Aerovent IM-172 User Manual

IM-172

August 2014

General Installation, Operation and Maintenance Instructions For Aerovent Products

Propeller Wall Fans

Models: BSBP, BSDDP

Aerovent Catalog 172 provides additional information on this equipment. This catalog

can be found at www.aerovent.com or by contacting your local Aerovent sales representative.

BSBP BSDDP

Model Nomenclature

Model

BSDDP = Wall Propeller Fan, Direct Drive

BSBP = Wall Propeller Fan, Belt Driven

Fan Size

Propeller Type

B = Backswept

Hub Designation

Blade Count

Blade Angle

BSDDP - 24 - B - 1 - 05 - 25

©2014 Aerovent

Receiving, Unpacking & Inspection

When the equipment is received all items should be

carefully checked against the bill of lading to be sure all

crates and cartons have been received. Before accepting

delivery, carefully inspect each carton or crate for

visible shipping damage. If any damage is noticed, the

carrier should make the proper notation on the delivery

receipt acknowledging the damage. Make notations of

all damage on all copies of the bill of lading and have

all copies countersigned by the delivering carrier. The

carrier should also fill out a Carrier Inspection Report.

The factory Traffic Department should then be contacted.

File claim for damage with the carrier. Physical damage

to the unit after acceptance is not the responsibility of

Aerovent.

Unpack each carton or crate and verify that all required

parts and proper quantities of each item have been

received. Refer to drawings for part descriptions. Report

shortages or missing items to your local representative

to arrange for replacement parts.

Storage

If fans are stored for any length of time, they should

be stored in a clean, dry location to prevent rust and

corrosion. Outdoor storage is not recommended. When

outdoor storage is necessary, fans should be protected

from the elements as completely as possible. Cover the

fan inlet and outlet and keep motors dry and clean.

For extended storage (more than 3 months) motor shafts

and bearings should be rotated monthly. If stored longer

Due to availability of carriers and truck space, it is not

possible to guarantee that all items will be shipped

together. Verification of shipments must be limited to

only those items on the bill of lading.

The unit nameplate must be checked to make sure

the voltage agrees with the power supply available.

CAUTION: Sheet metal parts, screws, clips and simiar

items inherently have sharp edges, and it is necessary

that the installer and service personnel excercise

caution.

The installation of this equipment shall be in accordance

with the regulations of authorities having jurisdiction and

all applicable codes. This equipment is to be installed

by an experienced installation company and fully trained

personnel. The mechanical installation of the exhaust

ventilator consists of making final connections between

the unit and building services, duct connections.

than 6 months, bearing grease in motor and fan should

be purged and replaced with compatible grease. Belts

should be rechecked for proper tension. Storage records

should be kept to assure proper maintenance. The

factory can advise warranty centers to provide motor

and bearing service if needed.

Limitation of Warranties and Claims

Seller warrants to the original purchaser that the

goods sold hereunder shall be free from defects in

workmanship and material under normal use and service

(except in those cases where the materials are supplied

by the buyer) for a period of one year from the date of

original installation or eighteen (18) months from the date

of shipment, whichever occurs first. The liability of seller

under this warranty is limited to replacing, repairing, or

issuing credit (at cost, F.O.B. factory and at seller’s

discretion) for any part or parts which are returned by

buyer during such period provided that:

a. seller is notified in writing within ten (10) days

following discovery of such defects by buyer, or

within ten (10) days after such defects should

reasonably have been discovered, whichever is

less;

b. the defective unit is returned to seller, transportation

charges prepaid by buyer;

c. payment in full has been received by seller or said

products;

d. seller’s examination of such unit shall disclose to its

satisfaction that such defects have not been caused

by misuse, neglect, improper installation, repair,

alteration, act of God, or accident.

No warranty made hereunder shall extend to any

seller product whose serial number is altered, effaced

or removed. Seller makes no warranty, express or

implied, with respect to motors, switches, controls,

or other components of seller’s product, where such

components are warranted separately by their respective

manufacturers. THIS WARRANTY IS EXPRESSLY IN LIEU

OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED,

WHETHER STATUTORY OR OTHERWISE, INCLUDING

ANY IMPLIED WARRANTY OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE. In no event

shall seller be liable to buyer for indirect, incidental

collateral, or consequential damages of any kind.

(BUYER’S FAILURE TO PAY THE FULL AMOUNT DUE

WITHIN SIXTY (60) DAYS OF DATE OF INVOICE SHALL

OPERATE TO RELEASE SELLER FROM ANY AND ALL

LIABILITY OR OBLIGATION ARISING PURSUANT TO

ANY WARRANTY, EXPRESS OR IMPLIED, WHETHER

STATUTORY OR OTHERWISE, INCLUDING ANY IMPLIED

WARRANTY OR MERCHANTABILITY OR FITNESS FOR

A PARTICULAR PURPOSE, MADE IN CONNECTION

WITH ANY CONTRACT FORMED HEREUNDER. BUYER

AGREES THAT SUCH FAILURE TO PAY SHALL

CONSTITUTE A VOLUNTARY WAIVER OF ANY AND ALL

SUCH WARRANTIES ARISING PURSUANT TO SUCH

CONTACT.)

2 Aerovent IM-172

Electrical Connection

1. Connect supply wiring to a disconnect switch.

Check the wiring diagrams on the motor for connections.

2. The motor is factory set at the voltage marked on

the fan nameplate. Check the line voltage with the

nameplate voltage and wiring diagrams.

3. The main power wiring should be sized for the

ampacity shown on the dataplate. Size wires in

accordance with the ampacity tables in Article 310

of the National Electrical Code. If long wires are

required, it may be necessary to increase wire size

to prevent excessive voltage drop. Wires should be

sized for a maximum of 3% voltage drop.

CAUTION: Use copper conductors only.

CAUTION: Protect wiring from sharp edges. Leave

some slack in the line to prevent damage.

4. (Optional) Disconnect switches are not fused. The

power leads must be protected at the point of distribution in accordance with the fan dataplate.

Check, Test & Start Procedure

5. On fans without a thermal protector integral to the

motor (refer to unit or motor dataplate to determine

if protector is present) a separate overload device

is required. Refer to Sections 430-32 of the N.E.C.

for sizing.

6. All units must be electrically grounded in accordance

with local codes or, in the absence of local codes,

with the latest edition of the National Electrical

Code (ANSI/NFPA 70). A ground lug is provided as

standard in the unit terminal box. Size grounding

conductor in accordance with Table 250-95 of the

National Electrical Code. DO NOT use the ground

lug for connecting a neutral conductor.

7. Supply voltage to the power ventilator should not

vary by more than 10% of the value indicated

on the unit dataplate. Phase unbalance must not

exceed 2%.

WARNING: Failure of motor due to operation on

improper line voltage or with excessive phase unbalance constitutes product abuse and may cause

severe damage to the unit’s electrical components.

WARNING

Electric shock hazard. Could cause severe injury or

death. Failure to bond the frame of this equipment

to the building electrical ground by use of the

grounding terminal provided or other acceptable

means may result in electrical shock. Disconnect

electric power before servicing equipment. Service

to be performed only by qualified personnel.

BEFORE START-UP: Disconnect power to this unit

before servicing the unit.

1. Check to verify that the propeller is free to rotate.

2. Verify that supply voltage on the line side of disconnect agrees with voltage on fan data plate and is

within the 10% utilization voltage.

3. Apply power to unit and check rotation of propeller

with the directional arrow on the unit.

WARNING: Rotation is critical. If allowed to operate

in the wrong direction, the motor will overload and

burn out.

WARNING: Especially check three-phase units for

rotation. For three-phase, rotation can be changed by

interchanging any two of the three line leads. If unit is

checked on temporary wiring, it should be rechecked

when permanently installed. Motor burn-out or tripped

overload protection devices are usually the result of

wrong rotation.

4. Electrical Input Check: Perform check of fan ampere

draw and verify that motor nameplate amps are not

exceeded. Take into account the service factor range

if motor is nameplated above a 1.0 service factor.

5. Fan RPM should be checked and verified with a

tachometer.

Aerovent IM-172 3

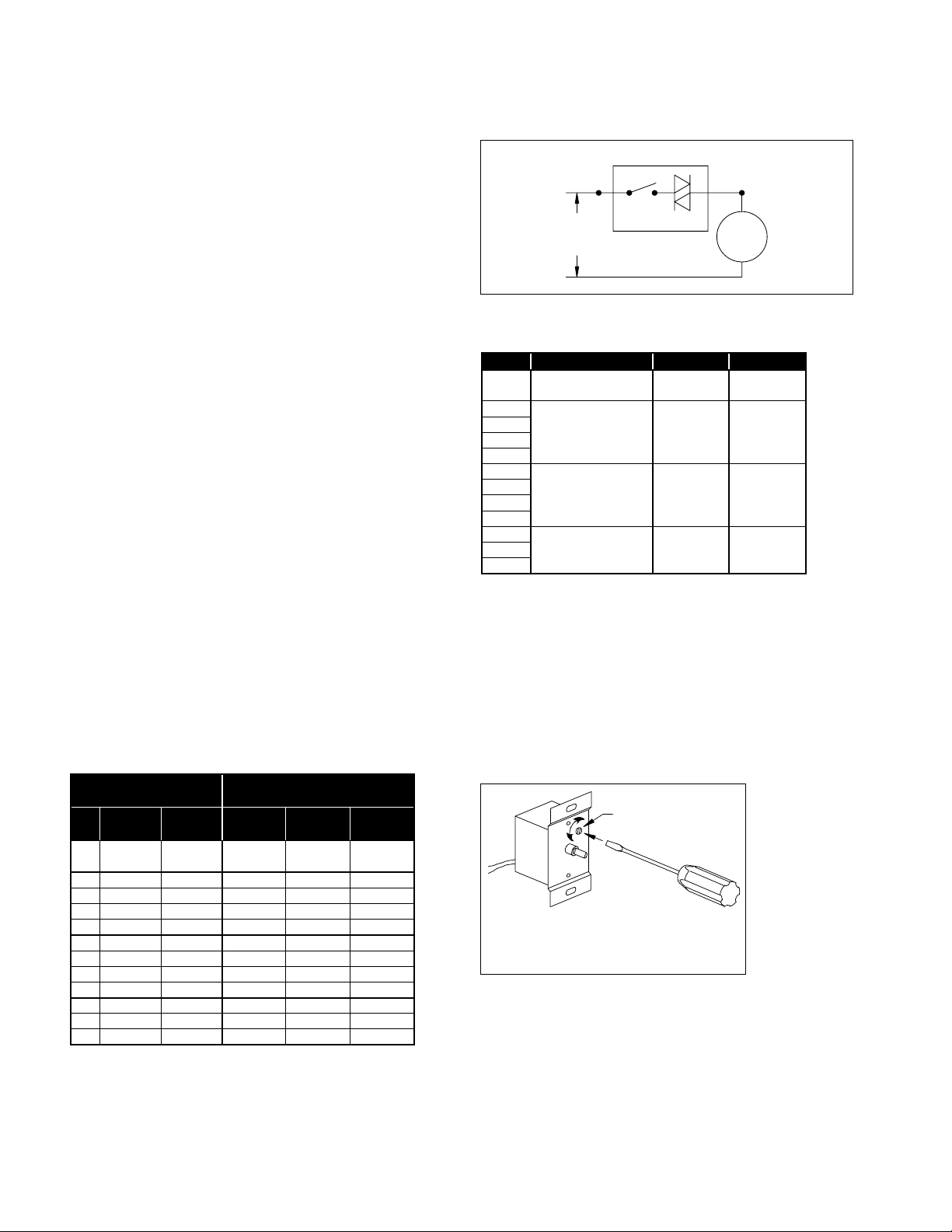

Speed Control Installation

The controller is designed to start the motor at high

speed and will then slow down. This gives the motor

good starting characteristics.

Speed control is available using 115/60/1 open type

PSC or shaded pole motors.

Installation

Connect control in series with motor and line voltage

(115V only). Never connect across line. See Figure 1.

Minimum Speed Setpoint

All controls are factory set to 65V±3V output as standard with an input voltage of 120V. If different minimum

speed is desired, the control may be adjusted by turning minimum speed pot clockwise to decrease minimum

speed and counterclockwise to increase minimum speed.

Refer to Figure 2.

Warning: If minimum speed is readjusted, verify unit

ampere draw does not exceed motor nameplate amps.

Do not operate unit in range where amp draw exceeds

motor nameplate.

Caution: These motors operate more efficiently in the

ranges set from the factory. Operating motor outside

these ranges (see Table 2) may cause motor to run

hotter and substantially shorten motor life.

Note: Lowering the minimum speed setpoint may

adversely affect motor start-up characteristics.

Warning: Certain failure modes of solid-state controls

such as half-waving can cause high levels of DC, motor

overheating and motor burn-out. Therefore, a thermal

overload protection (integral with motor) is required to

limit the maximum motor temperature under such a

failure.

Note: Do not allow any sleeve bearing motor to

operate below 500 RPM. Operation below 500 RPM will

substantially shorten bearing life.

Figure 1. Connection Diagram, Speed Control

SPEED CONTROLLER

AC

LINE

(115V)

SWITCH TRI-AC

MOTOR

Table 2. Speed Controller RPM Range

HP RPM MAX. RPM MIN. RPM

1/8

1/8

1/6

1/4

1/2

1/6

1/4

1/2

1/3

1/2

3/4

NOTES:

1. Speed control available only with 115/60/1 open motors (thermally

2. Three-speed motor (multiple tap winding).

3. Speed control should not be connected to low speed tap on motor

4. Speed control connected to high speed tap on motor.

5. Speed control connected to medium speed tap on motor.

1650/1500/1350

1140 1140 900

1

1725 1725 1200

protected).

because of starting characteristics.

2,3

860 860 500

1650

1500

4

5

1300

950

4

5

Table 1. Speed Controller Size

MOTOR

HP RPM VOLTAGE

1650/1500/

1/8

1350

1/8 860 115V X

1/6 860 115V X

1/4 860 115V X

1/2 860 115V X

1/6 1140 115V X

1/4 1140 115V X

1/2 1140 115V X

1 1140 115V X

1/3 1725 115V X

1/2 1725 115V X

3/4 1725 115V X

115V X

SPEED CONTROLLER

DESIGNATION / FLA

KBWC-15K

5 AMP

KBWC-110

10 AMP

KBWC-115

15 AMP

Figure 2. Low End Setpoint Adjustment

SETPOINT

ADJUSTMENT

SCREW

NOTE: 5 amp model shown. On 10 and 15 amp

models, adjustment is made through clearance

hole in heat sink.

4 Aerovent IM-172

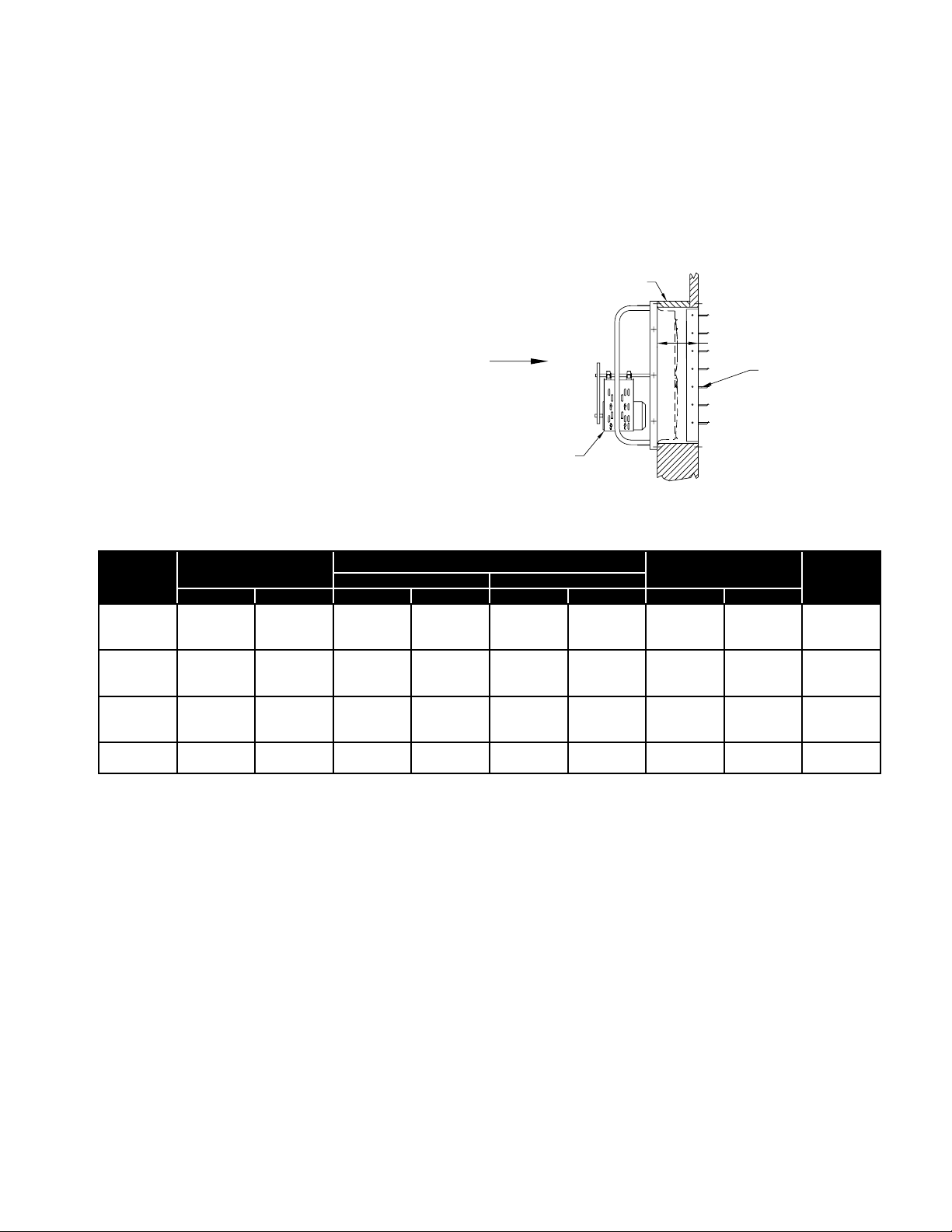

Panel Installation (without accessories) — BSBP & BSDDP

WALL OPENING REQUIREMENTS

Wall opening size and the distance between propeller and damper are two important dimensions for fan installation.

Fans mounted to the wall require a different wall opening size than those mounted in collars or wall boxes. Propellerto-damper distance (M) is important to reduce turbulance at the damper which may lead to premature failure, and to

prevent the propeller blades from hitting the actuator on motorized damper units. Use general installation procedure

from page 4.

To achieve the minimum 'M' dimension,

this installation requires a spacer (by others)

SPACER

(BY OTHERS)

between the fan and the wall.

If the wall is equal to or greater than the

minimum 'M' dimension, the fan can be

mounted directly to the wall.

PROP

SIZE

14 -- 17.00 -- 14.50 -- 17.50 -- 14 x 14

18 -- 22.00 -- 19.50 -- 22.50 -- 19 x 19

21 25.00 25.00 22.50 22.50 25.50 25.50 22 x 22 22 x 22

30 36.00 36.00 33.50 33.50 36.50 36.50 33 x 33 33 x 33

36 42.00 42.00 39.50 39.50 42.50 42.50 39 x 39 39 x 39

48 54.00 54.00 51.50 51.50 54.50 54.50 51 x 51 51 x 51

54 60.00 -- 57.50 -- 60.50 -- 57 x 57 -60 66.00 -- 63.50 -- 66.50 -- 63 x 63 --

PANEL SQ.

BSBP BSDDP BSBP BSDDP BSBP BSDDP BSBP BSDDP

SURFACE MOUNT RECESS (IN WALL)

WALL OPENING (MIN.)

AIR

FLOW

FAN

MIN

DAMPER SIZE

BACKDRAFT

DAMPER

'M'

(MIN.)

16.0016 -- 20.00 -- 17.50 -- 20.50 -- 17 x 17

16.0024 28.00 28.00 25.50 25.50 28.50 28.50 25 x 25 25 x 25

16.0042 48.00 48.00 45.50 45.50 48.50 48.50 45 x 45 45 x 45

19.00

Aerovent IM-172 5

Loading...

Loading...