Aerovent IM-120 User Manual

8" Min.

4"

Membrane

Mastic

Mastic

Existing

Roofing

Roof Structure

Ventilator

Base

IM-120

April 2007

General Installation, Operation and Maintenance Instructions For Aerovent Products

Model 53, 40C and SV40 Roof Ventilators

Installation

1. Check for possible damage in shipment to roof ventilator.

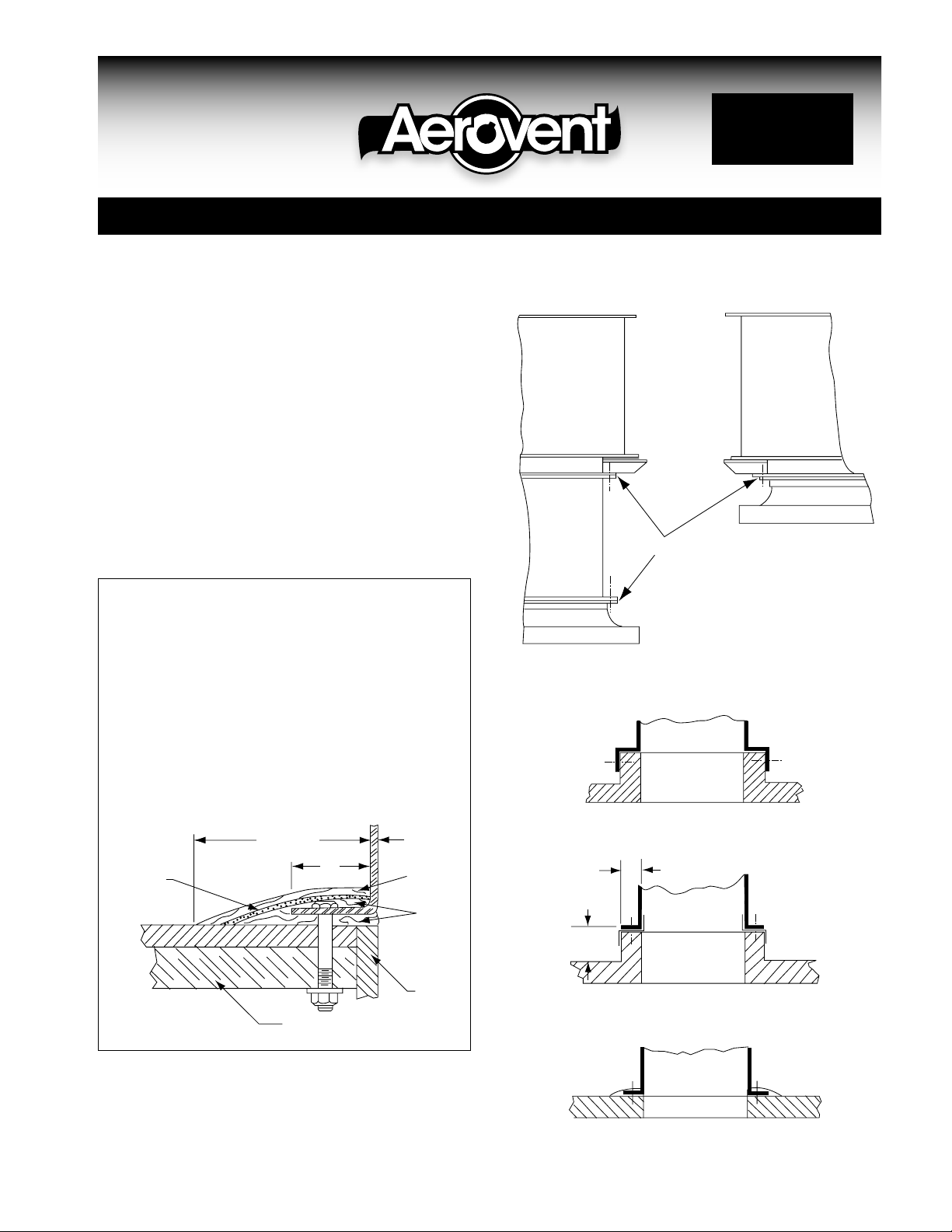

2. Assemble stack cap section, fan and curb base.

3. Caulk between flanges of damper section, fan section

and curb base (see illustration).

4. Install assembled ventilator onto roof curb. Secure

ventilator to curb with bolts (see illustration).

5. Check propeller for proper rotation.

6. Make certain dampers operate smoothly and are free

from obstruction.

STACK

CAP

SECTION

FAN

CAULK

STACK

CAP

SECTION

CURB BASE

Model 53

Detail of Mounting

Flat Type Curb Base on Existing Roof

Use Hydro Shield and heavy-duty glass membrane — Addex Corporation (or equal).

1. Set ventilator curb base in mastic.

2. Apply mastic over curb base flange.

3. Work membrane into mastic.

4. Trowel mastic over membrane and work in

.

CURB BASE

Model 40C & SV40

STD. CURB BASE

4"

6" MIN.

Field Procedure: Caulk ventilator at locations where indicated

to prevent leakage.

Caulk

Seam

ROOF CURB

New Roof

Caulk

FLAT TYPE

CURB BASE

ROOF CURB

New Roof

FLAT TYPE

CURB BASE

Seam

Flashing

Existing Roof

©2007 Aerovent

Care and Maintenance

Good fan maintenance requires regular and systematic

inspection of all fan parts. Severity of the application

should determine frequency of inspection.

Regular fan maintenance should include the following:

1. Propeller — The propeller in an axial flow fan must

be kept reasonably clean if it is to perform properly. Fans handling fresh air for ventilating purposes

will seldom need cleaning. Fans exhausting process

air should be cleaned as required. Dirt or chemical

deposits will usually build up on a propeller evenly,

and they present no problem to performance or operation until they become thick enough to break away

in crust-like pieces. When this happens, the propeller

may be thrown out of balance and the resulting vibration could be serious. The dirt or chemical deposits

should be removed by solvent cleaning or scraping.

If the propeller has been coated, be careful not to

cut through this protective covering. If the propeller

shows excessive wear, it should be replaced immediately. Refer to General Installation and Maintenance

IM-100 for proper procedure in removing and replacing the propeller.

2. V-Belt Drive — Check V-belt drive for proper alignment and tension. See General Installation and

Maintenance IM-101 for instructions.

3. Fan Bearings — Lubricate the bearings (if belt driven).

Bearing lubrication instructions are detailed in IM-

100.

4. Screws and Bolts — Check tightness of all screws

and bolts throughout the ventilator assembly.

5. Stack Cap — Periodically check damper blades and

remove accumulated dirt. Check bronze damper bearings for smooth operation.

®

5MPP04/07

AEROVENT | WWW.AEROVENT.COM

5959 Trenton Lane N | Minneapolis, MN 55442 | Phone: 763-551-7500 | Fax: 763-551-7501

Loading...

Loading...