Aerovent ES-2-06 User Manual

ENGINEERING SUPPLEMENT

INSTALLATION, OPERATION & MAINTENANCE MANUAL

Fans with CE Mark

Contents

Introduction .........................................................................1

Personal Protection ............................................................

Hazardous Materials ..........................................................

Installation

Shipping and Receiving ................................................

Handling .........................................................................

Unit Storage ...................................................................

Foundations and Supporting Structures

- Industrial Fans .......................................................

Fan Installation - Factory Assembled Units ...............

Fan Installation - Disassembled Units ........................

Bearing Installation ........................................................

Grouting ..........................................................................

Drive Mounting ..............................................................

Flexible Couplings .........................................................

Duct Connections ..........................................................

Guards and Enclosures ................................................

Electrical Supply and Controls ....................................

Maintenance

Motor Maintenance .......................................................

Drive Maintenance .......................................................

Bearing Maintenance ................................................... 1 0

Wheel and Shaft Maintenance ...................................1 0

Structural Maintenance ............................................... 1 0

Fan Operation

Proper Use and Application ......................................

Sound ...........................................................................

Operation Checklist .....................................................

Optional Accessories ...................................................

Troubleshooting Guidelines .........................................

Disposal ........................................................................

Appendix A - Commercial Ventilator Installation

Instructions ...................................................................

Appendix B - Axial Fans ................................................

Introduction

This bulletin has been prepared to guide the users of

fans in the proper installation, operation and mainte

nance procedures to insure maximum equipment life

with trouble-free operation. Personnel operating or main

taining this equipment shall be trained in the proper

procedures for doing so.

Since many fans of this type have custom features or

components, please refer to the attached documentation

and appendices for additional information. When manu

facturers of components provide detailed installation and

operation manuals, they will be provided. Because of the

wide variety of equipment covered in this bulletin, the

instructions given here are general in nature.

For safe installation, startup and operational life of

this equipment, it is important that all involved with the

equipment be well versed in proper fan safety practices

and read this bulletin. Please review the safety section

before beginning any work. It is the user’s responsibil

ity to make sure that all requirements of good safety

practices and any applicable safety codes are strictly

adhered to. Only properly trained personnel should oper

ate and maintain this equipment.

©2006 Twin City Fan Companies, Ltd.

1

1

1

2

2

2

3

4

5

8

8

8

8

8

9

9

10

10

11

12

12

12

13

13

14

-

-

-

-

-

ES-2-06

Issue Date: 7-1-06

Rev. Date: NEW

Personal Protection

For safety reasons maintenance personnel should wear

personal protection equipment when attempting to main

tain fans. People with long hair are advised to tuck hair

back possibly into a cap.

Personal protection equipment should include the

following:

• Safety glasses or goggles approved by local safety

authority

• Protective shoes with steel toecaps and oil resistant soles

• Heavy gloves that can cope with sharp edges or

exposure to hazardous chemicals. This is especially

important when hazardous residues are present in

fans.

• Breathing apparatus if toxic gases or vapors are

expected to be present.

• Close fitting clothing

Do not wear:

• Rings

• Bracelets

• Necklaces

• Loose items of clothing

It is the responsibility of the maintenance personnel

to determine that the lighting is sufficient for the work

being performed. Additional portable lighting may be

required as there are no lighting fixtures supplied with

the fans.

Hazardous Materials

Twin City Fan Companies, Ltd. is not always made

aware of the materials that may be handled with a fan

and therefore can not warn the user of these hazards.

Because of this, the end user must identify the mate

rial hazards present and indicate this on the fan with

a warning label. If there is risk of residual hazardous

material being left in a fan if the gas or vapor being

handled can accumulate as a deposit, all maintenance

and operation personnel must be trained to handle such

hazards before having access to the fan.

Lubricants used on fan components could be hazard

ous if they contact someone’s eyes or are consumed.

For additional general safety practices for air moving

equipment, see AMCA Bulletin 410.

Installation

Shipping and Receiving

All Twin City Fan Companies, Ltd. products are carefully

constructed and inspected before shipment to insure the

highest standards of quality and performance. Compare

all components with the bill of lading or packing list to

verify that the proper unit was received. Check each unit

for any damage that may have occurred in transit. Any

damage should be reported immediately to the carrier and

the necessary damage report filed.

-

-

-

Handling

Handling of all air moving equipment should be conducted by trained personnel and be consistent with safe

handling practices. Verify the lift capacity and operat

ing condition of handling equipment. Maintain handling

equipment to avoid serious personal injury.

On most units, lifting lugs are fashioned to protect

the fan and fan housing from damage. Secure lifting

equipment to all provided lifting lugs to avoid instability

while moving the equipment. Units shipped completely

assembled may be lifted with slings and spreader bars.

(Use well-padded chains, cables or nylon straps.) Never

lift a fan by the inlet or discharge flange, shafting or

drives, wheel or impeller, motor or motor base, or in any

other manner that may bend or distort parts. Never lift

with slings or timbers passed through the fan inlets.

Figure 1. Lifting Lug Locations

Lifting Lugs

Lifting Lugs

Partial or disassembled units require special handling. All

parts should be handled in a fashion which protects the

coatings and parts from damage. Components should be

handled such that forces are not concentrated to avoid

bending or distortion.

The housing should be lifted using straps and spread

ers. Do not distort housing or side plates when lifting.

Bearing pedestals should be lifted using straps or

padded chains. Under no circumstance should an

attached or separated bearing pedestal be lifted by the

shaft, bearings, drives, motor or wheel.

The shaft and wheel assembly may be lifted using

a hoist and a spreader with a sling around the shaft

at points nearest the wheel. Use the spreader bar to

ensure that the slings do not push against the sides of

the wheel as this may distort the wheel. Take care not

to scratch the shaft where the wheel or bearings will

be mounted. Never lift or support the assembly by the

wheel. Always support the assembly by the shaft when

lifting or storing. Do not support the shaft or the wheel

on the housing sides.

Wheels shipped separately can be lifted by slings run

ning between the blades or around the hub. Never lift

the wheel by blades or flanges. Always transport wheels

by lifting. Do not roll the wheel as this can damage

coatings and change the balance of the wheel.

Bent shafting is a source of vibration and bearing

failure, so handle the shaft with care. Any scratches on

the shaft may be removed with fine emery cloth or a

stone.

For roof ventilators, also see instructions specific to

handling roof ventilators in Appendix A.

-

-

-

Pins to hold insulation to the housing are supplied

for some high temperature fan designs. Use caution

when handling and working around fans that have these

insulation pins as the points are sharp.

Unit Storage

If fan installation is to be delayed, store the unit in

an environmentally stable and protected area. Vibration

should not exceed 0.051 mm peak – peak displacement

at the storage site unless the fan is properly isolated

from the vibration. The unit should be reasonably pro

tected from any accidental impacts. Cover the fan to

protect coatings and to prevent any foreign material or

moisture from entering the inlet or discharge. Take care

to protect the motor, drives and bearings. The following

precautions should be taken during extended storage to

ensure the equipment is not damaged:

• Extended storage requires monthly inspections.

Check for corrosion or damage to the unit and for

debris within the fan.

• Bearings tend to take on moisture if the atmo

sphere they are stored in is not at a constant

temperature. To avoid corrosion, it is necessary to

keep the bearings full of grease and to rotate them

periodically. Even when full of grease, bearings will

take on moisture, so it is necessary to purge the

bearings with new grease to expel moisture every

thirty days. It is recommended that the bearings be

purged with grease while being rotated by hand.

Do not use high-pressure greasers as they may

ruin the bearing seals.

• The drives and belts should be removed if the fan

is to be stored for a prolonged period. The drives

should be labeled for service and stored in a dry

place. Belts should be removed, coiled without

kinks, placed in a heavy carton, and stored in a

dry, well-ventilated place. To prevent belt deterio

ration storage conditions should not exceed 85°F

and 70% humidity. If belts show signs of deteriora

tion, they should be replaced prior to startup.

• Motors should be stored in a clean, dry, vibrationfree location. The packaging should be opened up

enough to allow air circulation around the motor.

The winding temperature should be kept slightly

above that of the surroundings to prevent conden

sation. This can be accomplished by energizing

the internal heaters, if the motor is so equipped,

or by using space heaters. If it is impossible to

heat the windings, the motor should be wrapped

tightly with a waterproof material that also encloses

several bags of desiccant. Replace the desiccant

regularly to prevent moisture problems. The motor

rotor should also be rotated regularly (monthly) to

assure the bearing parts are well greased.

-

-

-

-

-

Foundations and Supporting Structures

— Industrial Fans

The best means of floor mounting a fan is on a welldesigned, flat, level concrete foundation. The foundation

should have a mass of at least three times that of

the supported assembly. The foundation should extend

150mm beyond the outer dimensions of the fan and

driver; however, it should be no more than twice the

area required for the equipment. If it is made larger, the

mass should be increased accordingly to resist rocking

modes of vibration. J or T type anchor bolts using one

size smaller than the nominal dimension of the base hole

shall be used. Anchor bolts should be tied into the rein

forcing bar of the foundation for the foundation. A pipe

-

2 Twin City Fan Companies Engineering Supplement 2-06

sleeve with a diameter of 2 to 21⁄2 times the anchor

bolt diameter should be provided around the anchor bolt

for final adjustment (see Figure 2). The mounting sur

face of the foundation should be smooth for good shim

contact. When deciding the thickness of the foundation,

approximately 25 to 40mm height should be allowed for

shimming, grouting, leveling, washers, nuts, etc.

The foundation plan on the customer submittal draw

ing indicates the mounting hole size and locations on

the fan.

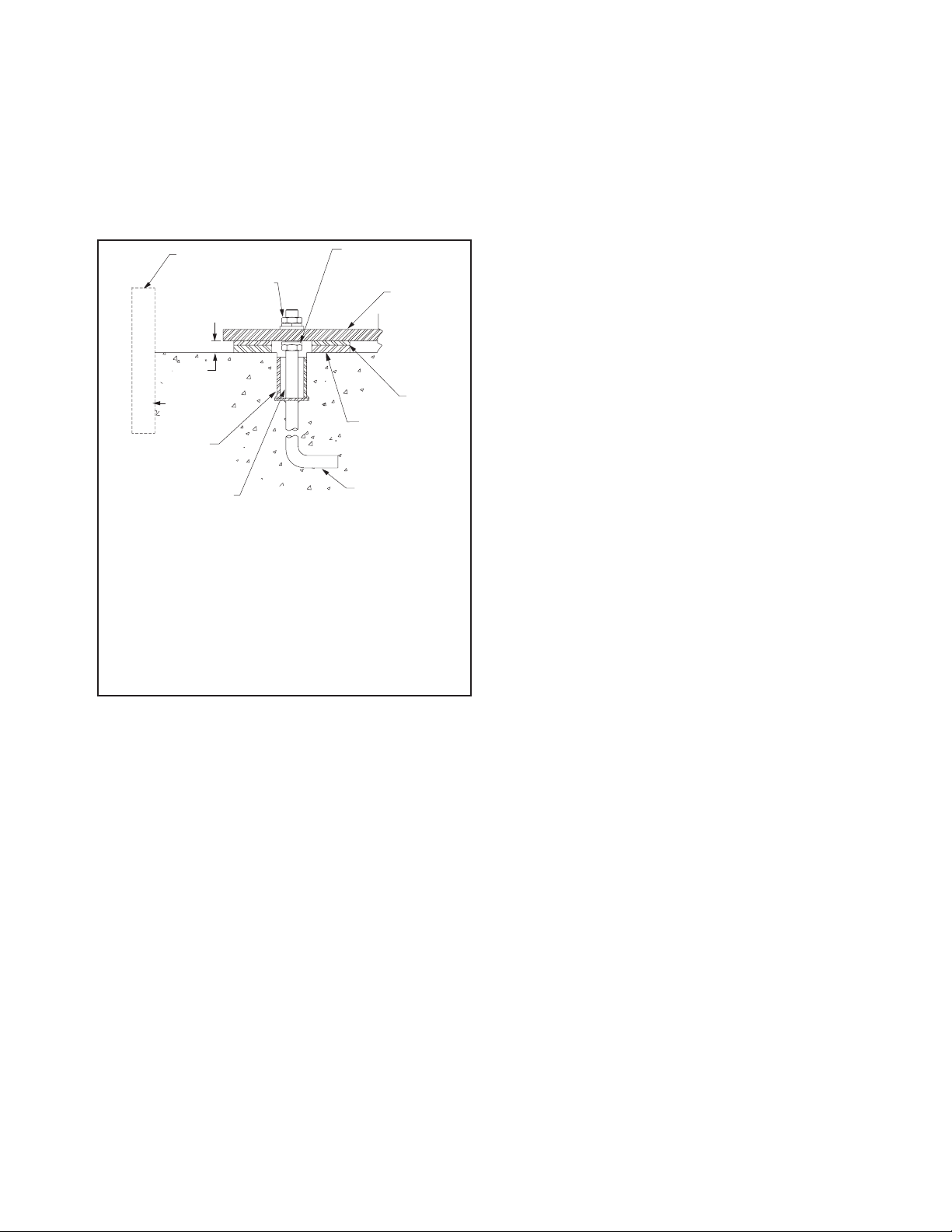

Figure 2. Typical Foundation Section

Fan Installation - Factory Assembled Units

General instructions for industrial centrifugal fans – For Axial

-

fans and commercial ventilators, follow steps below noting

instructions specific to those fan types in Appendix A and B.

Follow proper handling instructions as given earlier.

1. Move the fan to the final mounting position.

2. Remove skid, crates and packing materials carefully.

-

3. If vibration isolation is to be used, place isolation

base on mounting bolts. Line up holes in fan base

with bolts as indicated on the foundation plan of

the customer submittal drawing.

4. Consult each specific fan’s submittal drawing for

proper installation arrangement and mounting dimen

sions. Place the fan on mounting structure. Carefully

level the unit (checking the level on the shaft) on

the foundation and shim as necessary using stain

less steel shims on both sides of each anchor bolt.

Anchor bolts are to be pre-tensioned per Table 1.

For metric grade bolts or materials not shown in

Table 1, check with bolt manufacturer for the proper

torque. (See details specific to commercial ventila

tors in appendix A for this step).

5. Check the alignment of the bearings. Shim or

reposition the bearings if necessary. In many split

housing roller bearings, the gap between the seal

carrier and housing can be measured with a feeler

NOTES:

¿ Temporary form for grout pouring.

¡ Hex nut, split ring lock washer and tapered or flat washer.

¬ 1" to 1.5" grout allowance to be filled with nonshrinking machinery

grout.

√ Pipe-bolt sleeve diameter 2 to 21/2 times bolt diameter for correc-

tion of alignment errors.

ƒ Care should be taken that anchor bolt sleeves are filled with

grout.

≈ J-Bolt leg should be fastened to foundation rebar.

≤ Shimming surface to be smooth, level, dressed if necessary.

« Full width stainless steel shims.

» Fan base angle or structural steel.

… Leveling nut, if used, should be backed off after shimming for final

tightening of hex nuts.

gage. The variation in this gap should be less than

half of the maximum gap measured. In roller bear

ings where this gap is not visible, alignment can

be verified by verifying the bearing is square with

the pedestal top. In ball bearings, the bearing outer

ring swivels in the housing to accommodate a small

amount of misalignment. Verify bearing set screws,

cap bolts, and collars are tightened per Tables 2a,

2b and 2c.

6. Check face alignment of sheaves on belt driven fans.

Parallel alignment should be within 5mm per meter of

center distance. Angular Misalignment should be less

than 1 degree. Check and record tension of belts

If a structural steel base or platform is to be used,

the structure must be designed for the weight of the fan,

live loads imposed by rotation of the rotor and driver,

and any external live loads. The structure should be

designed to ensure that no natural frequency will occur

within 30% of the fan speed. This is especially true if

the structure supports more than one fan.

Any ducting should have independent support. Do

not use the fan to support ducting. The fan frame

can be designed to carry some external loads. Consult

the factory if this is a concern. Isolating the fan from

ductwork with flex connections eliminates transmission

of vibration. Fans handling hot gases require expansion

joints at both the inlet and discharge to prevent exces

sive loads caused by thermal growth. Refer to AMCA

Publication 201 for good practices in ductwork geometry

and configuration. When possible, ductwork shall be

located where there is least risk of personnel tripping,

walking into or falling over the ductwork. If not possible,

warnings shall identify this hazard.

See Appendix A Commercial Ventilator Installation

Instructions for commercial ventilator foundation details.

Fans should not be located underneath other machin

ery where there might be a risk of harmful liquid falling

onto fans from above.

Fans should be installed where they are readily acces

sible to maintenance personnel, so that such personnel

are not required to stoop or crawl to access fans.

-

-

-

to see if it is sufficient. Proper belt tension is speci

fied on the included datasheet. If belt tension needs

adjustment, instructions on belt tensioning are given

in the Drive Mounting section of this manual. Sheaves

on belt driven fans are often provided with taperlock

bushings. When tightening bushing bolts, proceed in a

progressive manner to avoid cocking the tapered sur

faces between the bushing and the sheave. Bushing

bolt torque specifications are indicated in Table 3.

7. Check alignment of factory mounted couplings, as

they are subject to misalignment during shipment.

Realign if necessary in accordance with the instruc

tions which are included with the shipment. NOTE:

Most couplings need lubrication.

8. Make sure there is no rubbing or binding and that

the wheel-inlet cone or wheel to fan housing clear

ances and overlap are correct. Overlap values or

other dimensions to verify proper wheel location are

given in the included documentation specific to the

fan. Wheel clearance should be verified to match

the specified value and be uniform. The measured

values should be recorded.

9. Check the tightness of the wheel on the shaft per

Table 4. The measured torque should be recorded.

10. Check the tightness of foundation bolts, motor

mounting bolts, and bearing mounting bolts per

Table 1. For metric bolts or grades not specified in

Table 1, check proper torque values per the bolt

Twin City Fan Companies Engineering Supplement 2-06 3

manufacture.

-

-

-

-

-

-

-

-

11. Check that bearings are fully lubricated and check

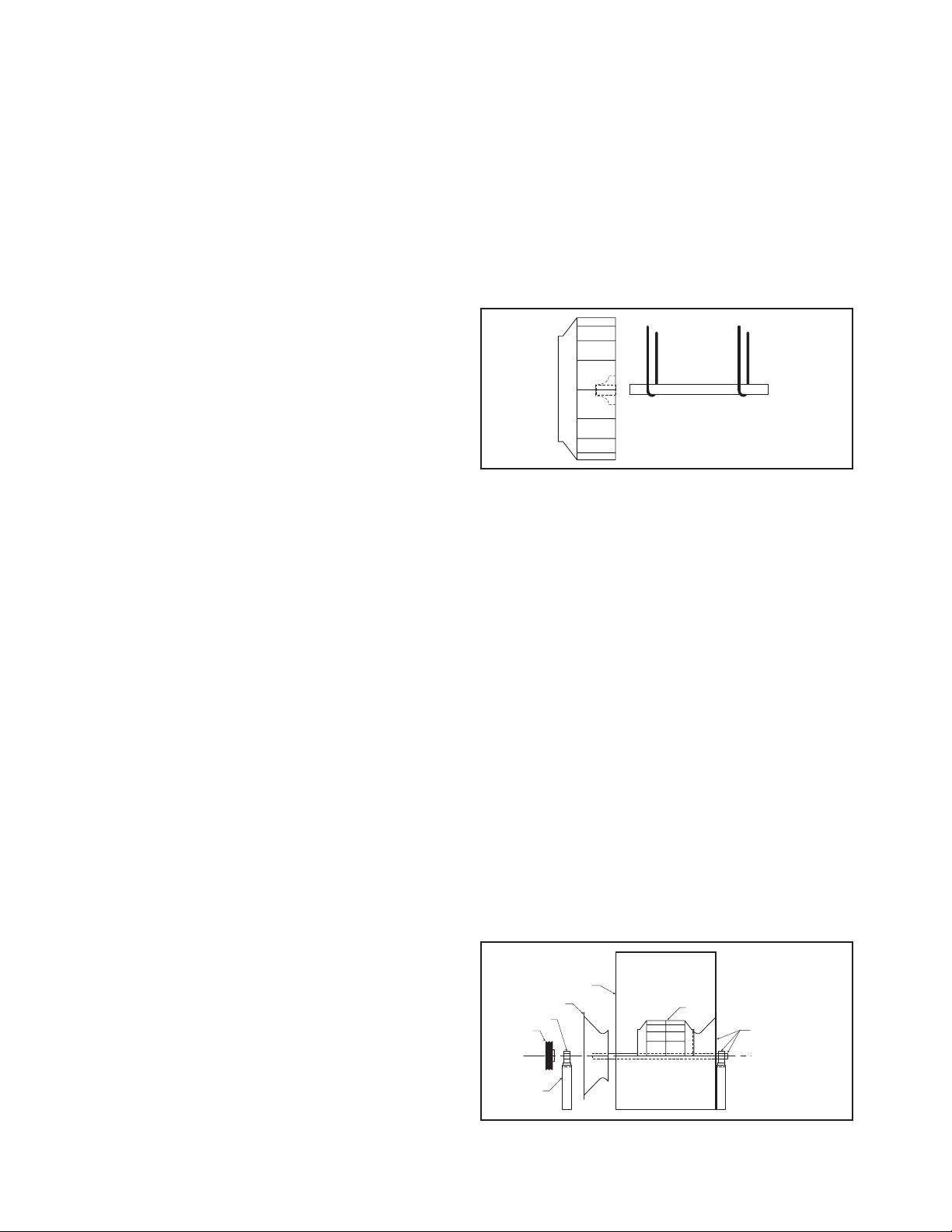

Shaft

Centerline

Bearing

Pedestal

Sheave

Bearing

Inlet Funnel

Housing Side

Wheel

Assembled Bearing,

Shaft, Funnel, and

Housing. Frame

Angles Not Shown.

the oil level in the static oil lube systems (if

supplied).

12. Install any accessories shipped loose from the

factory.

Fan Installation - Disassembled Units

General instructions for industrial centrifugal fans – For Axial

fans (including mounting arrangements for inline centrifugal

fans), follow assembled fans instructions above and use

Appendix B for assembly details.

A unit is considered “disassembled” if any component

required for proper operation is shipped or supplied sepa

rately or in pieces. Reference earlier instructions concern

ing proper handling of fan components. Assembly shall

only be performed by trained personnel familiar with the

-

-

bore hubs), or for bushing bore hubs, progressively tighten the bushing bolts per Table 3.

Record the measured torque value.

c. Insert shaft through opening in drive side. (If

splithoused unit, lower into position.)

d. Install bearings onto shaft. Do not tighten bear

ing setscrews at this time. The bearing housing

should be perpendicular and the bearing base

parallel to the axis of the shaft to prevent loads

caused by misalignment.

e. Mount assembly, bolt bearings to drive stand.

Shaft must be parallel with side of bearing

pedestal.

Figure 3. Drive Component Assembly

assembly of this type of equipment.

1. Move the lower half of the housing to its mounting

location (split housing).

2. Remove skids, crates, and packing materials carefully.

3. If vibration isolation is to be used, place the vibra

tion isolation base on mounting bolts. Line up holes

in fan base with bolts.

4. Place the lower housing on the mounting structure.

Carefully level the lower housing on the foundation

and shim as necessary using stainless steel shims

on both sides of each anchor bolt.

5. If the bearing pedestal(s) are separated they should

be installed next.

a. Move bearing pedestal(s) to mounting location.

b. Put vibration base, if any, in place. Set pedestal(s)

on bolt(s).

c. Do not distort bearing pedestal by forcing it to

align with a non-level foundation. Shim beneath

the pedestal as necessary.

d. Check the bearing centerline height. Adjust the

height to match centerline height of the hous

ing. High temperature units may require a lower

housing centerline when cold so that it will be

centered when hot.

e. Bring the bearing pedestal into square with the

housing using careful measurements or a large

square.

f. Bolt the pedestal into position.

6. If the wheel and shaft were shipped unassembled,

you must now install the shaft in the wheel.

a. First use solvent to clean the protective coating

off the shaft. Check all surfaces for corrosion or

nicks and clean if necessary with fine emery cloth

or a stone. After thoroughly cleaning the shaft

8. Arrangement 3 (Split-housed) units (See Figure 4):

a. Parts on DWDI units are assembled in the fol

lowing order as viewed from opposite drive side:

Bearing bar assembly and opposite bearing, fun

nel, (housing side), wheel, (housing side), funnel,

drive side bearing bar assembly, drive bearing

and sheaves. Mount bearing bar assembly to

housing. Center wheel in funnels.

b. Parts on SWSI units are assembled in the

following order as viewed from opposite drive

side: Bearing bar assembly and opposite bearing,

-

funnel, (housing side), wheel, (housing side),

drive side bearing bar assembly, drive bearing

and sheaves. Mount bearing bar assembly to

housing.

c. Assemble parts in above order on shaft.

d. Move assembly into position. Lightly bolt bearings

into place.

e. Shaft should be parallel with discharge of hous

ing. Move bearings to accommodate. Follow

bearing alignment instructions per step 5 in fac

tory assembled units section above.

f. Level shaft; shim bearings if required. Tighten

bearing setscrews.

Figure 4. Split-housed Drive Component Assembly

with solvent, do not touch it with bare hands as

perspiration can cause rust or pitting over time.

b. Remove keys from the shaft.

c. Clean the inside of the wheel bore with solvent.

Make sure the setscrews will not interfere when

inserting the shaft into the wheel bore.

7. Arrangement 1, 9 or 10: Drive Component

Assembly:

a. Insert shaft into wheel from back side of wheel

b. When shaft is flush with wheel hub, put key into

4 Twin City Fan Companies Engineering Supplement 2-06

(Fig 3).

keyway and tighten wheel setscrews (for straight

9. Install motor on base. Carefully align shafts for drive

installation.

-

-

-

-

-

10. Mount drives as follows:

a. Slip (do not pound) proper sheave onto cor-

responding shaft. CAUTION: PLACING FAN

SHEAVE ON MOTOR CAN OVERSPEED WHEEL

AND CAUSE STRUCTURAL FAILURE.

Figure 5.

b. Align sheaves with a straight

edge extended along the

-

Sheave Alignment

perimeters of both sheaves,

just making contact in two

places on outside perimeters

of both sheaves (see Figure

5). Parallel alignment should

be within 5mm per meter

of center distance. Angular

Misalignment should be less

than 1 degree.

c. Tighten down sheave bolts.

d. Install a matched set of

belts. Adjust belt tension as

indicated in “Drive Mounting”

step #3.

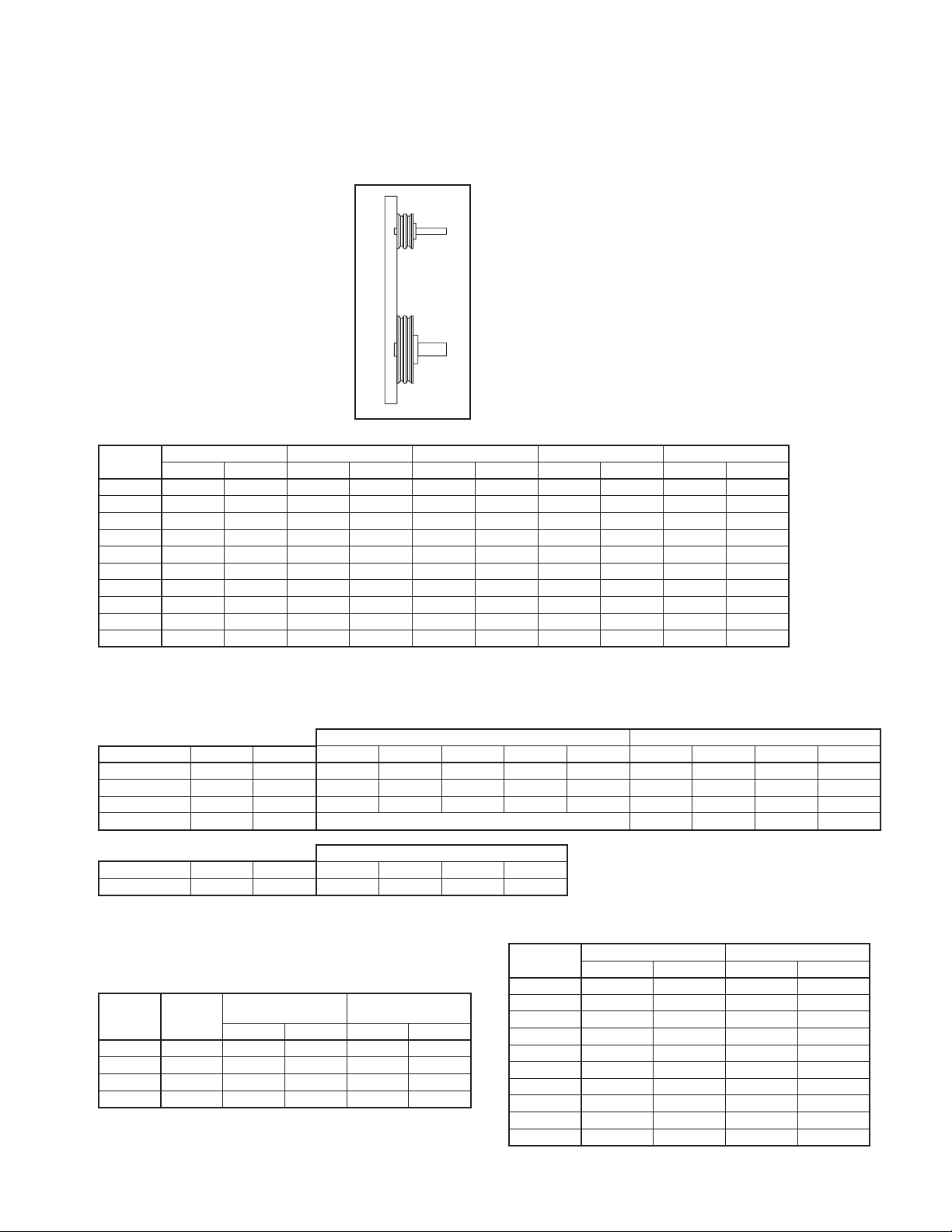

Table 1. Bolt Tightening Torque

Size

1/4 - 20

5/16 - 18

3/8 - 16

7/16 - 14

1/2 - 13

5/8 - 11

3/4 - 10

7/8 - 9

1 - 8

1 1/4 - 7

Grade 2 Grade 5 Grade 8 Aluminum Stainless

(Ft - lbs) (N - m) (Ft - lbs) (N - m) (Ft - lbs) (N - m) (Ft - lbs) (N - m) (Ft - lbs) (N - m)

5.5 7.5 8 10.8 12 16.3 3.8 5.2 6.3 8.5

11 15 17 23 25 34 6.7 9.1 11 15

22 30 30 41 45 61 11.9 16 19 26

30 41 50 68 70 95 19 26 31 42

55 75 75 102 110 149 26 35 43 58

100 136 150 203 220 298 59 80 92 125

170 230 270 366 380 515 81 110 128 174

165 224 430 583 600 813 125 169 194 263

250 339 645 874 900 1220 184 249 287 389

500 678 1120 1518 1500 2034 336 456 523 709

e. Tighten belts to proper belt tension. Record the

belt tension used. See drive mounting section for

tensioning instructions. Proper tension is specified

in the datasheet included with the fan.

11. Fans that have motors and drives mounted at the

factory are trim balanced prior to shipment. This

is not possible on units that are shipped without

motors and drives. The addition of drive compo

nents in the field can create unbalance forces. Twin

City Companies, Ltd. recommends final balancing

of the unit after the drive components are installed.

Failure to do so voids the Twin City Fan Companies,

Ltd. warranty.

12. Repeat the installation checks indicated for factory

assembled units to assure proper tightness and

alignment of all components.

Bearing Installation

Bearings are only to be field installed when accompanied by installation instructions from the bearing manu

facturer. When field installation is required, follow the

manufactures instructions carefully to install bearings.

-

Table 2a. Bearing Cap Bolt Torque Specifications (see page 6)

Table 2b. Metric Set Screw Torque Specifications

METRIC SHAFTS SET SCREW SIZE LOCKING COLAR SCREW SIZE

Manufacturer BRG ID Units M5 M6 M8 M10 M12 M4 M5 M6 M8

Dodge

Dodge

Dodge

SKF

Manufacturer BRG ID Units 12-35mm 40-45mm 50-65mm

SKF

Table 2c. IP Set Screw Torque Specifications (see page 7)

Table 3. Browning Split Taper Bushing Tightening Torque

Bolt

Size

1/4 - 20

5/16 - 18

3/8 - 16

1/2 - 13

S2000 N-m - - 17.8 35 57 - - - SCAH N-m 3.4 6.9 16 28 51 5.85 10.75 20.5 45

SCMAH N-m 3.4 6.9 16 28 51 5.85 10.75 20.5 45

SY N-m See Below 4.2 7.4

BEARING DIAMETER

70-100mm

SY N-m 4 6.5 16.5 28.5

Table 4. Set Screw Tightening Torque (other than bearing set screws)

Steel Set Screws Stainless Set Screws

Ft - lbs N - m Ft - lbs N - m

5.5 7.5 5.8 7.9

11 15 11 15

22 30 19 26

30 41 28 38

55 75 42 57

100 136 82 111

170 230 115 156

165 224 - 250 339 - 500 678 - -

Bushing

Type

H 8 11 8 11

P, B 17 23 13 18

Q, R 30 41 24 33

S 70 95 - -

Iron/Steel Hub,

Sheave

Ft - lbs N - m Ft - lbs N - m

Aluminum

Hub

Set Screw

Size

1/4 - 20

5/16 - 18

3/8 - 16

7/16 - 14

1/2 - 13

5/8 - 11

3/4 - 10

7/8 - 9

1 - 8

1 1/4 - 7

Twin City Fan Companies Engineering Supplement 2-06 5

Loading...

Loading...