Aerovent IM-401 User Manual

®

IM-401

August 2014

General Installation, Operation and Maintenance Instructions For Aerovent Products

MODEL ATA & ATABD TUBEAXIAL FANS

1.0 GENERAL DESCRIPTION

Model ATA and ATABD axial fans come in various configurations that offer flexibility to meet the needs of the end user.

1.2 DEFINITIONS

An axial fan consists of a propeller type impeller,

motor driven and ducted or shrouded so that the blades are

enclosed to increase operating efficiency.

An adjustable pitch impeller is one where the blade

angle can be changed, but only when the propeller is stationary.

1.3 Arrangements

Fans are available in two different configurations,

defined as follows:

Arrangement 4 (ATA) — The impeller is mounted

directly on the motor shaft with both motor and impeller

enclosed in the fan case.

Arrangement 9 (ATABD) — The impeller is mounted

on a bearing-supported shaft, belt driven by a motor supported on the fan case.

1.4 APPLICATION

Fans can be installed in a free inlet or ducted inlet application. Mounting arrangements include legs for floor mounting, flanges for direct duct connections or brackets for vertical

or horizontal mount from the floor or ceiling.

1.5 ACCESSORIES

The following accessories are available on Model ATA

and ATABD fans.

a. Inlet bell

b. Inlet screen

c. Inlet and outlet cones

d. Companion flanges

e. Flexible connectors

f. Vibration isolators

g. Radial inlet vane dampers

h. Backdraft dampers

1.6 OPTIONS

a. Legs for horizontal floor mounting

b. Clips for horizontal ceiling suspension

c. Brackets for vertical floor or suspension mounting

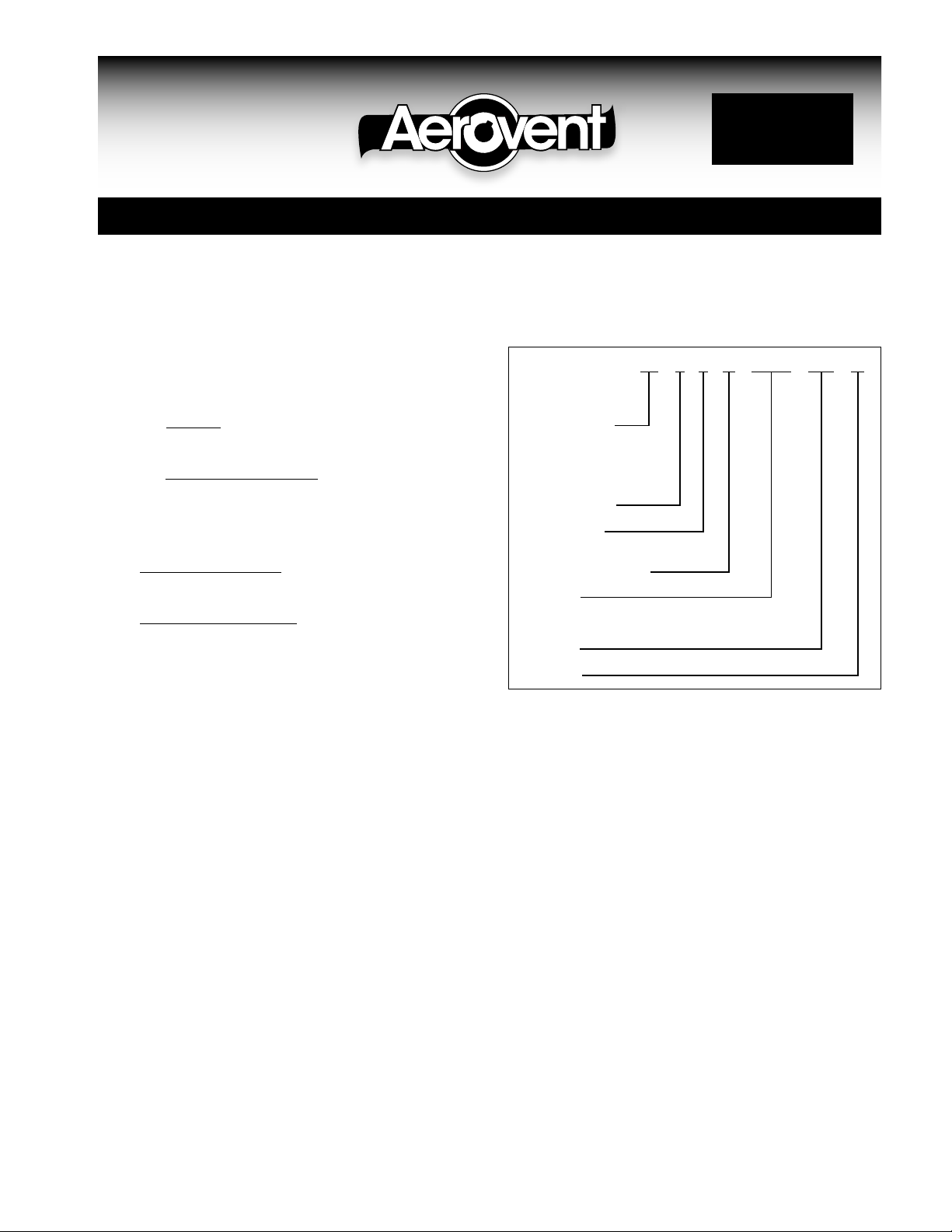

1.6 NAMEPLATE NOMENCLATURE

The model number information on each fan nameplate is

explained in Figure 1.

Figure 1.

100 - A - 3 - 27 - ATABD - 1067 - 10

Wheel Dia. (cm)

035, 040, 050

063, 071, 080

090, 100, 112

125

Propeller Design

No. of Blades

3 or 6

Blade Angle (Degrees)

Fan Type

ATA = Direct Drive

ATABD = Belt Drive

Fan RPM

Motor HP

2.0 INSTALLATION

2.1 RECEIVING/INSPECTION/STORAGE

All fans are shipped on wooden pallets. Each fan is

normally covered with plastic for weather protection. The fan

should remain on the pallet and covered or protected from the

weather until installation.

Carefully inspect the fan upon arrival for damage

incurred during shipment. Immediately report any damage to

both the factory and the carrier. For short-term storage, prior

to installation, the fan should remain covered with plastic

wrap on the shipping pallet and stored in a clean, dry location

away from the elements. If storage is to be for a period longer

than six (6) months, consult factory for long-term storage

instructions.

2.2 LIFTING

Fans should be lifted using slings. The slings can be

placed under the pallet and a spreader bar used as required.

2.3 MOUNTING

Depending on the type of fan support specified, the

fan can be floor mounted on legs, supported on a structural

frame for vertical airflow or ceiling hung by clip supports or

duct mounted.

©2014 Aerovent

2.3.1 Vibration Isolators

All fans are dynamically balanced to reduce vibration.

However, it is recommended that the fan be supported on

vibration isolators. Isolators should be selected for each installation in accordance with individual requirements. Concrete

inertia pads are generally not required with ATA and ATABD

fans.

2.4 DUCT CONNECTIONS

All fans should be aligned with the ductwork. A flexible

connection should be provided between the fan and duct to

prevent structure-borne noise from being transmitted to the

ductwork.

If the fan is to be attached directly to the duct without

a flexible connection, special care must be exercised to align

the fan and duct flanges so the fan is not subject to structural

loads from the ductwork. These loads could distort the fan

housing, causing the blades to hit or rub the case, or change

the blade tip to housing clearance and affect performance.

2.5 ELECTRICAL

All wiring should conform to local electrical codes and

the job specification. In NEMA standard MG-2, the phenomena of transient torques is addressed. We advise that measures

be taken to protect your equipment from transient torque and

power interruptions.

2.5.1 Power Connection

The motor leads terminate in the conduit box. The

leads are factory connected for the voltage specified for the

job. Motor leads for wye-delta and part-winding starts are

not connected. Rigid conduit should be run from the motor

starter to the fan with a short section of flexible conduit at the

conduit box to allow for fan movement.

Wire size and motor overloads should be sized in

accordance with the fan nameplate electrical data. The conduit

box is located on the outside of the case on all direct driven

fans. On belt driven fans the motor is outside the fan case and

the connection will be made directly to the motor.

2.5.2 Motor Rotation

Check motor rotation by jogging the motor. The propeller should rotate in the direction indicated by the rotation

arrow on the fan case. It is important that correct motor rotation be established on ducted fans as the propeller will not be

visible after an inlet duct is installed. Reverse any two motor

leads to change direction of rotation of three-phase motors.

2.5.3 Final Check Before Putting

Fan Into Operation

1. Check for correct supply voltage and motor overloads.

2. Insure that all loose debris is removed from fan and ducts.

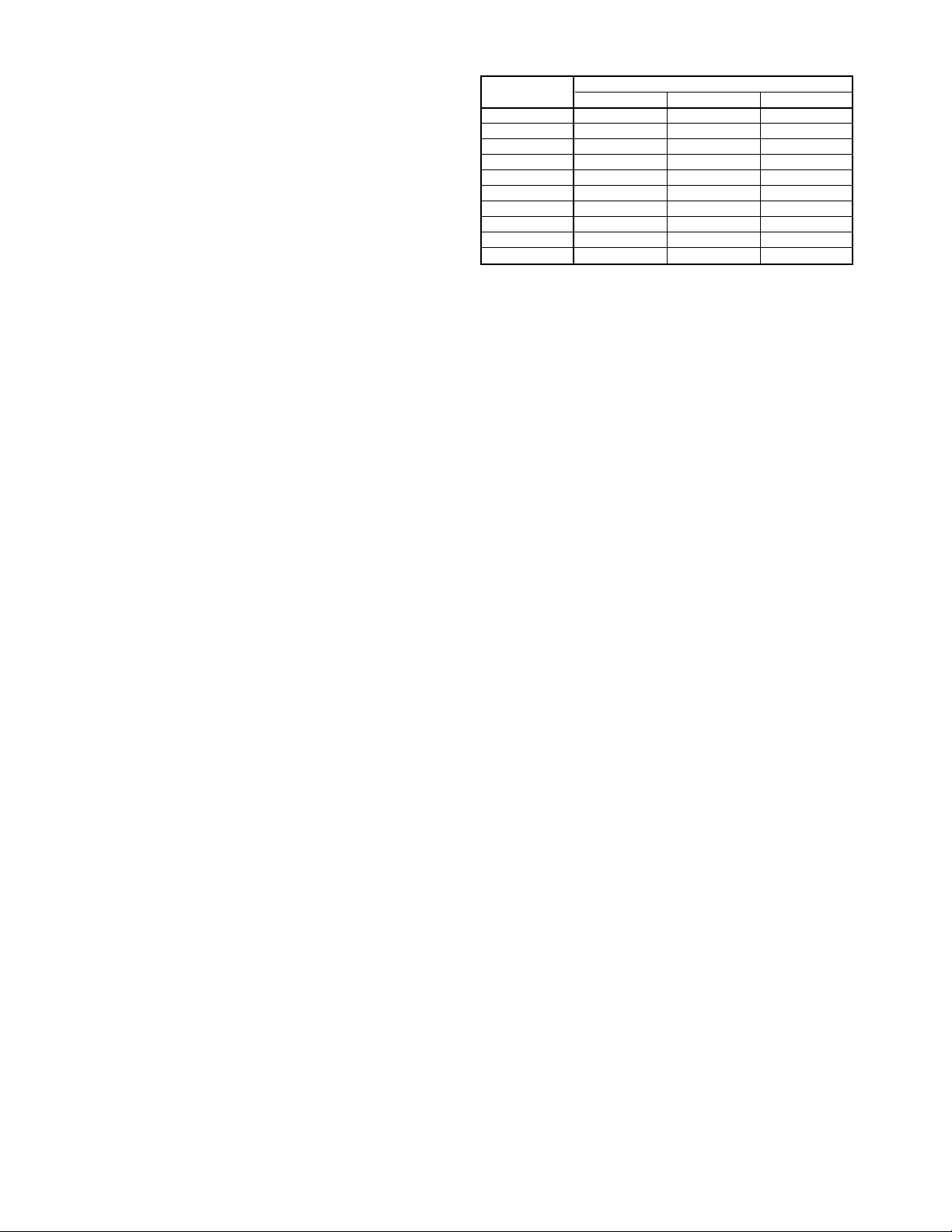

3. Check that the propeller is centered in the fan case and that

the blade tip clearance is not less than the minimum values

in Figure 2.

4. Hand rotate to assure free movement.

5. Bump the fan starter to check rotation.

6. Start the fan and verify that the vibration levels are

satisfactory.

7. Check the current draw. Do not exceed the full load amperage as specified on the nameplate.

Figure 2.

NOMINAL BLADE TIP CLEARANCE (INCHES)

FAN SIZE MINIMUM NOMINAL MAXIMUM

035 .028 .063 .098

040 .032 .071 .110

050 .039 .087 .134

063 .047 .110 .173

071 .055 .126 .197

080 .063 .142 .220

090 .079 .177 .276

100 .079 .177 .276

112 .098 .217 .335

125 .098 .217 .335

3.0 FAN BLADE ADJUSTMENT

3.1 GENERAL

Models ATA and ATABD feature an adjustable pitch

propeller. The blade pitch has been factory set to meet the

airflow requirement of the job specification. If required, the

pitch may be changed to meet other airflow requirements on

the job site. Contact the factory for recommended new setting

and request an AXIPAL blade protractor.

NOTE: If the blade angle is reduced by more than five

(5) degrees from the value preset on delivery, the clearance

between the blades and the casing will be reduced. Check that

the blade tip clearance is not less than the minimum values in

Figure 2. If the blade angle is increased, check the tip clearance for minimum clearance as the leading and trailing tips will

get closer to the fan casing.

4.0 MAINTENANCE

4.1 GENERAL

ATA and ATABD fans are a quality product designed

and manufactured for minimum maintenance and long operating life. They should provide years of trouble-free service if

the following maintenance procedures are followed.

There are no moving parts in the propeller assembly.

Therefore, routine maintenance is generally limited to motor

lubrication, bearing lubrication of the belt driven models and

belt replacement.

4.2 FAN BALANCE

The propeller assembly shall be statically and dynamically balanced in accordance with ANSI/AMCA 204-96

"Balance Quality and Vibration Levels for Fans" to Fan

Application Category BV - 3, Balance Quality Grade G6.3. In

addition, direct drive fan propellers shall be balanced on the

motor shaft after final assembly in the fan casing, in the manufacturing facility, to the following peak velocity values, filter-in,

to the fan test speed:

Fan Application Rigidly Mounted Flexibly Mounted

Category (in./s) (in./s)

BV-3 0.15 0.20

4.3 LUBRICATION

4.3.1 Motor Lubrication

Motor bearings do not require initial lubrication unless

the fan has been in storage over six months. If this is the case,

the motor should be lubricated initially.

2 Aerovent IM-401

Loading...

Loading...