Aerovent IM-166 User Manual

IM-166

September 2009

General Installation, Operation and Maintenance Instructions For Aerovent Products

AMX Mixed Flow Fans

Introduction

This bulletin has been prepared to guide the users of

AMX Mixed Flow Fans in the proper installation, operation and maintenance procedures to insure maximum

equipment life with trouble-free operation.

Shipping and Receiving

All Aerovent products are carefully constructed and

inspected before shipment to insure the highest standards of quality and performance. Compare all components with the bill of lading or packing list to verify that

the proper unit was received. Check each unit for any

damage that may have occurred in transit. Any damage

should be reported immediately to the carrier and the

necessary damage report filed.

Handling

Handling of all air moving equipment should be conducted by trained personnel and be consistent with safe

handling practices. Verify the lift capacity and operating

condition of handling equipment. Maintain handling

equipment to avoid serious personal injury.

Units shipped completely assembled may be lifted

with slings and spreader bars. Use well-padded chains,

cables or nylon straps (see Figure 1). On most units,

lifting lugs are fashioned to protect the fan and fan

housing from damage. Never lift a fan by the inlet or

discharge flange, shafting or drives, wheel, motor or

motor base, or in any other manner that may bend or

distort parts.

If installation is to be delayed, store the unit in a

protected area. Protect the fan and motor bearings from

moisture and vibration (or shock loading). For extended

storage, wrap entire unit in plastic. Wrap loosely so air

may circulate around the fan and moisture does not

collect, or use a desiccant. Extended storage requires

monthly inspections. Check for corrosion or damage to

the unit and for debris within the fan. Rotate the fan

wheel a few revolutions. Stop the wheel in a position

other than the initial position. Grease the bearings every

month with a grease compatible with the grease supplied with the bearings.

Foundations and Supporting Structures

The AMX series can be mounted horizontally, vertically,

or at any angle if ordered accordingly. Mounting brackets

are available to accept both vibration isolating hangers

or pads. Typical mounting arrangements are shown in

Figures 2 through 8. Floor or wall mounted fans may be

installed on a flat, rigid foundation.

When mounting to concrete, anchor bolts should be

“L” or “T” shaped with sufficient length for nuts, washers, shims, and threads for draw-down. Each bolt should

be placed in a sleeve or pipe with diameter larger than

the bolt to allow for adjustment. When the mounting

surface and the surface of the fan base do not match,

shim level. Do not distort the fan when tightening the

anchor bolts.

A fan mounted to or within a structure should be

placed as close as possible to a rigid member such as

a wall or a column. The structure must be designed for

rotating equipment. Static design for strength is not sufficient to insure operation at low vibration levels. Supports

for suspended fans must be cross-braced to prevent

side-sway. Structural resonance should be at least 20%

from fan operating speed. Vibration isolators may help

block the transmission of vibration into a structure.

Any ducting should have independent support; do not

use the fan to support ducting. Flexible connections are

required whenever the fan is supported on vibration

isolators.

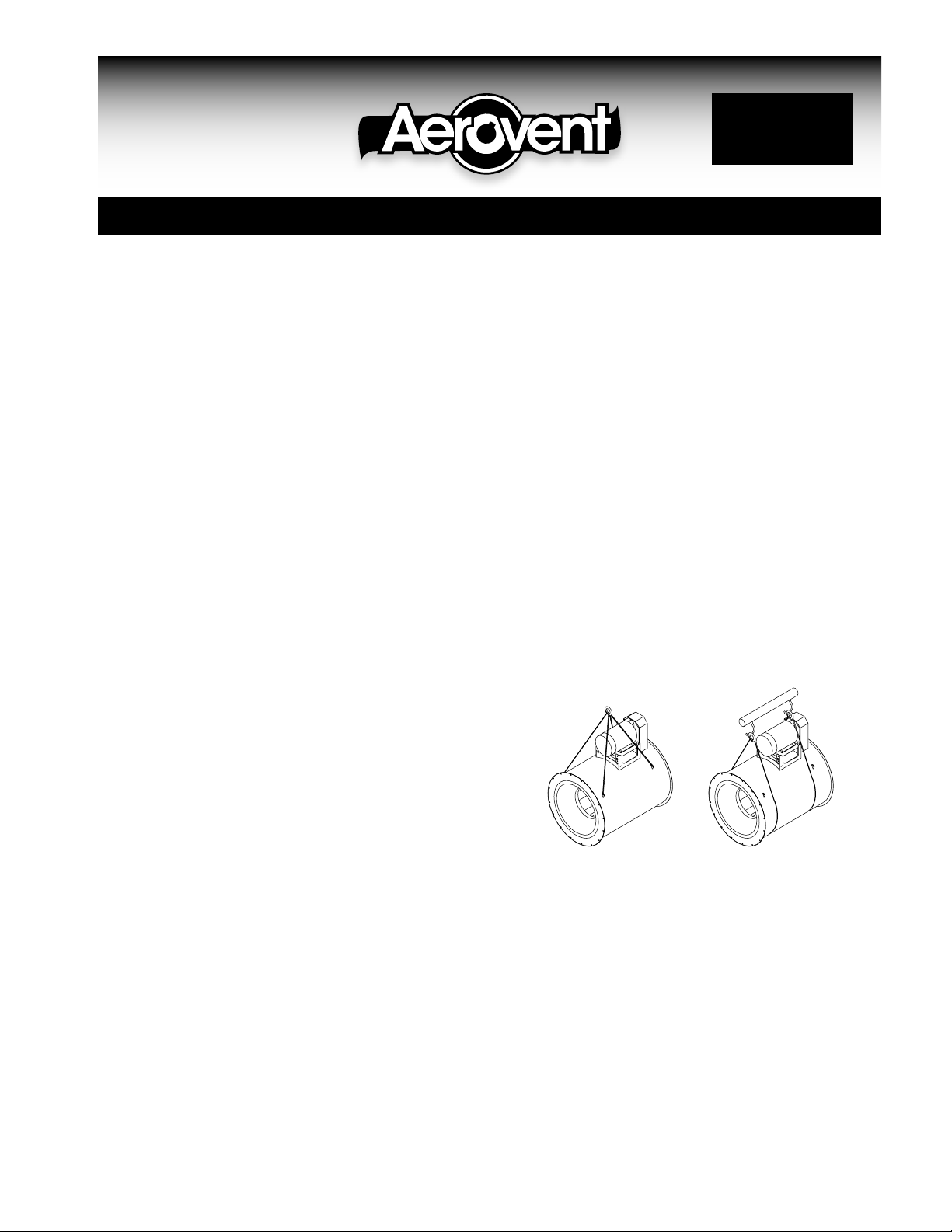

Figure 1.

Lifting With Lifting Lugs Lifting With Straps &

(Standard) Spreader Bar (Not Provided)

Fan Installation, Factory Assembled Units

Follow proper handling instructions as given earlier.

1. Move the fan to the final mounting position.

2. Remove skid, crates and packing materials carefully.

3. Attach vibration isolators (if used) to appropriate

mounting clips on fan. Locate fan in position using

lifting instructions above.

4. Carefully level unit using shims (on rigid mounted

fans) at mounting hole locations. Fans mounted with

vibration isolators may be leveled by adjusting the

hardware.

5. Continue with Operations Checklist.

©2009 Aerovent

Motor Maintenance

The three basic rules of motor maintenance are:

1. Keep the motor clean.

2. Keep the motor dry.

3. Keep the motor properly lubricated.

Blow dust off periodically (with low pressure air) to

prevent motor from overheating.

Some smaller motors are lubricated for life. Lubrication

requirements are normally attached to the motor. Use

the motor manufacturer’s recommendations for relubrication. If this information is not available, the following

schedule may be used. Motors less than 10 HP running

about eight hours a day in a clean environment should

be lubricated once every five years; motors 15 to 40

HP, every three years. For motors in dusty or dirty

environments or running 24 hours a day: divide the

service interval by 4. Do not over lubricate.

Drive Maintenance and Installation

V-belt drives need periodic inspection, retensioning, and

occasional belt replacement. When inspecting drives,

look for dirt buildup, burrs or obstructions that can

cause premature belt or drive replacement. If burrs are

found, use fine emery cloth or a stone to remove them.

Be careful that dust does not enter the bearings.

Check sheaves for wear. Excessive slippage of belts

on sheaves can cause wear and vibration. Replace worn

sheaves with new ones. Carefully align sheaves to avoid

premature sheave failure.

Inspect the belts for wear. If fraying or other wear is

observed to be mostly on one side of the belts, the

drives may be misaligned. Reinstall the drives according

to the following instructions:

1. Slip (do not pound) proper sheave onto corresponding

shaft. CAUTION: Placing fan sheave on motor can over-

speed wheel and cause structural failure.

2. Align sheaves with straightedge extended along

sheaves, just making contact in two places on outside perimeters of both sheaves.

3. Tighten sheave bolts (or setscrews if appropriate).

Table 1 can be used to determine the amount of

torque required.

4. Install a matched set of belts. Adjust the motor position to obtain slack, install, and tighten belts. Using

a pry bar will damage belts.

5. Tighten belts to proper belt tension. Ideal tension is

just enough so that the belts do not slip under peak

load. When using drive tensioning data supplied by

V-belt drive manufacturers, new belts can be tensioned

to a value 50% greater than for normal operation. This

will reduce retensioning requirements after break-in.

Recheck sheave alignment after tensioning.

6. After initial installation of belts, recheck belt tension

again after a few days. (New belts require a break-in

period of operation.)

7. When replacing belts, replace the entire set. After

initial replacement and tensioning, recheck belt tension after a few days. (New belts require a break-in

period of operation.) Never use belt dressing on any

belts.

8. Fans that have motors and drives mounted at the

factory are trim balanced prior to shipment. This is

not possible on units that are shipped without motors

and drives. The addition of drive components in the

field can create unbalance forces. Aerovent recommends final balancing of the unit after the drive

components are installed. Failure to do so may void

the warranty.

Motor Support Adjustment

Two different types of motor mounts, post and saddle,

are used on AMX Mixed Flow fans. Which mount to use

depends on the size of the fan and motor.

On the post type motor mount, the motor plate is

supported on four threaded rods. Belt tension is adjusted by loosening the four nuts on top of the motor plate

and raising the motor plate by adjusting the four nuts

underneath it. The top nuts should then be tightened to

hold the motor plate in place.

On the saddle type motor mount, the motor pivots

on one side and adjustment of belt tension is achieved

by loosening the nuts on top of the motor plate on the

other side, then raising the motor plate by adjusting the

nuts underneath the motor plate. The nuts on top of the

motor plate should again be tightened to hold the motor

plate in place. Several holes are provided on the pivot

side, and the pivot point can be raised for gross belt

adjustment. If this adjustment is made, however, the

motor plate should be as parallel as possible to the fan

centerplane. Care should be taken to maintain drive

alignment and proper belt tension.

Bearing Maintenance

Proper lubrication of the fan drive bearings helps assure

maximum bearing life. All fans are equipped with decals

indicating relubrication intervals for normal operating

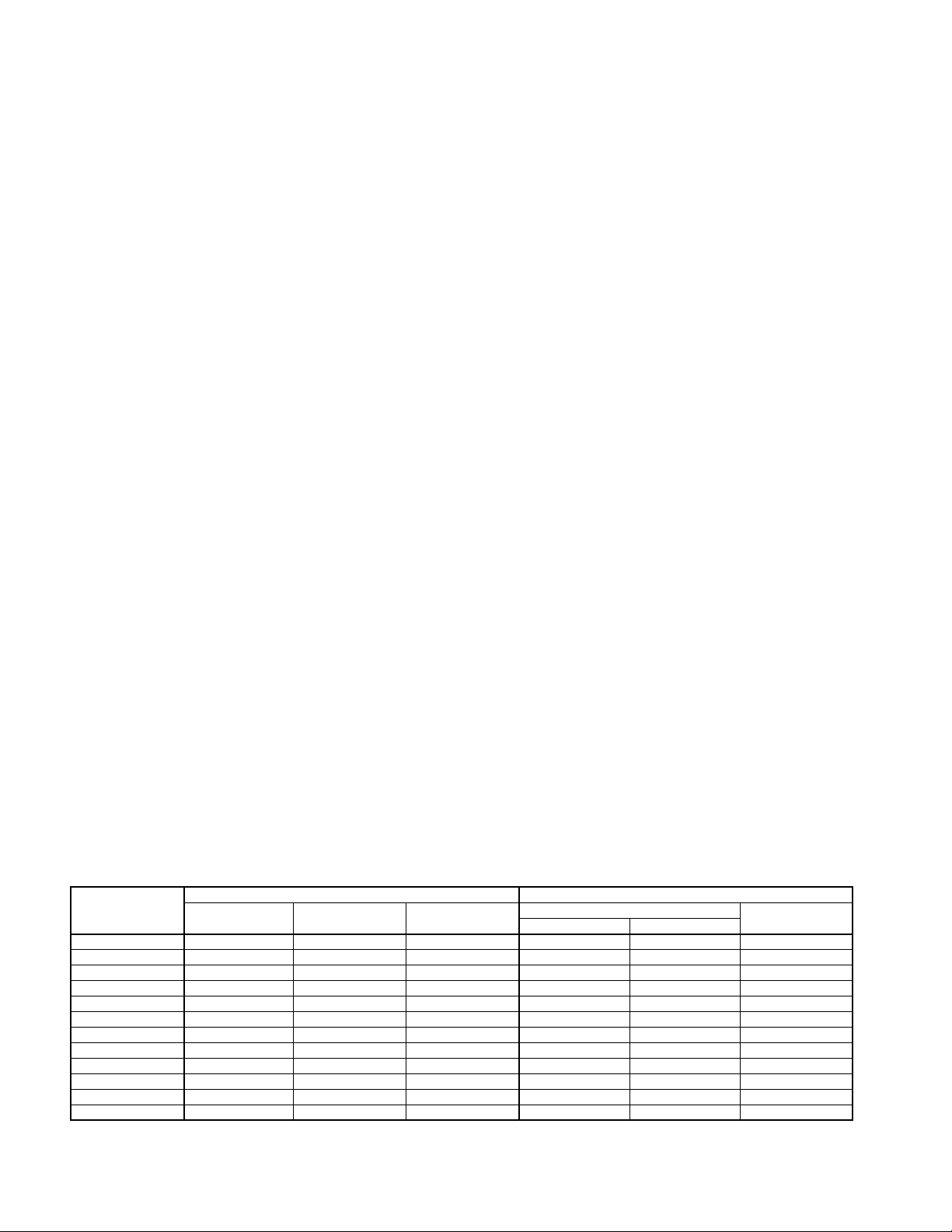

Table 1. Tightening Torque (Ft.-Lbs.)

FASTENER TAPER BUSHINGS

SIZE BROWNING SPLIT QD

#10 — — — — — 5

1

1-8 250 645 900 — — —

1

Tolerance: +5%

For wheel setscrews use Grade 2 values.

The above torque values are for nonlubricated fasteners.

⁄4-20 5.5 8 12 7.9 7.5 9

5

⁄16-18 11 17 25 16 13 15

3

⁄8-16 22 30 45 29 24 30

7

⁄16-14 30 50 70 — — —

1

⁄2-13 55 75 110 70 — 60

9

⁄16-12 — — — — — 75

5

⁄8-11 100 150 220 — — 135

3

⁄4-10 170 270 380 — — —

7

⁄8-9 165 430 600 — — —

1

⁄4-7 500 1120 1500 — — —

GRADE 2 GRADE 5 GRADE 8

IN IRON IN ALUM. HUB FOR DRIVE

2

Aerovent IM-166

conditions. See Table 2 for typical lubrication data.

However, every installation is different and the frequency

of relubrication should be adjusted accordingly.

On high moisture applications, the lubrication frequency may need to be doubled or tripled to adequately protect the bearings. Double the relubrication frequency on fans with vertical shafts.

Observation of the conditions of the grease expelled

from the bearings at the time of relubrication is the best

guide as to whether regreasing intervals and amount of

grease added should be altered.

Greases are made with different bases. There are

synthetic base greases, lithium base, sodium base, etc.

Avoid mixing greases with different bases. They could

be incompatible and result in rapid deterioration or

breakdown of the grease. The lubrication sticker identifies a list of acceptable lubricants. All bearings are filled

with a lithium-based grease before leaving the factory.

When the fans are started, the bearings may discharge

excess grease through the seals for a short period of

time. Do not replace the initial discharge because leakage

will cease when the excess grease has worked out.

Sometimes the bearings have a tendency to run hotter

during this period. There is no reason for alarm unless

it lasts over 48 hours or gets very hot (over 200°F). When

relubricating, use a sufficient amount of grease to purge

the seals. Rotate bearings by hand during relubrication.

Wheel and Shaft Maintenance

Periodically inspect the shaft and wheel for dirt buildup,

corrosion, and signs of excess stress or fatigue. Clean

the components. If the wheel is removed for any reason,

make sure that it is securely attached to the shaft before

restarting the fan.

Structural Maintenance

All structural components or devices used to support or

attach the fan to a structure should be checked at

regular intervals. Vibration isolators, bolts, foundations,

etc., are all subject to failure from corrosion, erosion,

and other causes. Improper mounting can lead to poor

operation characteristics or fan fatigue and failure. Check

metallic components for corrosion, cracks, or other signs

of stress. Concrete should be checked to insure the

structural integrity of the foundation.

Operation Checklist

• Verify that proper safety precautions have been followed.

• Electrical power must be locked off.

Check fan mechanism components:

• Nuts, bolts, setscrews are tight.

• Mounting connections are properly made and tightened.

• Bearings are properly lubricated.

• Wheel, drives and fan surfaces are clean and tightened.

• Rotating assembly turns freely and does not rub.

• Drives on correct shafts, properly aligned, and properly tensioned.

Check fan electrical components:

• Motor is wired for proper supply voltage.

• Motor was properly sized for power of rotating

assembly.

• Motor is properly grounded.

• All leads are properly insulated.

Trial “bump”:

• Turn on power just long enough to start assembly

rotating.

• Check rotation for agreement with rotation arrow.

• Listen for any unusual noise.

Run unit up to speed:

• Bearing temperatures are acceptable (<200°F) after

one to two hours of operation.

• Check for excess levels of vibration. Filter in readings should be 0.15 inches per second or less.

After one week of operation:

• Check all nuts, bolts and setscrews and tighten if

necessary.

• Re-adjust drive tension if necessary.

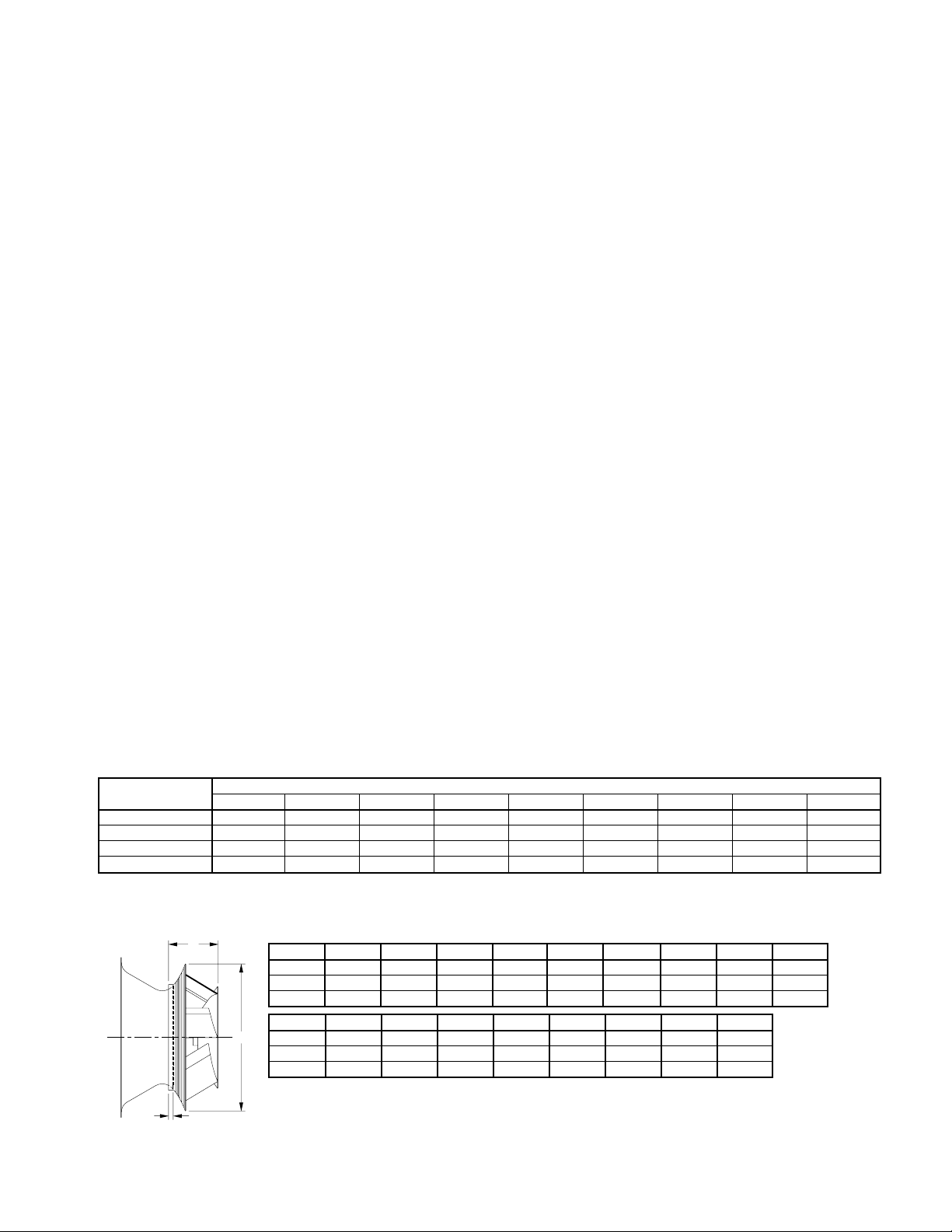

Table 2. Relubricating Schedule (Months) — Ball Bearing Pillow Blocks

SPEED (RPM)

SHAFT DIA.

1

⁄2"– 111⁄16" 6 6 5 3 3 2 2 2 1

15

⁄16" – 27⁄16" 6 5 4 2 2 1 1 1 1

1

11

⁄16" – 215⁄16" 5 4 3 2 1 1 1 — —

2

7

⁄16" – 315⁄16" 4 3 2 1 1 1 — — —

3

500 1000 1500 2000 2500 3000 3500 4000 4500

Table 3. AMX Wheel-Funnel Overlap

C

B

SIZE 150 165 182 200 222 245 270 300 330

A 18.25 20.00 22.25 24.50 27.00 30.00 33.00 36.50 40.25

B 0.56 0.63 0.69 0.75 0.88 0.97 1.06 0.94 1.03

C 6.19 6.75 7.56 8.31 9.13 10.19 11.19 12.38 13.63

SIZE 365 402 445 490 542 600 660 730

A

A 44.50 49.00 54.25 60.00 66.00 73.00 80.75 89.00

B 1.13 1.25 1.38 1.56 1.69 1.88 2.09 2.28

C 15.13 16.63 18.38 20.25 22.31 24.63 27.25 30.00

Note: Use “B” dimension for positioning wheel.

Aerovent IM-166

3

Loading...

Loading...