories Included

Test Lead Kit with probes, alligator, and grabber attachments.

User’s Guide, Service Guide, test report, and power cord.

100 V / 12 0 V / 220 V / 24 0 V

45 Hz to 66 Hz and 360 Hz to 440 Hz.

Automatically sensed at power-on.

25 VA peak ( 10 W avera ge )

Full accuracy for 0

Full accuracy to 80% R.H. at 40°C

-40°C to 70°C

88.5 mm x 212.6 mm x 348.3 mm

3.6 kg (8 lbs)

Designed to CSA 231, UL 1244,

IEC 1010-1 (1990)

CISPR 11, IEC 801,

MIL-461C (data on file)

MIL-T-28800E Type III, Class 5

(data on file)

3 years stan dard

°C to 55°C

±10%.

Triggering and Memory

Reading

HOLD Sensitivity:

Samples per Trigger:

Trigger Delay:

External Trigge r Delay:

External Trigge r Jitter:

Memory:

Math Functions

Null, Min/Max/Average, dB, dBm, Limit Test (with TTL output).

dBm ref e ren ce resi s ta nc es : 50, 75 , 93, 11 0, 12 4, 12 5, 13 5, 15 0,

250, 300, 500, 600, 800, 900, 1000, 1200, or 8000 ohms.

Standard Programming Languages

SCPI (Standa rd C omm ands fo r Pr ogr amm ab le In st ru men t s)

Agilent 3478A Language Emulati on

Fluke 8840A, Fluke 8842A Language Emulation

Remote Interface

GPIB (IEEE-488.1, IEEE-488.2) and RS-232C

This ISM device complies with Canadian ICES-001.

Cet appareil ISM est co nforme à la norme NMB-001

du Canada.

0.01 %, 0.1% , 1%, or 10% of read ing

1 to 50,000

0 to 36 00 sec ( 10

< 1 ms

< 500

µs

512 readings

µs step size )

18

N10149

Chapter 1 Specific ations

67.53

Product Dimensions

Product Dimensions

Product Dimensions

1

TOP

All dimensions are

shown in millimeter s.

19

Chapter 1 Specific ations

To Calculate Total Measurement Error

To Calculate Total Measurement Error

Each specifi ca t i on includes co rrection factor s whi ch a ccount for error s

present due to operational limitations of the multimeter. This section

explains these errors and shows how to appl y them to your mea suremen ts.

Refer to “Interpreting Multimeter Specifications,” starting on page 22,

to get a better understanding of the terminology used and to help you

interpret the multimeter’s specifications.

The multimeter’s accuracy specifications are expressed in the form:

( % of reading + % of range ). In addition to the reading er ror an d ran g e

error, you may need to add additional errors for certain operating

conditions. Check the list below to make sure you include all

measurement errors for a given function. Also, make sure you apply the

conditions as described in the footnotes on the specification pages.

• If you are operatin g the m ultim e t er outsid e th e 23° C ± 5°C

temperat ure r ange s pec ifi ed , apply an addi tion a l temperature

coeffic ient error.

• For dc voltage, dc current, and resistance measurements, you may

need to apply an additional reading speed error or autozero OFF error.

• For ac voltage and ac current measurements, you may need to apply

an additional low frequency erro r or crest factor error.

Understanding the “ % of reading ” Error The reading error

compensate s fo r i na ccuracies that re sul t fr om t he function and range

you select, as well as the input signal level. The reading error varies

according to the input level on the selected range. This error is

expressed in percent of reading. The following table shows the reading

error applied to the multimeter’s 24-hour dc voltage specification.

Range

10 Vdc

10 Vdc

10 Vdc

Input Level

10 Vdc

1 Vdc

0.1 Vdc

Reading Error

(% of reading)

0.0015

0.0015

0.0015

Reading

Error Voltage

≤ 150 µV

≤ 15 µV

≤ 1.5 µV

20

Chapter 1 Specific ations

To Calculate Total Measurement Error

Understandi ng th e “ % of rang e ” Error The range error compensates

for inaccuracies that result from the function and range you select.

The range erro r con trib u tes a cons ta nt er r or , expr esse d as a percen t of

range, independent of the input signal level. Th e follow in g ta bl e show s

the range error applied to the multimeter’s 24-hou r dc v oltage speci fication.

1

Rang e

10 Vdc

10 Vdc

10 Vdc

Input Level

10 Vdc

1 Vdc

0.1 Vdc

Range Error

(% of range)

0.0004

0.0004

0.0004

Range

Error Voltage

≤ 40 µV

≤ 40 µV

≤ 40 µV

Total Measurement Error To compute the total measurement error,

add the reading error and range error. You can then convert the total

measurement error to a “percent of input” error or a “ppm (part-permillion) of input” error as shown below.

% of input error =

ppm of input error =

Total Measurement Error

Inp u t Signal Level

Total Measurement Error

Inp u t Signal Level

× 100

× 1,000,000

Error Example Assume that a 5 Vdc signal is input to the multimeter on the 10 Vdc range.

Compute the total measurement error using the 90-day accuracy

specifications:

± (0.0020% of reading + 0.0005% of range).

Reading Error

Range Error

Total Error

= 0.0020%

= 0.0005%

µV + 50 µV

= 100

× 5 Vdc

× 10 Vdc

= 100 µV

= 50

µV

=

± 150 µV

= ± 0.0030% of 5 Vdc

= ± 30 ppm of 5 Vdc

21

Chapter 1 Specific ations

Interpreting Multimeter Specifications

Interpreting Multimeter Specifications

This section is provided to give you a better understanding of the terminology

used and wil l help you in terpre t the mu ltimete r’s spe cificatio ns.

Number of Digits and Overrange

The “number of digits” specification is the most fundamental, and

sometimes, the most confusing characteristic of a multimeter.

The number of digits is equal to the maximum number of “9’s” the

multimeter can measure or display. This indicates the number of full

digits. Most multimeters have the ability to overrange and add a partial

1

or “

⁄

” digit.

2

For example, the Agilent 34401A can measure 9.99999 Vdc on the 10 V

range. This represents six full digits of resolution. The multimeter can

also overrange on the 10 V range and me asur e up to a maximum of

12.00000 Vdc. This corresponds to a 6

overrange capability.

1

⁄

-digit measurement with 20%

2

Sensitivity

Sensitivity is the minimum level that the multimeter can detect for a

given measurement. Sensitivity defines the ability of the multimeter to

respond to small changes in the input level. Fo r example, suppose you

are monitoring a 1 mVdc signal and you want to adjust the level to

within

measurement w ould re quire a multim eter with a sen sitivit y of at least 1

You could use a 6

You could also use a 4

For ac voltage and ac current measurements, note that the smallest

value that can be measured is different from the sensitivity. For the

Agilent 34401A, these functions are specified to measure down to 1% of

the selected range. For example, the multimeter can measure down to

1 mV on the 100 mV range.

22

±1 µV. To be able to respond to an adjustme nt this smal l, this

1

⁄

-digit multimeter if it has a 1 Vdc or smaller range.

2

1

⁄

-digit multimeter with a 10 mVdc range.

2

µV.

Chapter 1 Specific ations

Interpreting Multimeter Specifications

Resolution

Resolution is the numeric ratio of the maximum displayed value divided

by the minimum dis pla yed valu e on a selec ted r a nge. Reso lution is

often expressed in percent, parts-per-million (ppm), counts, or bits.

For example, a 6

1

⁄

-digit multimeter with 20% overrange capability can

2

display a measurement with up to 1,200,000 counts of resolution.

This corresponds to about 0.0001% (1 ppm) of full s cale, or 21 bits

including the sign bit. All four specifications are equivalent.

Accuracy

Accuracy is a measure of the “exactness” to which the multimeter’s

measurement uncertainty can be determined relative to the calibration

reference used. Absolute accuracy includes the multimeter’s relative

accuracy specification plus the known error of the calibration reference

relative to national standards (such as the U.S. National Institute of

Standards and Technology). To be meaningful, the accuracy specifications

must be accompanied with the conditions under which they are valid.

These conditions should include temperature, humidity, and time.

1

There is no standar d co nv en tion a mon g mu lt im eter man u fac tu re rs for

the confidence limits at which specifications are set. The table below

shows the probability of non-conformance for each specificatio n with the

given assumptions.

Specification

Criteria

Mean

± 2 sigma

Mean

± 3 sigma

Mean

± 4 sigma

Probability

of Failure

4.5%

0.3%

0.006%

Variations in performance from reading to reading, and instrument to

instrument, decrease for increasing number of sigma for a given

specification. This means that you c an a chi eve greater act ual m easurement

precision for a specific accuracy specification number.

The Agilent 34401A is designed and tested to meet performance better

than mean

±4 sigma of the published accuracy specifications.

23

Chapter 1 Specific ations

Interpreting Multimeter Specifications

Transfer Accuracy

Transfer accuracy refers to t he error introduce d by the multimeter

due to noise and short-term drift. This error becomes apparent when

comparing two nearly-equal signals for the purpose of “transf erring”

the known ac cur a c y of one dev ic e to the ot h er .

24-Hour Accuracy

The 24-hour accuracy specification indicates the multimeter’s relative

accuracy over its full measurement range for short time intervals and

within a stable environment. Short-term accuracy is usually specified

for a 24-hour period and for a

±1°C temperatu r e ran g e.

90-Day and 1-Year Accuracy

These long-term accuracy specifications are valid for a 23°C ± 5°C

temperature range. These specifications include the initial calibration

errors plus the multimeter’s long-term drift errors.

Temperature Coefficients

Accuracy is usually specified for a 23°C ± 5°C temperature range.

This is a common temperature range for many operating environments.

You must add additional temperature coefficient errors to the accuracy

specification if you are operating the multimeter outside a 23°C ± 5°C

temperature range (the specification is per °C).

24

Chapter 1 Specific ations

Configuring for Highest Accuracy Measurements

Configuring for Highest Accuracy Measurements

The measurement configurations shown below assume that the

multimeter is in its power-on or reset state. It is also assumed that

manual ranging is enabled to e nsure proper full scale range selection.

DC Voltag e, DC Current, and Resistance Measurements:

• Set the resolution to 6 digits (you can use the 6 dig its slow mode for

further nois e reduction).

• Set the input resistance to greater than 10 GΩ (for the 100 mV, 1 V,

and 10 V ranges) for the best dc voltage accuracy.

• Use 4-wire ohms for t he best resistance acc uracy.

• Use Math Null to null the test lead resistance for 2-wire ohms, and to

remove interconnection offset for dc voltage measurements.

1

AC Voltage and AC Current Measurements:

• Set the resolution to 6 digits.

• Select the slow ac filter (3 Hz to 300 kHz).

Frequency and Period Measurements:

• Set the resolution to 6 digits.

25

26

2

2

Quick Start

Quick Start

One of the first things you will want to do with your multimeter is to

become acquainted with its front panel. We have written the exercises

in this chapter to prepare the multimeter for use and help you g et

familiar with some of its front-panel operations.

The front panel has two rows of keys to select various functions and

operations. Most ke ys have a shifted function printed in blue above

the key. To perform a shifted function, press

annunciator will turn on). Then, press the key that has the desired

label above it. For example, to select the dc current function,

Shift DC V .

press

Shift (the Shift

If you accident a l ly press

Shift annunciato r.

The rear cover of this bo ok is a fold -out Qu ick Re feren ce Gu ide. On t his

cover you will fi nd a quick summary of various multi m eter features.

Shift , just press it again to turn off the

28

Loading...

Loading...