Page 1

A

455

4

MXG461..

CVATIX™

MXG461..P

MXF461..

MXF461..P

Modulating control valves

with magnetic actuators,

PN16

for chilled and low-temperature hot water systems or

for systems with media containing mineral oils (MX..461..P)

• Fast positioning time (< 2 s), high-resolution stroke (1 : 1000), high rangeability

• Equal-percentage or linear valve characteristic (user-selected)

• Operating voltage AC 24 V

• Switch-selected control signal DC 0/2...10 V or DC 4...20 mA

• DC 0…20 V phase cut control signal with SEZ91.6 external interface

• Indication of operating state, position feedback and manual control

• Wear-free inductive stroke measurement

• Fail-safe feature: A → AB closed when de-energized

• Low friction, robust, no maintenance required

MXG461..

MXG461..P

MXF461..

MXF461..P

Use

The control valves are mixing or throughport valves with the ready fitted magnetic

actuator for position control and position feedback. The short positioning time, high

resolution and high rangeability make these valves ideal for modulating

• control of chilled and low-temperature hot water systems

• control or dosing control of fluids containing mineral oil (SAE05...SAE50), mineral-oil-

based diesel fuels, heat transfer oils

in closed circuits.

Special silicon-free version available, type suffix ..M.

CA1N4455en

15.12.2009

Building Technologies

Page 2

A

pplication examples

MX..461..P

Type summary

• Temperature control in mixing circuits for motor oil circulation

• Temperature control in mixing circuits for screw-compressors (compressed air)

• Temperature control of fuel circuits in mixing circuits for petrol and diesel oil

• High pressure control for the calibration of components for electronic injection

components

• Control of cutting-oil emulsion for industrial grinding machines

Type reference DN kVS

MX..461.. MX..461..P 1)

MX..461.15-0.6 MX..461.15-0.6P

MX..461.15-1.5 MX..461.15-1.5P

MX..461.15-3.0 MX..461.15-3.0P

MX..461.20-5.0 MX..461.20-5.0P

MX..461.25-8.0 MX..461.25-8.0P

MX..461.32-12 MX..461.32-12P

MX..461.40-20 MX..461.40-20P

MX..461.50-30 MX..461.50-30P

MXF461.65-50 MXF461.65-50P

M3P80FY M3P80FYP

M3P100FY M3P100FYP

[m3/h] [kPa] [kPa]

0,6

15

20 5,0

25 8,0

32 12

40 20

50 30

65 50

80 80

100 130

1)

for media containing mineral oils

.. = F for flanged valves

G for threaded valves

= max. permissible differential pressure across the valve’s control path, valid for the entire

Δp

max

actuating range of the motorized valve

Δp

= max. permissible differential pressure (close off pressure) at which the motorized valve will

S

close securely against the pressure (used as throughport valve)

= nominal flow rate of cold water (5 to 30 °C) through the fully opened valve (H

k

VS

differential pressure of 100 kPa (1 bar)

1,5

3,0

High performance

range

Type reference DN Type suffix Description Examples Datasheet

MXG461..M

MXF461..M

MXG461..U 15…50 U Set of 3 NPT threaded fittings

MXF461..U 65 U - MXF461.65-50U N4455

15…50

15…50

Accessories

Type reference Description

ALG..3 (.. = DN) Set of 3 threaded fittings for 3-port valves, consisting of 3 union nuts, 3 discs and

3 flat seals

Z155/.. (.. = DN)

SEZ91.6 External interface for DC 0…20 V phase cut control signal, refer to data sheet

Blank flange set with blank flange, seal, screws, spring washers and nuts

N5143

Order

When ordering, please give quantity, product name and type reference.

Δp

ΔpS

max

300 300 AC 24 V

M Siliconfree grease

enclosed

Operating

voltage

see datasheet N4454

Positioning

signal time

DC 0...10 V

or

DC 2…10 V

or

DC 4...20 mA

MXG461.15-3.0M N4455

MXG461.15-3.0U N4455

< 2 s

100

Spring

) at a

return

Product number Stock number Description

MXG461.25-8.0 MXG461.25-8.0 Threaded valve with magnetic actuator

ALG253 ALG253 Set of threaded union fittings

MXF461.20-5.0 MXF461.20-5.0 Flanged valve with magnetic actuator

Z155/20F Z155/20F Set of blank flanges

Delivery

Valve body and magnetic actuator form one assembly and cannot be separated.

The threaded fitting sets and blank flanges are packed and supplied separately.

2/14

Siemens Modulating control valves with magnetic actuators, PN16 CA1N4455en

Building Technologies 15.12.2009

Page 3

A

Replacement

electronics module

SE1, ASE2

Should the valve electronics prove faulty, the electronics module must be replaced by

the ASE1 (DN15…32) or ASE2 (DN40…65) replacement electronics module.

Mounting Instructions no. 35678 are included.

Rev. no.

See overview, page 14.

Technical and mechanical design

For a detailed description of operation, refer to data sheet CA1N4028E.

Control operation

Spring return facility

Control

Manual control

The electronics module converts the positioning signal to a phase-cut power signal

which generates a magnetic field in the coil. This causes the armature to change its

position in accordance with the interacting forces (magnetic field, counterspring,

hydraulics). The armature responds rapidly to any change in signal, transferring the

corresponding movement directly to the valve plug, enabling fast changes in load to be

corrected quickly and accurately.

The valve’s position is measured continuously (inductive). The internal positioning

controller balances any disturbance in the system rapidly and delivers the position

feedback signal. The valve stroke is proportional to the positioning signal.

If the positioning signal is interrupted, or in the event of a power failure, the valve’s

return spring will automatically close control path A → AB.

The magnetic actuator can be driven by a Siemens controller or a controller of other

manufacture that deliver a DC 0/2...10 V or DC 4... 20 mA output signal.

To achieve optimum control performance, it is recommended to use a 4-wire

connection.

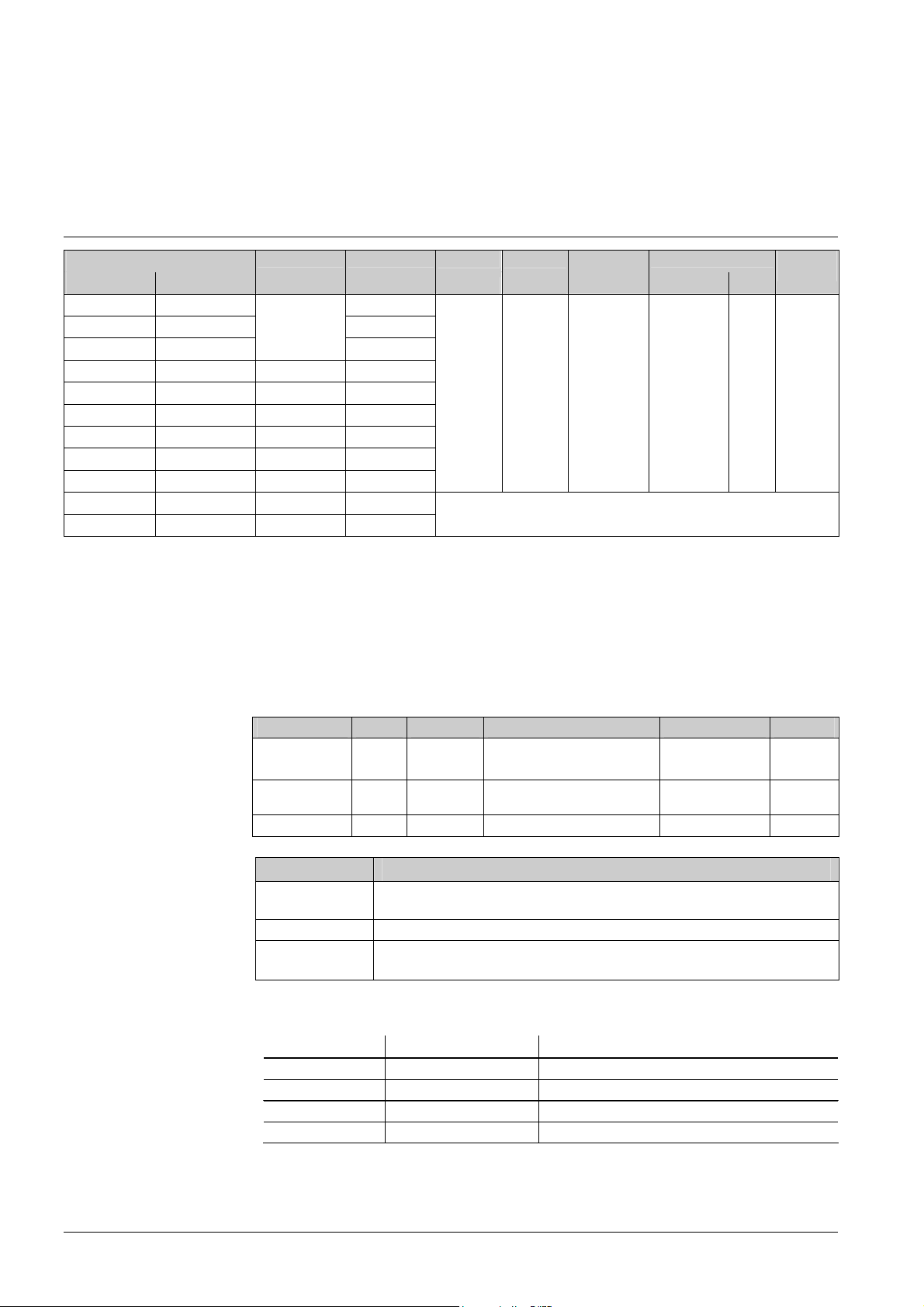

MANUAL

The valve control path (ports A → AB) can be opened

OFF

manually to between 80 and 90 % of the full stroke

(depending on DN) by pressing the hand wheel

AUTO

inwards and turning it clockwise (MANUAL setting).

This disables the control signal from the controller, the

MANUAL

green LED is flashing.

OFF

4455Z03

To disable automatic control of the valve, press the

hand wheel inwards and turn it anti-clockwise (to the

OFF position). The valve will close, the green LED is

flashing.

AUTO

For automatic control, the hand wheel must be set to

the AUTO position (the hand wheel will spring out),

the green LED is lit.

3/14

Siemens Modulating control valves with magnetic actuators, PN16 CA1N4455en

Building Technologies 15.12.2009

Page 4

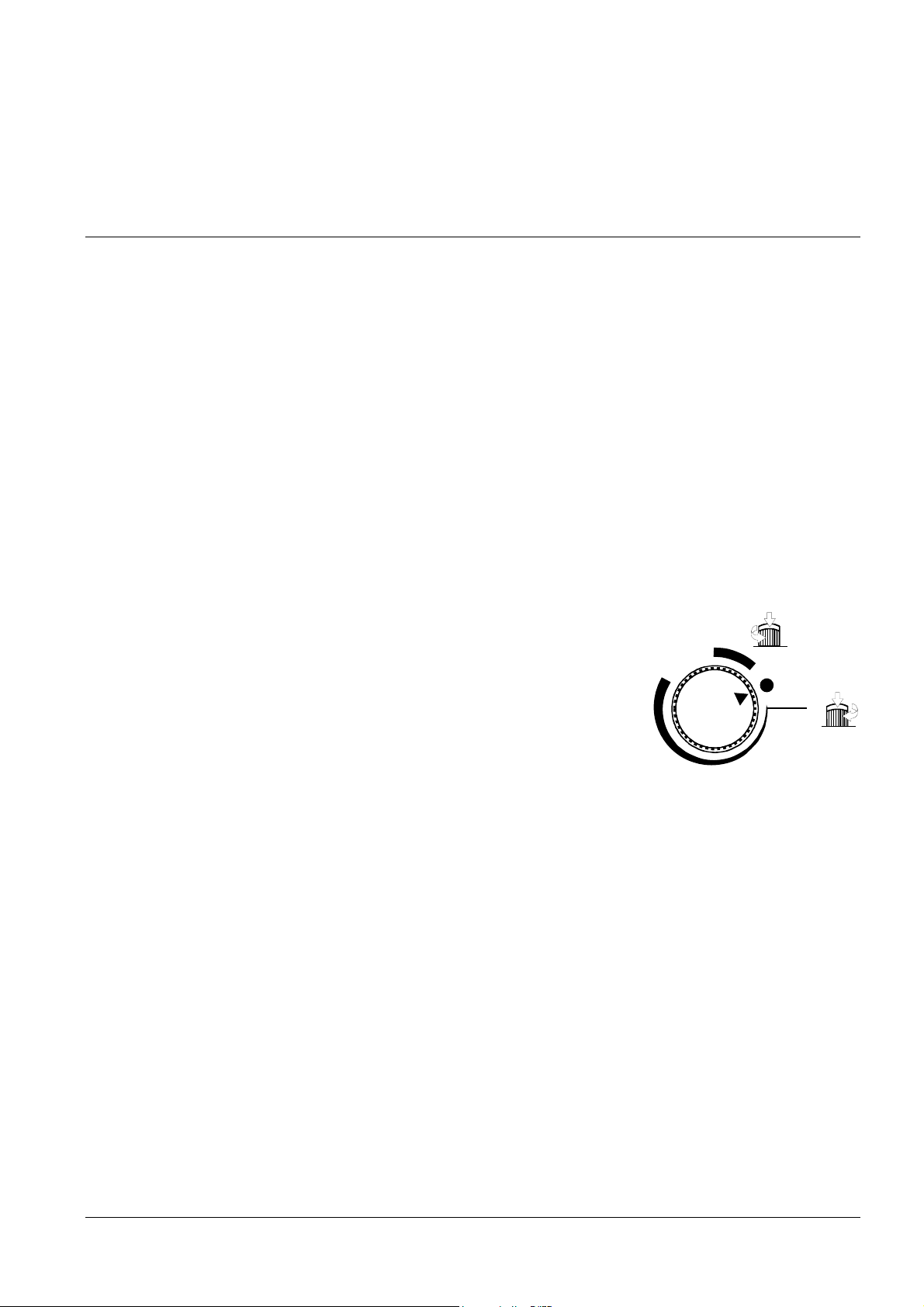

Operator controls and

indicators in the

electronics housing

1

YF X YM Y G G0

4455Z02

1 Connection terminals

2 Hand wheel

3 Opening for autocalibration

4 DIL switch for mode control

V

log

2...10V

4...20mA

ON

mA

2

3

4

4455Z01

V

lin

123

0...10V

V

ON

5

5 LED for indication of operating stat

Configuration

DIL switches

2...10V

4...20mA

V

log

123

V

lin

0...10V

4455Z01

mA

ON

OFF

V

ok

green

calib. / Man

error calib .

red

error

4461Z28

Switch Function ON / OFF Description

ON

Valve characteristic

OFF

.

(equal percentage) 1)

V

log

.

(linear)

V

lin

ON DC 2...10 V, DC 4...20 mA

Positioning signal Y

[V] or [mA]

assignment

OFF DC 0...10 V

ON [mA]

OFF [V]

1)

1)

1) Factory setting

Assignment positioning signal Y:

Voltage or current

ON

Y

ON

Selection of valve characteristic

(Positioning signal against volumetric

flow): Equal-percentage or linear

ON

ON

ON

0...10 V 2...10 V

ON

.

V

.

V

4...20 mA

4455Z08

Y

Y

4455Z09

4/14

Siemens Modulating control valves with magnetic actuators, PN16 CA1N4455en

Building Technologies 15.12.2009

Page 5

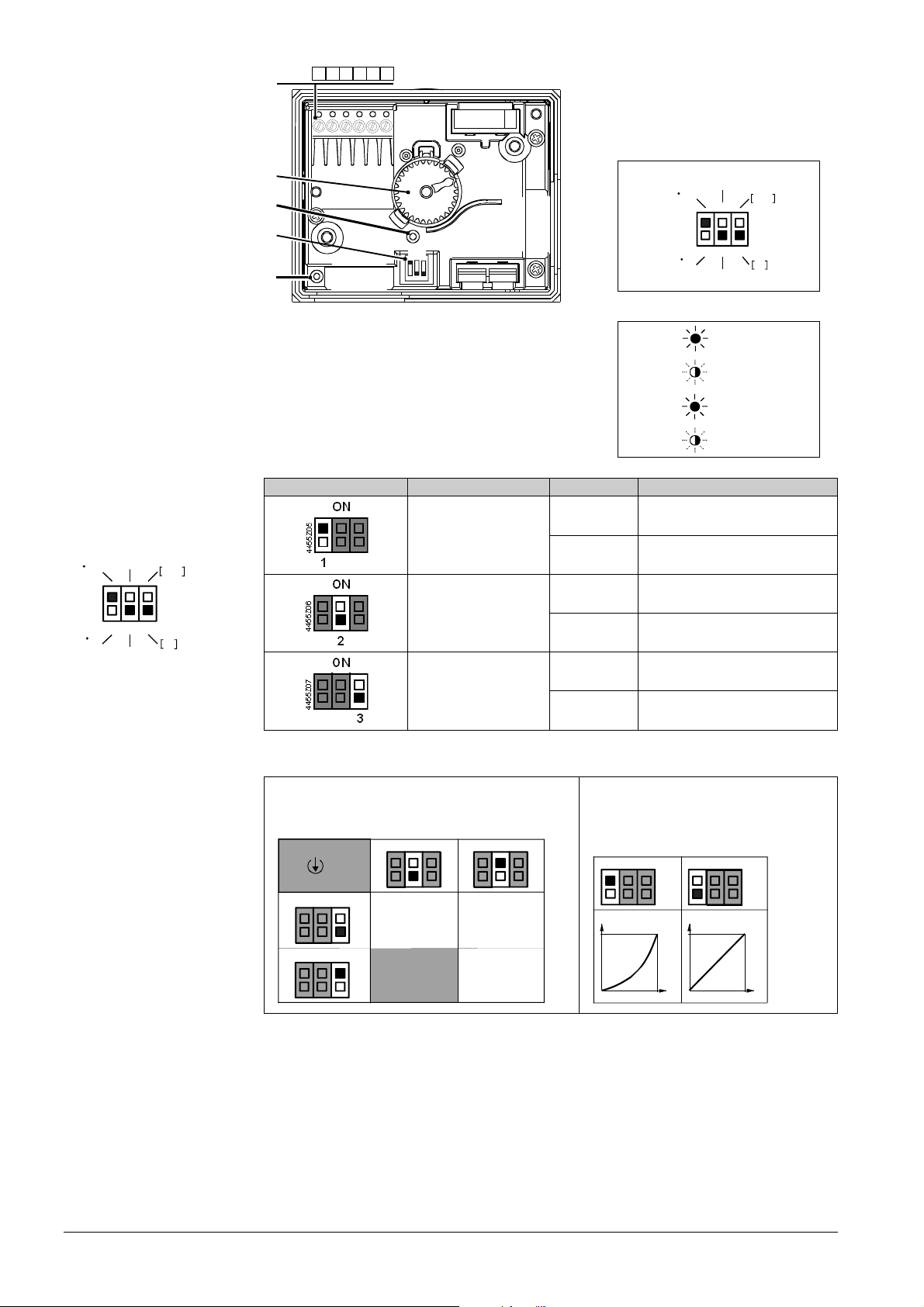

Forced control input

YF

no function fully open closed

YF – Function

Signal priority

Calibration

G0

G

Y

YM

Connections Transfer

X

YF

V

100 %

0 %

0 % 100 %

• YF not connected

• valve will follow the Y-signal

Function

Y

• YF connected to G

• valve will fully open control

G0

G

Y

YM

X

YF

V V

A AB

100 %

0 %

0 % 100 %

path A AB

1. Hand wheel position MANUAL (open) or OFF (close)

2. Forced control signal YF

3. Signal input Y

The MX..461.. and MX..461..P magnetic valves are

factory-calibrated at 0 % and 100 % stroke.

G0

G

Y

YM

X

YF

A ABA AB

100 %

Y

0 %

0 % 100 %

• YF connected to G0

• valve will close control path

A AB

4455Z10

Y

When commissioning the valves, however,

(especially under extreme conditions of use) there

may still be some leakage via control path A → AB

with a 0 % stroke control signal (DC 0 V, DC 2 V or

DC 4 mA).

In this case, the valve can be recalibrated simply

and quickly:

1. Hand wheel [2] in AUTO-position

2. Use a pointed implement (ø 2 mm) to operate the

button in the opening [3] once

3. While recalibration is in progress, the LED [5] is

flashing green for approximately 10 seconds.

The valve will be briefly closed and fully opened.

If the electronics module is replaced, the valve’s

electronics must be recalibrated. For that, the hand

wheel must be set to AUTO.

5/14

Siemens Modulating control valves with magnetic actuators, PN16 CA1N4455en

Building Technologies 15.12.2009

Page 6

Indication of

operating state

Sizing

Flow chart

The two-color LED display indicating operating status can be viewed by opening the

cover of the electronics module.

LED Indication Function Remarks, troubleshooting

Green Lit

Flashing

Red Lit

Flashing

Both Dark

Control mode Automatic operation; everything o.k.

Calibration

In manual control

Calibration error

Internal error

Mains fault Check mains network (outside the frequency or

No power supply

Electronics faulty

Wait until calibration is finished

(green or red LED will be lit)

Hand wheel in MANUAL or OFF position

Recalibrate (operate button in opening 1x)

Replace electronics module

voltage range)

Check mains network, check wiring

Replace electronics module

As a general rule, the LED can assume only the states shown above (continuously red

or green, flashing red or green, or off).

Δp

= differential pressure across the fully open valve and the valve’s control path A → AB by a

100

Note for media other

than water

V

V

100

Δpmax = max. permissible differential pressure across the valve’s control path for the entire actuating

100 kPa = 1 bar ≈ 10 mWC

1 m

volume flow

= volume flow through the fully open valve (H

range of the motorized valve

3

/h = 0.278 l/s water at 20 °C

When sizing valves for media other than water, note that the medium properties

• specific heat

V

100

)

100

• density

• kinematic viscosity

differ from water. All variables depend on temperature. The design temperature is the

lowest medium temperature in the valve.

6/14

Siemens Modulating control valves with magnetic actuators, PN16 CA1N4455en

Building Technologies 15.12.2009

Page 7

Note on viscosity

Kinematic viscosity

≤ 10 mm

> 10 mm

Valve characteristic

1)

Connection type

4-wire connection

Viscosity may change considerably on temperature changes depending on the

medium. Plant functionality may be impaired if the medium temperature does not

guarantee viscosity values compatible with troublefree valve functioning.

2

2

/s

influence on volume flow is negligible.

Kinematic viscosity υ [mm

/s] in HVAC plants always is lower than 10 mm2/s, i.e. its

2

/s

For details please contact your local Siemens branch office.

Equal percentage Linear

Volumetric flow Volumetric flow

[%]

100

80

60

40

20

0

2

4

6

12

10 [V]

86420

10 [V]

20 [mA]

[%]

4455D02

100

80

60

40

20

0

y

y

2

y

4

6

12

86420

10 [V]

10 [V]

20 [mA]

4455D03

y

y

y

Positioning signals Positioning signals

The 4-wire connection should always be given preference!

SNA P

STR IF Cross-sectional area [mm

MED

1,5 2,5 4,0

2

]

Type reference [VA] [W] [VA] [A] max. cable length L [m]

MX..461.15-0.6

MX..461.15-1.5

MX..461.15-3.0

MX..461.20-5.0

MX..461.25-8.0

MX..461.32-12

MX..461.40-20

MX..461.50-30

MXF461.65-50 46

SNA = nominal apparent power for selecting the transformer

= typical power consumption

P

med

= Minimal required transformer power

S

TR

I

= required slow fuse

N

L = max. cable length; with 4-wire connections, the max. permissible length of the separate

1.5 mm

1)

All information at AC 24 V

29 5 50 3,15 70 110 170

44 40 70 110

6 75 4

30 50 80

2

copper positioning signal cable is 200 m

Engineering notes

Conduct electric connections in accordance with local regulations on electric

installations as well as the internal or connection diagrams.

Attention

Observe safety regulations and restrictions designed to ensure the safety of

people and property at all times!

Fit a strainer upstream of the valve to increase reliability.

7/14

Siemens Modulating control valves with magnetic actuators, PN16 CA1N4455en

Building Technologies 15.12.2009

Page 8

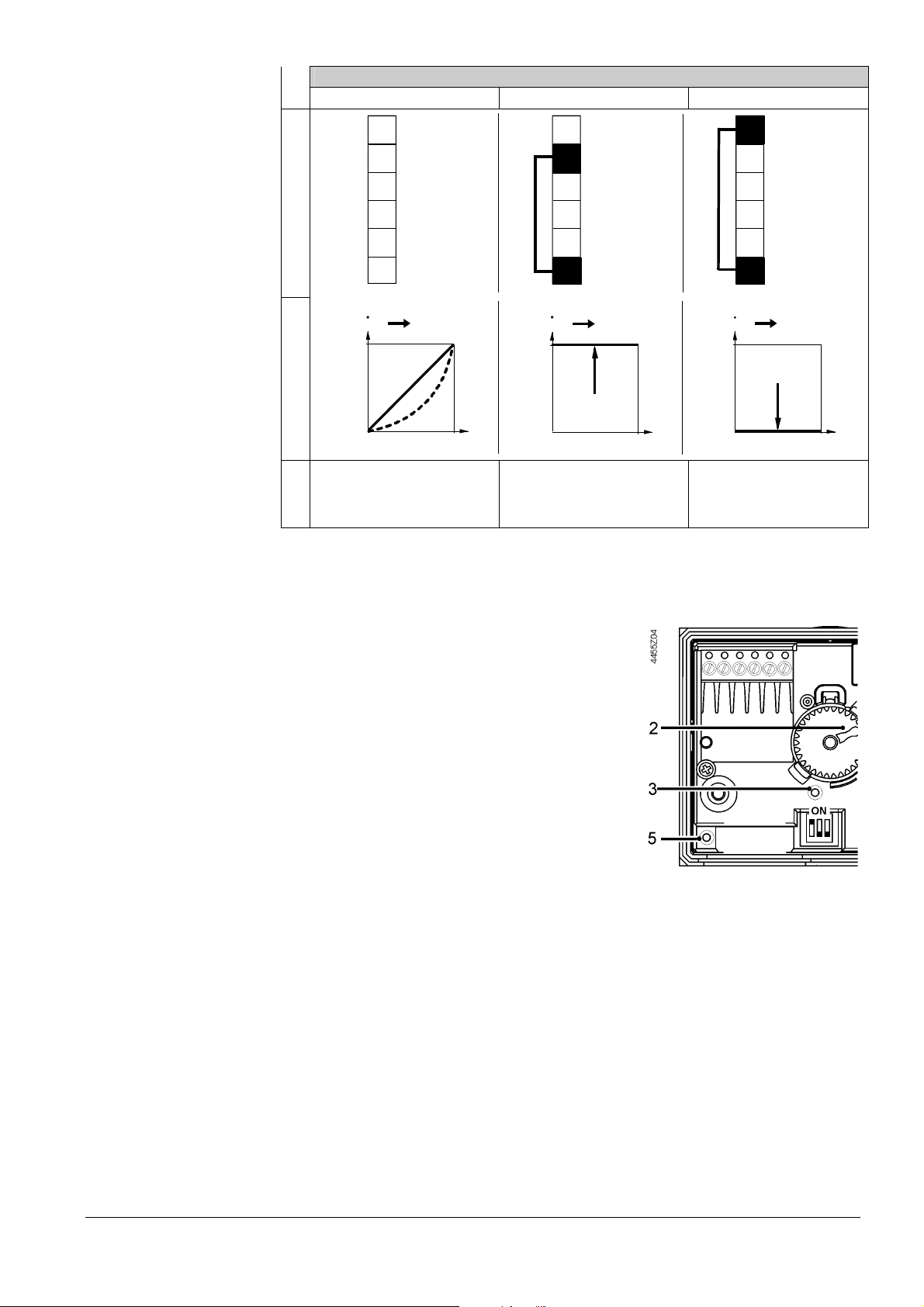

Mounting notes

A

Caution

Orientation

ccess for installation

Use as straight-through

valves

MXG461.. threaded

valves in straightthrough applications

Mounting and operating instructions are printed on the actuator and on the electronics

module.

The valve may only be used as a mixing or throughport valve, not as a diverting

valve. Observe the direction of flow!

A strainer should be fitted upstream of the valve. This increases reliability.

Degree of protection valid only with M20 cable gland

supplied by the installer.

4455Z11

IP54

90°

90°

IP54

It is essential to maintain the specified minimum clearance above and to the side of the

actuator and/or electronics module! (refer to "Dimensions", page 12)

DN15…DN32

= 100 mm

DN40…DN65 = 150 mm

Only three-way MX..461.. valves are supplied. They may be used as straight-through

valves by closing off port "B".

Port "B" can be sealed with the accessories

supplied (cover, gasket) and the union nut of the

ALG..3 coupling.

MXF461.. flanged

valves in straightthrough applications

Installation notes

Maintenance notes

4455Z13

Port "B" can be sealed with part Z155/.. which must

be ordered as a separate item.

The part comes complete with blank flange, seal,

screws, spring washers and nuts.

DN15…DN32 blank flange (Z155/15F..Z155/32F)

DN40…DN65 blank flange (Z155/40..Z155/65)

4455Z12

• The MXG..461.. valves are flat-faced allowing sealing with the gaskets provided with

the ALG..3 set of 3 threaded fittings.

• Do not use hemp for sealing the valve body threads.

• The actuator may not be lagged.

For notes on electrical installation, see "Connection diagram".

The valves and actuators are maintenance-free.

The low friction and robust design make regular servicing unnecessary and ensure a

long service life.

The valve stem is sealed from external influences by a maintenance-free gland.

If the red LED is lit, the electronics must be recalibrated or replaced.

8/14

Siemens Modulating control valves with magnetic actuators, PN16 CA1N4455en

Building Technologies 15.12.2009

Page 9

Repair

Caution

Caution

If the valve electronics prove faulty, the electronics module must be replaced by the

ASE1 (DN15…32) or ASE2 (DN40…65) replacement electronics module.

Mounting instructions no. 35678 are included.

Always disconnect power before fitting or removing the electronics module.

After replacing the electronics module, calibration must be triggered in order to

optimally match the electronics to the valve (refer to "Calibration", page 5).

Under

operating conditions within the limits defined by the application data, the

actuator will become hot, but this does not represent a burn risk. Always

maintain the minimum clearance specified, refer to "Dimensions", page 12.

Disposal

Do not dispose of the actuator in domestic waste. This applies in particular to the PCB.

The law may demand special handling of certain components, or it may make

environmental sense.

Observer all current local laws.

Warranty

Observe all application-specific technical data.

If specified limits are not observed, Siemens Switzerland Ltd / HVAC Products

does not assume any responsibility.

Technical data

Functional actuator data

Power supply Extra low-voltage only (SELV, PELV)

Operating voltage AC 24 V +20 / –15 %

Frequency 45...65 Hz

Typical power consumption P

Refer to table " Connection type ", page 7

med

Standby < 2 W (valve closed)

Rated apparent power SNA Refer to table " Connection type ", page 7

Required fuse IN Slow, refer to table "Wiring connection", page 7

Input Positioning signal Y DC 0/2...10 V or DC 4...20 mA

Impedance DC 0/2...10 V 100 kΩ // 5nF

DC 4...20 mA 100 Ω // 5nF

Forced control YF

Impedance 22 kΩ

Close valve (YF connected to G0) < AC 1 V

Open valve (YF connected to G) > AC 6 V

No function (YF not wired) Positioning signal Y active

Output Position feedback signal X DC 0...10 V; load resistance > 500 Ω

Stroke measurement

Nonlinearity

Inductive

± 3 % of end value

Positioning time < 2 s

Electrical connection Cable entry 2 x ∅ 20.5 mm (for M20)

Connection terminals Screw terminals for 4 mm

2

wire

Minimal wire cross section 1.5 mm2

Maximum cable length Refer to "Connection type", page 7

9/14

Siemens Modulating control valves with magnetic actuators, PN16 CA1N4455en

Building Technologies 15.12.2009

Page 10

Functional valve data

PN class PN 16 to EN 1333

Permissible operating pressure 1 MPa (10 bar)

Differential pressure Δpmax / ΔpS Refer to table "Type summary", page 2

Leakage rate at

Δp = 0.1 MPa (1 bar)

A → AB max. 0.02 % k

B → AB < 0.2 % k

(to DIN EN 1349)

VS

depending on operating

VS

conditions

Valve characteristic

1)

Equal percentage, n

= 5.3 to VDI / VDE 2173 or

gl

linear, optimized near the closing point

Permissible media MX..461..

Chilled and low-temperature hot water, water

with anti-freeze;

Recommendation: water treatment to VDI 2035

MX..461..P

Mineral oils SAE05 ... SAE50, mineral-oil-based

diesel fuels, heat transfer oils

Medium temperature 1...130 °C

Stroke resolution ΔH / H

1 : 1000 (H = stroke)

100

Hysteresis typically 3 %

Position when deenergized A → AB closed

Mounting position Upright to horizontal

Mode of operation Modulating

Manual operation Possible, max. 90 %

Materials

Valve body Cast iron EN-GJL-250

Plug CrNi steel (X12CrNiS18 8)

Seat Brass (CuZn39Pb3)

Valve stem seal MX..461.. EPDM (O-ring)

MX..461..P Fluororubber – FPM product (Viton)

Bellows Tombac (CuSn6), bronze (CuSn9), CrNi steel

Dimensions / weight Dimensions Refer to "Dimensions", page 12

Weight Refer to "Dimensions", page 12

Norms and standards CE conformity

to EMV-requirements

Immunity EN 60730-1:2000/A16:2007

2004/108/EC

2)

Emission EN 60730-1:2000/A16:2007

Electrical safety 60730-1

Protection class Class III to 60730

Pollution degree Class 2 to EN 60730

Housing protection

Upright to horizontal

Vibration

3)

IEC 60068-2-6

IP54 to EN 60529 (with M20 cable gland)

(1 g acceleration, 1...100 Hz, 10 min)

Conform to UL standards

CSA, Canada

C-tick

UL 873

C22.2 No. 24

N 474

Environmental compatibility ISO 14001 (Environment)

ISO 9001 (Quality)

SN 36350 (Environmentally compatible

products)

RL 2002/95/EG (RoHS)

Permissible operating pressure PED 97/23/EC

Pressure accessories As per article 1, section 2.1.4

Fluid group 2: DN15…DN50 • Without CE-marking as per article 3, section 3

(sound engineering practice)

DN 65 • Category I, module A, with CE-marking

1)

Can be selected via DIL switch

2)

Transformer 160 VA (e.g. Siemens 4AM 3842-4TN00-0EA0)

3)

In case of strong vibrations, use high-flex stranded wires for safety reasons.

10/14

Siemens Modulating control valves with magnetic actuators, PN16 CA1N4455en

Building Technologies 15.12.2009

Page 11

General

environmental conditions

MX..461.., MX..461..P Climatic conditions Class 3K5 Class 2K3 Class 1K3

MX..461..P Mechanically active substances

Connection terminals

Operation

EN 60721-3-3

Transport

EN 60721-3-2

Storage

EN 60721-3-1

Temperature -5...+45 °C -25...+70 °C -5...+45 °C

Humidity

Mechanical conditions

5...95 % r.h. 5...95 % r.h. 5...95 % r.h.

EN 60721-3-6

Class 6M2

EN 60721-3-3 EN 60721-2 EN 60721-2

Class 2M2 Class 2M2

Biological requirements

Chemically active substances

Mechanically active substances

Class 3B2

Class 3C1

Class 3M2

Connection diagrams

Caution

Terminal assignment

for controller with

4-wire connection

(to be preferred!)

AC 24 V operating

voltage

Positioning signal

Position feedback signal

Force control input

R = Inner resistance between G0 and YM, approx 10 kΩ

System neutral

System potential

DC 0...10 V / 2...10 V / 4...20 mA

Measuring neutral (= G0)

DC 0...10 V

If controller and valve receive their power from separate sources, only one

transformer may be earthed on the secondary side.

Common transformer Separate transformer

Terminal assignment

Common transformer

for controller with

3-wire connection

U

Siemens Modulating control valves with magnetic actuators, PN16 CA1N4455en

Building Technologies 15.12.2009

Indication of valve position (only if required). DC 0 ...10 V → 0...100 % volumetric flow V

Twisted pairs. If the lines for AC 24 V power supply and the DC 0...10 V (DC 2...10 V,

DC 4... 20 mA) positioning signal are routed separately, the AC 24 V line need not be twisted.

100

11/14

Page 12

Warning

Piping must be connected to potential earth!

DIL switch

Calibration

Application e

xamples

Hydraulic circuits

Caution

Factory setting: Valve characteristics equal-percentage, positioning signal DC 0...10 V.

Details see "Configuration DIL switches", page 4.

See "Calibration", page 5.

The examples shown below are basic diagrams with no installation-specific details.

The valve may only be used as a mixing or through-port valve, not as a diverting

valve. Observe the direction of flow!

AB

B

A

A

Mixing circuit Mixing circuit with

AB

B

A

B

bypass (underfloor

heating system)

A

B

10 x DN [min. 0.5 m]

AB

C

Injection circuit Diverting circuit Injection circuit

A

B

AB

D E

with throughport

valve

A

AB

4461Z 17

Dimensions

MXG461..

threaded valves

Dimensions in mm

12/14

Siemens Modulating control valves with magnetic actuators, PN16 CA1N4455en

Building Technologies 15.12.2009

Page 13

MXF461..

flanged valves

Type reference DN Rp

[inch] G [inch]

MXG461.15-0.6

MXG461.15-1.5

MXG461.15-3.0

MXG461.20-5.0 20 Rp ¾ G 1¼B 95 47.5 52.5 61 260 4.2

MXG461.25-8.0 25 Rp 1 G 1½B 110 55 56.5 65 270 4.7

MXG461.32-12 32 Rp 1¼ G 2B 125 62.5 67.5 76 285

MXG461.40-20 40 Rp 1½ G 2¼B 140 70 80.5 94 320 9.3

MXG461.50-30 50 Rp 2 G 2¾B 170 85 93.5 109 340

15 Rp ½ G1B 80 40 42.5 51 240 3.8

L1 L2 L3 L4 H2 H

min.

100

150

E F Weight

[kg]

80 100

5.6

11.9

Remarks: • L4: When used as a throughport valve

• Internally threaded Rp... to ISO 7-1

• Externally threaded G...B to ISO 228-1

• Fittings to ISO 49 / DIN 2950

• Also valid for MXG461..P, MXG461..M, MXG461..U

Type

reference

MXF461.15-0.6

MXF461.15-1.5

MXF461.15-3.0

MXF461.20-5.0 20 105 75 150 75 75 260 7.0

MXF461.25-8.0 25

MXF461.32-12 32 140 100 180 90 90 285

MXF461.40-20 40

MXF461.50-30 50 165 125 230 115 105 340 19.8

MXF461.65-50 65

DN B D D2 K L1 L2 L3 H2 H E F Weight

15 14 95 65 130 65 65 250 5.8

∅ ∅

4x14

16

115

18

150 110 200 100 100 322 15.4

4x18

22

185

min. [kg]

100

85 160 80 80 272 8.0

145 290 145 125 392

80 100

11.0

150

28.6

Remarks:

• Counter-flanges must be supplied by the installer!

• Flange dimensions to ISO 7005-2

• Also valid for MXF461..P, MXF461..M, MXF461..U

13/14

Siemens Modulating control valves with magnetic actuators, PN16 CA1N4455en

Building Technologies 15.12.2009

Page 14

Revision numbers

ge

Type

reference

Valid from

manufact.

date

MXG461.15-0.6 12/09

MXG461.15-1.5 12/09

MXG461.15-3.0 12/09

MXG461.20-5.0 12/09

MXG461.25-8.0 12/09

MXG461.32-12 12/09

MXG461.40-20 12/09

MXG461.50-30 12/09

MXF461.15-0.6 12/09

MXF461.15-1.5 12/09

MXF461.15-3.0 12/09

MXF461.20-5.0 12/09

MXF461.25-8.0 12/09

MXF461.32-12 12/09

MXF461.40-20 12/09

MXF461.50-30 12/09

MXF461.65-50 12/09

1)

MXG461.15-0.6P

1)

MXG461.15-1.5P

1)

MXG461.15-3.0P

1)

MXG461.20-5.0P

1)

MXG461.25-8.0P

1)

MXG461.32-12P

1)

MXG461.40-20P

1)

MXG461.50-30P

1)

MXF461.15-0.6P

1)

MXF461.15-1.5P

1)

MXF461.15-3.0P

1)

MXF461.20-5.0P

1)

MXF461.25-8.0P

1)

MXF461.32-12P

1)

MXF461.40-20P

1)

MXF461.50-30P

1)

MXF461.65-50P

Type reference

Valid from

manufact.

date

1)

12/09

1)

12/09

1)

12/09

1)

12/09

1)

12/09

1)

12/09

1)

12/09

1)

12/09

1)

12/09

1)

12/09

1)

12/09

1)

12/09

1)

12/09

1)

12/09

1)

12/09

1)

12/09

1)

12/09

1)

MMYY = Month, Year of manufacturing

Type reference

MXG461.15-0.6M

MXG461.15-1.5M

MXG461.15-3.0M

MXG461.20-5.0M

MXG461.25-8.0M

MXG461.32-12M

MXG461.40-20M

MXG461.50-30M

MXF461.15-0.6M

MXF461.15-1.5M

MXF461.15-3.0M

MXF461.20-5.0M

MXF461.25-8.0M

MXF461.32-12M

MXF461.40-20M

MXF461.50-30M

Valid from

manufact.

date

1)

12/09

1)

12/09

1)

12/09

1)

12/09

1)

12/09

1)

12/09

1)

12/09

1)

12/09

1)

12/09

1)

12/09

1)

12/09

1)

12/09

1)

12/09

1)

12/09

1)

12/09

1)

12/09

Type reference

MXG461.15-0.6U

MXG461.15-1.5U

MXG461.15-3.0U

MXG461.20-5.0U

MXG461.25-8.0U

MXG461.32-12U

MXG461.40-20U

MXG461.50-30U

MXF461.65-50U

Valid from

manufact.

date

1)

12/09

1)

12/09

1)

12/09

1)

12/09

1)

12/09

1)

12/09

1)

12/09

1)

12/09

1)

12/09

14/14

2009 Siemens Switzerland Ltd Subject to chan

Siemens Modulating control valves with magnetic actuators, PN16 CA1N4455en

Building Technologies 15.12.2009

Loading...

Loading...