Aerovent IM-230 User Manual

IM-230

June 1997

General Installation, Operation and Maintenance Instructions For Aerovent Products

Belt Driven Plug Fans

Aerovent plug fans are designed for continuous duty in

air-moving systems, handling clean air where the fan

becomes an integral part of another system.

As a general rule, these fans are designed to be

installed in any position; however, reduced bearing life

may result in some vertical applications, which require

maximum static pressures and horsepowers.

The mounting panel, which is an integral part of the

assembly, permits easy installation to any well supported

plenum.

Upon receipt of equipment, inspect the fan and its

accessories for possible damage in shipment. Make

certain the wheel rotates without binding. Never lift the

plug fan by its motor, fan wheel or shaft. Lifting eyes

are provided for this purpose.

If the unit is not to be put in operation for a period

of time and is to be stored, the following precautions

should be observed:

1. Select a clean, dry location to prevent rust.

2. For outside storage, protect against the elements by

covering the entire fan.

3. Make certain bearings are filled with grease. (See

General Installation and Maintenance Manual IM-100

for lubrication procedure.)

4. Keep motors dry and clean.

5. Periodically inspect unit to see if conditions are present which could cause damage.

V-Belt Drive

Normally these units are shipped with motor and drives

in place, and it is only necessary to check for belt

alignment and proper tensioning. In cases where these

units are furnished less the motors and/or drives, the

mounting procedure is as follows:

1. Mount the motor on the adjustable base and secure

with the hardware provided. When located properly,

the motor end bell should be in a line with the end

of the motor base.

2. Remove the rust preventative compound on the end

of the fan shaft with a suitable solvent and wipe the

motor shaft clean.

3. Coat shaft with a light film of oil and mount sheaves

onto the shafts. Do not force the sheaves onto the

shafts as this may damage the fan and motor bearings. Do not apply any lubricant to the bushings,

threaded components, or setscrews. Be sure to wipe

©1997 Aerovent

off any excess lubricant in order to prevent the likelihood of any of the drive components from coming

loose during operation.

4. Install the belts. Belts should be worked carefully over

the grooves of each sheave until they are properly in

place. Belts should never be forced on with a screwdriver or similar tool as this may break the cords in

the belts. After the belts have been installed, adjust

the sheaves so that both shafts are at right angles to

the belts. Once proper alignment is assured, tighten

sheaves in place.

5. Take up slack by adjusting the motor base adjustment screws. Proper belt tension is important. If belts

are too tight, undue wear on fan and motor bearings

will result. Insufficient tension shortens belt life and

may cause vibration. Use drive manufacturer’s recommendations for correct belt tension.

6. IMPORTANT: BEFORE PUTTING THE UNIT INTO

CONTINUOUS OPERATION, INSTALL BELT GUARD.

7. After several days of operation, check belt tension

and sheave alignment.

Bearings

Before the unit is put in operation, tighten bearing collar setscrews and bearing anchor bolts. Rotate shaft to

check alignment.

All grease lubricated bearings are completely filled

with grease prior to shipment from the factory. This prevents the condensation of moisture in the pillow block

during shipment and before the unit is installed.

IMPORTANT: The bearings will discharge excess

grease through the seals for a short period of time after

start-up. Do not replace this initial discharge because

leakage will cease after the excess grease has been

purged from the bearings. Also, the purging of the

excess grease will cause the bearings to heat up but

the heat will dissipate after the purging.

Observation of the condition of the grease expelled

from the bearing at the time of relubrication is the best

guide as to whether the regreasing intervals and amount

of grease added should be altered. When regreasing,

use lubrication instructions for fan ball bearings as outlined in IM-100 which is included with the shipment.

Avoid mixing different types of grease. Bearings should

be flushed and refilled with fresh grease at approximately one-year intervals. DO NOT OVER LUBRICATE.

Maintenance

Regular and systematic inspection of all fan parts is the

key to good fan maintenance. Frequency of inspection is

determined by the severity of the application and local

conditions. Once a maintenance schedule is established,

it should be strictly followed. Regular fan maintenance

should include the following:

1. Check fan wheel for any build-up of foreign material

or excessive wear from abrasion. Both can cause

vibration which creates a serious safety hazard. Any

build-up of foreign material should be removed. If the

wheel shows excessive wear, replace it immediately.

Cleaning of the wheel should be accomplished, if

possible, without removing it from the shaft. If the

plenum is furnished with an access door, the wheel

can be cleaned through this opening. If no door is

supplied, then the inlet cone must be removed to

expose the wheel. If for some reason the wheel is

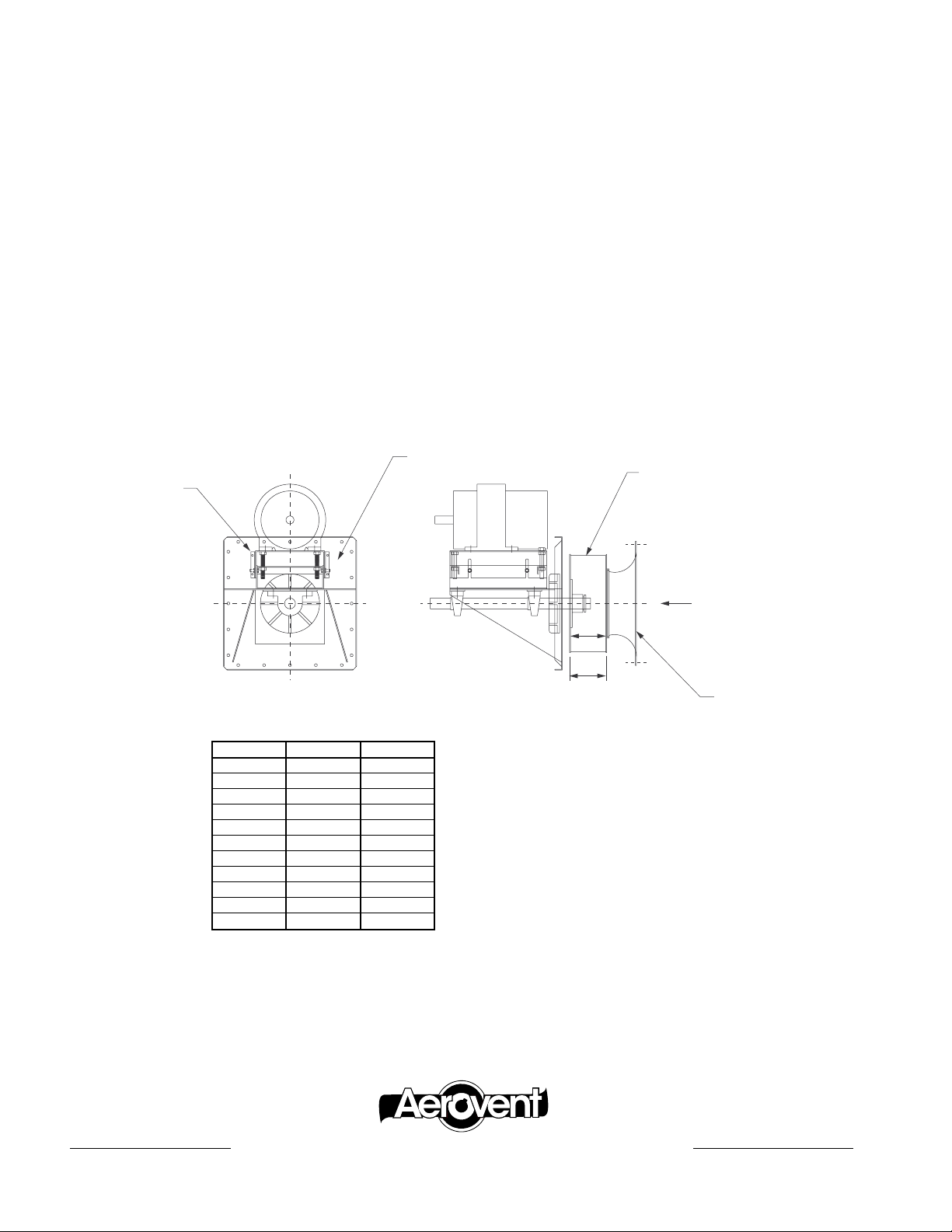

Mounting Panel

Adjustable

Motor Base

removed from the shaft, take note of the “A” dimension called out in the chart below. This dimension

must be held if the proper performance is to be

maintained.

2. V-BELT DRIVE: Check V-belt for proper alignment and

tension. (See General Installation and Mainten-ance

Manual IM-101.)

3. FAN BEARINGS: Lubricate the bearings as detailed in

the ball bearing lubrication instructions in the General

Installation and Maintenance Manual (IM-100).

4. SCREWS AND BOLTS: Check tightness of all screws

and bolts throughout the assembly

Wheel

SIZE A W

12 4

14 57⁄32 51⁄32

16 527⁄32 521⁄32

18 621⁄32 63⁄8

20 73⁄8 71⁄16

22 81⁄4 715⁄16

25 95⁄16 815⁄16

28 1017⁄32 101⁄16

32 1127⁄32 1111⁄32

35 1315⁄16 123⁄4

39 1427⁄32 143⁄16

5

⁄8 47⁄16

Airflow

A

W

Inlet Cone

“A” dimension (inlet cone to wheel

back plate) must be held. This

dimension is critical to fan performance. “A” dimension shown is

based on 100% wheel width and

must be adjusted if wheel furnished

is other than 100% full width.

®

AEROVENT | WWW.AEROVENT.COM

5959 Trenton Lane N | Minneapolis, MN 55442 | Phone: 763-551-7500 | Fax: 763-551-7501

Loading...

Loading...