Aerovent IM-201 User Manual

®

IM-201

August 2014

General Installation, Operation and Maintenance Instructions For Aerovent Products

AXICO® ANTI-STALL

(Direct Drive)

1.0 GENERAL DESCRIPTION

1.1 DEFINITIONS

A vaneaxial fan is an axial fan with a vane section

downstream of the rotor. The vane section converts the rotating component of the airflow into axial flow and pressure,

increasing the static pressure capability of the rotor.

An adjustable pitch rotor is one where the blade angle

can be changed, but only when the rotor is stationary.

A variable pitch rotor, also called controllable pitch,

is one where the blade angle can be changed while the fan is

running.

1.2 ARRANGEMENTS

Axial fans are available in two different configurations,

defined as follows:

Arrangement 4, Type 2 — The rotor is mounted

directly on the motor shaft, and the motor is upstream of the

rotor, with both rotor and motor enclosed in the fan tube.

Arrangement 4, Type 3 — The rotor is mounted

directly on the motor shaft, and the motor is upstream of the

rotor, but supported outside the fan tube.

Aerovent axial fans offer the following combinations

of these basic definitions, using the nomenclature shown:

Description AXICO

Vaneaxial Fan X

Adjustable Pitch FPDA

Variable Pitch:

Electric Control FPMC

Hand Crank Control FPMC

Pneumatic Control FPAC

Arrangement 4, Type 2 X

Arrangement 4, Type 3 X

1.3 APPLICATION

If the application requires that the inlet to the fan be

ducted, Arrangement 4 Type 3 cannot be used. All the other

arrangements are furnished with an inlet duct flange to which an

inlet duct or an inlet bell can be fastened.

Arrangement 4 Type 3 fans are ideally suited for plenum applications with a free inlet condition as this arrangement can permit the fan to be placed much closer to the coils

or filters upstream.

1.4 ACCESSORIES

Various accessories are available for AXICO fans.

a. Inlet bell and screen (standard on Arrangement 4 Type 3

fans)

b. Inlet cones

c. Vane section (standard on AXICO fans)

d. Discharge diffuser sections (two types)

e. Acoustic discharge diffuser sections

f. Flexible duct connections and band clamps

g. Gravity backdraft dampers

h. Vibration isolation

1.5 OPTIONS

AXICO fans may be furnished with various options to

meet job requirements:

a. Legs for floor mounting.

b. Brackets for vertical, horizontal, or angular mounting from

the floor or ceiling.

c. Electric operator or manual hand-wheel for adjustment of

AXICO FPMC when in operation, or quadrant and clamp

adjustment when the fan is turned off

d. AXICO fan operators and positioners located at other than

top dead center

1.6 NAMEPLATE NOMENCLATURE

The model number information on each fan nameplate is

explained on page 14.

2.0 INSTALLATION

2.1 RECEIVING/INSPECTION/STORAGE

Each Aerovent fan is shipped on a wooden pallet and

is covered with plastic for weather protection.

Carefully inspect the fan upon arrival for damage

incurred during shipment. Immediately report any damage to

both the factory and the carrier.

For short-term storage prior to installation, the fan

should remain covered with plastic wrap on the shipping pallet

and stored in a clean, dry location away from the elements. If

storage is to be for a period longer than 30 days, see page 15

for long-term storage instructions.

©2014 Aerovent

2.2 LIFTING

Aerovent fans should be lifted using slings. Note that

on AXICO fans the slings should be placed under the skids,

and spreader bars used as required. Under no circumstances

should the vane section be used for lifting.

2.3 MOUNTING

Depending on the type of fan support specified, the

fan can be floor mounted on legs, supported on a structural

frame or ceiling hung if clips or support brackets are included,

and again supported on the floor on a frame, or ceiling hung

if the fan is for vertical airflow.

2.3.1 Vibration Isolators

The fan is dynamically balanced to reduce vibration to

a low level. However, it is recommended that the fan be supported on vibration isolators. Isolators should be selected for

each installation in accordance with individual requirements.

The weight distribution between mounts is not equal

on Aerovent fans. Consult the factory for isolator selection

or mount loads. Isolators should be selected to support the

unequal load with equal deflection. A subbase can be used

to equally distribute the load to the isolators. Concrete inertia

pads are generally not required on Aerovent axial fans. When

mounting isolators or tie-down bolts through the base frame

of an Arrangement 4 Type 3 fan, it is recommended that you

use a beveled washer between the base frame and the nut. See

Figure 1.

Figure 1.

Beveled

Washer

2.3.2 Fan Reactions

It is essential to minimize fan movement due to starting torque and air thrust force. These forces must be resisted

to maintain duct alignment and prevent damaging the flexible

connectors. Isolators must be selected with adequate stiffness

to resist these forces. Snubbers may be required in some installations to limit the fan movement.

2.4 DUCT CONNECTIONS

All fans should be closely aligned with the ductwork. A

flexible connection should be provided between the fan and

duct to prevent structure-borne noise from being transmitted to the ductwork. Use band clamps and seal with Borden’s

Arabol, or equal, to insure mechanical security and prevent

leakage on all flexible connections.

NOTE: Provide a 1-inch to 2-inch gap between the fan

and duct to allow for fan movement.

2.4.1 Diffuser and Cone Connection

On AXICO fans, the standard discharge is not intended to be directly connected to the fan vane section. Support

the diffuser independently of the fan and provide a flexible

connection between the fan and the diffuser. On all Aerovent

fans, inlet cones can be directly connected and they also

become part of the load to be isolated.

2.4.2 Inlet Bell Connection

The inlet bell may be mounted in a plenum wall with a

flexible connection between the outer edge of the bell and a

hole in the partition. Provide a 2-inch to 3-inch gap to allow

for fan movement.

The inlet bell may be installed protruding into the plenum where space is limited. A metal ring should be installed

between the inlet bell and the case flange and a flexible connection installed between the ring and the plenum wall.

2.5 ELECTRICAL

All wiring should conform to local electrical codes and

the job specification.

2.5.1 Power Connection

The motor leads terminate in the conduit box. The

leads are factory connected for the voltage specified for the

job. Motor leads for wye-delta and part-winding starts are

not connected. Rigid conduit should be run from the motor

starter to the fan with a short section of flexible conduit at the

conduit box to allow for fan movement.

Wire size and motor overloads should be sized in

accordance with the fan nameplate electrical data. The conduit

box is located on the outside of the case on all ducted, direct

driven fans. If the motor is outside the fan case, connection

will be made directly to the motor.

2.5.2 Motor Rotation

Check motor rotation by jogging the motor. The rotation should be clockwise when viewed from the inlet of the

fan. Reverse any two motor leads to change rotation.

NOTE: It is important that correct motor rotation be

established on ducted fans as the rotor will not be visible after

an inlet duct is installed.

2.5.3 Electrical Data

If the fan is a variable pitch AXICO fan, it is recommended that the fan not be run until the controls are operational. The fan should be started in accordance with Section

2.5.4 and the electrical data measured and compared to motor

nameplate ratings.

2.5.4 Final Check Before Putting

Fan Into Operation

1. Check for correct supply voltage and motor overloads.

2. Insure that all loose debris is removed from fan, fan

room, plenum and/or all ducts.

3. Check that motor bolts are tight and rotor is centered in

fan case with adequate blade tip clearance all- around. See

Section 6.6 for motor bolt torque data, and Section 6.7 for

minimum blade tip clearance.

4. Hand rotate and then bump the fan starter to check rotation.

5. Start the fan and verify that the vibration is acceptable.

If the fan is a variable pitch AXICO, make the following

additional checks.

6. Check that the air supply pressure is correct (60 to 100

psig).

2 Aerovent IM-201

7. Set controller at a low set point for minimum pitch (3 psig

branch pressure to the positioner) for direct acting.

8. Verify once again that the vibration is acceptable.

9. Increase the set point for maximum pitch and measure

motor current. Check that full load current does not

exceed motor nameplate data. Also verify that the vibration level at full pitch is acceptable.

10. Verify that blade pitch changes smoothly throughout

the full range as the controller set point is moved. If the

AXICO fan has an electric operator, follow the same procedure except of course varying the signal input circuit to

the Honeywell electric opener.

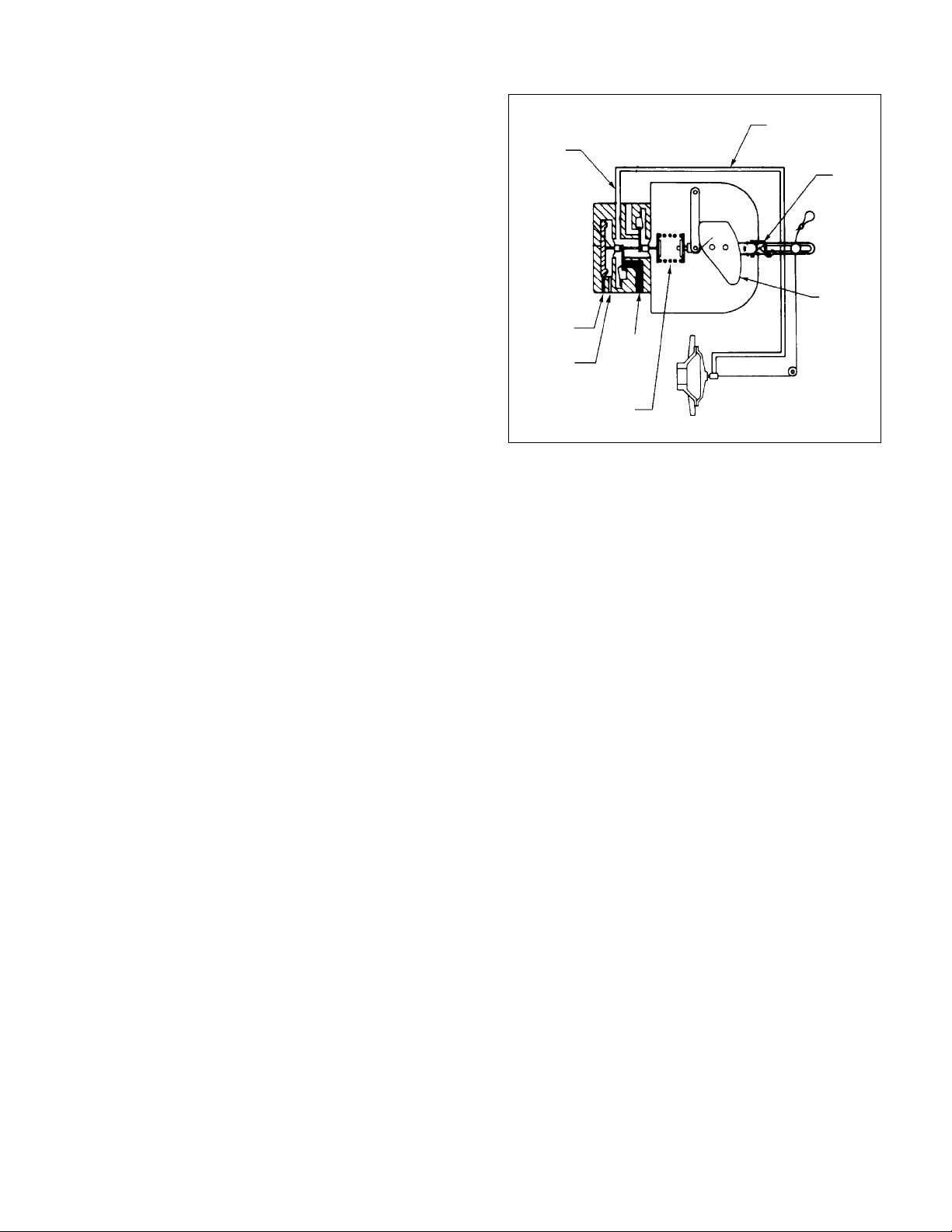

Figure 2. Schematic of Pilot Positioner and

Direct Acting FPAC Fan

Operating

Air To

Diaphragm

(Top Port)

Valve Air

Zero

Return

Spring

3.0 AXICO FAN BLADE ADJUSTMENT

3.1 FPAC FAN

The FPAC fan has a pneumatic diaphragm incorporated in the hub to operate the blade pitch changing mechanism. Air is supplied to the diaphragm through a rotary union

connected to a valve positioner mounted n the vane section.

The positioner is mechanically connected to the diaphragm by

a flexible cable.

3.1.1 Positioner — Function

The function of the positioner is to modulate the air

pressure to the diaphragm in response to the control pressure.

By means of the mechanical feedback it can sense the blade

pitch and thus satisfy the control set point. The positioner will

provide linear response to the control pressure.

The positioner is factory set to operate in the direct acting mode. This means that a decreasing control pressure will

cause a decrease in blade pitch and less airflow.

3.1.2 General Description of How It Works

The pilot positioner is a single acting, singe-stage,

force-balance type control device. Mounted on an AXICO

fan, and cable-connected to the rotor operating mechanism, it

uses an auxiliary air supply and a feedback cam controlled by

the cable to position the rotor mechanism in accordance with

the 3-15 psig air signal from the controller.

Figure 2 is a schematic diagram of this system.

Remember that the feedback spring maintains upward pressure on the positioner arm at all times, and this keeps the

cable in tension. Since the positioner is direct acting, a 3 psig

instrument gauge pressure results in 0 psig valve gauge pressure or minimum pitch position. When the instrument gauge

indicates 15 psig, this results in maximum valve pressure and

thus maximum pitch. The tendency of the fan blades is to go

to minimum pitch, so that, when the diaphragm pressure is

reduced, the spider will move towards the rotor, pulling the

positioner arm down and compressing the feedback spring.

3.1.3 Positioner Connections

There are three 1∕4" NPT ports on the positioner. The

top port is connected to the diaphragm on the fan rotor.

The middle port should be field connected to the controller

(branch line). The bottom port should be field connected to

main air supply. Supply air should be clean and dry instru-

ment air. Moisture or dirt in the supply air will cause

the pilot on the positioner to malfunction after repeated

exposure. The supply pressure to the positioner should be

regulated as required to achieve full pitch. The supply pressure

needed is a function of fan speed and size.

Controller

Input Signal

Air (Middle

Port)

Vent

Main Air

Supply

(Bottom

Feedback

Spring

Port)

Fan Rotor

Feedback

Cam

3.1.4 Positioner Calibration and Adjustment

The positioner is factory calibrated and no further

adjustment is normally required. The calibration can be easily checked and corrected if normal fan control cannot be

achieved. The positioner must be adjusted if replaced or the

cable is removed from the lever arm.

To adjust the positioner, proceed as follows:

1. With fan off, disconnect the air line on the positioner to

the fan rotor and connect this line to a

1

∕4" NPT pressure

regulator.

2. Check that the cable is in alignment with the hole where

it enters the stator vane core. If not, adjust the positioner

on the mounting bracket (not the pin in the slotted arm),

keeping the positioner horizontal with respect to the case.

3. Adjust the pressure regulator to supply full line pressure

to the fan diaphragm. Loosen the cable clamp on the

positioner arm and pull cable tight. Mark the cable where

it protrudes through the stator case. This is the maximum

pitch position. Reduce the pressure to the diaphragm to

zero and start the fan while maintaining tension on the

cable by pulling upward on the cable. The fan will now be

in the minimum pitch position.

Mark the cable again in the minimum pitch position. Turn

off the fan.

WARNING: Do not release cable tension while fan is in

operation. Wait until fan has come to a complete stop.

NOTE: The blades may not fully return to the minimum

pitch position unless fan is operating.

4. Adjust the pressure to the diaphragm to move the cable

midway between the two reference marks. Measure carefully and maintain this position. Remove the side cover

plate on the positioner. Grasp the positioner arm and move

it to align the line engraved on the cam with the centerline

of the cam roller (see Figure 2). Tighten the cable clamp.

NOTE: The positioner is now mechanically adjusted at

mid-range with the fan blade pitch mechanism at the mid

position.

Aerovent IM-201 3

5. Reconnect air line from the diaphragm to the positioner.

6. Proceed with the positioner calibration, as described

below:

a. Connect a 1∕4-NPT pressure regulator to the instrument

port to simulate a control pressure.

b. Turn on the supply air. Adjust the regulator to 9 psig

control pressure.

c. The mark on the cam should point to the center of the

cam follower. If not, turn spring adjusting nut to align

the mark.

d. Replace the cover plate and reconnect the control pres-

sure line to the middle port.

e. The positioner is now adjusted and calibrated to provide

linear blade pitch control from a 3 to 15 psig control

pressure.

NOTE: It is advised that a 0-30 psi pressure gauge of

known accuracy be used during the calibration procedure.

NOTE: In the event that a positioner has to be replaced

with a new part, the pin in the slotted arm on the new

part should be placed in the identical position as on the

old one. Specifically, the slot marking should match the

distance between the marks made on the cable in item 3

of the adjustment instructions above.

3.1.5 Air Consumption

The bleed rate of the positioner is zero. Under operating conditions, an FPAC fan will use a maximum of 0.25

SCFM of supply air.

3.2 FPMC FAN

The FPMC fan is a mechanical version of the AXICO

fan. Pitch control is achieved by a mechanical linkage connected to a thrust bearing in the hub cover. This arrangement

is available in three versions:

1. FPMC with electric operator mounted on the outside of

the vane section.

2. FPMC with a manual gear/jack mounted inside the core

of the vane section, and a handwheel mounted on the side

of the vane section to adjust pitch. This version can be

adjusted while the fan is running.

3. FPMC with the same linkage as on the motor-operated

version, but the input end of the linkage is clamped in one

position on a quadrant. This version cannot be adjusted

while the fan is running.

3.2.1 FPMC, Electric Motor Operator

The 120 VAC operator is used with FPMC fans. This

operator provides position proportion control of the AXICO

mechanical blade linkage. The operators are furnished with

end limit switches which have been factory set to match minimum and maximum pitch conditions required for each fan.

The motor will rotate the output shaft through an arc of 150°,

but the switches have been set to give the necessary linkage

stroke within this 150° arc. Operating time is 60 seconds for

the full 150°, so on an AXICO fan the time will be somewhat

shorter. The motor has a 135 ohm balancing slide wire which

must also be connected to the control relay. The motor is also

equipped with a 135 ohm feedback slide wire to permit an

output signal which can be used as the input signal to a second

relay which would control a parallel fan.

3.2.1.1 Control

Since fan pitch is being used to control duct system

static pressure in the majority of cases, a pressure sensing

transducer or slide wire bridge must be used in conjunction

with a balancing relay. This relay will operate a single pole

double throw switch to feed power of the correct polarity

to the operator motor to achieve CW or CCW rotation of

the output shaft. If the balancing slide wire is not connected,

the motor would run until the limit switch cuts power to the

motor in that circuit direction. Not until polarity is reversed

would the motor operate, and then it would go through full

stroke in the opposite direction until the second limit switch is

opened.

By connecting the balancing slide wire circuit back

to the balancing relay, the relay is now able to compare the

requirements of the duct sensor with the actual rotation of the

operator, and the comparison will make or break the SPDT

switch, changing operator rotational direction in a stepping

manner. Thus, the system becomes proportional.

3.2.1.2 Actuator Electrical Connection

All electric connections should be in strict accordance with the job specification and local electric codes. Refer

to the current manufacturer's owner's manual for a schematic

wiring diagram.

3.2.1.3 Actuator Replacement

The actuator is factory adjusted to provide the

full range of blade pitch movement. Should the actuator be

replaced, the limit switches must be adjusted to prevent the

motor from stalling at the maximum and minimum pitch positions.

To replace the actuator proceed as follows:

1. Remove the crankarm from the motor shaft without disturbing the ball joint and pushrod location.

2. Remove wiring and mark terminal locations.

3. Remove four mounting bolts and replace actuator with

new unit.

4. Remove four screws from the end cover and remove the

cover.

5. Connect 120 VAC power to the proper terminals, according to the owner's manual, to drive motor to mid-position

of shaft rotation as indicated by wiper arm location.

6. Move pitch control lever to mid-position and install crankarm on motor shaft.

7. Drive motor counterclockwise, according to the owner's

manual, to the maximum pitch position.

8. Adjust limit switch (LS1), according to the owner's manual, to open at this position.

9. Drive motor clockwise, according to the owner's manual,

to the minimum pitch position.

10. Adjust limit switch (LS2), according to the owner's manual, to open at this position.

CAUTION: Check that the limit switches are properly

adjusted and that the actuator motor does not stall at

either of the two extreme positions.

11. Reconnect wiring, according to the owner's manual, and

replace covers.

3.2.1.4 Actuator Linkage Adjustment

Should the linkage be removed during fan disassembly, it may be adjusted as follows:

1. Position the pitch control lever and actuator motor at

mid-position per Section 3.2.1.3.

2. Install crankarm in an upward vertical position on motor

shaft.

3. Install ball joint on crank arm at the minimum radius

from shaft, which will permit the wiper arm to operate

within the length of the slide wire. It must not run off at

either end.

4 Aerovent IM-201

4. Install push rod and tighten ball joint.

5. Adjust limit switches per Section 3.2.1.3.

3.2.1.5 Actuator Pitch Adjustment

The maximum and minimum blade pitch is mechanically

set in the rotor. The limit switches in the actuator can be reset

to reduce the range between these limits to provide different

maximum and minimum airflows. This may be done as follows:

1. Remove terminal box and/or end covers from actuator as

required.

2. Energize terminals, according to the owner's manual, with

120 VAC to drive the blades to minimum pitch.

3. Start the fan and energize the proper terminals, according to the owner's manual, to increase the pitch until the

desired maximum airflow is obtained.

4. Adjust limit switch (LS1), according to the owner's manual, to open at this position. This will stop the motor at

the new maximum pitch position.

5. Energize terminals, according to the owner's manual, to

decrease the pitch until the desired minimum airflow is

obtained.

6. Adjust limit switch (LS2), according to the owner's manual, to open at this position. The motor will stop at the

new minimum pitch position.

7. Check limit switch adjustment by driving motor through

range.

8. Replace terminal box and/or end covers as required.

3.2.2 FPMC Fan, Handwheel Version

An external handwheel on the vane section is connected to a miniature wormgear jack inside the core of the

vane section. This in turn is connected to the hub cover of

the rotor. If the handwheel is installed on the right side of

the fan, looking in the direction of airflow, counterclockwise

rotation of the wheel will increase blade pitch. If installed on

the left side, clockwise rotation will increase pitch. With this

arrangement the blade pitch can be changed while the fan is

running.

3.2.3 FPMC Fan, Quadrant

With this version of the FPMC, the external linkage to

the rotor is clamped in one position by a handwheel on a fixed

bolt. The blade forces are such that the fan must be turned off

to adjust the blade pitch. Move the lever upstream to decrease

pitch, downstream to increase it.

3.3 AXICO FPDA FAN

The FPDA fan is an adjustable pitch fan. The blade

pitch has been factory set to meet the airflow requirement of

the job specification. The blade pitch may be changed to meet

other airflow requirements. The hub fairing is marked with

degree marks at the leading edge of the fan blade The first

mark near the inlet side of the fairing is 60°. The last mark

near the center of the fairing is 25°. The intermediate marks

are in 5° increments. The marks are referenced to the center

of the leading edge of the fan blade.

3.3.1 Blade Pitch Adjustment

To set the blade pitch proceed as follows:

NOTE: An 8 mm key with a square drive adaptor fitted

to a torque wrench is required.

1. Remove the stator section access panel per steps 1 through

5 of Section 5.7 to gain access to the fan blades on

Arrangement 4 Type 2 fans. Access on other fans may be

gained by removal of the protective inlet screen if desired.

2. Loosen the four M12 blade bolts until the blade is free to

rotate.

3. Rotate the blade to align the center of the leading edge with

the desired pitch mark.

CAUTION: Do not exceed 55° blade pitch without consulting factory.

4. Alternately tighten opposite blade bolts to 40 ft-lb.

CAUTION: It is important that the bolts are torqued to the

specified value. Do not hand-tighten the bolts.

5. Repeat Steps 2 through 4 for all blades.

6. Replace stator section access panel or inlet screen.

CAUTION: The motor current should be checked not to

exceed the nameplate rating when blade pitch has been

increased.

4.0 INSTRUMENTATION (PITCH

CONTROL) AXICO FANS

4.1 GENERAL

Various parameters such as pressure, temperature, gas

concentration, relative humidity, or velocity can be measured

to provide the required system airflow. The sensor is connected to a controller which provides an electrical or pneumatic

control signal to the fan. The fan pitch is modulated to meet

the system airflow set point requirement.

4.2 FPAC FAN

The FPAC AXICO fan is factory adjusted to go from

minimum to maximum pitch with a 3 to 15 psig pneumatic

control signal. Two-position or multi-position pitch settings

may be obtained with intermediate control pressures. The

blade pitch may also be manually controlled by supplying the

control pressure from a pressure regulator.

4.3 FPMC FAN

The FPMC fan actuator is adjusted at the factory to go

from minimum and maximum pitch with limit switches at the

ends of the stroke. The limit switch settings may be changed

to reduce the range of blade pitch for two-position step

control from contact closure. See Figure 3 for typical wiring

diagram.

4.4 PARALLEL FAN OPERATION

When two or more fans are installed to operate in parallel, two problems are commonly experienced.

1. When less than all the fans are in operation, air circulates

backwards through the fan that is shut down, causing it to

freewheel backwards. This can be very damaging to the

motor when the fan is restarted.

2. When all fans are running together, they may not be completely stable.

SOLUTION: The signal to all fans must be a common

signal, and it should be a heavily damped signal so the changes

of blade angle occur very slowly. Also the fans must have their

positioners calibrated so that all positioner arms are at the

same angle for a given control pressure. A second check can

be made to insure that motor amps match within 5% at a given

signal pressure.

NOTE: STARTING A FAN WHILE THE ROTOR

ASSEMBLY IS WINDMILLING BACKWARDS VOIDS

ALL MOTOR AND FAN WARRANTIES.

Aerovent IM-201 5

Loading...

Loading...