Aerovent IM-180 User Manual

IM-180

April 2005

General Installation, Operation and Maintenance Instructions For Aerovent Products

Fiberglass Centrifugal Fans

Aerovent solid fiberglass fans are designed for long, trouble-free service in severe

corrosive conditions. Care should be exercised during installation and operation in

order to obtain maximum life.

Inspection

1. Inspect the equipment for any shipping damage. Freight

damage claims should be filed immediately with the carrier

if any damage is noted. Remove any foreign material such as

tags or packing from any moving parts or from within the

housing.

2. Turn motor, drive and impeller by hand to see that no misalignment has taken place in shipment. (All units have been

test run before shipment.)

3. Check all bolts, fasteners, lube lines, etc., and tighten if necessary.

Installation

For satisfactory operation, a good foundation and/or support

is essential. Foundations should be level, rigid and of sufficient

mass. A concrete base with mass at least 2 to 3 times the weight

of the fan and drive is preferred. If a steel platform is used, all

supports should be sturdy, rigid and braced in all directions.

When mounting, do not distort or twist. Shim or grout

under fan base, if necessary, to see that mating parts are accurately aligned before tightening bolts to avoid applying excessive

pressures at the flanges.

Use gaskets between the fan flanges and the connecting

duct flanges to eliminate condensate leakage. A soft compress-

4. Compare the voltage, hertz and phase stamped on the motor

with the current characteristics of the line to which the

motor is to be connected.

CAUTION: Temperature limitations for use with fiberglass

fans must be carefully observed. Do not install adjacent to

steam lines or in any location where 200°F temperature may be

exceeded. Fumes carried by the ducts must also be held below

this temperature.

ible corrosion resistant gasket should be employed. It is recommended that new gaskets be used anytime a joint is to be

replaced.

For best results, a flexible connection consisting of a flexible sleeve and corrosion proof tie bands are recommended.

An access door in the scroll of the fan is convenient for quick

inspection of the fan to check for build-up of dirt on blades,

etc. Do not support the weight of the stack or duct by the inlet

or outlet connections.

Operation

1. Fans must not be operated under conditions which would

lead to the build-up of solids on the fan blades. This could

cause an unbalanced condition and lead to premature failure. (Each fan has been statically and dynamically balanced

before leaving the factory.)

2. Check alignment of the V-belt drive by means of a straightedge. Align and adjust belt tension, if necessary. An adjustable motor base is provided as standard on Arrangement 9

and 10. After adjustment, be sure adjusting bolts are tight.

(See IM Manual Bulletin 101.)

3. All fans are lubricated at the factory and have been given a

run-in test before shipment. Aerovent’s fiberglass centrifugal

©2005 Aerovent

fans are furnished as standard with a shaft hole closure consisting of a thin Teflon membrane secured with a stainless

steel plate to minimize the leakage of corrosive gases around

the bearings. However, as a further precaution against bearing contamination, a more frequent lubrication schedule

than that outlined in IM-100 is recommended.

4. Turn the wheel over by hand to make sure that it runs free

and clear. Adjust if necessary.

5. Jog the fan electrically and note rotation. Each centrifugal

fan is marked to indicate direction of rotation. Reverse electrical leads, if necessary, to obtain proper rotation.

6. Do not exceed maximum operating speed as shown in the

table below.

Max. Safe Speeds For

Wheels At 70°F Temp

SIZE CL I CL II CL III

12 3080 4005 5082

16 2425 3153 4002

20 1941 2523 3046

25 1540 2002 2372

32 1213 1576 1837

39 970 1261 1455

Correction Factors

For Max. Speed

at Various Temps

TEMP.

°F

70 1.00

100 1.00

150 0.85

200 0.55

FACTOR

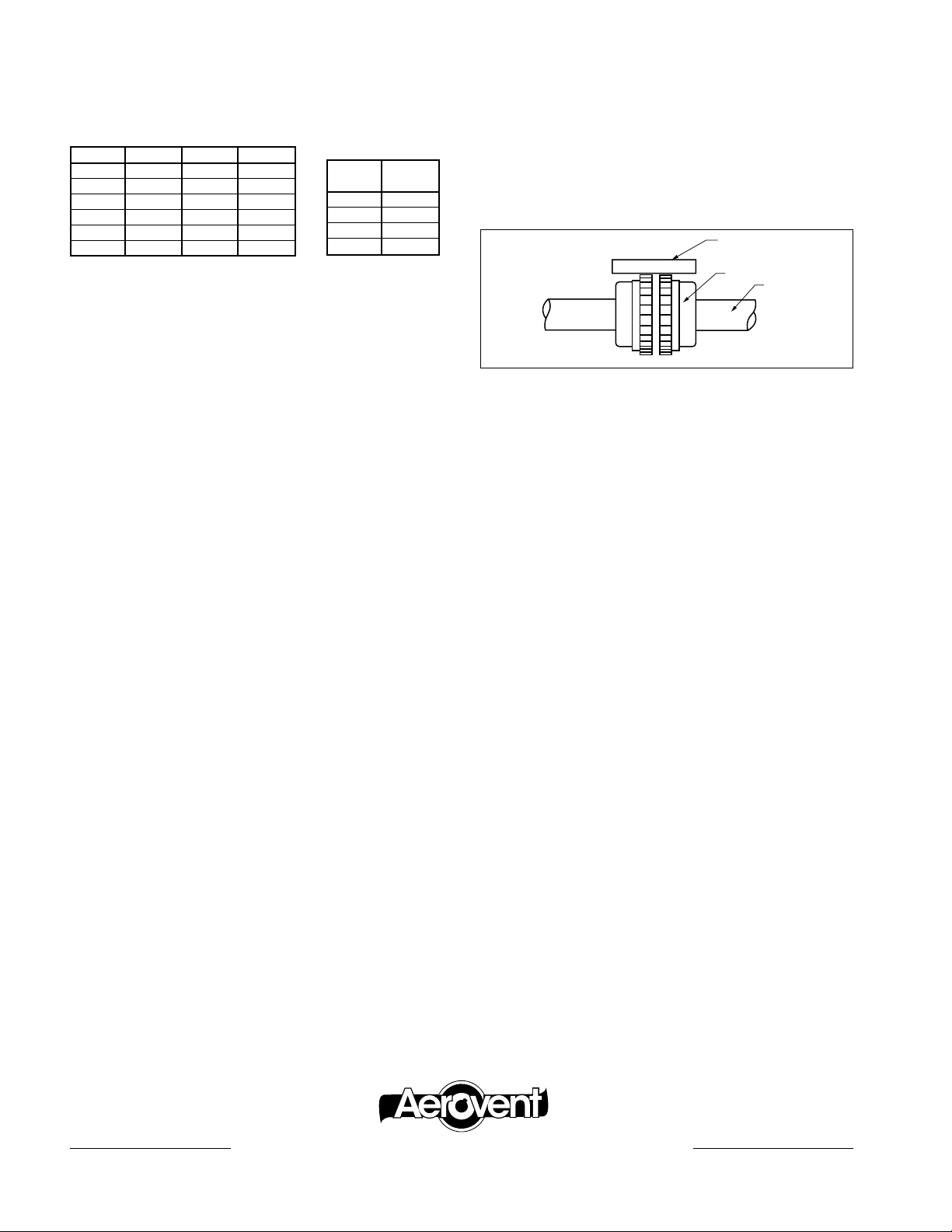

Couplings

Direct-coupled fans should be checked for correct coupling

alignment before putting the unit in operation. Also, check

lubricant following manufacturer’s recommendations for type

and amount of lubricant used. For field installation, the coupling should be mounted as follows:

1. Remove dirt or rust from fan and motor shafts and coat with

grease or oil for easy mounting of coupling.

Maintenance

Regular and systematic inspection of all fan parts is the key to

good fan maintenance. Frequency of inspection is determined

by the severity of the application and local conditions. Once a

maintenance schedule is established, it should be strictly adhered

to. Regular fan maintenance should include the following:

1. Check after one day operation.

2. Check after one week operation.

3. Check periodically once a month until experience indicates

that a longer period is satisfactory.

Fan Wheel

The fan wheel must be kept reasonably clean if it is to perform

properly. Dirt or chemical deposits will usually build up on the

wheel evenly and they present no problem to performance or

operation until they become thick enough to break away in

crust-like pieces. When this happens, the wheel may be thrown

out of balance and the resulting vibration could be serious.

When removing this crustaceous accumulation, care should be

taken not to clean the fan wheel with sharp objects which might

damage the laminated surface and reduce corrosion resistance.

Should the wheel show excessive wear, it should be replaced.

2. Mount the coupling halves on the shafts with the fans separated by the coupling manufacturer’s specified gap.

3. The coupling should be checked for parallel and angular

alignment with a straightedge and feeler gauge. Exact tolerances are specified by the coupling manufacturer.

4. Once a proper alignment is assured, complete the assembly

and lubricate the coupling before putting the unit into operation. After a short period of operation, recheck alignment.

Straightedge

Coupling

Shaft

V-Belts

On belt-driven units, check V-belt drive for proper alignment

and tension (see IM-101). If belts show wear, they should be

replaced with a matched set of belts. If unit is direct coupled,

check coupling alignment.

Fan Bearings

Check fan bearings for adequate lubrication, wear, tightness

and overheating. (See bearing section of IM-100 for lubrication

specifications.)

Fasteners

Check tightness of all nuts and bolts taking care not to overtighten nuts on encapsulated housing bolts.

Condensate Drain

If fan is equipped with a condensate drain in the housing, check

to be sure it is not clogged.

Spare Parts

A spare parts list is not supplied with the fan. There are very few parts which would ever require replacing. For

ordering these, mention part by name such as wheel, bearing or shaft and refer to model number and serial number

on label. If possible, advise order number and date of original purchase.

®

AEROVENT | WWW.AEROVENT.COM

5959 Trenton Lane N | Minneapolis, MN 55442 | Phone: 763-551-7500 | Fax: 763-551-7501

Loading...

Loading...