Aerovent IM-100 User Manual

IM-100

August 2014

General Installation, Operation and Maintenance Instructions For Aerovent Products

Introduction

This manual has been prepared to guide the users of

Aerovent equipment in the proper installation, operation

and maintenance procedures to insure maximum equip

ment life and trouble-free operation.

-

Receiving

Products leaving the assembly plant have been

inspected and are in satisfactory operating condition.

The carrier assumes full responsibility for material from

the time it leaves the plant until it is delivered to the

user. Therefore, material should be inspected for dam

age immediately so that any damage claims against the

carrier can be made before acceptance of the shipment.

No equipment is to be returned without an authorized

returned goods tag.

-

Handling

All products must be handled with extreme care to

avoid misalignment of rotating components. Never lift a

unit assembly by using the shaft, drive sheaves, wheel

or motor as a point of attachment. If it is apparent

that slings will not clear a portion of the product being

hoisted, a spreader should be used to avoid damage.

Initial Operation

All Aerovent fans are lubricated at the factory and have

been given a run-in test before shipment. Read carefully

all installation and maintenance manuals before follow

ing the startup check list.

-

Safety Precautions

Any piece of machinery should be treated with respect

and not overconfidence. Overconfidence usually leads to

carelessness and carelessness leads to injury. Following

is a list of DOs and DO NOTs:

DO

1. Make sure the unit is stopped and electrical power

is locked out before putting hands into the inlet or

outlet openings or near the belt drive. A warning

sign on the START SWITCH cautioning not to start

is recommended when the unit is being serviced.

2. Follow maintenance instructions.

DO NOT

1. Put hands near or allow loose or hanging clothing to

be near belts or sheaves while the unit is running.

2. Put hands into inlet or outlet while the unit is run

ning. It is sometimes difficult to tell whether or not a

fan is running.... be sure it is not running and cannot

be operated before any inspection.

-

©2014 Aerovent

Startup Checklist

1. Inspect the equipment for any shipping damage.

Remove any foreign material such as tags or packing

from any moving parts or from within the fan housing.

2. Compare the voltage, hertz, and phase stamped on

the motor with the current characteristics of the line

to which the motor is to be connected.

3. Lock out the power source at the disconnect switch.

4. Turn motor, drive, and propeller by hand to see that

no misalignment has taken place in shipment. Check

V-belt drive for proper alignment and belt tension.

5. Check all bolts, screws and fasteners and tighten if

necessary. Make certain all set screws, locking col

lars and bearing mounting bolts are secure.

6. Secure and check clearance of access doors, belt

guards and inlet and outlet guards.

7. If equipped with dampers, check for correct linkage

operation. Make sure that the operator opens or

closes these control devices to the proper positions.

8. Jog the fan electrically and note the rotation. Reverse

two electrical leads, if necessary, to obtain proper

rotation as marked with rotation arrow on fan. Do

not allow the propeller to run backwards except

momentarily.

9. Centrifugal Fans: Close dampers as required for

adequate system resistance to prevent the motor

from overloading.

CAUTION: With fans that use the forward-curve or

radial type of wheel, it is possible to overload the motor

if the fan is operated at a lower static pressure than

that which the fan is rated. Check the catalog rating of

the fan for proper speed and resistance.

10. Start the fan and observe its operation.

11. Take a motor amp reading and compare with the

amp rating on the motor. (The actual running amps

should not exceed motor nameplate amps x service

factor, exceptions may be taken for air over motors.)

-

Fan Balance

Fan propellers are statically and dynamically balanced

within acceptable tolerances at the factory. Damage in

shipping and handling or poor installation of the unit

may upset the unit balance. A propeller that is not

properly balanced can lead to excessive vibration caus

ing undue wear on the entire unit. It is recommended

that after installation a vibration test be made on the

fan by an experienced technician.

CAUTION: For units furnished less final drive compo

nents at customer request, the addition of drive components in the field can create critical vibration modes.

Aerovent strongly recommends a final unit balance

procedure after all rotating components are installed.

Failure to do so voids Aerovent’s warranty.

-

-

All Aerovent fan assemblies are statically and dynamically balanced to Balance Quality Grade G6.3. Each

fan is factory run tested for vibration in accordance

with ANSI/AMCA 204-96 "Balance Quality and Vibration

Levels for Fans" to Fan Application Category BV-3, to

the following peak velocity values, filter-in, at the fan

test speed:

Fan Application Rigidly Mtd. Flexibly Mtd.

Category (in./sec.) (in./sec.)

BV-3 0.15 0.20

While fans are test run and carefully balanced in

the factory, vibration cannot be guaranteed under field

conditions due to mounting and installation variables.

Vibration measurements, when possible, should be

taken at each fan shaft bearing in two planes per

pendicular to the axis of rotation (planes to have 90

degree interval), and one measurement parallel to the

axis of rotation. On direct drive units, the perpendicular

measurements will be taken at each end of the motor

casing, taking care not to take measurements on the

fan shroud on TEFC motors. The axial measurement

can be taken on the motor foot or mounting base. In

some cases, primarily on axial flow units, it will not

be possible to take measurements at the bearings or

motor. On these units, the measurements should be

taken on the inner shell near the bearings. If this is not

possible, then take the readings on the outer shell near

the bearing locations.

If vibration is excessive, shut down the fan and

determine the cause.

Common Causes of Excessive Vibration

1. Support structure not sufficiently rigid or level.

Vibration amplified by resonance in ductwork or sup

-

port structure.

2. V-belt drive misalignment. Belt tension is too tight or

too loose.

3. Bearing locking collar or mounting bolts loose.

Propeller set screw loose.

4. Material accumulation on propeller.

5. Centrifugal Fans: Wheel rubbing on inlet cone.

Motors

Most integral horsepower totally-enclosed motors have

drain plugs in the end bells for drainage of condensa

tion. On all roof ventilators, the bottom or lower plug

has been removed for continuous drainage.

All other style fans are shipped with the drain plugs

installed. The user should remove the proper drain plug.

For horizontally mounted units with the motor in the

airstream, remove the downstream drain plug. For verti

cally mounted units, remove the bottom or lower drain

plug.

With motors supplied by the user, drain plugs may

not have been provided. Check with the motor manu

facturer regarding drainage and condensation.

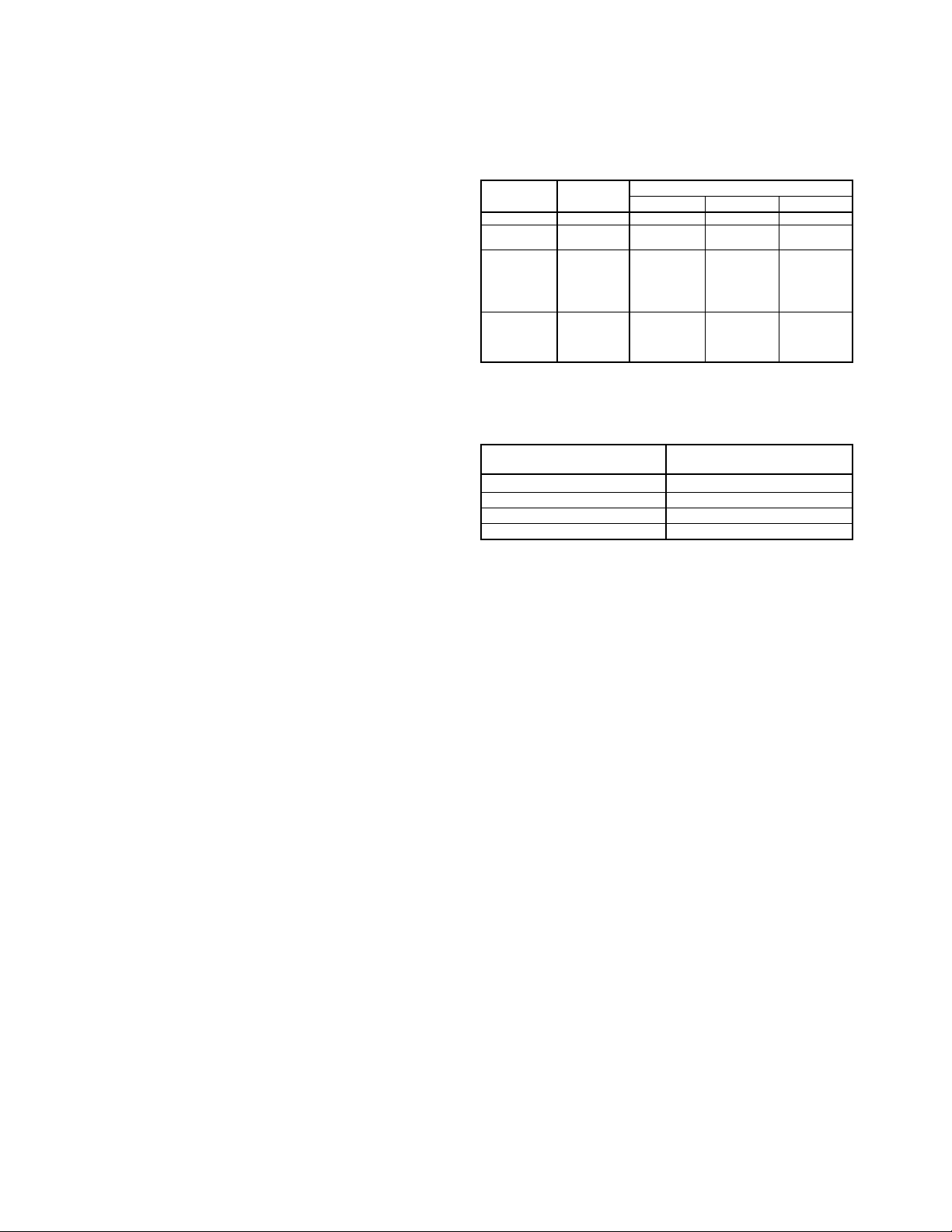

Lubrication Instructions for Ball

The table below suggests relubrication intervals for

motors on normal, steady running, light duty indoor

loads in relatively clean atmosphere at 40°C (105°F)

ambient temperature or less. Fractional horsepower

motors follow a schedule similar to that shown under

frames 143T to 215T.

Motor Lubrication Intervals

TYPE OF INSULA- FRAME SIZE

ENCLOSURE TION 143T–215T 254T–326T 364T–449T

Open-DP B 2 yrs. 18 mos. 1 yr.

Enclosed-FC B

Open-DP F

Enclosed-NV B

Enclosed-FC F

Open-DP H 1 yr. 9 mos. 6 mos.

Enclosed-Lint

Free-FC B

Enclosed-NV F

Enclosed-FC H

Enclosed-Lint

Free-FC F

NOTE: For motors over 1800 RPM, use

duty, dusty locations, use

tion/shock, use

SHAFT DIAMETER AMOUNT OF

(AT FACE OF BRACKET) GREASE TO ADD

1

1

2

1

⁄3 of tabled period.

VOLUME - REFERENCE TABLE

3

⁄4" to 11⁄4" 1/8 cu. in. or 0.1 oz.

1

⁄4" to 17⁄8" 1/4 cu. in. or 0.2 oz.

7

⁄8" to 23⁄8" 3/4 cu. in. or 0.6 oz.

3

⁄8" to 33⁄8" 2 cu. in. or 1.6 oz.

18 mos. 1 yr. 9 mos.

9 mos. 6 mos. 3 mos.

1

1

⁄2 of tabled period. For severe-duty high vibra-

⁄2 of tabled period. For heavy

Motors with no provision for lubrication are equipped

with sealed bearings and require no maintenance.

Motors mounted in inaccessible locations are provided

with extended grease lines to facilitate lubrication if

provisions for lubrication are provided. The bearings are

equipped with relief fittings to prevent over-lubrication.

The grease lines are filled with lubricant at the factory.

Procedure for Relubrication

1. Stop motor.

2. Remove grease relief plugs in bearing housings.

3. Grease with hand gun until new grease appears at

relief hole.

4. Run motor for ten (10) minutes before replacing relief

plugs.

CAUTION: Do not over-lubricate. This is a major cause

of bearing and motor failure. Make sure dirt and con

-

taminants are not introduced when adding grease.

Type of Grease

Lubricate with the following greases or their equivalent:

Amoco Rykon Premium #2

Chevron BRB-2 – Standard Oil or Calif.

SRI-2 – Standard Oil Company

Gadus S2 V100 2 - Shell Oil Company

Mobilith AW2

For motors lubricated with special greases, check lubri

cation tag on motor.

-

Bearing Motors

Grease-lubricated bearings, as furnished, are adequate

for a long period of operation without relubrication. A

good maintenance schedule for regreasing will vary

widely depending on motor size, speed and environment.

2 Aerovent IM-100

Lubrication Instructions for

Fan Ball Bearings

Bearings and grease lines on belt driven fans are lubricated in assembly. When lubrication is required, add

grease slowly while the shaft is rotating until grease

comes rapidly out of the seal.

For extreme conditions, lubricate according to experi

ence. For normal conditions, lubricate the bearings with

Mobilith AW2 or an equivalent.

Bearings and grease lines on axial fans that are

ordered for high moisture or above normal temperatures

have been lubricated with a special lubricant, Plastilube

#2. Lubricate at regular intervals with Plastilube #2 as

indicated in the special lubrication chart listed below.

Plastilube #2 is available from Sulflo, Inc. 1158 Erie

Avenue, North Tonowanda, New York 14120.

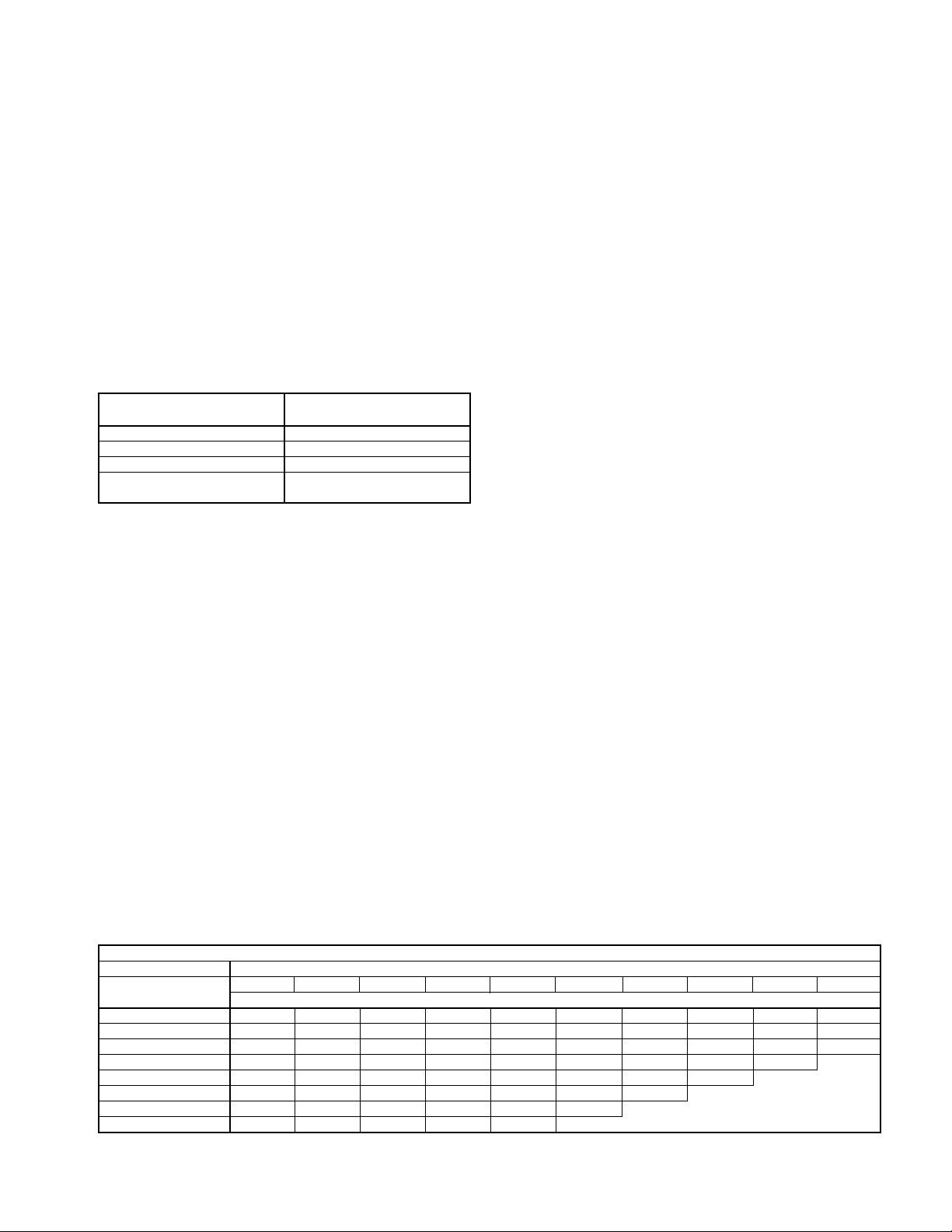

Special Lubrication Frequency For

High Temperature and High Moisture

AIRSTREAM

TEMPERATURE

TO 250°F 4500

TO 350°F 1500

TO 500°F 1000

WET ATMOSPHERE AT

ROOM TEMPERATURE

HOURS

1000 TO 1500

-

To rotate the fan, follow the procedure listed below:

The blade marked number 1 should be rotated to

top center. The blade number and date should be

recorded in a log book which is to be stored in a

protective pouch attached to the fan. During storage,

the fan propeller should be rotated by hand at least

ten (10) revolutions every thirty (30) days to circulate

the lubricant in the bearings in the motor or on the fan

shaft. After the tenth revolution, stop with a blade at

top center which is not the same one as is listed for

the previous date in the log book.

Fans which are V-belt driven should be prepared for

storage as follows:

Carefully remove the belts, coil them (without kinks)

in matched sets and place them in a heavy carton.

Mark the carton with fan identification and store the

carton in a dry, well-ventilated area. Belts must not be

left exposed to sunlight or subjected to storage ambient

conditions exceeding 85°F, 70% relative humidity. Belts

which show signs of deterioration should be replaced

prior to startup. Before reinstalling belts, review the sec

-

tion on “Belt Tension.”

NOTE: Procedures for storage of Aerovent equipment

as outlined above are intended as a general guide only.

Storage conditions will vary depending on the loca

tion. Common sense and practical experience should

determine to what extent the above procedures will be

followed.

Storage of Equipment

Fan Bearings

Since bearings tend to “breathe” on equipment stored

in areas with other than a constant temperature, mois

ture will condense internally. Therefore, it is necessary

to keep the bearings completely full of grease and

periodically rotated to make certain that all internal

parts are coated with grease. Even a full bearing will

eventually pick up moisture and, therefore, must be

periodically purged with new grease.

Grease should be purged from the bearings to

remove condensed moisture, and the fan wheel rotated

by hand every thirty (30) days. This practice should be

done more often if weather is severe or if there is a

wide variation in temperature.

CAUTION IN PURGING: The fan should be rotated

while greasing and high pressure pneumatic greasers

should be avoided. See “Lubrication Instructions for Fan

Motors

Motors must be stored under cover in a clean, dry,

vibration-free location. Remove sufficient packaging

material to allow circulation of air around the motor.

Maintain the temperature of the windings a few degrees

above that of the surrounding air to protect against

condensation. If the motor is equipped with internal

heaters, the heaters should be energized throughout

the storage period to prevent this condensation. If

the motor does not have internal heaters, this can be

accomplished using any other safe, reliable method of

heating. Measure and record the ambient air tempera

ture and winding temperature monthly.

In the event that the motor is not equipped with

internal heaters and space heating equipment is unavail

able, wrap the motor as tightly as possible with heavy

duty polyethylene. Enclose bags of desiccant (such as

silicagel) with the motor to minimize moisture problems.

Check the desiccant regularly and replace it periodically

as dictated by climate requirements.

Ball Bearings.”

Lubrication Frequency for Horizontal Shaft Installations (see Note for vertical shaft installations)

LUBRICATION FREQUENCY

SHAFT SIZE

(INCHES)

1

1

1

2

2

3

3

NOTES: Reduce this lubrication frequency schedule by half for vertical shaft installations.

Consult manufacturer for specific recommendations.

1

1

⁄16 – 17⁄16 6 6 6 6 6 6 4 4 2 1

1

7

⁄8 – 23⁄16 6 6 4 4 2 2 1 1 1

1

7

⁄16 – 31⁄2 6 4 2 1 1 1

15

500 1000 1500 2000 2500 3000 3500 4000 4500 5000

RELUBRICATION CYCLE (MONTHS)

⁄2 – 1 6 6 6 6 6 6 4 4 2 2

⁄2 – 13⁄4 6 6 6 4 4 2 2 2 1 1

⁄4 –27⁄16 6 4 4 2 2 1 1 1

1

⁄2 – 3 6 4 4 2 1 1 1

⁄16 – 4 6 4 2 1 1

OPERATING SPEED (RPM)

-

-

Aerovent IM-100 3

Loading...

Loading...