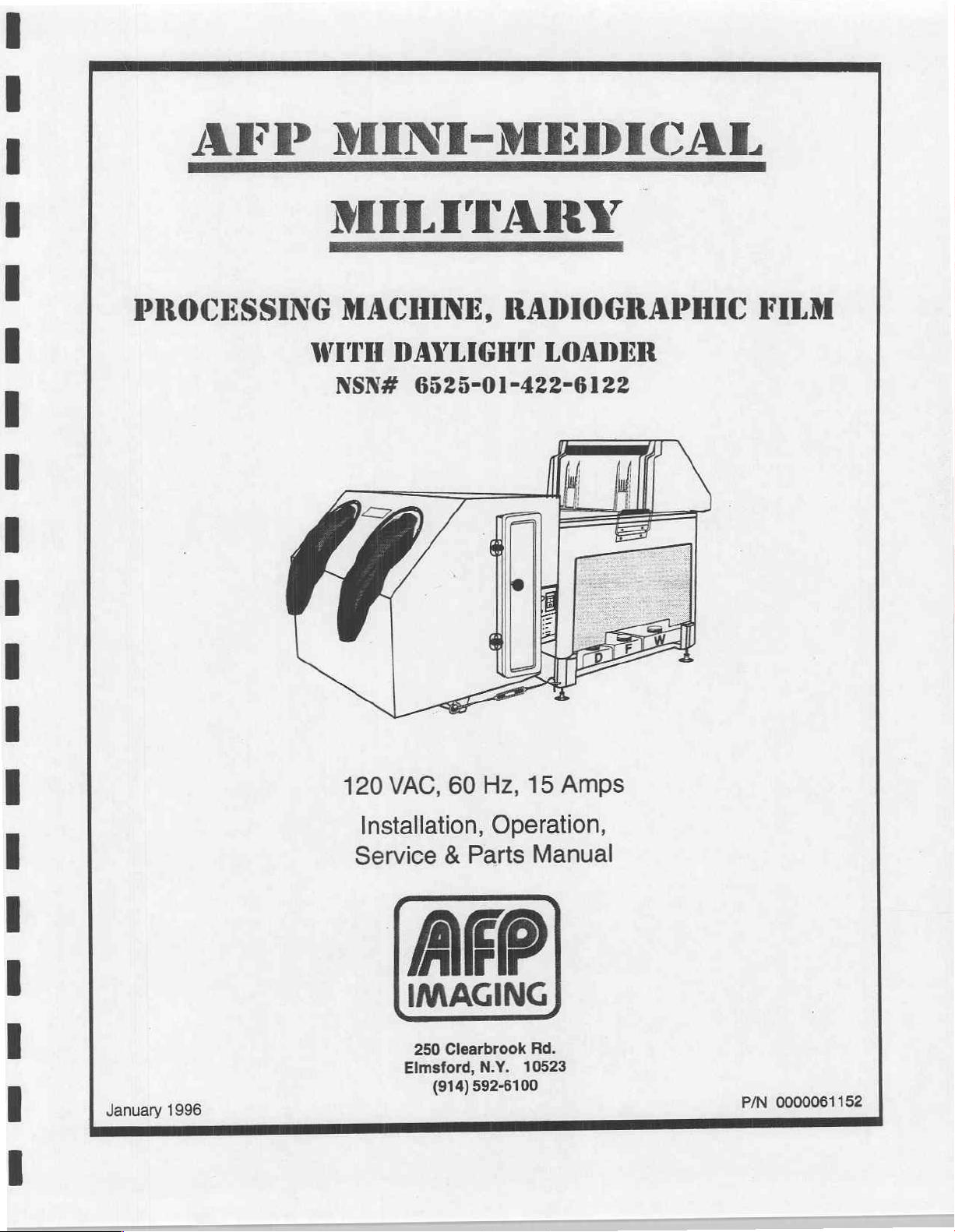

Page 1

AFP

PROCESSING

MINI-MEDICAL

MILITARY

MACHINE,

WITH

NSN#

DAYLIGHT

6525-01-422-6122

RADIOGRAPHIC

LOADER

FILM

January

1996

120

VAC,

Installation,

Service & Parts

60

Hz,

Operation,

IMAGING

250

Clearbrook

Elmsford,

(914)

N.Y.

592-6100

15

Amps

Manual

Rd.

10523

0000061152

P/N

Page 2

IMAGING

AFP

IMAGING

workmanship

within

product

the

remainder

this

warranty

components

prepay

reasonable

parts

including,

been

repaired

not

to

be

removed.

CORPORATION

and

material

30

days

of

installation,

or

component

of

the

period

which

all

transportation

service

but

or

altered

unreasonably

This

warranty

=

=

-

Instability

and

Lack

recommended

Changes

sensitized

for

of

equipment

original

is

expressly

it

finds

defective.

costs

and

labor

not

limited

with

withheld,

also

of

replenishing

of

applied

in

materials

warrants

12

months

date

of

period

or

limited

and

return

charges

to

lamps,

parts

or

or

(3)

shall

NOT

sensitized

rates

adequate

by

the

characteristics

to

of

normal

shipment

is

replaced

ninety

to

repair

Upon

authorization

the

incident

photocells,

by

persons

to

any

APPLY

materials

of

chemical

quality

sensitized

or

or

chemicals

days

equipment

to

product

WARRANTY

the

original

usage,

from

AFP

by

AFP

from

or,

in

any

warranty

or

not

approved

on

to

any

or

chemical

and

production

material

process

after

purchaser

from

the

warehouse

under

this

the

date

of

its

discretion,

from

AFP,

to

a

location

claim.

consumable

in

writing

which

the

AFP

product

concentrations

wash

water

control

and

chemical

procedures

delivery

of

that

each

new

AFP

date

of

installation.

will

be

used

to

warranty,

installation,

replacement

a

This

supplies

serial

whose

immersions

made

the

such

proper

party

specified

warranty

(2)

by

AFP,

number

unsatisfactory

procedures

suppliers;

by

suppliers

AFP

product

item

whichever

of

by

AFP.

to

provided,

or

or

product

Tf

begin

is

is

no

warranty

warranty

covered

is

longer.

free

by

non-expendable

asserting

does

any

sequences;

as

That

NOT

AFP

name

has

performance

a

claim

party

APPLY

product

however,

been

of

to

the

purchaser;

from

defects

card

is

period.

this

same

AFP’s

obligation

original

under

this

shall

also

(1)

to

or

component

that

such

altered,

or

condition

in

returned

In

the

to

event

warranty

during

equipment

warranty

bear

all

any

expendable

which

approval

defaced,

or

is

due

AFP

any

for

or

shall

has

is

to:

-

-

-

=

THE

IMPLIED

AND

WARRANTIES

WARRANTIES,

AREEXCLUDED

THE

PROVISIONS

THE

EXCLUSIVE

AGES

(WHETHER

LABOR,

TIME,

CONSEQUENTIAL

THIS

PRODUCT.

SOLONG

THIS

AND

AS

WRITING

REMEDY

STATEMENT

SUCH

STATEMENTS

Lack

of

Failure

to

recommended

Unusual

Accident,

humidity

for

which

ABOVE

EXPRESS

THERE

ARE

OF

MERCHANTABILITY

EXPRESSED

AND

SHALL

FOR

REPAIR

AND

SOLEREMEDY

IN

TORT,

MATERIALS,

DAMAGES

THIS

EXCLUSIVE

AFP

IS

WILLING

CONSTITUTES

AS

AGREED

MADE

BY

ANY

ARE

sufficient

follow

physical

neglect,

control,

for

the

product

the

or

volume

AFP

electrical

misuse,

transportation

LIMITED

NO

WARRANTIES

OR

IMPLIED,

NOT APPLY

OR

REPLACEMENT

DUE

TO

NEGLIGENCE

CUSTOMER

IN

CONNECTION

REMEDY

AND

ABLE

THE

FINAL

TO

BY

THE PARTIES

REPRESENTATIVE

SUPERSEDED

of

sensitized

maintenance,

product

operation;

stress;

failure

of

or

was

intended;

WARRANTY

BEYOND

AND

FITNESS

OR

INFERABLE

TO

THIS

OF

THE

PURCHASER.

PROFITS,

WITH

SHALL

TO

REPAIR

COMPLETE

TO

WHICH

BY

THIS

DOCUMENT.

materials

venting,

electric

causes

IS

IN

THOSE

for

or

safety

power,

other

than

LIEU

economical

procedures

air

conditioning,

ordinary

OF

ALL

OTHER

STATED

IN

FOR A PARTICULAR PURPOSE

FROM

THE

COURSE

PRODUCT.

OF

DEFECTIVE

OR

OTHERWISE)

GOODWILL,

THE

FURNISHING,

NOT

BE

OR

REPLACE

AND

THIS

SALE.

DIFFERS

PARTS

AFP

SHALL

INCLUDING

OR

ANY

DEEMED

DEFECTIVE

EXCLUSIVE

AFP

NEITHER

FROM

PROVIDED

NOT

OTHER

OPERATION

TO

HAVE

EXPRESSION

THE TERMS

AFP

use

in

WARRANTIES,

THIS

DOCUMENT.

OF

DEALING

BELIABLEFOR

BUT

INDIRECT,

FAILED

PARTS

AUTHORIZES

product

the

purposes

AND

IN

THIS

NOT

LIMITED

OR

FAULTY

OF

IN

THE

OF

THE

OF

THIS

operation;

EXPRESSED

THE

IMPLIED

ALL

OTHER

OR

USAGE

WARRANTY

ANY

OTHER

TO,

SPECIAL,

INCIDENTAL

PERFORMANCE

ITS

ESSENTIAL

PRESCRIBED

TERMS

NOR

ADOPTS ANY

WRITING

OF

TRADE,

SHALL

LOSS

PURPOSE

MANNER,

OF

WARRANTY

AND

OR

BE

DAM-

OF

OR

OF

ALL

AFP

IMAGING

CORP.

250

Clearbrook

Road,

Elmsford,

N.Y.

10523

Page 3

Warranty

Information

Section 1 -

AFP

Mini-Medical

X-Ray

Table

Introduction

Figure

with

Content

Description

Operation

Capabilities

Transport

Figure

Developer

Fixer

Developer & Fixer

Anti-Crystallization

Wash

Dryer

Cover

General

Specifications

1-1,

Daylight

1-2,

System

System

System

Interlock

Film

115VAC

Of

Contents

AFP

Mini-Medical

Loader, Storage

System

Transport

System

System

Replenishment

Switch

Military

Processor

X-Ray

and

Film

Transport

Processor

case

#1

1-1

1-2

1-2

1-2

1-2

1-2

1-3

1-4

1-4

1-5

1-5

1-5

1-5

1-5

1-6.

Section 2 -

Installation

Unpacking & Setup

Unpacking & Setup

Introduction

Pre-Installation

Figure

Location

Dimensions

Weight

Ventilation

Electrical

Plumbing

Installation

Set

Figure

Set

2-1,

Up

Unpack

Position

2-2,

Up

(Cont'd)

Instructions

Instructions

Processor & Stand

Processor

Packing

for

for

Crates

Transport

Transport

I

Case

Case

Dimensions

#1

#2

EDR

DD DE

D D

©

©

D

AMIN:

D

D

ň

©

DA

è

iù

pep

Mini

Medical

Military

Page 4

Index

Section 2 -

Set

Set

Replenish

Batch

Processor

Test

Transporting

Final

Processor

Operational

Notes

Installation

Processor

Figure

Figure

Figure

Up

(Cont'd)

Daylight

Figure

Up

(Cont'd)

Figure

Daylight

Replenishment

2-3,

2-4,

2-5,

2-6,

2-7,

(Cont'd)

Assembly

Placing

Dryer

Film

Loader

Mounting

Mounting

Loader

Mode

Figure

Mode

Figure

Checkout

Cleaning

Figure

Figure

2-8,

“Replenish”

2-9,

"Batch"

Inspection

Film

With

Before

Water

Before

Set

Up

Checklist

2-10,

Set

Test

Checklist

2-11,

Operational

Operation

Processor

Power

Storage

Assembly

Daylight

Film

Set

Up

Mode

Adding

in

Tanks

Up

Checklist

onto

Packing

Receptacle

Box

and

Cover

Loader

Storage

Mode

Box

Operation

Operation

Chemicals

as a Processor

Checklist

to

Case

#1

2-6

2-6

2-7

2-7

2-7

2-7

2-8

2-8

2-9

2-9

2-10

2-10

2-11

2-11

2-12

2-13

2-14

2-14

2-15

2-15

2-16

2-16

2-17

Section 3 -

Medical

Mini

Military

Operation

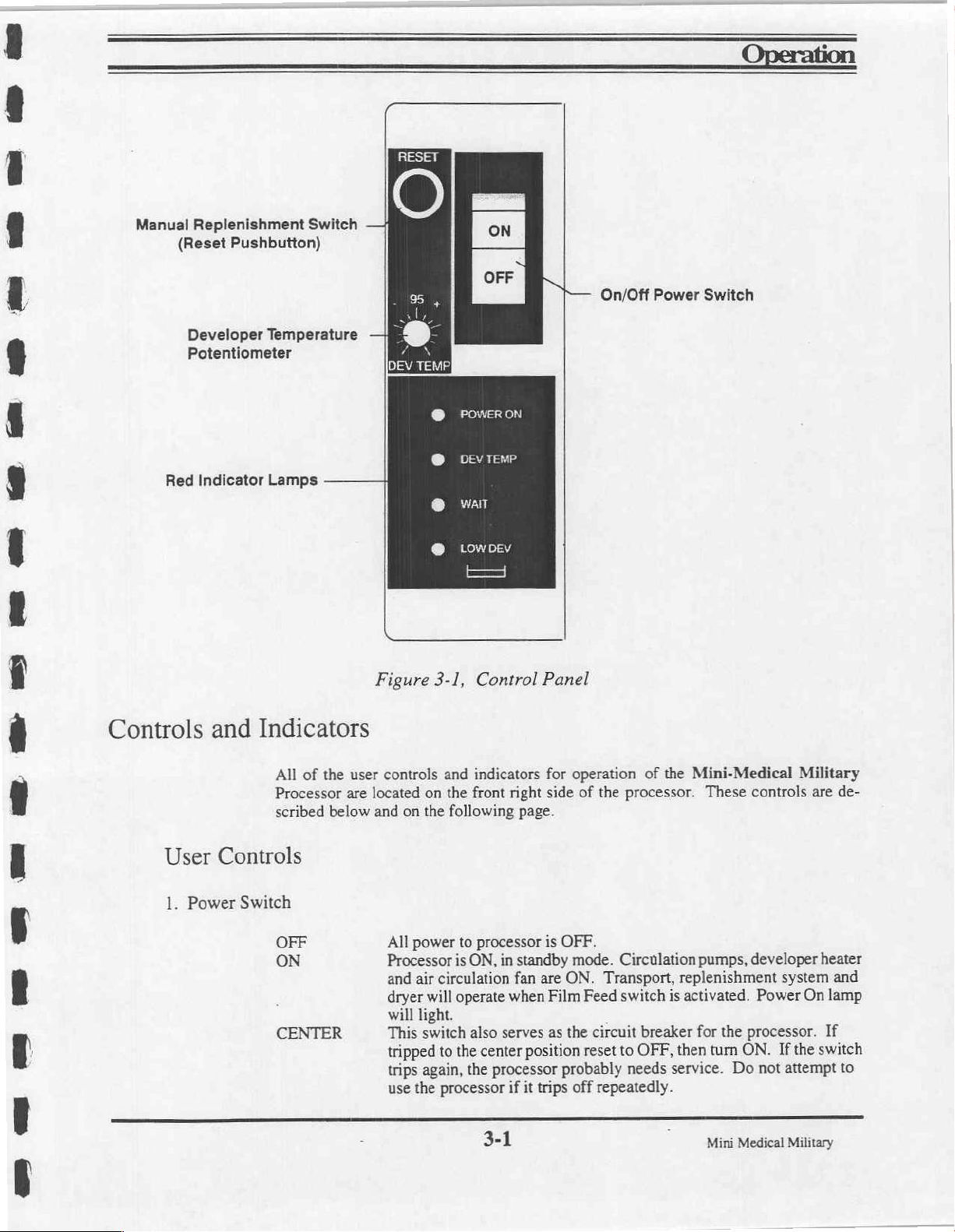

Figure

Controls

Loading

Daily

Processing

and

Indicators

User

Controls

Chemicals

Up

Start

Processor

Check

Check

Film

Daylight

3-1,

Control

Power

Manual

Power

Dev

Wait

Low

Drain

Switch

Replenishment

ON/OFF

Temp

Lamp

Dev

Valves

Overflow

Top

Cover

Fill

ON,

Developer

Drive

Loader

Operation

Panel

Lamp

(3)

Lines

Interlock

Tank

Wash

and

Fixer

II

Switch

Levels

3-

3-

3-1..

3-

3-2

3-2

3-2

3-2

3-2

3-2

3-2

3-2

3-3

3-4

3-4

3-4

3-4

3-5

3-5

Page 5

Section 3 -

Section 4 -

Operation

Shutdown

Quality Control

Checklists

(Cont'd)

and

Daily

Cleaning

Drain

Wash

Clean

Top

Cover,

Wipe

Off

Processor

Developer

Fixer

Replenishment

Manual

Replenishment

Automatic

for

Daily

Use

Startup

Tank

Guides & Rollers

Pushbutton

Operation

Shutdown

and

Daily

Cleaning

Maintenance / Storage

Maintenance

Maintenance

Cleaning

Mini-Medical

Mini-Medical

Weekly

Monthly

Annual

Special

Long

Term

Removing

Lubrication

Program

Records

Processor

Daily

Weekly

Monthly

Yearly

Figure

Or After

4-1,

Processor

Figure

Cleaning

4-2,

Cleaning

Maintenance

Maintenance

Storage & Inspection

Old

Lubricants

Points

Figure

4-3,

Maintenance

Long

Maintenance

Maintenance

Maintenance

or

Before

or

After

Notes

Lubrication

Term

Transport

90

and

(Reset

Switch)

Schedule

Storage

Schedule

Log

Log

or

Storage

Day

Plus

Storage

Information

Points

for

Periods

ひひ

WW WW

ひひ

ココ

ココ

コ

WWW WWW

WW

PEW

oooooeoeo

==

5

1

D

D

PREPRESS

D

卡

D

不

D

D

下

下

&

卡

d

下

i

下

O

aga

ser

4-7

IN

Mini

Medical Military

Page 6

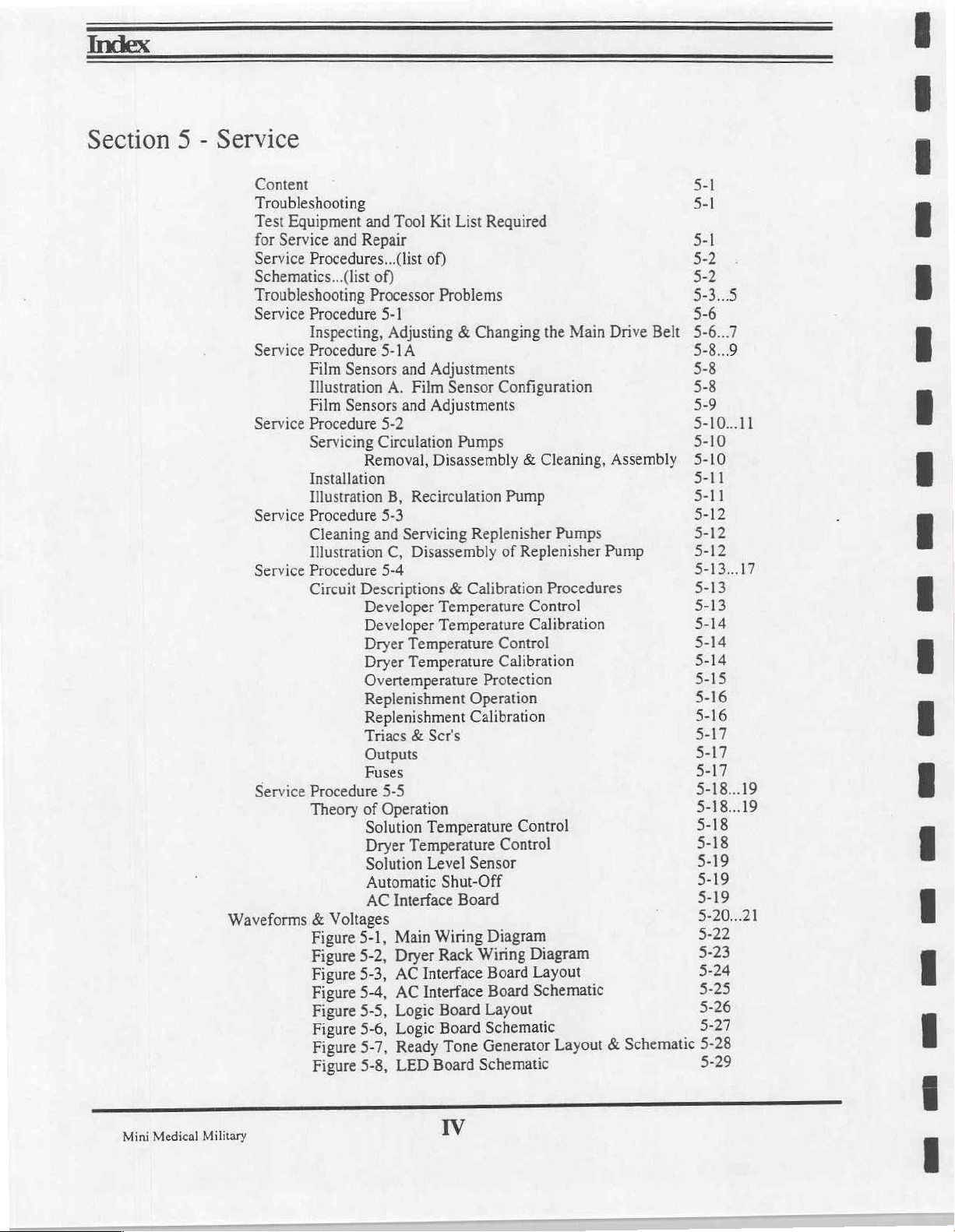

Section 5 -

Service

Content

Troubleshooting

Test

Equipment

for

Service

Service

Schematics...(list

Procedures.

Troubleshooting

Service

Service

Procedure

Inspecting,

Procedure

Film

Illustration

Film

Service

Procedure

Servicing

Installation

Illustration

Service

Service

Procedure

Cleaning

Illustration

Procedure

Circuit

i

Service

Procedure

Theory

Waveforms & Voltages

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

and

and

Repair

Processor

Sensors

Sensors

Removal,

Descriptions & Calibration

Developer

Developer

Dryer

Dryer

Overtemperature

Replenishment

Replenishment

Triacs & Scr's

Outputs

Fuses

of

Solution

Dryer

Solution

Automatic

AC

5-1,

5-2,

5-3,

5-4,

5-5,

5-6,

5-7,

5-8,

Tool

Kit

List

Required

(list

of)

of)

Problems

5-1

Adjusting & Changing

5-1A

and

Adjustments

A.

Film

Sensor

and

Adjustments

Configuration

5-2

Circulation

B,

Pumps

Disassembly & Cleaning,

Recirculation

Pump

5-3

and

Servicing

C,

Disassembly

Replenisher

of

5-4

Temperature

Temperature

Temperature

Temperature

Control

Calibration

Protection

Operation

Calibration

5-5

Operation

Temperature

Temperature

Level

Shut-Off

Interface

Main

Wiring

Dryer

Rack

AC

Interface

AC

Interface

Logic

Board

Logic

Board

Tone

Ready

Board

LED

Control

Sensor

Board

Diagram

Wiring

Board

Board

Layout

Schematic

Generator

Schematic

the

Main

Pumps

Replenisher

Procedures

Control

Calibration

Control

Diagram

Layout

Schematic

Layout

Drive

Belt

Assembly

Pump

Schematic

&

an

nn

qo

A

a

a

ta

da

a

SU

-O0

Ga GA

вый

A

tn

GQ

Ga

q

e

GA En

ーー

En

E)

GA

ニニ

+19

Un

0moIUaauRARUVVUUNNN-

En

ニニ

と

と

En

on

Un

と

En

こと

OOo

En

„21

En

らい

Un En

らら

や

ROBA

En

©

Un

©

En

©

SRG

GA

5-28

5-29

Mini

Medical

Military

IV

Page 7

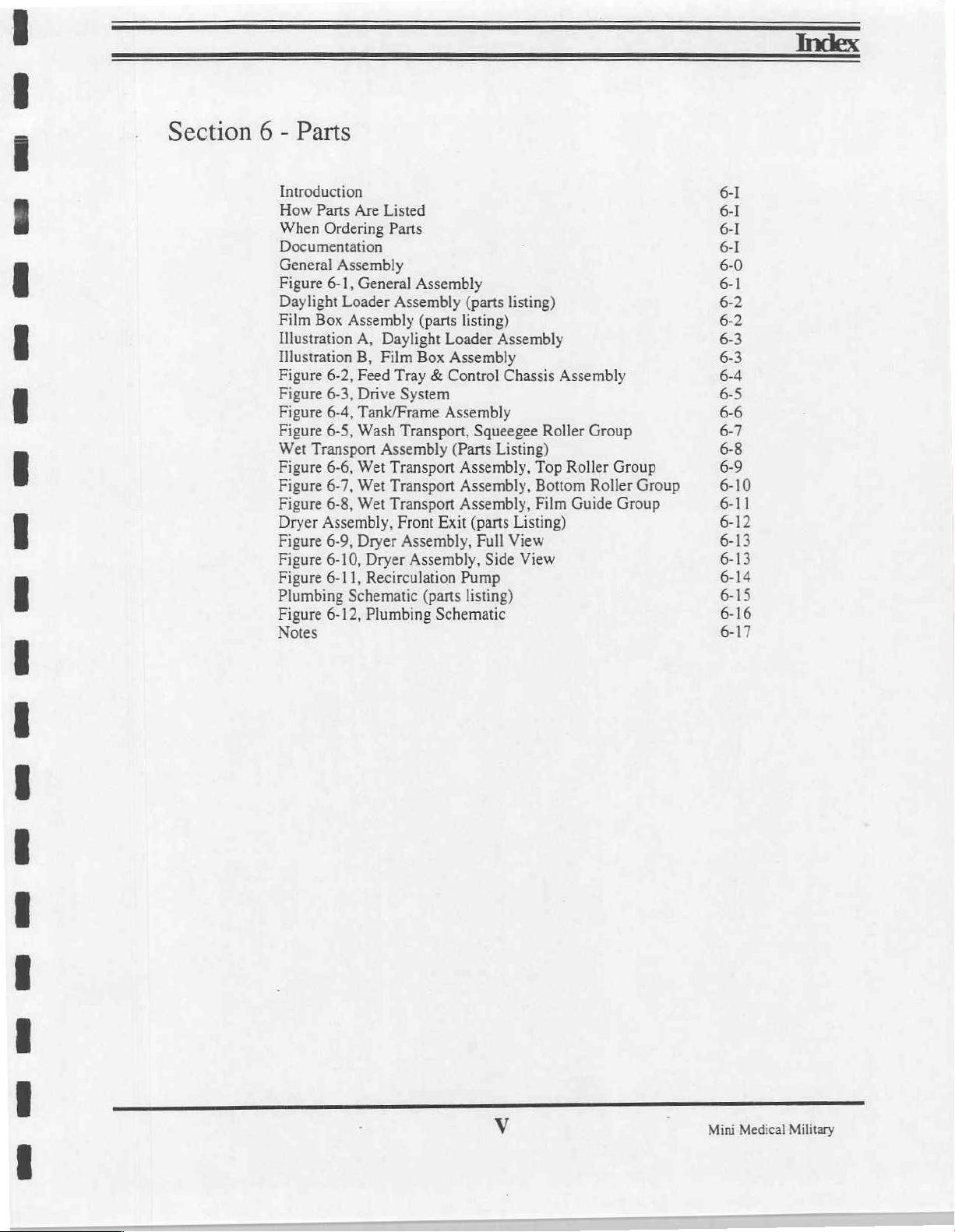

Section 6 -

Introduction

How

When

Documentation

General

Figure

Daylight

Film

Illustration

Illustration

Figure

Figure

Figure

Figure

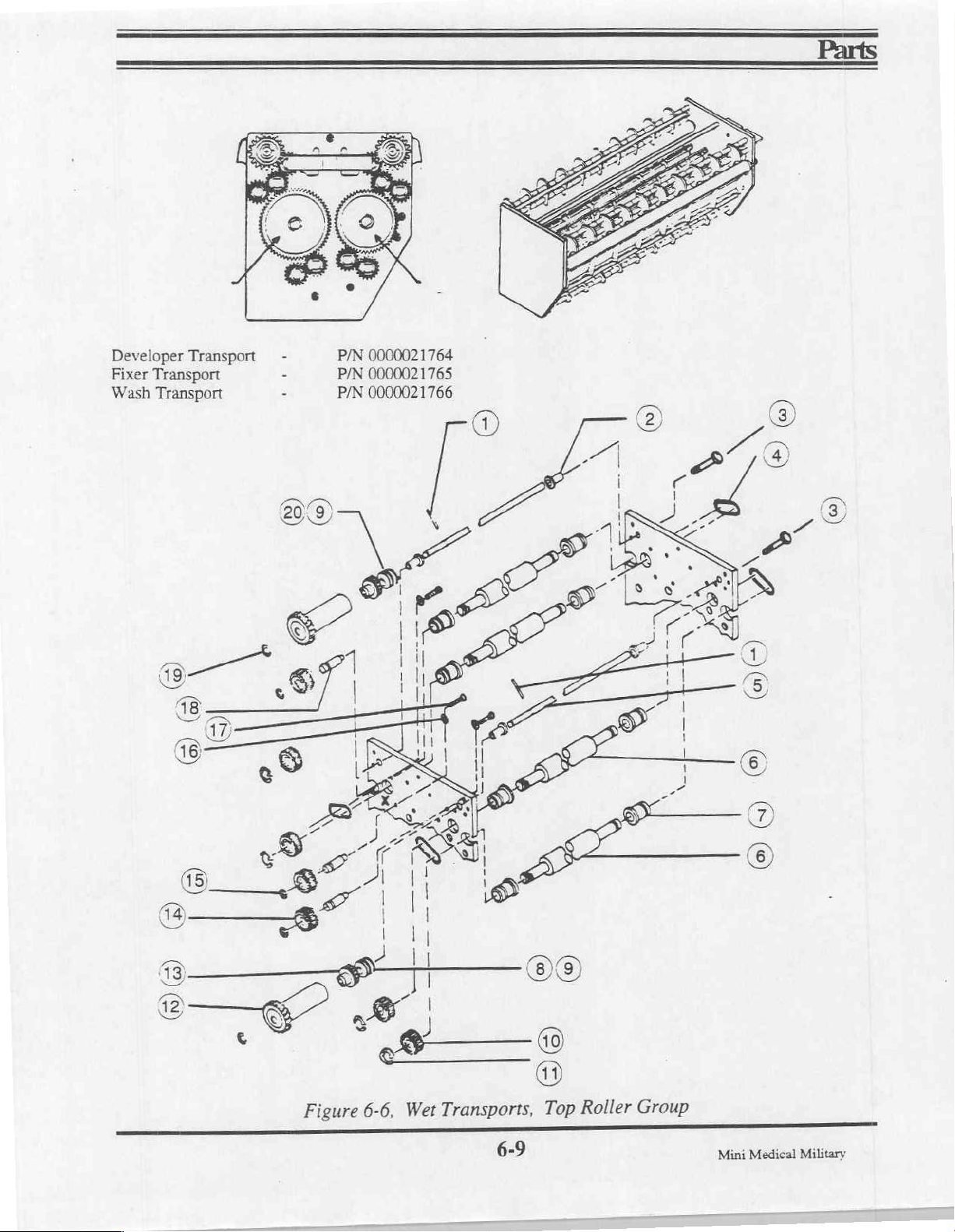

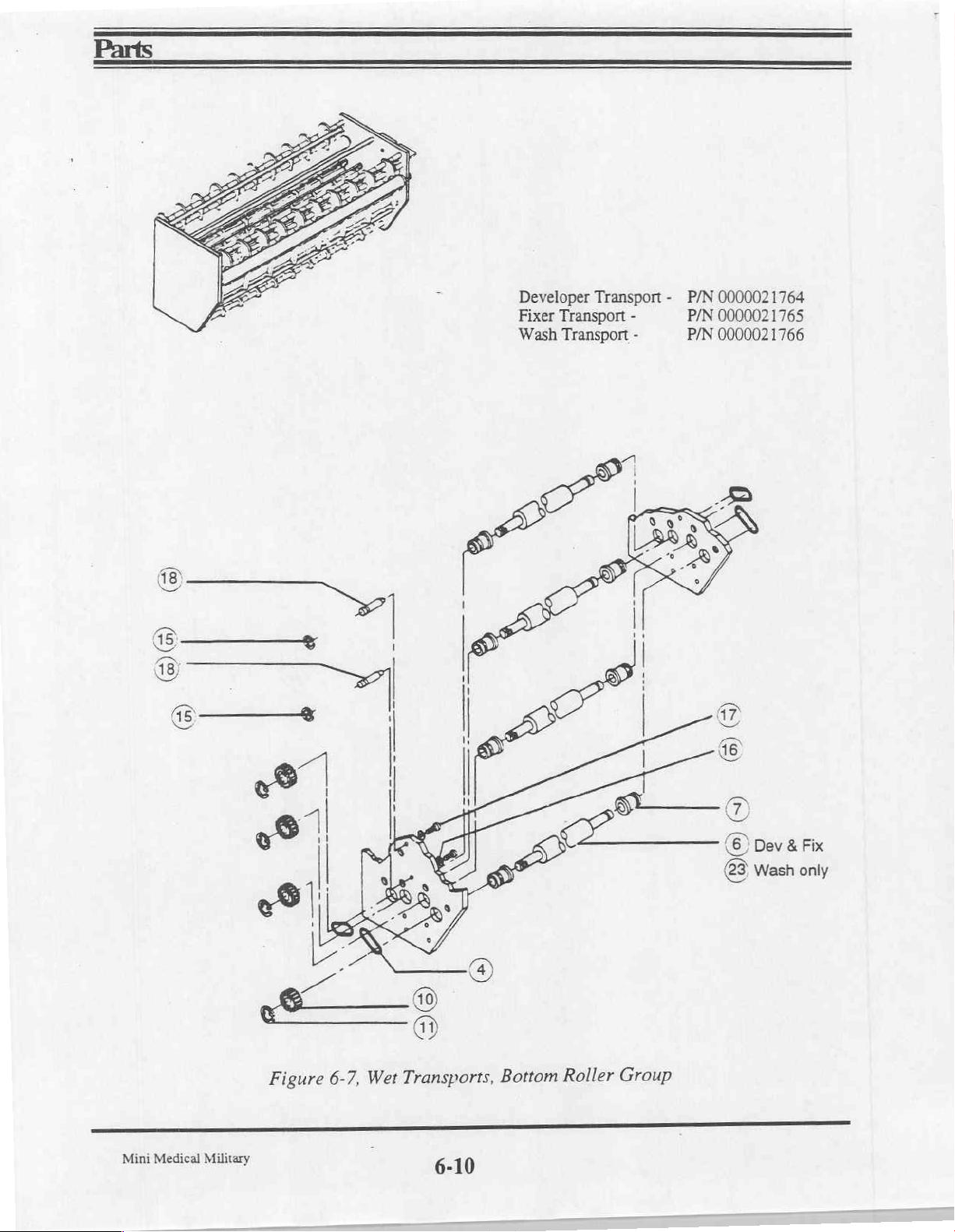

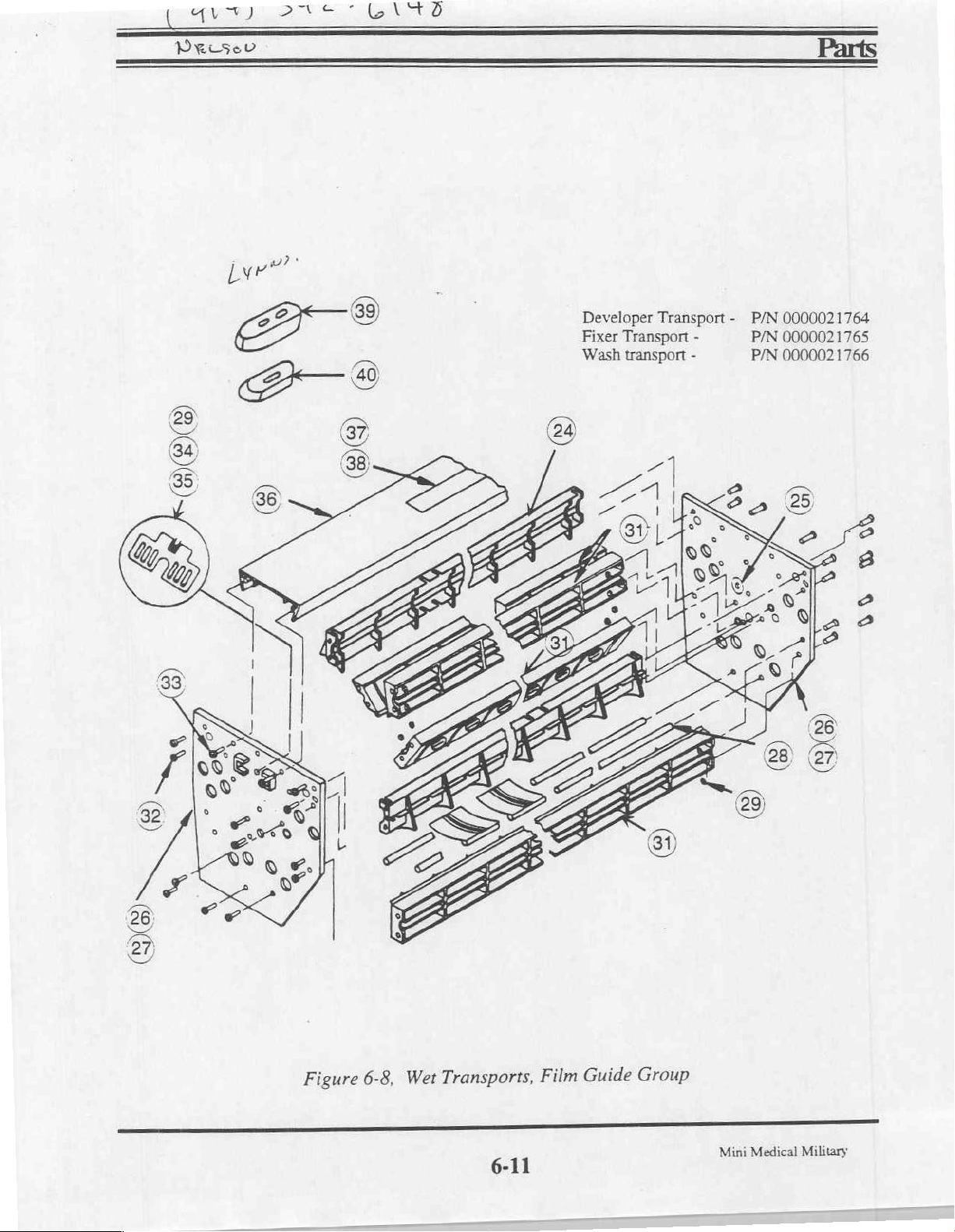

Wet

Figure

Figure

Figure

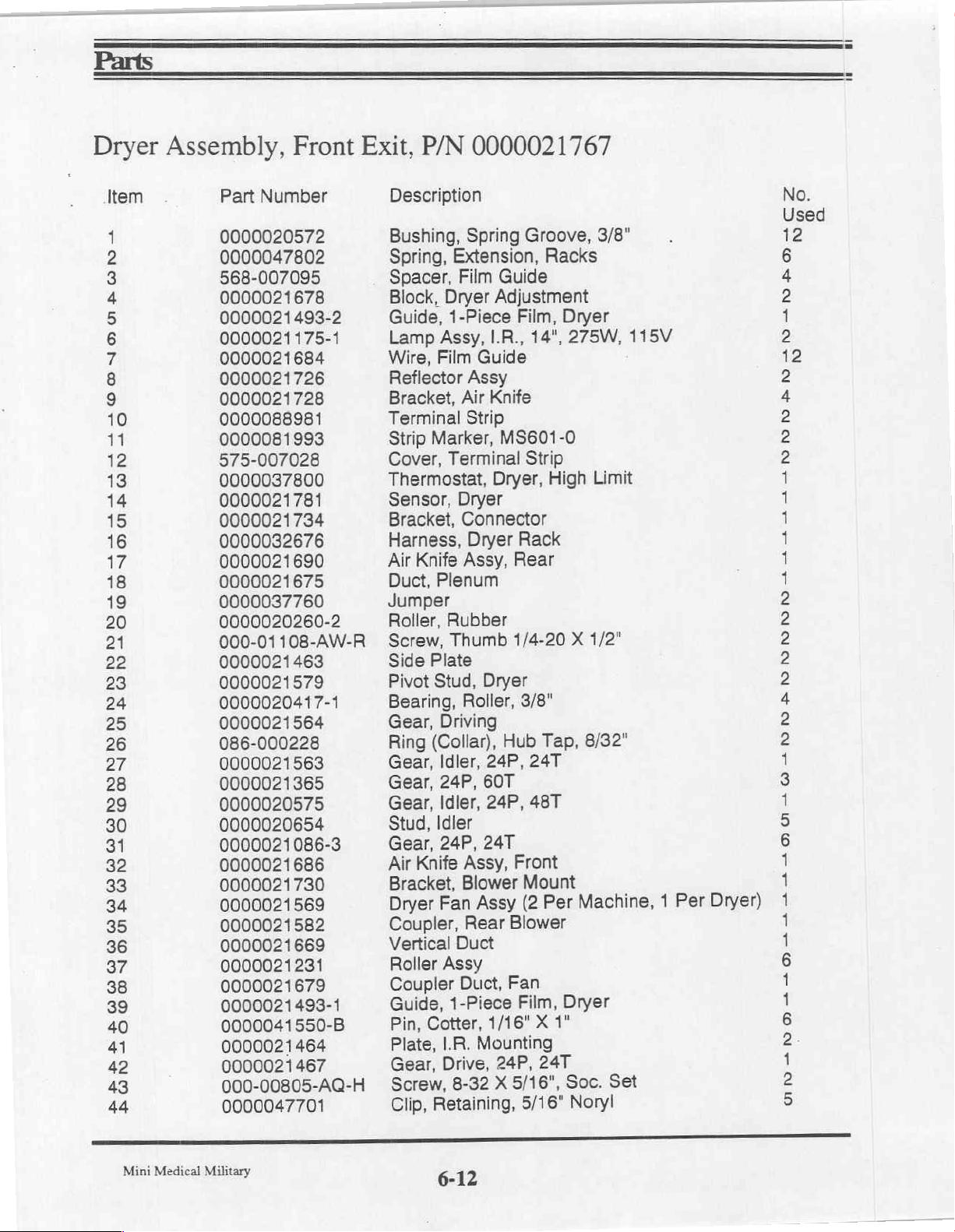

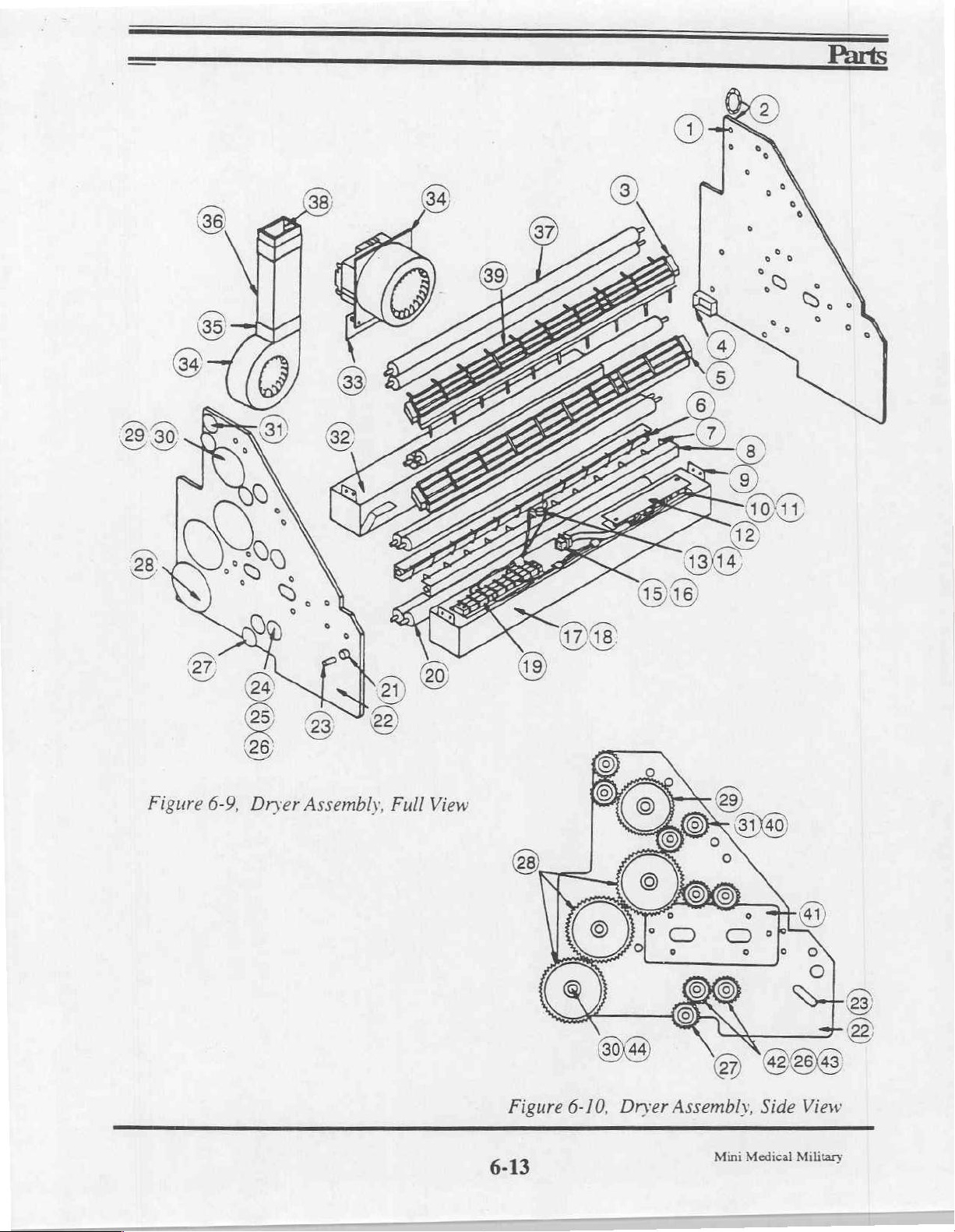

Dryer

Figure

Figure

Figure

Plumbing

Figure

Notes

Parts

Parts

Ordering

Assembly

6-1,

Loader

Box

Assembly

6-2,

6-3,

6-4,

6-5,

Transport

6-6,

6-7,

6-8,

Assembly,

6-9,

6-10,

6-11,

Schematic

6-12,

Are

Listed

Parts

General

A,

B,

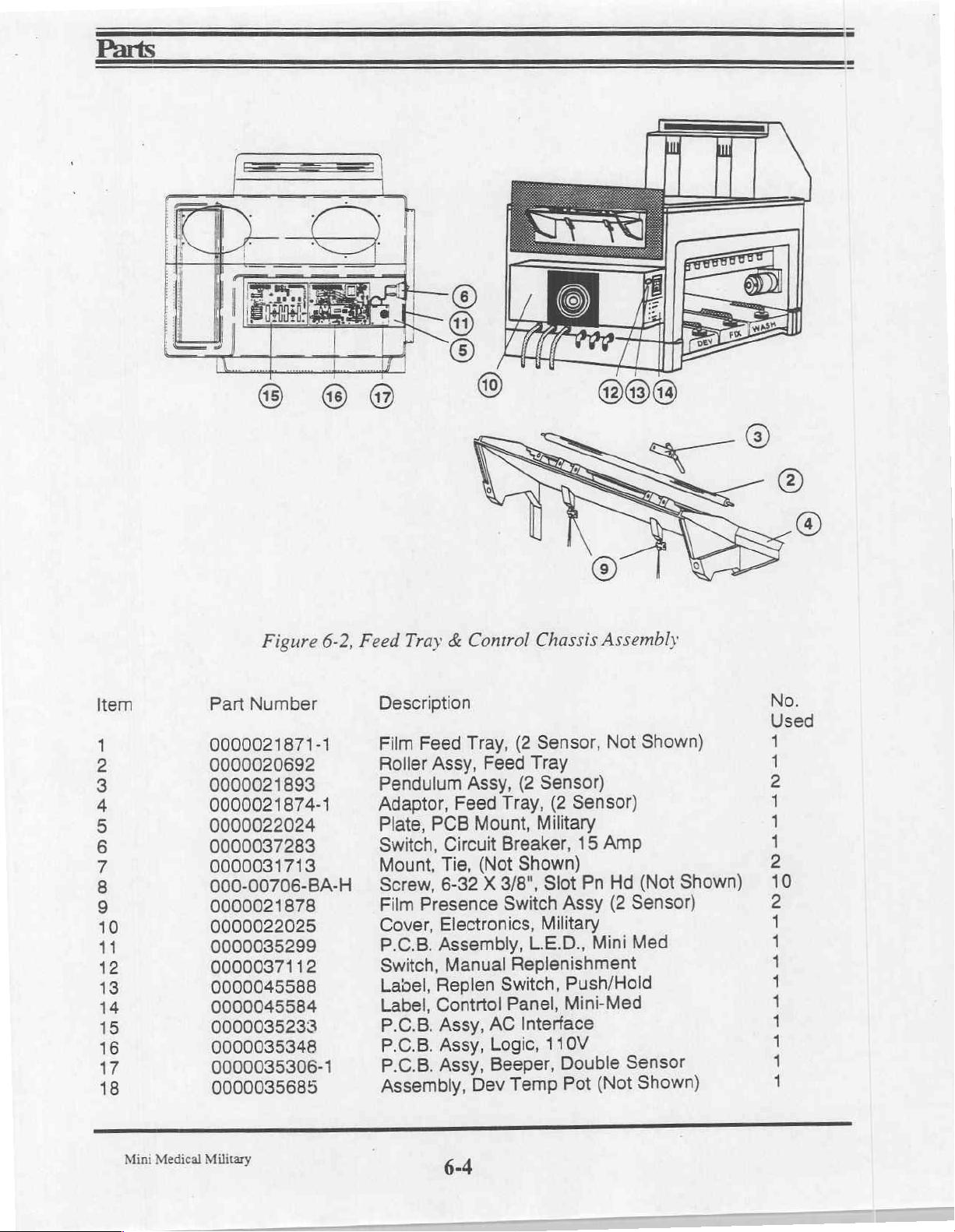

Feed Tray & Control Chassis

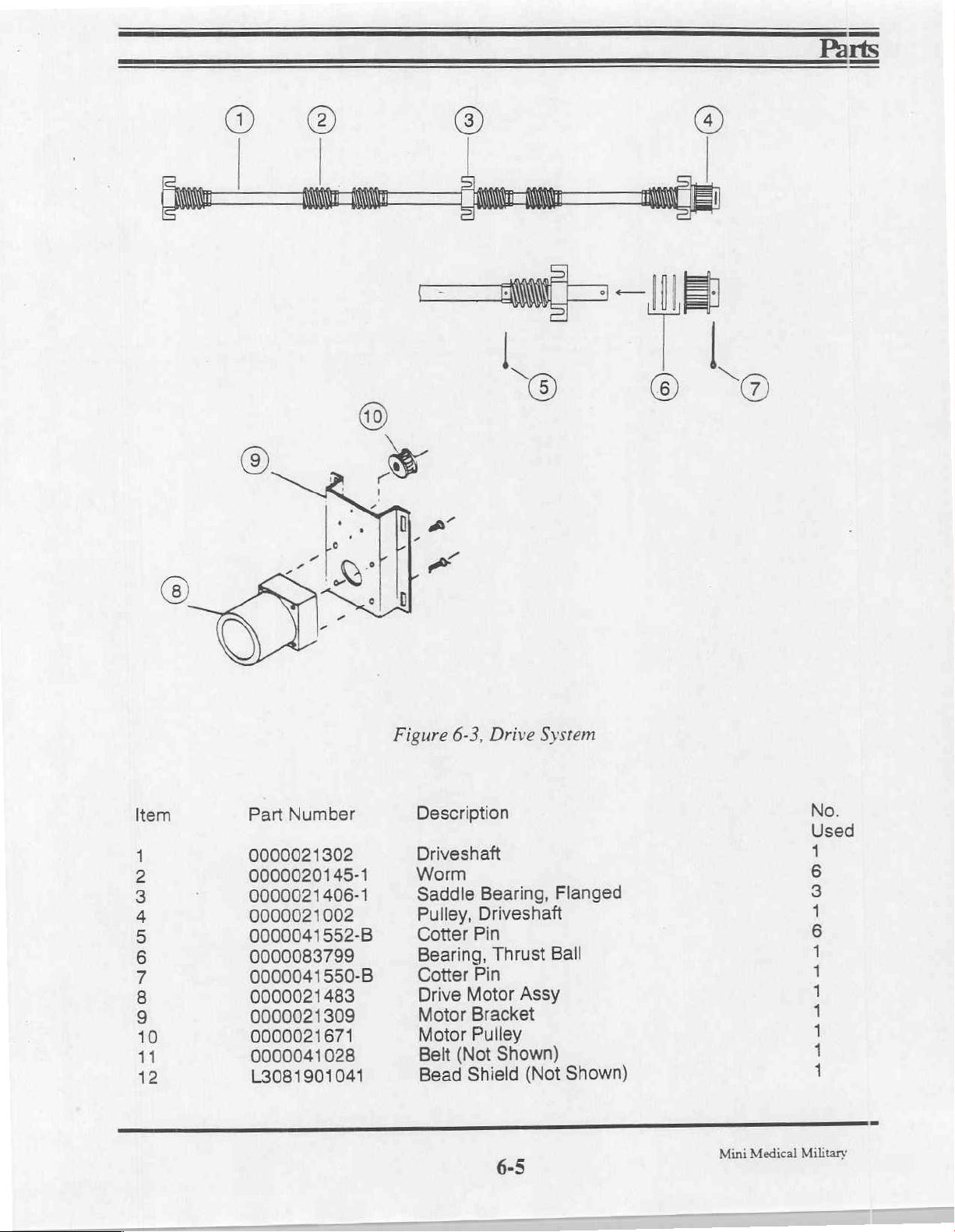

Drive

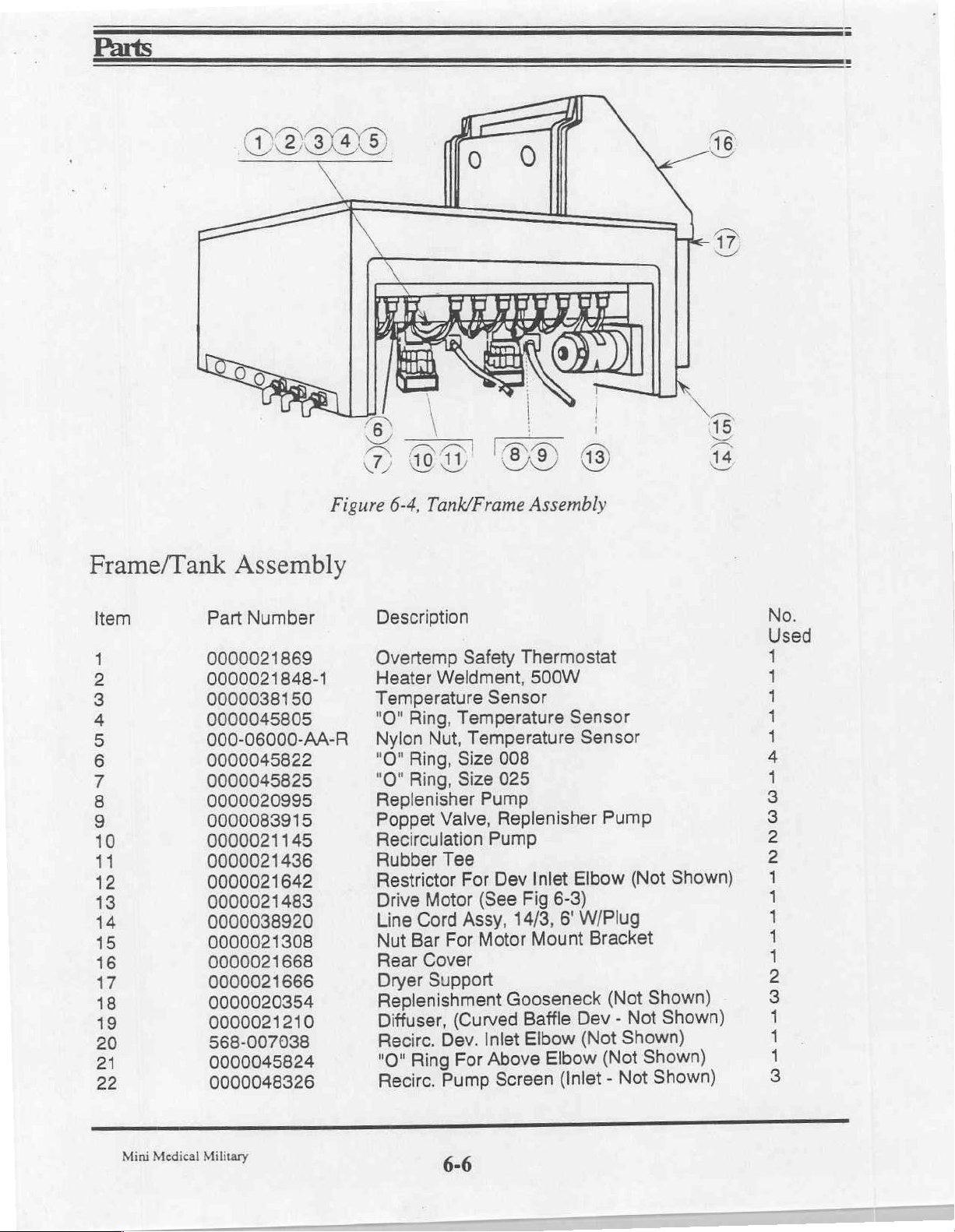

Tank/Frame

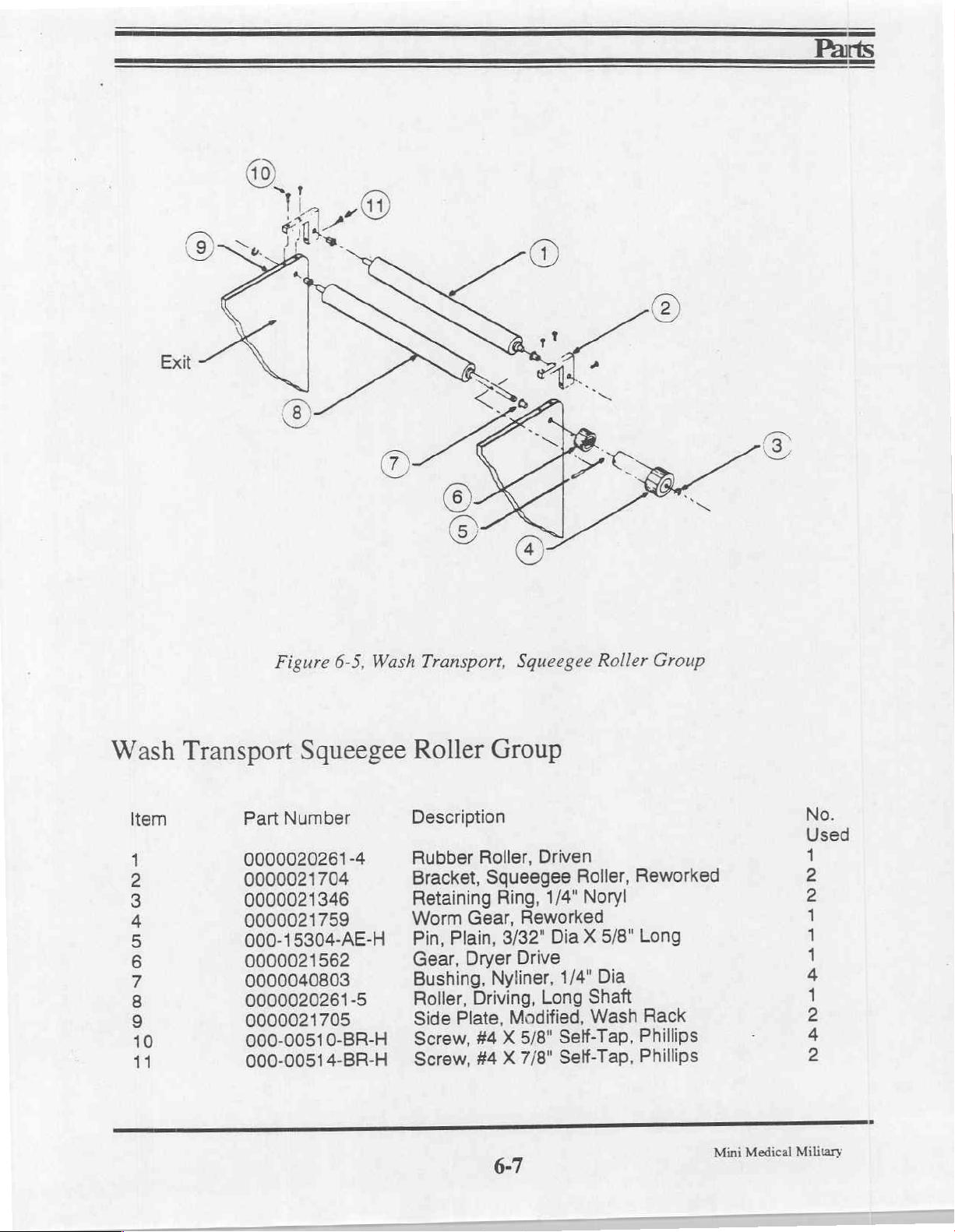

Wash

Wet

Wet

Wet

Dryer

Dryer

Recirculation

Plumbing

Assembly

Assembly

(parts

Daylight

Film

Loader

Box

System

Assembly

Transport,

Assembly

Transport

Transport

Transport

Front

Exit

Assembly,

Assembly,

(parts

Schematic

(parts

listing)

listing)

Assembly

Assembly

Squeegee

(Parts

Listing)

Assembly,

Assembly,

Assembly,

(parts

Full

View

Side

Pump

listing)

Top

Bottom

Film

Listing)

View

Assembly

Roller

Group

Roller

Guide

Group

Roller

Group

Group

の

ひひ

の

ひひ

の

の

ひひ

の

の

ひひ

ひひ

の

ひひ

の

の

の ひ

の

ひひ

の

の

ひひ

の

ひひ

ひみ

の

二

ー ら

らい

の

いよ

ひ

さぶ

Mini

Medical

Military

Page 8

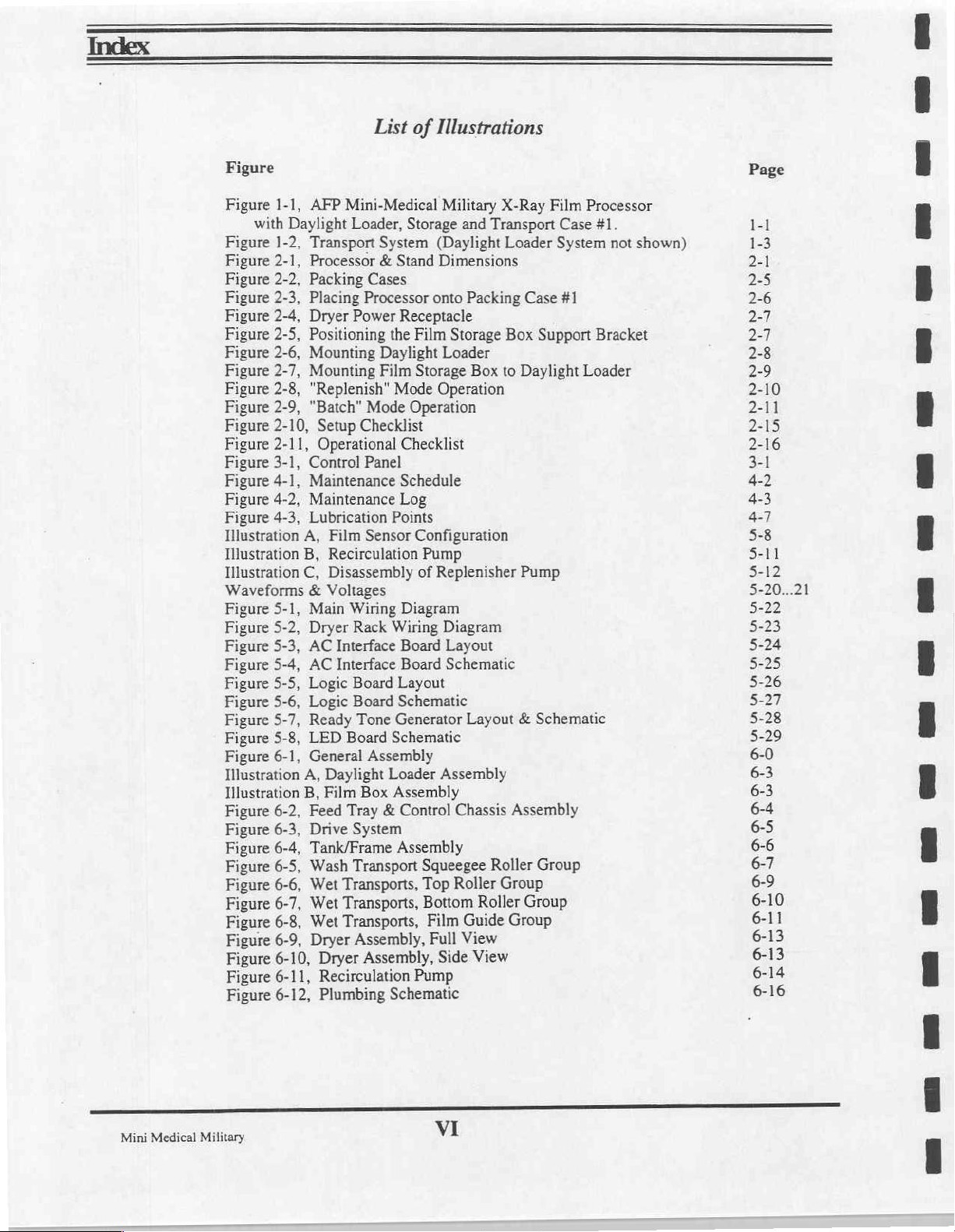

List

of

Illustrations

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Illustration

Illustration

Illustration

Waveforms & Voltages

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Illustration

Illustration

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

1-1,

with

1-2,

2-1,

2-2,

2-3,

2-4,

2-5,

2-6,

2-7,

2-8,

2-9,

2-10,

2-11,

3-1,

4-1,

4-2,

4-3,

5-1,

5-2,

5-3,

5-4,

5-5,

5-6,

5-7,

5-8,

6-1,

6-2,

6-3,

6-4,

6-5,

6-6,

6-7,

6-8,

6-9,

6-10,

6-11,

6-12,

AFP

Mini-Medical

Daylight

Loader,

Transport

System

Processor & Stand

Packing

Placing

Dryer

Cases

Processor

Power

Positioning

Mounting

Mounting

"Replenish"

"Batch"

Setup

Operational

Control

Maintenance

Daylight

Film

Mode

Checklist

Panel

Maintenance

Lubrication

A,

Film

Sensor

B,

Recirculation

C,

Disassembly

Main

Wiring

Dryer

Rack

AC

Interface

AC

Interface

Logic

Board

Logic

Board

Ready

LED

General

A,

B,

Feed

Tone

Board

Assembly

Daylight

Film

Box

Tray & Control

Drive

System

Tank/Frame

Wash

Transport

Wet

Transports,

Wet

Transports,

Wet

Transports,

Dryer

Assembly,

Dryer

Assembly,

Recirculation

Plumbing

Military

Storage

(Daylight

Dimensions

onto

Receptacle

the

Film

Storage

Loader

Storage

Mode

Operation

Operation

Checklist

Schedule

Log

Points

Configuration

Pump

of

Replenisher

Diagram

Wiring

Board

Board

Diagram

Layout

Schematic

Layout

Schematic

Generator

Schematic

Loader

Assembly

Assembly

Chassis

Assembly

Squeegee

Top

Roller

Bottom

Film

Full

View

Side

Pump

Schematic

X-Ray

and

Transport

Packing

Box

Film

Case

Loader

Box

to

System

Case

#1

Support Bracket

Daylight

Processor

Loader

Pump

Layout & Schematic

Assembly

Roller

Group

Group

Roller

Group

Guide

Group

View

#1.

not

shown)

Page

=

いこ

D =

と

D

1

ひい

D

ささ

1

6

ぷ

1

や

も

D

と

1

ここ

こと

D

ここ

uno

e

tom

BR

Un

do

On Un

re

21

Un

(D

D

En

D

Un

D

Ca

D

1

Un En

En

En

BRIRRBOSDOR—

SS

vn

©

©

©

À

h

299999

Dia

nn

Medical

Mini

Military

VI

Page 9

TO

REDUCE

THE

INFORMATION

EQUIPMENT,

BEFORE

Á

WARNING:

A

WARNING:

A

WARNING:

snap

and

Á

WARNING:

installed.

entangled

À

DANGER:

MENT.

A

CAUTION:

electrician.

fied

THE

AND

ATTEMPTING

SERIOUS

NEVER

ALWAYS

injure

you.

NEVER

Beware

in

of

them.

POTENTIALLY

NEVER

IMPORTANT

RISK

OF

ON

ALL

move

rotating

make

SAFETY

INJURY

THIS

OR

SHEET,

INSTRUCTIONS

INSTALLATION,

BODILY

the

use

care

operate

gears

INJURY

equipment

when

the

eguipment

and

FATAL

electrical

connections

ILLNESS,

ALL

USE,

opening

belts,

VOLTAGES

INFORMATION

READ,

PRECAUTIONARY

INCLUDED

OR

MAINTENANCE.

can

result

without

enough

the

shipping

without

rollers

and

ARE

to

the

UNDERSTAND,

WITH

from

improper

help

carton.

its

protective

chains,

PRESENT

equipment

THE

and/or

Strapping

and

keep

unless

AND

LABELS

EQUIPMENT,

handling

lifting

panels

from

IN

THIS

you

HEED

ON

or

usage.

tools.

bands

and

guards

becoming

EQUIP-

are

a

quali-

THE

can

A

WARNING:

A

WARNING:

qualified

A

connections

A

A

A

through

electronics

CAUTION:

or

CAUTION:

WARNING:

CAUTION:

the

water

PROCESSORS,

DANGER!

FATAL

follow

IF

the

hazard

SWALLOWED.

manufacturer.

A.

CAUTION:

certain

that

all

ALWAYS

NEVER

technician,

ALWAYS

servicing

ALWAYS

NEVER

NEVER

system.

AND

PROCESSOR

POISON!

warnings

Install

TO

all

AVOID

plumbing

route

power

attempt

shut

off

electrical

components.

replace

touch

supply

operate

the

PROCESSING

KEEP

and

the

fluids

correctly

POSSIBLE

complies

with

supply

electrical

power

fuses

at

with

those

voltages;

equipment

ACCESSORIES:

OUT

OF

REACH

ventilation,

before

operating.

DRINKING

local

codes.

wiring

service

the

disconnect

of

they

until

CHEMICALS

use

and

through a nearby

on the

the

can

it

is

equipment

device

same

type

be

lethal.

reliably

and

electrically

MAY

OF

CHILDREN.

disposal

WATER

instructions

CONTAMINATION,

disconnect

before

rating.

BE

Always

unless

making

grounded,

HARMFUL

of

the

device.

you

are

electrical

review

chemicals

and

make

a

not

OR

A

WARNING:

in

eyes,

on skin, on

ventilation.

CALS

ALWAYS

MANUFACTURER.

PROCESSING

clothing.

FOLLOW

Avoid

THE

CHEMICALS

breathing

SAFETY

CAN

CAUSE

vapor,

mist

or

RECOMMENDATIONS

SEVERE

dust,

and

BURNS.

use

only

OF

with

THE

Do

not get

adequate

CHEMI.

-

Page 10

LITERATURE.

The

following

publications

relate

to

safety

in

film

processing.

Publication

ANSI.

Technical

Wastes

J4,

J28,

J43, A Simple

J50,

J52,

K13,

S39,

PH

(6

Safe

Handling

Disposal

Effluents

Sampling

Disposal

Processing

Photolab

Water

Processing

4.37,

Photographic

Effluents

Data

Sheet,

pages)

of

Photographic

of

Photographic

and

Solutions

Waste-Treatment

and

Flow-measurement

of

Small

Solutions

Design

Conservation

Volumes

Processing

Photographic

Chemicals

Processing

System

of

Photographic

in

Photographic

Processing

Methods

Available

American

1430

New

E.

I.

Photo

Wilmington

Dept.

Eastman

343

State

Rochester,

From

National

Broadway

York,

DuPont

N.

Products

412-L

Kodak

Street

New

Standards

Y.

10018

DeNemours

Department

Delaware

Co.

York

and

19898

14650

Institute

Co.

(Inc.)

The

preceding

processing. No

mation.

assistance.

Please

information

claim

do

not

is

made

fail

is

presented

as

to

to

contact

as a guide

the

currency,

your

to

accuracy

chemicals

precautions

or

completeness

supplier

to

associated

obtain

additional

with

photographic

of

the

listed

advice

infor-

and

Page 11

Section

1

Introduction

-

General

Index

-

Section

Section

Section

Section

Section

Section

1

-

Introduction

2

-

Installation

3

-

Operation

4

-

Maintenance

5

-

Service

6

-

Parts

/

Storage

AFP

Mini-Medical

X-Ray

Film

Military

Processor

Page 12

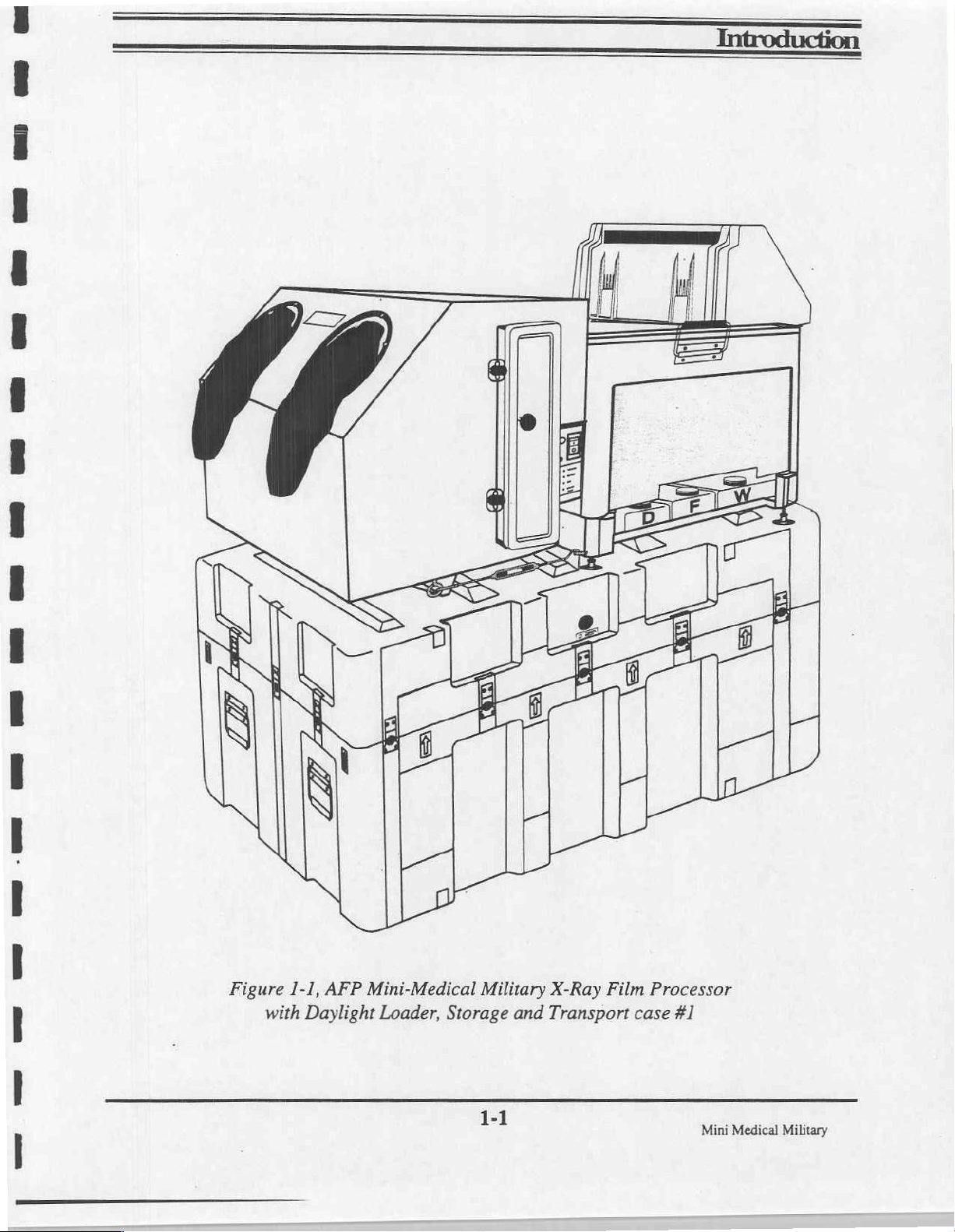

Figure

1-1,

with

AFP

Mini-Medical

Daylight

Loader,

Military

Storage

1-1

X-Ray

and

Transport

Film

case

Processor

#1

Mini

Medical

Military

Page 13

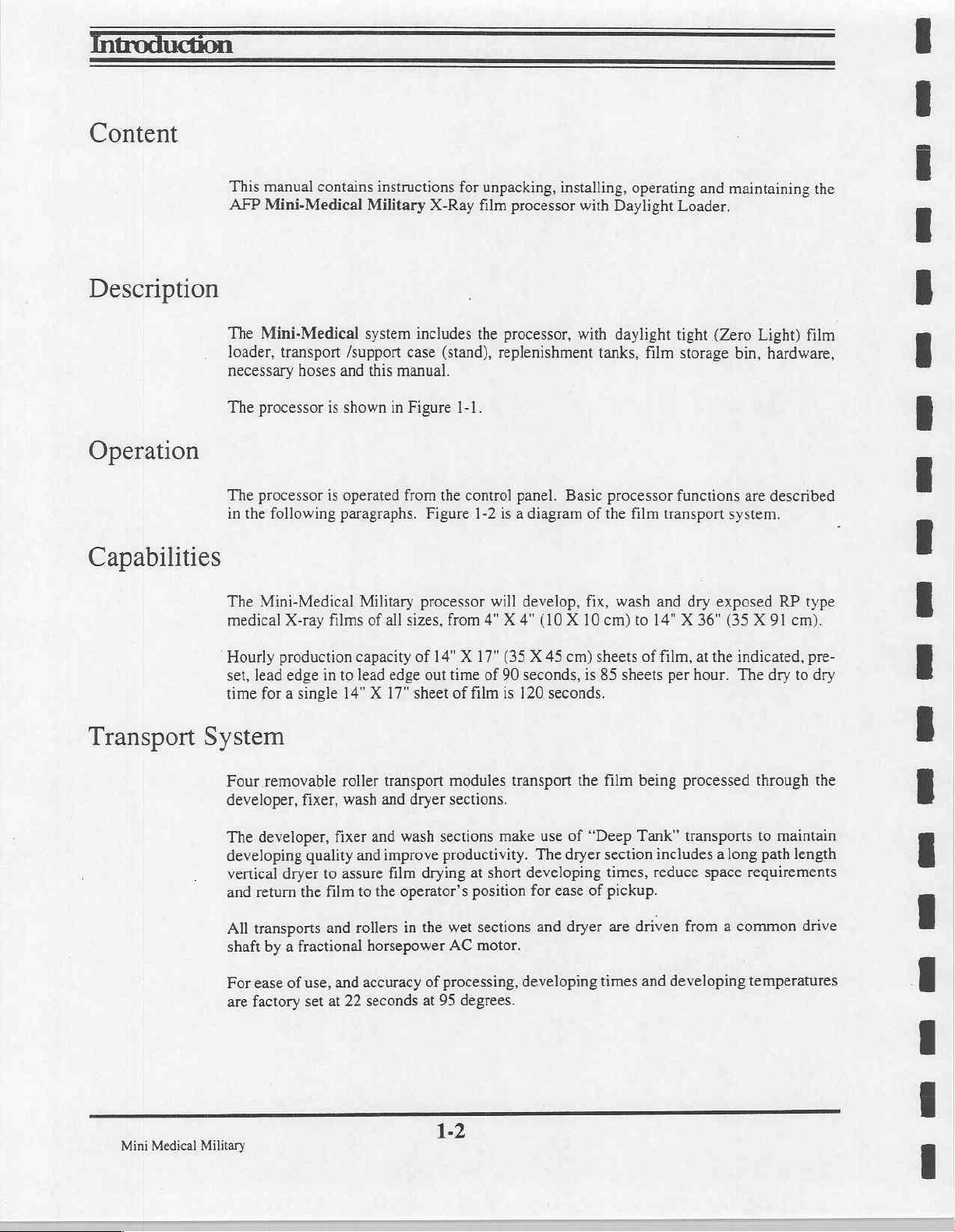

Introduction

Content

This

AFP

Description

The

loader,

necessary

The

Operation

manual

Mini-Medical

Mini-Medical

processor

contains

transport

hoses

and

is

shown

instructions

Military

system

/support

this

manual.

in

X-Ray

includes

case

(stand),

Figure

for

unpacking,

film

processor

the

processor,

replenishment

1-1.

installing,

with

with

operating

Daylight

daylight

tanks,

film

and

Loader,

tight

(Zero

storage

maintaining

Light)

bin,

film

hardware,

the

The

in

Capabilities

The

medical

Hourly

set,

time

Transport

System

Four

developer,

The

developing

vertical

and

All

shaft

processor

the

following

Mini-Medical

production

lead

for a single

removable

developer,

return

transports

is

X-ray

films

edge

in

fixer,

quality and

dryer

to

the

film

and

paragraphs.

to

roller

fixer

assure

by a fractional

operated

capacity

14" X 17”

wash

rollers

from

Military

of

all

lead

edge

transport

and

and

wash

improve

film

to

the

operator's

in

horsepower

the

control

Figure

processor

sizes,

of

out

sheet

dryer

drying

the

1-2

will

from

4" X 4"

14" X 17" (35 X 45

time

of

of

film

modules

sections.

sections

productivity.

wet

AC

make

at

short

position

sections

motor.

panel.

is a diagram

90

is

transport

Basic

develop,

(10 X 10

cm)

seconds,

120

seconds.

use

of

The

dryer

developing

for

ease

and

dryer

processor

of

the

film

fix,

wash

cm)

to

sheets

of

is

85

sheets

the

film

being

“Deep Tank”

section

times,

of

pickup.

are

driven

functions

transport

and

14" X 36"

film,

per

includes a long

reduce

system.

dry

exposed

(35 X 91

at

the

indicated,

hour.

The

processed

transports

space

from a common

are

described

RP

type

cm).

pre-

dry

to

dry

through

to

path

requirements

the

maintain

length

drive

For

ease

of

use,

and

accuracy

are

factory

Mini

Medical

Military

set

at

22

seconds

of

processing,

at

95

degrees.

1-2

developing

times

and

developing

temperatures

Page 14

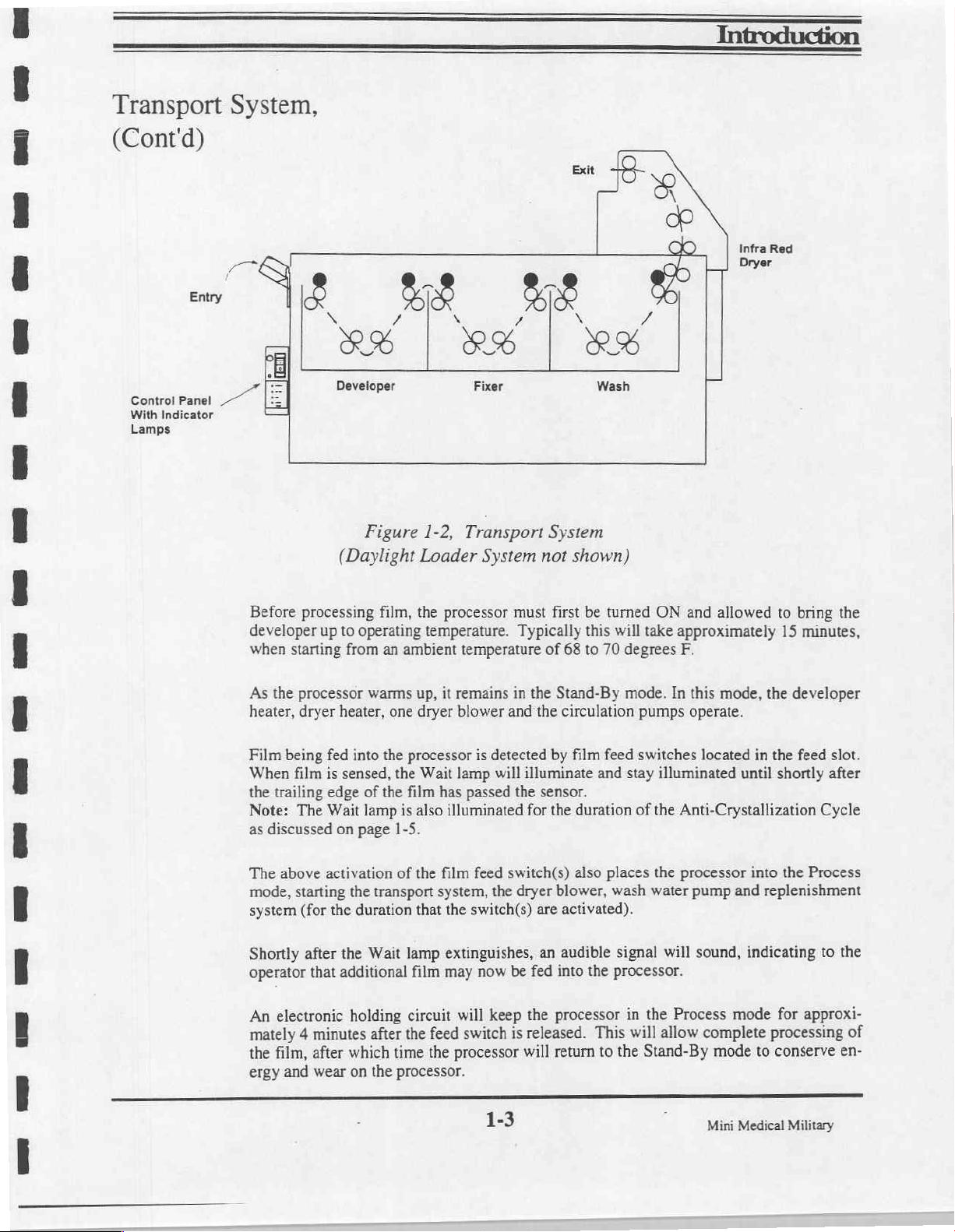

Introduction

Transport

(Cont'd)

Control

With

Panel

Indicator

Lamps

System,

LY

ラク

[E]

ES

м

LX RS

Developer

Figure

(Daylight

Loader

1-2,

Fixer

Transport

System

Exit

2%

System

not

shown)

Wash

&

do

Infra

Dryer

Red

Before

developer

when

As

heater,

Film

When

the

Note:

as

The

mode,

system

Shortly

operator

An

mately 4 minutes

the

ergy

processing

up

starting

the

processor

dryer

being

fed

film

is

trailing

discussed

above

edge

The

Wait lamp

activation

starting

(for

the

after

that

electronic

film,

after

and

wear

film,

to

operating

from

an

ambient temperature

warms

heater,

sensed,

into

of

one

the

processor

the

the

film

is

on

page

1-5.

of

the

the

transport

duration

the

Wait lamp

additional

holding

which

on

film

circuit

after

the

time

the

processor.

the

processor

temperature.

up,

it

remains

dryer

blower

Wait lamp

has

also

illuminated

film feed

system,

that

the

and

is

detected

will

passed

switch(s)

the

switch(s)

extinguishes,

may

now

will

keep

feed

switch

the

processor

must

first

Typically

of

68

in

the

Stand-By

the

circulation

by

film

illuminate

the

sensor.

for

the

duration

also

dryer

blower,

are

activated).

an

audible

be

fed

into

the

processor

is

released.

will

return

be

turned

this

will

to

70

degrees

mode.

feed

and

stay

of

places

wash

signal

the

processor.

in

This

will

to

the

ON

and

allowed

take

approximately

F.

In

this

mode,

pumps

switches

operate.

located

illuminated

the

Anti-Crystallization

the

processor

water

pump

will

sound,

the

Process

allow

complete

Stand-By

in

until

into

and

indicating

mode

mode

to

replenishment

to

bring

15

minutes,

the

developer

the

feed

slot.

shortly

after

Cycle

the

Process

to

for

approxi-

processing

conserve

the

the

of

en-

1-3

j

Mini

Medical

Military

Page 15

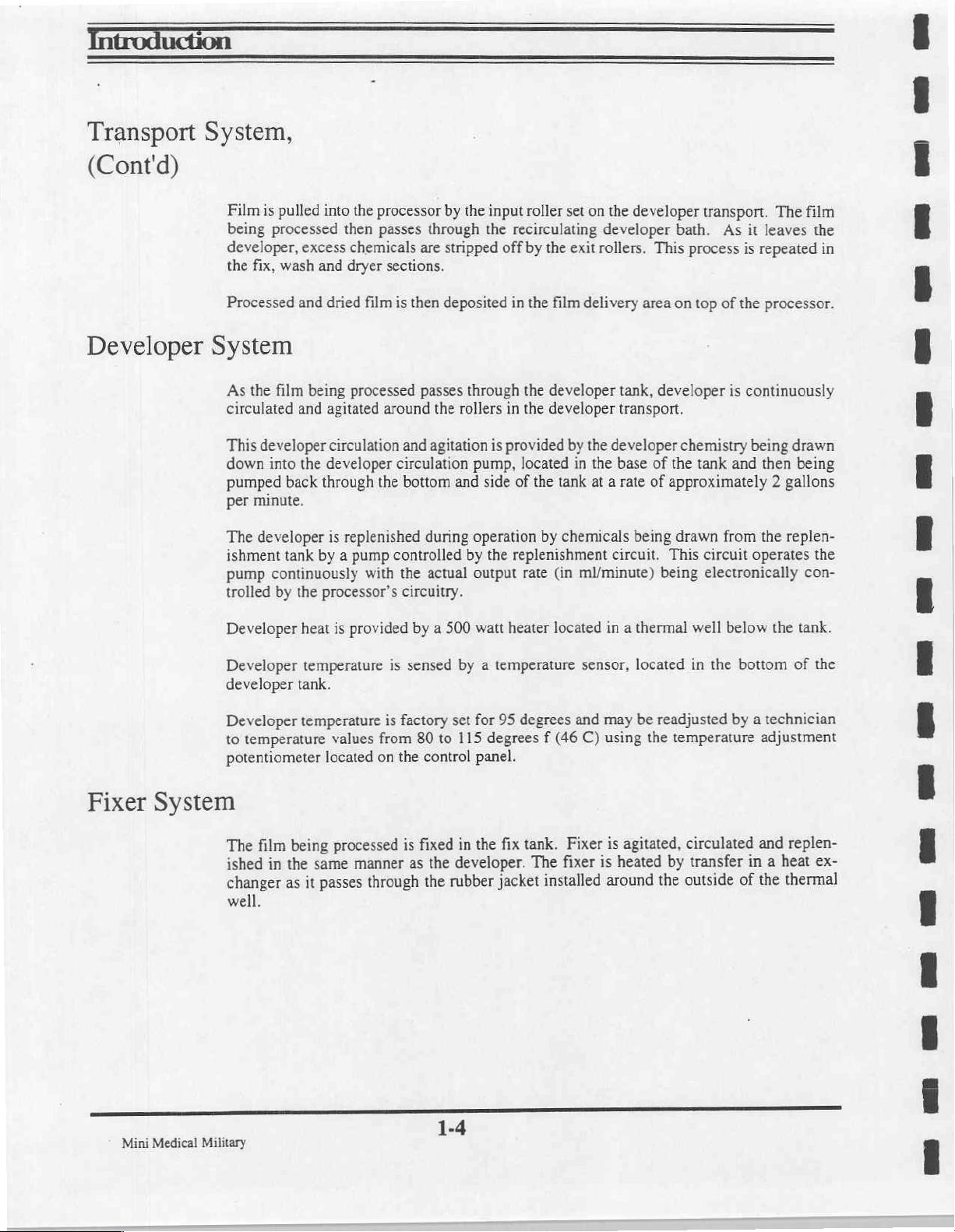

Introduction

Transport

(Cont'd)

Developer

System,

Film

is

pulled

being

processed

developer,

the

fix,

wash

Processed

System

As

the

film

circulated

This

developer

down

into

pumped

per

The

ishment

pump

trolled

back

minute.

developer

tank

continuously

by

into

then

excess

and

and

the

the

chemicals

and

dryer

dried

being

processed

agitated

circulation

developer

through

is

replenished

by a pump

processor’s

the

processor

passes

sections.

film

around

the

controlled

with

by

the

through

are

stripped

is

then

deposited

passes

through

the

rollers

and

agitation

circulation

bottom

during

the

circuitry.

and

by

actual

pump,

operation

output

input

roller

the

recirculating

off

by

the

in

the

the

developer

in

the

developer

is

provided

located

side

of

the

by

the

replenishment

rate

set

on

the

developer

exit

rollers.

film

delivery

by

the

developer chemistry

in

the

tank

at a rate

chemicals

circuit.

(in

ml/minute)

developer

bath.

This

process

area

on top

tank,

developer

transport.

base

of

the

of

approximately 2 gallons

being

drawn

This

being

transport.

As

of

tank

from

circuit

electronically

The

it

leaves

is

repeated

the

processor.

is

continuously

being

drawn

and

then

the

replen-

operates

film

the

in

being

the

con-

Fixer

Developer

Developer

developer

Developer

to

potentiometer

System

The

temperature

film

the

in

ished

changer

well.

as

heat

is

provided

temperature

tank.

temperature

values

located

processed

being

manner

same

passes

it

by a 500

is

sensed

is

factory

from

80

on

the

control

fixed

is

as

through

watt

heater

by a temperature

set

for

95

to

115

degrees f (46

panel.

fix

the

in

developer.

the

the

rubber

jacket

located

degrees

Fixer

tank.

fixer

The

installed

in a thermal

sensor,

and

may

C)

using

agitated,

is

heated

is

around

well

below

located

be

in

the

bottom

readjusted

the

temperature adjustment

by

outside

the

by a technician

in

of

and

the

circulated

transfer

the

tank.

of

replen-

heat

a

thermal

the

ex-

Mini

Medical

Military

1-4

Page 16

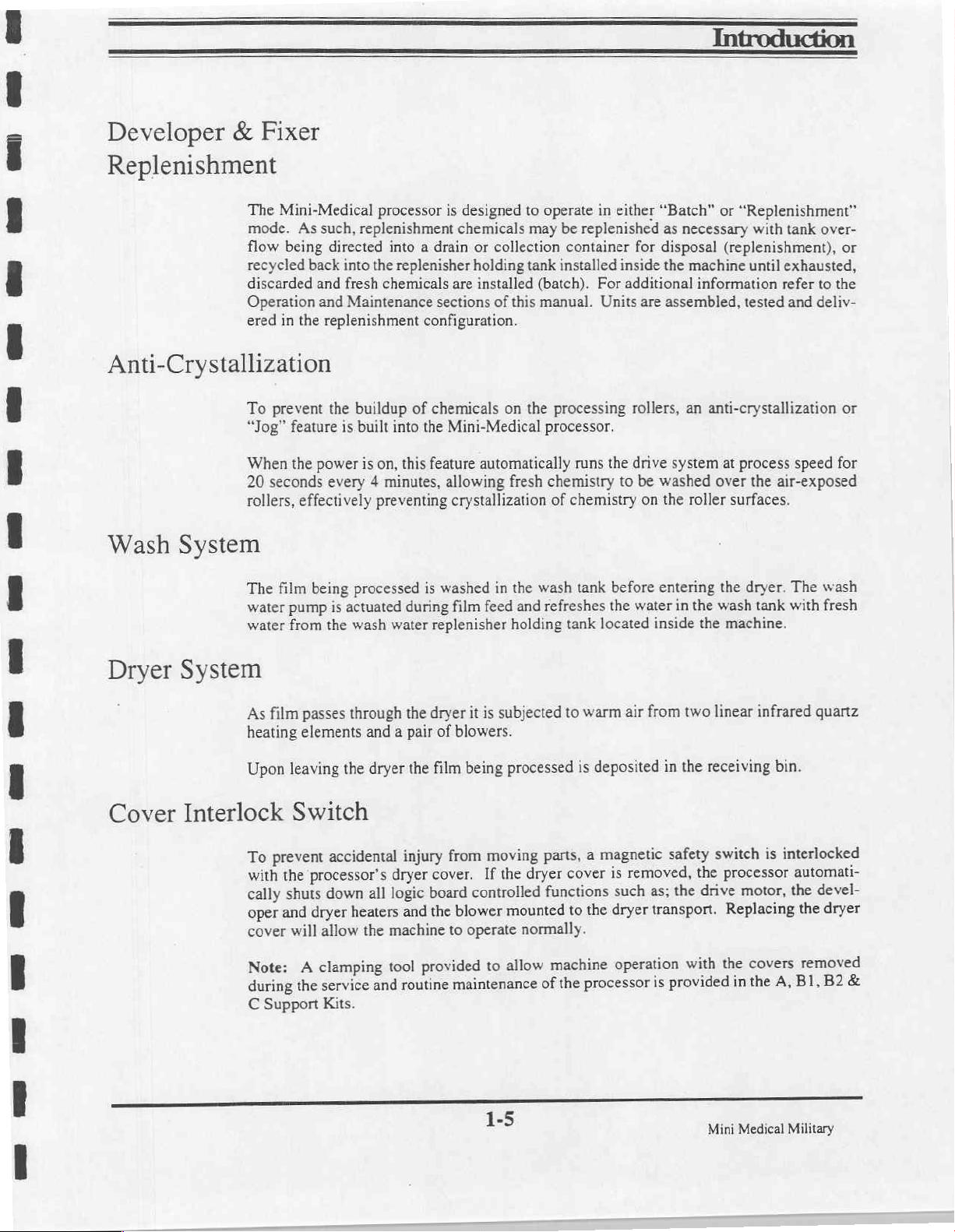

Developer & Fixer

Replenishment

The

Mini-Medical

mode.

flow

recycled

discarded

Operation

ered

Anti-Crystallization

To

“Jog”

When

20

rollers,

As

such,

being

back

and

and

in

the

prevent

feature

the

power

seconds

effectively

directed

into

fresh

Maintenance

replenishment

the

buildup

is

every 4 minutes,

processor

replenishment

is

into a drain

the

replenisher

chemicals

sections

configuration.

of

chemicals

built

into

the

Mini-Medical

is

on,

this

feature

allowing

preventing

crystallization

designed

chemicals

or

collection

holding

are

installed

of

this

on

automatically

fresh

to

operate

may

be

container

tank

installed

(batch).

manual.

the

processing

processor.

runs

chemistry

of

chemistry

in

either

“Batch”

replenished

as

for

disposal

inside

For

additional

Units

are

rollers,

the

drive

to

be

washed

on

the

Introduction

or

“Replenishment”

necessary

the

machine

information

assembled,

an

system

roller

with

(replenishment),

until

tested

anti-crystallization

at

process

over

the

surfaces.

tank

over-

or

exhausted,

refer

to

the

and

deliv-

or

speed

for

air-exposed

Wash

Dryer

Cover

System

The

water

water

System

As

film

heating

Upon

Interlock

prevent

To

with

cally

oper

cover

Note:

during

Support

C

film

being

pump

is

from

the

passes

elements

leaving

Switch

accidental

processor’s

the

down

shuts

dryer

and

will

allow

clamping

A

service

the

Kits.

processed

actuated

wash

water

through

and a pair

dryer

the

dryer

logic

all

heaters

the

machine

tool

and

is

washed

during

replenisher holding

the

dryer

of

film

the

from

injury

cover.

board

the

and

to

provided

routine

in

film

feed

it

is

blowers.

being

moving

If

controlled

blower

operate

to

maintenance

the

wash

and

refreshes

tank

subjected

processed

the

mounted

to

parts,

cover

dryer

functions

to

normally.

machine

allow

the

of

tank

before

the

water

located

warm

air

deposited

is

magnetic

a

removed,

is

such

dryer

the

operation

processor

entering

in

the

inside

the

from

two

linear

receiving

the

in

switch

safety

the

drive

the

as;

transport.

with

provided

is

the

dryer.

wash

tank

machine.

infrared

bin.

is

processor

motor,

Replacing

covers

the

A,

the

in

The

wash

with

fresh

quartz

interlocked

automati-

devel-

the

dryer

the

removed

&

B2

Bl,

1-5

Medical

Mini

Military

Page 17

Introduction

General

Materials

Material

Developing

Developer,

Specifications

RP

type

medical

Size

Minimum

Maximum

thicknesses

Base

Time

Factory

Model

Mini-Medical

set

Fix, & Wash

Capacity:

1.9

Size:

Size:

as

follows:

Military

gallons

X-Ray

(7.2

films

and

compatible

4"

X

4"

14"

X

-

0.004

Dev.

Time

22

sec.

Systems

L.).

(10

36"

(35.6

0.008"

K

10

chemicals

cm)

X

91.4

cm)

Linear

36"

designed

Speed

(91.5

cm)

for

per

RP

type

minute

processing.

Wash:

feed

Integral

Dryer

Replenisher

Two

one

processor

tanks

processor

System

Twin

thermostat.

Temperature:

Temperature

Developer

Control

Fixer

approximates

Ambient

cycle.

(1)

There

(2) 1 gallon

2.2

gallon

and

by

means

and

Infrared

Control:

is

Factory

Panel

variable

the

temperature;

no

is

System

(3.76

(8.27

are

an

of

three

as

such,

lamps

Factory

Set

as

from

developer

water

L.)

replenisher

L.)

replenisher

integral

with

part

self-priming

are

an

integral

air

circulation

set

at

130

follows:

80

to

temperature

Volume

in

flow

of

the

degrees

110

degrees

equivalent

standby

bottle

pumps.

part

mode.

bottles,

one

for the

machine.

of

the

blowers

f.

(54.5

F.

(26.8 - 37.7

to

developer

each

for

Wash

are

Solutions

These

are

machine.

and

overtemperature

C).

C)

replenishment

the

Developer

located

are

delivered

also

located

inside

in

the

safety

during

and

the

to

the

base

cutoff

Fixer

base

working

of

film

and

of

the

the

Mini

Medical

Military

Page 18

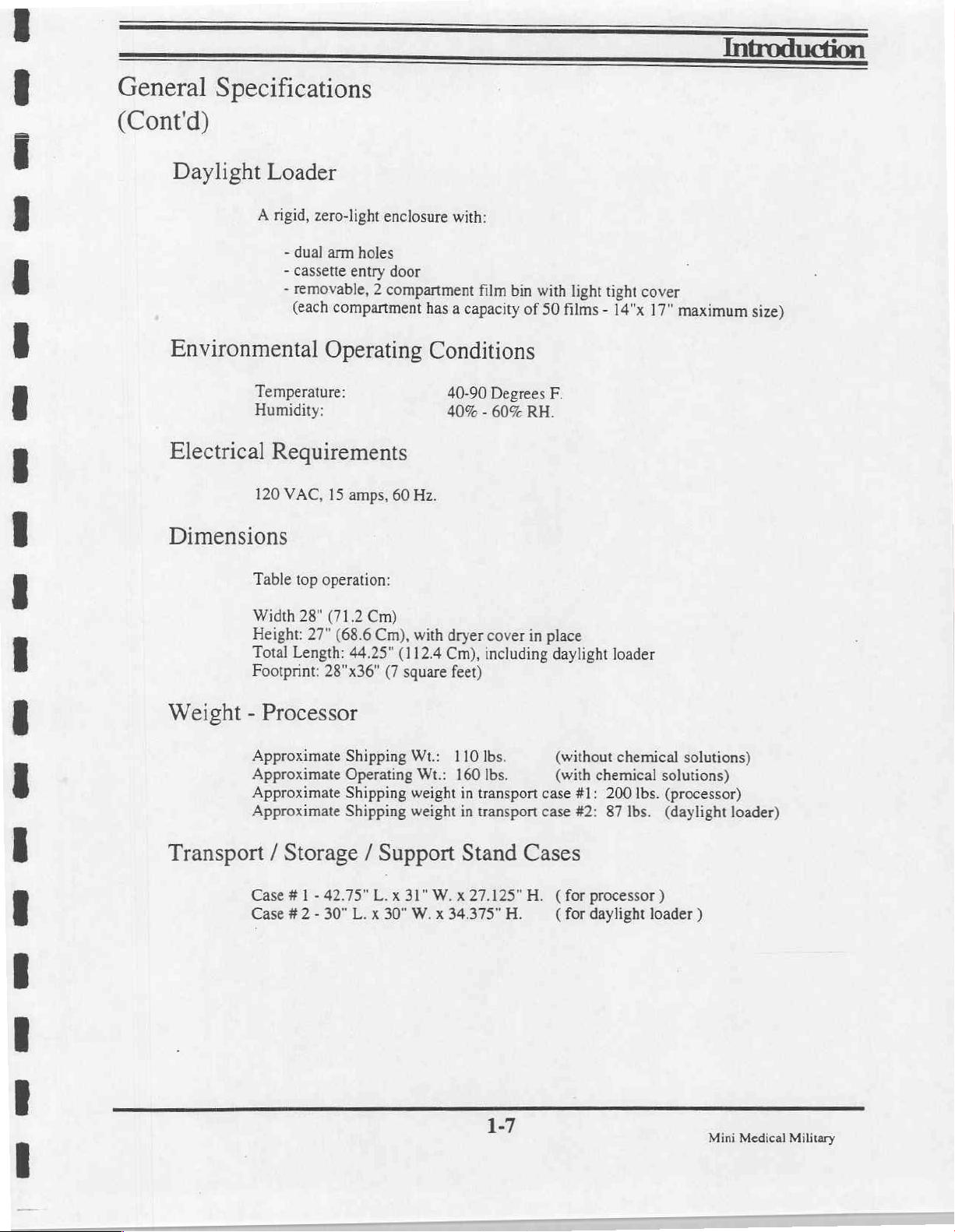

Introduction

General

(Cont'd)

Daylight

Environmental

Electrical

Dimensions

Specifications

Loader

A

rigid,

zero-light

-

dual

arm

-

cassette

-

removable,

(each

compartment

Operating

Temperature:

Humidity:

Requirements

120

VAC,

15

enclosure

holes

entry

door

2

compartment

amps,

60

with:

film

has

a

capacity

Conditions

40-90

Degrees

40% - 60%

Hz.

bin

of

RH.

with

50

films

F.

light

-

tight

14"x

cover

17"

maximum

size)

Table

top

operation:

Width

28" (71.2

Height:

Total

27"

Length:

Footprint:

Cm)

(68.6

Cm),

44.25"

28"x36"

(112.4

(7

square

with

dryer

Cm),

feet)

Weight - Processor

Approximate

Approximate

Approximate

Approximate

Shipping

Operating

Shipping

Shipping

Wt.:

Wt.:

weight

weight

Transport / Storage / Support

Case # 1 - 42.75"

Case # 2 - 30"

L. x 31"

L. x 30"

W. x 27.125"

W. x 34.375"

cover

including

110

Ibs.

160

Ibs.

in

transport

in

transport

Stand

in

Cases

H. ( for

H.

place

daylight

(without

(with

case

#1:

case

#2:

processor

(

for

daylight

loader

chemical

chemical

200

Ibs.

87

Ibs.

)

loader

solutions)

solutions)

(processor)

(daylight

loader)

)

Mini

Medical Military

Page 19

Section

2

Installation

-

General

Index

-

Section

Section

Section

Section

Section

Section

1

-

Introduction

2

-

Installation

3

-

Operation

4

-

Maintenance

5

-

Service

6

-

Parts

/

Storage

AFP

Mini-Medical

X-Ray

Film

Military

Processor

Page 20

==

Dev

ME

377353

ーー

+

les!

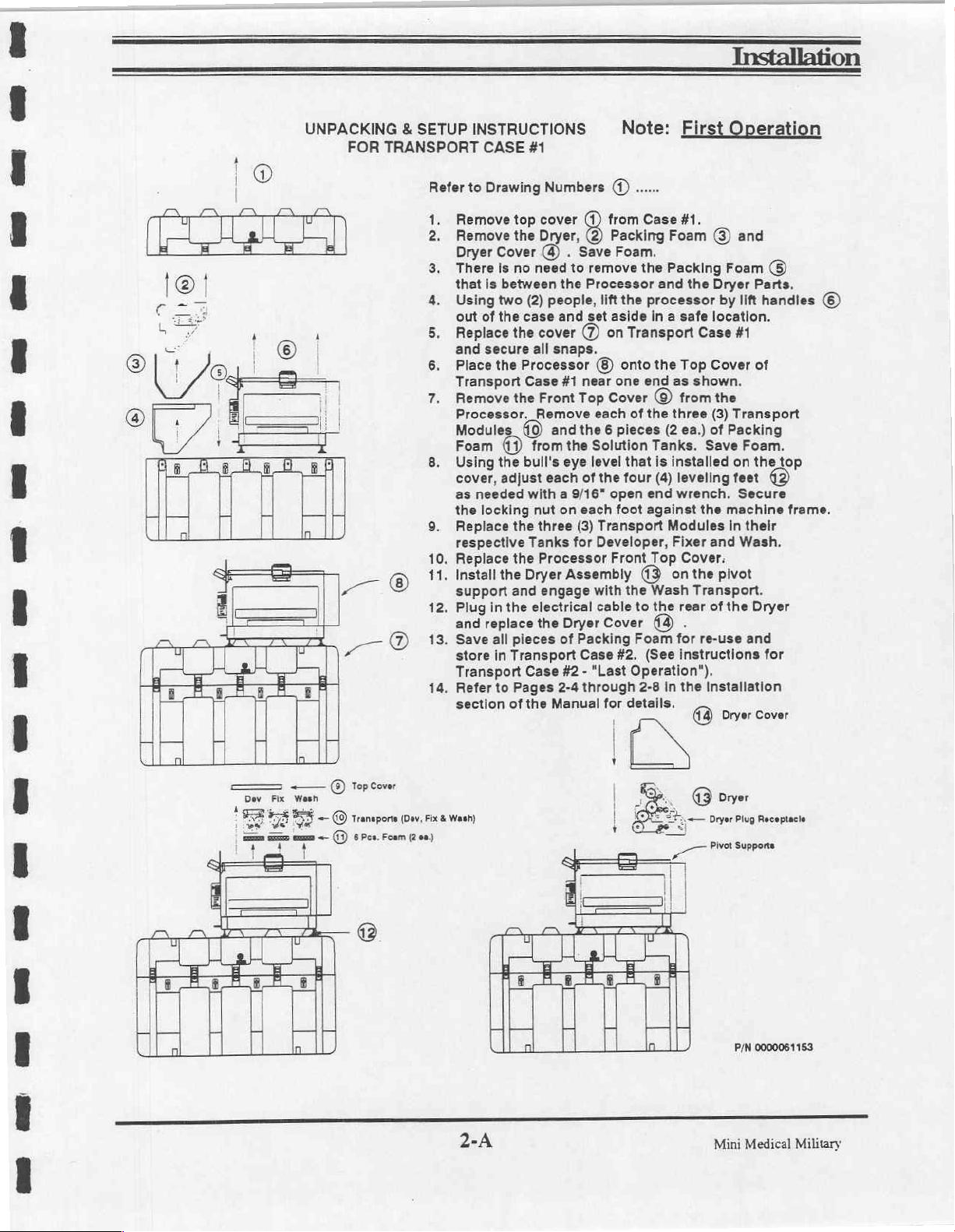

UNPACKING & SETUP

FOR

TRANSPORT

ーー

⑨

E

—O

repcew

transport

Pen

Foam

Fix

Wash

Refer

1.

È

3.

10.

11.

12.

13.

.

(Dav,

Fix & Wash)

(200)

INSTRUCTIONS

CASE

#1

to

Drawing

Remove

Remove

Dryer

There

that

Using

out

Replace

and

Place

Transport

Remove

Processor.

Modules

Foam

Using

cover, adjust

as

the

Replace

respective

Replace

Install

support

Plug

and

Save

store

Transport

Refer

section

top

the

Cover

is

no

is

between

two

of

the

the

secure

the

the

(11)

the

needed

locking

the

the

the

and

in

the

replace

all

pieces

in

Transport

to

Pages

of

need

(2)

case

all

Processor

Case

Remove

(9

from

bull's

with a 9/16"

nut

Tanks

Dryer

electrical

Case

the

Numbers

cover

Dryer,

@) . Save

the

people,

and

cover © on

snaps.

#1

Front

and

eye

each

on

three

Processor

(1)

from

(2) Packing

Foam.

to

remove

Processor

lift

set

aside

near

one

Top

Cover © from

each

the 6 pieces

the

Solution

level

of

the

open

each

foot

(3)

Transport

for

Developer,

Front

Assembly

engage

the

with

cable

Dryer

of

Packing

Case

#2 - "Last

2-4

through

Manual

Cover

for

i

+

|

Note:

......

Case

#1.

Foam

the

Packing

and

the

processor

in a safe

Transport

onto

the

Top

end

as

of

the

three

(2

ea.)

Tanks.

that

is

installed

four

(4)

leveling

end

wrench.

against

Modules

Fixer

Top

Cover.

(13

on the

the

Wash

to

the

rear

dd

Foam

for

#2.

(See

instructions

Operation").

2-8

in

the

details.

№

Eir:

@)

Foam

the

Dryer

by

location.

Case

#1

Cover

shown.

the

(3)

Transport

of

Packing

Save

on

feet

the

machine

in

and

pivot

Transport.

of

the

re-use

Installation

(3)

Dryor

43

dryer

ーー

pwr

Plug

eration

and

(8)

Parts.

lift

handles

of

Foam.

the

top

Secure

frame.

their

Wash.

Dryer

and

for

Cover

Receptacle

©)

P/N

0000061153

Mini

Medical Military

2-A

Page 21

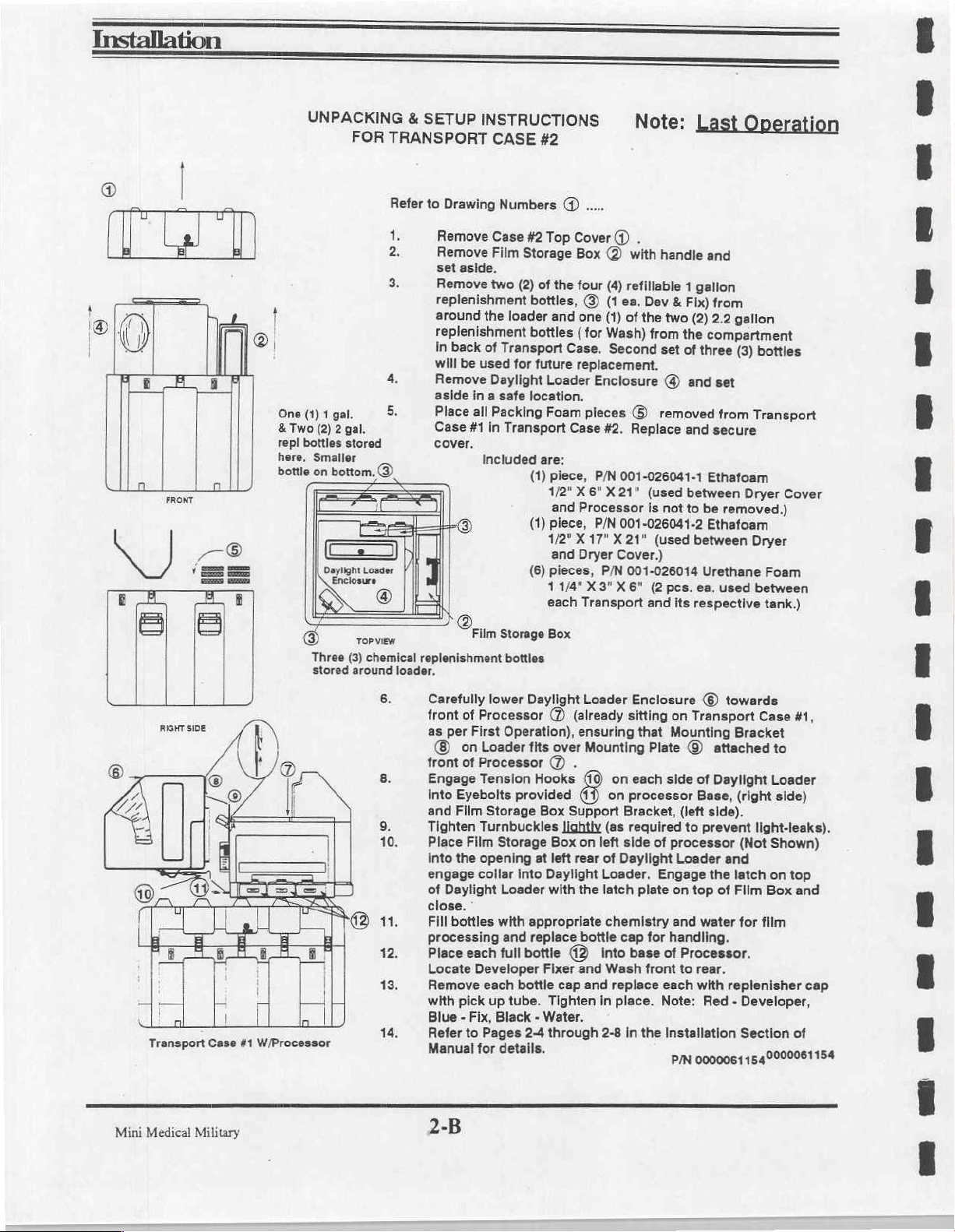

Installation

o

FRONTI

|

-

UNPACKING

One

(1)

1

&

Two

(2)

repl

bottles

here.

Smaller

bottle

on

bottom.

EI

Daylight

S

©

Three

stored

FOR

gal.

2

gal.

stored

se

ES

nr

ToP

(3)

around

&

SETUP

TRANSPORT

Refer

to

2

3.

4.

5.

©

Loader

©

view

chemical

replenishment

loader.

INSTRUCTIONS

CASE

Drawing

Remove

Remove

set

Remove

replenishment

around

replenishment

In

back

will

Remove

aside

Place

Case

cover.

]

Case

Film

aside.

two

the

of

used

be

Daylight

in

a

all

Packing

#1

in

Included

Film

Numbers

loader

Transport

for

safe

Transport

Storage

bottles

#2

@

#2

Top

Storage

(2)

of

the

bottles,

and

bottles

future

Loader

location.

Foam

are:

(1)

piece,

1/2"

and

(1)

piece,

1/2"

and

(8)

pieces,

114"X3"X6"

each

Box

Cover

(D

Box

(2)

with

four

(4)

refillable

@

(1

ea.

one

(1)

(for

Case.

replacement.

of

Wash)

Second

Enclosure

pieces

Case

X

Processor

X17"

Dryer

©)

#2.

Replace

P/N

001-026041-1

6"

X

21"

P/N

001-026041-2

X21"

Cover.)

P/N

001-026014

Transport

Note:

.

handle

Dev

&

the

two

from

set

@

removed

(used

is

not

(used

(2pcs.

and

its

Last

Operation

and

1

gallon

Fix)

from

(2)

2.2

the

of

and

gallon

compartment

three

(3)

set

from

and

secure

Ethafoam

between

to

between

ea.

respective

Dryer

be

Fatal)

Ethafoam

Urethane

used

bottles

Transport

Cover

Dryer

Foam

between

tank.)

RIGHT

Transport

Medical

Mini

SIDE

Case

#1

Military

|

|

W/Processor

6.

Carefully

front

as

(© on

front

Engage

into

and

Tighten

Place

into

engage

of

close.

Fill

processing

Place

Locate

Remove

with

of

Processor

per

First

Loader

of

Processor

Tension

Eyebolts

Film

Storage

Turnbuckles

Film

the

opening

collar

Daylight

*

bottles

each

Developer

each

pick

lower

up

Blue - Fix,

Refer

to

Pages

Manual

for

2-B

Daylight

Operation),

fits

(7)

over

Loader

(already

ensuring

Mounting

Y)

Hooks

provided

Storage

at

into

Loader

with

appropriate

and replace

full

bottle

bottle

tube.

Black - Water.

2-4

details.

Box

Support

Jightly

Box

on

left

rear

Daylight

with

the

bottle

42

Fixer

and

cap

Tighten

through

(0)

(7)

and replace

Enclosure

sitting

that

on

each

on

processor

Bracket,

(as

required

left

side

of

Daylight

Loader.

latch

plate

chemistry

cap

into

base

Wash

front

in

place.

2-8

in

the

©

towards

on

Transport

Mounting

Case

Bracket

Plate © attached

side

of

Daylight

Base,

(right

(left

side).

to

prevent

of

processor

Loader

Engage

on

top

and

water

tor

handling.

of

Processor.

to

rear.

each

with

Note;

Red - Developer,

Installation

P/N

0000061

light-leaks).

(Not

and

the

latch

of

Film

for

film

replenisher

Section

1540000061154

to

Loader

side)

Shown)

on

top

Box

#1,

and

cap

of

Page 22

oe

Installation

44

1/4"

2

が

|

μαι

m

e

cp

Bs

Ee

1

a

—

2

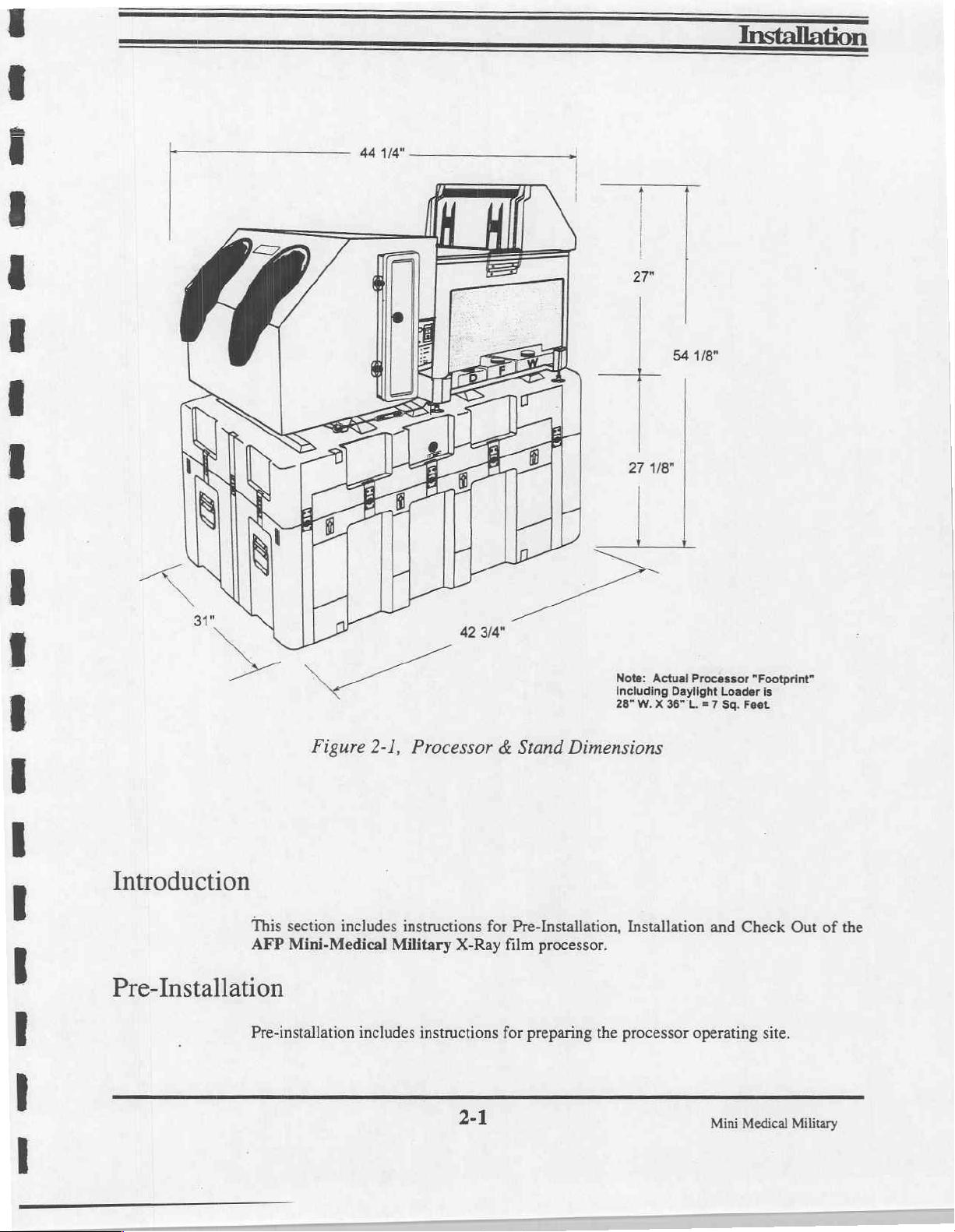

Figure

3

2-1,

Processor & Stand

B

Dimensions

27

1/8"

|

Note:

Actual

Including

28"

W. X 36"

54

1/8"

|

|

Processor

Daylight

L.

= 7

"Footprint"

Loader

Sq.

Feet

is

ww EE

ww

—

Introduction

This

section

AFP

Mini-Medical

Pre-Installation

Pre-installation

includes

instructions

Military

includes

for

X-Ray

instructions

film

for

2-1

Pre-Installation,

processor.

preparing

Installation

the

processor

and

Check

operating

Mini

Medical

Out

of

site.

Military

the

Page 23

Installation

Location

Dimensions

AFP

Mini-Medical

is

made

possible

sor.

Packing

level

surface.

by

Case

Military

the

Daylight

#1

is

intended

processors

Loader

for

may

Assembly

use

as

be

operated

the

processor

ina

mounted

stand,

daylight

to

the

feed

and

should

environment.

end

of

be

placed

the

proces-

This

on

a

Mini-Medical

print)

the

unit

“front”

Packing

Weight

The

Mini-Medical

mately

To

support

Ventilation

WARNING:

tems

provide

Provide

cessor

confined

ditions.

Processors

of

work

for

of

the

Case

space.

routine

processor

#1

The processor

cleaning

is

of

sufficient

Military

160

lbs.

when

operating.

this

weight

Some

when

used

for

at

least

adequate

generates a moderate

space.

Packing

processing

in a poorly

ten

complete

ventilation

Daylight

occupy

and

below

the

size

Processor

Case

chemical

ventilated

for

proper

amount

Loader

approximately

should

preventive

feed

to

be

maintenance.

tray

must

be

used

weighs

#1

is

used

fumes

area.

If

changes

allows

of

machine

of

heat

for

air

when

flexibility

7.0

square

positioned

as

the

approx.

as a stand.

may

the

processor

per

operation

to

be

routed

support

110

irritate

hour.

operating

in

selecting

feet

allow

Drain

to

be

stand

lbs.

when

See

figure

eyes

is

to

and

operator

and

(28" x 36"

easy

access

tubes,

leading

readily

for

processor

empty,

2-3.

and/or

operate

in a confined

comfort.

must

not

processor

actual

foot-

to

all

sides

out

of

accessible.

operation.

and

approxi-

respiratory

area,

The

be

placed

site

and

con-

of

the

The

sys-

pro-

in

a

Electrical

Medical

Mini

Military

Electrical

sor

dot)

connections

plugs

into a standard

grounded

plug

must

120

assembly

include a ground

VAC,

60

Hz,

15

is

provided.

2-2

and

conform

amp., 3 wire

to

military

outlet. A hospital

codes.

The

grade

proces-

(green

Page 24

Pre-Installation,

(Cont'd)

Plumbing

WARNING:

mended

The

Military

1. A water

2. A sink

safety

following

Processor:

or

cleaning

3. A drain

Caution:

photographic

or

In

Obey

all

precautions

plumbing

source

film

for

tub,

with

transport

collection

some

situations,

processing

instructions

when

handling,

requirements

wash

water

and

running

tempered

modules.

system

suitable

regulations

wastes

other

of

the

chemical

using

are

recommended

for

cleaning

water,

for

may

than

in

manufacturer,

and

disposing

for

the

approximately

disposing

require

the

of

the

sanitary

and

of

chemicals.

installation

processor.

12" X 16",

photographic

capturing

sewer

system.

follow

of

the

Mini-Medical

for

chemical

and

safe

all

recom-

use

when

wastes.

disposal

of

2-3

©

Mini

Medical

Military

Page 25

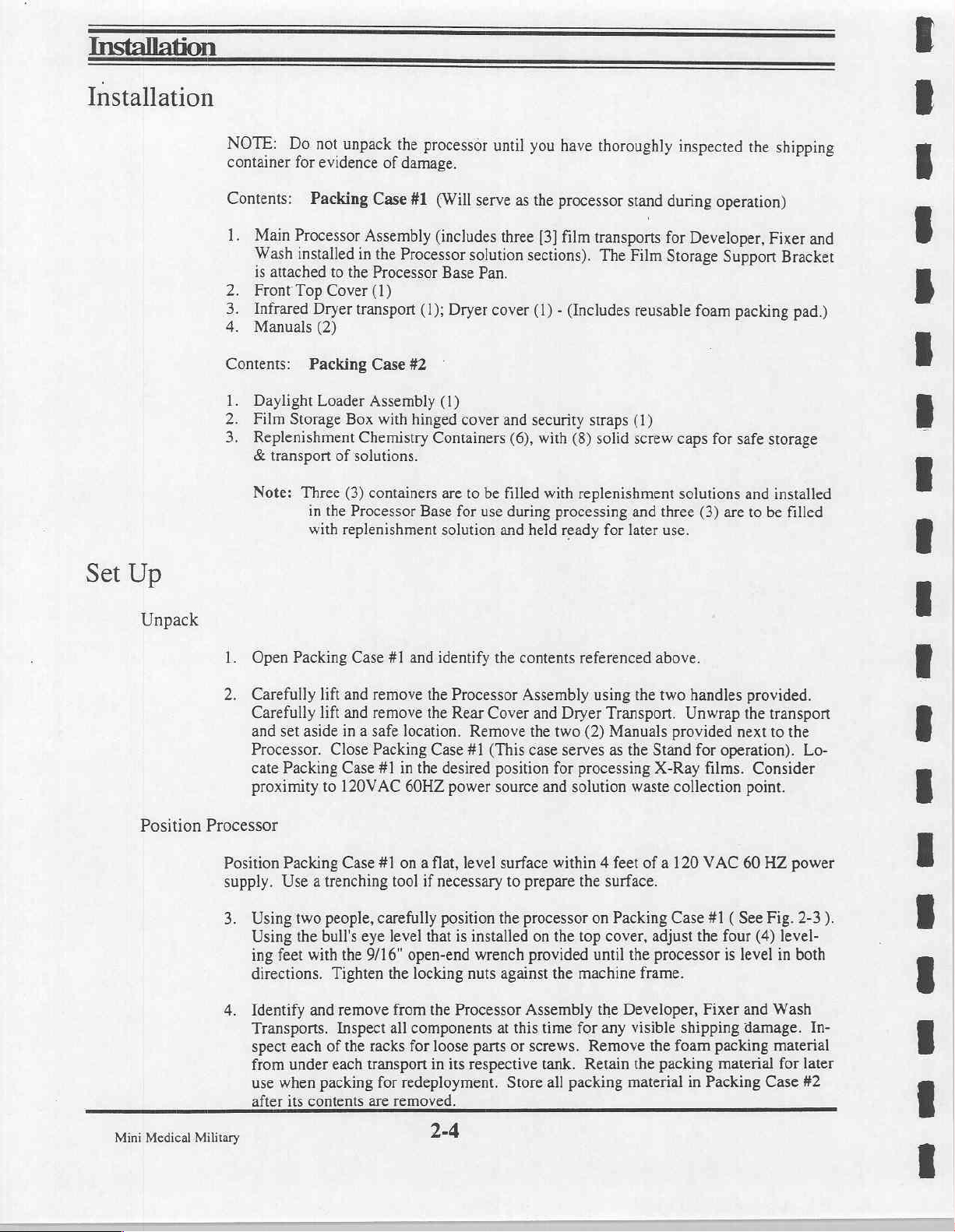

Installation

Installation

Set

Up

NOTE:

container

Contents:

1.

2.

3.

4.

Contents:

1.

2.

3.

Do

for

Main

Processor

Wash

attached

is

Top

Front

Infrared

Manuals

Daylight

Film

Storage

Replenishment

&

transport

Note:

not

unpack

evidence

Packing

installed

Packing

Three

in

with

in

the

to

Cover

transport

Dryer

(2)

Loader

Box

Chemistry

of

solutions.

(3)

the

Processor

replenishment

the

processor

damage.

of

Case

#1

Assembly

the

Processor

Processor

(1)

(1);

Case

#2

Assembly

with

hinged

Containers

containers

Base

until

(Will

serve

(includes

Base

Dryer

(1)

are

solution

three

solution

Pan.

cover

cover

and

to

be

for

use

and

filled

during

you

have

as

the

processor

[3]

film

sections).

-

(1)

security

(6),

with

with

processing

held

ready

thoroughly

stand

transports

The

Film

straps

solid

for

later

reusable

(1)

screw

and

(Includes

(8)

replenishment

inspected

during

for

Developer,

Storage

foam

caps

for

solutions

three

(3)

use.

the

shipping

operation)

Fixer

Support

are

Bracket

packing

safe

storage

and

installed

to

be

filled

and

pad.)

Unpack

Position

1.

Open

2.

Carefully

Carefully

and

Processor.

cate

proximity

Processor

Position

supply.

3.

Using

Using

ing

feet

directions.

4.

Identify

Transports.

spect

from

use

when

after

Packing

set

aside

Packing

Packing

Use a trenching

two

the

each

under

its

Case

lift

and

lift

and

in a safe

Close

Case

to

120VAC

Case

people,

bull's

eye

with

the

Tighten

and

remove

Inspect

of

the

each

packing

contents

#1

remove

remove

Packing

#1

#1

tool

carefully

level

9/16"

the

from

all

racks

transport

for

are

removed.

and

identify

the

the

location.

Case

in

the

desired

60HZ

on a flat,

if

necessary

position

that

open-end

locking

the

components

for

loose

in

the

Processor

Rear

Cover

Remove

#1

(This

position

power

source

level

surface

to

the

is

installed

wrench

nuts

against

Processor

at

parts

its

respective

redeployment.

contents

Assembly

and

the

two

case

for

and

within 4 feet

prepare

processor

on

the

provided

the

Assembly

this

time

or

screws.

tank.

Store

all

referenced

using

Dryer

Transport.

(2)

Manuals

serves

as

the

processing

solution

the

surface.

on

Packing

top

cover,

until

machine

the

Developer,

for

any

Remoye

Retain

packing

material

above.

the

two

provided

Stand

X-Ray

waste

collection

of a 120

Case

adjust

the

processor

frame.

visible

the

foam

the

packing

handles provided.

Unwrap

for

the

shipping

in

the

next

operation).

films.

VAC

Fixer and

Packing

Consider

point.

60

#1 ( See

four

(4)

is

level

damage.

packing

material

HZ

Fig.

Case

transport

to

the

power

level-

in

Wash

material

for

Lo-

2-3

).

both

In-

later

#2

Medical

Mini

Military

2-4

Page 26

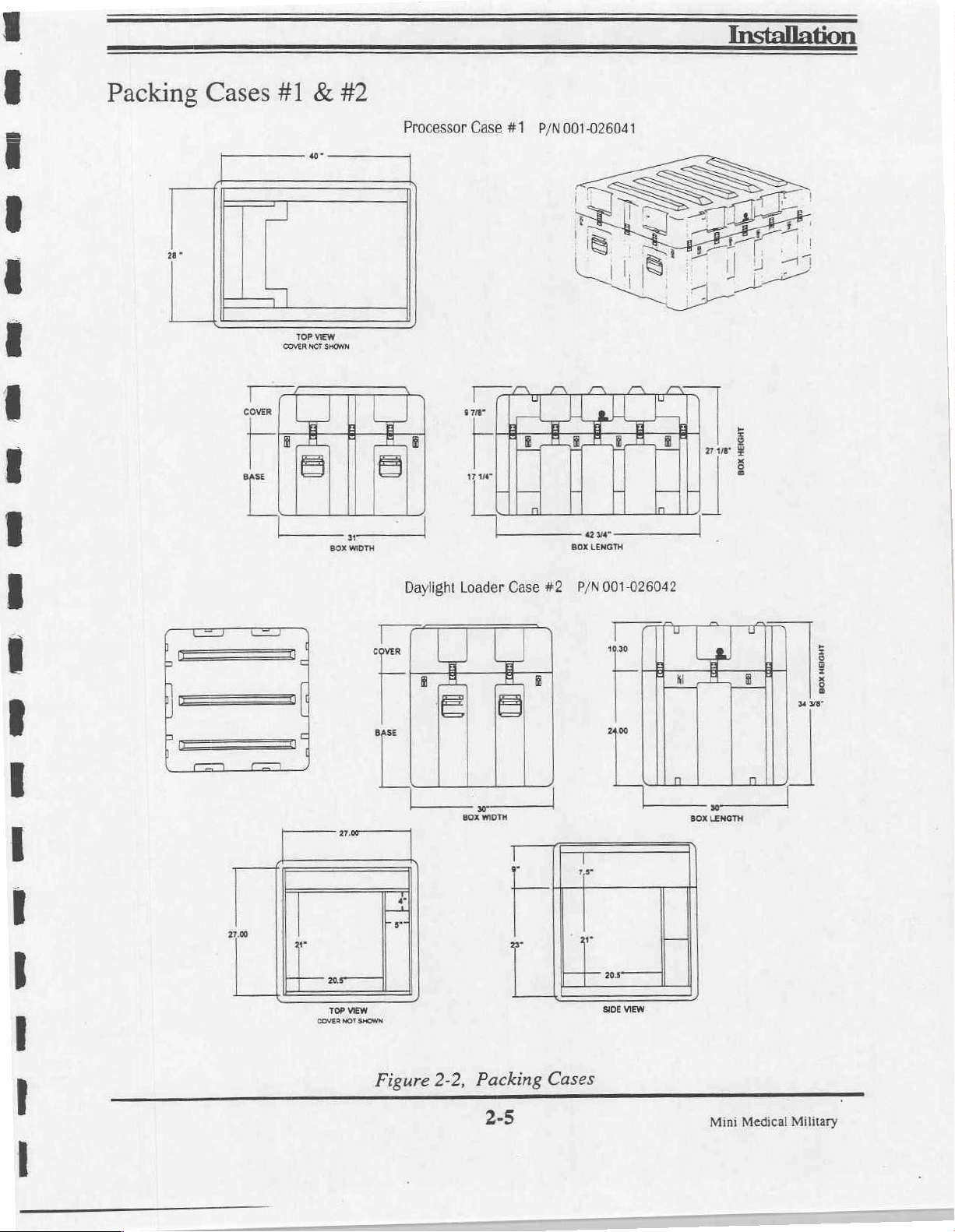

Packing

Cases

#1 & #2

Fa

Processor

Case

#1

P/N001-026041

Figure

2-2,

Packing

2-5

Cases

Mini

Medical

Military

Page 27

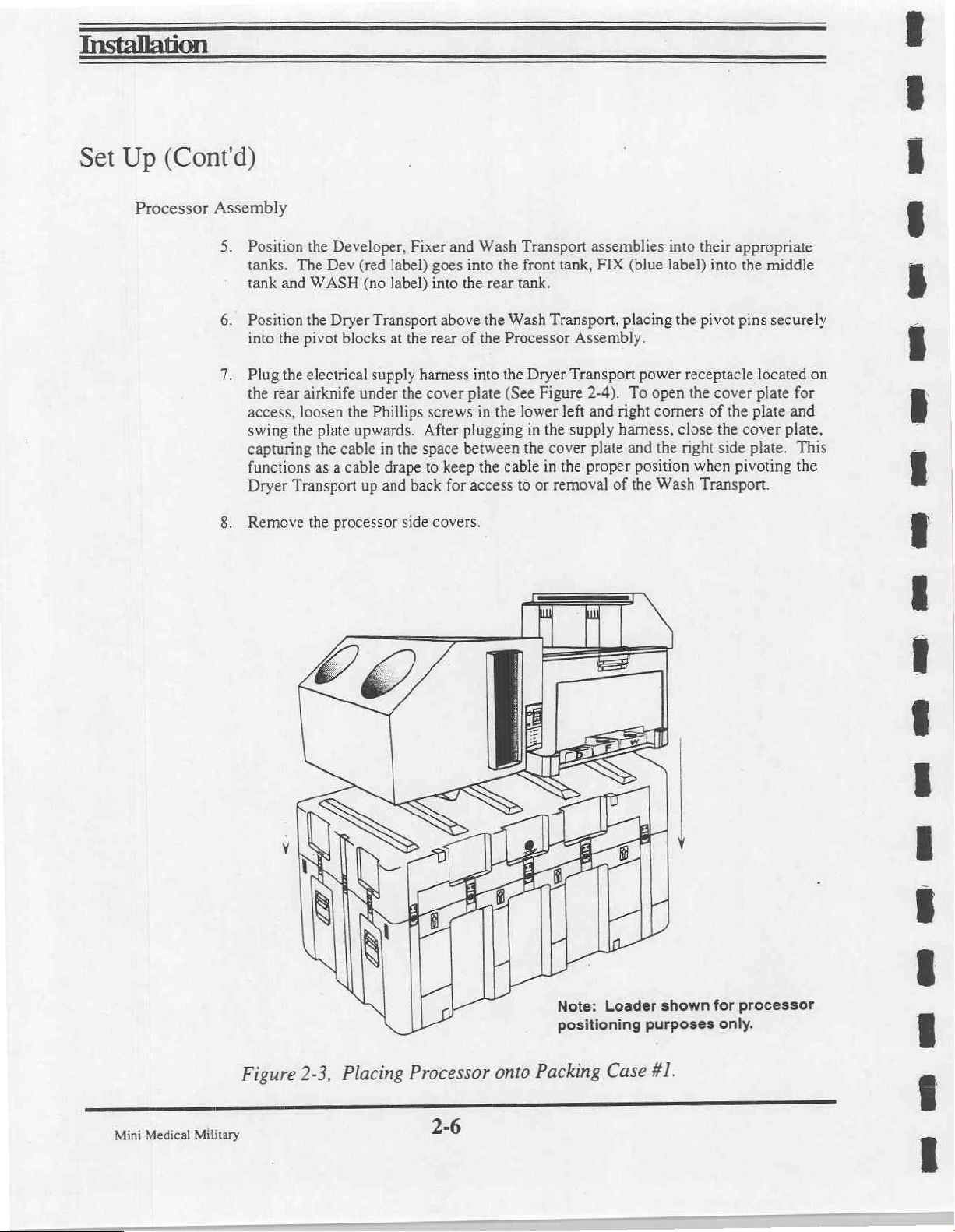

Set

Up

(Cont'd)

ww

Processor

Assembly

5.

Position

tanks.

tank

6.

Position

into

the

7.

Plug

the

rear

access,

swing

capturing

functions

Dryer

8.

Remove

the

Developer,

The

Dev

and

WASH

the

Dryer

pivot

the

electrical

airknife

loosen

the

plate

the

as a cable

Transport

the

processor

(red

(no

Transport

blocks

supply

under

the

Phillips

upwards.

cable

in

up

and

Fixer

label)

label)

at

the

harness

the

After

the

space

drape

back

side

and

goes

into

into

the

above

rear

of

cover

plate

screws

plugging

between

to

keep

for

covers.

Wash

the

rear

the

Wash

the

Processor

into

the

(See

in

the

the

cable

access

Transport

front

tank,

tank.

Transport,

Assembly.

Dryer

Transport

Figure

lower

left

in

the

supply

the

cover

in

the

to

or

removal

assemblies

FIX

(blue

placing

power

2-4).

To

open

and

right

corners

harness,

plate

and

the

proper

position

of

the

Wash

into

their

label)

into

the

pivot

receptacle

the

cover

of

close

the

right side

when

Transport.

appropriate

the

middle

pins

securely

located

plate

for

the

plate

and

cover

plate,

plate.

This

pivoting

the

on

su

Medical

Mini

Figure

Military

2-3,

Placing

Processor

2-6

onto

Note:

positioning

Packing

Loader

purposes

Case

shown

#1.

for

processor

only.

nan

w

ceo

um

UB

=

Page 28

Installation

Set

TOP

FOR

WITH

FILM

Up

(Cont'd)

LOCK

PLATE

ENGAGEMENT

TOP

LATCH

BOX

DOOR

Figure

Figure

2-4,

2-5,

Dryer

Film

Power

LOWER

ENGAGEMENT

Storage

Receptacle

STEEL

POSITIONING

Box

and

LATCH

WITH

Cover.

PLATE

ANGLE

DAYLIGHT

FOR

LOADER

a

o

_

|

9.

Open

Packing

in a safe

repacking

Daylight

Loader

10.

The

the

the

11.

Mount

Note:

Assembly

Daylight

processor

front

the

Arm

Case

location.

for

Store

redeployment.

Loader

by

four

of

the

processor

Daylight

holes

face

#2.

Remove

all

processor

Assembly

(4)

1/4-20

by

Loader

Assembly

forward

contents

Mounting

screws.

three

(3)

in

front

2-7

(referenced

packing

Plate

The

Film

8-32

screws.

to

the

Mounting

of

the

Processor

on

materials

is

in

supplied

Feed

Tray

Plate

Assembly.

page

4)

this

case

secured

is

supplied

(See

Mini

and

put

for

later

to

the

Figure

Medical

aside

use

when

front

of

secured

2-6).

Military

to

Page 29

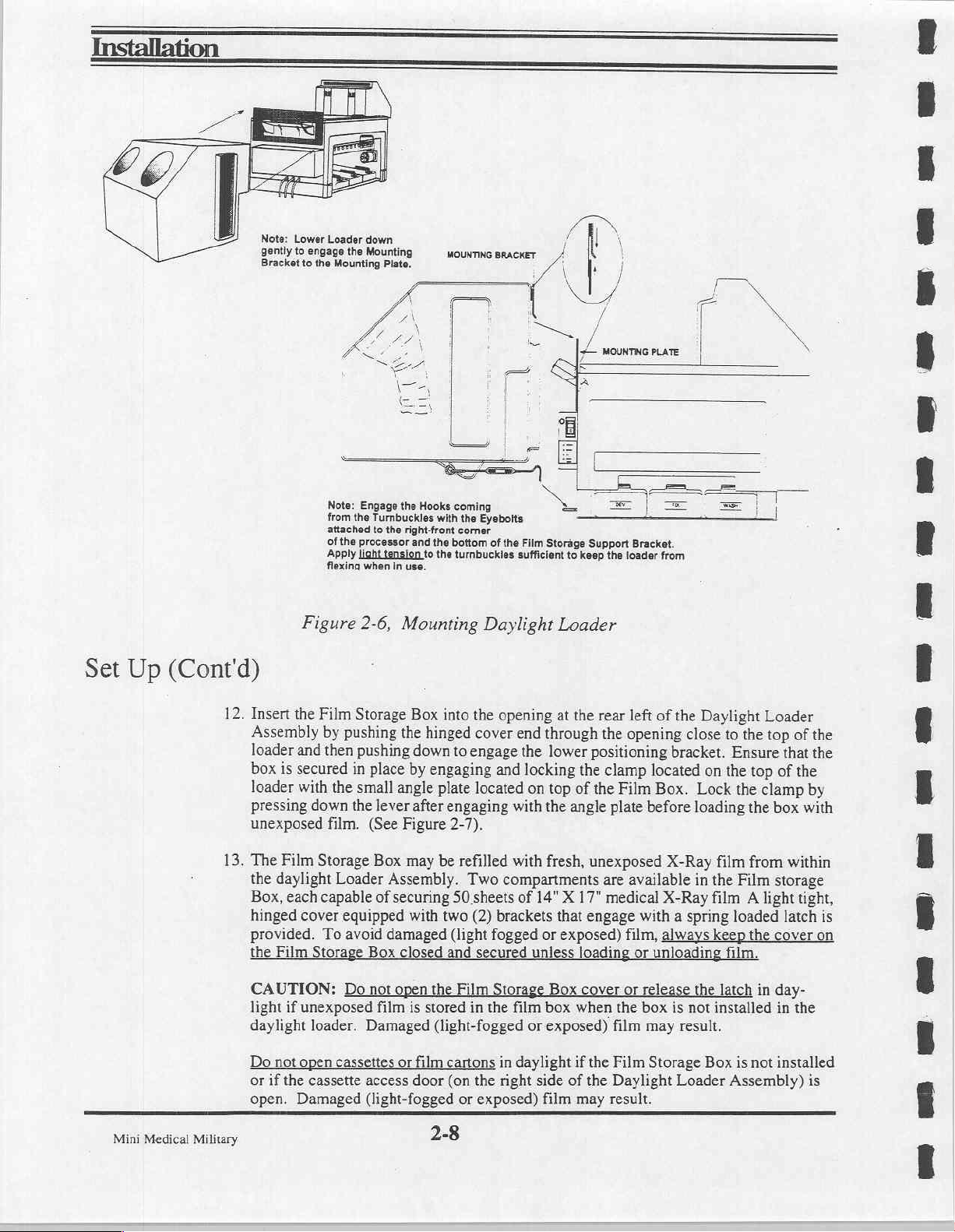

Note:

Lower

Loader

down

the

Mounting

Mounting

Note:

Engage

from

the

Turnbuckles

attached

to

of

the

processor

Apply

light

flexina

tension

when

2-6,

Plate.

the

Hooks

the

right-front

and

the

to

in

use.

Mounting

MOUNTING

BRACKET

A

coming

with

the

Eyebolts

corner

bottom

of

the

turnbuckles

the

Daylight

sufficient

Set

Up

(Cont'd)

gently

to

engage

to

Bracket

Figure

the

[

Film

X

À

i

<

Storage

Support

to

keep

Loader

Bracket.

the

loader

P%

from

12.

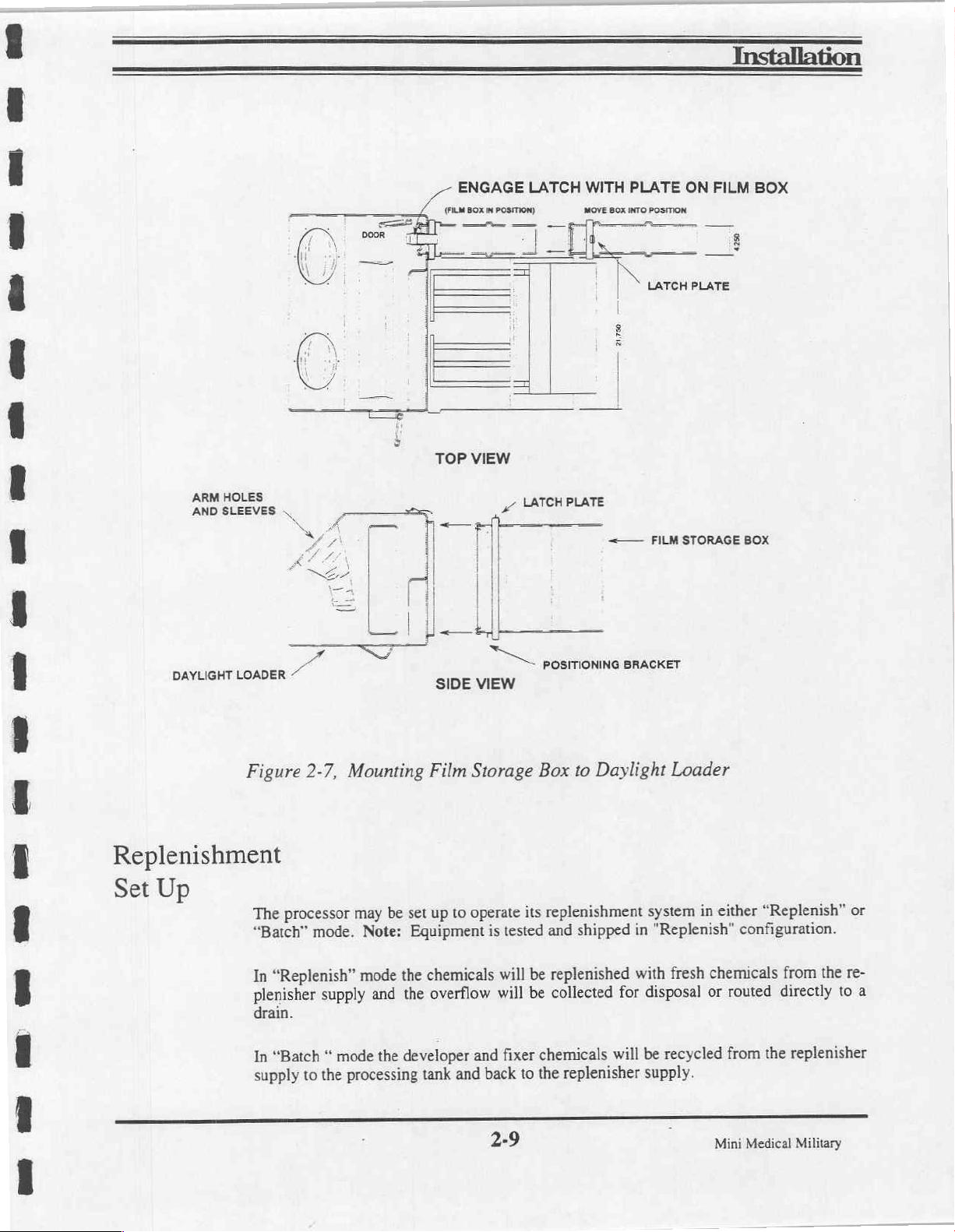

Insert

the

Film

Storage

pushing

Assembly

loader

box

loader

pressing

unexposed

13.

The

the

Box,

hinged

provided.

the

CAUTION:

light

daylight

Do

not

or

if

Mini

Medical

Military

open.

by

then

and

secured

is

the

with

down

film.

Film

Storage

daylight

each

capable

cover

To

Film

Storage

if

unexposed

loader.

open

the

cassette

Damaged

pushing

in

small

the

Loader

equipped

avoid

Do

cassettes

Box

into

hinged

the

to

down

engaging

by

place

plate

angle

engaging

after

lever

Figure

(See

Box

Assembly.

of