Page 1

GF-115-C

OMM-0084_0D

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526- 0288

USER MANUAL

Other manuals for this product include:

Gas Fired Boiler Systems

Modulex E8 Controller

• MLX-303

E8 Controller for MLX Series Boilers

Boiler Communications Module (BCM)

for MLX Series Boilers

Installation, Operation, and Maintenance

Modulating, Condensing,

Hot Water Boiler Models:

• MLX-454

• MLX-606

• MLX-757

• MLX-909

• MLX-1060

And BC Module (BCM)

.

• GF-115-H MLX Series Boiler Manual

• GF-115-G MLX Gas Design Guide

• GF-115-P-H MLX Piping Guide

• GF-115-V MLX Venting Guide

• GF-115-E MLX Electrical Power Guide

Revised: 11/30/2012

PR1: 11/30/12 Page 1 of 112

Page 2

GF-115-C

Modulex E8 Controller and BCM

Operations and Maintenance Manual

OMM-0084_0D

Technical Support:

1-800-526-0288

www.aerco.com

(Mon–Fri, 8am-5pm EST)

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Disclaimer

The information contained in this manual is subject to change without notice from AERCO International,

Inc. AERCO makes no warranty of any kind with respect to this material, including but not limited to

implied warranties of merchantability and fitness for a particular application. AERCO International is not

liable for errors appearing in this manual. Nor for incidental or consequential damages occurring in

connection with the furnishing, performance, or use of this material.

PR1: 11/30/12 Page 2 of 112

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526- 0288

Page 3

GF-115-C

OMM-0084_0D

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526- 0288

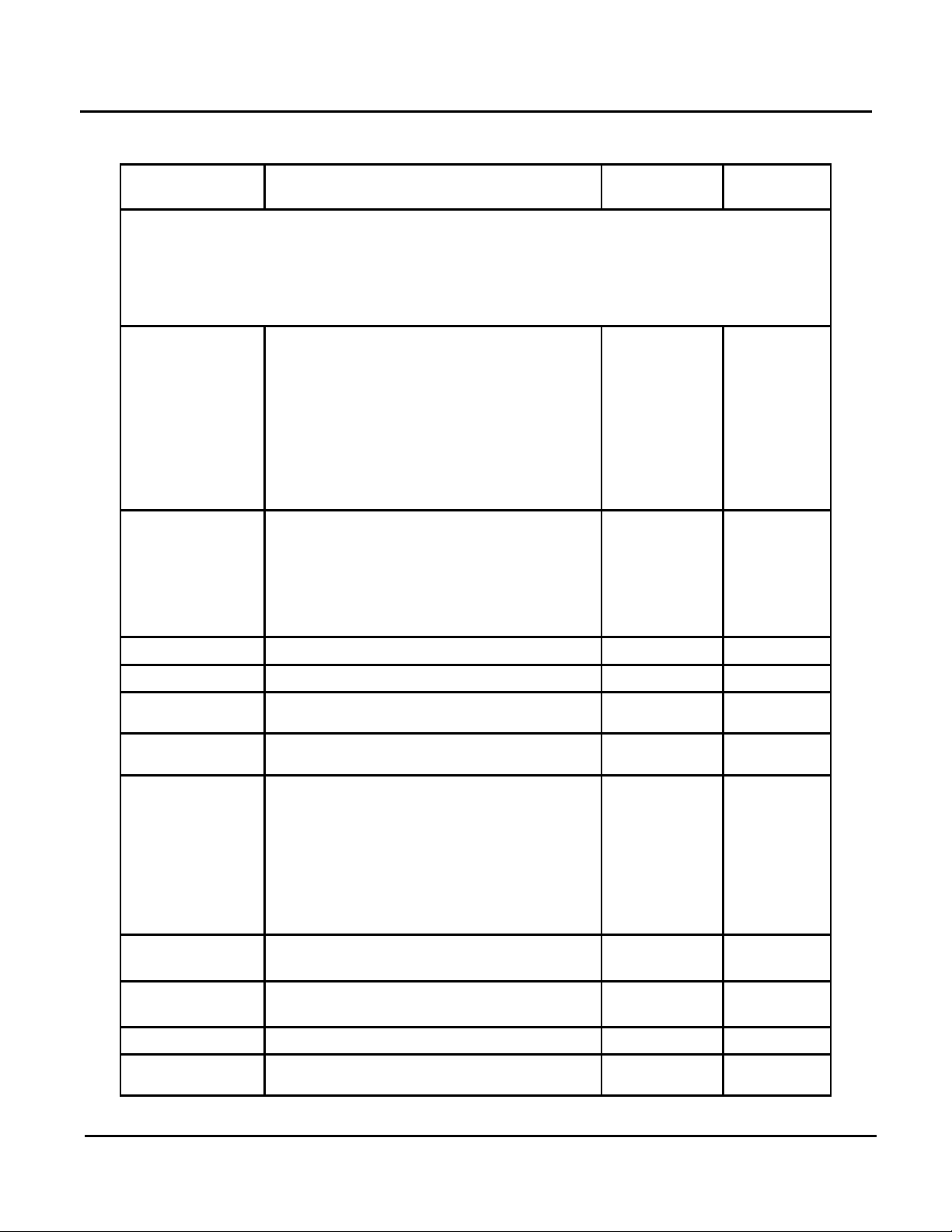

Table of Contents

Table of Contents .......................................................................................... 3

1. INTRODUCTION ..................................................................................... 7

1.1 Safety and Warnings ........................................................................................ 7

2. E8 CONTROLLER AND BCM DESCRIPTION .......................................... 9

2.1 E8 Controller Features And Functions ........................................................... 9

2.2 BCM Features And Functions ....................................................................... 10

3. E8 CONTROLLER OPERATION ............................................................ 11

3.1 NORMAL Mode Operation (Door Closed)..................................................... 11

3.1.1 NORMAL Mode Display Functions ................................................................... 11

3.1.2 HEATING Mode Selection (in NORMAL Mode) ............................................. 12

3.1.3 MENU Mode Operation (Door Open) ................................................................ 13

3.2 Software Menus .............................................................................................. 14

3.2.1 Basic Menu/Sub-Menu Navigation and Selection .............................................. 15

3.2.2 Basic Parameter Navigation, Selection, and Revision ........................................ 16

4. E8 CONTROLLER MENUS AND SUB-MENUS ...................................... 17

4.1 DISPLAY Menu ............................................................................................... 18

4.2 USER Menu ..................................................................................................... 21

4.3 TIME PROGRAM Menu and Sun-Menus ....................................................... 24

4.4 EXPERT Menu and Sub-Menus ..................................................................... 25

4.4.1 Available V-Curve Preset Voltage Curves for 0 – 10 Volt Input ....................... 31

4.5 EXPERT HS Menu (Not Used) ...................................................................... 32

4.6 GENERAL Menu ............................................................................................. 32

4.6.1 DATE / TIME Menu ........................................................................................... 32

4.6.2 SERVICE Menu .................................................................................................. 34

4.7 E8 Controller Initial Startup ........................................................................... 37

4.7.1 CAP/MODULE Function (Maximum Kilowatts per Burner) ............................ 39

4.7.1 Available Settings for Relay Functions 1 – 4 ...................................................... 40

5. E8 OPERATING MODE: Set-up and Programming .................................. 41

5.1 Indoor/Outdoor Reset Mode .......................................................................... 41

5.1.1 Wiring Connections............................................................................................. 41

5.1.2 Indoor/Outdoor Reset Operation Configuration ................................................. 41

5.1.3 Viewing the Boiler Setpoint ................................................................................ 43

5.2 Constant Set Point Mode ............................................................................... 43

5.2.1 Wiring Connections............................................................................................. 44

5.2.2 Constant Setpoint Mode Configuration............................................................... 44

5.2.3 Viewing Constant Set Point ................................................................................ 44

PR1: 11/30/12 Page 3 of 112

Page 4

GF-115-C

Modulex E8 Controller and BCM

Operations and Maintenance Manual

OMM-0084_0D

5.2.4 Configuring Set Point High and Low Limits Per Outside Temperature Sensor . 44

5.3 0 to 10 Volt Remote Set Point Mode ............................................................. 47

5.3.1 Remote Signal Source Wiring Connections ........................................................ 47

5.3.2 Configuring Remote Signal Source..................................................................... 48

5.3.3 Setting the Voltage and Set Point Limits for U1/U2 and T1/T2 ......................... 49

5.3.4 Setting the Curve 11-UO Voltage ....................................................................... 50

5.3.5 Viewing the Set Point .......................................................................................... 51

5.4 Domestic Hot Water Operation Using A Tank Sensor ................................ 51

5.4.1 Sensor Wiring Connections ................................................................................. 51

5.4.2 Configuring the Controller for DHW With a Tank Sensor ................................. 52

5.4.3 Setting the DHW Set Point ................................................................................. 53

5.4.4 Displaying Temperatures Associated With DHW .............................................. 54

5.5 DHW Operation Using an Aquastat .............................................................. 55

5.5.1 Sensor Wiring Connections ................................................................................. 55

5.5.2 Configuring the Controller for DHW With an Aquastat ..................................... 55

5.5.3 Setting the DHW Set Point ................................................................................. 55

5.5.4 Displaying Temperatures Associated With DHW .............................................. 55

5.6 Boiler & Pump Enable/Disable ...................................................................... 55

6. CONNECTION DIAGRAMS .................................................................... 57

6.1 Power Terminal Assignments ....................................................................... 58

6.2 Sensor Terminal Assignments ...................................................................... 59

7. BOILER COMMUNICATIONS MODULE (BCM) ..................................... 61

7.1 Boiler Communications Module (BCM) Description ................................... 61

7.2 BCM Fault Relay ............................................................................................. 63

7.2.1 BCM Fault Relay Wiring .................................................................................... 63

7.2.2 Clearing Faults .................................................................................................... 63

7.3 BCM Configured as Back-Up Controller ...................................................... 64

7.3.1 BCM Back-Up Controller Wiring ....................................................................... 64

7.4 BCM Configured as Primary Controller Utilizing Modbus .......................... 65

7.4.1 Operating Scenario .............................................................................................. 65

7.4.2 Physical Modbus RS485 Wiring ......................................................................... 66

7.4.3 Disconnecting the E8 from the E-Bus on the BCM Board. ................................ 67

7.4.4 AERCO BMS II/ACS Master to BCM Slave Wiring Connections. ................... 68

7.4.5 EMS or BAS Master to BCM Slave Wiring Connections .................................. 68

7.5 RS485 Loop Termination Resistors and Bias .............................................. 68

7.5.1 Master AERCO BMS II/ACS or EMS/BAS Terminating Resistor and Bias ..... 68

7.5.2 BCM Controller Terminating Resistor and Bias ................................................. 69

7.6 Modbus Network Wiring Diagram ................................................................. 70

7.7 Modbus Software Set-Up ............................................................................... 73

7.7.1 BCM Set-Up for Modbus Operation ................................................................... 73

PR1: 11/30/12 Page 4 of 112

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526- 0288

Page 5

GF-115-C

Modulex E8 Controller and BCM

Operations and Maintenance Manual

OMM-0084_0D

7.7.2 Monitoring and Configuration Only ................................................................... 74

7.7.3 AERCO BMS II/ACS Modbus Control and Monitoring .................................... 74

7.7.4 Modbus Remote Setpoint Control and Monitoring ............................................. 74

7.7.5 EMS or BAS Set-Up As Master to BCM Controller Slaves ............................... 74

7.8 Multiple Modulex Boiler Heating Mode – Utilizing a BMS II or ACS ........... 74

7.8.1 Sequence of Operation (Example: Four-Modulex boiler installation) ................ 75

8. E8 CONTROLLER MENU LISTINGS ..................................................... 77

8.1 DISPLAY Menu ............................................................................................... 77

8.2 USER Menu ..................................................................................................... 79

8.3 TIME PROGRAM Menu .................................................................................. 81

8.4 EXPERT Menu ................................................................................................ 84

8.5 GENERAL Menu ............................................................................................. 89

8.5.1 DATE / TIME Sub-Menu ................................................................................... 89

8.5.2 SERVICE Sub-Menu .......................................................................................... 90

9. BCM MODBUS AND ADDRESS ASSIGNMENTS ................................... 93

9.1 BCM Modbus Communication & Support Requirements ........................... 93

9.1.1 Function Codes .................................................................................................... 93

9.1.2 Modbus Support Requirements ........................................................................... 93

9.2 BCM Controller Standard Holding Register Assignments ......................... 94

9.2.1 BCM Controller Standard Input Register Assignments ...................................... 94

9.2.2 BCM Controller Standard Holding Register Assignments ................................. 94

10. E8, BCM, AND BMM FAULT CODES ................................................. 101

10.1 Processing and Clearing Fault Codes ........................................................ 102

10.2 Fault Codes and Descriptions ..................................................................... 103

10.2.1 E8 Controller Fault Codes ............................................................................. 104

10.2.2 BCM (Boiler Communications Module) Fault Codes ................................... 106

10.2.3 BMM (Burner Management Module) Fault Codes ....................................... 108

PR1: 11/30/12 Page 5 of 112

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526- 0288

Page 6

GF-115-C

Modulex E8 Controller and BCM

Operations and Maintenance Manual

OMM-0084_0D

(This page left intentionally blank)

PR1: 11/30/12 Page 6 of 112

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526- 0288

Page 7

GF-115-C

OMM-0084_0D

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526- 0288

WARNING

!

!

CAUTION

!

!

DANGER

!

!

DANGER

!

!

1. INTRODUCTION

The information in this manual provides a guide to the operation of the Modulex Boiler using

the E8 Controller and the Boiler Communications Module (BCM) mounted on the front of the

unit. Sections 3, 4, 5, 6, and 8 provide descriptions and procedures for the E8 Controller.

Sections 7, 9, and 10 provide similar information for the BCM.

It is imperative that the initial startup procedures be performed by factory trained personnel.

Operation by untrained personnel, prior to the initial startup, will void the equipment warranty.

In addition, CAUTIONS and WARNINGS in this manual must be observed at all times.

1.1 Safety and Warnings

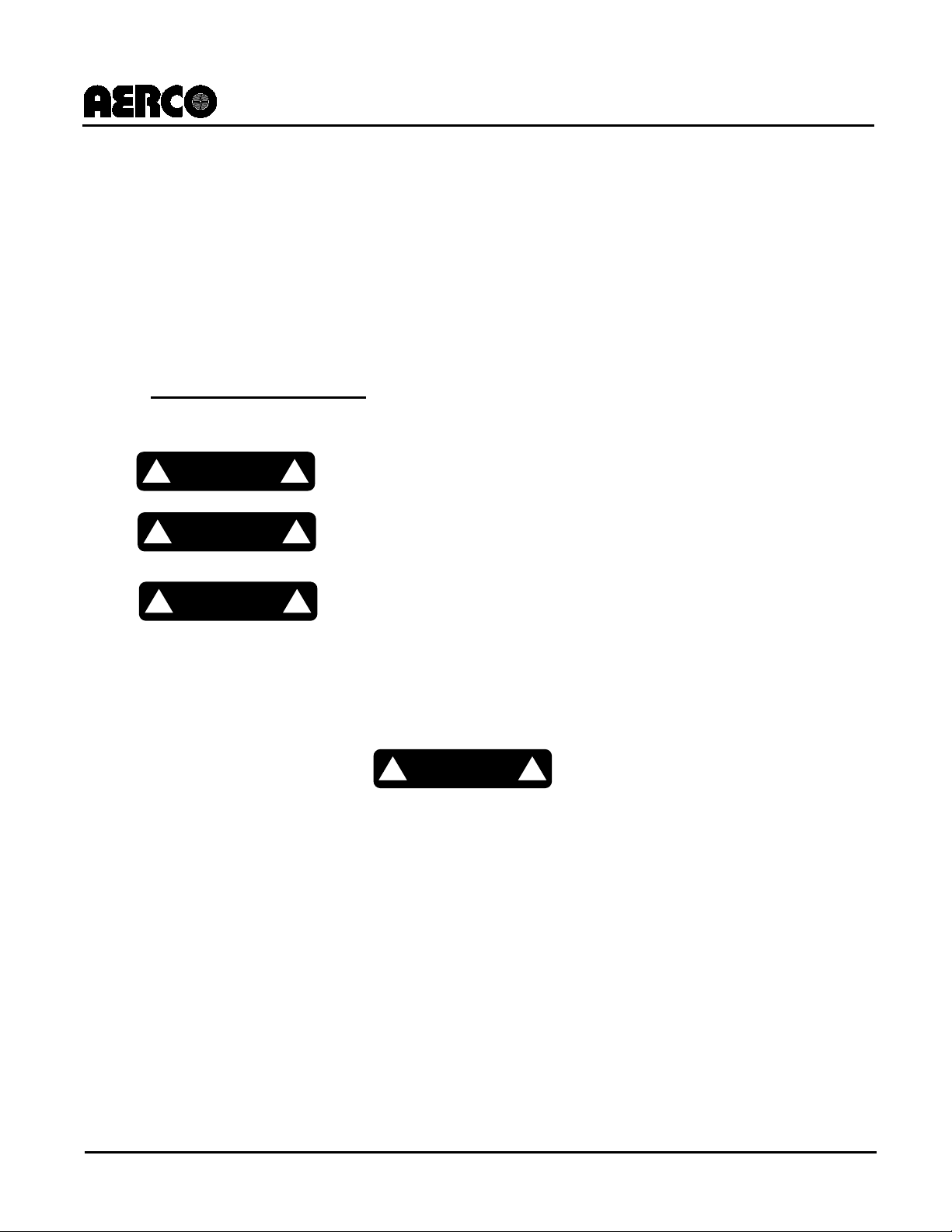

The following defined symbols are used throughout this manual to notify the reader of potential

hazards of varying risk levels.

Indicates an imminently hazardous situation, which if not avoided,

WILL result in death or serious injury.

Indicates a potentially hazardous situation, which if not avoided,

MAY result in death or serious injury.

Indicates a potential hazardous situation, which if not avoided,

COULD result in minor or moderate injury. Also may caution

against unsafe practices.

Note that all hazard notifications and notes are presented enclosed in a rectangle with filleted

(round) corners, as shown below, in order to differentiate them from the main text.

It is of utmost importance to observe all CAUTIONS and

WARNINGS presented in this manual to avoid injury, death, and

damage to the equipment. Failure to properly heed safety

warnings and cautions may result in the voiding of applicable

warranties.

PR1: 11/30/12 Page 7 of 112

Page 8

GF-115-C

Modulex E8 Controller and BCM

Operations and Maintenance Manual

OMM-0084_0D

(This page left intentionally blank)

PR1: 11/30/12 Page 8 of 112

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526- 0288

Page 9

GF-115-C

OMM-0084_0D

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526- 0288

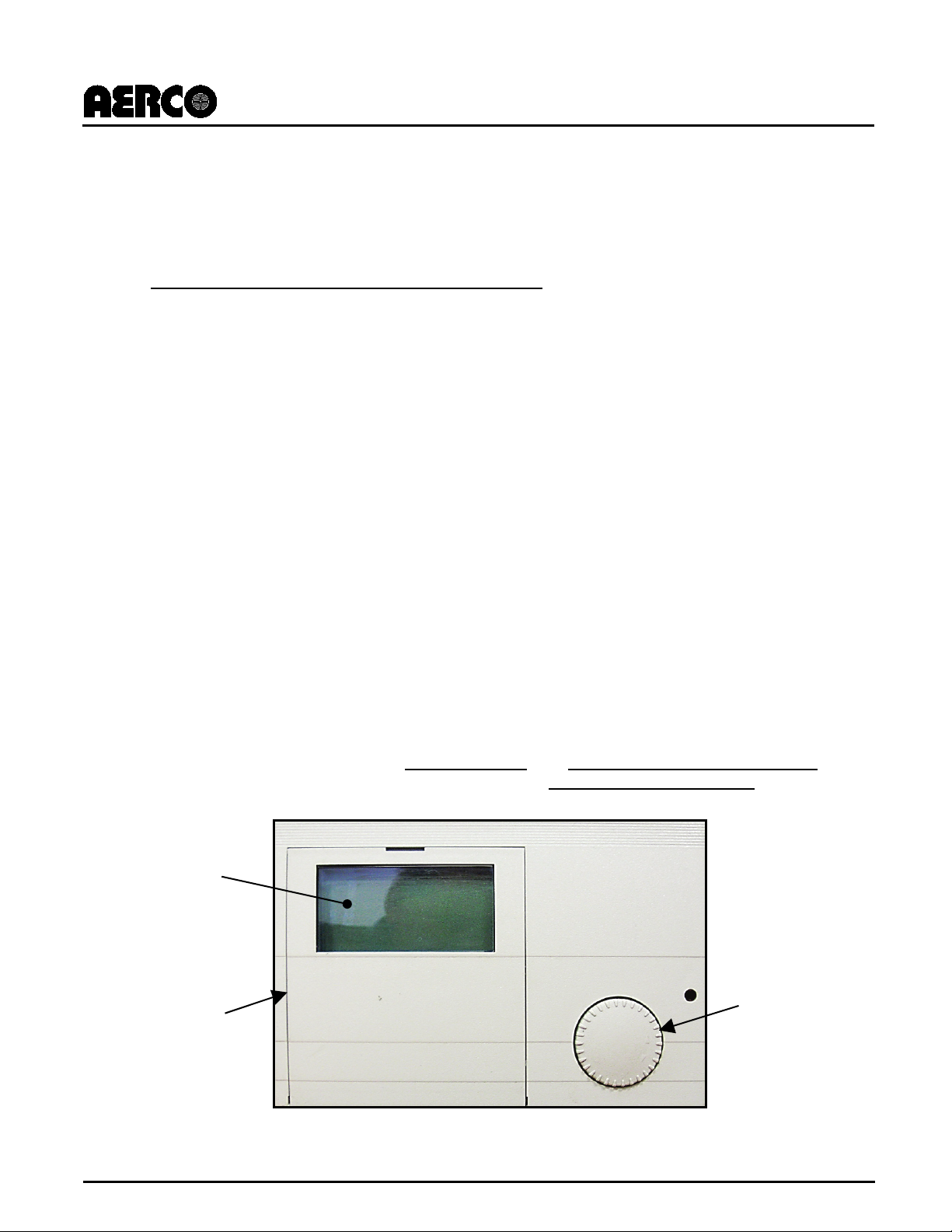

Rotary Knob

LCD Display

Hinged Cover

2. E8 CONTROLLER AND BCM DESCRIPTION

Modulex boilers contain advanced and reliable electronic controls, which includes the E8

Controller and the BCM (Boiler Communications Module), providing comprehensive

programming and monitoring of the Modulex boiler and its functions. Features and functions of

the E8 Controller are described in the following sections.

2.1 E8 Controller Features And Functions

A standard component included in Modulex units, the E8 Controller is responsible for the

staging and modulation of individual thermal heating modules in a Modulex boiler and also

monitors supply and return water temperatures and domestic hot water zones.

The E8 Controller is housed in a compact enclosure measuring 5.7” (145 mm) x 3.9” (100 mm).

The Controller is mounted on the front of the Modulex Boiler and contains all of the controls,

indicators and displays necessary to adjust, operate and troubleshoot the Modulex Boiler. The

E8 features the following functions for Modulex boilers:

• Shares the heating load among as many of the boiler's thermal heating modules as

possible. maximizing the overall operating efficiency of the boiler.

• Provides access to all testing/programming parameters of each individual heating module:

operation test, operation time, boiler freeze protection and pump's anti seize program.

• Drives lead-lag burner operation based on operating hours. The boiler module with the least

burner operating hours is the first to start and the burner with the most operating hours is the

first to stop.

• Supports DHW (Domestic Hot Water) production using a dedicated sensor to control a

dedicated pump or 3-way diverting valve for storage tank temperature control.

• Supports a manual operation service mode to control individual modules during

troubleshooting or combustion calibration procedures.

• Drives diagnostics such as relay and senor testing.

• Supports Modbus integration with AERCO BMS II and AERCO Control System (ACS) or

Building Automation Systems. AERCO also offers a Communication Gateway to support

BACnet, Lonworks and N2 system integration.

Window

(in closed

position)

Figure 2-1: Modulex E8 Controller Front Panel

PR1: 02/23/12 Page 9 of 112

Page 10

GF-115-C

Modulex E8 Controller and BCM

Operations and Maintenance Manual

OMM-0084_0D

2.2 BCM Features And Functions

The BCM (Boiler Communications Module) is an electronic module in Modulex boilers (one per

burner), which supports full interoperability to BAS (Building Automation Systems) via Modbus

protocol to make remote communications and control possible. In addition, it provides

customers with a remote alarm contact to notify customers of faults detected within any of

boiler's multiple thermal modules. Finally, in the event the boiler's master controller stops

working, the BCM also takes over operations of the boiler.

As a back-up controller, the BCM further increases the reliability of a product line already known

for its uniquely redundant design. Each Modulex boiler combines between two and seven

independent, 151,500 BTU/hr., pre-assembled thermal modules housed in a common

enclosure. Each module has its own dedicated controller with a combustion safeguard, variablespeed fan, modulating gas valve, electronic ignition, modulating burner, flow temperature

sensor, thermostat and heat exchanger. The independent operation of these thermal modules

increases each boiler's overall reliability. If a single module requires maintenance or repair, the

other module(s) in the boiler can maintain the system load requirements -- thereby providing a

level of redundancy that was previously only realized in multi-boiler installations.

A photo of the module is shown in Figure 2-2 below. Additional information for the BCM

component can be found in Section 7, 9, and 10.

Figure 2-2: Modulex BCM (Boiler Communications Module)

PR1: 11/30/12 Page 10 of 112

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526- 0288

Page 11

GF-115-C

OMM-0084_0D

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526- 0288

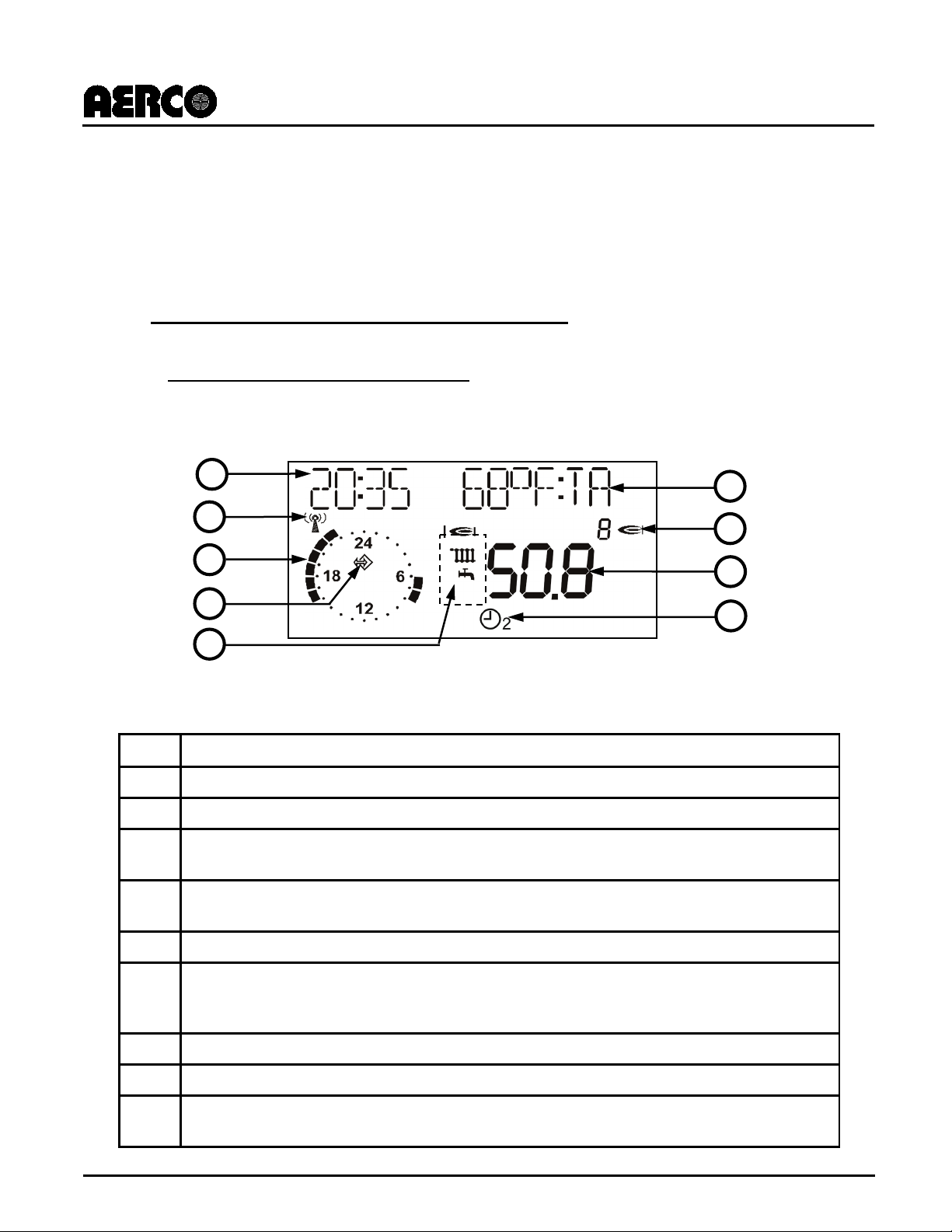

Heating Mode display symbol. The display symbols apply to all internal heating

circuits for which a separate heating mode has been selected. Note that each

H B E

D

I G F C A

3. E8 CONTROLLER OPERATION

The E8 Controller operates in NORMAL Mode when the controller door is closed, which allows

for monitoring the boiler status through the display window and setting the HEATING Mode.

When the door is opened, the unit enters MENU Mode, and in this mode the boiler may be

initialized, configured, and adjusted. The controls and display for the E8 controller are described

in the following sub-sections.

3.1 NORMAL Mode Operation (Door Closed)

When the hinged door is closed on the E8, the unit is in NORMAL Mode.

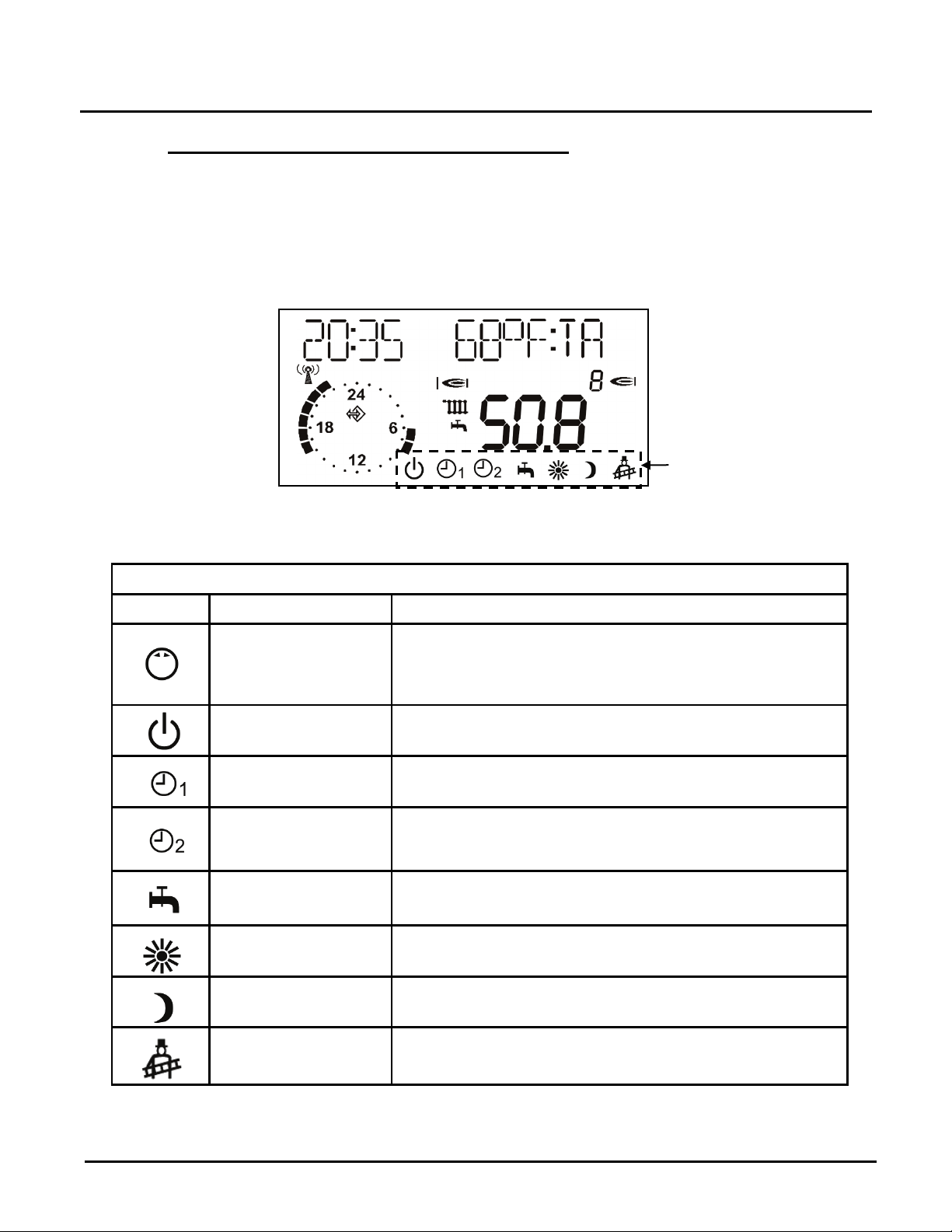

3.1.1 NORMAL Mode Display Functions

Figure 3-1 describes the types of information provided on the LCD display when in NORMAL

Mode (door closed). Note that the display in the illustration is only an example, and that an E8

Controller in service will show information appropriate for its configuration.

Figure 3-1: E8 LCD Display in NORMAL Mode (Door Closed)

E8 Controller Display in NORMAL Mode

Item Functions

A

Current time (24 hour format)

B

DCF reception OK (only if receiver is connected via eBUS)

Display of the active heating program for the first heating circuit (here: 6:00 to 08:00

C

a.m. and 4:00 to 10:00 p.m.)

Bus icon (if this icon does not appear, check data line to connected CAN controllers

D

=> check eBUS via DISPLAY level)

E

Status display: Shows symbols for Internal Burner 1 Relay ON; Heating Mode; Hot Water Preparation.

F

symbol occupies a different space across the display bottom. See Figure 3-2.

G

Display of current temperature of HS 1 or header temperature when cascading.

H

Display of number of active heat generators (only applies when cascading).

Selectable display and Error Codes (refer to "DISPLAY SEL" parameter in the USER

I

menu).

PR1: 02/23/12 Page 11 of 112

Page 12

GF-115-C

Modulex E8 Controller and BCM

Operations and Maintenance Manual

OMM-0084_0D

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526- 0288

SYMBOL

MODE NAME

DESCRIPTION

Turn the Rotary Knob to select the heating mode

heating mode is indicated by a symbol at

the bottom of the display. It takes effect when the setting

is not changed for 5 seconds.

HEATING Mode Symbols:

3.1.2 HEATING Mode Selection (in NORMAL Mode)

Heating modes may be selected using the Rotary Knob on the controller when the hinged door

is in the closed position (NORMAL Mode). As the Rotary Knob is turned, each appropriate

heating mode symbol is displayed, in turn, along the lower edge of the display.

Mode changes take effect when the setting is not changed for 5 seconds. The symbols and

description for the available heating modes are shown in Figure 3-2.

Only currently selected

mode will be displayed.

Figure 3-2: Heating Mode Display Symbols and Description

E8 Controller HEATING Modes

Heating Mode

Selection

Standby / OFF

Automatic Mode 1

Automatic Mode 2

Summer Mode

Day

Mode

Night

Mode

required. The

(Heat OFF and hot water (HW) preparation OFF, only

frost protection mode)

(Heat according to timer program 1; HW according to

HW program)

(Heat according to timer program 2; HW according to

HW program)

(Heating OFF, HW according to HW program)

(24 Hour heating with comfort temperature 1; HW

according to HW program)

(24 Hour heating with reduced temperature; HW

according to program)

Service Mode

PR1: 11/30/12 Page 12 of 112

(Automatic reset after 15 minutes. Boiler regulated at

max boiler temperature)

Page 13

GF-115-C

Modulex E8 Controller and BCM

Operations and Maintenance Manual

OMM-0084_0D

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526- 0288

Insert narrow screwdriver deep into holes and lift up

When lit, this LED indicates that the value shown in the display can be

D

position (10/2 o’clock) screwdriver adjustable switch.

FLOW (in EXPERT/HEAT

F

E

D

C B A

G

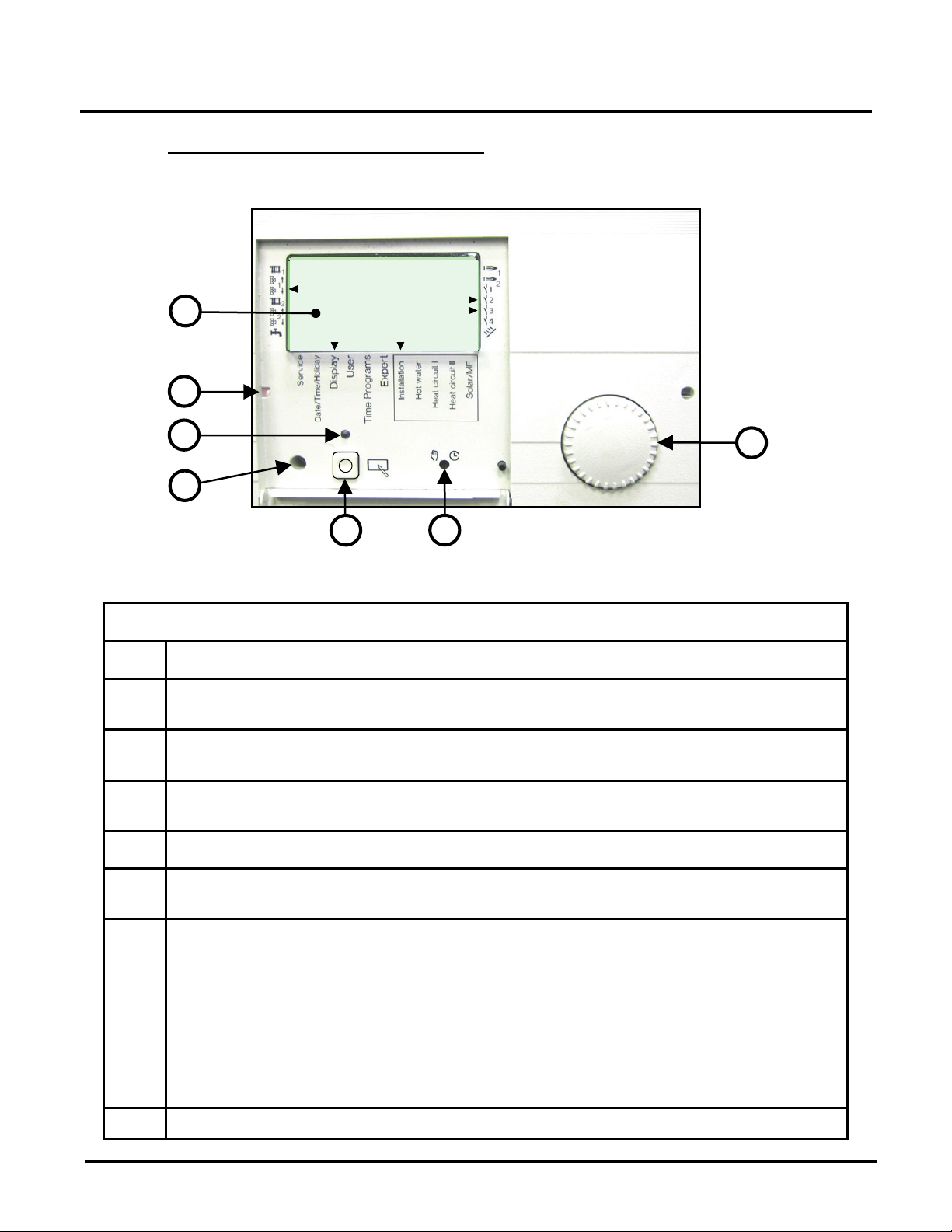

3.1.3 MENU Mode Operation (Door Open)

Opening the E8 controller hinged door reveals the E8 controls (Figure 3-3) and initiates the

MENU Mode, which enables access to an extensive set of software menus.

INSTALLATION

Figure 3-3: E8 Controller Controls (cover open in MENU Mode)

E8 Controller Controls and Indicators

ITEM FUNCTION

A

B

C

E

F

LCD display: Selected Menu/Sub-menus, parameter names/values, and selected

busses are indicated in the LCD display when in MENU Mode.

Mounting Key Access Holes:

controller to remove.

Change LED:

changed using the Rotary Knob (A).

Optical Adaptor: For PC connection

Program Key: Used to select a sub-menu level, select a parameter value to change, or

save a new parameter value.

Manual/Automatic Switch: A 2-

Normally, this switch is set to the Automatic (2 o’clock) position to allow program control

of the boiler. When set to the Manual (10 o’clock) position, a flashing “EMERG –

MODE” message is displayed. Heating Circuit 1 (HC1) pump and the first burner stage

are switched on. Pumps for Heating Circuit 2 (HC2) and Domestic Hot Water (DHW) will

also be switched on if sensors are installed and enabled. The pump(s) will turn off when

the flow temperature reaches the value set for MAX TCIRCUIT 1 menu). The first burner stage will cut off when the boiler temperature

reaches the value set for MAX T-MODUL (in EXPERT/INSTALLATION menu).

G Rotary Knob: Used to navigate through menus and parameters or adjust parameters.

PR1: 11/30/12 Page 13 of 112

Page 14

GF-115-C

Modulex E8 Controller and BCM

Operations and Maintenance Manual

OMM-0084_0D

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526- 0288

INSTALLATION

HOT WATER

HEAT CIRCUIT I

HEAT CIRCUIT II

SOLAR/MF

INSTALLATION

HOT WATER

HEAT CIRCUIT I

HEAT CIRCUIT II

SOLAR/MF

CIRCL TIME

HOTW-PROG

HTG-PROG 1

HTG-PROG 2

INSTALLATION

HOT WATER

HEAT CIRCUIT I

HEAT CIRCUIT II

SOLAR/MF

SERVICE

DATE/TIME

HOLIDAY

CLOCK CHANGE

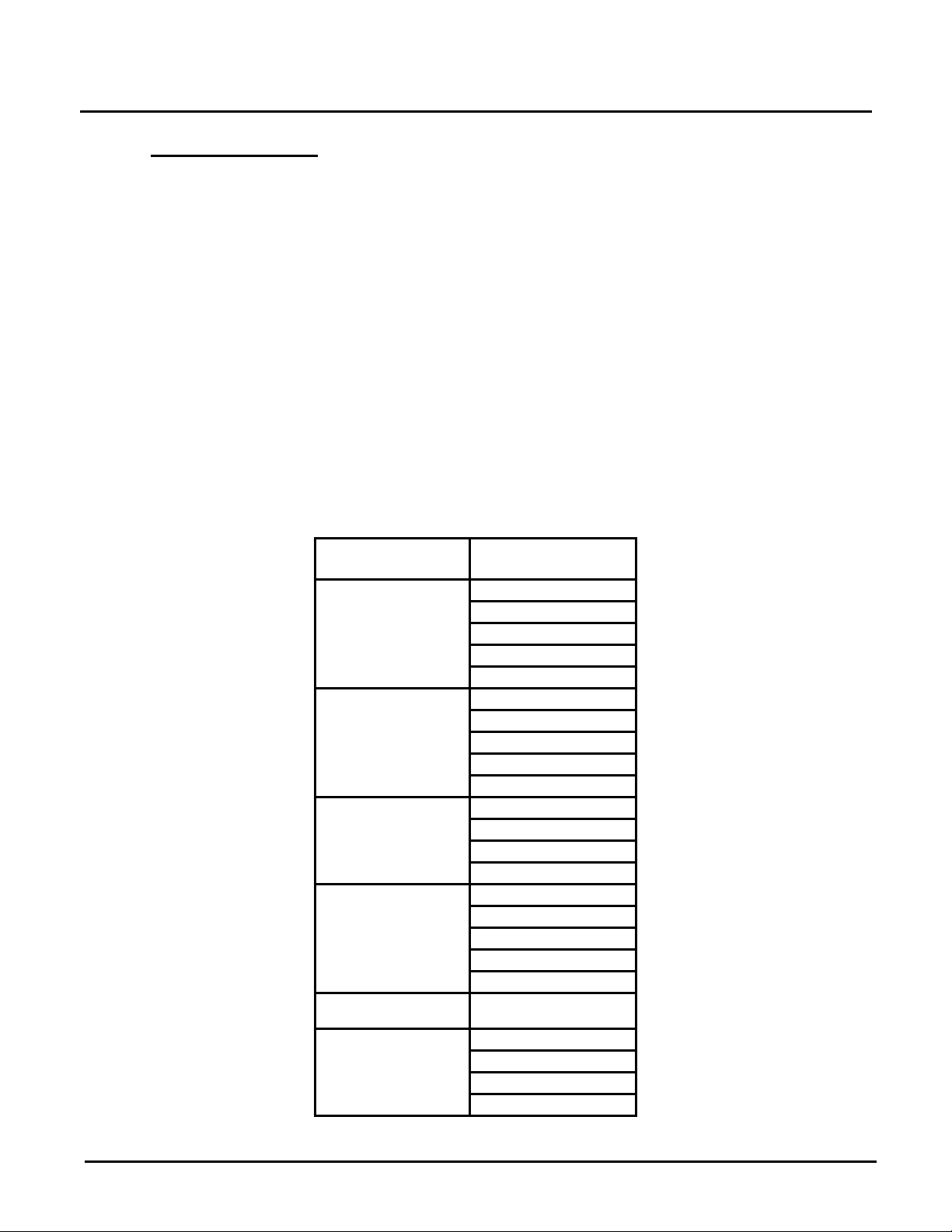

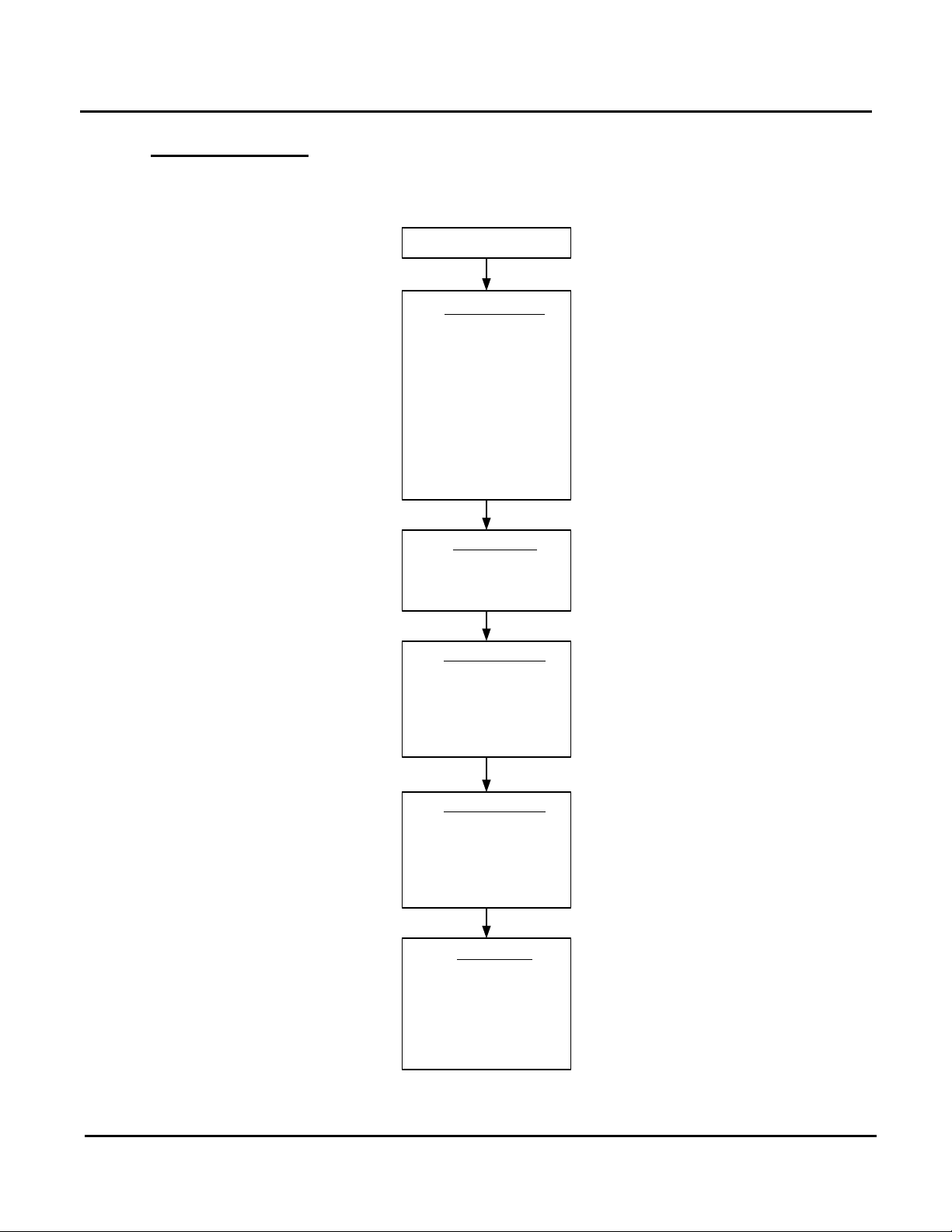

3.2 Software Menus

Software menus are divided into five main menus, each with a set of sub-menus (Table 3-1).

The rotary knob on the front of the E8 Controller is used to sequentially cycle through the

menus and the sub-menus. Two small arrows at the bottom of the display point to the selected

menu and sub-menu name, respectively. Note that some menus and sub-menus are read-only

or not available, according to the boiler used and the initial startup configuration.

NOTE

The menu processing steps presented in this manual assume that all required

(one-time) INSTALLATION menu items have already been entered at setup. It

should be noted that whenever the unit is powered down and then powered up

again, the INSTALLATION menu will reappear. When this occurs, the

INSTALLATION menu items DO NOT need to be reentered. Normally, after entry

of the required initial INSTALLATION menu entries, turning the Rotary Knob

clockwise will automatically advance the Controller to the DISPLAY menu group.

All items in this group are “Read Only” and cannot be changed.

See Sub-section 4.7, E8 Controller Initial Startup for more information about

initial setup and configuration of the E8 Controller.

Table 3-1: Main Menus and Sub-Menus

MAIN MENUS SUB-MENUS

DISPLAY

USER

TIME

PROGRAMS

EXPERT

EXPERT HS

INSTALLATION

GENERAL

PR1: 11/30/12 Page 14 of 112

Page 15

GF-115-C

Modulex E8 Controller and BCM

Operations and Maintenance Manual

OMM-0084_0D

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526- 0288

Points down to

Points right to

Points left to

Points down to

Sub-MENU

MENU

Sub-MENU Name

Selected

Buss(es)

Selected Bus(es)

Selected

Selected

MENU Name

Names

Sub-MENU

Name

Names

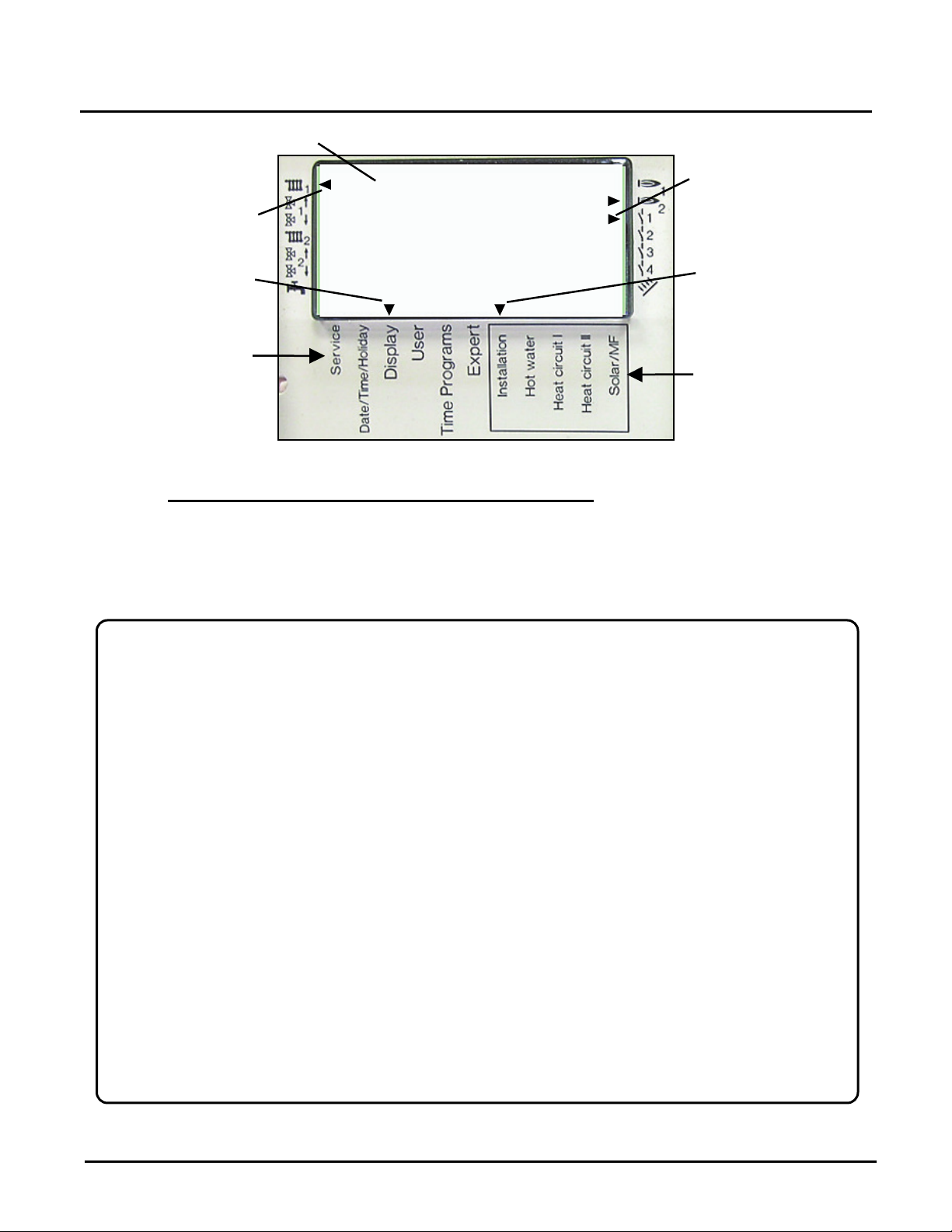

Figure 3-4: E8 Display in MENU Mode (after first opening hinged door)

3.2.1 Basic Menu/Sub-Menu Navigation and Selection

Selected Menu and Sub-menu are indicated by two black arrows at display bottom pointing to

the Menu and Sub-menu names silk-screened below the display (see Figure 3-4).

Following initial startup and one-time entry of the required INSTALLATION menu items (see

E8 Controller Initial Startup, sub-section 4.7), to access, view and/or change menu items

follow these instructions:

Menu/Sub-Menu Navigation and Selection

1. When the ON/OFF switch on the front of the boiler is turned ON and the swing-down hinged

panel is opened, the controller will enter MENU Mode and INSTALLATION will be displayed

(Figure 3-4) in the LCD. This is the initial INSTALLATION menu and it is assumed that all

entries have already been made. See sub-section 4.8 for INSTALLATION menu initial entry

information.

2. Turn the Rotary Knob clockwise until the display advances to the DISPLAY menu. The dial

on the clock face will rotate one revolution counterclockwise and then go off. The display will

then show INSTALLATION, which is the first sub-menu in the DISPLAY menu group (Figure

3-4). The two small black arrows at bottom of the display will point down to the menu and

submenu names, in this case DISPLAY and INSTALLATION, respectively.

3. To view functions included in the INSTALLATION sub-menu, press the Program Key (Item

E, Figure 3-3). If desired, turn the Rotary Knob to scroll through the functions in the

INSTALLATION sub-menu. As previously mentioned, these display functions are read-only

and cannot be changed. Once you reach the end of the sub-menu, RETURN will appear in

the display.

4. To exit this sub-menu and advance to the next sub-menu in the DISPLAY menu, press the

Program Key. INSTALLATION will again be displayed. Turn the Rotary Knob clockwise until

the next sub-menu is displayed.

5. Repeat steps 2, 3 and 4 to view the remaining main menus and their associated sub-menus.

The remaining main menus are: USER, TIME PROGRAM, EXPERT, EXPERT HS (Not

Applicable to Modulex), and GENERAL.

PR1: 11/30/12 Page 15 of 112

Page 16

GF-115-C

Modulex E8 Controller and BCM

Operations and Maintenance Manual

OMM-0084_0D

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526- 0288

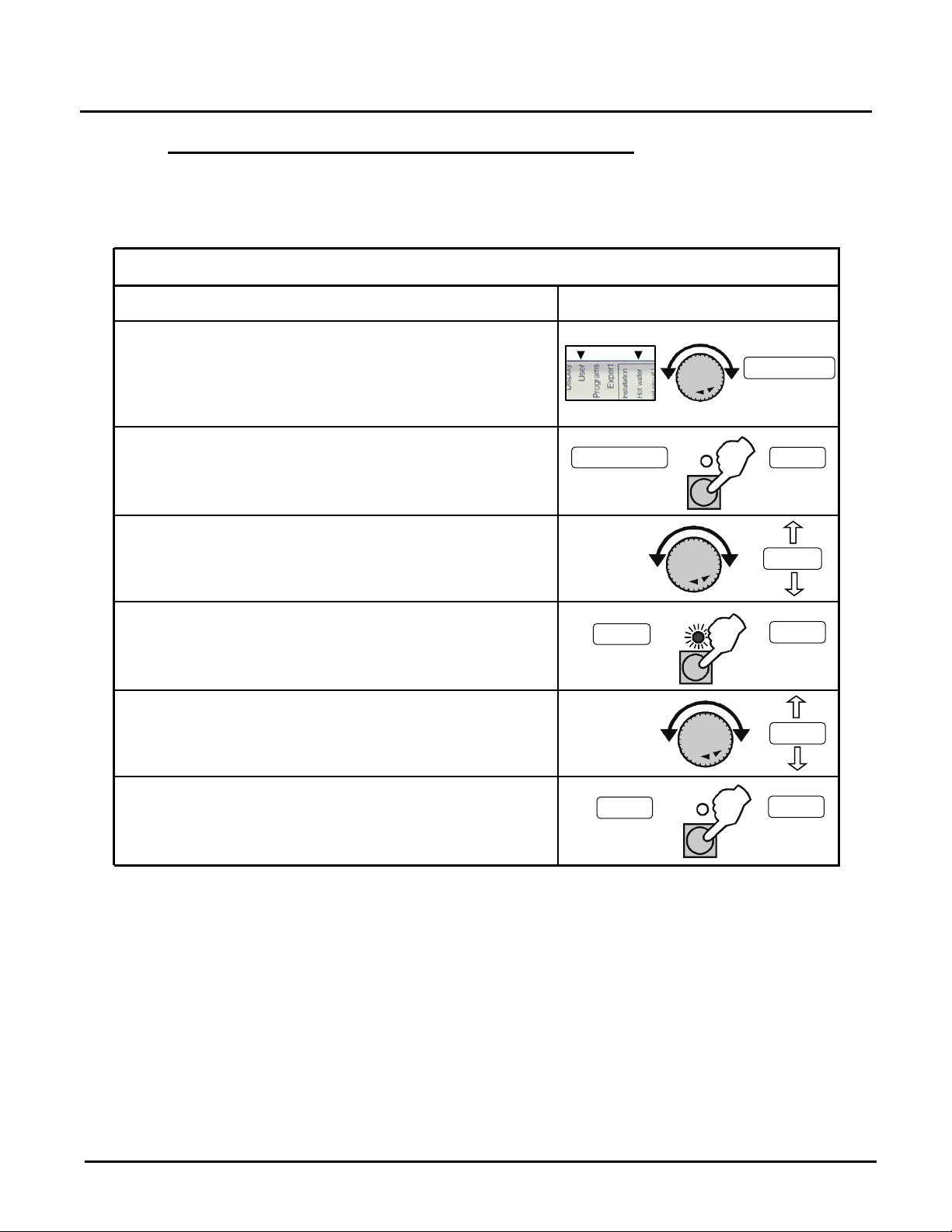

Parameter Change Procedure

Use Rotary Knob to navigate to desired Menu/Sub-

Press Program Key to access parameters in the

selected (displayed) sub-menu.

Turn Rotary Knob to sequence through the available

parameters.

To change a parameter value, press the Program Key

To change the displayed parameter value, turn Rotary

To save the displayed parameter value to the controller

will turn off indicating the new value has been saved.

-

-

T-DHW

displayed

sub-menu

displayed

values

accessed

displayed

value

Displayed

Example: User Menu & Hot Water Sub-menu

parameters

accessed

Cycle thru

cycle thru

push!

push!

push!

Display Detail

Description

Examples

Displayed

Sub-menu

3.2.2 Basic Parameter Navigation, Selection, and Revision

When in the USER, TIME PROGRAM, EXPERT, or GENERAL Main Menu, virtually all sub-

menu items can be changed if the desired. Perform the following steps to access, view, and/or

change menu item parameters:

menu. Menu and sub-menu are indicated by two small

black arrows at bottom of LCD display pointing down to

menu/sub-menu names below display (see Figure 3-

HOT

WATER

HOT-WATER

when desired parameter is displayed. The Change LED

will light up indicating the displayed parameter may now

be changed.

Knob; clockwise to increase value and counterclockwise to decrease the value.

memory, press the Program Key. The Change LED

parameters

T-DHW

parameter

values

142.0

DHW

T

140.0

141.0

142.0

Value Saved!

PR1: 11/30/12 Page 16 of 112

Page 17

GF-115-C

OMM-0084_0D

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526- 0288

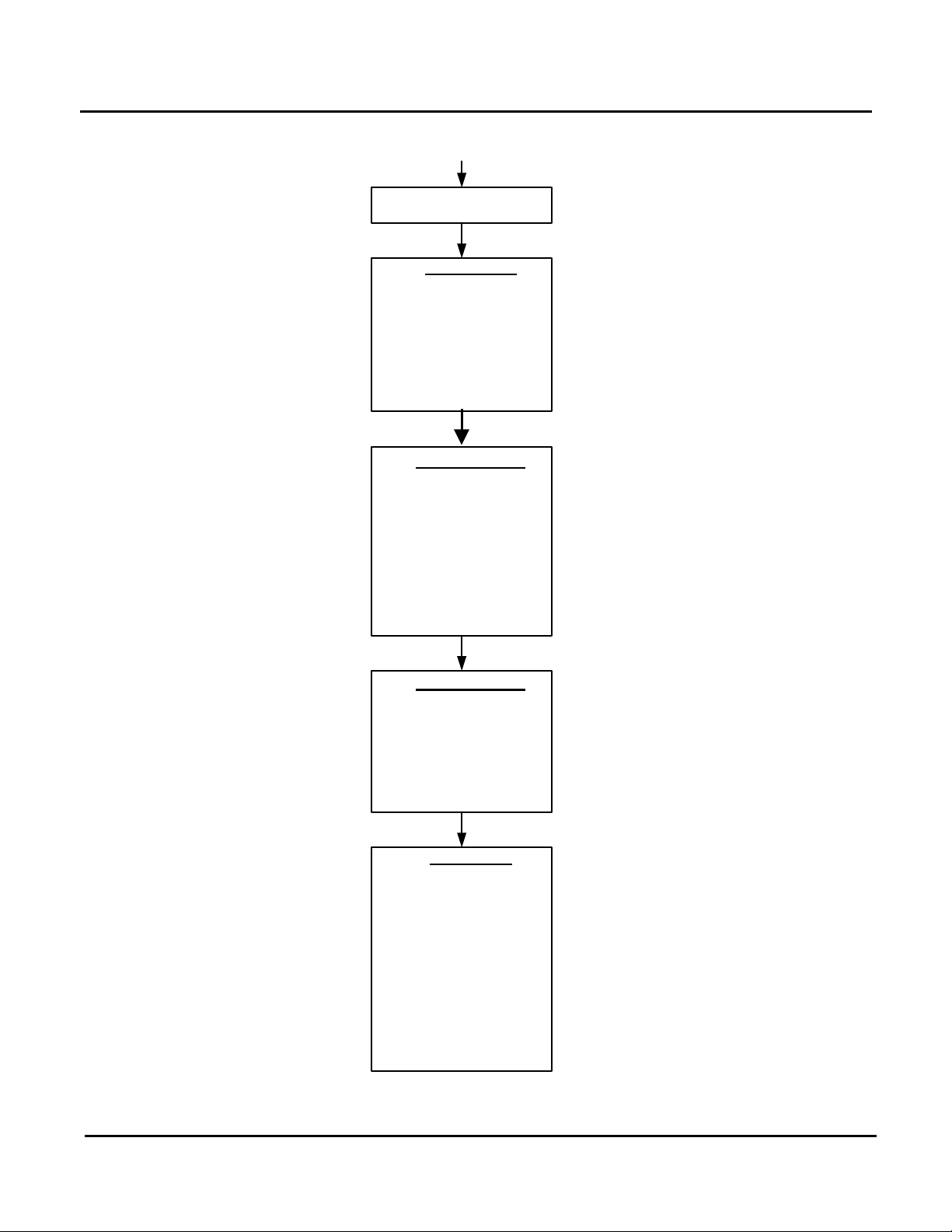

4. E8 CONTROLLER MENUS AND SUB-MENUS

This section provides flow-chart illustrations and tabular listings of all Menu and Sub-Menu functions.

Overall menu hierarchy is shown below:

1. DISPLAY

a. INSTALLATION

b. HOT WATER

c. HEAT CIRCUIT I

d. HEAT CIRCUIT II

e. SOLAR/MF

2. USER

a. INSTALLATION

b. HOT WATER

c. HEAT CIRCUIT I

d. HEAT CIRCUIT II

e. SOLAR/MF

3. TIME PROGRAMS

a. CIRCL TIME

b. HOTW-PROG

c. HTG-PROG 1

d. HTG-PROG 2

4. EXPERT

a. INSTALLATION

b. HOT WATER

c. HEAT CIRCUIT I

d. HEAT CIRCUIT II

e. SOLAR/MF

5. EXPERT HS

a. INSTALLATION

6. GENERAL

a. SERVICE

b. DATE/TIME

c. HOLIDAY

d. CLOCK CHANGE

IMPORTANT!

In the following flow-chart illustrations and tabular listings, descriptions, entry

ranges, and default values are provided for only the commonly used functions

which are referenced in Section 5, titled E8 Operating Mode: Set-Up &

Programming. These commonly used functions are shown in Bold Italics in

the illustrations and tables which follow. Refer to Section 8 for additional

information on functions marked “Not Applicable” in the illustrations and tables

provided.

PR1: 02/23/12 Page 17 of 112

Page 18

GF-115-C

Modulex E8 Controller and BCM

Operations and Maintenance Manual

OMM-0084_0D

DISPLAY

INSTALLATION

T-OUTSIDE

T-EXT DES

T-COLL DES

T-COLLECTOR

T-BOIL

T-SOLID FUEL

T-RETURN 1

T-RETURN 2

T-BUFFER T

T-BUFFER M

T-BUFFER L

T-STORAGE 3

MODGRAD

RETURN

HOT WATER

T-DHW RATED

T-DHW

T-DHW L

RETURN

HTG CIRCUIT 2

T-ROOM DES A

T-ROOM

HUMIDITY

T-FLOW RATED

T-FLOW

N-OPT-TIME

RETURN

SOLAR M/F

T-MF1

T-MF2

T-MF3

T-MF4

T-COLLECTOR

T-DHW

T-DHW L

RETURN

HTG CIRCUIT 1

T-ROOM DES A

T-ROOM

HUMIDITY

T-FLOW RATED

T-FLOW

N-OPT-TIME

RETURN

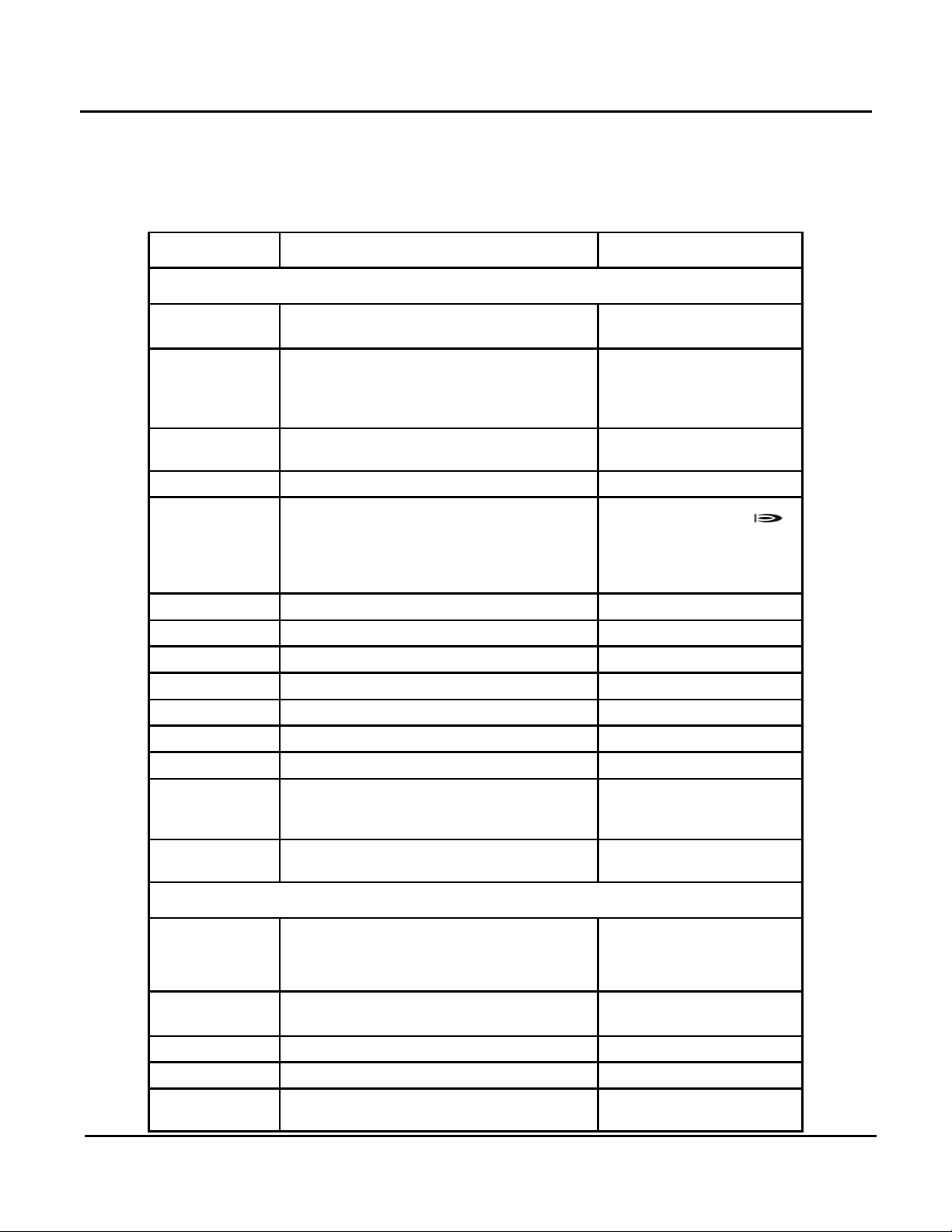

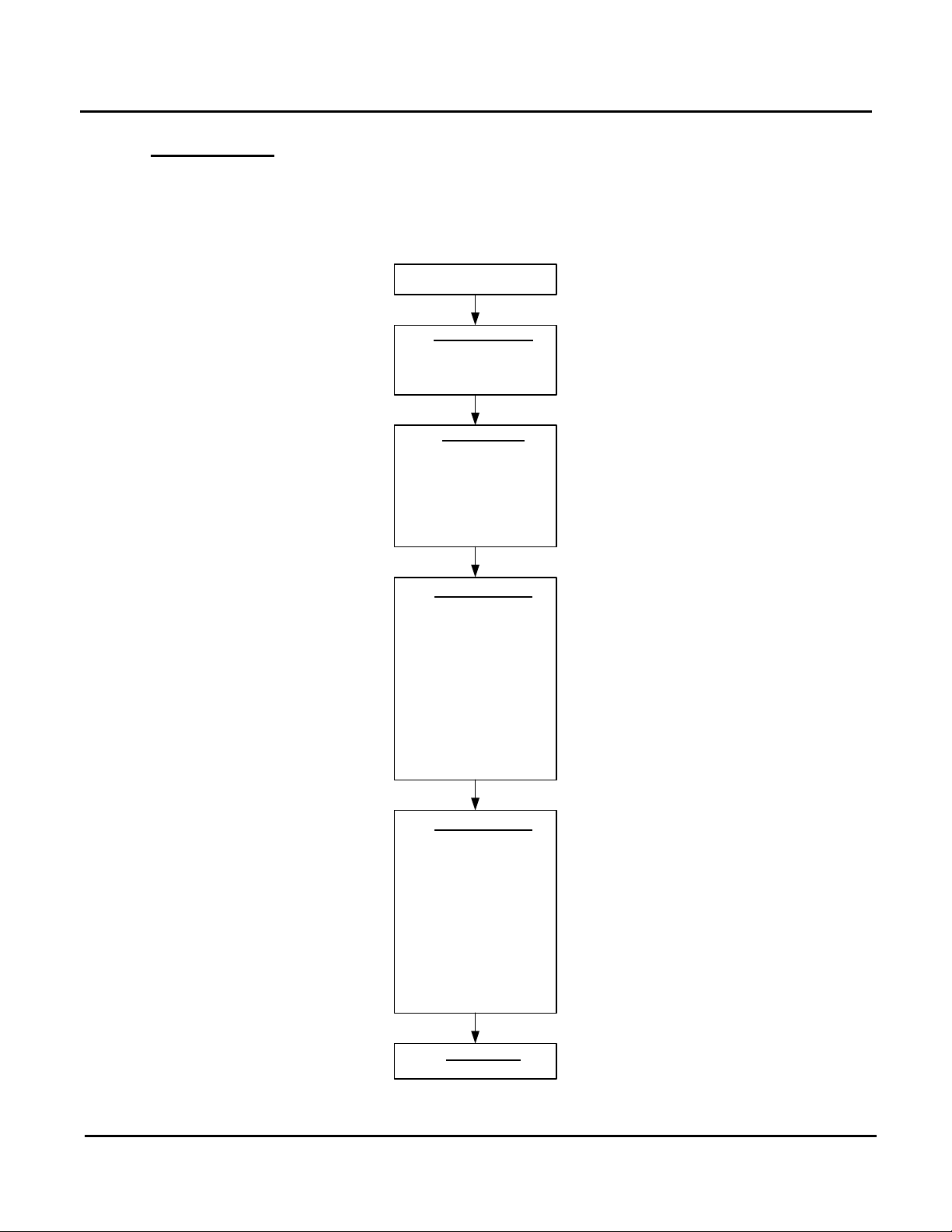

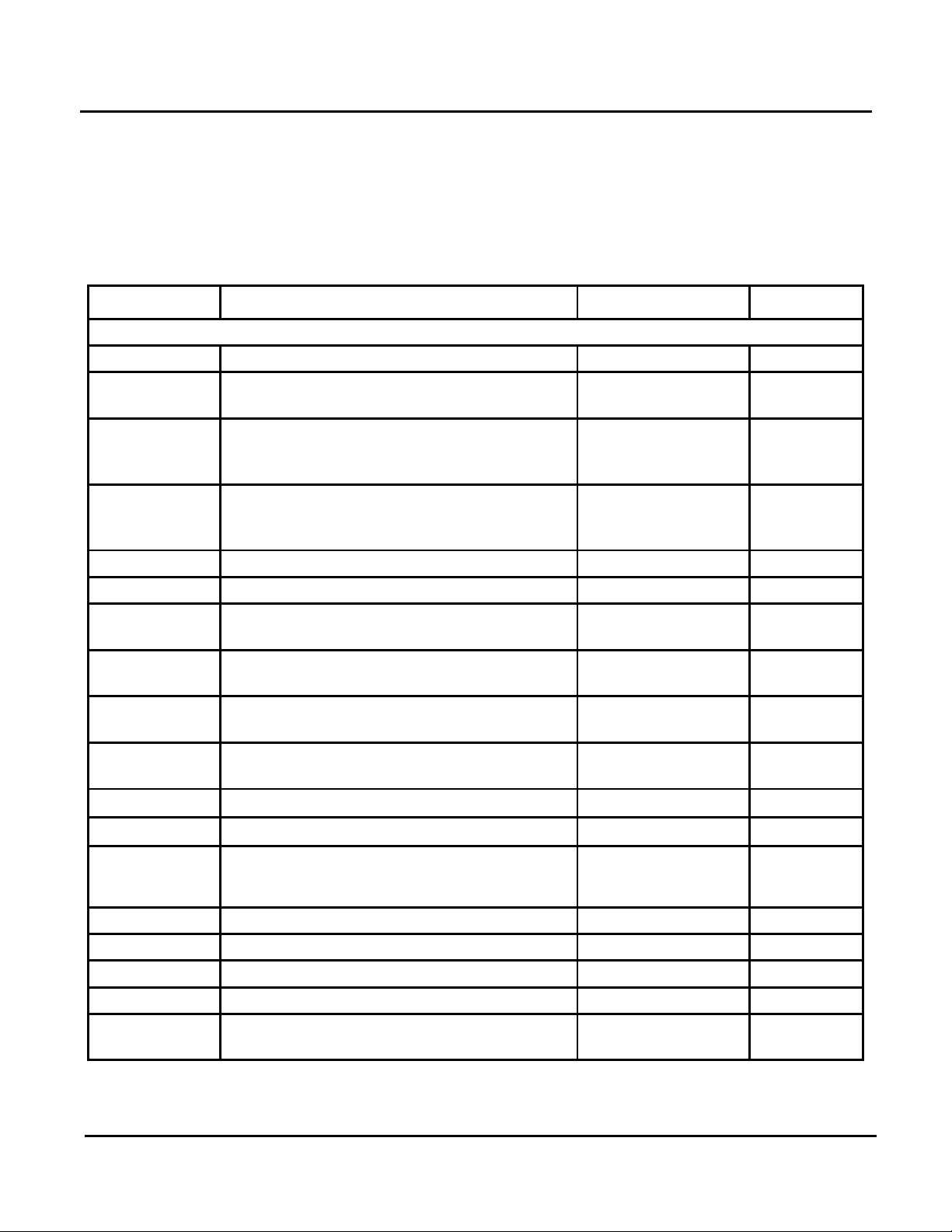

4.1 DISPLAY Menu

The DISPLAY Menu contains an INSTALLATION, HOT WATER, HEATING (HTG) CIRCUIT 1

& 2 and a SOLAR M/F Sub-Menu as shown in Figure 4-1 and in Table 4-1.

Figure 4-1: DISPLAY Menu Flow Chart

PR1: 11/30/12 Page 18 of 112

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526- 0288

Page 19

GF-115-C

Modulex E8 Controller and BCM

Operations and Maintenance Manual

OMM-0084_0D

Boiler Set Point temperature in Indoor/ Outdoor

T-COLLECTOR

sequence between Heat Modules.

Knob to sequence between Heat Modules.

Sub-Menu.

Based on heating prog and

USER/HOT WATER menu.

T-DHW L

Not Applicable

T-CIRCL

Not Applicable

WATER Sub-Menu.

All DISPLAY Menu & Sub-Menu functions are READ ONLY and

cannot be changed. Temperature readings shown are in °F.

FUNCTION DESCRIPTION REMARKS

INSTALLATION Sub-Menu

NOTE

Table 4-1: DISPLAY Menu Listing

T-OUTSIDE Outside air temperature

T-EXT DES

T-COLL DES

T-BOIL

T-SOLID FUEL Not Applicable

T-RETURN 1 Not Applicable

T-RETURN 2 Not Applicable

T-BUFFER T Not Applicable

T-BUFFER M Not Applicable

T-BUFFER L Not Applicable

T-STORAGE 3 Not Applicable

MODGRAD

Boiler Set Point setting in 0 to 10 volt input

mode

Reset and Constant Set Point modes.

Header Set Point temperature (cascade)

Press Program Key to display temperature

and ON/OFF status of individual Heat

Modules (HS) which range from 2 (MLX-

303) to 7 (MLX-1060). Turn Rotary Knob to

Press Prog Key to display Modulation % for

individual Heat Modules (HS). Turn Rotary

Displayed only if outside

air sensor is installed.

A 0 to 10 volt external

input signal can be used to

change the Boiler set

point.

The Burner symbol ( )

is displayed when the

respective Heat Module is

ON.

RETURN

Press Program Key to exit INSTALLATION

HOT WATER Sub-Menu

T-DHW RATED

T-DHW Actual hot water temperature

RETURN

PR1: 11/30/12 Page 19 of 112

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526- 0288

DHW set point temperature

Press Program Key to exit the HOT

operating mode. Actual

DHW set point as set in

Only if tank sensor is

installed

Page 20

GF-115-C

Modulex E8 Controller and BCM

Operations and Maintenance Manual

OMM-0084_0D

FUNCTION

DESCRIPTION

REMARKS

T-DHW

T-FLOW RATED

FLOW

N-OPT-TIME

Not Applicable

CIRCUIT 1 Sub-Menu.

T-MF3

Not Applicable

T-MF4

Not Applicable

1

T-DHW

Not Applicable

T-DHW L

Not Applicable

M/F Sub-Menu.

Table 4-1: DISPLAY Menu Listing (Continued)

HTG CIRCUIT 1 Sub-Menu

T-ROOM DES A Not Applicable

T-ROOM Current room air temperature.

HUMIDITY Room humidity (%).

T-DHW RATED Hot water set point temperature

Current hot water temperature

Current flow set point temperature

Current flow temperature

RETURN

HTG CIRCUIT 2 Sub-Menu

Functions for HTG (Heating) Circuit 2 are identical to HTG Circuit 1 Functions

above.

Press Program Key to exit HTG

Only if indoor sensor is

connected

Only if humidity sensor

is installed and

parameters set for

heating circuit.

Appears only if heating

circuit is programmed

as hot water circuit

Same as above

Not applicable

SOLAR M/F Sub-Menu

T-MF1

T-MF2

T-COLLECTOR

RETURN

PR1: 11/30/12 Page 20 of 112

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526- 0288

Not Applicable

Not Applicable

Not Applicable

Press Program Key to exit SOLAR

Currently not used

Currently not used

Currently not used

Currently not used

Currently not used

Currently not used

Currently not used

Page 21

GF-115-C

Modulex E8 Controller and BCM

Operations and Maintenance Manual

OMM-0084_0D

USER

INSTALLATION

LANGUAGE

CONTRAST

DISPLAY SEL

RETURN

HOT WATER

1X DHW

T-DHW 1

T-DHW 2

T-DHW 3

BOB VALUE

CIRCL-P-DHW

ANTILEGION

RETURN

SOLAR M/F

RETURN

HTG CIRCUIT 1

MODE

T-ROOM DES 1

T-ROOM DES 2

T-ROOM DES 3

T-REDUCED

T-ABSENCE

T-LIMIT DAY

T-LIMIT N

HEATSLOPE

OPTIM HEAT

MAX OPT-TIME

ECONO OPTI

PC ENABLE

RETURN

HTG CIRCUIT 1

MODE

T-ROOM DES 1

T-ROOM DES 2

T-ROOM DES 3

T-REDUCED

T-ABSENCE

T-LIMIT DAY

T-LIMIT N

HEATSLOPE

OPTIM HEAT

MAX OPT-TIME

ECONO OPTI

PC ENABLE

RETURN

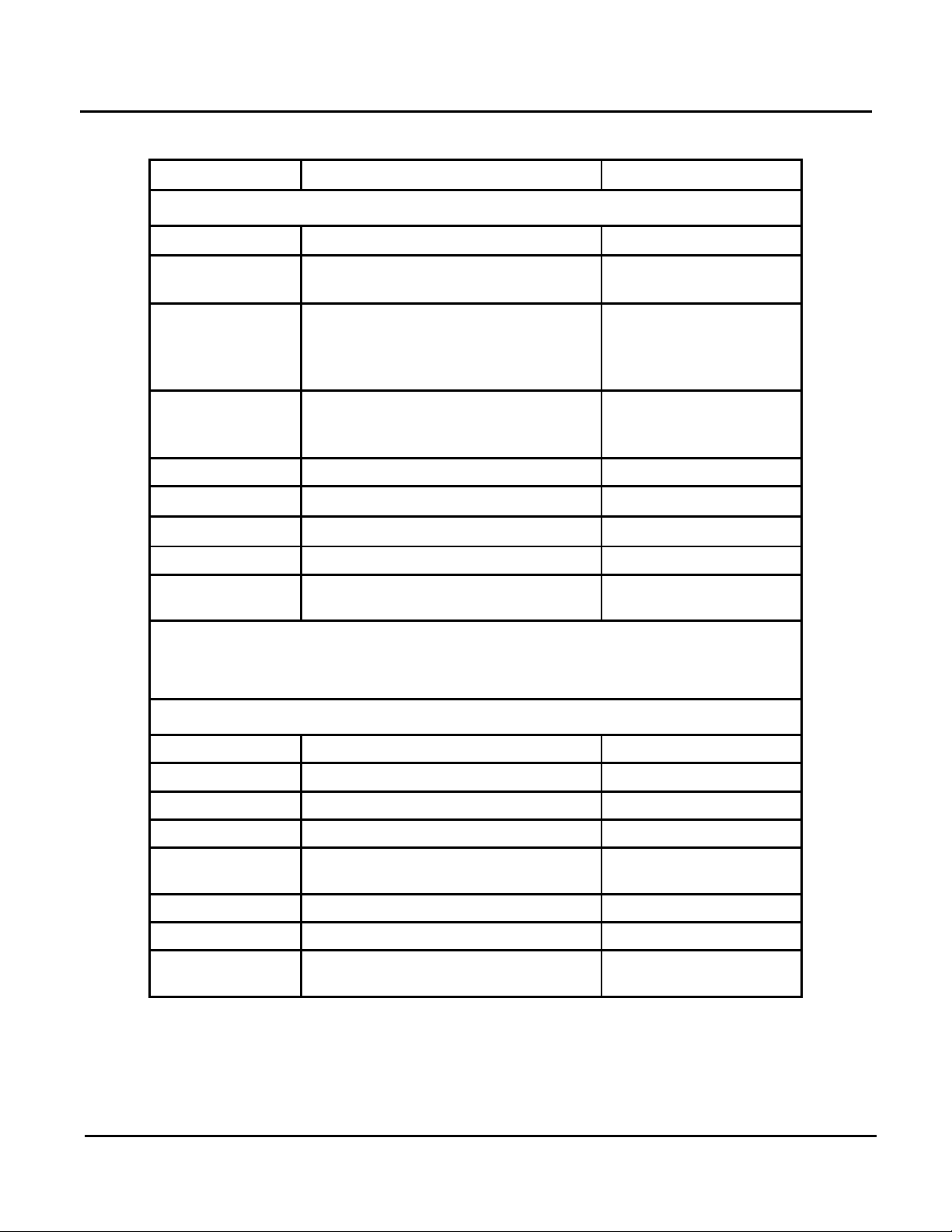

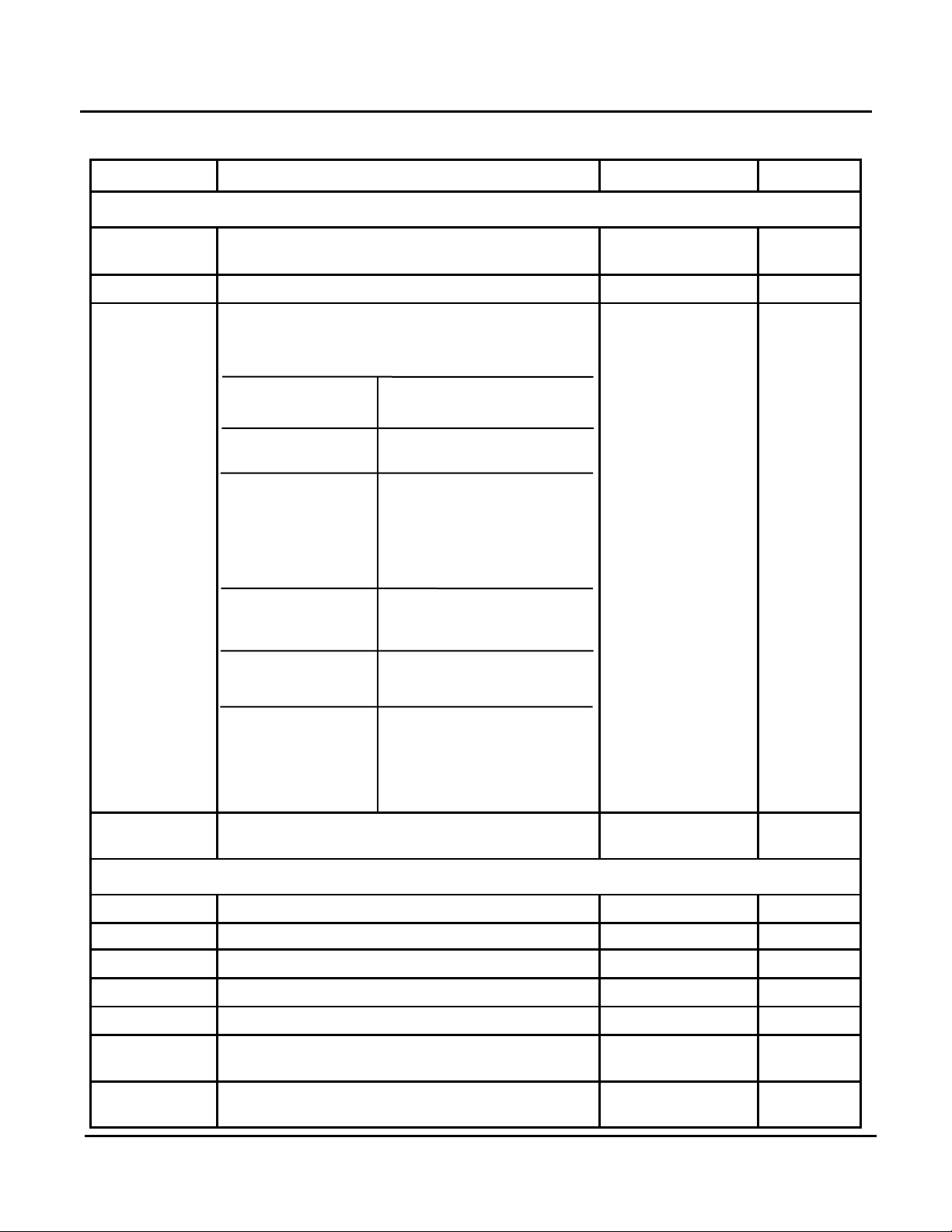

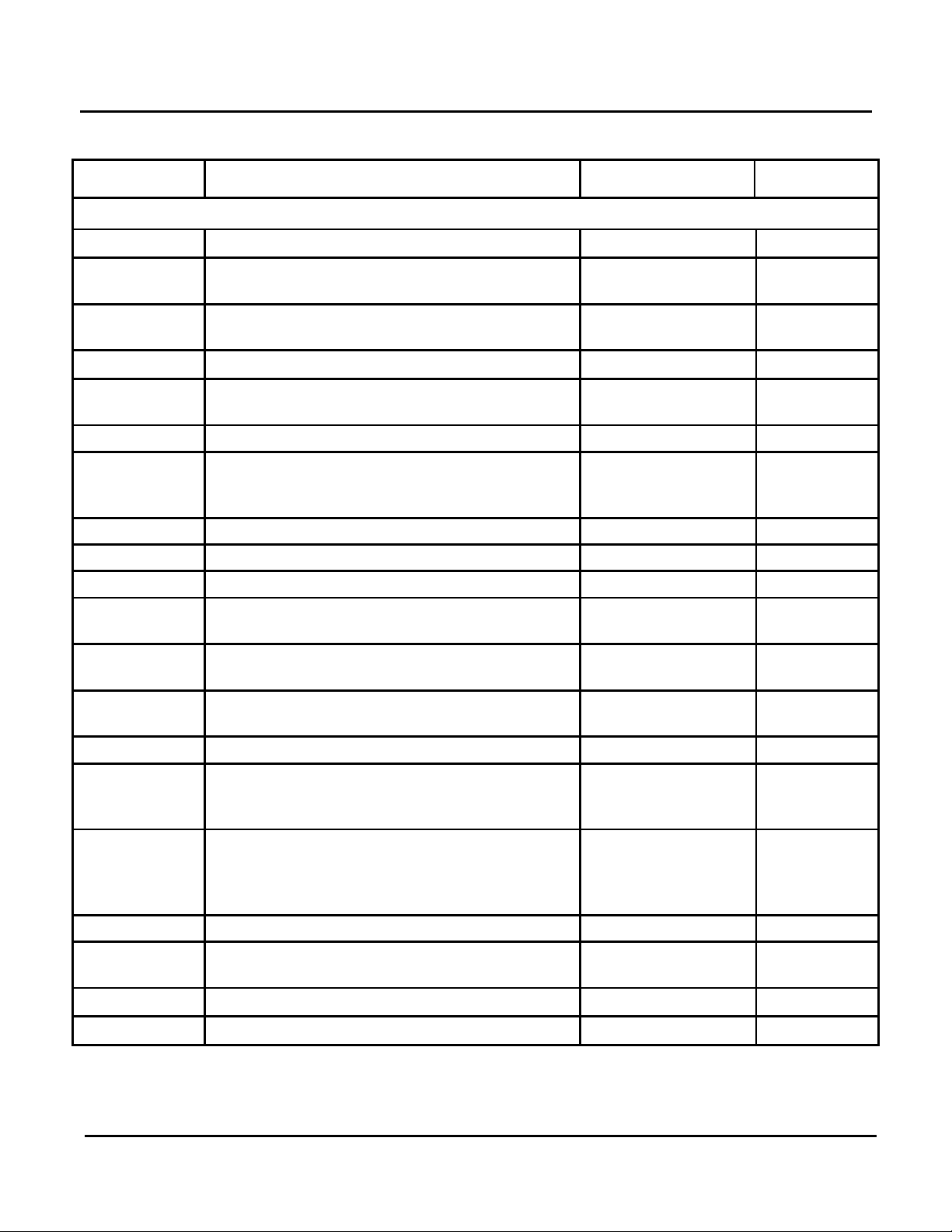

4.2 USER Menu

The USER Menu (Figure 4-2) contains the same Sub-Menus as the DISPLAY Menu.

However, the USER Menu items are not “Read Only” and therefore can be changed. The SubMenu functions in the USER Menu also differ from those contained in the DISPLAY Menu.

Tabular listings for the USER Menu items are provided in Table 4-2.

Figure 4-2: USER Menu Flow Chart

PR1: 11/30/12 Page 21 of 112

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526- 0288

Page 22

GF-115-C

Modulex E8 Controller and BCM

Operations and Maintenance Manual

OMM-0084_0D

CONTRAST

00

Domestic Hot Water

connected).

Menu.

T-DHW 1

Hot Water set point

50°F - 158°F

140°F

T-DHW 2

Not Applicable

T-DHW 3

Not Applicable

DHW

Menu.

Table 4-2: USER Menu Listing

FUNCTION DESCRIPTION ENTRY RANGE DEFAULT

INSTALLATION Sub-Menu

LANGUAGE Selects display language.

Adjusts display contrast

Sets the day of the week or the sensor

temperature (°F) to appear in the display when

the swing-down panel is closed.

Day: SUN – SAT

T-OUTSIDE: Outside Temperature

FLOW TEMP (1/2): Flow Temp. For Heating

Circuit 1 or 2 supply

DISPLAY

SEL

water temperature. (Only

if sensor is installed)

T-DHW:

Temperature.

T-BOILER; Boiler Outlet Temperature.

T-ROOM (1 / 2): Room Temp, Heating

Circuit 1 or 2 (ONLY if

Remote Control is

12 languages are

available.

-20 to 20

ENGLISH

See

DESCRIPTION

Column

- - - -

RETURN

HOT WATER Sub-Menu

1X DHW Not Applicable

BOB-VALUE Not Applicable

CIRCL-P-

RETURN

PR1: 11/30/12 Page 22 of 112

Press Program Key to exit INSTALLATION Sub-

Not Applicable

Press Program Key exit HOT WATER Sub-

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526- 0288

Page 23

GF-115-C

Modulex E8 Controller and BCM

Operations and Maintenance Manual

OMM-0084_0D

Night

T-ROOM DES 1

Not Applicable

T-ROOM DES 2

Not Applicable

T-REDUCED

Not Applicable

T-ABSENCE

Not Applicable

-23.0°F–104.0°F

periods.

-23.0°F–104.0°F

1°F.

OPTIM HEAT

Not Applicable

ECONO OPTI

Not Applicable

PC-ENABLE

Not Applicable

CIRCUIT 1 (or 2) sub-menu.

display to the TIME PROGRAM Menu.

Table 4-2: USER Menu Listing (Continued)

FUNCTION DESCRIPTION ENTRY RANGE DEFAULT

HTG CIRCUIT 1 Sub-Menu

- - - -, Standby,

MODE Displays Timer Mode for Boiler

Auto 1, Auto 2, Day,

- - - -

T-ROOM DES 3

T-LIMIT DAY Applies during day-time heating periods

T-LIMIT N

HEATSLOPE

MAX OPT-TIME

RETURN

HTG CIRCUIT 2 Sub-Menu

Functions for HTG Circuit 2 are identical to HTG Circuit 1 Functions listed above.

Not Applicable

Applies during reduced night-time

Indicate number of degrees that the flow

temperature changes if the outside

temperature increases or decreases by

Not Applicable

Press Program Key to exit HTG

- - - -,

- - - -,

0.00 – 3.00 1.20

66.0°F

50.0°F

SOLAR M / F Sub-Menu (No Functions Currently In This Sub-Menu)

Pressing the Program Key with SOLAR

M/F displayed will change display to

RETURN

PR1: 11/30/12 Page 23 of 112

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526- 0288

RETURN. Press Program Key again to

redisplay SOLAR M/F. Turning the

Rotary Knob clockwise will advance thd

Page 24

GF-115-C

Modulex E8 Controller and BCM

Operations and Maintenance Manual

OMM-0084_0D

TIME PROGRAM

CIRCL TIME

MONDAY

TUESDAY

WEDNESDAY

THURSDAY

FRIDAY

SATURDAY

SUNDAY

MO-FR

SA-SU

MO-SU

RETURN

HOTW-PROG

MONDAY

TUESDAY

WEDNESDAY

THURSDAY

FRIDAY

SATURDAY

SUNDAY

MO-FR

SA-SU

MO-SU

RETURN

HTG-PROG 1

MONDAY

TUESDAY

WEDNESDAY

THURSDAY

FRIDAY

SATURDAY

SUNDAY

MO-FR

SA-SU

MO-SU

RETURN

HTG-PROG 2

MONDAY

TUESDAY

WEDNESDAY

THURSDAY

FRIDAY

SATURDAY

SUNDAY

MO-FR

SA-SU

MO-SU

RETURN

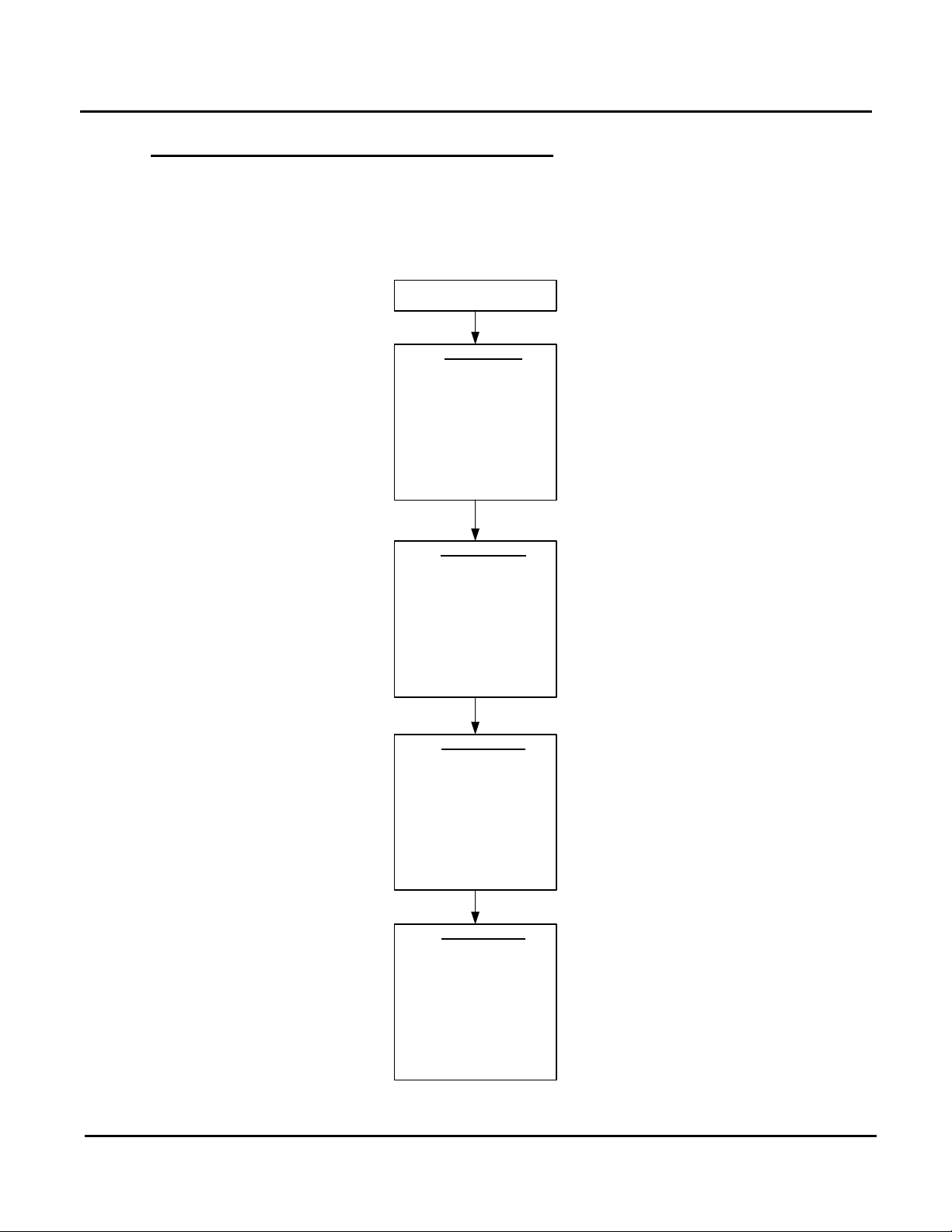

4.3 TIME PROGRAM Menu and Sun-Menus

Day and Time-related functions can be set using the TIME PROGRAM Menu and its

associated Sub-Menus. However, at the present time, none of the Sub-Menus and functions

in the TIME PROGRAM Menu are being utilized. This menu is shown in Figure 4-3.

Refer to Section 8 for additional information on these Menu and Sub-Menu functions.

Figure 4-3: TIME PROGRAM Menu Flow Chart

PR1: 11/30/12 Page 24 of 112

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526- 0288

Page 25

GF-115-C

Modulex E8 Controller and BCM

Operations and Maintenance Manual

OMM-0084_0D

EXPERT

INSTALLATION

CODE-NO

BUS ID HS

BUS ID 1

BUS ID 2

AF SUPPLY

BUS TERM

EBUS SUPPLY

TIME MASTER

MAX T COLL

MIN T COLL

MAX T-HS2

MIN T-HS2

V-CURVE

CURVE 11-U1

CURVE 11-U2

CURVE 11-T1

CURVE 11-T2

CURVE 11-UA

HYSTERESIS

FOUND MODULS

CAP/MODULE

NEW CONFIG

MIN MOD CASC

HW-BOILER

CONTR DEVIAT

DES OUTPUT

BLOCK TIME

MAX T-MODUL

DYN UPWARD

DYN DOWNWARD

RESET TIME

MODULAT MAX

MODULAT MIN

MIN MOD HS

SEQUENCE 1

SEQUENCE 2

SEQU CHANGE

SEQ SW TIME

LOCK TIME

HYST BURNER 2

HS COOL FUNC

T-HS COOL

HEATSOURCE 1

HS1 BUS

HEATSOURCE 2

STORAGE HS 2

BUFFER

RETURN

CONTINUED ON SHEET 2

4.4 EXPERT Menu and Sub-Menus

The EXPERT Menu contains the following Sub-Menus: INSTALLATION, HOT WATER, HEAT

CIRCUIT 1, HEAT CIRCUIT 2 and SOLAR M/F as shown in Figure 4-4. As this figure shows,

the EXPERT Menu includes an extensive list of Sub-Menu functions, particularly in the

INSTALLATION Sub-Menu. Tabular listings for the EXPERT Menu and Sub-Menu items are

provided in Table 4-3.

Whenever “CODE NO.” is displayed, it indicates that the valid password must be entered. This

is accomplished by entering code 0000 (four zeros) by pressing the Program Key four (4)

times.

PR1: 11/30/12 Page 25 of 112

Figure 4-4: EXPERT Menu Flow Chart (Sheet 1 of 2)

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526- 0288

Page 26

GF-115-C

Modulex E8 Controller and BCM

Operations and Maintenance Manual

OMM-0084_0D

EXPERT

HTG CIRCUIT 1

HC FUNCTION

PUMP MODE

MIXER OPEN

MIXER CLOSE

MAX T-FLOW

MIN T-FLOW

T-FROST PROT

OUT-TEMP-DEL

SLOPE OFFSET

B-HEAT SINK

RETURN

HOT-WATER

DHW RELIEF

PARALLEL

T-BOILER DHW

HYST DHW

DHW FOLLOWUP

THERM INPUT

WALL HUNG

LOAD THROUGH

RETURN

HTG CIRCUIT 2

HC FUNCTION

PUMP MODE

MAX T-FLOW

MIN T-FLOW

T-FROST PROT

OUT-TEMP-DEL

B-HEAT SINK

RETURN

SOLAR M/F

RELAY FUNC 1

T-MF 1 SETP

MF1 HYST

RELAY FUNC 2

T-MF 2 SETP

MF2 HYST

RELAY FUNC 3

T-MF 3 SETP

MF3 HYST

RELAY FUNC 4

T-MF 4 SETP

MF4 HYST

F15 FUNCTION

RETURN

CONTINUED FROM SHEET 1

Figure 4-4: EXPERT Menu Flow Chart (Sheet 2 of 2)

PR1: 11/30/12 Page 26 of 112

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526- 0288

Page 27

GF-115-C

Modulex E8 Controller and BCM

Operations and Maintenance Manual

OMM-0084_0D

INSTALLATION Sub-Menu

CODE-NO

Permits entry of valid Code No.(0000)

0000 - 9999

0000

the boiler

CHANGE

numbers must not be assigned twice.

be assigned twice.

AF SUPPLY

Outdoor sensor power supply

00, 01 (OFF/ON)

01 (ON)

BUS TERM

Bus terminating resistor (Must be set to 01)

00, 01 (OFF/ON)

01 (ON)

SUPPLY

MASTER

point temperature.

temperature.

0 to 10 Volt input Voltage curves. Choose

customize a curve.

CURVE 11-U1

Low voltage setting

0.00V – 10.00V

0.000

CURVE 11-U2

High voltage setting

0.00V – 10.00V

10.00

CURVE 11-T1

Minimum set point temperature

32.0°F – 248.0°F

59.0°F

CURVE 11-T2

Maximum set point temperature

32.0°F – 248.0°F

185.0°F

this setting will stop/start the Boiler.

NOTE

Whenever “CODE NO.” is displayed, it indicates that the valid

password must be entered. This is accomplished by entering code

0000 (four zeros) by pressing the Program Key four (4) times.

Table 4-3: EXPERT Menu Listing

FUNCTION DESCRIPTION ENTRY RANGE DEFAULT

BUS ID HS

BUS ID 1

BUS ID 2

EBUS

TIME

MAX T-COLL

MIN T-COLL

MAX T-HS2

MIN T-HS2

BUS ID HS MUST be set to - - - - to operate

The heating circuits are sequentially

numbered starting with „01“, heating circuit

Heating circuits are sequentially numbered

starting with “01“, heating circuit numbers must not

Switches the Ebus supply ON/OFF 00, 01 (OFF/ON) 01 (ON)

Not Applicable

Sets the maximum allowable header set

Sets the minimum allowable header set point

Not Applicable

Not Applicable

01 - 08

(00), 01 – 15 01

(00), 01 – 15 - - - -

86.0°F – 230.0°F 185.0°F

50.0°F – 176.0°F 50.0°F

DO NOT

V-CURVE

CURVE 11-UO

from preset curves (see para. 3.5.1) or

Stop/Start voltage level. Going below/above

PR1: 11/30/12 Page 27 of 112

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526- 0288

00 – 11 11

0.00V – 10.00V 1.00

Page 28

GF-115-C

Modulex E8 Controller and BCM

Operations and Maintenance Manual

OMM-0084_0D

(Continued)

HYSTERESIS

Not Applicable

–

MODULS

for service.

module.

NEW CONFIG

Not Applicable

CASC

HW-BOILER

Not Applicable

00 – 08

00

actual water temperature.

DES OUPUT

Required system output [in %]

0 – 100%

00

SWITCH TIME

Not Applicable

(N/A)––

(N/A)

BLOCK TIME

Not Applicable

(N/A)

(N/A)

MODUL

UPWARD

DOWNWARD

RESET TIME

Not Applicable

5 – 500

50

after the delay time elapses.

off

MIN MOD HS

Not Applicable

0% - 60%

35%

HW

SEQUENCE 1

SEQUENCE 2

Boiler sequence 2

87654321

Table 4-3: EXPERT Menu Listing (Continued)

FUNCTION DESCRIPTION ENTRY RANGE DEFAULT

INSTALLATION Sub-Menu

FOUND

CAP/MODULE

MIN MOD

CONTR

DEVIAT

MAX T-

DYN

DYN

Displays the number of heat modules available

Displays the maximum Kw output of each heat

Not Applicable 01 – 08 01

Control Deviation indicates the temperature

difference between the Boiler set point and the

Maximum temperature of Heat Module 122.0°F to 230.0°F 194.0°F

Not Applicable (N/A) (N/A)

Not Applicable (N/A) (N/A)

Display

00 – 1000 Kw 40 Kw

Display °F

MODULAT

MAX

MODULAT

MIN

MOD LEVEL

PR1: 11/30/12 Page 28 of 112

Start Level. If this modulation percentage is

exceeded, the next heat module is connected

Stop Level. If value drops below this

modulation percentage, the last heat generator

(module) of the current sequence is switched

Not Applicable

Boiler sequence 1 12345678

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526- 0288

50% - 100% 30%

10% - 60% 35%

Page 29

GF-115-C

Modulex E8 Controller and BCM

Operations and Maintenance Manual

OMM-0084_0D

ENTRY

RANGE

SEQU CHANGE

Sequence change mode

01 – 06

06

SEQ SW TIME

Time to sequence change (hours)

10 – 800

200

LOCK TIME

Not Applicable

00 min – 30 min

00

HYST BURNER2

Not Applicable

–

T-HS COOL

Not Applicable

Identification of Boiler Type being used:

06 = Multi-Stage, modulating (cascade via BUS)

Heat Source

HEATSOURCE 2

Not Applicable

N/A–

N/A

STORAGE HS2

Not Applicable

N/A–

N/A

BUFFER

Not Applicable

N/A

N/A

SCREED

Not Applicable

N/A

N/A

SCREED PROGR

Not Applicable

N/A

N/A

RETURN

Press Program Key to exit INSTALLATION Sub-Menu.

HOT WATER Sub-Menu

DHW RELIEF

Not Applicable

N/A

N/A

02 = Pump Parallel Running

DHW)

HYST DHW

Hot Water Hysteresis

48°F – 129°F

48°F

min.

Storage Tank With Thermostat = 01

WALL HUNG

Not Applicable

LOAD THROUGH

Not Applicable

RETURN

Press Program Key to exit HOT WATER Sub-Menu.

Table 4-3: EXPERT Menu Listing (Continued)

FUNCTION DESCRIPTION

DEFAULT

INSTALLATION Sub-Menu (Continued)

HS COOL-FCT Not Applicable

00 = No Boiler

HEATSOURCE 1

HS 1 BUS

01 = Single-Stage, switching

02 = Single-Stage, modulating

03 = 2-Stage, switching

04 = 2 individual, switching

05 = Multi-Stage, switching

Communication connection between Controller and

See

DESCRIPTION

00 – 04 02

06

(Multi-Stage

Modulating)

Parallel pump operation.

PARALLEL

T-BOILER DHW

DHW FOLLOWUP Pump Run-Down Time

THERM INPUT

PR1: 11/30/12 Page 29 of 112

00 = Hot Water Priority

01 = Hot Water Partial Priority

Boiler temperature increase during Hot Water

operation.

Boiler Temp = (DHW Temp Setting) + (T-BOILER

Storage Tank With Sensor = 00

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526- 0288

00, 01, 02

32°F – 194°F 97°F

00 min. – 30

00, 01

01

00 min.

00

Page 30

GF-115-C

Modulex E8 Controller and BCM

Operations and Maintenance Manual

OMM-0084_0D

ENTRY

RANGE

mixing valve.

Circulation pump mode control for

03 = Continuous pump operation

MIXER CLOSE

Maximum allowable water temperature

setting for the heating circuit.

Minimum allowable water temperature

setting for the heat circuit.

Specifies the minimum allowable outside

INSTALLATION Mode)

DEL

OFFSET

B-HEAT SINK

Not Applicable

N/A

N/A

Press Program Key to exit HEAT

CIRCUIT 1 (or 2) Sub-Menu.

Table 4-3: EXPERT Menu Listing (Continued)

FUNCTION DESCRIPTION

HEAT CIRCUIT 1 & 2 Sub-Menus

The Sub-Menu Functions for HEAT CIRCUIT 1 & HEAT CIRCUIT 2 are identical, except for

the MIXER OPEN & MIXER CLOSE Functions which apply only to HEAT CIRCUIT 1. The

Function values in this Sub-Menu level will change, depending on the Heat Circuit Function

(HC FUNCTION) selected.

Heat Circuit Function defines type of

circuit:

00 = Standard Heat Circuit

01 = Control to fixed flow temperature

HC FUNCTION

PUMP MODE

02 = Swimming pool control (HC 2

ONLY)

03 = Hot Water Circuit

04 = Return flow temp. Increase via

ON/OFF switching of pumps.

00 = Standard pump control

01 = Pump switching per heating limits

02 = Pump switching per heating program

00 – 04

00 – 03 00

DEFAULT

00

(Standard

Heat

Circuit)

MIXER OPEN

MAX T-FLOW

MIN T-FLOW

T-FROST PROT

OUT-TEMP-

SLOPE

RETURN

Not Applicable

Not Applicable

air temperature setting for the Frost

Protection Mode. If temperature drops

below this value, the system switches to

the Frost Protect Mode and the pumps

are switched ON.

(This Function should be set to 0°F in the

Not Applicable N/A N/A

Not Applicable N/A N/A

68°F – 230°F 176°F

50°F – 230°F 50°F

-5°F – 41°F 32°F

PR1: 11/30/12 Page 30 of 112

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526- 0288

Page 31

GF-115-C

Modulex E8 Controller and BCM

Operations and Maintenance Manual

OMM-0084_0D

ENTRY

RANGE

SOLAR M/F Sub-Menu

FUNCTION

SET TEMP

HYST (1-4)

02 = Light sensor

Sub-Menu.

Table 4-3: EXPERT Menu Listing (Continued)

FUNCTION DESCRIPTION

MF (1-4)

MF (1-4)

MF (1-4)

F15 FUNCTION

RETURN

Not Applicable

Not Applicable

Not Applicable

F15 Function

00 = Room Sensor for Heating Circuit 2

01 = 0 – 10V iInput

Press Program Key to exit SOLAR M/F

00 -02 00

DEFAULT

4.4.1 Available V-Curve Preset Voltage Curves for 0 – 10 Volt Input

The following listing (Table 4-4) shows the available preset V-Curve settings for operation in

the 0 to 10 Volt Mode:

Table 4-4: V-Curve Preset Voltage Curves for 0 – 10 Volt Input

CURVE NO. U1 U2 T1 T2 UO

0 2.0 V 10.0 V 32°F 194°F 2.0 V

1 2.5 V 0.3 V 100°F 176°F 5.0 V

2 2.5 V 0.3 V 100°F 167°F 5.0 V

3 2.5 V 0.3 V 100°F 113°F 5.0 V

4 4.0 V 0.1 V 68°F 185°F 5.0 V

5 4.0 V 0.1 V 68°F 167°F 5.0 V

6 4.0 V 0.1 V 68°F 131°F 5.0 V

7 4.0 V 0.1 V 68°F 189°F 5.0 V

8 4.0 V 0.1 V 68°F 189°F 5.0 V

9 4.0 V 0.1 V 68°F 163°F 5.0 V

10 4.0 V 0.1 V 68°F 127°F 5.0 V

11 4.0 V 0.1 V 68°F 194°F 5.0 V

PR1: 11/30/12 Page 31 of 112

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526- 0288

Page 32

GF-115-C

Modulex E8 Controller and BCM

Operations and Maintenance Manual

OMM-0084_0D

DATE/TIME

HOLIDAY

YEAR START

MONTH START

DAY START

YEAR STOP

MONTH STOP

DAY STOP

TIME-DATE

TIME (MIN)

TIME (HOUR)

YEAR

MONTH

DAY

RETURN

CLOCK CHANGE

MONTH START

DAY START

MONTH STOP

DAY STOP

4.5 EXPERT HS Menu (Not Used)

(Not applicable to Modulex boilers)

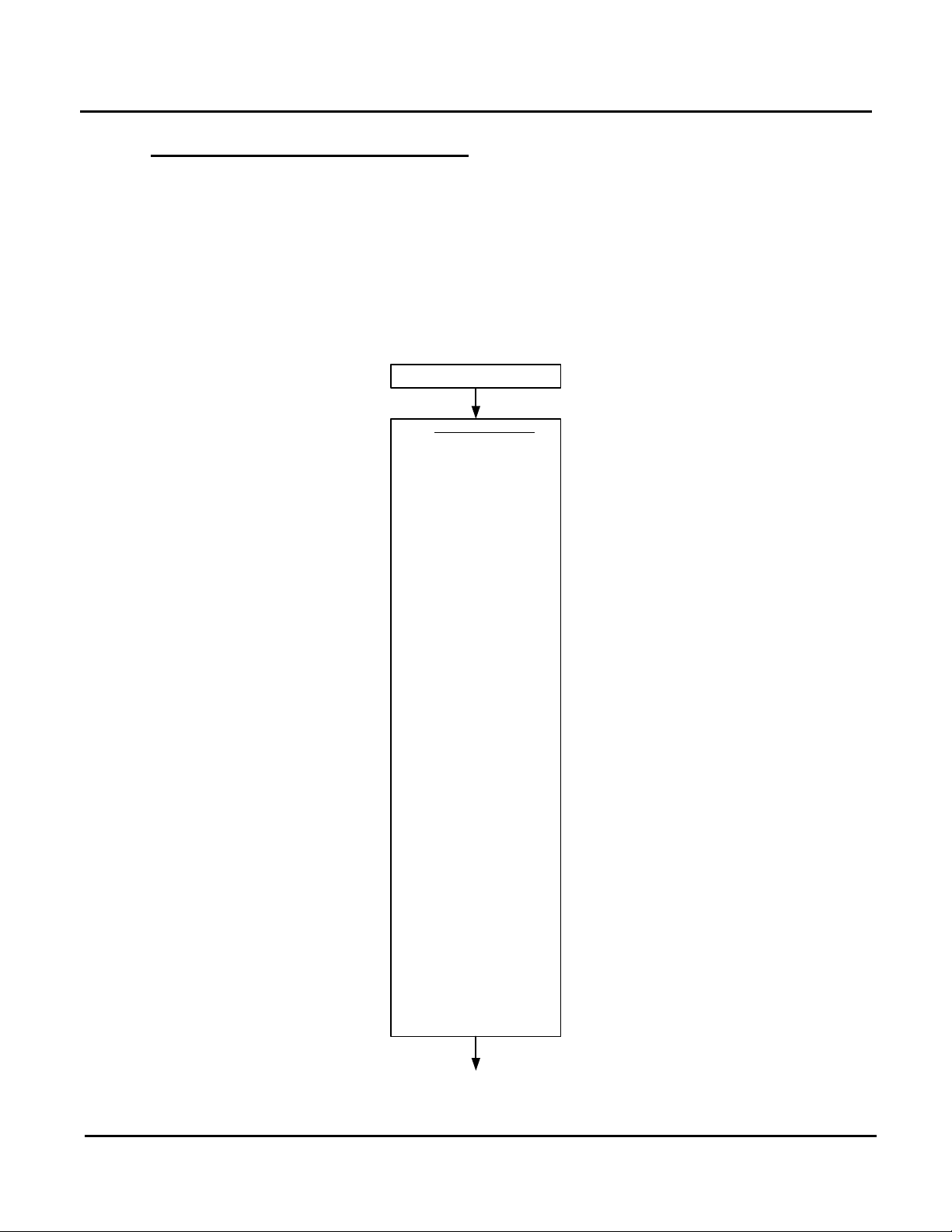

4.6 GENERAL Menu

The GENERAL Menu contains a DATE/TIME Menu and a SERVICE Menu.

4.6.1 DATE / TIME Menu

This Sub-Menu is used to set the time, date, holiday (vacation) schedule and, where

necessary, enter clock change settings (daylight savings time, etc). The DATE/TIME menu

functions are illustrated and described in Figure 4-5 and Table 4-5.

PR1: 11/30/12 Page 32 of 112

Figure 4-5: DATE/TIME Menu Flow Chart

NOTE

All items in the following DATE/TIME Menu must be entered in sequence.

Press the Program Key to step through the menu functions. Use the Rotary

Knob to adjust/change entries. Press the Program Key to store entries and

sequence to the next function

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526- 0288

Page 33

GF-115-C

Modulex E8 Controller and BCM

Operations and Maintenance Manual

OMM-0084_0D

TIME

Set current time (min., hours)

00:00 – 24:00

YEAR

Set current year

XXXX

MONTH

Set current month

01 – 12

DAY

Set currrent day

01 – 31

YEAR

Set current holiday start year

XXXX

START

DAY START

Set current holiday start day

01 – 31

YEAR STOP

Set current holiday end year

XXXX

STOP

DAY STOP

Set current holiday end day

01 – 31

START

DAY START

Set clock change start day

01 – 31

MONTH END

Set clock change end month

01 – 12

DAY END

Set clock change end day

01 – 31

Key.

Table 4-5: DATE / TIME Menu Listing

FUNCTION DESCRIPTION ENTRY RANGE

TIME – DATE Sub-Menu

This Sub-Menu is used to set the time, date, holiday schedule and, where necessary, enter

clock change settings (daylight savings time, etc).

HOLIDAY Sub-Menu

This Sub-Menu sets the start and end dates for Holiday (Vacation) periods where no heat or

hot water is required.

MONTH

MONTH

CLOCK CHANGE Sub-Menu

This Sub-Menu is used in areas where seasonal time changes are required for “Daylight

Savings“, etc.

MONTH

RETURN

Set current holiday start month 01 – 12

Set current holiday end month 01 – 12

Set clock change start month 01 -12

When CLOCK CHANGE reappears, press Program

PR1: 11/30/12 Page 33 of 112

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526- 0288

Page 34

GF-115-C

Modulex E8 Controller and BCM

Operations and Maintenance Manual

OMM-0084_0D

SERVICE

SENSOR TEST

F1

F2

F3

F5

F6

F8

F9

F11

F12

F13

F14

RELAY TEST

CODE NO

01 - 11

SW NO 259-04

BURNER TIME

BURNER START

LIMITER TEST

SERVICE

RESET USER

RESET EXPERT

RESET PRG

RETURN

RETURN

CASCADE MANU

BOILER 01 – 00%

BOILER 02 – 00%

BOILER 03 – 00%

BOILER 04 – 00%

BOILER 05 – 00%

BOILER 06 – 00%

BOILER 07 – 00%

BOILER 08 – 00%

BOILER INT – 00%

RETURN

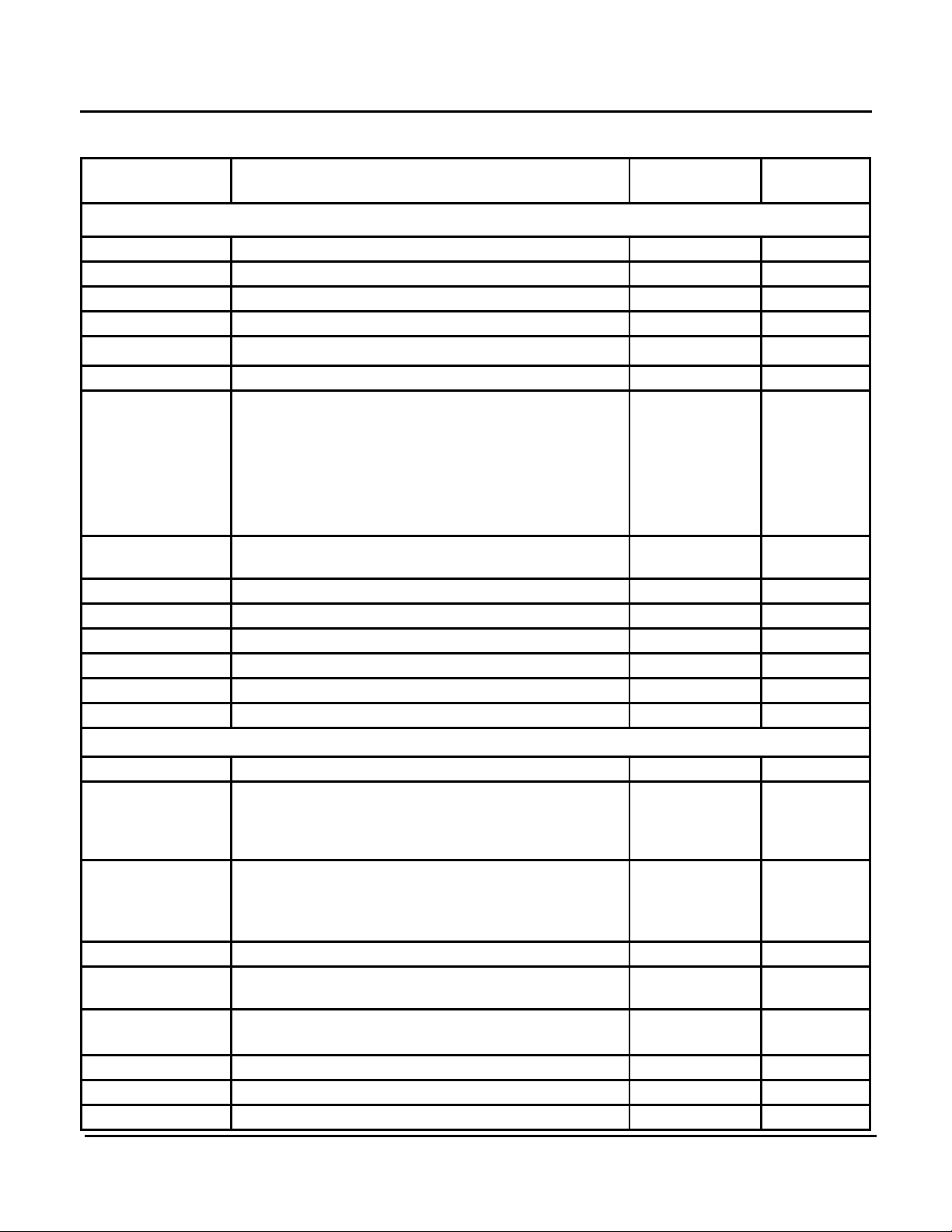

4.6.2 SERVICE Menu

The SERVICE Menu contains all the test and diagnostic functions/values required for

Customer Service Engineers to troubleshoot the equipment in a timely manner. The SERVICE

Menu items are illustrated and described in Figure 4-6 and Table 4-6 respectively.

Some of the functions in this Sub-Menu require a valid Code No. (password) to be entered,

prior to accessing/changing Function values. When prompted by a “CODE NO.” display, enter

0000 (four zeros) by pressing the Program Key four (4) times. This will allow function access.

Figure 4-6: SERVICE Menu Flow Chart

PR1: 11/30/12 Page 34 of 112

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526- 0288

Page 35

GF-115-C

Modulex E8 Controller and BCM

Operations and Maintenance Manual

OMM-0084_0D

RELAY TEST Sub-Menu

No relay

A1: Pump, Heating Circuit 1

A3: Hot Water Charging Pump

A4: Mixer OPEN, Heating Circuit 2

A7: HS2 ON [2-stage:HS 1+2 (after 10s) ON]

Multifunction 1

Multifunction 2

A10: Multifunction 3

A11: Collector Pump / Multifunction 4

SENSOR

temperature heating circuit 1

Flow temperature, heating circuit 2

Flow temperature, heating circuit 2

Heat generator /header temperature

Outside temperature

Table 4-6: SERVICE Menu Listing

FUNCTION DESCRIPTION REMARKS

This Sub-Menu is used to check the status of the relays contained in the

Controlller. These relays are numbered 00 through 11 and are defined as shown

below. CODE NO. Entry is required to access these relays.

RELAY NO.

00

01

02

03

04

05

06

07

08

09

10

11

SENSOR TEST Sub-Menu

This Sub-Menu is used to check and display the temperature readings of the

sensors connected to the Controller.

F1

A2: Pump, Heating Circuit 2

A5: Mixer CLOSED, Heating Circuit 2

A6: HS 1 ON

A8: Mixer OPEN Heating Circuit 1 /

A9: Mixer CLOSED Heating Circuit 1 /

Buffer storage temperature Lower

F2

F3

F5

F5

F6

F8

F9

PR1: 11/30/12 Page 35 of 112

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526- 0288

Buffer storage temperature middle or room

Upper buffer storage temperature

Upper hot water temperature

Page 36

GF-115-C

Modulex E8 Controller and BCM

Operations and Maintenance Manual

OMM-0084_0D

FUNCTION

DESCRIPTION

REMARKS

SENSOR TEST Sub-Menu

multifunction 1

multifunction 2

temperature multifunction 3

multifunction 4

input

currently installed in the Controller

menu functions.

8)

(1-8)

Start with Program Key (hold down)!

DO NOT USE

00

DO NOT USE

RETURN

Exit level using Program Key

Table 4-6: SERVICE Menu Listing (Continued)

F11

F12

F13

F14

F15; Light; 0-10V I

OTHER ENTRIES

Additional items and functions in the SERVICE Sub-Menu include the following:

SW NO XXX-XX

CASCADE MANU

(1-8)

BURNER TIME (1-

Flow temperature heating circuit 1 or temperature

Hot water temperature lower or temperature

Solid fuel boiler temperature or collector 2 or

Collector 1 temperature or temperature

Room temperature heating circuit 2 or measured

value of the light sensor or voltage value 0-10V

Specifies the Software Version and Index number

Starting different burner stages of the cascade

See GF-115-H, Section 7, Sub-section 7.5 for

additional startup instructions using these sub-

Program Key – Burner time for all stages

BURNER START

LIMITER TEST

(1-8)

SERVICE

Program Key – Burner start for all stages

Safety temperature limiter test with heat generator

temperature display

Input of date or operating hours for service

messages

WARNING: NEVER ATTEMPT TO USE THE FOLLOWING RESET FUNCTIONS.

RESET USER 00

RESET EXPERT

RESET T-PRG 00

PR1: 11/30/12 Page 36 of 112

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526- 0288

DO NOT USE

Page 37

GF-115-C

Modulex E8 Controller and BCM

Operations and Maintenance Manual

OMM-0084_0D

4.7 E8 Controller Initial Startup

Initial startup of the Modulex Controller requires a number of one-time entries to be made in

the initial INSTALLATION Menu that appears in the display when the E8 controller door is first

opened. Table 4-7 on the next page lists the description, entry range, and default entry for all

parameter. Instructions for entry into this menu is shown below.

NOTE

All items in the INSTALLATION Menu must be entered in

sequence. Press the Program Key to step through the menu

functions. Use Rotary Knob to adjust/change entries. Press the

Program Key to store entries and sequence to the next menu

item.

Initial Startup INSTALLATION Entry

1. Set the POWER rocker switch, located to the right of the Controller, to the ON (1)

position.

2. Open the panel cover on the Controller. The LCD display will read INSTALLATION. All

values in this level must be entered, in sequence, without interruption. The initial entries

required include: LANGUAGE, TIME and DATE as shown in the INSTALLATION Table

at right.

3. The first function that appears is LANGUAGE. By default, the display should show

ENGLISH. If ENGLISH is not displayed, turn the Rotary Knob until ENGLISH appears.

4. Press the Program Key to store setting.

5. Next, TIME will be displayed. Enter the current time (minutes, hours) using the Rotary

Knob. Press the Program Key to store each value.

6. The next items displayed are the YEAR, MONTH and DAY. Enter each item using the

Rotary Knob and press the Program Key as previously described to store the entry.

7. Following entry of all LANGUAGE, TIME and DATE entries, continue entering the

remaining items shown in Figure 4-7 and Table 4-7 until all required items have been

entered. Use the Program Key and Rotary Knob to select, adjust and store all entries as

previously described.

8. Continue step 7 until RETURN appears in the display, indicating that you are at the end

of the INSTALLATION menu.

9. Press the Program Key to exit the INSTALLATION menu.

PR1: 11/30/12 Page 37 of 112

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526- 0288

Page 38

GF-115-C

Modulex E8 Controller and BCM

Operations and Maintenance Manual

OMM-0084_0D

PARAMETERS

DESCRIPTION

DEFAULT

LANGUAGE

Set Language

ENGLISH

TIME

Set current time (min., hrs)

00:00 – 24:00

YEAR

Set current year

XXXX (4 digits)

MONTH

Set current month

00-12

DAY

Set current day of month

00-31

CONF DEVICE

Confirm Device

- - - -, 01 – 06

- - - -

HEATSOURCE 1

Heat Source 1

00 – 06

06

HS1 BUS

Heat Source 1 Bus

00 – 04

02

HEATSOURCE 2

Heat Source 2

00 – 05

00

STORAGE HS2

Storage Heat Source 2

00 – 03

00

BUFFER

Buffer

00, 01, 02

00

HC FUNCTION 1

Heating Circuit Function 1

00, 01, 03

00

HC FUNCTION 2

Heating Circuit Function 2

00 – 04

00

CAP/MODULE

See Paragraph 4.8.1 for instructions.

00 – 1000 Kw

40 Kw

4.8.2)

Setpoint

MF1 HYST

Multifunction Relay 1 Hysteresis

4°F – 18°F

9°F

4.8.2)

Setpoint

MF2 HYST

Multifunction Relay 2 Hysteresis

4°Ra – 18°Ra

9°F

RELAY FUNC 3

Relay Function 3

00 – 26

01

Setpoint

MF3 HYST

Multifunction Relay 3 Hysteresis

4°F – 18°F

9°F

RELAY FUNC 4

Relay Function 4

00 – 26

02

Setpoint

MF4 HYST

Multifunction Relay 4 Hysteresis

4°F – 18°F

9°F

BUS ID 1

Bus Identification No. 1

00 – 15

01

BUS ID 2

Bus Identification 2

00 – 15

02

5K SENSOR

5,000 Ohm Sensor

00=5K, 01=1K

00 = 5 K

Table 4-7: INSTALLATION Menu Listing

INSTALLATION Sub-Menu

ENTRY RANGE

RELAY FUNC 1

T-MF1 SETP Temperature – Multifunction Relay 1

RELAY FUNC 2

T-MF2 SETP Temperature – Multifunction Relay 2

T-MF3 SETP Temperature – Multifunction Relay 3

T-MF4 SETP Temperature – Multifunction Relay 4

Relay Function 1 (See Paragraph

Relay Function 2 (See Paragraph

00 – 26 00

86°F – 194°F 86°F

00 – 26 00

86°F – 194°F 86°F

86°F – 194°F 86°F

86°F – 194°F 86°F

PR1: 11/30/12 Page 38 of 112

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526- 0288

Page 39

GF-115-C

Modulex E8 Controller and BCM

Operations and Maintenance Manual

OMM-0084_0D

4.7.1 CAP/MODULE Function (Maximum Kilowatts per Burner)

When the Program Key is pressed with CAP/MODULE displayed, the display may show

“SCAN”, indicating that the Controller is searching for related MODULE (BOILER) functions.

Once the scan is complete, follow instructions below.

CAP/MODULE Function (Setting Max. Kw per Burner)

1. Press the Program Key. The display will show CODE NO., requesting the valid code to be

entered.

2. Enter code 0000 (four zeros) by pressing the Program Key four times. The red LED will

remain lit while the four code digits are entered.

3. Press the Program Key

4. The display will show BOILER 1 (meaning Heat Module 1), along with kilowatt (Kw) setting

for the first Module. The default setting for each Boiler Module is 40 Kw.

NOTE

The 40 Kw setting is only a control parameter. It does not

represent the maximum input of each module.

5. If the desired Kw setting is not displayed, press the Program Key and change the setting

using the Rotary Knob. Once the desired setting is displayed, press the Program Key to

store the value.

6. Continue scrolling through each BOILER (Heat Module) and observe the Kw setting for

each one. Change as needed by repeating step 5.

7. Once all BOILER modules have been set, RETURN will be displayed.

8. Press the Program Key to continue with the next menu function (RELAY FUNC 1) in the

INSTALLATION Menu Table.

PR1: 11/30/12 Page 39 of 112

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526- 0288

Page 40

GF-115-C

Modulex E8 Controller and BCM

Operations and Maintenance Manual

OMM-0084_0D

FUNCTION

DESCRIPTION

01

Header Pump

03

Booster Pump

06

Pump HS2

21

Pulsed Circulation Pump

23

Solar Integration

25

Return Flow Temperature Increase HS2

4.7.1 Available Settings for Relay Functions 1 – 4

Table 4-8 lists the available Function selections for Multi-Function (MF) Relays 1 thru 4:

Table 4-8: Relay 1-4 Functions

00 No MF Relay Function

02 Circulation (Time)

05 Pump HS1

20 Temperature-Controlled Circulation Pump

22 Solid Fuel Boiler Integration (Not Applicable)

24 Return Flow Temperature Increase HS1

26 Return Flow Temperature Increase Via Buffer Storage

PR1: 11/30/12 Page 40 of 112

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526- 0288

Page 41

GF-115-C

OMM-0084_0D

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526- 0288

5. E8 OPERATING MODE: Set-up and Programming

The following paragraphs provide the detailed set-up and programming procedures necessary

to configure the Modulex Boiler for service operation.

NOTE

When performing the following operating mode set-up procedures,

refer to Section 3 of this document for illustrations and

descriptions of the Controller operating controls and displays.

Refer to Section 6 for Controller wiring connections.

5.1 Indoor/Outdoor Reset Mode

This mode is used to adjust the boiler set point based on the outdoor air temperature and a

programmed heating curve. The heating curve can be customized using functions provided in

the USER menu. The outdoor air sensor provided with the Modulex boiler must be installed to

enable this mode of operation. The following paragraphs provide the procedures necessary to

wire and configure the controller for operation in the Indoor/Outdoor Reset mode.

5.1.1 Wiring Connections

The outdoor air sensor provided with the boiler should be mounted on the outer North or

North-East side of the building away from windows, doors and vents. Never mount the outdoor

air sensor in a location where it is exposed to direct sunlight.

Wire the sensor using shielded 2-conductor, 18 AWG wire (Belden #8760, or equiv.). Connect

the outdoor air sensor wire leads to terminals 9 (F9) and 10 (GND) of Connector 1 on the rear

of the Controller. There is no polarity to observe when connecting the wire leads. Refer to the

wiring diagrams in Section 6 for the locations of sensor connections. This sensor must be

connected prior to configuring the Controller (Paragraph 5.1.2).\

5.1.2 Indoor/Outdoor Reset Operation Configuration

The Indoor/Outdoor Reset Mode is configured using the USER menu as shown in instructions

on the next page.

IMPORTANT

The outdoor air sensor MUST be connected as described in

paragraph 5.1.1 above, prior to configuring the Controller for

Indoor/Outdoor Reset Mode operation.

PR1: 02/23/12 Page 41 of 112

Page 42

GF-115-C

Modulex E8 Controller and BCM

Operations and Maintenance Manual

OMM-0084_0D

60

70

80

90

100

110

120

130

140