Aerovent IM-165 User Manual

IM-165

April 2005

General Installation, Operation and Maintenance Instructions For Aerovent Products

Centaxial Fans

Direct and Belt Driven

Aerovent Centaxial fans are designed for continuous duty in

air-moving systems handling clean air. As a general rule, these

fans are designed to be installed in any position. However,

larger fans and fans with high horsepower loading may not be

suitable for vertical installation. It is advisable to check with

the factory to determine if vertical installation is satisfactory.

Upon receipt of equipment, inspect the fan and its accessories for possible damage in shipment. Make certain the

wheel rotates without binding. Never lift the Centaxial fan by

its motor, fan wheel or shaft. Lifting eyes are provided for this

purpose.

If the unit is not to be put in operation for a period of

time and is to be stored, the following precautions should be

observed:

1. Select a clean, dry location to prevent rust.

2. For outside storage, protect against the elements by covering the inlet and outlet of the fan.

3. Make certain bearings are filled with grease. (See General

Installation and Maintenance Manual IM-100 for lubrication procedure.)

4. Keep motors dry and clean.

5. Periodically inspect unit to see if conditions are present

which could cause damage.

Discharge

End

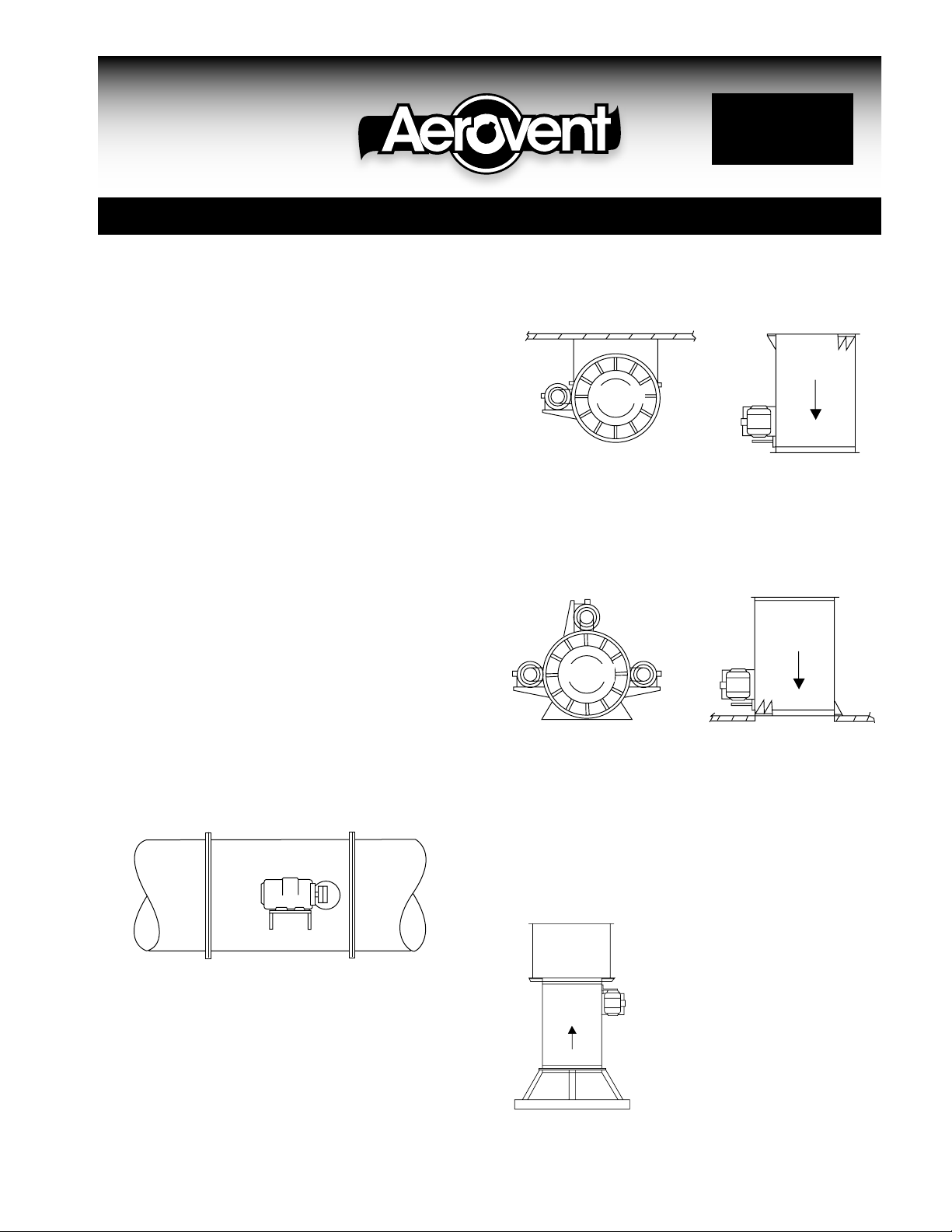

Horizontal - Ceiling Vertical - Ceiling

When suspending the fan from overhead with rods or other

arrangements, support of the load should be accomplished

by means of diagonal bracing to prevent side sway. Welded

construction of the support should be used rather than bolted

due to the loosening of bolts by vibration.

Discharge

End

Horizontal - Floor Vertical - Floor

AIRFLOW

AIRFLOW

Mounting Arrangements

Duct Mounted

The mounting flanges on the Centaxial fan are capable of

supporting the fan in ductwork and are of the same size at

the inlet and outlet for easy installation in a straight-line duct

system. However, the ducts must be structurally sufficient to

support the load. The following bolt sizes are required when

mounting fan to duct: 3∕8" on sizes 12 through 44; 1∕2" on sizes

49 and larger.

©2005 Aerovent

A concrete foundation should be provided for mounting the

centaxial fan on the floor. The size of the fan will determine

the size of the foundation. The concrete base should extend

approximately 6" beyond the outline of the fan and should

have a weight capable of supporting the unit. Anchor bolts

should be provided for bolting to the foundation.

Roof Ventilator

Where the centaxial fan is to be

HEAD

SECTION

mounted as part of a roof ventilator assembly, caulking must be done

after assembly between flanges of

FAN

SECTION

the head section and fan section and

base. Guy wire bracing is required

on all large size units to prevent side

sway.

See IM 120 for further instruc-

BASE

tions regarding roof ventilator installation.

All dimensions in inches.

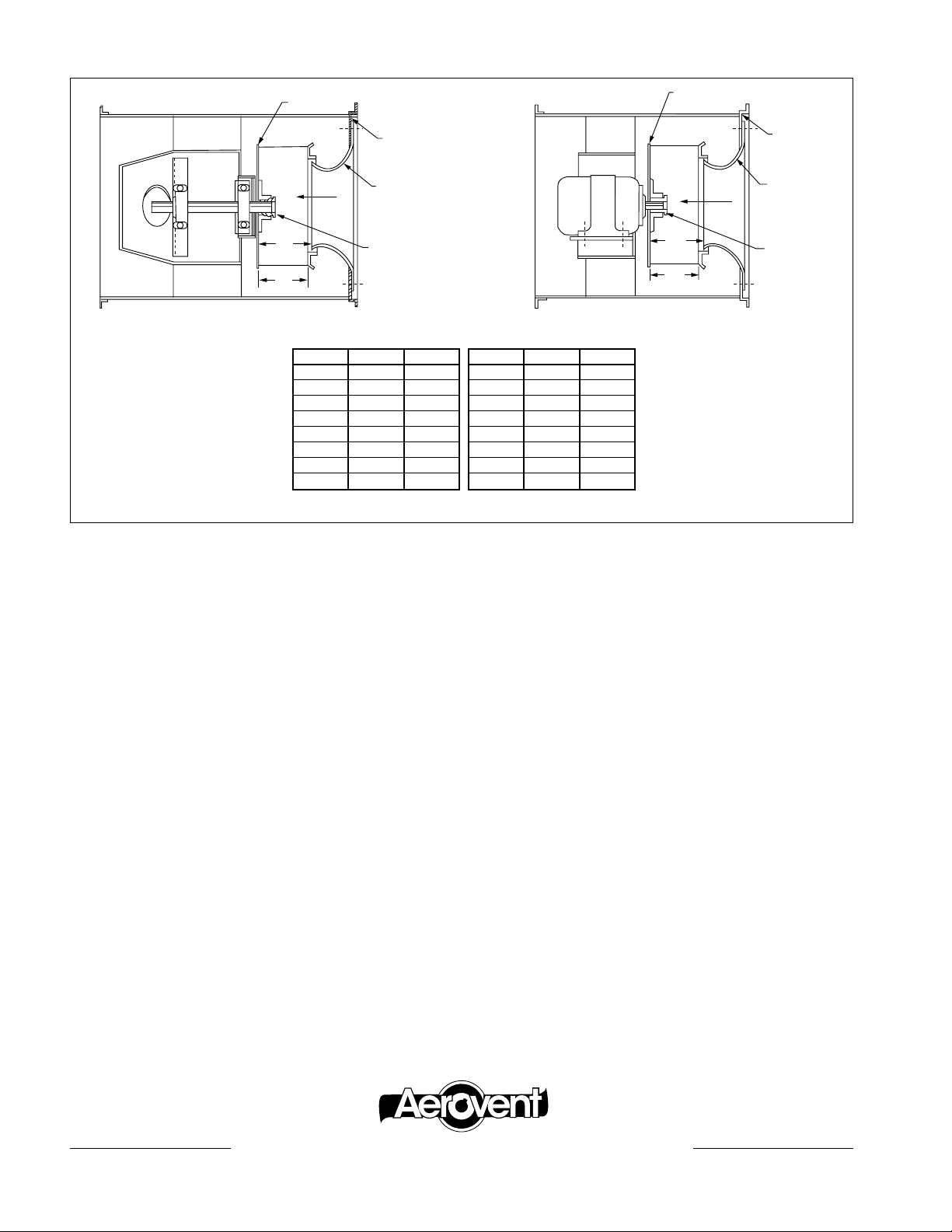

Wheel

Back Plate

A

W

Guide Vanes

Wheel

A

W

Wheel

Back Plate

Airflow

Bar Ring

Inlet Cone

Taper Lock

Bushing

Guide

Vanes

Belt Driven Direct Drive

SIZE A W*

12 4

14 57⁄32 51⁄32

16 527⁄32 521⁄32

18 621⁄32 63/8

20 73/8 71⁄16

22 81⁄4 715⁄16

25 95⁄16 815⁄16

28 1017⁄32 101⁄16

5

⁄8 57⁄16

*100% wheel width

SIZE A W*

32 11

35 135⁄16 123/4

39 1427⁄32 143/16

44 169⁄16 157/8

49 189⁄16 1723⁄32

55 207/8 1927⁄32

63 243/4 2211⁄16

71 2615⁄32 251⁄2

27

⁄32 1111⁄32

“A” dimension (inlet cone to wheel back plate) must be held. This dimension is

critical to fan performance. “A” dimension shown is based on 100% wheel width

and must be adjusted if wheel furnished is other than 100% full width.

Airflow

Bar Ring

Inlet Cone

Taper Lock

Bushing

General Maintenance

A regular fan maintenance schedule should be established to

include the following:

1. Fan Wheel: The fan wheel in a centaxial fan must be kept

reasonably clean if it is to perform properly. Where dirt

build-up is slight, very little unbalance can result. Air heavily laden with grease and dirt will deposit a great deal on

impeller blades. Conditions should be observed and cleaning performed as required for smooth fan operation and,

in the case of grease, removal of this type of fire hazard.

One problem that often develops is the unbalance

which occurs when particles of dirt and grease are thrown

from the blades. This unbalance condition will naturally

cause excessive wear and noise. If the wheel shows excessive wear, it should be replaced.

Cleaning of the wheel should be accomplished, if pos-

sible, without removing it from the shaft. If the fan is

furnished with an access door, the wheel can be cleaned

through this opening. If no door is supplied, then the inlet

cone must be removed to expose the wheel. If for some

reason the wheel is removed from the shaft, take note

of the “A” dimension called out in the chart above. This

dimension must be held if proper performance is to be

maintained.

2. V-Belt Drive: Check V-belt drive for proper alignment

and tension. (See General Installation and Maintenance

Manual IM-100.)

3. Fan Bearings: Lubricate the bearings as detailed in

the ball bearing lubrication instructions in the General

Installation and Maintenance Manual (IM-100).

4. Screws and Bolts: Check tightness of all screws and

bolts throughout the assembly.

®

AEROVENT | WWW.AEROVENT.COM

5959 Trenton Lane N | Minneapolis, MN 55442 | Phone: 763-551-7500 | Fax: 763-551-7501

1.5MSS05/10

Loading...

Loading...