Ag-Bag MB7010HyPac User Manual

AG-B AG® INTERNATIONAL

MB7010 HyPac

A900015

Section 0

OPERATOR’S MANUAL

1

Ag-Bag International, Ltd.

MB7010 HyPac November 2003

®

USING THE MANUAL.

This manual has been designed to be used with the G6000 Ag-Bagger®. Read this manual carefully to

learn how to operate and service your Ag-Bagger® correctly. Failure to do so could result in personal

injury or equipment damage.

This manual should be considered a permanent part of your Ag-Bagger® and should remain with the

machine when you sell or trade it.

For ease of use this manual is divided into the following sections. Each section has its own Table of

Contents and Index. To access each section simply click on the blue high lighted words or

numbers. When in a particular section simply click on the blue page numbers to jump to that

page. The Table of Contents and Index both have these high lighted numbers

Section 0: This section contains information general in nature, Ag-Bag® policy, Warranty and whom to

contact.

Section 1: Safety. This section presents safety information for use with the Ag-Bagger®. General

information as well as specific safety guidelines is detailed here. Labels used on the Ag-Bagger® and

general safety warnings are also shown.

Section 2: Machine Overview. The machine overview section shows and identifies the location of

many of the commonly used features of the Ag-Bagger

®

Section 3: Features and Controls. Pictures depicting the many features and controls with a short

description of what each does are shown in this section.

Section 4: Set-up and Operating Procedures. This section gives you and your employee’s general

information on the setup and operation of your Ag-Bagger®.

Section 5: Bagging and the Terrain. This section deals with placing the bag and preparing the site for

best result. Also covered is keep the correct tension on the cables for best compactions.

Section 6: Trouble Shooting. This section is not intended to address all the possible problems that

might arise during bagging. It is intended to review some of the common problems that might arise

during the bagging operation.

Section 7: Service and Maintenance. The information provided in this section is given for general

information only. It is to help you to service and maintain the Ag-Bagger®.

Appendix A : Parts. The parts manual for your Ag-Bagger® are contained in this section.

Appendix B: The 3M’s of Silage. A more technical look at bagging is presented in this section.

Appendix C: Bagging Instructions. A more detailed look and discussion of the bagging operation.

IT IS YOUR RESPONSIBILITY TO READ ALL SECTIONS OF THIS MANUAL BEFORE

OPERATING YOUR AG-BAGGER®!

Section 0

1

Ag-Bag International, Ltd.

G6000 April 2003

SAFETY

BE A SAFE OPERATOR

By thinking before acting and reading your operators manual you will be a SAFE OPERATOR.

AVOID ACCIDENTS , most accidents, whether they occur in industry, on the farm, at home, or on

the highway, are caused by the failure of some individual to follow simple and fundamental

safety rules or precautions. For this reason most accidents can be prevented by recognizing

the real cause and doing something about it before the accident occurs.

Regardless of the care used in the design and construction of any type of equipment, there

are many conditions that cannot be completely safeguarded against without interfering with

reasonable accessibility and efficient operation. A careful operator is the best insurance against

an accident.

STOP MACHINE AND TURN OFF ENGINE TO ADJUST, LUBRICA TE, OR SERVICE.

Section 1

1

Ag-Bag International, Ltd.

MB7010 HyPac November 2003

SAFETY

Table of Contents

SIGNAL WORDS.................................................................................................................................. 3

EQUIPMENT SAFETY GUIDELINES ................................................................................................... 4

LIGHTING AND MARKING .................................................................................................................... 4

SAFETY SIGN CARE: .......................................................................................................................... 5

HOW TO INST ALL SAFETY SIGNS:.................................................................................................... 5

TIRE SAFETY: ...................................................................................................................................... 5

BEFORE OPERATION: ....................................................................................................................... 6

DURING OPERATION: ......................................................................................................................... 7

FOLLOWING OPERATION: ................................................................................................................. 8

HIGHWAY AND TRANSPORT OPERATIONS: .................................................................................... 8

PERFORMING MAINTENANCE: .......................................................................................................... 9

DANGER LABELS...............................................................................................................................1 1

WARNING LABELS ............................................................................................................................ 12

CAUTION LABELS ............................................................................................................................. 14

NOTICE LABELS................................................................................................................................ 15

OTHER LABELS ................................................................................................................................ 17

INFORMA TION SIGNS........................................................................................................................ 19

INDEX ................................................................................................................................................. 22

STOP MACHINE AND TURN OFF ENGINE TO ADJUST, LUBRICA TE, OR SERVICE.

Ag-Bag International, Ltd.

MB7010 HyPac November 2003

2

Section 1

SAFETY

TAKE NOTE! THIS SAFETY ALERT SYMBOL FOUND THROUGHOUT THIS MANUAL IS USED TO CALL

YOUR A TTENTION TO INSTRUCTIONS INVOLVING YOUR PERSONAL SAFETY AND THE SAFETY OF

OTHERS. FAILURE TO FOLLOW THESE INSTRUCTIONS CAN RESUL T IN INJURY OR DEATH.

THIS SYMBOL MEANS

ATTENTION

BECOME ALERT

YOUR SAFETY IS INVOLVED!

SIGNAL WORDS

Note the use of the signal words DANGER,

WARNING and CAUTION with the safety messages. The appropriate signal word for each has

been selected using the following guidelines:

Indicates imminently

hazardous situation

that, if not avoided, will

result in death or serious injury. This signal word is to be limited to the

most extreme situations typically for machine

components that, for functional purposes, cannot

be guarded.

Indicates a potentially

hazardous situation

that, if not avoided,

could result in death

or serious injury, and includes hazards that are exposed when guard are removed. It may also be

used to alert against unsafe practices

Indicates a potentially

hazardous situation

that, if not avoided,

may result in minor or

moderate injury. It may also be use to alert against

unsafe practices.

If you have questions not answered in this manual, or require additional copies, or the manual is

damaged, please contact your Ag-Bag® Dealer or Ag-Bag® International Ltd., 2320 S.E. Ag-Bag Lane,

Warrenton, OR, 97146. (Telephone) 800-334-7432. (FAX) 503-861-1648.

STOP MACHINE AND TURN OFF ENGINE TO ADJUST, LUBRICA TE, OR SERVICE.

Section 1

3

Ag-Bag International, Ltd.

MB7010 HyPac November 2003

SAFETY

EQUIPMENT SAFETY GUIDELINES

Safety of the operator is one of the main concerns in designing and developing a new piece of

equipment. Designers and manufacturers build in as many safety features as possible. However, every year many accidents occur which could have been avoided by a few seconds of

thought and a more careful approach to handling equipment. You, the operator, can avoid

many accidents by observing the following precautions in this section. To avoid personal

injury, study the following precautions and insist those working with you or for you follow them.

In order to provide a better view, certain photographs or illustrations in this manual may show

an assembly with a safety shield removed. However, equipment should never be operated in

this condition. Keep all shields in place. If shield removal becomes necessary for repairs,

replace the shield prior to use.

Replace any CAUTION, WARNING, DANGER or NOTICE label that is not readable or is missing.

Do not attempt to operate this equipment under the influence of drugs or alcohol.

Review the safety instructions with all users annually.

This equipment is dangerous to children and persons unfamiliar with its operation. The opera-

tor should be a responsible adult familiar with farm machinery and trained in this equipment’s

operation. Do not allow persons to operate or assemble this unit until they have read

this manual and have developed a through understanding of the safety precautions

and how it works.

Do not paint over, remove or deface any safety signs or warning labels on your equipment.

Observe all safety signs and practice the instructions on them.

Never exceed the limits of a piece of machinery. If its ability to do a job, or to do so safely, is in

question - DON’T TRY IT.

LIGHTING AND MARKING

It is the responsibility of the operator to know the lighting and marking requirements of the local

highway authorities and to install and maintain the equipment to provide compliance with the

regulations. Add extra lights when transporting at night or during periods of limited visibility.

STOP MACHINE AND TURN OFF ENGINE TO ADJUST, LUBRICA TE, OR SERVICE.

Ag-Bag International, Ltd.

MB7010 HyPac November 2003

4

Section 1

SAFETY

SAFETY SIGN CARE:

Keep safety signs clean and legible at all times.

• Replace safety signs that are missing or have become illegible

• Replaced parts that displayed a safety sign should also display the current sign.

• Safety signs are available from your authorized Ag-Bag

®

Dealer or Ag-Bag Interna-

tional, Ltd.

HOW TO INSTALL SAFETY SIGNS:

• Be sure that the installation area is clean and dry.

• Decide on the exact position before you remove the backing paper.

• Remove the smallest portion of the split backing paper.

• Align the decal over the specified area and carefully press the small portion with the

exposed sticky backing in place.

• Slowly peel back the remaining paper and carefully smooth the remaining portion of

the decal in place.

• Small air pockets can be pierced with a pin and smoothed out using the piece of decal

backing paper.

Section 1

TIRE SAFETY:

• Failure to follow proper procedures when mounting a tire on a wheel or rim can pro-

duce an explosion which may result in serious injury or death.

• Do not attempt to mount a tire unless you have the proper equipment and experience

to do the job.

• Inflating or servicing tires can be dangerous. Whenever possible, trained personnel

should be called to service and/or mount tires.

• Always order and install tires and wheels with appropriate capacity to meet or exceed

the anticipated weight to be placed on the equipment.

STOP MACHINE AND TURN OFF ENGINE TO ADJUST, LUBRICA TE, OR SERVICE.

5

Ag-Bag International, Ltd.

MB7010 HyPac November 2003

SAFETY

REMEMBER:

Your best assurance against accidents is a careful and responsible operator. If there

is any portion of this manual or function you do not understand, contact your local

authorized Ag-Bag® Dealer or Ag-Bag International, Ltd.

BEFORE OPERATION:

• Carefully study and understand this manual.

• Do not wear loose-fitting clothing which may catch in moving parts.

• Always wear protective clothing and substantial shoes.

• It is recommended that suitable protective hearing and (eye protection) sight protec-

tors be worn.

• Keep wheel lug nuts or bolts tightened to specified torque.

• Assure that agricultural implement tires are inflated evenly.

• Give the unit a visual inspection for any loose bolts, worn parts or cracked welds, and

make necessary repairs. Follow the maintenance safety instructions included in this manual.

• Be sure that there are no tools lying on or in the equipment.

• Do not use the unit until you are sure that the area is clear, especially children and

animals.

• Don’t hurry the learning process or take the unit for granted. Ease into it and become

familiar with your new equipment.

• Practice operation of your equipment and its attachments. Completely familiarize yourself

and other operators with its operation before using.

• Move tractor to the widest recommended settings to increase stability.

• Securely attach to towing unit. Use a high strength, appropriately sized hitch pin with a

mechanical retainer and attach safety chain.

• Do not allow anyone to stand between the tongue or hitch and the towing vehicle when

backing up to the equipment.

STOP MACHINE AND TURN OFF ENGINE TO ADJUST, LUBRICA TE, OR SERVICE.

Ag-Bag International, Ltd.

MB7010 HyPac November 2003

6

Section 1

SAFETY

DURING OPERATION:

• SAFETY CHAIN - if equipment is going to be transported on a public highway, a safety

chain should be obtained and installed. Always follow state and local regulations regarding a

safety chain and auxiliary lighting when towing farm equipment on a public highway. Be sure to

check with local law enforcement agencies for your own particular regulations. Only a safety

chain (not and elastic or nylon/plastic tow strap) should be used to retain the connection

between the towing and towed machine in the event of separation of the primary attaching

system.

• Install the safety chain by crossing the chains under the tongue and secure to the draw

bar cage or hitch or bumper frame.

• Beware of bystanders, particularly children! Always look around to make sure that it

is safe to start the engine of the towing vehicle or move the unit. This is particularly import with

higher noise levels and quiet cabs, as you may not hear people.

• NO PASSENGERS ALLOWED - Do not carry passengers anywhere on, or in, the

tractor or equipment, except as required for operations.

• Keep hands and clothing clear of moving parts.

• Do not clean, lubricate or adjust your equipment while it is operating.

• When halting operation, even periodically, set the tractor or towing vehicle brakes,

disengage the PTO, shut off the engine and remove the ignition key.

• Pick the levelest possible route when transporting across fields. Avoid the edges of

ditches or gullies and steep hillsides.

• Maneuver the tractor or towing vehicle at safe speeds.

• Avoid overhead wires or other obstacles. Contact with overhead lines could cause

serious injury or death.

• Allow for unit length when making turns.

• Do not walk or work under raised components or attachments unless securely posi-

tioned and blocked.

Section 1

• Keep all bystanders, pets and livestock clear of the work area.

STOP MACHINE AND TURN OFF ENGINE TO ADJUST, LUBRICA TE, OR SERVICE.

7

Ag-Bag International, Ltd.

MB7010 HyPac November 2003

SAFETY

FOLLOWING OPERATION:

• Following operation, or when unhitching, stop the tractor, set the brakes, disengage

the PTO and all power drives, shut off the engine and remove the ignition keys.

• Store the unit in an area away from human activity.

• Do not permit children to play on or around the stored unit.

• Make sure all parked machines are on a hard, level surface and engage all safety

devices.

• Wheel chocks may be needed to prevent unit from rolling.

HIGHWAY AND TRANSPORT OPERATIONS:

• Adopt safe driving practices:

• Keep the brake pedal latched together at all times. NEVER USE INDEPEN-

DENT BRAKING WITH MACHINE IN TOW AS LOSS OF CONTROL AND/OR

UPSET OF UNIT CAN RESUL T.

• Always drive at a safe speed relative to local conditions and ensure that your

speed is low enough for an emergency stop to be safe and secure. Keep speed to a

minimum.

• Reduce speed prior to turns to avoid the risk of overturning.

• Avoid sudden uphill turns on steep slopes.

• Always keep the tractor in gear to provide engine braking when going downhill.

Do not coast.

• Do not drink and drive!

• Comply with state and local laws governing highway safety and movement of

farm machinery on public roads.

• Use approved accessory lighting, flags, and necessary warning devices to

protect operators of other vehicles on the highway during daylight and nighttime transport. Various safety light and devices are available from you Ag-Bag® Dealer.

STOP MACHINE AND TURN OFF ENGINE TO ADJUST, LUBRICA TE, OR SERVICE.

Ag-Bag International, Ltd.

MB7010 HyPac November 2003

8

Section 1

SAFETY

• The use of a flashing amber light is acceptable in most localities. However, some

localities prohibit their use. Local laws should be checked for all highway lighting and marking

requirements.

• When driving the tractor and equipment on the road or highway at night or during the

day, use flashing amber warning lights and a slow moving vehicle (SMV) identification emblem.

• Plan your route to avoid heavy traffic.

• Be a safe and courteous driver. Always yield to oncoming traffic in all situations, in-

cluding narrow bridges, intersections, etc.

• Be observant of bridge loading ratings. Do not cross bridges rated lower than the

gross weight at which you are operating.

• Watch for obstructions overhead and to the side while transporting.

• Always operate equipment in a position to provide maximum visibility at all times.

PERFORMING MAINTENANCE:

• Good maintenance is your responsibility. Poor maintenance is an invitation to trouble.

• Make sure there is plenty of ventilation. Never operate the engine of the towing vehicle

in a closed building. The exhaust fumes may cause asphyxiation.

• Before working on this machine, stop the towing vehicle, set the brakes, disengage

the PTO and all power drivers, shut off the engine and remove the ignition keys.

• Be certain all moving parts on the machine have come to a complete stop before

attempting to perform maintenance.

• Always use a safety support and block the wheels. Never use a jack to support the

machine.

• Always use the proper tools or equipment for the job at hand.

Section 1

• Use extreme caution when making adjustments.

• Follow the torque chart in this manual when tightening bolts and nuts.

STOP MACHINE AND TURN OFF ENGINE TO ADJUST, LUBRICA TE, OR SERVICE.

9

Ag-Bag International, Ltd.

MB7010 HyPac November 2003

SAFETY

• Never use your hands to locate a hydraulic leak on attachments. Use a small piece of card-

board or wood. Hydraulic fluid escaping under pressure can penetrate the skin.

• When disconnecting hydraulic lines. Shut off hydraulic supply and relieve all hydraulic pres-

sure.

• Openings in the skin and minor cuts are susceptible to infection from hydraulic fluid. If injured

by escaping hydraulic fluid, see a doctor at once. Gangrene can result. Without immediate

medical treatment, serious infection and reactions can occur.

• Replace all shields and guards after servicing and before moving.

• After servicing, be sure all tools, parts and service equipment are removed.

• Do not allow grease or oil to build up on any step or platform.

• Never replace hex bolts with less than grade five bolts unless otherwise specified. Refer to bolt

torque chart for head identification marking.

• Where replacement parts are necessary for periodic maintenance and servicing, genuine fac-

tory replacement parts must be used to restore your equipment to original specifications. Ag-Bag

International will not claim responsibility for use of unapproved parts and/or accessories and other

damages as a result of their use.

• If equipment has been altered in any way from original design, Ag-Bag International, Ltd. does

not accept any liability for injury or warranty.

• A fire extinguisher and first aid kit should be kept readily accessible while performing mainte-

nance on this equipment.

STOP MACHINE AND TURN OFF ENGINE TO ADJUST, LUBRICA TE, OR SERVICE.

Ag-Bag International, Ltd.

MB7010 HyPac November 2003

10

Section 1

SAFETY

This section of the manual presents the Labels used on the Ag-Bagger®. Also presented are other

information that you should know in order to operate the Ag-Bagger® in a safe manner. Unless otherwise noted the decals shown are the actual decals used on the machine.

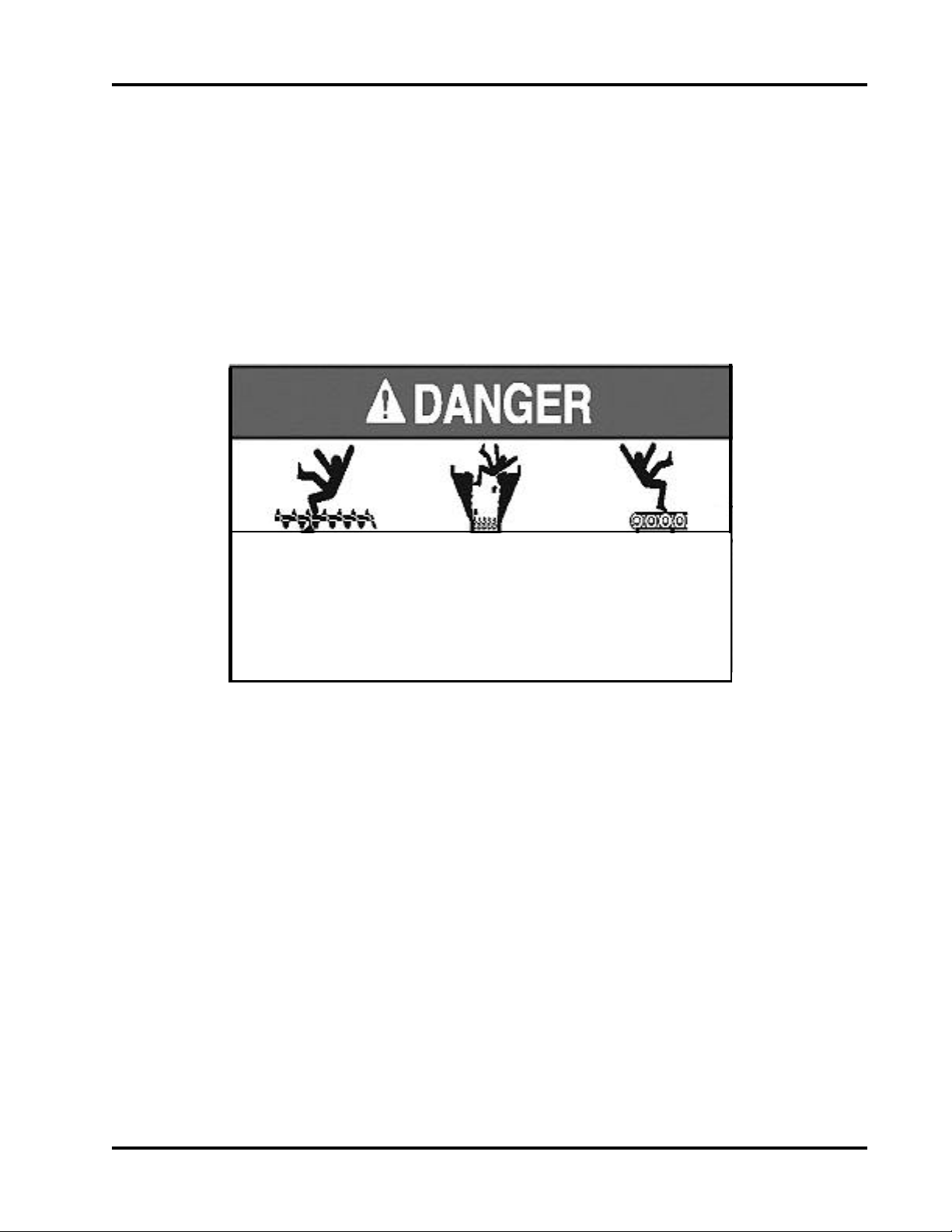

DANGER LABELS

FALL HAZARD

Do NOT climb on or in. Moving parts can crush and cut.

Falling into machine could result in serious injury or death.

Read safety instructions in operator’s manual before

climbing on or into this equipment.

FALL HAZARD. Never climb on or into the Ag-Bagger® unless the tractor has been completely shut

down. If you are going in to the hopper area, to prevent any possibility of injury the PTO shaft should be

disconnected from the tractor. Climbing onto the conveyor should never be done, any item needing to

be cleared from this area can be done from the outside. Never allow anyone to ride or set on the AgBagger® at anytime. Children should not be allowed near the Ag-Bagger® when it is in operation. To

replace this decal reorder part number 1530015 from your Ag-Bag® Dealer.

Section 1

STOP MACHINE AND TURN OFF ENGINE TO ADJUST, LUBRICA TE, OR SERVICE.

11

Ag-Bag International, Ltd.

MB7010 HyPac November 2003

SAFETY

WARNING LABELS

It is your Responsibility to Read,

Understand, and Follow safe

operating practices defined in the

Operators Manual shipped with

this unit.

Failure to do so may result in

Personal Injury to you or

others. If the manual is missing,

obtain a replacement from your

Dealer.

YOUR RESPONSIBILITY . As indicated on the label it is the responsibility of the operator for the safe

operation of the Ag-Bagger®. Make sure that anyone who will operate or work around the Ag-Bagger

has read and understands the information that is provided in this Operator’s Manual. To replace this

decal reorder part number 1530069 from your Ag-Bag® Dealer.

®

STOP MACHINE AND TURN OFF ENGINE TO ADJUST, LUBRICA TE, OR SERVICE.

Ag-Bag International, Ltd.

MB7010 HyPac November 2003

12

Section 1

SAFETY

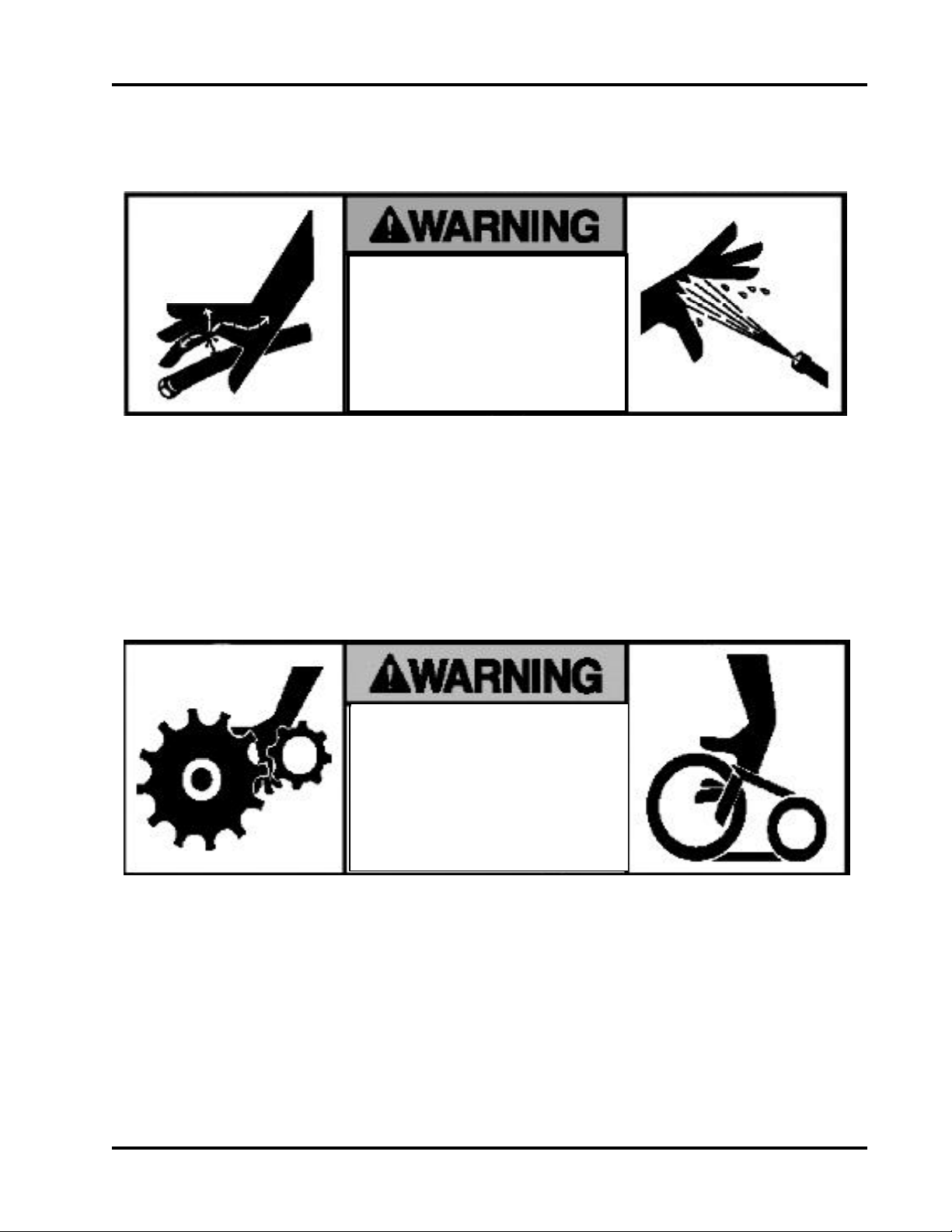

WARNING LABELS (CONT.)

SKIN INJECTION HAZARD.

Avoid contact with high

pressure fluid.

BEFORE SERVICING:

Relieve stored hydraulic pressure.

Failure to follow this warning can

result in serious injury.

SKIN INJECTION HAZARD. Hydraulic oils and fluid under high pressure can be injected under the

skin. The oil/fluid can cause serious illness. Always shut down the tractor and relieve all stored pressure on the hoses before servicing. Never run your hand over a hydraulic hose you suspect has a leak.

To replace this decal reorder part number 1530127 from your Ag-Bag® Dealer.

KEEP SHIELDS

IN PLACE.

Pinch hazard exists.

DO NOT operate equipment

unless shields are in place

KEEP SHIELDS IN PLACE. There are numerous shields located on the Ag-Bagger® they are placed

to keep the operator safe from serious injury. Never remove a shield while the Ag-Bagger® is in operation. Make sure the tractor has been shut off before removing any shield, and that the shield has been

replaced before operation resumes. To replace this decal reorder part number 1530038 from your AgBag® Dealer.

STOP MACHINE AND TURN OFF ENGINE TO ADJUST, LUBRICA TE, OR SERVICE.

Section 1

13

Ag-Bag International, Ltd.

MB7010 HyPac November 2003

SAFETY

WARNING LABELS (CONT.)

ROTATING DRIVELINE

KEEP AWAY.

KEEP SHIELD IN PLACE

U-joint yokes must be locked in place.

Adjust tractor or drawbar and implement

hitch to proper dimensions.

Keep tractor master, shield, PTO

guard, and implement guards in place.

ROTATING DRIVELINE. The PTO shaft is an important part in the operation of the Ag-Bagger® it turns

at a high rate of speed and the manufacturer has affixed a Danger Decal on it warning of the possibility

of serious injury or death. The reason for this Warning Decal is to let you know that you should make

sure that all shields are in place anytime the PTO shaft is in operation. If you are going to remove a

PTO shield make sure the tractor power is off. It is important to maintain the PTO shaft on a regular

basis, see the Service and Maintenance portion of the Operator’s Manual for instructions. To replace

this decal reorder part number 1530059 from your Ag-Bag® Dealer.

CAUTION LABELS

CHECK LUG NUTS . Because the Ag-Bagger® may be towed on a

public highway, you should check the lug nuts on a regular basis.

Check the Service and Maintenance portion of the Operator’s Manual

for torque details. To replace this decal reorder part number 1530011

from your Ag-Bag® Dealer.

STOP MACHINE AND TURN OFF ENGINE TO ADJUST, LUBRICA TE, OR SERVICE.

CHECK LUG

NUTS.

Check Lug Nuts

Regularly.

Consult Operator’s

Manual for torque

specifications.

Ag-Bag International, Ltd.

MB7010 HyPac November 2003

14

Section 1

SAFETY

CAUTION LABELS (CONT.)

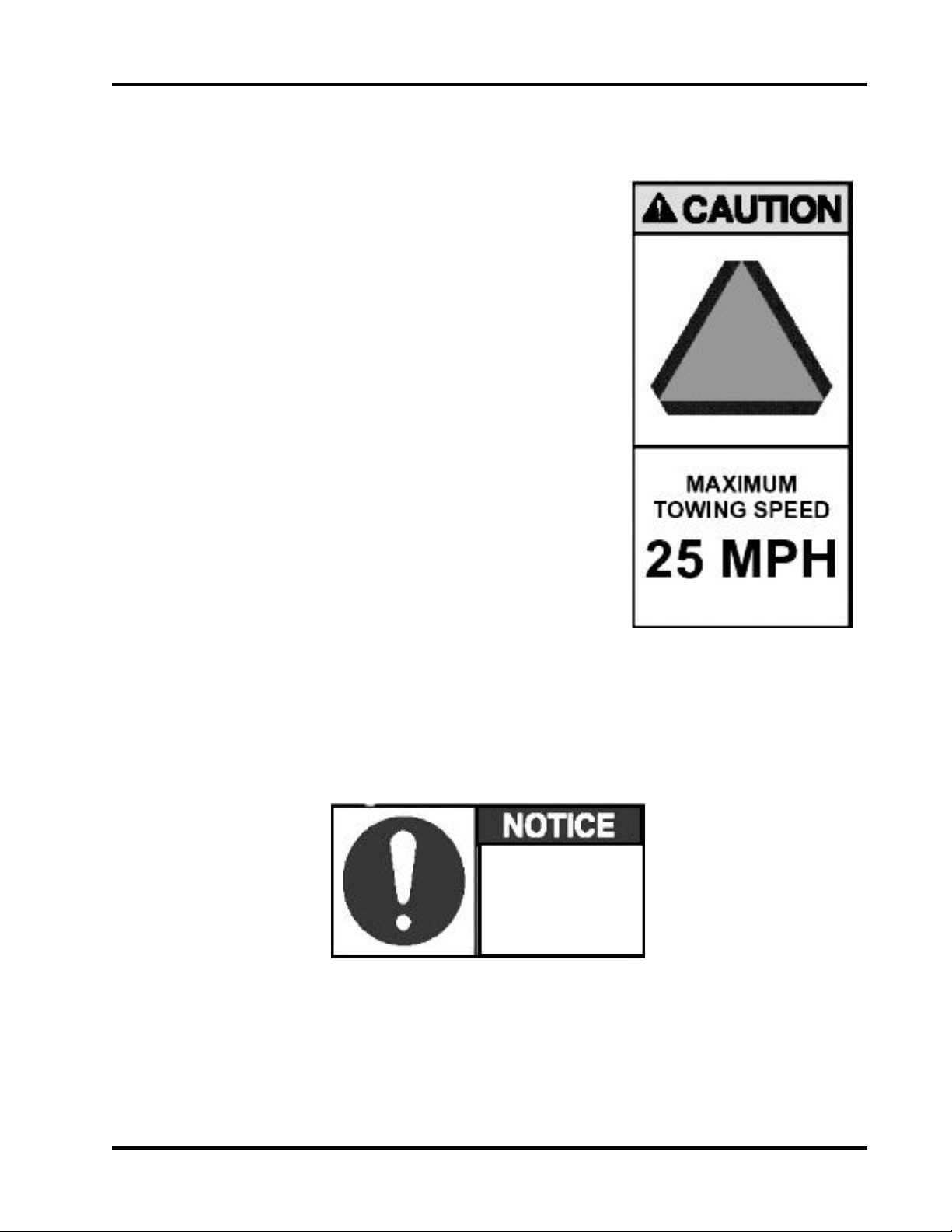

MAXIMUM TOWING SPEED. Although you can tow the Ag-Bag-

ger on the open highway do not exceed 25 mile per hour. It should

be remembered that the Ag-Bagger® does not have brakes, also

the wheels and axles are not bolted to the frame but are held in

place by a pin and hair pin. Under no circumstances should you tow

the Ag-Bagger® while the wheels are in the bagging position. Make

sure you read and understand the section on preparing the Ag-Bagger for transit in the Operator’s Manual. The PB6000 has its wheels

fixed in place, this requires that it be towed in the bagging position

and should be towed a lower speed. To replace this decal reorder

part number 1530041 from your Ag-Bag® Dealer.

NOTICE LABELS

Grease rotor

bearing 4 pumps

per bag.

GREASE ROTOR BEARING. The Ag-Bagger® is equipped with two Rotor Bearing Grease Whips.

The zerk fittings are located on the frame on either side of the tunnel. For the best results with your AgBagger® use the type grease recommended in the Service and Maintenance portion of the Operator’s

Manual. To replace this decal reorder part number 1530096 from your Ag-Bag® Dealer.

STOP MACHINE AND TURN OFF ENGINE TO ADJUST, LUBRICA TE, OR SERVICE.

Section 1

15

Ag-Bag International, Ltd.

MB7010 HyPac November 2003

SAFETY

NOTICE LABELS (CONT.)

HYDRAULIC OIL ONLY . The Operator’s Manual makes recom-

mendations for the correct viscosity of hydraulic oil to be used in

your Ag-Bagger® hydraulic system. To keep you warranty valid use

only the viscosity listed in the Service and Maintenance section of

the Operator’s Manual. To replace this decal reorder part number

1530028 from your Ag-Bag® Dealer.

HYDRAULIC

OIL ONLY.

Use only hydraulic

oil with viscosity

recommended in

the

Operator’s Manual

for this machine

TRACTOR TO BE IN NEUTRAL. During the process of bagging

the tractor is pushed forward as the bag fills. In order to minimize

damage to the Ag-Bagger®, your tractor, and the correct compaction of the product being bagged, it is important the tractor be in

neutral and all brakes be released before starting to bag. To replace

this decal reorder part number 1530065 from your Ag-Bag® Dealer.

STOP MACHINE AND TURN OFF ENGINE TO ADJUST, LUBRICA TE, OR SERVICE.

TRACTOR TO

BE IN NEUTRAL

AND BRAKES

OFF WHILE

OPERATING

BAGGER.

Ag-Bag International, Ltd.

MB7010 HyPac November 2003

16

Section 1

SAFETY

OTHER LABELS

OIL CHAIN

AT LEAST TWICE PER BAG

OIL CHAIN. The chain is behind a safety shield located on the left side of the front of the Ag-Bagger.

Follow all safety procedures for removing the shield. To prevent excessive wear oil the chain twice per

bag. To replace this decal reorder part number 1530054 from your Ag-Bag® Dealer.

ENGLISH/SPANISH. The final decal currently in use on the Ag-Bagger® is an old style Warning Decal.

It has both English and Spanish instructions. The decal is used mainly as a reminder. A simulation of

the Decal is on the following page.

STOP MACHINE AND TURN OFF ENGINE TO ADJUST, LUBRICA TE, OR SERVICE.

Section 1

17

Ag-Bag International, Ltd.

MB7010 HyPac November 2003

SAFETY

OTHER LABELS (CONT.)

WARNING

PRECACION

1. DO NOT reach or place any part of your body inside the hopper.

NO TRATE de alcanzar o ponga ninguna parta del cuerpo adentro de la mezcladora.

2. DO NOT attempt to service, remove or unclog any material while machine is in operation.

NO TRATE de reparar, remover, o destapar material cuando la maquina esta en

operacion.

3. DO NOT climb or ride on machine during operation or transport.

NO TREPE o monte la maquina cuando esta en operacion or transportando.

4. Make sure everyone is clear of machine BEFORE STARTING ENGINE OR ENGAGING POWER. KEEP CHILDREN AWAY AT ALL TIMES.

Haga seguro que nadie este en o ALREDEDOR DE LA MAQUINA ANTES QUE EL

MOTOR ARRANQUE, MANTEGA NINOS LEJOS DE LA MAQUINA.

5. DO NOT stand behind backstop net or near cables under tension.

NO se pare detras de la malla o cerca de cables en tension.

6. STAY CLEAR of hoses under pressure.

MANTENGASE LEJOS de las mangas a presion.

7. Keep all SHIELDS IN PLACE.

Mantenga los ESCUDOS EN SU PROPIO LUGAR.

8. Keep HANDS, FEET AND CLOTHING AWAY FROM INTAKE AREA AND ALL OTHER

MOVING PARTS OF MACHINE.

Mantenga las MANOS, PIES, Y ROPA FUERA DEL AREADE ADMISION.

9. Think SAFETY AND USE CAUTION in entire operation area.

SEA PRECAVIDOY SEA CUIDADOSO en la area de operacion.

STOP MACHINE AND TURN OFF ENGINE TO ADJUST, LUBRICA TE, OR SERVICE.

Ag-Bag International, Ltd.

MB7010 HyPac November 2003

18

Section 1

SAFETY

INFORMATION SIGNS

TRANSPORT SAFETY . These signs are provided for information purposes only. They do not appear

on the Ag-Bagger®, but instead they are used as part of this manual in provide information of a safety

nature.

Transport Safety

1 Make sure you are in

compliance with all local

regulations regarding

transporting equipment on public

roads and highways

2 Make sure the slow

moving vehicle emblem and all

the lights and reflectors that are

required by the local highway

and transport authorities are in

place, and clean and can be

seen clearly by all overtaking

and oncoming traffic.

3 Attach securely to the

towing vehicle using a retainer

on the tow hitch pin and a safety

chain

4 Do not allow anyone to

ride on the Ag-Bagger® or towing

vehicle during transport.

5 Stay away from over

head obstructions and power

lines. Electrocution can occur

without direct contact.

6 Always use hazard

warning flashers on towing

vehicle when transporting unless

prohibited by law.

7 Add extra lights or use

pilot vehicles when transporting

during times of limited visibility.

8 Secure all components

and accessories before

transporting.

Section 1

STOP MACHINE AND TURN OFF ENGINE TO ADJUST, LUBRICA TE, OR SERVICE.

19

Ag-Bag International, Ltd.

MB7010 HyPac November 2003

SAFETY

INFORMATION SIGNS (CONT.)

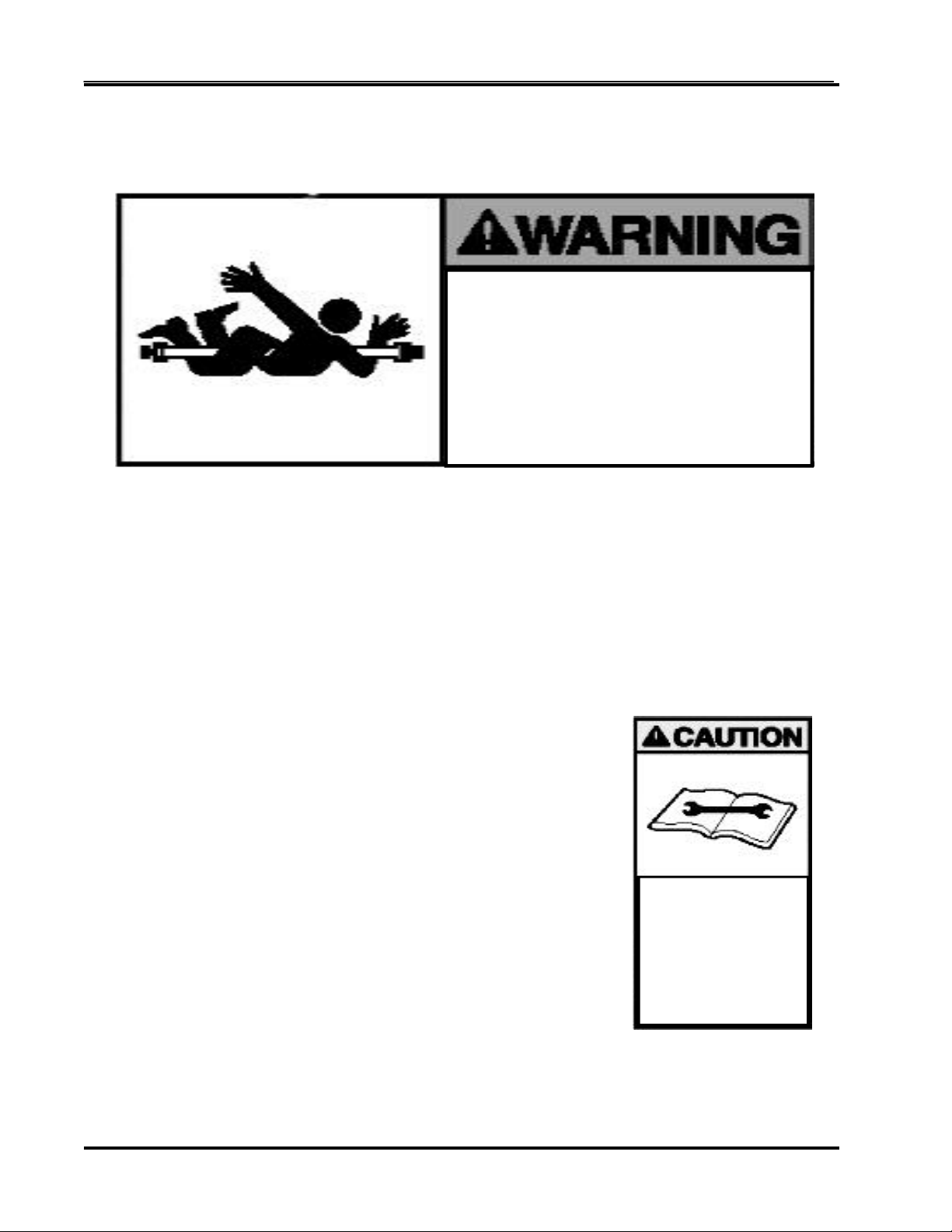

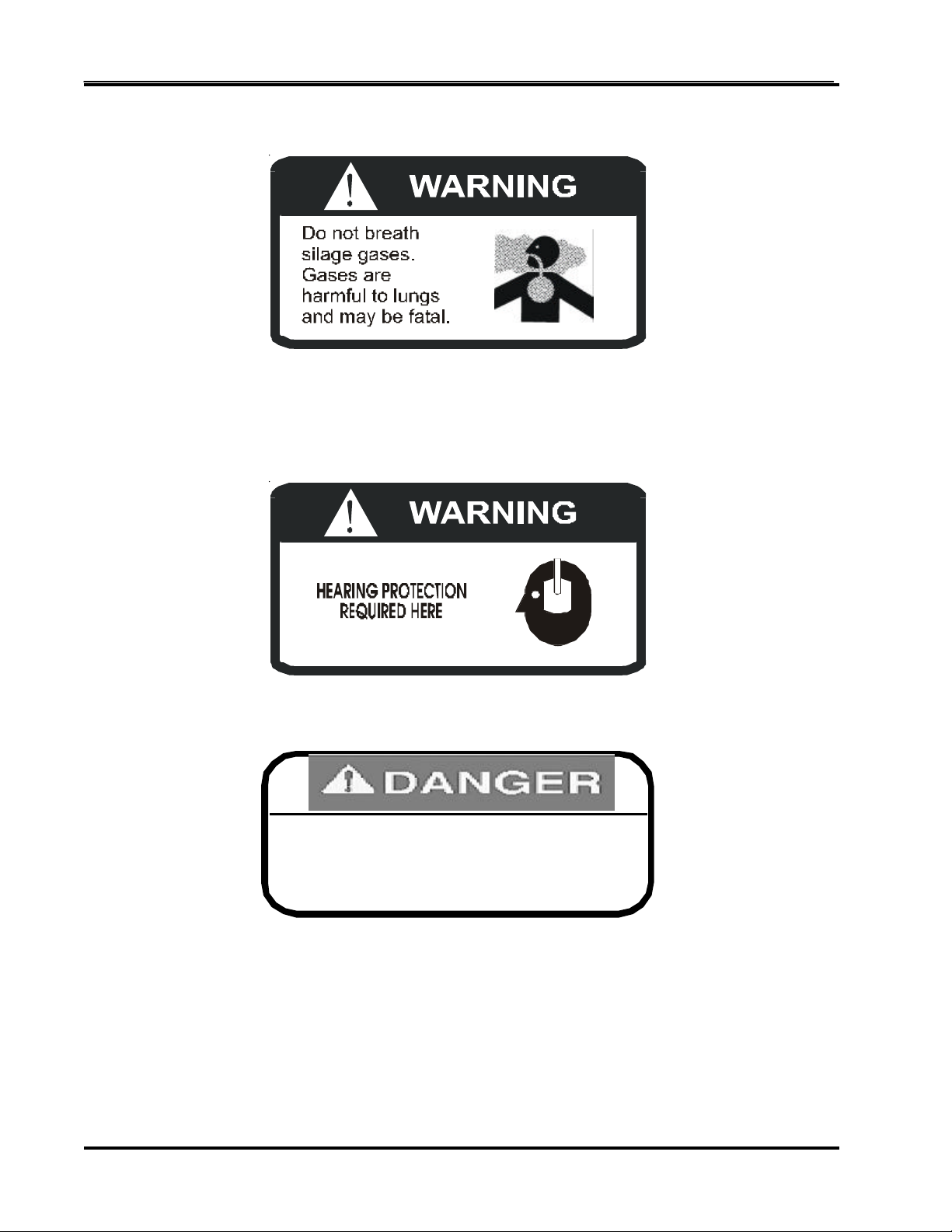

SILAGE GASES - The ensiling process inside the bag may produce gases. Do not breath gases

expelled from the bag. These gases may contain various forms of nitric fumes that can be harmful to

your lungs. If enough fumes are inhaled they can be fatal.

NOISE - Long-term exposure to loud noise can impair and cause loss of hearing. Use hearing protection.

Bodily injury or death may occur. Prior to servicing

the Ag-Bagger® turn of the tractor and wait for all

moving parts to stop.

SERVICING THE AG-BAGGER® - Do not attempt to perform service or maintenance to the Ag-Bag-

ger® or PTO shaft unless the tractor has been turned off and all moving parts have stopped.

STOP MACHINE AND TURN OFF ENGINE TO ADJUST, LUBRICA TE, OR SERVICE.

Ag-Bag International, Ltd.

MB7010 HyPac November 2003

20

Section 1

SAFETY

INFORMATION SIGNS (CONT.)

NO SMOKING - Handle fuel with care while fueling. Fuel is extremely flammable and explosive.

BATTERY - Handle battery with caution. Sulfuric acid in the battery’s electrolyte is strong enough to

burn skin, cause blindness if splashed in eye’s and damage clothing.

CABLES - Always wear protective gloves when handling cables for any reason. Serious inju-

ries can occur.

STOP MACHINE AND TURN OFF ENGINE TO ADJUST, LUBRICA TE, OR SERVICE.

Section 1

21

Ag-Bag International, Ltd.

MB7010 HyPac November 2003

Index

SAFETY

B

BATTERY 21

L

Labels - Caution

Caution Labels 14

CHECK LUG NUTS 14

MAXIMUM TOWING SPEED 15

Labels - Danger

Danger Labels 11

FALL HAZARD 11

Labels - Information Only

BATTERY 21

CABLES 21

Information Signs 19

NO SMOKING 21

Noise 20

Servicing the Ag-Bagger® 20

Silage Gases 20

TRANSPORT SAFETY 19

Labels - Notice

GREASE ROTOR BEARING 15

HYDRAULIC OIL ONLY 16

Notice Labels 15

TRACTOR TO BE IN NEUTRAL 16

Labels - Other

ENGLISH/SPANISH 17

OIL CHAIN 17

Other Labels 17

Labels - Warning

KEEP SHIELDS IN PLACE 13

ROTATING DRIVELINE 14

SKIN INJECTION HAZARD 13

Warning Labels 12

YOUR RESPONSIBILITY 12

S

Safety Instructions

BEFORE OPERATION: 6

DURING OPERATION: 7

EQUIPMENT SAFETY GUIDELINES 4

FOLLOWING OPERATION: 8

How to Install Safety Signs: 5

LIGHTING AND MARKING 4

PERFORMING MAINTENANCE: 9

REMEMBER 6

SAFETY SIGN CARE: 5

TIRE SAFETY: 5

TRANSPORT OPERATIONS 8

SIGNAL WORDS 3

Signal Words

CAUTION 3

DANGER 3

WARNING 3

N

NO SMOKING 21

STOP MACHINE AND TURN OFF ENGINE TO ADJUST, LUBRICA TE, OR SERVICE.

Ag-Bag International, Ltd.

MB7010 HyPac November 2003

22

Section 1

M ACHINE OVERVIEW

The machine overview section shows and identifies the location of many of the commonly

used features of the Ag-Bagger®. The pictures should be used as a reference to quickly locate

the different options and features of your Ag-Bagger®. Also the terms Front, Rear, Right-Side,

and Left-Side are used else where in this manual for you convenience.

®

AG-B

AGGER

M

ODEL

MB7010 HyPac

Section 2

1

Ag-Bag International, Ltd.

MB7010 HyPac November 2003

M ACHINE OVERVIEW

Table of Contents

FRONT VIEW ....................................................................................................................................... 3

REAR VIEW ......................................................................................................................................... 4

RIGHT SIDE VIEW............................................................................................................................... 5

LEFT SIDE VIEW ................................................................................................................................. 6

INDEX ................................................................................................................................................... 7

Ag-Bag International, Ltd.

MB7010 HyPac November 2003

2

Section 2

M ACHINE OVERVIEW

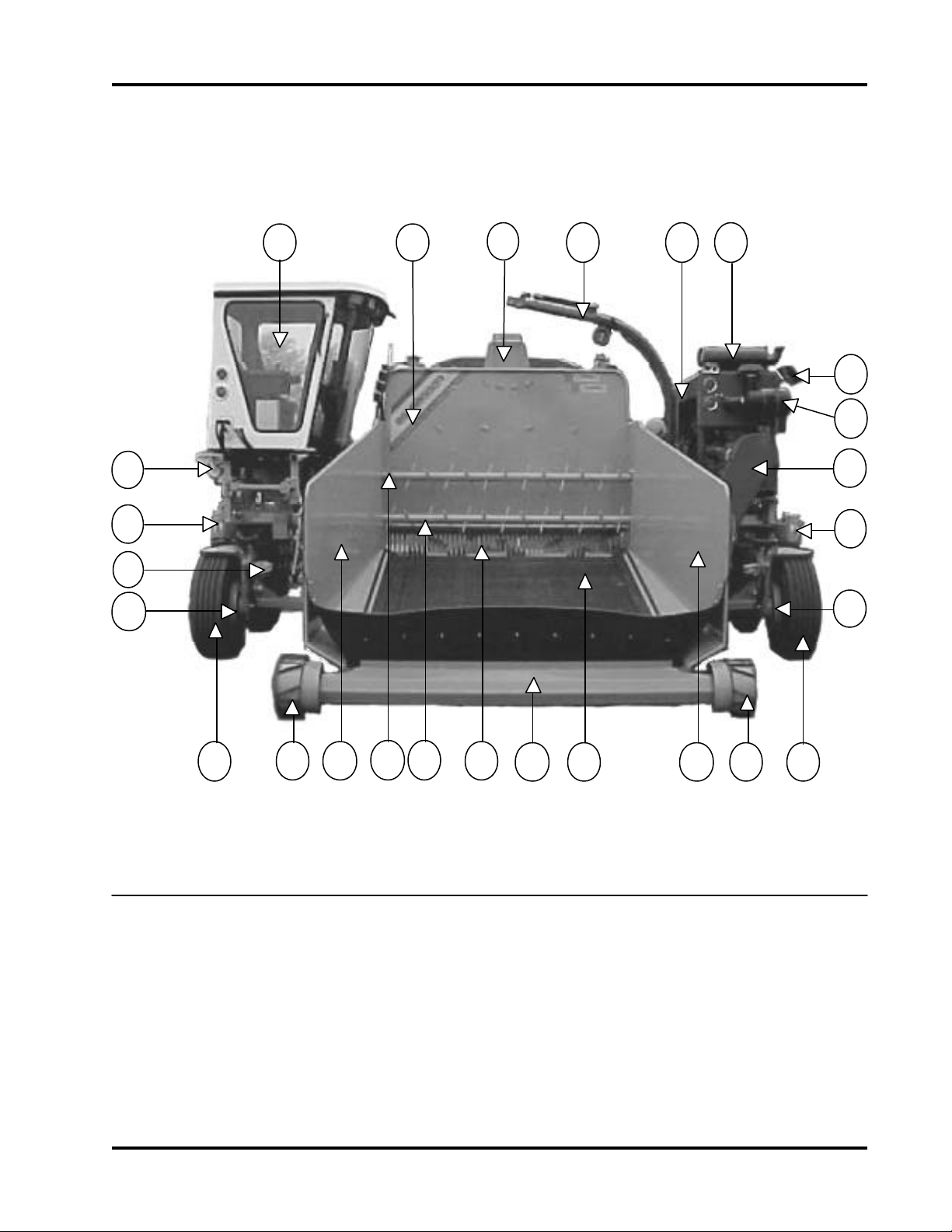

12

11

10

13 14 15

16 17 18

19

20

21

11

9

9

1

1. 385/65R 19.5 TIRE

2. FEED TABLE WHEEL

3. FEED TABLE WING

4. FEED TABLE BELT - ENDLESS

5. FEED TABLE

6. ROTOR & STRIPPER BAR

7. BEATER BAR - LOWER

Section 2

2

8

67

FRONT VIEW

8. BEATER BAR - U PPER

9. WHEEL DRIVE

10. AIR BRAKE CANNISTER

1 1. WHEEL COLUMN

12. AIR CONDITIONER UNIT

13. SOUND G ARD® CAB

14. FUEL & HYDRAULIC TANKS

3

45

15. INOCULANT APPLICATOR MOUNT

16. BAG BOOM

17. ENGINE COWLING

18. EXHAUST SYSTEM

19. SAFETY MIRROR

20. ENGINE AIR CLEANER

21. BELT DRIVE

3

MB7010 HyPac November 2003

23

Ag-Bag International, Ltd.

1

M ACHINE OVERVIEW

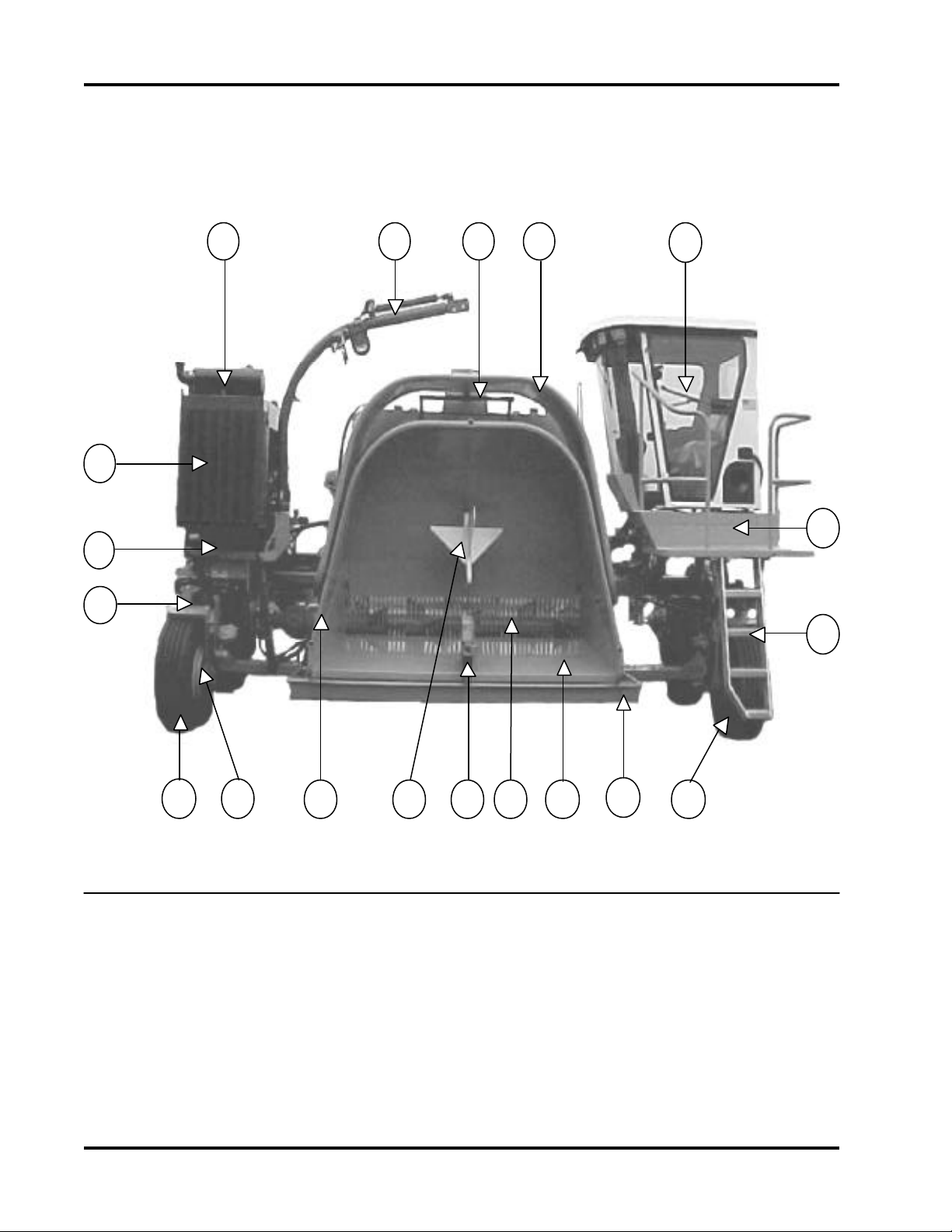

11

10

9

12 13 14 15

16

17

18

8

1. 385/65R 19.5 TIRE

2. BAG PAN

3. TUNNEL FLOOR

4. ROTOR & STRIPPER BAR

5. ANCHOR SUPPORT

6. ANCHOR

Ag-Bag International, Ltd.

MB7010 HyPac November 2003

67

4

5

REAR VIEW

7. 10’ TUNNEL

8. WHEEL DRIVE

9. WHEEL COLUMN

10. ENGINE M OUNTING FRAME

1 1. RADIATOR SCREEN

12. ENGINE EXHAUST

4

3

2

13. BAG BOOM

14. BAG CRADLE

15. 10’ TUNNEL EXTENSION

16. SOUND G ARD® CAB

17. OPERATOR’S PLATFORM

18. ACCESS LADDER

11

Section 2

M ACHINE OVERVIEW

6 7

8

9

10

11

12

1. 385/65R 19.5 TIRE

2. HYDRAULIC LIFT JACK

3. FEED TABLE

4. FEED TABLE WING

Section 2

RIGHT SIDE VIEW

5. FEED TABLE WHEEL

6. BELT DRIVE

7. AIR CHAMBER

8. SAFETY MIRROR

5

121345

9. ENGINE AIR CLEANER

10. ENGINE EXHAUST

1 1. BAG BOOM

12. RADIATOR SCREEN

Ag-Bag International, Ltd.

MB7010 HyPac November 2003

M ACHINE OVERVIEW

9 10

8

1. FEED TABLE WHEEL

2. FEED TABLE WING

3. FEED TABLE

4. 385/65R 19.5 TIRE

LEFT SIDE VIEW

5. HYDRAULIC LIFT JACK

6. AIR CONDITIONER UNIT

7. ACCESS LADDER

8. OPERATOR’S PLATFORM

2344 567

9. 10’ TUNNEL

10. SOUND G ARD® CAB

1

Ag-Bag International, Ltd.

MB7010 HyPac November 2003

6

Section 2

Loading...

Loading...