Page 1

Mini-Medical Series

Troubleshooting Reference

Trained Service Personal ONLY

Observe ALL safety Procedures in the service manual

Reference: Installation, Operation, Service & parts Manual (P/N:0000061122)

Page 2

Table of Contents

1. No Dryer Heat -Wet Film (Fan not working)_______________ 1

2. No Dryer Heat -Wet Film (heaters not working)____________ 2

3. No Developer Heat (Light Film)_________________________3

4. Over Heated Developer (Dark Film)______________________4

5. Machine Doesn’t Go Into Standby Mode__________________5

6. Low Developer Light is Always On_______________________6

7. Developer Heating Time is Too Long_____________________7

8. Replenishment Pump is not Working_____________________8

9. Fixer/Developer is Disappearing From the Machine_________9

10. The Machine Doesn’t Come On-No LED on Logic Board_____10

11. The Main Breaker Trips When the Machine is Turned On_____11

12. Only One Replenishment Pump is Working All the Time______11

13. Resistances reference for 115V Processors ________________12

14. Resistances reference and parts numbers for 230V Processors_13

Note: If you have a 230V Processor, please consult page 11 for common

resistances values and parts numbers.

Key

> Greater Than

< Lower Than

= Equal To

≈ About the Same

Page 3

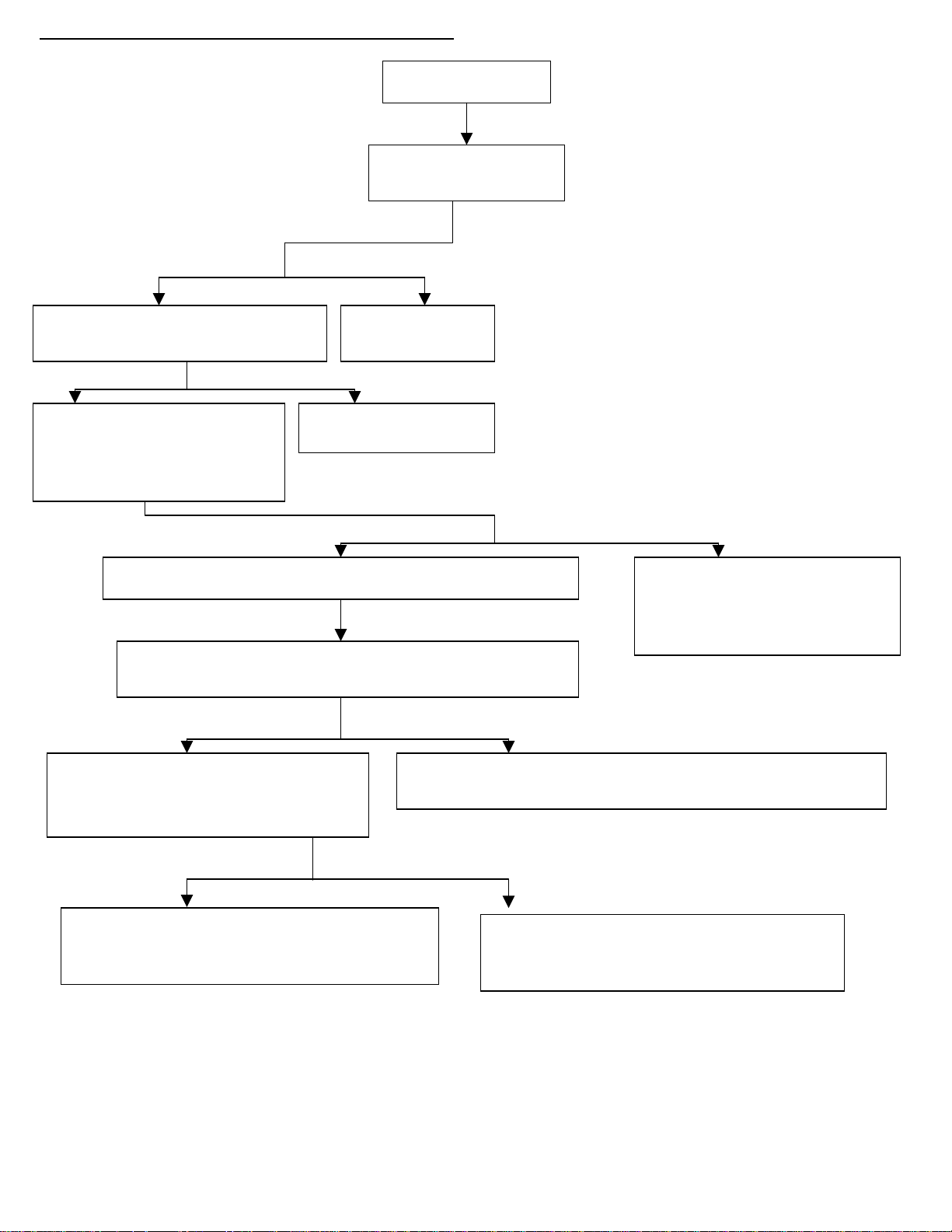

1)

plug

p

g

No Dry Heat -Wet Film (Upper Fan is not Working)

Wet Film

Check Fuse F7 on the

A/C Board

Fuse Good Fuse bad

Check Voltage between TB1-1 (Logic

Board) and J1-4 (A/C Board)

Replace Fuse F7

P/N:

0000032013

Voltage No Voltage

Check the voltage between the

two external slots of the J11 Plug

located on the right side of the

machine.

Replace A/C Board

P/N: 9992305008

Voltage No Voltage

Check the dryer rack wiring on the back of the machine

Unplug the 6-P connector and check the voltage between

the orange and the thick white wires inside the plug.

There is a broken wire between

the J11 plug and the A/C Board.

Replace the PC board above the

. P/N: 0000035316

Voltage No Voltage

Plug the connector back & check

Voltage between 2 and 4 (white &

orange wires on the right strip)

Replace the harness (between the J11 plug and the dryer rack

lug. P/N: 0000032677 (Harness for the Dryer Rack)

Voltage No Voltage

Replace the upper fan.

P/N: 0000021569 (115V)

P/N: 0000021637 (230V- S/N 8677 & hi

her)

Replace the harness (between the plug and

the strip on the dryer).

P/N: 0000032676

Note: If the dryer is working check / fix replenishment rates:

Weak fixer doesn’t harden well and therefore, the film will not dry adequately.

1

Page 4

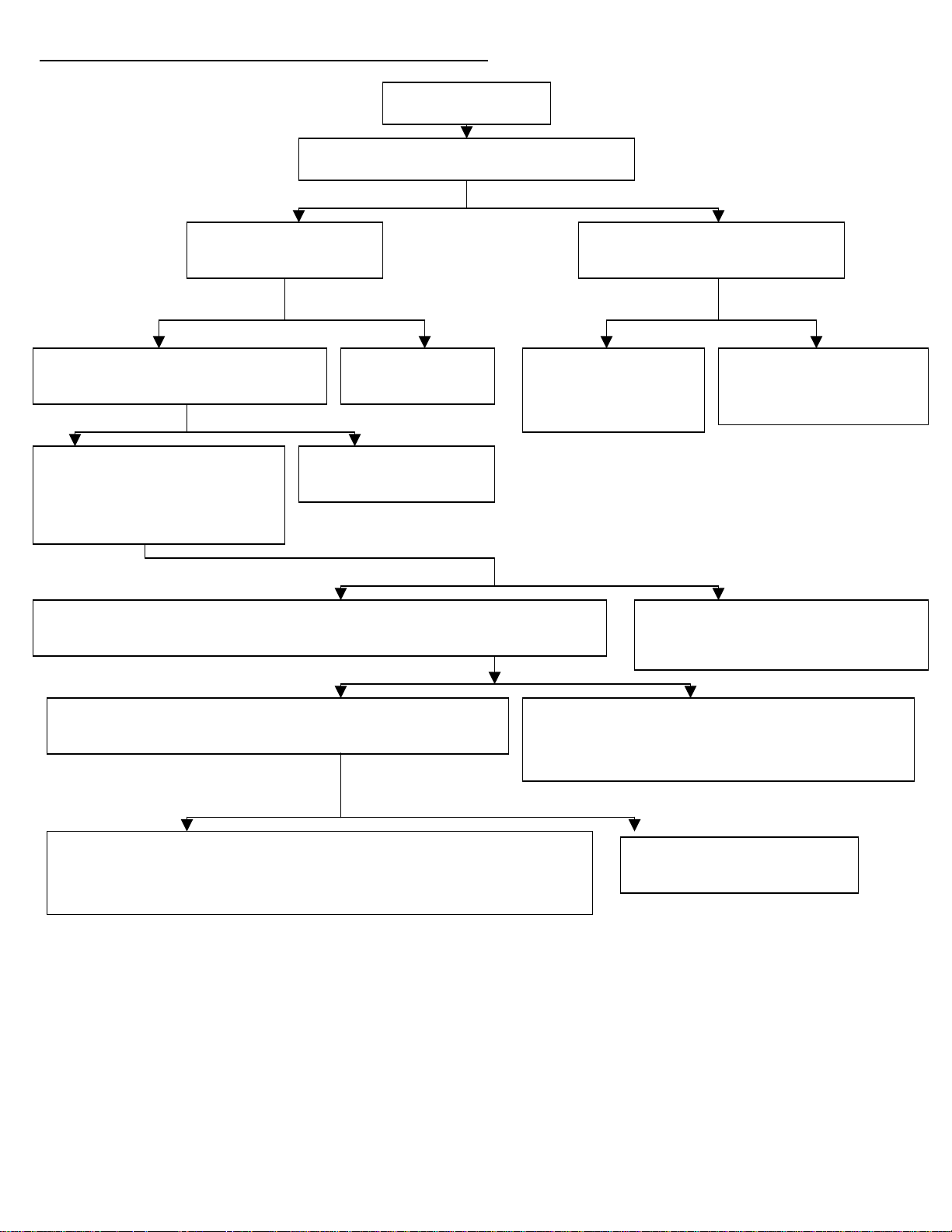

2)

No Dry Heat -Wet Film (Dryer Lamps are not Working)

Wet Film

Check Light L1 on the Logic Board

Light On Light Off

Check Fuse F5 on the

A/C Board

Disconnect J5 from the Logic

Board (Temp’ Sensor).

Fuse Good Fuse bad Light is On Light is Off

Check Voltage between TB1-1 (Logic

Board) and J1-1 (A/C Board)

Replace Fuse F5

P/N: 0000032013

Voltage No Voltage

Replace

Temperature Sensor

P/N: 0000021781

Replace Logic Board

P/N: 9992305017 (115V)

P/N: 0000035304 (230V)

Check the voltage between the

two external slots of the J10 Plug

located on the right side of the

machine.

Replace A/C Board

P/N: 9992305008

Voltage No Voltage

Check the dryer rack wiring on the back of the machine. Unplug the 6-P connector and

check the voltage between the thick white wire and brown wire inside the plug.

There is a broken wire between the J11

plug and the A/C Board. Replace the PC

board above the plug. P/N: 0000035316

Voltage No Voltage

Check the voltage between 2 (Right to left-white wire on

the right) and 2 (Left to right-brown wire on the left).

Replace the harness (between the J11 plug and

the dryer rack plug. P/N: 0000032677 (Harness

for the Dryer Rack)

Voltage No Voltage

If the heaters are not working at this point, replace them.

P/N: 0000021175-1 (115V)

P/N: 0000021775-2 (230V)

Replace Over Temp’ Safety

P/N: 0000037800

Note: If the dryer is working check / fix replenishment rates:

Weak fixer doesn’t harden well and therefore, the film will not dry adequately.

2

Page 5

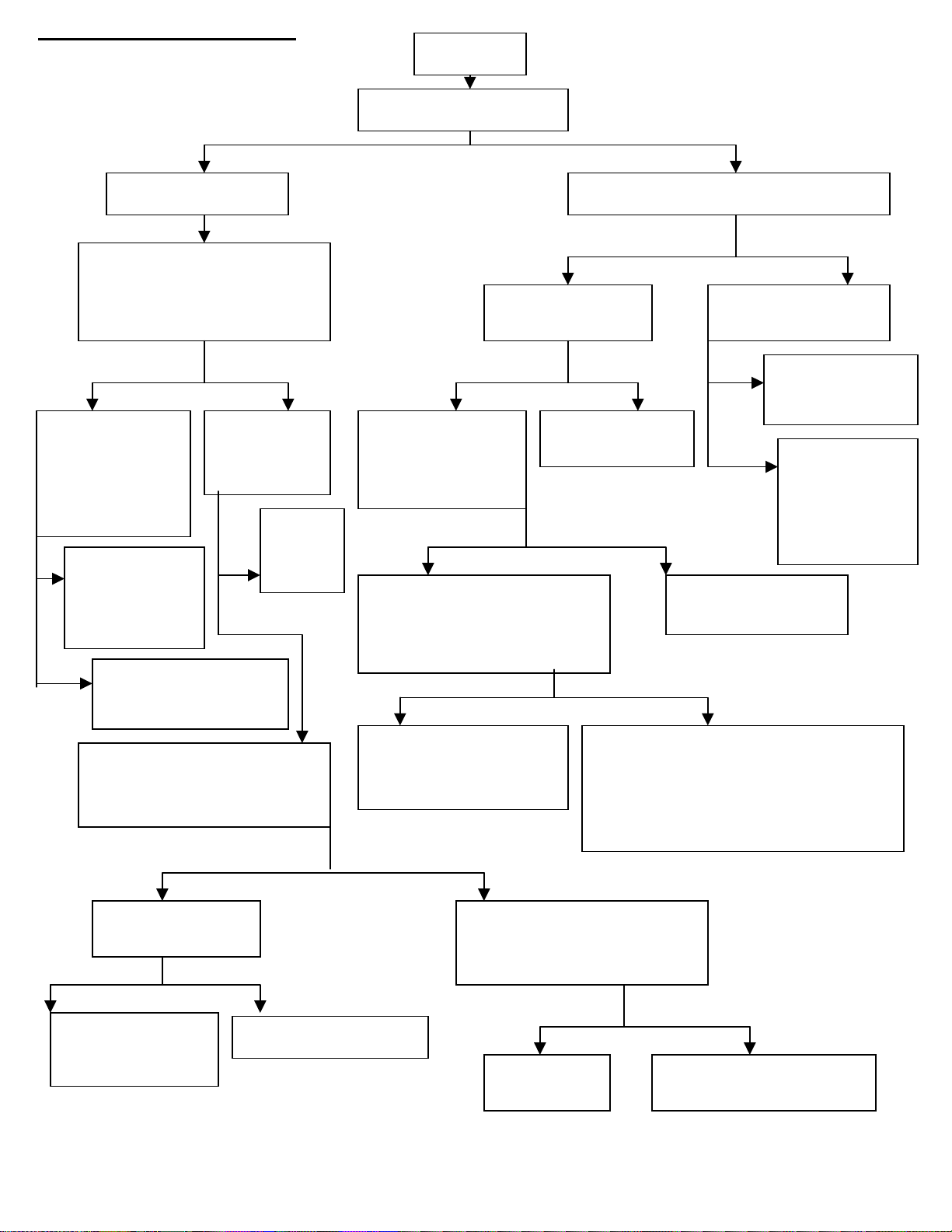

3)

p

p

p

No Developer Heat (Light Film)

Light Film

Check DEV Temp Light

Light No Light

Fill Developer Tank

Check light, L2, on the Logic board

Light No Light

Check the voltage between

the two external slots of the J4

lug located on the right side

of the machine (115V)

Check Fuse F4 on

the A/C Board

Disconnect J4 on the

Logic Board

Voltage No Voltage Fuse Good Fuse bad Light

Check the

N

resistance of the

heat exchanger

Should be:

23Ω±10%

Voltage No Voltage

Bad Bad

Good

Replace Heat

Exchanger

P/N: 0000021848-1

(115V)

P/N: 0000021848-2

Good

Voltage No Voltage

Rotate R-20 clockwise on

logic board until the DEV

Temp is blinking steadily.

Exchange I/C’s U1 & U2 on

the A/C board and see if the

roblem was solved

Check if fuse

F4 on the

A/C Board

Replace

Fuse F4

P/N:

000003201

Check Voltage

between TB1-1

(Logic Board) &

J1-2 (A/C Board)

Check the voltage between

the two external slots of the J4

lug located on the right side

of the machine.

Replace the Heat Exchanger:

P/N: 0000021848-1 (115V)

P/N: 0000021848-2 (230V)

Replace Fuse F4

P/N: 0000032011

Check if there is a broken wire between

the J4 plug and the A/C Board or

whether the connections on the PC

board behind the J4 plug are loose.

P/N:

0000035316 (PC Board + Harness)

No Light

Replace A/C Board

P/N: 9992305008

Replace Temp’

Sensor

P/N: 0000038157

Replace Logic

Board

P/N: 9992305017

(115V)

P/N: 0000035304

(230V)

DEV Temp is On DEV Temp is Off

Check if Dryer

lamps are working

Not Working Working

Check voltage between J1-2

on the A/C Board and TB1-1

on the Logic Board

Voltage No Voltage

Replace the A/C

board

P/N: 9992305008

Machine should work.

Machine

should work

There is a broken wire

between the two boards

Note: check / fix developer replenishment rates: Weak developer chemistry will not develop well.

3

Page 6

Dark Films-Over Heated Developer

p

p

p

4)

Light is On Light is Off

Light Stays On Light turns Off

Voltage No Voltage

Add Developer so it covers the low level sensor and calibrate the temperature by rotating trim

ot R-20 on the Logic Board counterclockwise to reduce the temperature. Let the machine

work for few minutes and test the temperature of the developer. Continuously check the light

L2 on the Logic Board while testing the temperature of the developer. Once the temperature

stabilizes at the required temperature the light L2 should go out.

If the develo

Replace the Logic Board

P/N: 09992305017

Note: Be sure the darkroom does not have light leaks that will pre-expose the film.

er temperature overshoots the specified temperature - see below:

Check Light L2 on the Logic Board

If the light is on the sensor calls the

heater to supply more heat. If the

developer is already over heated, the

roblem might be with the sensor or

with the Logic Board.

Disconnect J4 from the Logic Board

and short and the two pins. That

bypasses the sensor.

Dark Films

Replace the AC Board

P/N: 9992305008

The machine is good.

Keep the pins shorted and check the voltage between TB1-1

(white wire on logic board) and J1-2 (red wire on AC board).

Replace the Sensor

P/N: 0000038157

4

Page 7

5)

Pumps Work Continuously-Machine doesn’t go into Standby mode

Machine fails to go into Standby Position- Calibrate the distance from magnets to pendulums

according to the description at the bottom of the page. If it didn’t solve the problem, see below.

Symptoms

Weak Magnets, Fixed

Pendulum in upper position

Switch Stuck in

Closed Position

Switch is adjusted too far

from the magnets

Unplug J13 from the Logic Board and wait

8-10 seconds for the pumps to shut down

Pumps do shut off Pumps don’t shut off

Problem is in the ready tone generator

board: Either the switch or the magnet.

Unplug connector J12 from the logic board and

wait 8-10 seconds for the pumps to shut down

Pumps do shut off Pumps don’t shut off

Unplug the right switch, J13, from the

ready tone generator board and short the

middle and right pins. Wait 8-10 seconds

for the pumps to shut down.

Replace the Logic Board

P/N: 9992305017 (115V)

P/N: 0000035304 (230V)

Replace the manual

replenishment switch

P/N: 0000037112

Pumps do shut off Pumps don’t shut off

Replace the right switch and the right pendulum.

P/N: 0000021878 (Switch)

P/N: 0000021893 (Pendulum)

Return J13 to place and repeat the

same procedure for the left switch,

J14 (short middle and right pins).

Pumps do shut off Pumps don’t shut off

Replace the left switch and the left pendulum.

P/N: 0000021878 (Switch)

P/N: 0000021893 (Pendulum)

Short J13 and J14

Simultaneously.

Pumps do shut off Pumps don’t shut off

Replace left and right switches and pendulums.

P/N: 0000021878 (Switch)

P/N: 0000021893 (Pendulum)

Replace the Ready Tone Generator Board.

P/N: 0000035306-1

If after replacement the problem still exists, you will have to calibrate the distance of the magnets from the pendulums.

The right distance can be determined by measuring the voltage between ground chassis (left bottom screw on the logic

board and the green middle wire on the sensor plug. The voltage should be zero when no film is in the feed tray and 11V

when a film is present (then the pendulums are lifted by the thickness of the film).

5

Page 8

6)

Low Developer Level Light is always ON

Low Developer Level Light is On

Fill developer tank up to sensor level

Light Still On No Light-Problem Solved

Clean the level sensor (Screw)

inside the developer tank

Machine should work

Light Still On No Light-Problem Solved

Check the wires between the level

sensor and the Logic Board, J8:

Unplug J8 and short the pins.

Machine should work

Light Still On No Light-Problem Solved

Replace Logic Board.

P/N: 9992305017 (115V)

P/N: 0000035304 (230V)

Make sure that the heat exchanger

ground wire (green wire) is in place.

If problem hasn’t been solved replace the sensor harness

P/N: 0000032578

5A)

Q)

During installation and initial set-up, the LOW DEV and DEV TEMP lights are ON even when the developer tank is

full with water.

A)

As water cannot conduct well enough, the level sensor will signal a low solution level to the PC board and

automatically disable the developer heater. Make sure to add kosher/coarse salt or some developer chemical to the

water to allow conductivity.

6

Page 9

7)

p

p

Developer Heating Time is too Long

Background:

The re-circulation pump circulates the developer through the heat exchanger and into the developer tank.

A thermostat measures the developer temperature at the exit from the heat exchanger. When the temperature

exceeds 165 F the thermostat will divert the current from the heat exchanger and by that will prevent further

heating. It will allow heating only when the temperature of the developer drops back to the reset point. When the

developer re-circulation pump is not working properly the amount of developer going through the heat exchanger

is small and therefore, heated fairly quickly. Since the th ermostat senses only the temperature of the fluid in its

roximity, which reaches 165 F quickly when the volume of fluid is small, it opens up and prevents additional

heating. As a result, the developer heating time is extended significantly.

Check if the re-circulation pump is working by

hysically listening to it or touching it, or by

observing the developer flow coming into the

developer tank. The inlets are located under the

white plastic diffuser and on the left wall of the

developer tank.

If the re-circulation pump is not working appropriately and

the developer flow is too weak than the pump has to be

replaced.

P/N: 0000022100 (115V-Newer model, blue/green pump)

P/N: 0000022101 (230V- Newer model, blue/green pump)

P/N: 0000021145 (115V-Older model, red/brown pump)

P/N: 0000021101 (230V- Older model, red/brown pump)

7

Page 10

8) The Replenishment Pump/s are not Working (Developer and/or Fixer Pumps).

(

p

p

Remove the right panel of the machine.

-If developer replenishment pump is not working:

Check the voltage between the two external slots of plug J3.

-If fixer replenishment pump is not working:

Check the voltage between the two external slots of plug J6.

Voltage No Voltage

Good Bad

LED ON NO LED

Shut down the machine and

unplug the pump’s plug.

Check resistance between the two

external

Good Resistance Bad Resistance

Make sure that the

end caps of the

umps are not

calcified and that

the hoses are clean

and free of

chemical build up.

ins: 134 Ω ± 10 %

Replace pump:

P/N: 0000020995

(115V)

P/N: 0000020995-1

230V)

Check if fuse F-1 on logic board is good

See if LEDs L5 and L6

are flashing when you

activate the pumps.

Replace fuse F1

P/N: 0000032003

Replace the logic board

P/N: 9992305017

Check for voltage between the logic board and the AC board:

For developer replenishment pump:

Check between TB1-1 & J1-7 (pink wire on AC board)

For fixer replenishment pump:

Check between TB1-1 & J1-6 (blue wire on AC board)

Voltage No Voltage

Replace the PC board located above

the plug.

P/N: 0000035316.

(Most probably the soldering of the

wire coming from the AC board to

the board above the plug was broken.

You can verify it by removing the PC

board and checking the connections).

Replace the AC Board

P/N: 9992305008

8

Page 11

9) Fixer/Developer is Disappearing from the Machine

Chemical can be disappearing from the machine in three different ways:

a) Evaporating.

b) Siphoning.

c) Leaking.

a)

If the temperature of the developer is about 95°F and therefore, the temperature

of the fixer cannot be more than that, the chemical could not be evaporating.

b)

Siphoning can happen when the white gooseneck tube outlet is inside the

chemical: the chemical will flow back to the reservoir tanks outside the machine.

To prevent it, reposition the gooseneck slightly above the chemical level. Don’t

raise it to much in order to prevent splashing of chemical during replenishment.

c)

Check the drainage ball valve located at the front of the processor. If this valve

is leaking the chemical will go directly to the drainage without anybody noticing

it.

P/N: 0000087222 (Gray W/Blue Handle)

P/N: 0000087220 (Black-older style)

If you will increase the replenishment rate to compensate the disappearance of

the chemical the problem will not be solved. The outcome will be a greater rate

of disappearance, as you will use more chemistry per sheet.

And by comparing it to the other chemical (that does not disappear and has a

regular replenishment rate) it will seem as if the disappearance rate is greater.

9

Page 12

10. The Machine Doesn’t Come On: No LED on the Logic Board.

j

p

p

g

Check for line voltage (115V) at the On/Off Switch when the machine is turned On.

See if lower fan, solenoid or motor works

Voltage / components work No Voltage / components don’t work

Check voltage on the Logic board between

the white and black wires located on TB1-1 and

TB1-5, respectively.

Voltage No Voltage

Disconnect connector J14 from the logic board and

ump the two pins. That will bypass the cover switch.

LED On LED still off

LED On LED still off

Replace Cover Switch.

P/N: 0000037051

Make sure that the following connectors are not connected

in reverse and that they are sitting correctly on the pins:

a) J7 on the logic board

b) J2 on the AC board

c) 8 Pin connector underneath the LED board

Make sure that all other connectors are also in

Problem resolvedmachine should work

Check the On/Off switch and voltage

source from the socket. Replace switch

if required. P/N: 0000037283

Make sure that the wires are secured in place.

If one of the connectors on the logic board, AC

board or LED board (underneath the left upper

anel) is not connected properly it will shut down

all LEDs on the lo

Replace the Logic board

P/N: 9992305017

ic board.

lace.

Page 13

11. The Main Breaker turns off When the Machine is turned On.

p

12.

One Replenishment Pump is Working Continuously

LED OFF LED ON

Replace the A/C Board.

P/N: 9992305008

Turn off the unit and remove the right panel from the processor.

Disconnect all plugs from the unit and then turn it back on.

If only one replenishment pump is working all the time check if

the corresponding LED on the logic board in On or Off:

LED L5-Developer Replenishment.

LED L6-Fixer Re

lenishment

If both LEDs are flashing all the time we have two problems:

1. The pumps should be flashing only for 8-10 seconds

when a film is inserted.

2. One pump is not working.

To resolve the first problem you should consult with

troubleshooting chart number 5.

To resolve the second problem you should consult with

troubleshooting chart number 8.

Page 14

AFP Imaging

250 Clearbrook Road

Elmsford, NY 10523

Tel: 1.914.592.6100

Fax: 1.914.592.6148

www.afpimaging.com

Mini Medical Resistance

120 Volt

Description Part Number Resistance Value

Recirculation Pump

March (red) (Old Style)

Recirculation Pump

Iwaki (blue/green)

(New Style)

Developer Heater 0000021848-1

Replenish Pump 0000020995

Water Solenoid 0000049008

Dryer Lamps (Heaters) 0000021175-1

Dryer Fan 0000021569

Drive Motor 9992305311

9992305035 (21145)

0000022100

10

31.8 Ω ± 10%

116 Ω ± 10%

23 Ω ± 10%

134 Ω ± 10%

430 Ω ± 10%

43 Ω ± 10%

26 Ω ± 10%

104.5 Ω ± 10%

Page 15

Mini Medical Resistance

230 Volt

Description

230 Volt

Recirculation Pump

March (red) (Old Style)

Recirculation Pump

Iwaki (blue/green)

Developer Heater 0000021848-2

Replenish Pump 0000020995-1

Water Solenoid 0000049013

Dryer Lamps (Heaters) 0000021175-2

Dryer Fan 0000021637

Drive Motor

230 50/60Hz

0000021525

00000022101

0000021490

Part Number Resistance Value ± 5%

Parts List for 230V

PC Logic Board

Drive Motor

Heater Assembly

0000021848-2

1 KΩ%

470 Ω

90 Ω

560 Ω

2.5 KΩ

170 Ω ea.

100 Ω

410 Ω

0000035304

0000021507

Replenishment Pump

0000020995-1

Heating Lamps I.R 0000021175-2

Recirculation Pump

0000021101

(old style-red/brown)

Recirculation Pump

0000022101

(new style-blue/green)

Fan Assy, Lower 0000021637

Heater, 550W 0000021848-2

11

Loading...

Loading...