Aerovent IM-500 User Manual

®

IM-500

August 2013

General Installation, Operation and Maintenance Instructions For Aerovent Products

Direct Fired Air Make-Up Unit

Table of Contents

Unit Information.......................................................................... |

|

1 |

Special Precautions....................................................................... |

|

2 |

Installation Codes................................................................... |

2 - 3 |

|

Unit Location Restrictions.......................................................... |

|

3 |

Sound and Vibration Information............................................ |

|

3 |

Installation Information........................................................ |

3 - 5 |

|

Electrical Installation.................................................................... |

|

5 |

Gas Piping Installation.......................................................... |

5 - 7 |

|

Operating Instructions and Parts...................................... |

7 |

- 12 |

Start-Up Procedure............................................................. |

12 |

- 14 |

Sequence of Operation..................................................... |

14 |

- 15 |

Circuit Analyzer/Troubleshooting.................................. |

15 |

- 16 |

Maintenance Recommendations...................................... |

16 |

- 18 |

Terms & Conditions/Warranty....................................... |

19 |

- 21 |

Start-Up Report................................................................... |

22 |

- 24 |

FOR YOUR SAFETY

If you smell gas:

1.Open windows.

2.Do not touch electrical switches.

3.Extinguish any open flame.

4.Immediately call you gas supplier

WARNING: Improper installation, adjustment, alteration, service or maintenance can cause property damage, injury or death. Read the installation, operating and maintenance instructions thoroughly before installing or servicing this equipment.

Gas-fired appliances are not designed for use in atmo- spheres containing flammable vapors or duct, or atmo- spheres containing chlorinated or halogenated chlorinated or halogenated hydrocarbons.

Recirculation of room air may be hazardous in the presence of: a) flammable solids, liquids and gases; b) explosive materials (ie., grain dust, coal dust, etc.); and c) substances that may become toxic when exposed to heat.

An electrical disconnect must be installed having adequate ampacity (see marking on the heater for voltage and ampacity), if the unit was not provided with one.

This disconnect shall be installed in accordance with

Article 430 of the National Electrical Code, ANSI/

NFPA 70.

This manual is the property of the owner. Please be sure to leave it with them when the installation and start-up of this equipment has been completed.

As Aerovent has a continuous product improvement program, we reserve the right to change designs and specifications without notice.

FOR YOUR SAFETY

The use and storage of gasoline or other flammable vapors and liquids in open containers in the vicinity of this appliance is hazardous.

Aerovent Regional Office |

Aerovent Headquarters |

800 S. High St. |

5959 Trenton Lane |

Covington, OH 45318 |

Minneapolis, MN 55442 |

(937) 473-3788 |

(763) 551-7500 |

©2013 Aerovent

Recirculating Units

WARNING

On heaters which recirculate air, outside ventilation air must be provided in accordance with the information shown on the heater nameplate.

Building Relief

Adequate building relief MUST be provided so as not to overpressureize the building when the heating system is operating at its rated capacity. It should be noted that this can be accomplished by taking into account, through stan- dard engineering methods, the structure’s designed infiltra- tion rate; by providing properly sized relief openings; or by interlocking a powered exhaust system; or by a combination of these methods.

Control Wiring

Entry for control wiring should be ran into the control room provided. Please consult unit drawing and locate the control room on that drawing.

REFER TO THE HEATER RATING PLATE FOR DETERMINING THE MINIMUM GAS SUPPLY PRESSURE FOR OBTAINING THE MAXIMUM GAS CAPACITY FOR WHICH THIS HEATER IS SPECIFIED.

Insulated Units

It is NOT recommended that a recirculation unit be installed in a building that is NOT insulated where the outside air temperature falls below 32o F.

Ventilation Air

Excessive recirculation or insufficient ventilation air, which results in inadequate dilution of the combustion products generated by the heater, may create hazardous concentra- tions of carbon monoxide, nitrogen oxide, and other com- bustion products in the heated space.

Fossil Fuel Powered Equipment

If gas fork trucks or other fossil fuel powered equipment are utilized in the conditioned area, additional ventilation requirements for the factility must be addressed separately.

Applications

If there is any doubt in the application of this heater, con- sult the manufacturer.

Ventilation Air

All ventilation air to this heater MUST be ducted directly from the outdoors.

Interlocks

If failure or malfunction of this heater creates a hazard to other fuel burning equipment in the building (e.g. when the heater is providing make-up air to a boiler room), the unit is to be interlocked to open inlet air dampers or other devices.

Inlet Ducts

When inlet ducts are installed, the heater MUST exchange the air inside the duct a minimum of 4X prior to an ignition attempt. Please consult the manufacturer for instructions.

2 |

Aerovent IM-500 |

Special Precautions

THE INSTALLATION AND MAINTENANCE INSTRUCTIONS IN THIS MANUAL MUST BE FOLLOWEDTOPROVIDESAFE,EFFICIENTAND TROUBLE FREE OPERATION. IN ADDITION, PARTICULAR CARE MUST BE EXERCISED REGARDINGTHESPECIALPRECAUTIONSLISTED BELOW.FAILURETOPROPERLYADDRESSTHESE CRITICALAREASCOULDRESULTINPROPERTY DAMAGE OR LOSS, PERSONAL INJURY OR DEATH.

1.In Canada, only 100% outside air unit may be installed.

They must be solely for replacing exhausted inside air with heated air.

2.Unit must be installed such that no source of flam- mable vapor, gases or dust is located within 20 feet horizontally of the unit, unless that source is separated from the unit by an enclosure of fire and vapor resistive materials.

3.Disconnect all power before making wiring connections to prevent electrical shock and equipment damage. All units must be wired in strict accordance with the wiring diagram furnished and the NEC.

4.Turn off all gas before installing equipment.

5.Gas pressure to the unit controls must never exceed the gas supply pressure on the data sheet. The unit and its individual shutoff valve must be disconnected from the gas supply during any pressure testing of gas supply piping system at pressures greater than the supply pressure shown on the unit’s data sheet. (Maximum pressure to the unit shall never exceed 5 psig.)

6.Check the gas supply pressure at the pressure gauge upstream from the pressure regulator. A pressure regulator, which will satisfactorily limit the gas supply pressure, must be installed with each heater. Purging air from gas lines and piping must be performed as described in ANSI Z223.1, latest edition, “National

Fuel Gas Code” (or CAN/CGA-B149 codes in Canada). STRAINERS BETWEEN THE SUPPLY

LINE AND AIR MAKE-UP UNIT ARE HIGHLY RECOMMENDED.

7.Check damper operation to insure damper blades travel to their full open position and that the damper end switch is functioning properly.

8.To prevent unit or building structural damage, do not operate unit where combustion air may be exposed to chlorinated, halogenated or acid vapor laden air.

9.Minimum clearances to combustibles must be maintained. The minimum clearances to be maintained are

6" from the top, ends and sides of the unit. Allow a 36" minimum clearance on the sides of the unit for servicing. Access doors are provided for servicing the gas controls, electric components and drive adjustment.

The unit must be installed such that the surface tempera-

ture of any adjacent combustible material shall not exceed

90o F above an ambient temperature of 77o F.

10.Do not block or modify combustion or ventilation air openings. Installation must conform to all local codes, or in the absence of local codes, with National Fuel Gas Code, ANSI Z223.1, latest edition (in Canada install according to CAN/CGA-B149, Installation

Code for Gas Burning Appliances and Equipment” or

CAN/CGA-B149-2, “Installation Code for Propane

Burning Appliances and Equipment”).

11.Do not operate unit without exhaust fan or fans operating. Insure proper interlock with exhaust fan system. Direct-fired units operate by heating air directly when the air is passed over the burner flame. On initial burn- er start-up, or on burner shut down some gas odor may be detected. The presence of gas odors under these temporary intermittent conditions does not indicate an equipment problem, nor do they indicate a hazardous or unsafe operating condition. Direct-fired equipment is not recommended for installations that may be highly sensitive to temporary gas odors. If gas odors persist after initial burner ignition, or for extended periods after burner shut down, discontinue use of unit and call a qualified service technician.

12.Installation in airplane hangars must be in accordance with the Standard for Aircraft Hangars, ANSI/NFPA

409 and in public garages in accordance with the

Standard for Parking Structures, ANSI/NFPA

13.Use spreader bars when lifting equipment.

14.Consult piping, electrical and venting instructions before installation. Keep all literature shipped with the unit for future servicing. Leave all literature with the owner.

15.If the failure or malfunction of this heater creates a hazard to other fuel burning equipment in the building, the unit must be interlocked to open inlet air dampers or other such devices.

Installation & Manufacturing

Codes

Manufacturing:

A.The units as constructed conform to ANSI Air Make-

Up std. Z83.4, Z83.18, Z223.1, and HFPA54.

B.Wiring within the control panel meets and carries the UL508 label and meets ANSI/INFPA #70-1987.

C.Piping within the unit meets ANSI Code Z223.1 National Fuel Gas Code.

D.Fan performance tested in accord with AMCA 210.

E.Fan Sound tested in accord with AMCA 310.

F.Insurance codes IRI and FM as requested.

G.Equipment components supplied carry the UL electrical listings.

Installation codes governing unit installation by contractors:

A.ANSI Z83.4, Z83.18, or Z223.1 (latest edition) as applicable.

3 |

Aerovent IM-500 |

B.All installation of this equipment must be performed by a qualified installation agency only defined in ANSI Z223.1.

C.Electrical ANSI/INFPA #70-1987.

D.Aircraft hangar NFPA 409.

E.National Fuel Gas Code NFPA 54.

F.Installation of air conditioning and ventilating systems NFPA 90A.

G.Parking Structures and Repair Garages NFPA 54.1.

Unit Location Restrictions and Considerations

CAUTION

Units must not be installed where they may be exposed to explosive or flammable atmospheres. In Canada, only 100% make-up air direct-fired units may be installed and they must be applied solely for replacing exhausted inside air with heated outside air.

1.Do not locate any gas-fired equipment where chlorinated or acid vapors are present in the combustion air atmosphere.

2.When locating units, consider general space and heat- ing requirements and availability of gas and electrical supply.

3.Maintain minimum clearances to combustibles. The minimum clearances are, 12" from the top, 12" from the bottom, 12" from the sides, and 12" from the ends.

4.Where necessary to provide working clearance beneath the unit, the unit shall be installed at a suitable height above the floor or otherwise adequately protected.

5.Allow 36" clearance on both sides of the unit for service access.

6.Do not modify or block combustion or ventilation openings. Do not modify burner profile opening.

7.Do not install direct-fired units down stream from any cooling system that utilizes refrigerants for cooling.

8.Be sure the structural support at the unit location is adequate to support the weight of the unit.

9.Units require field support of the accessory filters and inlet hood.

10.Some models may be split shipped to accommodate maximum shipping widths. When assembling unit sec- tions, make sure that the sections are properly caulked and secured before operating the equipment.

11.Provide sufficient airflow across the burner. Refer to unit data sheet for required airflow (cfm).

12.Units with motor horsepower below 7.5 hp are sup- plied with an adjustable motor sheave. Units with 7.5 hp motors and above are supplied as standard with fixed motor and blower drives. Units are supplied from the factory with drives set for static pressure conditions provided at the time of order. Check to make sure the actual job site conditions match the conditions for which the unit was ordered. If proper airflow cannot

be established with the drives furnished with the unit, contact the factory for information on drive changes.

13.For economical installation and operation, locate each unit close to the space it will serve, and close to the utilities that will serve the unit.

Site Preparation

Before attempting to install the unit, be sure the site is properly prepared.

1.Make sure there is enough clearance around the installation site to properly and safely rig and lift the equipment.

2.Watch for overhead power lines, or nearby utilities to prevent accidental contact and damage.

3.Make sure the unit supports are adequate to support the equipment.

Sound and Vibration Levels

All mechanical equipment generates some sound and vibration that may require attenuation. Locate the equipment away from critical areas whenever possible. Frequently units can be mounted above utility areas, corridors, restrooms, and other non-critical areas. Generally a unit should be located within 15 feet of a primary support beam. Smaller deflections mean less vibration and noise transmission.

Field installed, factory supplied vibration isolators are available for suspended or rail/slab mounted units. Internal, factory mounted blower and motor isolation may be ordered as an option at the time the unit is ordered.

Installation

Duct Connections

To assure proper airflow from the discharge of the unit follow these recommendations:

1.Be sure properly sized and designed discharge ducts are installed. Velocities should be selected from 2,000 ft/min to no more than 3,000 ft/min for optimum effi- ciency of operation.

2.Units should have a common discharge plenum of at least three (3) hydraulic duct diameters.

3.As a general rule, all discharge ducts should have a

straight run of at least three (3) hydraulic duct diameters before making turns in the ductwork.

Hydraulic Duct Diameter for Rectangular Ducts = Dh = 4A/P

Hydraulic Duct Diameter for Circular Ducts = Dh = D

Where:

Dh = Hydraulic Diameter

A = Cross Sectional Area of Rect. Duct P = Perimeter of Rectangular Duct

D = Diameter of Round Cut

4 |

Aerovent IM-500 |

Return ducts should be designed in the same manner. Where ductwork (or other enclosure) is installed to the inlet or outlet of the unit in such a way as to cause a possible gas trap and accumulation of a flammable mixture, a pre- purge cycle shall be incorporated to provide not less than 4 complete air changes to the ductwork (or enclosure) by volume prior to an ignition attempt.

Fire Dampers

Fire dampers installed in the inlet or outlet duct systems shall be provided with electrical interlocks connected in the safety limit control circuit so as to cause the heater to shut down in case of fire in the ductwork, or heater. The electrical interlocks must be so arranged that the safety circuit is electrically energized only when the fire damper is in the wide open position.

Utility Connections

Electric and control connections can be made from the side or the bottom of the unit. The factory supplied gas connector is located on the side of the unit. The units normally are supplied with factory mounted disconnects; holes can be cut in the fixed side panels, or bottom of the unit for elec- trical connections. Sealing of holes cut in the unit casing for utility connections should be done with care to prevent air and water leaks. All external wiring connections for outdoor units must be made with seal tight conduit. All wiring must be in accordance with the National Electric Code.

Rigging Instructions

Each unit is supplied with four mounting and lifting brackets with 1” clearance holes for lifting hooks. When units are supplied with factory mounted accessories, “DO NOT use the accessory lifting eyes to support the load of the unit”. The accessory lifting eyes should only be used to steady the load. The main load should be placed on the unit’s lifting lugs.

The unit lifting lugs are supplied at the top of the Aerovent units and provide maximum strength for lifting.

In order to lift the unit without damaging the case, SPREADER BARS MUST BE USED!

A bead of caulking must be applied to the face of all flanges just prior to mounting and bolting. Then, bead should be applied to outside seams after installation.

CAULKING IS NOT SUPPLIED WITH THE UNIT!

Unit Installation

Follow the site preparation instructions for applicable curb, rail, or slab mounted as noted in this section of the manual. Check the nameplate of the unit before lifting to insure that the model and serial number shown matches that shown on the shipping papers. Check unit dimensions and mounting holes prior to installation to ensure smooth installation experience.

If the unit is mounted on a factory supplied curb:

1.Install roof curb using roof curb instructions (as noted in this section of the manual).

2.Thoroughly clean and dry the top of the curb surface.

3.Attach a curb gasket around the top perimeter of the curb.

4.Lift the unit into place and set the unit down evenly on curb. Check to make sure unit is level and is firmly seated on all corners of the curb.

5.If units are supplied with accessories for field mount- ing, attach all accessories after the unit has been set in place.

6.Make final unit connections to the electric power supply and remote control circuits. Connect gas lines.

NOTE: Blow lines clean of shavings and sealant before connecting to the unit pipe train (strainers are recommended between gas supply lines and manifold pipe train). Caulk all utility clearance holes and seams on the unit after connections have been made.

If the unit is to be rail or slab mounted, use similar direc- tions as noted in this installation section.

Slab Mounted Units

For ground level installation of unit, prepare a level con- crete slab at least 4" thick and extending 6 inches beyond the unit on an adequate footing and a generous bed of gravel for proper drainage. The slab should include threaded anchor bolts to fit mounting holes and spaced according to unit mounting dimension per unit drawings for securing the unit in place. The anchor bolts should extend at least 2" above surface of the mounting slab to allow clearance for mounting washers and nuts (bolts, mounting washers, and nuts by others).

Other Notes:

Units are not always shipped in one piece. Some field assembly is typically required. Hardware is included; sealant and gaskets are not in all cases. FCBT units include a sealing tape for the flanges. ALL others units do not include any sealants. Please contact your local representative for the breakdown of the number of pieces prior to shipping.

Aerovent ships units in the most economical way. Should it be desired to ship a larger or vertical unit in one piece, please contact your representative immediately.

Inspect all seams after installation and recaulk as needed. A small hole in the caulk or a seam not caulked will allow water penetration.

Roof Curb Mounted Units

Roof curbs should have a minimum height of 14". 24" high roof curbs are available and raise the unit above roof water and snow levels where required and are special ordered. The curb can be installed with the roof in advance of the unit. The curb is shipped knocked down with separate instructions for its assembly, flashing, and sealing with the roof.

Rail Mounted Units

To ensure longevity and integrity of the section joints, con- tinuous rail mounting is preferred.

When rail mounting the units, use two continuous rails

for the length of the unit (in direction of airflow). |

|

Where V-bank filters, dampers, and |

inlet |

hoods are supplied additional supports are |

not |

5 |

Aerovent IM-500 |

required, as |

structural |

design |

of |

accessories |

||

will |

support |

these items. |

However, |

rails |

should |

|

be |

extended |

to support |

cross |

members |

of the |

|

accessories. Check the drawings in the front of this manual.

Electrical Connections

CAUTION:

Disconnect power source before making wiring connections to prevent electrical shock and/or equipment damage.

WARNING:

ALL UNITS MUST BE WIRED STRICTLY IN ACCORDANCE WITH THE WIRING DIAGRAM FURNISHED WITH THE UNIT AND IN ACCORDANCE WITH THE NATIONAL ELECTRIC

CODE ANSI/NFPA 70, LATEST EDITION. UNIT

MUST BE ELECTRICALLY GROUNDED IN CONFORMANCE TO THIS CODE. ANY WIRING DIFFERENT FROM WIRING DIAGRAM SUPPLIED SHOULD BE CLEARED WITH FACTORY ENGINEERING WITH WRITTEN APPROVAL FOR VALIDATION OF UNIT WARRANTY.

Any damage to, or failure of this equipment caused by incorrect wiring of the unit is not covered under the standard product warranty.

Electrical wiring diagrams are furnished with each unit and can be found in the O&M manual, and a permanent laminated diagram is located on the inside of the electric control cabinet door. All units are supplied with a labeled terminal strip for ease of wiring.

The power supply to the standard unit is be protected with a lockable type fused disconnect switch. If a discon- nect switch is not supplied with the unit, the field supplied disconnect must have adequate ampacity and must be installed in accordance with Article 430 of the National

Electrical Code, ANSI/NFPA 70.

External electrical service connections which must be made include:

1.Main power supply to unit (120, 208, 240, 480, or 575 volt).

2.Remote control panel. Consult unit wiring diagram.

3.Separate 120V service for lighting and receptacles as required.

4.Control wires connected to the remote temperature selector must not be run close to or inside conduit with power or ignition wires. Doing so may cause the unit to function erratically or may destroy the amplifier. If shielded wires are used, shield must be insulated and grounded at the amplifier location only.

Supply voltage must be within 10 percent of the power rating with each phase balanced to within 2 percent of each other. If not, advise the power company.

Before powering unit, make sure all multivoltage components (transformers, motors, etc.)

are wired in accordance with the correct supply voltage.

The lighting circuits and unit receptacles require the installation contractor to supply a separate 120 volt single supply source to the unit and be installed in accordance with Article 210 of the National Electrical Code ANSI/NFPA 70 - 1987.

Gas Piping Installation

CAUTION:

Gas pressure to main gas manifold must NEVER EXCEED 5 psi.

The unit and its individual shutoff valve(s) must be disconnected from the gas supply during any pressure testing of the piping system. Before assembling piping to unit manifold contractor should be sure all rust, piping compound and shavings have been removed from new piping. (Strainers are recommended between unit pipe train and supply piping.)

Always check the unit’s data form to determine the cor- rect gas supply pressure for which the unit was designed.

1.Installation of piping must be in accordance with local codes, and ANSI Z223.1, latest edition, “National Fuel

Gas Code”. (In Canada CAN/CGA-B149 Code).

2.Piping to units must conform to local and national requirements for type and volume of gas handled, and pressure drop allowed in the line. Refer to the air make-up data form to determine the Btu capacity of the unit and the type of gas the unit is designed to use. Using this information refer to the ASHRAE Guide

Fundamentals Handbook, or other gas pipe sizing guide to determine the correct supply pipe size. Allow sufficient pipe size based on allowable pressure drop in supply line. Where several units are served by the same main, the total capacity of all the units served by

the main must be used. Avoid pipe sizes smaller than 1/2".

3.After threading and reaming the ends, inspect piping and remove loose dirt and chips.

4.Support piping so that no strains are imposed on the unit controls.

5.Use two wrenches when connecting field piping to units.

6.Provide a drip pocket before each unit and in the line where low spots cannot be avoided.

7.Take-off to unit should come from top or side of main to avoid trapping condensate.

8.Piping subject to wide temperature variations should be insulated.

9.Pitch piping at least 1/4" per 15 feet of horizontal run.

10.Compounds used on threaded joints of gas piping must be resistant to action of liquefied petroleum gases.

6 |

Aerovent IM-500 |

11.Purge air from gas piping before lighting unit.

12.After air has been purged, check for gas leaks in the piping system using a soap water solution.

13.Install a ground joint union and gas cock external of the unit for easy servicing of controls.

14.Allow at least 5 feet of piping between any high pressure regulator and the unit control pipe train.

Gas Supply Pressure – 5 lbs. or less

The Aerovent air make-up unit is standardly furnished with the Maxitrol modulating system. This device controls the firing rate of the burner to maintain the desired operating temperature.

It functions as a regulator and modulator which will not allow the burner manifold pressure to exceed that which produces the maximum firing rate, and also will reduce the pressure below this value to modulate the burner throughout the normal 25 to 1 turn down ratio. The upstream pressure supplied to the unit pipe train must not exceed 5 pounds. This is the maximum for suitable operation. The minimum operating pressure will vary depending upon the unit size and pipe train size. This pressure is marked on the pressure gauge. As long as the gas pressure supplied to the unit is maintained at some value between the minimum as marked on the gauge and 5 pounds maximum, the air make-up unit will perform at its rated capacity.

If the gas supply system is designed for a pressure higher than 5 pounds, it is necessary to install an additional regulator upstream of the connection to the unit. See following instructions for gas supply over 5 pounds.

The downstream pressure from the line regulator will vary somewhat depending upon the firing rate of the air make-up unit. Variations can also be caused by other gas equipment connected to the distribution system. It is neces- sary, therefore, to be sure that the setting of the supply line regulator is such that the pressure supplied to the unit will always be at least equal to the minimum and not exceeding 5 psi.

NOTE:

DO NOT VENT THE VENT VALVE AND PRESSURE REGULATOR IN THE SAME VENT PIPE. SEPARATE VENT LINES TO OUTSIDE ATMOSPHERE MUST BE RUN FOR THE UNIT TO OPERATE PROPERLY. COMBINING THE VENT LINES TO ATMOSPHERE WILL CAUSE THE HIGH LIMIT GAS PRESSURE CONTROL TO LOCK OUT THE FLAME SAFETY SYSTEM AND SHUT DOWN THE UNIT.

NOTE:

A PRESSURE REGULATOR MAY BE REQUIRED TO MEET THE STATE OR LOCAL CODE. CONSULT YOUR STANDARDS.

Gas Supply Pressure – Over 5 lbs.

When the supply line pressure to an air make-up unit exceeds 5 pounds or may at times fluctuate above 5 pounds, it is necessary to install a line pressure regulator ahead of the input to the air make-up unit. The size must be selected

to handle the maximum capacity of the unit, and the type of regulator selected to work at the maximum inlet pressure and having a capability of maintaining the outlet pressure at some value between 8 ounces and 5 pounds. As a rule, the outlet pressure from the line pressure regulator may be adjusted anywhere between 2 and 4 pounds. If the regula- tor was furnished by Aerovent, it has been sized according to the information in the original order and shown on the parts list. Regulators are sized according to capacity and pressure and not according to pipe size; therefore, the size of the pipe at the inlet to the air make-up unit may not be the same as the pipe size of the regulator.

To be sure the supply line is properly sized, it is sug- gested that the representative of the local gas company be consulted about pipe sizing. The line regulator should be installed close to the air make-up unit. There should be no elbows, couplings, valves, or fittings within at least ten pipe diameters of the inlet and the discharge of the pressure regulator. A shut-off cock should be placed upstream of the regulator so that it can be removed for servicing if nec- essary. It is a good idea, also, to install a pressure gauge on the upstream side having a scale range sufficient to indicate the supply line pressure.

It is very important to connect the regulator vent with pipe or tubing extended to the outside with the end protected from the weather. Do not vent the regulator into the air make-up unit or the duct system, or near the inlet to the air make-up unit.

NOTE:

DO NOT VENT THE VENT VALVE AND PRESSURE REGULATOR IN THE SAME VENT PIPE. SEPARATE VENT LINES TO OUTSIDE ATMOSPHERE MUST BE RUN FOR THE UNIT TO OPERATE PROPERLY. COMBINING THE VENT LINES TO ATMOSPHERE WILL CAUSE THE HIGH LIMIT GAS PRESSURE CONTROL TO LOCK OUT THE FLAME SAFETY SYSTEM AND SHUT DOWN THE UNIT.

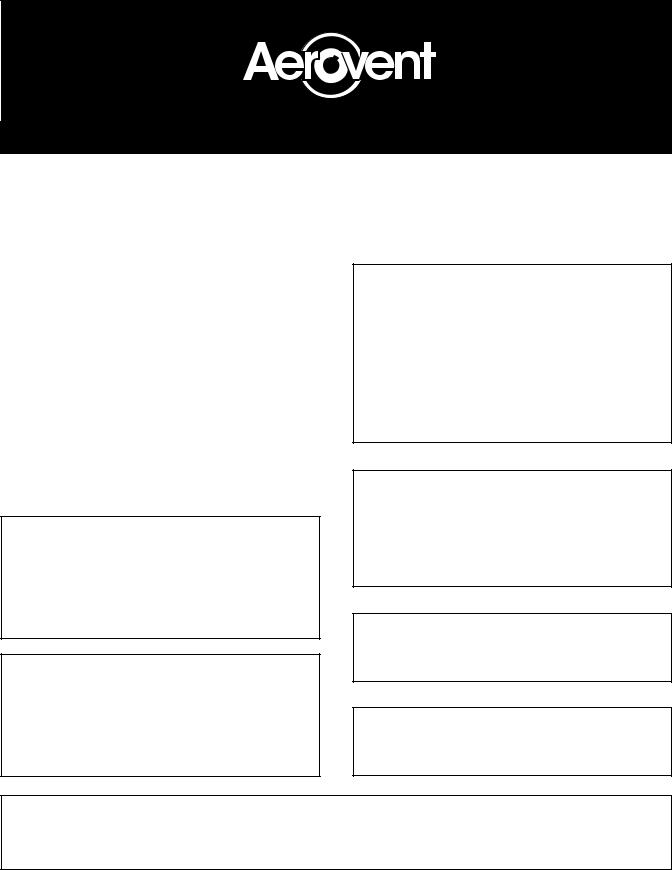

Figure 1. Typical Gas Regulator

7 |

Aerovent IM-500 |

Figure 2. Piping Configuration

Operation Instructions

PRIOR TO OPERATION

Although this unit has been assembled and test fired at the factory, the following pre-operational procedures should be performed to assure the unit has not been damaged or misaligned during shipment. This will help assure proper on-site operation.

1.Remove all shipping straps, braces, and tie-downs.

2.Check burner to insure proper location and if airflow is moving across burner correctly. The burner may be wrapped, if so remove wrapping. This is important if unit was split for shipping convenience. Also check to be sure sections were caulked when assembled.

3.Check blower and motor sheave alignment, as well as belt tension.

4.Check bearings for alignment and tightness of mounting bolts, bolts securing taper lock bushings to shaft, and that locking collars are secure.

5.Check all electrical connections to insure wires are making good contact and are secure in their terminals. Check tightness of jumpers between terminals.

6.Check gas piping for leaks using a soap/water solution.

After these preliminary checks have been made, the unit can be prepared for start-up.

Start-Up and Check Out

Each unit is supplied with a service manual which includes a Field Start-Up Form. The Field Start-Up Form must be followed and properly filled out and signed by the installer. It then is to be mailed or faxed back to Aerovent, 800 S. High St, Covington OH 45318. The fax number is (937) 473-3793.

Before continuing with the start-up and checkout proce- dure, it is important to familiarize yourself with the safety controls furnished with the unit.

Airflow Proving Switch

(Aerovent Part #19240-01)

The airflow proving switch monitors the differential pressure across the venturi sensor located at the burner profile plate to insure that sufficient airflow exists before allowing the burner to operate. The airflow proving switch is located in the gas controls cabinet and is electrically interlocked with the flame safeguard control system. The air flow venturi is located at the burner profile plate with pressure taps leading from that location to the pressure switch. The venturi amplifies the signal to the pressure sensing device and minimizes nuisance shutdowns.

High Temperature Limit Control

(Aerovent Part #18756-01E)

The high temperature limit control shuts down the burner if excessive discharge temperatures are experienced. The limit control is located in the blower discharge air chamber. The limit control is electrically interlocked with the flame safeguard control relay.

Figure 3.

Figure 4. High Temperature Limit

8 |

Aerovent IM-500 |

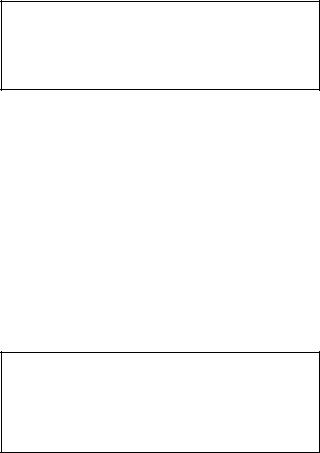

Flame Safeguard Control

(Aerovent Part #25941-01)

All units are equipped with a Honeywell RM7895C flame safety relay. This relay senses if a pilot flame and main burner flame have been established through the use of an ultraviolet (UV) scanner. For more information about the

Honeywell flame relay, visit the Honeywell web site.

The flame safeguard relay has a built in component self checking module, pre-purge timer, and an ignition timing flame sensing circuit. The pre-purge timer allows purging of any residual gas or fumes in the unit before a try for ignition. Pre-purge is approximately 10 seconds. After pre-purge occurs, the spark ignition will start. If the pilot flame is not proven within the time period allowed (10 to 25 seconds) the relay will go into lockout and it will have to be manually reset before a try for re-ignition can occur. This can be accomplished by pressing the reset button on the remote station or at the unit thus preventing a trip to the air make-up unit. If after several (2-3) tries the unit won’t light off, have a maintenance man inspect the unit to determine cause of relay lockout. Note: The power light will blink; this is a normal operating condition.

Figure 5. Flame Relay

C7027 Ultra Violet Scanners

(Aerovent Part #2281-01E)

Units are equipped with a C7027A UV scanner. This device is shipped removed from the flame sighting tube to prevent damage during shipment. Unwrap the device and mount on the sighting tube. The UV scanner is a ultra-violet light sensing device. It takes advantage of the fact that a flame will emit some of its light in the low frequency ultra violet light range. The scanner uses an electronic eye to scan for the presence of this ultra violet light. If flame is detected, it sends this signal to the RM7895C flame relay.

Figure 6. UV Flame Detector (Purple Peeper)

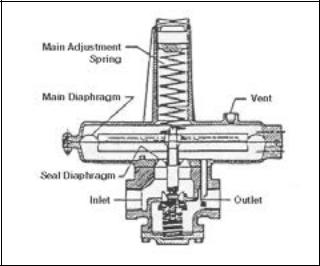

Gas Pipe Train Configuration

(Aerovent Part #2281-01E)

The type of manifold supplied with the unit varies depending on whether the unit was ordered with a FM or IRI manifold. To determine which arrangement was supplied with the unit, see the manifold descriptions noted on the product specification and general description page in the front of this manual.

Figure 7. FM Piping

Figure 8. IRI Piping

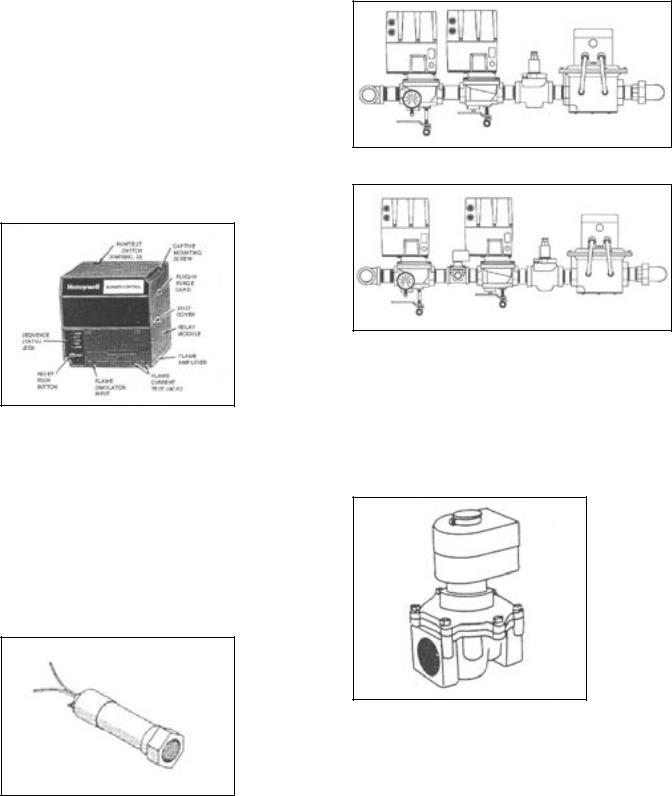

Pilot Solenoid Gas Valve

(Aerovent Part #422-05E)

The pilot solenoid gas valve serves as a separate shut-off valve for the pilot gas during normal operation and provides means for interrupted pilot and main flame supervision during normal operation of the unit.

Figure 9. Pilot Valve

9 |

Aerovent IM-500 |

Loading...

Loading...