Page 1

AFP

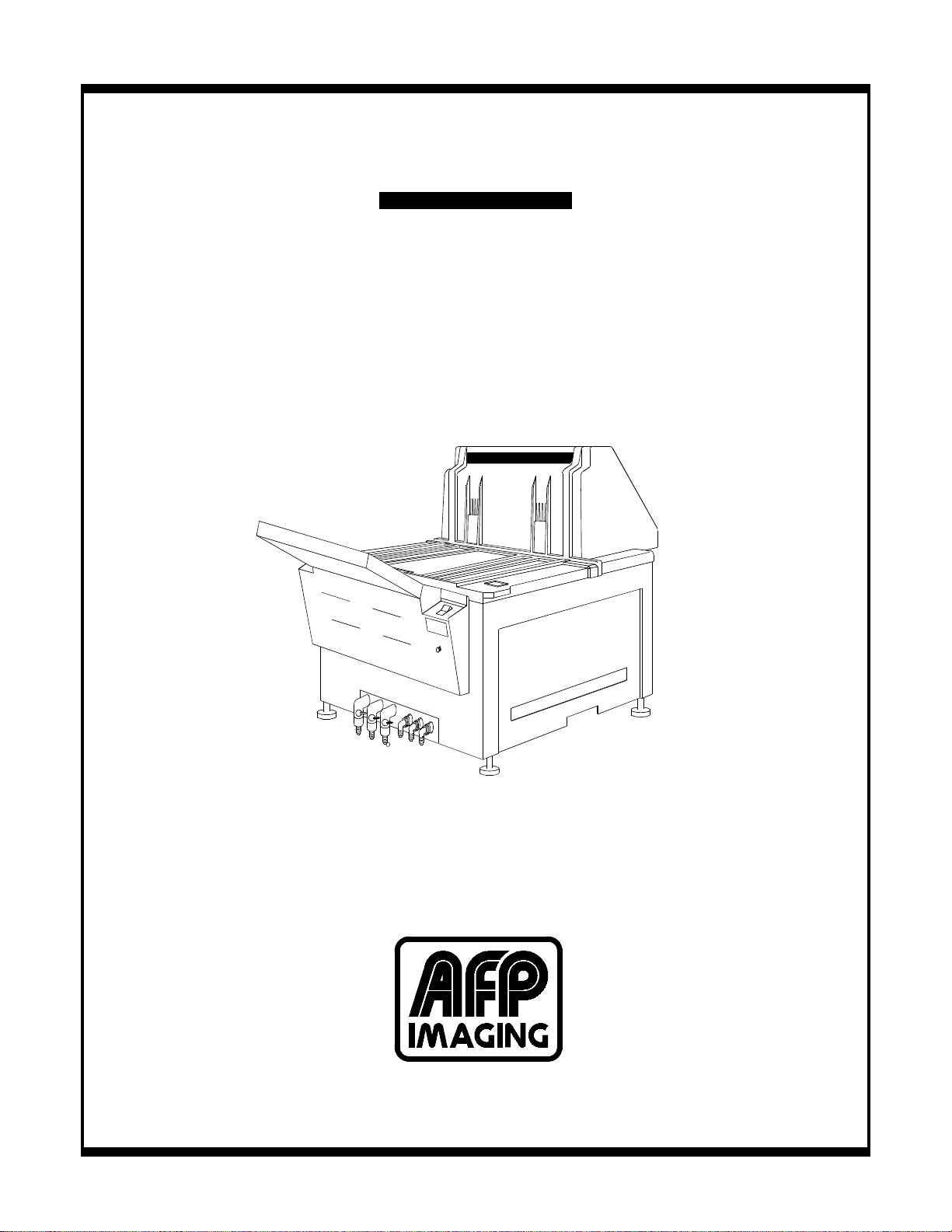

X-Ray Film Processors

"Mini-Medical" Series

Installation, Operation,

Service & Parts Manual

250 Clearbrook Rd.

Elmsford, N.Y. 10523

December 15, 2001 0000061122 REV 04

(914) 592-6100

Page 2

WARRANTY

AFP Imaging Corporation warrants to the original purchaser that each newAFP product is free from defects in

workmanship and material for 12 months from date of installation or 18 months from date of sale, whichever occurs first.

If no warranty card is returned to AFP within 30 days of installation, the maximum warranty period will be 13 months from

date of shipment from AFP’s warehouse. In the event any product or component of equipment is replaced by AFP

under this warranty, such item is covered by this same warranty for the remainder of the original period or ninety days

from the date of installation, whichever is longer. AFP’s obligation during this warranty period is expressly limited to repair

or, at its discretion, replacement of non-expendable original equipment or components which it finds defective.

Upon authorization from AFP, a proper party asserting a claim under this warranty shall prepay all transportation costs

and return the equipment to a location specified by AFP. That party shall also bear all reasonable service and labor

charges incident to any warranty claim. This warranty does NOT APPLY (1) to any expendable parts including, but not

limited to lamps, photocells, or consumable supplies (2) to any AFP product or component which has been repaired or altered

with parts or by persons not approved in writing by AFP, provided, however, that such approval is not to be

unreasonably withheld, or (3) to any product on which the serial number or name has been altered, defaced, or

This warranty also shall NOT APPLY to any AFP product whose unsatisfactory performance or condition is due to:

- Instability of sensitized materials or chemical concentrations

and replenishing rates of chemical and wash water immersions or sequences;

- Lack of applied adequate quality production control procedures as

recommended by the sensitized material and chemical suppliers;

- Changes in characteristics or process procedures made by suppliers of

sensitized materials or chemicals after delivery of the AFP product to the purchaser;

removed.

- Lack of sufficient volume of sensitized materials for economical AFP product operation;

- Failure to follow the installation, maintenance, venting, or safety procedures

recommended for AFP product operation;

- Unusual physical or electrical stress;

- Accident, neglect, misuse, failure of electric power, air conditioning,

humidity control, transportation or causes other than ordinary use in the purposes

for which the product was intended;

THE ABOVE EXPRESS LIMITED WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR

IMPLIED AND THERE ARE NO WARRANTIES BEYOND THOSE STATED IN THIS DOCUMENT. THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE AND ALL OTHER

WARRANTIES, EXPRESSED OR IMPLIED, OR INFERABLE FROM THE COURSE OF DEALING OR USAGE OF

TRADE, ARE EXCLUDED AND SHALL NOT APPLY TO THIS PRODUCT.

THE PROVISIONS FOR REPAIR OR REPLACEMENT OF DEFECTIVE PARTS PROVIDED IN THIS WARRANTY

SHALL BE THE EXCLUSIVE AND SOLE REMEDY OF THE PURCHASER. AFP SHALL NOT BE LIABLE FOR

ANY OTHER DAMAGES (WHETHER IN TORT, DUE TO NEGLIGENCE OR OTHERWISE) INCLUDING BUT NOT

LIMITED TO, LOSS OF LABOR, TIME, MATERIALS, CUSTOMER PROFITS, GOODWILL, OR ANY OTHER

INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES IN CONNECTION WITH THE FURNISHING, OPERATION OR FAULTY PERFORMANCE OF THIS PRODUCT. THIS EXCLUSIVE REMEDY SHALL NOT

BE DEEMED TO HAVE FAILED OF ITS ESSENTIAL PURPOSE SO LONG AS AFP IS WILLING AND ABLE TO

REPAIR OR REPLACE DEFECTIVE PARTS IN THE PRESCRIBED MANNER

THIS WRITING CONSTITUTES THE FINAL COMPLETE AND EXCLUSIVE EXPRESSION OF THE TERMS OF

WARRANTY AND REMEDY AS AGREED TO BY THE PARTIES TO THIS SALE. AFP NEITHER AUTHORIZES

NOR ADOPTS ANY STATEMENT MADE BY ANY REPRESENTATIVE WHICH DIFFERS FROM THE TERMS OF

THIS WRITING AND ALL SUCH STATEMENTS ARE SUPERSEDED BY THIS DOCUMENT.

0000061122

AFP IMAGING CORP. 250 Clearbrook Road, Elmsford, N.Y. 10523

Page 3

REVISION RECORD

Title: AFP X-Ray Film Processors "Mini-Medical Series"

Document Number: 0000061122

Revision Effective Date Description

01 August 1, 1992 Initial Release

02 January 1, 1997 Total Publication Revision

03 April 26, 2001 Warranty Page Revised

04 December 15, 2001 Total Publication Revision

Page 4

Page 5

AFP Mini-Medical

X-Ray Film Processor

Table Of Contents

Section 0 - Safety Information

Section 1 - Introduction

Content 1-1

Description 1-1

Operation 1-2

Capabilities 1-2

Transport System 1-2...4

Developer System 1-4

Fixer System 1-4

Developer & Fixer Replenishment 1-5

Anti-Crystallization 1-5

Wash System 1-5

"No Plumbing" System (Optional) 1-5

Dryer System 1-6

Cover Interlock Switches 1-6

General Specifications 1-7...8

Accessories 1-9

Index

Section 2 - Installation

Introduction 2-1

Pre-Installation 2-1

Location 2-1

Dimensions & Weight 2-2

Through-the-Wall Installation 2-2

Ventilation 2-2

Electrical 2-2

Plumbing 2-3

"No Plumbing" System Option 2-3

Installation 2-4

Set Up 2-4

Assemble Stand 2-4

Position Processor 2-4

Connect Replenishment 2-4

Replenish Mode 2-5

Batch Mode 2-6

Connect Plumbing 2-7

"No Plumbing" Option 2-7

Control Panel Position 2-8

I

Mini Med Series0000061122

Page 6

Index

Section 2 - Installation (Continued)

Processor Checkout 2-9

Operational Checkout 2-9...10

Transport Film 2-11

Complete Checkout 2-11

Processor Set Up Checklist 2-12

Operational Checklist 2-13

Notes 2-14

Section 3 - Operation

Controls and Indicators 3-1

User Controls 3-1

Power Switch 3-1

Manual Replenishment Switch 3-2

Power ON LED 3-2

Dev Temp LED 3-2

Wait LED 3-2

Low Dev LED 3-2

Drain Valves 3-2

Overflow Lines 3-2

Top Cover Interlock Switch 3-2

Loading Chemicals 3-3

Daily Start Up 3-4

Processor ON, Fill Wash Tank 3-4

Check Developer and Fixer Levels 3-4

Check Drive 3-4

Processing Film 3-5

Shutdown and Daily Cleaning 3-5

Drain Wash Tank 3-5

Clean Top Cover, Guides & Rollers 3-5

Wipe Off Processor 3-5

Quality Control 3-6

Developer 3-6

Fixer 3-6

Replenishment 3-7

Checklists for Daily Use 3-8

Startup 3-8

Operation 3-8

Shutdown and Daily Cleaning 3-8

Mini Med Series 0000061122

II

Page 7

Section 4 - Maintenance

Maintenance Program 4-1

Maintenance Records 4-1

Cleaning 4-1

Mini-Medical Processor Maintenance Schedule 4-2

Daily 4-2

Weekly 4-2

Monthly 4-2

Yearly 4-2

Mini-Medical Processor Maintenance Log 4-3

Weekly Cleaning 4-4

Monthly Cleaning 4-5

Clean Tanks 4-6

Inspect Processor 4-6

Prepare Fresh Chemicals 4-7

Lubrication 4-7

Annual Maintenance 4-7

Removing Old Lubricants 4-8

Lubrication Points 4-8

Index

Section 5 - Service

Content 5-1

Troubleshooting 5-1

Service Procedures 5-2

Service Procedures Index 5-2

Schematics 5-2

Troubleshooting Processor Problems 5-3...5

Service Procedure 5-1, Main Drive Belt 5-6

Service Procedure 5-1A, Film Sensors/Adjustments 5-7...8

Figure 5-1, Film Sensor Location Configurations 5-8

Service Procedure 5-2, Servicing Circulation Pumps 5-9...11

Figure 5-2, Recirculation Pump Head, Early Style 5-11

Figure 5-3, Recirculation Pump, Later Style 5-11

Service Procedure 5-3, Servicing Replenisher Pumps 5-12

Service Procedure 5-4, Circuit Descriptions &

Developer Temperature Control 5-13

Developer Temperature Calibration 5-14

Dryer Temperature Control 5-14

Over Temperature Protection 5-15

Dryer Temperature Calibration 5-15

Replenishment Operation 5-16

Replenishment Calibration 5-16

Triacs & SCR's 5-17

Outputs 5-17

Fuses 5-17

Calibration Procedures 5-13...17

III

Mini Med Series0000061122

Page 8

Index

Section 5, Service (Cont'd)

Service Procedure 5-5, Theory of Operation 5-18...5-19

Solution Temperature Control 5-18

Dryer Temperature Control 5-18

Solution Level Sensor 5-19

Automatic Shut-Off 5-19

AC Interface Board 5-19

Waveforms & Voltages 5-20...5-21

Schematics & Wiring Diagrams 5-22...5-30

Main Wiring Diagram 5-22

Dryer Rack Wiring Diagram 5-23

AC Interface Board Schematic 5-24

Logic Board Schematic 5-25

Logic Board Layout 5-26

AC Interface Board Layout 5-27

Ready Tone Generator Layouts & Schematics 5-28...5-29

LED Board Layout & Schematic 5-30

Mini Med Series 0000061122

IV

Page 9

Section 6 - Parts

Introduction 6-1

How Parts Are Listed 6-1

When Ordering Parts 6-1

Maintenance Kit 6-1

Documentation 6-1

Part Listings

General Assembly 6-2

Figure 6-1, General Assembly 6-3

Figure 6-2a, Feed Tray & Control Chassis Assembly 6-4

Figure 6-2b, Feed Tray & Control Chassis Assembly 6-5

Figure 6-3, Drive System 6-6

Figure 6-4, Tank/Frame Assembly 6-7

Figure 6-5, Recirculation Pumps 6-8

Recirculation Pump Parts (For P/N 0000021145) 6-8

Wet Rack Assembly 6-9

Figure 6-6, Wet Rack Assembly, Top Roller Group 6-10

Figure 6-7, Wet Racks, Bottom Roller Group 6-11

Figure 6-8, Wet Racks, Film Guide Group 6-12

Figure 6-9, Wash Rack, Squeegee Roller Group 6-13

Dryer Assembly, Front Exit 6-14

Figure 6-10, Dryer Assembly, Full View 6-15

Figure 6-11, Dryer Assembly, Side View 6-15

Dryer Assembly, Rear Exit 6-16

Figure 6-12, Dryer Assembly, Rear Exit, Full View 6-17

Figure 6-13, Dryer Assembly, Rear Exit, Side View 6-17

Plumbing Schematic (Early Style Parts Listing) 6-18

Figure 6-14, Plumbing Schematic (Early Style) 6-19

Plumbing Schematic, (Later Style Parts Listing) 6-20

Figure 6-15, Plumbing Schematic (Later Style) 6-21

Notes 6-22

Index

Section 7 - Accessories

Processor Support Stand 7-1

Support Stand Parts 7-2

Stand Turning Kit 7-3

Mounting Options Utilizing Turning Kit 7-4

Side Plumbing Kit 7-5

Through-the-Wall Installation Kit, Front Exit 7-6

Through-the-Wall Installation Kit, Rear Exit 7-7

Notes 7-8

V

Mini Med Series0000061122

Page 10

Page 11

Section 0

Safety Information

- General Index -

Section 0 - Safety Information

Section 1 - Introduction

Section 2 - Installation

Section 3 - Operation

Section 4 - Maintenance

0000061122

Section 5 - Service

Section 6 - Parts

Section 7 - Accessories

AFP Mini-Medical

X-Ray Film Processors

Page 12

Page 13

IMPORTANT SAFETY INFORMATION

TO REDUCE THE RISK OF INJURY OR ILLNESS, READ, UNDERSTAND, AND HEED THE INFORMATION ON THIS SHEET, ALL PRECAUTIONARY

LABELS ON THE EQUIPMENT, AND ALL INSTRUCTIONS INCLUDED WITH THE EQUIPMENT BEFORE ATTEMPTING INSTALLATION, USE, OR

MAINTENANCE.

WARNING: SERIOUS BODILY INJURY can result from improper handling or usage.

WARNING: NEVER move the equipment without enough help and/or lifting tools.

WARNING: ALWAYS use care when opening the shipping carton. Strapping bands can snap and injure you.

WARNING: NEVER operate the equipment without its protective panels and guards installed. Beware of rotating gears and belts, rollers,

and chains, and keep from becoming entangled in them.

DANGER: POTENTIALLY FATAL VOLTAGES ARE PRESENT IN THIS EQUIPMENT.

CAUTION: NEVER make electrical connections to the equipment unless you are a qualified electrician.

WARNING: ALWAYS route power supply wiring through a nearby disconnect device.

WARNING: NEVER attempt electrical service on the equipment unless you are a qualified electronics technician.

CAUTION: ALWAYS shut off power at the disconnect device before making electrical connections or servicing electrical components.

CAUTION: ALWAYS replace fuses with those of the same type and rating.

WARNING: NEVER touch supply voltages; THEY CAN BE LETHAL.

CAUTION: NEVER operate the equipment until it is reliably electrically grounded, NOT through the water system.

CAUTION: "DEV" indicates "developer solution".

PROCESSORS AND PROCESSOR ACCESSORIES

DANGER! POISON!

OF REACH OF CHILDREN. Always review and follow the hazard warnings and the ventilation, use, and disposal instructions of the chemicals

manufacturer. Install all fluids correctly before operating.

CAUTION: TO AVOID POSSIBLE DRINKING WATER CONTAMINATION, make certain that all plumbing complies with local codes.

WARNING: PROCESSING CHEMICALS CAN CAUSE SEVERE BURNS. Do not get in eyes, on skin, or on clothing. Avoid breathing vapor,

mist or dust, and use only with adequate ventilation. ALWAYS FOLLOW THE SAFETY RECOMMENDATIONS OF THE CHEMICALS

MANUFACTURER.

PROCESSING CHEMICALS MAY BE HARMFUL OR FATAL IF SWALLOWED. KEEP OUT

LITERATURE

The following publications relate to safety in film processing.

PUBLICATION AVAILABLE FROM

ANSI.PH 4.37 Photographic Processing Effluents American National Standards Institute

Technical Data Sheet, Photographic Processing Wastes ( 6 pages) E.I. DuPont DeNemours and Co., Inc.

1430 Broadway

New York, N.Y. 10018

Photo Products Dept.

Wilmington, Delaware 19898

J4: Safe Handling of Photographic Chemicals Eastman Kodak Co.

J28: Disposal of Photographic Processing Effluents and Solutions 343 State Street

J43: A Simple Waste-Treatment System Dept. 412-L

J50: Sampling and Flow-measurement Methods Rochester, N.Y. 14650

J52: Disposal of Small Volumes of Photographic Processing Solutions

K13: Photolab Design

S39: Water Conservation in Photographic Processing

The preceding information is presented as a guide to precautions associated with photographic processing. No claim is made as to the currency, accuracy or

completeness of the listed information. Please do not fail to contact your chemicals supplier to obtain additional advice and assistance.

0000061122

Page 14

Page 15

Section 1

Introduction

- General Index -

Section 0 - Safety Information

Section 1 - Introduction

Section 2 - Installation

Section 3 - Operation

Section 4 - Maintenance

0000061122

Section 5 - Service

Section 6 - Parts

Section 7 - Accessories

AFP Mini-Medical

X-Ray Film Processors

Page 16

Page 17

Introduction

Content

Description

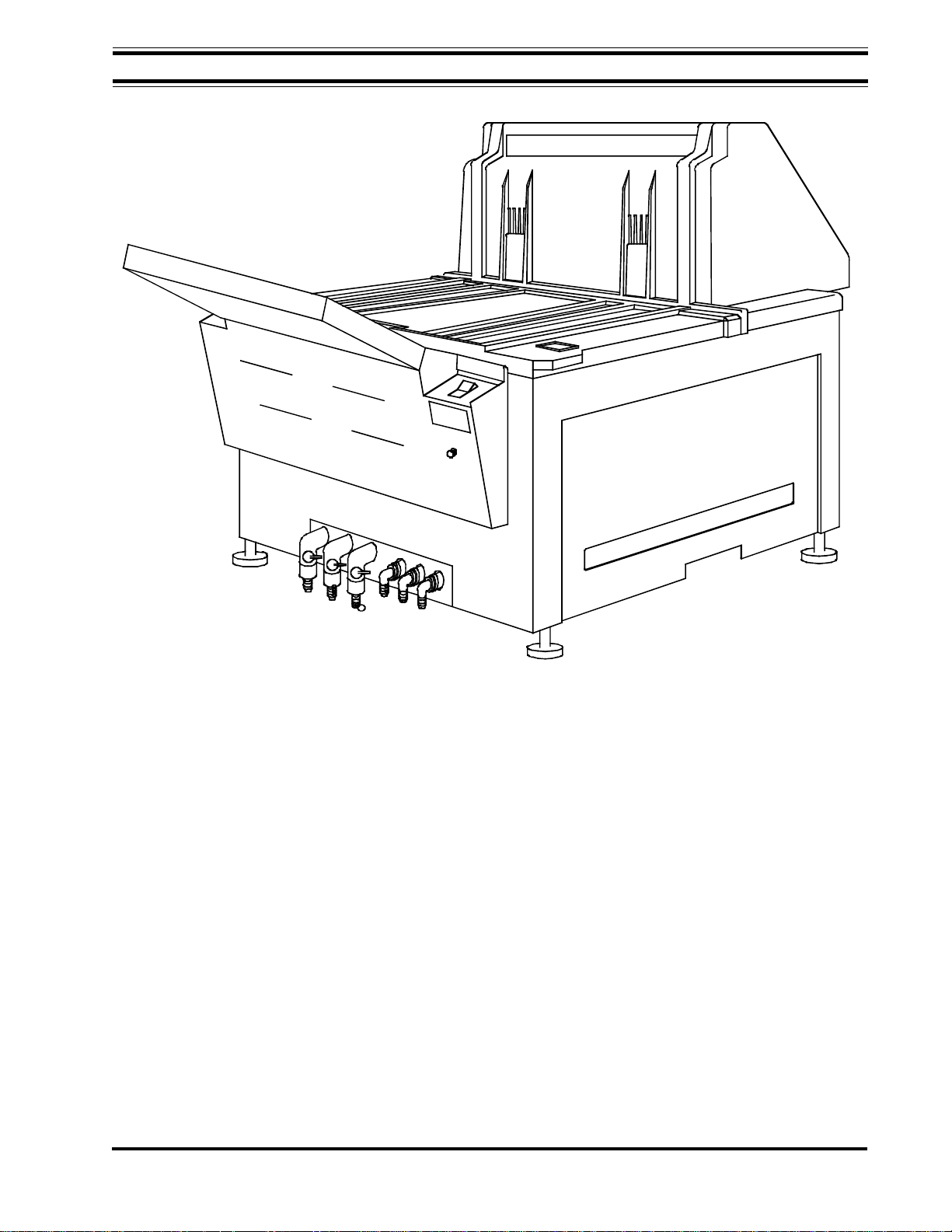

Figure 1-1, AFP Mini-Medical Series X-Ray Film Processor

This manual contains instructions for installing, using and maintaining the three different

models of the AFP Mini-Medical Series of X-Ray film processors. This series includes the

Mini-Medical, the Mini-Medical/90 and the Mini-Medical/EP processors. With the exception of pre-set processing speed and developer temperatures, these three processors are

identical in appearance, operation, maintenance and service. Differences, where existing,

will be noted in the text of this manual.

The Mini-Medical system includes the processor, with daylight tight film feed tray, support

stand, replenishment tanks, necessary hoses and this manual.

Major processor sections and components are shown in Figure 1-1.

0000061122

1-1

Mini Med Series

Page 18

Introduction

Operation

The processor is operated from the control panel. Basic processor functions are described

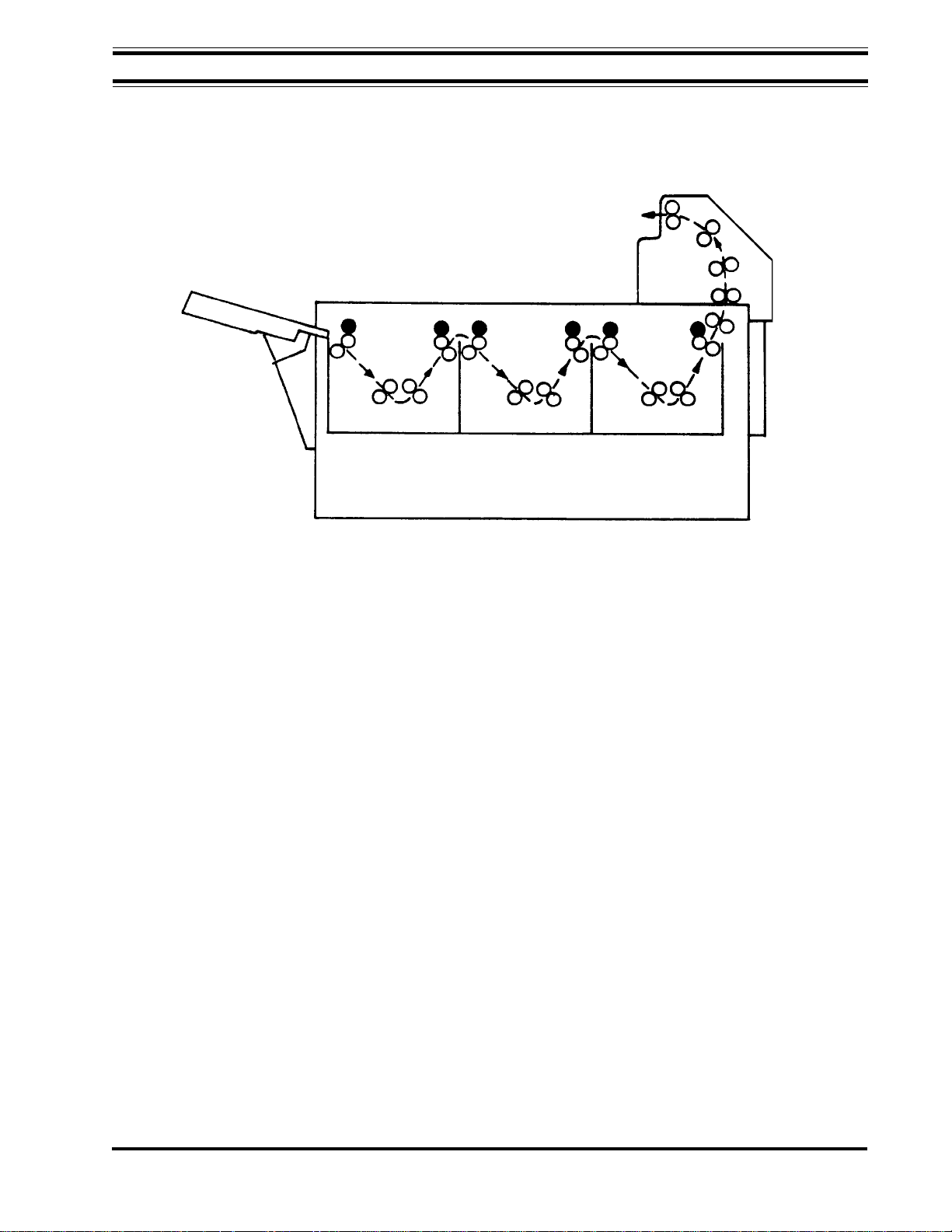

in the following paragraphs. Figure 1-2 is a diagram of the transport system.

Capabilities

Mini-Medical processors develop, fix, wash and dry exposed RP type medical X-ray films

of all sizes, from 4" X 4" (10 X 10 cm) to 14" X 36" (35 X 91 cm).

Hourly production capacity of 14" X 17" (35 X 45 cm) sheets of film, at the indicated, preset, lead edge in to lead edge out time, is:

Model Lead-to-Lead Productivity

Mini-Medical 130 sec 55 sheets per hour

Mini-Medical/90 90 sec 85 sheets per hour

Mini-Medical/EP 180 sec 42 sheets per hour

Transport System

Four removable roller rack modules transport the material being processed through the

developer, fixer, wash and dryer sections.

The developer, fixer and wash sections make use of “Deep Tank” racks to maintain developing quality and improve productivity. The dryer section includes a long path length

vertical dryer to assure material drying at short developing times, reduce space requirements and return the film to the operator’s position for ease of pick-up.

All racks and rollers in the wet sections and dryer are driven from a common drive shaft by

a fractional horsepower ac motor.

For ease of use, and accuracy of processing, developing times and developing temperatures

are factory set at the following values:

Model Dev. Time Developer Temp.

Mini-Medical 29 sec 90 Degrees f (32 C.)

Mini-Medical/90 22 sec 95 Degrees f (35 C.)

Mini-Medical/EP 44 sec 95 Degrees f (35 C.)

Mini Med Series 0000061122

1-2

Page 19

Transport System, (Cont'd)

Introduction

Figure 1-2, Transport System

Before processing film, the processor must first be turned ON and allowed to bring the

developer up to operating temperature.

As the processor warms up, it runs for one (1) process cycle (approximately 5 minutes) and

then remains in the Stand-By mode. In this mode, only the developer heater, one dryer

blower and the circulation pumps operate.

Film being fed into the processor is detected by a dual film sensor assembly located in the

feed slot. When film is sensed, the Wait lamp will illuminate and stay illuminated until

shortly after the trailing edge of the film has passed the sensor(s).

The above activation of the film feed sensor(s) also places the processor into Process mode,

starting the transport system, the dryer heaters and blowers and, as long as the feed switch

is tripped, operating the replenishment system.

Shortly after the Wait lamp extinguishes, an audible signal will sound, indicating to the

operator that additional film may be fed into the processor.

0000061122

An electronic holding circuit will keep the processor in Process mode for approximately 4

minutes after the feed switch is released. This will allow complete processing of the film,

after which time the processor will return to the Stand-By mode to conserve energy, water

and wear on the processor.

1-3

Mini Med Series

Page 20

Introduction

Transport System,

Cont'd)

Film is pulled into the processor by the input roller set on the developer rack. The film then

passes through the recirculating developer bath. As it leaves the developer, excess chemicals are squeegeed off by the exit rollers. This process is repeated in the fix, wash and dryer

sections.

Processed and dried film is then deposited in the film delivery area on top of the processor.

Developer System

As the film passes through the developer tank, developer is continuously circulated and

agitated around the rollers in the developer rack.

This developer circulation and agitation is provided by the developer chemistry being drawn

down into the developer circulation pump, located in the base of the tank, and then being

pumped back through the side of the tank, at a rate of approx. 2 gallons per minute.

Fixer System

The developer is replenished during operation by chemicals being drawn from the replenishment tank by a pump controlled by the replenishment circuit. This circuit operates the

pump continuously, with the actual output rate, in ml/minute, being electronically controlled by the processor’s circuitry.

Developer heat is provided by a 500 watt heater located in a heat-exchanger below the tank.

Developer temperature is sensed by a temperature sensor, located in the bottom of the developer tank.

Developer temperature is factory set at the values shown on Page 1-2, and may be readjusted by the installing technician to temperature values from ambient to 115 degrees f

(46 C.)

The film is fixed in the fix tank. Fixer is agitated, circulated and replenished in the same

manner as the developer. The fixer is not heated.

Mini Med Series 0000061122

1-4

Page 21

Developer & Fixer

Replenishment

Mini-Medical Series processors are designed to operate in either “Batch” or “Replenishment” mode. As such, replenishment chemicals may be replenished as necessary, with tank

overflow being directed into a drain or collection container for disposal, or recycled until

exhausted, then discarded and fresh chemicals installed. For additional information refer to

the Operation and Maintenance sections of this manual.

Anti-Crystallization

To prevent the build-up of chemicals on the processing rollers, an anti-crystallization or

“Jog” feature is built into all Mini-Medical processors.

This feature automatically runs the drive system at process speed for 20 seconds every 4

minutes, allowing fresh chemistry to be washed over the air-exposed rollers, effectively

preventing crystallization of chemistry on the roller surfaces.

Introduction

Wash System

The film being processed is washed in the wash tank before entering the dryer. The wash

water solenoid is actuated during the processing cycle and refreshes the water in the wash

tank with tempered water from an external source.

“No Plumbing’’

System (Optional)

The available “No Plumbing” wash water recirculation system P/N 9992305003 (115 VAC)

or P/N 9992305004 (230VAC) allows the installation of Mini-Medical processors without

external plumbing connections.

When using this option, wash water is recirculated from a 7 gallon reservoir, to the processor, and then back into the 7 gallon reservoir.

Processing chemistry (developer & fixer) is recirculated through each respective processing tank and replenishment container until its activity level is no longer satisfactory, at

which time it is drained and replaced.

0000061122

1-5

Mini Med Series

Page 22

Introduction

Dryer System

As film passes through the dryer, it is subjected to warm air from two linear infrared quartz

heating elements and a pair of fans.

Upon leaving the dryer the film is deposited in the receiving bin.

Cover Interlock Switch

To prevent accidental injury from moving parts, a mechanical safety switch is interlocked

with the processor’s top cover. If the top cover is removed, the processor automatically

shuts down.

Mini Med Series 0000061122

1-6

Page 23

General Specifications

Films

RP type medical X-Ray films and compatible chemicals designed for RP type processing.

Film Size

Minimum Size: 4" X 4" (10 X 10 cm)

Maximum Size: 14" X 36" (35.6 C 91.4 cm)

Base thicknesses 0.004 - 0.008"

Developing Time

Factory set as follows:

Model Dev. Time Linear Speed

Introduction

Mini-Medical 29 sec 20" per minute

Mini-Medical/90 22 sec 36" per minute

Min-Medical/EP 44 sec 10" per minute

Developer, Fix, & Wash

Systems

Capacity: 1.9 gallons (7.2 L.).

Temperature Control:

Developer: Factory Set as follows:

Mini-Medical 90 Degrees f. (32 C.)

Mini-Medical/90 95 Degrees f. (35 C.)

Mini-Medical/EP 95 Degrees f. (35 C.)

Fixer Ambient

Wash: Controlled by incoming water supply, .25 GPM (.95 LPM) during process and anticrystallization cycle. There is no water flow in standby mode.

Dryer System

Temperature: Factory set at 120 degrees f. (49 C.).

0000061122

1-7

Mini Med Series

Page 24

Introduction

General Specifications,

Continued

Environmental Conditions

Temperature: 40-80 Degrees f.

Humidlty: 40% - 60% RH.

Electrical Requirements

120 VAC, 15 amps, 60 Hz.

230 VAC, 7.5 amps, 50 Hz. (Optional)

Dimensions

Width 22" (56.1 Cm) Stand Only: Width 22.875"

Height: 24.5" (62.2 Cm) Height 29.5"

Length: 33" (84.1 Cm) Length 22.125"

(Including feed tray) Allow 1" (approximately) for leveling

Weight

Approximate Shipping Wt.: 110 lbs.

Approximate Operating Wt.: 160 lbs.

Air Conditioning Heat Load (Approximate)

Total Heat @ 60Hz Process Mode Standby Mode

2800 B.T.U./Hour 1800 B.T.U./Hour

Darkroom venting is required. Use a blower and vent combination that allows for approximately 300 CFM air flow through the darkroom.

Component Power Requirements

Component Amperage @ 115VAC

Solenoid 0.10

Developer Heater 4.55

Recirculation Pumps (2) 0.22 Ea.

Replenisher Pumps (2) 0.35 Ea.

Dryer Lamps (2) 2.17 Ea.

Fan Motors (2) 0.44 Ea.

Drive Motor 0.76

Total: 11.77 Amps

Mini Med Series 0000061122

1-8

Page 25

Accessories

Introduction

Stand Turn Kit (Allows sideways positioning of processor on stand for access to replenisher

containers) P/N 9992305001.

Side Plumbing Kit (Moves plumbing from front to side of processor) P/N 9992305002.

“No Plumbing’ Wash Water Recirculation Kit.

P/N 9992305003 (115 VAC)

P/N 9992305004 (230 VAC)

Specifications are subject to change without prior notice.

0000061122

1-9

Mini Med Series

Page 26

Introduction

Mini Med Series 0000061122

Page 27

Section 2

Installation

- General Index -

Section 0 - Safety Information

Section 1 - Introduction

Section 2 - Installation

Section 3 - Operation

Section 4 - Maintenance

0000061122

Section 5 - Service

Section 6 - Parts

Section 7 - Accessories

AFP Mini-Medical

X-Ray Film Processors

Page 28

Page 29

Attention:

When testing or operating the processor with water (as opposed to chemistryj), there will be a

LOW LEVEL condition in effect which will disable the solution heater. This is due to the fact that water

by itself cannot conduct well enough. To prevent this, add 1-2 tablespoons of salt or a cup of used or

fresh developer to the developer tank.

Mini Med Series

0000061122

Page 30

Page 31

22"

Installation

24"

33"

Introduction

This section includes instructions for Pre-Installation, Installation and Check Out of AFP

Mini-Medical X-Ray film processors.

Pre-Installation

Pre-installation includes instructions for preparing the processor operating site.

Have these operations completed before the scheduled installation date.

If the installing technician is delayed by incomplete site preparation, you may be charged

for costs during the delay.

Location

AFP Mini-Medical Series processors must be operated in a darkroom suitably safelighted

for the film being used.

Figure 2-1, Processor Dimensions

2-1

Mini Med Series0000061122

Page 32

Installation

Dimensions

Weight

Ventilation

Mini-Medical Processors occupy 8.0 square feet (22.5" X 24") (57 X 61 cm.) of floor or

counter space. The processor should be positioned to allow easy access to all sides of the

unit for routine cleaning and preventive maintenance. Drain tubes, leading out of the “front”

of the processor, below the feed tray, must be readily accessible.

The Mini-Medical Processors weigh approx. 110 lbs. when empty, and approximately 160

lbs. when operating.

To support this weight a Processor Stand Assembly is included. Instructions for the assembly of this stand can be found in Section 7, Accessories. If the stand is not used, a sturdy,

stable and level stand, table or counter must be provided.

WARNING: Some processing chemical fumes may irritate eyes and/or respiratory systems

when used in a poorly ventilated area. If the processor is to operate in a confined area,

provide for at least ten complete changes of air per hour.

Provide adequate ventilation for proper machine operation and operator comfort. The processor generates a moderate amount of heat when operating and must not be placed in a

confined space, such as a closet.

For best processing results, relative humldity should be between 40% and 60%.

Electrical

Electrical connections must include a ground and conform to local codes. The processor

plugs into a standard 120 VAC, 60 Hz, 15 amp., 3 wire outlet. As a factory installed option,

Mini-Medical Processors may also be configured for 230 VAC, 50 Hz, operation.

Through-the-Wall

Installation

If your processor is to be Installed through the darkroom wall, refer to Section 7, pages 6

and 7.

Mini Med Series 0000061122

2-2

Page 33

Pre-Installation,

Continued

Plumbing

WARNING: Obey all instructions of the chemicals manufacturer, and follow all recommended safety precautions when handling, using and disposing of chemicals.

The following plumbing requirements are recommended for installation of the Mini- Medical Processors:

1) A flow controlled water source for wash water and for cleaning the processor.

2) A sink, with running tempered water, approximately 12" X 16", for use when cleaning

rack modules.

3) A drain suitable for dumping photographic chemical wastes.

Installation

Caution: In some locales, environmental regulations may require the capturing and safe

disposal of photographic processing wastes other than in the sanitary sewer system.

Check with your local authorities if you are unsure of regulations in your area.

NOTE: The replenisher and drain connections may be run out of the front of the processor

in standard configuration or, using the optional Side Drain Kit P/N 9992305002, these lines

may be routed out either the right or left side of the processor. See Section 7, Accessories

for additional details.

"No Plumbing" System Option

The available “No Plumbing” wash water recirculation system, p/n 9992305003 (115 VAC)

or p/n 9992305004 (230 VAC), allows the installation of Mini-Medical Processors without

the need for an external water supply or drains. If this system is being installed with the

processor, refer to the instructions packed with that unit and to Section 7, Accessories, in

this manual.

This completes the pre-installation preparations you are expected to have completed before

the processor installation date.

2-3

Mini Med Series0000061122

Page 34

Installation

Installation

NOTE: Do not unpack the processor until you have thoroughly inspected the shipping container for evidence of damage. If there is any damage, contact your shipper immediately for

instructions on filing a claim.

Set Up

Unpack the processor and accessory boxes and inspect for any visible shipping damage. As

above, if any damage is discovered after unpacking, contact the shipper immediately for

instructions on filing a claim.

Remove the processor side covers. Remove each of the rack modules and any packing

material from the tanks. Inspect each of the racks for loose parts or screws.

Assemble Stand

Following the instructions in Section 7, Accessories, unpack and assemble the included

processor stand.

Position Processor

Using two people, carefully position the processor on its stand.

Using a level placed across the walls of the processing tanks, adjust the leveling feet until

the processor is level in both directions.

Connect Replenishment

The processor may be set up to operate its replenishment system in either “Replenish” or

“Batch” mode.

In “Replenish” mode the chemicals will be replenished with fresh chemicals from the

replenisher supply and the overflow will be collected for disposal or routed directly to a

drain.

In “Batch “ mode the developer and fixer chemicals will be recycled from the replenisher

supply to the processing tank and back to the replenisher supply.

Mini Med Series 0000061122

2-4

Page 35

Replenish Mode

DEV

FIX

To Repl. Pump (s)

To Drain

In “Replenish” mode, fresh replenisher will be pumped from the replenisher supply to the

processing tank. Excessive chemicals in the processing tank will flow out of the tank at an

overflow port and into either a container for disposal or an appropriate drain line. In this

manner, constant processing chemical strength may be maintained for longer periods of

operation.

To install the processor for “Replenish” mode replenishment operation proceed as follows:

(See Figure 2-2)

1) Attach the red developer replenisher pickup tube from the developer replenisher pump

to the developer replenisher reservoir fitting.

2) Route the red developer drain line and red overflow line from the processor to an overflow container or drain line.

3) Attach the blue fixer replenisher pickup tube from the fixer replenisher pump to the fixer

replenishment reservior fitting.

Installation

4) Route the blue fixer developer drain line and blue overflow line from the processor to the

overflow container or drain line.

Figure 2-2, Replenish Mode Operation

2-5

Mini Med Series0000061122

Page 36

Installation

)

Batch Mode

In “Batch” mode the replenisher will be recycled from the replenisher supply to the processing tank and will then, via the tank overflow port, return to the replenisher supply to be

recycled again. As the chemical's processing strength becomes depleted, the entire batch is

disposed of and new chemistry installed.

To install the processor for “Batch” mode replenishment operation proceed as follows:

(See Figure 2-3)

1) Route the red developer replenisher pickup tube from the developer replenisher pump to

the developer replenishment reservior or to a container of developer replenisher.

2) Route the red developer drain line and red overflow line from the processor to the same

container as the developer replenisher pickup tube.

3) Route the blue fixer replenisher pickup tube from the fixer replenisher pump to the fixer

replenishment reservoir or to a container of fixer replenisher.

4) Route the blue fixer developer drain line and blue overflow line from the processor to the

same container as the fixer replenisher pickup tube.

To Drain

To Repl. Pump (s

DEV

FIX

Figure 2-3, Batch Mode Operation

Mini Med Series 0000061122

2-6

Page 37

Connect Plumbing

Wash water into the processor is controlled by the water solenoid valve. When the processor is in the process mode the solenoid is actuated, allowing wash water to flow into the

bottom of the wash tank. Excess water in the wash tank flows over the overflow port and

down the drain.

To connect the wash water proceed as follows: (See Figures 2-2 and 2-3)

1) Route the supplied reinforced water hose from the output of your water panel to the

fitting on the wash water solenoid under the right side of the processor.

2) Route the clear wash water drain line and the clear overflow line from the utility section

of the processor to the building drain or a suitable overflow container.

CAUTION: If you are draining your processor directly into a sanitary sewer, be certain that

such connections are in accordance with local plumbing codes and comply with all local

and federal EPA anti-pollution requirements.

Installation

DO NOT drain the processor into any drain lines that are made of copper pipe as chemical

reactions will quickly damage the pipes.

"No Plumbing" System Option

The available “No Plumbing” wash water recirculation system, P/N 9992305003 (115 VAC)

or 9992305004 (230), allows the installation of any of the Mini-Medical Series processors

without the need for an external water supply or drains. If this system is being installed

with the processor, refer to the instructions packed with that unit and to Section 7, Accessories, in this manual.

2-7

Mini Med Series0000061122

Page 38

Installation

Control Panel Positioning

In some installations, such as with the right side of the processor against a wall, it may be

difficult for the processor operator to view the LED’s on the Display Panel to the left of the

feed tray.

If this is the case, to make the LED Display Panel more visible, use the following procedure

to reverse the positions of the Power Switch/Circuit Breaker and the LED Display Panel.

1) Disconnect the processor power cable from its outlet.

2) Remove the two screws holding the control chassis panel to the front of the processor.

Carefully lower the panel until it is supported by its restraining straps.

3) Locate the small screw(s) that holds the LED Display Panel and the Power Switch panel

in place. Remove the screws.

4) Carefully unlace the cables for each panel from the retaining clips back as far as the

center of the loom.

5) Re-install the panels in the desired position,taking care to replace the cables through the

retaining clips.

6) Replace the panel securing screws and close the control chassis and secure it with its two

screws.

7) Return the processor to service.

Mini Med Series 0000061122

2-8

Page 39

Processor Checkout

Following set up, inspect the processor as described below to make sure it is ready for use.

WARNING: During this inspection, be sure that the processor power is disconnected at the

wall plug.

Inspect and clean the processor tanks, racks and hoses as described below:

1) Open the drain valves on the front of the processor for the developer, fixer and wash

tanks. Use warm water to rinse each tank clear of dust and debris. Close all drain valves.

2) Shine a light through all hoses to check for foreign matter. To remove anything, disconnect hose at one end, flush with water, and reconnect.

3) Check, and tighten if necessary, loose hose clamps and/or hardware on the processor.

4) Check that processor is level from front-to-rear and side-to-side. Correct as necessary.

Installation

Operational Checkout

Read these instructions completely before starting the processor.

WARNING: Never operate the processor without an electrical ground connection.

1) Close the tank drain valves.

2) If not already done, remove the three racks and set aside.

3) Carefully pour about 1.5 gallons of warm water into each of the solution tanks. Do Not

attempt to fill the tank to the overflow.

Attention:

When testing or operating the processor with water (as opposed to chemistry), there will be

a LOW LEVEL condition in effect which will disable the solution heater. This is due to the

fact that water by itself cannot conduct well enough. To prevent this, add 1-2 tablespoons

of salt or a cup of used or fresh developer to the developer tank

4) Install all three racks in their appropriate tanks.

5) With the Power Switch OFF, plug in the power cord.

2-9

Mini Med Series0000061122

Page 40

Installation

Operational Checkout

Continued

Caution: Never attempt to operate the processor without liquid in the tanks.

6) Switch the Power Switch to ON.

7) The transport system will run at Process speed for the duration of one processing cycle,

the recirculation pumps will operate and the dryer heaters and fans will be activated.

NOTE: If either of the recirculation pumps do not prime, squeeze the rubber elbow on the

inlet side of the pump(s) to purge the air from the line.

8) Inspect all rack modules to verify that they are turning freely.

9) Carefully inspect the underside of the processor for any signs of leakage. Correct if

necessary.

10) Operate the Manual Replenishment switch to run the replenishment pumps until the

developer and fixer tanks are full of water to the overflow port.

11) Activate the Film Feed switch with a piece of film. The Wait light will turn ON and

every few seconds the replenishment pumps will cycle. Remove the film from the sensor.

In a few seconds the Wait light will go out and the beeper will sound.

12) When the Dev Temp lamp turns OFF, check the temperature of the developer with a

metal stem or digital thermometer*. If it is not correct for the film you will be using, adjust

the temperature as outlined in Section 5, Service.

*Warning: Do not use a mercury thermometer. If a mercury thermometer breaks, it will

contaminate the machine

Mini Med Series 0000061122

2-10

Page 41

Transport Film

Transport several pieces of film of your usual size(s) through the processor. Inspect and, if

necessary, correct for the following:

1) Film Feed switch operation. The Wait lamp should stay on continuously until a few

seconds after the trailing edge of the material being processed is clear of the Film Feed

switch.

As the Wait light turns off, an audible beeper will sound indicating it is safe to feed in

another piece of material.

The processor will remain in the process mode for approximately 5 minutes after the film

feed switch is released.

2) Drift or Skewing. The film should feed through the processor in a straight line. If it

drifts, skews or wrinkles, check the racks for proper seating or loose assembly screws. Be

certain you are feeding the film in straight before checking racks.

Installation

3) Drying. Be sure the dryer is operating properly. Film processed in water alone may still

be slightly tacky or damp when exiting the processor.

Complete Checkout

1) Turn the Power Switch OFF. Unplug the power cord.

2) Drain each of the processing tanks and the replenishment containers for the developer

and fix replenishment systems. Close all drain valves.

3) Wipe any excess water from the racks and tanks.

The processor is now ready to be charged with fresh chemistry as instructed in Section 3,

OPERATION.

2-11

Mini Med Series0000061122

Page 42

Installation

Processor Set Up Checklist

1) Uncrate processor. Inspect for shipping damage.

2) Assemble processor stand.

3) Set processor on stand.

4) Level processor.

5) Inspect tank and racks for loose parts.

6) Install replenisher system, replenish or batch mode.

7) Connect wash water system and drain.

8) Rinse out wet tanks, inspect recirculation lines.

9) Perform Operational Checkout.

Figure 2-4, Setup Checklist

Mini Med Series 0000061122

2-12

Page 43

Operational Checklist

l) Close drain valves.

2) Remove racks.

3) Partially fill tanks with warm water.

4) Replace racks.

5) Plug in processor, apply Power.

6) Inspect transport drive system.

7) Check recirculation plumbing for leaks.

8) Top off tanks using Manual Replenishment switch.

Installation

9) Check Film Feed switch and “Beeper” operation.

10) Check temperature control systems.

11) Check developing time.

12) Check for dryer heat and operation of both fans.

13) Check transport of material.

14) Drain Processor.

15) Charge with fresh chemistry.

Figure 2-5, Operational Checklist

2-13

Mini Med Series0000061122

Page 44

Installation

Notes:

Mini Med Series 0000061122

2-14

Page 45

Section 3

Operation

- General Index -

Section 0 - Safety Information

Section 1 - Introduction

Section 2 - Installation

Section 3 - Operation

Section 4 - Maintenance

0000061122

Section 5 - Service

Section 6 - Parts

Section 7 - Accessories

AFP Mini-Medical

X-Ray Film Processors

Page 46

Page 47

Operation

9

3

4

5

6

NOTE: For operator convenience, the

LED Display Panel and the Power Switch

Panel may be switched, right to left,

during installation of the processor.

See Page 2-8 for details.

8

7

1

2

Controls and Indicators

All of the user controls and indicators for operation of Mini-Medical Processors are

located on the front of the processor. These controls are described below and on the

following page.

User Controls

1. Power Switch

OFF All power to processor is OFF.

ON Processor is ON, (runs one approximate 5 minute process cycle initially),

then reverts to standby mode. Circulation pumps, developer heater and air

circulation fan are ON. Transport, replenishment system and dryer will

operate when Film Feed switch is activated. Power On lamp will light.

CENTER This switch also serves as the circuit breaker for the processor. If tripped to

the center position reset to OFF, then turn ON. If the switch trips again, the

processor probably needs a service call. Do not use the processor if it trips

off repeatedly.

Figure 3-1, User Controls

0000061122

3-1

Mini Med Series

Page 48

Operation

User Controls,

Continued

2. Manual Replenishment Switch

3. Power ON LED

4. Dev Temp LED

5. Wait LED

Provides for manual operation of replenishment pumps. Use to “top off” tanks or to

turn over chemistry when activity levels have dropped.

Lights when Power Switch is ON.

Lights when developer heater is ON. Wait for light to cycle OFF before first use each

day.

Illuminates when Film Feed switch is activated. To prevent fogging of film, wait until

lamp goes OFF or beeper sounds before opening feed tray.

6. Low Dev LED

Lamp ON indicates that developer is too low for safe operation. To prevent damage to

the processor, the developer heat function is turned OFF when a low level condition

exists.

7 Drain Valves

Drains the Developer, Fixer, Wash tank and recirculation pumps.

8. Overflow Lines

Drain lines from developer, fix & wash overflow ports.

9 Top Cover Interlock Switch

To prevent accidental injury from moving parts, a safety switch is interlocked with the

processor’s top cover. If the top cover is removed, the processor automatically shuts

down. This interlock may be overridden for service use only by using the service hold

down tool included in the Maintenance Kit provided with each unit.

Mini Med Series

Caution: DO NOT attempt to process film in this unit when the interlock is overridden.

3-2

0000061122

Page 49

Loading Chemicals

Always begin with a clean processor. The processor should have been cleaned in the

normal course of installation or maintenance.

With the developer and/or fixer tank cleaned and drained, add processing chemicals as

described below:

WARNING: Read and heed safety precautions given by your chemical manufacturer

in mixing, using and disposing of processing solutions.

To prevent chemical splashing and the risk of contamination follow these instructions

carefully.

1) Close the tank drain valves at the front of the processor.

2) If not already done, remove the three racks and set aside.

3) Cover the developer tank with a sheet of newspaper to protect it from accidental

splashes of fixer.

Operation

4) Carefully pour about 1.5 gallons of fixer working solution into the fix tank. Do Not

attempt to fill the tank to the overflow.

5) Cover the fixer tank with a sheet of newspaper to protect it from accidental splashes

of developer.

6) Carefully pour about 1.5 gallons of developer working solution into the developer

tank. Do Not attempt to fill the tank to the overflow.

7) Carefully pour about 1.5 gallons of warm water into the wash tank. Do Not attempt

to fill the tank to the overflow.

8) Replace the racks. Lower them into the tanks slowly to prevent splashing. Check for

correct seating on the locating pins and driveshaft.

9) Attach the replenisher hoses to the fittings on the replenisher supply containers.

10) Turn the Power Switch-ON. Operate the Manual Replenishment switch to run the

replenishment pumps until the developer and fixer are seen in the overflow drain tubes.

0000061122

3-3

Mini Med Series

Page 50

Operation

Daily Start Up

Processor ON,

Fill Wash Tank

The daily start up procedure is as follows:

1) Close the wash tank drain valve.

2) Switch the Power Switch to the ON position. The processor will start in the process

mode and run for approximately 5 minutes, filling the wash tank. If, at the end of the

process cycle, the wash water has not reached the overflow port, trip the Manual Replenishment switch to initiate another processing cycle.

3) Allow the developer to warm up to operating temperature (Dev Temp light will

cycle OFF). Check for leaks around all hose fittings.

Caution: Always inspect to see that all drain tubes are properly positioned and draining

correctly. All drain tubes must be routed in a continuously downward direction, without dips or loops that can cause airlocks.

Caution: A kink or twist in a drain tube can cause a serious chemical or water spill in

the processor.

Check Developer

and Fixer Levels

If not previously done, check the developer and fix tanks to see that they contain adequate solution. Prepare fresh replenisher if necessary and using the Manual Replenishment switch, top off each tank with chemistry to the overflow port.

Check Drive

With the Power Switch in the ON position, check all turning drive gears to see that they

mesh properly and turn without binding. Make sure the transport rollers are turning

freely, without interference or binding.

Mini Med Series

3-4

0000061122

Page 51

Processing Film

Feed film into the processor. As it actuates the feed sensor, the WAIT lamp on the

control panel will light.

If you turn the room lights on after feeding film, to prevent fogging the end of your

film, do not open the daylight cover until after the Wait light goes out or the beeper

sounds.

After the processor completes its processing cycle it will automatically return to Stand-

By mode.

Shutdown and Daily Cleaning

Basic care of the processor goes hand-in-hand with its operation. Following each day’s

work, allow 15 minutes to clean the processor as described below.

Drain Wash Tank

Operation

Open the wash tank drain valve and allow the wash water to drain. Rinse out the wash

tank with fresh warm water, then close the drain valve.

Clean Top Cover,

Guides & Rollers

Using a separate wet cloth for developer and fixer, wipe the exposed rollers on each

rack.

Caution: Do not use the same cloth for fixer and developer racks. Fixer may contami-

nate the developer.

Wipe off Processor

Thoroughly wipe the inside and outside surfaces of the top cover and side panels with

a damp cloth. Replace the top cover, leaving a slight opening over the drive shaft to

prevent condensation of chemistry vapors.

0000061122

3-5

Mini Med Series

Page 52

Operation

Quality Control

Developer

Fixer

A good quality control program is essential to the production of quality radiographs.

It is recommended that a quality control program for your processor be established and

maintained to assure the quality of your output.

Following are some suggestions for those areas that should be monitored. Contact your

film and chemistry technical representative for additional information and assistance.

Developer activity can be monitored by use of pre-exposed control strips, available

from your film supplier, or by careful monitoring of your production work.

Exhausted fixer will usually result in dark streaks in your film’s emulsion that may

appear immediately after processing or may not appear until hours or even days after

processing.

Exhausted fixer can also contribute to transport problems such as jams and will frequently prevent proper drying from taking place, resulting in sticky film surfaces.

The general health of your fixer can be determined by monitoring the pH of the chemistry.

When pH is too high, films may jam in the wash tank and the dryer. To determine pH,

immerse pH test strips, available from your dealer, in the fixer and read its pH value

from the resultant color change on the strip. If the pH rises toward the chemical

manufacturer’s recommended upper limit, dump the old fixer and replace with fresh

chemicals.

NOTE: Only terminal-type silver recovery systems are recommended for use with this

processor. Do not try to re-use fixer after silver has been removed.

Mini Med Series

3-6

0000061122

Page 53

Replenishment

Operation

Replenishment in Mini-Medical Processors consists of “topping” off the developer and

fixer tanks with fresh working solution at the start of each shift and automatic replen-

ishment by the replenishment system.

Automatic replenishment is accomplished by the film tripping one or both of the Film

Feed Switches which, in turn, actuates the electronic replenishment circuitry. Depend-

ing on technician set adjustments, the developer and fixer pumps will cycle on and off

during film feeding to replenish the working solution in the developer and fixer tanks.

Manual Replenishment may be required for one of three reasons. They are:

1) To top off the tanks at start-up.

2) To restore chemical strength after several days of shut down.

3) To compensate for a basic under-replenishment condition. (See NOTE below)

NOTE: Chemistry requirements vary by the type of work and average size of films you

are processing. If you find that you must frequently use the Manual Replenishment

switch to add fresh chemistry, it is recommended that you have your technician adjust

the replenishment control circuits as required to allow for adequate automatic replen-

ishment.

0000061122

3-7

Mini Med Series

Page 54

Operation

Checklists for Daily Use

Startup

1. Check solution levels.

a) Top off processing tanks and fill wash tank.

2. Power Switch to ON, check drive gears for meshing;

allow 15-30 minutes warm up.

3. Clean feed tray, receiving bin.

4. Check developer activity, fixer pH.

Operation

1. Feed material, trip Film Feed switch to start processing cycle.

2. Wait until Wait light goes out or beeper sounds before opening film feed tray.

Shutdown and Daily Cleaning

1. Switch off power.

2. Drain and rinse wash tank, close valve.

3. Clean:

a) roller surfaces, rack and tank area

b) splashes from inside top cover.

4. Wipe outside surfaces of the processor, inside surfaces of feed tray & cover box

and both side panels.

5. Leave top cover slightly open to prevent condensation.

NOTE: Duplicate these checklists and post them near the processor.

Mini Med Series

3-8

0000061122

Page 55

Section 4

Maintenance

- General Index -

Section 0 - Safety Information

Section 1 - Introduction

Section 2 - Installation

Section 3 - Operation

Section 4 - Maintenance

0000061122

Section 5 - Service

Section 6 - Parts

Section 7 - Accessories

AFP Mini-Medical

X-Ray Film Processors

Page 56

Page 57

Maintenance Program

Maintenance of Mini-Medical Processors consists of cleaning and adjustment operations,

routinely performed, to keep the processor operating correctly. Early in the life of your

processor set up a maintenance program, with specific people responsible for performing

each maintenance task.

Maintenance Records

Good preventive maintenance is essential to assure a long and trouble free life for your

processor. Keeping on-going records of maintenance will help assure that the work is

performed when scheduled.

Figure 4-1 is a Maintenance Schedule that lists tasks to be performed at prescribed maintenance intervals.

Figure 4-2 is a Maintenance Log for keeping monthly records of maintenance performed.

Make additional copies and post near the processor.

Maintenance

Cleaning

Cleaning is the most important form of maintenance. If chemicals are allowed to accumulate on processor parts they can cause corrosion or other damage which may seriously

affect production and output quality.

Perform daily cleaning, as outlined on the Maintenance Schedule, Figure 4-1, as part of the

shutdown procedure.

Weekly cleaning, described below, should take about thirty minutes following the last shutdown and daily cleaning.

Do not replace items removed for daily cleaning until after weekly cleanup has been completed.

Caution: Never use harsh abrasive material to clean racks or processing tanks. Never

use scrub pads such as "Scotchbrite" on rollers.

0000061122

4-1

Mini Med Series

Page 58

Maintenance

Daily Clean:

Developer Rollers

Top Covers, Side Panels

Feed Tray, Receiving Bin

Check:

Chemical Levels

Replenisher Levels

Weekly Clean:

Developer Rack

Fix Rack

Wash Rack

Wash Tank

Tank Exteriors

Mini-Medical Processor

Maintenance Schedule

Monthly Clean:

Developer Tank, Circulation &

Replenishment System

Fixer Tank, Circulation &

Replenishment System

Wash Tank, Drain & Overflow System

Check:

Hose Clamps & Plumbing

Rack Bearings

Lubrication Points

Yearly Clean:

Developer & Fixer Circulation Pumps

Check:

Drive Belt

Drive Motor Brushes

Lubrication Points

Mini Med Series

Figure 4-1, Maintenance Schedule

4-2

0000061122

Page 59

Mini-Medical Processor

Maintenance Log

Maintenance

DAY

MONTH

INITIAL UPON COMPLETION

CLEAN DEV. ROLLERS

RECORD

CLEAN TOP COVERS

CLEAN SQUEEGEE ROLLERS

CLEAN FEED TRAY

CLEAN RECEIVING BIN

CHECK CHEMICAL LEVELS

DAILY

CLEAN DEV. TRANSPORT

CLEAN FIX TRANSPORT

CHANGE WASH WATER

CLEAN WASH TRANSPORT

1

2

3

4

5

6

7

DATEHRS

MONTHLY MAINTENANCE

8

9

10

11

12

13

14

15

16

17

YEARLY MAINTENANCE

18

19

20

21

22

23

LUBRICATION

24

25

26

27

28

29

30

31

Note: If Processor is run 80 hours or more a week, perform maintenance twice as often.

WEEKLY

CLEAN WASH TANK

CLEAN TANK EXTERIORS

CHANGE DEVELOPER

CHANGE FIXER

OPERATION

CLEAN DEVELOPER SYSTEM

CLEAN FIXER SYSTEM

CLEAN WASH SYSTEM

CHECK HOSE CLAMPS

CHECK LUBRICATION DIAGRAM

CLEAN FIX & WASH PUMPS

CHECK DRIVE BELT

CHECK MOTOR BRUSHES

CHECK LUBRICATION DIAGRAM

DRIVE SHAFT BRGS (MONTHLY)

DRIVE SHAFT GEARS (MONTHLY)

DRYER TRANSPORT GEARS (MONTHLY)

1. Duplicate this copy to provide a supply of log sheets.

2. Perform operations as instructed in User's Manual.

3. List operating hours at each operation and initial.

4. Retain completed log sheets for continuing history.

* Where applicable

NOTES

INIT

*

0000061122

Figure 4-2, Maintenance Log

4-3

Mini Med Series

Page 60

Maintenance

Weekly Cleaning

1) Remove the developer, fixer and wash racks. To prevent chemical contamination, wash

off each rack separately with clean, lint-free cloths and warm water. Clean each roller over

its entire surface. Use isopropyl alcohol if necessary to remove traces of adhesives.

NOTE: Soft scrub pads, such as nylon net over sponge, work well on rollers. Metallic, or

non-metallic, scrub pads such as "Scotchbrite", must not be used on rollers as they will

damage the roller surface.

2) Inspect each rack thoroughly. Verify that the rollers turn freely and that all guides and

baffles are properly in place. Carefully set each rack aside to drain and dry while you are

cleaning the rest of the processor.

3) Clean the outside surfaces of the processing tank, using warm water with a sponge or

non-metallic scrub pad.

Caution: Never use steel wool on any part of the processor as its residue may cause

rust to form on the metallic parts of the processor.

4) Clean the dryer rollers and rack parts with a damp cloth and wipe dry.

5) Replace all removed racks and other parts.

Mini Med Series

4-4

0000061122

Page 61

Monthly Cleaning

As film is processed, by-products are released into the developer, fix and wash systems.

These must be removed by regular cleaning. Every month, schedule two hours of processor

downtime to thoroughly clean the developer, fixer and wash systems.

NOTE: This cleaning will replace the scheduled Weekly Cleaning due on the same date.

1) Open the drain valves, drain and dispose of the used developer, fixer and wash water.

Allow the tanks and recirculation systems to drain completely.

Caution: When filling or rinsing the processor tanks, use water no hotter than 120

degrees F (54 degrees C).

2) Bring a small bucket or container of warm water to the processor and place the red and

blue intake hoses going to the replenisher pumps into the container. Press and hold the

manual replenishment switch (located on the upper right hand front corner of the machine)

until the water comes out clear. Remove the intake hoses from the container and press and

hold the switch again until the pumps and lines are purged. Replace the hoses to their

original chemistry containers.

Maintenance

3) Rinse out each tank and then close the drain valves and fill the wash tank with warm

water.

4) Systems Cleaning.

The use of Developer Systems and Fixer Systems Cleaners are recommended for cleaning

the developer and fixer system. Carefully follow the manufacturer’s instructions and precautions. Dissolve any powdered chemicals in water before adding to the tank. Be sure to

accomplish the neutralizing and rinsing steps recommended by the systems cleaner manufacturer.

WARNING: Beware of all rotating gears, shafts and drive belts when operating the

processor with its access panels removed.

5) After the developer and fixer systems are thoroughly cleaned, neutralized and rinsed, fill

each tank with fresh warm water and install the racks. Switch processor ON and allow the

transport and recirculation systems to run for about 15 minutes as a final rinse.

(Continued on Next Page)

0000061122

4-5

Mini Med Series

Page 62

Maintenance

Monthly Cleaning,

Continued

Systems cleaning will remove most, if not all, of the chemical residue from the transport

racks. For additional cleaning and inspection, proceed as outlined below:

A) Remove the rack from the tank.

B) Clean the developer and fix racks without disassembling them.

C) Appropriate Systems Cleaner may be used to remove stubborn deposits. Never use

“Scotchbrite” type pads on roller surfaces. Rinse the rack thoroughly after it has been

cleaned.

D) Inspect all rack end plates for wear. Be sure the rollers turn freely.

Bearing wear differs according to the solution in which the rack is used. Since bearings

tend to wear more quickly in the fixer solution, the fixer rack end plates should be checked

more frequently for wear.

Clean Tanks

Inspect the empty processing tank for foreign matter and, if necessary, use a soft scrub pad

or brush and warm water to clean the tank interior. Flush the tank with warm water and

drain.

Inspect Processor

Check the hose clamps on the developer, fixer and wash pumps and the base of each pump

for leaks. Secure as necessary.

Caution: Do not over-tighten clamps. This can cause leakage or damage to the pump

heads.

(Continued on Next Page)

Mini Med Series

4-6

0000061122

Page 63

Prepare Fresh Chemicals

When the developer and fixer systems are clean, prepare and load fresh chemicals in accordance with instructions in Section 3, Operation, and the manufacturer’s instructions and

precautions.

Monthly Lubrication

Refer to Figure 4-2, Maintenance Log and Figure 4-3, Lubrication Points and lubricate as

indicated. Be sure to clean off all old lubricants and any excessive new lubricants.

Annual Maintenance

Once a year, following a routine monthly cleaning, perform the following tasks on the

processor:

1) Inspect the drive gears on each rack and replace any gears that are excessively worn or

damaged.

Maintenance

2) Refer to Service Procedure 5-1. Inspect, and adjust or replace if necessary, the main

drive belt.

3) Refer to Service Procedure 5-2. Inspect and clean the fixer circulation pump. The

developer pump is usually cleaned adequately by systems cleaning and does not require

additional servicing.

4) Refer to Service Procedure 5-3. Inspect and clean the developer and fixer replenishment

pumps.

5) Refer to Figure 4-2, Maintenance Log and Figure 4-3, Lubrication Points and lubricate

as indicated.

Be sure to clean off all old lubricants and any excessive new lubricants.

0000061122

4-7

Mini Med Series

Page 64

Maintenance

Removing Old Lubricants

Dust and dirt, mixed with oil or grease, can prevent fresh lubricants from reaching the

surfaces that need it most.

Before applying new lubricant, clean accumulations of grease from the gears. Hold a rag

alongside each gear, and brush debris from the gear onto the rag. Clean as much of every

drive gear as possible, then run the processor transport system very briefly, and clean again

until all portions of the gears have been exposed for cleaning.

After the drive gears have been cleaned, lubricate them as indicated in Figure 4-3.

Lubrication Points

Location Interval Lubricant

Drive Shaft Bearings & Worm Gears Monthly Oil/Teflon Oiler

Dryer Gears Monthly Oil/Teflon Oiler

NOTE:

DO NOT lubricate any gears or other parts that come in contact with solutions or water.

Figure 4-3, Lubrication Points

Mini Med Series

4-8

0000061122

Page 65

Section 5

Service

- General Index -

Section 0 - Safety Information

Section 1 - Introduction

Section 2 - Installation

Section 3 - Operation

Section 4 - Maintenance

0000061122

Section 5 - Service

Section 6 - Parts

Section 7 - Accessories

AFP Mini-Medical

X-Ray Film Processors

Page 66

Page 67

Content

Service

This section contains information on trouble-shooting and repairing AFP Mini-Medical

Series Processors.

Always consult the Troubleshooting Chart before attempting service or repair, or before

calling a service representative.

Even if you do not plan to service the processor yourself, the chart will help you explain

the problem to a service representative.

WARNING: Be extremely careful when trouble-shooting or servicing the processor

with the power on. Dangerous, potentially lethal, electrical voltages are present at

several points.

Following the Troubleshooting Charts are instructions for performing adjustment and

repair procedures that may be required to keep the processor functioning.

Also in this section is a description of the control electronics in the processor, with

applicable schematics and a wiring diagram. These will enable users who are trained

and equipped for electronics trouble-shooting to trace failures in the electronics.

NOTE: The circuit cards in this processor are not considered field repairable and in the

event of a component failure, should be replaced.

Attempting to repair them could invalidate any remaining warranty, or may cancel the

exchange credit value that some cards may have.

Troubleshooting

The Troubleshooting Charts are divided into three columns. To use either chart, find

on the left, under symptom, a problem that sounds like yours. In the middle column, in

diminishing order of likelihood, are the Probable Causes for such a symptom. The

right-hand column, Remedy, provides corrective action(s) for each probable cause.

(Continued on Next Page)

0000061122

5-1

Mini Med Series

Page 68

Service

Service Procedures

Following the Troubleshooting Charts are service procedures for repair and maintenance

of the processor.

Below is an index to those procedures:

Procedure Title

5-1 Inspecting, Adjusting & Changing the Main Drive Belt

5-lA Film Sensors and Adjustments

5-2 Servicing Circulation Pumps

5-3 Servicing Replenisher Pumps

5-4 Calibration Procedures

5-5 Circuit Descriptions

Schematics

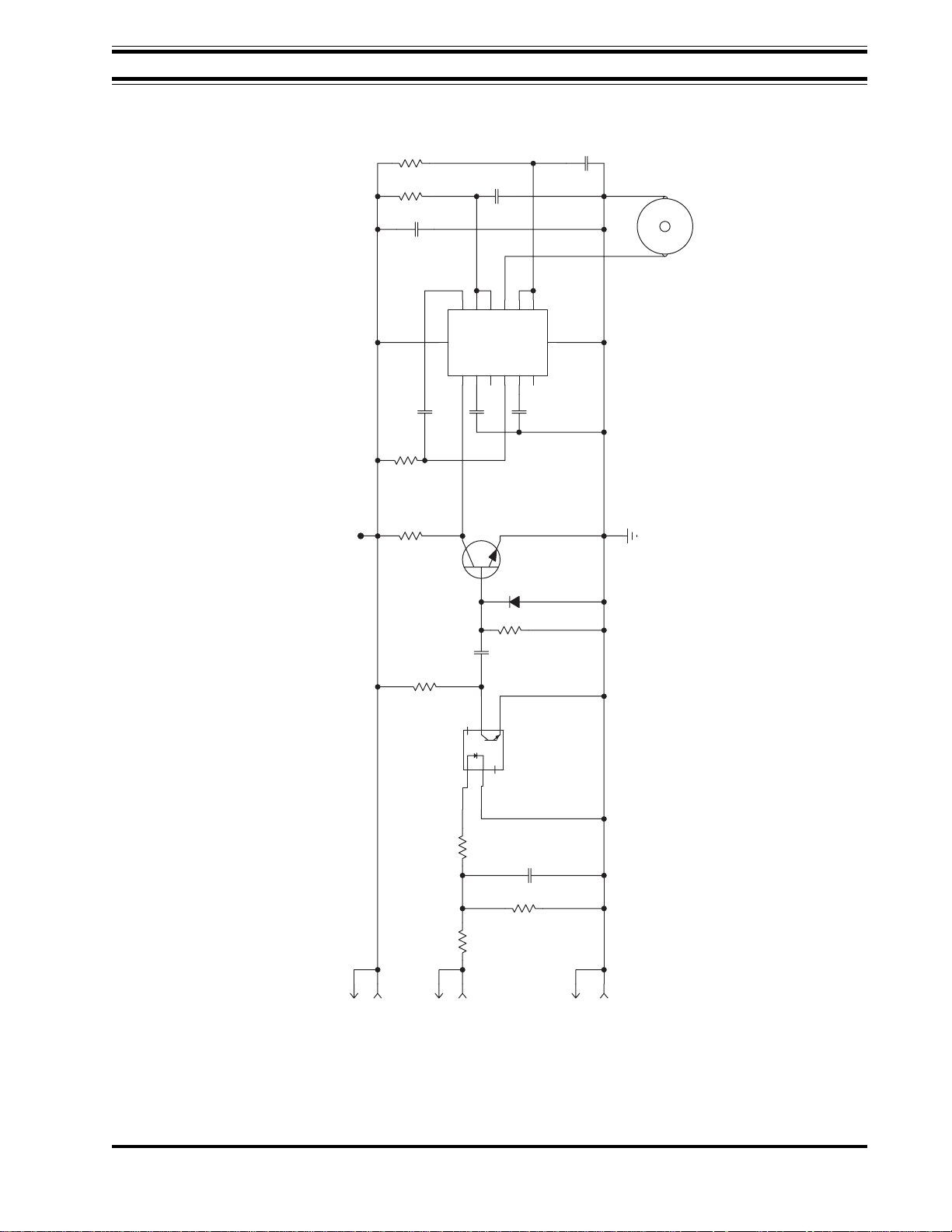

The following schematics are included for servicing AFP Mini Medical Series X-Ray

film processors.

Figure 5-1 AC Interconnect Diagram

Figure 5-2 Dryer Rack Wiring Diagram

Figure 5-3 AC Interface Board

Figure 5-4 AC Interface Board Schematic

Figure 5-5 Logic Board Schematic

Figure 5-6 Logic Board Layout

Figure 5-7 Ready Tone Generator Schematic

Mini Med Series

5-2

0000061122

Page 69

Troubleshooting

Processor Problems

Symptom Probable Cause Remedy

Service

1. Developing time not

constant.

2. Solution temperature

too high.

3. Solution temperature

too low.

A. Excessive load on drive motor.

B. Solution levels low.

A. Temperature control setting

moved.

B. Shorted heater triac.

C. Defective temperature sensor.

(Open)

D. Logic failure.

A. Heater failed.

B. Heater triac failed. (Open)

C. Temperature control setting

moved.

D. Shorted temperature sensor.

E. Logic failure.

A. Check that racks are

seated and turn freely.

B. Add chemicals as

required.

A. Restore correct setting.

B. Replace heater triac.

C. Replace temperature

sensor.

D. Replace logic board.

A. Replace heater.

B. Replace heater triac.

C. Restore correct setting.

D. Replace sensor.

E. Replace logic board.

4. Dryer temperature

too low.

5. Dryer temperature

too high.

6. Film jams.

0000061122

A. Failed heating element.

B. Open overtemp switch on

dryer.

C. Shorted temperature sensor.

A. Open temperature sensor.

B. Blower failure.

C. Logic failure.

A. Fi lm not fe d in squarely.

B. Improper fixing, fixer too old,

pH too high, or improperly

mixed fixer or fixer replenisher.

5-3

A. Replace element.

B. Will reset when cool.

Inspect for cause ; fan not

running, dirt build-up, etc.

C. Replace sensor

A. Replace sensor.

B. Replace blower.

C. Replace logic board.

A. Feed film in carefully,

leading edge parallel to

rollers.

B. Check pH. If pH is above

5.0, dump and mix fresh.

Follow the mfg's

instructions exactly.

Mini Med Series

Page 70

Service

Troubleshooting

Processor Problems,

Continued

Symptom Probable Cause Remedy

7. Films overlap or

become skewed

during transport.

8. Film is tacky, wet or

curled when leaving

dryer.

9. Dirt particles on film.

A. Bound rollers.

B. Rack end plate bearings worn.

C. Missing rack springs.

A. Improper fixing.

B. Dryer temperature too low.

A. Foreign particles in dryer or on

squeegee rollers.

B. Algae deposits on film.

C. Foreign particles on squeegee

A. Clean each roller;

check for causes of

binding.

B. Replace bearings.

C. Replace springs.

A. See 5B.

B. Check dryer for

proper operation.

A. Run several outdated

sheets of unexposed

film.

B. Clean wash tanks &

racks with nylon

scrub brush and

warm water. Drain

wash tank each

night.

C. Clean squeegee

roller(s).

10. Scratches on film

emulsion.

Mini Med Series

A. Dirt on feed rollers

B. Chemicals crystallized on

underside of top film guides.

C. Dirt or silver accumulation on

rollers.

D. Roller in rack not turning.

E. Dirty feed tray surface.

5-4

A. Clean feed rollers.

B. Clean film guides.

C. Clean rollers using a

nylon scrub pad and

warm water, or

developer systems

cleaner for developer

racks/fixer systems

cleaner for fix racks.

D. Check all rollers for

operation; repair as

required.

E. Clean feed tray.

0000061122

Page 71

Troubleshooting

Processor Problems,

Continued

Symptom Probable Cause Remedy

Service

11. Increase in image

12. Decrease in image

density.

A. Film is over exposed.

B. Developer temperature too high.

C. Excessive developing time due

to mechanical binding.

D. New developer improperly mixed.

.

A. Film is under exposed.

B. Developer under replenished

or exha usted.

C. Developer temperature too low.

D . Developer time too short.

E. New developer improperly

mixed.

A. Coordinate exposure

with developing time.

B. Have service technician

troubleshoot developer

temperature.

C. See symptom 1.

D. Dump and mix fresh,

following mfg's

instructions exactly.

A. Coordinate exposure

B. Change developer.

Check replenishment

rates.

C. See Symptom 3.

D. Check developer for

low level.

E. Dump developer and

mix fresh.

13. Over replenishing.

14. No functions

0000061122

A. Shorted film presence switch.

B. Shorted manual replenishment

switch.

C. Pendulum magnet weak or

stuck in the up position.

D. Logic failure

A. Interupter switch not activated.

B. Interupter switch defective.

A. Replace switch.

B. Replace switch.

C. Clean or replace

pendulum.

D. Replace logic board.

A. Put top cover in place.

B. Replace switch.

Note: The interupter switch may be bypassed for troubleshooting purposes only by

either utilizing the hold down tool (P/N 0000021801) to keep the switch activated.

Jumping the pins on J-14 on the logic board is an alternate method.

5-5

Mini Med Series

Page 72

Service

Service Procedure 5-1

Inspecting, Adjusting & Changing

the Main Drive Belt

The main drive belt requires only minimal maintenance and normally lasts many years

with normal use.

Inspection

The belt should be inspected yearly. Replacement is indicated if any of the following

conditions are found:

1) Excessive slack that cannot be corrected.

2) Frayed or badly worn edges.

3) Missing or damaged drive lugs on the belt surface.

Adjustment

CAUTION: Overtightening the belt will cause the belt to jump on the wormshaft

pulley and will cause the saddle bearing nearest the pulley to become excessively

hot.