AgfaPhoto d-lab.2 8060/803, d-lab.2 8060/255, d-lab.2plus 8060/261, d-lab.2 8060/804, d-lab.2plus 8060/813 Operation Manual

...Page 1

Operation Manual

Digital Minilabs

d-lab.2plus:

8060/261

8060/813, 8060/814

8060/271, 8060/273

8060/158 + 8060/255

d-lab.2:

8060/260,

8060/803, 8060/804,

8060/270, 8060/272,

8060/157 + 8060/255

netlab.2plus:

8060/505

Operation

Order number DD+18060A162D0

Edition 2005-05-01

Version English, 04092_01

Page 2

Modification History

Version Edition Modifications

04092_00 2004-10-01

04092_01 2005_05_01

Combination of the Operation Manual – Operation

for the machines d-lab.2, d-lab.2plus, and

netlab.2plus;

Update to Software Version 8.0

Update to Software Version 8.5

© 2005 AgfaPhoto GmbH. Alle Rechte vorbehalten.

No part of these instructions may be reproduced, copied, or transmitted in any

form or by any means without prior written permission by AgfaPhoto GmbH.

AgfaPhoto is used under license of Agfa-Gevaert AG

Page 3

d-lab.2, d-lab.2plus, netlab.2plus: Operation Contents

Contents

Introduction........................................................................................................................1-i

1

1.1 Applied Standards and Rules....................................................................................................................................1-1

1.2 Explanations for the Operation and Service Manual.......................................................................................1-2

1.2.1 Available Documentation.......................................................................................................................1-2

1.2.2 Guideline for the User..............................................................................................................................1-3

1.2.3 Conventions.................................................................................................................................................1-4

1.2.3.1 Pictographs......................................................................................................................................1-4

1.2.3.2 Text styles........................................................................................................................................1-4

1.2.3.3 Safety notes.....................................................................................................................................1-5

1.3 Legal Situation ...............................................................................................................................................................1-6

1.3.1 Manufacturer Information......................................................................................................................1-6

1.3.2 Copyright ......................................................................................................................................................1-6

1.3.3 Warranty........................................................................................................................................................1-7

1.3.3.1 Liability of the Owner ..................................................................................................................1-7

1.3.3.2 Warranty and Liability .................................................................................................................1-7

1.3.3.3 Exclusion of Liability ....................................................................................................................1-8

1.3.4 Appropriate Use..........................................................................................................................................1-8

1.3.5 Inappropriate Use ......................................................................................................................................1-8

1.4 Consumables and Spare Parts..................................................................................................................................1-9

1.5 Hotline...............................................................................................................................................................................1-9

1.6 Safety Notes and Rules............................................................................................................................................1-10

1.6.1 General .......................................................................................................................................................1-10

1.6.2 In Operation..............................................................................................................................................1-11

1.6.3 Handling of Chemicals .........................................................................................................................1-11

1.6.4 Service / Repair Routines ...................................................................................................................1-12

1.6.5 Disposal of the Machine......................................................................................................................1-12

1.6.6 Warnings and Information Labels on the Machine ...................................................................1-13

1.7 Transport, Installation, First Operation ..............................................................................................................1-22

1.8 Storage ...........................................................................................................................................................................1-22

1.8.1 Chemicals..................................................................................................................................................1-22

1.8.2 Photographic Paper ...............................................................................................................................1-22

2 General Description, Work Routines and Operation ..............................................................2-i

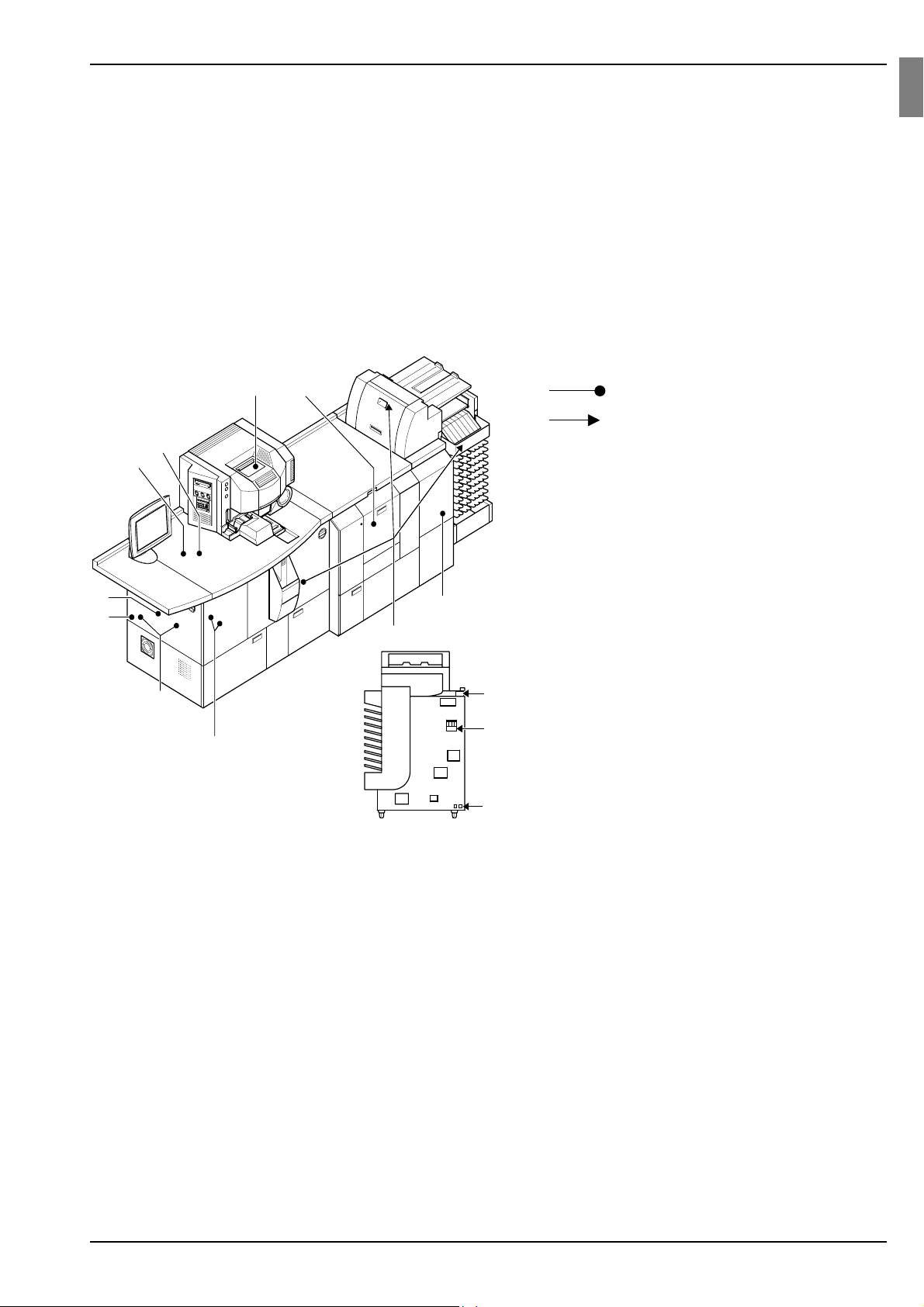

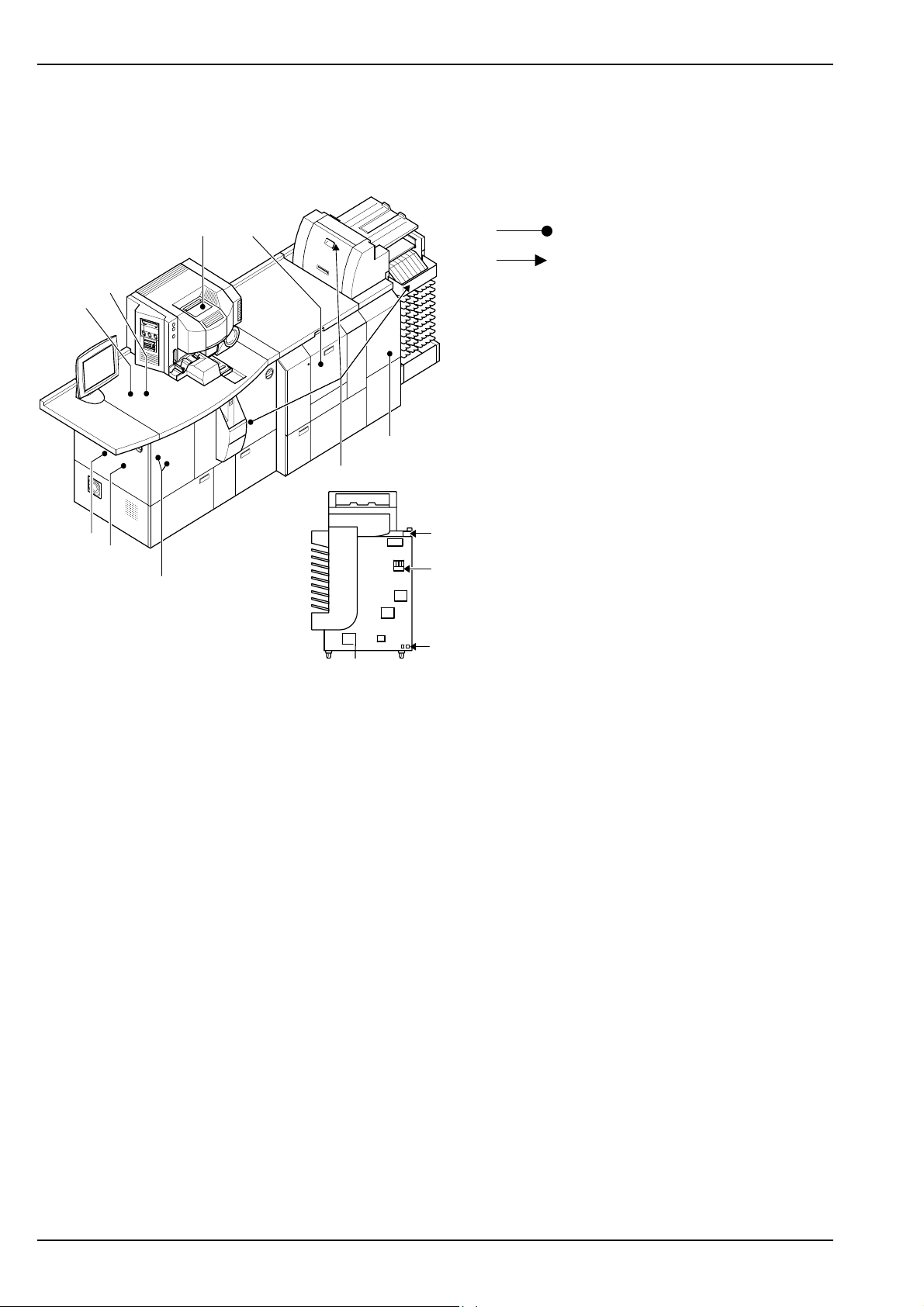

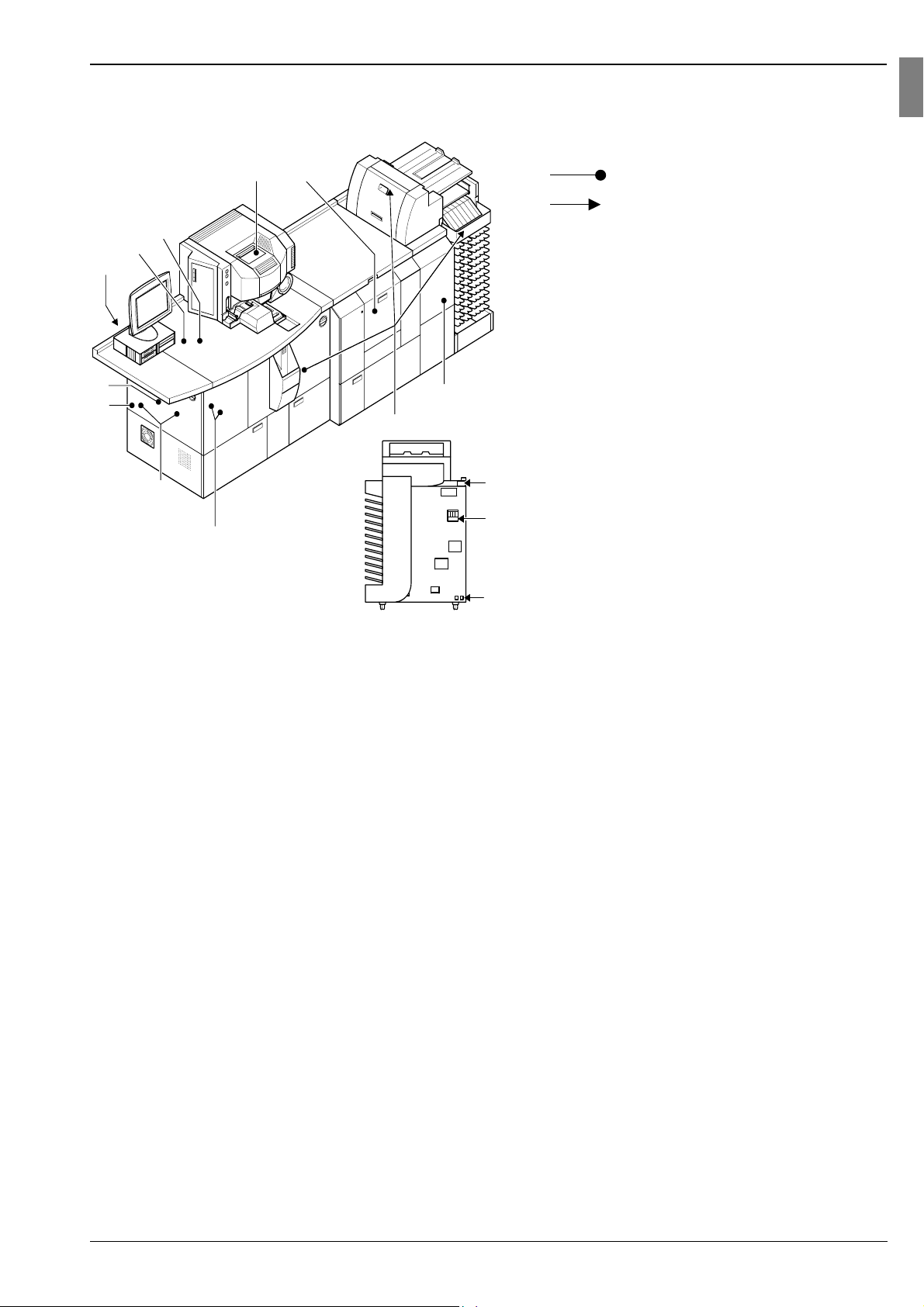

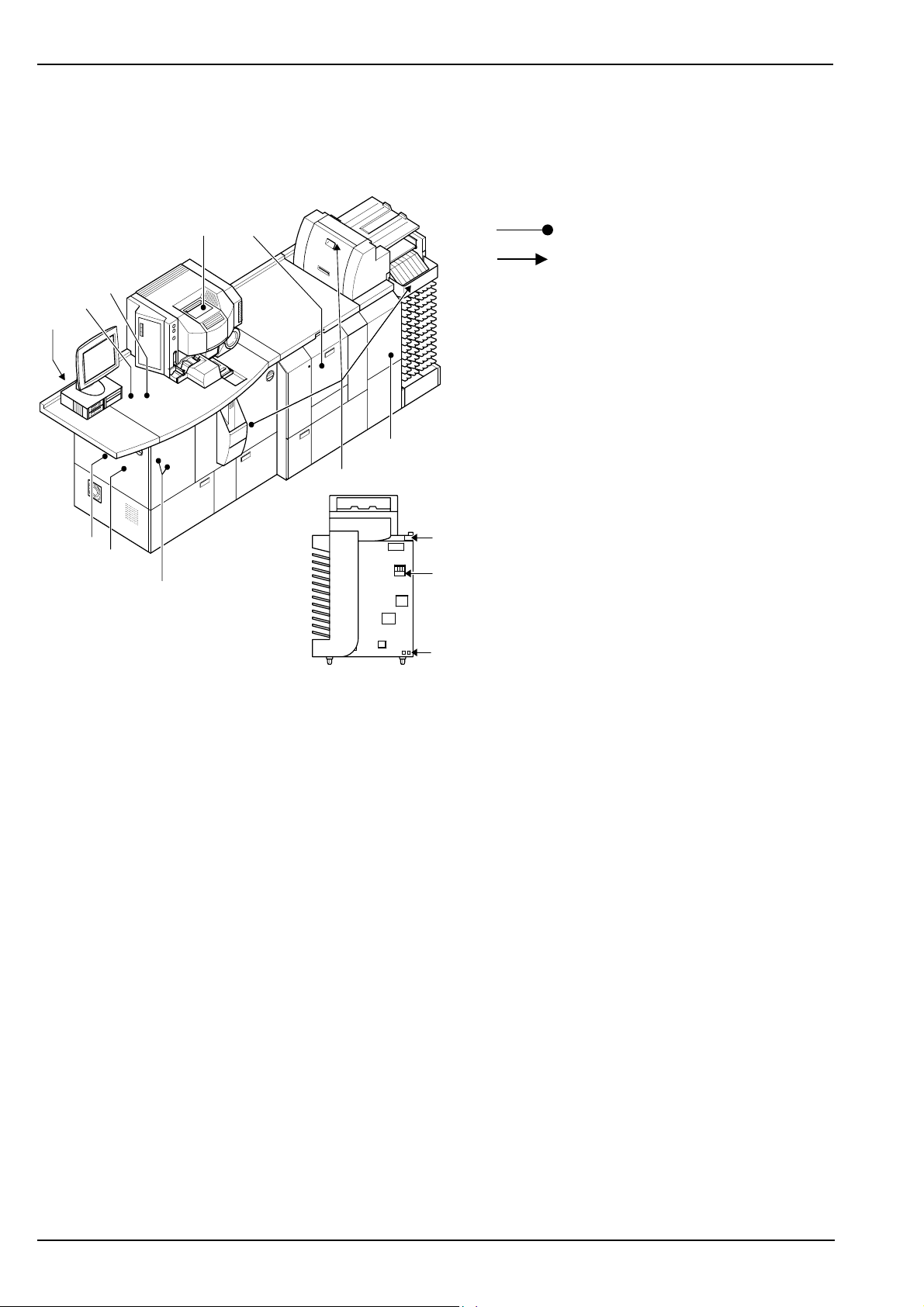

2.1 General Description......................................................................................................................................................2-1

2.2 Product Description......................................................................................................................................................2-7

2.2.1 Corresponding Film Types and Images .............................................................................................2-7

2.2.2 Image Editing..............................................................................................................................................2-7

2.3 Operation Routines.......................................................................................................................................................2-8

2.3.1 Drive Bay

Applies only to d-lab.2plus, netlab.2plus................................................................................................2-8

2.3.2 Scanner

Applies only to d-lab.2/2plus ....................................................................................................................2-9

2.3.3 Main computer ........................................................................................................................................2-10

2.3.4 Printer .........................................................................................................................................................2-11

2.3.5 Paper Processor.......................................................................................................................................2-12

2.3.6 Sorter...........................................................................................................................................................2-13

2.3.7 Densitometer ...........................................................................................................................................2-14

2.4 Controls on the Minilab...........................................................................................................................................2-15

2.4.1 Keys and Pilot Lamps............................................................................................................................2-15

2.4.2 Touchscreen Monitor ............................................................................................................................2-16

AgfaPhoto 2005-05-01 / PN 04092_01 0-i

Page 4

Contents d-lab.2, d-lab.2plus, netlab.2plus: Operation

2.4.3 Main Breaker and Ground Fault Interrupter................................................................................. 2-17

2.5 Switching the Machine On and Off..................................................................................................................... 2-18

2.5.1 Preparations Prior to Switch-on........................................................................................................2-18

2.5.2 Automatic Switch-On (Timer) ............................................................................................................ 2-18

2.5.3 Switching On with the ON Key ......................................................................................................... 2-19

2.5.4 Switching the Machine On and Off with the Main Breaker................................................... 2-20

2.5.5 System Start.............................................................................................................................................2-22

2.5.6 User Login .................................................................................................................................................2-22

2.5.7 The Start Screen...................................................................................................................................... 2-23

2.5.8 Log-in of Another User .........................................................................................................................2-24

2.5.9 End of Work and Shutdown................................................................................................................2-24

2.5.9.1 Sleep Mode...................................................................................................................................2-25

2.5.9.2 Switching the Machine Off .....................................................................................................2-25

2.6 Screen Layout and Controls on the Screen......................................................................................................2-27

2.6.1 Information Area.....................................................................................................................................2-28

2.6.2 Buttons.......................................................................................................................................................2-30

2.6.3 Pulldown Menus.....................................................................................................................................2-31

2.6.4 Popup Windows ...................................................................................................................................... 2-32

2.6.5 Input Screens........................................................................................................................................... 2-34

2.6.5.1 Entering Text ................................................................................................................................2-34

2.6.5.2 Entering Numbers.......................................................................................................................2-35

2.6.6 Reorder Keyboard

Applies only to d-lab.2/2plus

................................................................................................................. 2-36

2.7 Main Menus .................................................................................................................................................................2-38

2.8 Calling Up Info ............................................................................................................................................................ 2-43

2.8.1 Film Drive Info

Applies only to d-lab.2/2plus

................................................................................................................. 2-45

2.8.2 Printer Info................................................................................................................................................2-46

2.8.3 Paper Processor Info .............................................................................................................................2-47

2.8.4 Order Info ..................................................................................................................................................2-48

2.8.5 Version Info .............................................................................................................................................. 2-49

2.8.6 Displaying the Error List....................................................................................................................... 2-50

2.9 Activating Help ...........................................................................................................................................................2-51

2.10 Ejecting the ZIP ..........................................................................................................................................................2-53

3 Changing Chemicals............................................................................................................ 3-i

3.1 Safety Information ........................................................................................................................................................3-1

3.2 Chemical Sets ................................................................................................................................................................3-3

3.3 Changing Chemical Solutions (MSC/d-lab Chemicals) .................................................................................3-4

3.4 Mixing Replenisher Chemicals (d-lab.2 Easy Paper Box)............................................................................ 3-10

3.5 Settings and Tests for the Chemicals.................................................................................................................3-11

4 Settings and Configurations ................................................................................................4-i

4.1 Overview...........................................................................................................................................................................4-1

4.2 Defining the User Interface, Defining Users, Assigning Rights...................................................................4-5

4.2.1 Defining the User Interface ...................................................................................................................4-5

4.2.2 Defining Users and User Rights ...........................................................................................................4-6

4.2.2.1 Defining a New User ...................................................................................................................4-7

4.2.2.2 Changing the Settings for an Existing User........................................................................ 4-9

4.2.2.3 Overview: Rights, which can be Assigned to a User......................................................4-10

4.2.2.4 Defining a User as Standard User.........................................................................................4-11

4.2.2.5 Changing the User .....................................................................................................................4-11

4.2.3 Deleting a User .......................................................................................................................................4-11

4.3 Defining Paper Width, Surfaces and Cut Lengths .........................................................................................4-12

4.3.1 Defining Paper Widths .........................................................................................................................4-12

0-ii 2005-05-01 / PN 04092_01 AgfaPhoto

Page 5

d-lab.2, d-lab.2plus, netlab.2plus: Operation Contents

4.3.2 Deleting Paper Widths .........................................................................................................................4-14

4.3.3 Defining Paper Surfaces.......................................................................................................................4-14

4.3.4 Renaming Surfaces ................................................................................................................................4-16

4.3.5 Deleting Surfaces ...................................................................................................................................4-16

4.3.6 Paper Codes according to AgfaPhoto Standard .......................................................................... 4-17

4.3.7 Defining Cut Lengths ............................................................................................................................4-18

4.3.8 Overview: Print Sizes ............................................................................................................................4-19

4.3.9 Deleting Cut Lengths............................................................................................................................4-20

4.4 Entering Machine Settings .....................................................................................................................................4-21

4.4.1 Setting Date and Time..........................................................................................................................4-22

4.4.2 Setting the Timer: Start and Shutdown..........................................................................................4-23

4.4.3 Defining the Standard User ................................................................................................................4-26

4.4.4 Installing / Activating Software .......................................................................................................4-27

4.4.4.1 Activating Software ...................................................................................................................4-27

4.4.4.2 Installing Software from CD................................................................................................... 4-29

4.4.5 Printer Settings .......................................................................................................................................4-30

4.4.6 Scanner Settings (Scratch Correction, Scanning Crop)

Applies only to d-lab.2/2plus

.................................................................................................................4-32

4.4.7 Paper Processor Settings.....................................................................................................................4-34

4.4.7.1 Setting the Replenishment Rates........................................................................................4-34

4.4.7.2 Setting the Temperatures and Calibrating the Sensors ...............................................4-36

4.4.7.3 Calibrating the Water Pumps ................................................................................................ 4-38

4.4.8 Other Settings..........................................................................................................................................4-43

4.4.8.1 General settings..........................................................................................................................4-44

4.4.8.2 Settings for negative printing

(only for d-lab.2/2plus)............................................................................................................4-45

4.4.8.3 Settings for digital orders........................................................................................................4-46

4.4.8.4 The dTFS function (digital Total Film Scanning: Image enhancement

in digital print files)................................................................................................................... 4-47

4.4.8.5 Autosave settings.......................................................................................................................4-49

4.5 Adjusting the Production Balance .......................................................................................................................4-50

4.5.1 General Information Regarding the Production Balance ........................................................ 4-53

4.5.2 Setting the Correction Impact (for Color Negatives and Digital).........................................4-54

4.5.3 Setting Sharpness - Edges (for Color Negatives and Digital) ................................................4-55

4.5.4 Setting the Saturation (for Color Negatives and Digital) ........................................................4-56

4.5.5 Setting Sharpness - Grain (for Color Negatives and Digital)..................................................4-57

4.5.6 Area Contrast (for Color Negatives and Digital)..........................................................................4-58

4.5.7 Setting Detail Contrast (for Color Negatives and Digital)....................................................... 4-59

4.5.8 Brightness correction (for color negatives and digital)............................................................4-60

4.5.9 Setting Color and Density Corrections (Digital) .........................................................................4-61

4.5.10 Activating / Deactivating the Contrast Management (only for Color Negative)

Applies only to d-lab.2/2plus

.................................................................................................................4-61

4.5.11 Red-eye correction (for color negatives and digital)................................................................. 4-61

4.5.12 Using TFS (only for Color Negatives)

Applies only to d-lab.2/2plus

.................................................................................................................4-63

4.5.13 Panorama Identification (only for Color Negatives)

Applies only to d-lab.2/2plus

.................................................................................................................4-65

4.5.14 Color / Density Logic (TFS; only for Color Negative)

Applies only to d-lab.2/2plus

.................................................................................................................4-65

4.5.15 Setting TFS Color (only for Color Negatives)

Applies only to d-lab.2/2plus

4.5.15.1 Dominant Parameters...............................................................................................................4-66

4.5.15.2 Parameters for Artificial Light Detection...........................................................................4-68

4.5.15.3 Parameter for Shift Correction...............................................................................................4-70

.................................................................................................................4-66

AgfaPhoto 2005-05-01 / PN 04092_01 0-iii

Page 6

Contents d-lab.2, d-lab.2plus, netlab.2plus: Operation

4.5.16 Setting TFS Density (only for Color Negatives)

Applies only to d-lab.2/2plus

................................................................................................................. 4-71

4.5.17 Setting the Selector Logic (only for Color Negatives)

Applies only to d-lab.2/2plus

................................................................................................................. 4-73

4.5.18 Setting Color and DX Corrections (for Color Negatives)

Applies only to d-lab.2/2plus

4.5.18.1 Color Corrections........................................................................................................................4-75

4.5.18.2 DX Corrections ............................................................................................................................4-76

................................................................................................................. 4-75

4.6 Settings for Network Orders ..................................................................................................................................4-78

4.6.1 Settings for Remote Orders: File Print ...........................................................................................4-79

4.6.2 Settings for Remote Orders: Autosave ........................................................................................... 4-80

4.6.3 Settings for Network Orders............................................................................................................... 4-81

4.6.4 Settings for d-workflow........................................................................................................................ 4-82

4.7 Defining and Editing Print Configurations .......................................................................................................4-84

4.7.1 Defining and Editing Paper Configurations.................................................................................. 4-85

4.7.2 Defining and Editing the Backprint Configurations ..................................................................4-87

4.7.3 Indexprint Configurations....................................................................................................................4-93

4.7.3.1 Importing Indexprint Layouts.................................................................................................4-93

4.7.3.2 Defining and Editing a Indexprint Configuration:...........................................................4-94

4.7.4 Defining and Editing Correction Configurations ........................................................................4-97

4.7.5 Defining and Editing Autosave Configurations.........................................................................4-100

4.7.6 Defining and Editing a Front Print Configuration ....................................................................4-104

4.7.7 Combiprint Configurations ...............................................................................................................4-106

4.7.7.1 Importing Combiprint Layouts............................................................................................ 4-106

4.7.7.2 Defining and Editing a Combiprint Configurations:.................................................... 4-107

4.8 Defining and Editing Order Configurations....................................................................................................4-109

4.8.1 Defining and Editing Order Configurations of the Single Type...........................................4-112

4.8.1.1 Film Mask: 135, 120, 110

Applies only to d-lab.2/2plus............................................................................................. 4-112

4.8.1.2 Film Mask: File Print...............................................................................................................4-113

4.8.1.3 Film Mask: IX240

Applies only to d-lab.2/2plus............................................................................................. 4-115

4.8.1.4 Film Mask: Slide

Applies only to d-lab.2/2plus............................................................................................. 4-117

4.8.2 Defining and Editing Order Configurations of the Package Type ......................................4-118

4.8.3 Defining and Editing Order Configurations of the Combiprint Type.................................4-120

4.8.3.1 Film Mask: 135, 120, 110

Applies only to d-lab.2/2plus............................................................................................. 4-120

4.8.3.2 Film Mask: IX240, Slide

Applies only to d-lab.2/2plus............................................................................................. 4-121

4.8.3.3 Film Mask: File Print...............................................................................................................4-122

4.8.4 Defining and Editing Order Configurations of the Reproduction Type ............................4-123

4.8.5 Defining a Configuration as Standard Configuration..............................................................4-125

4.9 Deleting a Print or Order Configuration ..........................................................................................................4-127

4.10 Pricing Configurations............................................................................................................................................4-128

4.11 Save and Load Settings and Configurations..................................................................................................4-129

5 Tests.................................................................................................................................. 5-i

5.1 Overview...........................................................................................................................................................................5-1

5.2 Printer Tests:Paper Balance Test (PBL) and Master Balance Test (MBL)..................................................5-2

5.2.1 Conditions for Printing an MBL and PBL..........................................................................................5-3

5.2.2 Initial PBL and MBL after the Machine Installation.....................................................................5-4

5.2.3 Daily Calibration with the MBL............................................................................................................5-5

5.2.4 Daily Calibration without MBL (Exception) .....................................................................................5-6

0-iv 2005-05-01 / PN 04092_01 AgfaPhoto

Page 7

d-lab.2, d-lab.2plus, netlab.2plus: Operation Contents

5.2.5 Calibration of a New Paper Configuration in Case of Emulsion Changes

or Changes in a Paper Configuration (not Master Paper)...........................................................5-6

5.2.6 Calibrating a New Paper Configuration or Changing the Emulsion

(Master Paper).............................................................................................................................................5-7

5.2.7 Complete New Calibration.....................................................................................................................5-8

5.3 Printing a PBL Test .......................................................................................................................................................5-9

5.3.1 General Procedure.....................................................................................................................................5-9

5.3.2 PBL Test with Laser Point....................................................................................................................5-11

5.3.3 Copying Laser Points during Calibration of a Paper Configuration.....................................5-12

5.3.4 Default Setting of Maximum Densities and Calibration Factors..........................................5-14

5.3.5 When Should Maximum Densities Be Changed? .......................................................................5-15

5.3.6 Changing the Maximum Densities of a Paper............................................................................. 5-16

5.3.7 Changing the Gray Balance of the Internal Densitometer.....................................................5-19

5.4 Printing an MBL Test.................................................................................................................................................5-20

5.5 Calibrating the Scanner (Pixel Correction, PIKO)

Applies only to d-lab.2/2plus

.....................................................................................................................................5-21

5.6 Checking the Process (Chemical control strip test)......................................................................................5-23

6 Production..........................................................................................................................6-i

6.1 Order Handling – Overview.......................................................................................................................................6-1

6.1.1 Preparations Before Production Start ................................................................................................6-1

6.1.2 Print Modes..................................................................................................................................................6-2

6.1.2.1 Print modes and Possible Film and File Formats ..............................................................6-2

6.1.2.2 Printing without or with Preview.............................................................................................6-4

6.1.2.3 Order Configurations....................................................................................................................6-5

6.1.2.4 Changing to another print mode.............................................................................................6-5

6.1.3 Order Handling ...........................................................................................................................................6-6

6.1.4 Order Tracing............................................................................................................................................6-10

6.1.5 Changing the Order Number..............................................................................................................6-10

6.1.6 Select or Change Configuration........................................................................................................6-11

6.1.6.1 Configuration Types for Print Orders................................................................................... 6-11

6.1.6.2 Display of the Current Configuration..................................................................................6-12

6.1.6.3 Changing the Configuration for the Complete Order....................................................6-16

6.1.6.4 Changing the Configuration for Individual Images of an Order

Applies only to d-lab.2/2plus................................................................................................6-17

6.1.6.5 Selecting Another Configuration for the Complete Order...........................................6-18

6.1.6.6 Selecting Another Configuration for Individual Images of an Order

Applies only to d-lab.2/2plus................................................................................................6-18

6.1.7 Inserting Films and Slides

Applies only to d-lab.2/2plus

.................................................................................................................6-19

6.1.8 End of Order (Automatic / Manual).................................................................................................6-20

6.1.9 Special Print Products and Motif Groups ......................................................................................6-21

6.1.9.1 Black and White Prints.............................................................................................................6-21

6.1.9.2 Sepia Prints and Prints with Color Cast.............................................................................6-23

6.1.9.3 Reorder

Applies only to d-lab.2/2plus of Black/White Films / Films Without

Extended DX Code.....................................................................................................................6-23

6.1.9.4 Portraits..........................................................................................................................................6-24

6.1.9.5 Border Prints ................................................................................................................................6-24

6.2 Preparing the Machine for Different Orders.....................................................................................................6-26

6.2.1 Changing the Paper Magazine and Loading Paper ...................................................................6-26

6.2.1.1 Removing the Paper Magazine.............................................................................................6-27

6.2.1.2 Removing the Paper..................................................................................................................6-27

6.2.1.3 Adjusting the Paper Widths....................................................................................................6-28

6.2.1.4 Loading Paper into the Magazine........................................................................................6-29

AgfaPhoto 2005-05-01 / PN 04092_01 0-v

Page 8

Contents d-lab.2, d-lab.2plus, netlab.2plus: Operation

6.2.1.5 Coding the Paper Magazine ...................................................................................................6-30

6.2.1.6 Inserting a Paper Magazine....................................................................................................6-30

6.2.2 Changing the Mirror Box

Applies only to d-lab.2/2plus

................................................................................................................. 6-31

6.2.3 Changing the Film Carrier

Applies only to d-lab.2/2plus

................................................................................................................. 6-32

6.3 Printing .......................................................................................................................................................................... 6-33

6.3.1 Working with the Autoprint Mode

Applies only to d-lab.2/2plus

6.3.1.1 Activating the Print Mode and Selecting a Configuration..........................................6-33

6.3.1.2 Autoprint without Preview......................................................................................................6-34

6.3.1.3 Autoprint with Preview.............................................................................................................6-35

................................................................................................................. 6-33

6.3.2 Working with Reorder Mode

Applies only to d-lab.2/2plus

6.3.2.1 Activating the Print Mode and Editing a Reorder List ..................................................6-40

6.3.2.2 Reorder without Preview .........................................................................................................6-44

6.3.2.3 Reorder with Preview................................................................................................................6-46

................................................................................................................. 6-40

6.3.3 Working with Manual Positioning Mode

Applies only to d-lab.2/2plus

6.3.3.1 Activating the Print Mode.......................................................................................................6-51

6.3.3.2 Image Editing and Printing.....................................................................................................6-52

................................................................................................................. 6-50

6.3.4 Working with File Print Mode ...........................................................................................................6-55

6.3.4.1 General Information ..................................................................................................................6-55

6.3.4.2 Using dTFS: Automatic Color and Density Corrections.................................................6-57

6.3.4.3 Load Image Files from Storage Media................................................................................6-58

6.3.4.4 Saving Digital Orders ................................................................................................................6-61

6.3.4.5 Loading a Saved Digital Order...............................................................................................6-62

6.3.4.6 Delete the Saved Digital Order .............................................................................................6-64

6.3.4.7 Printing File Prints without Preview....................................................................................6-65

6.3.4.8 Printing File Prints with Preview..........................................................................................6-67

6.3.5 Working with Slide Print Mode

Applies only to d-lab.2/2plus

6.3.5.1 Activating the Print Mode.......................................................................................................6-72

6.3.5.2 Image Editing and Printing.....................................................................................................6-74

................................................................................................................. 6-72

6.3.6 Working with the Slide Film Print Mode

Applies only to d-lab.2/2plus................................................................................................................. 6-76

6.3.6.1 Activating the Print Mode.......................................................................................................6-76

6.3.6.2 Image Editing and Printing.....................................................................................................6-77

6.4 The Functions Image Editing and Special ........................................................................................................ 6-80

6.4.1 Image Editing........................................................................................................................................... 6-81

6.4.1.1 Activation ......................................................................................................................................6-81

6.4.1.2 Making Color and Density Corrections...............................................................................6-82

6.4.1.3 Cropping ........................................................................................................................................6-83

6.4.1.4 Image Improvement..................................................................................................................6-84

6.4.2 Special........................................................................................................................................................6-85

6.4.2.1 Enter and Format Text for the Exposure.............................................................................6-86

6.4.2.2 Setting a Border..........................................................................................................................6-88

6.4.3 Saving an Image as File.......................................................................................................................6-89

6.5 Manual red eyes correction ...................................................................................................................................6-91

6.6 Index prints...................................................................................................................................................................6-95

6.6.1 Index Prints in the Different Print Modes ..................................................................................... 6-96

6.6.2 Sequence and Designations of the Thumbnails......................................................................... 6-97

6.6.3 Quantity, Size, and Aspect Ratio of the Thumbnails ................................................................6-97

6.6.4 Print Index Print Only ........................................................................................................................... 6-98

0-vi 2005-05-01 / PN 04092_01 AgfaPhoto

Page 9

d-lab.2, d-lab.2plus, netlab.2plus: Operation Contents

6.7 Saving Images with Autosave ...............................................................................................................................6-99

6.7.1 Printing and Saving Images ............................................................................................................ 6-100

6.7.2 Save Images Only, Without Printing............................................................................................ 6-101

6.8 Network Orders ........................................................................................................................................................ 6-102

6.8.1 The Minilab in a Network................................................................................................................. 6-102

6.8.2 Manual Start of Network Orders.................................................................................................... 6-104

6.8.3 Automatic Start of Network Orders .............................................................................................. 6-105

6.8.4 Deleting Network Orders.................................................................................................................. 6-106

6.9 Printing Price Labels (Option) ........................................................................................................................... 6-107

6.10 Saving and Displaying Statistics....................................................................................................................... 6-108

6.10.1 Displaying Statistics........................................................................................................................... 6-108

6.10.2 Saving Statistics................................................................................................................................... 6-109

6.11 Clickrate (Option) .................................................................................................................................................... 6-110

7 Troubleshooting..................................................................................................................7-i

7.1 Avoiding Problems........................................................................................................................................................7-1

7.2 Display of Error Messages ..........................................................................................................................................7-2

7.3 Activating Help for Error Messages........................................................................................................................7-3

7.4 Problems During Scanning

Applies only to d-lab.2/2plus

7.5 The Machine Fails to React to Operator Inputs.................................................................................................7-4

7.5.1 Resetting the Machine with the Stop Button................................................................................7-5

7.5.2 Resetting the Machine with the ON key..........................................................................................7-6

7.6 Procedure if an Error Occurs .....................................................................................................................................7-8

7.6.1 General Procedure.....................................................................................................................................7-8

7.6.2 Procedure for Unsolved Errors ..............................................................................................................7-8

7.6.3 Screen Remains Gray for More Than 3 Minutes after Reset .....................................................7-9

7.6.4 Image Processing Errors.......................................................................................................................7-10

7.6.5 Paper Processor and Printer Errors...................................................................................................7-11

7.6.6 Printer Errors.............................................................................................................................................7-12

7.6.7 Other Errors...............................................................................................................................................7-12

7.7 Removing a Paper Jam

Applies to d-lab.2 ..........................................................................................................................................................7-13

7.7.1 General procedure..................................................................................................................................7-13

7.7.2 Paper Jam in the Printer......................................................................................................................7-15

7.7.3 Paper Jam in the Transport Unit (TU)..............................................................................................7-16

7.7.4 Paper Jam in the Transfer Positions Transport Unit (TU) and Print Engine (PE)..............7-20

7.7.5 Paper Jam in the Print Engine (PE) ..................................................................................................7-21

7.7.6 Paper Jam between Transport Unit (TU) and

Lane Distributor (LD)..............................................................................................................................7-23

7.7.7 Paper Jam in the Lane Distributor (LD) ..........................................................................................7-24

7.7.8 Paper Jam between Lane Distributor (LD) and

Sheet Transfer (ST)..................................................................................................................................7-25

7.7.9 Paper Jam in the Paper Processor....................................................................................................7-26

7.7.10 Paper jam between dryer and paper outlet..................................................................................7-27

7.8 Removing a Paper Jam

Applies to d-lab.2plus/netlab.2plus.......................................................................................................................... 7-28

7.8.1 General procedure..................................................................................................................................7-28

7.8.2 Paper Jam in the Printer......................................................................................................................7-30

7.8.3 Paper Jam in the Feeder Unit FU......................................................................................................7-31

7.8.4 Paper Jam in the Transfer Positions between Feeder Unit FU and Print

Machine PM..............................................................................................................................................7-35

7.8.5 Paper Jam in the Print Machine PM ...............................................................................................7-36

........................................................................................................................................7-3

AgfaPhoto 2005-05-01 / PN 04092_01 0-vii

Page 10

Contents d-lab.2, d-lab.2plus, netlab.2plus: Operation

7.8.6 Paper Jam between the Feeder Unit FU and Sheet Distributor SD..................................... 7-38

7.8.7 Paper Jam in the Sheet Distributor SD ..........................................................................................7-39

7.8.8 Paper Jam between Sheet Distributor SD and Sheet Transfer ST........................................ 7-40

7.8.9 Paper Jam in the Paper Processor ................................................................................................... 7-41

7.8.10 Paper Jam between dryer and outlet unit .................................................................................... 7-42

8 Maintenance ...................................................................................................................... 8-i

8.1 Safety Instructions........................................................................................................................................................8-1

8.2 Maintenance Routines – Schedule and Overview...........................................................................................8-2

8.3 Daily Maintenance .......................................................................................................................................................8-8

8.3.1 Cleaning the APS Film Carrier

Applies only to d-lab.2/2plus

....................................................................................................................8-8

8.3.2 Cleaning the Drive Rollers in the Film Carrier

Applies only to d-lab.2/2plus

8.3.2.1 In the Running Machine ..........................................................................................................8-10

8.3.2.2 When the Machine is Off.........................................................................................................8-10

................................................................................................................. 8-10

8.3.3 Cleaning the Film Brushes

Applies only to d-lab.2/2plus

................................................................................................................. 8-11

8.3.4 Running a Process Check in the Paper Processor .....................................................................8-11

8.4 Weekly Maintenance Routines.............................................................................................................................8-12

8.4.1 Cleaning the Film Carrier

Applies only to d-lab.2/2plus

................................................................................................................. 8-12

8.4.2 Cleaning the Film Takeup

Applies only to d-lab.2/2plus

................................................................................................................. 8-12

8.4.3 Cleaning the Film Chute

Applies only to d-lab.2/2plus

................................................................................................................. 8-13

8.4.4 Remove Paper Dust

Applies to d-lab.2 ...................................................................................................................................... 8-14

8.4.4.1 Transport Unit (TU) .....................................................................................................................8-14

8.4.4.2 Single sheet buffer (SR) and sheet bridge (SB)................................................................8-15

8.4.4.3 Print engine (PE): Remove Paper Dust ...............................................................................8-16

8.4.4.4 Lane distributor (LD): Remove Paper Dust and Deposits .............................................8-19

8.4.4.5 Sheet Transfer (ST)......................................................................................................................8-20

8.4.5 Remove Paper Dust

Applies to d-lab.2plus and netlab.2plus............................................................................................... 8-21

8.4.5.1 Feeder Unit (FU) ..........................................................................................................................8-21

8.4.5.2 Sheet Stocker (SR) and Sheet Bridge (SB).........................................................................8-23

8.4.5.3 Print Machine (PM)....................................................................................................................8-24

8.4.5.4 Sheet Distributor (SD): Remove Paper Dust and Deposits ..........................................8-27

8.4.5.5 Sheet Transfer (ST)......................................................................................................................8-28

8.4.6 Paper Processor: Cleaning the CD Feed Unit, Tank Crossovers, and the

Squeegee Unit......................................................................................................................................... 8-29

8.4.7 Checking the Solution Levels............................................................................................................8-33

8.4.8 Cleaning the Chemical Filters...........................................................................................................8-34

8.4.9 Cleaning the Filters in the ASTOR and Water Inlets................................................................. 8-35

8.4.10 Cleaning the Densitometer Calibration Plate ............................................................................. 8-36

8.4.11 Lane shifter (LS): Cleaning the transport belt.............................................................................. 8-38

8.5 Monthly Maintenance Routines........................................................................................................................... 8-39

8.5.1 Cleaning the Exposure Filters

Applies only to d-lab.2/2plus

................................................................................................................. 8-39

8.5.2 Checking and Calibrating the Solution Temperatures............................................................. 8-41

8.5.3 Cleaning or Replacing the Air Filters.............................................................................................. 8-41

8.5.4 Replacing the Scanner Lamp and Resetting the Operation Counter

Applies only to d-lab.2/2plus

................................................................................................................. 8-45

8.5.5 Replacing the Chemical Filters.........................................................................................................8-47

0-viii 2005-05-01 / PN 04092_01 AgfaPhoto

Page 11

d-lab.2, d-lab.2plus, netlab.2plus: Operation Contents

8.5.6 Cleaning the Processing Racks.........................................................................................................8-48

8.5.7 Cleaning the Dryer Rack......................................................................................................................8-51

8.5.8 Clean the paper outlet (PO)................................................................................................................8-53

8.6 Maintenance Routines Every 6 Months.............................................................................................................8-57

8.6.1 Cartridge feeder: Cleaning the Mechanism and Light Barriers

Applies only to d-lab.2/2plus

.................................................................................................................8-57

8.7 Maintenance When Required ................................................................................................................................8-57

8.7.1 Removing the Dust from the Lens

Applies only to d-lab.2/2plus

.................................................................................................................8-57

8.7.2 Back Printer: Replacing the Ink Ribbon.........................................................................................8-58

8.7.3 Emptying the Effluent Tanks ..............................................................................................................8-60

8.8 Spare Parts and Accessories ..................................................................................................................................8-62

9 Technical Data....................................................................................................................9-i

9.1 Machine versions ..........................................................................................................................................................9-1

9.2 Complete System..........................................................................................................................................................9-1

9.3 Main Computer ..............................................................................................................................................................9-5

9.4 Prescanner / Scanner

Applies only to d-lab.2/2plus........................................................................................................................................9-6

9.5 Printer ................................................................................................................................................................................9-7

9.6 Paper Processor .............................................................................................................................................................9-8

9.7 Heat Emission .................................................................................................................................................................9-9

9.8 Operating Conditions................................................................................................................................................9-10

9.9 Storage and Transport ..............................................................................................................................................9-10

9.10 Consumables and Operating Materials..............................................................................................................9-10

10 Environmental Protection and Disposal ..............................................................................10-i

10.1 Handling of Chemicals.............................................................................................................................................10-1

10.1.1 Legal Regulations...................................................................................................................................10-1

10.1.2 Disposal......................................................................................................................................................10-1

10.1.2.1 Exhausted Processing Solutions...........................................................................................10-1

10.1.2.2 Liquid Residues ...........................................................................................................................10-2

10.1.2.3 Chemical Containers.................................................................................................................10-2

10.1.2.4 Chemical Filters..........................................................................................................................10-2

10.2 Energy Saving Hints ..................................................................................................................................................10-2

11 Machine Shutdown............................................................................................................11-i

11.1 Machine Shutdown (Down Time up to 2 Weeks)...........................................................................................11-1

11.2 Machine Shutdown (Down Time longer than 2 Weeks)..............................................................................11-2

11.3 Resuming Operation .................................................................................................................................................11-3

11.4 Final Machine Shutdown.........................................................................................................................................11-4

11.5 Deinstalling the Machine .......................................................................................................................................11-4

12 List of Abbreviations and Glossary ....................................................................................12-1

13 Index...............................................................................................................................13-1

14 Appendix ..........................................................................................................................14-i

14.1 Conformity Declaration............................................................................................................................................. 14-i

AgfaPhoto 2005-05-01 / PN 04092_01 0-ix

Page 12

Contents d-lab.2, d-lab.2plus, netlab.2plus: Operation

■

0-x 2005-05-01 / PN 04092_01 AgfaPhoto

Page 13

d-lab.2, d-lab.2plus, netlab.2plus: Operation Introduction

1 Introduction

1.1

Applied Standards and Rules....................................................................................................................................1-1

1.2 Explanations for the Operation and Service Manual.......................................................................................1-2

1.2.1 Available Documentation.......................................................................................................................1-2

1.2.2 Guideline for the User..............................................................................................................................1-3

1.2.3 Conventions.................................................................................................................................................1-4

1.2.3.1 Pictographs......................................................................................................................................1-4

1.2.3.2 Text styles........................................................................................................................................1-4

1.2.3.3 Safety notes.....................................................................................................................................1-5

1.3 Legal Situation ...............................................................................................................................................................1-6

1.3.1 Manufacturer Information......................................................................................................................1-6

1.3.2 Copyright ......................................................................................................................................................1-6

1.3.3 Warranty........................................................................................................................................................1-7

1.3.3.1 Liability of the Owner ..................................................................................................................1-7

1.3.3.2 Warranty and Liability .................................................................................................................1-7

1.3.3.3 Exclusion of Liability ....................................................................................................................1-8

1.3.4 Appropriate Use..........................................................................................................................................1-8

1.3.5 Inappropriate Use ......................................................................................................................................1-8

1.4 Consumables and Spare Parts..................................................................................................................................1-9

1.5 Hotline...............................................................................................................................................................................1-9

1.6 Safety Notes and Rules............................................................................................................................................1-10

1.6.1 General .......................................................................................................................................................1-10

1.6.2 In Operation..............................................................................................................................................1-11

1.6.3 Handling of Chemicals .........................................................................................................................1-11

1.6.4 Service / Repair Routines ...................................................................................................................1-12

1.6.5 Disposal of the Machine......................................................................................................................1-12

1.6.6 Warnings and Information Labels on the Machine ...................................................................1-13

1.7 Transport, Installation, First Operation ..............................................................................................................1-22

1.8 Storage ...........................................................................................................................................................................1-22

1.8.1 Chemicals..................................................................................................................................................1-22

1.8.2 Photographic Paper ...............................................................................................................................1-22

1

AgfaPhoto 2005-05-01 / PN 04092_01 1-i

Page 14

Introduction d-lab.2, d-lab.2plus, netlab.2plus: Operation

■

1-ii 2005-05-01 / PN 04092_01 AgfaPhoto

Page 15

d-lab.2, d-lab.2plus, netlab.2plus: Operation Introduction

1.1 Applied Standards and Rules

1

The machine is in compliance with the requirements of the standards and rules listed

below:

98/37/EG:

Machine Directives

73/23/EWG:

Directive for Low Voltage

89/336/EWG:

Electromagnetic Compatibility (according to Modifications 91/ 263/EEC and 2/31/EEC)

EN 60950:

Safety of Information Technology Equipment

EN 60825-1:

Safety of Laser Equipment

EN 55022:

Information Technology Equipment – Radio interference – Limits and Methods of

Measurements

EN 55024:

Information Technology Equipment – Immunity Standard - Limits and Methods of

Measurements

EN 61000-6-2:

Electromagnetic Compatibility (EMC) - Part 6-2: Basic Standard; Immunity Standard for

Industrial Areas (IEC 61000-6-2:1999, modified)

EN 61000-3-2:

Electromagnetic Compatibility (EMC) - Part 3-2: Limit Values - Limit Values for Harmonic

Emissions (IEC 61000-3-2:2000, modified)

EN 61000-3-3:

Electromagnetic Compatibility (EMC) - Part 3-3: Limit Values – Limitation of voltage

changes, voltage fluctuations and flicker in public low voltage supply networks for

equipment with a current <= 16 A per conductor, which are not subject to any special

connection conditions (IEC 61000-3-3:1994 + A1:2001)

AgfaPhoto 2005-05-01 / PN 04092_01 1-1

Page 16

Introduction d-lab.2, d-lab.2plus, netlab.2plus: Operation

1.2 Explanations for the Operation and Service Manual

1.2.1 Available Documentation

The complete Operation and Service Manual comprises of several documents (see

table below).

Operation Manuals Owner Photo-

Technician

Assistant

Operation

Installation

●

●

●

Service Manuals Owner Photo-

Technician

Assistant

Repair

Parts List

Circuit Diagrams

Preinstallation

●

●

●

●

●

The customer receives the “Preinstallation” instructions when the machine is ordered.

The Operation Manuals “Installation” and “Operation” are included with the machine

shipment. The “Operation” folder includes a CD with the complete Operation Manual

(except circuit diagrams).

All other sections of the Operation and Service Manual can be ordered from AgfaPhoto.

The Operation Manuals “Installation” and “Operation” must be kept around the machine

to ensure that all users have access to these instructions.

The Operation Instructions section "Operation" applies to the following machines:

Machines with gas laser:

d-lab.2 Type 8060/260

d-lab.2plus Type 8060/261

Machines with solid state laser:

d-lab.2 select Type 8060/803 and Type 8060/804

d-lab.2 basic Type 8060/270 and Type 8060/272

d-lab.2 (70mm) Type 8060/157 + 8060/255

d-lab.2plus select Type 8060/813 and Type 8060/814

d-lab.2plus basic Type 8060/271 and Type 8060/273

d-lab.2plus (70mm) Type 8060/158 + 8060/255

netlab.2plus basic Type 8060/505

1-2 2005-05-01 / PN 04092_01 AgfaPhoto

Page 17

d-lab.2, d-lab.2plus, netlab.2plus: Operation Introduction

1.2.2 Guideline for the User

Operation / Service Manual Contents

1

Preinstallation

Installation The machine is delivered by a forwarding company.

Operation The “Operation” section of the Operation Manual includes all important

The owner takes care of the listed preinstallation measures and returns the

checklist to AgfaPhoto no later than two weeks prior to the installation date.

This “Installation” section of the Operation Manual describes the transport to the

operation site, as well as the installation and implementation of the machine.

The machine is installed by an AgfaPhoto authorized technician and put in

operation.

information required to ensure operation:

Chapter 1:

Notes on the Operation Manual, legal notes, safety notes, transport and storage.

Chapter 2:

Introduction of the components, functions and controls of the machine, help

function and information.

Chapter 3:

Description of the mixing process for chemicals.

Chapter 4:

Prior to production the Minilab must be set up to meet the requirements of the

laboratory (machine settings) and the order handling (print configurations).

Chapter 5:

Description of the tests, which ensure the production quality.

Chapter 6:

Step by step description of the order handling.

Chapter 7:

Description of possible problems, which may be solved by the customer.

Chapter 8:

Description of the required maintenance routines on the machine.

Chapter 9:

Listing of the technical specifications of the Minilab.

AgfaPhoto 2005-05-01 / PN 04092_01 1-3

Page 18

Introduction d-lab.2, d-lab.2plus, netlab.2plus: Operation

Operation / Service Manual

Operation (continued) Chapter 10:

Contents

Description of measures for environmental protection and the disposal of the

machine.

Chapter 11:

Description of measures for closing down a machine.

Chapter 12:

Explanation of the abbreviations and special terms used in these instructions.

Chapter 13:

Key Word Index

Chapter 14:

Appendix

1.2.3 Conventions

1.2.3.1 Pictographs

The symbols used in the instructions have the following meaning:

Operating steps

Result of the operating step

This symbol is used for warning notes.

Special tools

1.2.3.2 Text styles

The following text passages are emphasized by bold print /

1. Screen designations

Example: Pressing OK will validate the displayed text and close the dialog window.

2. Button designations

Example: Press the Reorder button to edit reorders.

3.

Italic print