AGERE D2517G, D2517D, D2511G, D2511D, D2502G Datasheet

Data Sheet

February 2000

1.5 µ m D2500-Type Digital

Isolated DFB Laser Module

Features

■

Integrated optical isolator

■

SONET/SDH compatible up to OC-48/STM-16

■

High-performance, multiquantum-well (MQW), distributed-feedback (DFB) laser

■

Low dispersion penalty for long-reach and

extended-reach applications

■

Industry-standard, 14-pin butterfly package

■

Characterized at 2.488 Gbits/s (NRZ)

■

Wide operating case temperature range of

–40 ° C to +70 ° C

■

InGaAs, PIN photodetector back-facet monitor

■

Low threshold current

■

High reliability

■

High optical power available

■

The 1.5 µ m D2500-Type Laser Module is offered in a 14-pin,

hermetic, butterfly package.

Qualified to meet the intent of

gies

* 468

*

T elcordia Technologies

Research, Inc.

is a trademark of Bell Communications

Telcordia Technolo-

Applications

■

Telecommunications:

— SONET/SDH

— Long reach

— Interexchange

■

Digital video

1.5 µ m D2500-Type Digital

Isolated DFB Laser Module

Data Sheet

February 2000

Description

The D2500-Type Digital Isolated DFB Laser Module

contains an internally cooled, InGaAsP, MQW, distributed-feedback (DFB) laser designed for 1.5 µ m applications. The laser is designed to be used in OC-12/

STM-4 (622 Mbits/s) and OC-48/STM-16 (2.488 Gbits/

s) for long-reach and extended-reach applications. It is

also capable of low dispersion penalties (<2 dB) for use

with fiber spans exceeding 170 km (3000 ps/nm).

The device is av ailable with an a verage output po wer of

0 dBm (3 dBm peak), which meets the SONET/SDH

standard. To eliminate the need for optical amplifiers in

some applications, the module can also be ordered

with higher output powers.

Controlled Feedback

The module contains an internal optical isolator that

suppresses optical feedback in laser-based, fiber-optic

systems. Light reflected back to the laser is attenuated

a minimum of 30 dB.

Controlled T emperature

An integral thermoelectric cooler (TEC) provides stable

thermal characteristics. The TEC allo ws for heating and

cooling of the laser chip to maintain a temperature of

25 ° C for case temperatures from –40 ° C to +70 ° C.

The laser temperature is monitored by the internal thermistor, which can be used with e xternal circuitry to control the laser chip temperature.

Controlled Power

An internal, InGaAs, PIN photodiode functions as the

back-facet monitor. The photodiode monitors emission

from the rear facet of the laser and, when used in conjunction with control circuitry, can control optical power

launched into the fiber. Normally, this configuration is

used in a feedback arrangement to maintain the average laser output power.

The minimum pigtail length is 39.4 in. (100 cm); the

minimum bend radius is 1.18 in. (30 mm).

The pigtail is a 900 µ m tight buffer fiber. Various connector and pigtail options are available.

Lucent Technologies Microelectronics Group optoelectric components are qualified to rigorous internal standards that are consistent with

Telcordia T echnologies

TR-NWT-000468. All design and manufacturing operations are

ISO

* 9001 certified. The module is fully quali-

fied for central office applications.

*

ISO

is a registered trademark of The International Organization for

Standardization.

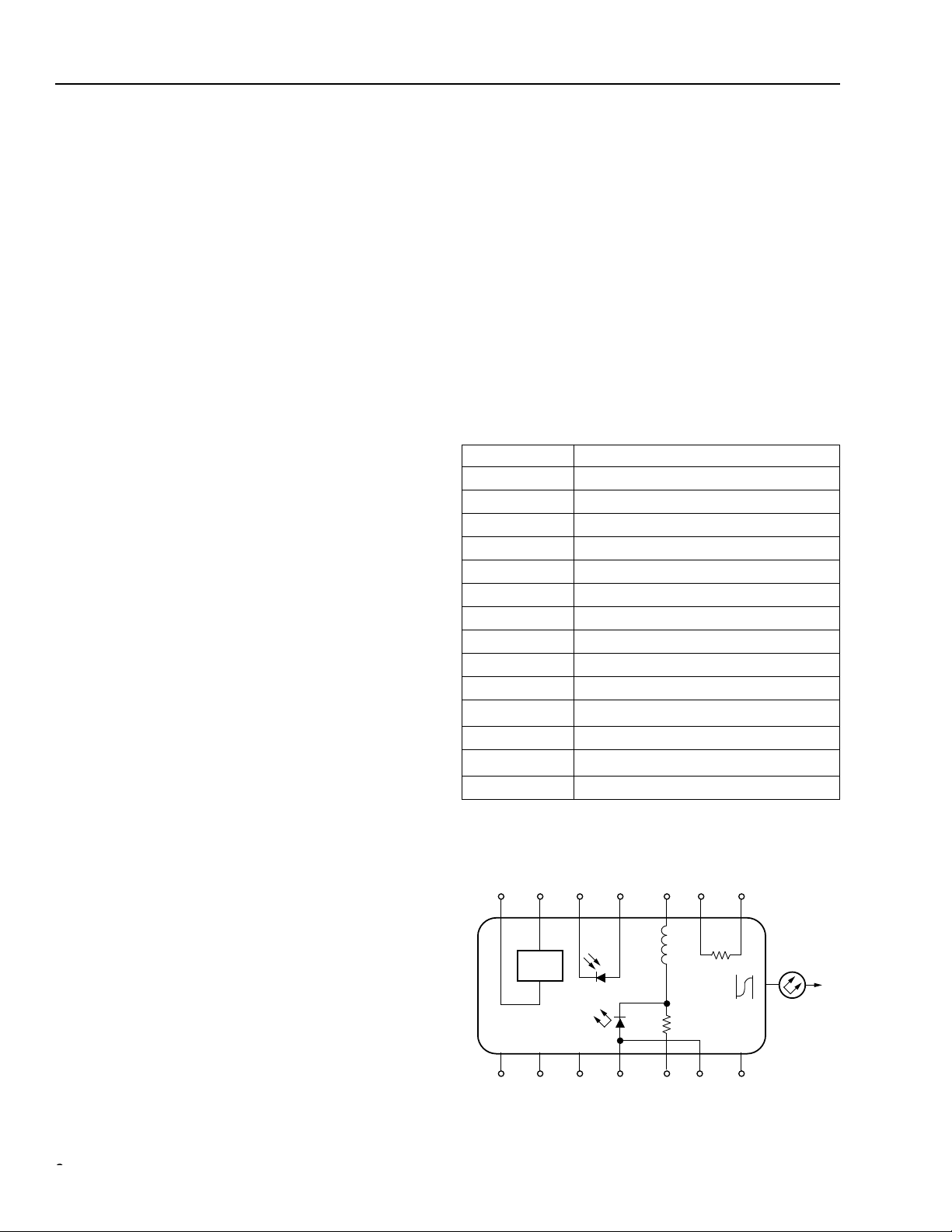

Pin Information

Pin Name

1 Thermistor

2 Thermistor

3 Laser dc Bias (cathode) (–)

4 Back-facet Monitor Anode (–)

5 Back-facet Monitor Cathode (+)

6 Thermoelectric Cooler (+)*

7 Thermoelectric Cooler (–)*

8 Case Ground

9 Case Ground

10 Case Ground

11

Laser Anode (+)

12 RF Laser Input Cathode (–)

13

Laser Anode (+)

14 Case Ground

* A positive current through the thermoelectric heat pump cools the

laser.

†Both leads should be grounded for optimum performance.

7654 321

–++ – –

L1

160 nH

TEC

†

†

TH

10 kΩ

Standard Package

The laser module is fabricated in a 14-pin, hermetic,

metal/ceramic butterfly package. The package also

incorporates a bias tee that separates the dc-bias path

from the RF input. The RF input has a nominal 25 Ω

PACKAGE

GROUNDS

8 9 10 11 12 13

Top view.

+–+

R1

20 Ω

ISOLATOR

14

1-567

impedance. The laser module is equipped with a single-mode fiber with an 8 µ m core and 125 µ m cladding.

Figure 1. Circuit Schematic

22 Lucent Technologies Inc.

°

°

1.5 µ m D2500-Type Digital

Isolated DFB Laser Module

Data Sheet

February 2000

Absolute Maximum Ratings

Stresses in excess of the absolute maximum ratings can cause permanent damage to the device. These are absolute stress ratings only. Functional operation of the device is not implied at these or any other conditions in excess

of those given in the performance characteristics of the data sheet. Exposure to absolute maximum ratings for

extended periods can adversely affect device reliability.

Parameter Symbol Min Max Unit

Laser Reverse Voltage V

dc Forward Current I

Operating Case Temperature Range T

Storage Case Temperature Range* T

Photodiode Reverse Voltage V

Photodiode Forward Current I

* Does not apply to shipping container.

RLMAX

FLMAX

C

stg

RPDMAX

FPDMAX

—2 V

— 150 mA

–40 70

–40 85

—

10 V

C

C

—1mA

Handling Precautions

Power Sequencing

To avoid the possibility of damage to the laser module

from power supply switching transients, follow this turnon sequence:

1. All ground connections

2. Most negative supply

3. Most positive supply

4. All remaining connections

Reverse the order for the proper turn-off sequence.

Electrostatic Discharge

CAUTION:This device is susceptible to damage as

a result of electrostatic discharge. Take

proper precautions during both handling

and testing. Follow guidelines such as

JEDEC Publication No. 108-A (Dec.

1988).

Lucent employs a human-body model (HBM) for ESDsusceptibility testing and protection-design evaluation.

ESD voltage thresholds are dependent on the critical

parameters used to define the model. A standard HBM

(resistance = 1.5 k Ω , capacitance = 100 pF) is widely

used and, therefore, can be used for comparison purposes. The HBM ESD threshold presented here was

obtained using these circuit parameters:

Mounting Instructions

The minimum fiber bend radius is 30 mm (1.18 in.).

To avoid degradation in performance, mount the mod-

ule on the board as follows:

1.Place the bottom flange of the module on a flat heat

sink at least 0.5 in. x 1.180 in. (12.7 mm x 30 mm) in

size. The surface finish of the heat sink should be

better than 32 µ in. (0.8 µ m), and the surface flatness

must be better than 0.001 in. (25.4 µ m). Using thermal conductive grease is optional; however, thermal

performance can be improved by up to 5% if conductive grease is applied between the bottom flange and

the heat sink.

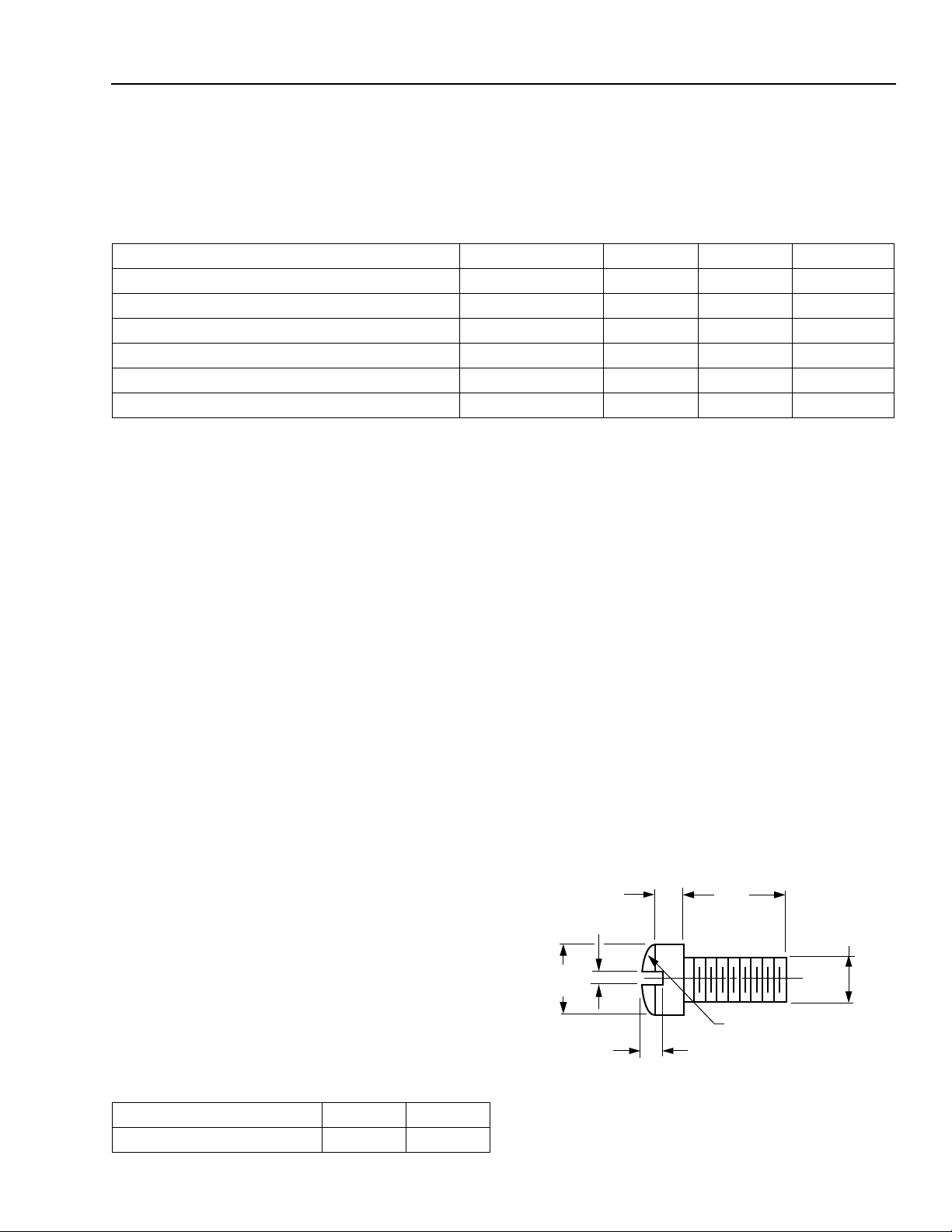

2.Mount four #2-56 screws with Fillister heads

(M2-3 mm) at the four screw-hole locations (see Outline Diagram). The Fillister head diameter must not

exceed 0.140 in. (3.55 mm). Do not apply more than

1 in.-lb. of torque to the screws.

0.062 (1.58)

0.031 (0.79)

0.140

(3.56)

Note: Dimensions are in inches and (millimeters).

0.118

(3.00)

0.129 (3.28) R

0.041 (1.04)

0.086

(2.18)

1-532

Parameter Value Unit

Figure 2. Fillister Head Screw

Human-body Model >400 V

Lucent Technologies Inc. 3

Loading...

Loading...